Patents

Literature

222results about How to "Excellent thermodynamic properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat exchanger

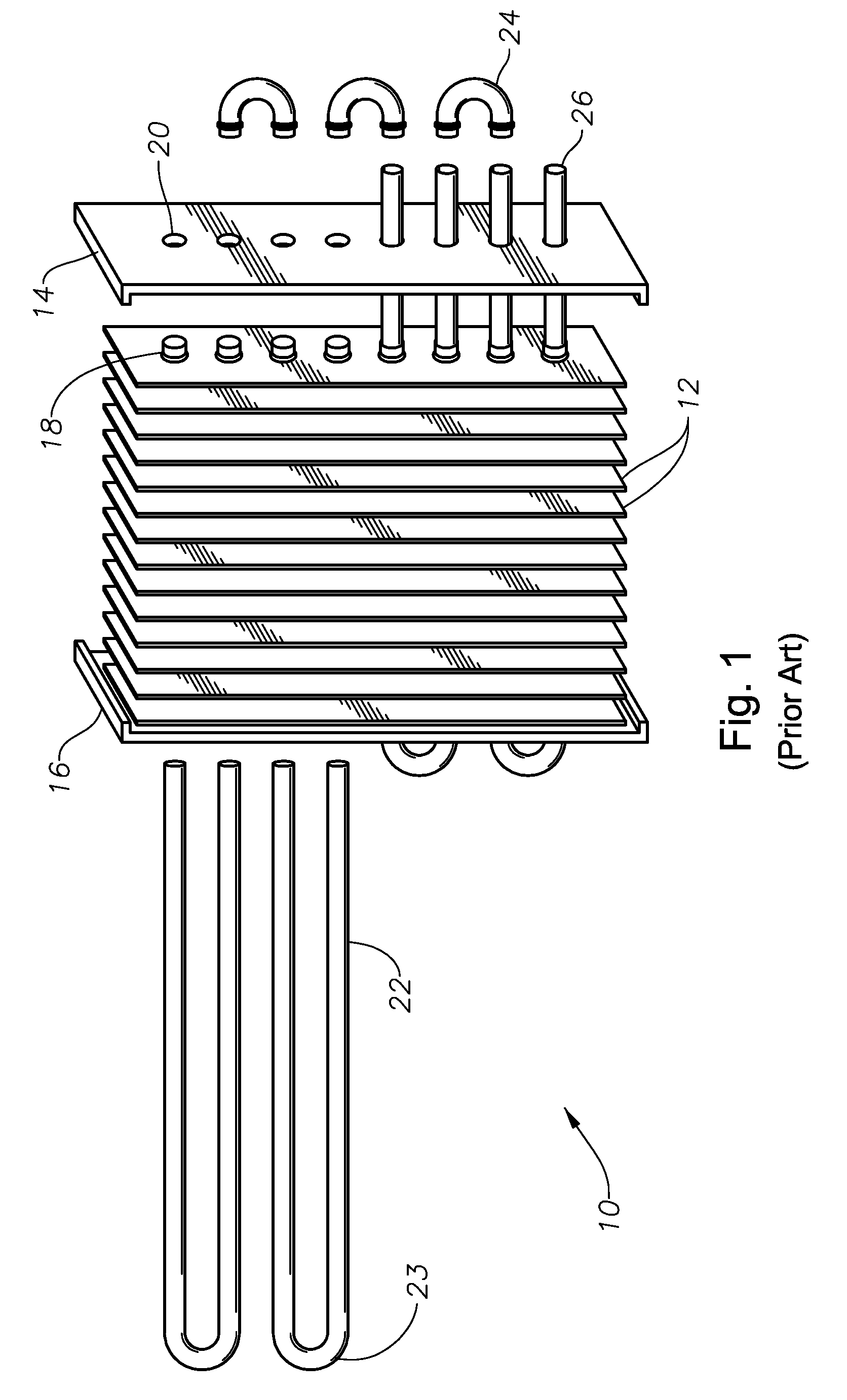

InactiveCN1410738AImprove pressure resistanceEvenly distributedReinforcing meansHeat exhanger conduitsWorking pressureHigh pressure

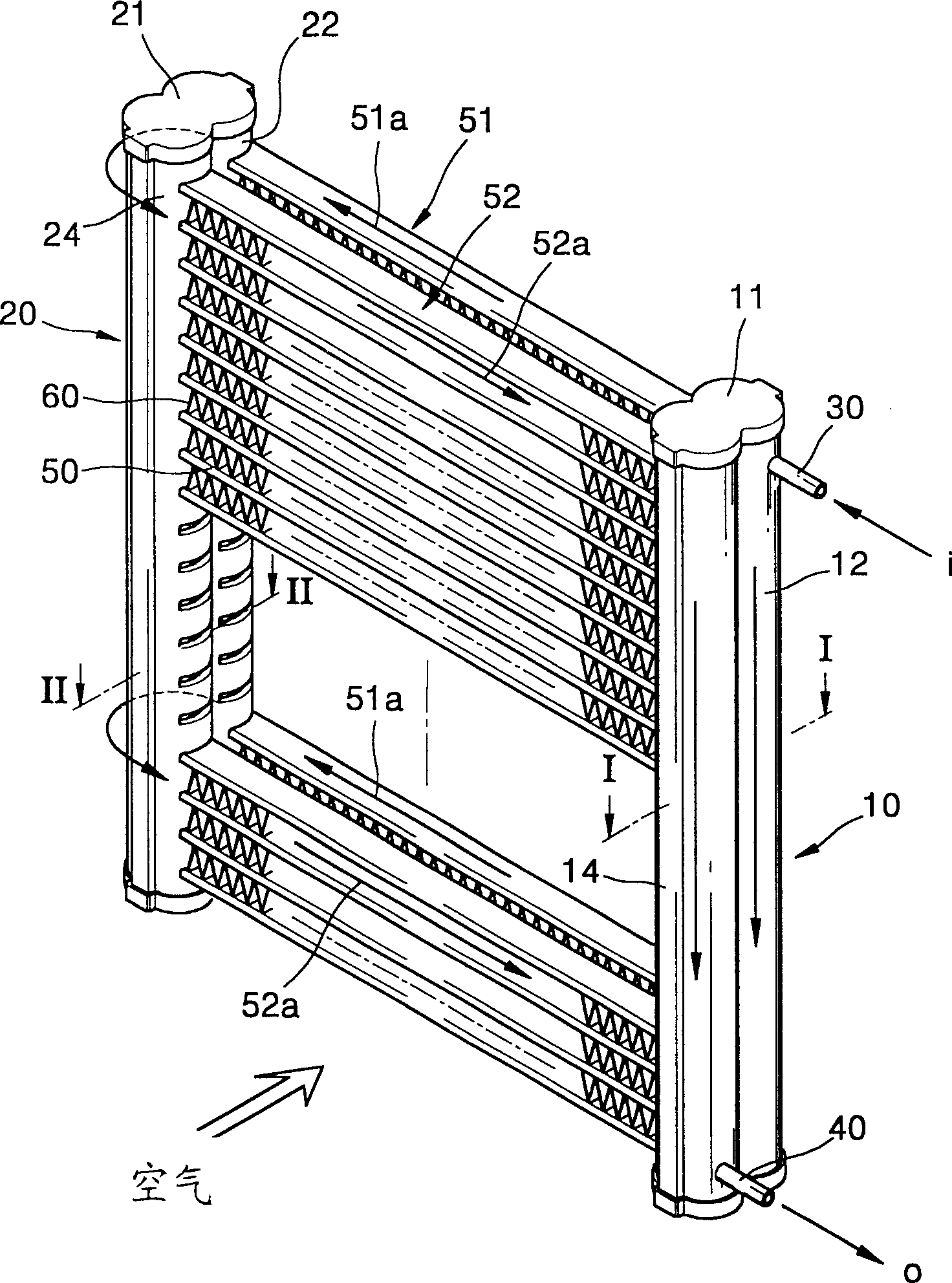

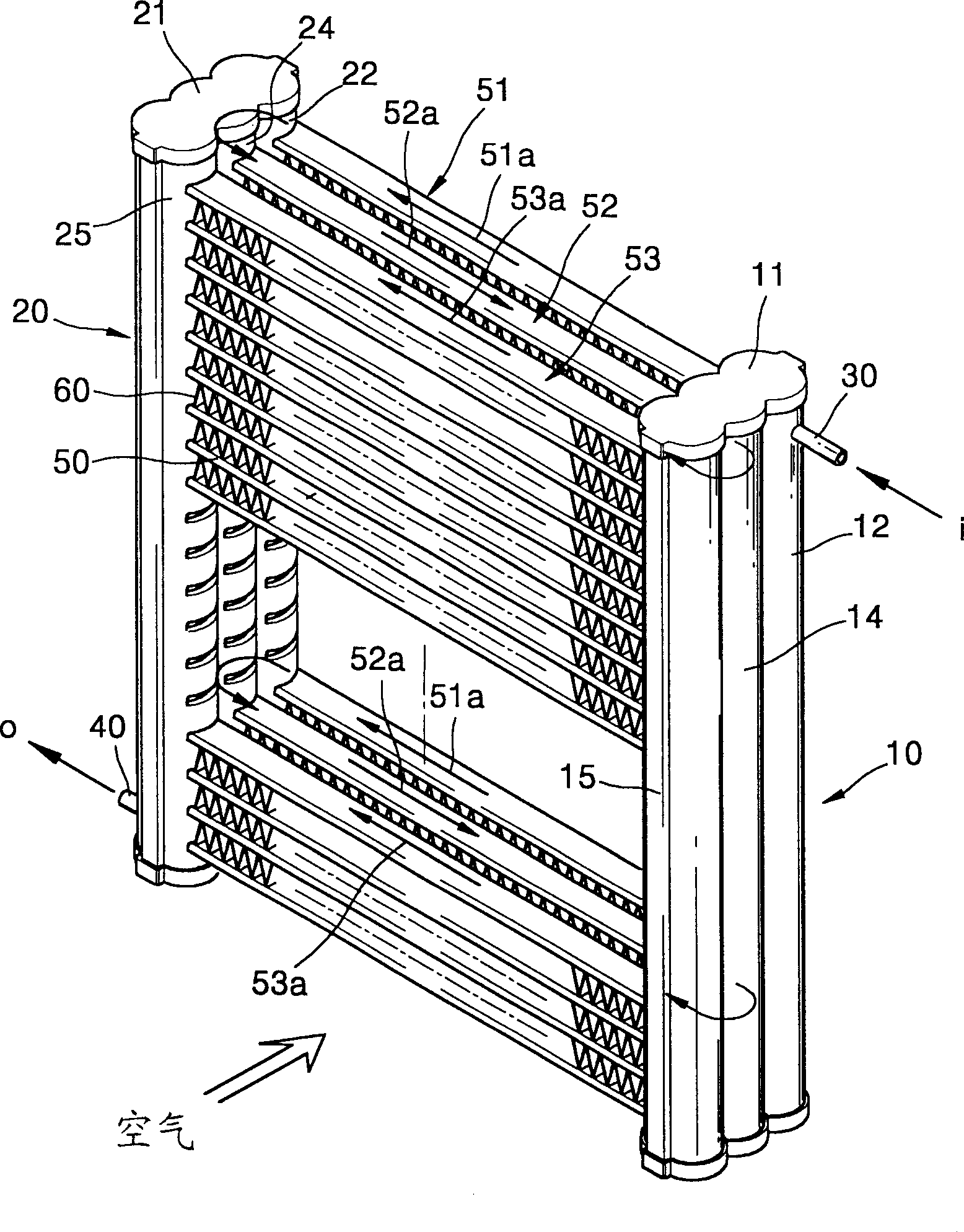

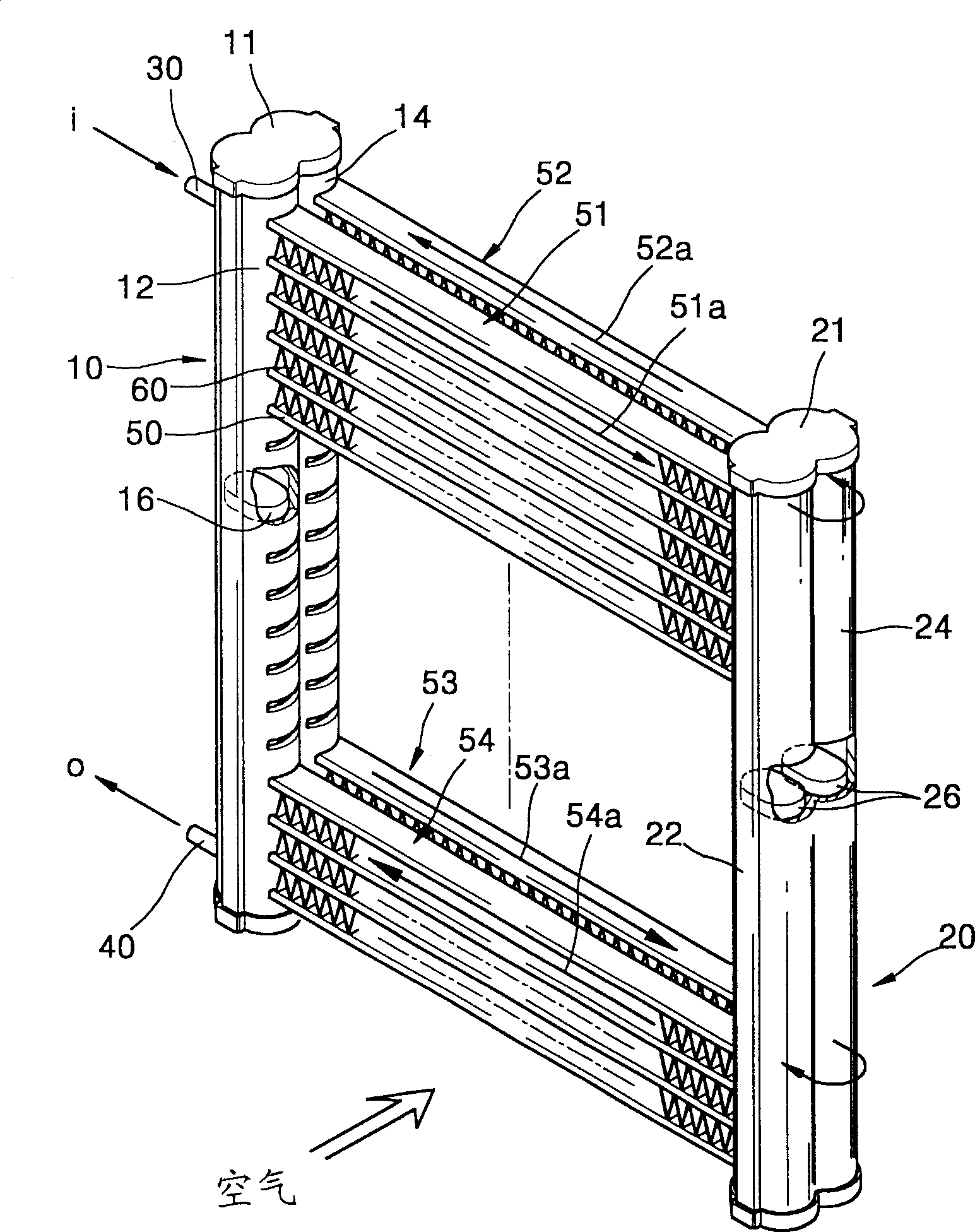

A heat exchanger uses a refrigerant acting under a high pressure, such as carbon dioxide, as a refrigerant. The heat exchanger includes first (10) and second (20) header pipes arranged a predetermined distance from each other and parallel to each other, each having at least two chambers (12,14,22,24) independently sectioned by a partition wall, a plurality of tubes (50) for separately connecting the chambers of the first (10) and second (20) header pipes, facing each other, wherein the tubes (50) are divided into at least two tube groups (51,52), each having a single refrigerant path, a refrigerant inlet pipe (30) formed at the chamber disposed at one end portion of the first header pipe (10), through which the refrigerant is supplied, a plurality of return holes (29) formed in the partition wall to connect two chambers adjacent to each other, through which the refrigerant sequentially flows the tube groups (51,52), and a refrigerant outlet pipe (40) formed at the chamber of one of the first and second header pipes connected to a final tube group of the tube groups along the flow of the refrigerant, through which the refrigerant is exhausted.

Owner:HANON SYST

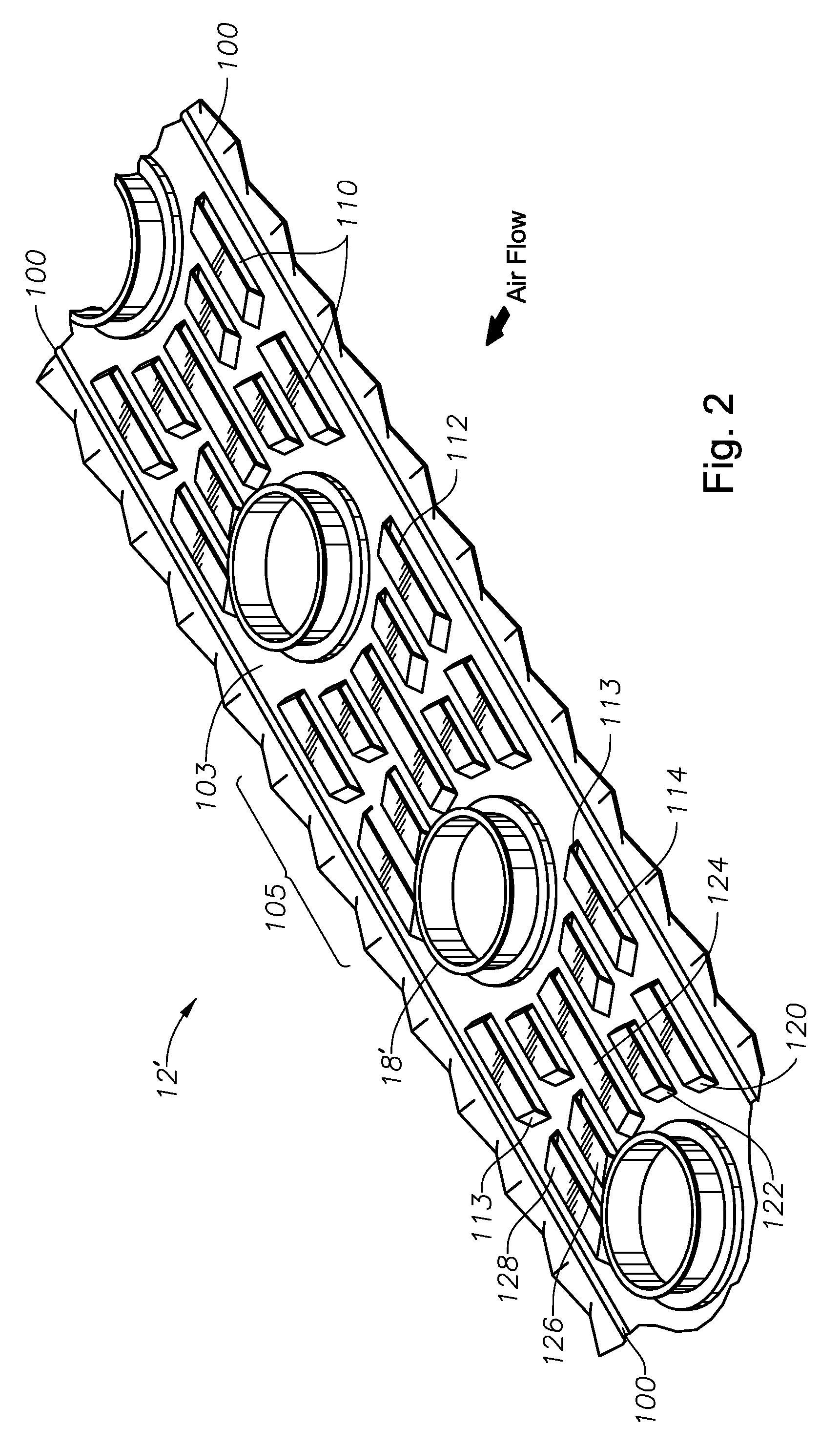

Method for Manufacturing Tube and Fin Heat Exchanger with Reduced Tube Diameter and Optimized Fin Produced Thereby

InactiveUS20090308585A1Increase stiffnessImprove rigidityHeat exhanger finsStationary conduit assembliesEngineeringImproved method

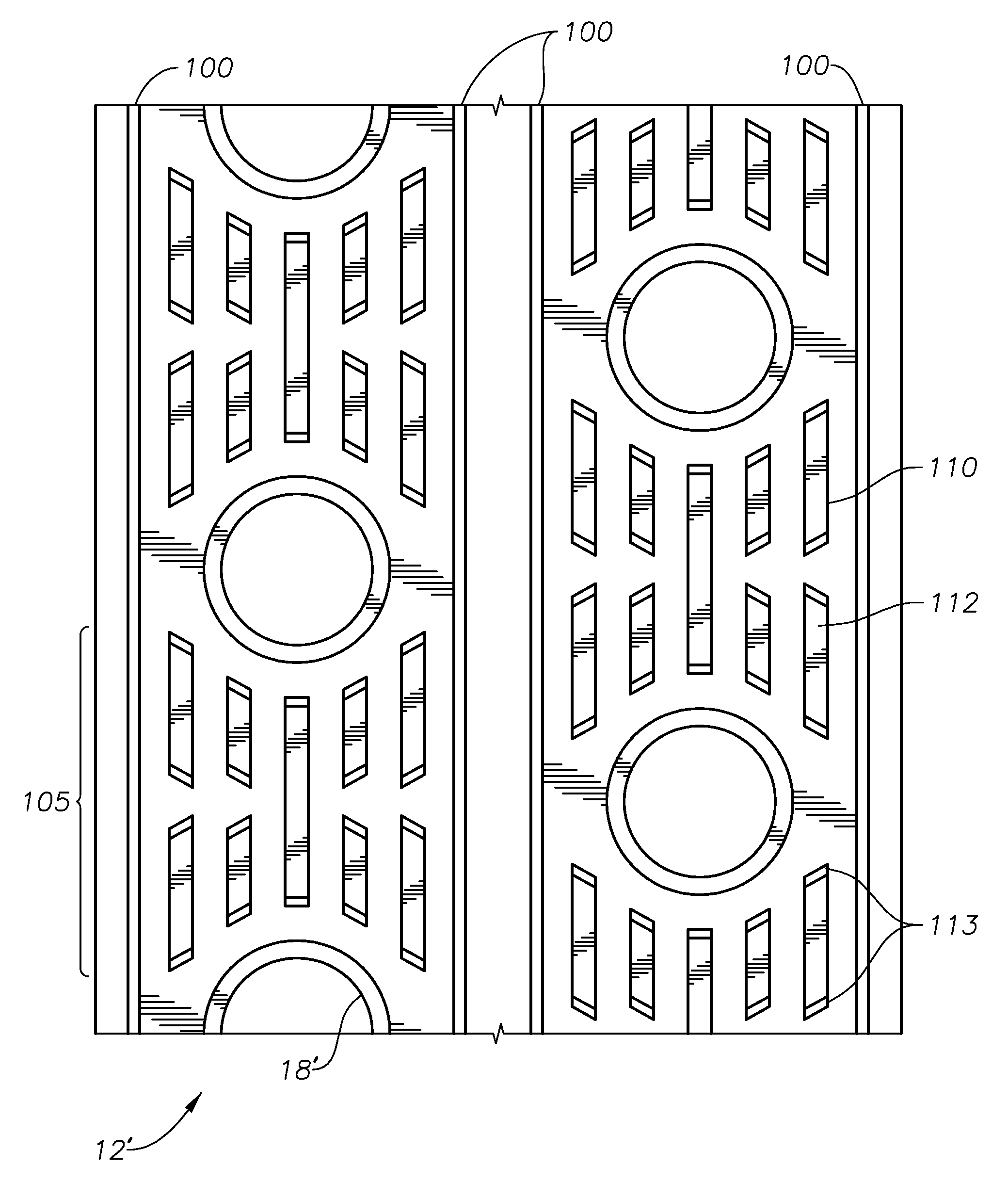

An improved method for manufacturing tube and fin heat exchangers that, according to a preferred embodiment, includes a process for increasing the stiffness and rigidity of heat exchanger fins. Stiffer fins have a greater tendency to maintain proper alignment within a stack of fins, which aids in lacing long stacks of fins with small (e.g., 5 mm) diameter tubing. Preferably, fin stiffness is increased by forming a plurality of longitudinal ribs within the fin during the fin stamping process. More preferably still, two ribs for each longitudinal row of collared holes are provided. The preferred embodiment also includes a slotted heat exchanger fin that is dimensioned and arranged for optimized thermodynamic performance when used with small diameter tubing, thus reducing the space required for a given heat exchanger system.

Owner:GOODMAN GLOBAL INC

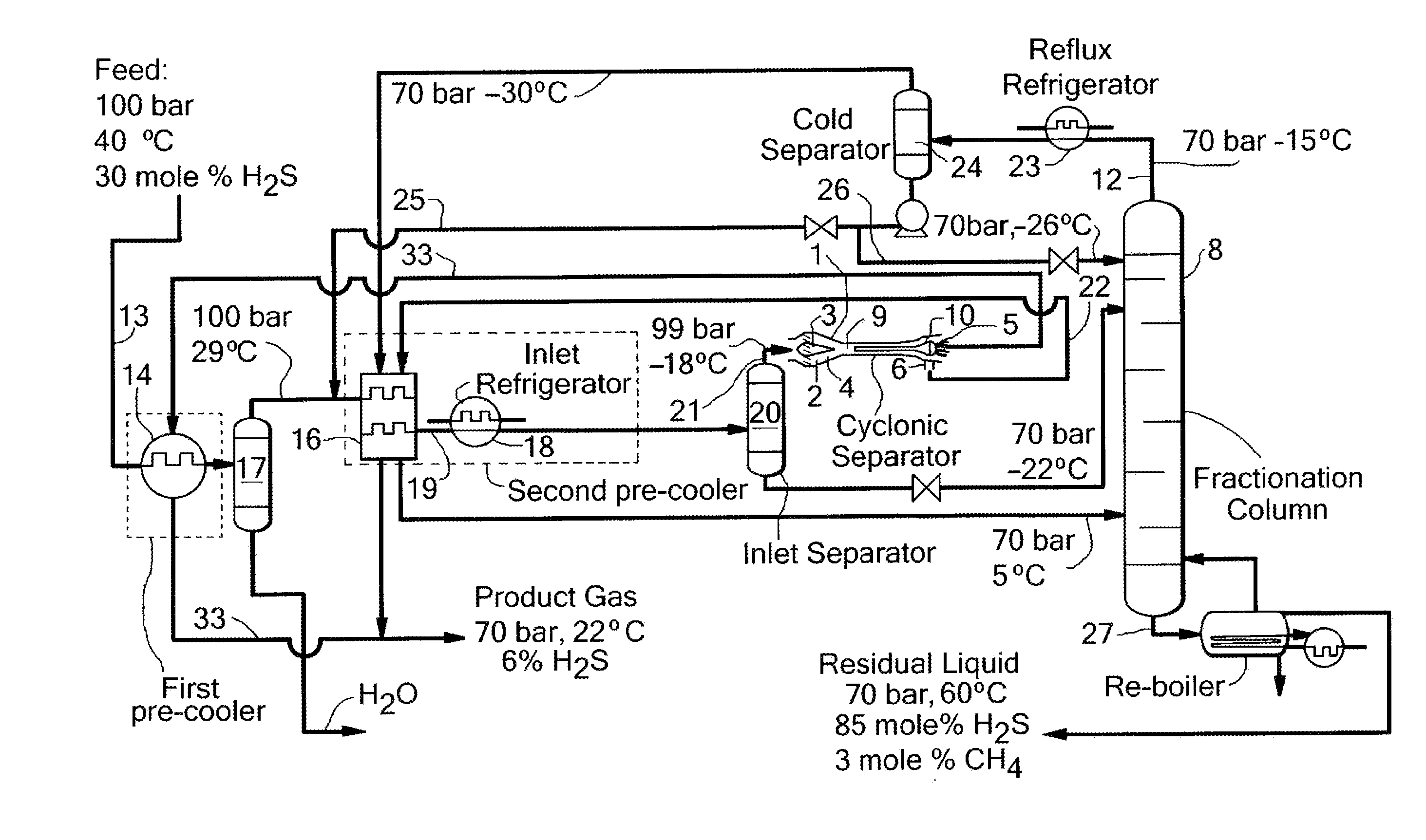

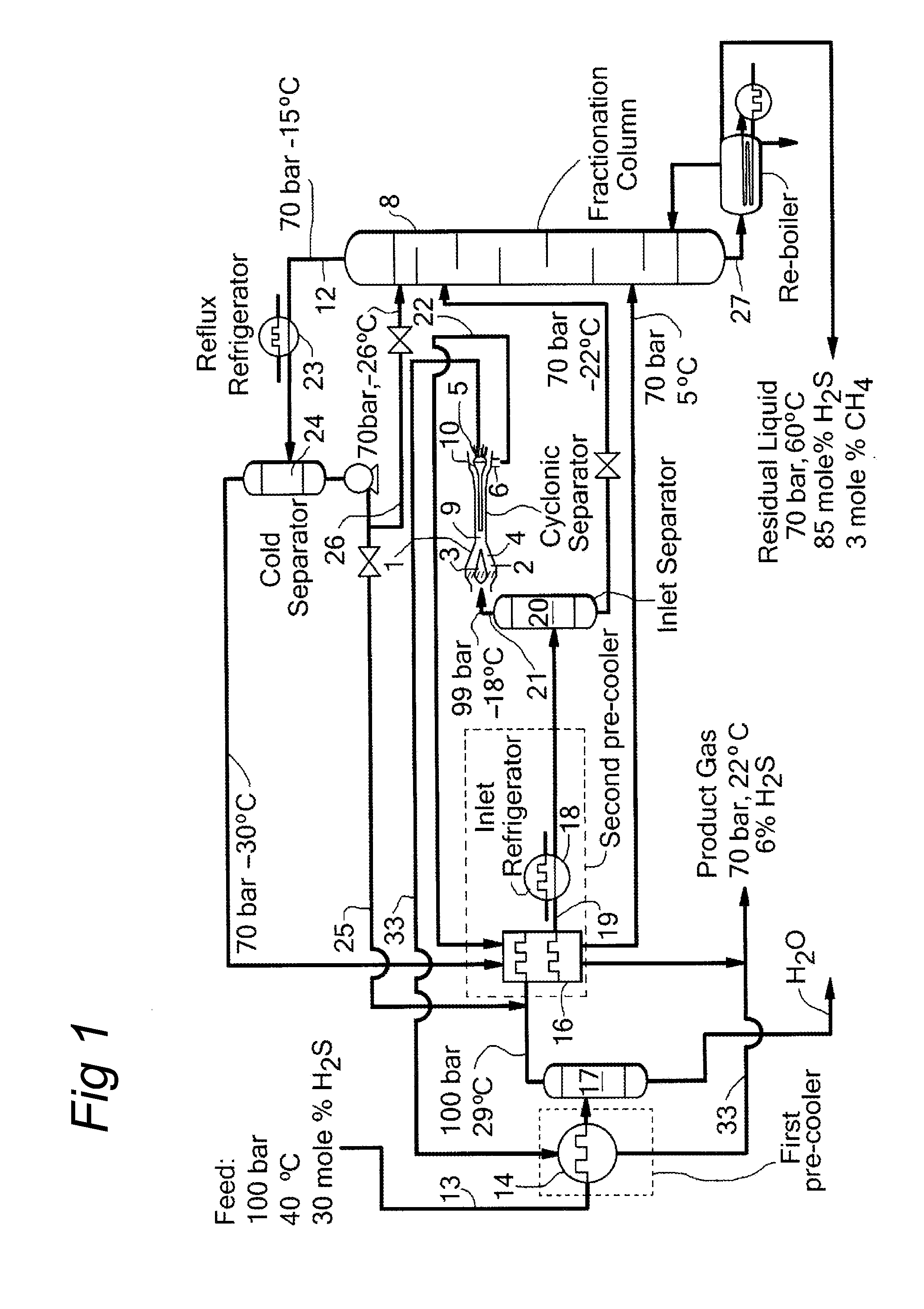

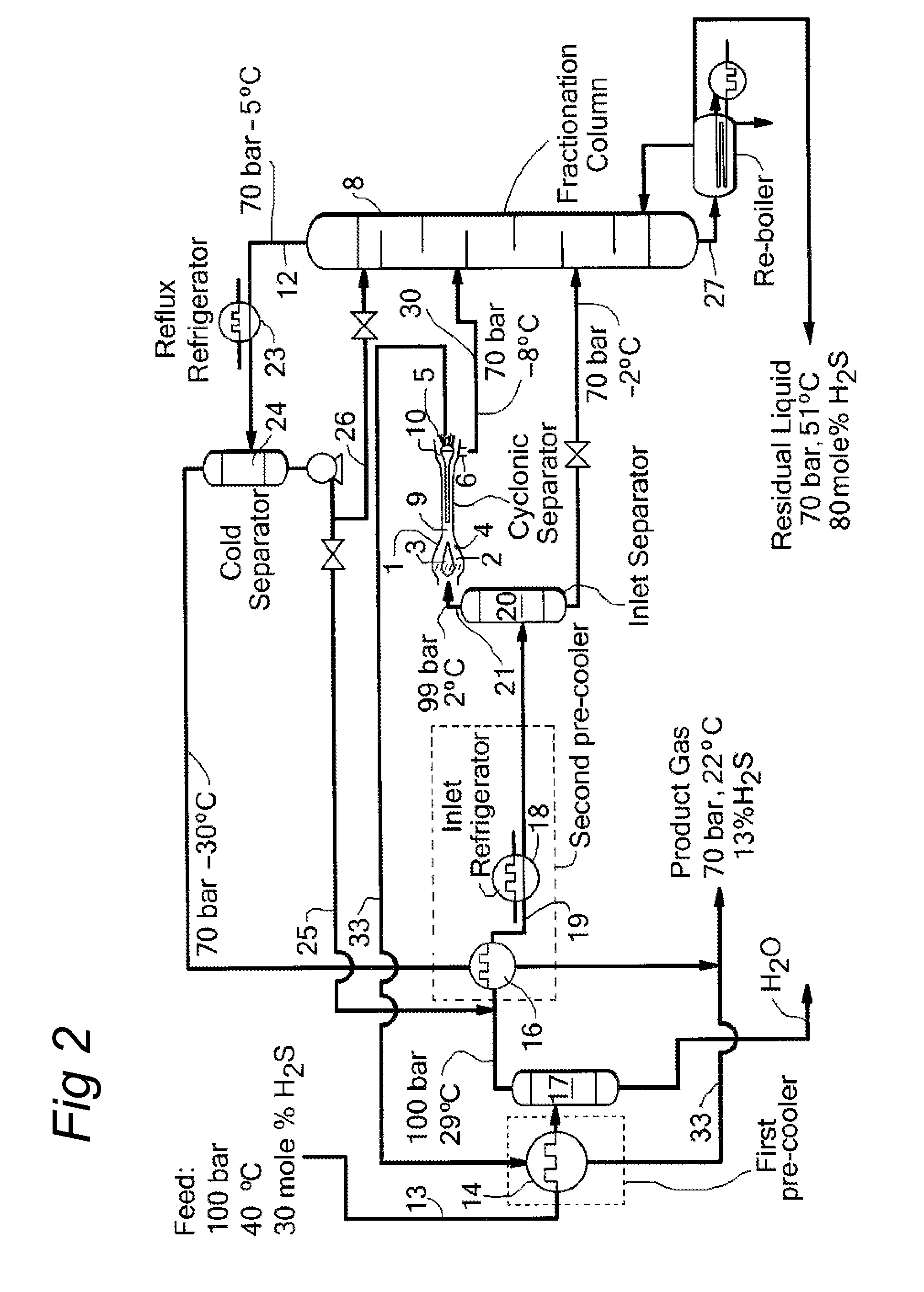

Method and system for removing h2s from a natural gas stream

ActiveUS20110036122A1Large outer diameterPromote recoverySolidificationGas treatmentFractionating columnTemperature and pressure

A method for removing hydrogen sulphide (H2S) from a natural gas stream comprising methane (CH4) and H2S comprises:—cooling the natural gas stream in a heat exchanger assembly (13,16,18);—feeding at least part of the cooled natural gas stream through a feed conduit (19,21) into a cyclonic expansion and separation device (1) in which the cooled natural gas stream is expanded in a nozzle (4) and thereby further cooled to a temperature and pressure below the dew point of H2S and is separated by inducing the cooled natural gas stream to swirl in a tubular separation chamber (9) thereby inducing centrifugal forces to separate the cooled natural gas stream into a cooled low density fluid fraction, which is H2S depleted and methane enriched, and a cooled high density fluid fraction, which is H2S enriched and methane depleted;—feeding the cooled low density fluid fraction to a product gas conduit (33) which is connected to the heat exchanger assembly (14) for cooling the natural gas stream fed to the cyclonic expansion and separation device (1); and—feeding the cooled high density fluid fraction to a fractionating column (8) for further separation.

Owner:TWISTER BV

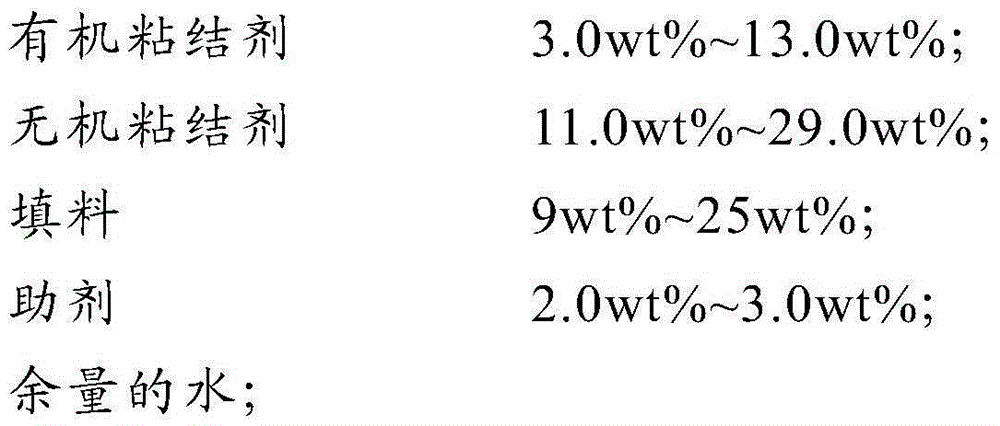

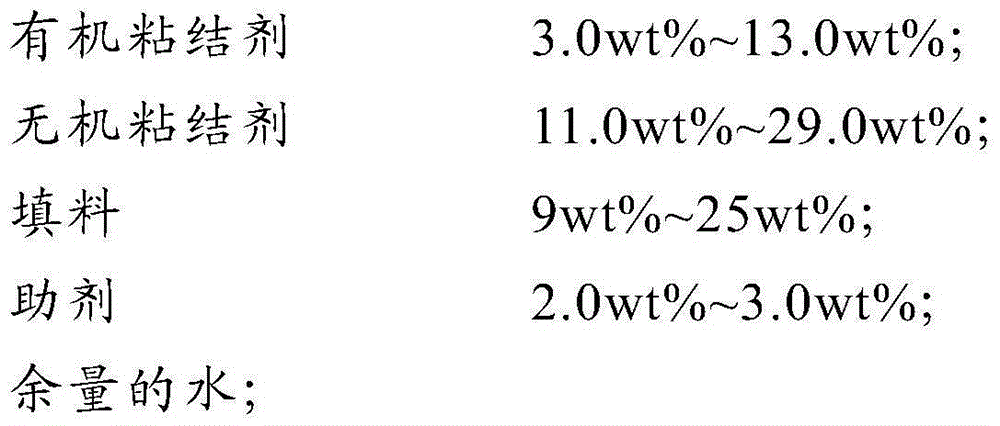

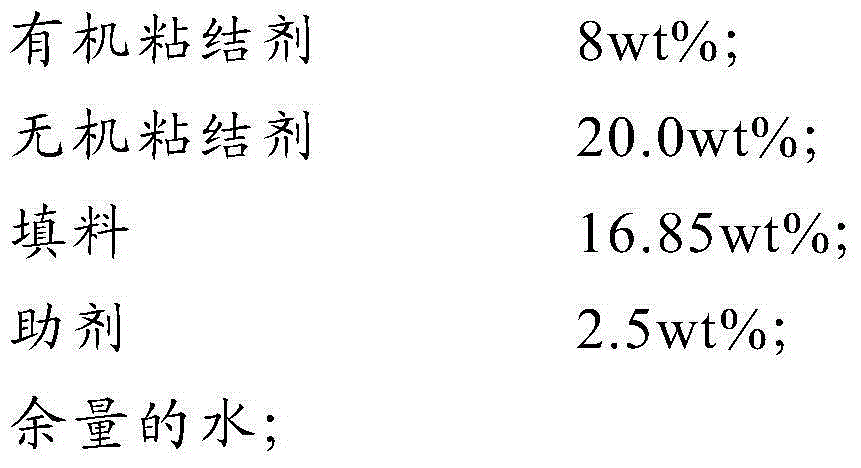

Ceramic paint and application thereof

The invention provides a ceramic paint which comprises 3.0-13.0 wt% of organic binder, 11.0-29.0 wt% of inorganic binder, 8.6-25 wt% of filler, 2.0-3.0 wt% of assistant and the balance of water. The organic binder is a pure acrylic emulsion, the inorganic binder is sodium water glass, and the filler comprises rare-earth oxide, graphite and boron nitride. The invention also provides application of the ceramic paint in industrial furnaces. Under the synergistic actions of the components, the ceramic paint has favorable comprehensive properties when being used as a ceramic coating.

Owner:铜陵兆山科技有限公司

Halogen-free flame-retardant bio-based epoxy resin precursor and preparation method and application thereof

ActiveCN109651595AReduce dependenceReduce pollutionEpoxy resin adhesivesEpoxy resin coatingsEpoxyPhenol

The invention discloses a halogen-free flame-retardant bio-based epoxy resin precursor and its preparation method. The preparation method comprises the following steps: firstly, a bio-based phenol monomer, a phosphorus-containing monomer and an aldehyde-containing bio-based phenol monomer are subjected to a simple condensation reaction; and then, the product is subjected to an epoxidation reactionto prepare the halogen-free flame-retardant bio-based epoxy resin precursor. The preparation method has simple process, is simple to operate, has good controllability, is easy to implement, and is suitable for large-scale industrial production. By preparing thermosetting epoxy resin from the bio-based epoxy resin precursor and an amine or anhydride curing agent, the modified epoxy resin can haveexcellent thermal property, mechanical property and flame retardant property, has the possibility of replacing the existing petroleum base products, and has a wider range of application.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

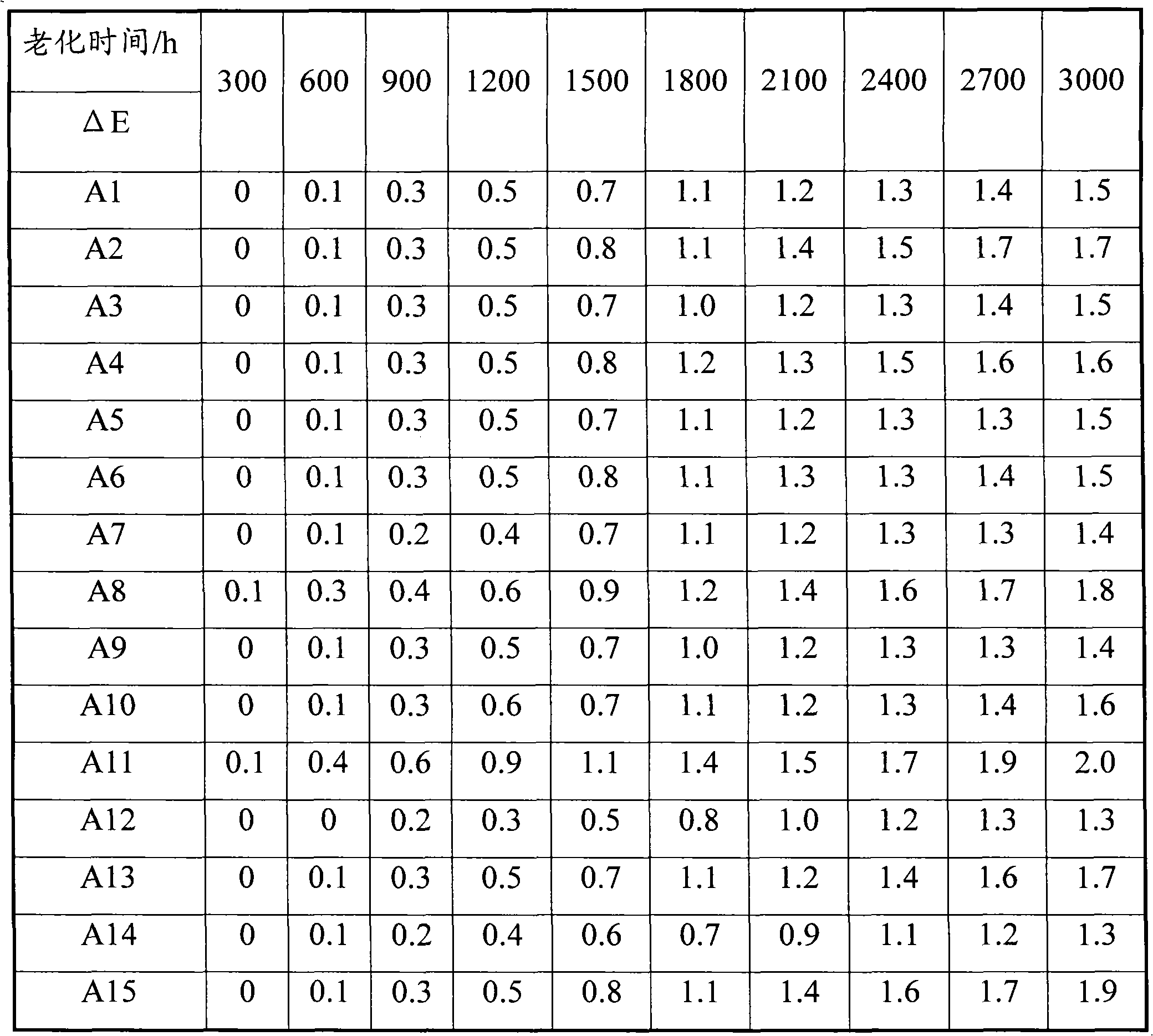

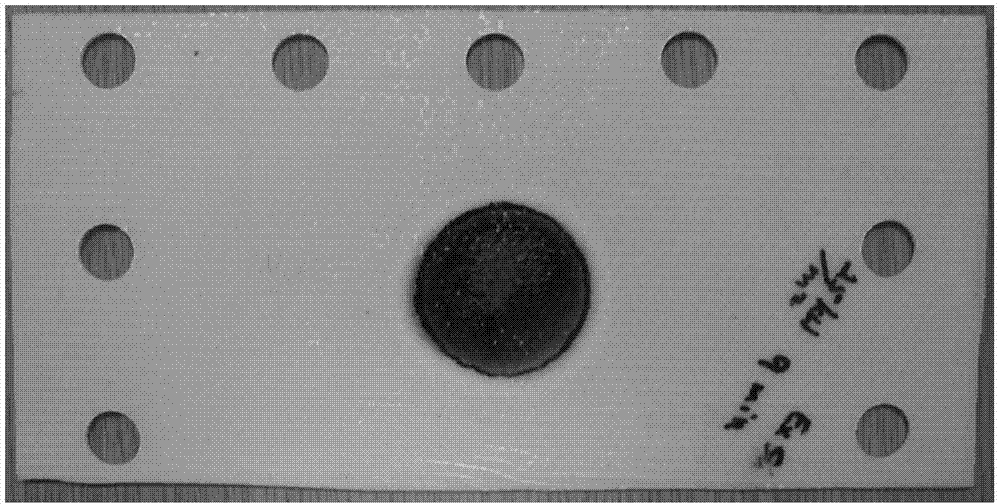

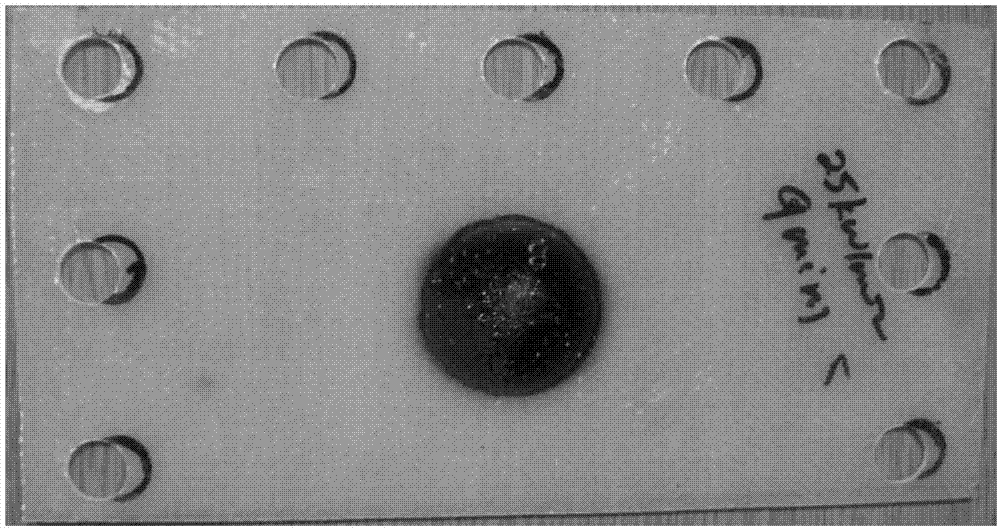

Weather-resistant white master batch, weather-resistant polyester material and preparation methods of weather-resistant white master batch and weather-resistant polyester material

ActiveCN102492269AWill not destroy physical and mechanical propertiesExcellent thermodynamic propertiesPolyesterHigh concentration

The invention relates to the field of polyester materials, particularly relates to a weather-resistant white master batch, a weather-resistant polyester material and preparation methods of the weather-resistant white master batch and the weather-resistant polyester material. In order to improve the weather resistance of the traditional polyester, the invention provides the weather-resistant white master batch and the weather-resistant polyester material. The weather-resistant white master batch comprises a carrier, a white pigment, a light stabilizer and an ultraviolet absorbent, wherein the white pigment comprises primary particles with particle sizes of 0.1-0.5mu m. The polyester material comprises 5-30% of the weather-resistant white master batch. According to the invention, the weather-resistant white master batch comprises high-concentration white pigment, thereby having better weather resistance; and the weather-resistant polyester material comprising the white master batch also has better weather resistance. The invention also provides the preparation methods of the weather-resistant white master batch and the weather-resistant polyester material. The preparation methods are simple in production processes and easy to operate.

Owner:NINGBO CHANGYANG TECH

Expansive type fire retardant, flame retardation polymer composition containing fire retardant and fiber enhanced polymer-based flame retardation composite material

The invention relates to an expansive type fire retardant, a flame retardation polymer composition containing the fire retardant and a fiber enhanced polymer-based flame retardation composite material prepared by the flame retardation polymer composition. The expansive type fire retardant comprises a carbon source, an acid source, a gas source and an anti-oxidant which contains dis(octadecyl)pentaerythritol diphosphite and / or hexadecyl pentaerythritol diphosphite. The composite material comprises the flame retardation polymeric material body and the continuous fiber positioned in the flame retardation polymeric material body, the flame retardation polymeric material body and the continuous fiber are integrated, the flame retardation polymeric material body can be obtained by solidifying the flame retardation polymer composition containing the fire retardant, and the prepared fiber enhanced polymer-based flame retardation composite material has excellent thermodynamics performance after being burned.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

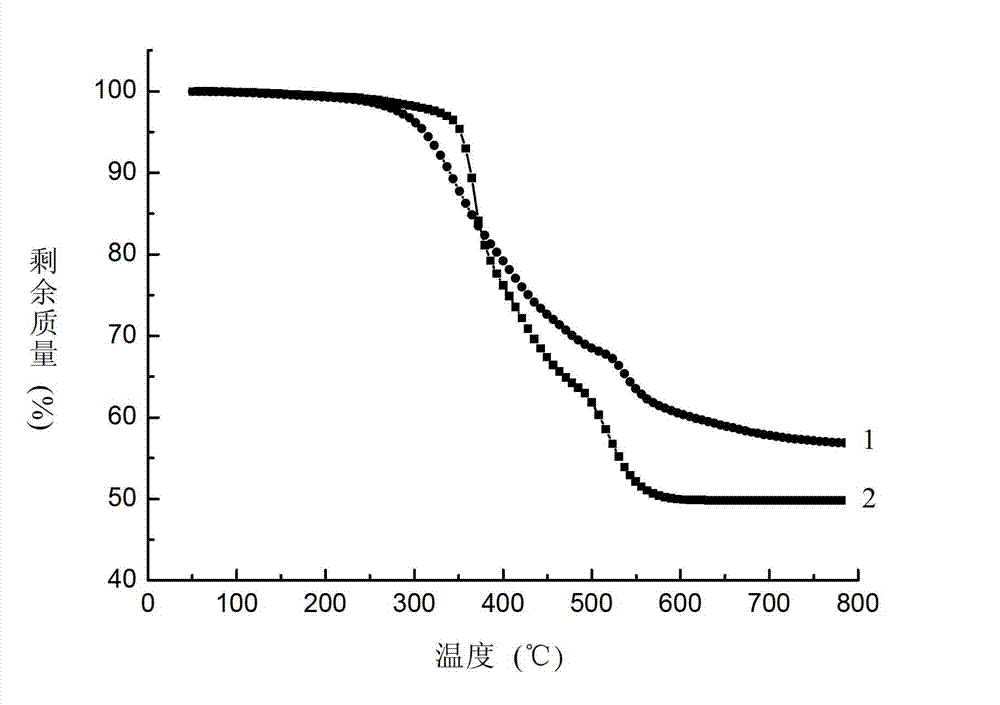

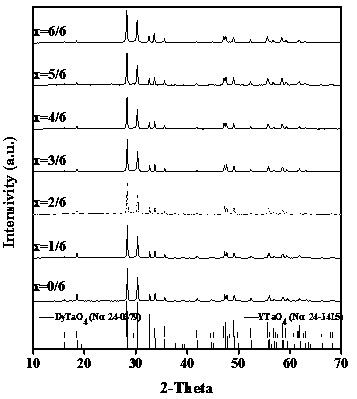

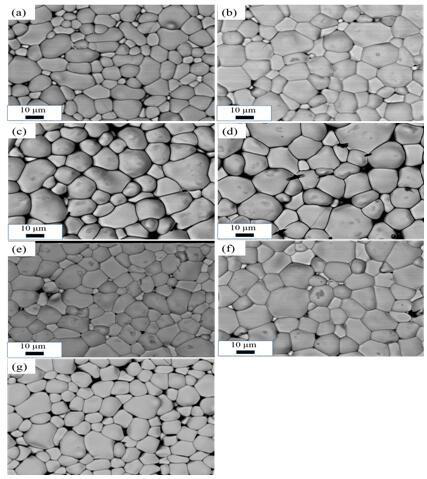

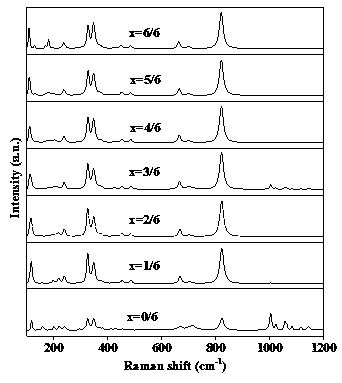

Compact ferroelastic dual rare earth tantalate solid solution high-temperature ceramic and preparation method thereof

The invention discloses compact ferroelastic dual rare earth tantalate solid solution high-temperature ceramic and a preparation method thereof, and belongs to the technical field of high temperatureresistant material of thermal barrier ceramic coating. The structural formula is (Y1-xDyx)TaO4 (x=0.1-0.9). Previously dried rare earth oxides (Y2O3, Dy2O3) and tantalum pentoxide (Ta2O5) are weighedaccording to the stoichiometric ratio required. Then, the materials are ball milled with ethanol as a solvent to obtain mixed powder A; the mixed powder A is sieved and compacted in a mold, and then ablank undergoes isostatic cool pressing to prepare a compact blank; and finally, the compact blank undergoes pressureless sintering to obtain the compact dual rare earth tantalate solid solution high-temperature ceramic. The dual rare earth tantalate solid solution high-temperature ceramic prepared by the method has characteristics of high process purity, low impurity content, high compactness, uniform grain size, low heat conductivity, large coefficient of thermal expansion, good toughness and the like.

Owner:KUNMING UNIV OF SCI & TECH

Ceramic surface material and surface coating

ActiveCN108531078AImprove toughnessImprove thermal stabilityFireproof paintsAnti-corrosive paintsRare earthButyl carbitol

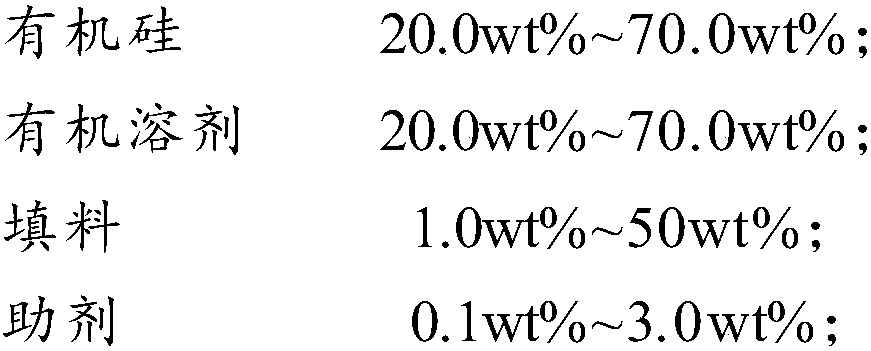

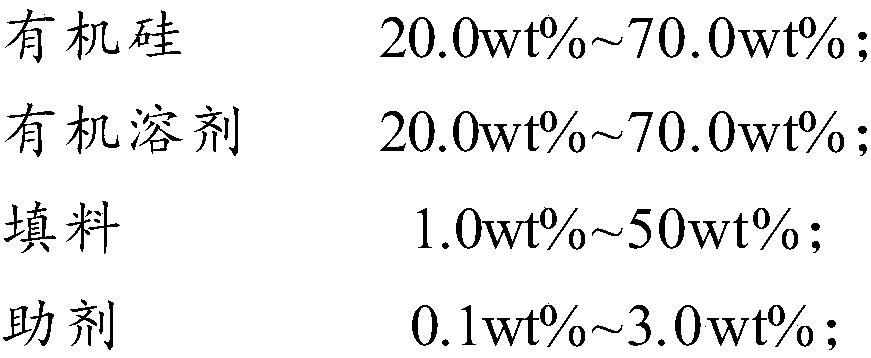

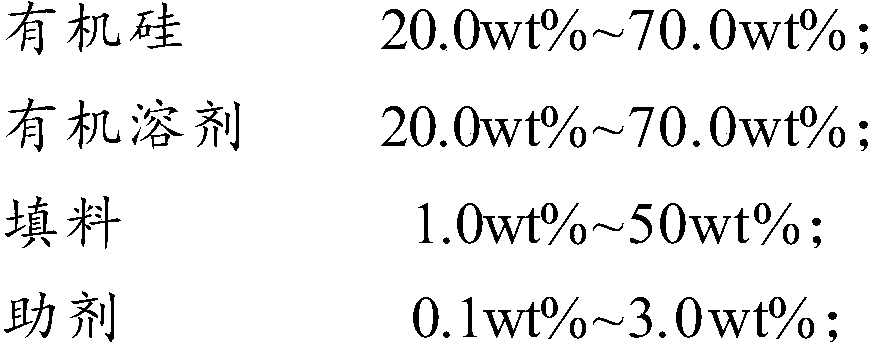

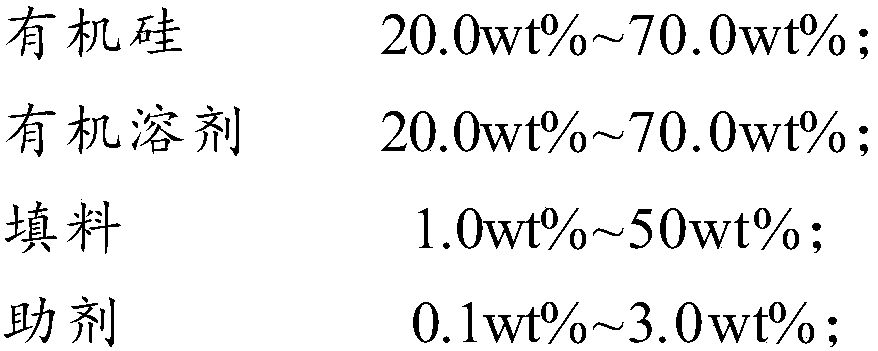

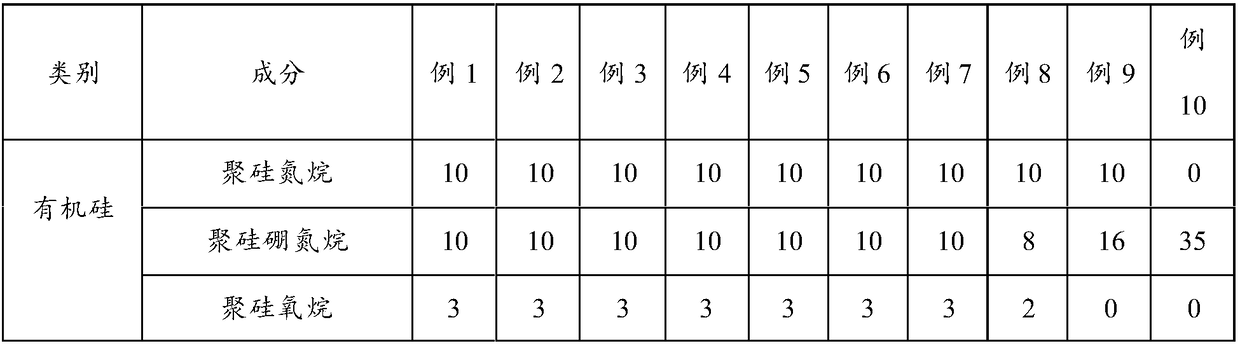

The invention provides a ceramic surface material. The ceramic surface material comprises 20.0wt%-70.0wt% of organosilicone, 20.0wt%-70.0wt% of an organic solvent, 10wt%-50wt% of filler and 0.1wt%-3.0wt% of an auxiliary, wherein the organic solvent is selected from one or more of butyl acetate, dimethylbenzene, n-butyl ether, butyl carbitol acetate, hexahydrotoluene, normal octane and butyl titanate; and the filler consists of graphene, graphite, transition group metallic oxide, composite silicate, rare earth oxide, nonmetal and metal. The components in the ceramic surface material cooperatively interact, and the ceramic surface material has good overall performance when used as a coating.

Owner:ZHAOSHAN TECH BEIJING CO LTD

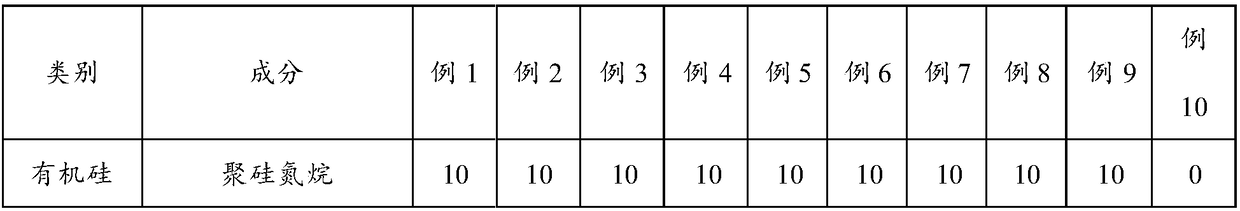

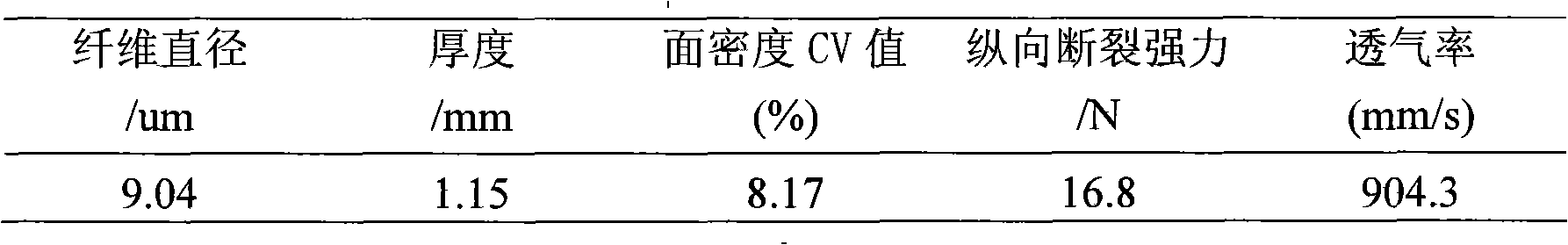

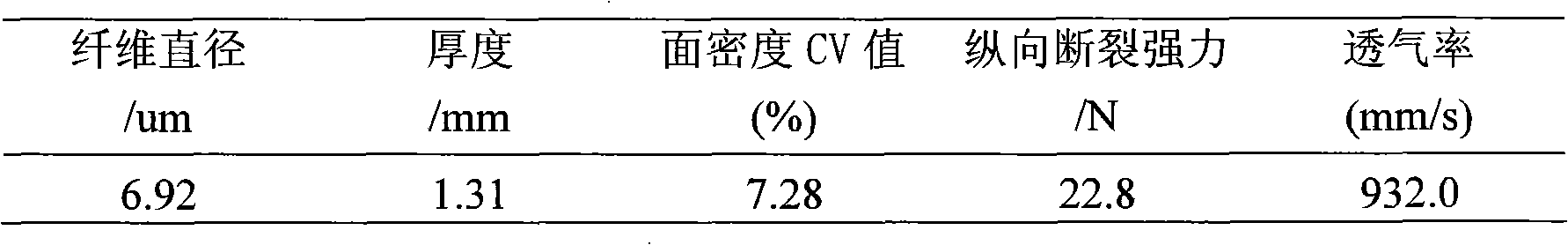

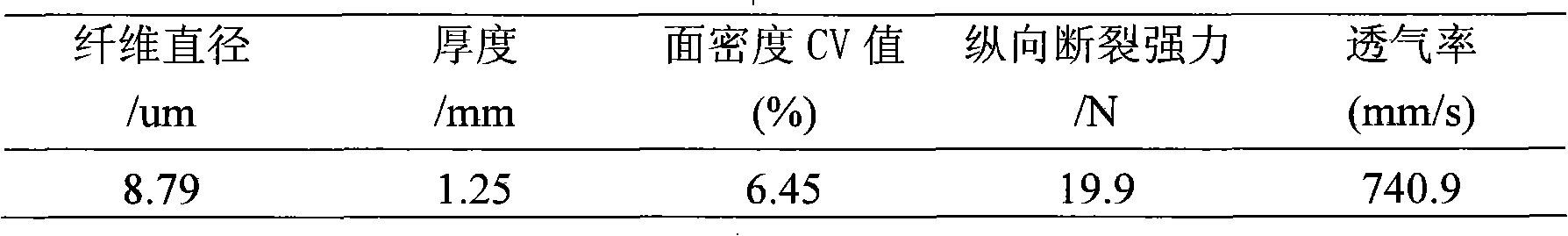

Manufacture method of biodegradable non-woven material

InactiveCN101775705AExcellent thermodynamic propertiesFine fiber diameterSpinning head liquid feederMonocomponent copolyesters artificial filamentPolymer scienceDicarboxylic acid

The invention provides a manufacture method of a biodegradable non-woven material, which is characterized in that the method comprises the following steps: slicing and drying polyethylene succinate-co-p-benzene dicarboxylic acid butanediol ester; heating and fusing polymer slices in a screw rod extruding press; extruding fused mass from spinneret holes of a mold head; using high-pressure air flow for spraying and blowing at both sides of the spinneret holes when the fused mass is extruded from the spinneret holes of the mold head; tensioning the fused mass into superfine fiber; receiving the superfine fiber through a receiving roller; and forming a biodegradable PBST fused spraying non-woven material through the self adhesive effect of the superfine fiber. The non-woven material manufactured by the method of the invention has good thermodynamic performance, fine fiber diameter, good ventilation performance, soft hand feeling and the like, and also has excellent biodegrading capability. The product can be used in the fields of filtering materials, sanitation materials, package materials and the like, and belongs to a product with good development prospects and high added value.

Owner:DONGHUA UNIV

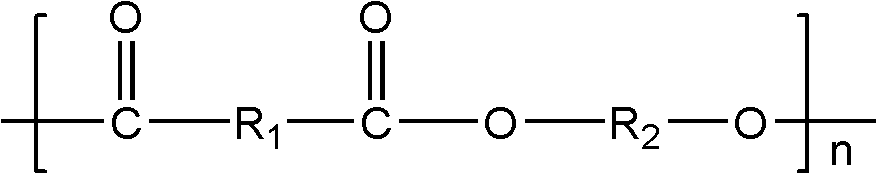

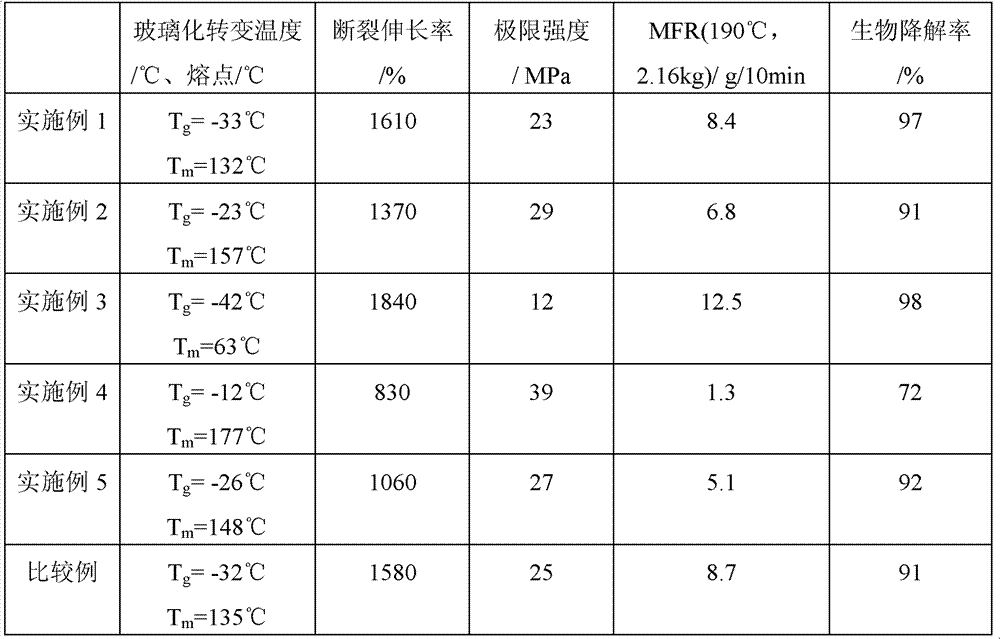

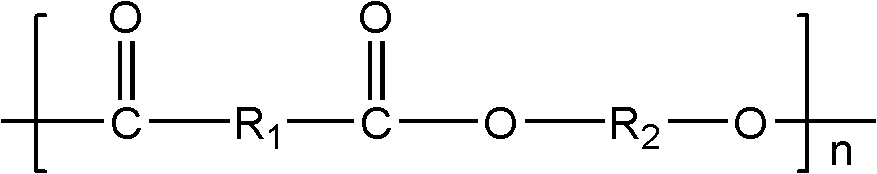

Biodegradable aromatic-aliphatic copolyester and preparation method thereof

ActiveCN103087305AExcellent thermodynamic propertiesPromote degradationMaterial synthesisCopolyester

The invention belongs to the technical field of polymer material synthesis and preparation, and discloses biodegradable aromatic-aliphatic copolyester and a preparation method thereof. The biodegradable aromatic-aliphatic copolyester disclosed in the invention has the a constitutional repeating unit as shown in the specification, wherein R1 is selected from groups as shown in the specification; R3 is selected from Li, Na, K, Rb, Cs, Fr, Be, Mg, Ca, Sr, Ba or Ra; R4 is selected from Li, Na, K, Rb, Cs, Fr, Be, Mg, Ca, Sr, Ba or Ra; R2 is selected from groups as shown in the specification; n=1-1000; p=0-11; q=2-13. According to the invention, binary acid or ester containing a sulfonate group is added, which effectively improves the hydrophilic performance of the copolyester, makes polyester plastics be easier to be adsorbed, decomposed, and absorbed by microbe such as bacteria and the like, and provides plastics with better biodegradability.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

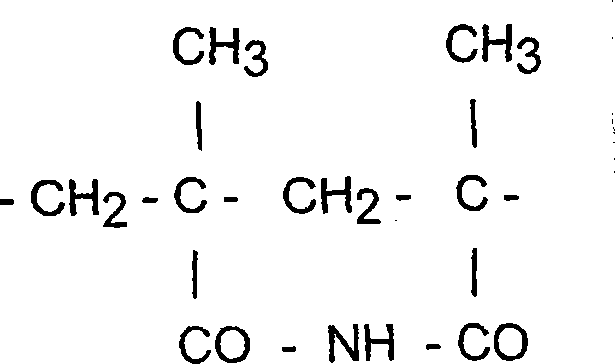

Polymethyl acryloyl imine foam material with appreciable improved thermodynamic property

InactiveCN101173057AExcellent thermodynamic propertiesImprove heat deformation resistanceLamination ancillary operationsSynthetic resin layered productsDouble bondThermal distortion

The invention relates to a preparation method of a polymethacrylimide foam material with obviously improved thermodynamic performance. The invention is characterized in that the polymerization product used for the polymethacrylimide foam material is added with 0.05wt percent to 5wt percent of olefinic unsaturated compound capable of free radical polymerization and with at least two double bonds and 1wt percent to 5wt percent magnesia. The invention also relates to the polymethacrylimide foam material with anti-thermal-distortion larger than 250 DEG C, and the usage of polymethacrylimide foam material in preparing interlayer component.

Owner:ROHM CO LTD

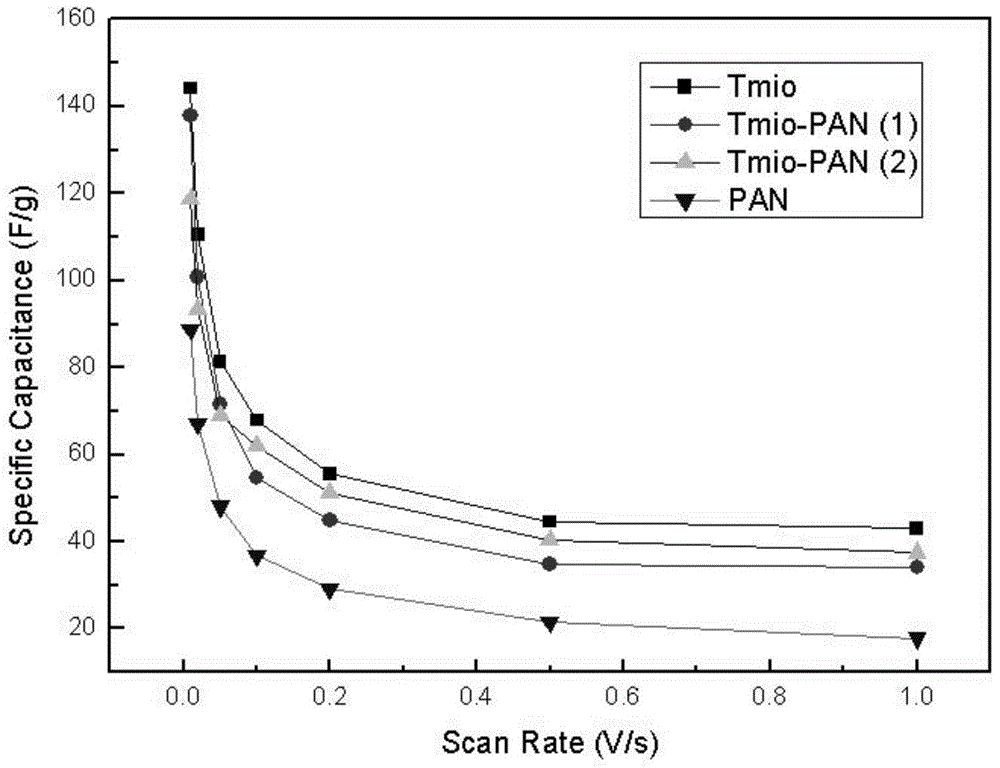

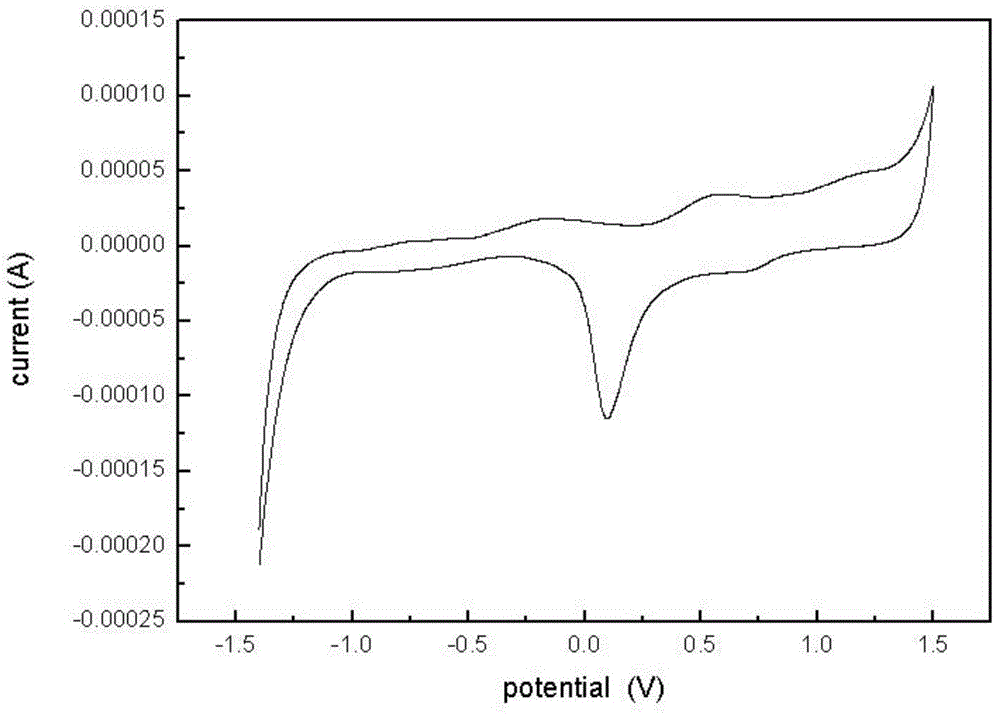

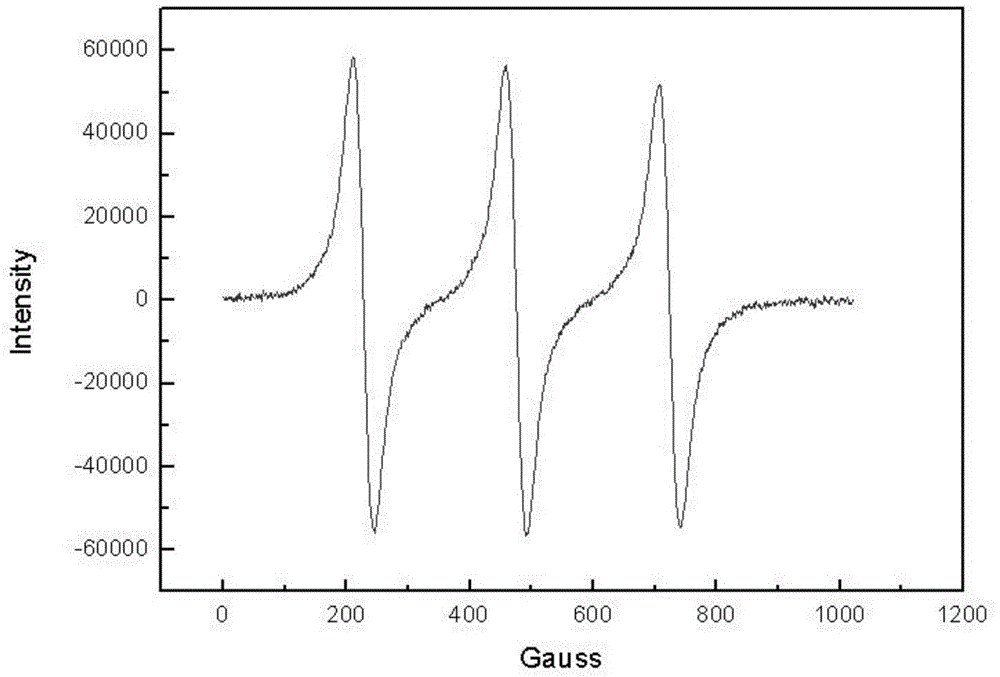

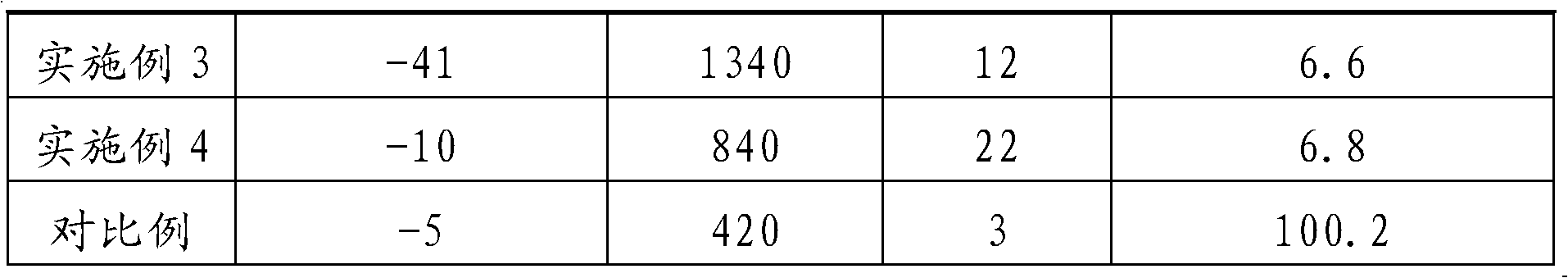

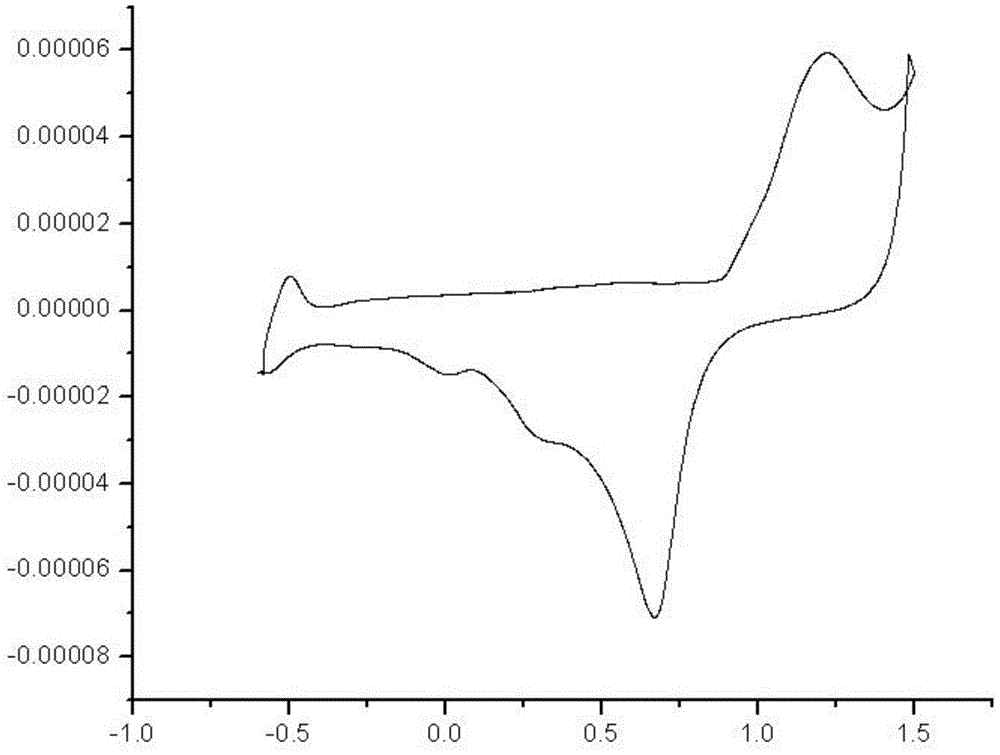

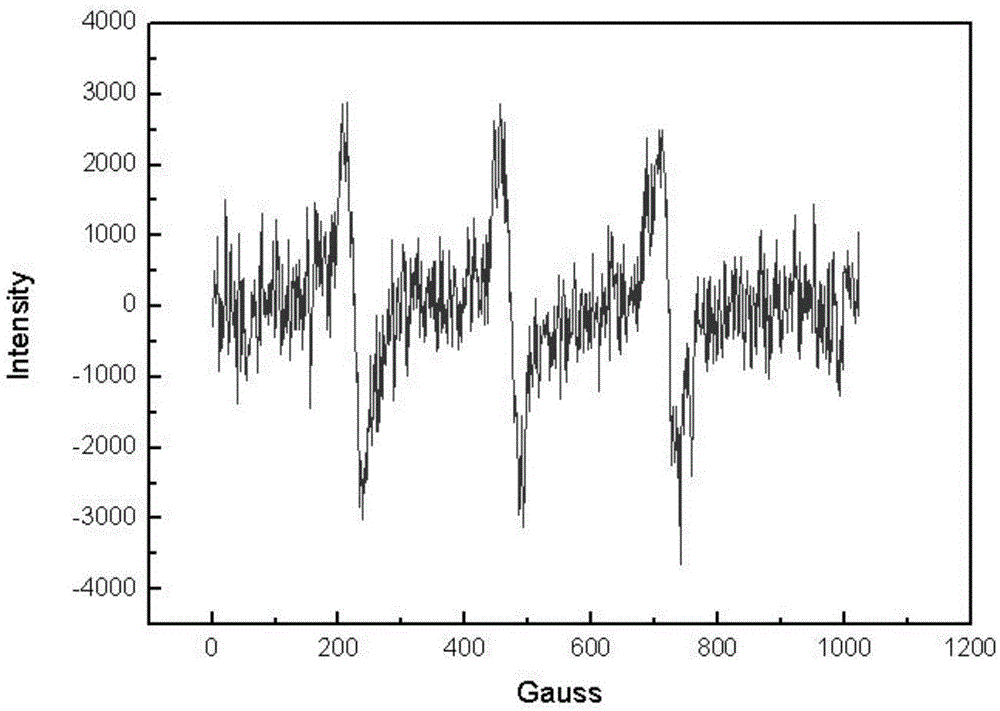

Isoindole nitrogen oxide free radical modified polyaniline and synthetic method and application thereof

The invention discloses an isoindole nitrogen oxide free radical modified polyaniline and a preparation method and an application thereof. 2-, 3-, 5- and 6-site side groups in aniline repeating structural units of a polyaniline high molecular material are chemically modified by an isoindole nitrogen oxide free radical derivative to obtain the product. Or 2-, 3-, 5- and 6-site side groups of aniline monomers are chemically modified by the isoindole nitrogen oxide free radical derivative, and then a polymerization reaction is carried out to obtain the product. Compared with polyaniline, the free radical polymer has better electrical conductivity, higher charge storage density, better capacitance retention rate, fast electrode reaction dynamics performance, and oxidation-reduction ability and characteristic three-line electron paramagnetic resonance spectra similar to isoindole free radicals; and the polymer has good rate capability and cycle stability in the processes of charging and discharging, and is expected to become a novel high-capacity and high-power battery material.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Ceramic paint and application thereof

The invention provides ceramic paint. The ceramic paint comprises 3.0wt%-6.8wt% of organic binders, 15.0wt%-45.0wt% of inorganic binders, 7wt%-35wt% of packing, 2.0wt%-3.0wt% of auxiliaries and the balance water. The organic binders are made of silicone emulsion, the inorganic binders are made of sodium water glass, and the packing comprises rare-earth oxide, graphite, mica, kaolin, copper chromite black, zirconia and chromium oxide. The invention further provides application of the ceramic paint to industrial furnaces. The ceramic paint and the application have the advantages that mutual synergistic effects can be realized by components in the ceramic paint, and accordingly the ceramic paint is excellent in comprehensive performance when used as a ceramic coating.

Owner:铜陵兆山科技有限公司

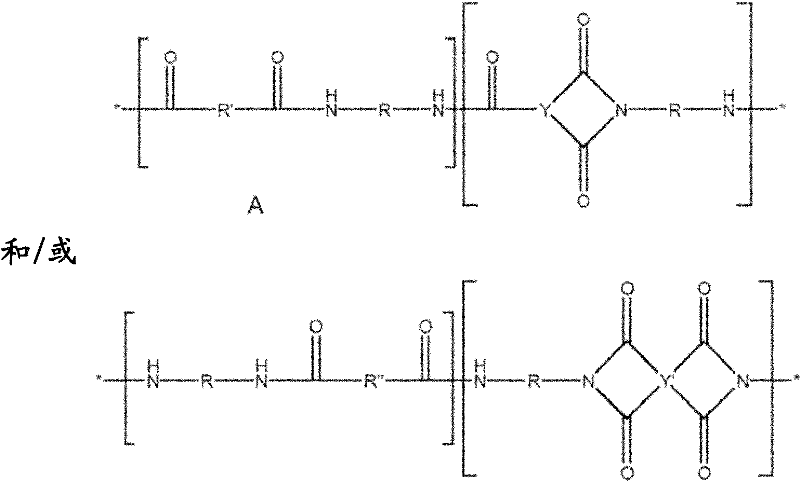

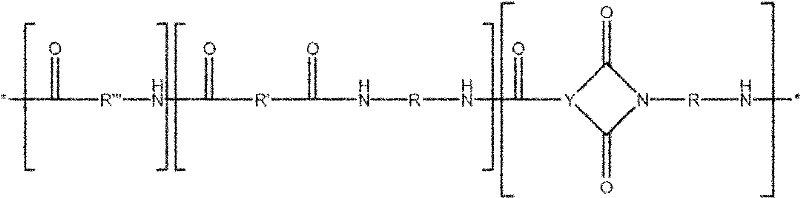

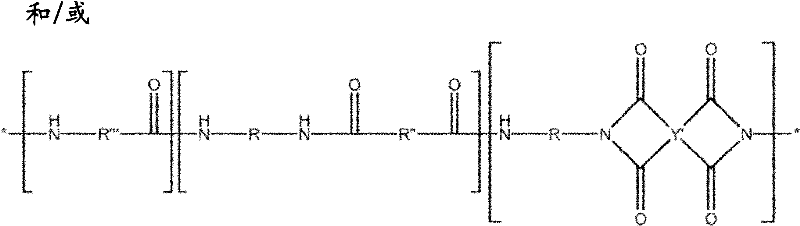

Process for preparing a polyamideimide, a polyamideimide and composition comprising this polyamideimide

The present invention relates to a process for preparing a semi-aromatic polyamideimide, and also to a polyamideimide and to a composition based on a thermoplastic matrix, comprising a polyamideimide. The invention relates more particularly to a process for preparing a polyamideimide by melt polymerization of at least one organic compound having carboxyl groups, of at least one diamine compound and optionally at least one diacid compound.

Owner:RHODIA OPERATIONS SAS

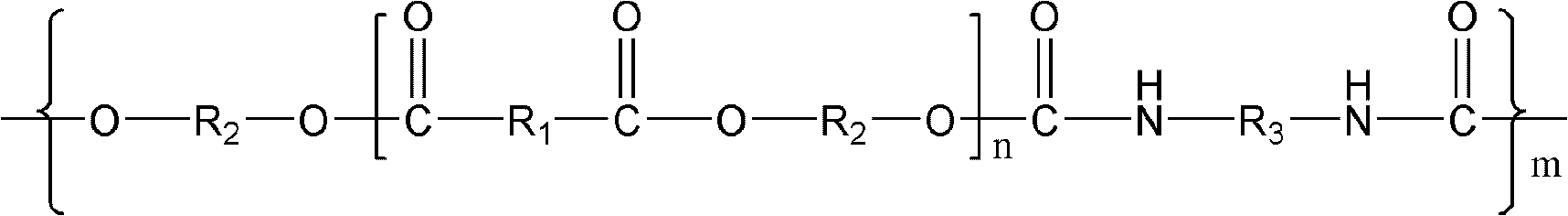

High-molecular-weight polyester plastic based on 2,3-butanediol and preparation method for same

The invention discloses a high-molecular-weight polyester plastic based on 2,3-butanediol. The polyester plastic has a repetition structure unit shown in the formula, wherein R1 is defined in the specification, p is 0-11, R2 is defined in the specification, R3 is defined in the specification, n is 1-1000, and m is 1-1000. The invention further discloses a preparation method for the high-molecular-weight polyester plastic based on 2,3-butanediol. The polyester plastic is a transparent polyester plastic due to the existence of the side-chain methyl of 2,3-butanediol, as well as is high in molecular weight, excellent in mechanical property, and wide in application prospect in the aspects of injection-moulded parts, optical devices, thin films, laminated materials and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Isoindole nitrogen oxide free radical modified polypyrrole and preparation method and application thereof

InactiveCN104530426AGuaranteed long-term reversibilityGuaranteed charge and discharge rate performanceCell electrodesCapacitancePolypyrrole

The invention discloses an isoindole nitrogen oxide free radical modified polypyrrole and a preparation method and an application thereof. 3- and 4-site side groups in pyrrole repeating structural units of a polypyrrole high molecular material are chemically modified by an isoindole nitrogen oxide free radical derivative to obtain the product. Or 3- and 4-site side groups of pyrrole monomers are chemically modified by the isoindole nitrogen oxide free radical derivative, and then a polymerization reaction is carried out to obtain the product. Compared with polypyrrole, the modified polypyrrole has better electrical conductivity, higher charge storage density, better capacitance retention rate, fast electrode reaction dynamics performance, and oxidation-reduction ability and characteristic three-line electron paramagnetic resonance spectra similar to isoindole free radicals; the polymer has good rate capability and cycle stability in the processes of charging and discharging; and after 500-cycle charging and discharging circulation, the coulomb efficiency can be still kept at 95% or more, and the modified polypyrrole is expected to become a novel high-capacity and high-power battery material.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

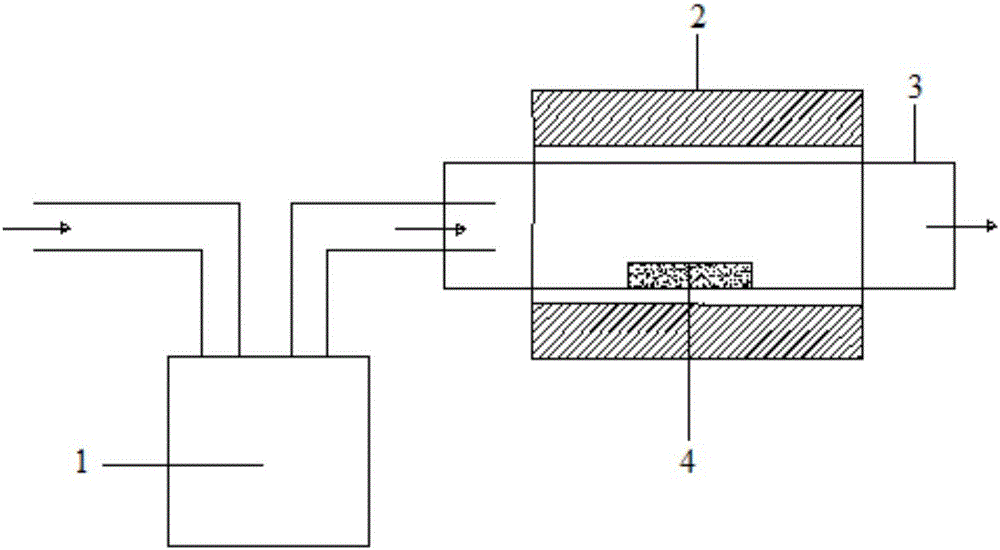

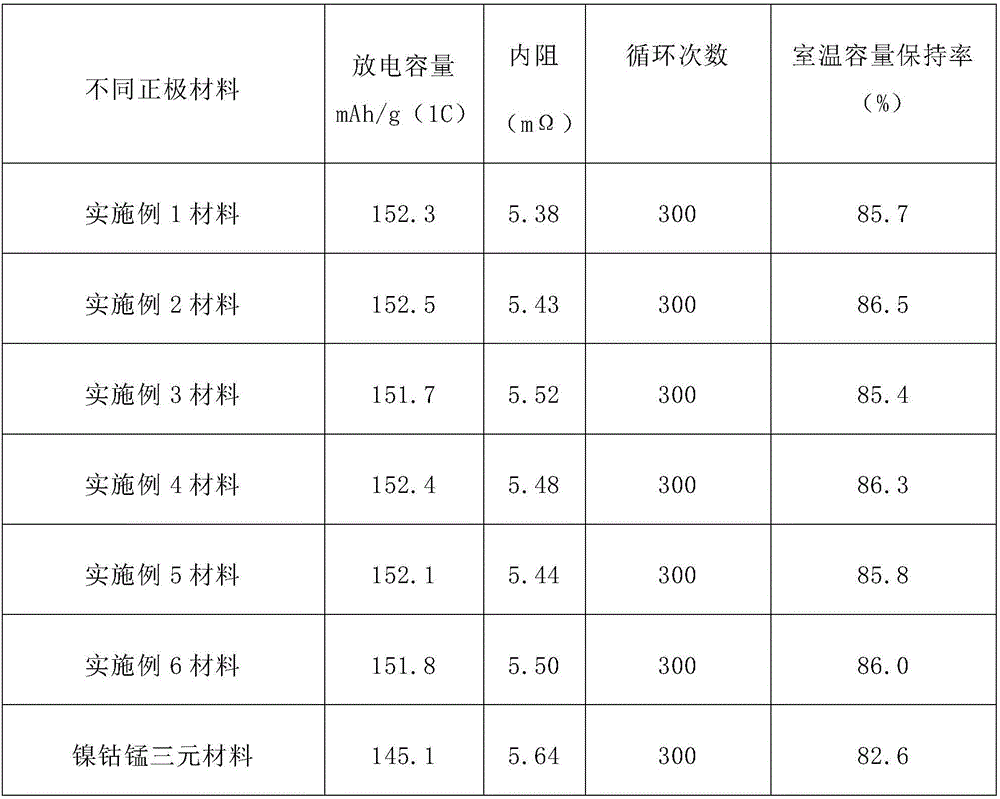

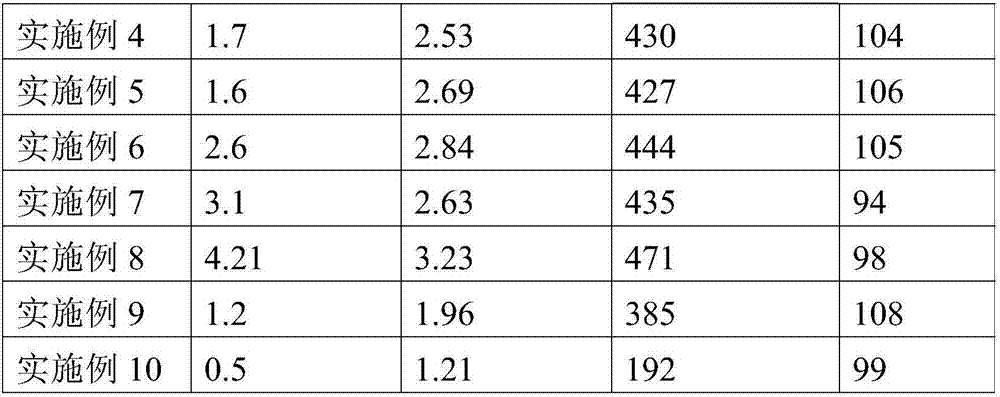

Preparation method for carbon nano-tube composite nickel-cobalt-magnesium-titanium four-component positive electrode material

ActiveCN106058218AHigh charge and discharge capacityHigh densityNon-aqueous electrolyte accumulatorsCell electrodesCatalytic pyrolysisReaction temperature

The invention discloses a preparation method of a carbon nano-tube composite nickel-cobalt-magnesium-titanium four-component positive electrode material, belonging to the field of lithium-ion batteries. The preparation method comprising the following steps: preparing a nickel-cobalt-magnesium-titanium four-component positive electrode material with a molecular formula of Li(Ni<x>Co<y>Mg<z>Ti<z>)O<2> by using a chemical co-precipitation method, wherein x+y+2z = 1, 0.7 <= x <1, 0.05 <= y <= 0.1, and 0.05 <= z <= 0.1; subjecting a selected metal catalyst and the nickel-cobalt-magnesium-titanium four-component positive electrode material in a certain ratio to ball milling so as to obtain a mixture A; and placing the mixture A into a quartz tube, introducing a gaseous carbon source, allowing reaction temperature to rise so as to realize a catalytic pyrolysis reaction of the gaseous carbon source with the mixture A and carrying out cooling to room temperature so as to obtain the perfectly-coated carbon nano-tube composite nickel-cobalt-magnesium-titanium four-component positive electrode material. According to the invention, the perfectly-coated composite positive electrode material can be obtained by selecting proper process and technological parameters, so the charge-discharge capacity and charge-discharge current density of conventional lithium-ion batteries can be improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

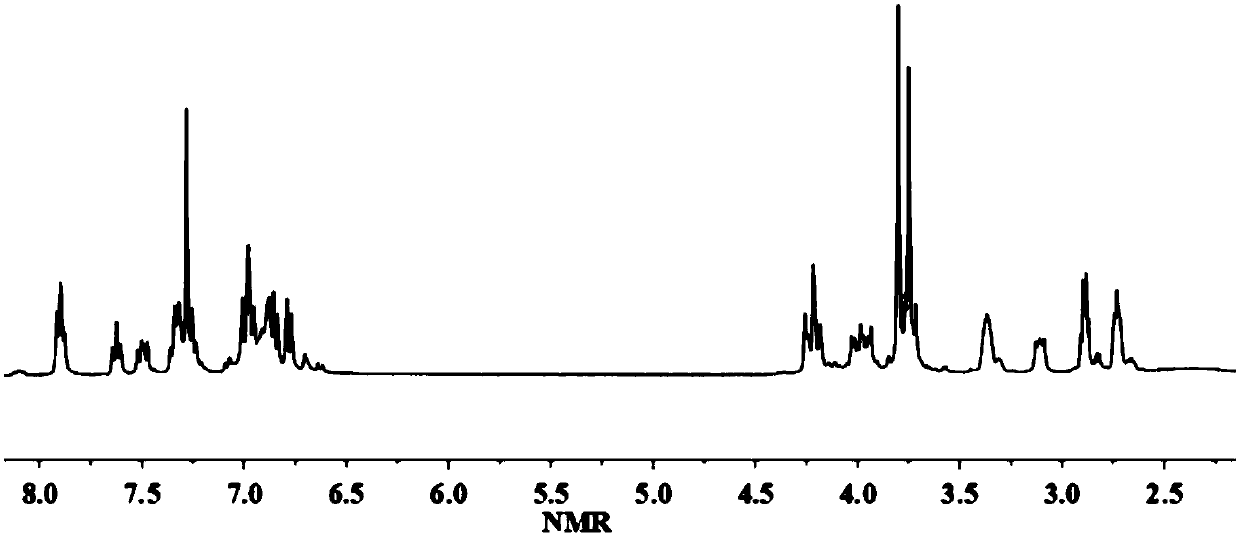

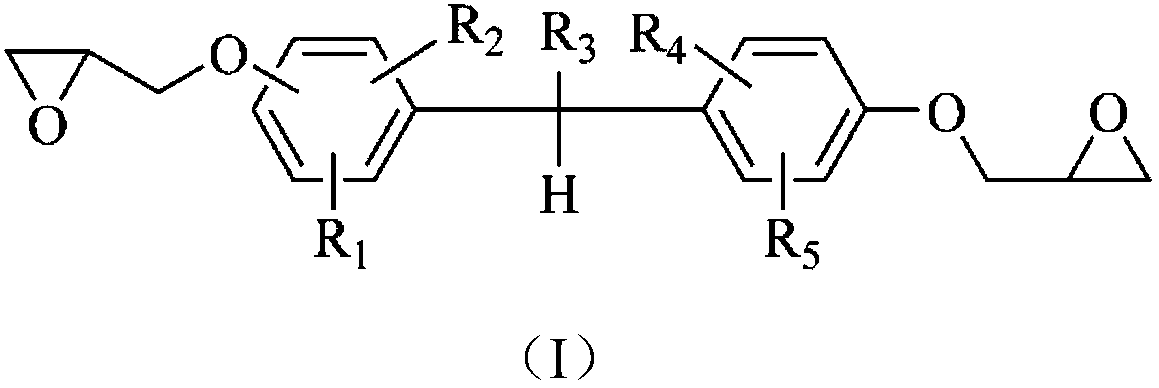

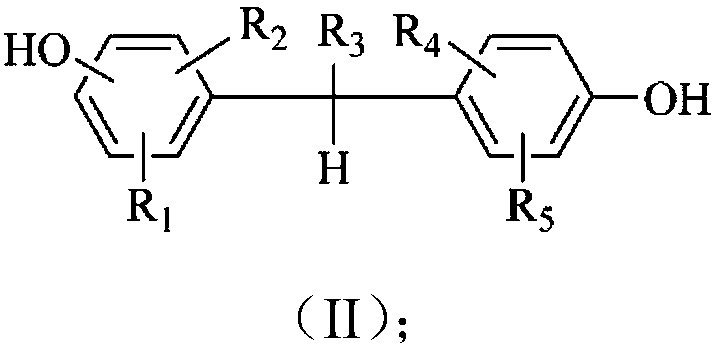

3,3',5,5'-tetramethyl-4,4'-biphenyldiglycid ether preparation method

InactiveCN1733745AReduce processing viscosityImprove solubilityOrganic chemistryPolymer scienceEther

The invention relates to a process for preparing 3,3',5,5'-tetramethyl-4,4'-biphenyl didycidyl ether, wherein the 3,3',5,5'-tetramethyl-4,4'-biphenol is reacted with excess epichlorohydrin under the action of phase transition catalyst. The prepared has low epoxy equivalent weight, high yield, and simple reaction steps.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

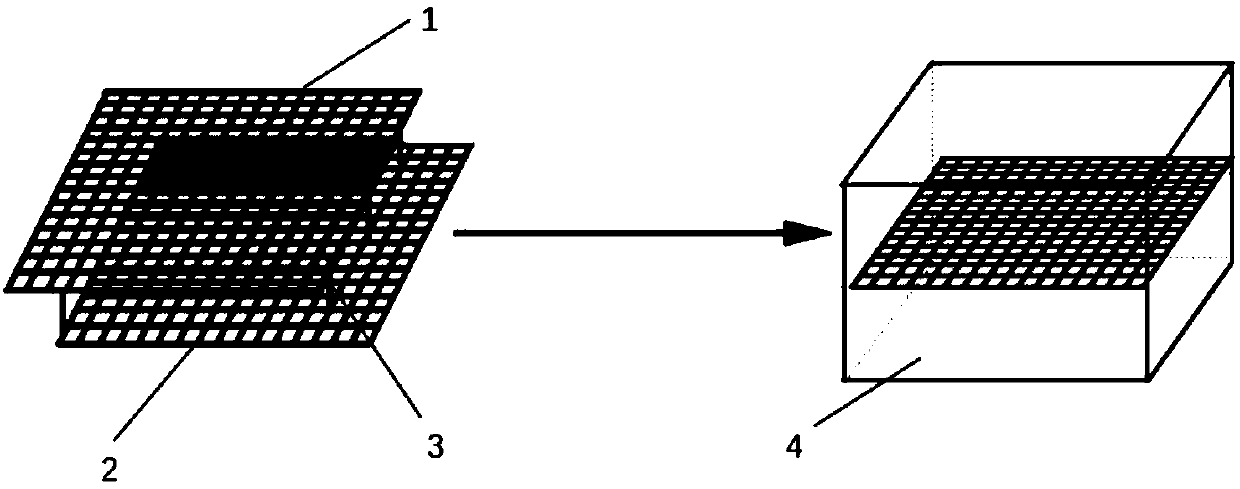

Method for manufacturing carbon-metlbond lamination retaining frame materials for rolling bearings

The invention relates to a method for manufacturing carbon-metlbond lamination retaining frame materials for rolling bearings, which comprises the steps that carbon fiber cloth is used as a substrate, prepared phenolic resin is used as a bonding body, and the carbon-metlbond lamination retaining frame materials are obtained through phenolic resin dipping of the carbon fiber cloth, hot pressing coiling formation and post curing. The carbon-metlbond lamination retaining frame materials have a higher heat conductivity coefficient and a lower thermal expansion coefficient, through detection, the use temperature reaches 150 to 220 DEG C, the heat conductivity coefficient is greater than or equal to 0.85 (W / m-K), the thermal expansion coefficient is smaller than or equal to 1.0*(10<-6> / DEG C), the tensile strength is greater than or equal to 150 Mpa, and the elastic modulus is greater than or equal to 50Gpa. The performance parameter is improved or reduced, so the retaining frame manufactured by the carbon-metlbond lamination materials can meet the use requirement of a rolling bearing at a high temperature and a high speed.

Owner:LUOYANG BEARING RES INST CO LTD

Luminescent polymer materials containing 8-hydroxy quinoline metal complex and their preparation and use

InactiveCN1583947AExcellent thermodynamic propertiesImprove solubilityLuminescent compositionsPolymer scienceQuinoline

Invention this person who involves high polymer contain 8-hydroxyl quinoline metal cooperate with polymer of thing give light the material and make France and use, organic / the high polymer and electricity send and give out light materials there is extensive application in the field of photoelectron. At present it is the organic / last shortcoming exist high plymer, it is prepare there aren't performance the good electricities not to make its unable. Last heavy luminescence material invention, 8 among material-cooperate with hydroxyl quinoline metal the contents high polymer 1-30% of weight for thing. This material from one kin alkenes been the single with containin by 8-hydroxyl quinoline mix alkenes of body the single and through free radical tool formate not lasting 8 first-hydroxyl quinoline mix High polymer, lie in it is to reserve vacancy since have 8-metal cooperate with thing of through cooperating not turning into not for 8ing-hydroxyl quinoline metal cooperate with high polymer of thing of at quinoline hydroxyl. Have craft to be simple, equipment with little investment aveantage. Will give out light material can use as organic / high polymer electricity is it give out light level show electricity of device is it give out light material and electron transmit materials to send.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Aramid nano-fiber modified chitosan composite film as well as preparation method and application thereof

ActiveCN106955599AEvenly dispersedHigh strengthSemi-permeable membranesPolymer scienceComposite film

The invention belongs to the technical field of chitosan composite materials and discloses an aramid nano-fiber modified chitosan composite film as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) adding aramid, an organic solvent, strong base and a dispersing aid into a container, heating, and uniformly stirring and dispersing, so as to obtain an aramid nano-fiber dispersing solution, wherein the organic solvent is a strong-polar organic solvent; and (2) adding chitosan-strong acid salt into the aramid nano-fiber dispersing solution, dissolving, carrying out film coating, adding the solution into a gel bath, standing, soaking into a cleaning agent, and drying, so as to obtain the aramid nano-fiber modified chitosan composite film. The composite film has excellent high-temperature resistance and thermodynamic property and relatively good film forming effect; and the preparation method is simple, a reagent is easily available and controllable, the cost is relatively low, and the industrial production is easily realized.

Owner:NANXIONG MATERIAL PRODION BASE OF CHINESE ACADEMY OF SCI GUANGZHOU CHEM +2

Resin composition and preparation method thereof

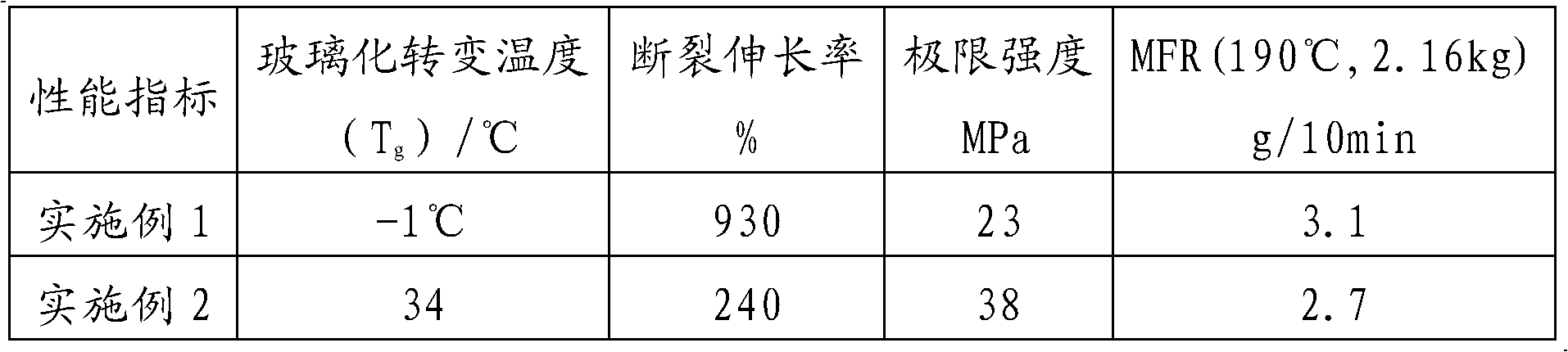

ActiveCN101724209AImprove impact resistanceImprove low temperature resistanceThermoplastic elastomerPolyvinyl chloride

The invention provides a resin composition, which contains the following constituents in part by weight: 100 parts of polrvinyl chloride resin, 3 to 50 parts of ABS resin and 3 to 30 parts of composite compatilizer which are blended, wherein the composite compatilizer consists of a thermoplastic elastomer graft and chlorinated polyethylene; the thermoplastic elastomer graft is the graft of styrene-butadiene-styrene block copolymer or styrene-pentadiene-styrene block copolymer and a polar monomer; and the mass ratio of the thermoplastic elastomer graft to the chlorinated polyethylene in the composite compatilizer is 10:90 to 60:40. The resin composition has extremely high shock resistance, excellent low temperature resistance, superior stretching resistance, good rigidity and good thermodynamic property. A method for preparing the composition of the invention is simple in process and easy in operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ceramic surface material and surface coating

ActiveCN108587458AImprove thermal stabilityImprove high temperature corrosion resistanceFireproof paintsAntifouling/underwater paintsSurface coatingTransition metal

The invention provides a ceramic surface material, which is prepared from 20.0 to 70.0 weight percent of organic silicon, 20.0 to 70.0 weight percent of organic solvents, 1.0 to 50 weight percent of filling materials and 0.1 to 3.0 weight percent of auxiliary agents, wherein the organic solvents are selected from one or several kinds of materials from butyl acetate, xylene, n-butyl ether, di-ethylenhje glycol mono butyl ether acetate, methylcyclohexane, normal octane and butyl titanate; the filling materials are prepared from graphene, graphite, transition metal oxide, compound silicate, rareearth oxides, nonmetal, nonmetal compounds, transition metal boride and metal. The ingredients in the ceramic surface material achieve the mutual cooperated effects, so that the better comprehensive performance is realized when the ceramic surface material is used as a coating.

Owner:ZHAOSHAN TECH BEIJING CO LTD

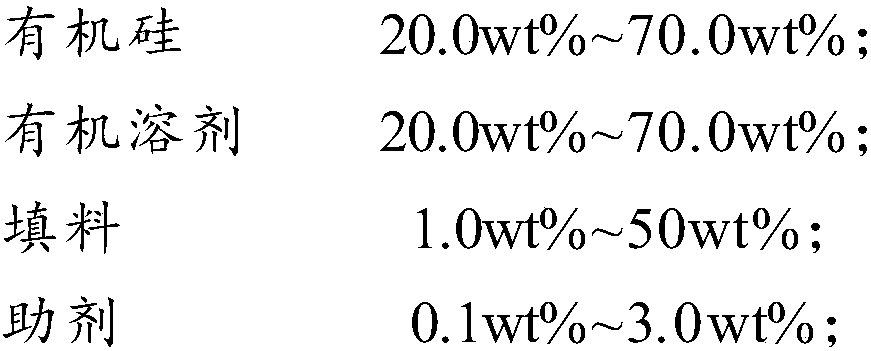

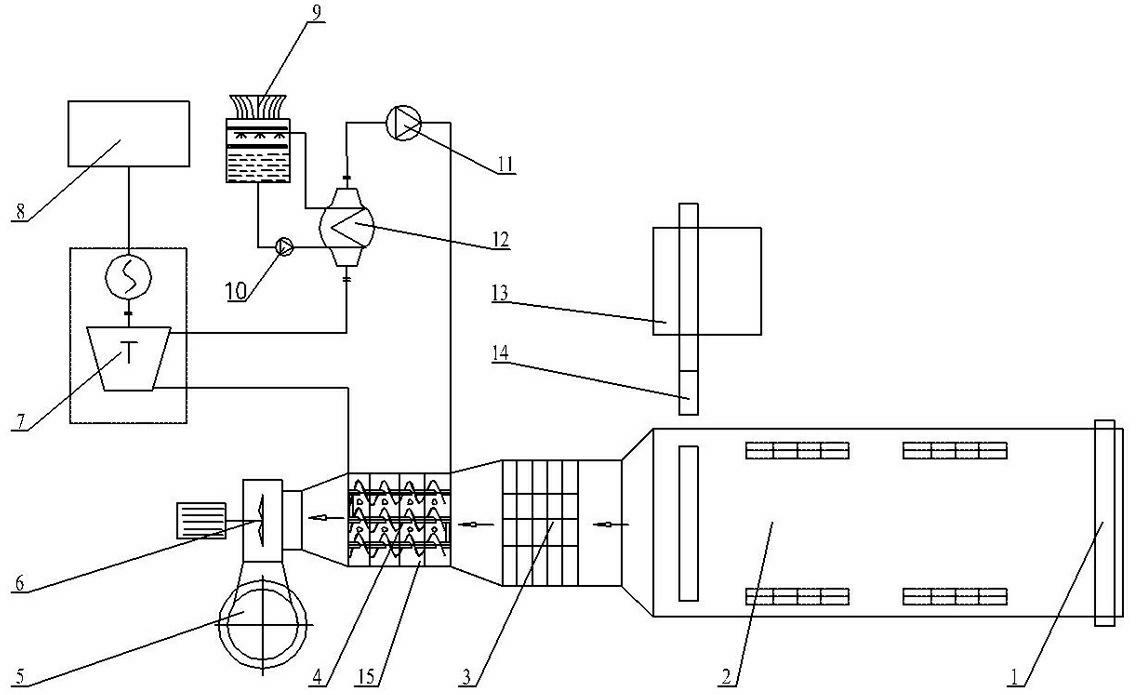

Carbon dioxide heating and cooling combined system

ActiveCN105135749ADestruction Potential 0High cooling capacity per unit volumeFluid heatersMechanical apparatusOzone layerEngineering

The invention discloses a carbon dioxide heating and cooling combined system. The system adopts two parts; one part adopts R134a as a high temperature part of a refrigerant, and the other part adopts carbon dioxide as a low temperature part of the refrigerant. The carbon dioxide heating and cooling combined system has the beneficial effects that: all of the refrigerant adopted by the system is an environment-friendly refrigerant; R134a is a medium-low-temperature environment-friendly refrigerant which is widely popular at present; carbon dioxide is adopted as a pure natural refrigerant; an ozone layer depletion potential value is 0; a global warming potential value is 1; carbon dioxide has relatively high unit volume refrigerating capacity and has excellent thermodynamic property; the system can completely recycle heat of condensation to generate high-temperature hot water, medium-temperature hot water and low-temperature hot water; an expansion machine which is additionally arranged in the system utilizes energy lost by throttling and reducing pressure, improves back pressure of carbon dioxide and greatly improves the efficiency of the whole system; heat of condensation of an additional support system is completely utilized by the system to increase a back temperature of carbon dioxide.

Owner:黑龙江爱科德科技有限公司

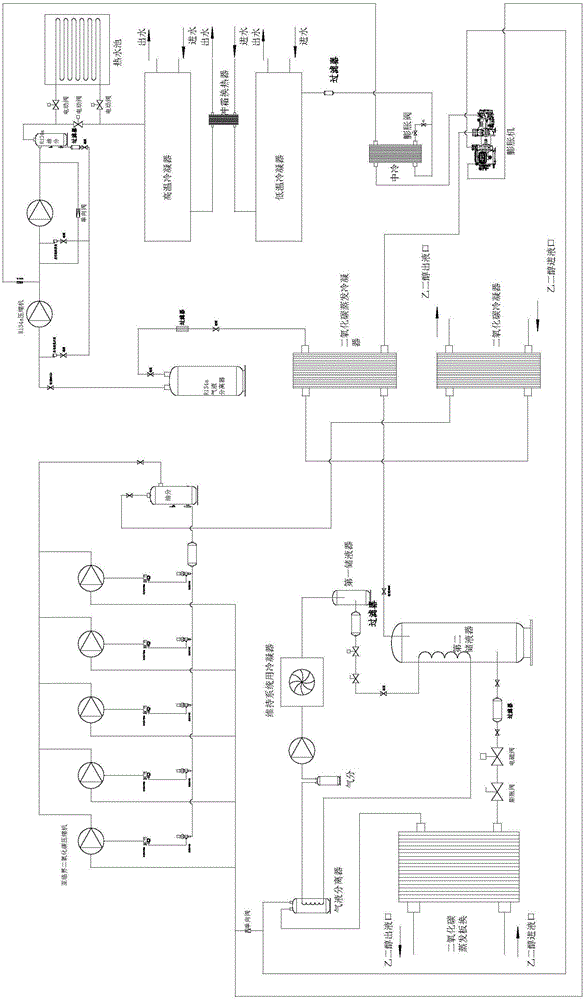

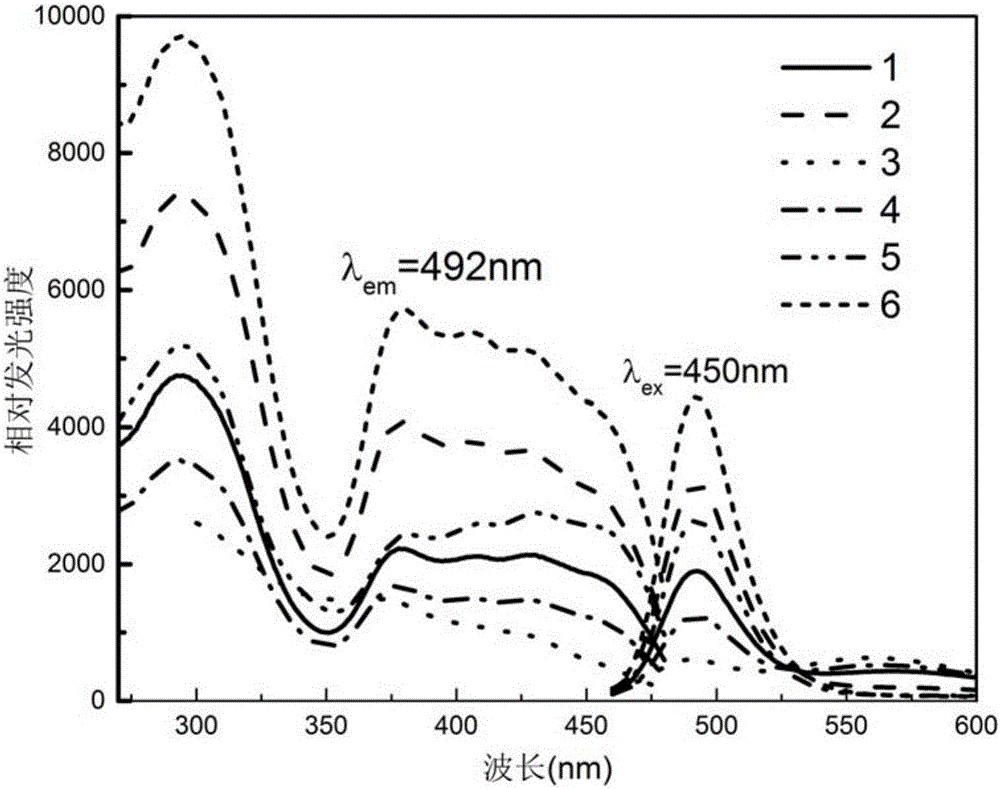

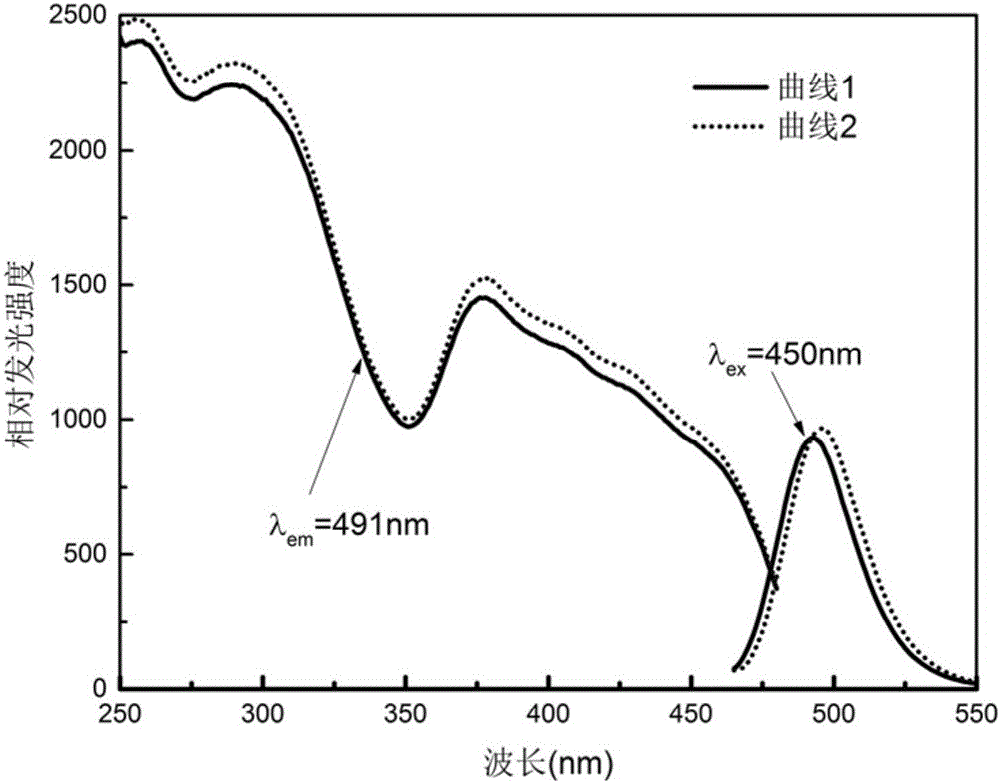

Rare earth doped fluorescent powder and synthetic method thereof and application of fluorescent powder in LED devices

ActiveCN106047341AGood chemical stabilityImprove luminous efficiencyLuminescent compositionsSemiconductor devicesSynthesis methodsElectronegativity

The invention discloses rare earth doped fluorescent powder and a synthetic method thereof and application of the fluorescent powder in LED devices, and belongs to the technical field of luminescent materials. The general chemical formula of the fluorescent powder is MS[2-y]AyO[2+y]N[2-y-4z / 3]Cz:Rx. According to the compound, C<4-> is substituted for N<3->, due to the fact that the electronegativity of C is smaller than that of N, the electron cloud expansion effect of the C<4-> is more obvious than that of the N<3->, after doping is conducted, rare earth ion 5d energy level splitting is increased, Stokes shift can change, and fluorescence parameters such as fluorescent peal and full half-peak width of the powder change. By adjusting generation of the above-mentioned doped ions, fluorescent powder with different fluorescent light colors and quantum efficiency can be obtained. The invention further discloses the application of the fluorescent powder in the field of LED devices. The fluorescent powder is applied to white LED light fixtures or light-emitting components which take blue LED or purple LED as a light source and can help to increase the color rendering indexes of the devices.

Owner:BEIJING YUJI SCI & TECH +2

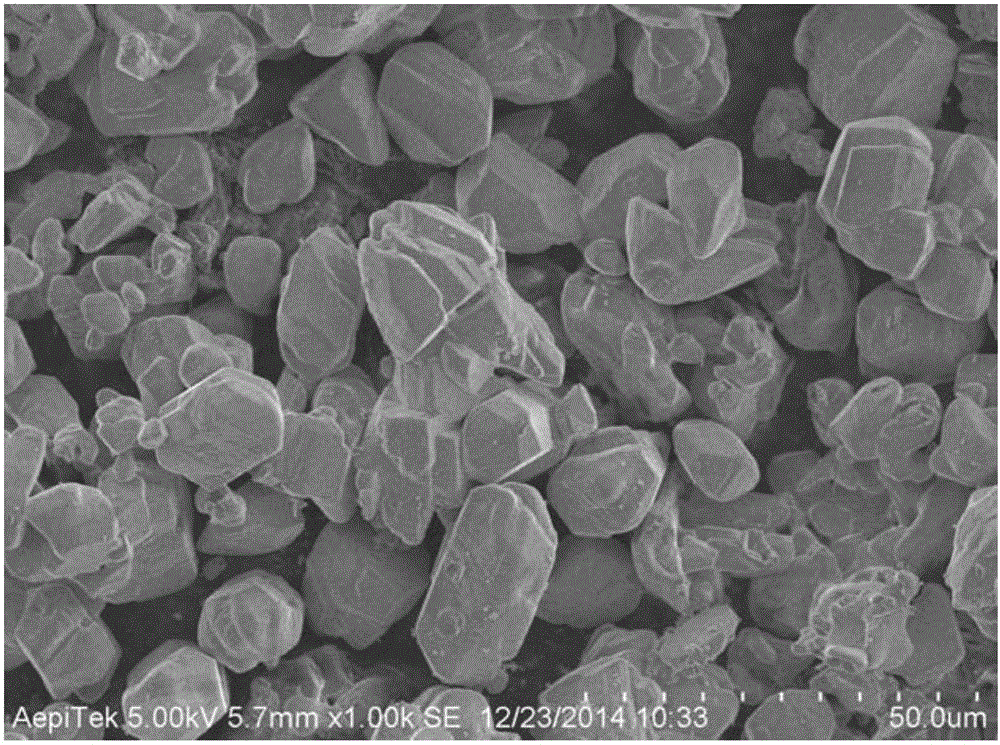

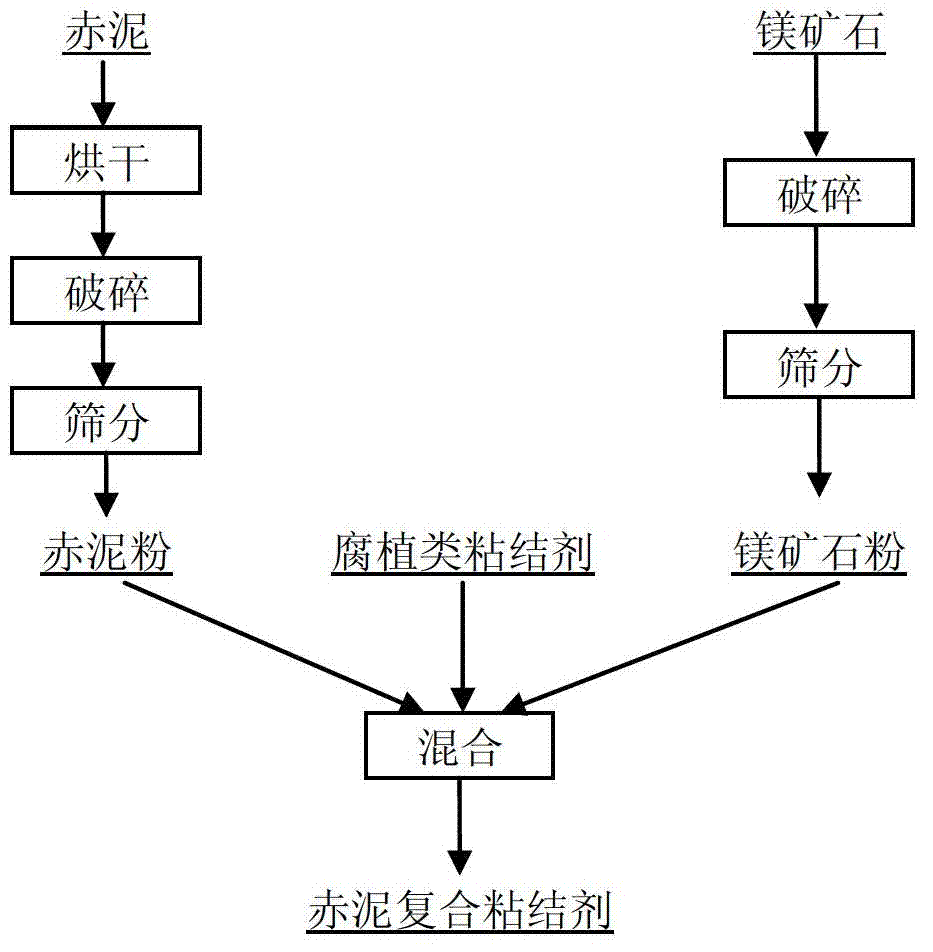

Red mud composite binder for oxidized pellets

The invention discloses red mud composite binder for oxidized pellets. The red mud composite binder is prepared by waste red mud of aluminum plants, magnesite stone and humus binder. The red mud composite binder has characteristics of good hydrophily, excellent binding effect, low price, high iron content and the like. The granularity of the red mud composite binder is smaller than 200 meshes, partial weight ratio is larger than or equal to 90%, and water content is smaller than or equal to 1%. Therefore, the red mud composite binder can partially or totally replace bentonite to be used for producing the oxidized pellets. Compared with the technology completely utilizing the bentonite to produce the oxidized pellets, production rates of pellet TFe, sinter TFe and an ironmaking system are all improved, and slag quantity of a blast furnace is reduced. Besides, the content of MgO in the pellets is increased, so that the thermodynamic property of the pellets is good, and operation of the blast furnace is facilitated.

Owner:LAIWU IRON & STEEL GRP

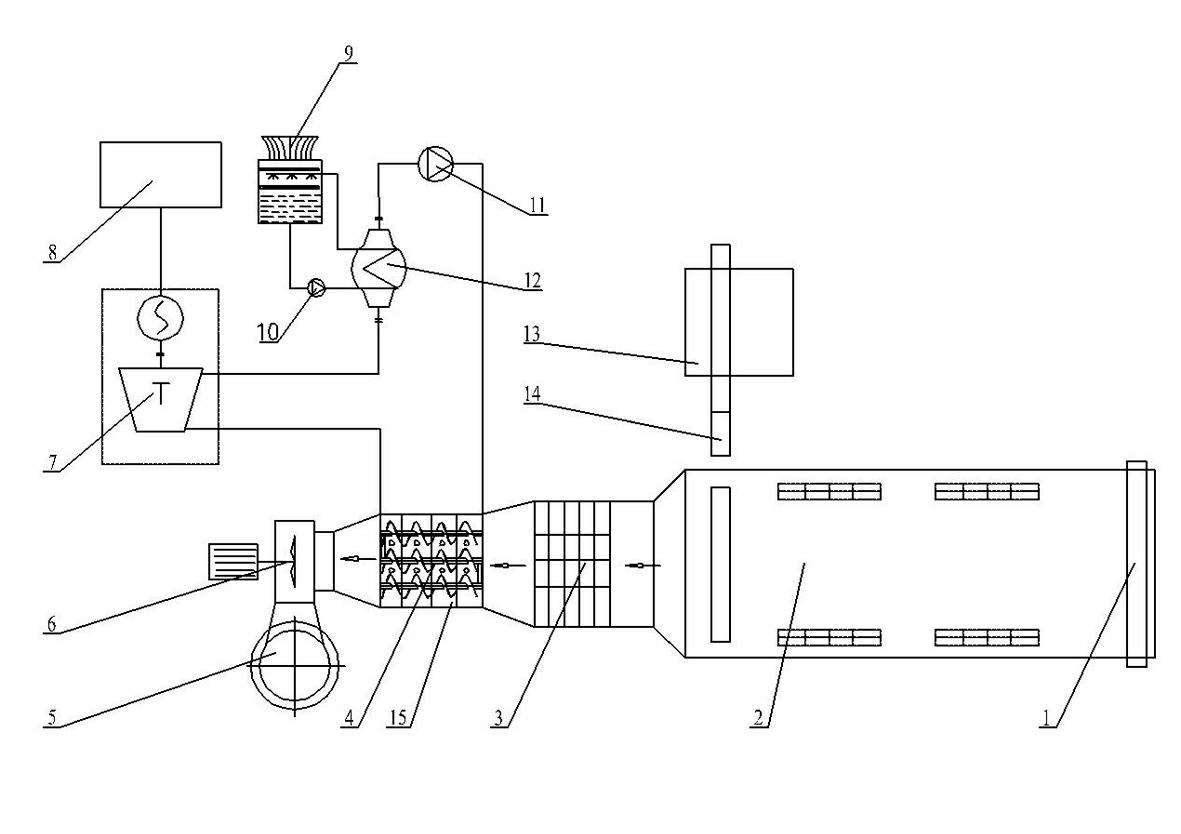

Low-grade smoke organic rankine cycle waste heat generating system of heating furnace in steel rolling plate plant

InactiveCN102121405AHigh densitySmall specific volumeEnergy industryIncreasing energy efficiencyOrganic Rankine cycleEngineering

The invention relates to a low-grade smoke organic rankine cycle waste heat generating system of a heating furnace in a steel rolling plate plant, wherein air, a coal gas heat exchanger and a working medium evaporation chamber are in the heating furnace; the working medium evaporation chamber is filled with normal pentane and is provided with a working medium tubular evaporator; a steam outlet of the working medium evaporator is connected with a steam inlet of a steam turbine generator set through a pipeline; the steam outlet of the steam turbine generator set is connected with a steam inlet of a fixed tube-plate type heat exchanging condenser through a pipeline; a liquid outlet of the fixed tube-plate type heat exchanging condenser is connected with a liquid inlet of a seal circulating pump through a pipeline; a liquid outlet of a working medium seal circulating pump is connected with a working medium liquid inlet of the evaporation chamber through a pipeline; a water outlet of a cooling tower is connected with a water inlet of a water circulating pump through a pipeline; a water outlet of the water circulation pump is connected with a cooling water inlet of the fixed tube-plate type heat exchanging condenser through a pipeline; and a cooling water outlet of the fixed tube-plate type heat exchanging condenser is connected with the cooling tower through a pipeline. According to the invention, the waste heat of tail gas of the heating furnace at the temperature of 300-100 DEG C can be recycled.

Owner:WUXI SANDA ENVIRONMENTAL PROTECTION TECH CO LTD

Ceramic surface material and surface coating

ActiveCN108641594AImprove toughnessImprove thermal stabilityFireproof paintsAntifouling/underwater paintsOrganosiliconEther

The invention provides a ceramic surface material. The ceramic surface material comprises 20.0-70.0 wt% of organosilicon, 20.0-70.0 wt% of an organic solvent, 1.0-50 wt% of a filler and 0.1-3.0 wt% ofan assistant, wherein the organic solvent is one or more selected from butyl acetate, xylene, n-butyl ether, diethylene glycol butylether acetate, methylcyclohexane, n-octane and butyl titanate; andthe filler is composed of graphene, graphite, transition metal oxide, composite silicate, rare earth oxide, nonmetal, a nonmetallic compound and metal. Components in the ceramic surface material havesynergistic effects, so the ceramic surface material has good comprehensive performances as a coating layer.

Owner:ZHAOSHAN TECH BEIJING CO LTD

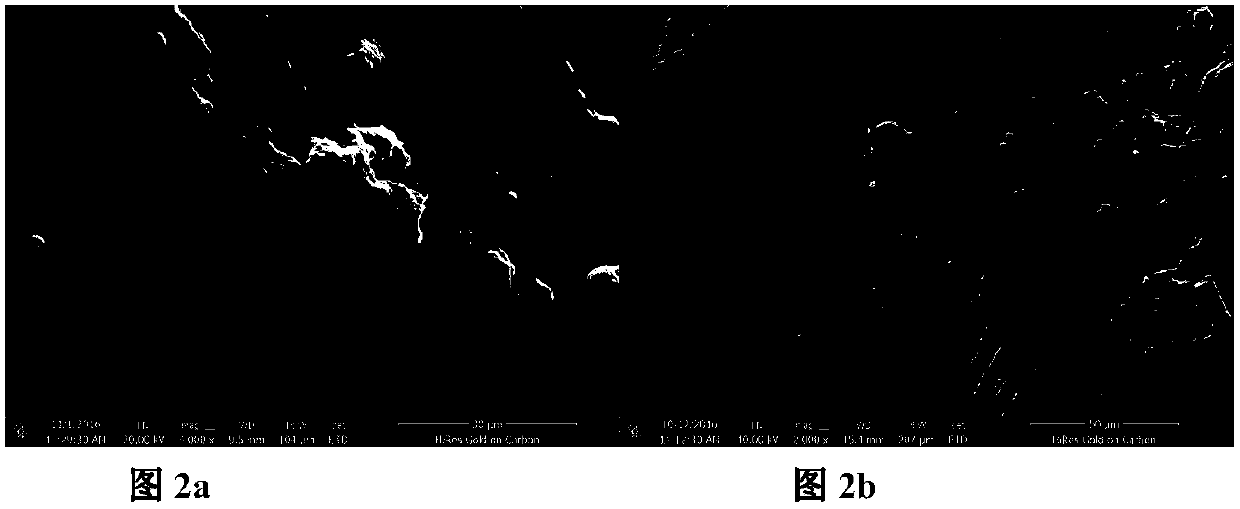

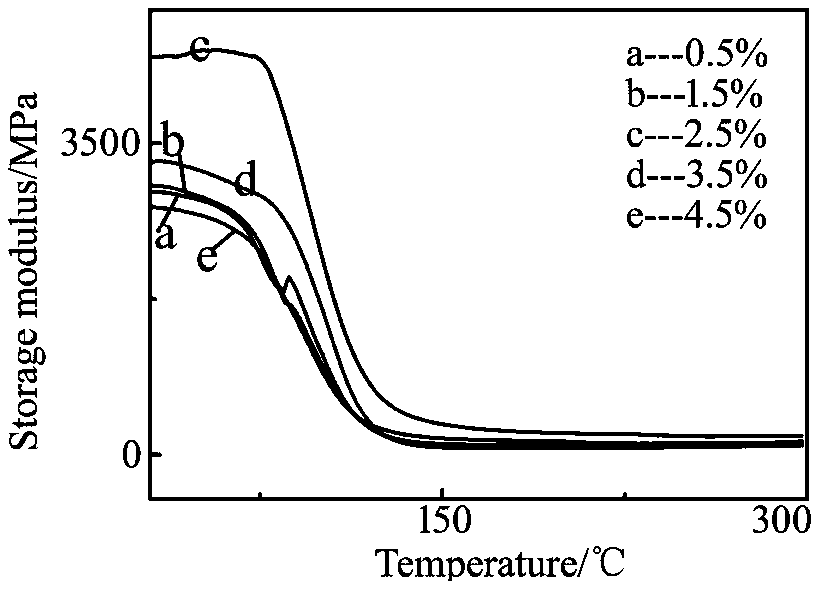

Preparation method for silane coupling agent modified CNTs/CFDSF/AG-80 epoxy resin composite material

InactiveCN107698739AEvenly distributedImprove conductivityCarbon fibresDry-cleaning apparatus for textilesEpoxyFiber

The invention relates to a preparation method for a silane coupling agent modified CNTs / CFDSF / AG-80 epoxy resin composite material. The preparation method mainly comprises the following steps: step 1,acidification of carbon nanotubes (CNTs) with a mixed acid solution of concentrated nitric acid and concentrated sulfuric acid; step 2, modification of O-CNTs obtained by acidification treatment through a silane coupling agent; step 3, surface cleaning and surface modification treatment of carbon fiber double-layer spaced fabric (CFDSF); and step 4, pouring and thermocuring of CFDSF with a prepared modified CNTs / AG-80 epoxy resin solution. According to the invention, the silane coupling agent modified CNTs / CFDSF / AG-80 epoxy resin composite material prepared through the above-mentioned preparation steps and concrete process parameters thereof and with advantages of good conductivity, thermodynamic properties and less usage amount of a conducting material has the following advantages: modified carbon nanotubes are uniformly distributed in a matrix; and the composite material has good conductive stability and can be extensively applied to the fields of electronics, electrostatic protection, electromagnetic shielding, microwave absorption, etc.

Owner:SHAANXI SCI TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com