Aramid nano-fiber modified chitosan composite film as well as preparation method and application thereof

A nanofiber, chitosan technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as limited application, and achieve the effects of excellent thermodynamic performance, simple preparation method, and easy availability of reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

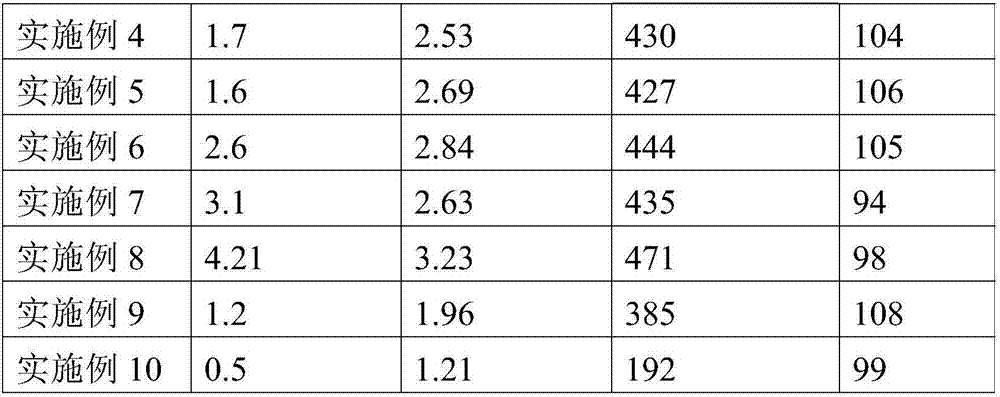

Examples

Embodiment 1

[0043] A kind of preparation of aramid fiber nanofiber reinforced modified chitosan composite film material, comprises the following steps:

[0044] (1) Add 5 parts by weight of aramid macro fiber raw material (KEVLER) to 100 parts by weight of dimethyl sulfoxide, then add 5 parts by weight of potassium tert-butoxide, 3 parts by weight of methanol, and stir at 50°C (150r / min ) 36h, obtain aramid fiber nanofiber dispersion liquid; Control stirring speed, can not be too fast;

[0045] (2) Add 5 parts by weight of chitosan-methanesulfonate into the aramid nanofiber dispersion (chitosan salt / aramid fiber mass ratio=1), continue to stir for 6h (150r / min), dissolve completely, and obtain Casting solution;

[0046] (3) Utilize the applicator to coat the film casting solution, put it into water and let it stand for 12 hours, then soak it in 5.0wt% sodium hydroxide solution for 2 hours, soak it in ethanol for 12 hours, soak it in n-hexane for 12 hours, take out the shaped film, Vacuum-...

Embodiment 2

[0048] A kind of preparation of aramid fiber nanofiber reinforced modified chitosan composite film material, comprises the following steps:

[0049] (1) Add 5 parts by weight of aramid macro fiber raw material (KEVLER) to 100 parts by weight of dimethyl sulfoxide, then add 5 parts by weight of potassium tert-butoxide, 3 parts by weight of methanol, and stir at 50°C (150r / min ) 36h, obtain aramid fiber nanofiber dispersion liquid; Control stirring speed, can not be too fast;

[0050] (2) Add 5 parts by weight of chitosan-hydrochloride in the aramid nanofiber dispersion (chitosan salt / aramid fiber mass ratio=1), continue to stir for 6h (150r / min), dissolve completely, and obtain cast Membrane fluid;

[0051] (3) Utilize the applicator to coat the film casting solution, put it into water and let it stand for 12 hours, then soak it in 5.0wt% sodium hydroxide solution for 2 hours, soak it in ethanol for 12 hours, soak it in n-hexane for 12 hours, take out the shaped film, Vacuum-...

Embodiment 3

[0053] A kind of preparation of aramid fiber nanofiber reinforced modified chitosan composite film material, comprises the following steps:

[0054] (1) Add 5 parts by weight of aramid macro fiber raw material (KEVLER) to 100 parts by weight of dimethyl sulfoxide, then add 5 parts by weight of potassium tert-butoxide, 3 parts by weight of methanol, and stir at 50°C (150r / min ) 36h, obtain aramid fiber nanofiber dispersion liquid; Control stirring speed, can not be too fast;

[0055] (2) Add 5 parts by weight of chitosan-sulfate into the aramid nanofiber dispersion (chitosan salt / aramid fiber mass ratio=1), continue to stir for 6h (150r / min), dissolve completely, and obtain a cast film liquid;

[0056] (3) Utilize the applicator to coat the film casting solution, put it into water and let it stand for 12 hours, then soak it in 5.0wt% sodium hydroxide solution for 2 hours, soak it in ethanol for 12 hours, soak it in n-hexane for 12 hours, take out the shaped film, Vacuum-dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com