Polymethyl acryloyl imine foam material with appreciable improved thermodynamic property

A technology of polymethacrylimide and foam materials, applied in chemical instruments and methods, synthetic resin layered products, lamination auxiliary operations, etc., can solve the problem of low heat deformation resistance, achieve good compression performance, Improved thermodynamic performance, high heat deformation resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

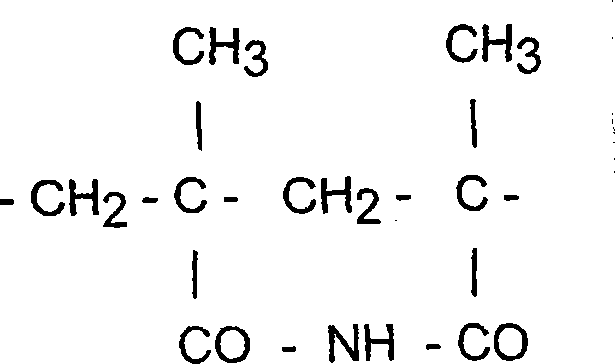

Method used

Image

Examples

Embodiment 1-4

[0043] Each weight part (T) of methacrylic acid, methacrylonitrile, formamide, 2-propanol, magnesium oxide (MgO) and allyl methacrylate or triallyl cyanurate Esters were mixed with 0.1 T of tert-butyl perpivalate, 0.1 T of tert-butyl perbenzoate and 0.034 T of tert-butyl per-2-ethylhexanoate.

[0044] The mixture was polymerized in a water bath at 38[deg.] C. for 72 hours between two glass plates with a peripheral seal to form a plate with dimensions 500 x 500 x 23 mm. The panel was then tempered at 115° C. for 3 hours in a circulating air heating cabinet. The resulting polymer sheet was foamed after removal of the glass plate by heating at approximately 230° C. for two hours in a circulating-air heating cabinet and subsequently tempered in the same manner at 115° C. for 3 hours and at 190° C. for 48 Hour.

[0045] Determination of the density of the foam board (kg / m 3 ), compressive strength according to DIN 53 421, heat deformation resistance according to DIN 53 424 (poin...

Embodiment 3

[0050] Polymethacrylimide foams of the inventive composition of Example 3 were prepared and measured after foaming of the polymer sheet with and without the two-step tempering treatment. Obtain the following intensity values.

[0051] foam density

[0052] For untempered specimens, the test is terminated after a given time exceeds 12% compression.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com