Rare earth doped fluorescent powder and synthetic method thereof and application of fluorescent powder in LED devices

A technology of rare earth doping and phosphor, which is applied in the field of rare earth doping phosphor and synthesis, which can solve the problems of reducing the fluorescent performance of phosphor, and achieve the effects of high luminous efficiency, high chemical stability, and high thermal quenching temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

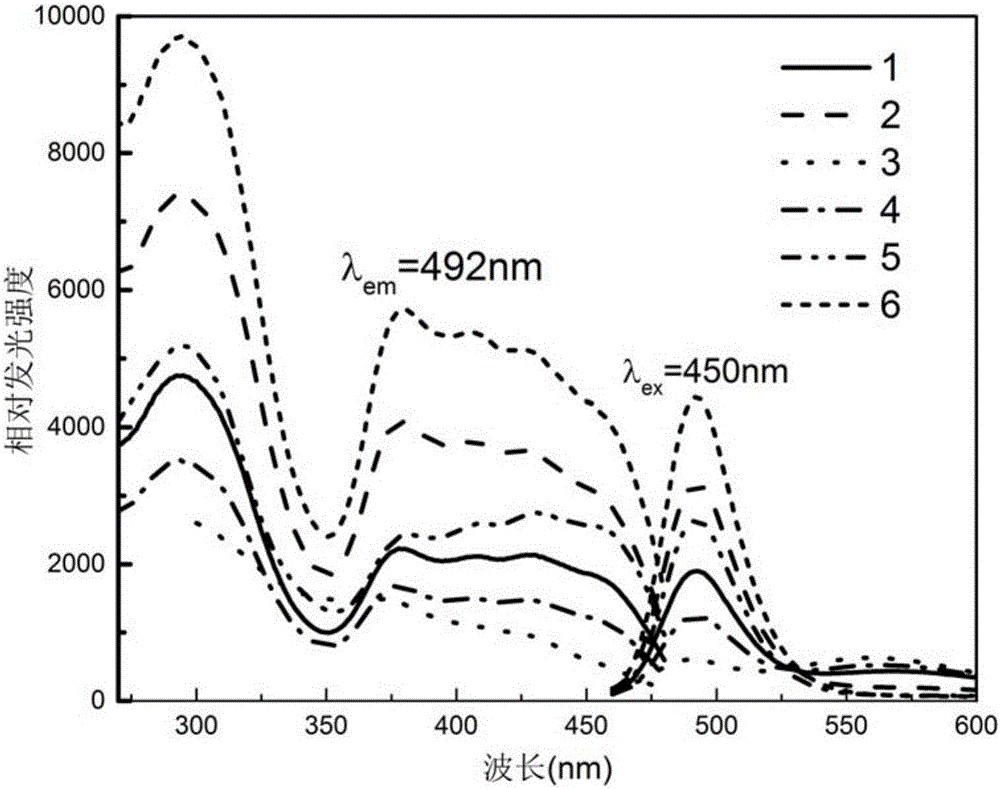

Embodiment 1

[0098] Reaction raw materials 35.24g barium carbonate, 2.96g strontium carbonate, 0g calcium carbonate, 5.64g silicon dioxide, 15.24g silicon nitride, 0.24g europium oxide and 0.01g high-purity graphite powder were placed in a ceramic mortar and ground and mixed for 30min to obtain a mixture , put the mixture through a 100-mesh sieve and put it into an alumina crucible for calcination in a horizontal tube furnace. During the calcination process, nitrogen-hydrogen mixed gas (hydrogen content 10%) was introduced, the gas flow rate was 0.3L / min, and the temperature was raised to 1490°C at a heating rate of 8°C / min. After holding for 8 hours, the temperature was lowered at a rate of 10°C / min. The temperature was lowered to 700°C and then cooled to room temperature with the furnace. The obtained product is lightly ground and passed through a 120-mesh sieve to obtain blue-green fluorescent powder (BaSr)Si 2 o 2 N 1.996 C 0.003 :Eu 2+ . figure 1 The middle curve 1 is the (BaSr)...

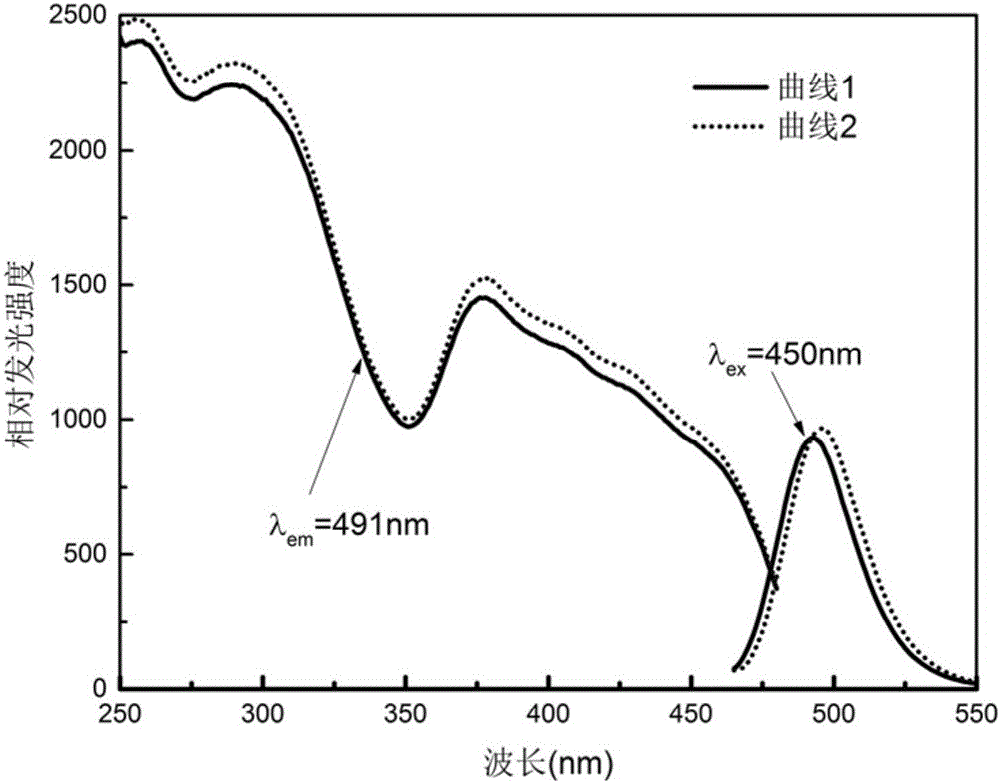

Embodiment 2

[0104] Reaction raw materials 64.68g barium carbonate, 9.31g silicon dioxide, 25.14g silicon nitride, 0.40g europium oxide, 1.12g potassium carbonate and 0.015g high-purity graphite powder are placed in ceramic mortar and grind and mix for 30min to obtain the mixture, and the mixture is passed 100-mesh sieve and put into alumina crucible for calcination in horizontal tube furnace. During the calcination process, nitrogen-hydrogen mixed gas (hydrogen content 10%) was introduced, the gas flow rate was 0.3L / min, the temperature was raised to 1510°C at a heating rate of 8°C / min, and after 8 hours of heat preservation, the temperature was lowered at a rate of 10°C / min The temperature was lowered to 700°C and then cooled to room temperature with the furnace. The obtained product is lightly ground and passed through a 120-mesh sieve to obtain the blue-green fluorescent powder BaSi 2 o 2 N 1.996 C 0.003 :Eu 2+ . figure 2 The middle curve 2 is the excitation and emission spectru...

reference example 1

[0106] The reaction raw materials 64.68g barium carbonate, 9.31g silicon dioxide, 25.14g silicon nitride, 0.40g europium oxide, and 1.12g potassium carbonate were placed in a ceramic mortar and ground and mixed for 30 minutes to obtain a mixture. Calcination was carried out in a horizontal tube furnace in aluminum crucibles. During the calcination process, nitrogen-hydrogen mixed gas (hydrogen content 10%) was introduced, the gas flow rate was 0.3L / min, the temperature was raised to 1510°C at a heating rate of 8°C / min, and after 8 hours of heat preservation, the temperature was lowered at a rate of 10°C / min The temperature was lowered to 700°C and then cooled to room temperature with the furnace. The obtained product is lightly ground and passed through a 120-mesh sieve to obtain blue-green phosphor (BaEu)Si 2 o 2 N 2 . figure 2 Curve 1 is the excitation and emission spectra of the sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com