Preparation method for silane coupling agent modified CNTs/CFDSF/AG-80 epoxy resin composite material

A silane coupling agent, epoxy resin technology, used in dry cleaning fiber products, textiles and papermaking, fiber processing, etc., can solve the problems of decreased mechanical properties, insufficient electrical conductivity, and poor overall mechanical properties, and achieve good electrical conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

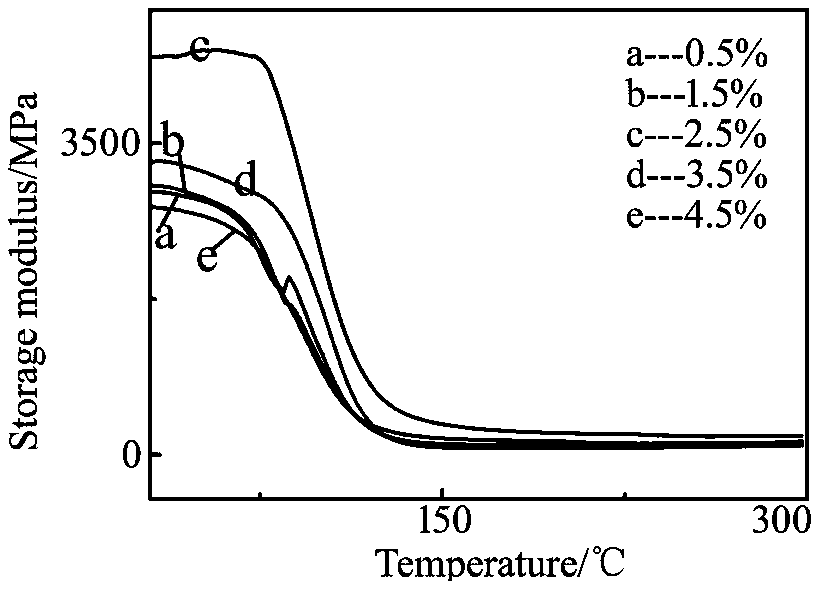

Embodiment 1

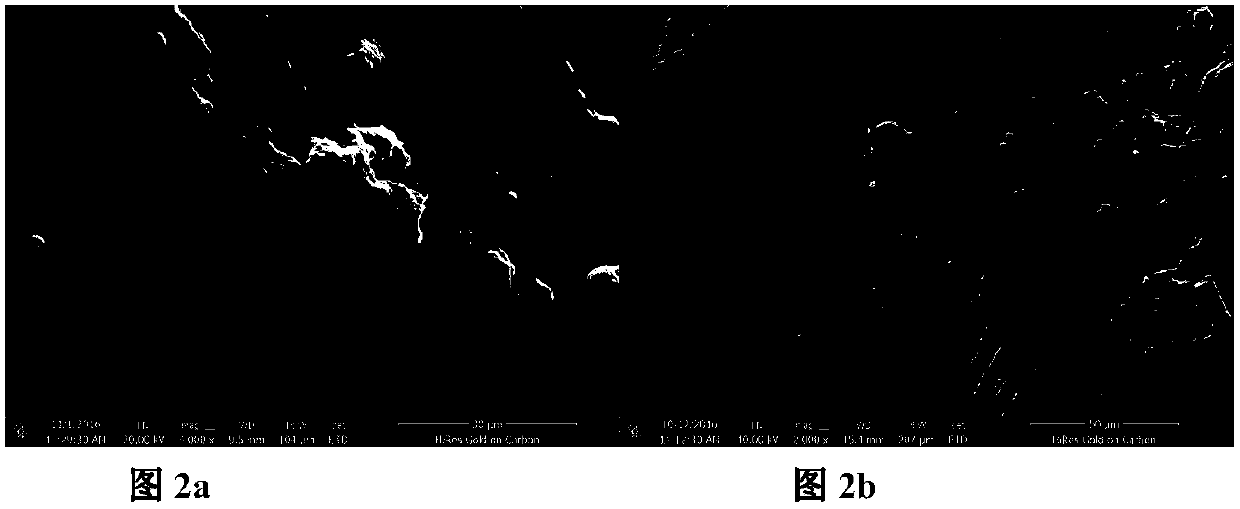

[0040] For the modification of carbon nanotubes (CNTs), the inventors of the present application have studied the use of silane coupling agents for modification and only acidification for modification. The present invention protects the use of silane coupling agents to modify CNTs / CFDSF / AG-80 preparation method of epoxy resin composite material;

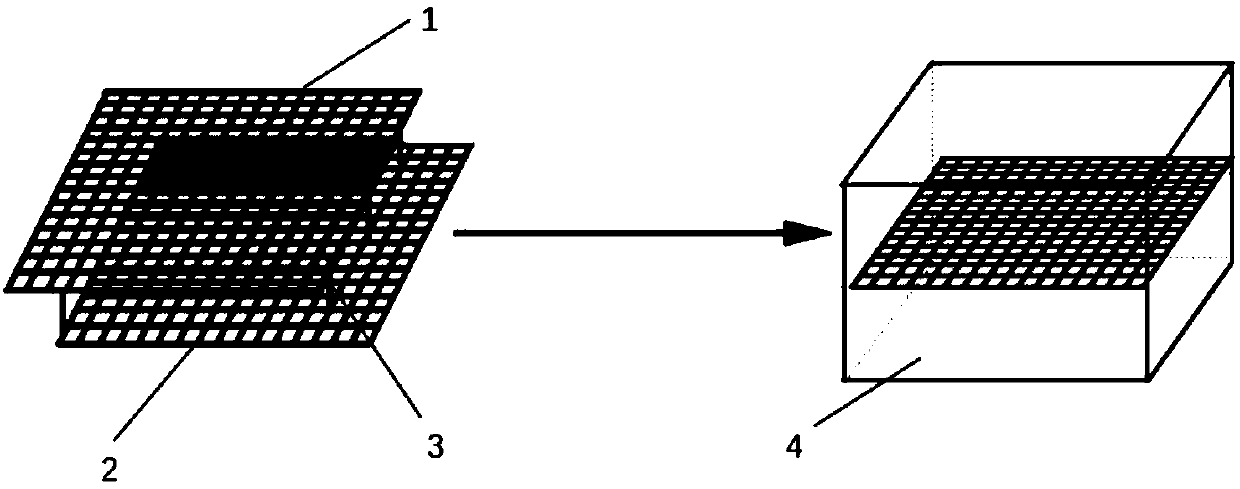

[0041] A preparation method for preparing silane coupling agent modified CNTs / CFDSF / AG-80 epoxy resin composite material, mainly comprising the following steps:

[0042] 1. Modification of carbon nanotubes (CNTs) with silane coupling agent

[0043] 1.1) The carbon nanotubes (CNTs) are modified with a silane coupling agent, and first acidified:

[0044] The CNTs were acidified with a mixed acid solution of concentrated nitric acid and concentrated sulfuric acid, and 2g of CNTs was placed in 250ml of a mixed acid solution of concentrated nitric acid and concentrated sulfuric acid, wherein the volume ratio of concentrated nitric acid ...

Embodiment 2

[0053] For the modification of carbon nanotubes (CNTs), the inventors of the present application have studied the use of silane coupling agents for modification and only acidification for modification. The present invention protects the use of silane coupling agents to modify CNTs / CFDSF / AG-80 preparation method of epoxy resin composite material;

[0054] A preparation method for preparing silane coupling agent modified CNTs / CFDSF / AG-80 epoxy resin composite material, mainly comprising the following steps:

[0055] 1. Modification of carbon nanotubes (CNTs) with silane coupling agent

[0056] 1.1) The carbon nanotubes (CNTs) are modified with a silane coupling agent, and first acidified:

[0057] The CNTs were acidified with a mixed acid solution of concentrated nitric acid and concentrated sulfuric acid, and 3.5g of CNTs were placed in 375ml of a mixed acid solution of concentrated nitric acid and concentrated sulfuric acid, wherein the volume ratio of concentrated nitric ac...

Embodiment 3

[0066] For the modification of carbon nanotubes (CNTs), the inventors of the present application have studied the use of silane coupling agents for modification and only acidification for modification. The present invention protects the use of silane coupling agents to modify CNTs / CFDSF / AG-80 preparation method of epoxy resin composite material;

[0067] A preparation method for preparing silane coupling agent modified CNTs / CFDSF / AG-80 epoxy resin composite material, mainly comprising the following steps:

[0068] 1. Modification of carbon nanotubes (CNTs) with silane coupling agent

[0069] 1.1) The carbon nanotubes (CNTs) are modified with a silane coupling agent, and first acidified:

[0070] The CNTs were acidified with a mixed acid solution of concentrated nitric acid and concentrated sulfuric acid, and 5 g of CNTs were placed in 500 ml of a mixed acid solution of concentrated nitric acid and concentrated sulfuric acid, wherein the volume ratio of concentrated nitric ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com