Patents

Literature

65results about How to "Improve heat deformation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition with increased stress cracking resistance

InactiveUS20100174022A1Improved stress crack resistanceImprove heat deformation resistanceInksOrganic dyesMeth-Crack resistance

Composition containing, based in each case on its total weight,A) 50.0% by weight to 99.5% by weight of at least one (meth)acrylate (co)polymer andB) 0.5% by weight to 50.0% by weight of at least one copolymer obtainable by polymerisation of a monomer mixture comprisingi. 70% by weight to 92% by weight of a vinylaromatic monomer andii. 8% by weight to 30% by weight of acrylonitrile or methacrylonitrile or mixtures thereof andiii. 0% by weight to 22% by weight of at least one further monomer, the composition having a haze according to ASTM D1003 of less than 2.0% at 23° C. and a haze according to ASTM D1003 of less than 4.0% at 40° C. and the composition containing at least one (meth)acrylate (co)polymer a) having a solution viscosity in chloroform at 25° C. (ISO 1628—part 6) of greater than 55 ml / g.The mouldings obtainable from the composition are distinguished in particular by improved stress cracking resistance and are suitable in particular for coverings, finishes or films.

Owner:EVONIK ROEHM GMBH

Coloured composition with increased stress cracking resistance

InactiveUS20100148401A1Improved stress crack resistanceImprove heat deformation resistanceOrganic dyesCeramic shaping apparatusCrack resistanceMeth-

The invention relates to a composition containing, in relation to the total weight of said composition, A) between 50.0% by weight and 99.5% by weight of at least one (meth)acrylate (co)polymer and B) between 0.5% by weight and 50.0% by weight of at least one copolymer, obtained by the polymerisation of a monomer mixture consisting of i. between 70% by weight and 92% by weight of a vinyl aromatic monomer and ii. between 8% by weight and 30% by weight of acryl nitrile or methacryl nitrile or mixtures thereof iii. between 0% by weight and 22% by weight of at least one other monomer, the composition having at 50° C. a ΔE of less than 0.15, ΔE being defined according to the relationship (1): (1) in which ΔL*: the modification of the colour co-ordinates L* compared with the colour co-ordinates L* at 23° C., Δa*: the modification of the colour co-ordinates a* compared with the colour co-ordinates a* at 23° C., Δb*: the modification of the colour co-ordinates b* compared to the colour co-ordinates b* at 23° C., and the composition contains at least one (meth)acrylate (co)polymer a) with a solution viscosity in chloroform at 25° C. (ISO 1628 part 6) greater than 55 ml / g. The moulded bodies that can be obtained from the composition are characterised in particular by improved stress cracking resistance and are suitable in particular for use in coatings, paints or films.

Owner:EVONIK ROEHM GMBH

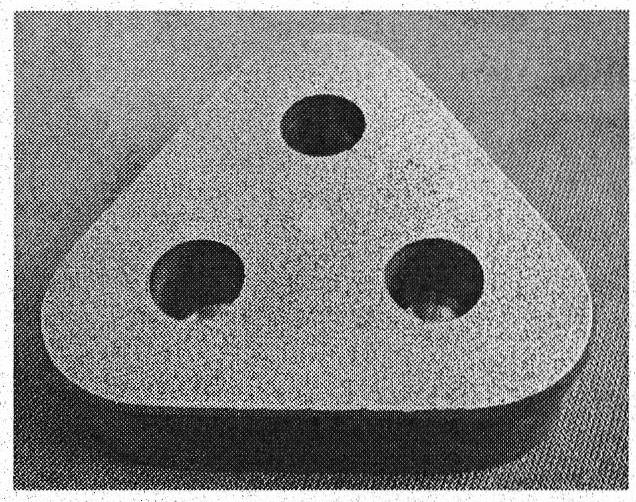

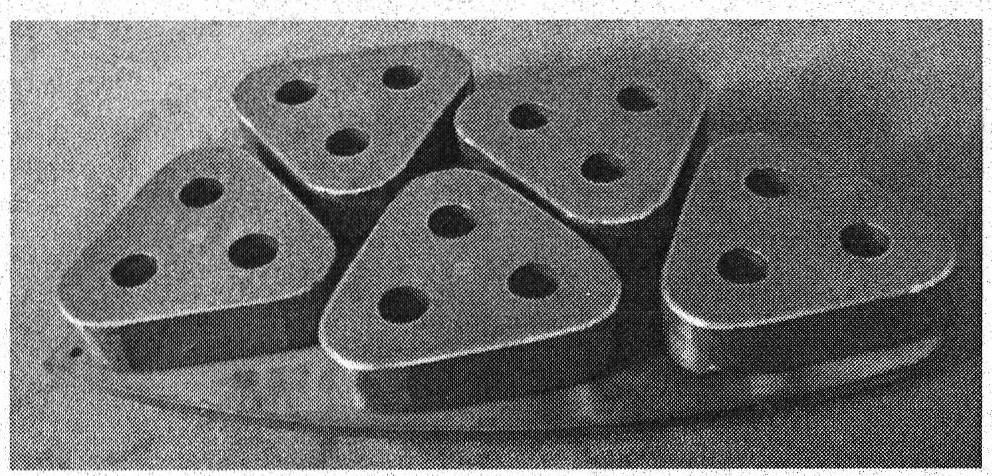

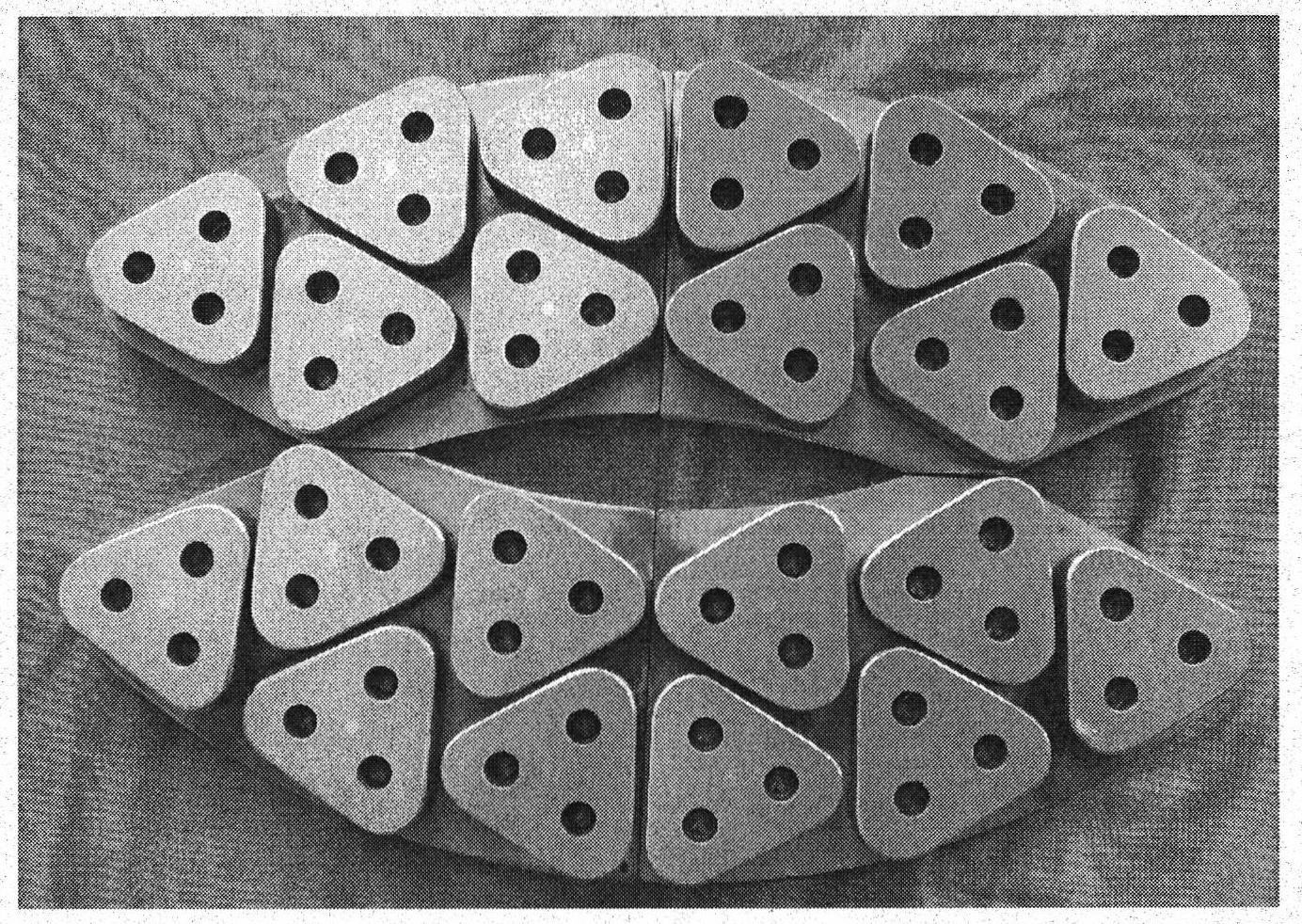

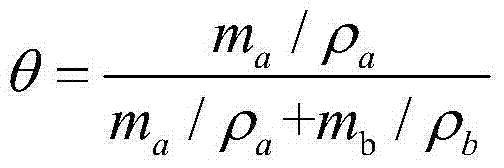

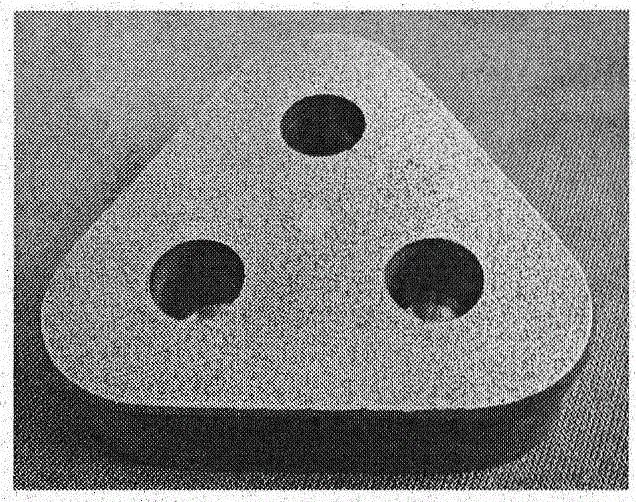

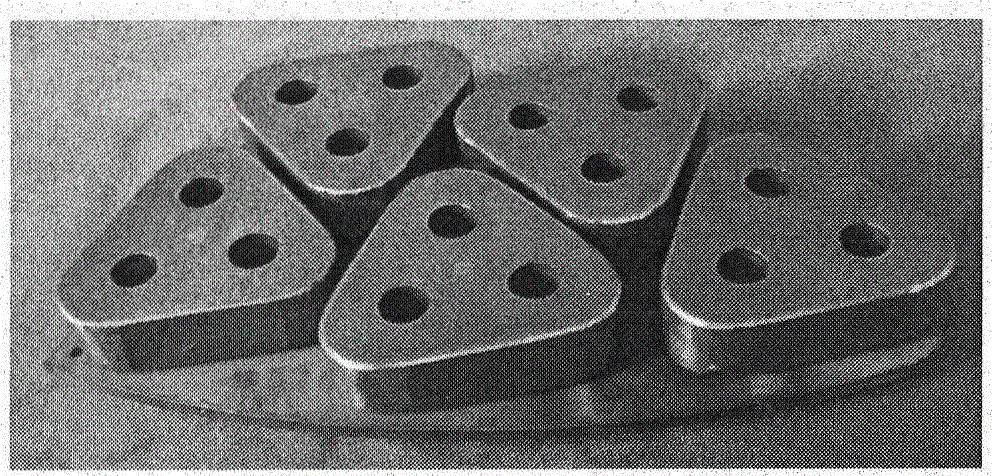

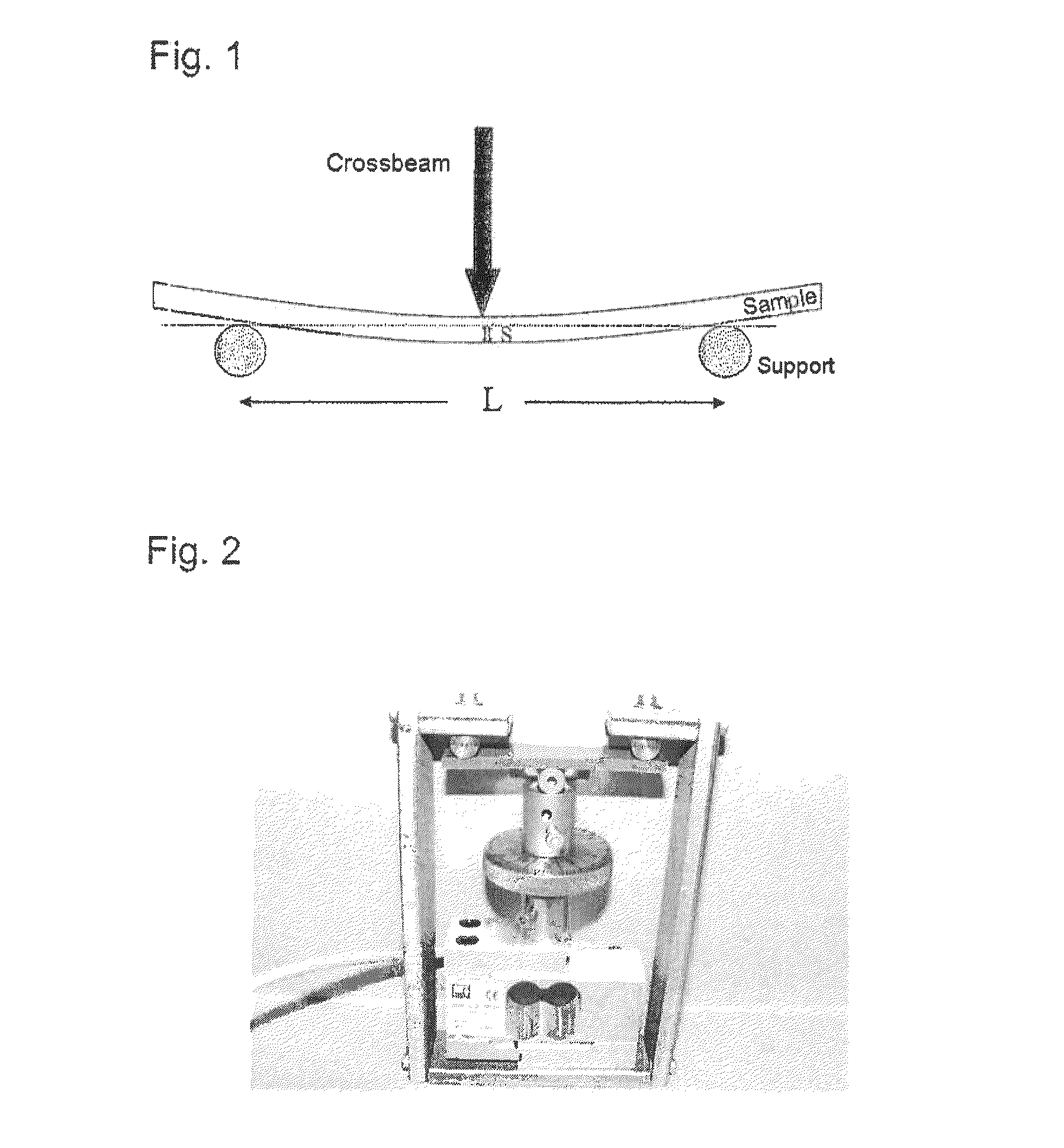

Ceramic/metallic double continuous phase composite material brake pad and preparation method thereof

The invention relates to the field of friction materials for braking of high-speed trains, in particular to a ceramic / metallic double continuous phase composite material brake pad and a preparation method thereof. The brake pad comprises the following components in percentage by weight: 15 to 40 percent of foam silicon carbide ceramics, 10 to 30 percent of friction element and 75 to 30 percent ofmetal. The method comprises the following steps of: preparing the silicon carbide foam ceramics having a three-dimensional network structure by employing a technology combining polymer pyrolysis withcontrollable infiltration reaction sintering; selecting a proper friction element and filling in mesh holes of the foam ceramics; and injecting melt copper alloy into a framework of the foam ceramicsby utilizing an extrusion casting method to obtain the ceramic / metallic double continuous phase composite material brake pad. The composite material brake pad can be paired with a 28CrMoV forged steel brake disc, has the characteristics of proper and stable friction coefficient, low wear rate, high heat resistance, high thermal or mechanical damage resistance, good process performance, low manufacturing cost, long service life and the like, completely meets the brake requirement of a high-speed train at a speed of 200 to 300km / h, and has good competitive advantage on the brake requirement of a high-speed train at the speed of 350km / h.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

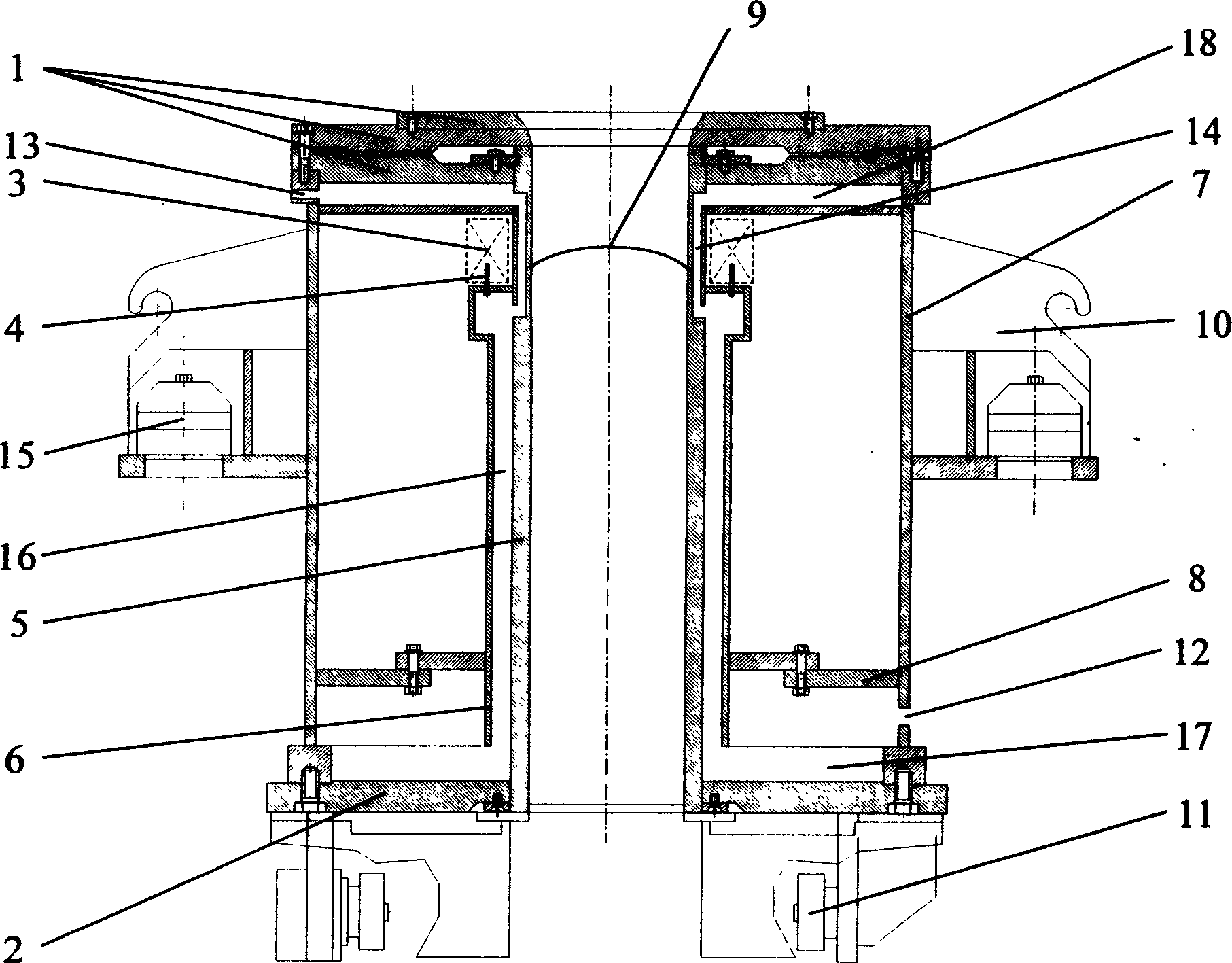

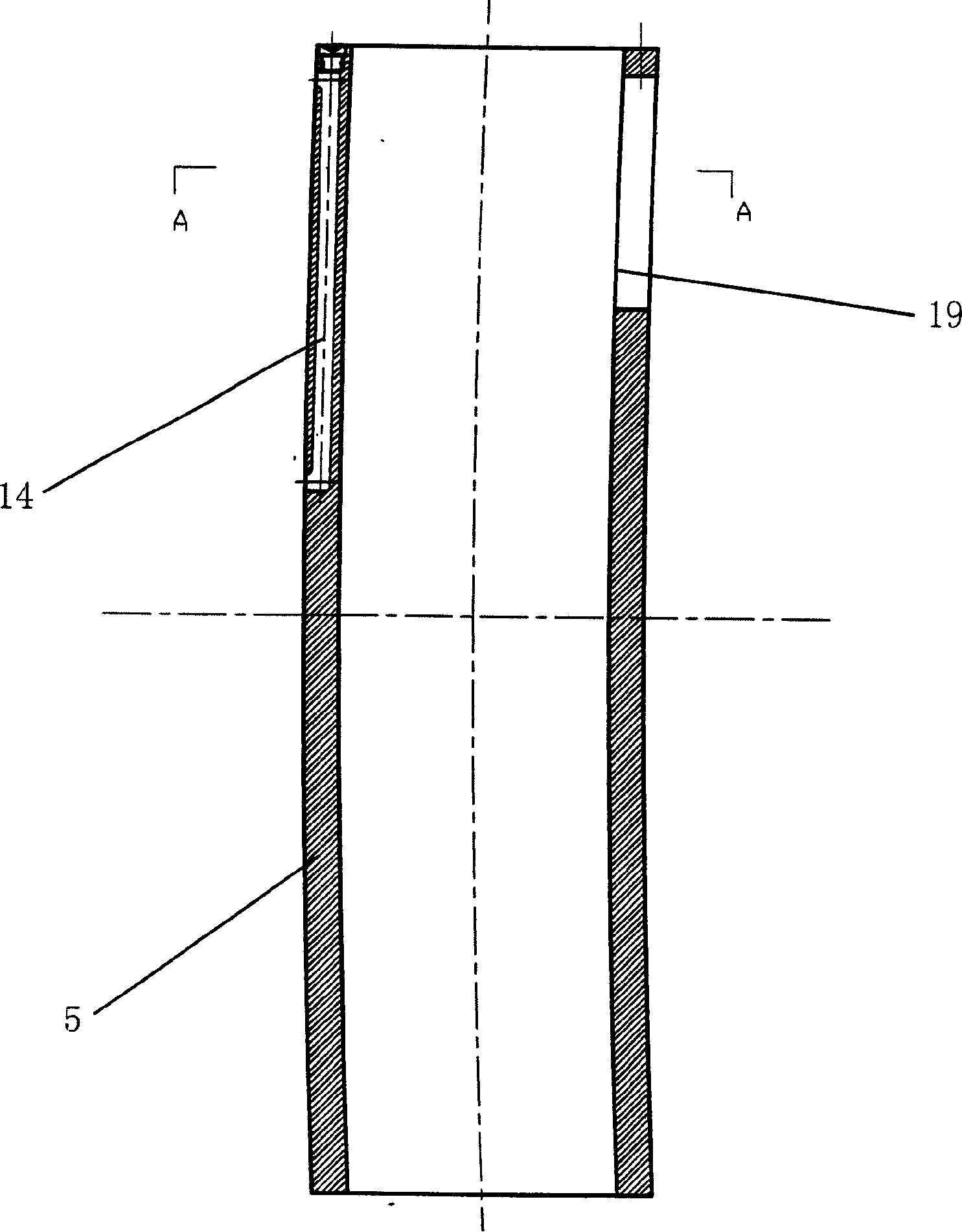

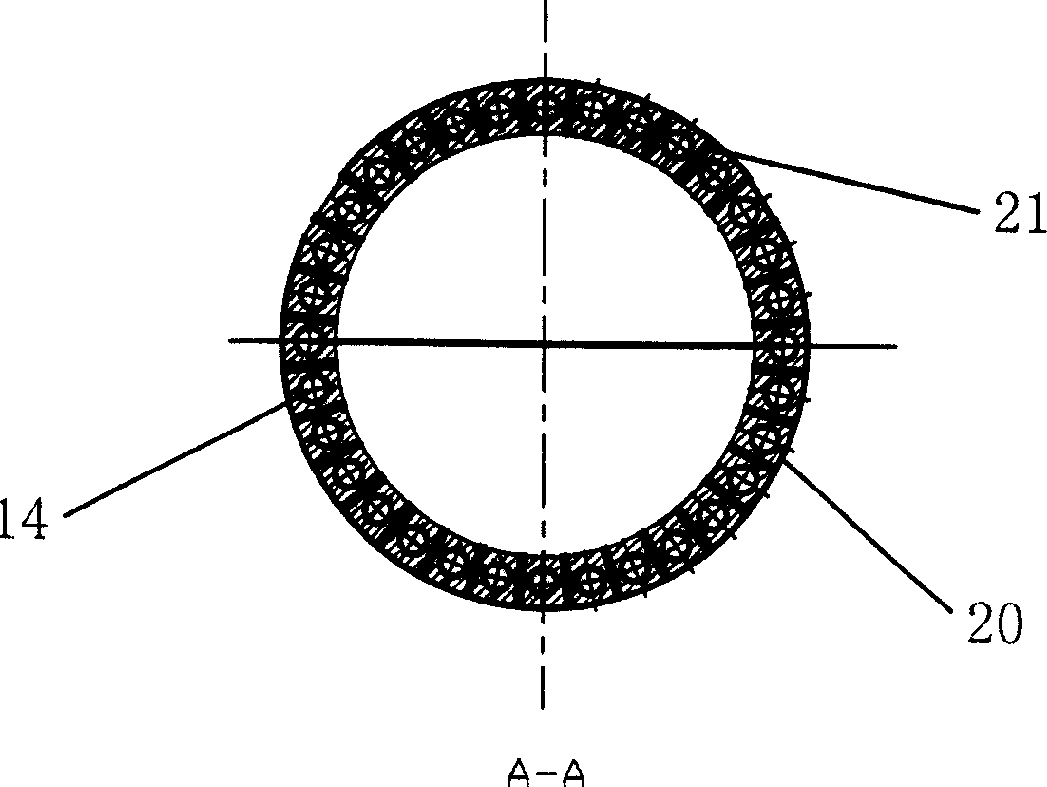

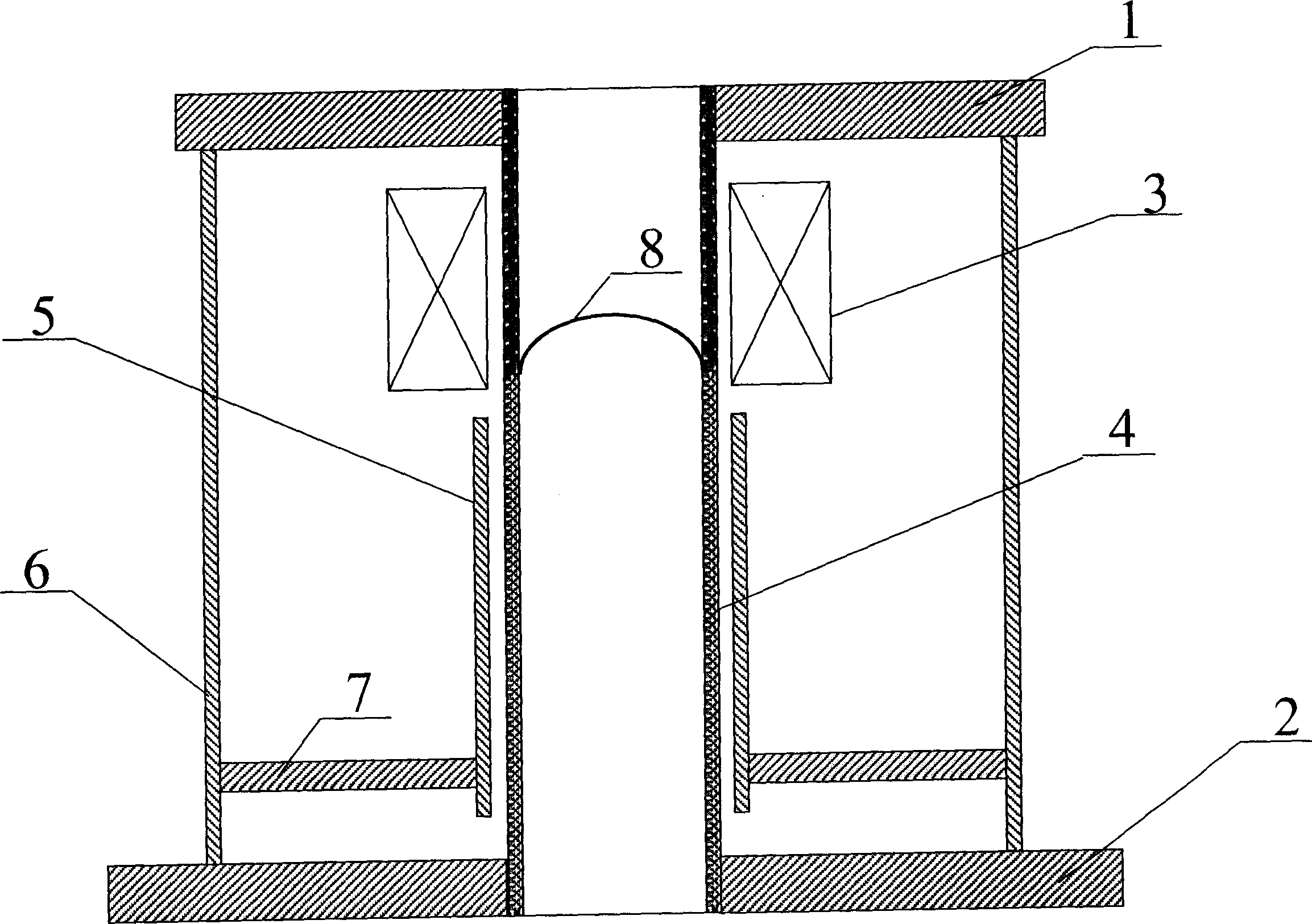

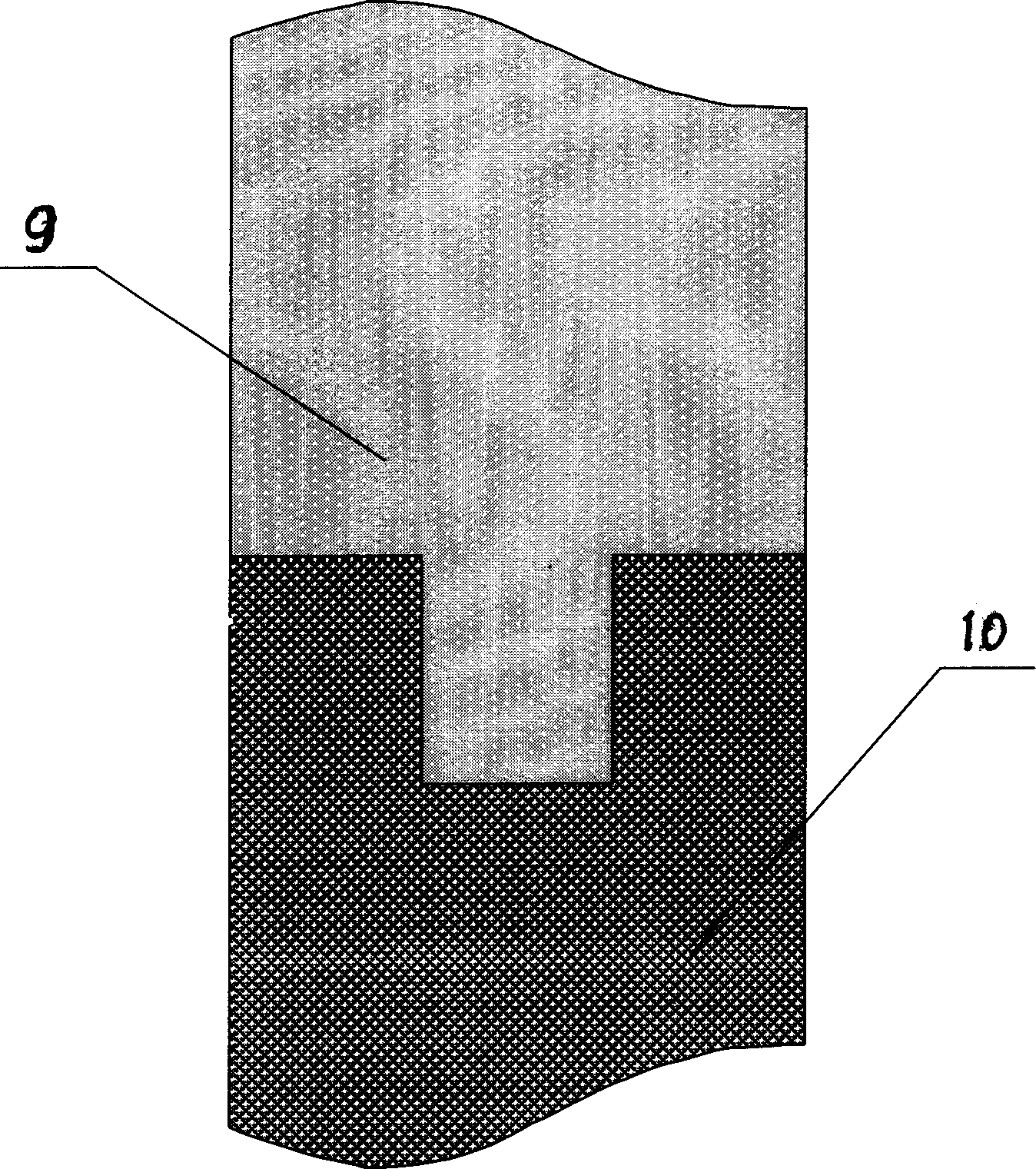

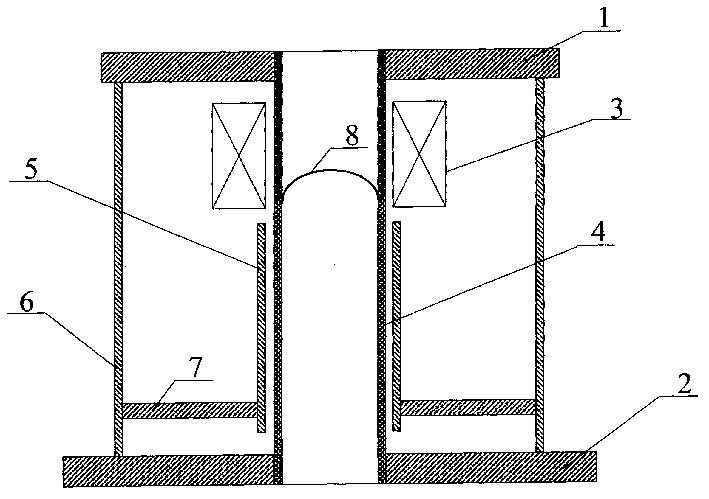

Water seam-split body internal water cooling type flexible contact electromagnetic continuous casting crystallizer

A water cooled electromagnetic crystallizer for conticasting is composed of upper and lower flanges, coil, sleeve pipe of crystallizer, cooling water jacket, cooling water tube, connection part and lifting gear. It features that the upper part of said sleeve pipe has local slit structure, the cooling water tube is arranged in split body and a water seam structure is formed between the lower part of said sleeve pipe and cooling water jacket.

Owner:NORTHEASTERN UNIV

Chemical resistance table slab rubber, preparation and use thereof

The invention discloses a chemical corrosion-resistant table rubber sheet, a preparation method and applications thereof. The table rubber sheet mainly consists of the following raw materials by weight percentage: 2 percent to 40 percent of anhydride curing agent, 2 percent to 40 percent of other types of acid anhydrides, 2 percent to 50 percent of epoxy resin systems, 40 percent to 93 percent of filler and 0.01 percent to 1 percent of initiator, wherein, the anhydride curing agent is maleic anhydride and the initiator is hydroperoxide or dialkyl peroxide. The preparation method of the invention includes the steps that maleic anhydride is introduced in common acid anhydrides and added with a peroxide initiator to initiate the free radical polymerization and form an interpenetrating network structure so as to improve the heat distortion temperature of products. Meanwhile, by adopting the preparation method of the invention, the products can be made from raw materials with lower prices, thus having relatively high market competitiveness. When being applied to an experiment table top in a laboratory, the table rubber sheet of the invention can has relatively good flatness on the sheet surface, good wearing resistance and chemical corrosion resistance as well as comparatively high heat distortion resistance.

Owner:GUANGDONG FUSHENG INNOVATIVE MATERIAL TECH LTD

Polymer powder with modified melting behaviour

InactiveUS20130274435A1Improve heat deformation resistanceIncrease valueAdditive manufacturing apparatusCeramic shaping apparatusSelective laser sinteringPolyamide

The present invention provides precipitated polymer powders based on a polyamide of the AABB type, obtained by the reprecipitation of the polyamides by at least partial dissolution followed by continuous cooling of the solution to below the precipitation temperature. The polyamides are prepared by polycondensation of diamines with dicarboxylic acids. The precipitated polyamides obtained are used in layer-by-layer shaping processes such as selective laser sintering.

Owner:EVONIK DEGUSSA GMBH

Polymethyl acryloyl imine foam material with appreciable improved thermodynamic property

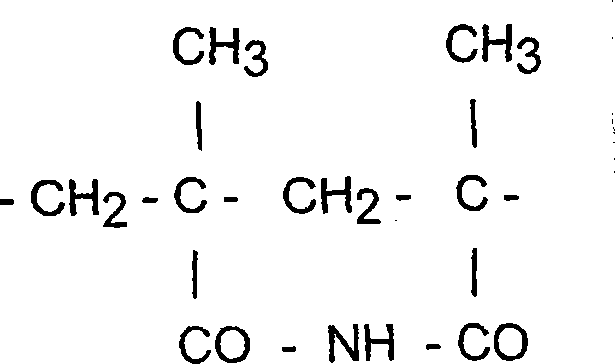

InactiveCN101173057AExcellent thermodynamic propertiesImprove heat deformation resistanceLamination ancillary operationsSynthetic resin layered productsDouble bondThermal distortion

The invention relates to a preparation method of a polymethacrylimide foam material with obviously improved thermodynamic performance. The invention is characterized in that the polymerization product used for the polymethacrylimide foam material is added with 0.05wt percent to 5wt percent of olefinic unsaturated compound capable of free radical polymerization and with at least two double bonds and 1wt percent to 5wt percent magnesia. The invention also relates to the polymethacrylimide foam material with anti-thermal-distortion larger than 250 DEG C, and the usage of polymethacrylimide foam material in preparing interlayer component.

Owner:ROHM CO LTD

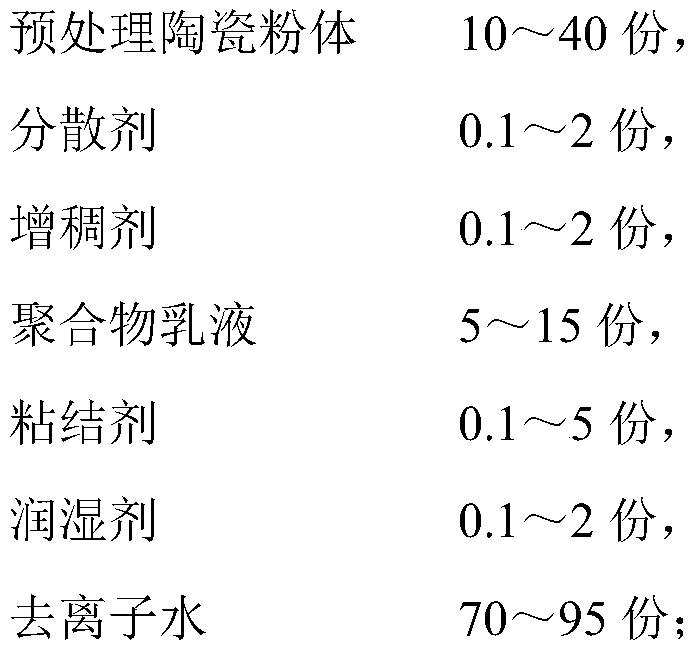

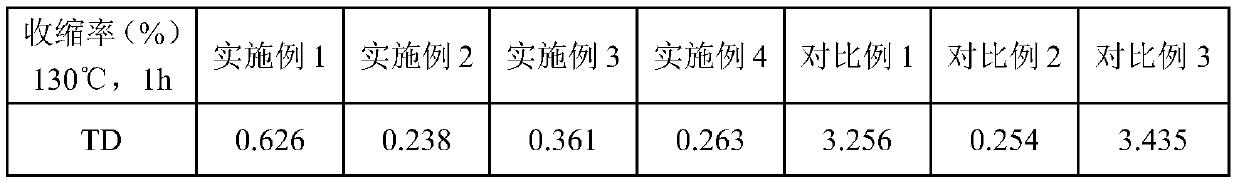

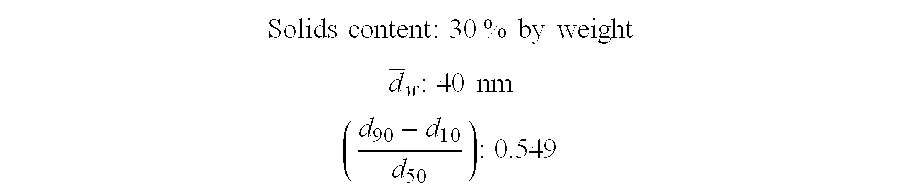

Functional coating diaphragm for lithium ion battery, and preparation method thereof

InactiveCN111509173AIncrease forceAchieving closed poresCell component detailsSecondary cells servicing/maintenancePower batteryThermal deformation

The invention discloses a functional coating diaphragm for a lithium ion battery, and a preparation method of the functional coating diaphragm. The preparation method comprises the following steps: uniformly mixing ceramic powder with a coupling agent to obtain pretreated ceramic powder; adding a dispersing agent and a thickening agent into deionized water, dissolving, then adding the pretreated ceramic powder and polymer emulsion, uniformly stirring and dispersing, adding a binding agent and a wetting agent, and uniformly stirring and dispersing to obtain modified ceramic slurry; coating onesurface or two surfaces of a base membrane with the modified ceramic slurry in a coating manner, and drying to obtain the functional coating diaphragm. According to the invention, through coating pretreatment of the coupling agent, the ceramic powder is non-polar, so that the acting force between the ceramic powder and a polymer is enhanced; according to the functional coating diaphragm prepared by the invention, pore closing of the diaphragm at a relatively low temperature can be realized, and the thermal deformation resistance of the diaphragm at a high temperature can be improved, so that the safety performance of a power battery can be effectively improved; and the preparation method is simple, low in cost and convenient for industrial production.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

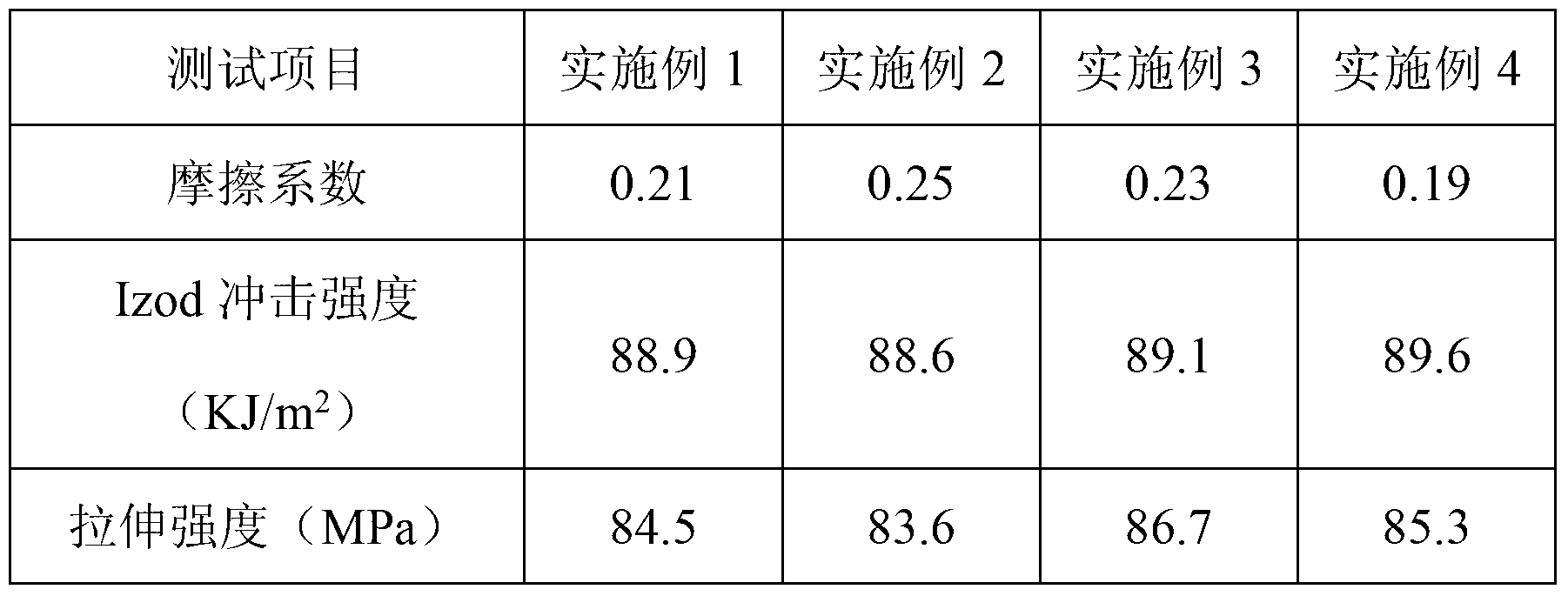

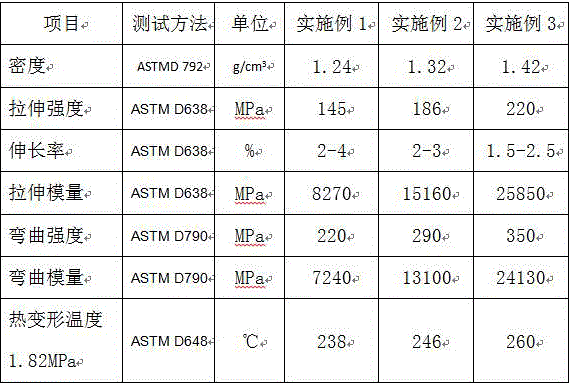

Reinforced and modified PA (Polyamide)6 composite material

InactiveCN103242651AImprove heat deformation resistanceImprove wear resistanceGlass fiberAntioxidant

The invention relates to engineering plastic and in particular relates to a reinforced and modified PA (Polyamide)6 composite material. The reinforced and modified PA6 composite material comprises the following components in parts by weight: 55-75 parts of PA6, 8-14 parts of glass fiber, 3-7 parts of MgO, 2-5 parts of dispersing agent, 1-2 parts of cross-linking agent and 0.1-0.5 part of antioxidant. The glass fiber adopted by the reinforced and modified PA6 composite material can be used for reinforcing the effect of the PA6, the MgO can be used for improving thermal deformation resistance capability of the PA6 to keep good dimension stability; and meanwhile, due to the lubricating and reinforcing effects of the nanometer particles. the wear resistance of the PA6 can be remarkably improved. The reinforced and modified PA6 composite material can be used for solving the problem that the PA6 in the prior art has defects in mechanical strength and wear resistance.

Owner:SUZHOU SUNWAY POLYMER

Metal ceramic die-casting die with tensile prestress and preparation method of metal ceramic die-casting die

InactiveCN108103500AImprove anti-adhesion performanceQuality improvementMetallic material coating processesSelf-propagating high-temperature synthesisManufacturing technology

The invention discloses a metal ceramic die-casting die with tensile prestress and a preparation method of the metal ceramic die-casting die and belongs to the technical field of coating preparation.The metal ceramic die-casting die comprises a die base and a metal ceramic layer which is arranged on the surface of the die base and has tensile prestress. By means of thermal adaptation between thedie base and the prepared metal ceramic layer, the metal ceramic layer has the tensile prestress after being prepared, and the metal ceramic layer and the die base are metallurgically or mechanicallybonded. Preparation of the metal ceramic layer with the tensile prestress comprises the following steps: a, removing an oxidation film from the die base, and performing oil-removal cleaning; b, preparing the metal ceramic coating with the tensile prestress by selecting one of a spray method, a vapor deposition method, a composite coating method, a self-propagating high-temperature synthesis methodand a high-temperature fusion method. With adoption of the coating prepared with the preparation technology, the technical problem that thermal fatigue resistance, wear resistance and heat distortionresistance of the die are not ideal is solved effectively, the service life of the die is prolonged, quality of workpieces is improved, and yield of the workpieces is increased.

Owner:XI AN JIAOTONG UNIV

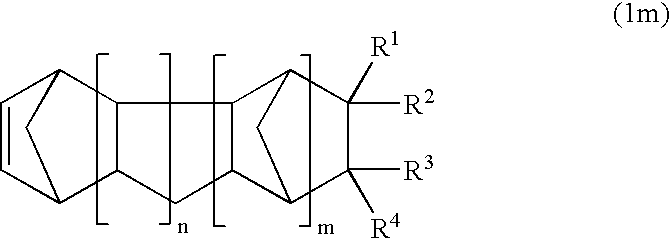

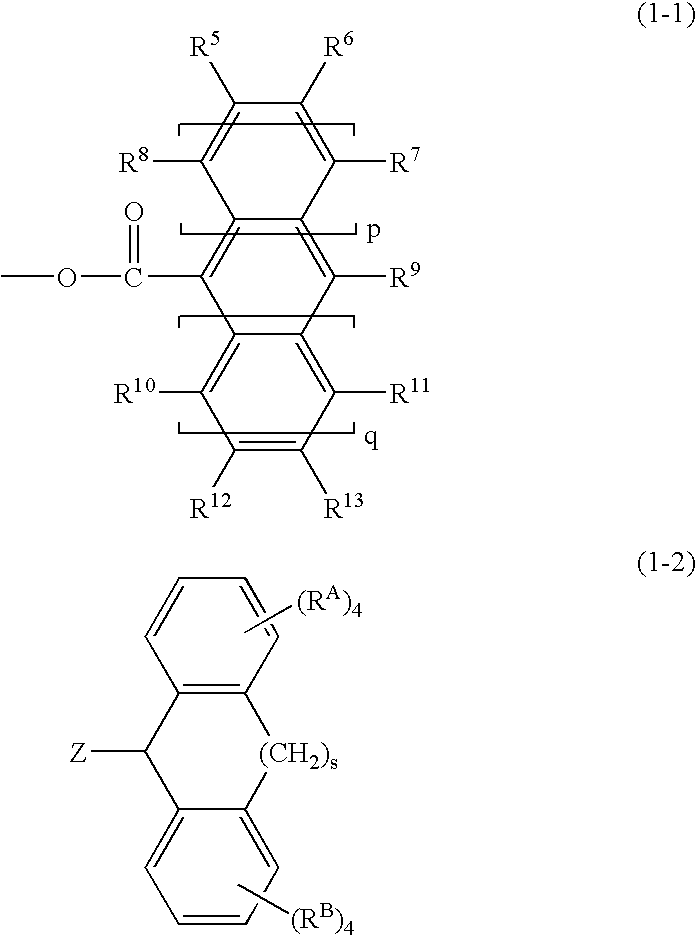

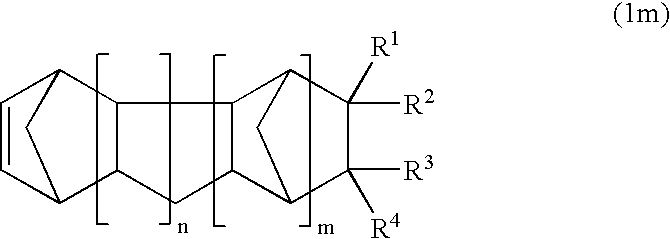

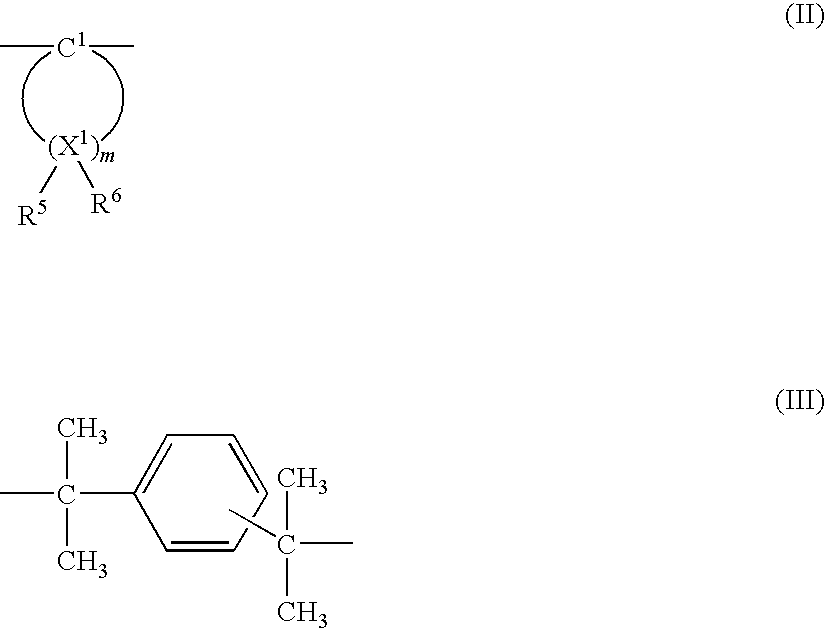

Norbornene derivative and norbornene polymer obtained therefrom through ring opening polymerization

InactiveUS20040242824A1Improve light resistanceImprove workabilitySilicon organic compoundsOrganic compound preparationPolymer scienceNorbornene

A novel norbornene derivative represented by a general formula (1m) shown below is provided. By conducting a ring opening polymerization of this norbornene derivative, or by performing a subsequent hydrogenation following the ring opening polymerization, a ring opening polymer or a hydrogenated product thereof with an excellent low birefringence can be obtained. [wherein, at least one of R<1 >to R<4 >is a group selected from the group consisting of groups represented by a general formula (1-1) shown below and groups represented by a general formula (1-2) shown below] [wherein, at least one of R, Rand Z is a group represented by the formula -C(O)O-].

Owner:JSR CORPORATIOON

Method for adhering a floor covering to a floor with a floor adhesive

InactiveUS6409860B1Good level of performance characteristicPeel strengthMonocarboxylic acid ester polymer adhesivesCovering/liningsOrganic solventPlasticizer

An aqueous composition is essentially free of organic solvents, plasticizers and additional tackifiers and contains water and 20-99% by weight of a polymer and 1-80% by weight of a filler, the percentages by weight being based on the sum of the components of the aqueous composition, with the exception of water.

Owner:BASF AG

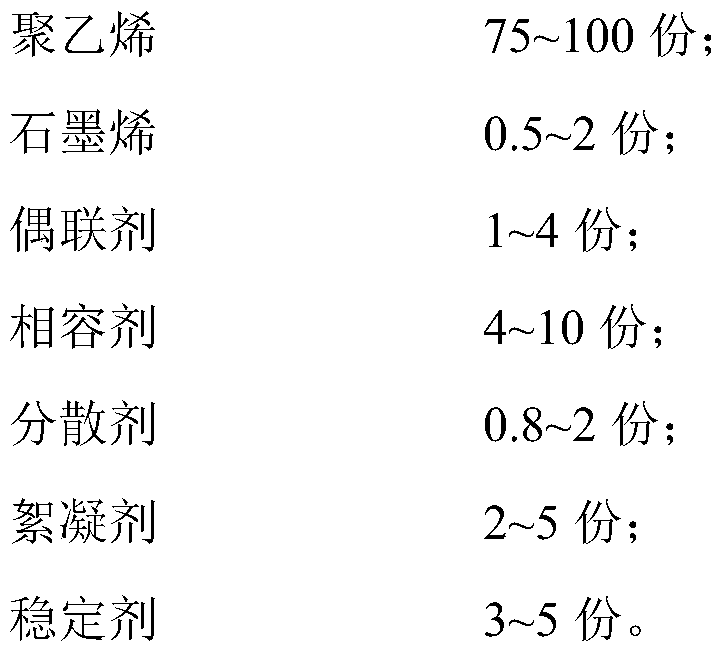

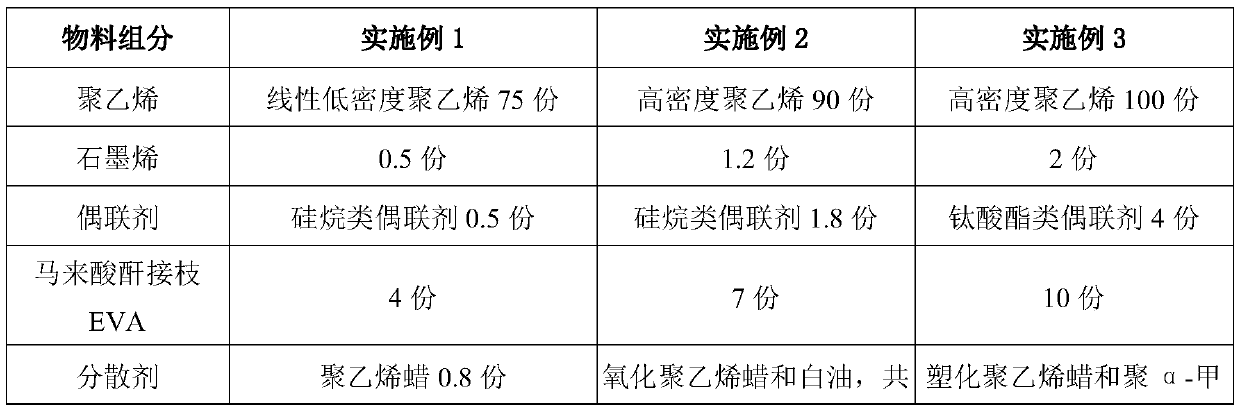

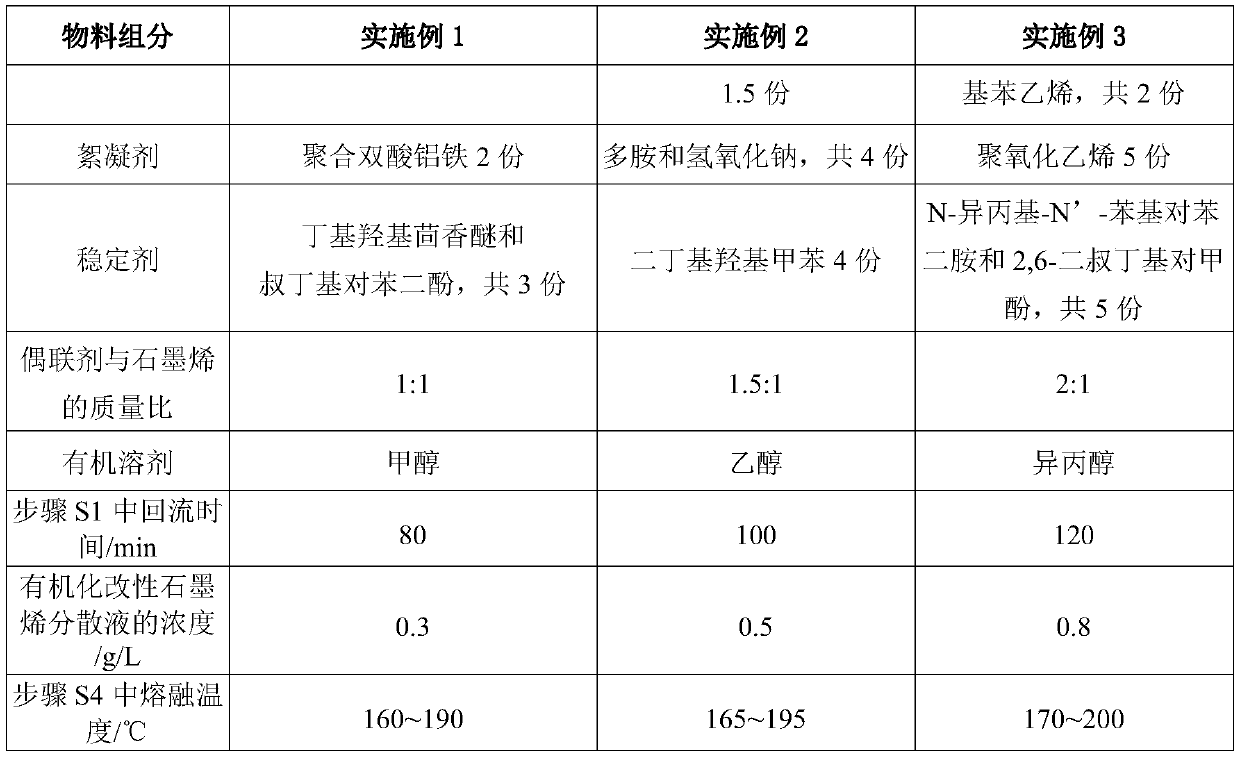

Modified graphene composite polyethylene material and preparation method thereof

The invention provides a modified graphene composite polyethylene material, which comprises, by weight, 75-100 parts of polyethylene, 0.5-2 parts of graphene, 1-4 parts of a coupling agent, 4-10 partsof a compatilizer, 0.8-2 parts of a dispersing agent, 2-5 parts of a flocculating agent and 3-5 parts of a stabilizer. Compared with the method in the prior art, the method of the invention has the following characteristics that graphene is used as the antistatic agent and the reinforcing agent, and is organically modified with the coupling agent, the maleic anhydride grafted EVA is used as the toughening compatilizer to form the antistatic toughening and reinforcing system of the polyethylene material, and finally the polyethylene material obtains the stable physical and chemical propertiesthrough the flocculating agent and the stabilizer, so that the composite polyethylene material with good mechanical properties and good antistatic properties is prepared in the case of the feeding ofa small amount of the modifier.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

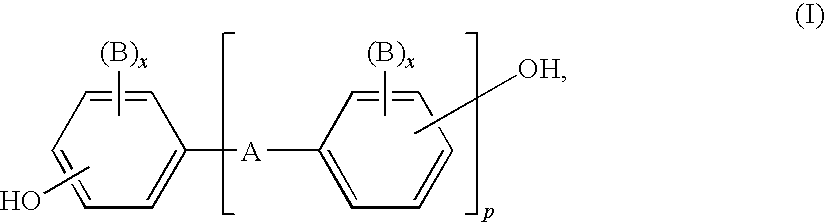

Impact-modified polycarbonate compositions

The present invention relates to non-aging, impact-modified polycarbonate compositions and moulding compositions comprising: A) from 60 to 86 parts by weight (based on the sum of components A+B+C) of aromatic polycarbonate and / or aromatic polyester carbonate, B) from 4 to 12 parts by weight (based on the sum of components A+B+C) of graft polymer comprising: B.1 from 10 to 50 wt. % (based on the graft polymer B) of a shell of at least one vinyl monomer, and B.2 from 90 to 50 wt. % (based on the graft polymer B) of a graft base of silicone-acrylate composite rubber, C) from 10 to 30 parts by weight (based on the sum of components A+B+C) of a polymer or copolymer based on vinyl monomer, and D) from 0 to 20 parts by weight of polymer additives. Components B and C are present in a ratio of the parts by weight of B:C in the range from 1:1.3 to 1:3.5. A composition of the present invention is generally free of inorganic fillers, and is distinguished by an improved balance of multiaxial low-temperature impact strength and flowability, good dyeability and a high heat distortion resistance.

Owner:COVESTRO DEUTSCHLAND AG

Soft touch electromagnetic non-lancing crystallizer utilized in continuous casting

A soft contact type non-groove crystallizer for electromagnetic conticasting of steel is composed of the sleeve pipe of crystallizer, casing and induction coil. Its sleeve pipe is composed of the lower copper (or Cu-ally) segment and the upper segment made of Cu-base composite. Its advantages are high and uniform magnetic penetrability, good cooling effect, high strength and thermal deformation resistance, and high P / C ratio.

Owner:NORTHEASTERN UNIV

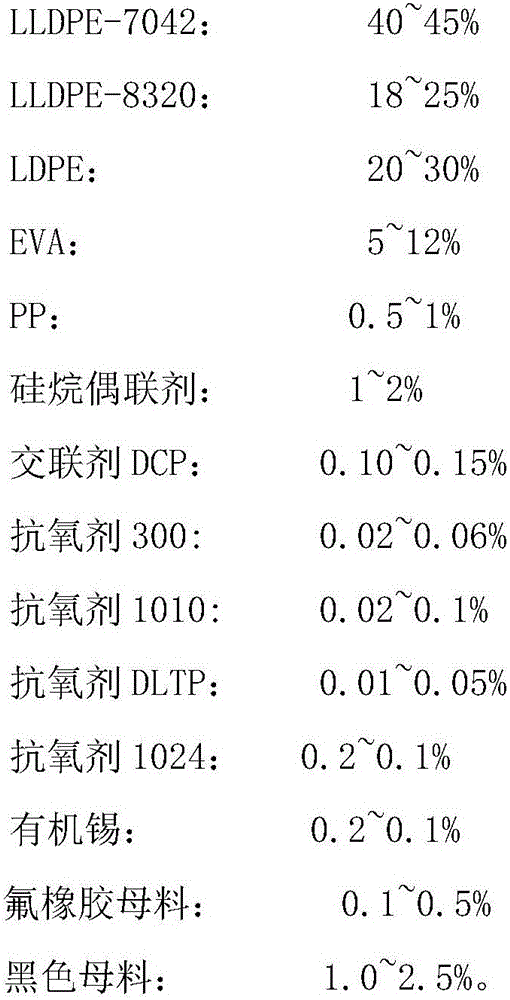

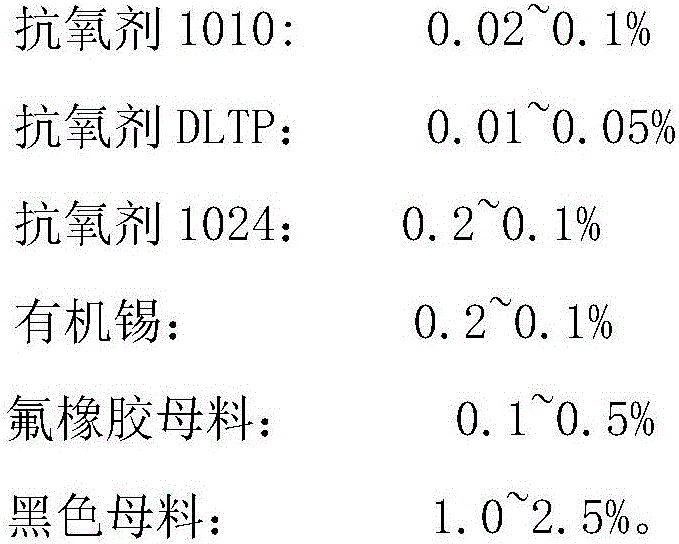

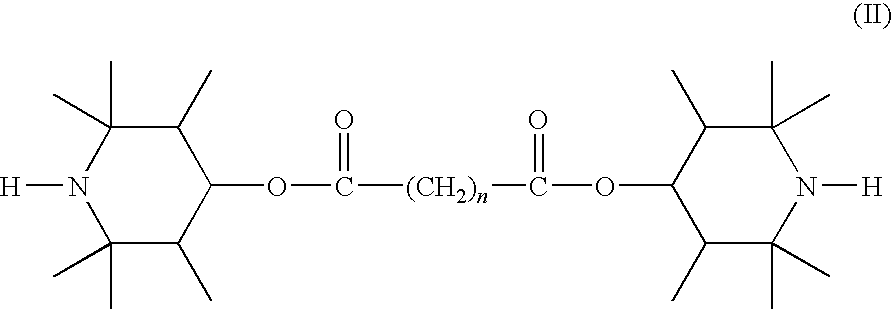

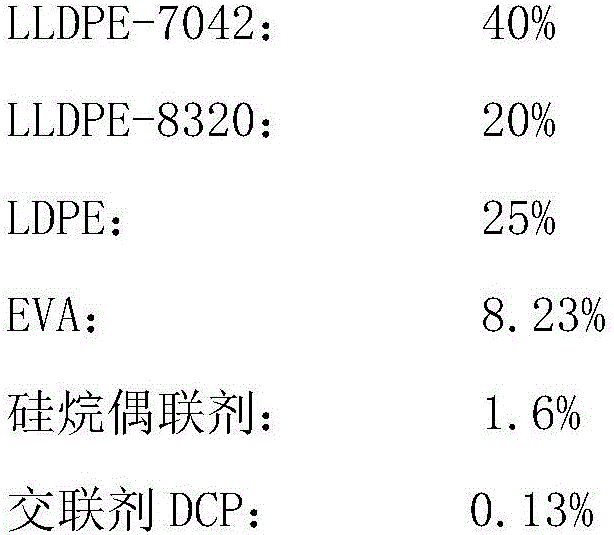

Method for preparing silane crosslinking polyethylene insulating material for 10 kV or below black wires and cables through one step

InactiveCN106009224AImprove insulation performanceStable speedPlastic/resin/waxes insulatorsCross-linkSilanes

The invention relates to the field of insulating materials, in particular to a silane crosslinking polyethylene insulating material for 10 kV or below black wires and cables. A method for preparing the insulating material for the 10 kV or below black wires and cables through one step mainly comprises the two steps of catalyst master batch preparation and finished product preparation. The insulating material is prepared from, by weight, LLDPE-7042, LLDPE-8320, LDPE, EVA, PP, a silane coupling agent, a cross-linking agent DCP, an antioxidant 300, an antioxidant 1010, an antioxidant DLTP, an antioxidant 1024, organotin, fluororubber master batches and black master batches. The insulating material is mainly used for insulating layers of the cables and mainly replaces a current PVC material, the insulating property is superior to that of PVC, PVC can emit toxic and harmful gases when the wires fire due to aging and the like, but the silane insulating material is poisonless and harmless.

Owner:浙江太湖远大新材料股份有限公司

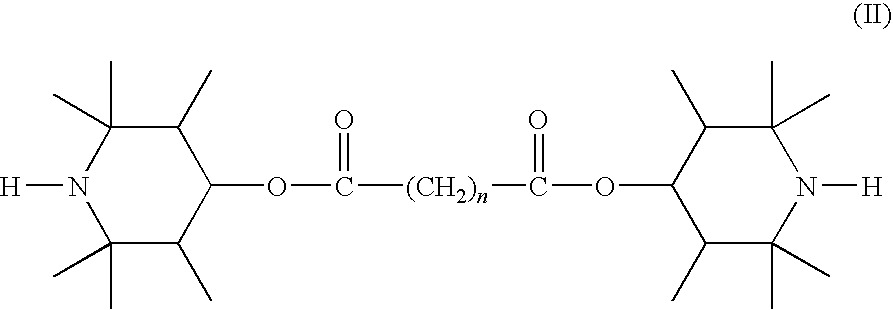

Self-lubricating high-abrasion-resistance nylon 66 composite material for truck connecting rod sleeve and preparation method of material

The invention discloses a self-lubricating high-abrasion-resistance nylon 66 composite material for a truck connecting rod sleeve. The composite material is prepared from, by weight, 50-85 parts of injection grade PA66 base material of which the viscosity ranges from 2.6 to 2.9, 15-50 parts of short-cut or continuous glass fibers, 0.1-0.8 part of antioxidant 1010 or 1098, 0.1-0.8 part of antioxidant 168, 0.1-0.8 part of carbon black, 0.1-1 part of lubricating agent calcium stearate and 1-20 parts of PTFE or graphite or molybdenum disulfide or aramid fibers. According to the self-lubricating high-abrasion-resistance nylon 66 composite material for the truck connecting rod sleeve, a nylon 66 based high polymer material blending modification technology is adopted, and by means of melting mixing and extruding methods such as glass fiber reinforcing, processing stabilizing and thermal-oxidation stabilizing, the high-performance high-abrasion-resistance nylon 66 composite material is obtained.

Owner:烟台恒大聚合体有限公司

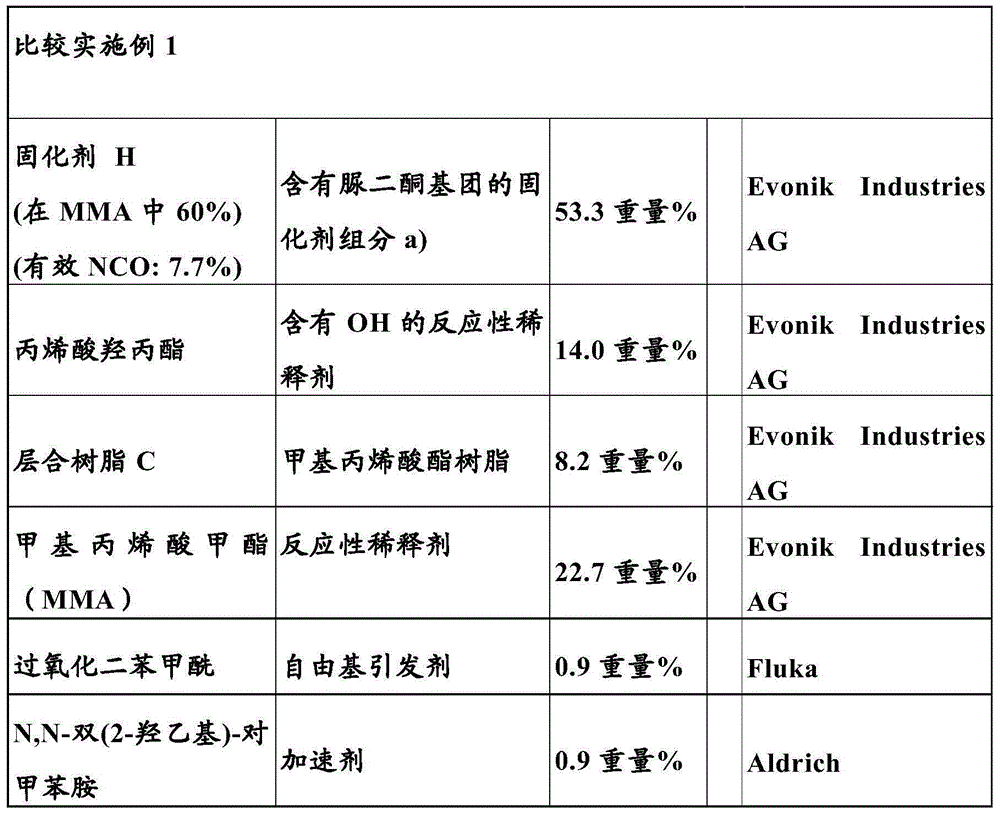

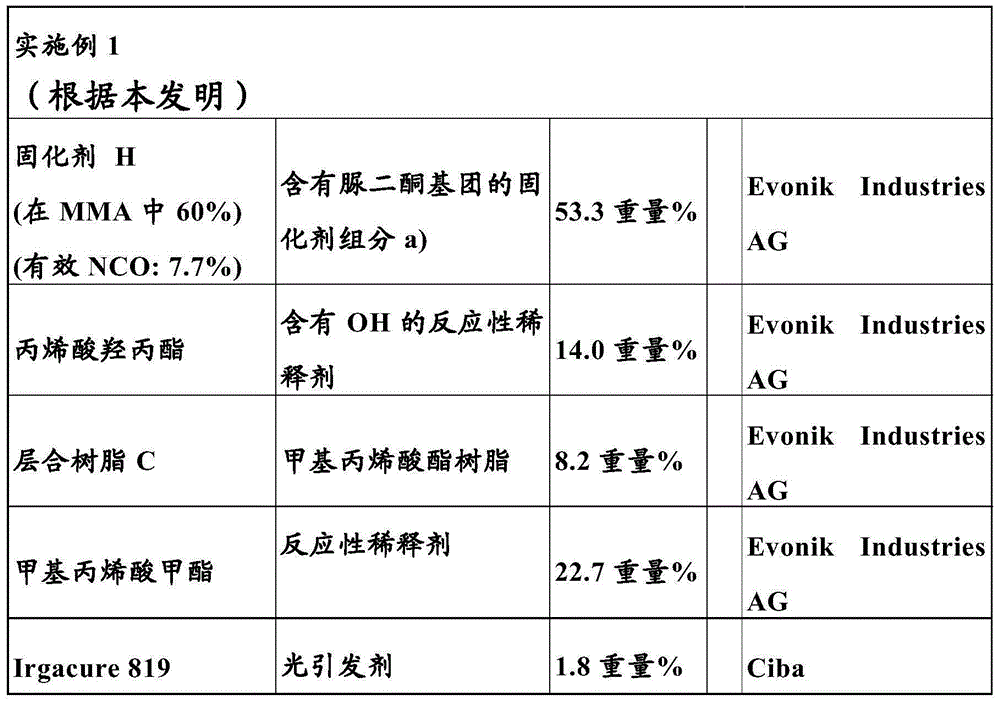

Composite semifinished products and mouldings produced therefrom and directly produced mouldings based on hydroxy-functionalized (meth)acrylates and uretdiones which are crosslinked by means of radiation to give thermosets

The invention relates to a process for producing polyurethane prepregs which are stable during storage, and to mouldings (composite components) produced therefrom. The prepregs or components are produced by mixing, for example, (meth)acrylate monomers, (meth)acrylate polymers, hydroxy-functionalized (meth)acrylate monomers and / or hydroxy-functionalized (meth)acrylate polymers with uretdione materials. Optionally, photoinitiators can also be added. This mixture or solution is applied by known processes to fibre material, e.g. carbon fibres, glass fibres or polymer fibres, and is polymerized with the aid of radiation or plasma applications. Polymerization, e.g. at room temperature or at up to 80 DEG C, gives thermoplastics or, respectively, thermoplastic prepregs which can subsequently be subjected to forming processes. By using elevated temperature, the hydroxy-functionalized (meth)acrylate constituents can then be crosslinked with the uretdiones already present in the system. It is thus possible to produce dimensionally stable thermosets and, respectively, crosslinked composite components.

Owner:EVONIK DEGUSSA GMBH

Composition with increased stress cracking resistance

InactiveUS8227549B2Improved stress crack resistanceImprove heat deformation resistanceInksOrganic dyesCrack resistanceMeth-

Owner:EVONIK ROEHM GMBH

Preparation method of polyolefin microporous diaphragm for lithium ion batteries

ActiveCN104733676AImprove hydrophilicityImprove heat deformation resistanceCell component detailsPorosityPolymer science

The invention belongs to the field of polymer functional films and preparations thereof, and particularly relates to a lithium ion battery diaphragm and a preparation method thereof. A polyolefin material is modified through the reactive extrusion of hydrophilic prepolymer and polyolefin, and then the obtained object is subjected to tape-casting and stretching, so that a hydrophilic polyolefin microporous diaphragm for lithium ion batteries is obtained. Compared with microporous membranes prepared by using unmodified polyolefin, the hydrophilicity, thermal deformation resistance and tensile properties of the polyolefin microporous diaphragm are obviously improved, and the other properties such as porosity and air permeability of the diaphragm are changed slightly.

Owner:CHANGZHOU UNIV

Graphene compound vinyl ester heavy anti-corrosion coating and preparation method thereof

InactiveCN107057532AEnhanced barrier functionReduce specific gravityFireproof paintsAnti-corrosive paintsCross-linkVinyl ester

The invention discloses a graphene compound vinyl ester heavy anti-corrosion coating, which comprises a component A and a component B, wherein the component A comprises the following components in parts by weight: 60-75 parts of phenolic vinyl ester resin, 0.5-2 parts of graphene, 20-30 parts of precipitated barium sulphate, 5-10 parts of sericite, 0.5-2 parts of a nano assistant, 0.5-1 part of an anti-settling agent, 0.5-2 parts of an accelerant; and the component B is 2-4 parts of a cross-linking agent. The preparation method comprises the steps of (1) adding the anti-settling agent, the nano assistant and the accelerant to the phenolic vinyl ester resin under a stirring state, stirring for 10min, adding graphene, stirring evenly, finally adding the sericite and the precipitated barium sulphate and stirring evenly to obtain a paste coating; and (2) mixing the paste coating and the cross-linking agent evenly to obtain a finished product coating. The heavy anti-corrosion coating which has excellent properties such as light weight, good chemical resistance, good solvent resistance and high wear resistance can be prepared.

Owner:DEYANG CARBONENE TECH

Preparation method of insulating material for electrical equipment

InactiveCN108084534AExcellent dielectric propertiesWith high voltageRubber insulatorsPlastic/resin/waxes insulatorsMolten stateEpoxy

The invention provides a preparation method of an insulating material for electrical equipment. The method comprises the following steps: a, leading waste rubber, epoxy resin and silicone rubber intoan internal mixer, performing banburying on the material till the mixture is molten, then sequentially adding a fire retardant, nanosilicon dioxide and carbon black, and reducing the temperature for banburying, so as to obtain a mixture I; mixing and putting a processing auxiliary material, polyimide, sodium alginate, lignin and an antioxidant into a mixer, heating, and performing ultrasonic oscillation, so as to obtain a mixture II; c, adding silicone oil and a coupling agent into the mixture II, putting the mixture II into a stirrer to perform stirring, then putting the mixture II in a vacuum environment, and performing defoaming treatment, so as to obtain a mixture III; and d. uniformly mixing the mixture I, the mixture III, organic tin and a curing agent, leading the mixture into a single screw to perform extrusion, adding the mixture into a dehydrator to perform dehydration, and putting the mixture into a closed container, leaving the mixture to stand, curing, and forming. The method is simple, short in preparation flow, mainly adopts a waste rubber material, and has certain environmental protection significance.

Owner:马鞍山佳夫尼电气科技有限公司

Ceramic/metallic double continuous phase composite material brake pad and preparation method thereof

The invention relates to the field of friction materials for braking of high-speed trains, in particular to a ceramic / metallic double continuous phase composite material brake pad and a preparation method thereof. The brake pad comprises the following components in percentage by weight: 15 to 40 percent of foam silicon carbide ceramics, 10 to 30 percent of friction element and 75 to 30 percent ofmetal. The method comprises the following steps of: preparing the silicon carbide foam ceramics having a three-dimensional network structure by employing a technology combining polymer pyrolysis withcontrollable infiltration reaction sintering; selecting a proper friction element and filling in mesh holes of the foam ceramics; and injecting melt copper alloy into a framework of the foam ceramicsby utilizing an extrusion casting method to obtain the ceramic / metallic double continuous phase composite material brake pad. The composite material brake pad can be paired with a 28CrMoV forged steel brake disc, has the characteristics of proper and stable friction coefficient, low wear rate, high heat resistance, high thermal or mechanical damage resistance, good process performance, low manufacturing cost, long service life and the like, completely meets the brake requirement of a high-speed train at a speed of 200 to 300km / h, and has good competitive advantage on the brake requirement of a high-speed train at the speed of 350km / h.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Core-shell structured ACR (Acrylate) latex, modified resin powder material and preparation methods thereof

The invention relates to the technical field of resin and discloses core-shell structured ACR (Acrylate) latex, a modified resin powder material and preparation methods thereof. The core-shell structured ACR latex is prepared from the following raw materials in parts by weight: deionized water, a core-layer comonomer, shell-layer polymer latex, a reaction initiator, a core-layer emulsifier and a cross-linking agent. The modified resin powder material disclosed by the method has the advantages that the notched impact strength, the thermal deformation resisting temperature and the ultraviolet aging resistance are better than those of the high-impact-resistance PVC (Polyvinyl Chloride) in the prior art, the production cost is reduced, and the problems of reactor sticking and coarse particles of the existing modified PVC production processes are solved; by using the PVC reinforcing action of a nano effect, the weather resistance and thermal deformation resistance of the PVC are further improved while the anti-impact modification of the PVC is improved.

Owner:XINJIANG ZHONGTAI CHEM CO LTD

Coloured composition with increased stress cracking resistance

InactiveUS8178624B2Improved stress crack resistanceImprove heat deformation resistanceOrganic dyesCeramic shaping apparatusCrack resistanceMeth-

Owner:EVONIK ROEHM GMBH

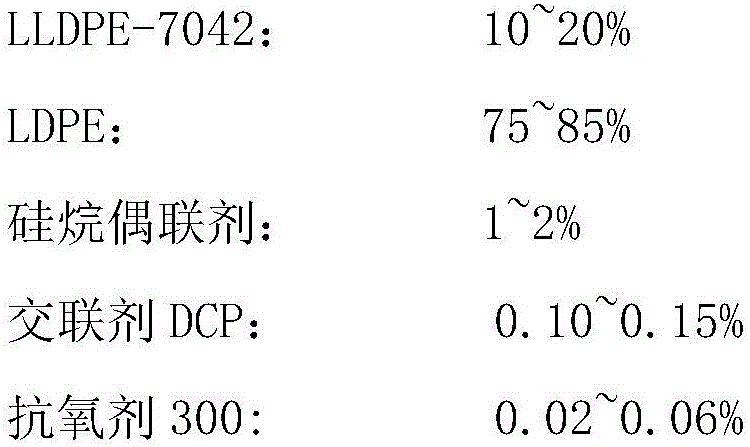

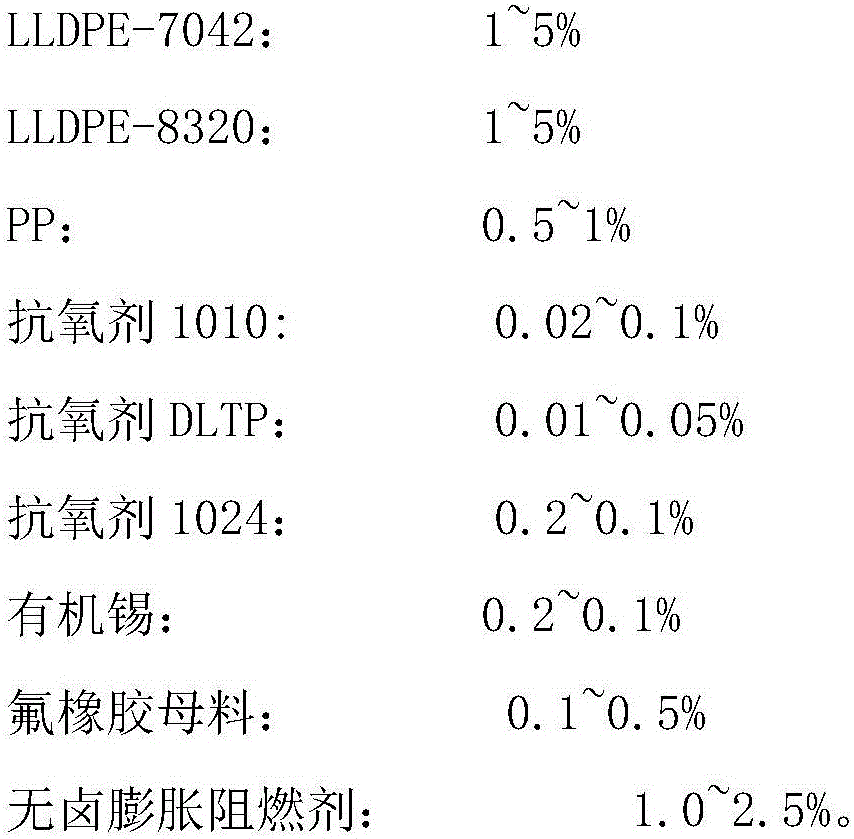

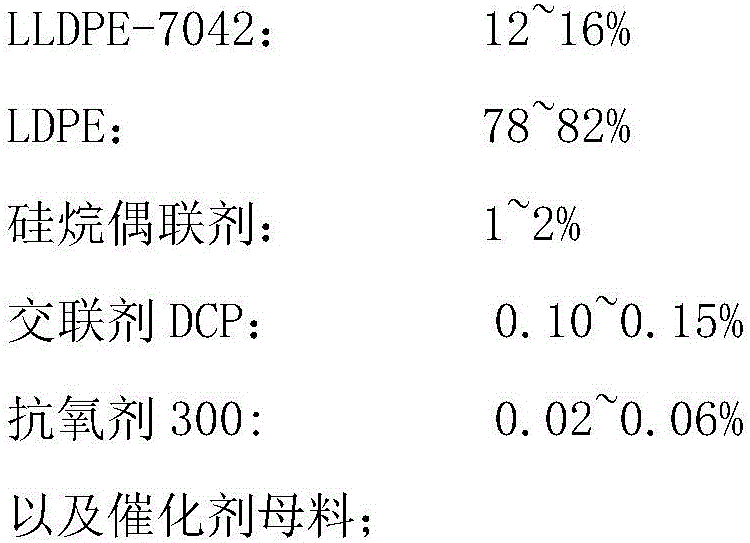

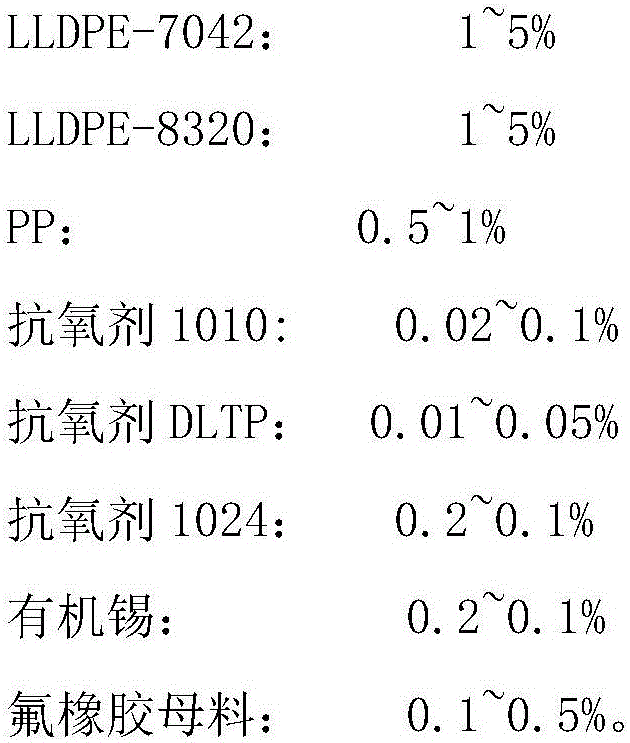

Non-halogen flame-retardant polyethylene sheath insulating material and preparation method thereof

InactiveCN106084409AImprove insulation performanceStable speedPlastic/resin/waxes insulatorsInsulated cablesLinear low-density polyethylenePolymer science

The invention relates to the field of insulating materials, in particular to a non-halogen flame-retardant polyethylene sheath insulating material and a preparation method thereof. The non-halogen flame-retardant polyethylene sheath insulating material is prepared from components as follows: LLDPE-7042 (linear low density polyethylene-7042), LDPE (low-density polyethylene), a silane coupling agent, a cross-linking agent DCP, an antioxidant 300 and a catalyst masterbatch, wherein the catalyst masterbatch comprises components as follows: LLDPE-7042, LLDPE-8320, PP (polypropylene), an antioxidant 1010, an antioxidant DLTP, an antioxidant 1024, organic tin, a fluororubber masterbatch and a non-halogen intumescent flame retardant. The material is mainly applied to an insulating layer of a cable and is mainly used for replacing a current PVC (polyvinyl chloride) material, the insulating property of the material is superior to that of PVC, and the silane insulating material is non-toxic and harmless while PVC can release toxic and harmful gas when a wire is on fire caused by aging and the like.

Owner:浙江太湖远大新材料股份有限公司

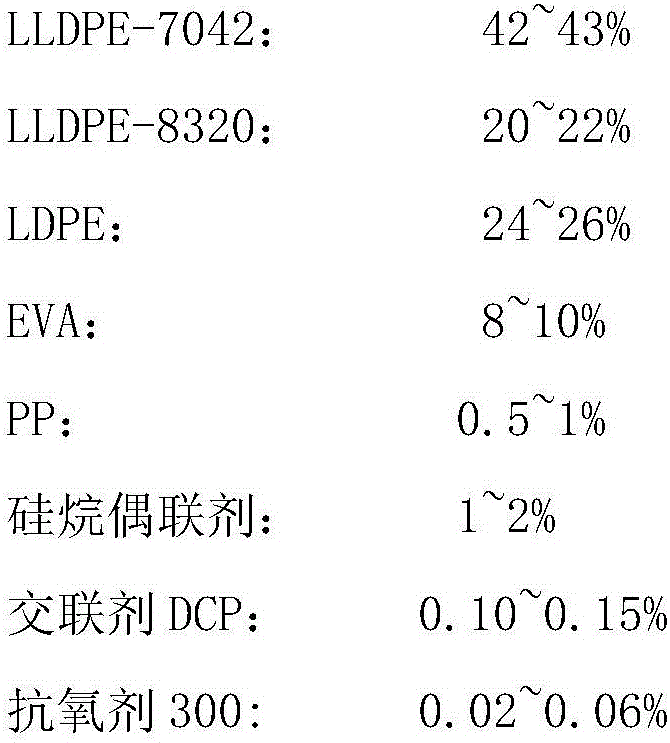

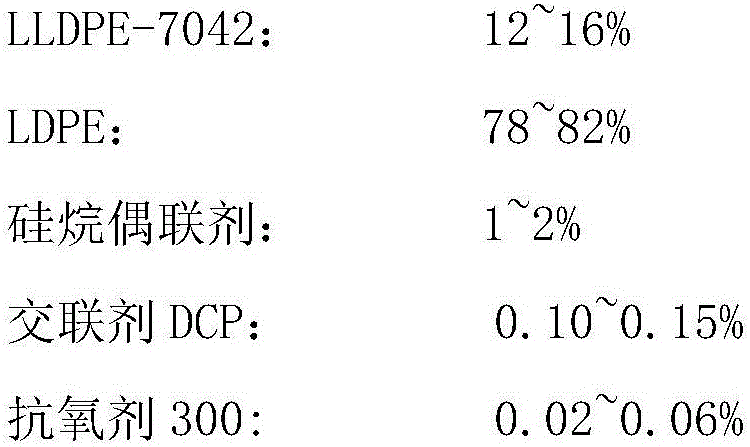

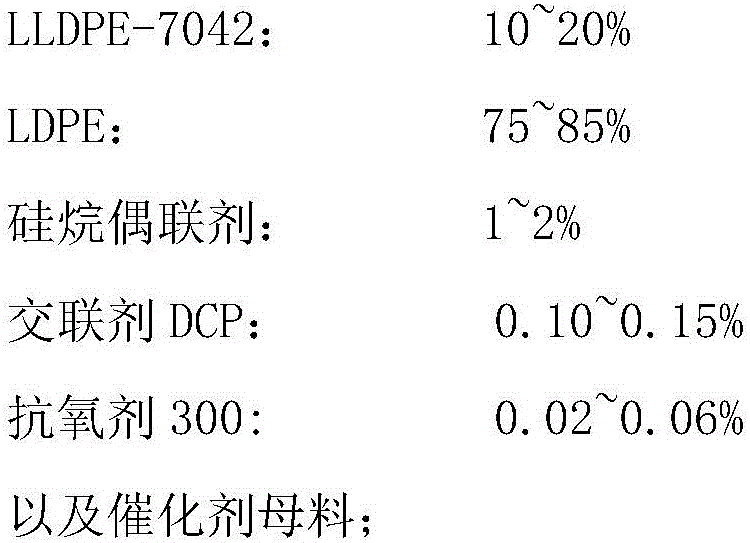

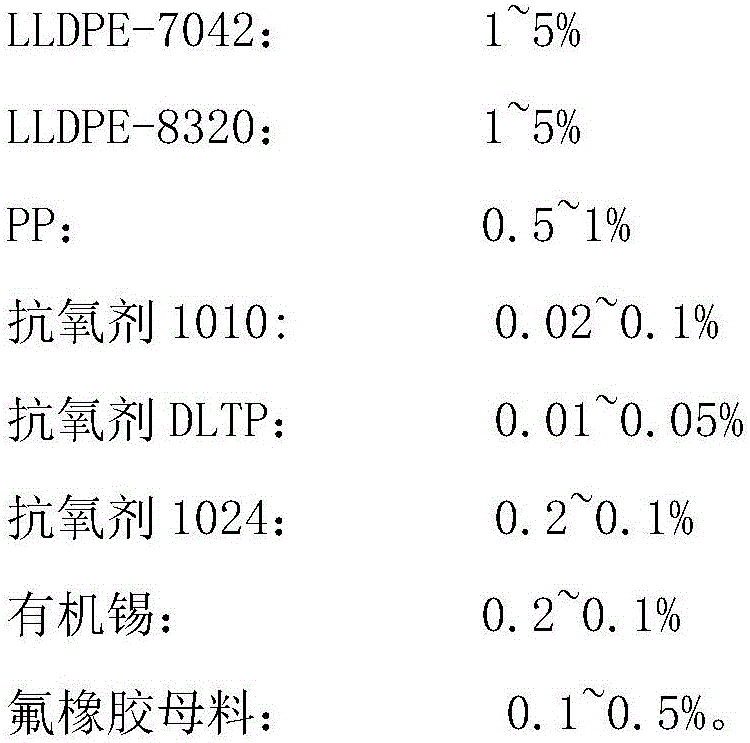

Method for preparing silane crosslinked polyethylene insulation material for electric wires and cables by two-step way

InactiveCN106188742AImprove insulation performanceStable speedPlastic/resin/waxes insulatorsClimate change adaptationLow-density polyethyleneLinear low-density polyethylene

The invention relates to the field of insulation materials, in particular to a silane crosslinked polyethylene insulation material for electric wires and cables. A method for preparing the silane crosslinked polyethylene insulation material for electric wires and cables by a two-step way mainly comprises two steps of 1, preparation of a catalyst master batch; 2, preparation of a finished product. The insulation material is prepared from the following components of LLDPE (linear low density polyethylene)-7042, LDPE (low density polyethylene), a silane coupling agent, a crosslinking agent DCP, an antioxidant 300 and the catalyst master batch; the catalyst master batch comprises the following components of LLDPE-7042, LLDPE-8320, PP (polypropylene), an antioxidant DLTP, an antioxidant 1024, organic tin and a fluororubber master batch. The insulation material has the advantages that the insulation material is mainly used for insulation layers of cables, and is mainly used for replacing the existing PVC (polyvinyl chloride) material; the insulation property is better than the insulation property of PVC, and the poisonous and harmful gas will be released by the PVC when the electric wire is aged and catches a fire, but the silane insulation material has no poison and harm.

Owner:浙江太湖远大新材料股份有限公司

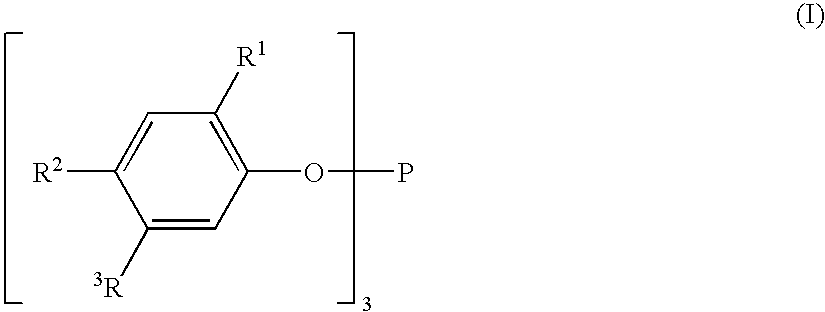

PA6 buckle material for fixing sound-absorbing module and preparation method of material

The invention discloses a PA6 buckle material for fixing a sound-absorbing module. The PA6 buckle material is prepared from, by weight, 50-85 parts of injection grade PA6 base material of which the viscosity ranges from 2.6 to 2.9, 15-50 parts of short-cut or continuous glass fibers, 0.1-0.8 part of antioxidant 1010 or 1098, 0.1-0.8 part of antioxidant 168, 0.1-1 part of UV agent 2020 or 770 or 4050, 0.1-1 part of UV agent 234 or 944 or 622, 1-3 parts of carbon black and 0.1-1 part of lubricating agent. According to the PA6 buckle material for fixing the sound-absorbing module, a nylon 6 based high polymer material blending modification technology is adopted, and by means of melting mixing and extruding methods such as glass fiber reinforcing, processing stabilizing and thermal-oxidation stabilizing, the PA6 buckle material for fixing the sound-absorbing module is obtained.

Owner:烟台恒大聚合体有限公司

Low temperature resistant transparent polypropylene compound for automobiles and preparation method of low temperature resistant transparent polypropylene compound

The invention discloses a low temperature resistant transparent polypropylene compound for automobiles and a preparation method of the low temperature resistant transparent polypropylene compound. Thelow temperature resistant transparent polypropylene compound is characterized by comprising the following components in percentages by weight: 55-80% of homo-polypropylene, 10-35% of random copolymerization polypropylene, 3-9% of a toughener, 3-5% of polyethylene, 0.6-1% of a heat resistant agent and 0.5-1% of a nucleating agent. The homo-polypropylene, the random copolymerization polypropylene,the tougher, the polyethylene, the heat resistant agent and the nucleating agent are uniformly mixed in a high-speed mixer, and then melted and mixed by a double-screw extruder to obtain the compoundso as to expect to solve the problems that an existing product prepared from polypropylene has insufficient low temperature resistant toughness or has the risk of high temperature deformation, and furthermore, an expansion kettle belongs to products installed on the periphery of an engine, and is maintained in a high-temperature environment for a long time, and especially in high temperature seasons, the expansion kettle is prone to thermal oxygen aging, deformation and even explosion.

Owner:重庆光亚富臻新材料有限公司

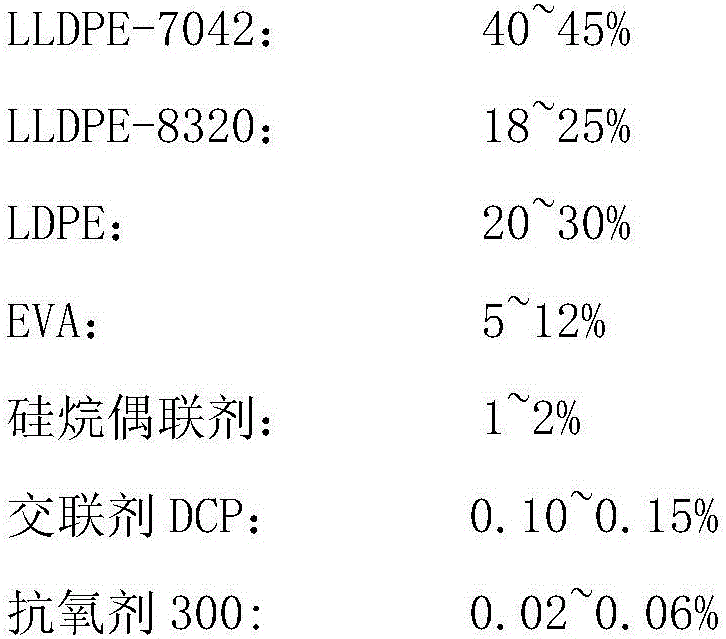

Method for preparing silane crosslinking polyethylene insulating material for 10 kV or below wires and cables through one step

InactiveCN106009234AImprove insulation performanceReduce quality problemsPlastic/resin/waxes insulatorsCross-linkMasterbatch

The invention relates to the field of insulating materials, in particular to a silane crosslinking polyethylene insulating material for 10 kV or below wires and cables. A method for preparing the insulating material for the 10 kV or below wires and cables through one step mainly comprises the two steps of catalyst master batch preparation and finished product preparation. The insulating material is prepared from, by weight, LLDPE-7042, LLDPE-8320, LDPE, EVA, PP, a silane coupling agent, a cross-linking agent DCP, an antioxidant 300, an antioxidant 1010, an antioxidant DLTP, an antioxidant 1024, organotin and fluororubber master batch. The insulating material is mainly used for insulating layers of the cables and mainly replaces a current PVC material, the insulating property is superior to that of PVC, PVC can emit toxic and harmful gases when the wires fire due to aging and the like, but the silane insulating material is poisonless and harmless.

Owner:浙江太湖远大新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com