Preparation method of polyolefin microporous diaphragm for lithium ion batteries

A polyolefin microporous film, lithium-ion battery technology, applied in battery pack parts, circuits, electrical components, etc., to achieve improved tensile properties, low porosity and air permeability, and uniform bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

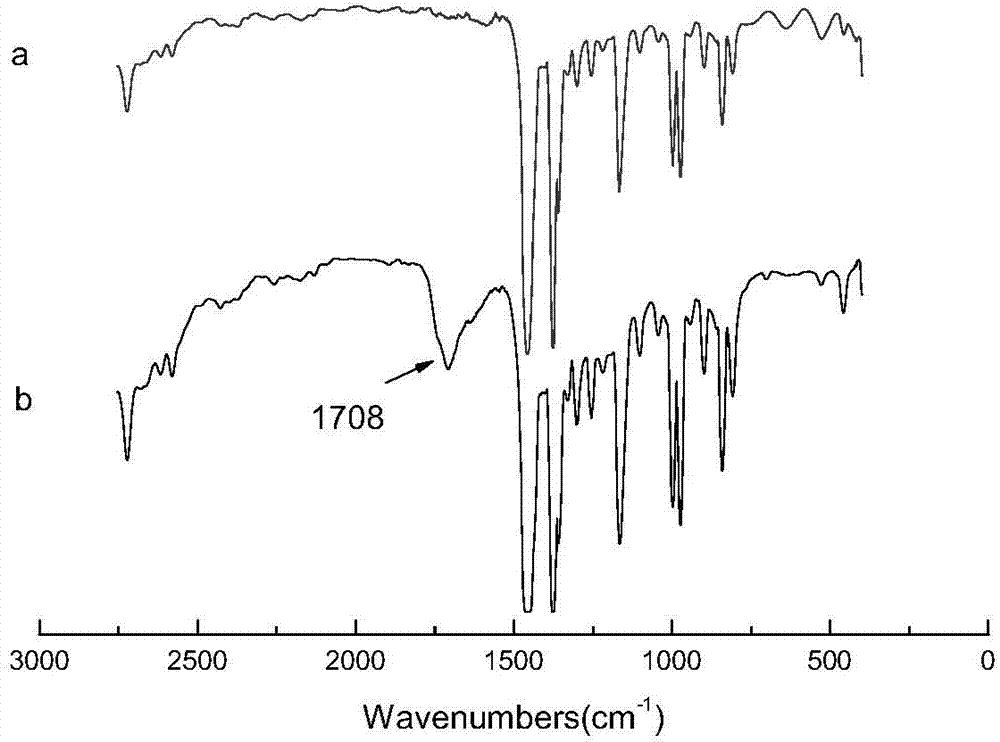

Image

Examples

Embodiment 1

[0047] Take 3g of α-methylstyrene, 27g of acrylic acid, 6g of azobisisobutyronitrile, and 90g of solvent N,N-dimethylformamide into a three-necked flask in sequence. After passing through nitrogen gas to deoxygenate for 20 minutes, the three-neck flask was placed in a water bath at a temperature of 65° C. for 24 hours. After the reaction, precipitate with ether and dry in vacuum at 50° C. to obtain a prepolymer (that is, a copolymer of α-methylstyrene and acrylic acid, hereinafter referred to as “PAA”).

[0048] After PAA is ground into powder, it is fully mixed with polypropylene masterbatch (F401, Sinopec Yangzi Petrochemical Co., Ltd.) (PAA copolymer accounts for 4% of the quality of polypropylene masterbatch), and passed through a twin-screw extruder at 220 ° C. Reactive extrusion granulation obtains modified polyolefin particles.

[0049] Cast the above-mentioned modified polyolefin particles after drying at 230° C., and control the draft ratio to 40, so that the thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com