Patents

Literature

107results about How to "Improve anti-adhesion performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compositions of polyacids and methods for their use in reducing adhesions

InactiveUS20050074495A1Improve anti-adhesion performancePrevent reformationPowder deliverySurgeryMicrosphereSurgical site

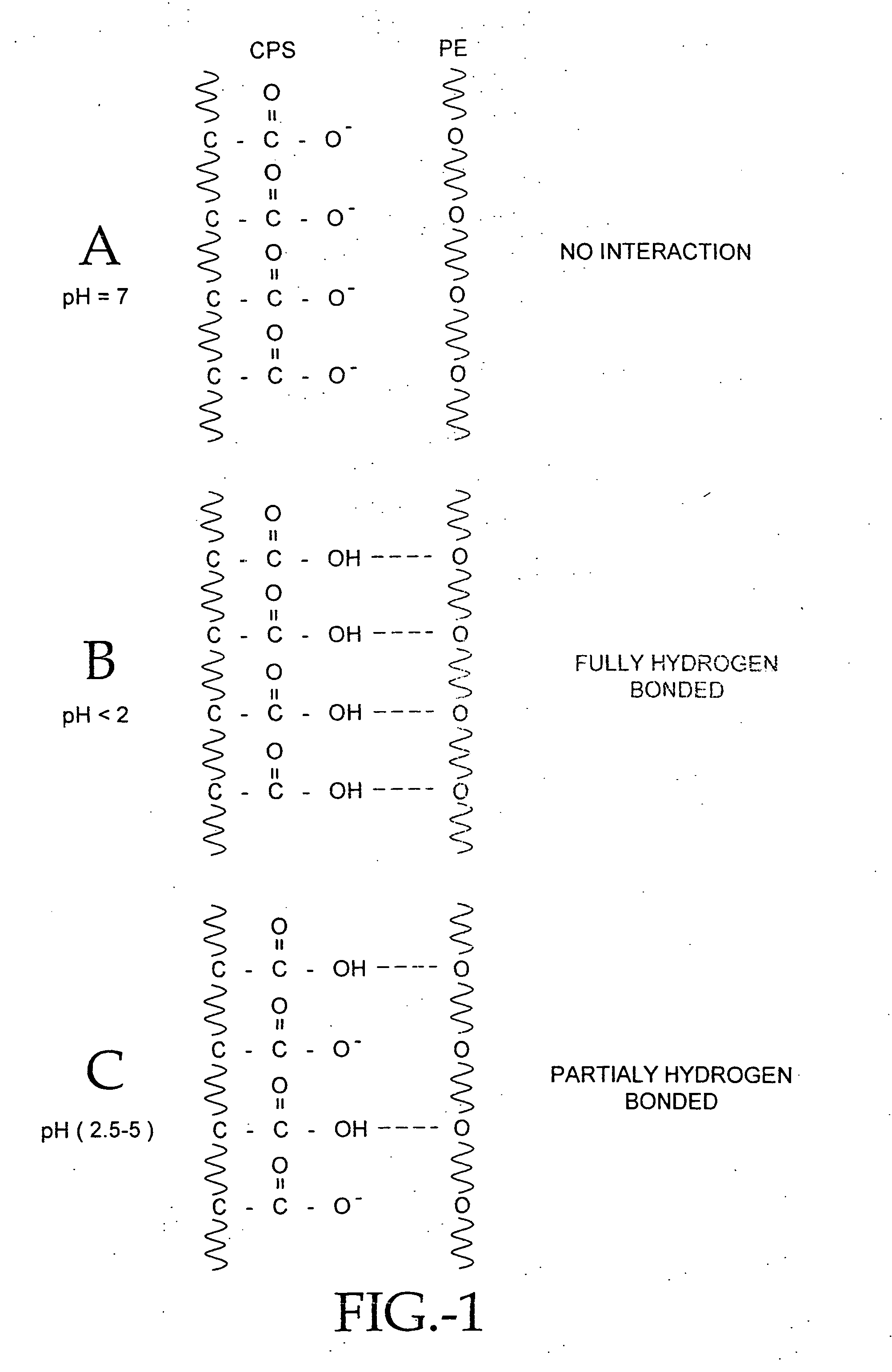

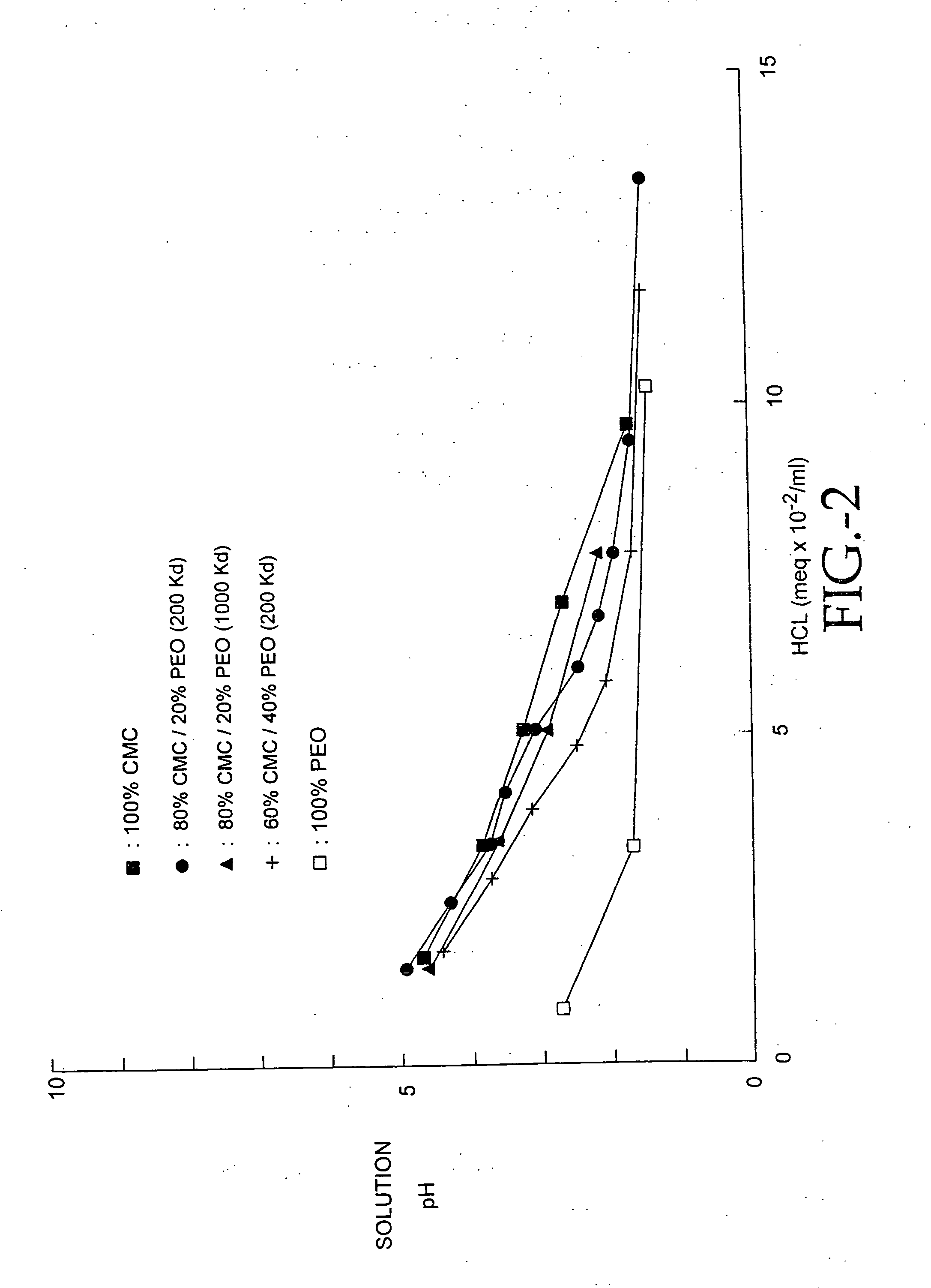

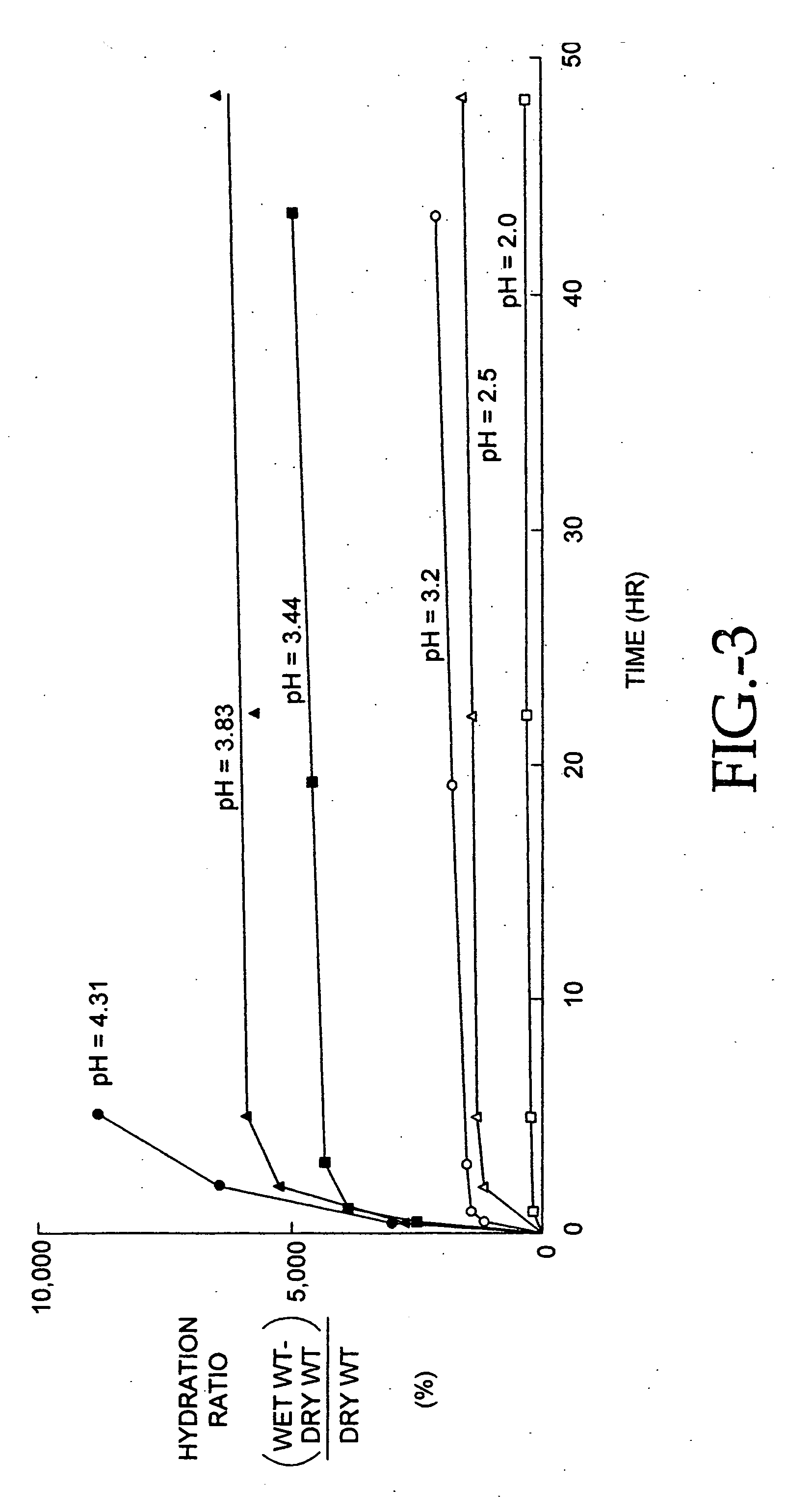

The present invention relates to improved methods for making and using bioadhesive, bioresorbable, anti-adhesion compositions made of inter-macromolecular complexes of carboxyl-containing polysaccharides, polyethers, polyacids, polyalkylene oxides, multivalent cations and / or polycations. The polymers are associated with each other and are then either dried into membranes or sponges or are used as fluids or microspheres. Bioresorbable, bioadhesive, antiadhesion compositions are useful in surgery to prevent the formation and reformation of post-surgical adhesions. The compositions are designed to breakdown in vivo, and thus be removed from the body. Membranes are inserted during surgery either dry or optionally after conditioning in aqueous solutions. The antiadhesion, bioadhesive, bioresorptive, antithrombogenic and physical properties of such membranes and gels can be varied as needed by carefully adjusting the pH and / or cation content of the polymer casting solutions, polyacid composition, the polyalkylene oxide composition, or by conditioning the membranes prior to surgical use. Multi-layered membranes can be made and used to provide further control over the physical and biological properties of antiadhesion membranes. Membranes and gels can be used concurrently. Antiadhesion compositions may also be used to lubricate tissues and / or medical instruments, and / or deliver drugs to the surgical site and release them locally.

Owner:FZIOMED

Anti-sticking and wear resistant polyurea coating and its preparation method

ActiveCN102492357ASolve the adhesionSolve corrosivePolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention relates to an anti-sticking and wear resistant polyurea coating and its preparation method. The coating is prepared by blending of component A and component B. Specifically, the component A is synthesized by the following raw materials by weight: 90-120 parts of isocyanate, 40-60 parts of polyether polyol and 20-30 parts of fluorocarbon diol; and the component B is prepared by the following raw materials by weight: 500-800 parts of polyether amine, 400-600 parts of organosilicon diamine, 300-400 parts of high activity polyether polyol, 400-500 parts of an amino chain extender, 80-100 parts of an amino cross-linking agent, 100-150 parts of a high boiling point diluent, 5-10 parts of a composite catalyst, 400-600 parts of composite nano-metal oxide surface active materials, 600-800 parts of a filling material, and 40-60 parts of a pigment. The invention also includes a preparation method of the anti-sticking and wear resistant polyurea coating. A coating layer obtained by spraying of the anti-sticking and wear resistant polyurea coating in the invention has strong adhesion, and has good adhesion resistance, wear resistance, corrosion resistance, as well as impact resistance. Therefore, the anti-sticking and wear resistant polyurea coating of the invention is especially suitable for spraying on the lining surface of a heavy transport dump truck.

Owner:湘江涂料科技有限公司

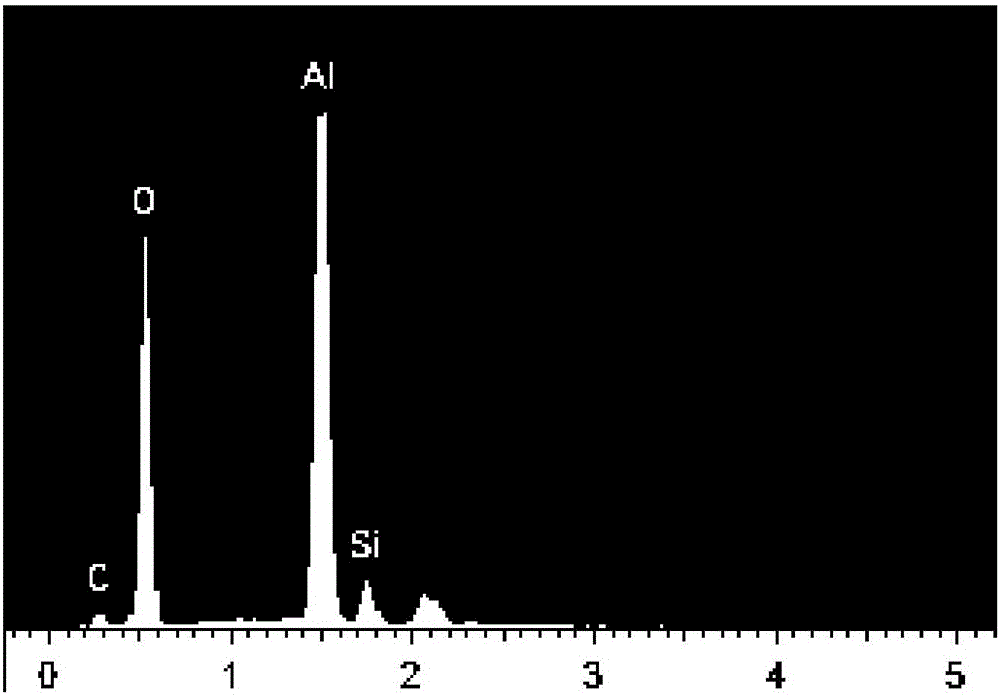

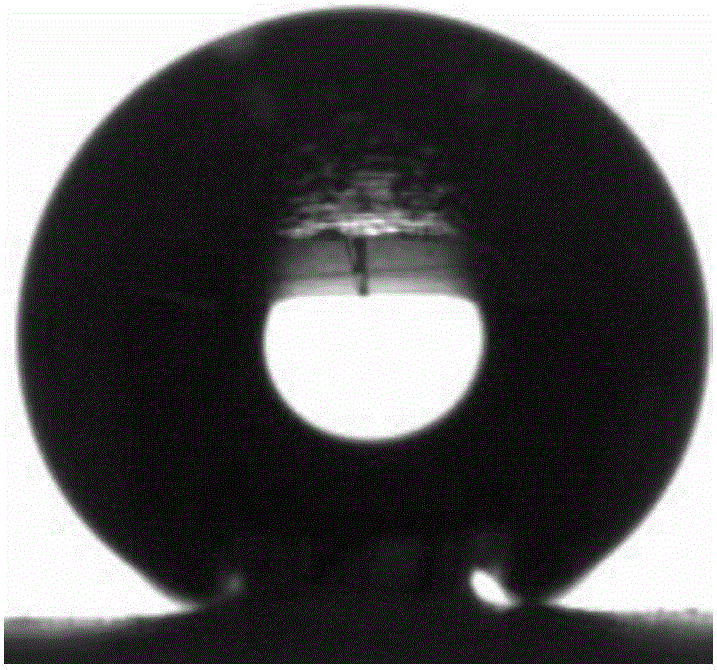

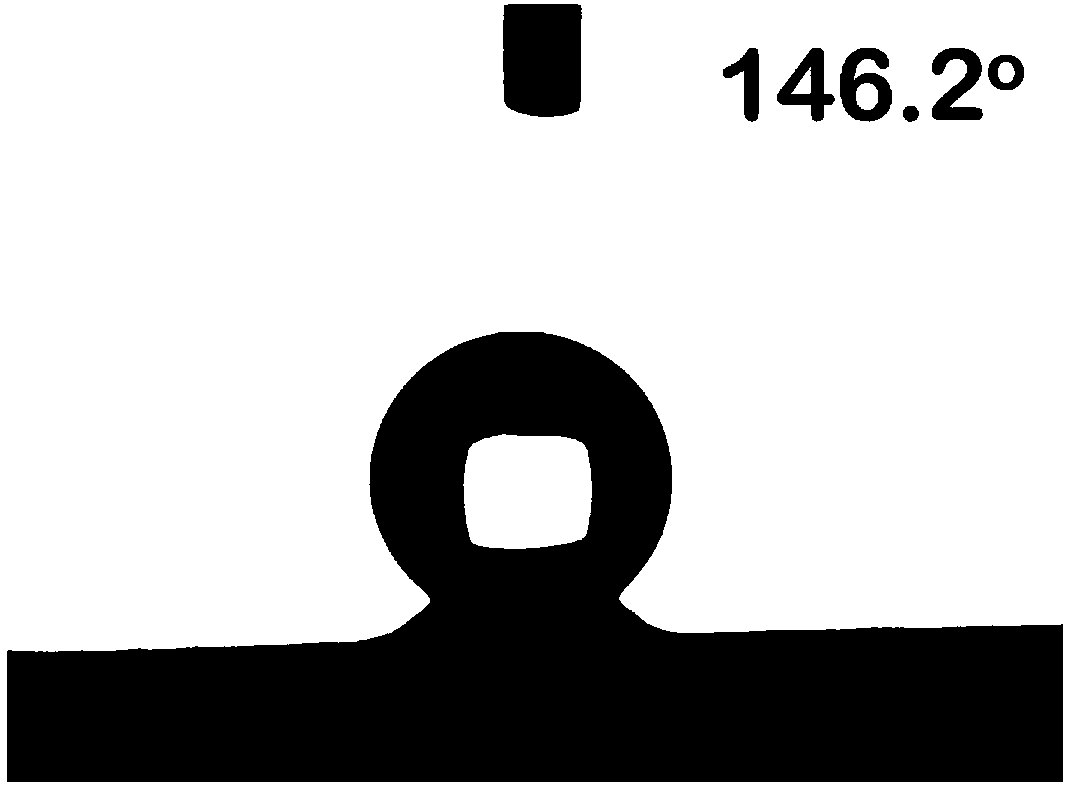

Preparation method for fluoride-free, non-toxic, economic and efficient aluminium-based superhydrophobic material

InactiveCN105921380AReduce resistanceImprove corrosion resistancePretreated surfacesCoatingsOrganic filmSuperhydrophobe

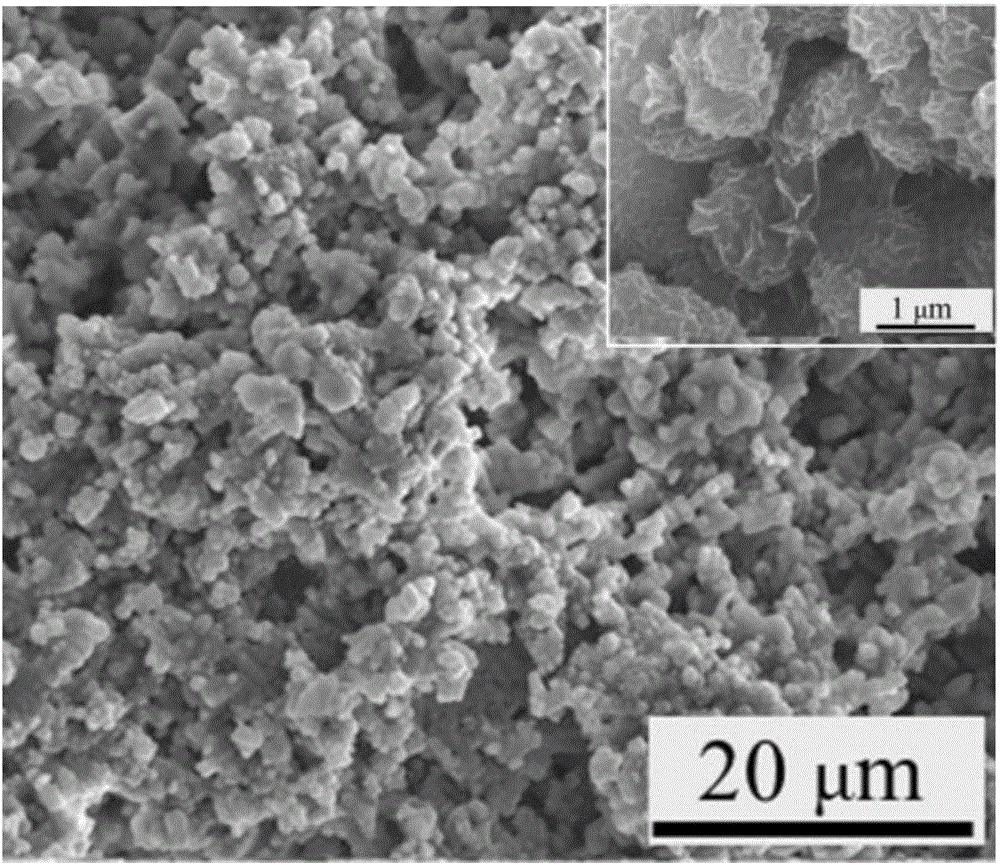

The invention discloses a preparation method for a fluoride-free, non-toxic, economic and efficient aluminium-based superhydrophobic material. The preparation method comprises the following steps: stably obtaining a micrometer-nanometer binary composite graded structure from aluminium and aluminium alloy through simple hydrochloric acid etching and water boiling sequentially; spin-coating a layer of fluoride-free, non-toxic and cheap polydimethylsiloxane solution on the micrometer-nanometer graded aluminium-based surface by virtue of a spin-coating method, curing and then forming an organic film layer, and thus achieving a superhydrophobic surface having a contact angle of 158 degrees with water and having a rolling angle of 2 degrees. The superhydrophobic surface is superhydrophobic with strong acid and strong base, and has high lasting stability due to the protection effect of the organic film layer. The superhydrophobic surface disclosed by the invention has the characteristics of being fluoride-free, non-toxic, simple and convenient to operate, economic and efficient.

Owner:SOUTH CHINA UNIV OF TECH

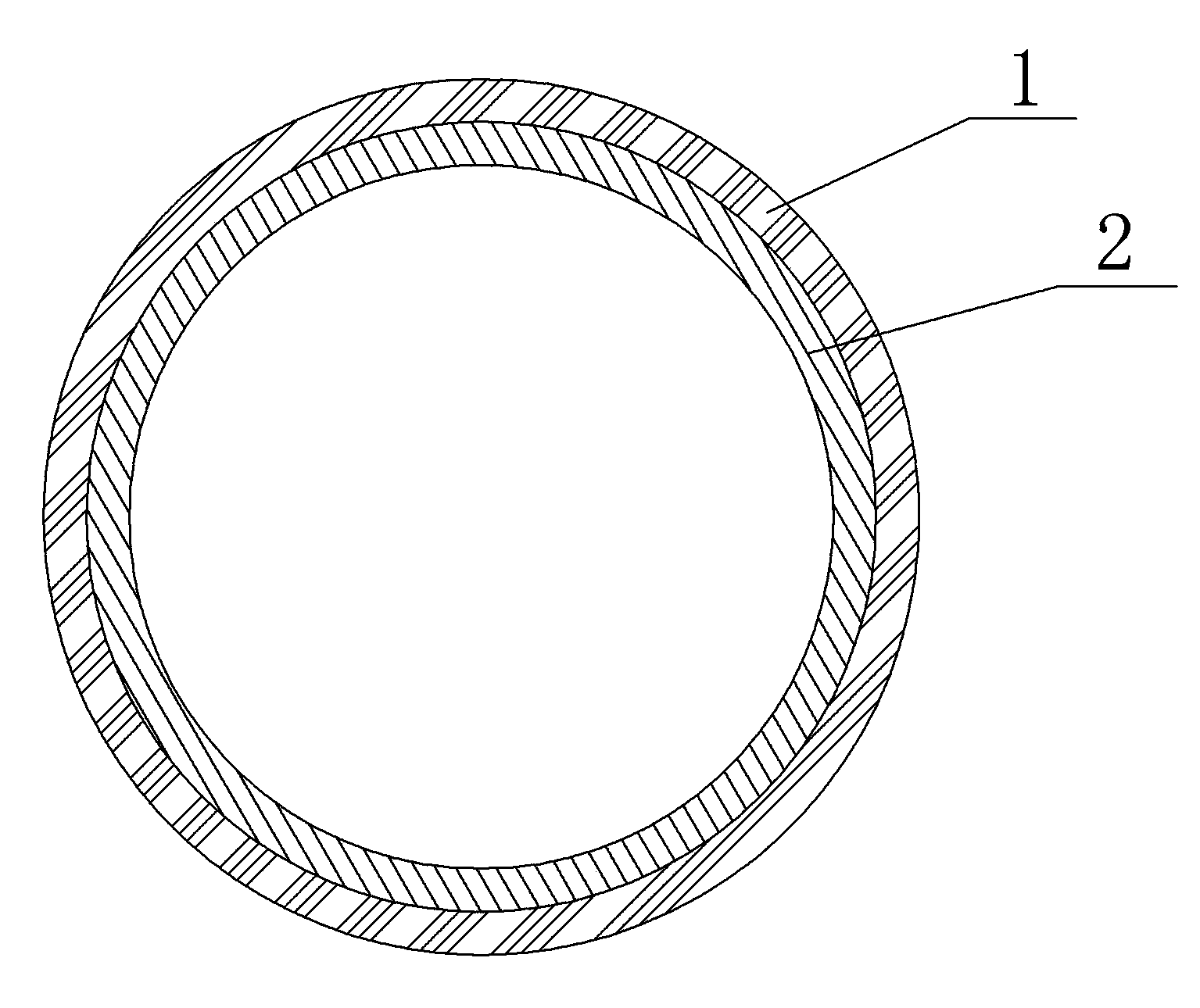

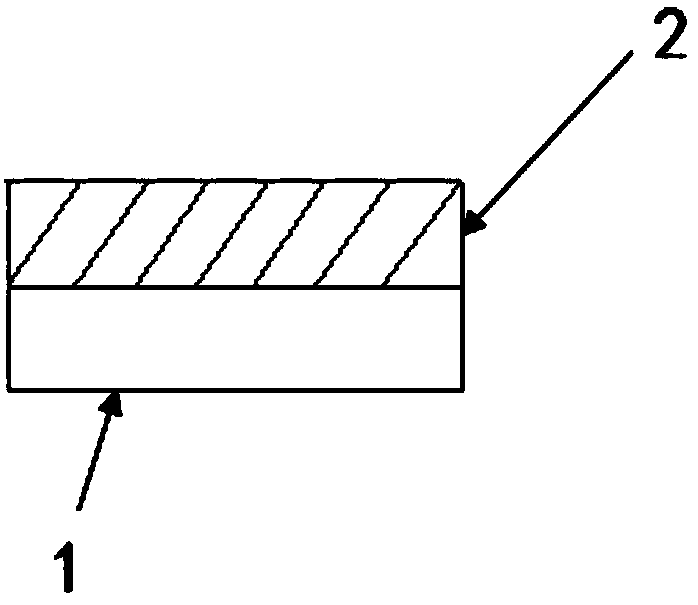

Double-layer composite tube and manufacturing method thereof

ActiveCN104019298AImprove stress resistanceFlow fastFlexible pipesLow-density polyethyleneWater quality

The invention discloses a double-layer composite tube and a manufacturing method thereof. The double-layer composite tube and the manufacturing method aim to solve the technical problems that black pigment is added into traditional HDPE tubes, accordingly inner walls are not smooth, water scale is prone to being generated, bacteria grow, and secondary pollution of water is caused. The double-layer composite tube comprises an inner layer and an outer layer, the inner layer is made of ultrahigh molecular weight polyethylene and ethylene-vinyl alcohol copolymers or low-density polyethylene, and the outer layer is made of high-density polyethylene, ethylene-vinyl alcohol copolymers and special melanin particles C of PE. The method includes the following steps of material proportioning and dehumidifying, material plastifying, material forming, vacuum sizing and spraying and cooling. The double-layer composite tube has the advantages of being good in toughness and flexibility, high in chemical stability, good in corrosion resistance, good in sealing performance, large in distribution power, long in service life, high in low temperature resistance, hygienic, free of toxin and the like. The manufacturing method is simple, easy to operate and capable of achieving integral production of the double-layer composite tube.

Owner:菏泽三垒塑业股份有限公司

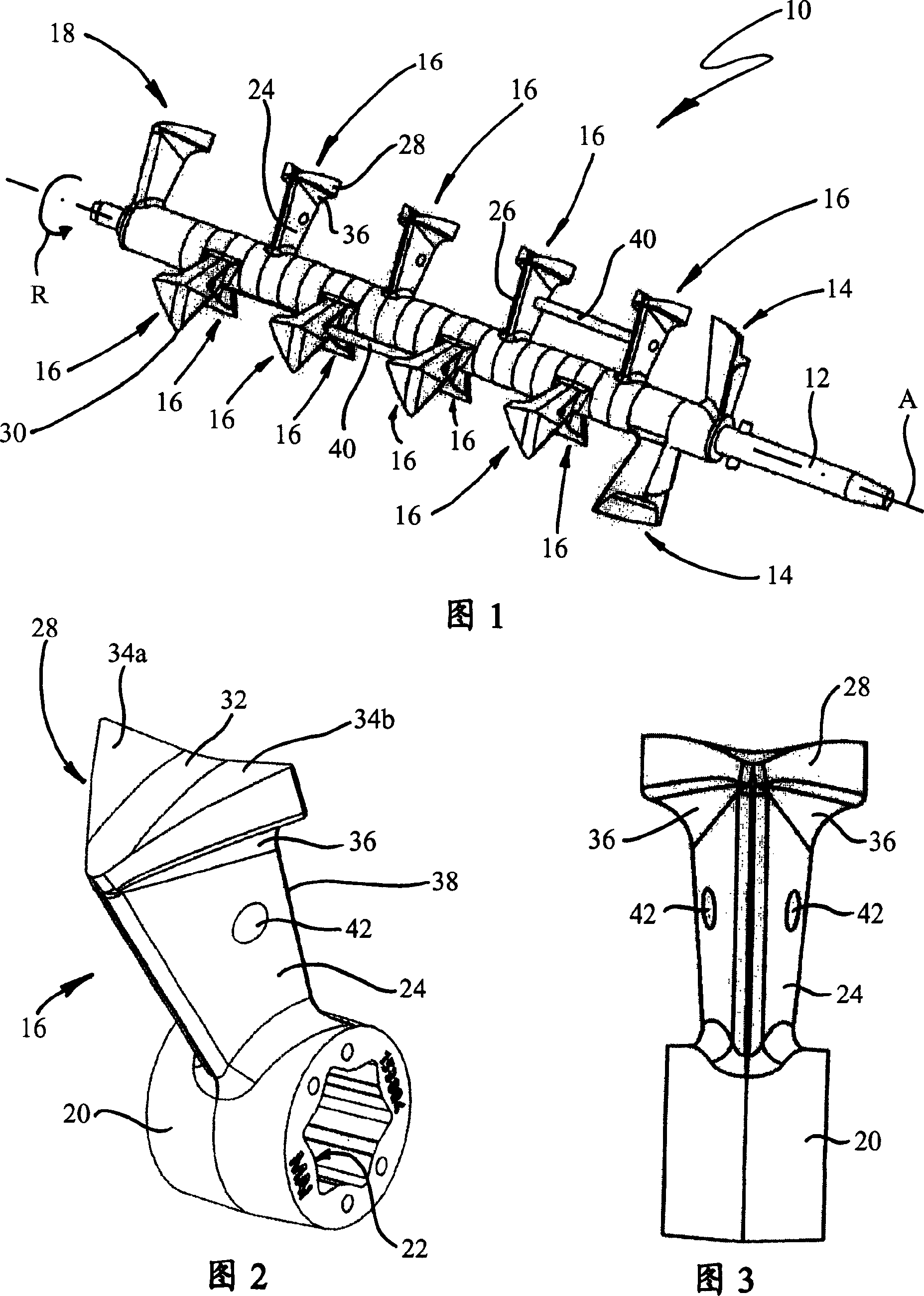

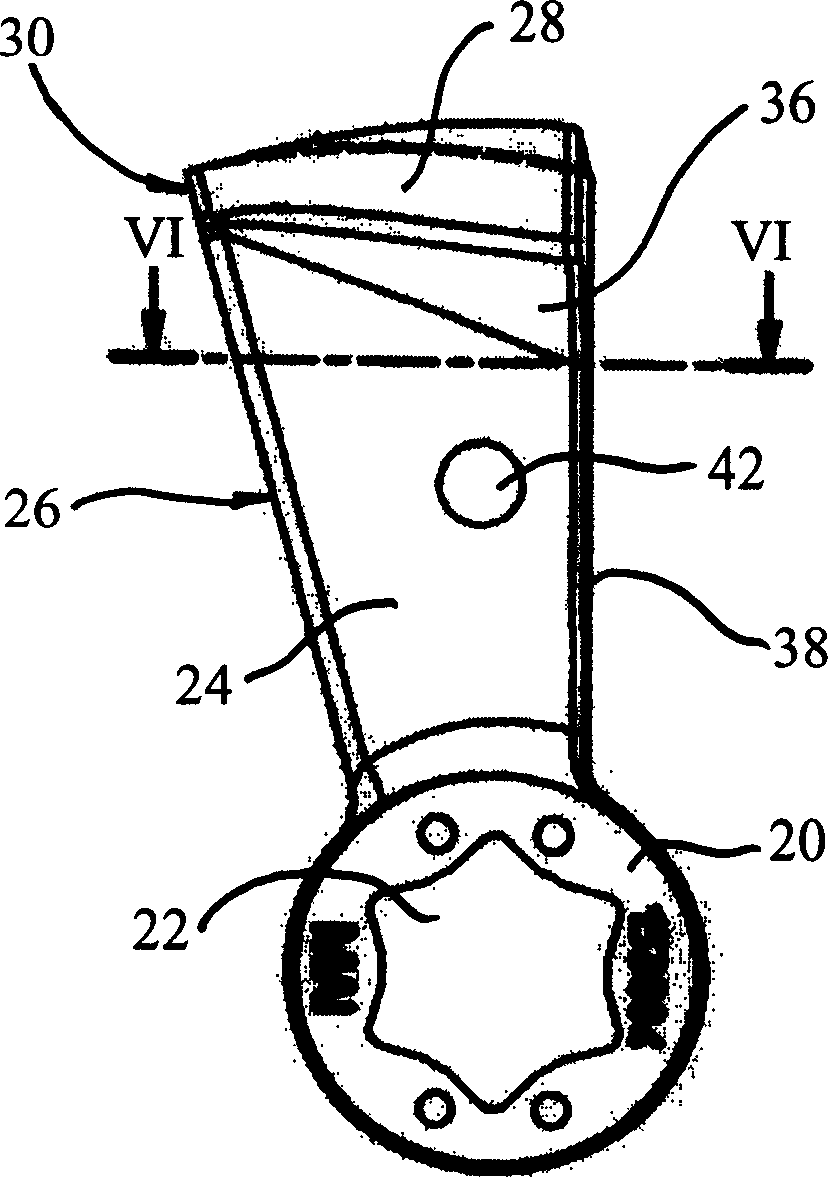

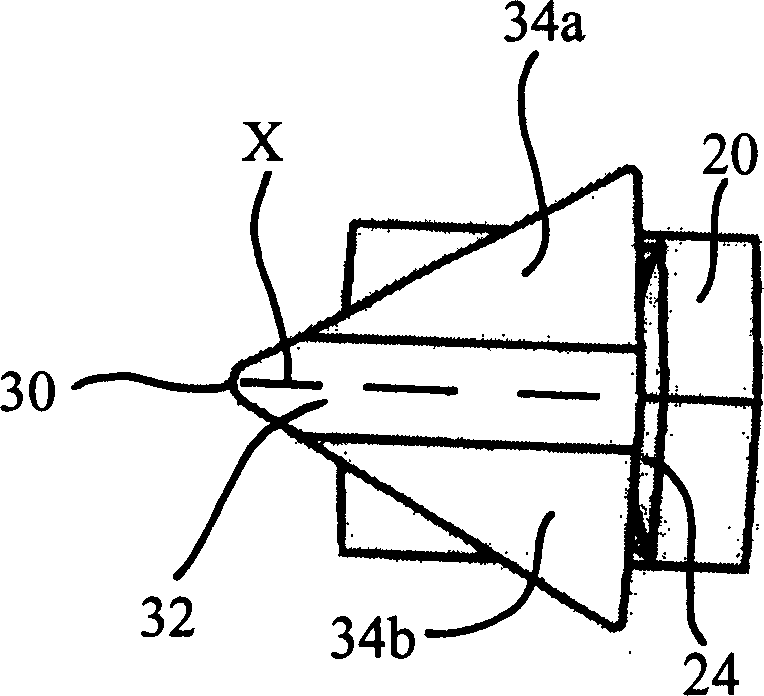

Stirring apparatus

InactiveCN1721156AMixed Strongly EffectiveWell mixedRotary stirring mixersTransportation and packagingRotational axisEngineering

A mixing mechanism (10) making suspension with liquid and solid burden includes a mixing space, a shaft (12) and a limitative axis (A). The shaft is revolved and arranged in the mixing space. The shaft is provided with vanes (16) which revolve along the rotation direction (R) of the shaft (12). At least two mixing vanes (16) include a matrix (24) with a wedgy section, which extends outwards from the axial direction of the shaft (12). The mixing vane includes a mixing vane head (28) with the wedgy section, which is connected with the free end of the matrix (24). The wedgy tips (26, 30) of the matrix (24) and the mixing vane head (28) point to the rotation direction (R) of the shaft (12). The mixing vane head (28) is wider than the matrix (24) on the axial direction. The matrix (24) has a transition region (36) on at least one side between the narrow matrix (24) and the wide mixing vane head (28). The transition region (36) is inclined relative to the shaft (12). When the rotating shaft (12) revolves along the rotation direction (R), the mixture to be mixed in the mixing space is transported inwards to the shaft (12).

Owner:MAY INT

Thermosensitive recording medium and recording method

ActiveUS20090215622A1Excellent effect in maintaining pure whiteSuitable for useAblative recordingThermographyConductive polymerLeuco dye

The present invention provides a thermosensitive recording medium including a white plastic support, a thermosensitive recording layer containing a binder resin as a binding agent, a colorless or pale color leuco dye and a color developer for heat-developing the leuco dye, a protective layer, and a back layer containing an electron-conductive needle filler and an ion-conductive polymer, wherein the thermosensitive recording layer is disposed on the white plastic support, the protective layer is disposed on the thermosensitive recording layer, and the back layer is disposed on a side of the white plastic support opposite to the side where the thermosensitive recording layer is disposed.

Owner:RICOH KK

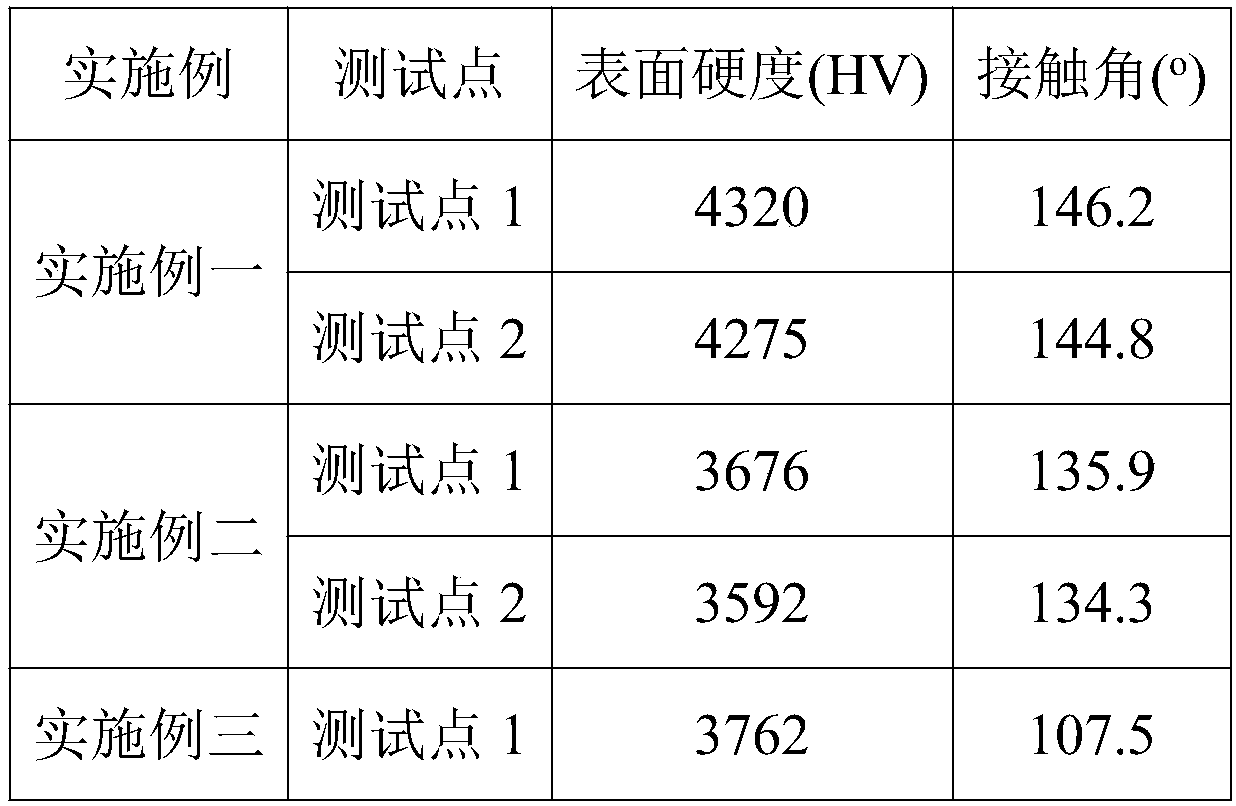

Metal ceramic die-casting die with tensile prestress and preparation method of metal ceramic die-casting die

InactiveCN108103500AImprove anti-adhesion performanceQuality improvementMetallic material coating processesSelf-propagating high-temperature synthesisManufacturing technology

The invention discloses a metal ceramic die-casting die with tensile prestress and a preparation method of the metal ceramic die-casting die and belongs to the technical field of coating preparation.The metal ceramic die-casting die comprises a die base and a metal ceramic layer which is arranged on the surface of the die base and has tensile prestress. By means of thermal adaptation between thedie base and the prepared metal ceramic layer, the metal ceramic layer has the tensile prestress after being prepared, and the metal ceramic layer and the die base are metallurgically or mechanicallybonded. Preparation of the metal ceramic layer with the tensile prestress comprises the following steps: a, removing an oxidation film from the die base, and performing oil-removal cleaning; b, preparing the metal ceramic coating with the tensile prestress by selecting one of a spray method, a vapor deposition method, a composite coating method, a self-propagating high-temperature synthesis methodand a high-temperature fusion method. With adoption of the coating prepared with the preparation technology, the technical problem that thermal fatigue resistance, wear resistance and heat distortionresistance of the die are not ideal is solved effectively, the service life of the die is prolonged, quality of workpieces is improved, and yield of the workpieces is increased.

Owner:XI AN JIAOTONG UNIV

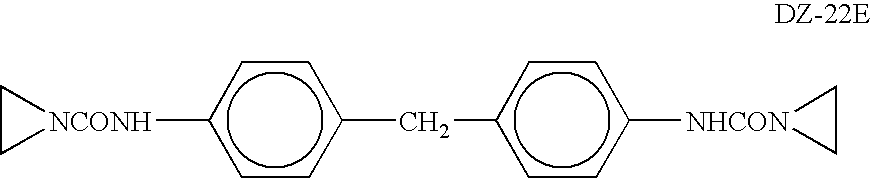

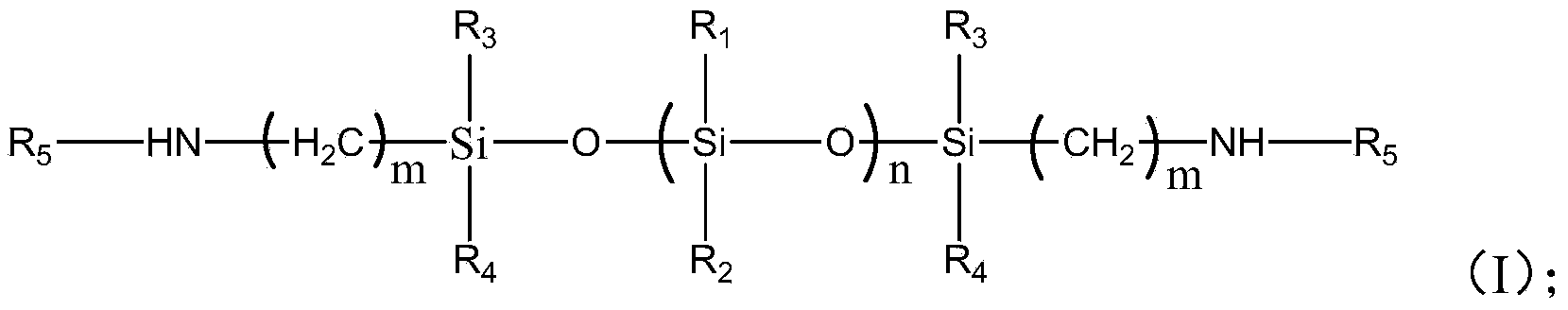

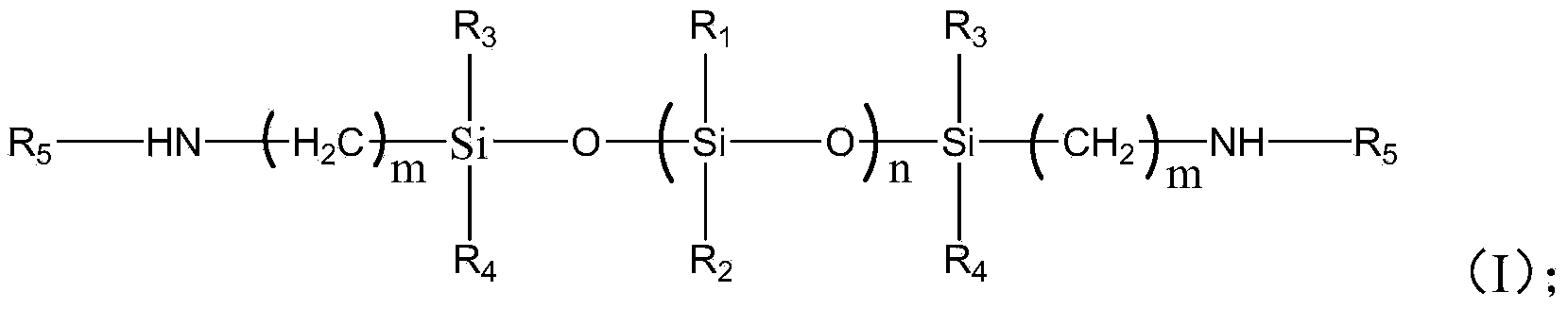

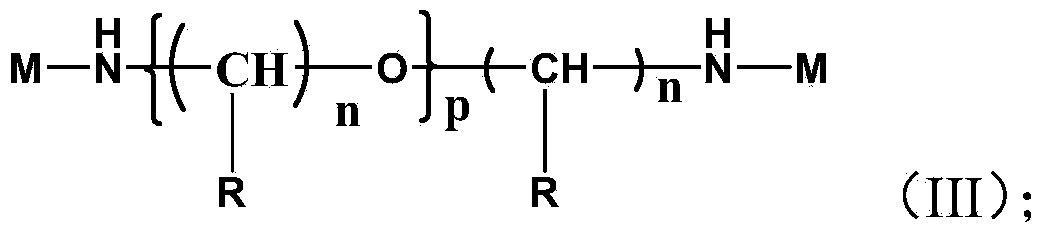

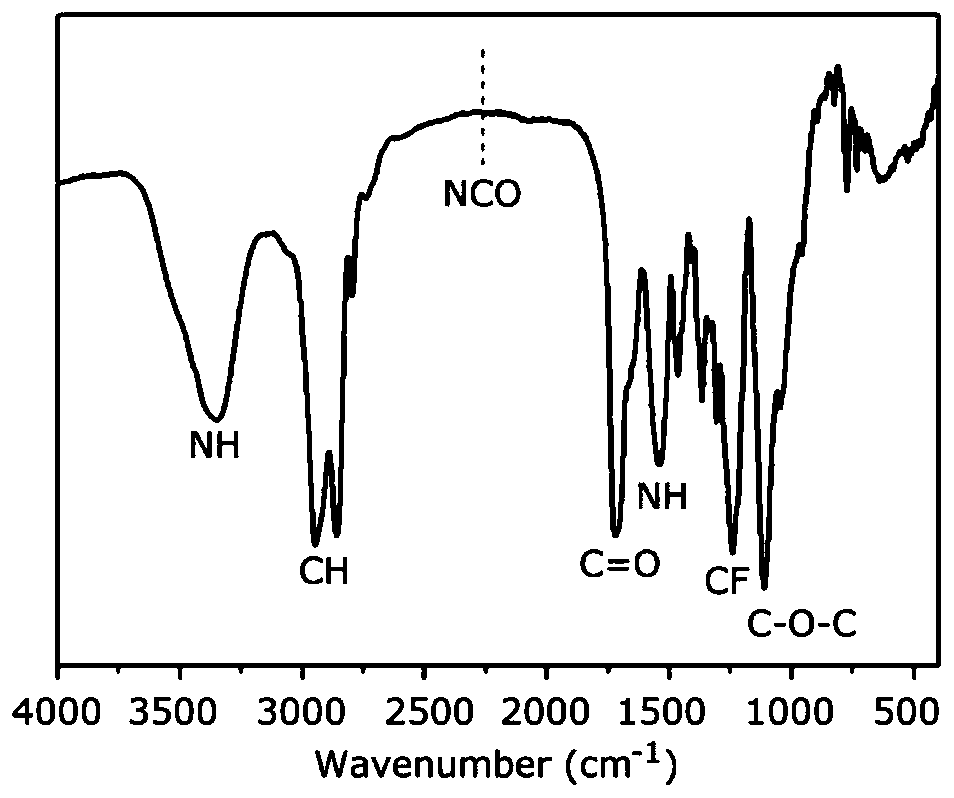

Polyureas copolymer with main chain containing siloxane composition unit and preparation method thereof

ActiveCN103834034AAvoid stickingExtended service lifePolyurea/polyurethane coatingsPolyesterEnd-group

The invention discloses a polyureas copolymer with a main chain containing siloxane composition units; the polyureas copolymer comprises the following constitution units: polysiloxanes constitutional units of aminoalkyl termination; polyether constitutional units of high-molecular amino termination; polyether alcohol or polyester alcohol constitutional units; single molecule chain extension double amine or low molecular amino termination polyether constitutional units; isocyanate constitutional units. Through the design of polysiloxanes molecular composition of aminoalkyl termination and adjustment of molecule mass; on one hand, a reaction amino group and an alkyloxy crosslinking group are introduced on a terminal group; on the other hand, a chain alkyl group or a perfluoro alkyl group are designed on a side chain; simultaneously three function hydroxy or amino groups are embedded in the composition, thereby obtaining excellent anti adhesiveness, abrasion resistance, corrosion resisting, impact resistance and anti contamination functions, effectively preventing contamination objects from pasting on special equipment, improving anti pollution function, solving adherence of adherence fluid, anti pollution and wearing corrosion problems, satisfying demands of different application fields, and prolonging service life of the special equipment.

Owner:HUBEI UNIV +1

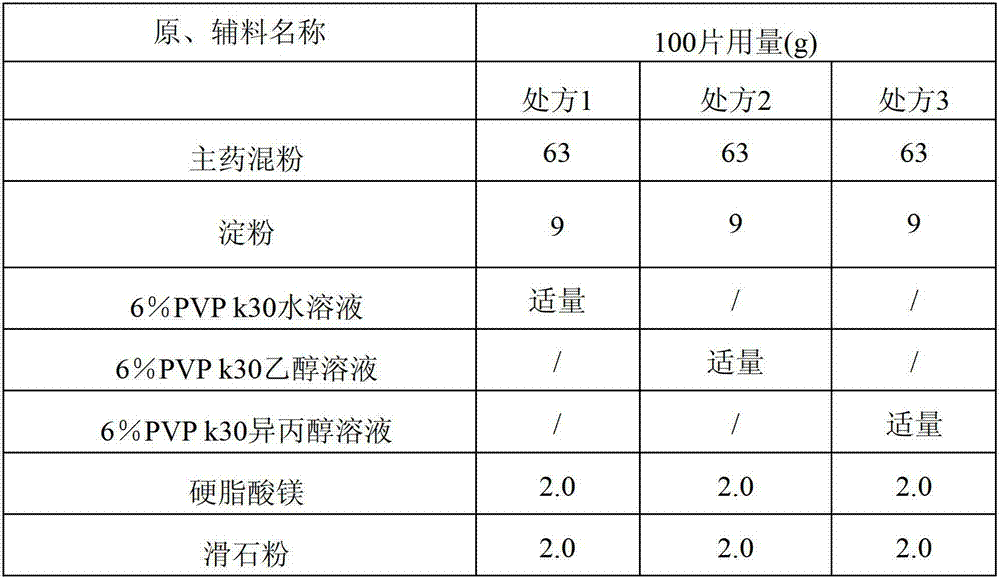

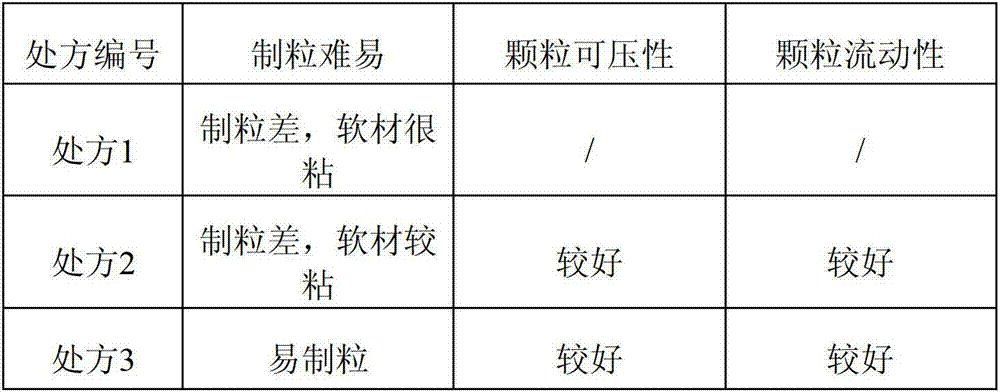

Compound alpha-keto acid tablets and preparation method and detection method thereof

ActiveCN102961378AEffective treatment effectAvoid product qualityPeptide/protein ingredientsComponent separationThreonineTyrosine

The invention discloses compound alpha-keto acid tablets and a preparation method and a detection method thereof. The preparation method comprises the following steps of: taking calcium 3-methyl-2-oxovalerate, ketoleucine calcium, alpha-ketophenylalanine calcium, keto-valine-calcium, D,L-alpha-hydroxymethionine calcium, lysine acetate, threonine, tryptophan, histidine and tyrosine, crushing the main medicaments respectively and sieving with a sieve of 100 meshes; sieving starch, talc powder and magnesium stearate and sieving with a sieve of 80 meshes respectively; mixing the main medicaments and the starch uniformly, preparing a soft material from 6 percent polyvinyl pyrrolidone (PVP) k30 isopropanol solution, granulating with a sieve of 20 meshes, and drying at the temperature of 40 DEG C; reshaping, adding magnesium stearate, the talc powder and crosslink povidone, and mixing uniformly; detecting an intermediate, and tabletting; and coating, and thus obtaining the compound alpha-keto acid tablets. The tablets with excellent granule pressing property, flowability, hardness and dissolution degree can be prepared by using the method, and the detection method can further ensure the quality of the prepared compound alpha-keto acid tablets.

Owner:GUIZHOU XINBANG PHARMACEUTICAL CO LTD

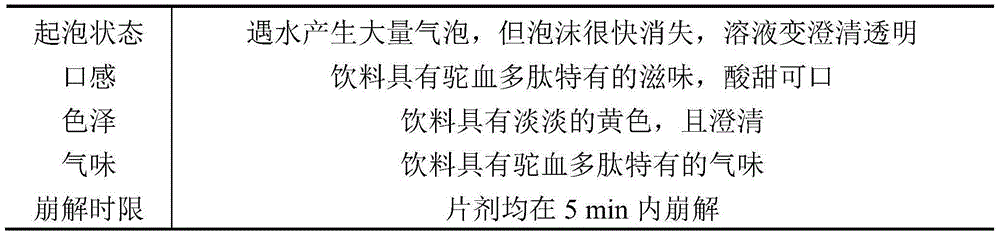

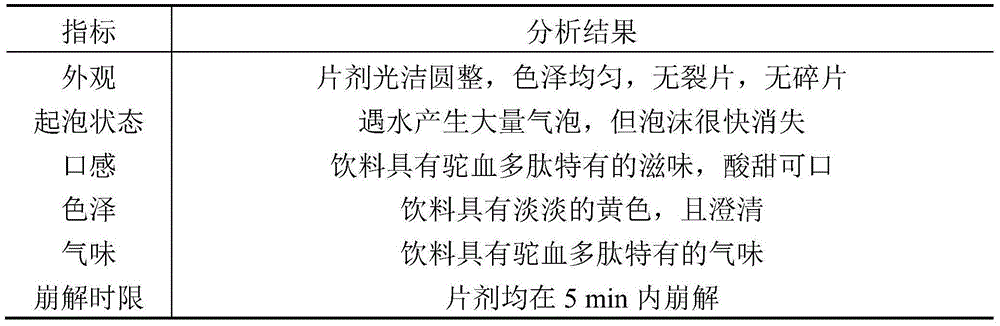

Camel blood polypeptide effervescent tablets and preparation method thereof

ActiveCN105146670ADisintegrates quicklyImprove solubilityFood ingredient as viscosity modification agentFood ingredient as foaming agentSodium bicarbonateEffervescent tablet

The invention discloses camel blood polypeptide effervescent tablets and a preparation method thereof. Camel blood polypeptides serve as a raw material, citric acid or / and malic acid, sodium bicarbonate, polyvinylpyrrolidone, lactose or / and mannitol, stevioside or aspartame and polyethylene glycol 8000 serve as auxiliary materials, and after mixing, blending, sterilizing and tabletting are performed, the camel blood polypeptide effervescent tablets are obtained. The camel blood polypeptide effervescent tablets have the immunity enhancing function, the anti-oxidation function, the anti-fatigue function and other functions and have the advantages of being sour and sweet in taste, capable of being easily absorbed by the human body, convenient to preserve and carry, high in bioavailability and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Composite treatment method for thermal spraying and electroplating of metal surface

InactiveCN101514454AImprove wear resistanceStrong impact resistanceMolten spray coatingSuperimposed coating processThermal sprayingSurface layer

The invention relates to metal working, in particular to a method for treating metal surface, which can be applied to (but not limited to) surface protection coatings of technological rolls for continuous production machine sets of steel enterprises. The invention provides a composite treatment method for thermal spraying and electroplating of metal surface, wherein the metal surface comprises a thermally-sprayed coating and a layer of electroplated plating. The treatment method comprises a step of thermally spraying the surface with a thermal spraying coating and a step of electroplating the surface of the thermal spraying coating with a layer of hard-chrome or nickel-base plating, wherein the thermal spraying coating comprises a base layer and a thermal spraying work surface layer. The method has the advantage of ensuring that the surface thermal spraying coating has excellent comprehensive performances such as excellent wear resistance, impact resistance, roughness maintaining capability and outstanding surface adhesion resistance so as to meet application requirements of surface-coated products on long-time steady actual production.

Owner:SHANGHAI BAOSTEEL EQUIP MAINTENANCE CO LTD

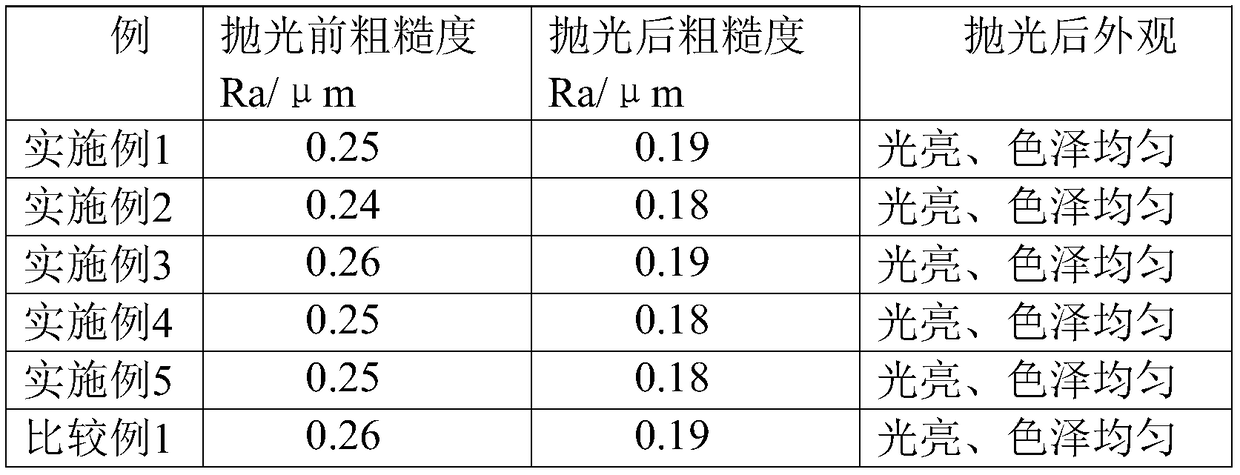

Cathode roller chemical polishing solution and polishing method

The invention belongs to the technical field of electrolytic copper foil production technologies and provides a titanium cathode roller chemical polishing solution and a polishing method. The polishing solution is composed of two kinds of organic acid and a surface active agent. The organic acid refers to oxalic acid with the reducibility concentration being 50-300g / L and citric acid capable of forming a stable complex with metal ions like cupric ions, nickel ions and titanium ions and with the concentration being 10-50g / L. The surface active agent refers to polyvinylpyrrolidone with the concentration being 0.01-0.5g / L. The cathode roller polishing method includes the steps that after a titanium cathode roller is put into the polishing solution after being cleaned and degreased, the rotaryroller is soaked for 10-20 minutes at the temperature of 20-60 DEG C, operation is easy, a mirror surface is formed on the surface of the cathode roller after polishing and manufactured electrolyticcopper foil has the advantages that crystals are fine and compact and stripping is made easy. The titanium cathode roller can meet the requirements of lithium battery copper foil after being repairedby the chemical polishing solution, and the requirements of the copper foil for a printed wiring board can also be met.

Owner:CHANGZHOU UNIV +1

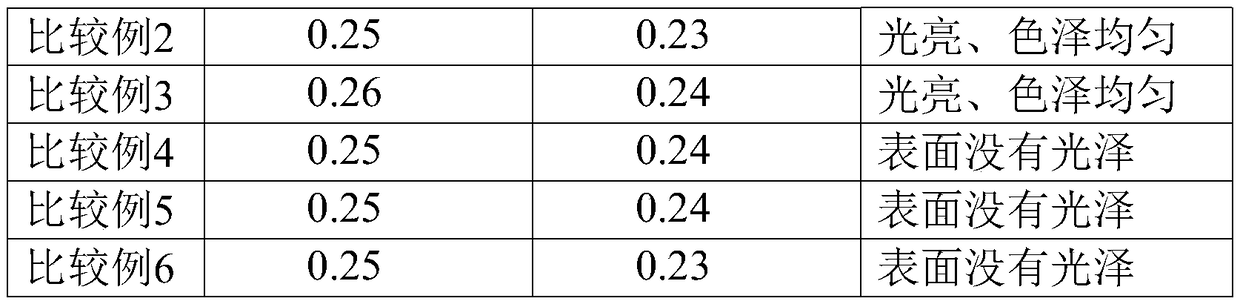

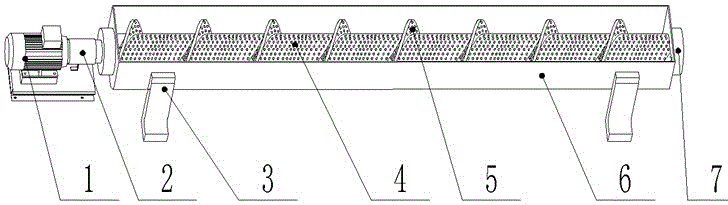

Bionic pulverized coal spiral conveying structure

PendingCN106800170AImprove anti-adhesion performanceImprove wear resistancePackagingThermodynamicsSpiral blade

Disclosed is a bionic pulverized coal spiral conveying structure. A spiral shaft and a spiral blade are provided with a plurality of round protrusions the same in size. The multiple round protrusions the same in size are arranged along the rotation curves of the spiral shaft and the spiral blade at equal intervals. The interval between the adjacent round protrusions is 40 mm. The screw pitch of the spiral blade is 200 mm. The bionic pulverized coal spiral conveying structure effectively reduces the adhesion between materials and the spiral shaft as well as between the materials and the spiral blade of the spiral shaft, and the conveying efficiency of the materials is improved.

Owner:TAIYUAN UNIV OF TECH

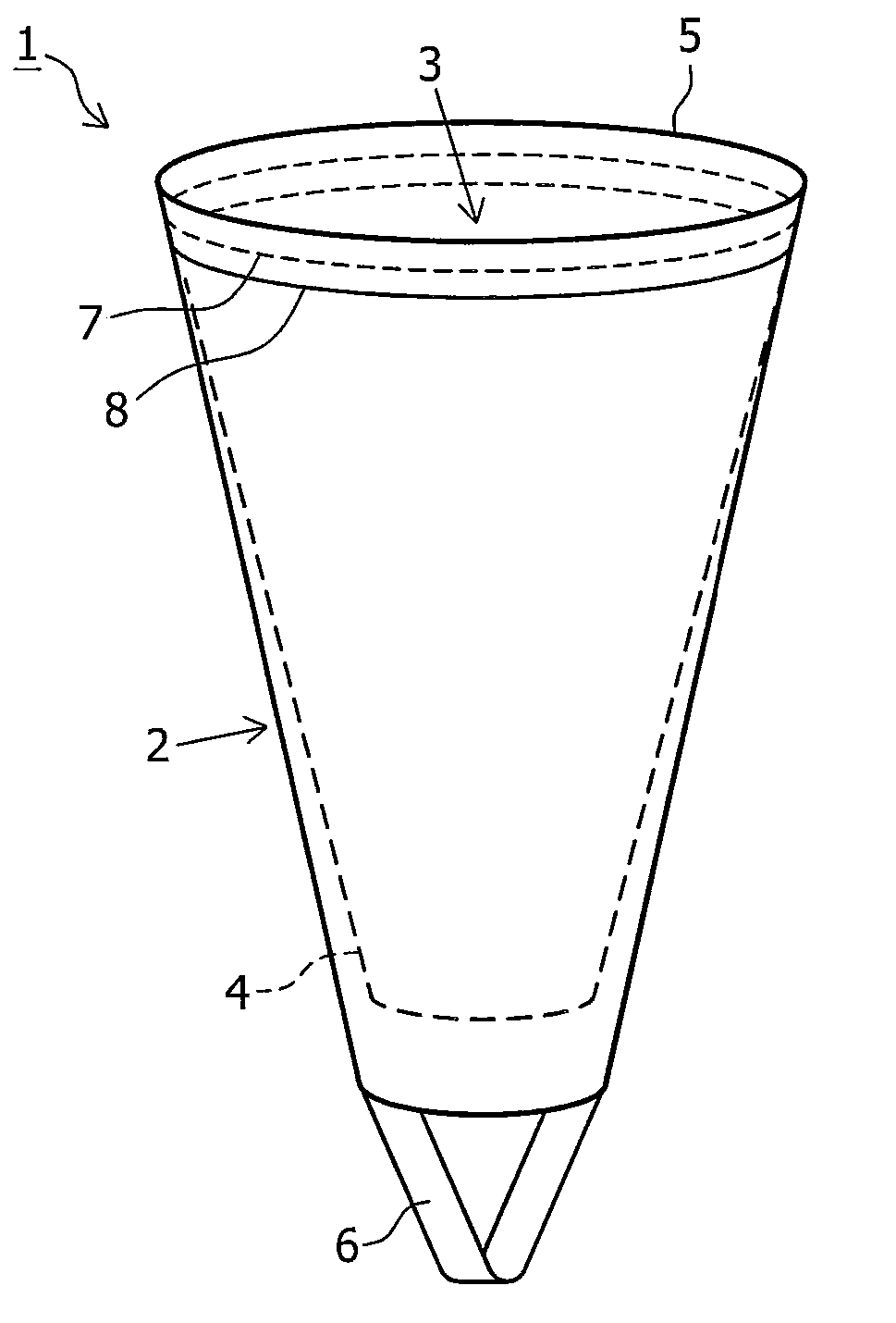

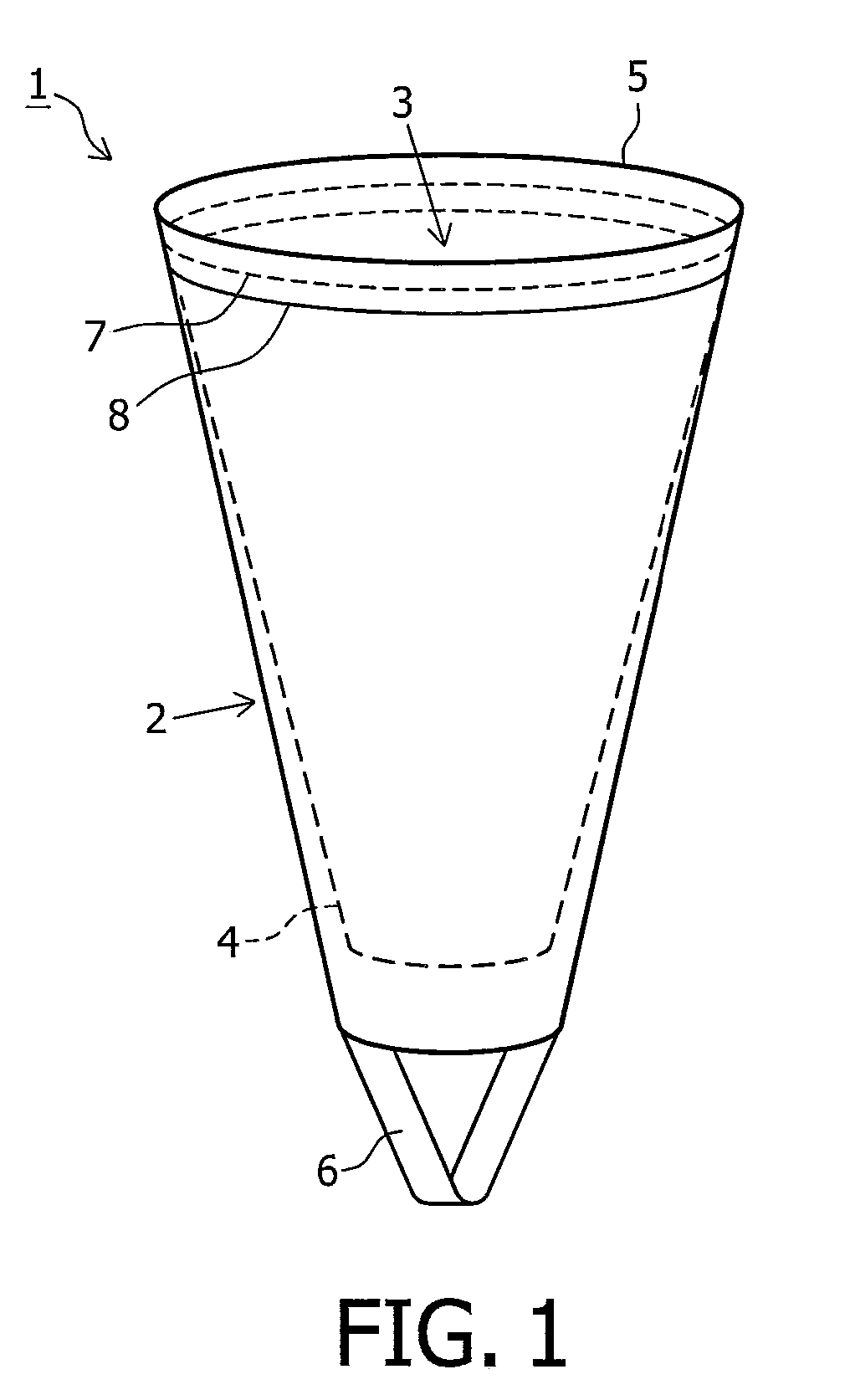

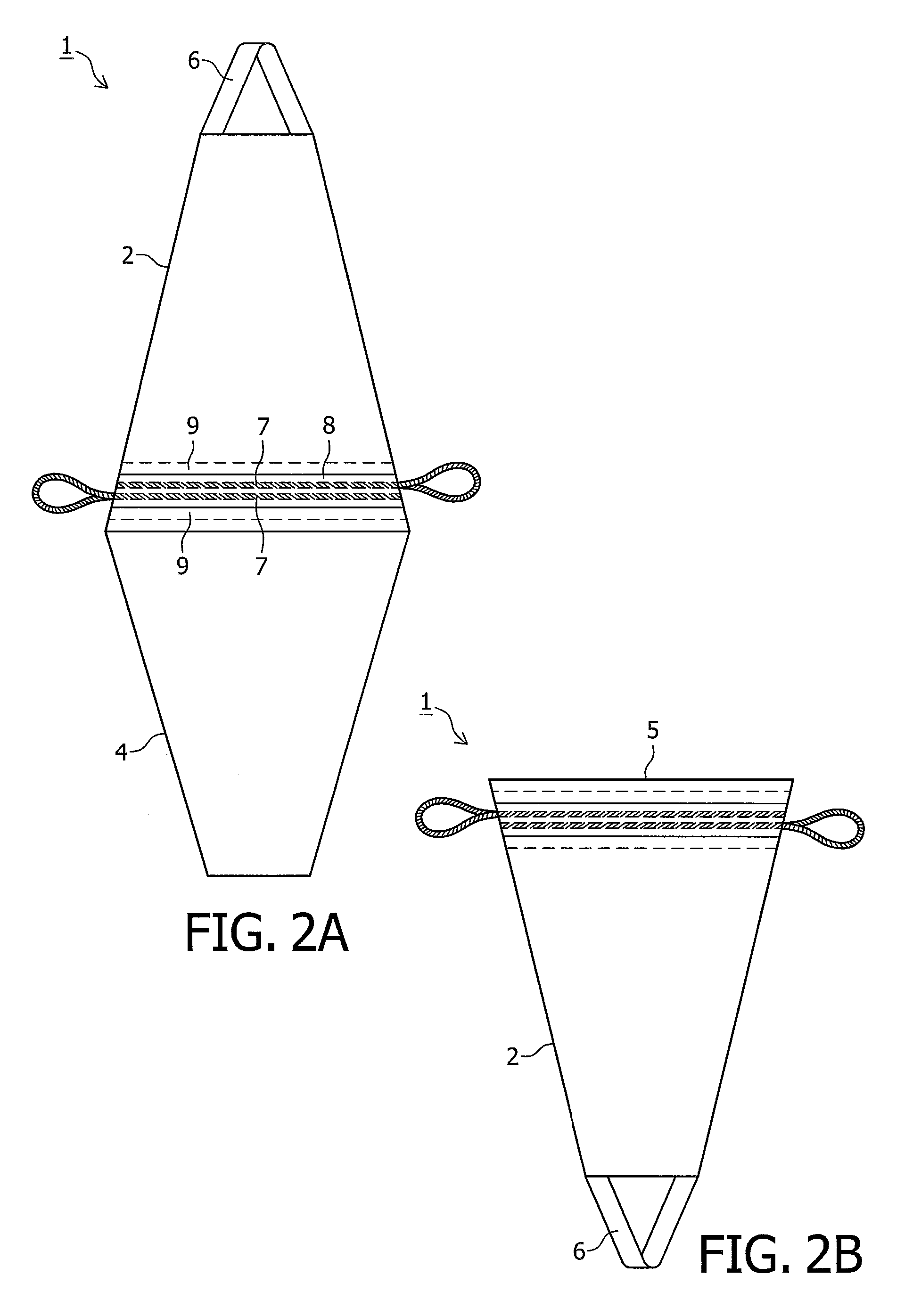

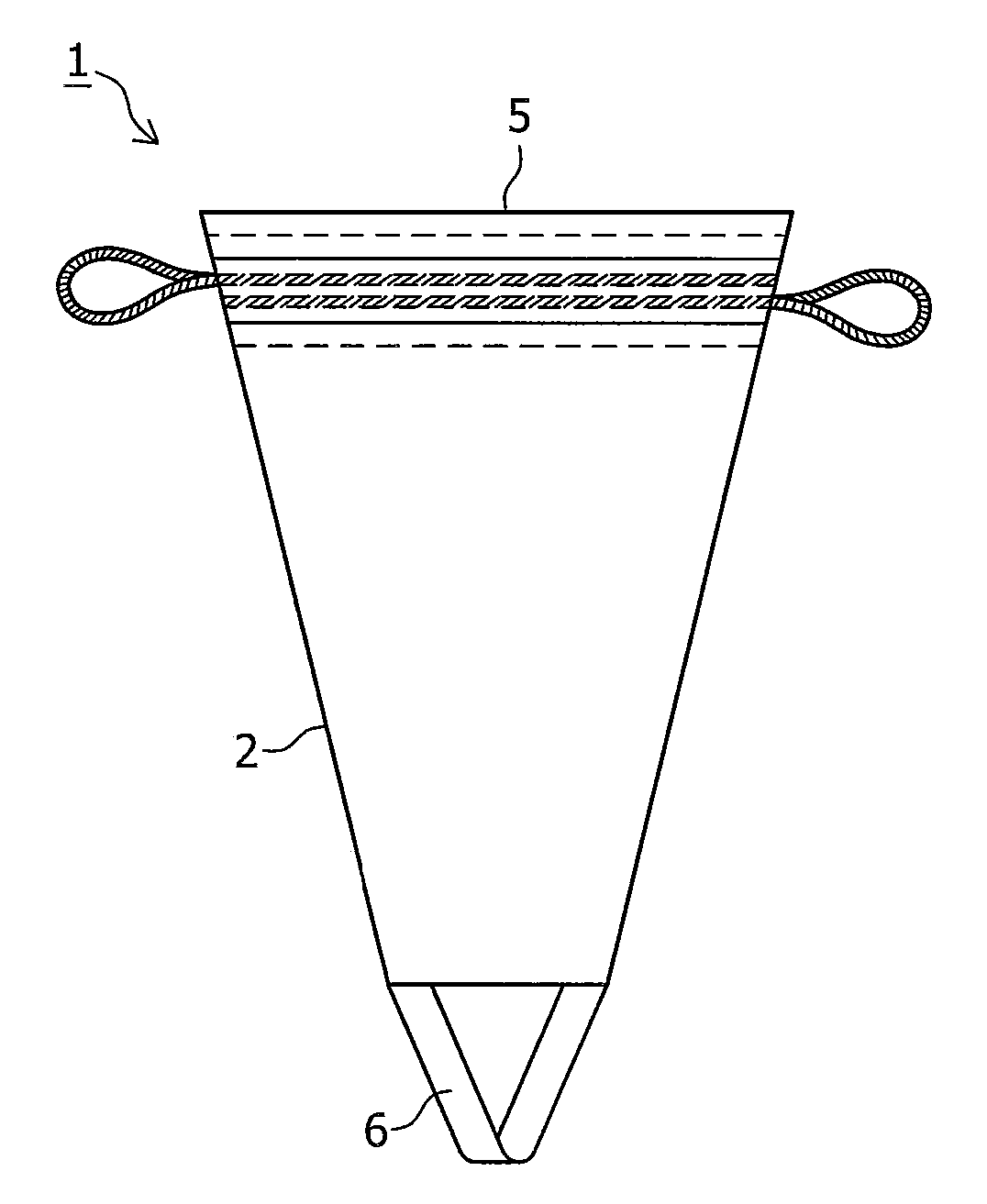

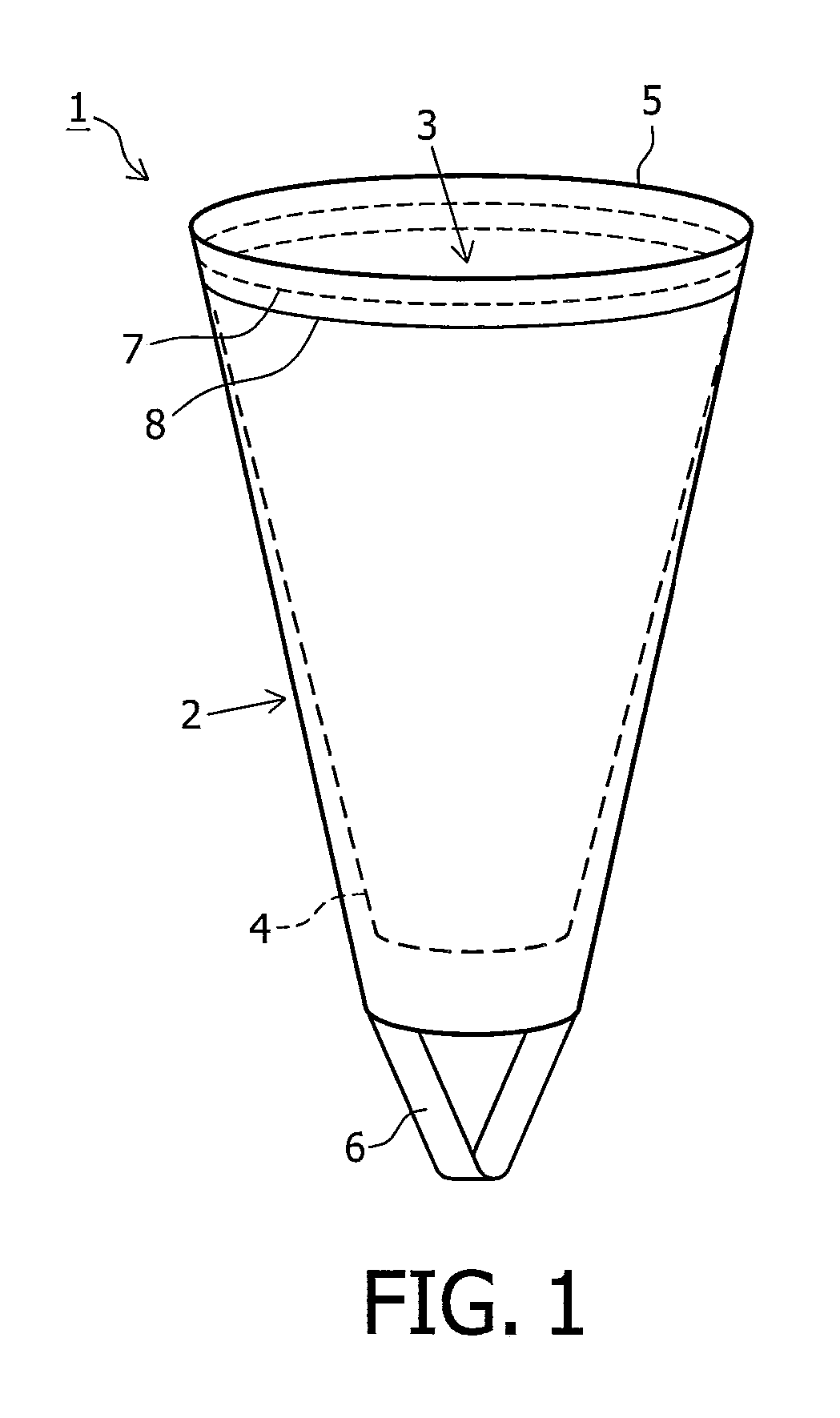

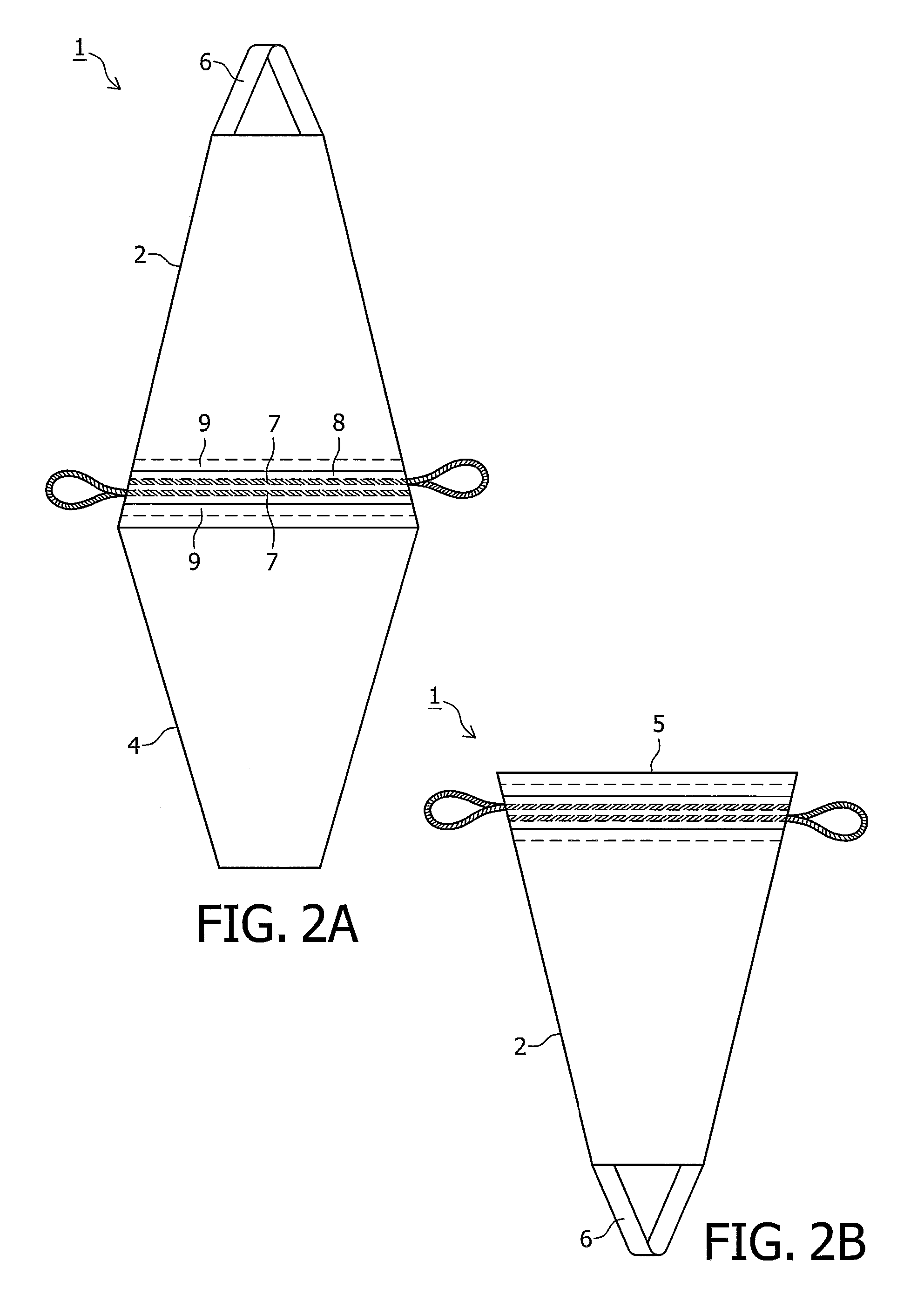

Aid for Pulling Elastic Stockings On and Off

ActiveUS20100270341A1Improve anti-adhesion performanceReduce frictional resistanceApparel holdersElastic hosieryElastic stockings

The invention relates to an aid for pulling elastic stockings on and off. The aid comprises a flexible, tube-like peripheral body of a smooth material with an insertion end for a foot. The peripheral body is provided with a lining of a smooth material which is attached to the peripheral body at the position of the insertion end and can otherwise be moved freely relative to the peripheral body from an inward folded position, in which the lining is situated in the peripheral body, to an outward folded position in which the lining is situated outside the peripheral body. The peripheral body further comprises tensioning means with which the aid can be secured at least temporarily round a leg. This makes the aid suitable for both pulling on and pulling off elastic stockings.

Owner:ARION HLDG

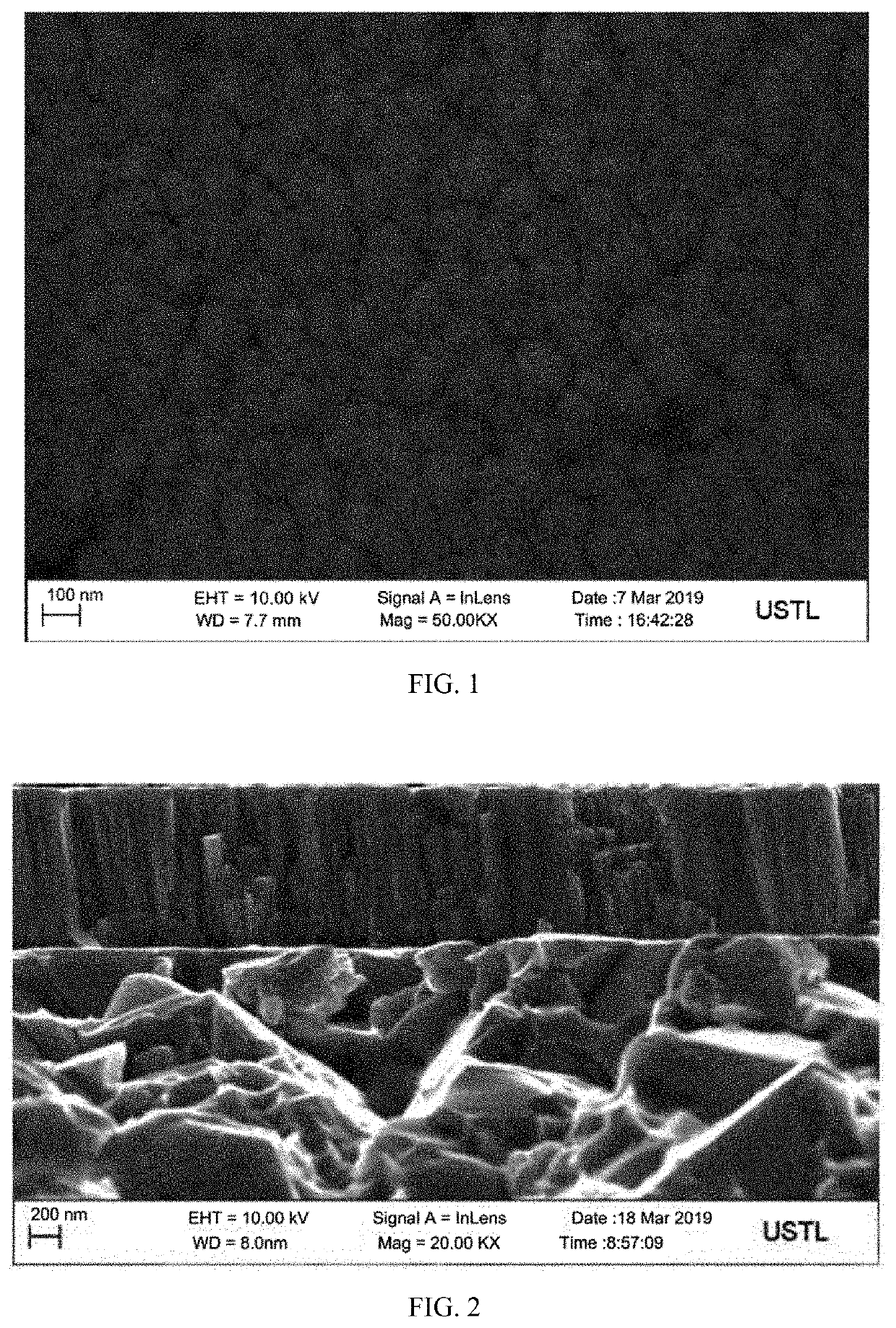

Hard coating having excellent adhesion resistance to soft metal

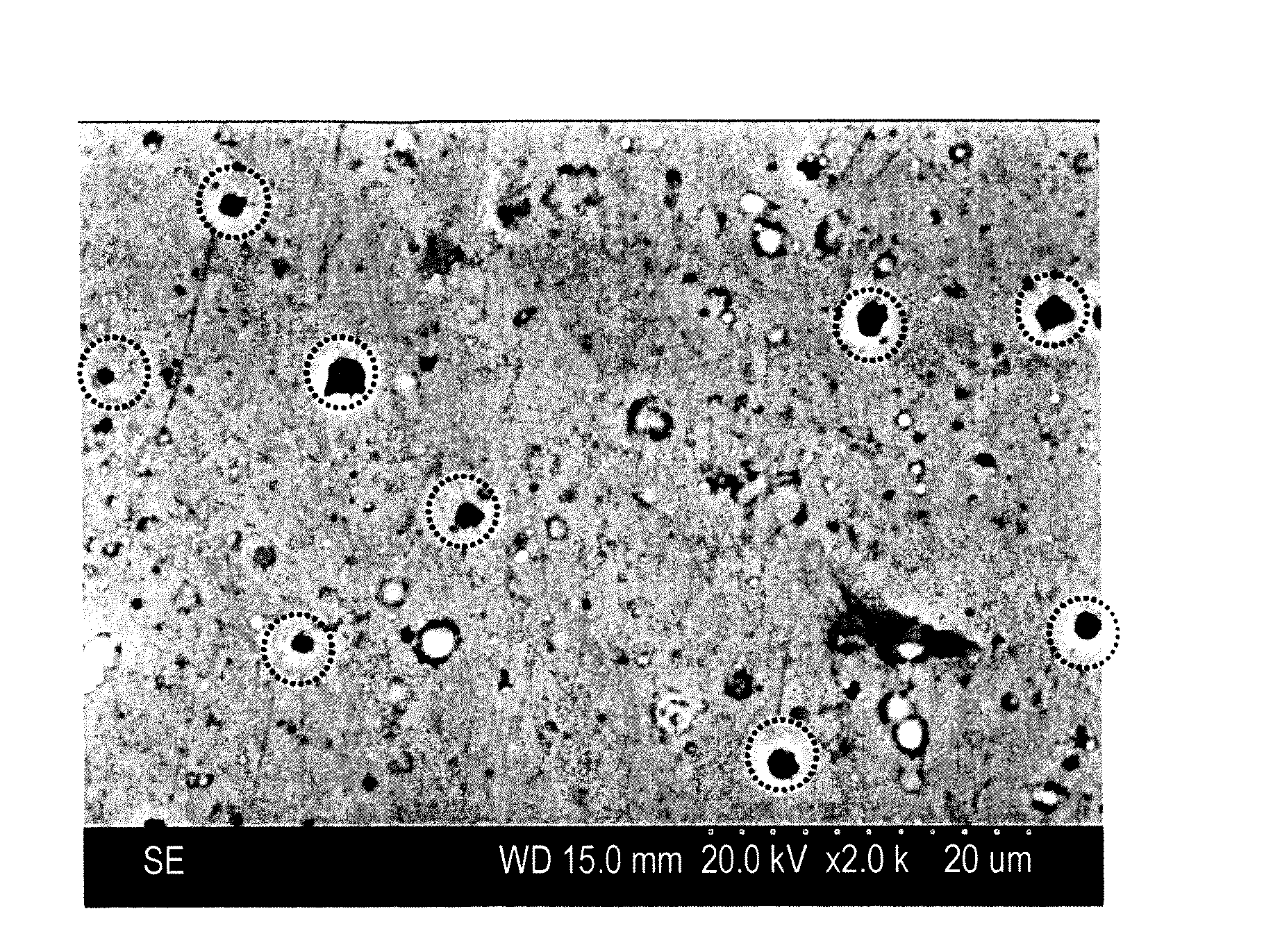

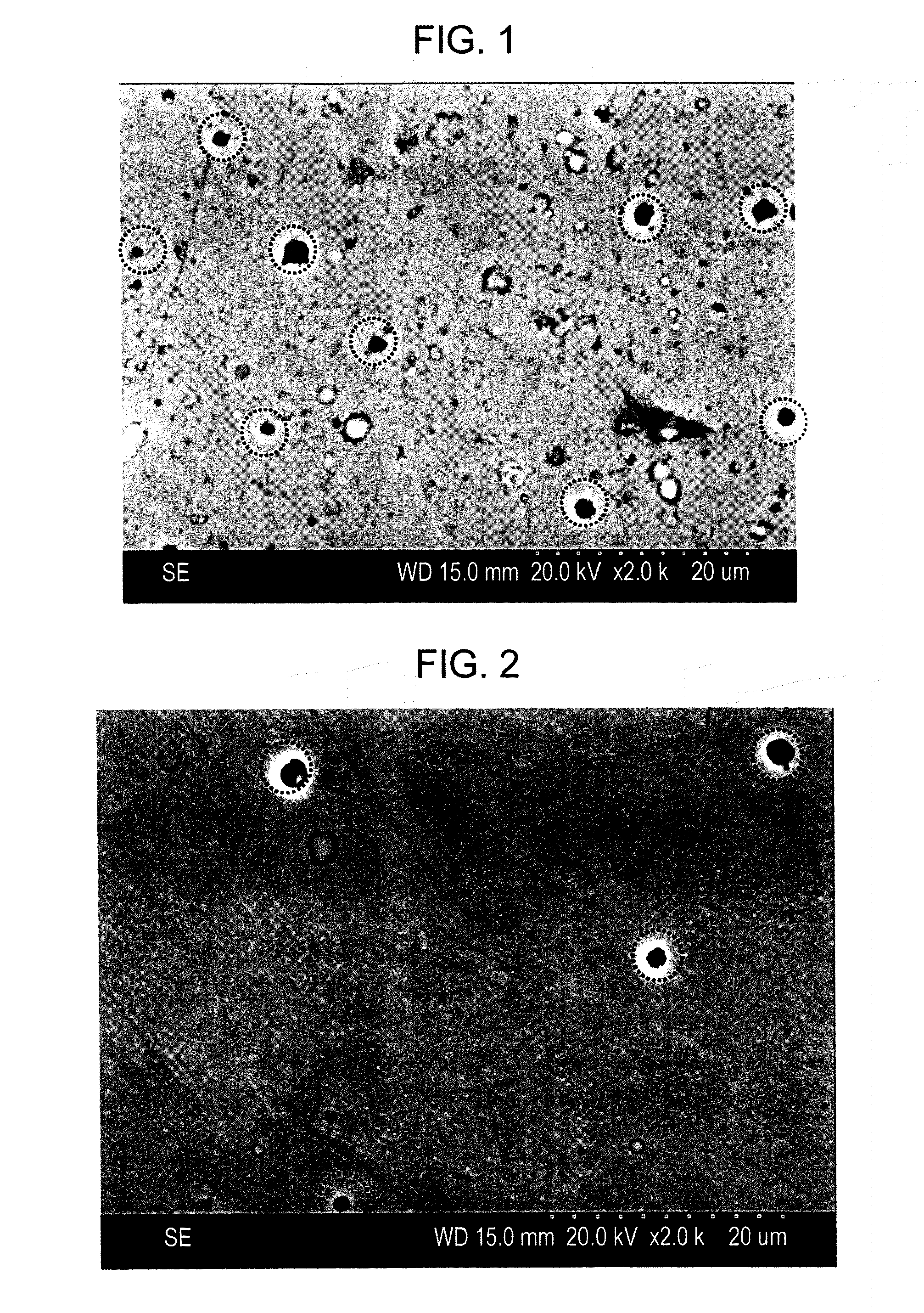

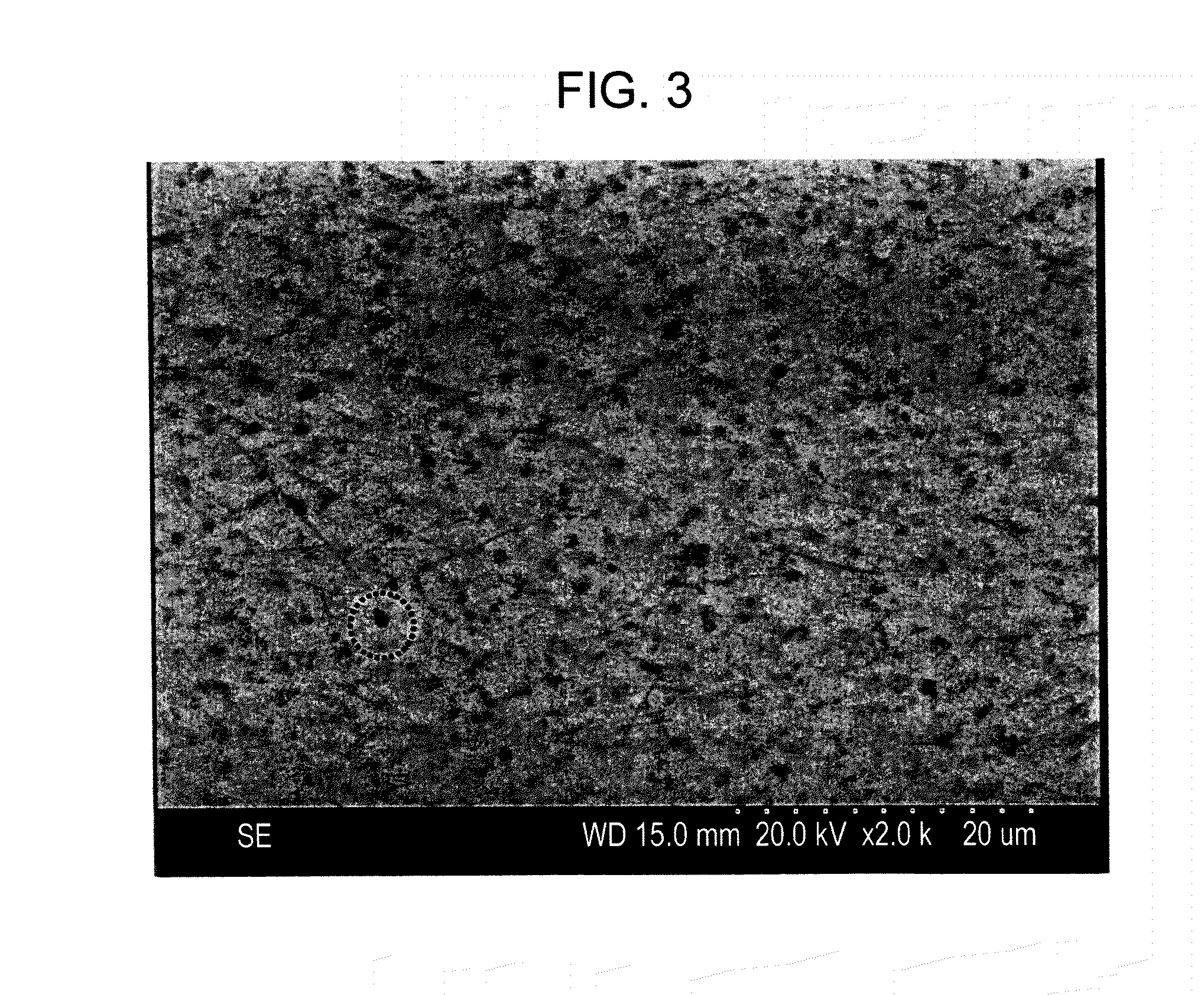

ActiveUS20150336851A1Improve anti-adhesion performanceLong period of timeDrawing mandrelsShaping toolsPolymer scienceMembrane surface

Provided is a hard coating film which is hardly adhered to a soft metal and is suitable for the coating of, for example, the surface of a hot pressing mold that may be in contact with the soft metal. The hard coating film is characterized in that, on the surface of the hard coating film, the arithmetic average roughness (Ra) is 0.05 μm or less and the average number of pin holes each having an equivalent circle diameter of 1 μm or more is 5 or less per field when at least five fields each having a size of 45×65 μm are observed on a scanning electron microscope at 2000-fold magnification.

Owner:KOBE STEEL LTD

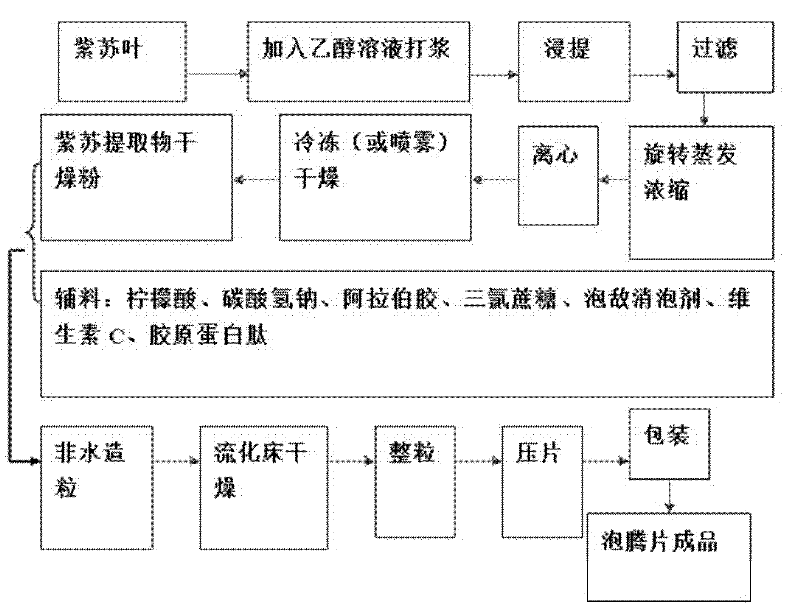

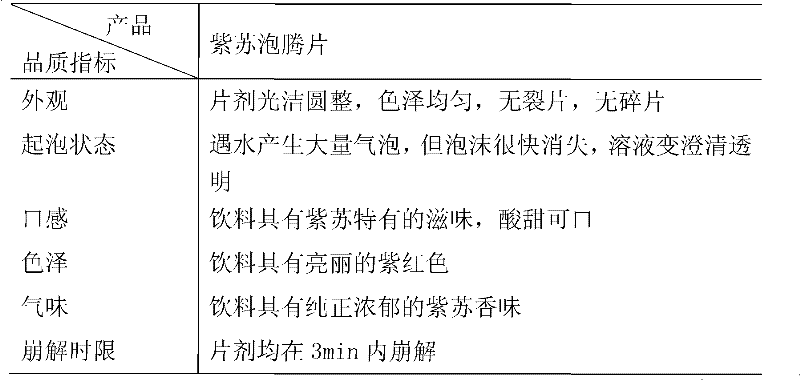

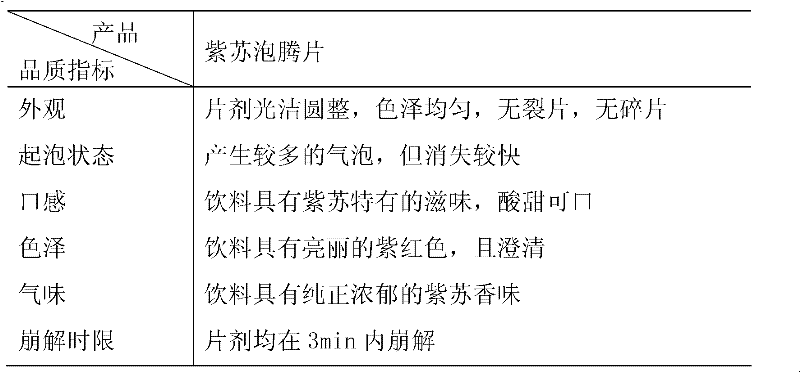

A kind of perilla effervescent tablet and preparation method thereof

InactiveCN102293404AFree radical scavengingNot easy to absorb moistureFood preparationSodium bicarbonateVitamin C

The invention discloses an effervescent tablet of perilla frutescens. , vitamin C and collagen peptide; the perilla effervescent tablet of the present invention is a new type of solid food with sweet and sour taste, unique flavor, certain nutritional value and health-promoting effect, convenient to eat and easy to carry; the present invention has important technical Reference value and broad market development prospects.

Owner:SHANGHAI JIAO TONG UNIV

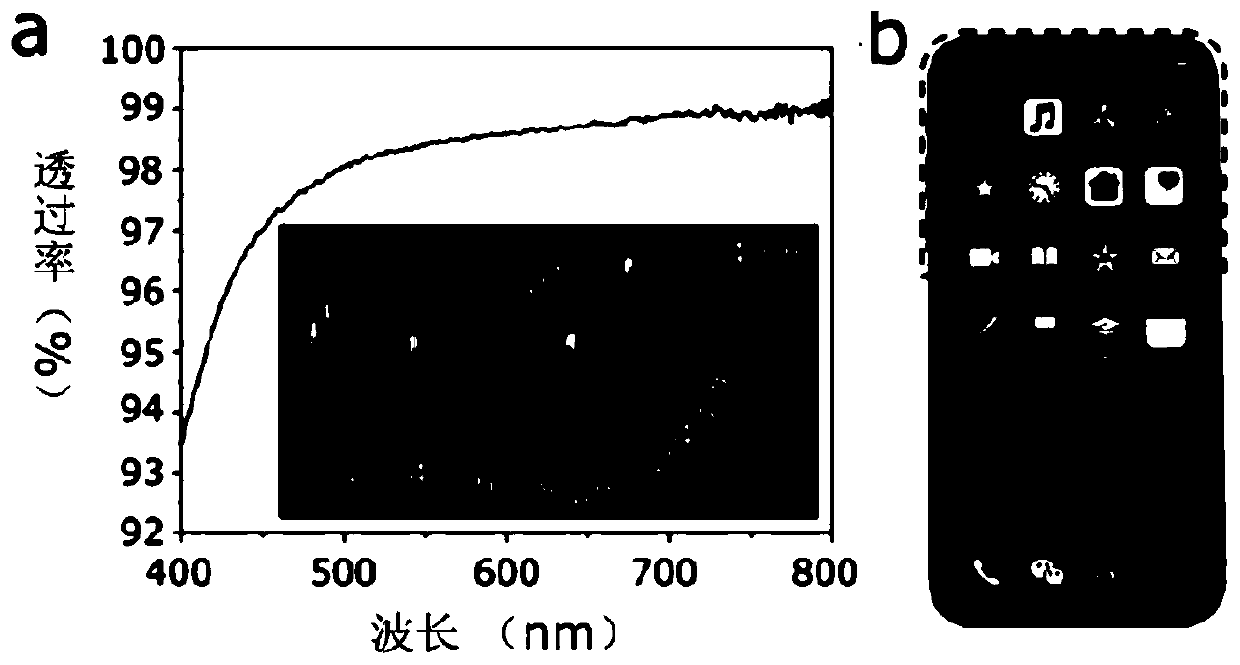

High elastic and high permeable antifouling polyurethane membrane and preparation method and application thereof

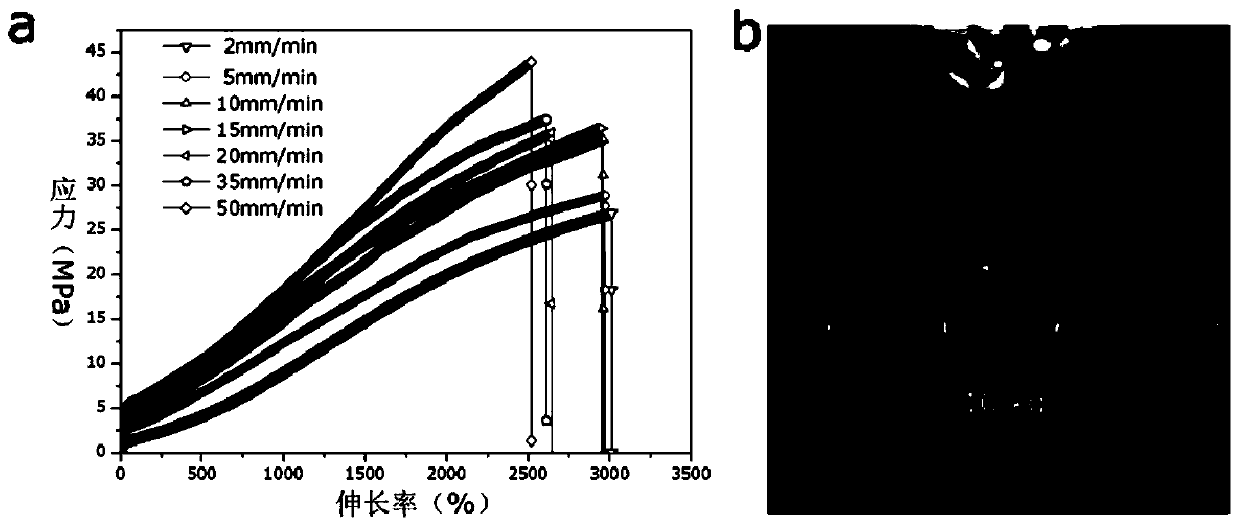

InactiveCN110423454ALow priceGood water solubilityAntifouling/underwater paintsPaints with biocidesHydrophilic monomerExtensibility

The invention belongs to the field of polymer membrane materials, and discloses a high elastic and high permeable antifouling polyurethane membrane and a preparation method and application thereof. Raw materials of the high elastic and high permeable antifouling polyurethane membrane are prepared from the following effective components in percentage by mass: 30-40% of a hard segment monomer, 40-50% of a soft segment monomer, 3-6% of a hydrophilic monomer, 0-3% of a cross-linked monomer, 0%-5% of a small molecule chain extender, and 10-15% of a low surface energy compound. According to the highelastic and high permeable antifouling polyurethane membrane, through polycondensation reaction, a chemical and physical double cross-linked antifouling polyurethane is synthesized; the membrane shows excellent low adhesion and antifouling properties; water, diiodomethane, cetane and other liquids with different surface tension do not adhere to the membrane at all, and slide off the membrane without leaving traces; and when the membrane is in a tensile state (the elongation is less than or equal to 1800%), the liquids can still slide off the membrane without leaving the traces, and it is shown that the membrane can simultaneously achieve the coexistence of low adhesion and extensibility.

Owner:GUANGZHOU UNIVERSITY

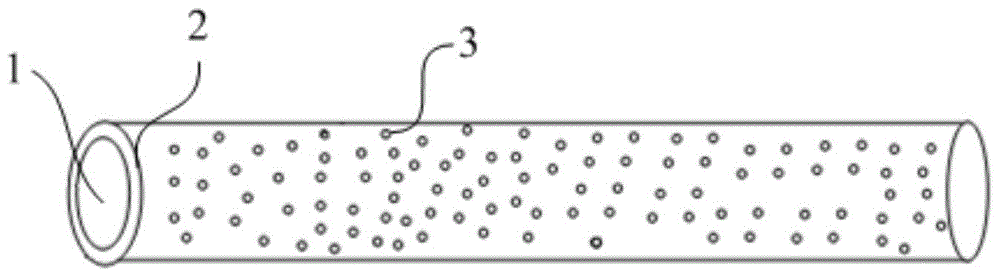

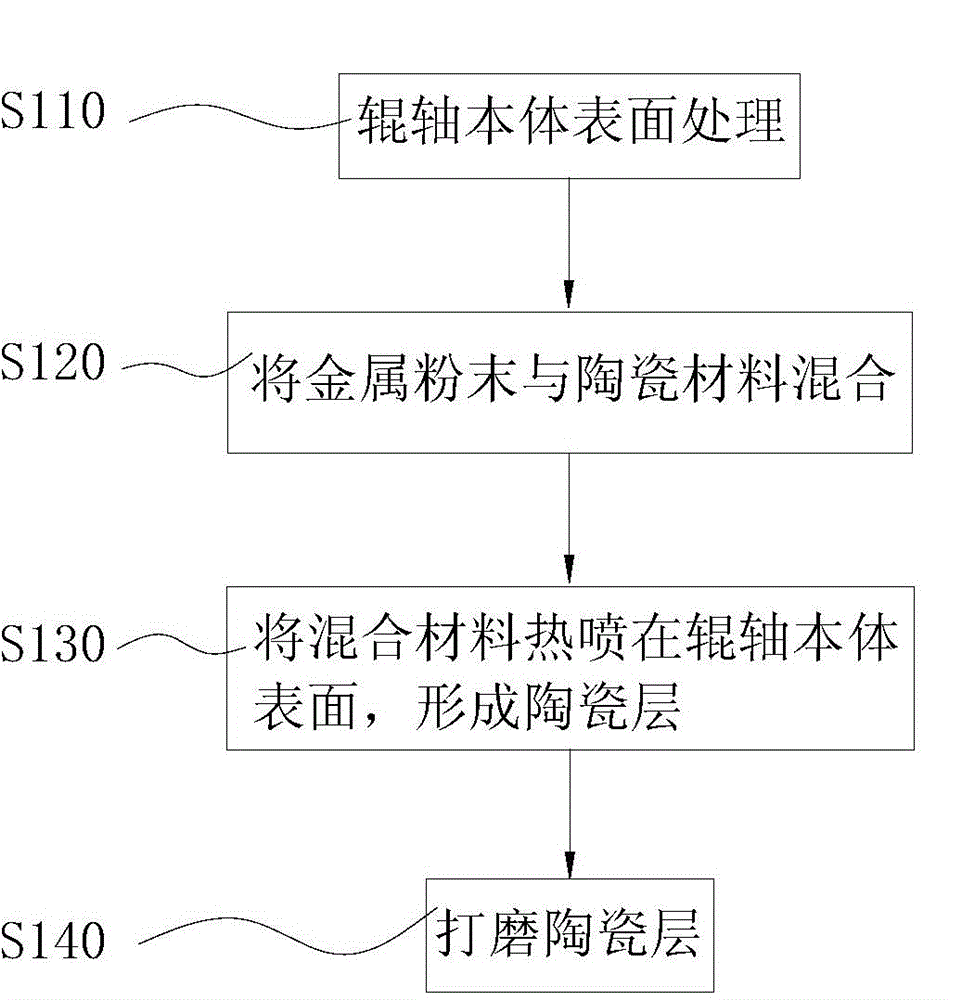

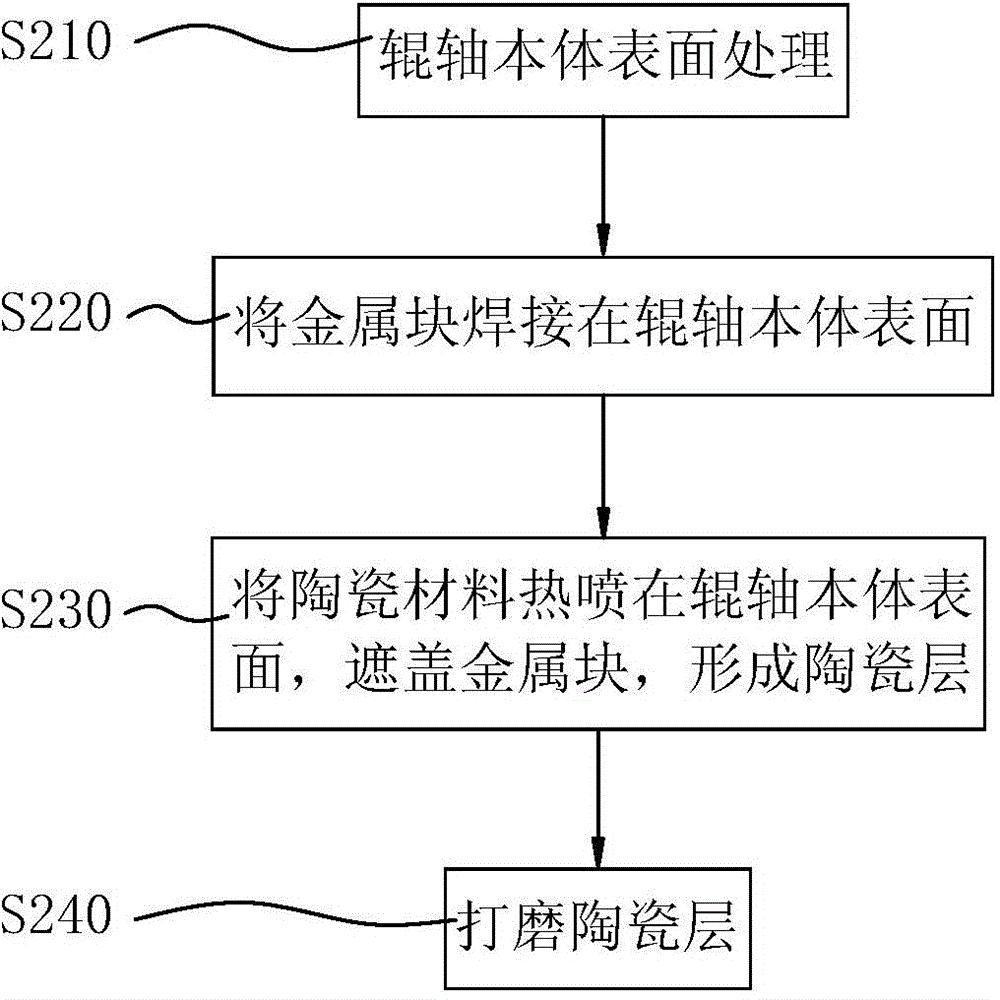

Roll shaft and production method thereof

ActiveCN104475306AImprove wear resistanceImprove adhesionPretreated surfacesCoatingsConductive materialsEngineering

The invention discloses a roll shaft and a production method thereof. The roll shaft comprises a roll shaft body, the surface of the roll shaft body is provided with a nonstick layer, and a conductive material is embedded in the nonstick layer. The nonstick layer arranged on the roll shaft body enhances the wear resistance of the roll shaft, prolongs the service life of the roll shaft and improves the sticking resistance of the roll shaft; and the conductive material embedded in the nonstick layer makes the roll shaft have an excellent electrostatic conduction performance.

Owner:GUANGDONG SHENGYI SCI TECH

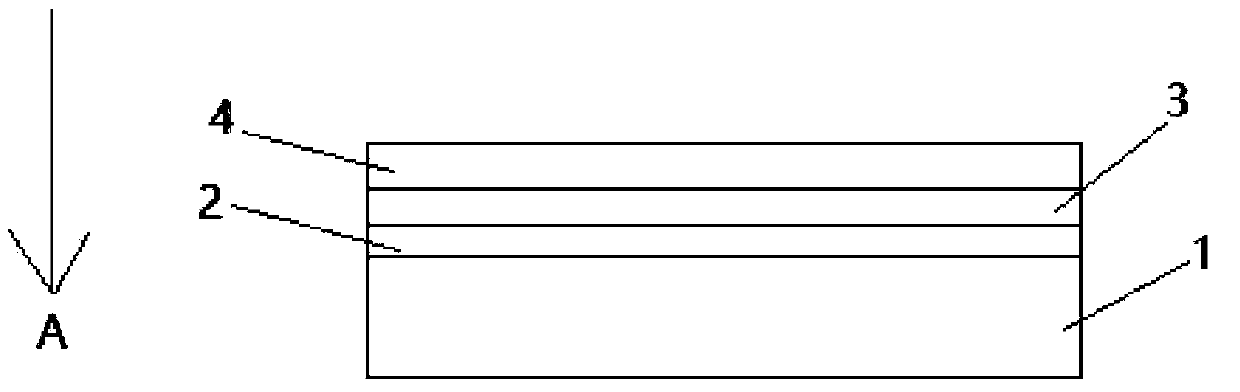

Method for manufacturing super-hydrophobic silicon substrate

ActiveCN103172017AClosely arrangedGood periodicityDecorative surface effectsChemical vapor deposition coatingMicro nanoXylylene

The invention relates to a method for manufacturing a super-hydrophobic silicon substrate. The method comprises the following steps of: photoetching and etching the silicon substrate through a traditional microelectronic process, thus processing a silicon column array in a micro scale; etching the silicon substrate by an oxygen plasma etching method; diluting and proportioning a nano-particle solution by deionized water, thus obtaining nano-particle suspension; soaking a silicon substrate structure subjected to hydrophilization treatment in the nano-particle suspension, and naturally evaporating the nano-particle suspension at room temperature in an evaporation table, or adding nitrogen to the nano-particle suspension for accelerating evaporation; etching nano-particles which are densely arranged on the surface of the structure by the oxygen plasma etching method within controlled reaction time, thus obtaining nano-particles of proper sizes; and settling intrinsically weak hydrophobic poly-p-xylylene by a chemical vapor deposition method, so that the poly-p-xylylene completely settles on the surface of the silicon substrate, and the final super-hydrophobic substrate is obtained. The micro-nano double-layer hierarchical composite structure is prepared by the micro-nano processing technique, the method is simple in process and high in periodicity, and the raw materials are easily available.

Owner:PEKING UNIV

Anti-sticking and wear resistant polyurea coating and its preparation method

ActiveCN102492357BStrong adhesionImprove wear resistancePolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention relates to an anti-sticking and wear resistant polyurea coating and its preparation method. The coating is prepared by blending of component A and component B. Specifically, the component A is synthesized by the following raw materials by weight: 90-120 parts of isocyanate, 40-60 parts of polyether polyol and 20-30 parts of fluorocarbon diol; and the component B is prepared by the following raw materials by weight: 500-800 parts of polyether amine, 400-600 parts of organosilicon diamine, 300-400 parts of high activity polyether polyol, 400-500 parts of an amino chain extender, 80-100 parts of an amino cross-linking agent, 100-150 parts of a high boiling point diluent, 5-10 parts of a composite catalyst, 400-600 parts of composite nano-metal oxide surface active materials, 600-800 parts of a filling material, and 40-60 parts of a pigment. The invention also includes a preparation method of the anti-sticking and wear resistant polyurea coating. A coating layer obtained by spraying of the anti-sticking and wear resistant polyurea coating in the invention has strong adhesion, and has good adhesion resistance, wear resistance, corrosion resistance, as well as impact resistance. Therefore, the anti-sticking and wear resistant polyurea coating of the invention is especially suitable for spraying on the lining surface of a heavy transport dump truck.

Owner:湘江涂料科技有限公司

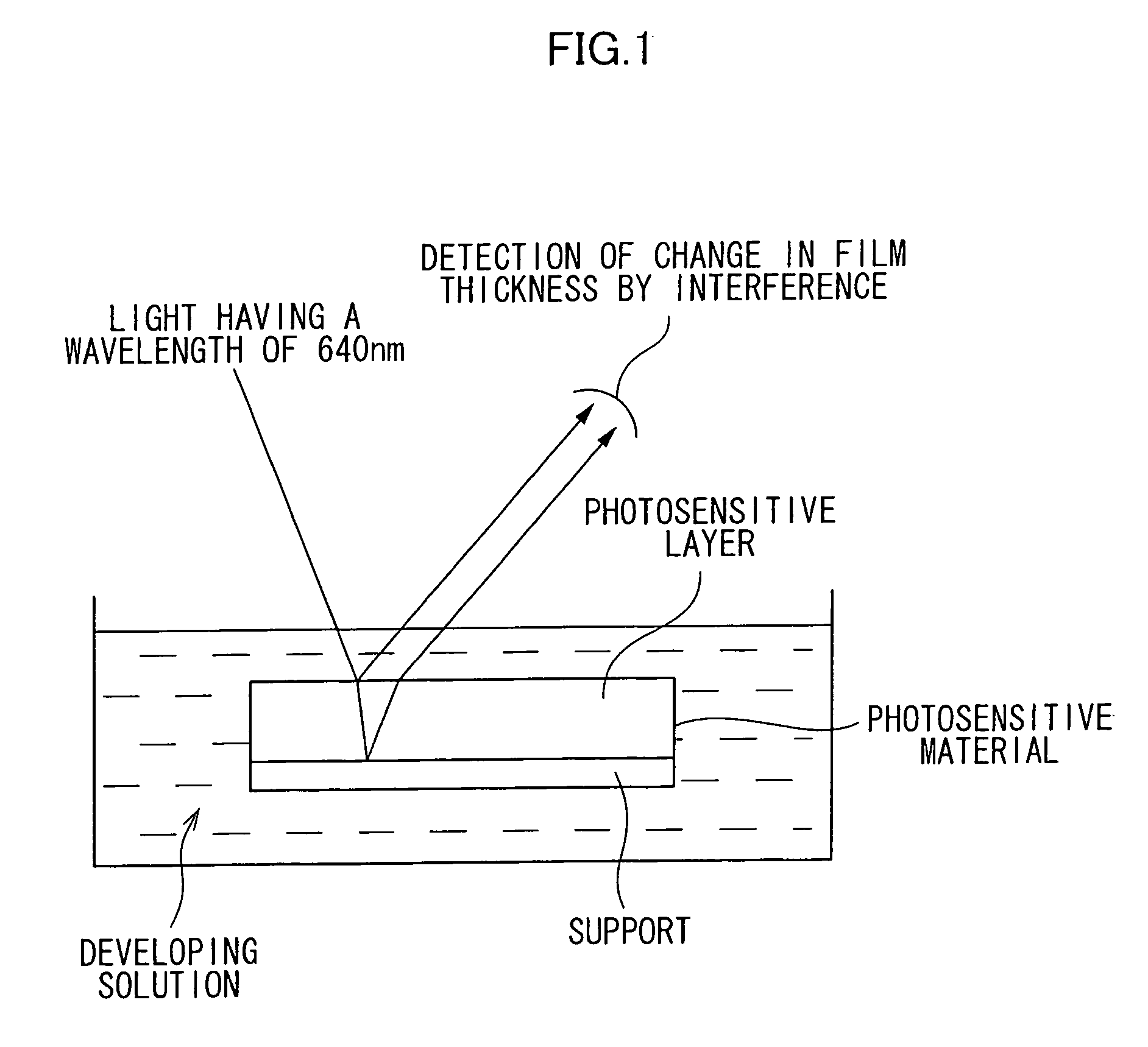

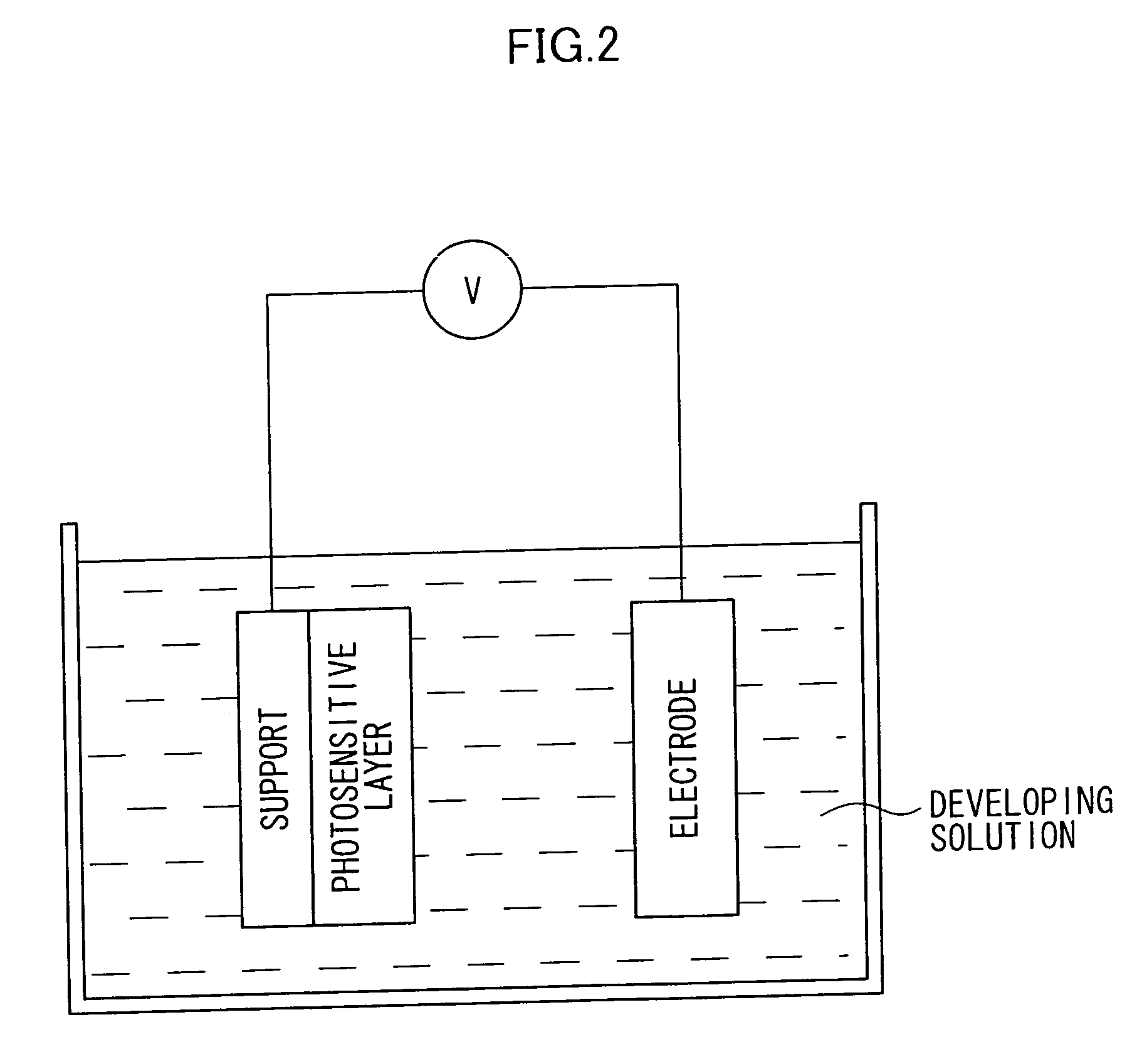

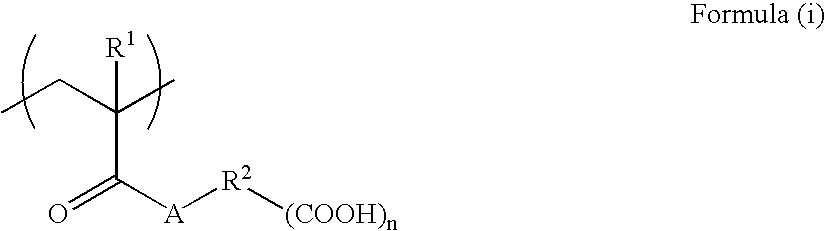

Planographic printing plate precursor

ActiveUS20060046192A1Improve scratch resistanceAvoid stickingRadiation applicationsPhotoprinting processesHydrogen atomSulfur

The present invention provides a planographic printing plate precursor having a support, a photosensitive layer and a protective layer. The photosensitive layer contains at least an infrared absorbing agent, a polymerization initiating agent, a polymerizable compound and a binder polymer having repeating units represented by the following Formula (i). Further, the protective layer contains at least an inorganic lamellar compound. In Formula (i), R1 represents a hydrogen atom or a methyl group; R2 represents a connecting group having two or more types of atom selected from the group consisting of a carbon atom, a hydrogen atom, an oxygen atom, a nitrogen atom, and a sulfur atom and having 2 to 82 atoms in total; A represents an oxygen atom or —NR3—, and R3 represents a hydrogen atom or a monovalent hydrocarbon group having 1 to 10 carbon atoms; and n is an integer of 1 to 5.

Owner:FUJIFILM HLDG CORP +1

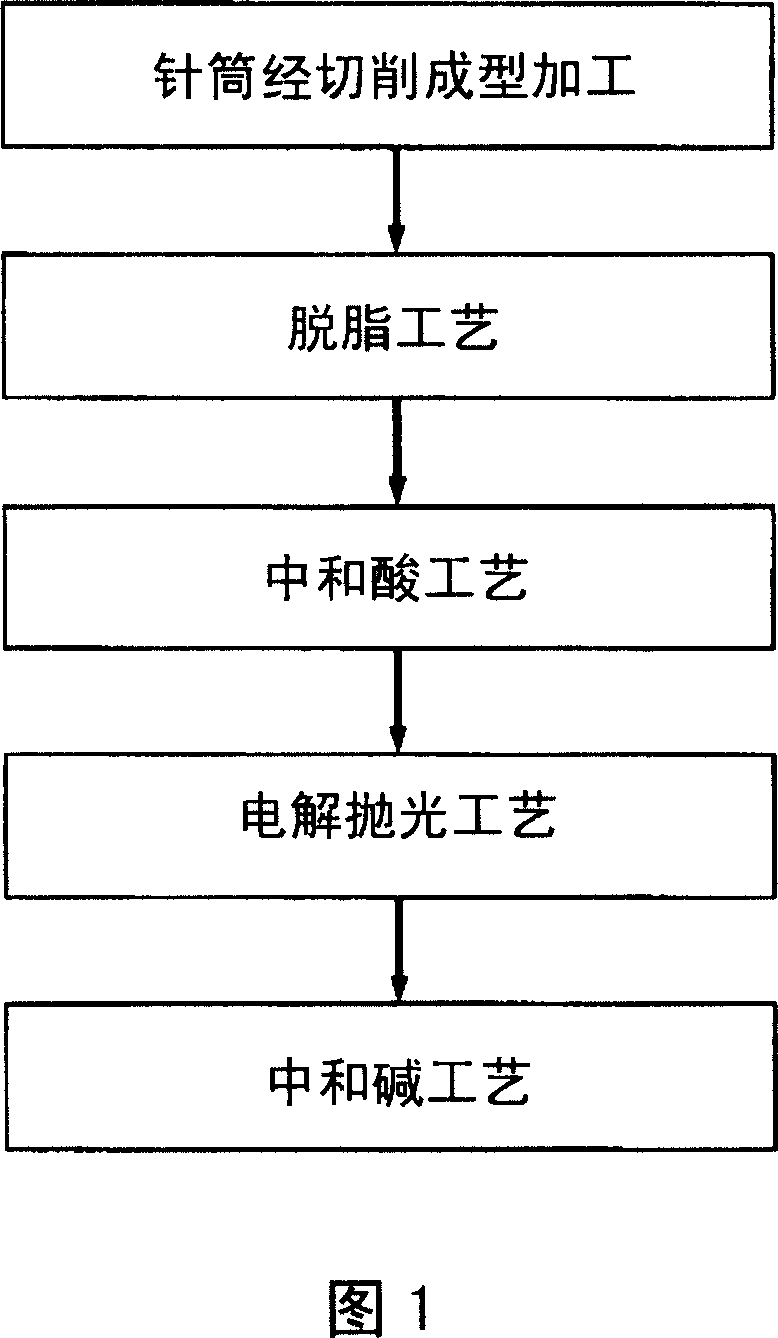

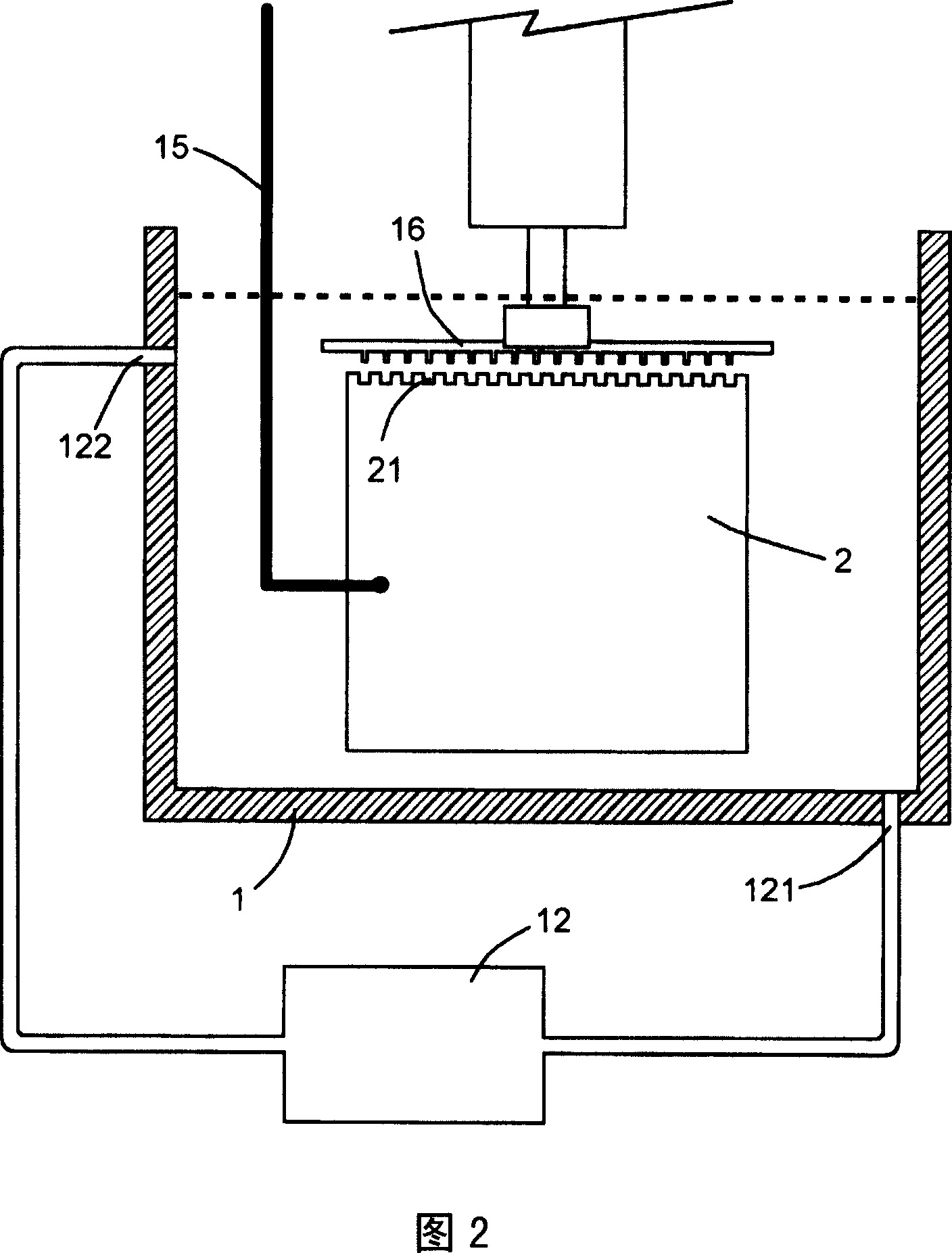

Manufacturing method for round knitting machine needle cylinder surface optimization

InactiveCN101126170ASliders move smoothlyExtended service lifeAnodisationCircular knitting machinesElectrolysisBiomedical engineering

The invention discloses a manufacturing method of optimizing the surface of a round needle weaving machine syringe. The manufacturing method comprises the following steps: providing a syringe work piece finished with cutting and shaping as well as processing operations; operating degreasing technique on the syringe work piece; operating electrolytic polishing technique and immersing the syringe work piece into the electrolytic polishing groove fed with electrolytic liquids so as to make the syringe electrically connected with the anode of a power supply; in addition, arranging a correspondingly shaped cathode nearby the part to be polished of the syringe, and selecting suitable operating parameters on voltage and electric current as well as electrolytic time so as to make the surface of the syringe work piece happed anode electrolytic reaction. In this way, the invention improves the smoothness, glossiness and anti adhesiveness as well as beauty of the surface of the slot for the syringe, and further simplifies the processing technique as well as achieves the improvement of the processing efficiency.

Owner:蔡志欣 +1

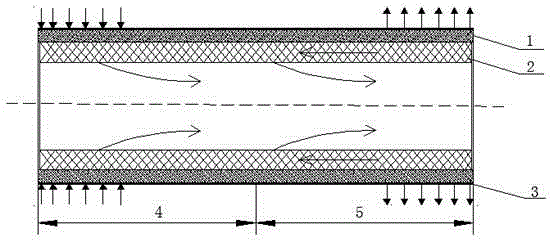

Self-cleaning heat pipe with super-hydrophilic liquid absorption core

InactiveCN104930891AImprove anti-adhesion performanceIncrease surface areaIndirect heat exchangersEngineeringNanoscopic scale

The invention discloses a self-cleaning heat pipe with a super-hydrophilic liquid absorption core. The self-cleaning heat pipe comprises a pipe shell, the super-hydrophilic liquid absorption core and a super-hydrophobic film. The pipe shell is provided with a closed cavity, the super-hydrophilic liquid absorption core and a heat-transfer medium are arranged in the closed cavity, the super-hydrophilic liquid absorption core comprises a liquid absorption core and a super-hydrophilic film, the liquid absorption core is a silk screen liquid absorption core, the super-hydrophilic film is arranged on the surface of the silk screen liquid absorption core, the thickness of a surface rough structure of the super-hydrophilic film ranges from 50 nanometers to 500 nanometers, the top diameter of the surface rough structure of the super-hydrophilic film ranges from 1 nanometer to 200 nanometers, and the top distance of the surface rough structure of the super-hydrophilic film ranges from 10 nanometers to 100 nanometers. The super-hydrophobic film covers the outer surface of the pipe shell, and the thickness of the super-hydrophobic film ranges from 50 nanometers to 500 nanometers. By nano-scale rough structure construction, the heat transfer performance of the heat pipe can be improved, the super-hydrophobic film has adhesion resistance, the problem of ash deposition of the outer surface of the heat pipe can be solved, and self-cleaning is realized. Self-cleaning and heat transfer performances of the heat pipe are effectively improved.

Owner:UNIV OF JINAN

Anti-adhesion hard coating for injection mold and preparation method thereof

ActiveCN109594042AImprove wear resistanceImprove anti-adhesion performanceVacuum evaporation coatingSputtering coatingSurface energySurface modification

The invention relates to an anti-adhesion hard coating for an injection mold and a preparation method thereof. A layer of composite coating containing a hard metal / a hard ceramic phase / a carbon material is deposited on the surface of an inner cavity of a mold, surface modification of low-surface energy and structural design of low-surface energy is performed on the coating, and the problems that the injection-molded hot blank is easy to adhere and the surface is wear-resistant are solved under the condition that a mold release agent is not used, the painting is omitted / the release agent is sprayed. The anti-adhesion hard coating for the injection mold and the preparation method thereof are tightly combined with a metal surface coating preparation technology and a plasma modification technology and the like, a heterogeneous composite coating structure is constructed, the outer surface of the coating is further modified, a hard composite coating for preventing the hot blank from being adhered on the surface of the injection mold is formed, the composite coating has the advantages that the surface of the injection mold has high abrasive resistance, and meanwhile good anti-adhesion performance is obtained.

Owner:SUZHOU CHAMPION COATING TECH

Aid for pulling elastic stockings on and off

ActiveUS9295353B2Reduce coefficient of frictionImprove anti-adhesion performanceApparel holdersEngineeringElastic hosiery

Owner:ARION HLDG

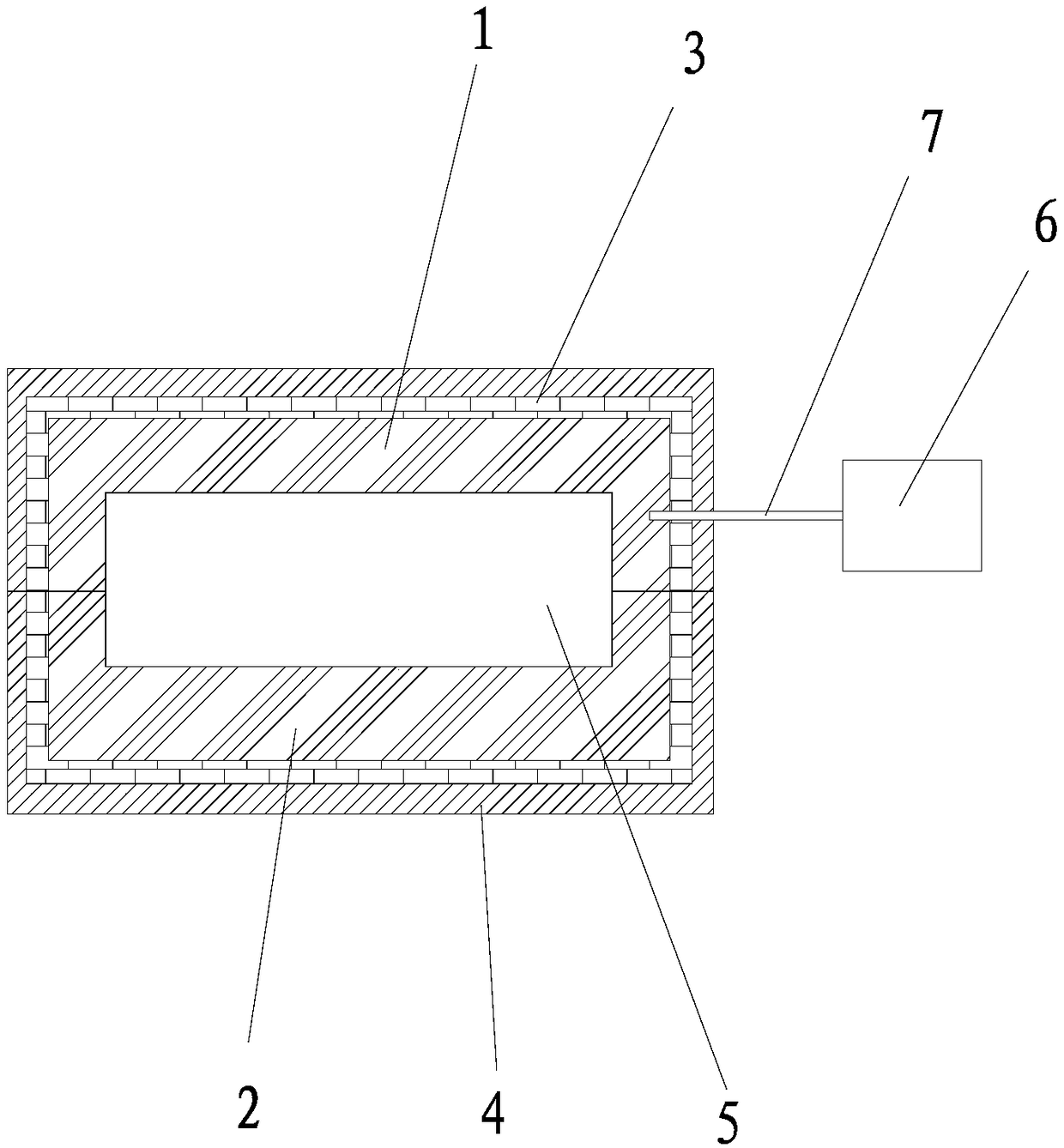

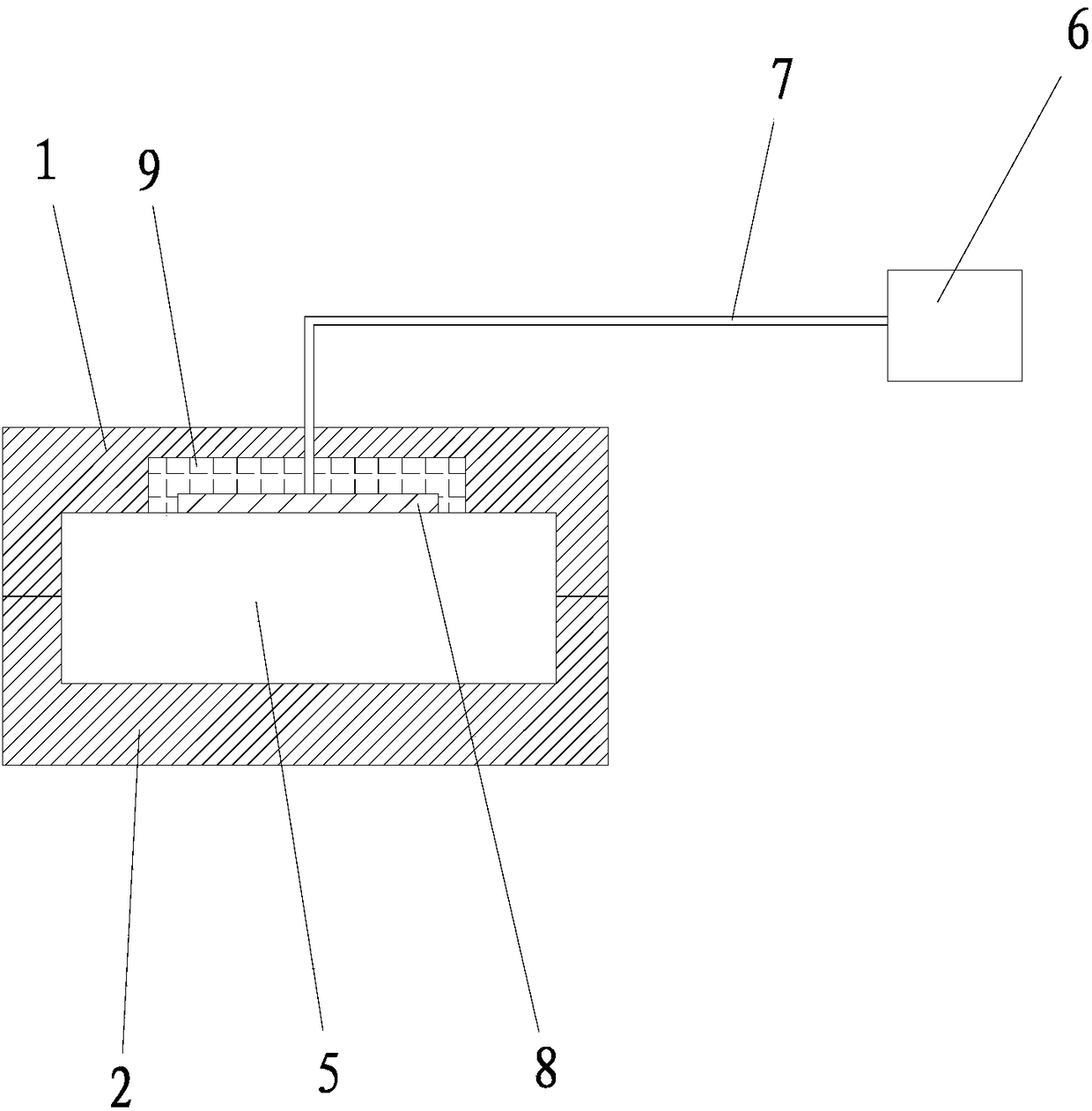

Radio frequency foaming device

PendingCN108262910AHeating evenlyGood radio frequency shielding effectCoatingsElectricityCoaxial cable

The invention discloses a radio frequency foaming device. The device comprises a foaming mold and a solid radio frequency power source, the solid radio frequency power source is electrically connectedwith the foaming mold or a radiation unit through a coaxial cable, and the radio frequency is sent out through the foaming mold or the radiation unit and is reflected in a mold cavity; and the temperature of to-be-foamed parent materials is gradually increased due to the fact that the wave-absorbing materials in the to-be-foamed parent materials in the mold cavity absorb the radio frequency, whenthe temperature is higher than the decomposition temperature of a foaming agent, the foaming agent rapidly decomposes and generates gas, then the foaming materials are promoted to expand until the whole mold cavity is filled, and therefore foaming of the foaming materials is realized. The foaming device can realize rapid, efficient and uniform foaming of the foaming materials. The device has a wide application prospect in the field of foaming material foaming.

Owner:QUANZHOU NORMAL UNIV

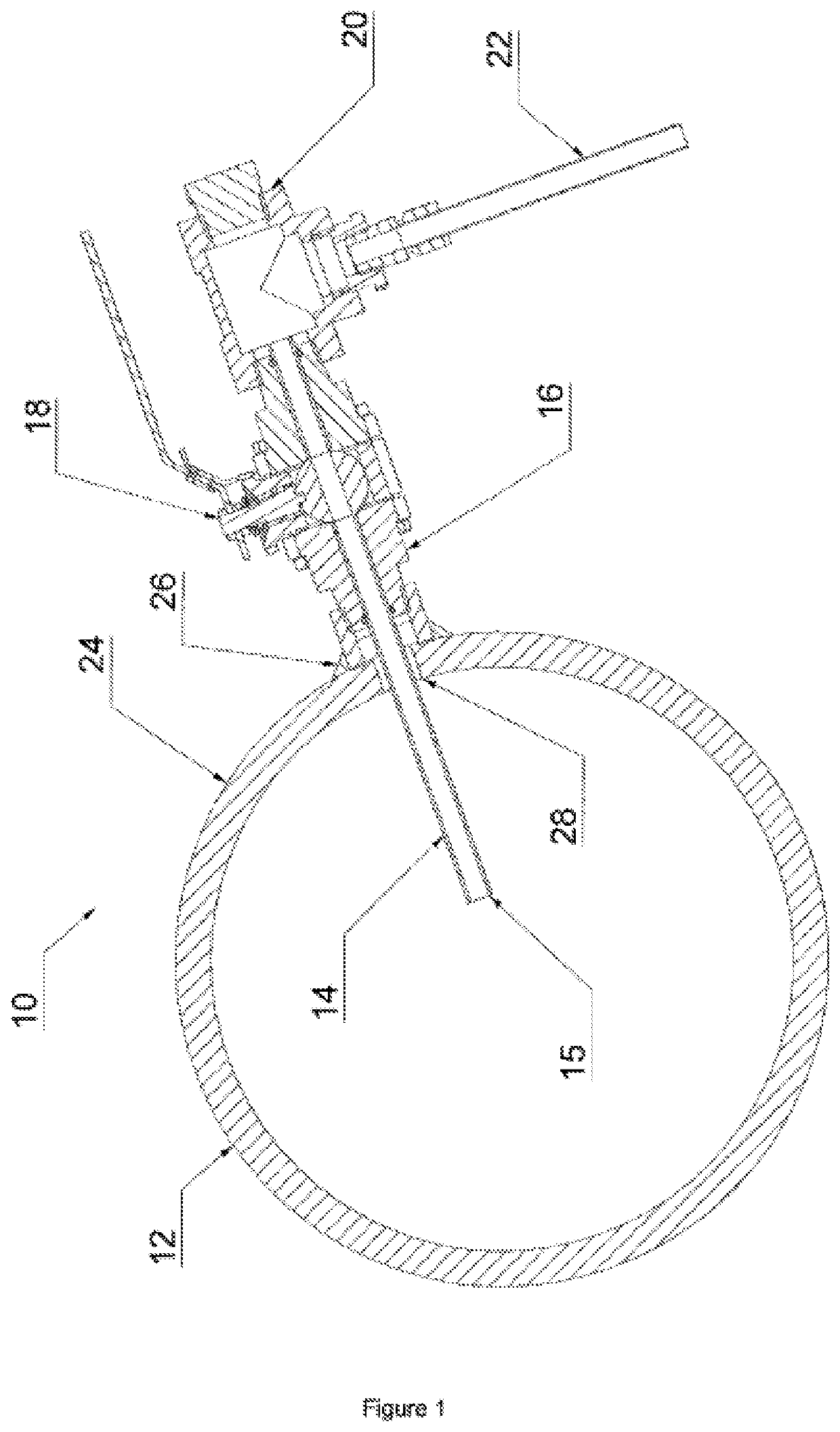

Fluid Sampling Device

PendingUS20200300387A1Easy to destroyAvoid accumulationWithdrawing sample devicesFlexible pipesEngineeringMechanics

A fluid sampling device for sampling fluids in a fluid process vessel through a port in a wall of the vessel, the sampling device comprising a flexible tube with an open end in fluid communication with the fluid process vessel, means to attach the sampling device to the process vessel, wherein at least a portion of the flexible tube is adapted to extend into the process vessel, wherein the length of the flexible tube extending into the process vessel is at least 5 times the outer diameter of the flexible tube.

Owner:ALCOA OF AUSTRALIA LTD

High-temperature-resistant ultra-high molecular weight polyethylene pipe and preparation method thereof

The invention discloses a preparation method of a high-temperature-resistant ultra-high molecular weight polyethylene pipe. The preparation method comprises the following steps: (1) preparing fluorine-containing adamantyl polycondensate; (2) preparing a mixture; and (3) performing extrusion molding. The invention also discloses the high-temperature-resistant ultra-high molecular weight polyethylene pipe prepared according to the preparation method of the high-temperature-resistant ultra-high molecular weight polyethylene pipe. The high-temperature-resistant ultra-high molecular weight polyethylene pipe disclosed by the invention not only keeps the advantages of excellent wear resistance, extremely high impact strength, excellent self-lubricating property, good chemical resistance and low temperature resistance, excellent adhesion resistance, sanitation, no toxicity, no pollution and recyclability of a traditional ultra-high molecular weight polyethylene pipe, but also improves the properties, such as weather resistance and heat resistance, of the traditional ultra-high molecular weight polyethylene pipe.

Owner:大庆思旭管业有限公司

Compound extreme pressure lithium-based lubricating grease additive and preparation method thereof

ActiveCN104140862AReasonable formulaImprove high temperature resistanceAdditivesAlkylphosphateTemperature resistance

The invention discloses a compound extreme pressure lithium-based lubricating grease additive and a preparation method thereof. According to the technical scheme disclosed by the invention, the compound extreme pressure lithium-based lubricating grease additive comprises the following raw materials in parts by weight: 100-120 parts of BS oil or high-viscosity synthetic oil, 10-15 parts of fluorine rubber, 3-5 parts of Span-80, 5-8 parts of thiadiazole derivatives and 1-3 parts of chlorine brominated alkyl phosphate flame retardant. The invention also discloses a preparation method of the compound extreme pressure lithium-based lubricating grease additive. The preparation method has the advantages of reasonable raw material formulation and advanced process, the production cost can be reduced and the addition of a plurality of additives in steps in the production process of the compound extreme pressure lithium-based lubricating grease is avoided, the produced compound extreme pressure lithium-based lubricating grease is more excellent in high temperature resistance, water spray resistance, adhesion resistance, extreme pressure anti-wear performance, oxidation resistance and the like and thus the produced compound extreme pressure lithium-based lubricating grease is more excellent in market competiveness.

Owner:XINXIANG HENGXING TECH CO LTD

Coatings for glass molding, preparation method and application thereof and molds having coatings

ActiveUS20210061702A1Avoid stickingImprove the immunityVacuum evaporation coatingSputtering coatingSurface roughnessNitrogen gas

Disclosed are a coating for glass molding, a preparation method and application thereof and a mold having the coating. The coating includes a nitride layer and nano precious metal particles which are dispersed in the nitride layer. A surface roughness of the coating is 2-12 nm. The preparation method of the coating includes: cleaning a substrate and targets under an inert gas; and under a mixed atmosphere of nitrogen and the inert gas, depositing, with a high-purity W target, a high-purity Cr target and a precious metal inserted Cr target, a Cr intermediate layer, a nitride layer and nano precious metal particles on a surface of the substrate. The coating has good oxidation resistance and excellent anti-adhesion property. Moreover, the coating effectively inhibits the adhesion between the glass body and the mold.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com