Method for manufacturing super-hydrophobic silicon substrate

A technology of superhydrophobicity and manufacturing method, which is applied in the direction of manufacturing microstructure devices, coatings, microstructure devices, etc., can solve problems such as theoretical analysis of unfavorable substrate surface wettability, and achieve low cost, simple process, and anti-corrosion The effect of the adhesion function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] A kind of superhydrophobic silicon substrate manufacturing method of the present invention, comprises the following steps:

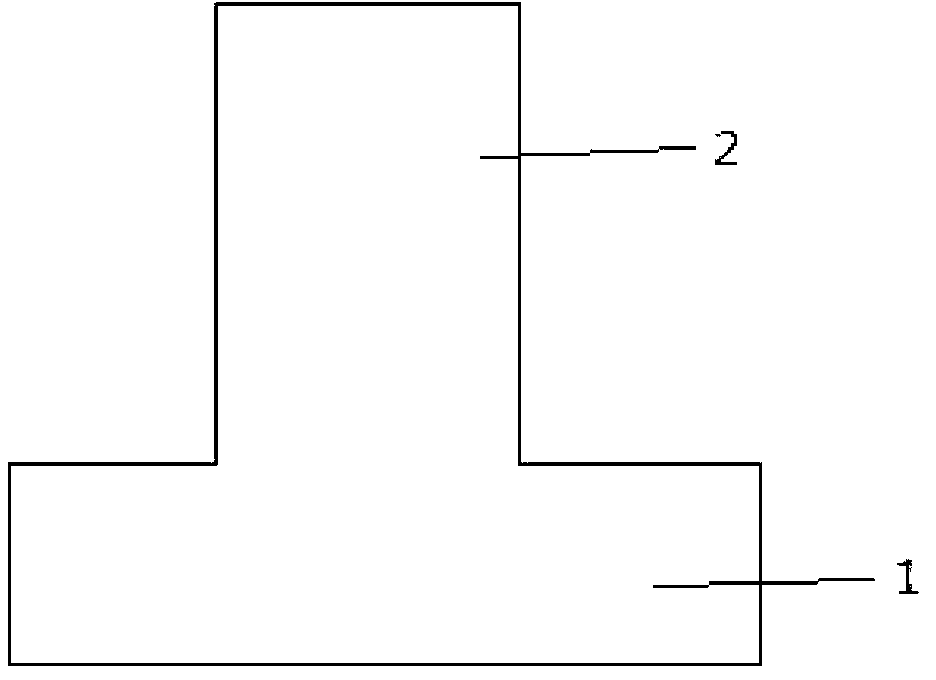

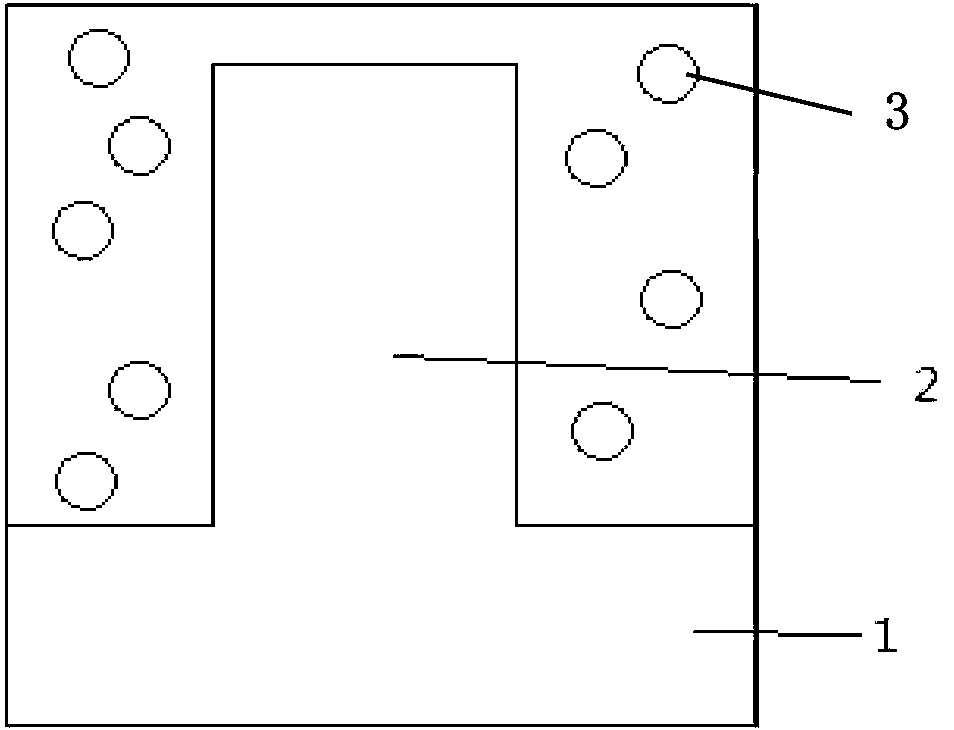

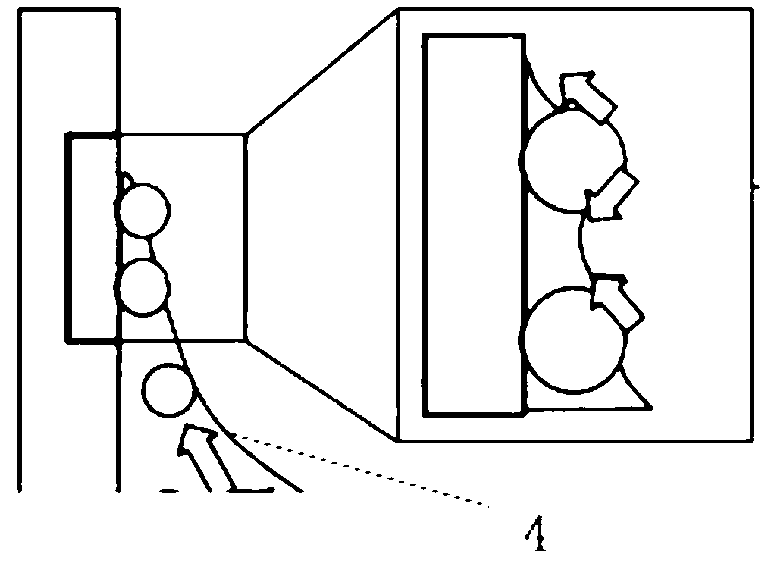

[0023] 1) if figure 1 As shown, a 4-inch n-type silicon substrate 1 with a 100 crystal orientation is subjected to photolithography and etching on the silicon substrate 1 through a traditional microelectronics process, and an array of micron-level silicon pillars 2 is processed; the size of the silicon pillars 2 Consider the size of the polystyrene nanoparticles 3 fixed on the silicon pillar 2 when imitating the nano-protrusions on the surface of the real lotus leaf. When the diameter of the polystyrene nanoparticles 3 is 700nm, the reference diameter of the silicon pillar 2 is designed to be 20 μm. The height of the etched silicon pillar 2 is 20 μm, so that the polystyrene nanoparticles 3 with a diameter of 700 nm can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com