Patents

Literature

123results about How to "Good periodicity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

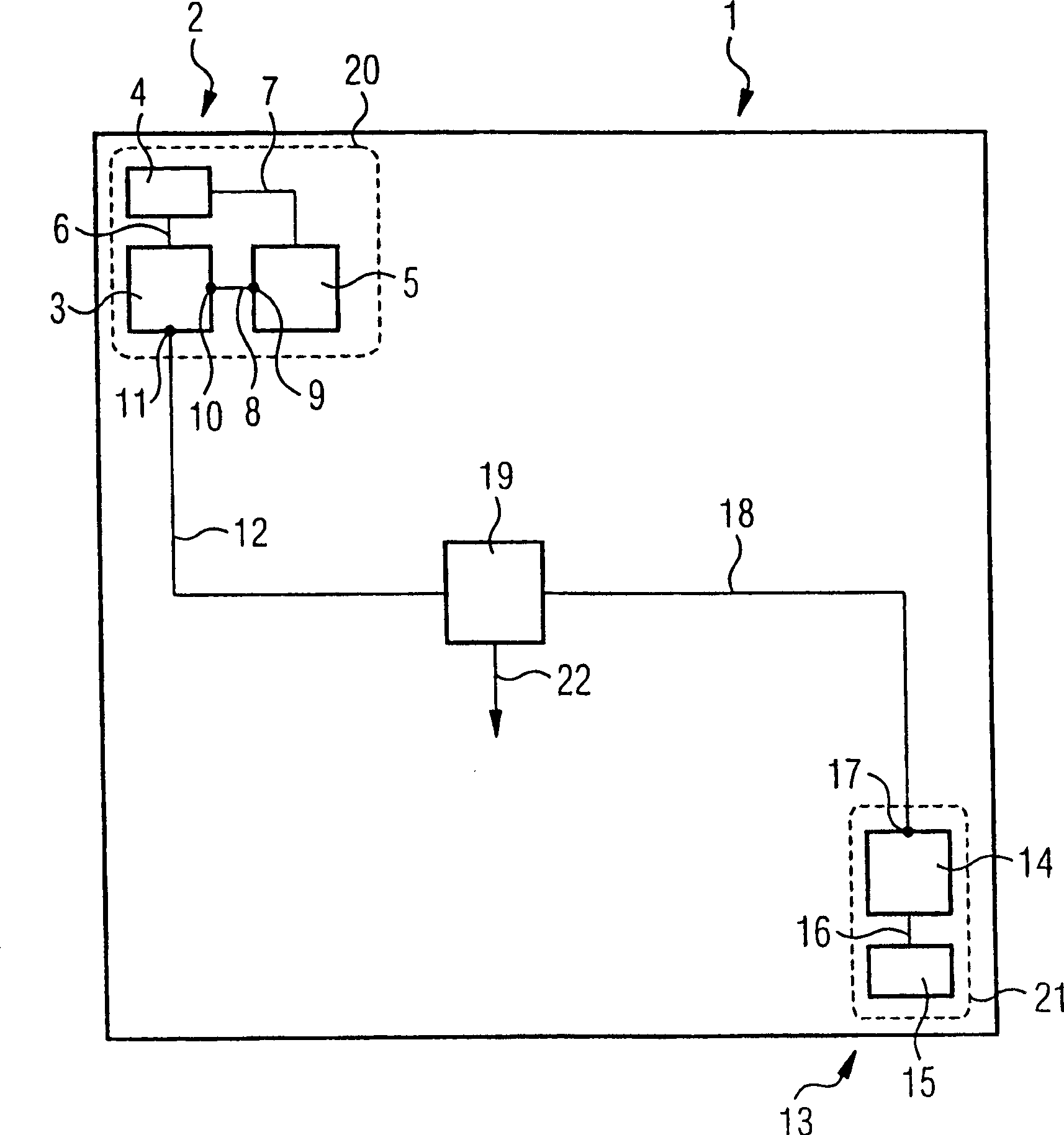

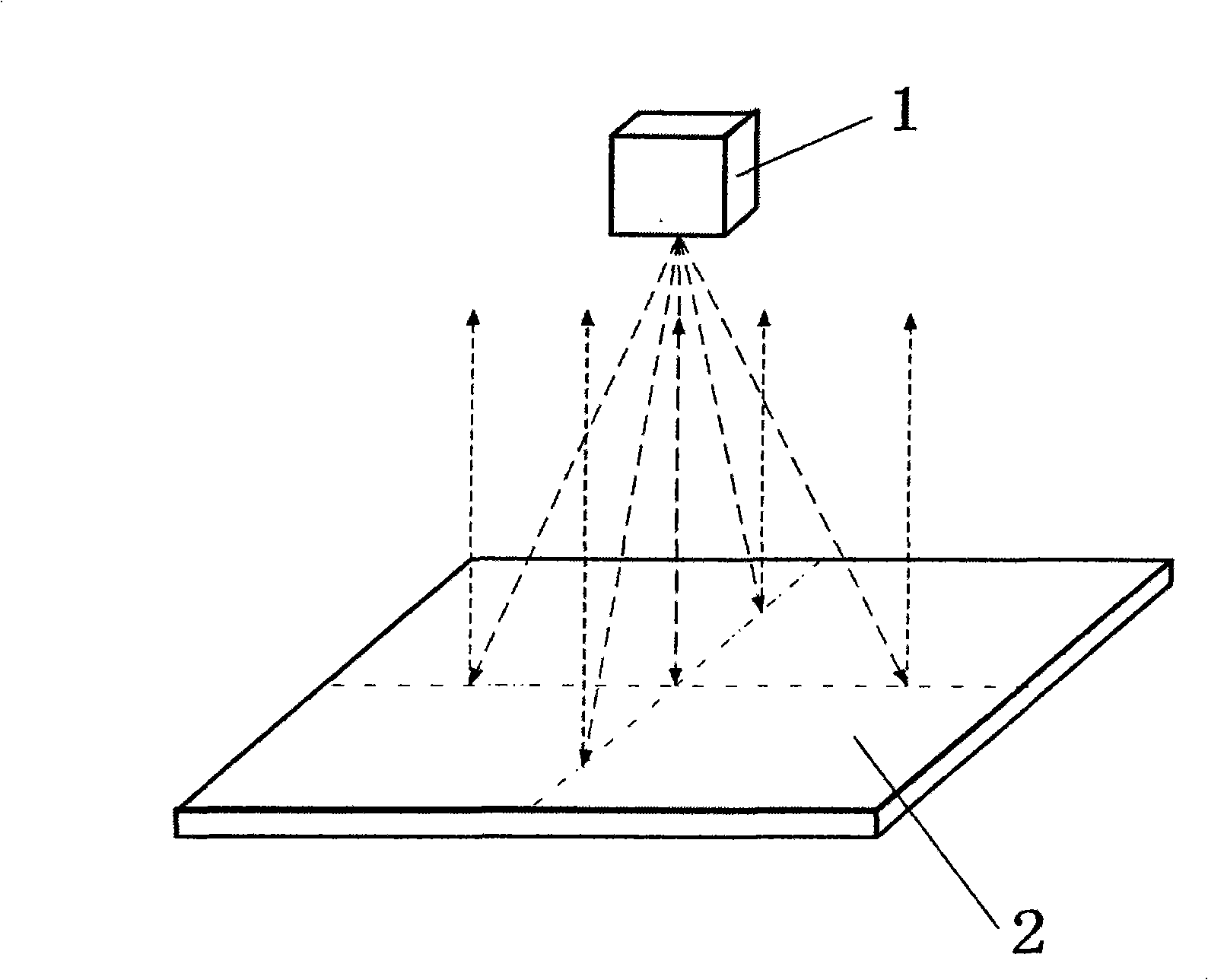

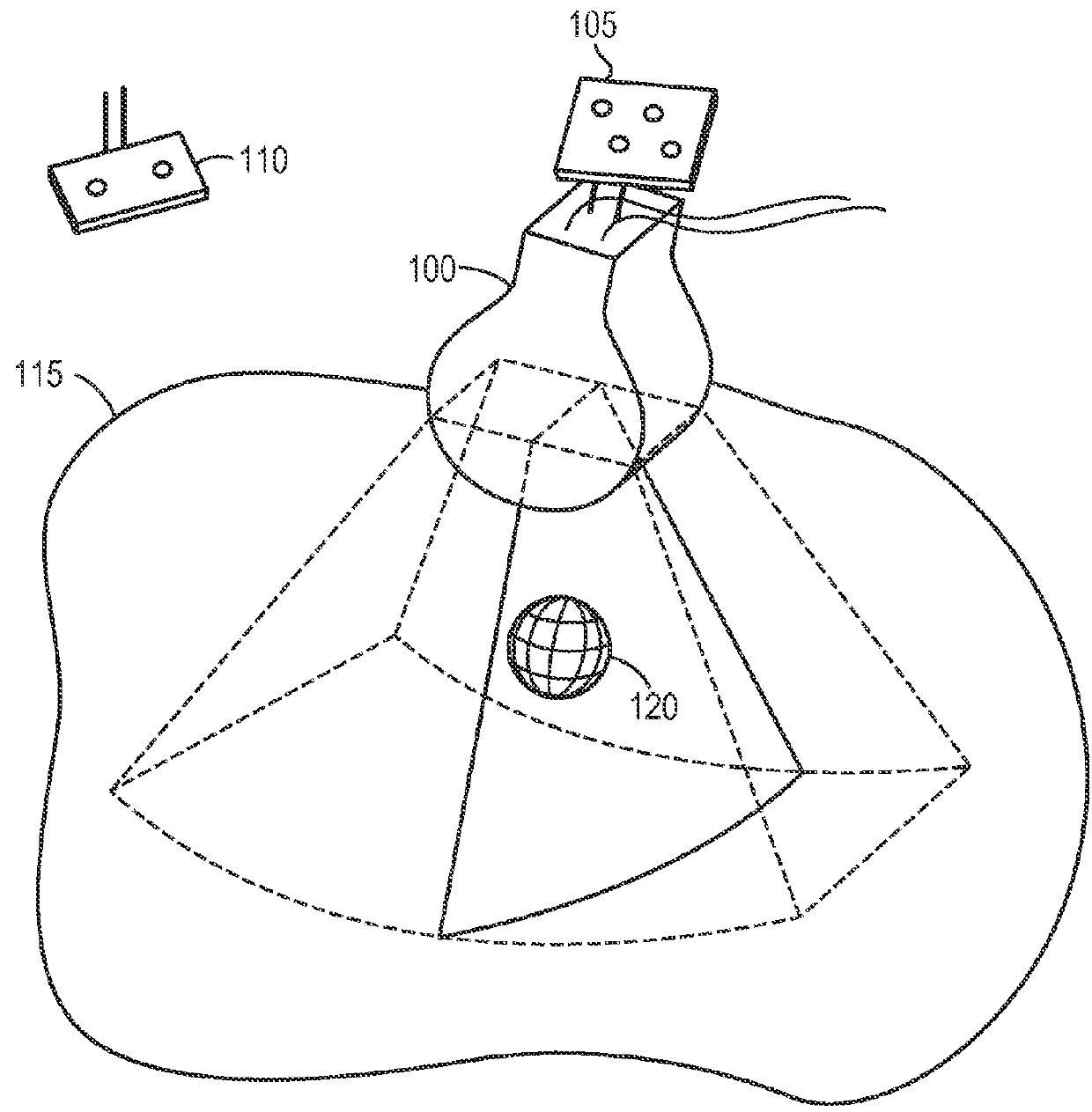

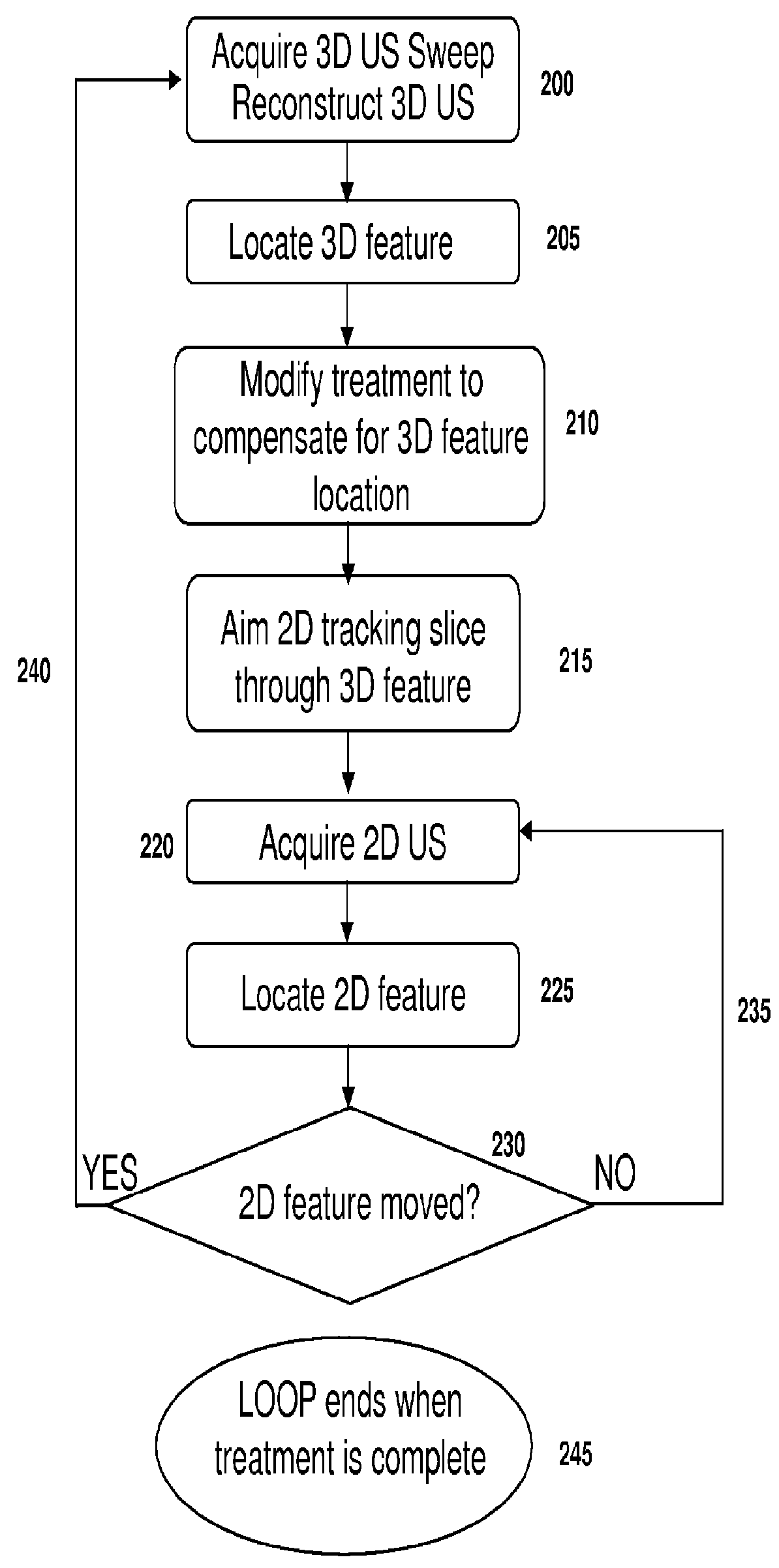

Feature Tracking Using Ultrasound

ActiveUS20120071758A1Reduce the burden onGood periodicityImage enhancementImage analysisSupporting systemSonification

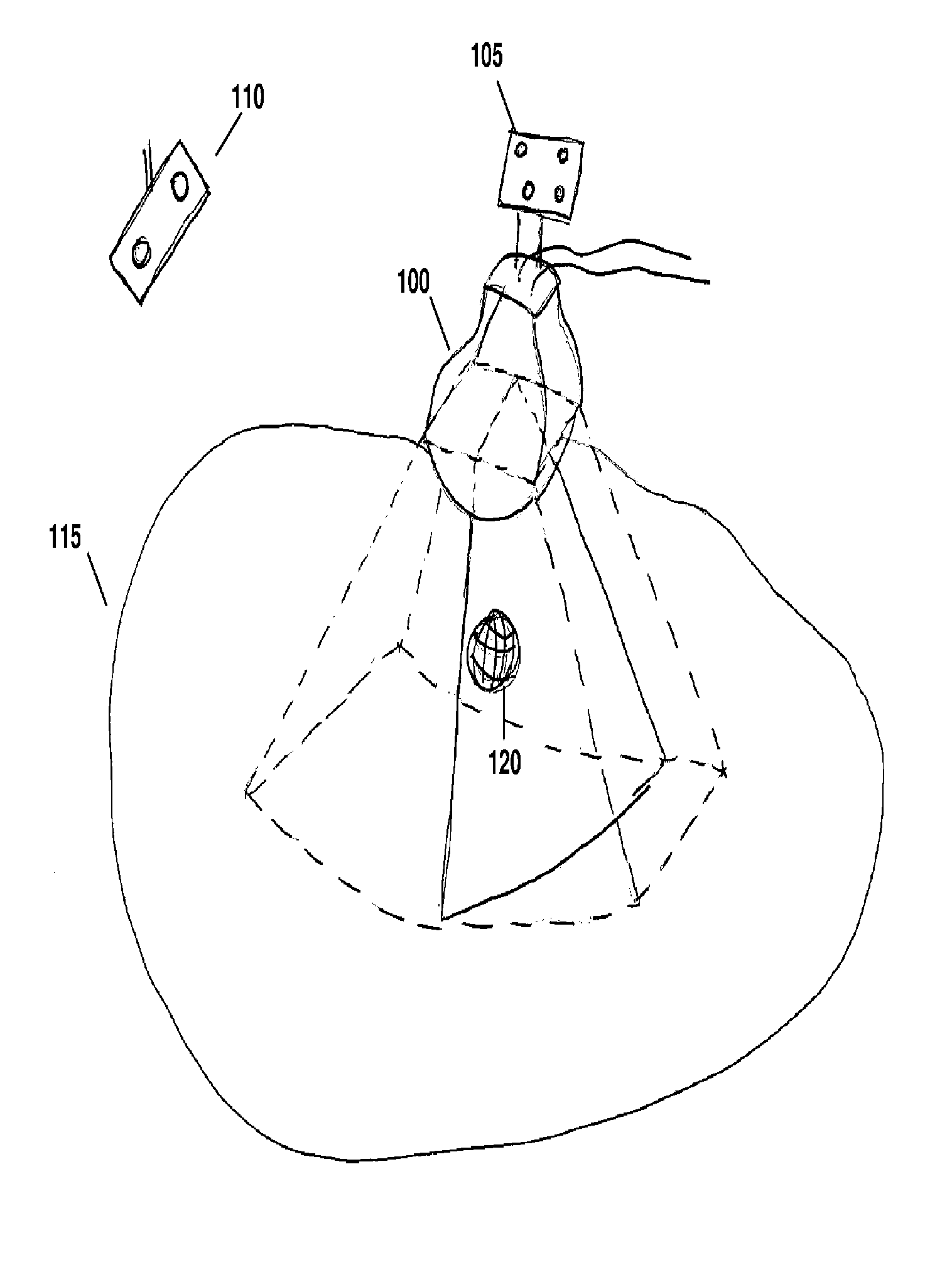

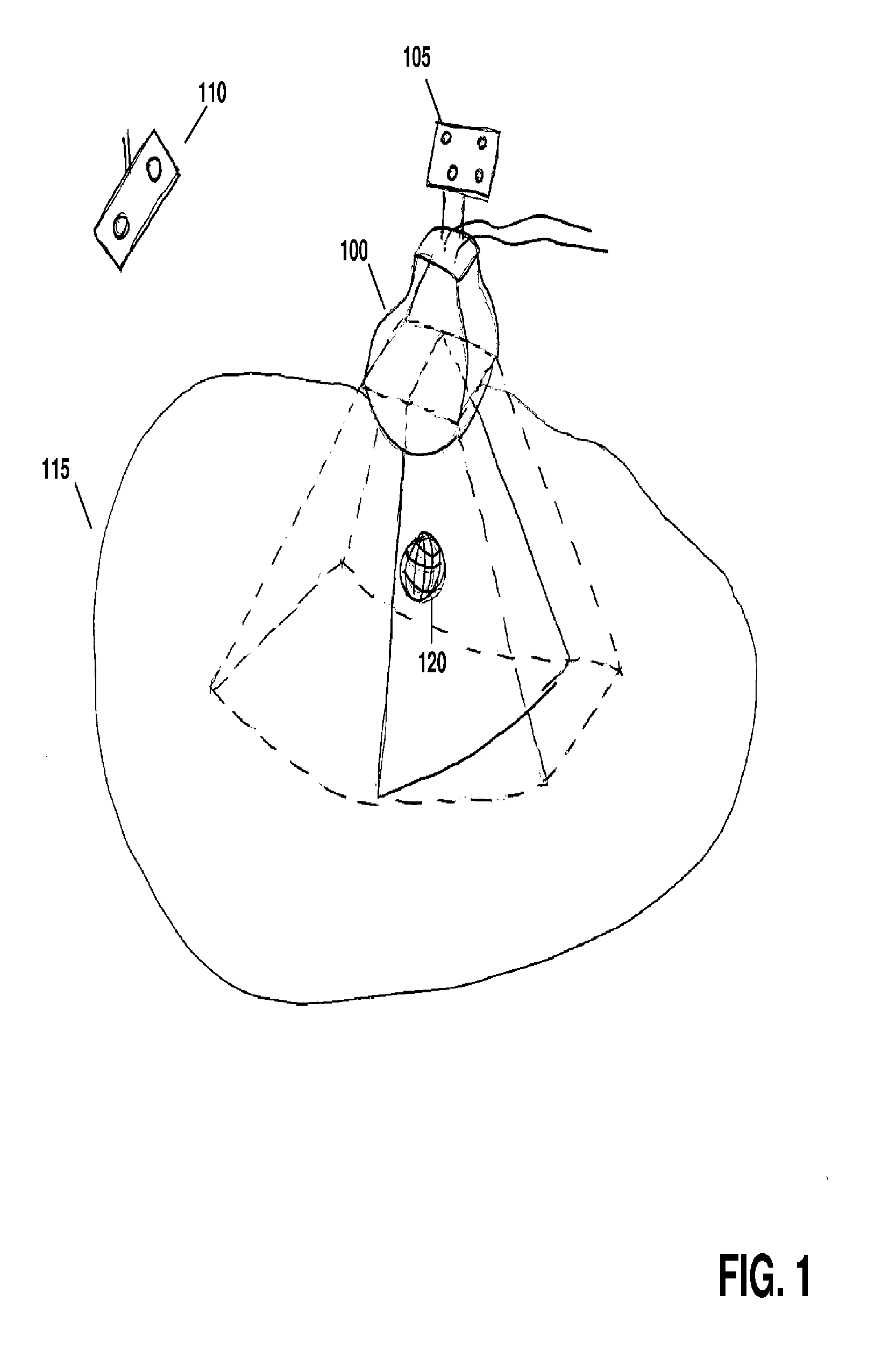

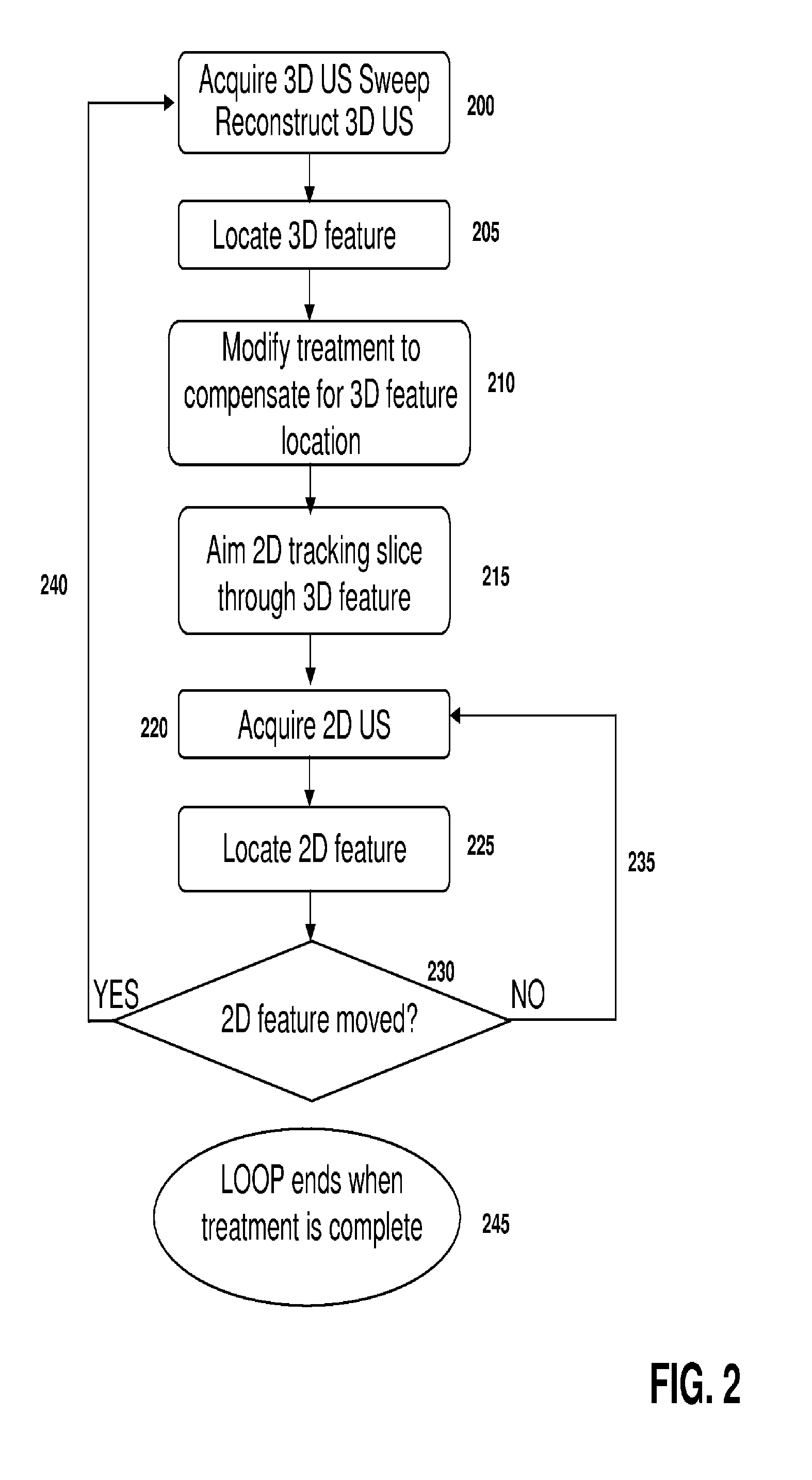

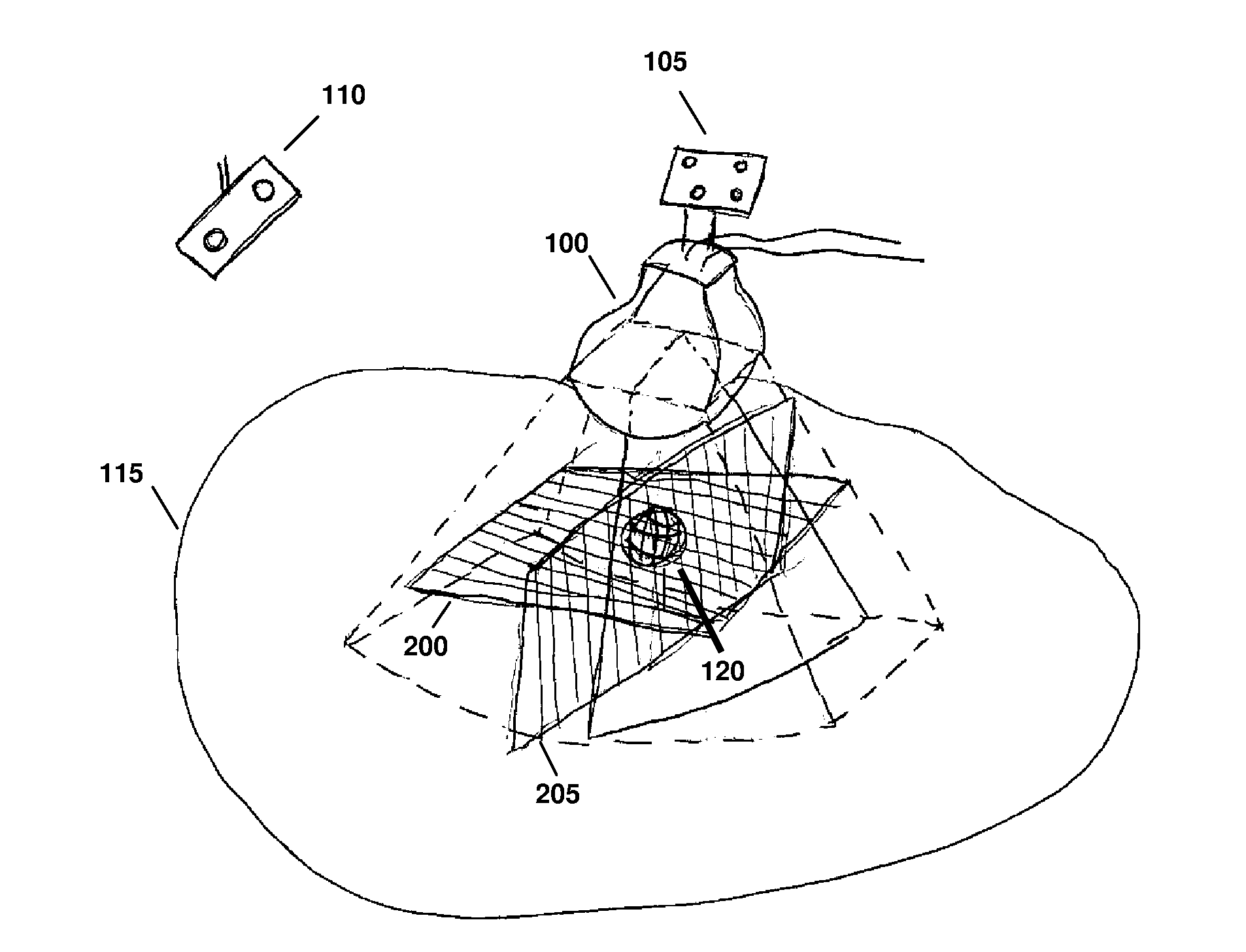

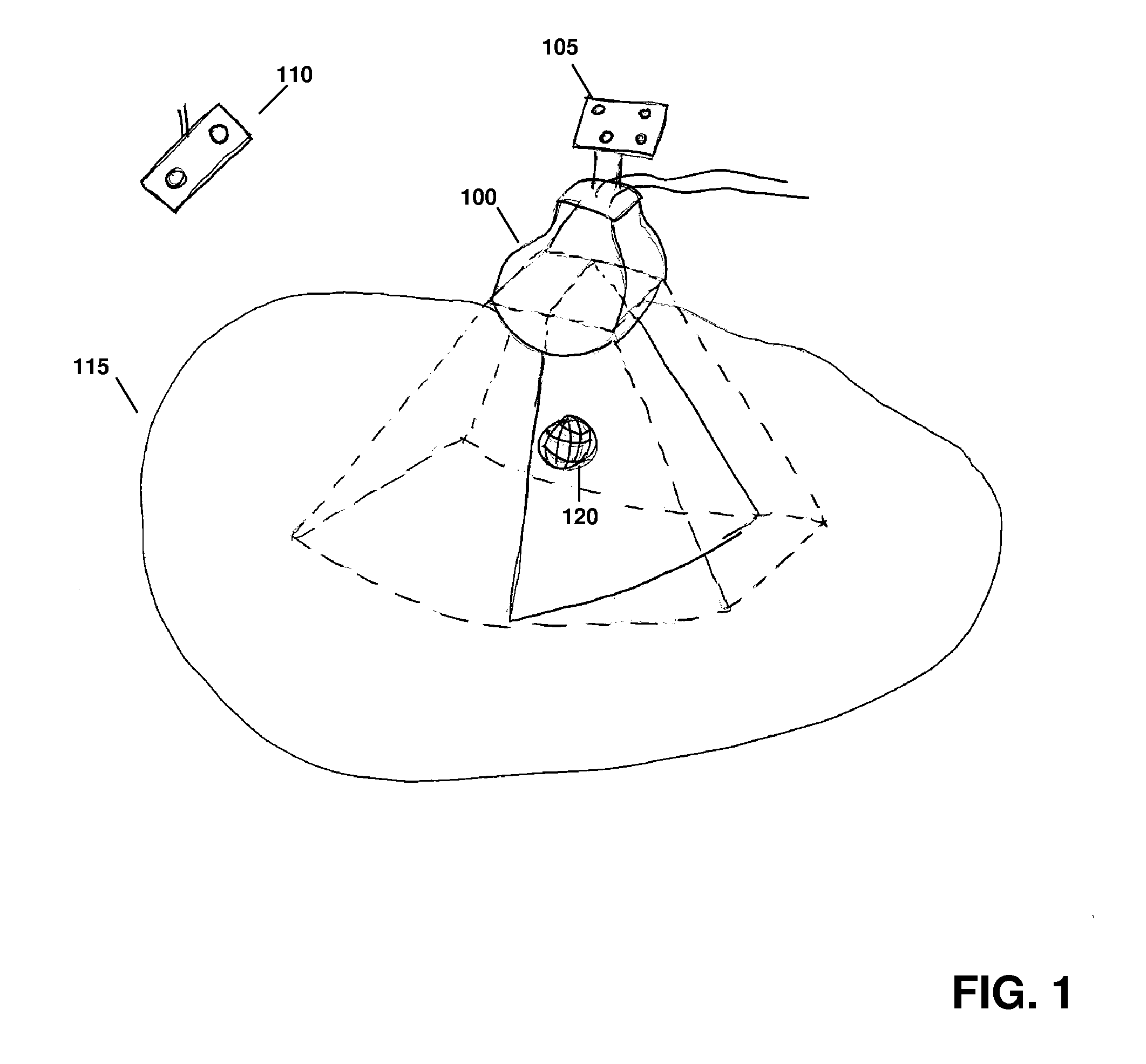

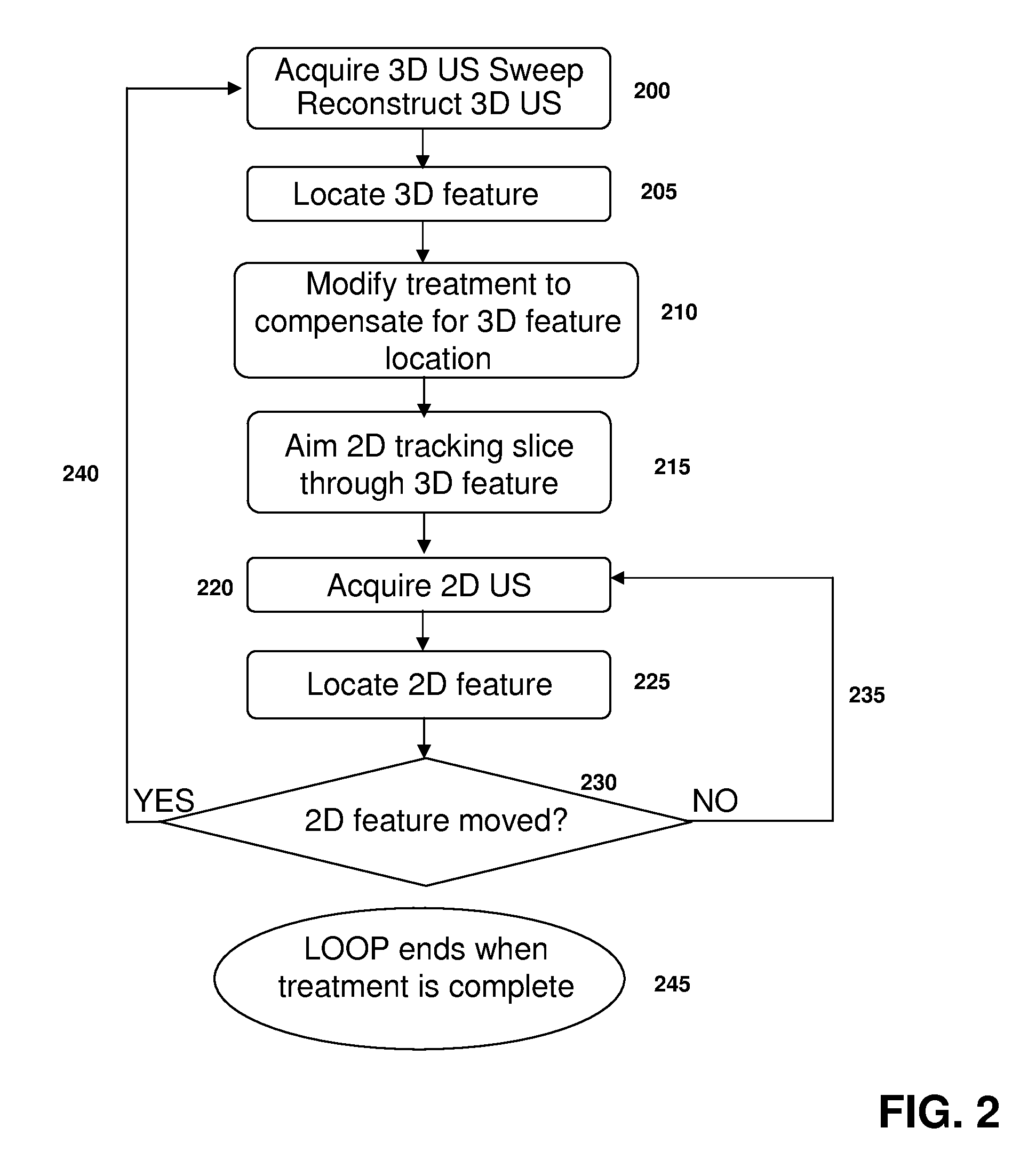

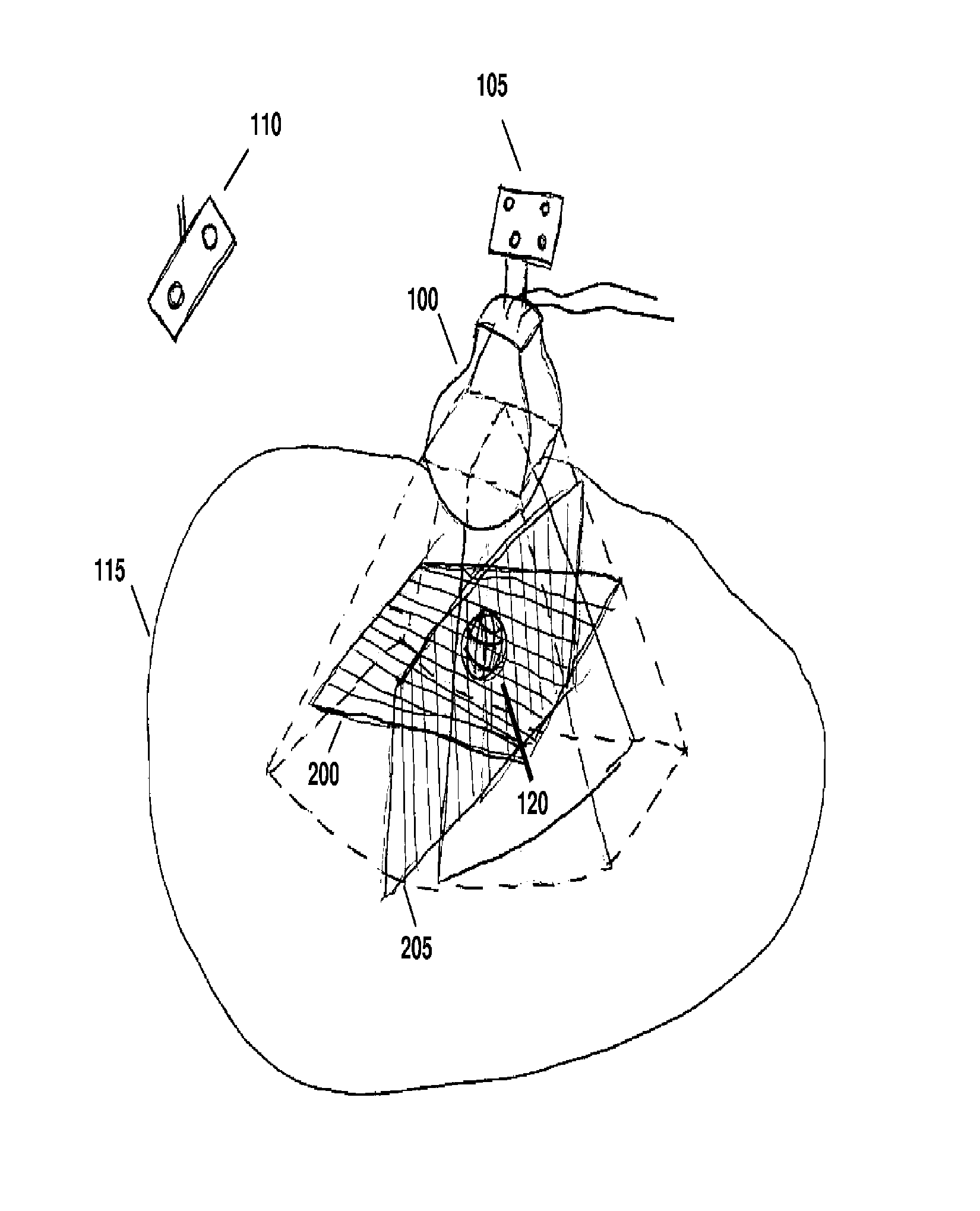

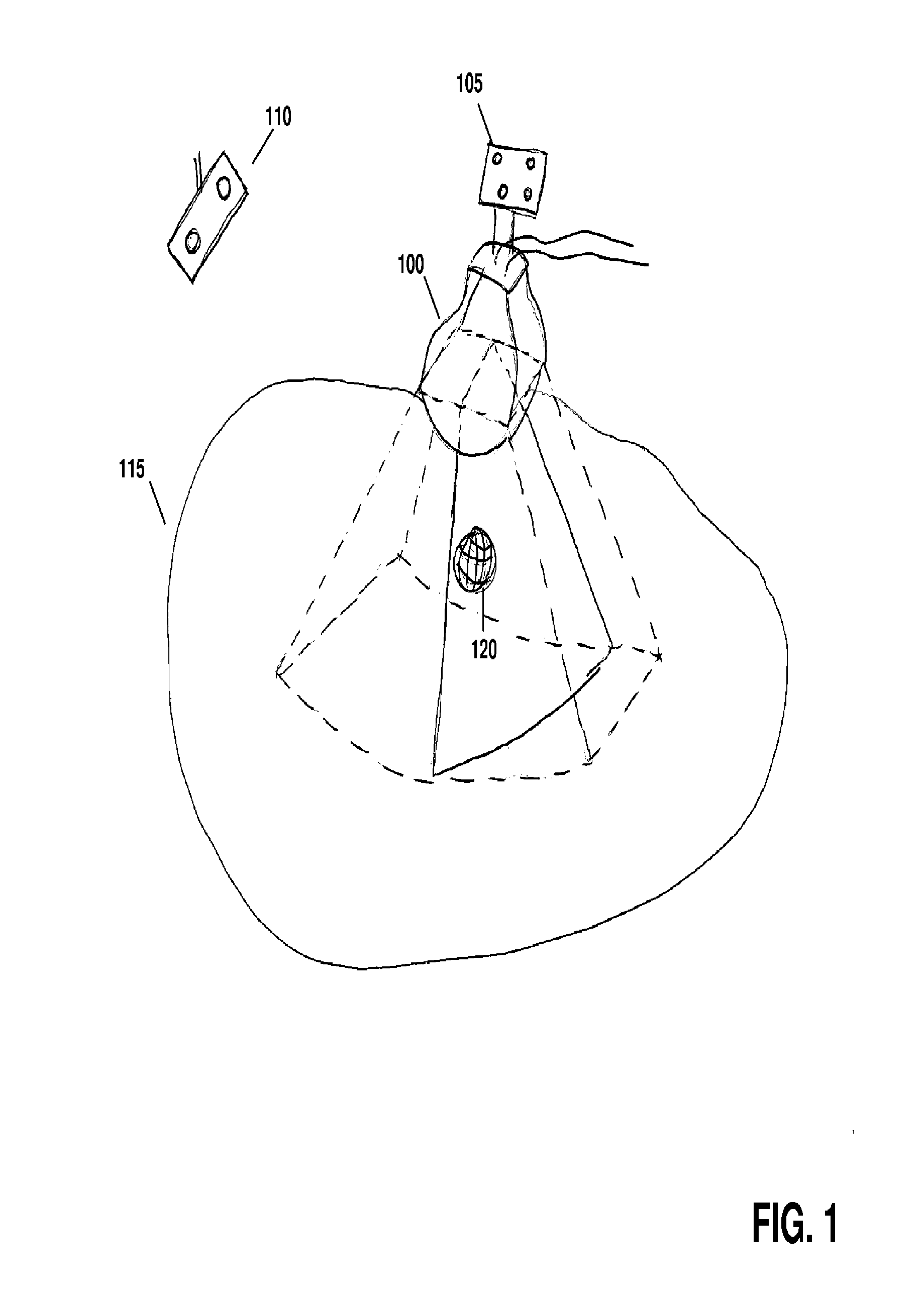

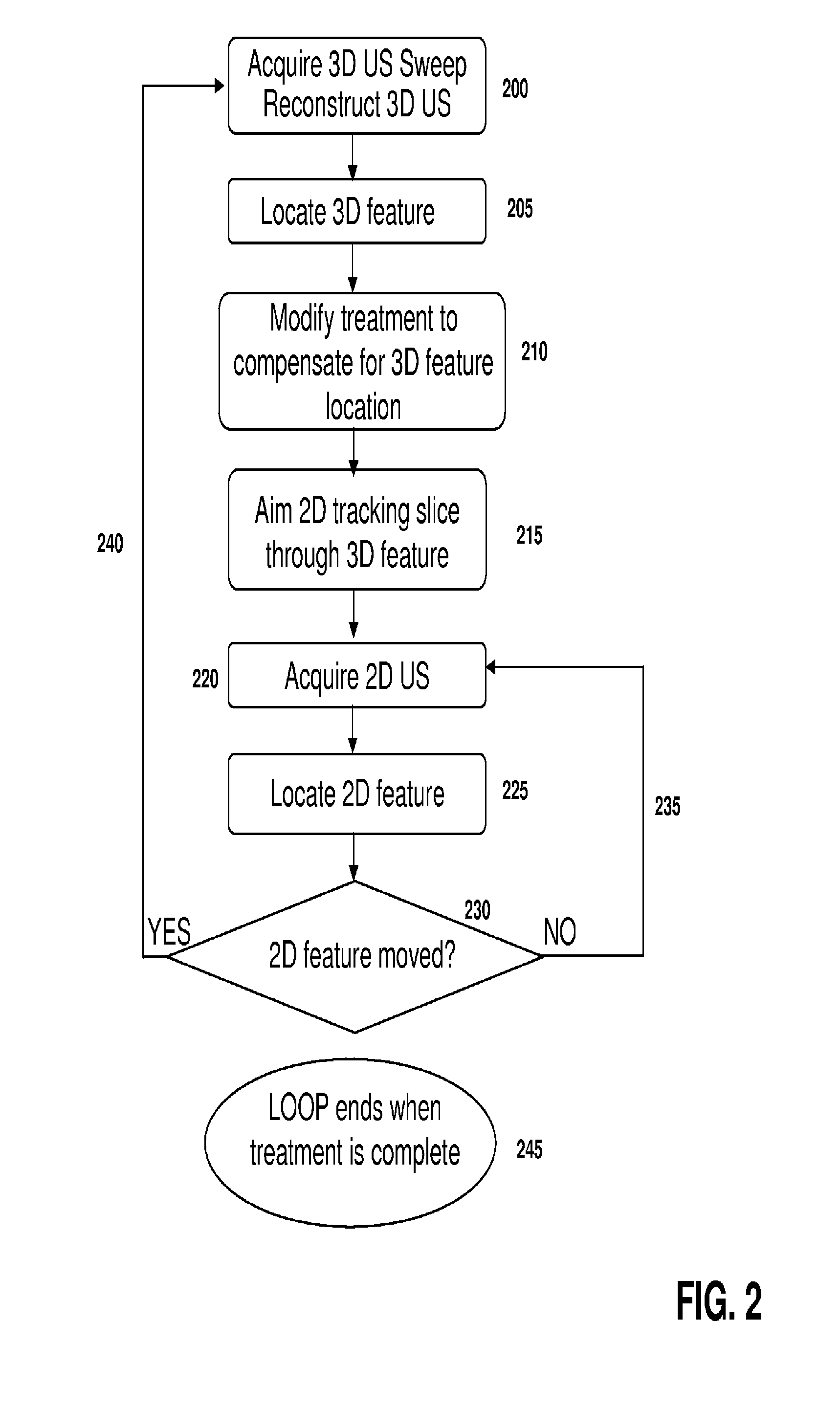

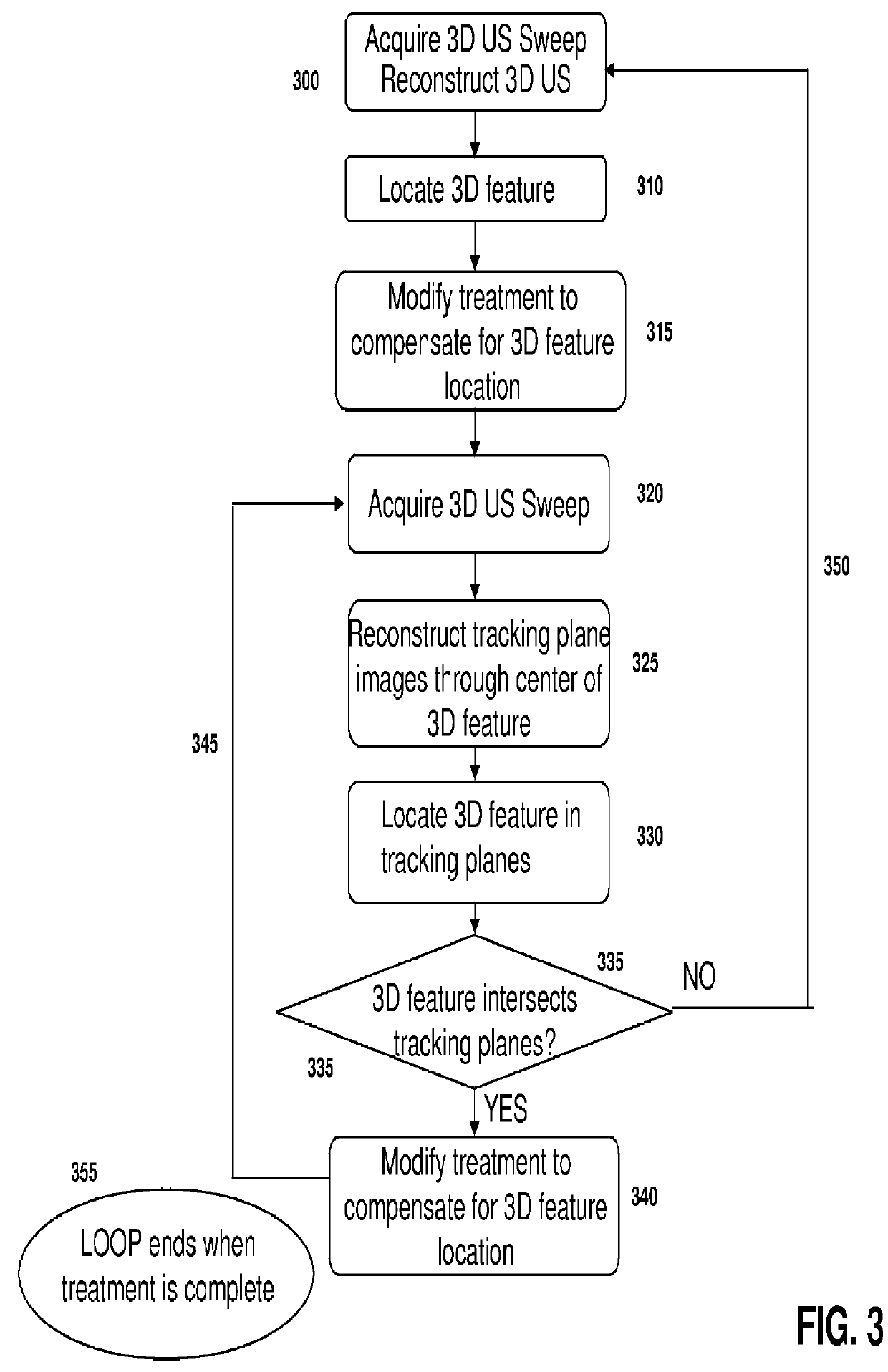

Various implementations of the invention provide techniques and supporting systems that facilitate real-time or near-real-time ultrasound tracking for the purpose of calculating changes in anatomical features during a medical procedure. More specifically, anatomical features within a patient undergoing a medical procedure are tracked by obtaining temporally-distinct three dimensional ultrasound images that include the feature of interest and obtaining a targeted subset of ultrasound images focused on the feature. Based on the targeted subset of ultrasound images, a displacement of the feature is determined and image parameters used to obtain the targeted subset of ultrasound images are adjusted based on the displacement. This results in a time-based sequence of three dimensional images and targeted ultrasound images of the feature that identify changes in the position, size, location, and / or shape of the feature.

Owner:ELEKTA AB

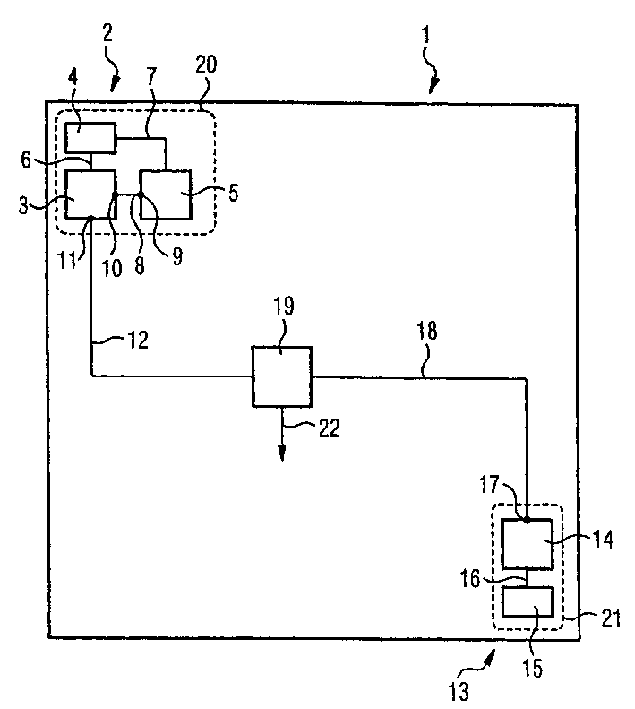

Feature Tracking Using Ultrasound

InactiveUS20110172526A1Reduce the burden onGood periodicityImage enhancementImage analysisSupporting systemSonification

Various implementations of the invention provide techniques and supporting systems that facilitate real-time or near-real-time ultrasound tracking for the purpose of calculating changes in anatomical features during a medical procedure. More specifically, anatomical features within a patient undergoing a medical procedure are tracked by obtaining temporally-distinct three dimensional ultrasound images that include the feature of interest and obtaining a targeted subset of ultrasound images focused on the feature. Based on the targeted subset of ultrasound images, a displacement of the feature is determined and image parameters used to obtain the targeted subset of ultrasound images are adjusted based on the displacement. This results in a time-based sequence of three dimensional images and targeted ultrasound images of the feature that identify changes in the position, size, location, and / or shape of the feature.

Owner:ELEKTA AB

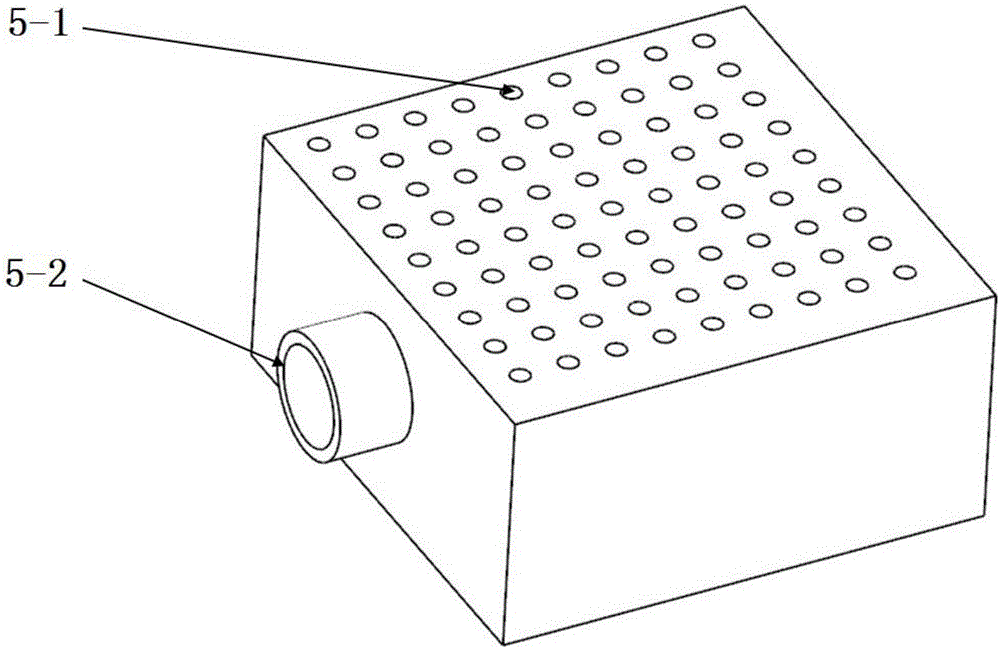

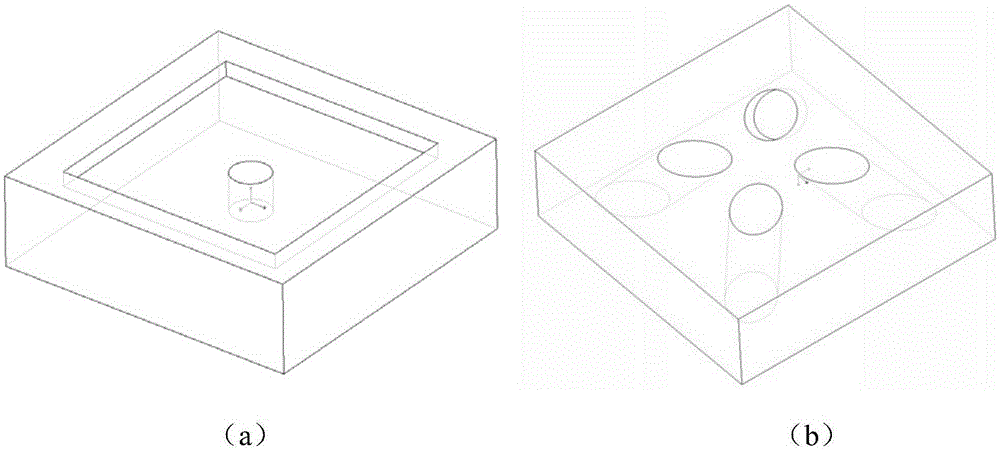

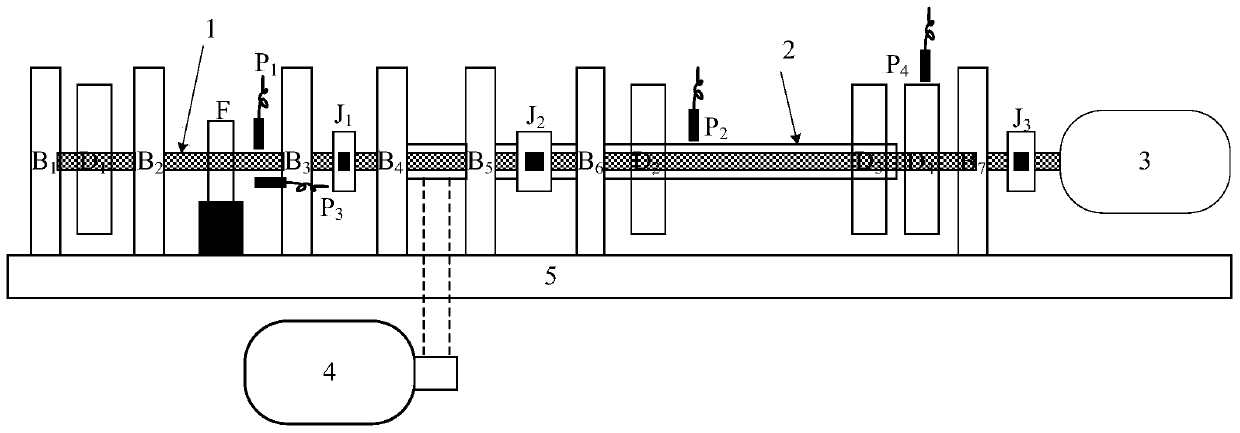

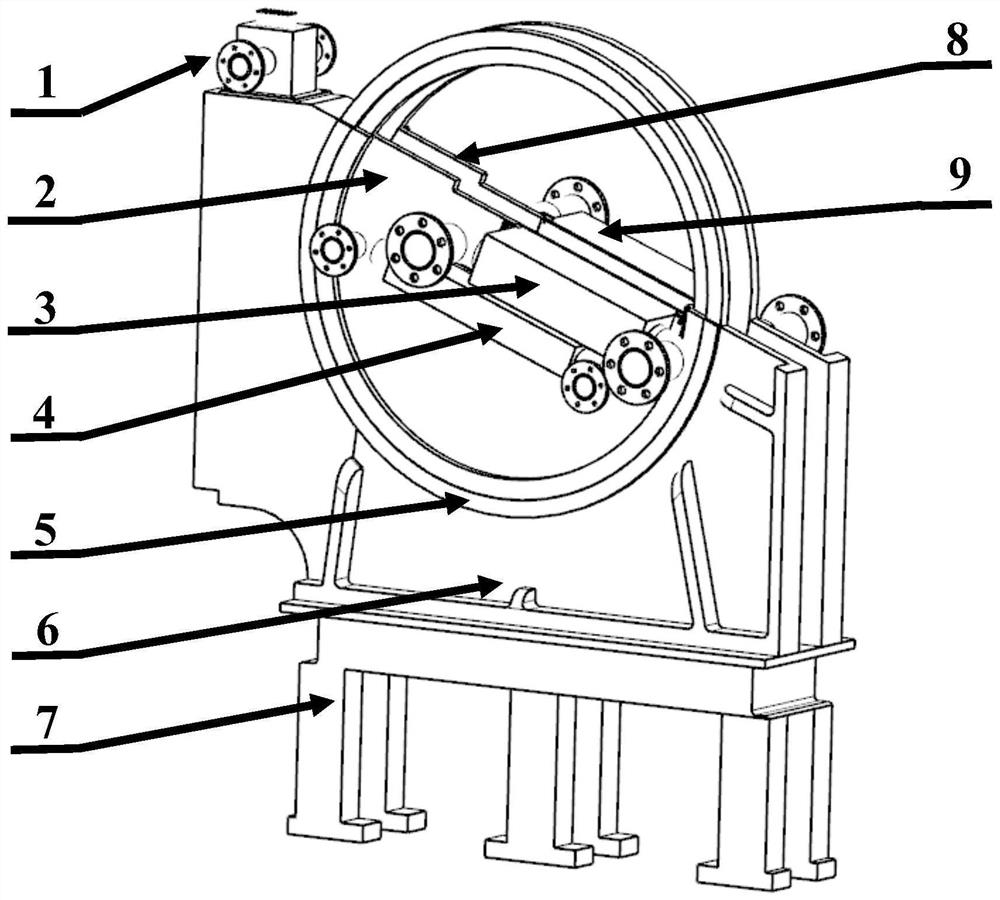

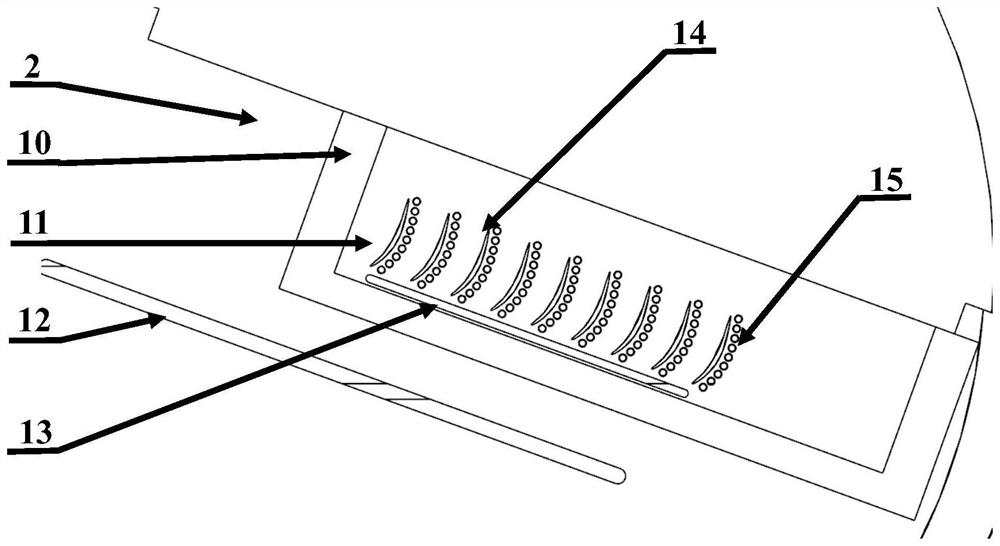

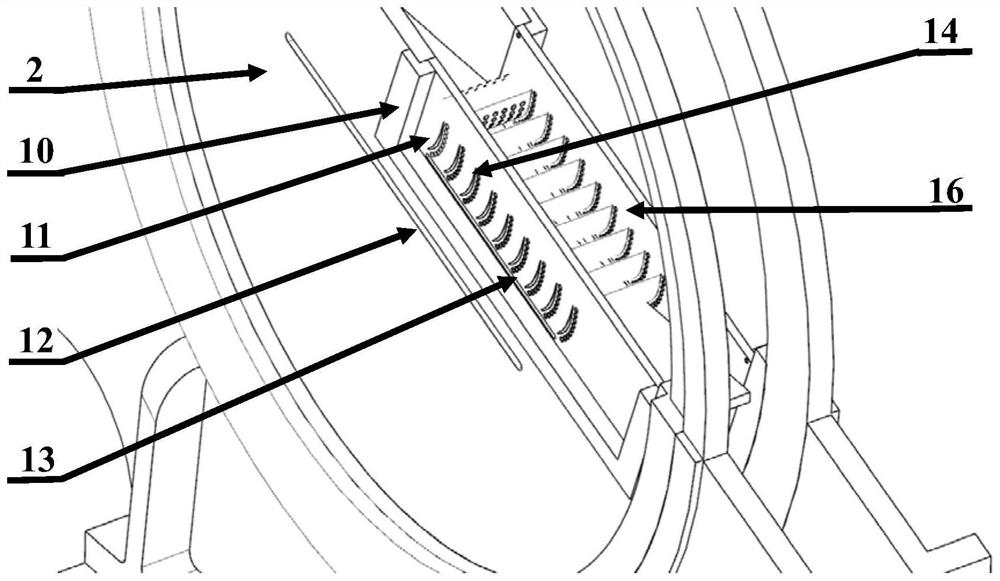

Gas compressor plane cascade experimental system with suction baffle structure

ActiveCN106640619AShort maintenance periodGood periodicityPump testingPump controlGas compressorVacuum pump

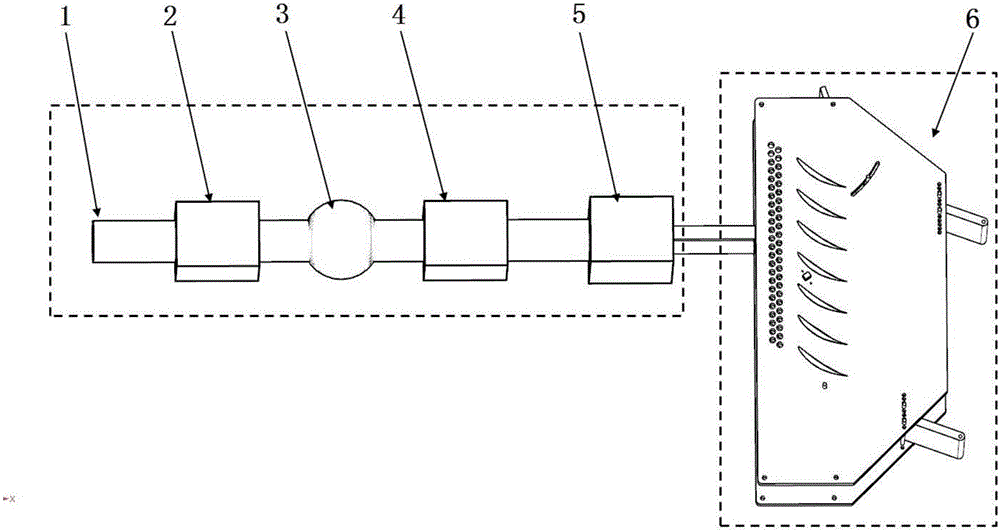

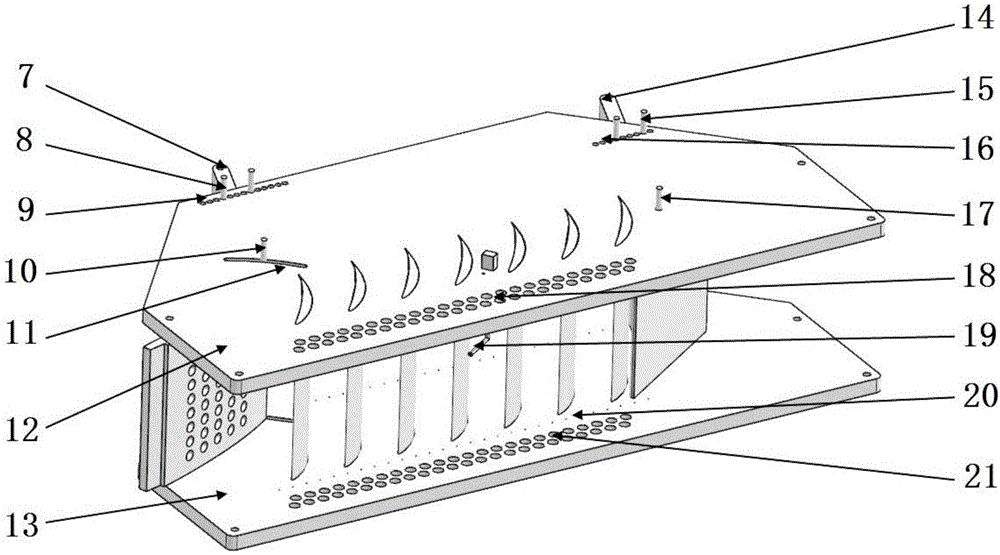

The invention provides a gas compressor plane cascade experimental system with a suction baffle structure. The gas compressor plane cascade experimental system comprises a suction device and a plane cascade experimental device. The plane cascade experimental device comprises a left end plate, a right end plate, an upper baffle, a plurality of experimental blades and a lower baffle, wherein the upper baffle is arranged between the left end plate and the right end plate, and the multiple experimental blades are distributed at intervals. The upper baffle and the lower baffle are connected between the left end plate and the right end plate through fixing shafts. The upper baffle is provided with suction holes. Left end plate suction holes are formed in the left end plate, and right end plate suction holes are formed in the right end plate. The suction holes are connected with a vacuum pump through a pipeline. A three-hole probe 1 is arranged between the left end plate and the right end plate. In the experimental process, the upper baffle and the lower baffle are adjusted so that a cascade can be good in periodicity, the boundary layer of incoming flow is sucked through the left end plate suction holes and the right end plate suction holes, the influence area of the boundary layer is reduced, and uniform incoming flow is achieved. The gas compressor plane cascade experimental system with the suction baffle structure is an effective path for exploring improvement of the performance of a gas compressor, the influence of the boundary layer of the incoming flow is reduced, and meanwhile, the periodicity of the plane cascade is improved.

Owner:DALIAN MARITIME UNIVERSITY

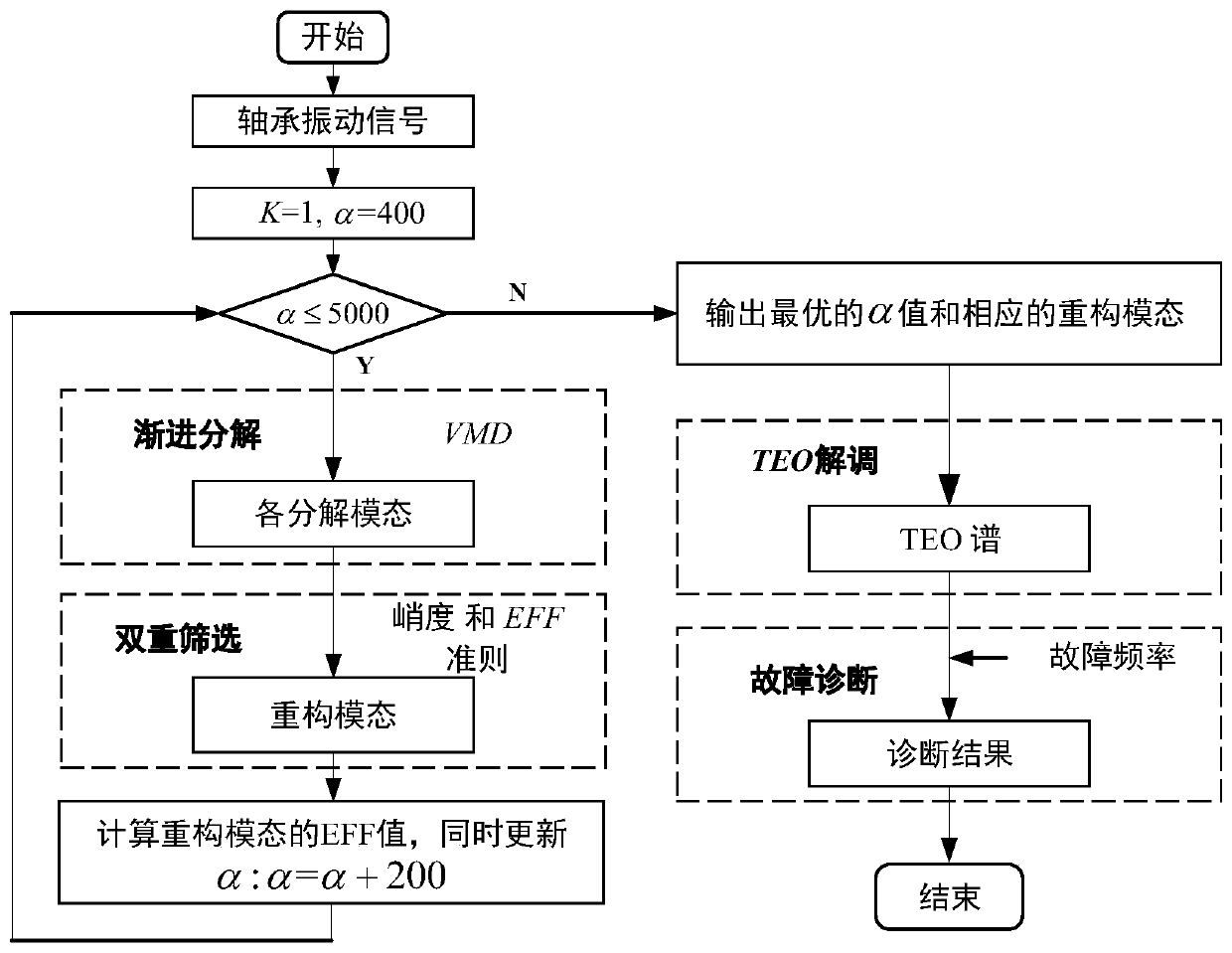

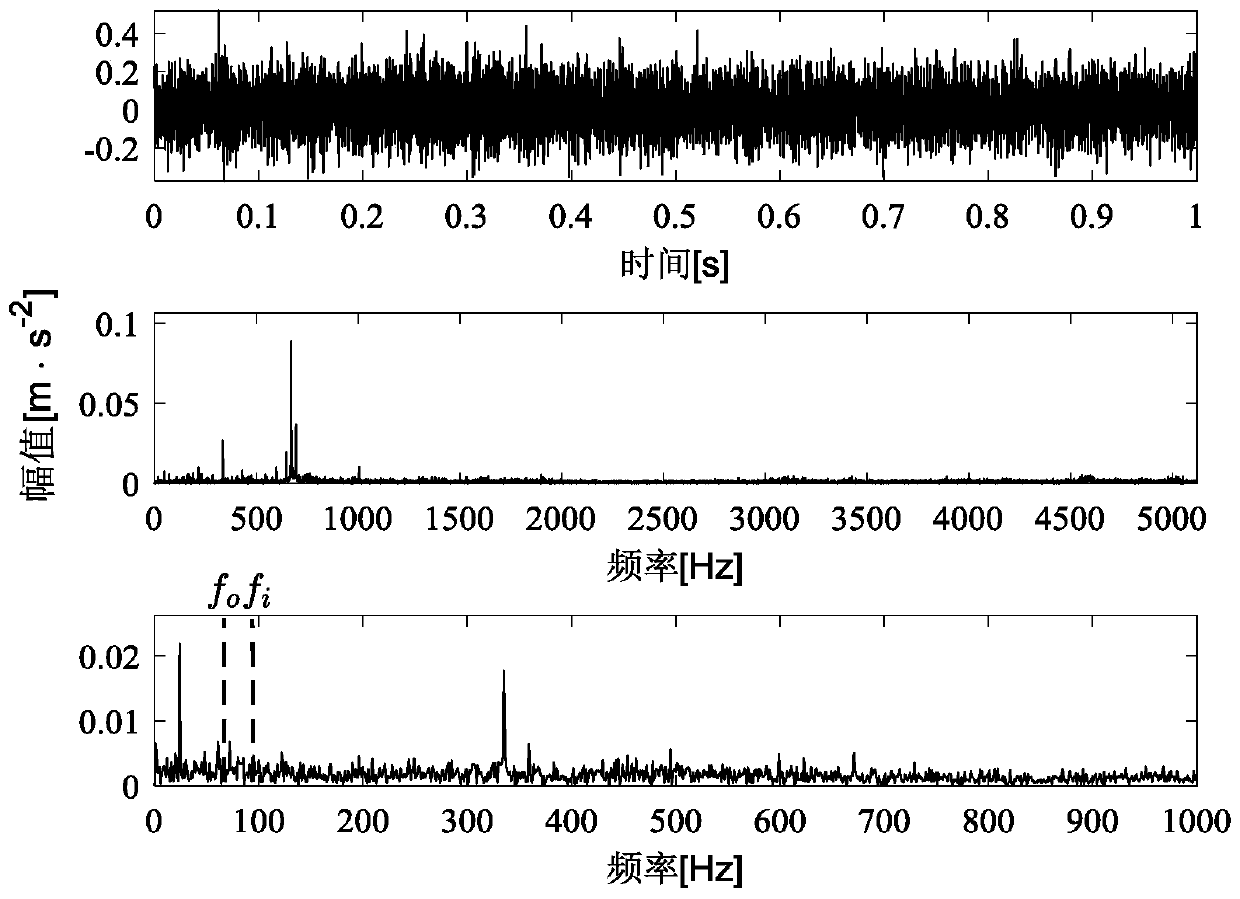

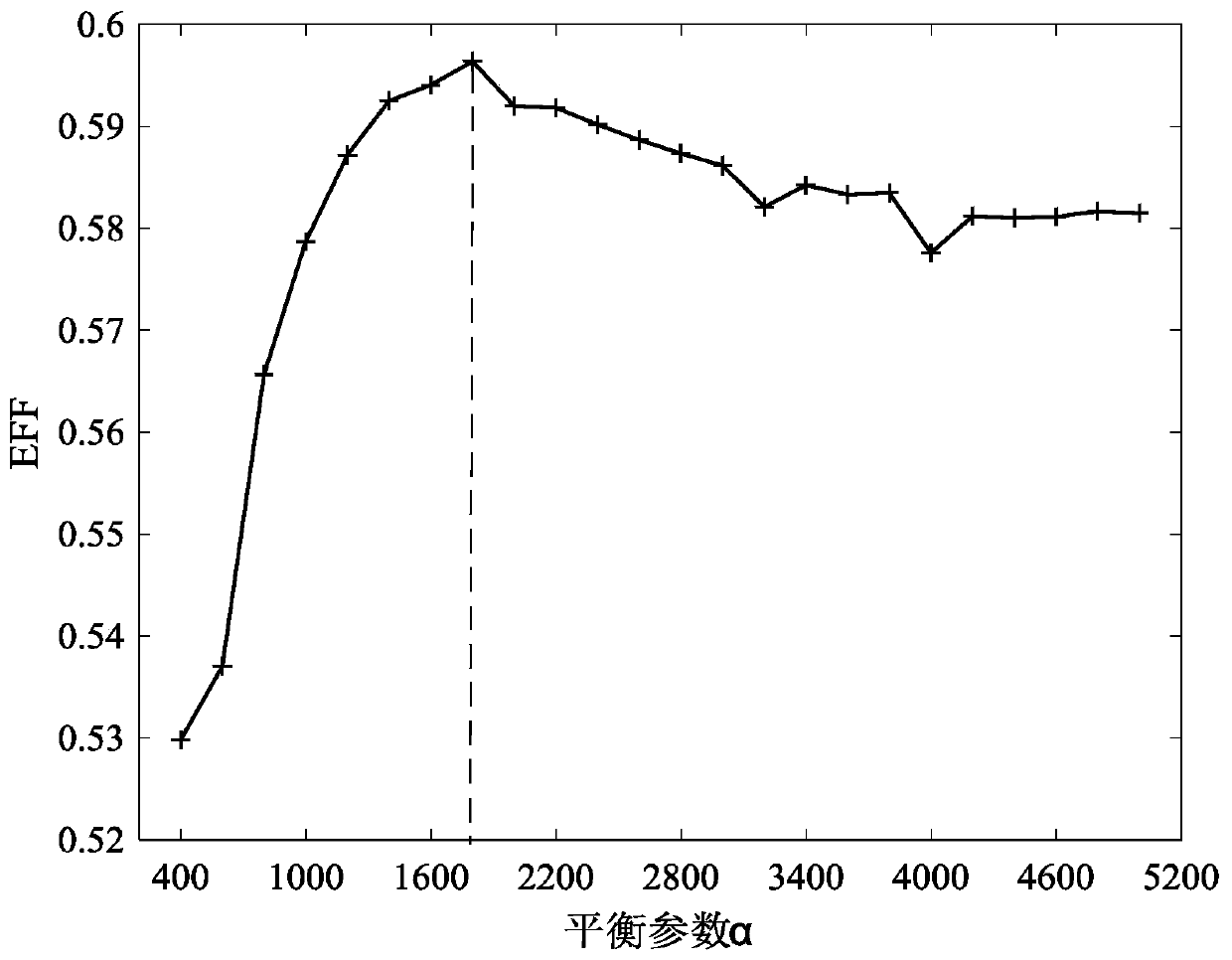

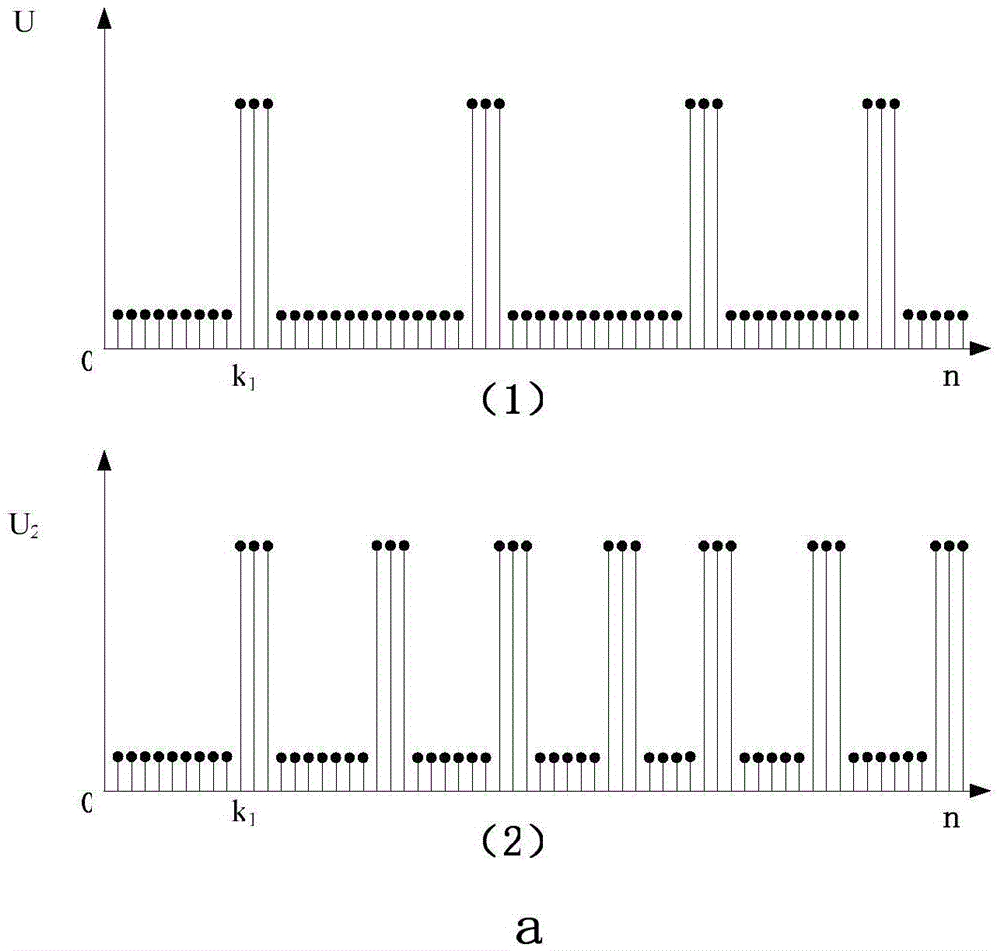

Rolling bearing early composite fault feature extraction method based on progressive VMD

PendingCN111178318AGood periodicityOvercoming the shortcoming of easy failure of fault diagnosisMachine part testingCharacter and pattern recognitionAlgorithmFeature extraction

The invention discloses a rolling bearing early composite fault feature extraction method based on progressive VMD. The method comprises the steps of 1, installing an acceleration sensor near a rolling bearing to collect vibration signals during bearing operation; 2, decomposing the acquired vibration signal by using a progressive VMD to obtain a series of decomposed modes; 3, screening the modesobtained after decomposition by using a dual screening criterion based on kurtosis and an energy fluctuation factor to determine a fault mode, and realizing reconstruction of the fault mode; 4, initializing the range and the search step length of the balance parameter alpha, repeating the step 2 and the step 3 for different alpha values, calculating the EFF value of the reconstruction mode, the maximum EFF value corresponding to the optimal alpha value, and then determining the reconstruction mode under the optimal alpha value; and 5, demodulating the reconstructed mode by using TEO to obtaina TEO spectrum, and obtaining a diagnosis result in combination with the bearing related fault characteristic frequency. On the basis of an EEMD recursion idea, the invention provides a progressive decomposition VMD method.

Owner:SOUTHEAST UNIV

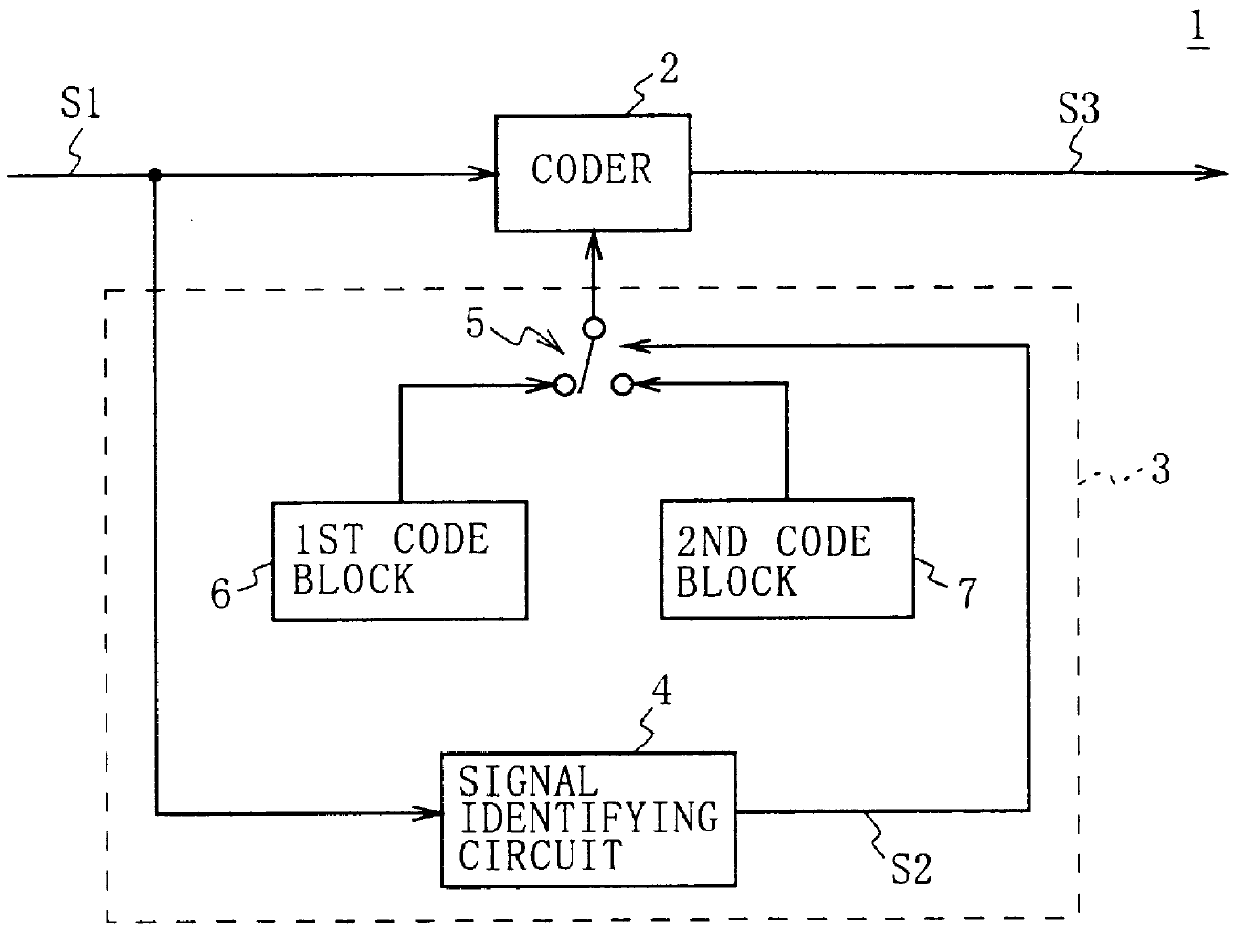

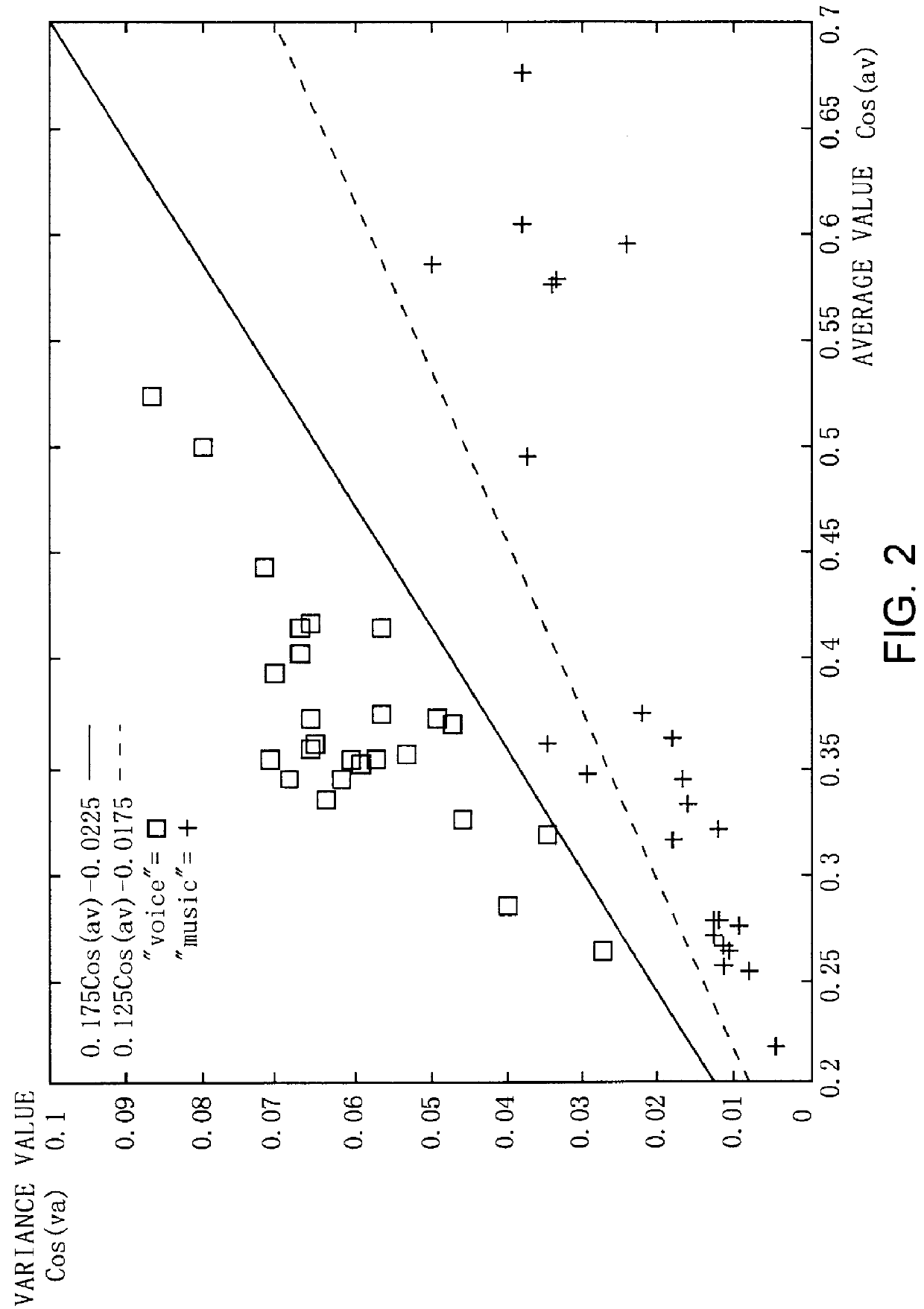

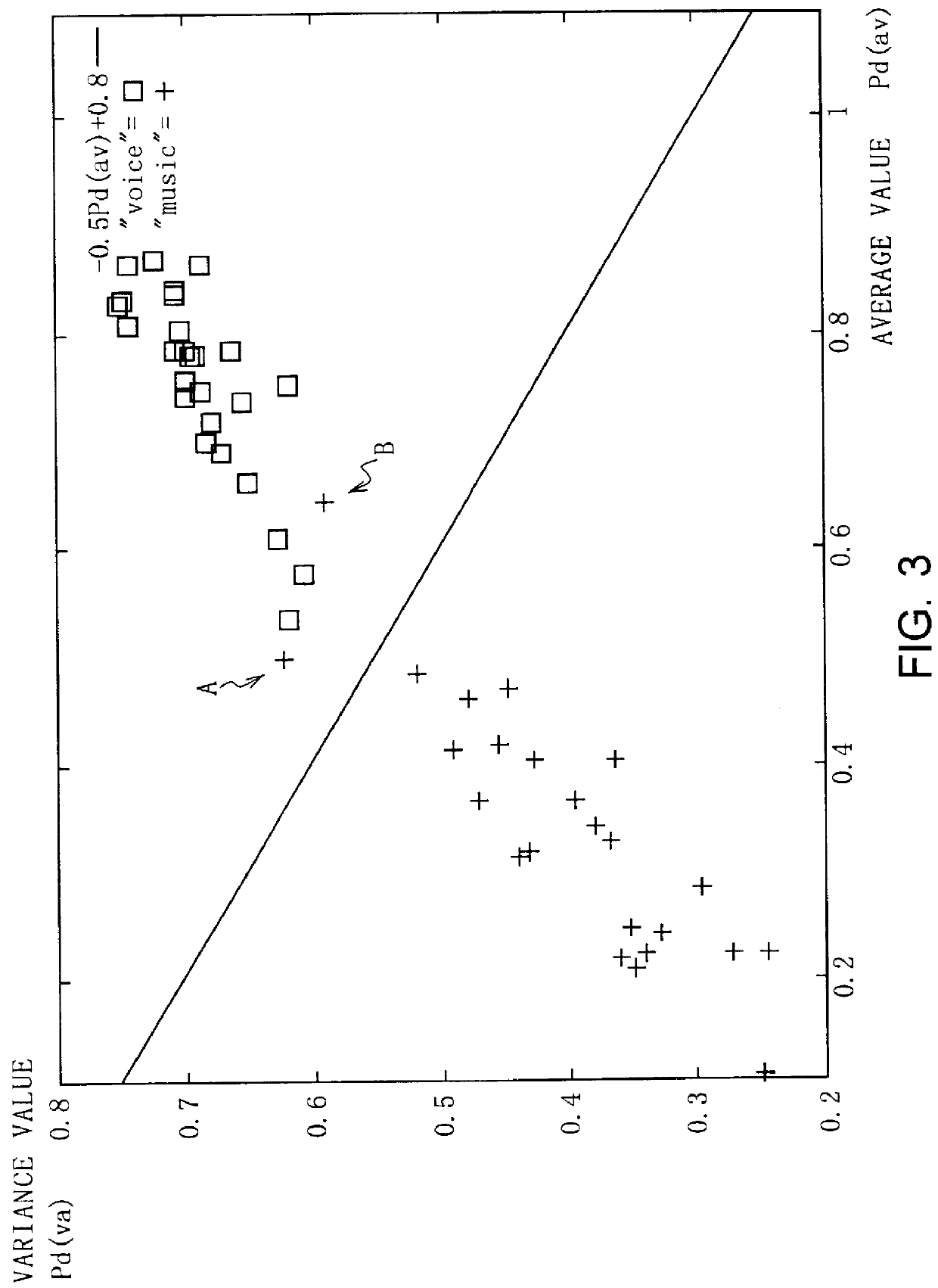

Signal identifying device, code book changing device, signal identifying method, and code book changing method

InactiveUS6167372AGood periodicityEasy to identifyCode conversionSpeech recognitionCode bookComputer science

A signal identifying device which can identify an input signal easily includes a pitch extracting (4Y) for extracting a pitch component of the input signal (S1), and energy calculating unit (4X) for calculating an energy component of the input signal, and identifying unit (4Z) for executing a predetermined operation to the pitch component and the energy component and for identifying whether the input signal is a voice signal or music signal. The voice signal generally has the characteristics evident in energy, and has strong periodicity (i.e., pitch component) comparing compared to the music signal.

Owner:SONY CORP

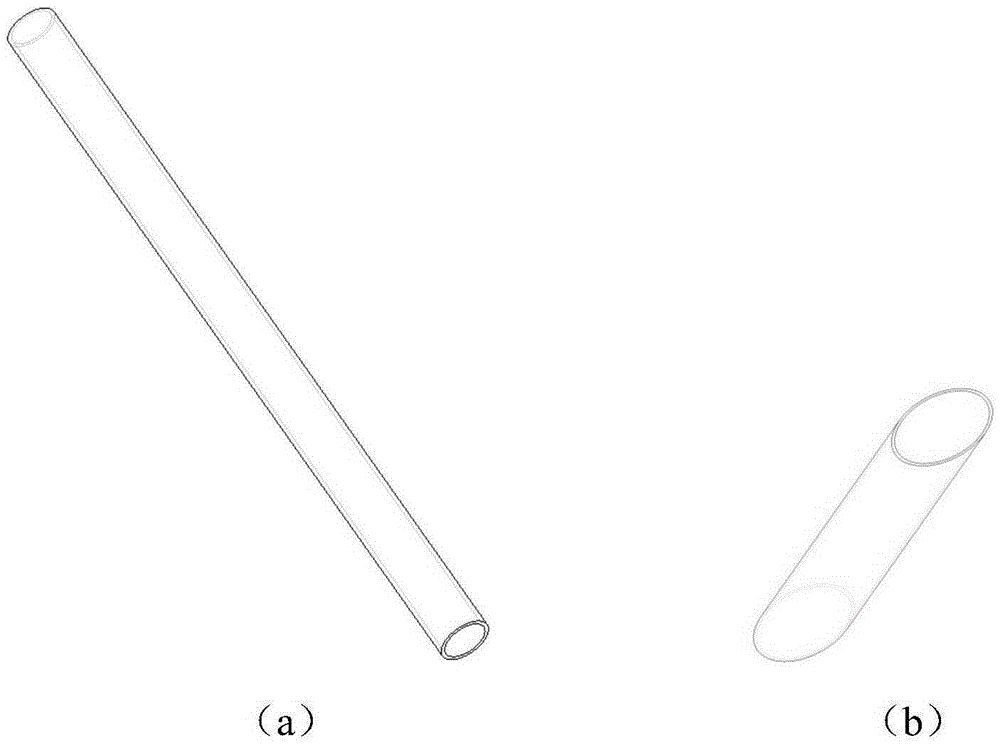

Method for preparing pyramid-shaped composite three-dimensional lattice sandwich structure

The invention discloses a method for preparing a pyramid-shaped composite three-dimensional lattice sandwich structure. The method for preparing the pyramid-shaped composite three-dimensional lattice sandwich structure comprises the steps that 1, a base provided with five tenons is prepared; 2, a hollow sandwich pipe is prepared; 3, lattice skin is prepared; 4, the base and the sandwich pipe are assembled into a lattice core of a sandwich structure; and 5, the skin and the lattice core are assembled into the lattice sandwich structure. The method for preparing the pyramid-shaped composite three-dimensional lattice sandwich structure has the advantages that the automation degree is high, and the production cycle is short; in addition, the pyramid-shaped composite three-dimensional lattice sandwich structure prepared through the method is high in structural strength and complete in mechanical property; the periodicity of pyramid-shaped lattice cell elements is good, and the application range is wide.

Owner:PEKING UNIV

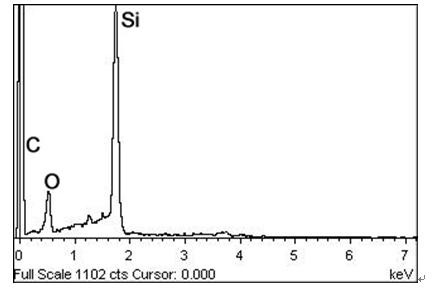

Graphite particle, carbon-graphite composite particle and their production process

ActiveCN101309859ADo not harm diffusionExcellent charge and discharge characteristicsGraphiteSecondary cellsCarbon layerElectrical battery

Disclosed are a graphite particle and a carbon-graphite composite particle suitable for negative electrodes for lithium ion secondary batteries, and processes for producing those particles. Specifically disclosed is a graphite particle having an average particle diameter of 5-50 [mu]m, wherein one or more recesses having a depth of 0.1-10 [mu]m are formed in the surface. The graphite particle is produced by a process comprising a mixing step for mixing raw material graphite particles and recess-forming particles; a press molding step for obtaining a molded article by press-molding the mixture composed of the raw material graphite particles and the recess-forming particles; a pulverization step for pulverizing the molded article; and a separation step for separating and removing the recess-forming particles from the pulverized molded article. A carbon-graphite composite particle is produced by performing a thermal CVD process for coating the surface of the graphite particle with a carbon layer.

Owner:NIPPON POWER GRAPHITE CO LTD

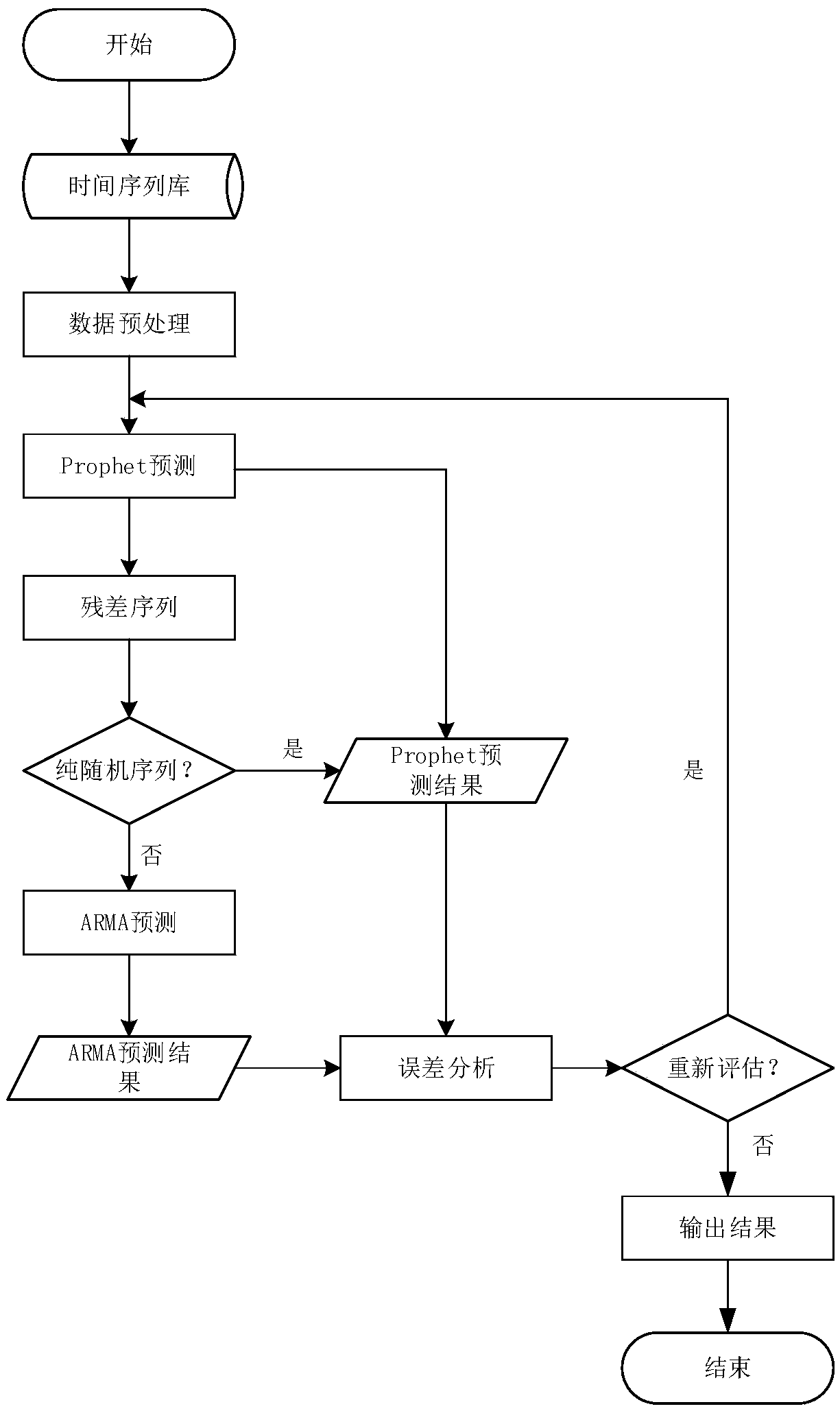

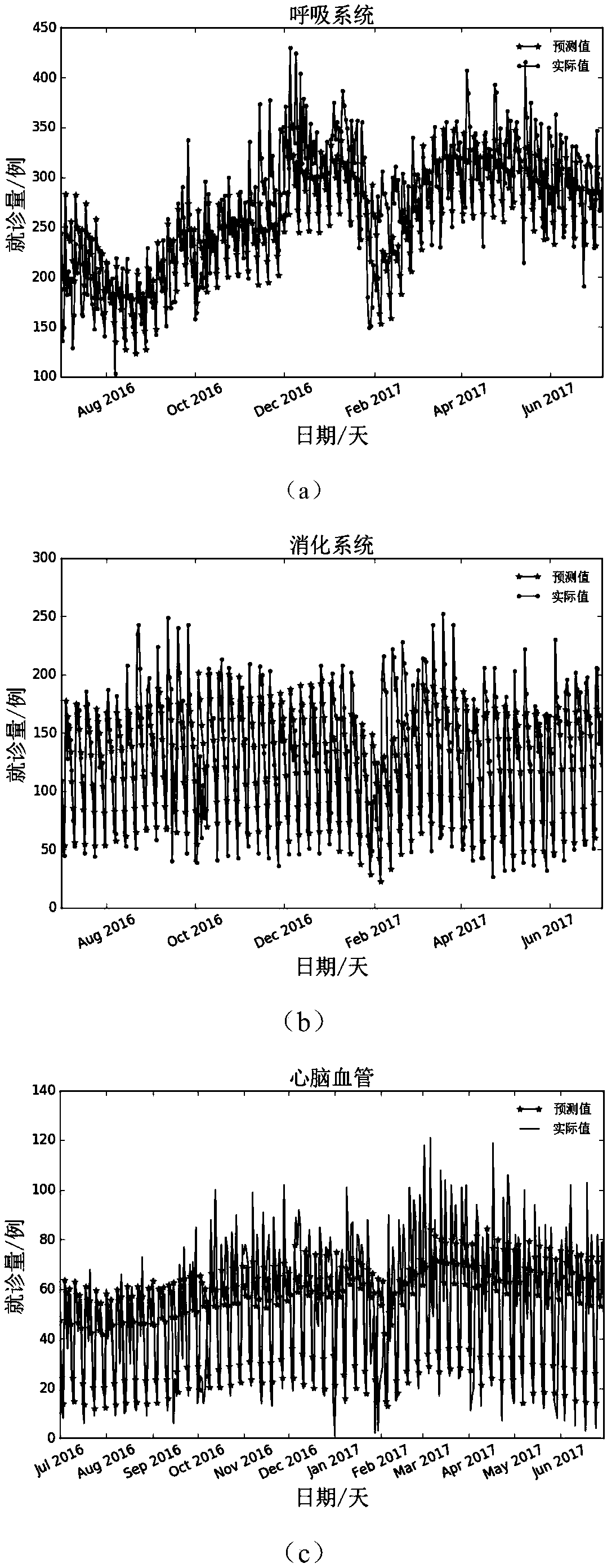

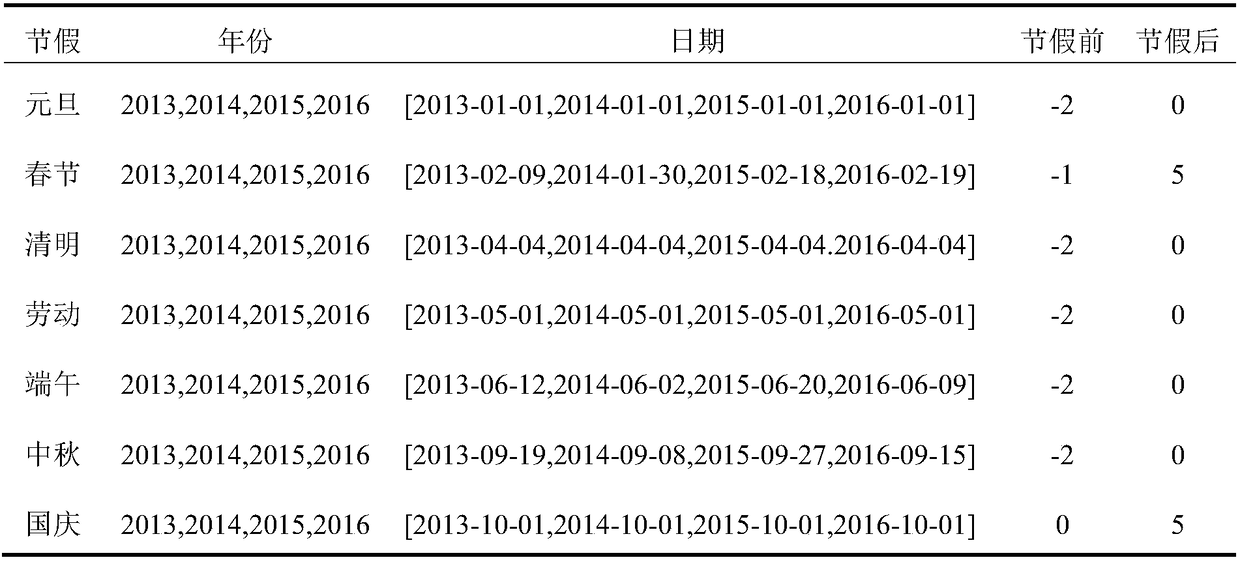

A Prophet-ARMA-based method for predicting outpatient visits in hospitals

ActiveCN109002904AGood periodicityMake up for forecast errorForecastingHealthcare resources and facilitiesPrediction methodsData mining

The invention discloses a Prophet-ARMA-based method for predicting outpatient visits in hospitals. The method comprises the following steps: 1, acquiring the outpatient data of the historical period adjacent to the period to be measured and generating the outpatient data set of each type of outpatient; 2, respectively inputting each outpatient data set into a Prophet model of each type of outpatient service to obtain first prediction data and fitting data; 3, calculating a residual sequence of each type of outpatient service; 4, respectively judging whether the residual sequence of each type of outpatient service is a pure random sequence, if not, inputting the residual sequence into the correspond ARMA model to obtain the second prediction data, and then executing the step 5; if yes, performing the step 6; 5, respectively adding the first prediction data and the second prediction data of the same type of outpatient clinics to obtain the prediction value of the amount of visit in the period to be tested; 6, taking the first prediction data as the prediction value of the attendance amount in the period to be measured. The invention combines Prophet and ARMA to improve the predictionaccuracy of the visiting quantity.

Owner:CENT SOUTH UNIV

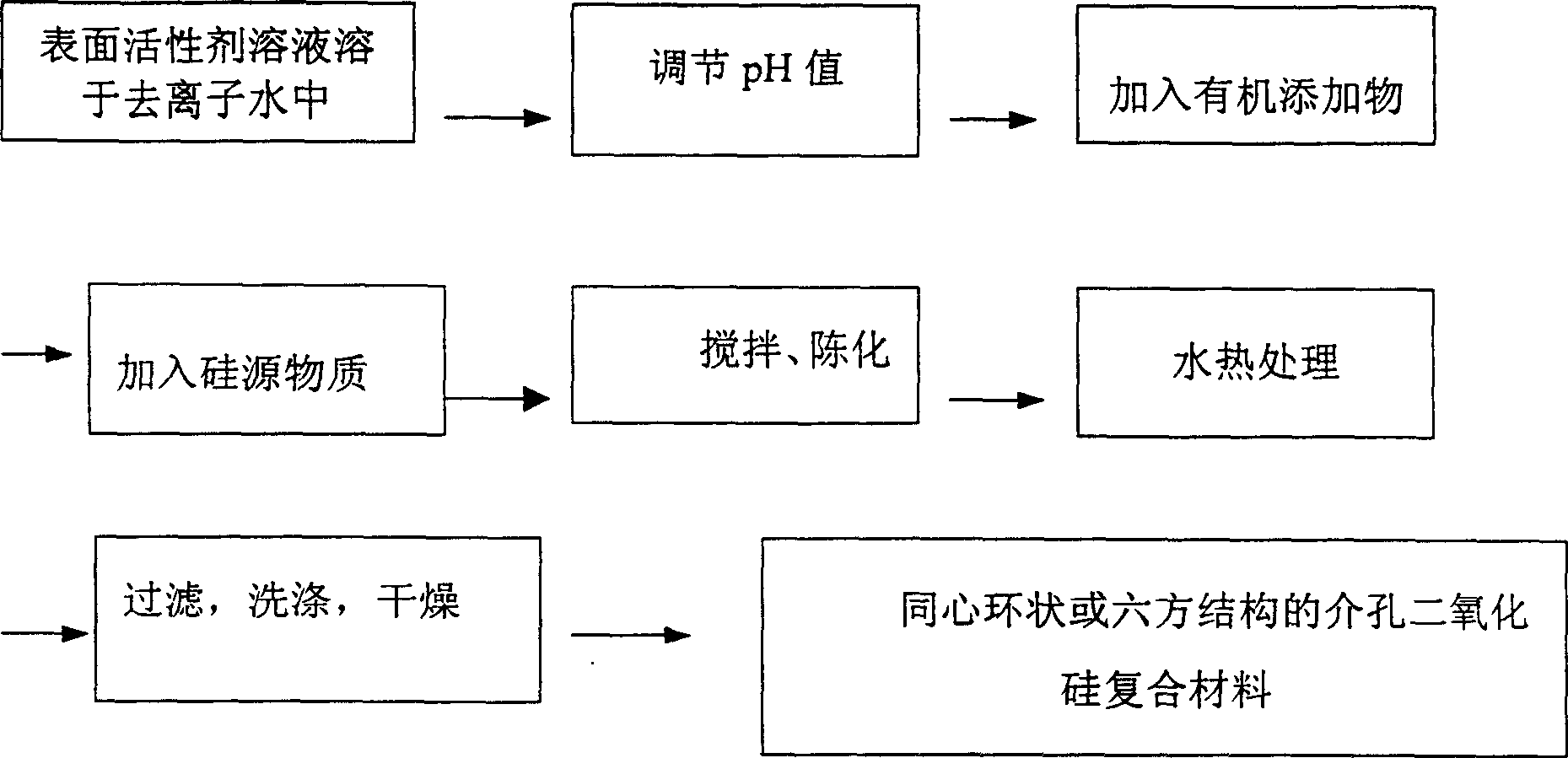

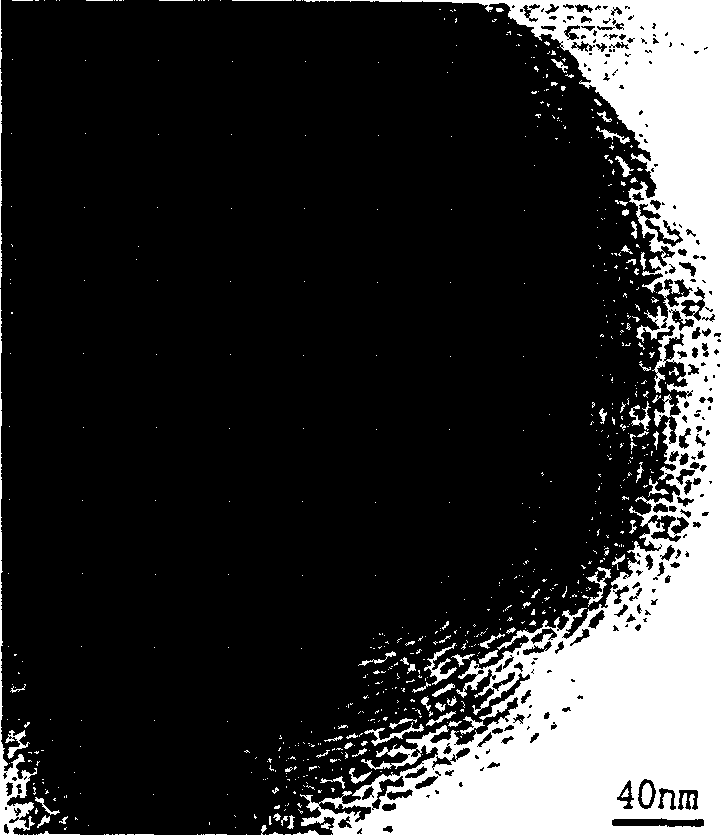

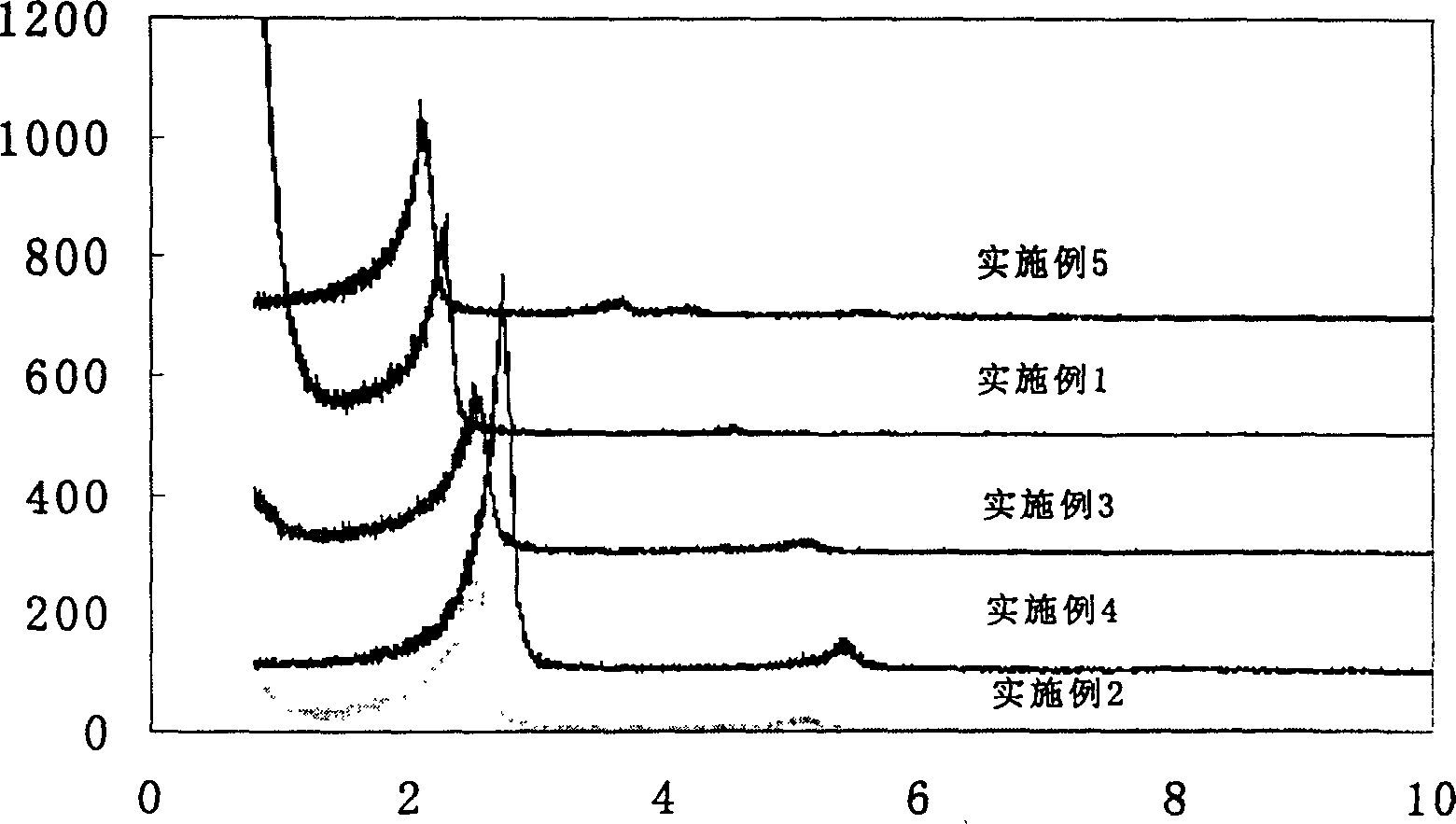

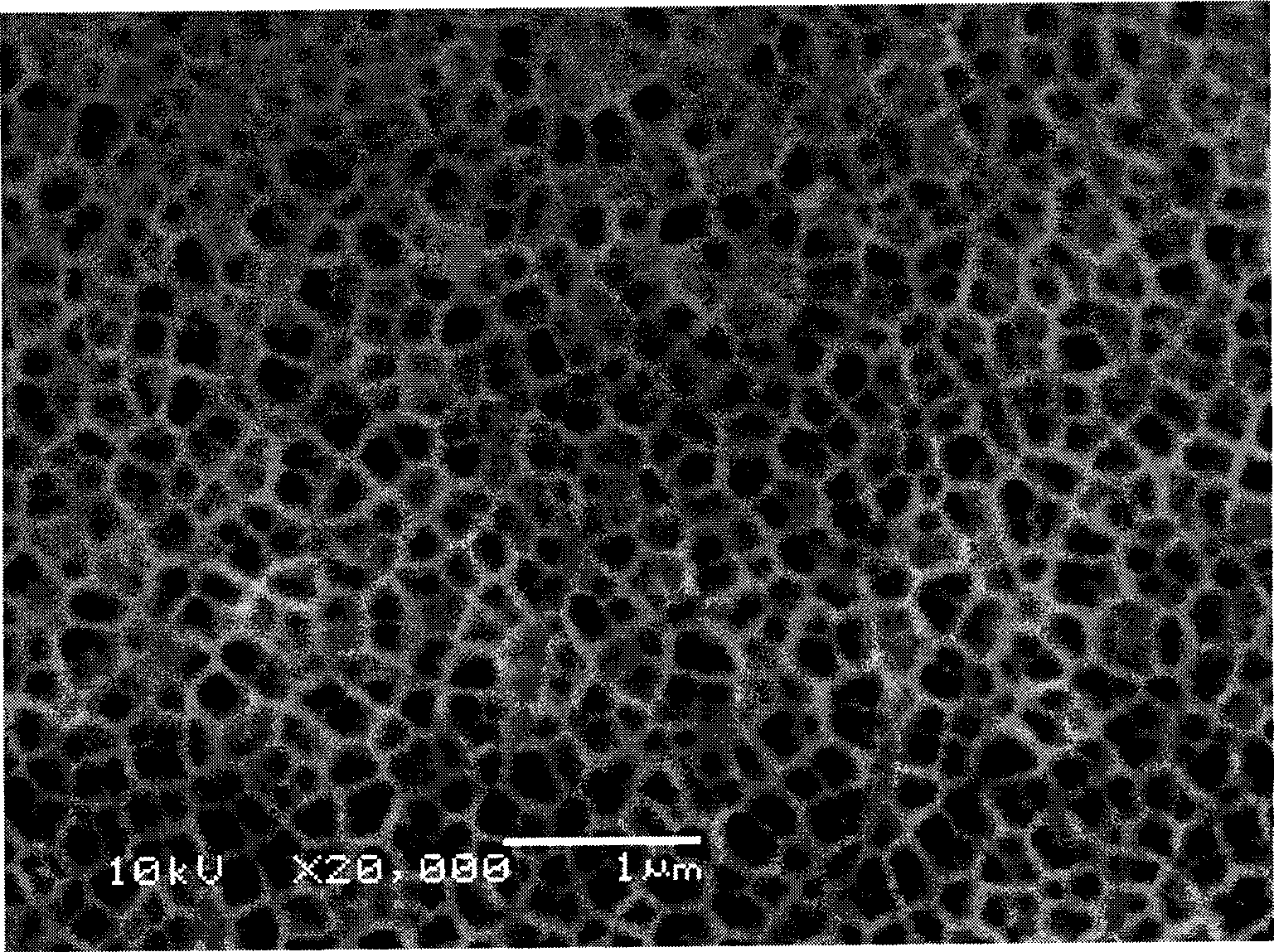

Silicon dioxide composite material containing media pores in concentric ring shaped or in hexagonal structure, and preparation method

InactiveCN1539733AGood periodicitySimple preparation processSilicaMolecular-sieve silica-polymorphsMesoporous silicaArtery organ

A mesoporous SiO2 composition has hexagonal structure or concentric rings structure, the distance between mesopores is 2-8 mm or 2-5 mm, and the organic additive in the arteries of mesoporous structure. Its preparing process includes dissolving surfactant in deionized water, using NaOH to regulate pH=8-12, dissolving organic additive in it, adding Si source, stirring, ageing, hydrothermally treating at 100-150 deg.C for 48-72 hrs, washing with deionized water and drying.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

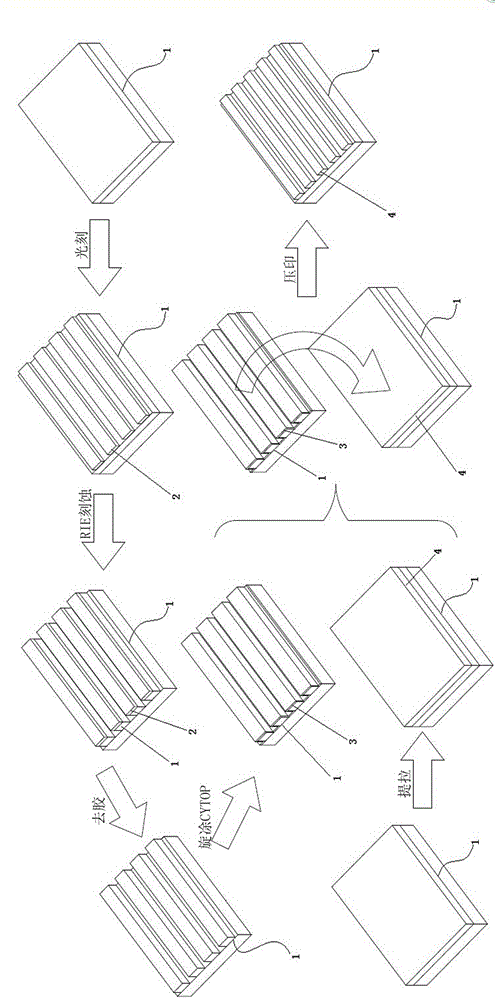

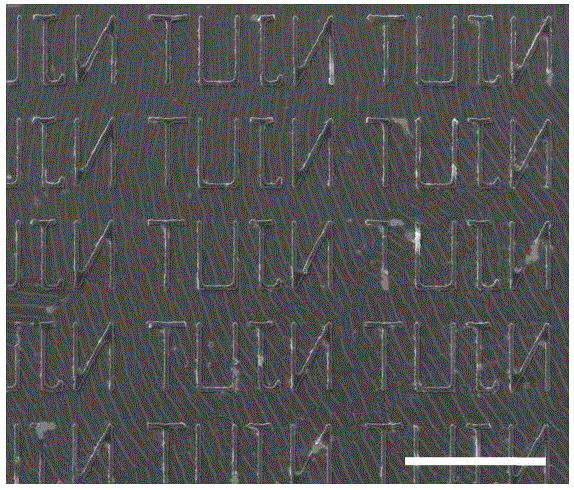

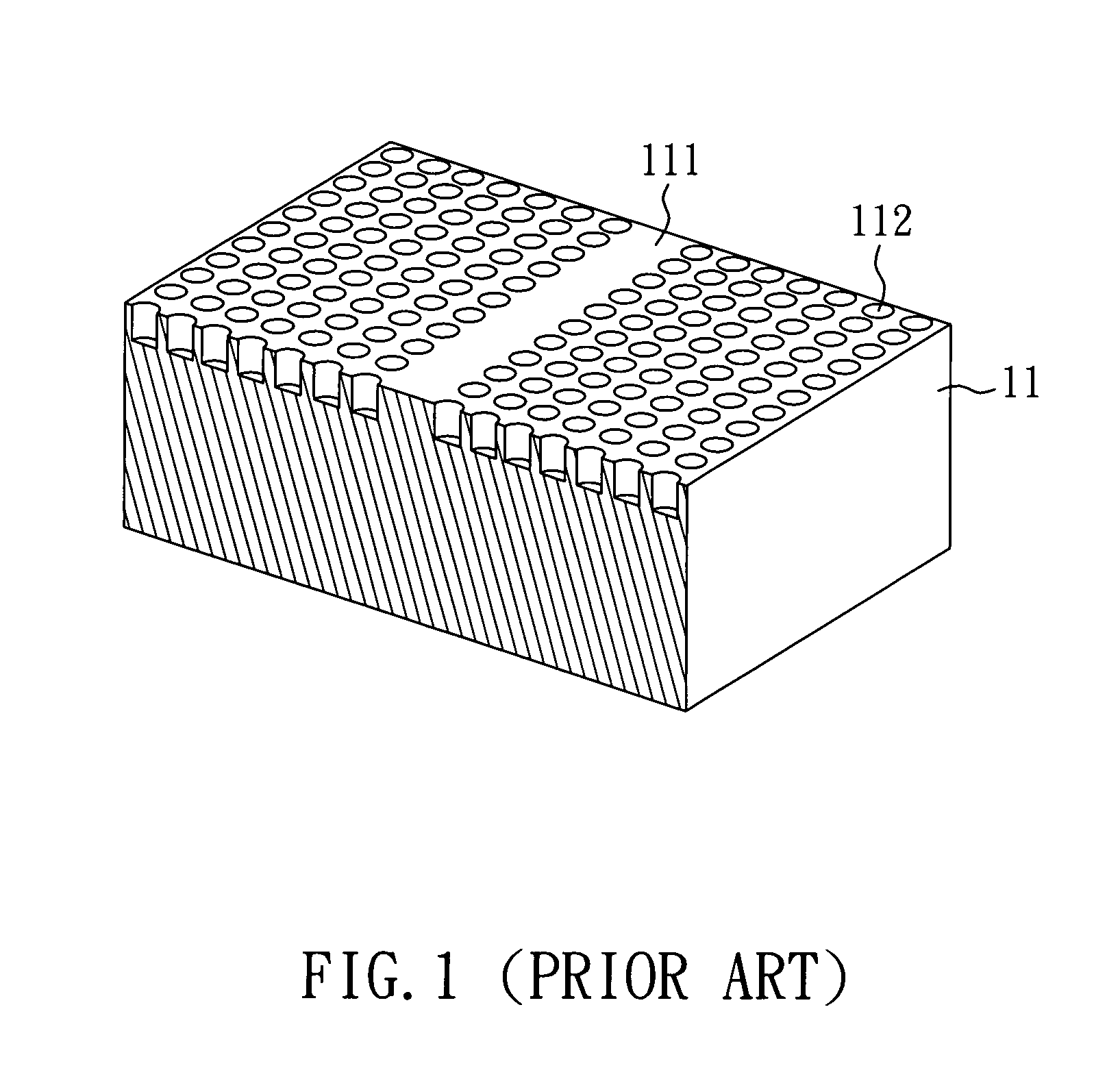

Method for constructing organic liquid crystal molecule single-crystal micro-wire patterned array by nanoimprint technology

The invention discloses a method for constructing an organic liquid crystal molecule single-crystal micro-wire patterned array by a nanoimprint technology. The method is divided into two parts; one part is a preparation of an imprint template; the other part is a preparation of an imprint base; the preparation of the imprint template comprises the following steps: firstly, cleaning a SiO2 / Si wafer base; secondly, carrying out positive photoresist photoetching and developing on the base to obtain an array pattern; thirdly, etching the photoetched SiO2 / Si wafer base by a reactive ion etching machine; fourthly removing the photoresist and obtaining an uneven template periodically arranged; fifthly spinning perfluorinated resin on the SiO2 / Si wafer base; and finally heating to finish the preparation of the imprint template; the preparation of the imprint base comprises the following steps: firstly, taking one cleaned SiO2 / Si wafer; secondly, lifting an organic small molecule membrane from the base on a step-by-step precision lifting platform to finish the preparation of the imprint base; the imprint template covers the base; certain pressure is applied; the imprint template is heated to the melting points of organic small molecules; heating is stopped after the temperature is kept constant for 15 minutes; the imprint template is cooled to room temperature; and the base is taken out, so as to obtain the periodic large-area organic small-molecule single-crystal micro-wire patterned array.

Owner:SUZHOU UNIV

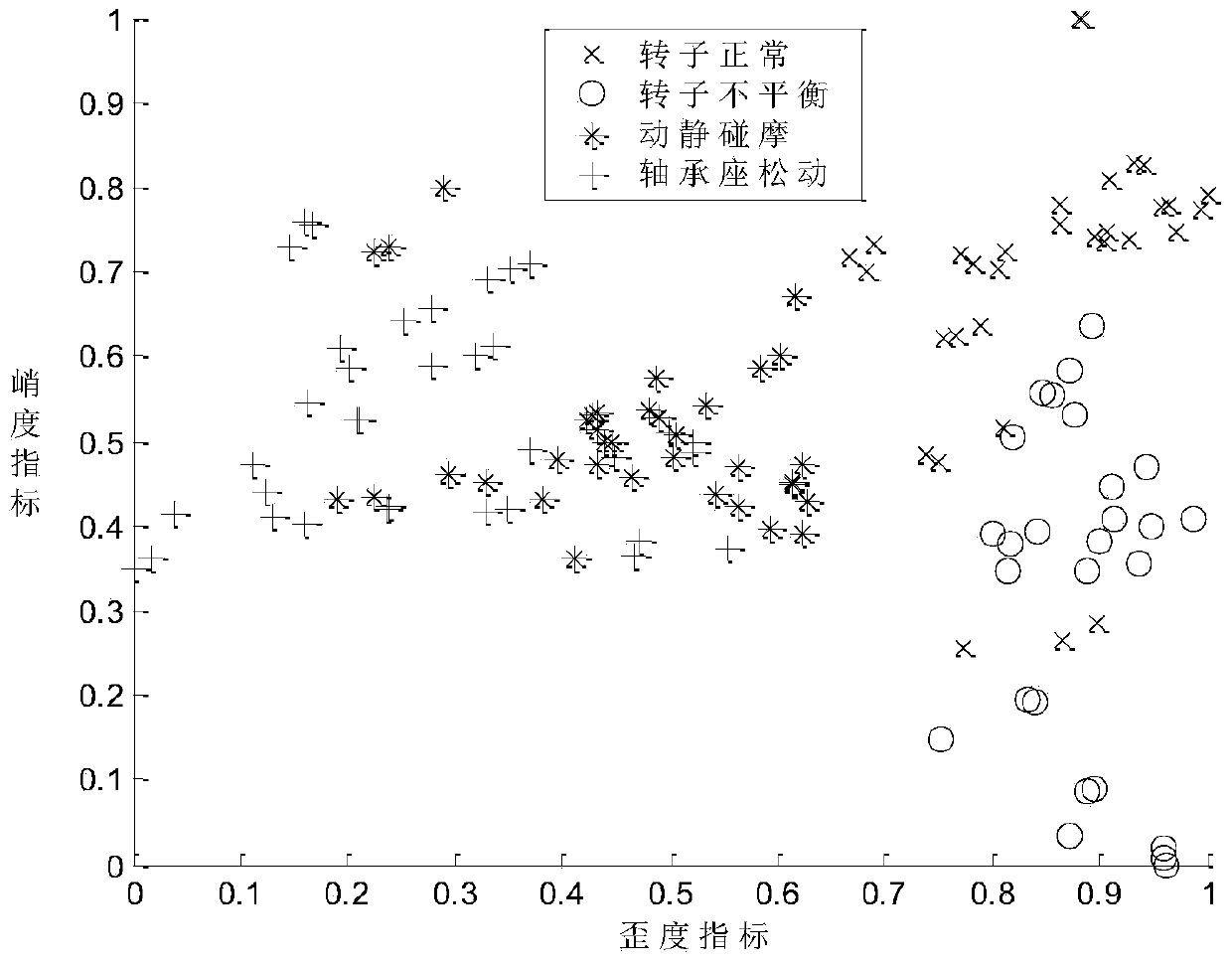

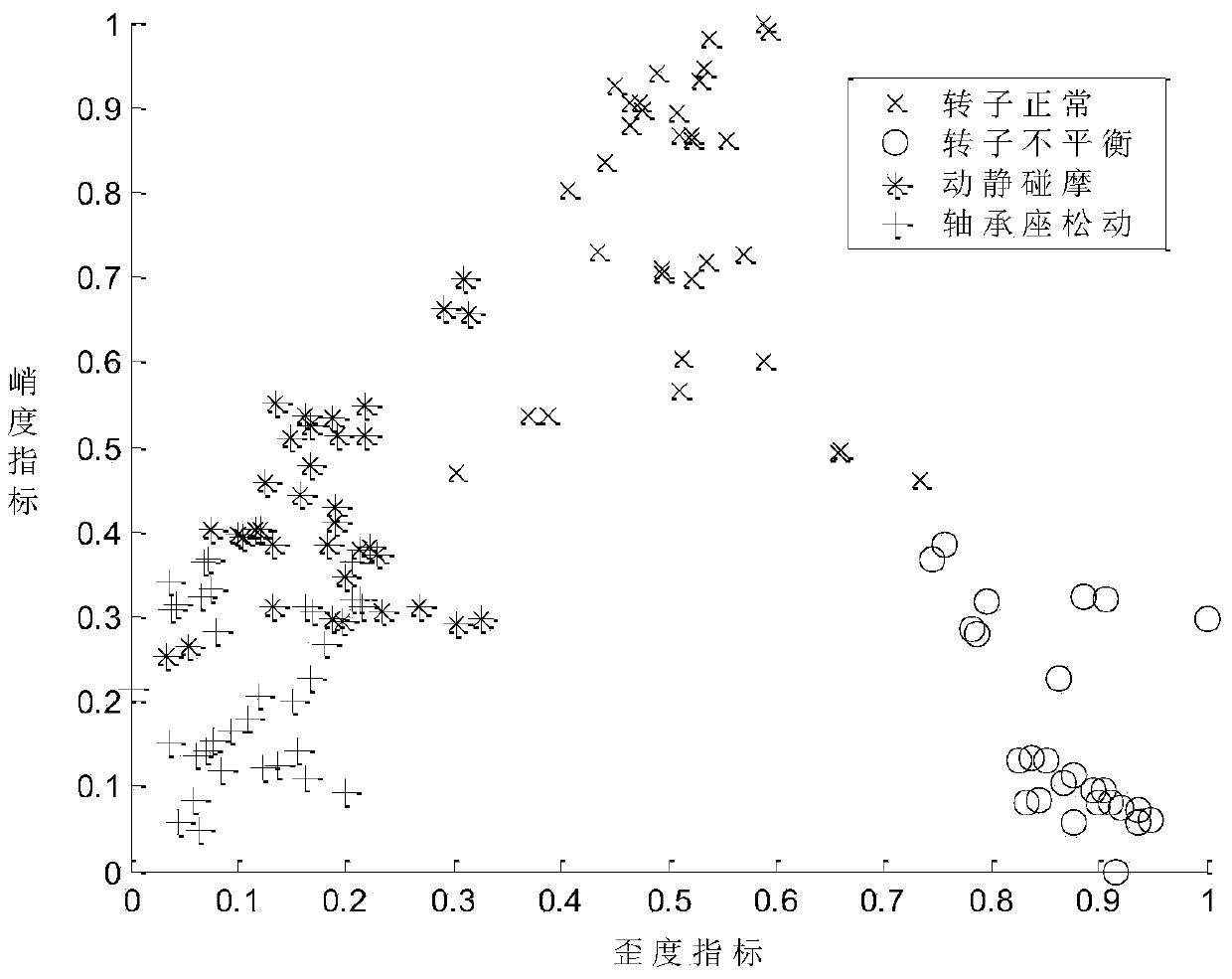

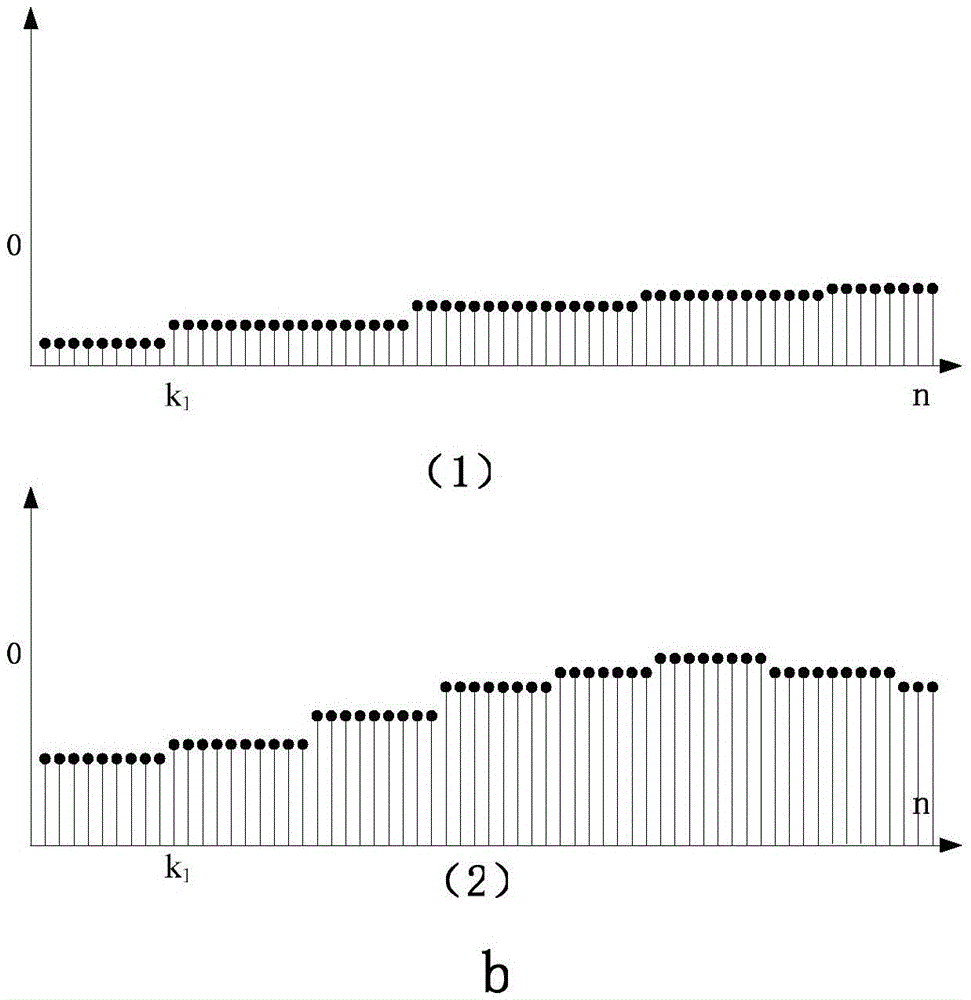

Mechanical vibration signal feature extraction method based on combination of stochastic resonance and kernel principal component analysis

InactiveCN104200065AImprove signal-to-noise ratioGood periodicitySpecial data processing applicationsTime domainFeature set

The invention relates to a mechanical vibration signal feature extraction method based on combination of stochastic resonance and kernel principal component analysis. The method comprises the steps that firstly, the stochastic resonance method is applied for conducting pretreatment on rotor oscillation original signals measured by a sensor, the signal periodicity is improved, and the oscillation signal to noise ratio is improved; then, a time domain feature set is extracted for the pretreated output signals; then the kernel principal component analysis method is adopted for conducting nonlinear feature transformation for the extracted time domain feature set, and therefore the final needed feature set is obtained. The method is applied to feature extraction and failure diagnosis of simulated failure of an engine rotor, the result shows that the feature set extracted through the method is of linear independence, the number of dimensions is smaller, the separability is higher, the precision and efficiency of the failure diagnosis can be effectively improved, and application in engineering practice is facilitated.

Owner:AIR FORCE UNIV PLA

Random number generator

InactiveCN1397034AGood periodicityRandom number generatorsSolid-state devicesEngineeringVoltage source

A random number generator on an integrated circuit has a first clock generator circuit with a first voltage supply for generating a first signal of a first frequency or of a first frequency range. A second clock generator circuit has a second voltage supply for generating a second signal of a second frequency or of a second frequency range, such that the second frequency or a mean value of the second frequency range is lower than the first frequency. A generator samples the first signal with the second signal and-generates at least one random number in dependence on the result of the sampling. The clock generator circuits are located as far away from one another as possible on the integrated circuit and / or the two voltage supplies are isolated from one another and / or at least one guard ring is placed around each of the clock generator circuits.

Owner:INFINEON TECH AG

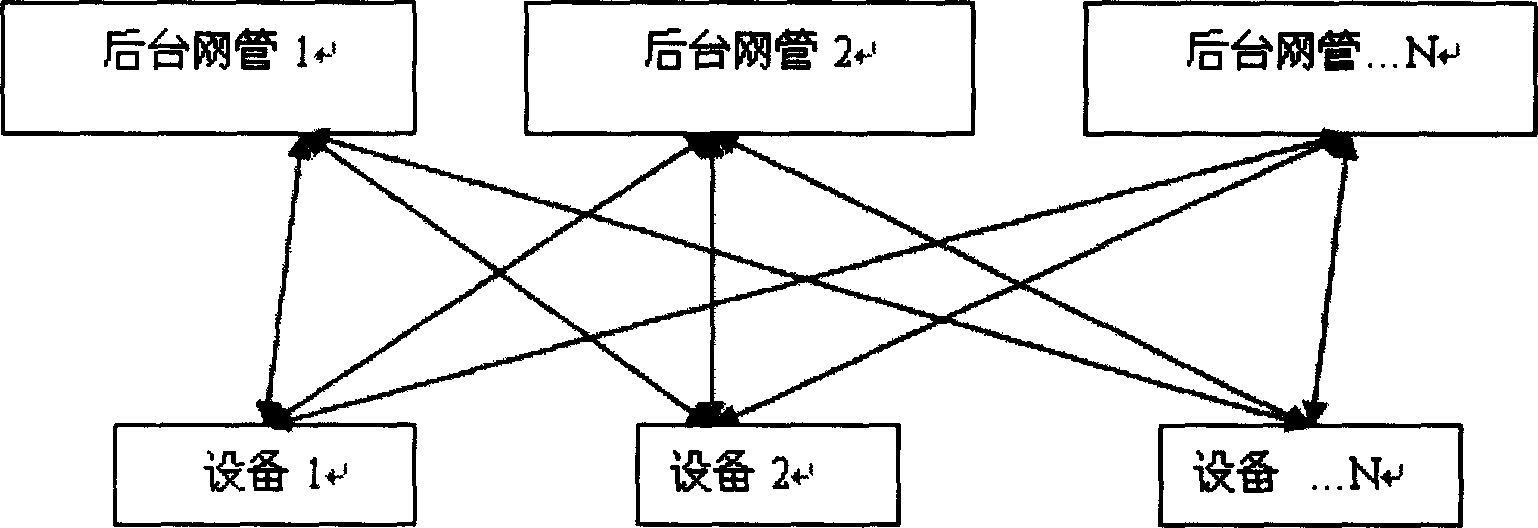

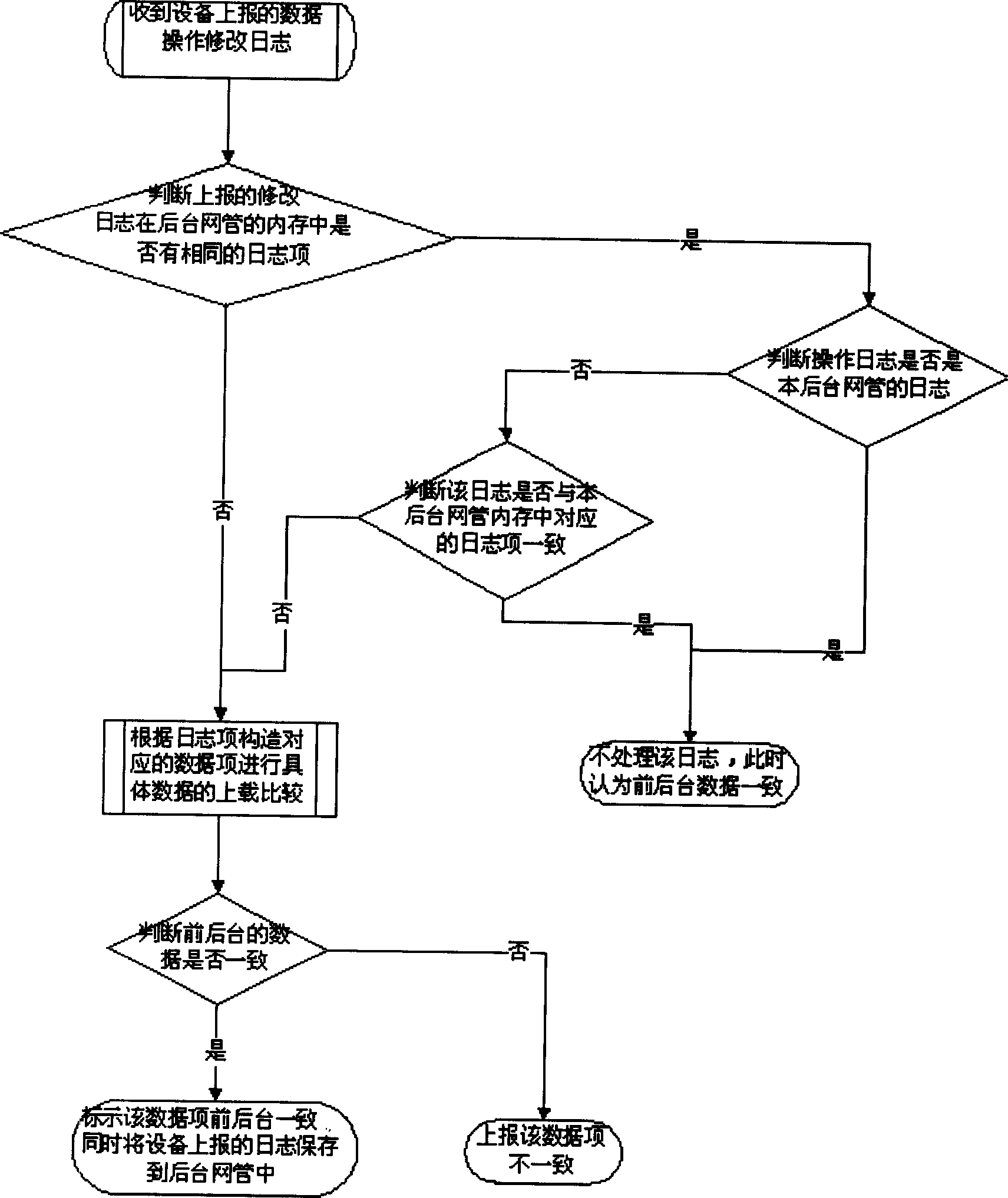

Method for real-time embodying disparity of network managment foreground and background data

ActiveCN1812331AReduce efficiency lossOvercome the disadvantage of not being able to reflect the inconsistency of front and back data in real timeData switching networksDependabilityFile comparison

This invention relates to communication field and provides a kind of method for real-time displaying the data of network managing foreground and background are inconsistent. Through defining each related data the journal information, whether the related data of foreground and background are consistent is detected by comparing the journal information corresponded to the said data. When the journal information is inconsistent, the detailed data will be further compared. This invention can achieve real-time and automatic effect.

Owner:ZTE CORP

Method for preparing bismuth nano wire array thermoelectric materials

The invention discloses a method for preparing bismuth nano wire array thermoelectric materials. The method is to take a high-purity BiCl3, glycerol and ammonia water solution as an electrodeposition solution, adopt electrochemical technology and utilize cyclic voltammetry to perform electrodeposition on an alumina template, and finally obtain the one-dimensional orderly Bi nano wire array thermoelectric materials with high thermoelectric conversion efficiency. The invention has simple preparation method and high filling rate; the maximum characteristic of the materials is that the materials can receive various forms of heat energy (including various types of radiant heat, solar energy, body temperature, heat generated in the system operation process, various types of waste heat and the like) from the environment and highly efficiently and directly convert the heat energy into electric energy which is then outputted; and due to the characteristics of the special high-density nano wire array structure, oxidation resistance, high temperature resistance, high field emission current density, low turn-on field, good emission stability and the like, the application of the materials to field emission microelectronic devices as cathode materials can be realized and the materials have wide commercial application prospect.

Owner:EAST CHINA NORMAL UNIVERSITY

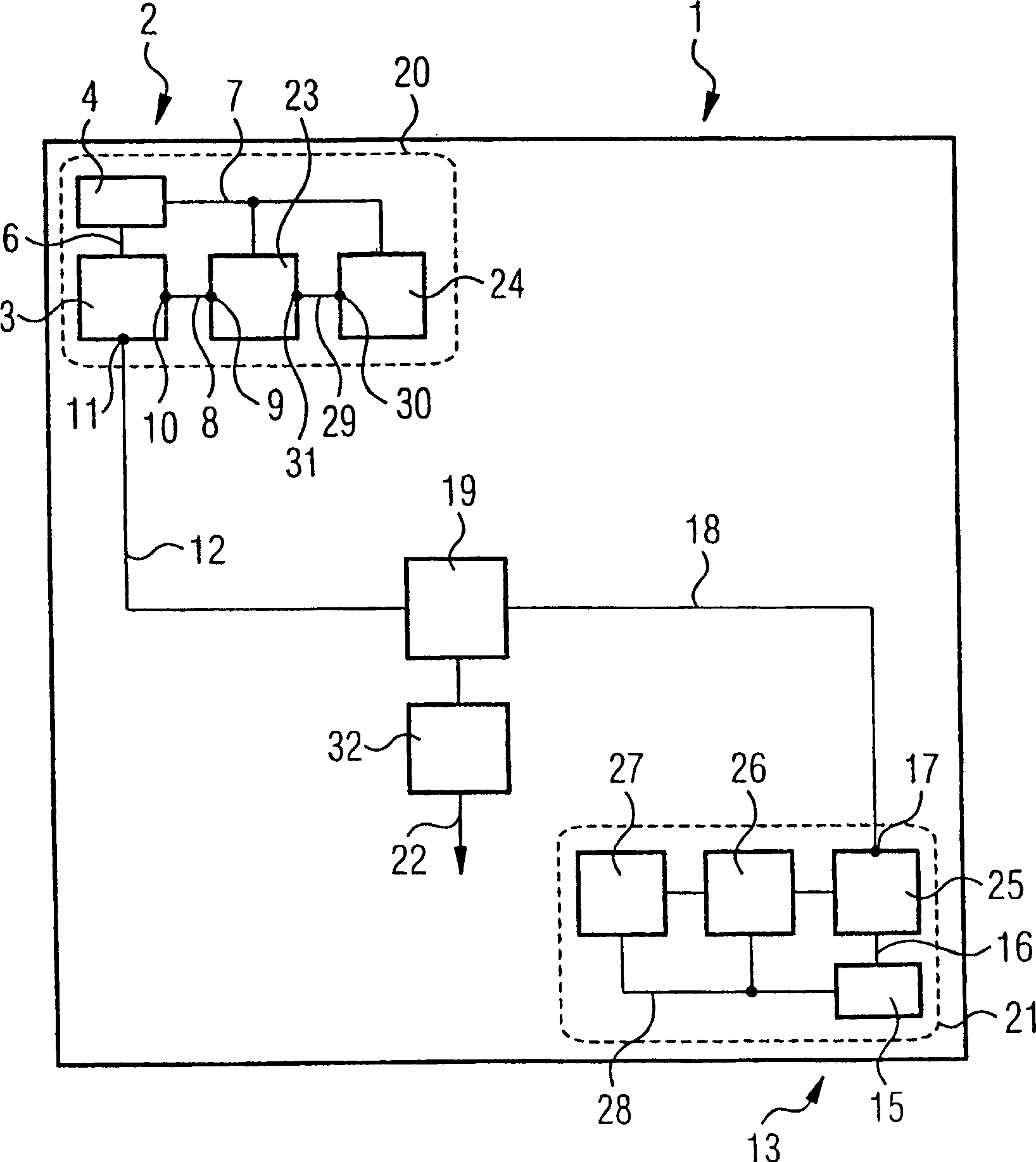

Feature tracking using ultrasound

ActiveUS20150375013A1Reduce the burden onGood periodicityImage enhancementImage analysisSupporting systemSonification

Various implementations of the invention provide techniques and supporting systems that facilitate real-time or near-real-time ultrasound tracking for the purpose of calculating changes in anatomical features during a medical procedure. More specifically, anatomical features within a patient undergoing a medical procedure are tracked by obtaining temporally-distinct three dimensional ultrasound images that include the feature of interest and obtaining a targeted subset of ultrasound images focused on the feature. Based on the targeted subset of ultrasound images, a displacement of the feature is determined and image parameters used to obtain the targeted subset of ultrasound images are adjusted based on the displacement. This results in a time-based sequence of three dimensional images and targeted ultrasound images of the feature that identify changes in the position, size, location, and / or shape of the feature.

Owner:ELEKTA AB

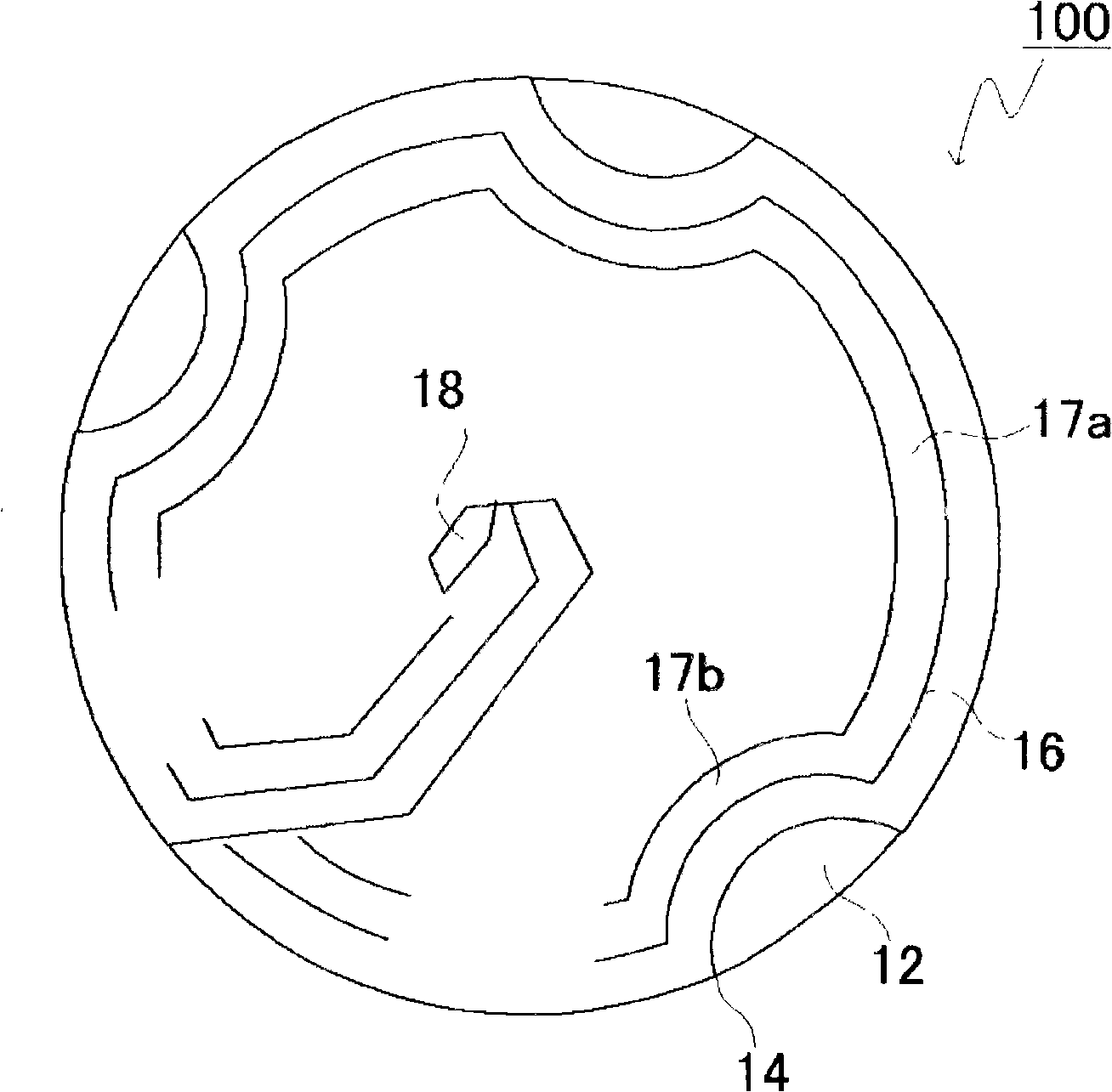

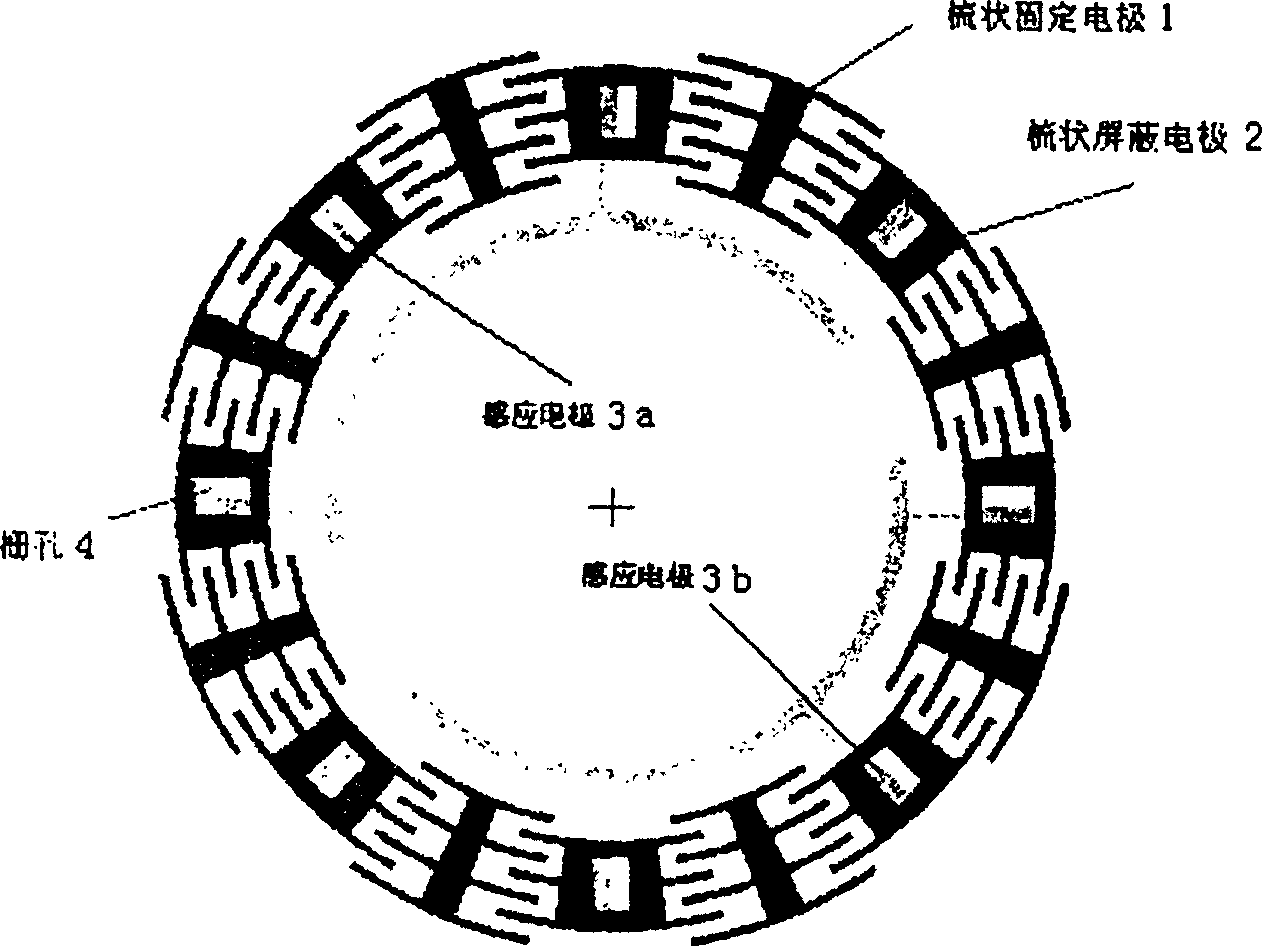

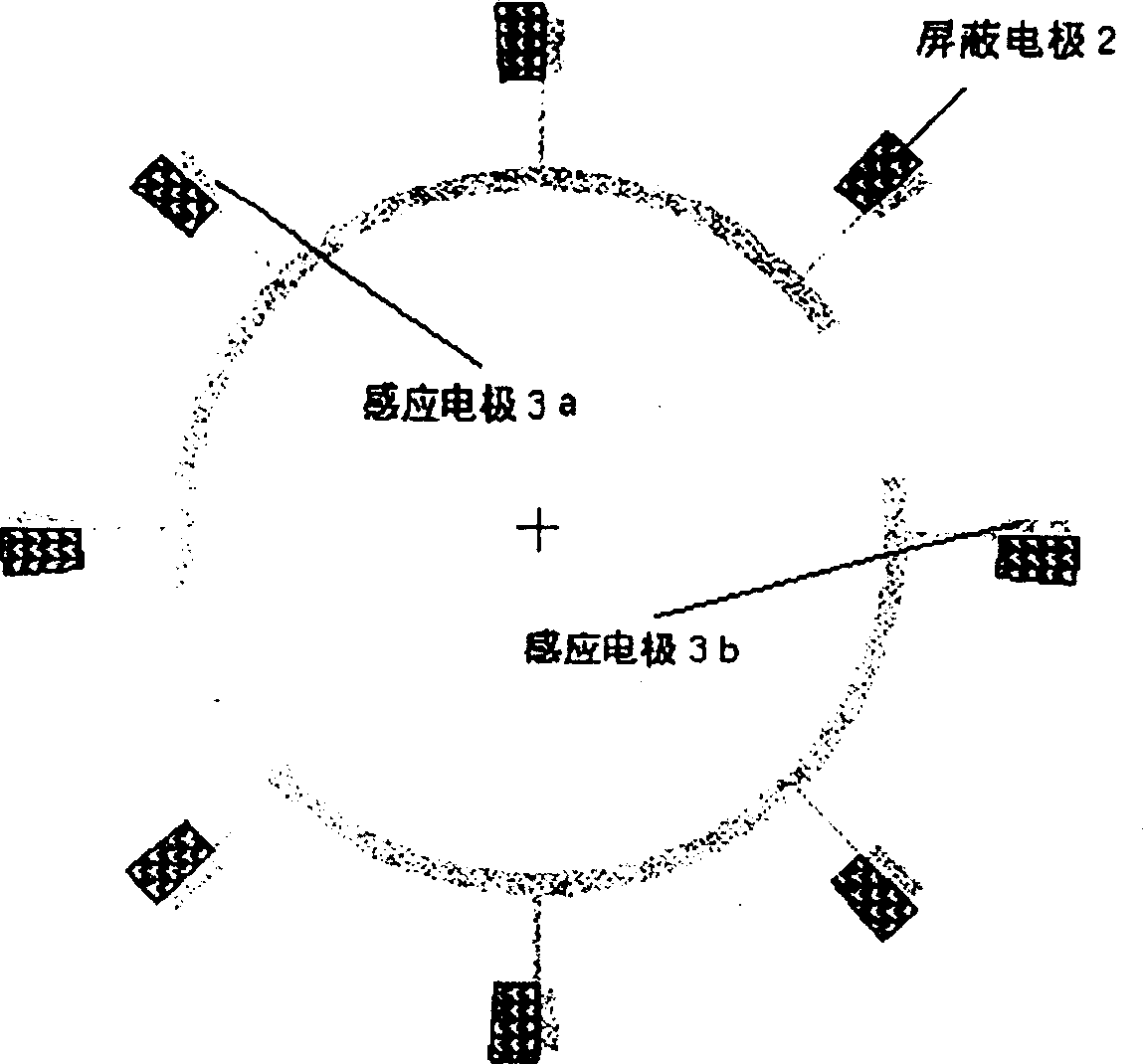

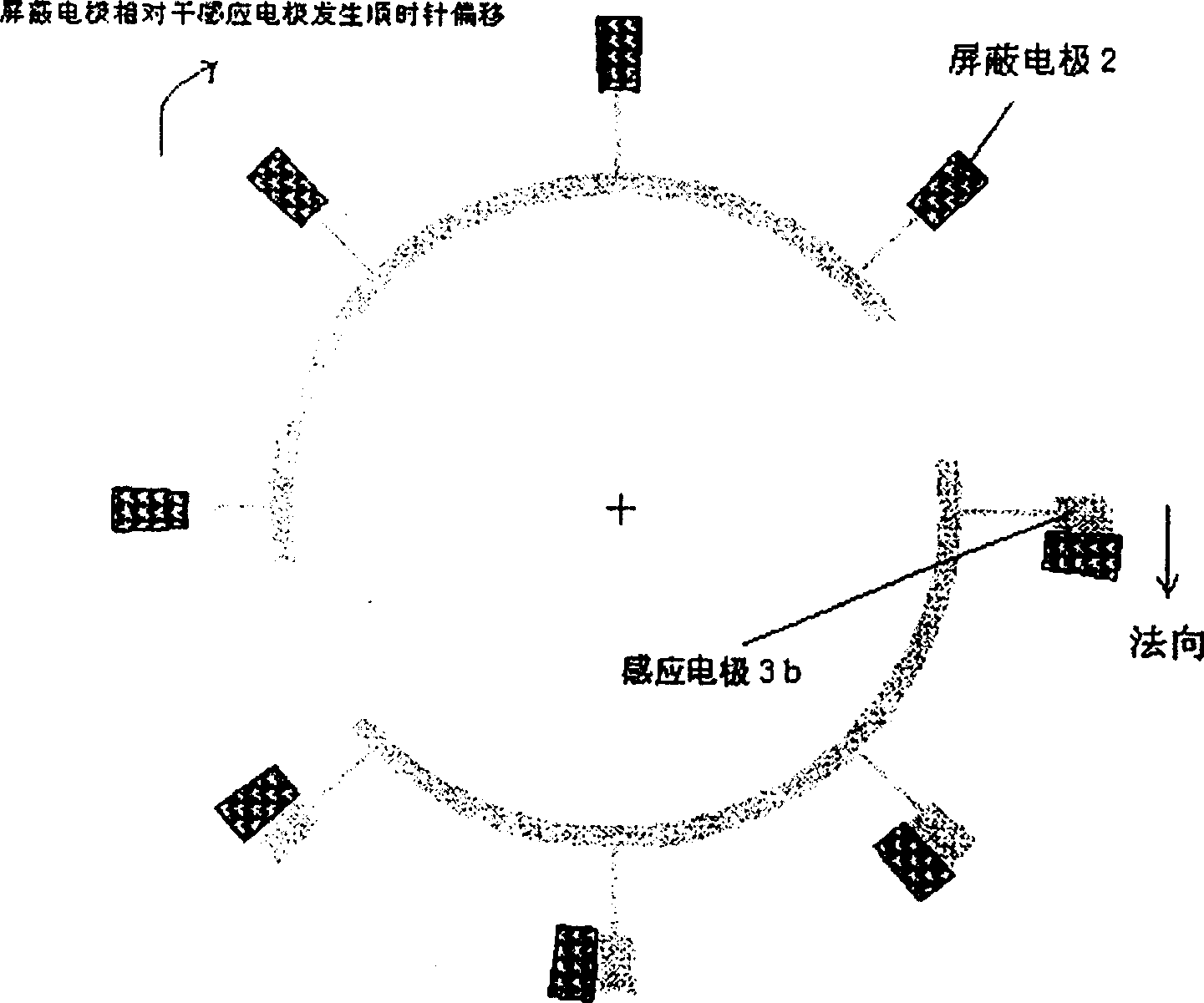

Round comb type minisize electric field sensor

InactiveCN1769913AAccurate displacementImprove stabilityElectrostatic field measurementsElectric field sensorElectric machine

Disclosed is a circular comb-type micro electric field sensor which comprises: comb-type fixed electrode (1) and comb-type bucking electrode (2) distributed along vibration direction with space on circumference; on the comb-type bucking electrode (2) being opened grid hole (4); a sensing electrode (3) being positioned under the grid hole (4). The inventive sensor has the advantages of having accurate offset and good periodicity, of facilitating to detect weak electric field signal and of having less signal interference between grid holes.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Method for constructing organic micron linear array with form board assisting in volatilization induced self-assemble

ActiveCN103413760AEasy to operateImprove bindingSemiconductor/solid-state device manufacturingMicro nanoOxygen plasma

The invention discloses a method for constructing an organic micron linear array with a form board assisting in volatilization induced self-assemble. The method comprises the following steps that (1) a substrate is washed through cleaning fluid in an ultrasonic mode, then the substrate is immersed in the piranha solution and processed by an oxygen plasma, and the surface of the substrate is made to have strong wettability; (2) the form board is constructed on the substrate; (3) the micron linear array is grown on the form board, the pre-processed form board is inserted in the organic solution for growth, and through volatilization induced self-assemble, the large-area highly-aligned organic micron linear array is obtained. The method is of great significance to manufacturing of large-area high-performance photoelectron micro-nano devices based on organic optoelectronic materials and further achieving of micro-nano device integration.

Owner:SUZHOU UNIV

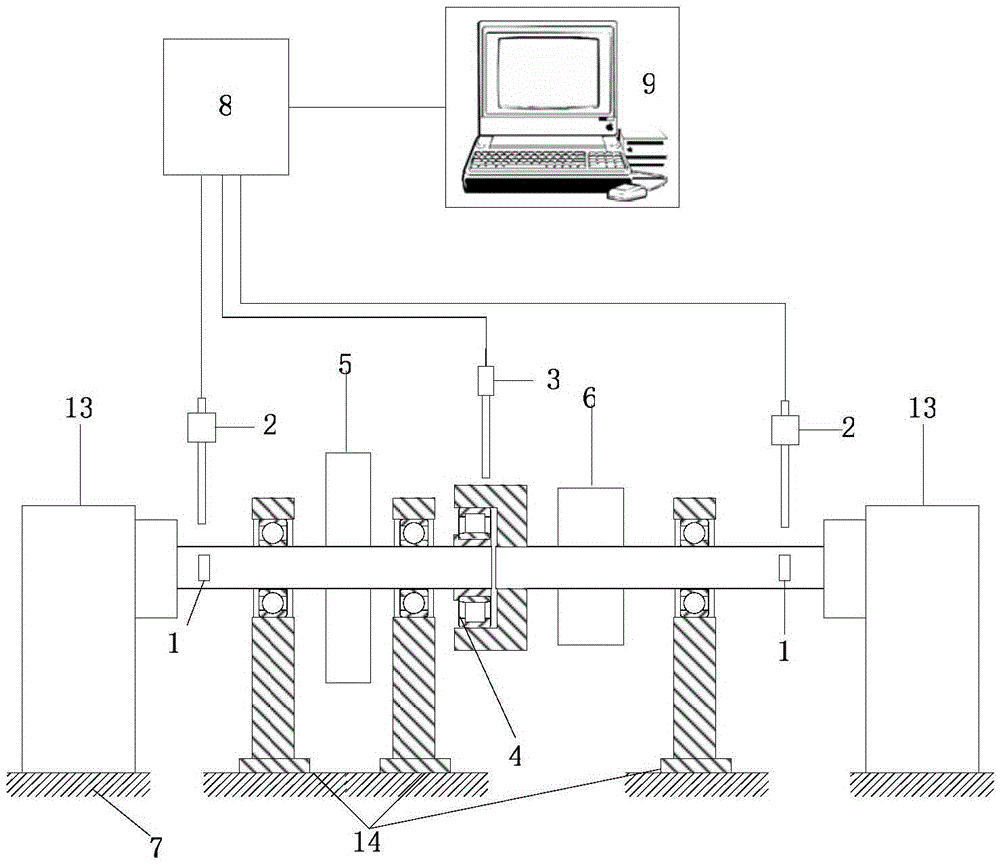

Fault detection method and device for aircraft engine intermediate bearing

The invention provides a fault detection method and device for an aircraft engine intermediate bearing. A low-voltage rotor and a high-voltage rotor in the detection device are mounted among three supporting frames; reflective paper patches are attached to a rotor shaft of the low-voltage rotor close to one end of a motor and a rotor shaft of the high-voltage rotor respectively. Two photoelectric sensors are utilized to collect rotational speed pulse signals, and an eddy current displacement sensor is utilized to collect vibration signals of the intermediate bearing; the problems that bearing fault characteristic frequency is poor in drift on a frequency spectrum and leptokurtosis can be well solved by determining fault characteristic frequency doubling, collecting the rotational speed pulse signals and original time domain vibration signals, obtaining zero phase position of an intermediate bearing slip domain, calculating a rotational speed-time function, converting original time-domain signals into intersection-angle-domain vibration signals and detecting the bearing fault through an envelope spectrum.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

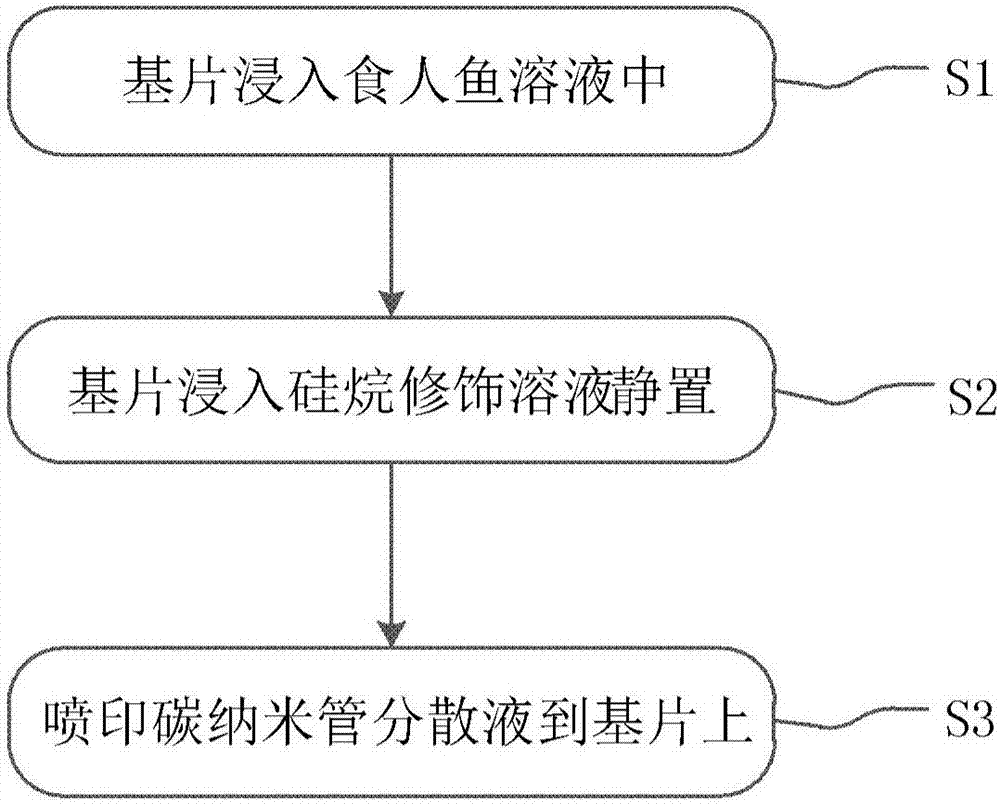

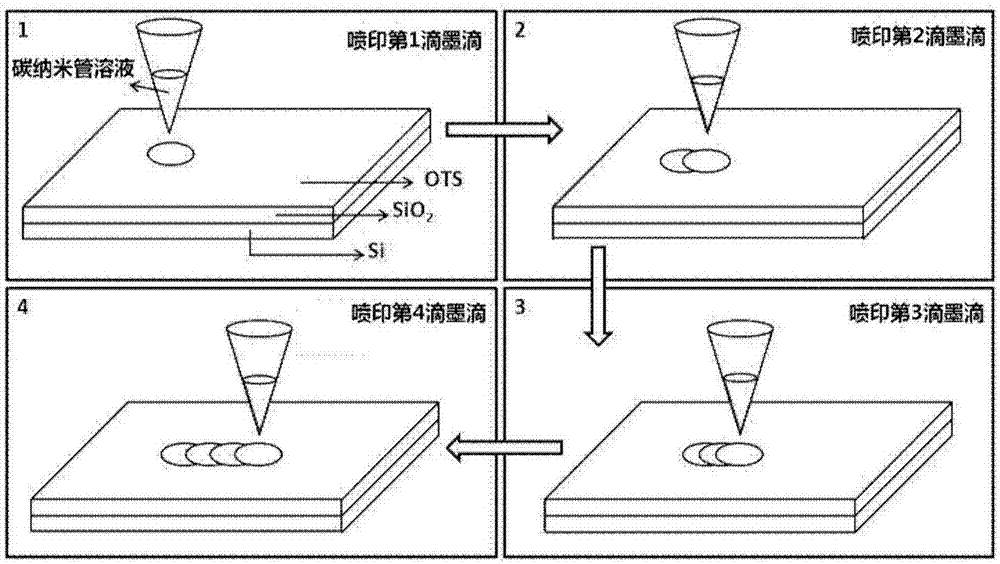

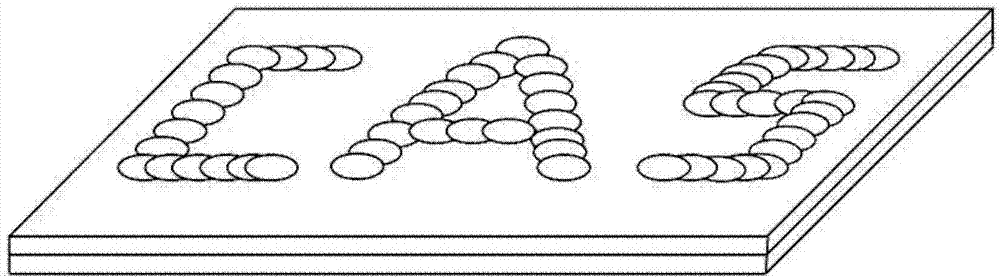

Single aligned carbon nano tube jet-printing arrangement method

ActiveCN107963610ASimple processAchieve patterningMaterial nanotechnologyNanostructure manipulationOctadecyltrichlorosilaneNano-device

The invention provides a single aligned carbon nano tube jet-printing arrangement method. The method comprises the steps that a substrate is modified with octadecyltrichlorosilane (OTS), so that the surface of the substrate has a hydrophobic property; precise control over the thin film position, the aligned density and patterning of aligned carbon nano tubes is achieved on the functional hydrophobic substrate through ink-jet printing, and a carbon nano tube thin film which is uniform in density and consistent in orientation and has different patterns is arranged. By means of the method, the carbon nano tube arrangement area of the size from several micrometers to the wafer level can be effectively controlled; the problems can be solved that in all existing arrangement methods, the arrangement position, the arrangement orientation, the arrangement density and the thin film array patterning of one-dimensional nano materials on the substrate cannot be efficiently and precisely controlled;the method can be widely used for preparing various high-performance photoelectric devices, logic circuits and functional thin films based on the carbon nano tubes, and the method also has a wide application prospect in the field of flexible wearable nano devices.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

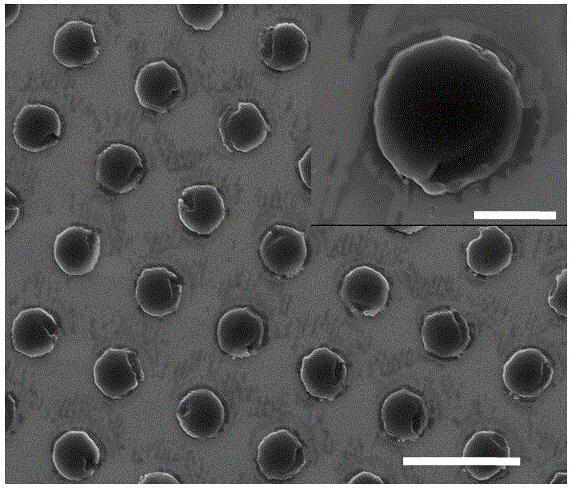

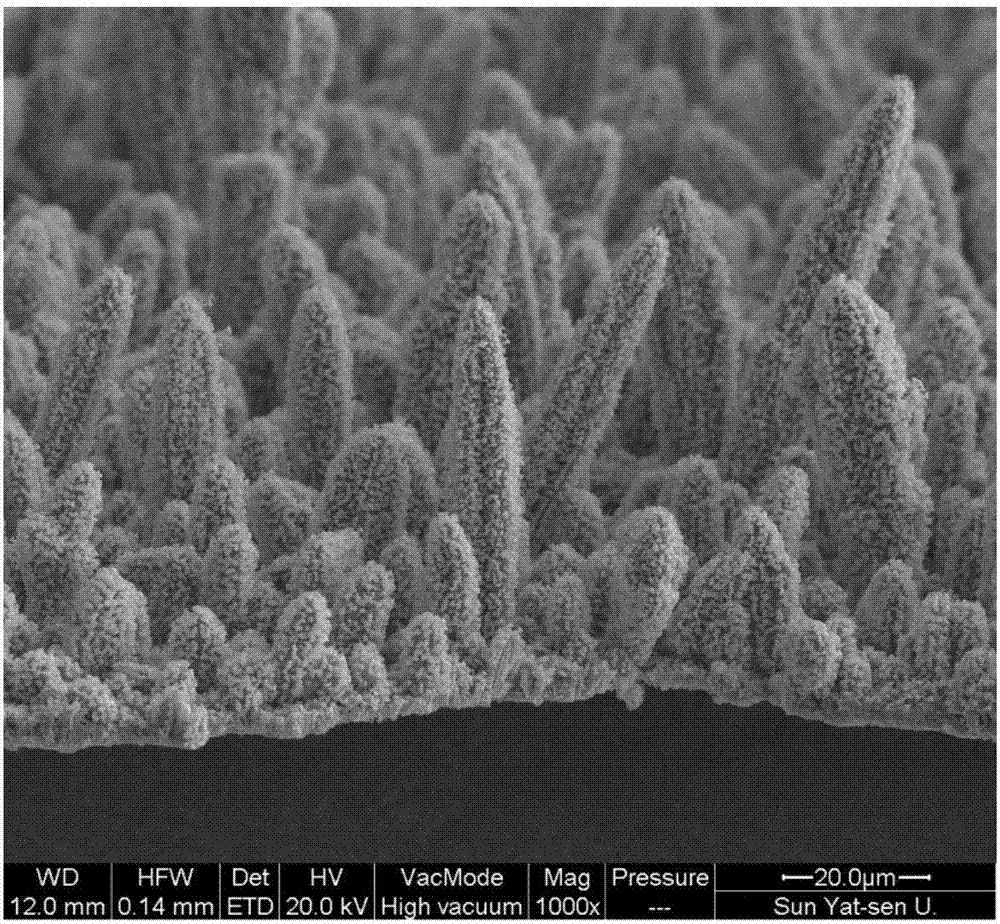

Laser-chemical preparation method of monocrystal silicon substrate sub-micron pyramid structure

ActiveCN104195644APrecise positioningPrecise control of densityPolycrystalline material growthAfter-treatment detailsWater bathsMicro structure

The invention discloses a laser-chemical preparation method of a monocrystal silicon substrate sub-micron pyramid structure, belonging to the field of crystalline silicon surface micro-structure preparation. The preparation method comprises the following steps: firstly, performing pretreatment on monocrystal silicon, and covering periodically close-packed microspheres on the surface of monocrystal silicon; performing irradiation by adopting a 248nm laser, wherein the single pulse energy density is 100-400mJ / cm<2>; performing certain treatment on a monocrystal silicon sample after irradiation, and removing the residual microspheres on the surface; after removal ends, dipping the monocrystal silicon sample into a sodium hydroxide aqueous solution containing ethanol under the environment that the water bath temperature is 70-80 DEG C, eroding for 10-30 seconds, taking out the monocrystal silicon sample, and washing by using deionized water to obtain a monocrystal silicon piece with a normal pyramid array. The laser-chemical preparation method disclosed by the invention exerts the laser controllability, can be used for rapidly and simply preparing the pyramid array with periodicity and uniformity, has high controllability in pyramid forming, can be used for adjusting the separation distance and morphology features of the pyramid array, also is low in raw material cost, and has relatively high practicability.

Owner:BEIJING UNIV OF TECH

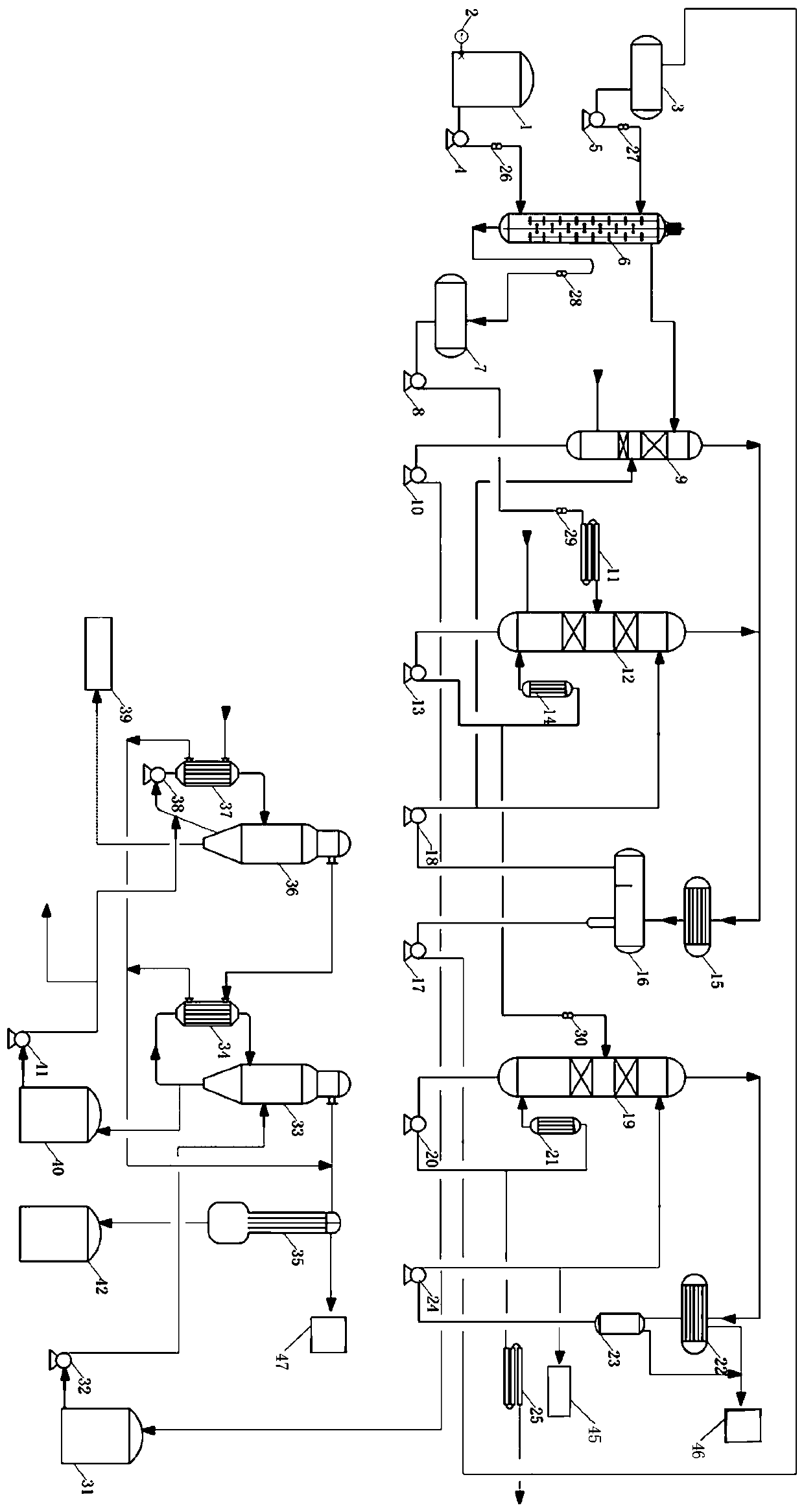

Separation and recycling system of NMP in salty solution

PendingCN109761425AAchieve separationReduce energy consumptionChloride preparationOrganic chemistryRoom temperatureSolvent

The invention belongs to the technical field of mixed solution recycling devices, and particularly relates to a separation and recycling system of NMP in a salty solution. The separation and recyclingsystem is mainly used for separation and recycling of NMP and salt in a solvent which is washed and neutralized, and comprises an extraction device, a stripping tower, an extraction agent removing device, an NMP purifying device and an evaporating device. The recycling system adopts dynamic extraction at room temperature, not only achieves separation of the solvent from water, but also greatly improves the recycling rate of the solvent, and the recycling rate of the solvent is as high as 99.95% or above; salt in a waste salty solution is recycled through the evaporating device, reuse of the salty solution is achieved, the cost is lowered, low emission of waste liquid is achieved, and the requirement of national environment protection is conformed.

Owner:河南神马芳纶技术开发有限公司

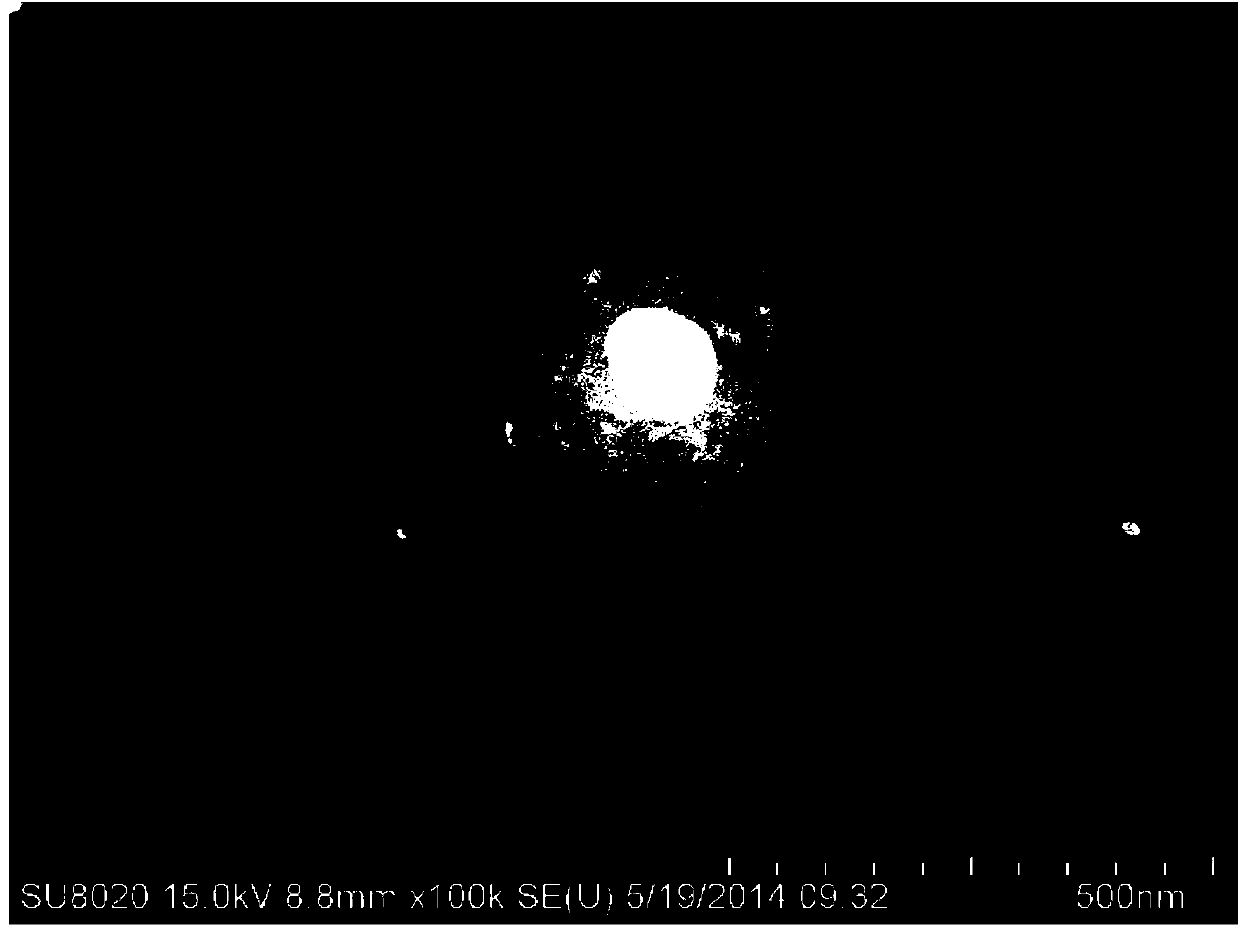

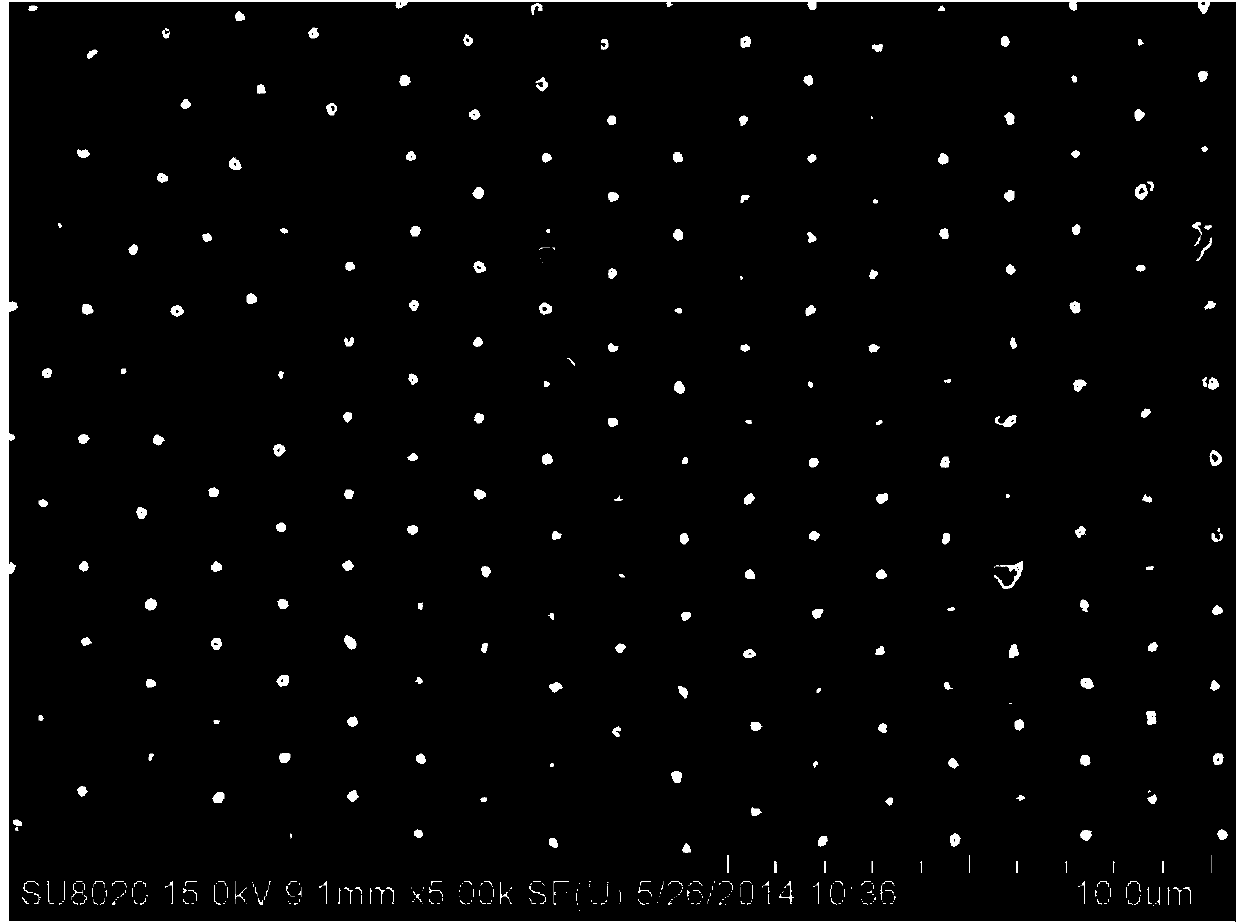

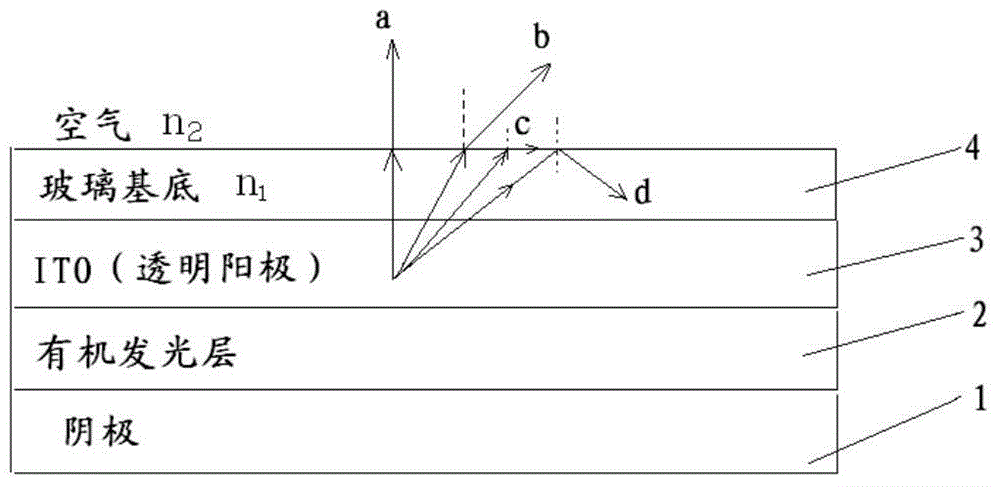

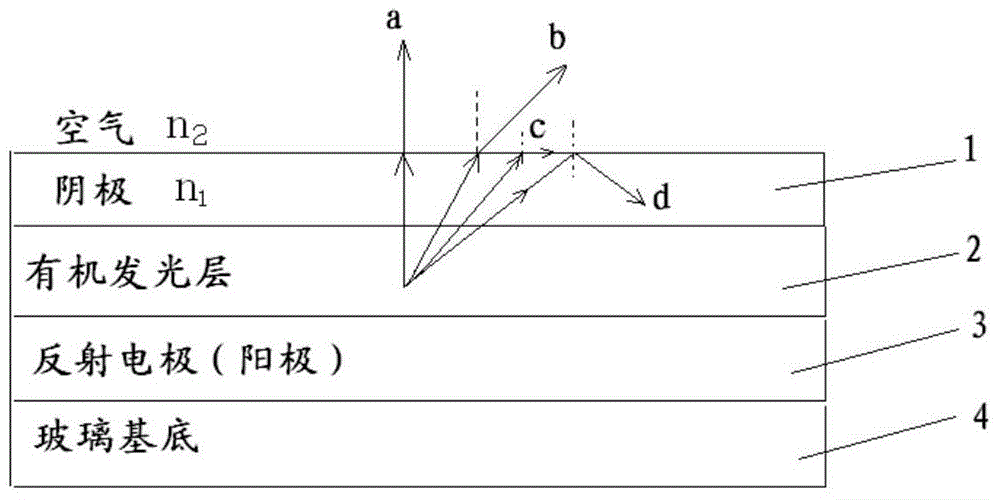

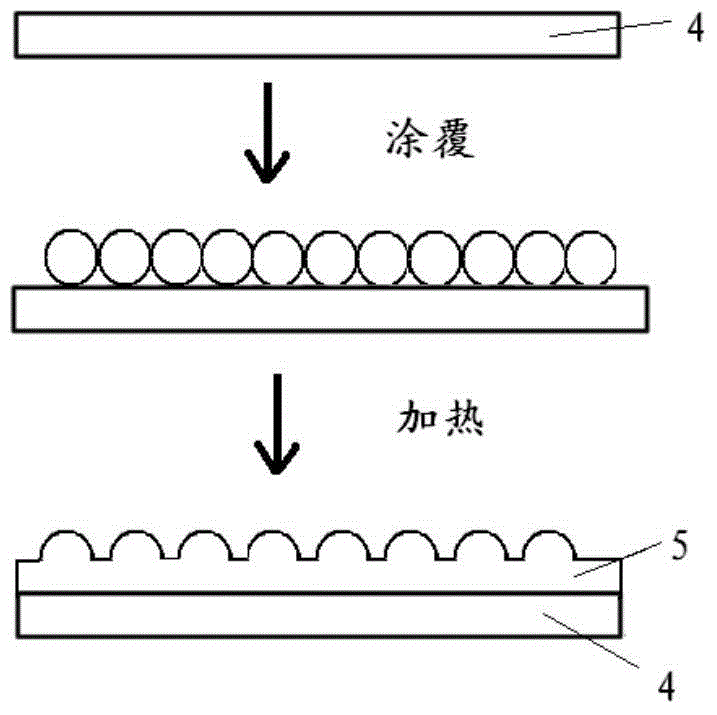

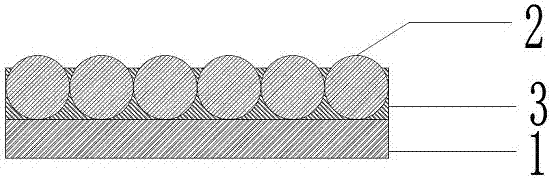

Method for preparing uneven particle layer, organic light-emitting device, and display device

ActiveCN105118934AEvenlyGood periodicitySolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceDisplay device

The invention provides a method for preparing an uneven particle layer, an organic light-emitting device (OLED), and a display device, belongs to the display technical field, and solves a problem of low light extraction efficiency of a conventional OLED. The method for preparing the uneven particle layer comprises steps of: forming a nanometer particle layer on a substrate; heating the substrate in order that nanometer particles in contact with the substrate are fused and nanometer particles at the surface are in solid states; cooling the substrate in order to form the nanometer particle layer with an uneven surface. The method is simple in technology and easy to be used in industrial production. The substrate containing the uneven particle layer is used by an OLED device so as to change the light propagation direction of the organic light-emitting layer of the OLED device, prevent internal total reflection at an interface, enable more light to be emitted to air, and improve the light extraction efficiency of the OLED device. The OLED prepared by the method is suitable for various display devices.

Owner:BOE TECH GRP CO LTD +1

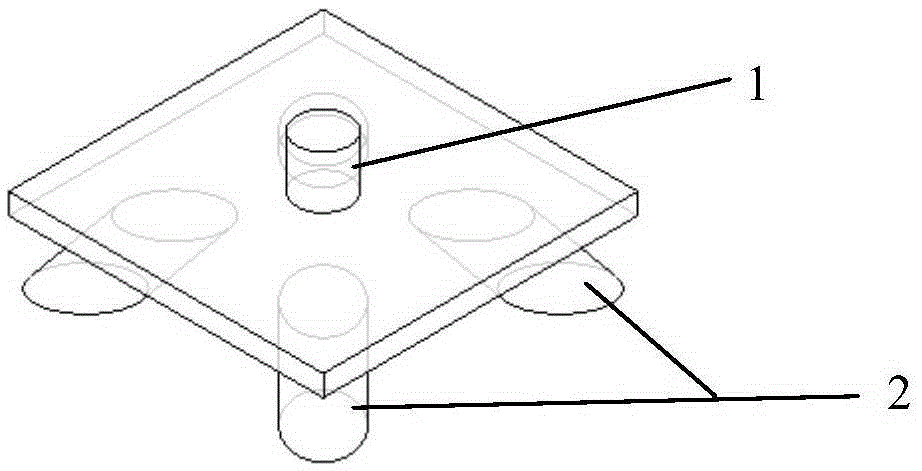

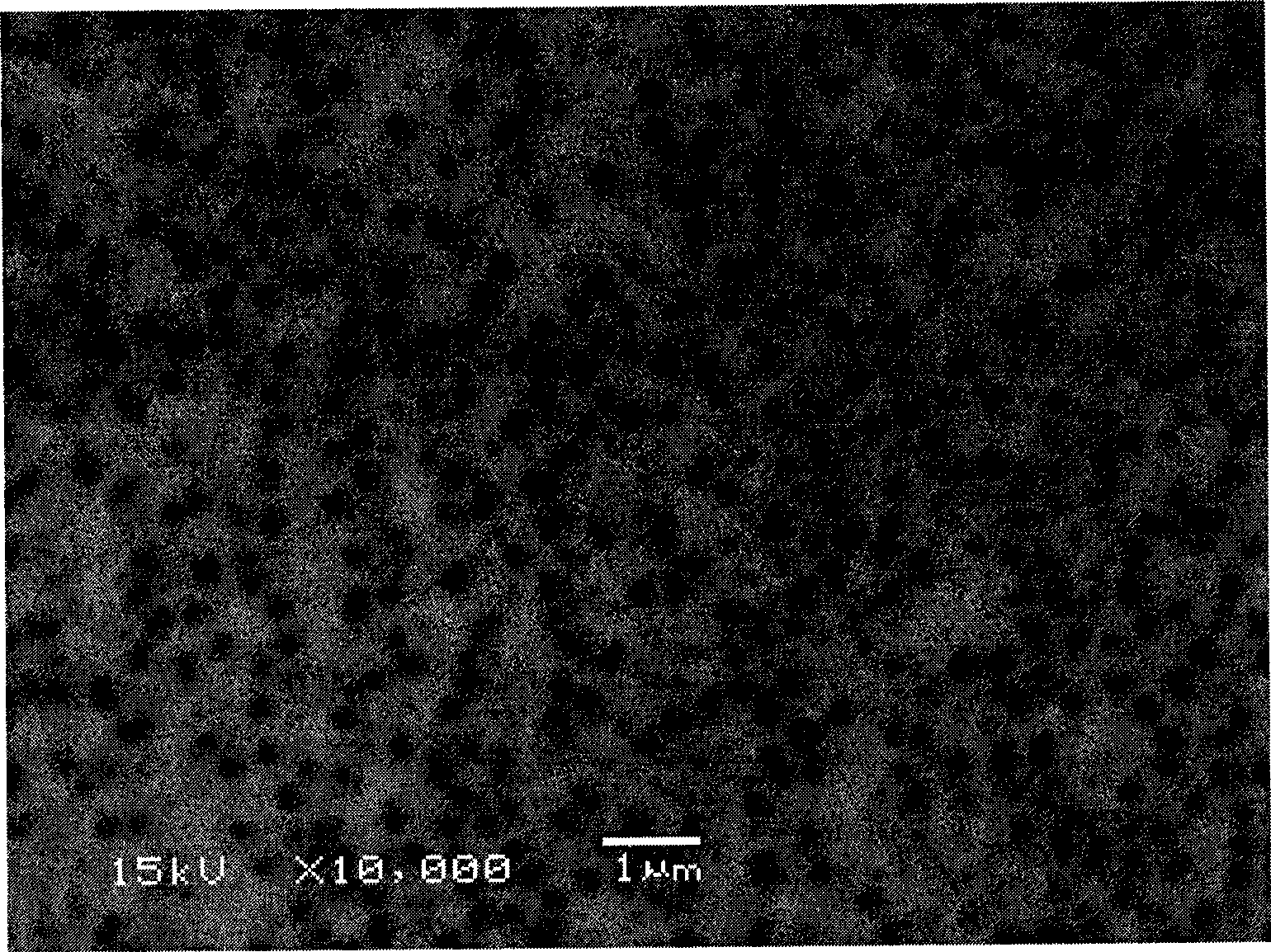

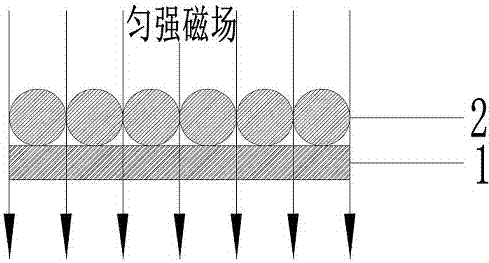

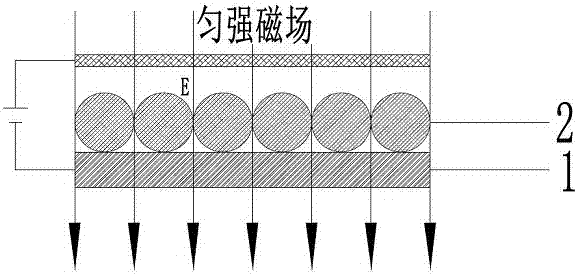

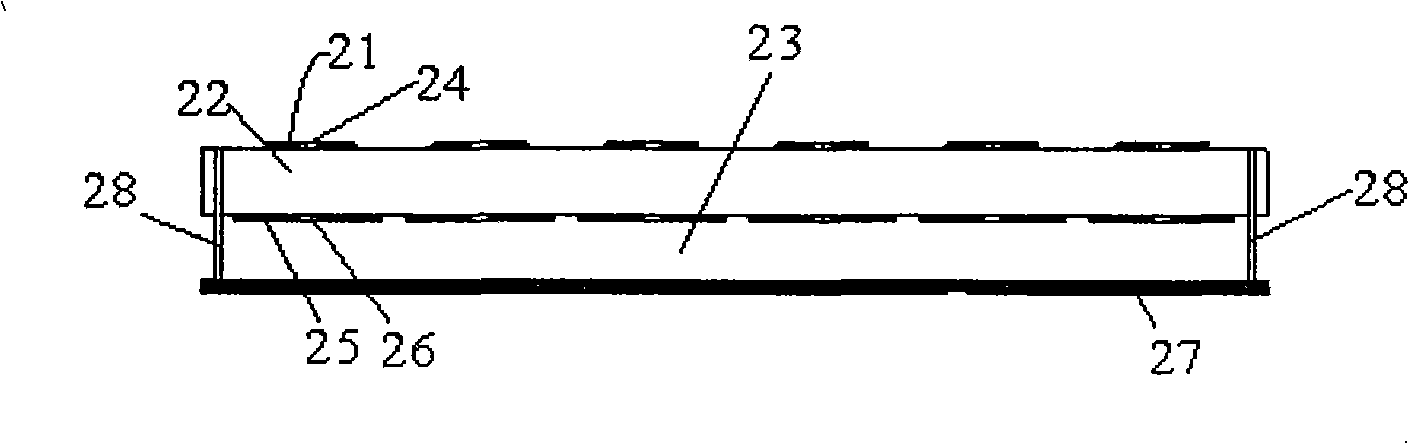

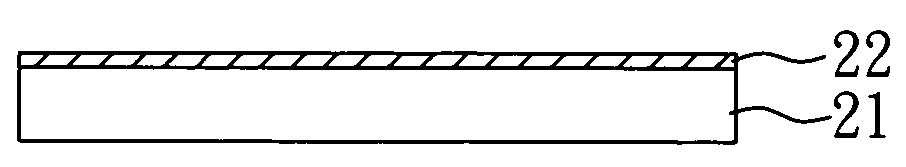

Manufacturing method of micro lens array

The present invention provides a manufacturing method of a micro lens array. The method comprises the following steps that: (1) a single-layer film of magnetic colloidal particles 2 is self-assembled on a substrate 1 by means of a magnetic field induced self-assembling method; (2) with the magnetic colloidal particles 2 adopted as a mask, an electro-deposition process is adopted to obtain a deposited layer; (3) polymer 4 is poured on the magnetic colloidal particles 2 and the deposited layer 3, after being solidified, the polymer 4 is peeled off, and therefore, a micro lens female mold 5 can be obtained; and (4) polymer 6 is poured on the micro lens female mold 5, the polymer 6 is solidified, so that a micro lens array 7 can be obtained through molding. According to the method of the invention, the size of the mold is changed by adjusting the thickness of the deposited layer and the size of the particles, and therefore, the size of the micro lens array can be controlled. The manufacturing method of the invention has the advantages of simple process, adjustable parameters, low production cost, reusable mold, high processing precision, high uniformity and the like.

Owner:HENAN POLYTECHNIC UNIV

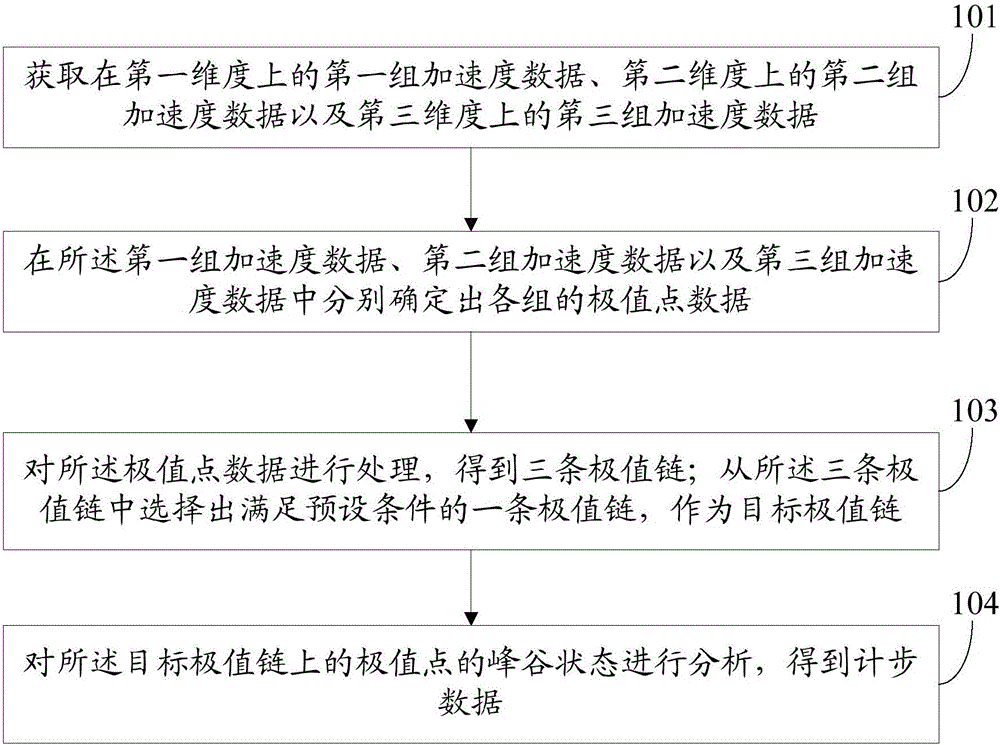

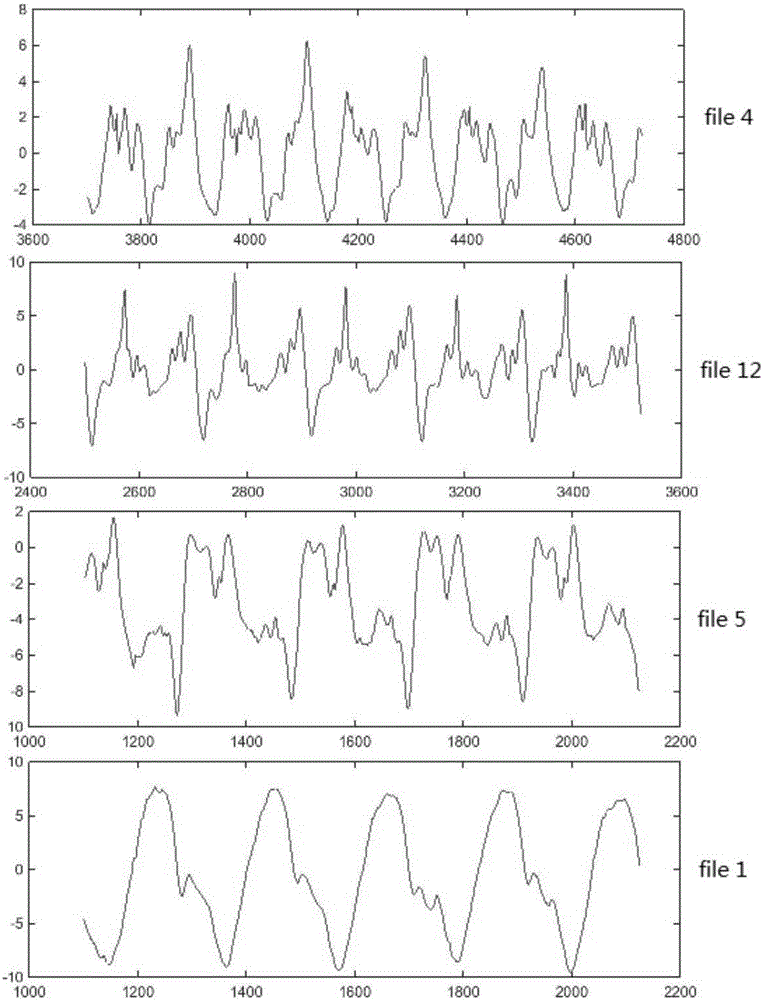

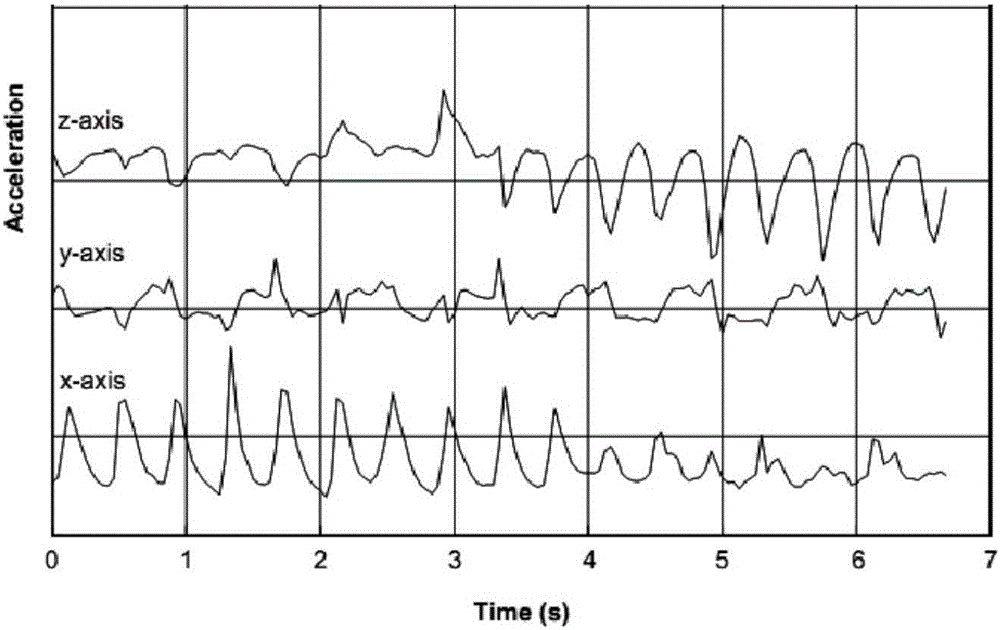

Data processing method and electronic equipment

ActiveCN106197470AGood periodicityEasy and accurate calculationDistance measurementStep countingData processing

The invention discloses a data processing method and electronic equipment. The method comprises the following steps: obtaining a first group accelerated speed data on a first dimension, a second group accelerated speed data on a second dimension, and a third group accelerated speed data on a third dimension; respectively determining the extreme point data of each group in the first group accelerated speed data, the second group accelerated speed data and the third group accelerated speed data; processing the extreme point data to obtain three extreme value chains; selecting the extreme value chain which can satisfy the preset condition in the three extreme value chains as a target extreme value chain; and performing analysis on a peak valley state of the extreme point on the target extreme value chain to obtain the step-counting data.

Owner:LENOVO (BEIJING) CO LTD

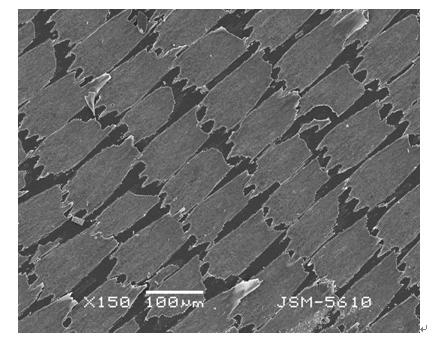

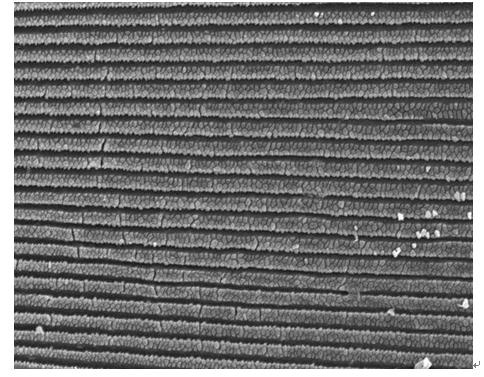

Periodic SiO2 flaky nano structure and preparation method thereof

The invention provides a periodic SiO2 flaky nano structure. The length of the periodic SiO2 flaky nano structure is 125-130 mu m, the width of the periodic SiO2 flaky nano structure is 65-70 mu m, the tail end of the periodic SiO2 flaky nano structure is provided with 4-5 sawteeth, the surface of the periodic SiO2 flaky nano structure is of a periodically distributed strip-shaped structure, and the distribution period of the strip-shaped structure is 2.6-3 mu m. The invention also provides a preparation method of the periodic SiO2 flaky nano structure. The periodic SiO2 flaky nano structure is prepared by utilizing a sol-gel method by taking a butterfly wing as a template and tetraethoxysilane as a raw material. The periodic SiO2 flaky nano structure can be subjected to large-scale preparation on a glass slide, has the characteristics of good periodicity and regular topography, and can be applied to special gratings or other optical devices and the like in the field of optics.

Owner:EAST CHINA NORMAL UNIV

Combined suction system for improving periodicity of planar cascade and quality of outlet flow field

PendingCN112304556ARealize the control effectGood periodicityAerodynamic testingEngineeringWall suction

The invention provides a combined suction system for improving the periodicity of a planar cascade and the quality of an outlet flow field. The combined suction system comprises an upper end wall suction cavity, a left turntable, a left turntable slideway, a cascade wind tunnel experiment table, a cascade wind tunnel experiment table fixing seat, a right turntable and a right turntable slideway. In the system, symmetric suction is conducted through the left grid plate and the right grid plate, symmetric suction is conducted through the front boundary layer structure of the left grid plate andthe right grid plate, the suction device arranged on the blade grid is controlled through the throttle valve, and control over the periodicity and the dense flow ratio of a flow field in the blade grid is achieved; according to the requirements of different blade grids. the number and the relative positions of the suction holes formed in the left grid plate and the right grid plate are adjusted, and the control effect of the periodicity and the dense flow ratio of a blade grid outlet flow field is achieved more efficiently in an energy-saving mode.

Owner:DALIAN MARITIME UNIVERSITY

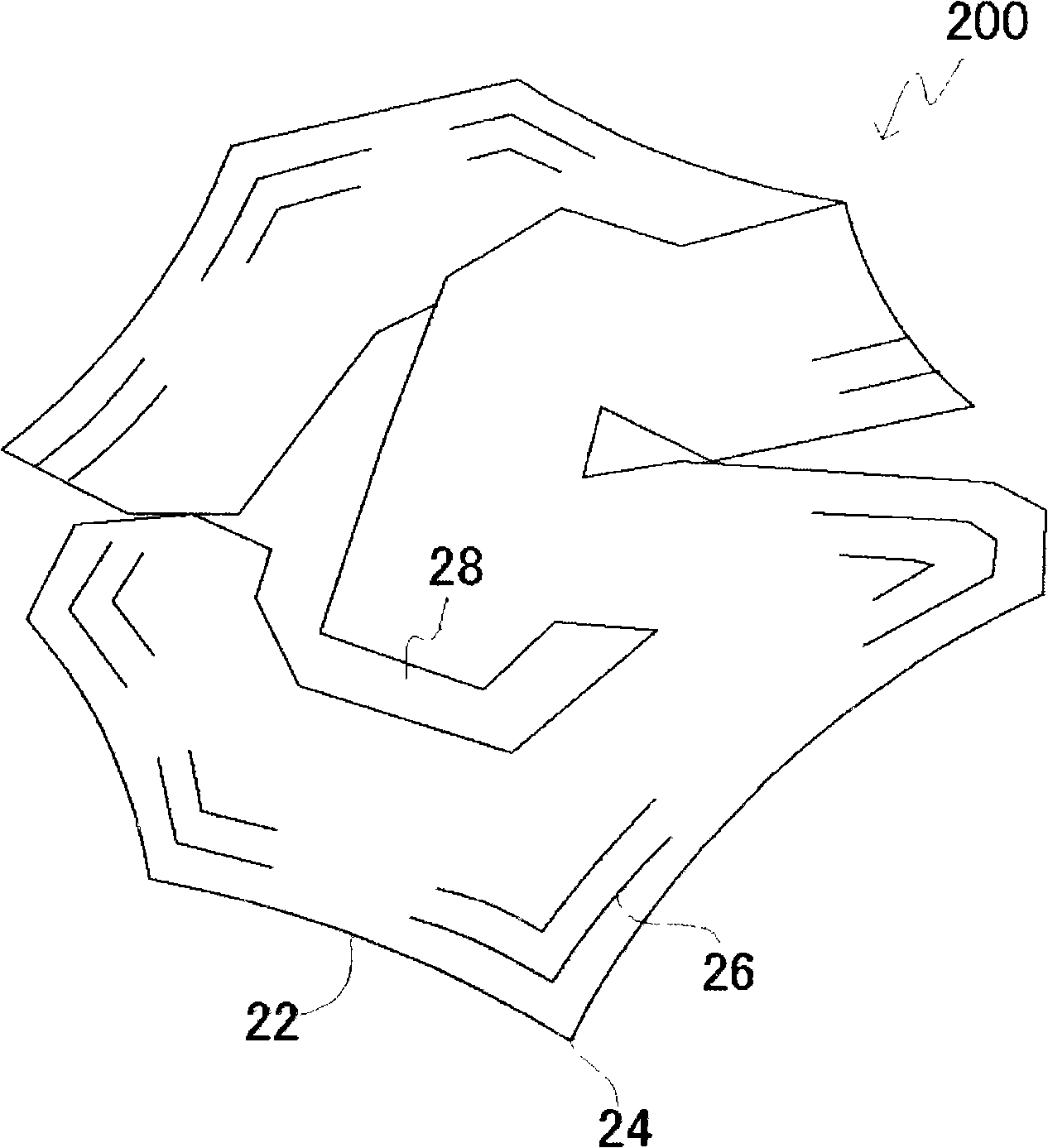

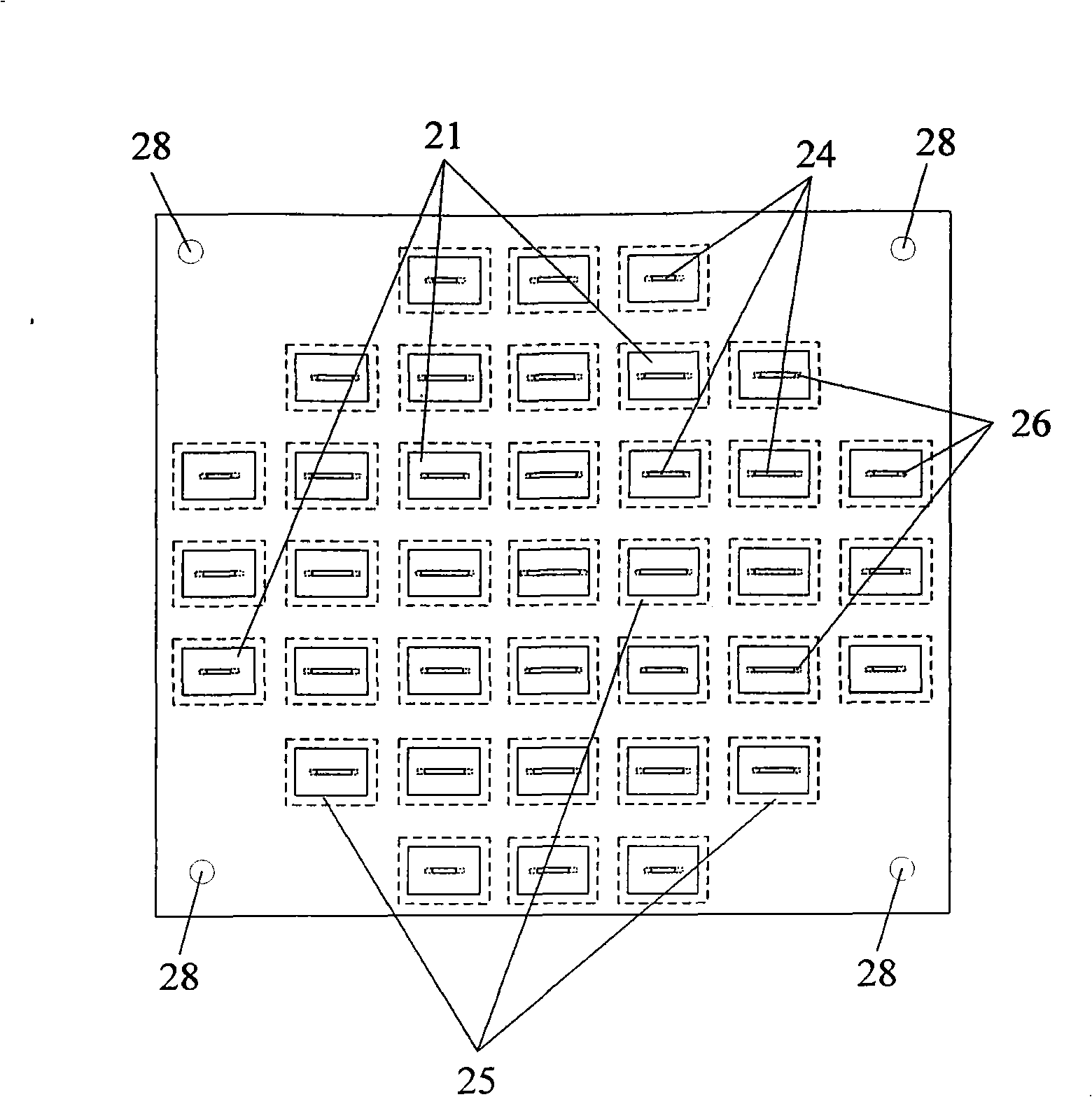

Gap-loaded wide-band microstrip reflective array

The invention discloses a slot-loading broadband micro-strip reflective array, which comprises a feed source (1) and a reflective array (2) away from the feed source (1) with a certain distance; the reflective array (2) comprises a grounding plate (27) and a medium substrate (22) arranged on the plane of the grounding plate (27); a gap (23) is arranged between the medium substrate (22) and the grounding plate (27); and the lower surface of the grounding plate (27) is opposite to the grounding plate (27). The slot-loading broadband micro-strip reflective array has simple structure; owing to the adoption of a double layer rectangular patch added with a slot and an air layer, the phase compensation value is improved by 50 to 80 percent, and therefore the size of the array is also increased correspondingly; in addition, gain band of -1dB dropping is also improved from 2 to 3 percent to 13 to 15 percent.

Owner:SOUTHEAST UNIV

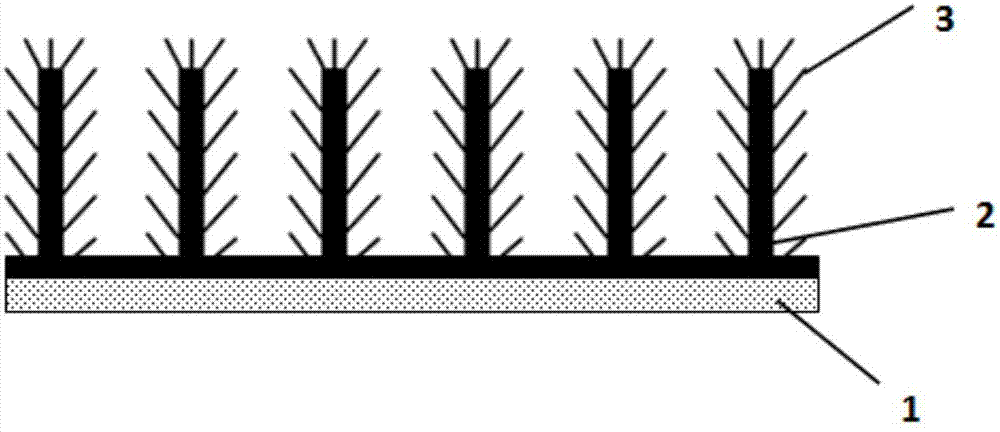

Three-dimensional nano-structure array and preparation method and application thereof

ActiveCN106981531AEasy to prepareReduce manufacturing costMaterial nanotechnologyFinal product manufactureNano structuringNanowire

The invention discloses a three-dimensional nano-structure array and a preparation method and an application thereof. The three-dimensional nano-structure array comprises regularly-arranged semiconductor nanowire arrays and semiconductor nanowire arrays grown in a radiation manner thereon. The nanowires grown in the prepared three-dimensional nano-structure array in a radiation manner are relatively small in diameters and relatively high in length and density, so that the specific surface area of the material is greatly enlarged, thereby enlarging the light absorption area of the three-dimensional nano-structure array and obviously reinforcing light absorption compared with a one-dimensional nanometer array; meanwhile, the fine and tiny nanowires are in radiation growth on the outer side of the regularly-arranged nanowires, and the nanowires grown in a radiation manner are relatively high in density, so that the light rays incident from each angle can be well absorbed, and sensitivity to the light ray incident angles of the three-dimensional nano-structure array is lowered; and when the three-dimensional nano-structure array is applied in the photovoltaic field, the problem of increasing of cost caused by a condition that the angle of a solar battery is changed constantly along with changes of illumination angles can be avoided.

Owner:SHANGQIU NORMAL UNIVERSITY

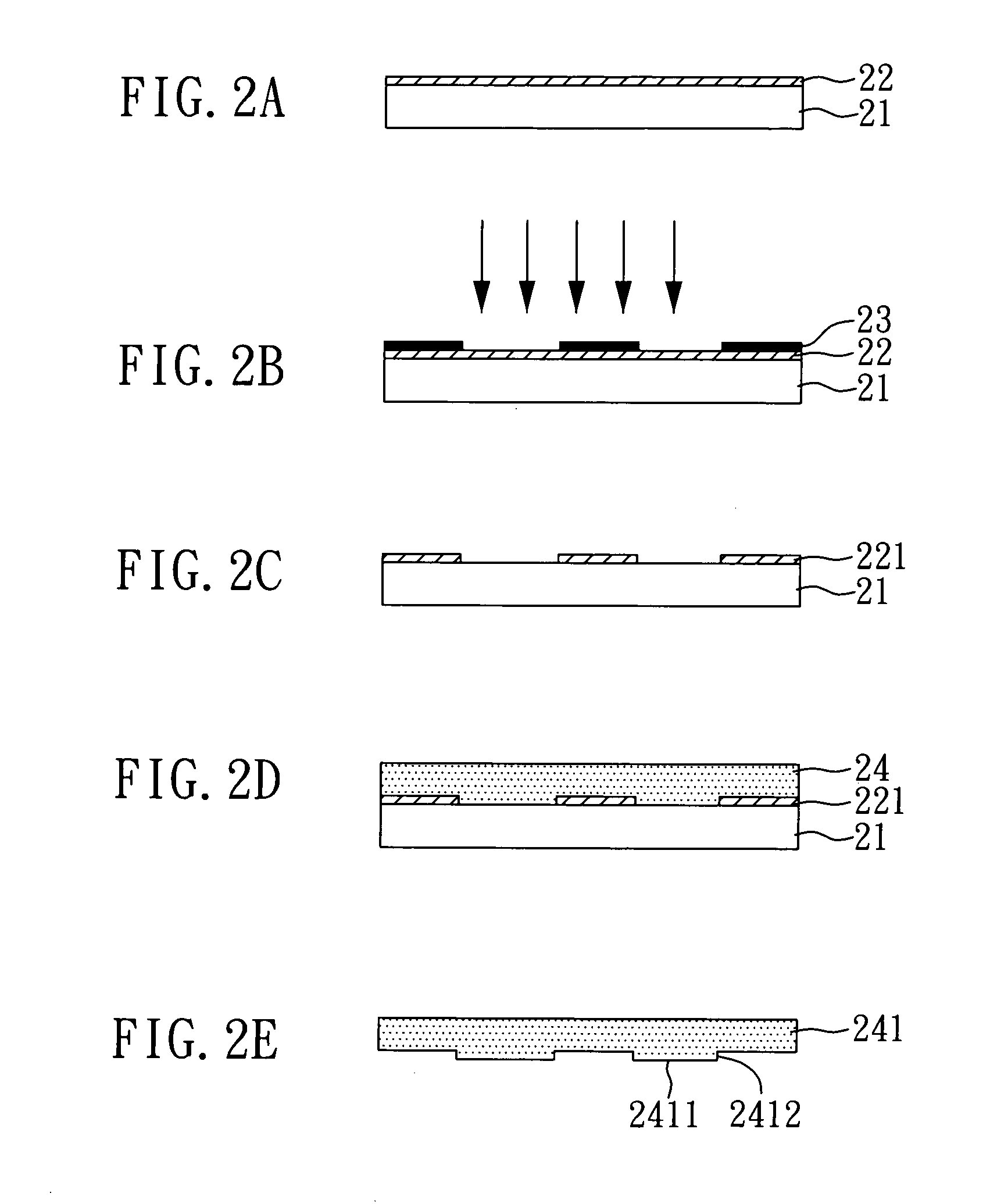

Method for preparing photonic crystal slab waveguides

InactiveUS20090197210A1Fast preparationGood periodicityPhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistPresent method

A method for preparing a photonic crystal slab waveguides is disclosed, wherein the photonic crystal slab waveguides are prepared by combining near-field phase-shifting contact lithography (NFPSCL) with interference lithography (IL). Conventional methods used for preparing the photonic crystal slab waveguides, such as electron beam lithography or direct laser writing, are time consuming. In contrast, the present method allows rapid production of many photonic crystal slab waveguides over a large area composed of microstructures.

Owner:NAT TAIWAN UNIV

Feature tracking using ultrasound

ActiveUS9248316B2Reduce the burden onGood periodicityImage enhancementImage analysisSupporting systemSonification

Various implementations of the invention provide techniques and supporting systems that facilitate real-time or near-real-time ultrasound tracking for the purpose of calculating changes in anatomical features during a medical procedure. More specifically, anatomical features within a patient undergoing a medical procedure are tracked by obtaining temporally-distinct three dimensional ultrasound images that include the feature of interest and obtaining a targeted subset of ultrasound images focused on the feature. Based on the targeted subset of ultrasound images, a displacement of the feature is determined and image parameters used to obtain the targeted subset of ultrasound images are adjusted based on the displacement. This results in a time-based sequence of three dimensional images and targeted ultrasound images of the feature that identify changes in the position, size, location, and / or shape of the feature.

Owner:ELEKTA AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com