Graphite particle, carbon-graphite composite particle and their production process

A graphite particle and manufacturing method technology, applied in the direction of graphite, carbon compounds, chemical instruments and methods, etc., can solve the problems of good diffusion and high-speed charge and discharge characteristics damage, and achieve excellent cycle performance, small resistance, and large charge and discharge energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

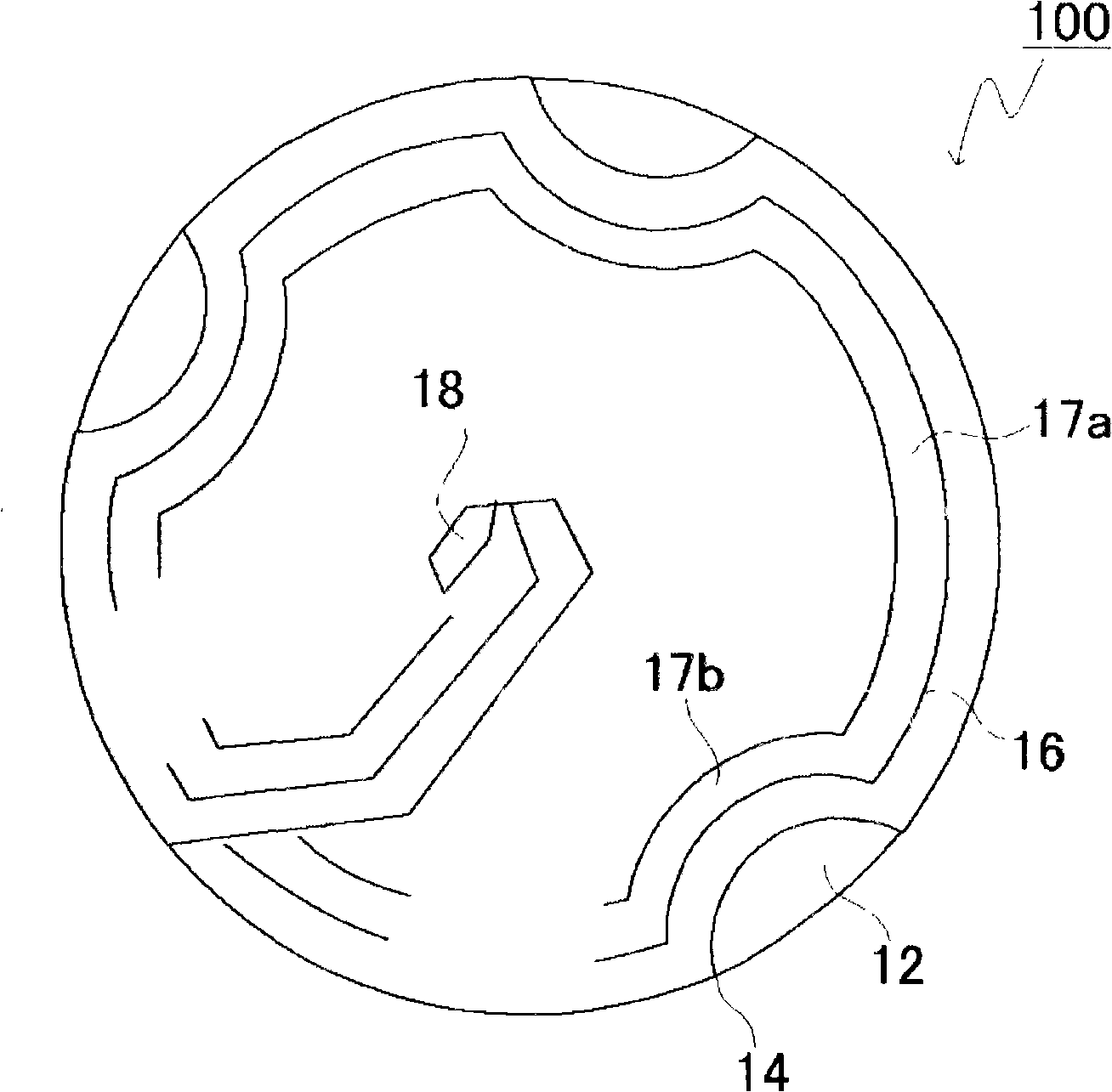

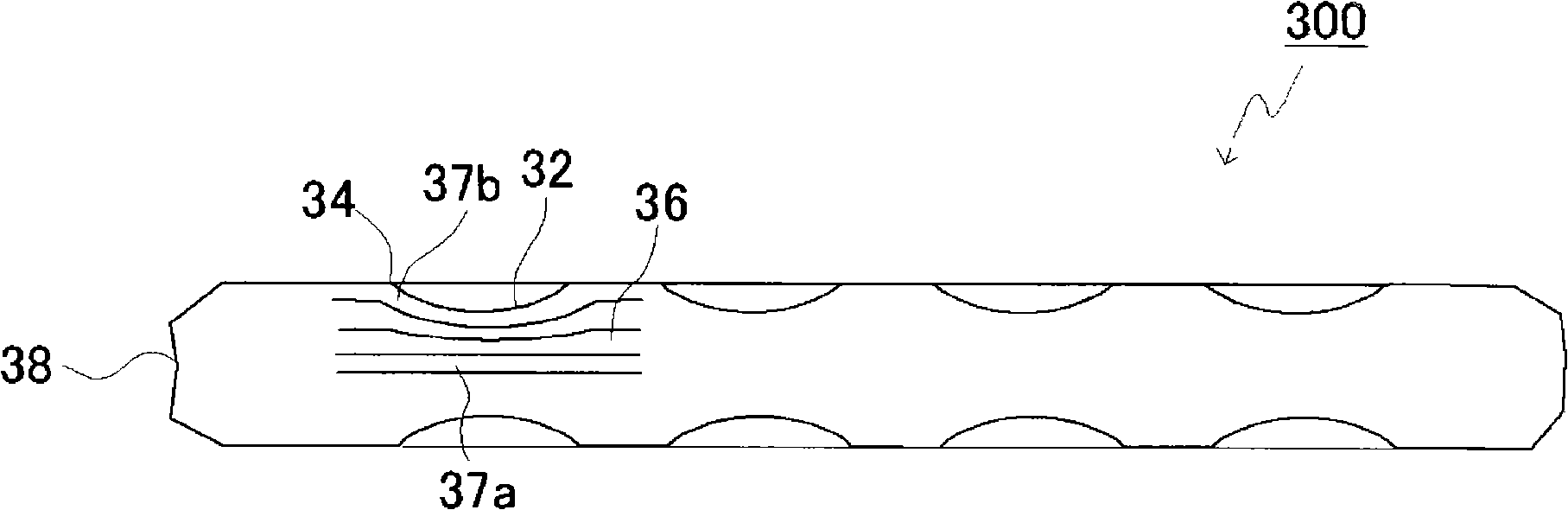

Embodiment 1

[0216] 100 g of copper particles (average particle size: 10 μm) was added to 100 g of flaky graphite (the average length along the plane direction was 28 μm, and the thickness was 5 μm), and mixed for 5 minutes with a stand mixer. After mixing, use a desktop molding machine to form a cylindrical shape of 4 to 5 cm φ under a pressure of 50 MPa. The molded product was pulverized with a mortar to an average particle diameter of 40 μm, and the pulverized product was immersed in a 5% by mass sulfuric acid solution at room temperature for 24 hours to dissolve and remove copper. The mixed solution of copper and graphite was filtered, washed with water, and the graphite was recovered, and dried at 105° C. for 12 hours. 10 g of the obtained graphite particles were kept at 900° C. for 20 minutes under a nitrogen flow in an electric furnace, and 2 g of toluene was added to perform CVD treatment. The treated particles were recovered, and the measurements of tamping density, average parti...

Embodiment 2

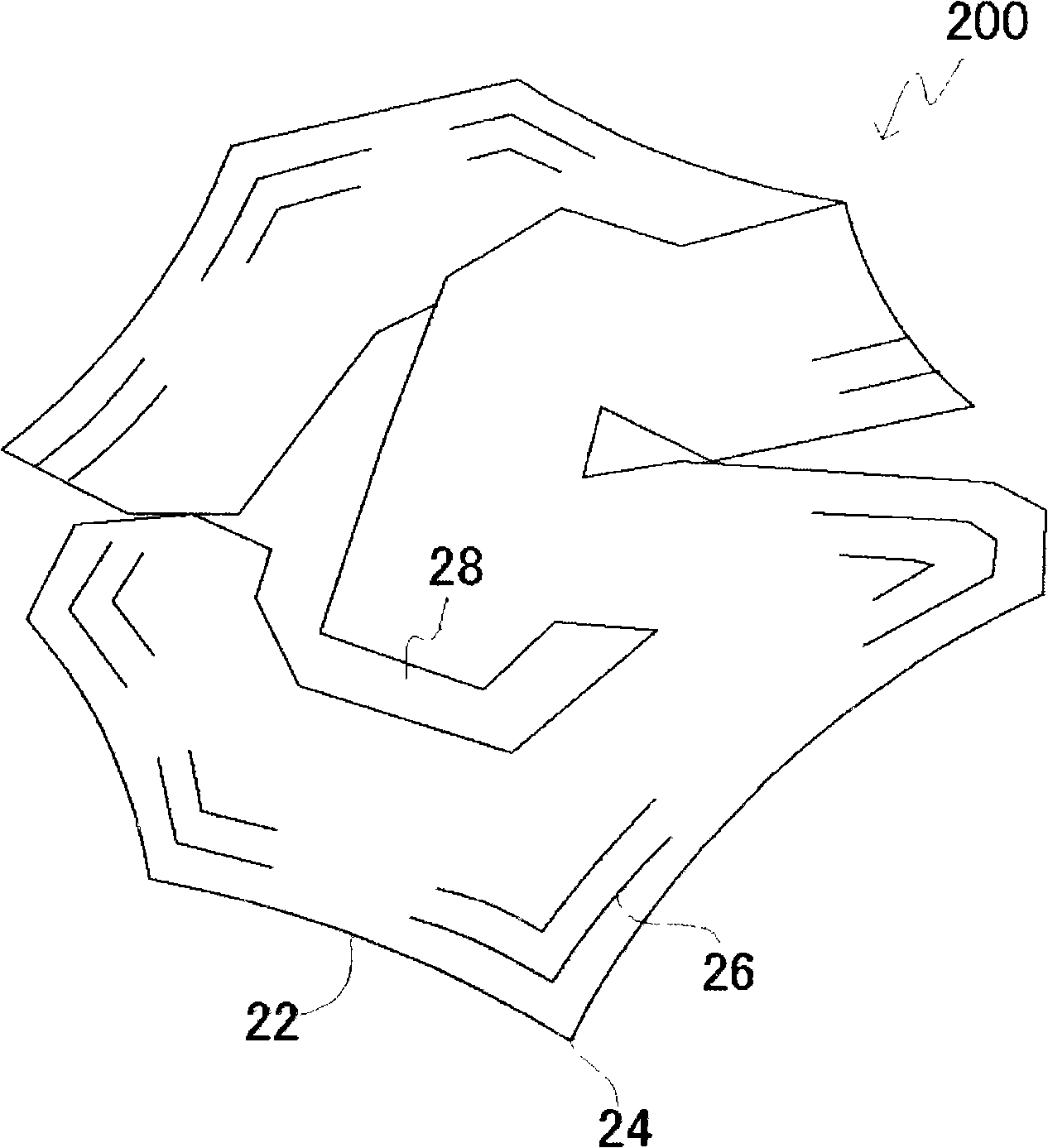

[0231] 10 g of silica particles (average particle size: 6 μm) were added to 100 g of spherical graphite (average particle size: 28 μm), and mixed for 5 minutes with a stand mixer. After mixing, use a desktop molding machine to form a cylindrical shape of 4 to 5 cm φ under a pressure of 50 MPa. The molded product was pulverized with a mortar, and the pulverized product was immersed in a 46% by mass hydrofluoric acid solution at room temperature for 24 hours to dissolve and remove silica. The mixed solution of silicon dioxide and graphite was filtered, washed with water, and the recovered graphite was kept dry at 105° C. for 12 hours. 10 g of the recovered particles were kept at 900° C. for 20 minutes under a nitrogen flow in an electric furnace, and 2 g of toluene was added to perform CVD treatment. The treated particles were recovered, and the measurements of tamping density, average particle diameter, SEM observation, carbon coating amount, recess depth, electrode density, e...

Embodiment 3

[0234] 20 g of polyethylene particles (average particle size: 5 μm) were added to 100 g of spherical graphite (average particle size: 26 μm), and mixed for 5 minutes with a stand mixer. After mixing, use a desktop molding machine to form a cylindrical shape of 4 to 5 cm φ under a pressure of 50 MPa. The molded product was pulverized in a mortar, and the pulverized product was fired in an electric furnace at 900° C. for 1 hour under a nitrogen flow to remove polyethylene. While maintaining 10 g of the recovered particles at 900° C. for 20 minutes under a nitrogen flow in an electric furnace, 2 g of toluene was added to perform CVD treatment. The treated particles were recovered, and the measurements of tamping density, average particle size, SEM observation, carbon coating amount, recess depth, electrode density, electrode evaluation, etc. were performed. The pore diameter of the concave part is 5.7 μm, and the depth of the concave part is 2.1 μm. The SEM photo of the obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com