FFS (Free Fall Sensor) type TFT-LCD (Thin Film Transistor-Liquid Crystal Display) array substrate and manufacture method thereof

A technology of an array substrate and a manufacturing method, which is applied in the field of thin film transistor liquid crystal display and its manufacturing, can solve problems such as lowering the transmittance and reducing the strength of the fringe electric field, so as to reduce power consumption, increase the overall transmittance, and increase the driving frequency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

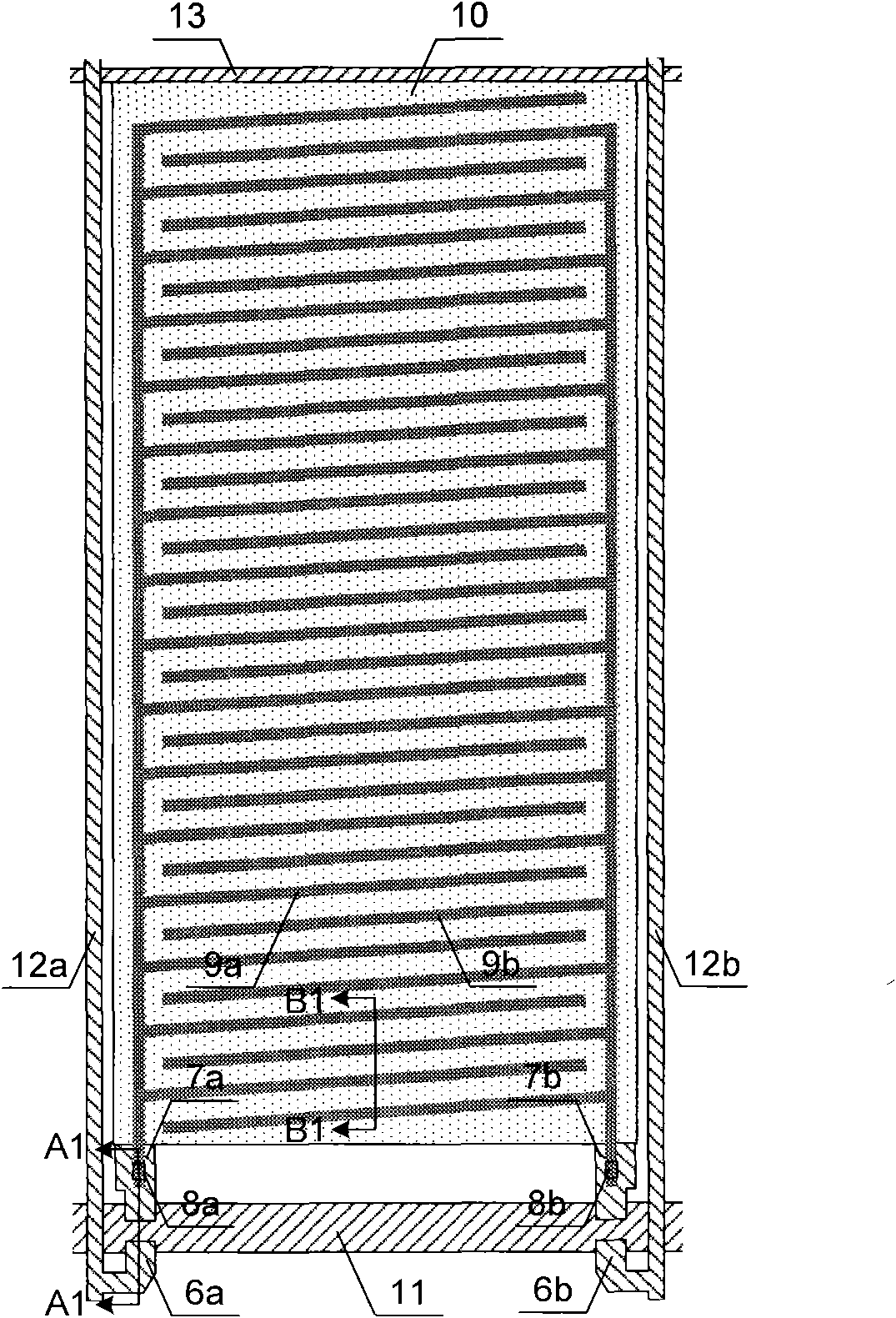

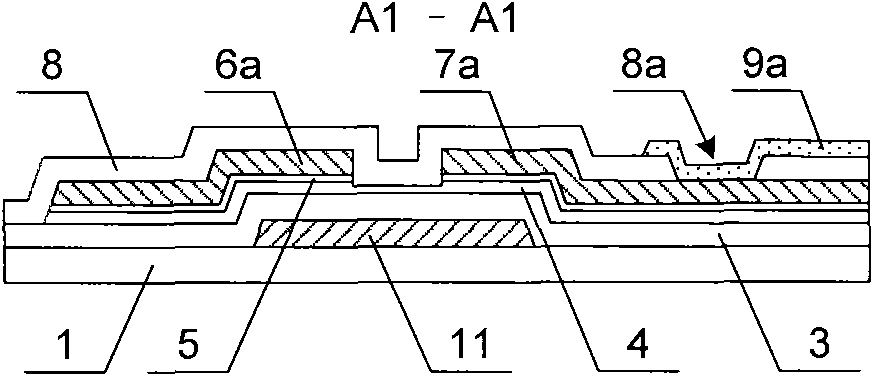

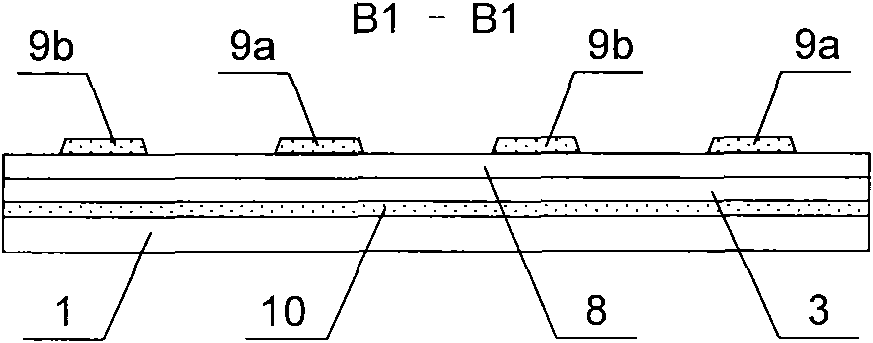

[0048] figure 1 It is a plan view of the FFS type TFT-LCD array substrate of the present invention, which reflects the structure of a pixel unit, figure 2 for figure 1 The cross-sectional view of A1-A1 in the middle, image 3 for figure 1 Sectional view of B1-B1 direction in the middle. Such as Figure 1 ~ Figure 3 As shown, the main structure of the FFS type TFT-LCD array substrate of the present invention includes a common electrode 10 formed on the substrate 1, a gate line 11, a first data line 12a, a second data line 12b, a first pixel electrode 9a, a second The pixel electrode 9b, the first thin film transistor, the second thin film transistor and the common electrode line 13; the first data line 12a and the second data line 12b arranged in parallel and two adjacent gate lines 11 define the pixel area, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com