Method and apparatus for manufacturing extended lead electrodes of secondary battery

A manufacturing method and battery technology, applied in lead-acid battery electrodes, battery electrodes, circuits, etc., can solve the problems of unstable plate dimensional accuracy, easy development of lead plate corrosion, and more time and effort, and achieve good charging and discharging characteristics. , the life characteristics and performance differences are small, the effect of reducing local stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

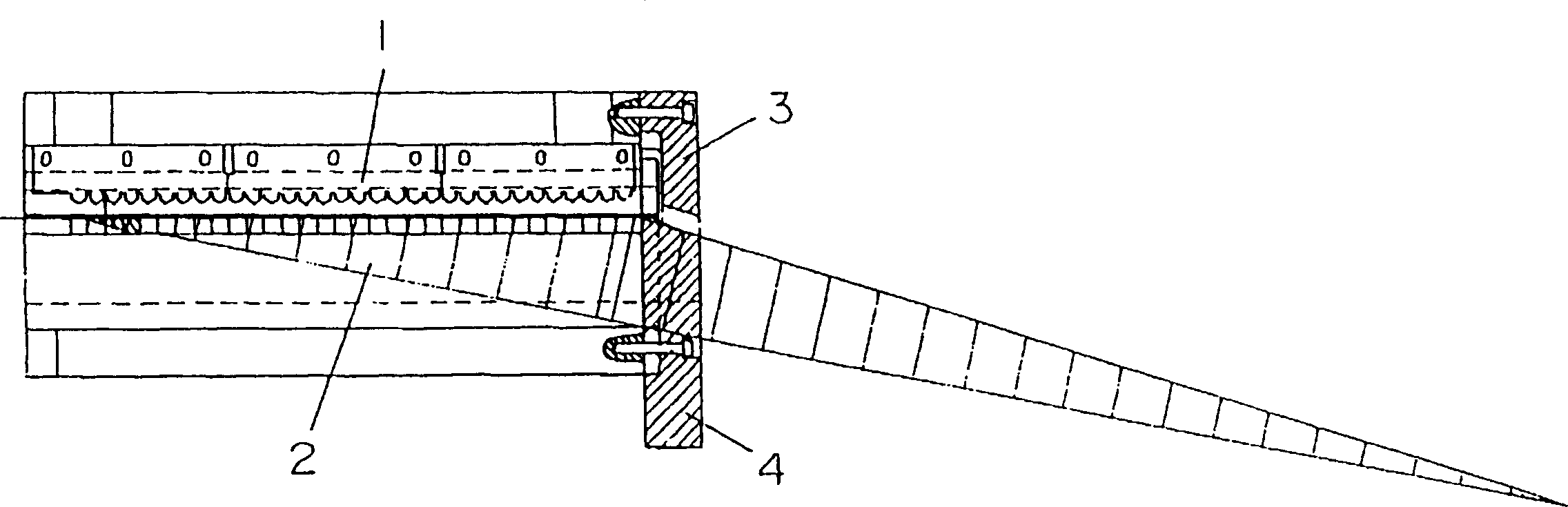

[0036] exist figure 1 A side view of an embodiment of an apparatus used in the method of manufacturing an extended battery grid of the present invention is shown in FIG.

[0037] exist figure 1 Among them, the manufacturing device of the battery lead plate has a processing knife 1 as a processing device, a bending device 3 and a base 4 .

[0038] The machining knife 1 has about 30 blades.

[0039] The strip-shaped thin plate 2 moves in the longitudinal direction on the lower side of the machining knife 1 .

[0040] The thin plate 2 moves synchronously with the processing knife 1 and the bending device 3 .

[0041] Through the reciprocating movement of the processing knife 1 up and down, a mesh-shaped incision is formed on the strip-shaped thin plate 2 .

[0042] The strip-shaped thin plate 2 is composed of a lead-tin-calcium alloy and has a thickness of about 1.0 mm.

[0043] The veneer 2 with the mesh-shaped incision expands and expands toward the width direction of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com