Silicon carbide wafer bevel grinding, milling and polishing machine and operation method thereof

A technology of silicon carbide crystal and polishing machine, which is applied in the field of grinding and polishing, grinding of silicon carbide wafer bevel, grinding, polishing processing equipment, silicon carbide wafer bevel grinding, which can solve the problem of difficult control of wafer grinding and grinding angle, Problems such as large width dimension error and low polishing processing efficiency can achieve the effect of stable width dimension, high machining accuracy and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

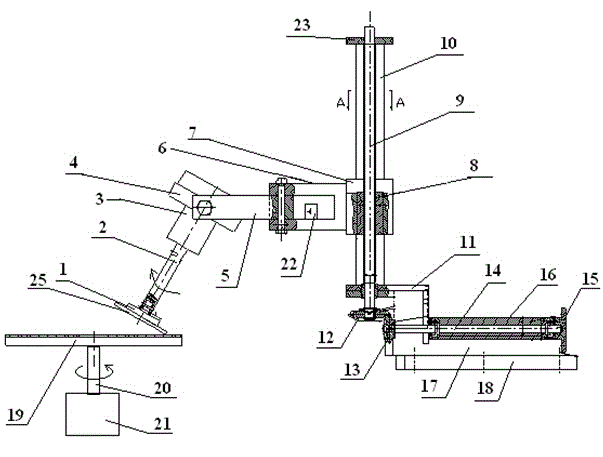

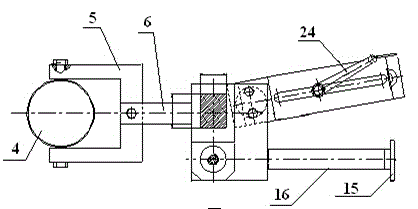

[0035] Such as figure 1 and figure 2As shown, a silicon carbide wafer bevel grinding, grinding and polishing machine, which includes a support piece (1), a rotating shaft (2) connected to the supporting piece (1), and a drive motor connected to the rotating shaft (2) ( 3), the drive motor (3) is installed on the motor bracket (4), the motor bracket (4) is installed on the vertical arm (5), the vertical arm (5) and the horizontal arm (6) ), the horizontal arm (6) is connected with the carriage (7), the carriage (7) is connected with the screw (9) through the inner bushing (8), and the outer periphery of the screw (9) is provided with a bushing (10) , the bushing sleeve (10) is fixed on the column (11), the lower end of the screw rod (9) is connected with the first bevel gear (12), and the first bevel gear (12) is connected with the second bevel gear (13), the The second bevel gear (13) is connected with the adjustment shaft (14), and the adjustment shaft (14) is connected wi...

Embodiment 2

[0044] A circular silicon carbide wafer bevel grinding, lapping and polishing method, which comprises the following steps:

[0045] a. If figure 1 As shown, firstly, the circular silicon carbide wafer (25) to be processed is bonded on the support sheet (1), then the grinding wheel is first installed on the upper end of the shaft (19), and then the motor (20) is started, and the motor (20) drives The grinding wheel on the shaft (19) rotates;

[0046] b. Rotate the runner (14), the runner (14) drives the adjustment shaft (13) to rotate, and then the adjustment shaft (13) drives the second bevel gear (13) and the first bevel gear (12) to rotate in turn, the first bevel gear The gear (12) drives the screw (9) to rotate, and the screw (9) drives the carriage (7) to move up and down, thereby driving the horizontal arm (6) and the vertical arm (5) to move up and down in turn, and then the vertical arm (5) ) to drive the drive motor (3) on the motor bracket (4) to move up and down, ...

Embodiment 3

[0054] Rectangular silicon carbide wafer bevel grinding, grinding and polishing method, it comprises the following steps:

[0055] a. First, bond the rectangular silicon carbide wafer to be processed on the support sheet (1), then install the grinding wheel on the upper end of the shaft (19), then start the motor (20), and the motor (20) drives the shaft (19) wheel rotation;

[0056] b. Rotate the runner (14), the runner (14) drives the adjustment shaft (13) to rotate, and then the adjustment shaft (13) drives the second bevel gear (13) and the first bevel gear (12) to rotate in turn, the first bevel gear The gear (12) drives the screw (9) to rotate, and the screw (9) drives the carriage (7) to move up and down, thereby driving the horizontal arm (6) and the vertical arm (5) to move up and down in turn, and then the vertical arm (5) ) to drive the drive motor (3) on the motor bracket (4) to move up and down, thereby adjusting the distance between the circular silicon carbide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com