Patents

Literature

115results about How to "Reduce local stress concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

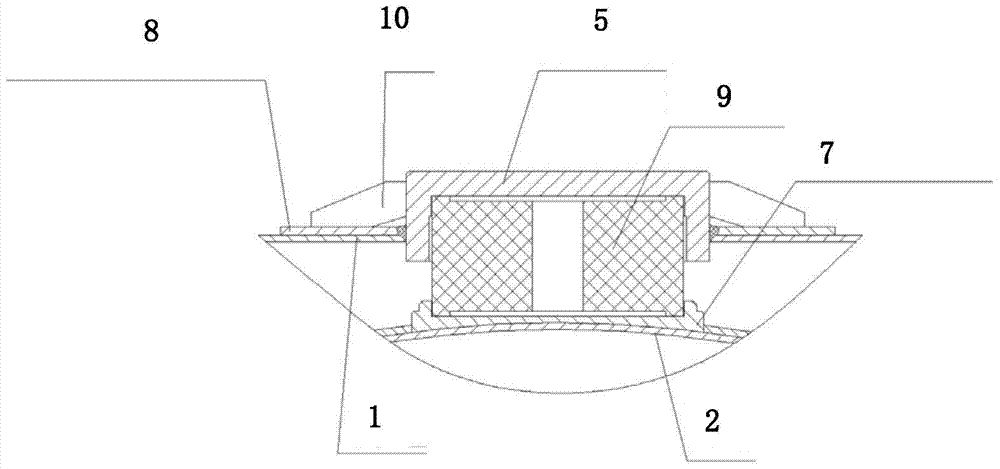

Semiconductor Device and Method for Manufacturing Semiconductor Device

InactiveUS20090243065A1Improve joint reliabilityLower elastic modulusSemiconductor/solid-state device detailsSolid-state devicesSurface mountingSemiconductor chip

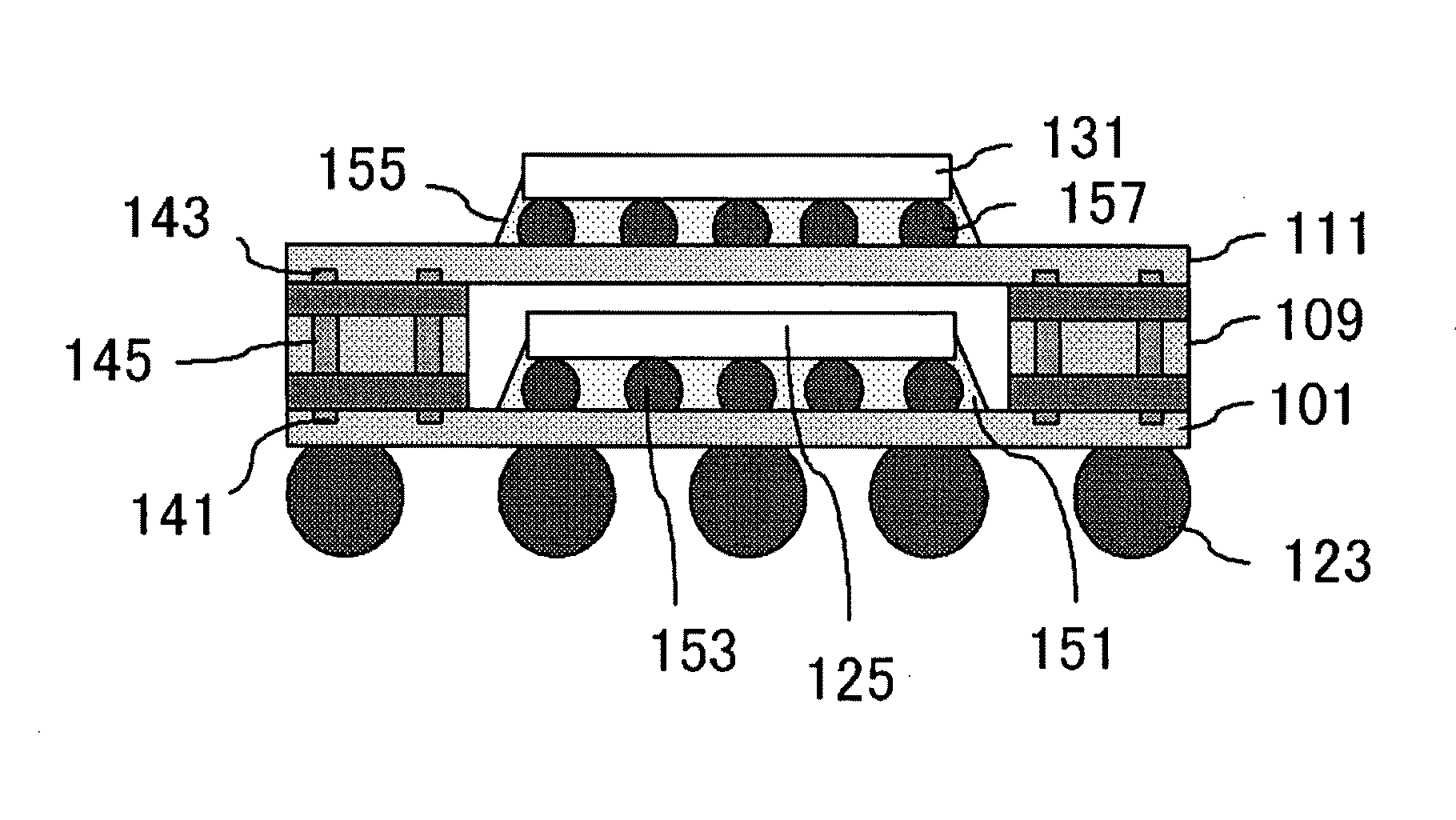

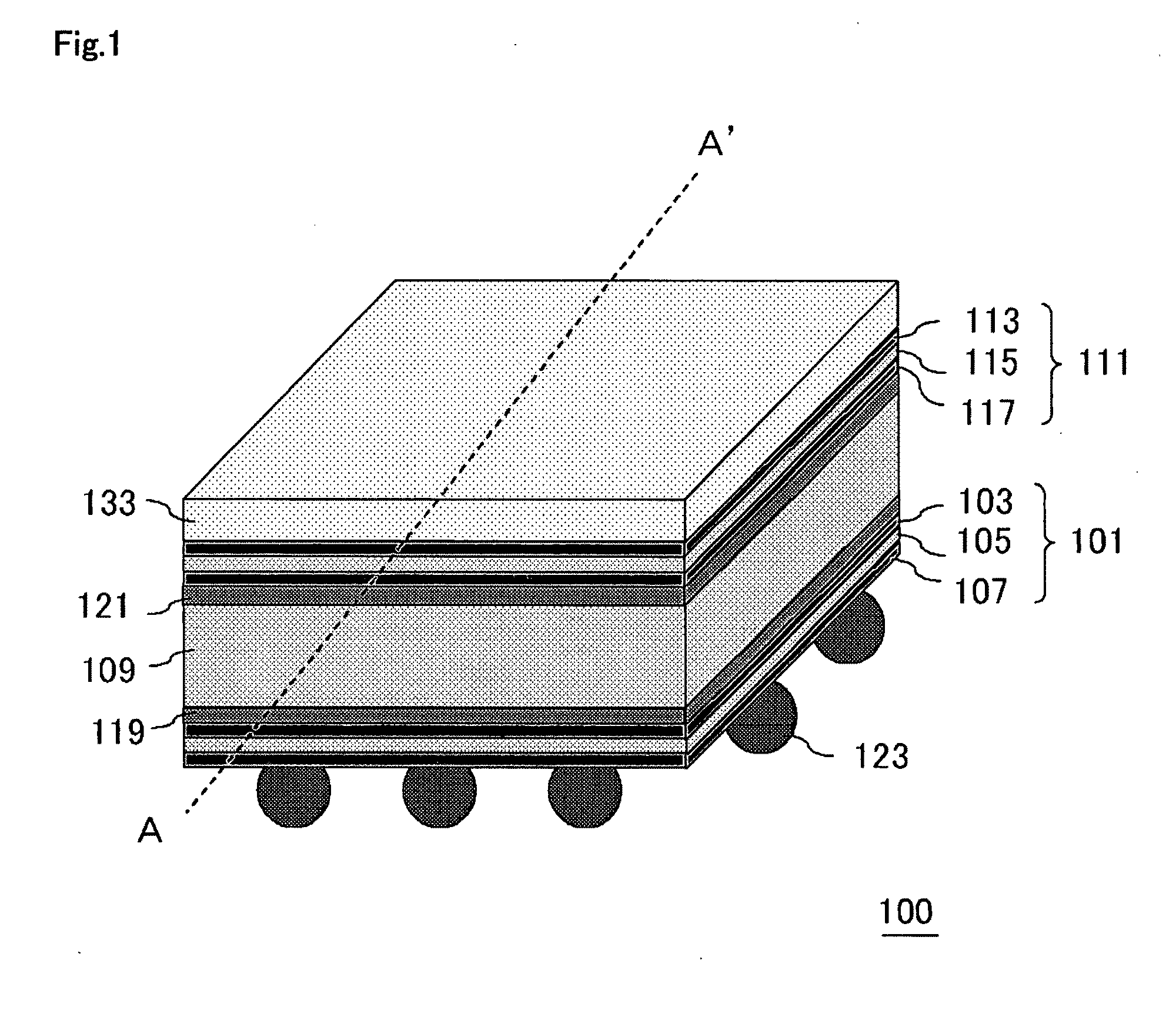

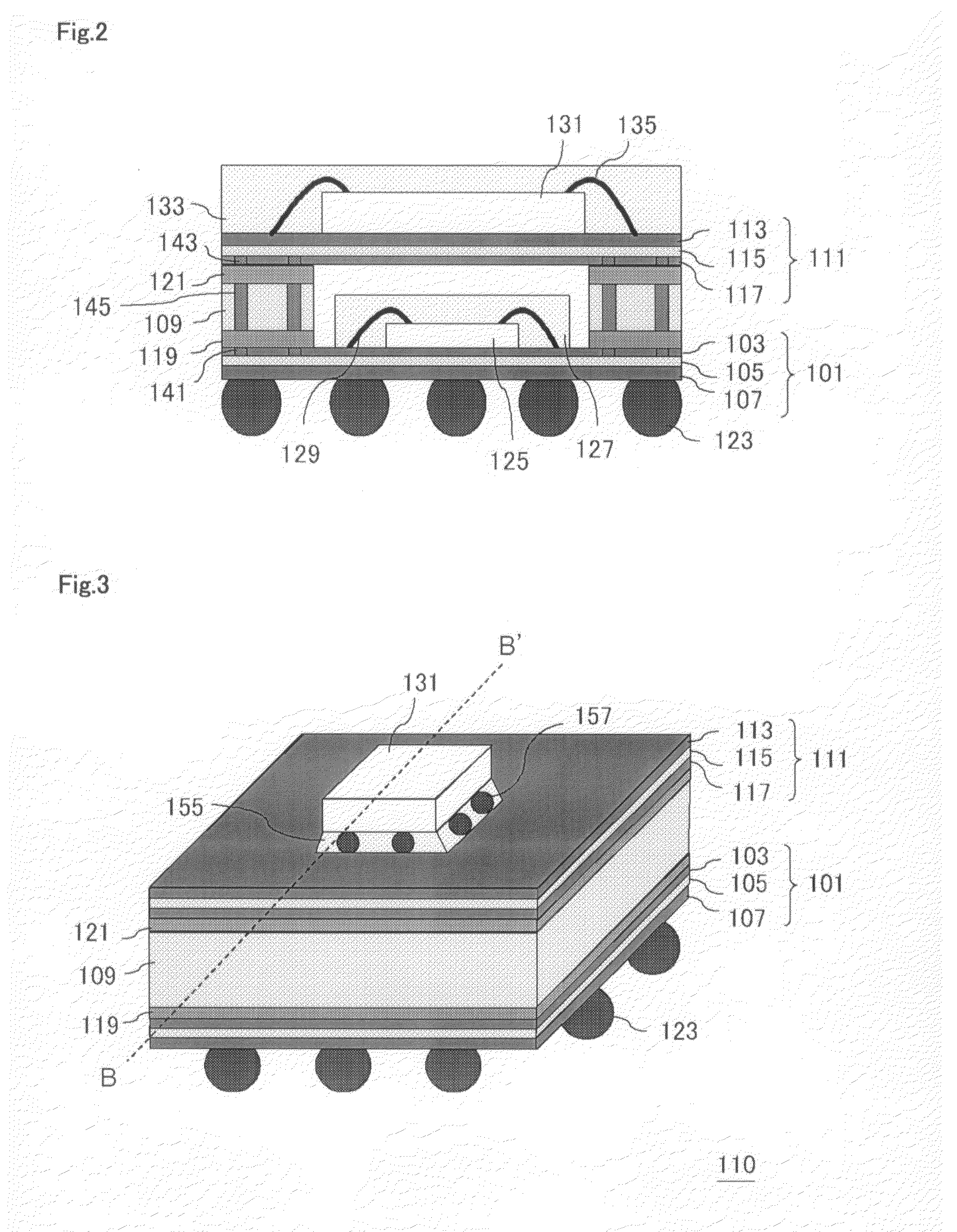

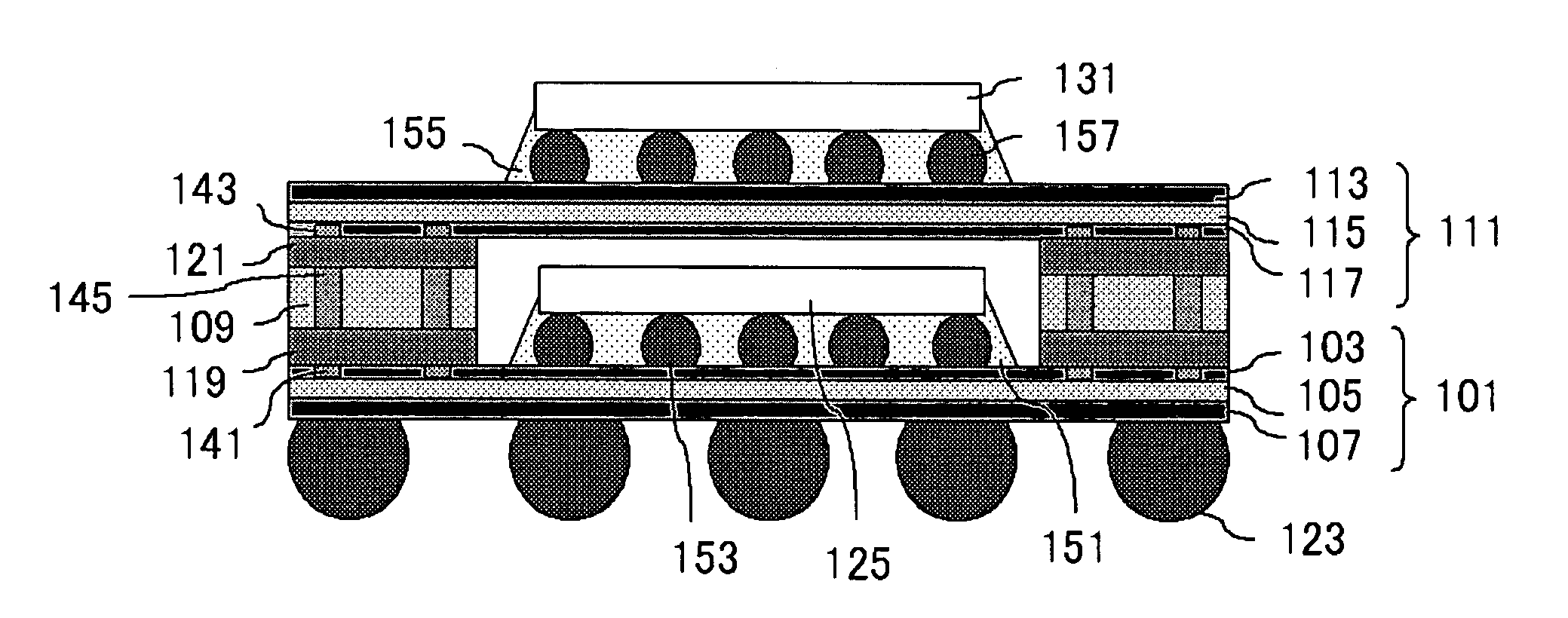

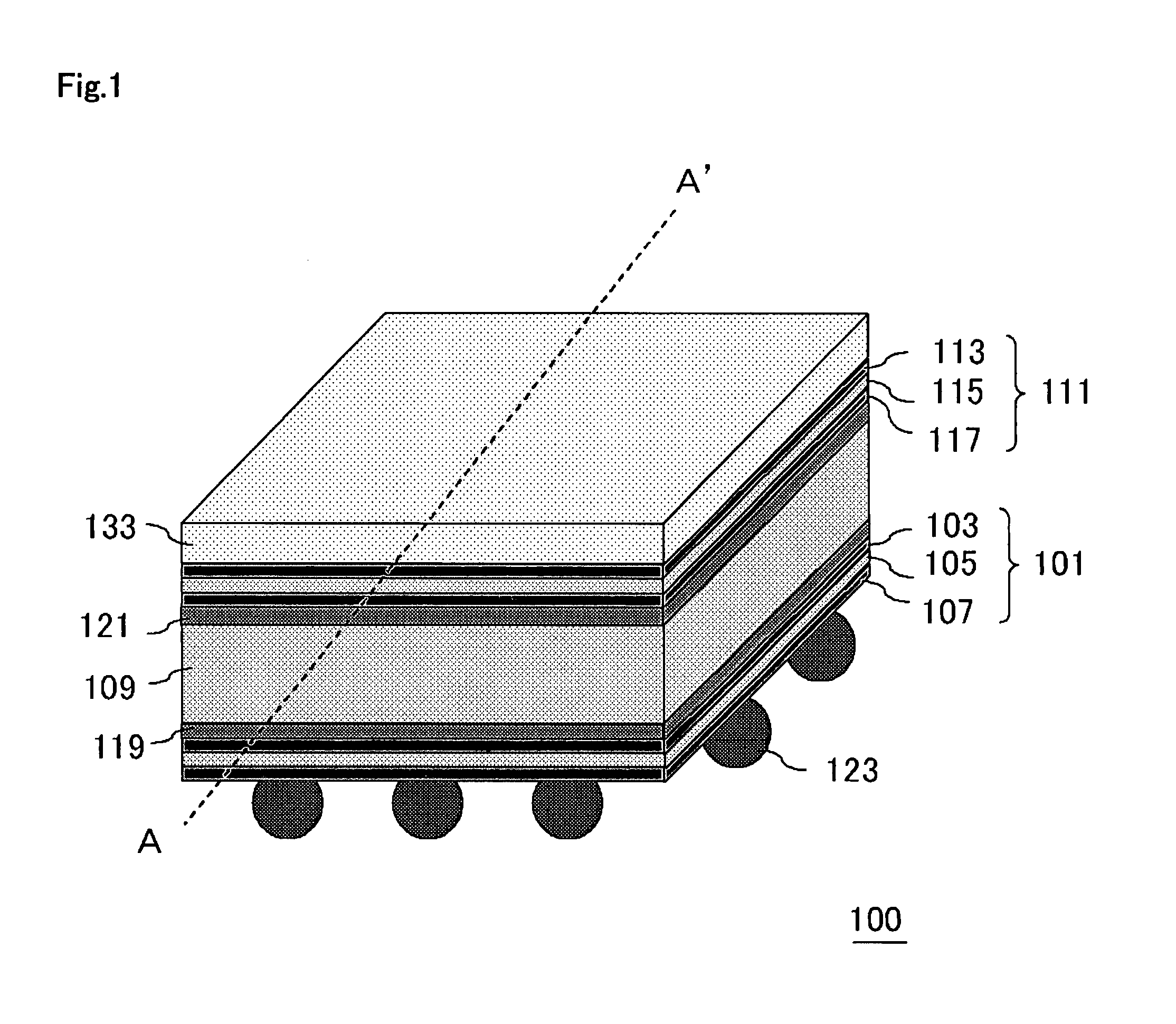

A semiconductor device (100) comprises a first resin substrate (101) on which a first semiconductor chip (125) is mounted a surface thereof; a second resin substrate (111) on which a second semiconductor chip (131) is mounted on a surface thereof; and a resin base material (109), joined to a front surface of the first resin substrate (101) and to a back surface of the second resin substrate (111), so that these surfaces are electrically connected. The resin base material (109) is disposed in a circumference of the first resin substrate (101) in the surface of the first resin substrate (101). Further, the first semiconductor chip (125) is disposed in a space section provided among the first resin substrate (101), the second resin substrate (111) and the resin base material (109) in the surface of the first resin substrate (101).

Owner:SUMITOMO BAKELITE CO LTD

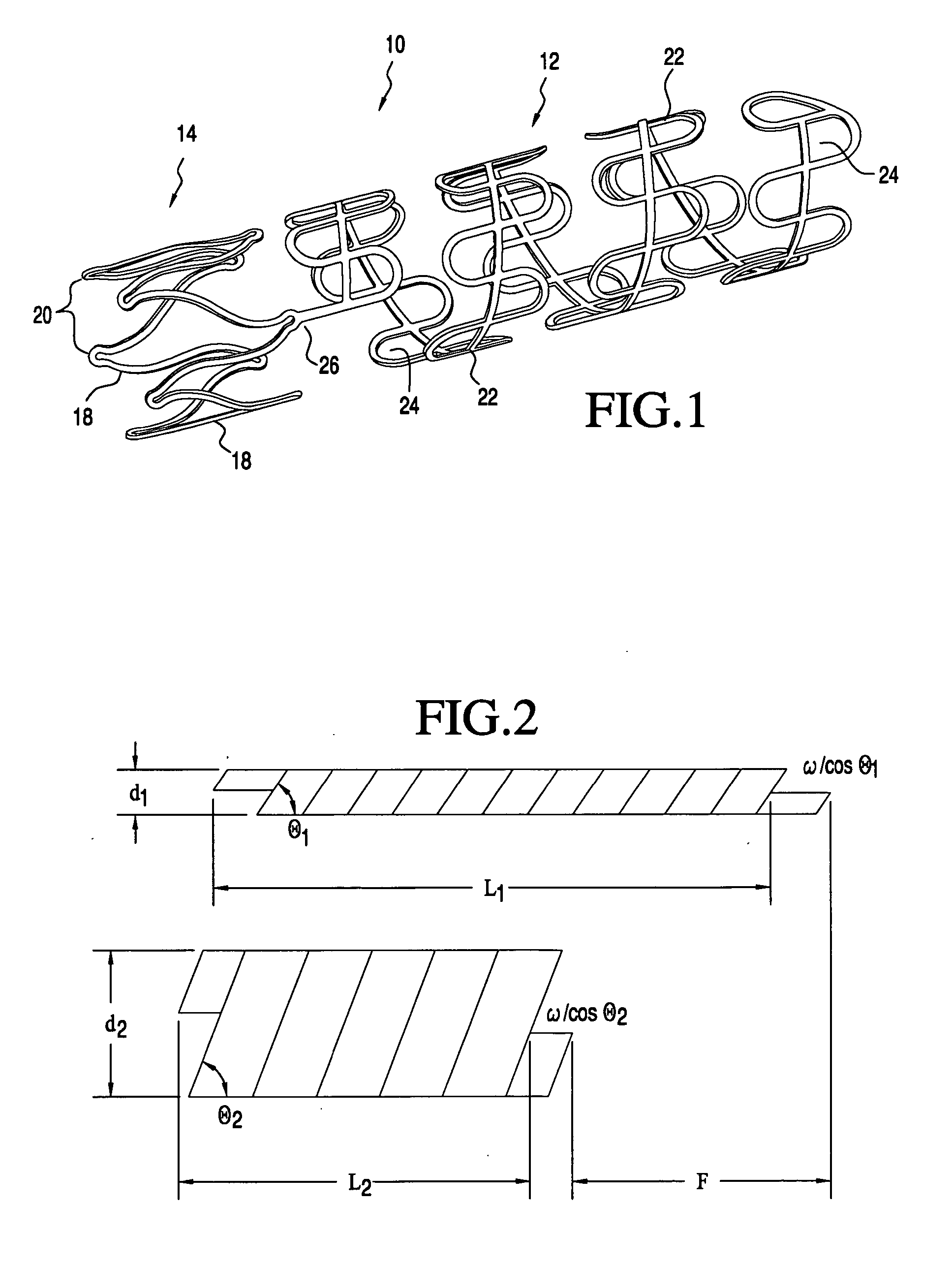

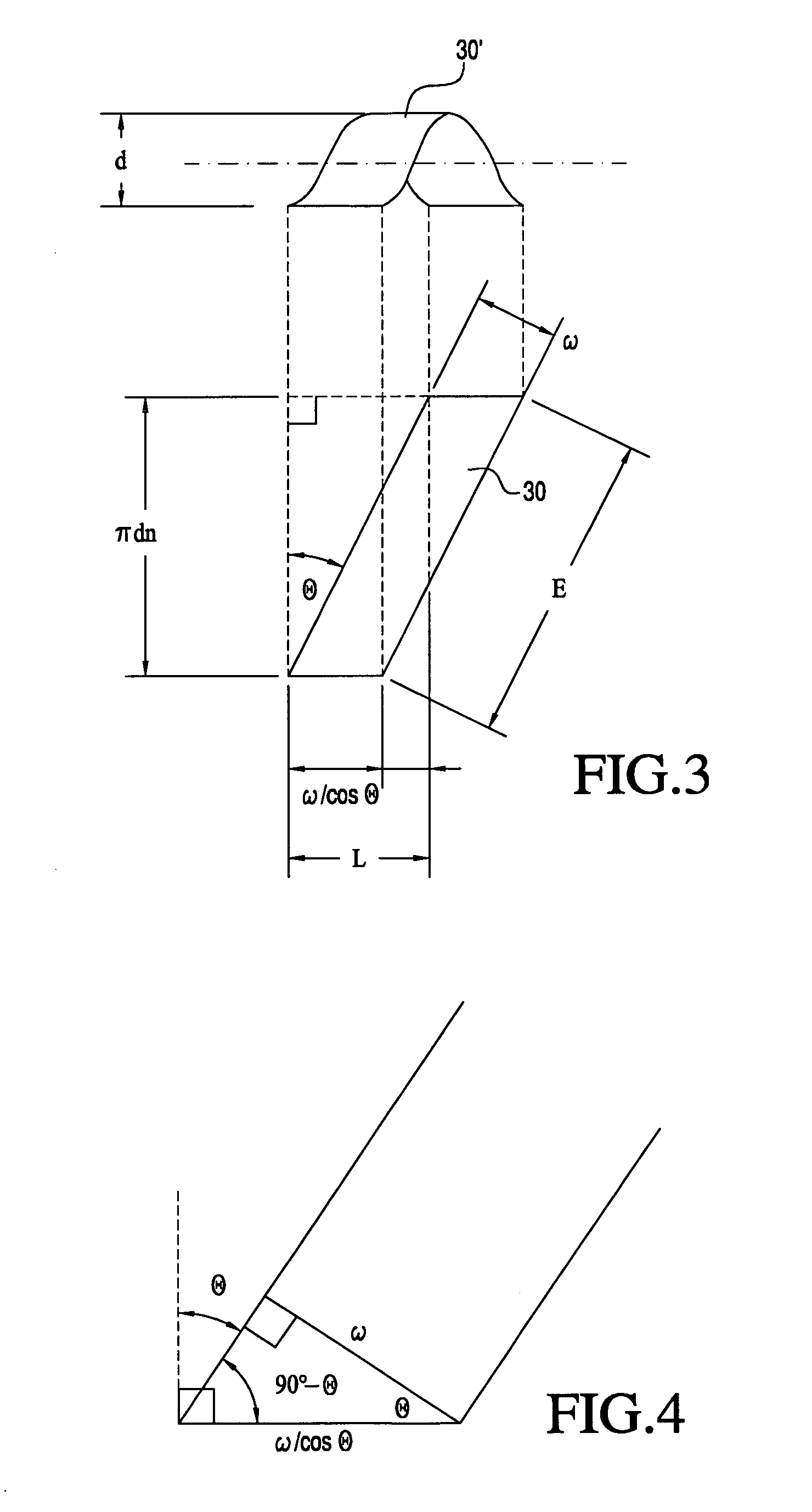

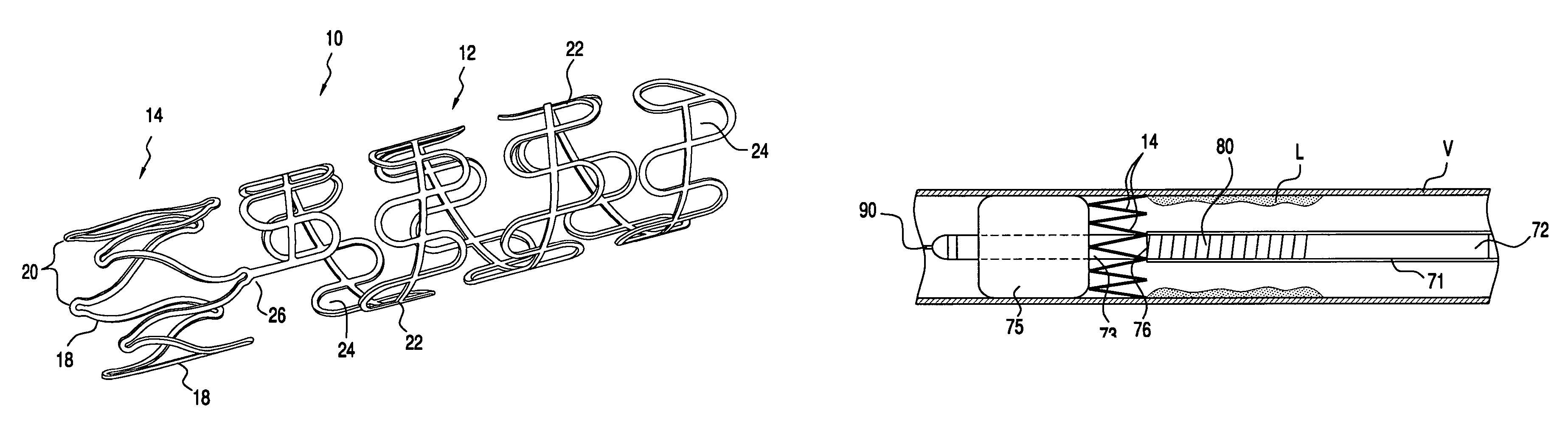

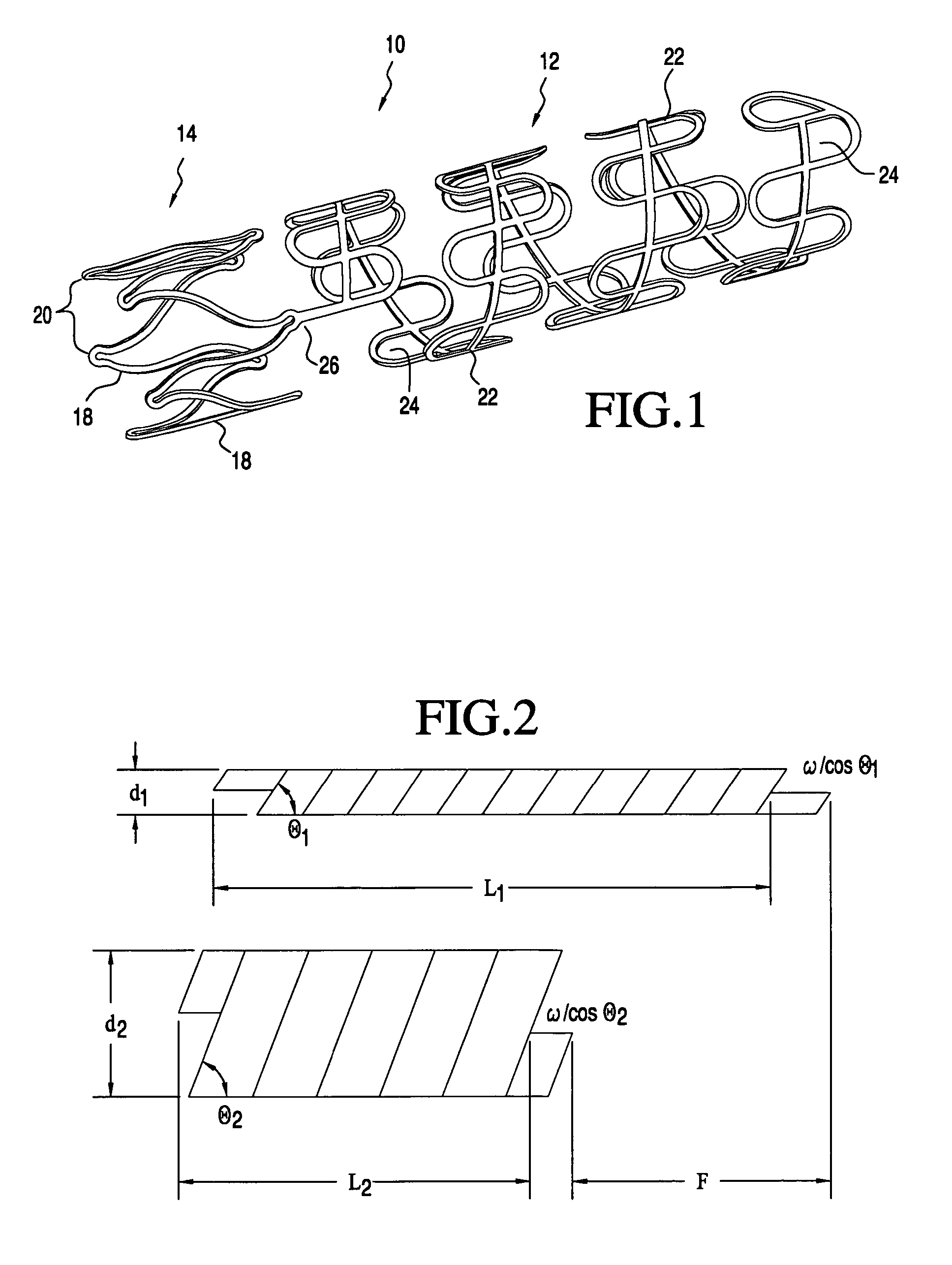

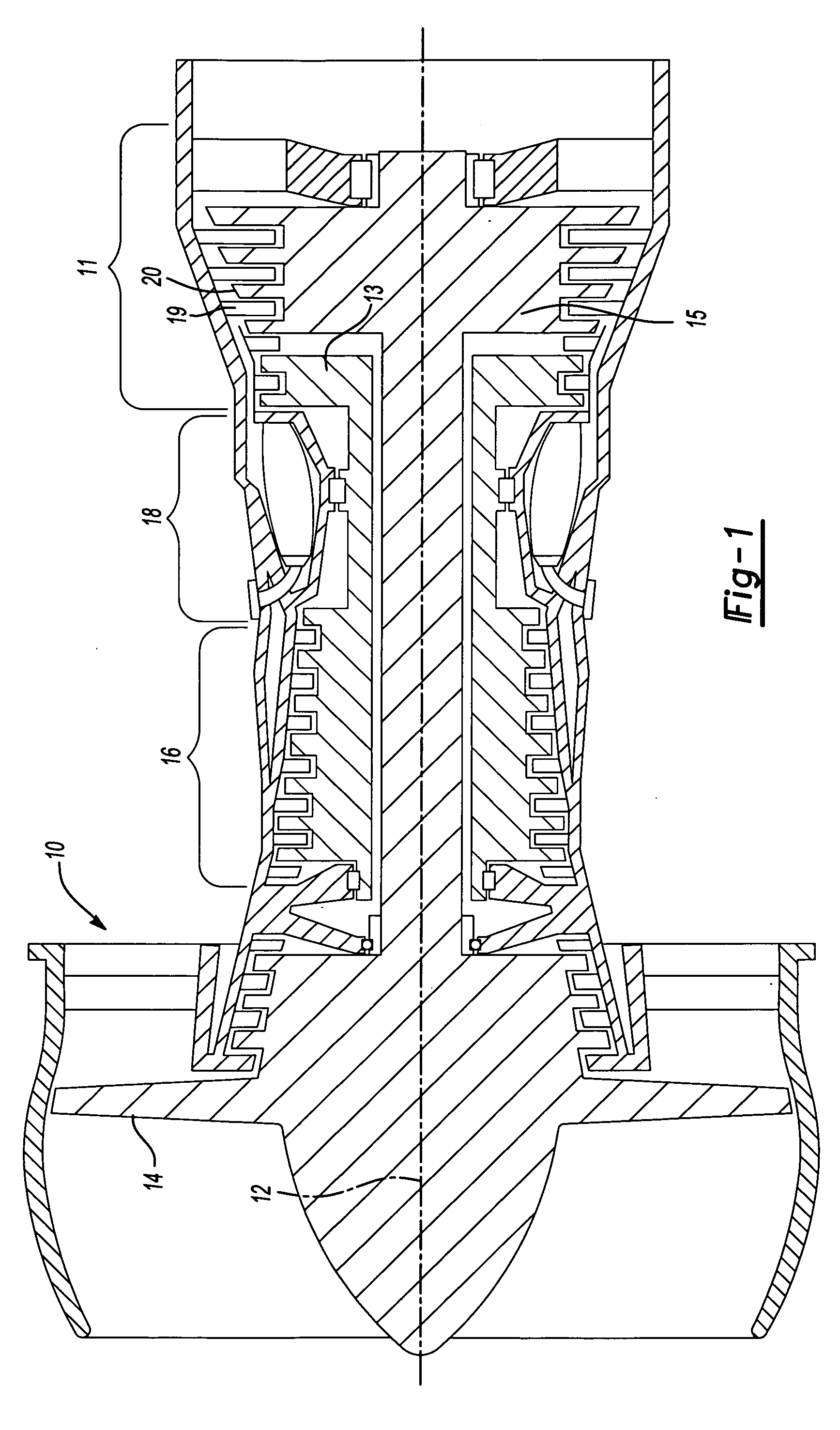

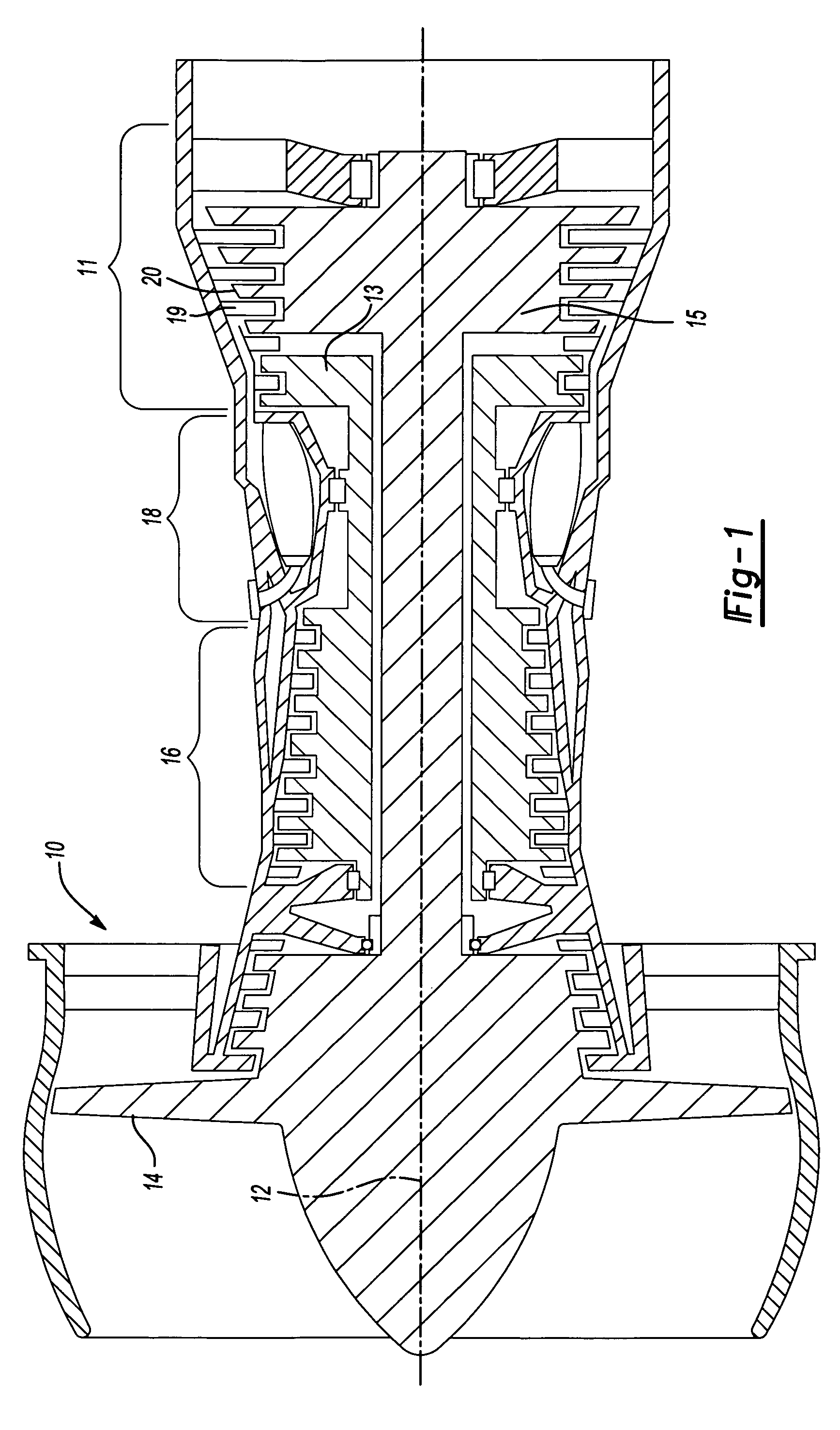

Delivery catheter that controls foreshortening of ribbon-type prostheses and methods of making and use

InactiveUS20050246010A1Improve accuracyReduced foreshorteningStentsBlood vesselsVascular prosthesisBlood vessel

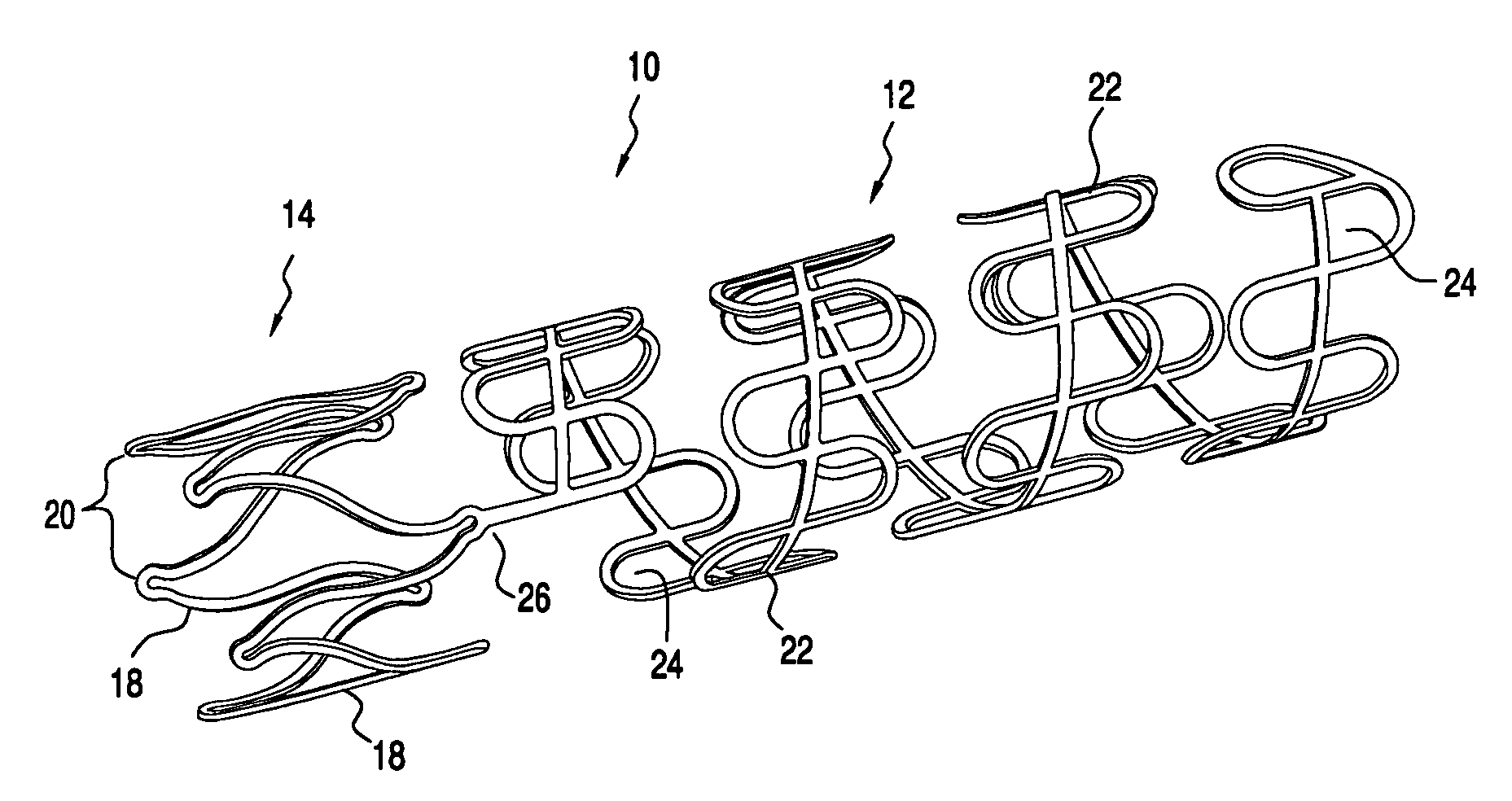

The present invention is directed to a delivery catheter for use in deploying a vascular prosthesis having a self-expanding helical section for use in a wide range of interventional applications. The delivery catheter comprises an elongated member having a helical ledge with a pitch selected to impose a predetermined amount of foreshortening on the vascular prosthesis during deployment. Methods of making and using the delivery catheter of the present invention also are provided.

Owner:NOVOSTENT CORP

Delivery catheter that controls foreshortening of ribbon-type prostheses and methods of making and use

InactiveUS7766960B2Improve accuracyReduced foreshorteningStentsBlood vesselsVascular prosthesisBlood vessel

The present invention is directed to a delivery catheter for use in deploying a vascular prosthesis having a self-expanding helical section for use in a wide range of interventional applications. The delivery catheter comprises an elongated member having a helical ledge with a pitch selected to impose a predetermined amount of foreshortening on the vascular prosthesis during deployment. Methods of making and using the delivery catheter of the present invention also are provided.

Owner:NOVOSTENT CORP

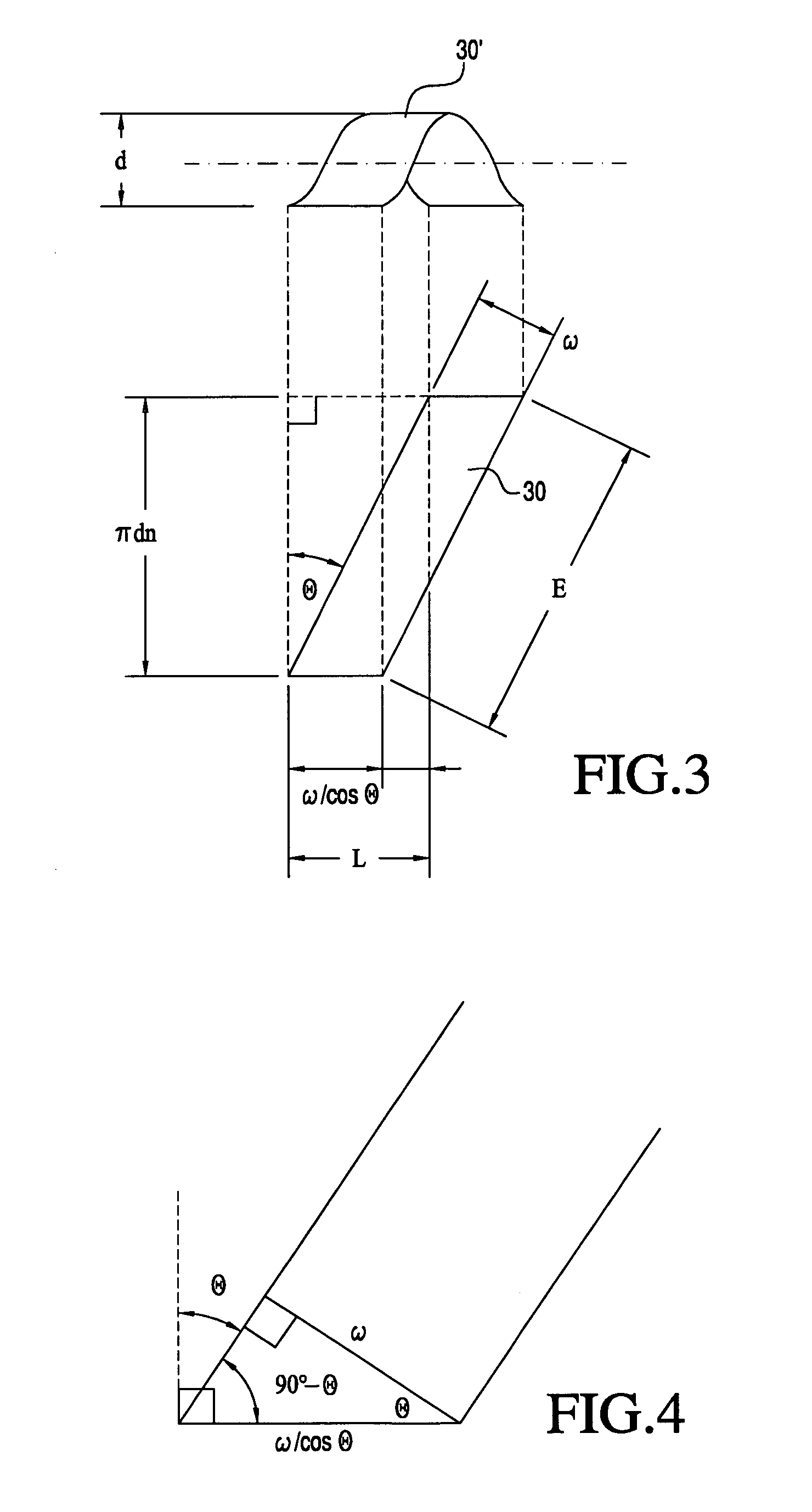

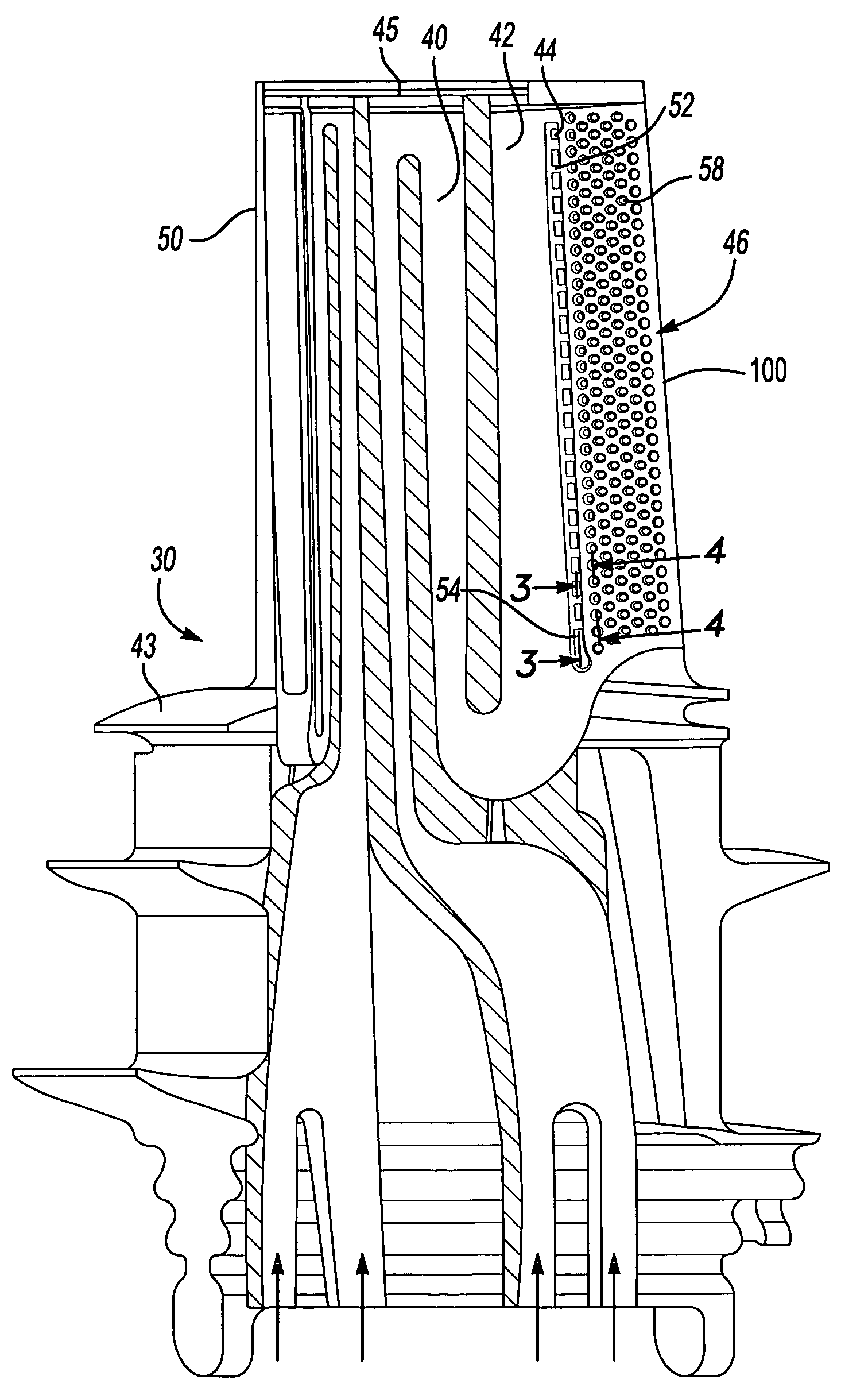

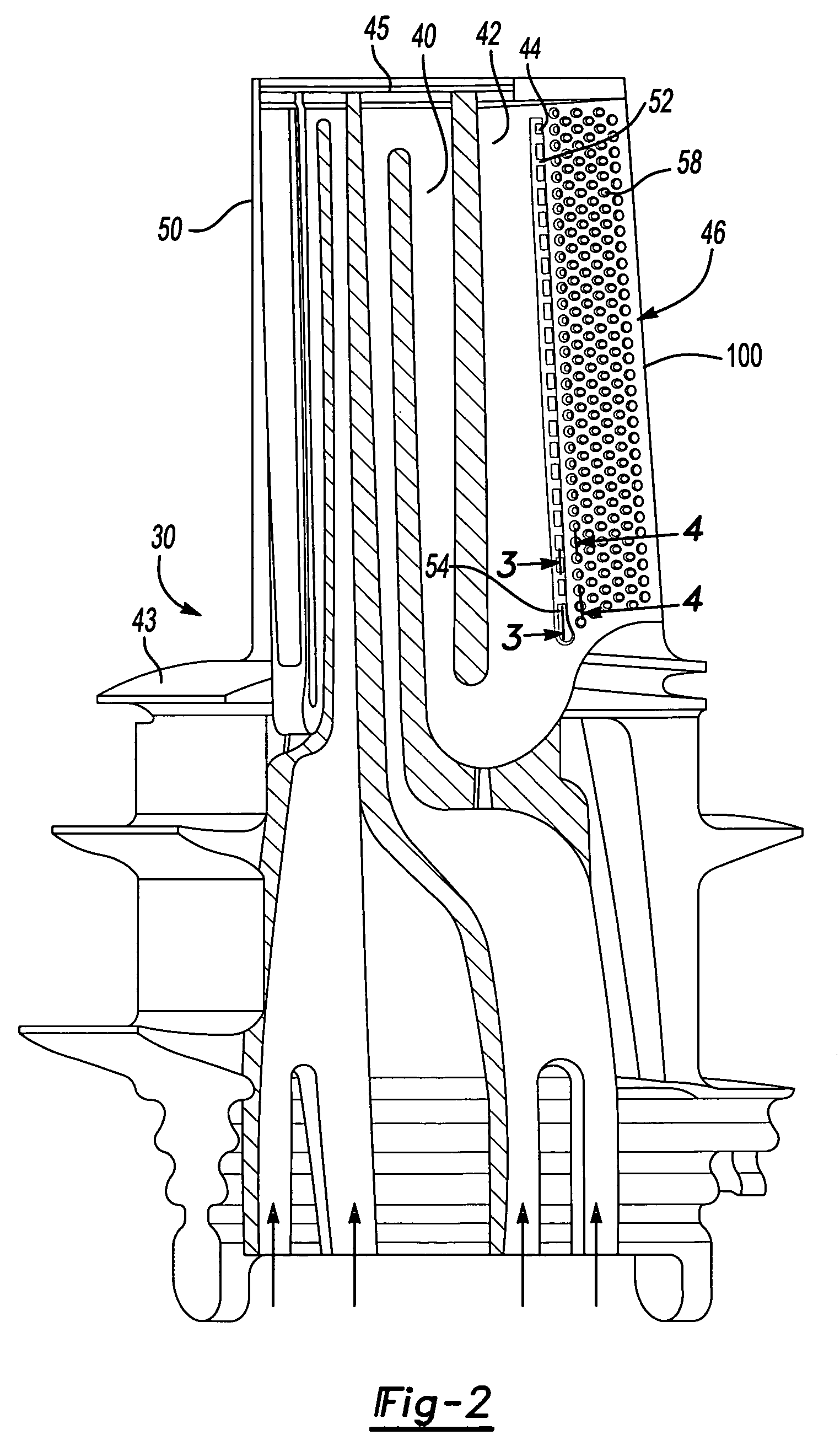

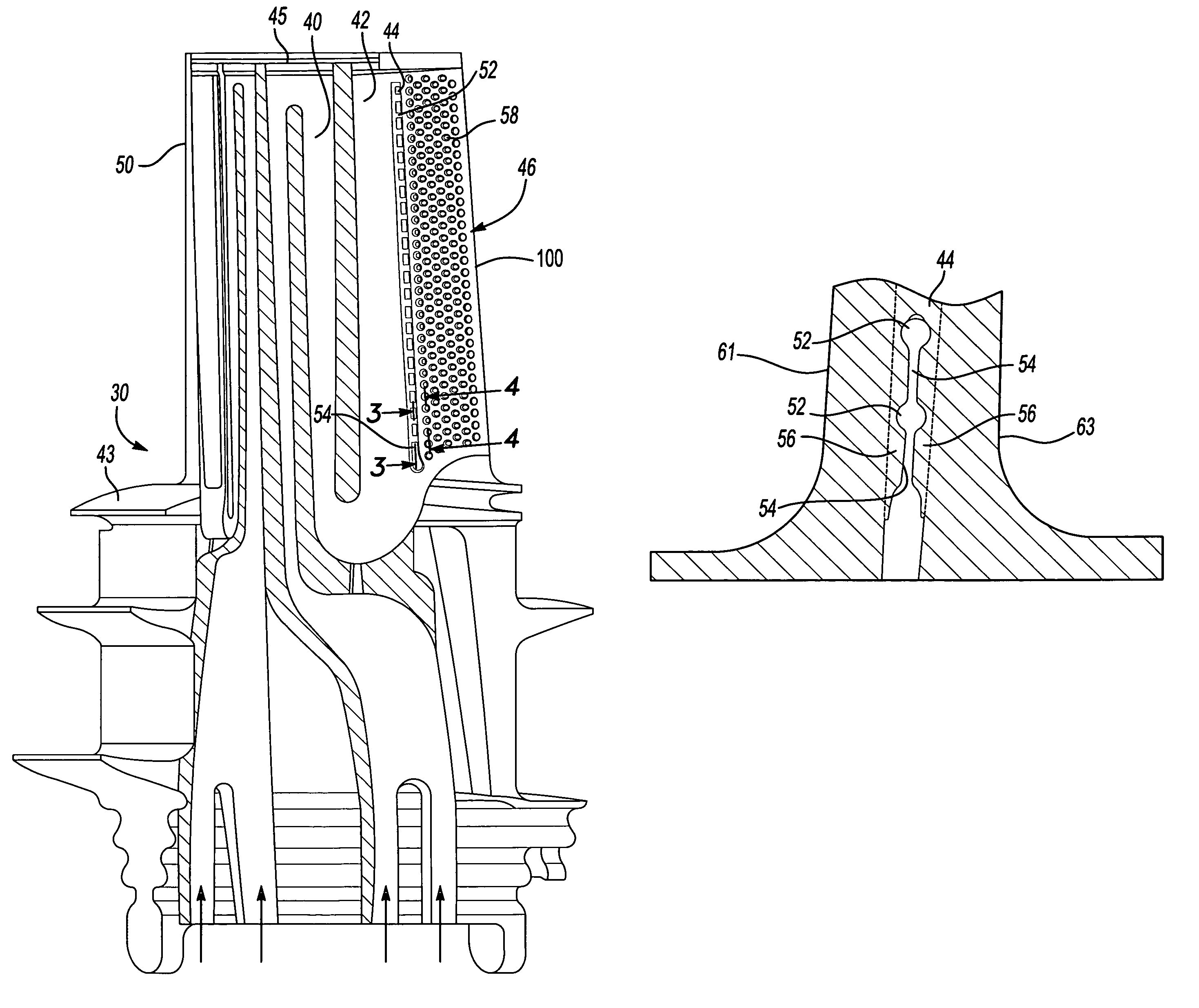

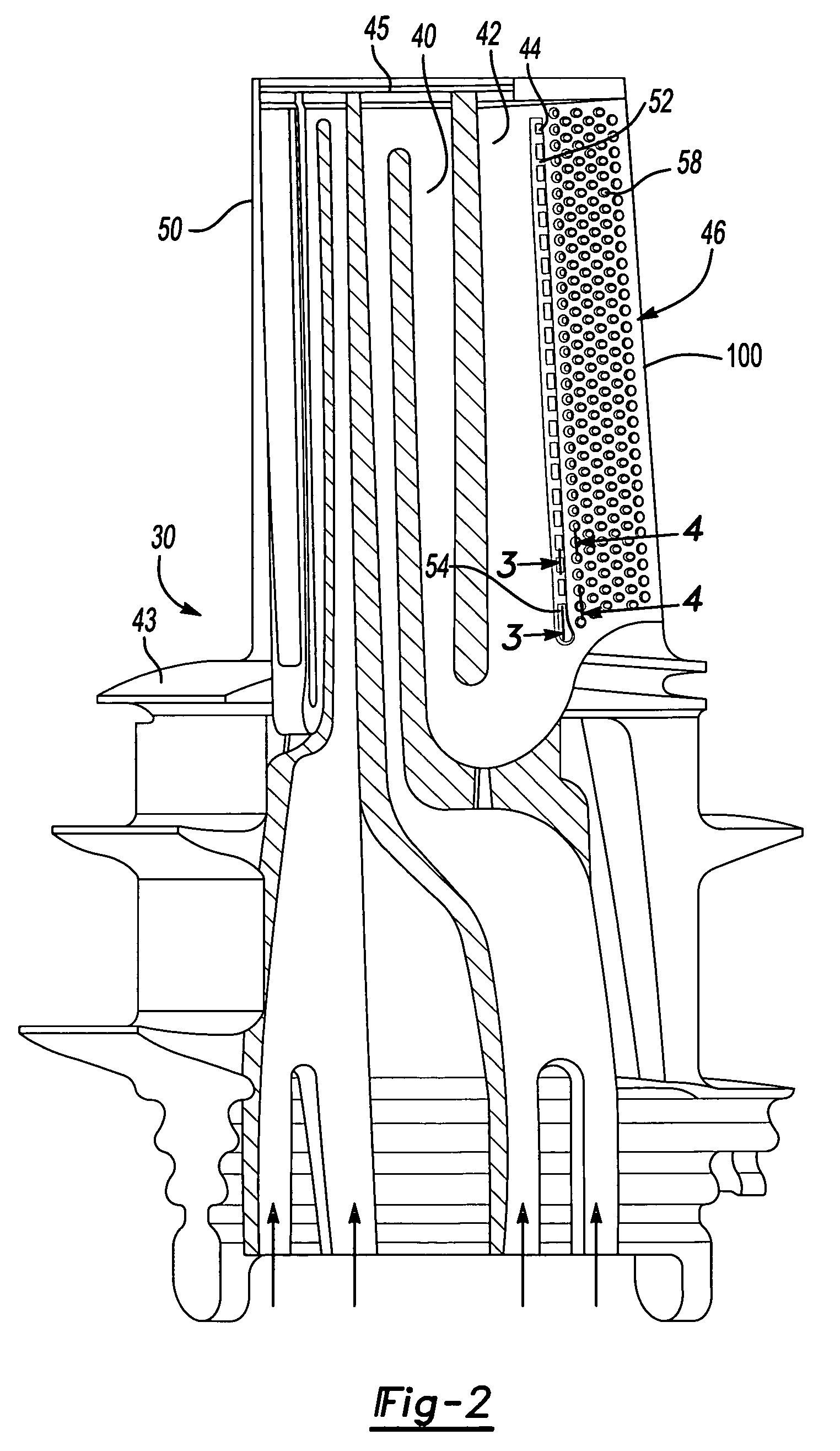

Turbine blade with split impingement rib

InactiveUS20080050244A1Distribution balanceReduce local stress concentrationEngine fuctionsBlade accessoriesStress concentrationTurbine blade

A gas turbine engine is provided with an airfoil component that is disclosed as a turbine blade. Internal cooling passages circulate air within the blade. An impingement rib separates a cooling air channel from a pedestal array, and includes cross-over holes to meter the flow of air into the pedestal array. A lower end of the impingement rib is split to reduce stress concentrations between the impingement rib and a platform. Further, the pedestals adjacent to the lower end of the impingement rib are formed to be stubs, which do not extend entirely across a width of the blade. The disclosed structure reduces the stress concentration at an area where the impingement rib meets the platform.

Owner:RAYTHEON TECH CORP

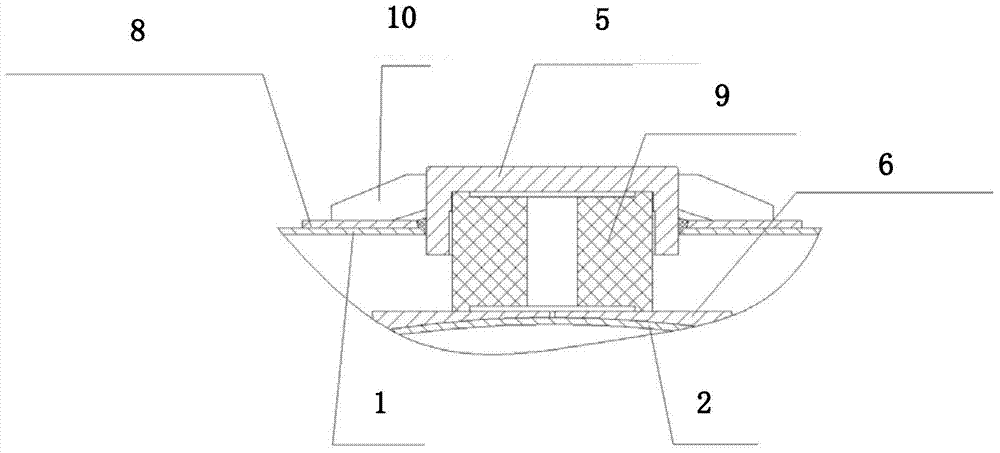

Semiconductor device and method for manufacturing semiconductor device

InactiveUS7829992B2Inhibition is effectiveImprove joint reliabilitySemiconductor/solid-state device detailsSolid-state devicesSurface mountingSemiconductor chip

A semiconductor device (100) comprises a first resin substrate (101) on which a first semiconductor chip (125) is mounted a surface thereof; a second resin substrate (111) on which a second semiconductor chip (131) is mounted on a surface thereof; and a resin base material (109), joined to a front surface of the first resin substrate (101) and to a back surface of the second resin substrate (111), so that these surfaces are electrically connected. The resin base material (109) is disposed in a circumference of the first resin substrate (101) in the surface of the first resin substrate (101). Further, the first semiconductor chip (125) is disposed in a space section provided among the first resin substrate (101), the second resin substrate (111) and the resin base material (109) in the surface of the first resin substrate (101).

Owner:SUMITOMO BAKELITE CO LTD

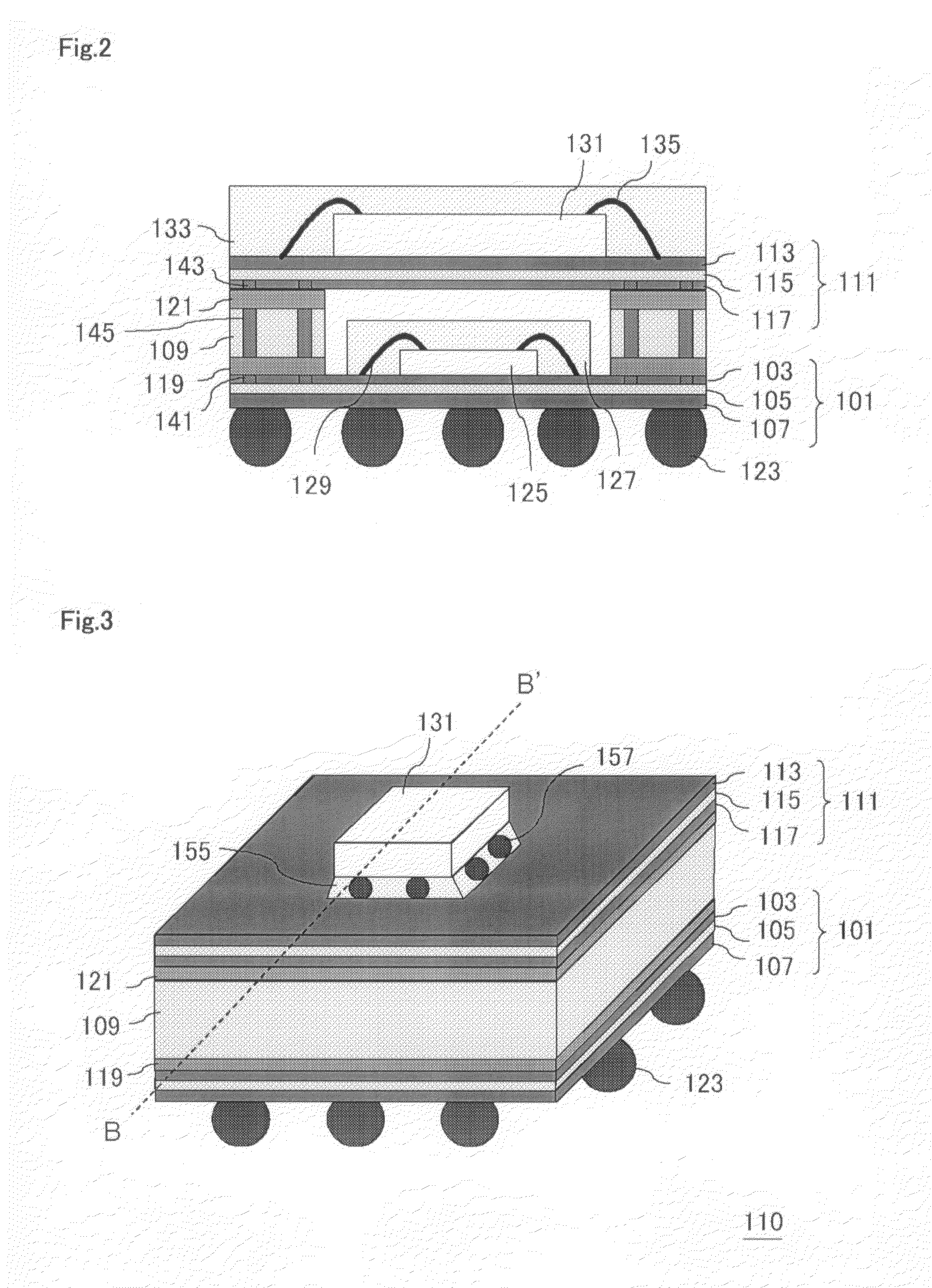

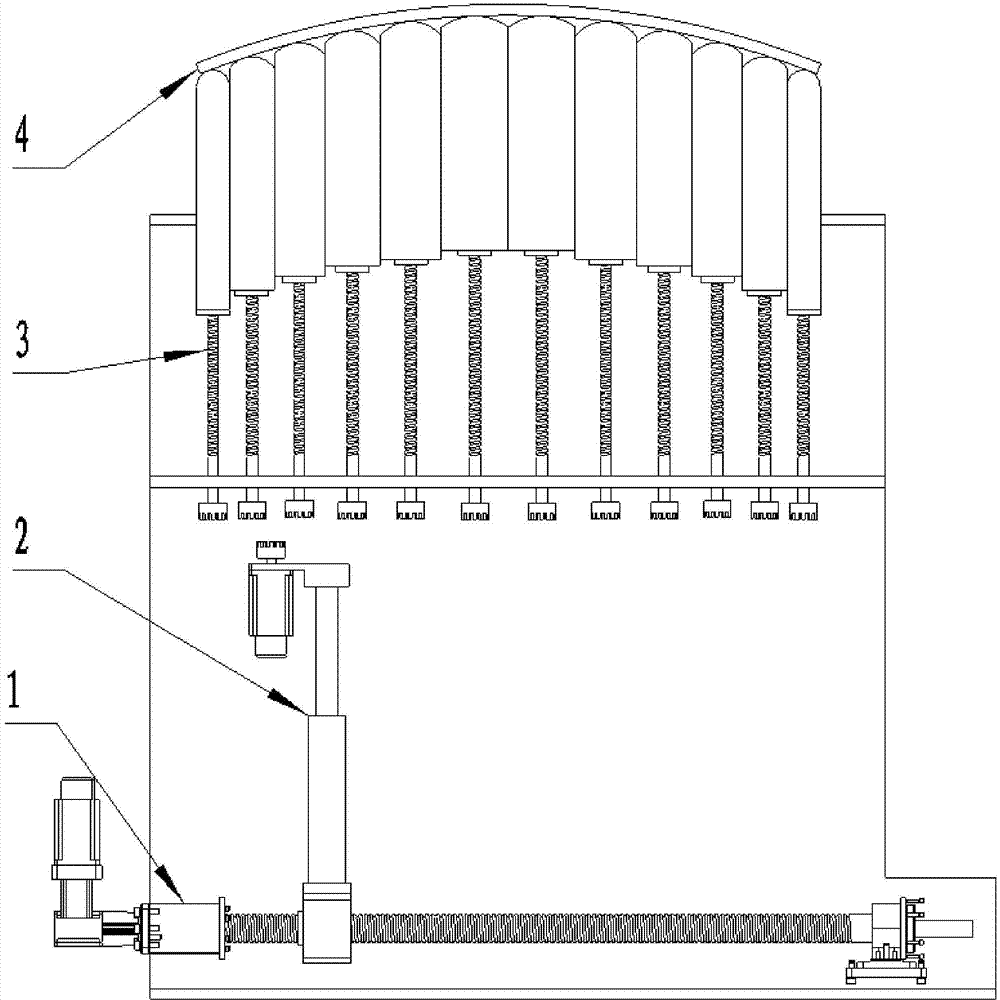

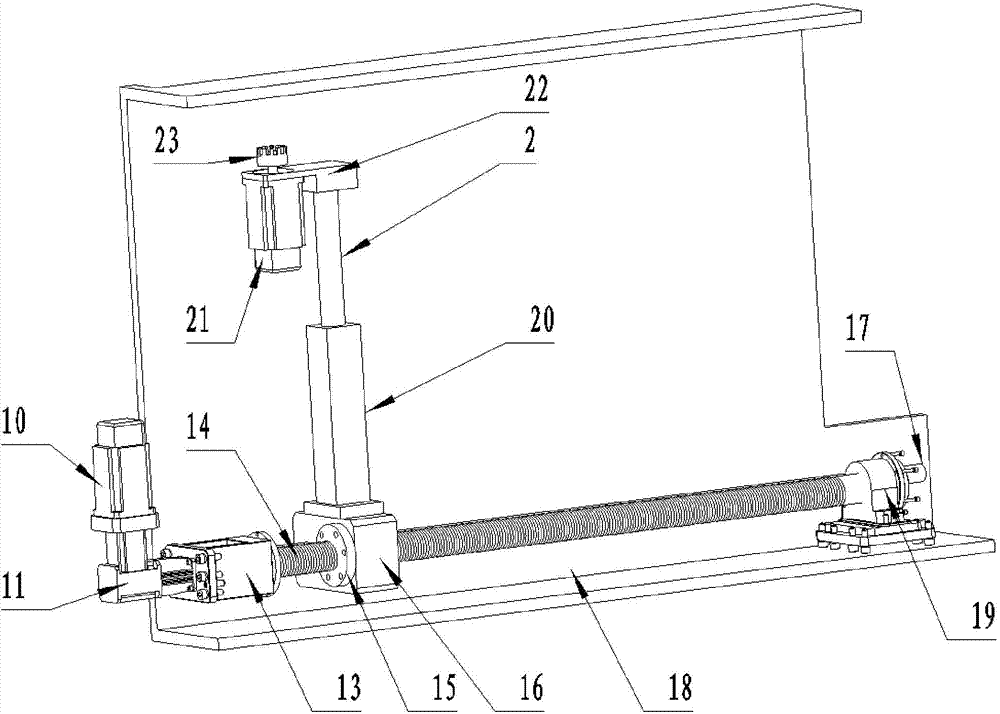

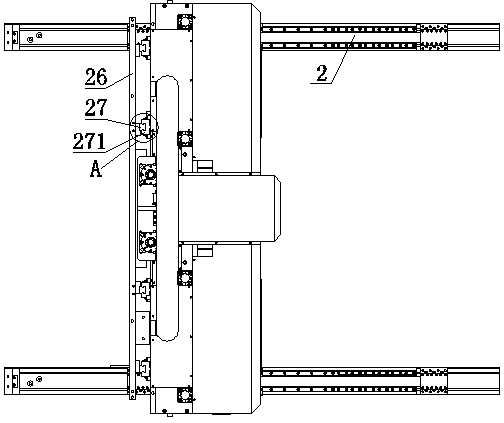

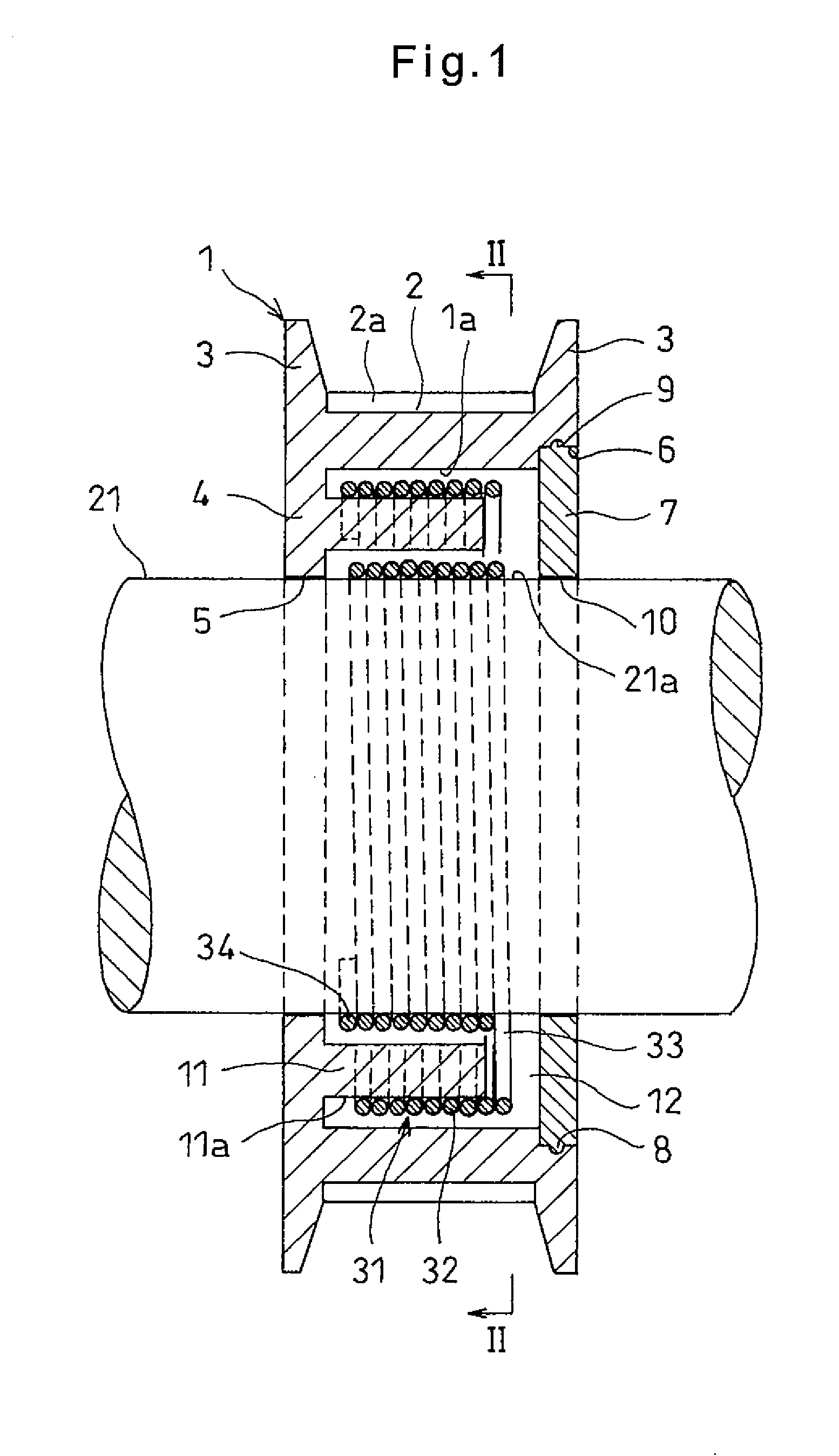

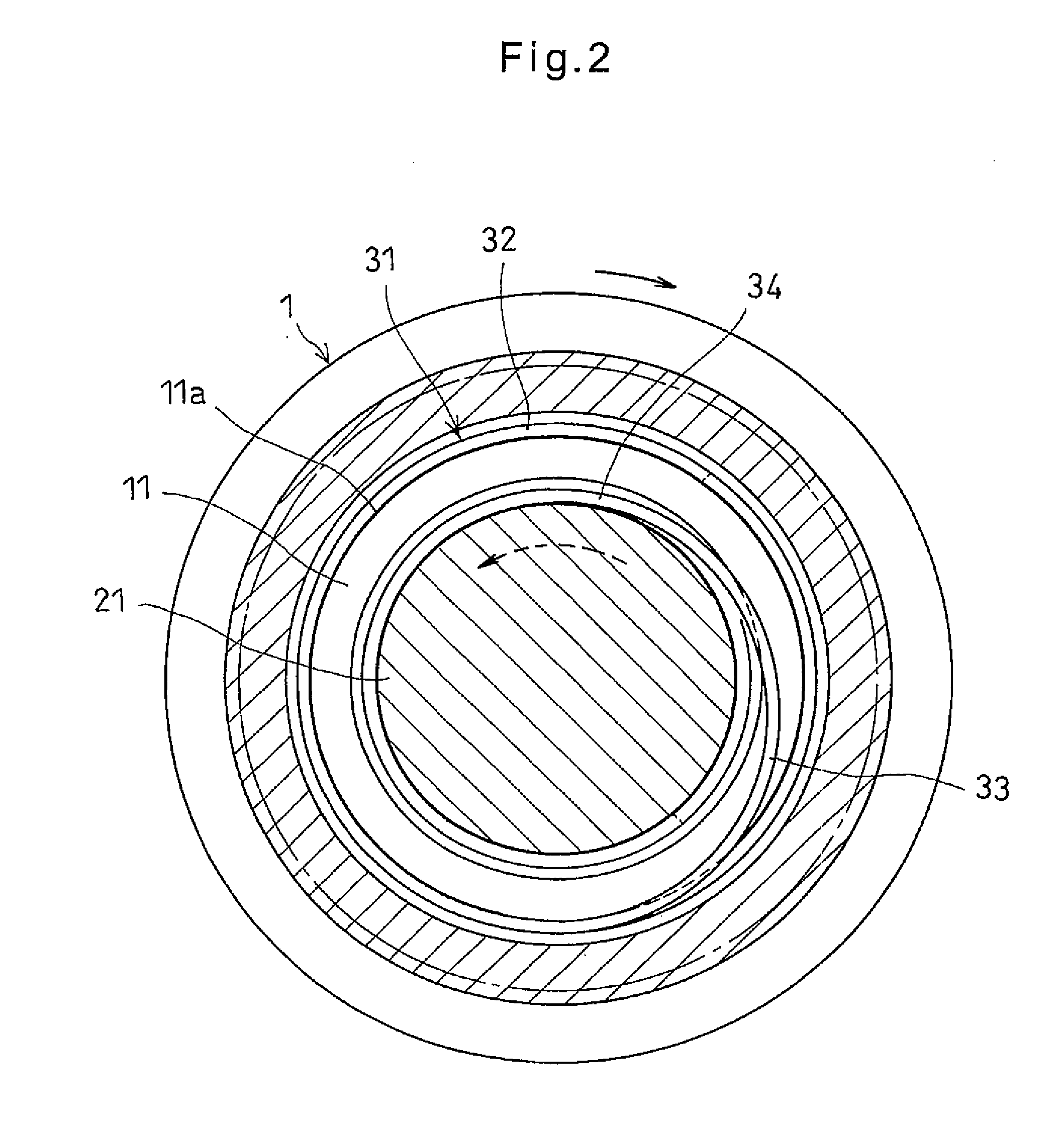

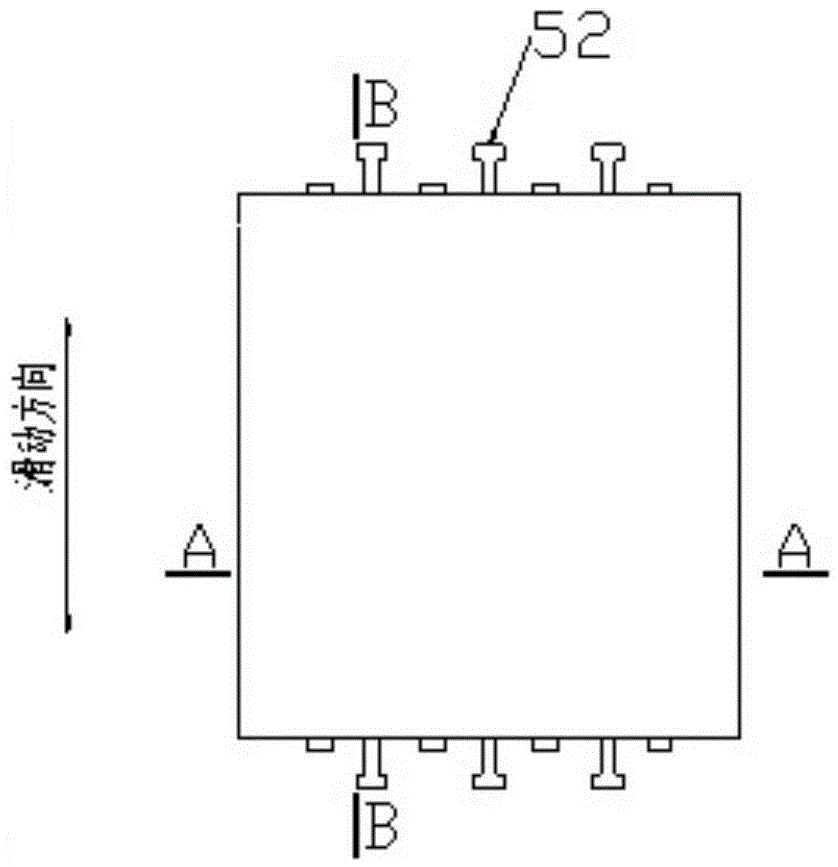

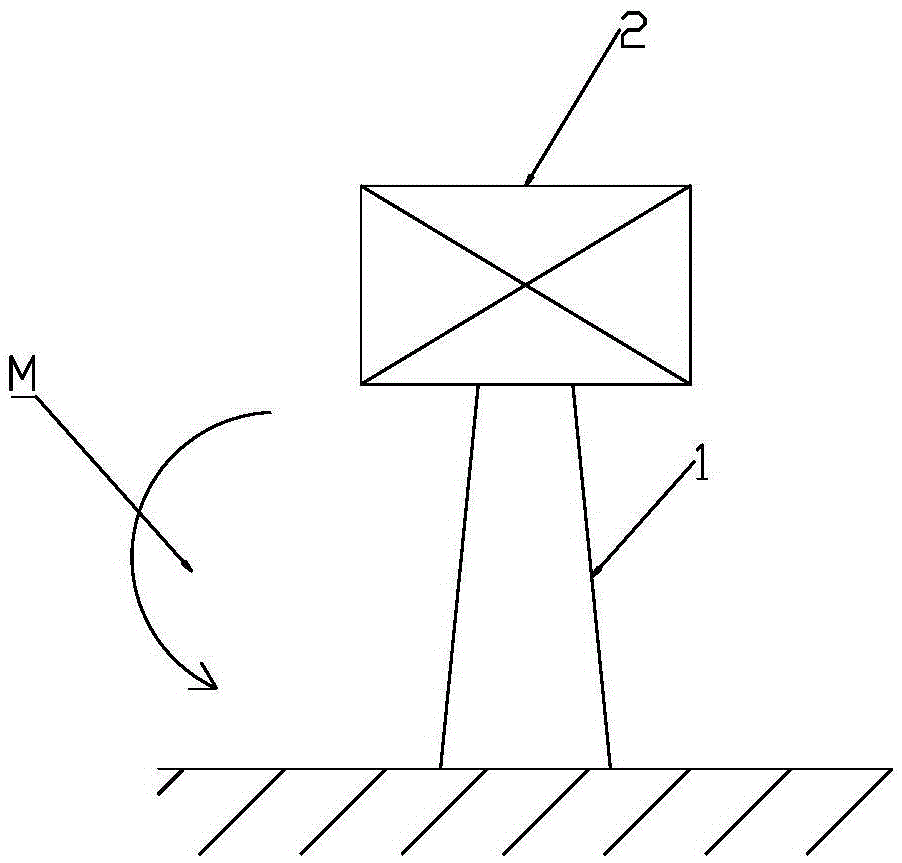

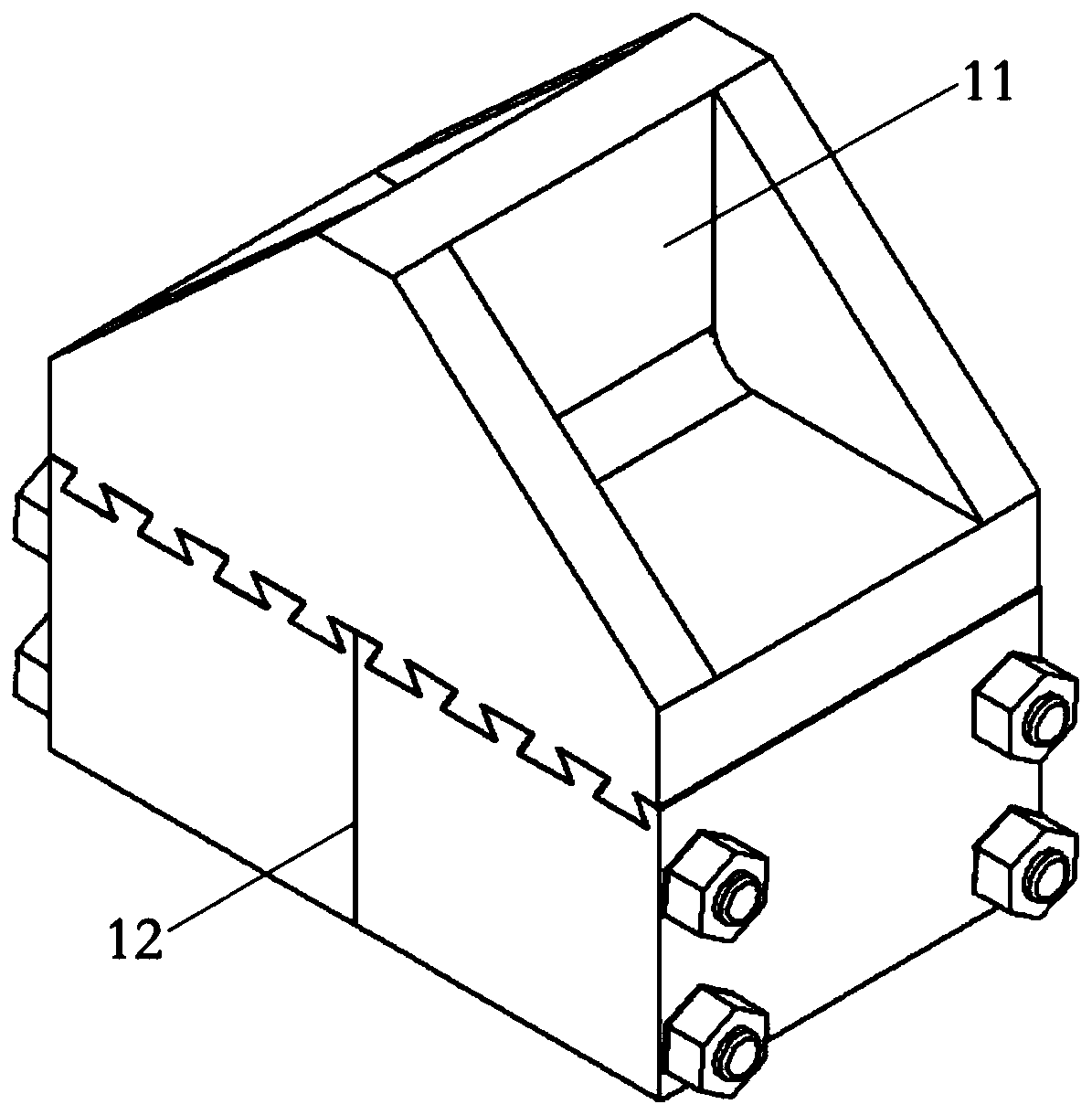

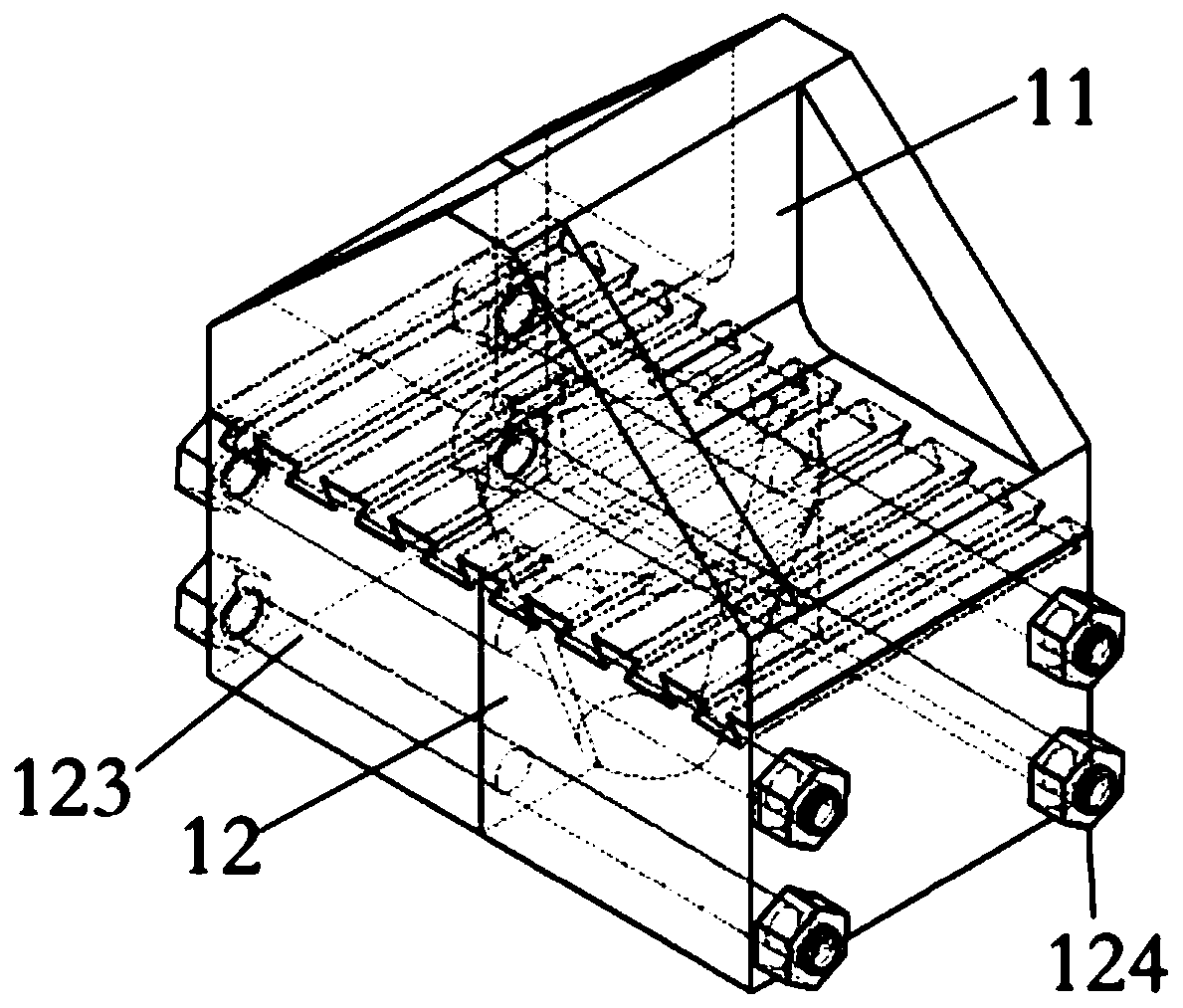

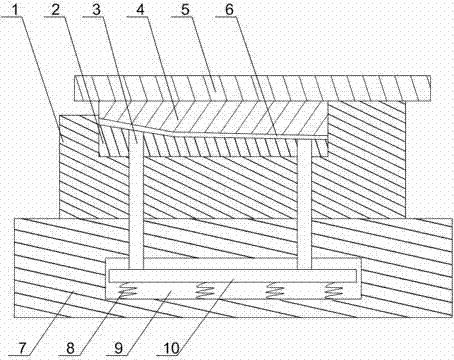

Flexible mold used for profile stretch bending

The invention provides a flexible mold used for profile stretch bending. The flexible mold comprises an X-direction positioning assembly (1), a Z-direction adjustment assembly (2) and a punch assembly (3), the X-direction positioning assembly (1) can adjust the position of the Z-direction adjustment assembly (2) in the X direction, the punch assembly (3) comprises a plurality of punches (33), and the Z-direction adjustment assembly (2) can adjust the position of each punch (33) in the punch assembly (3) in the Z direction. The flexible mold can meet production requirements of small-batch stretch bending of airplane profiles with a plurality of types, the mold design and manufacturing cycle is shortened, the number of molds is reduced, and the airplane development speed is increased. The flexible mold used for profile stretch bending can also be used for stretch bending production work of airplane profiles differing in specification and curvature.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

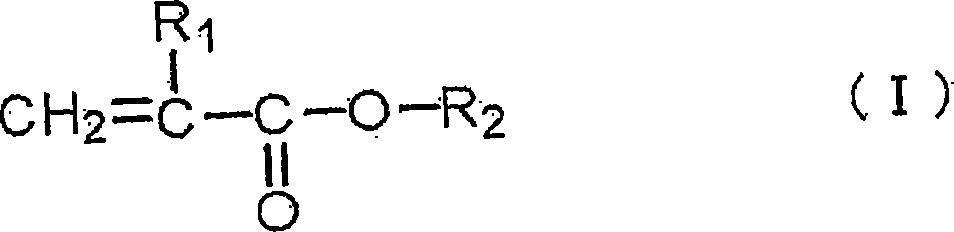

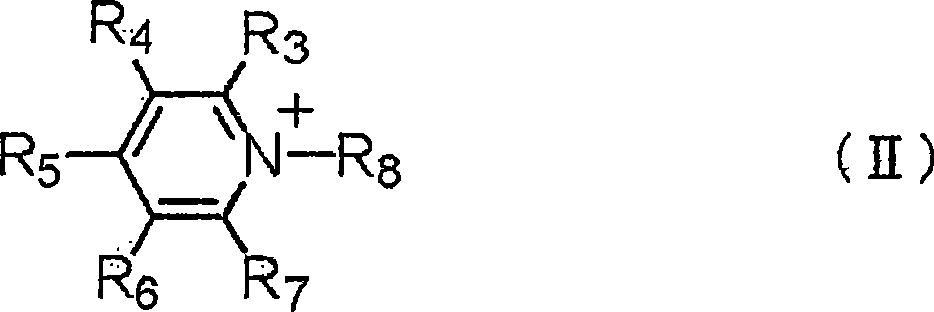

Optical film coated with adhesive

ActiveCN101144868ASuppresses electrostatic chargePrevent floatingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMeth-Pyridinium

An optical film with an adhesive layer on at least one surface of the optical film: wherein said adhesive layer is formed from a composition containing: (A) an acryl resin comprising a first acryl resin which has a structural unit derived from (meth)acrylate as a main component, and a structural unit derived from unsaturated monomer having one olefinic double bond and at least one hydroxyl group in a molecule with a weight-average molecular weight of 500,000 to 2,000,000, wherein the amount of said structural unit derived from unsaturated monomer having a hydroxyl group is 0.5 to 10 parts by weight relative to 100 parts by weight of the acryl resin; wherein R1 represents a hydrogen atom or a methyl group, R2 represents an alkyl group or an aralkyl group having 1-14 carbon atoms that may be substituted by an alkoxy group having 1-10 carbon atoms, (B) an ionic compound containing a pyridinium based cation; wherein at least one of R3 through R7 represents an alkyl group having 1-6 carbon atoms, the remainders each independently represent hydrogen or an alkyl group having 1-6 carbon atoms, R6 represents an alkyl group having 1-12 carbon atoms; and (C) a crosslinker.

Owner:SUMITOMO CHEM CO LTD

Acrylic resin composition

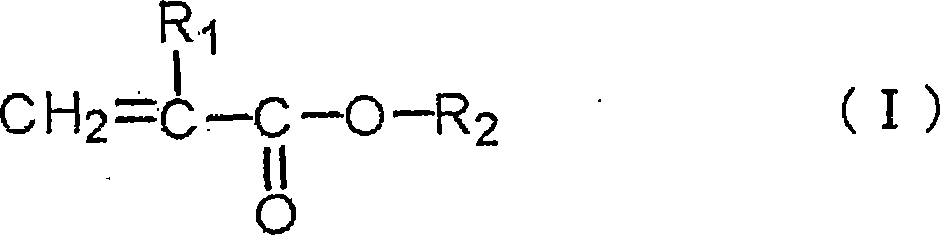

InactiveUS20050065252A1Suppress color unevennessReduce local stress concentrationSynthetic resin layered productsSpecial tyresMethacrylateHydrogen atom

An acrylic resin composition comprising the following acrylic resins (1) and (2): acrylic resin (1): an acrylic resin containing a structural unit derived from a monomer (a) (structural unit (a)), a structural unit derived from a monomer (b) (structural unit (b)) and a structural unit derived from a monomer (c) (structural unit (c)) and containing the structural unit (c) in an amount of 0.05 to 5 parts by weight based on 100 parts by weight of the acrylic resin (1); acrylic resin (2): a straight chain acrylic resin containing the structural unit (a) as the main component; (a): a (meth)acrylate of the formula (A) (wherein, R1 represents a hydrogen atom or methyl group, R2 represents an alkyl group having 1 to 14 carbon atoms or an aralkyl group having 1 to 14 carbon atoms, and a hydrogen atom in the alkyl group R2 or a hydrogen atom in the aralkyl group R2 may be substituted with an alkoxy group having 1 to 10 carbon atoms.), (b): a monomer containing an olefinic double bond in the molecule and at least one 5- or more-membered heterocyclic group in the molecule, (c): a monomer containing at least two olefinic double bonds in the molecule.

Owner:SUMITOMO CHEM CO LTD

Turbine blade with split impingement rib

InactiveUS7713027B2Evenly distributedReduce local stress concentrationEngine fuctionsBlade accessoriesStress concentrationTurbine blade

A gas turbine engine is provided with an airfoil component that is disclosed as a turbine blade. Internal cooling passages circulate air within the blade. An impingement rib separates a cooling air channel from a pedestal array, and includes cross-over holes to meter the flow of air into the pedestal array. A lower end of the impingement rib is split to reduce stress concentrations between the impingement rib and a platform. Further, the pedestals adjacent to the lower end of the impingement rib are formed to be stubs, which do not extend entirely across a width of the blade. The disclosed structure reduces the stress concentration at an area where the impingement rib meets the platform.

Owner:RTX CORP

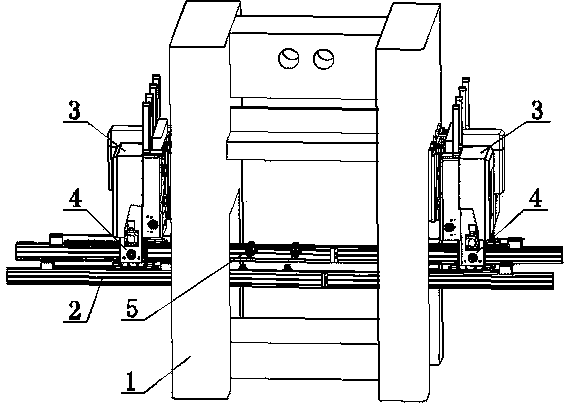

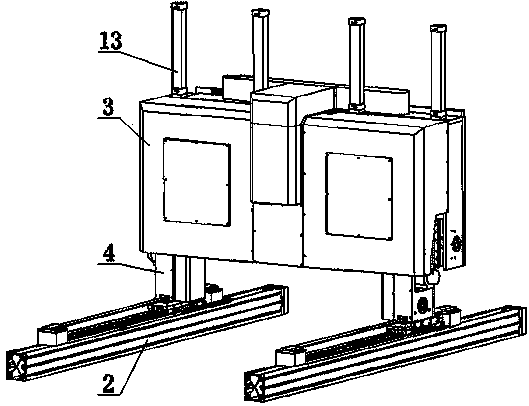

Three-dimensional mechanical arm conveyer for stamping equipment

InactiveCN103357777ASmall footprintUniform and reliable forceProgramme-controlled manipulatorMetal-working feeding devicesEngineeringManipulator

The invention relates to the technical field of stamping automation, in particular to a three-dimensional mechanical arm conveyer for stamping equipment. The three-dimensional mechanical arm conveyer for the stamping equipment comprises two fixture arms and a transmission body, and the transmission body comprises a rack which is provided with two supporting arms, a lifting transmission mechanism and a clamp opening transmission mechanism. The lifting transmission mechanism can drive the supporting arms to move up and down, the clamp opening mechanism can drive the supporting arms to move inwards and outwards, the two supporting arms are connected with the two fixture arms in a sliding mode, fixtures which can clamp stamping parts are mounted on the fixture arms, the supporting arms are provided with left-right transversely moving transmission mechanisms which can drive the fixture arms to move from left to right, the two supporting arms are symmetrically arranged on the front side of the rack, and the two fixture arms are symmetrically arranged on the back side of the rack. By means of the three-dimensional mechanical arm conveyer for the stamping equipment, lifting and transmission strength can be uniform, the occupied space of the transversely moving conveying part is reduced, and the three-dimensional mechanical arm conveyer can cooperate with large stamping equipment in use.

Owner:DONGGUAN JINGTIAN AUTOMATION EQUIP

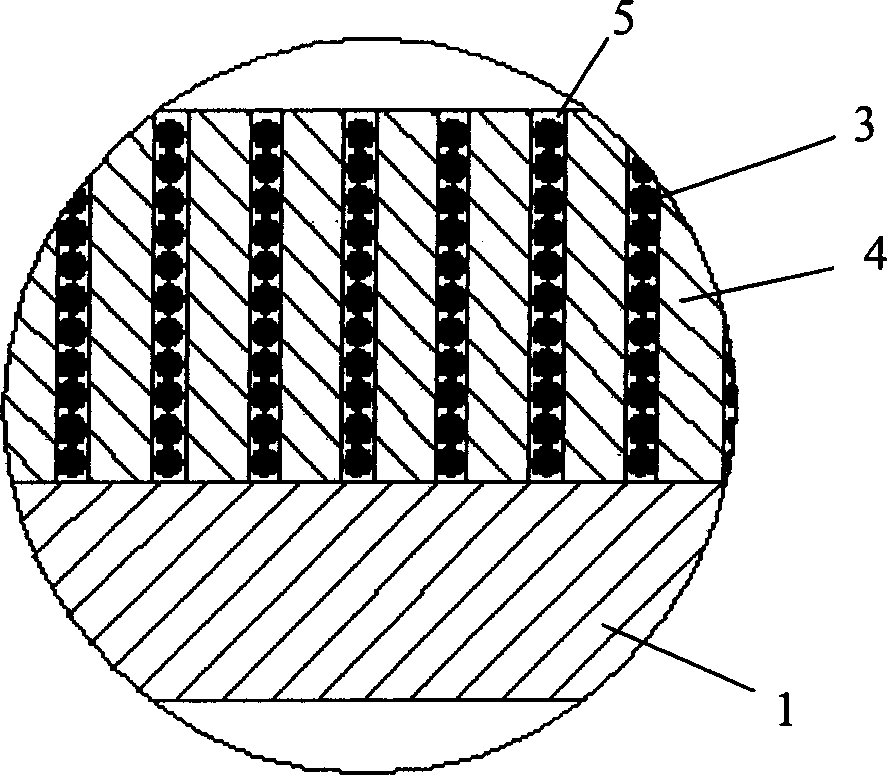

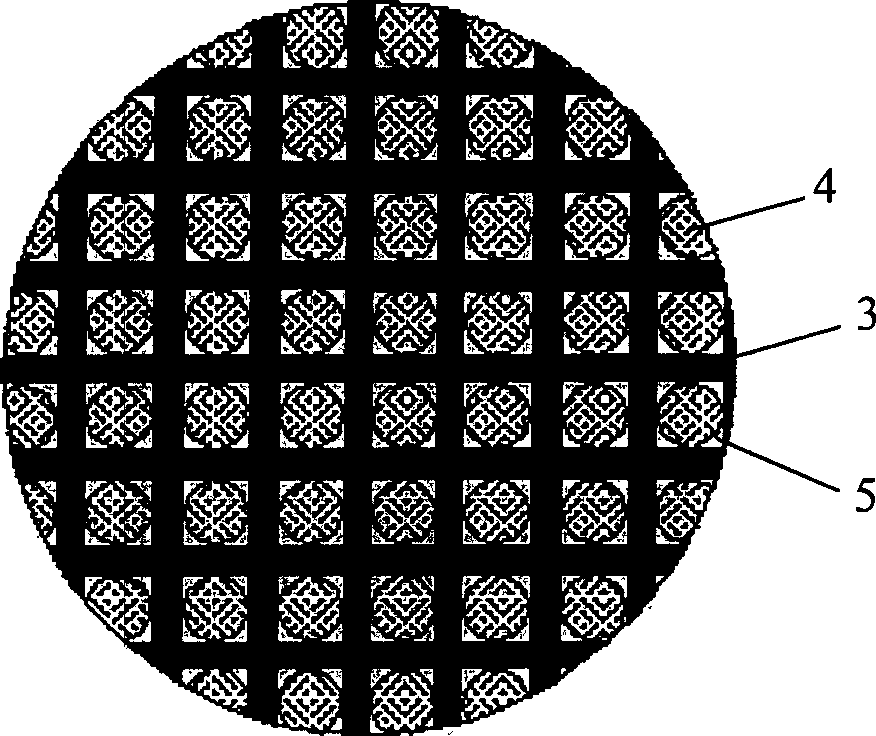

Abrasion proof pipe with ternary composite material as liner and preparing technique thereof

This invention discloses a ternary compound material underlay anti-wearing tube and its process method, which comprises outer steel tube and anti-wearing underlay, wherein, the anti-wearing underlay is composed of metal wire net, ceramics bar and compound materials and the ceramics is imbedded in the metal wire net holes into one part by compound materials. The processed compound materials underlay anti-wearing tube is one of straight tube, bent tube or three-way tube.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

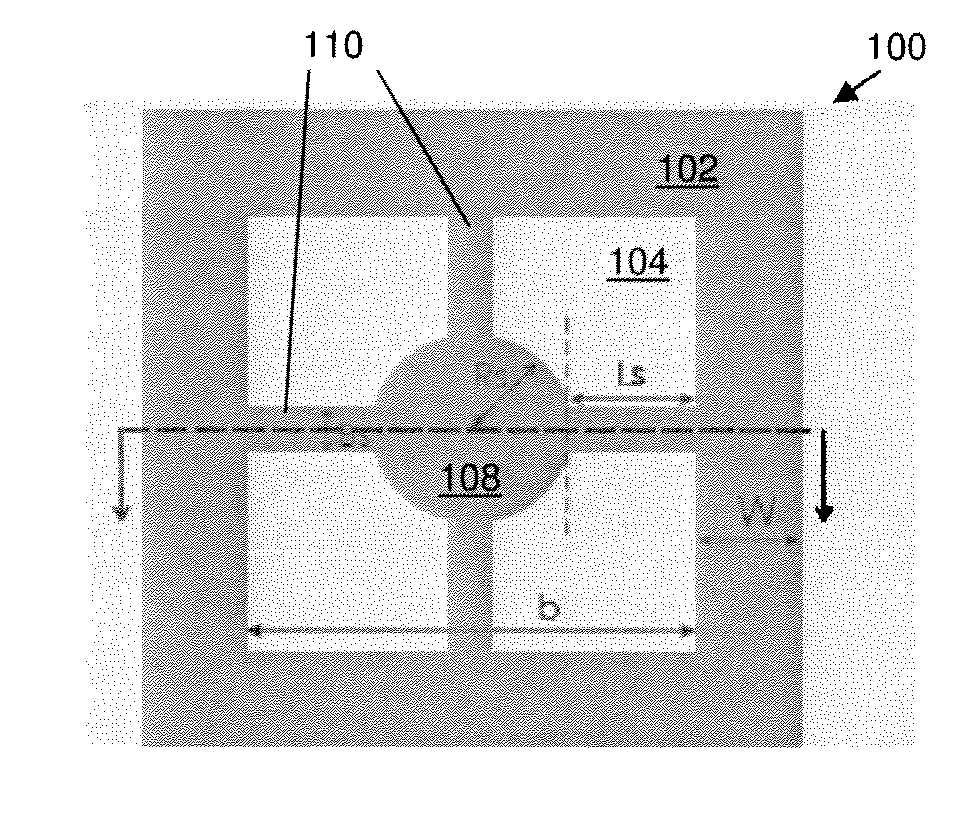

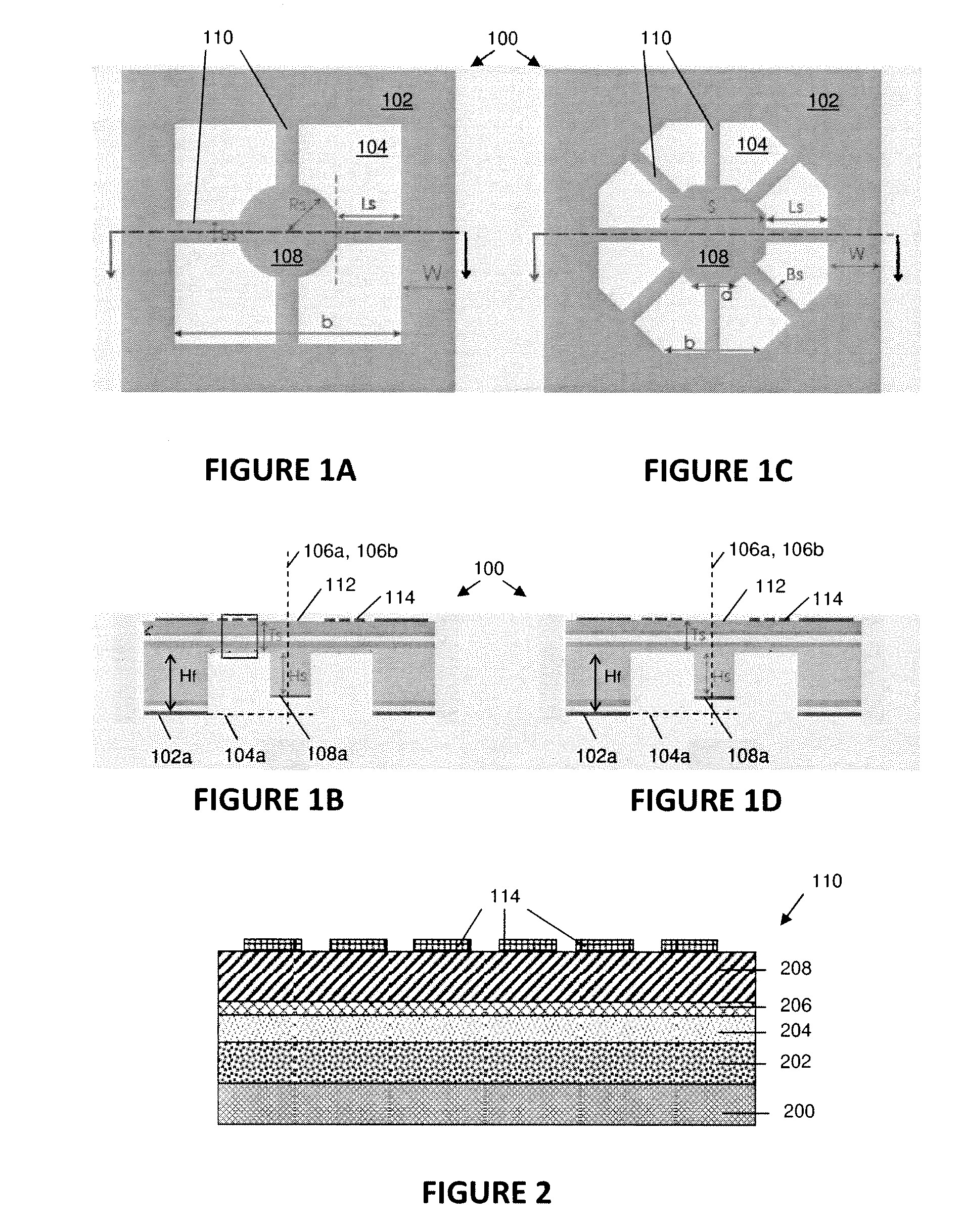

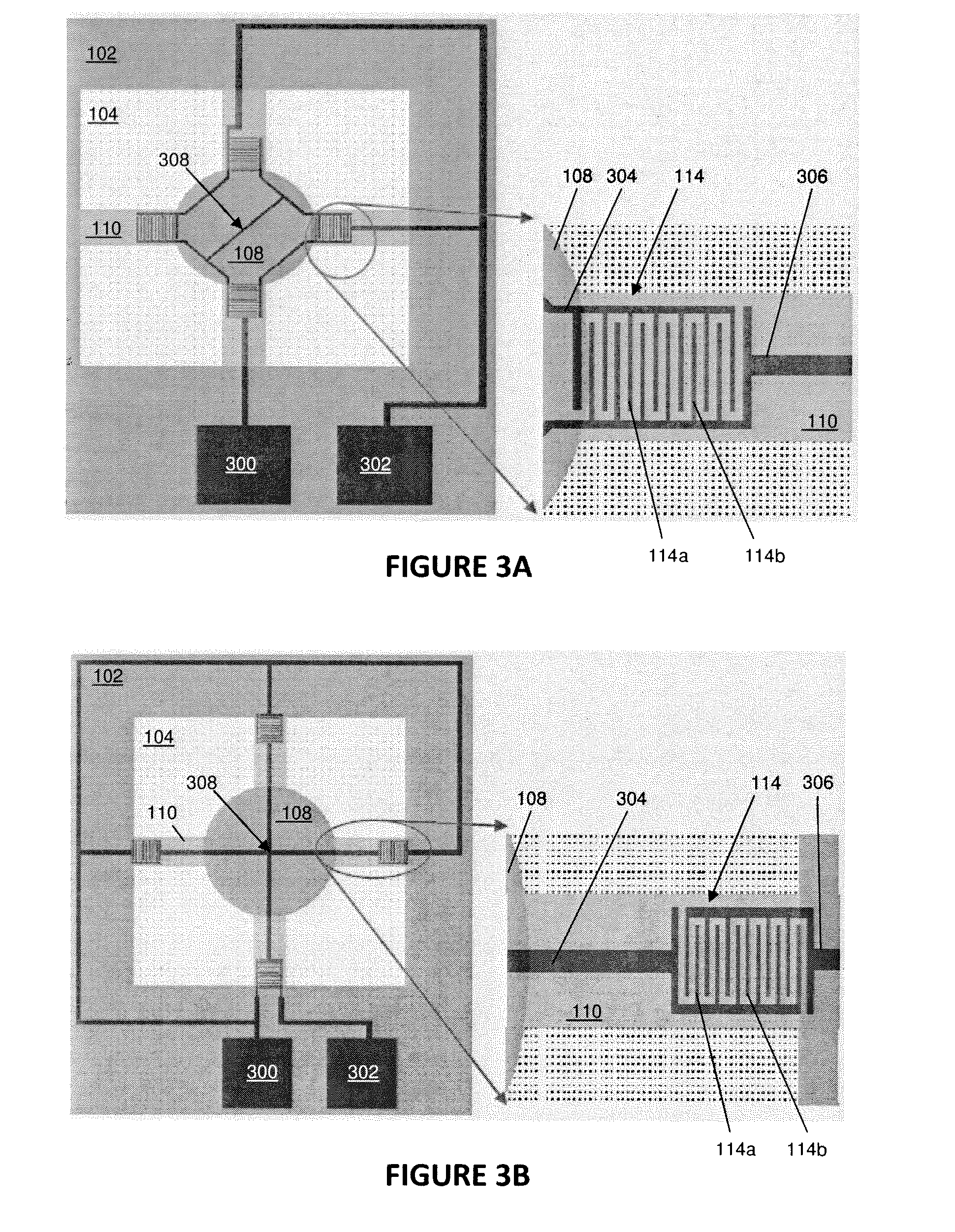

Miniaturized piezoelectric accelerometers

ActiveUS20110296918A1Reduce the possibilityMinimize resultPiezoelectric/electrostrictive device manufacture/assemblyAcceleration measurement using interia forcesSeismic massClassical mechanics

The miniaturized piezoelectric accelerometer includes a support frame (102) having a cavity (104) and a seismic mass (108) supported by a plurality of suspension beams (110) extending from the support frame (102). Each of the suspension beams (110) has a piezoelectric thin film coated on a top surface thereof, with a pair of inter-digital electrodes (114) deposited on an upper surface of each piezoelectric thin film. The presence of acceleration excites bending and thus strain in the piezoelectric thin film, which in turn causes electrical signals to be generated over terminals of the electrodes (114). To collect constructively the output of the electrodes (114), one terminal of each of the electrodes (114) is routed to and electrically connected at a top surface (308) of the seismic mass (108).

Owner:AGENCY FOR SCI TECH & RES

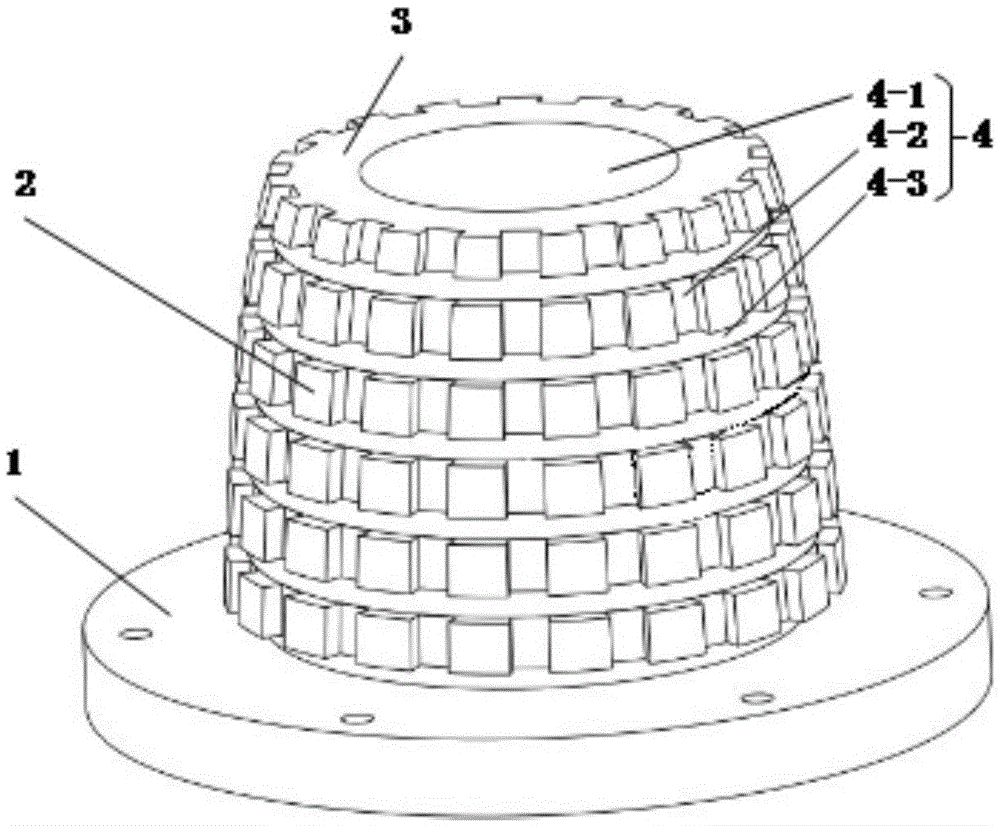

Clamping device and method used for precise machining of outer surface of shape-preserving fairing

ActiveCN105619145AImprove machining accuracyReduce local stress concentrationPositioning apparatusMetal-working holdersMachiningBiomedical engineering

The invention discloses a clamping device and method used for precise machining of the outer surface of a shape-preserving fairing and relates to a clamping device and method. The problem that according to an existing clamping device and method for the outer surface of a shape-preserving fairing, the inner surface of the fairing is completely attached to the clamping device, and consequently the machining precision is low is solved. A plurality of contact units are arranged on the outer side wall of a clamping base body in the circumferential direction and the axial direction of the clamping base body in a matrix manner. The outer surfaces of the multiple contact units are located on the same curved face. The curve equation of the curved face is consistent with the curve equation of the inner surface of the shape-preserving fairing. A filling unit is formed by a center through hole, a longitudinal through groove and a transverse through groove of the clamping base body jointly. The contact units and the clamping base body are fixedly and integrally installed. An annular groove is machined in the position, connected with a base, on the clamping base body. The method includes the first step of fixing of the fairing, the second step of inverted filling and the third step of connecting and fixing after solidification. The clamping device and method are used for precision machining of the outer surface of the shape-preserving fairing.

Owner:HARBIN INST OF TECH

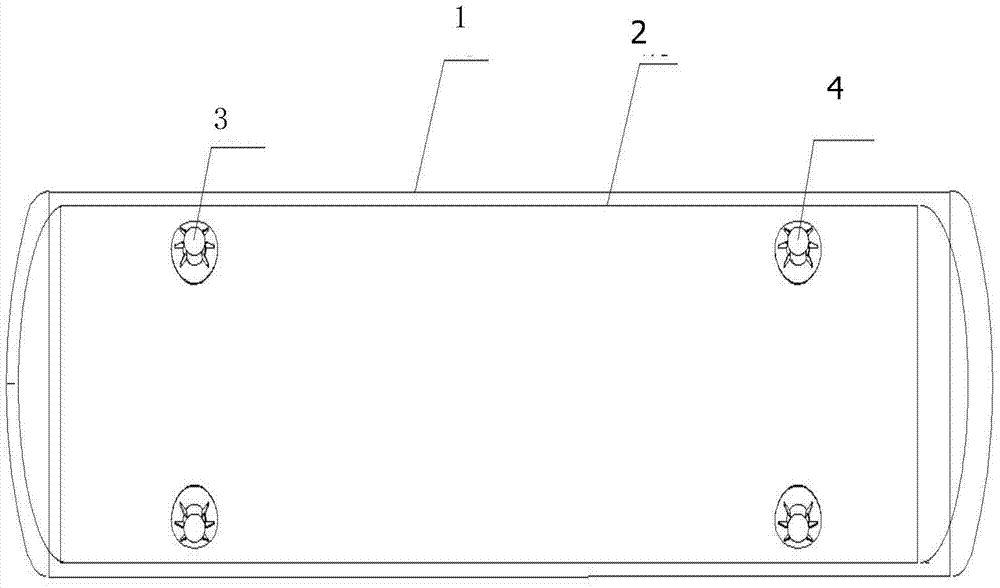

Inner tank and outer tank structural support

The invention relates to an inner tank and outer tank structural support comprising a sliding support component and a fixing support component between the inner tank and the outer tank. The sliding support component comprises an outer tank support cover arranged on the outer tank, an inner tank sliding support arranged on the inner tank, and a glass fiber reinforced plastics support used for connecting the outer tank support cover and the inner tank sliding support; the fixing support component comprises an outer tank support cover arranged on the outer tank, an inner tank fixing support arranged on the inner tank and a glass fiber reinforced plastics support used for connecting the outer tank support cover and the inner tank fixing support; an outer tank support cover stiffening ring and rib plate sets are arranged on the outer tank, and the rib plate sets are respectively connected with the outer tank support cover stiffening ring and the outer tank support cover. The inner tank and outer tank structural support is capable of reducing welding quantity, improving reliability and increasing braced force.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

Geopolymer-based artificial flood control stone prepared from all wastes and preparation method thereof

The invention discloses a geopolymer-based artificial flood control stone prepared from all wastes and a preparation method of the geopolymer-based artificial flood control stone. The geopolymer-basedartificial flood control stone comprises the following raw materials in parts by weight: 288-412 parts of a waste silicon-aluminum material; 85-150 parts of alkali-containing waste; 29-75 parts of waste sulfate mineral; 1501-1860 parts of recycled aggregate; 216-241 parts of reclaimed water; 0-2 parts of waste fiber; and 0-5 parts of crop waste. The process is simple, the prepared artificial flood control stone has no appearance defect; the stone has the advantages of large volume density, high strength (more than 34 MPa), good weathering resistance, freezing resistance and abrasion resistance and the like, is convenient to throw, good in integrity, strong in stability, freeze-thaw resistance, weathering resistance and high-speed sand-containing water flow abrasion resistance in the usingprocess, is not easy to lose under high-speed water flow, and is an ideal substitute product for natural stone standby stone prevention.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER +1

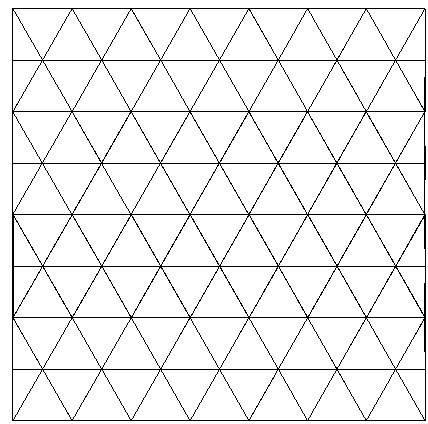

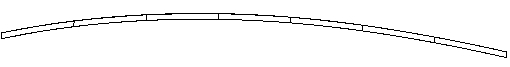

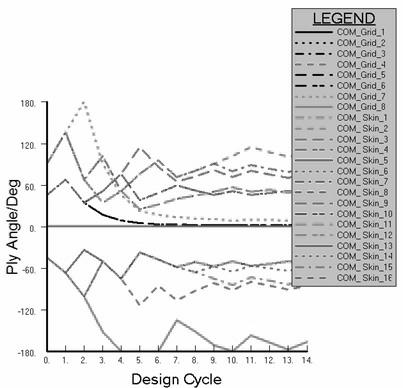

Aircraft wing box using grid structure and design method

InactiveCN102514709AImprove carrying capacityImprove fatigue lifeWingsSpecial data processing applicationsStress concentrationStress distribution

The invention relates to an aircraft wing part and especially to an aircraft wing box using a grid structure and a design method thereof. The aircraft wing box comprises grid ribs and skin panels; the skin panels wrap the outer sides of the grid ribs so as to form the aircraft wing box; and the aircraft wing box is characterized in that the grid ribs and a plurality of reinforcing ribs mutually intersect and form grid configuration, the grid ribs and the skin panels are both made of a plurality of layers of fiber reinforced composite laminates, the skin panels are fixed at the outer sides of the grid ribs and the grid ribs are made of eight layers of fiber reinforced composites laid at different angles. According to the invention, the grid ribs and the skin panels in a shape of an equilateral triangle are used, and compared to traditional wing boxes, the aircraft wing box provided in the invention has the following advantages: more superior stress distribution under the action of external load can be obtained, higher specific strength, specific rigidity and structural efficiency are obtained, the phenomenon of local stress concentration is reduced, weight of the structure is decreased, dangerous point stress which easily causes a composite material to lose efficacy is reduced, and bearing capacity and the fatigue life of the structure are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

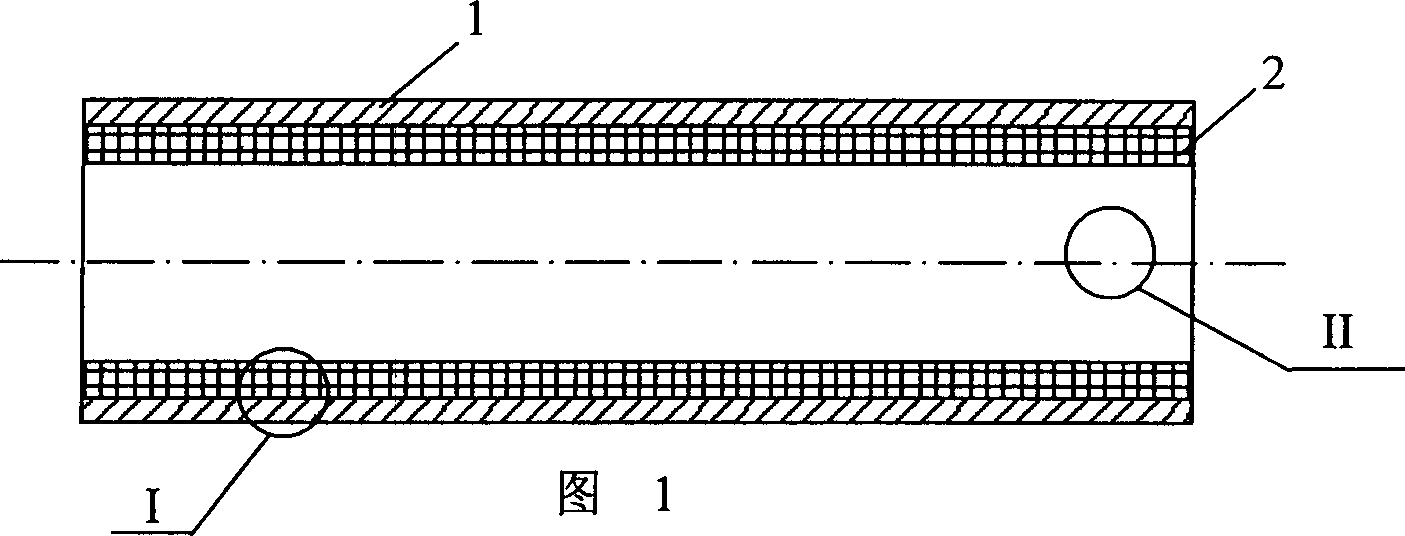

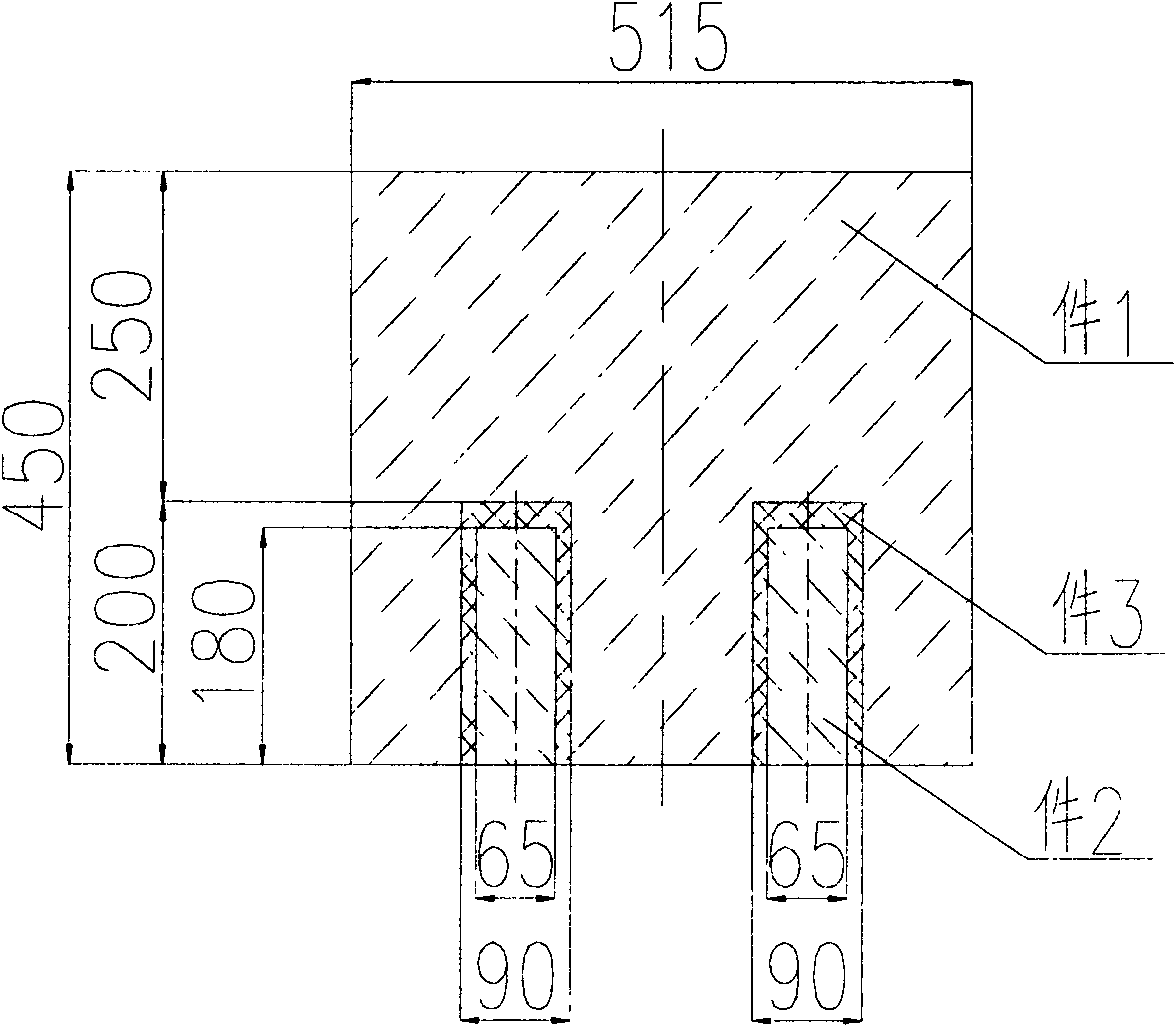

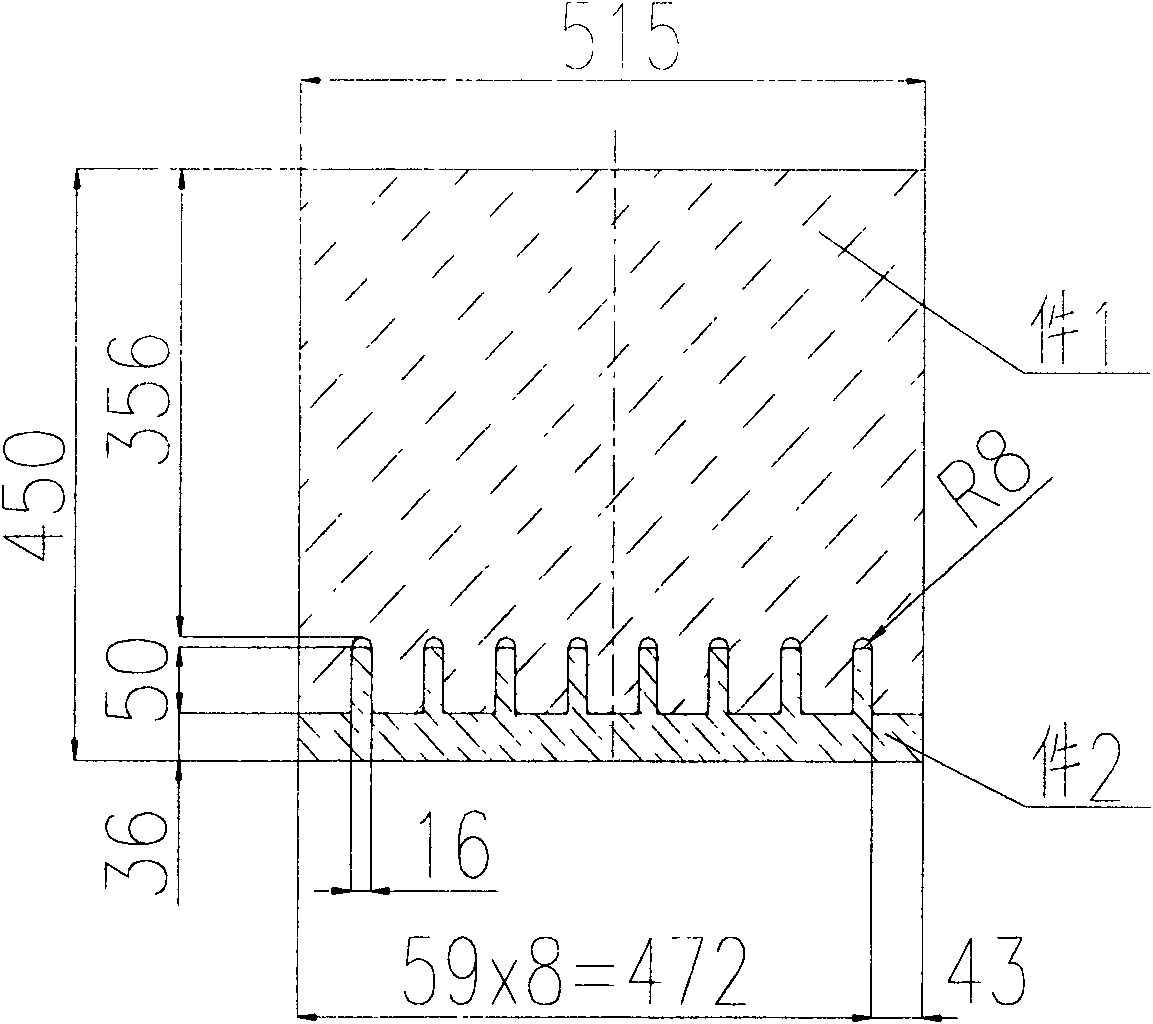

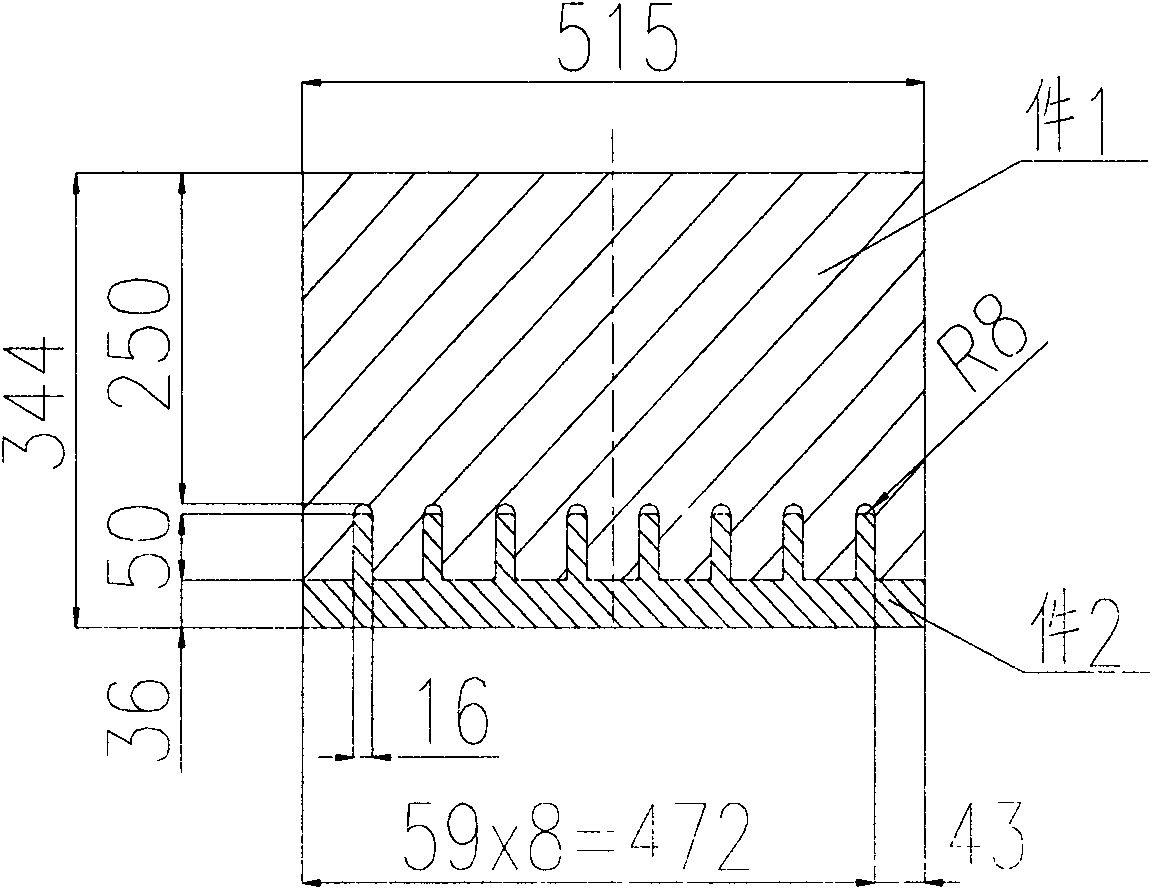

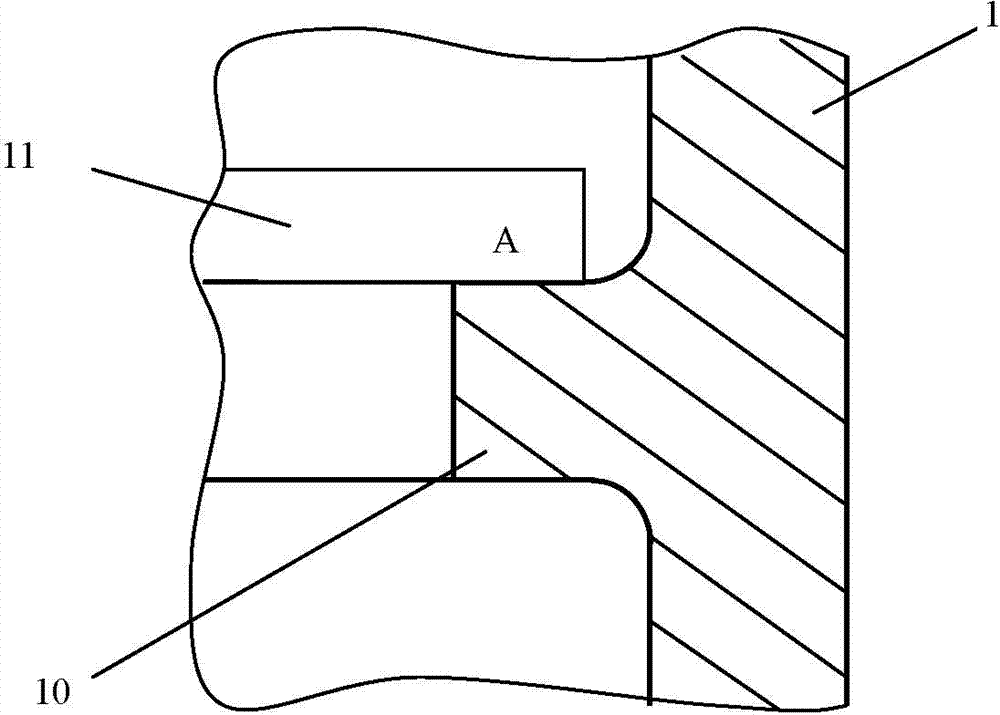

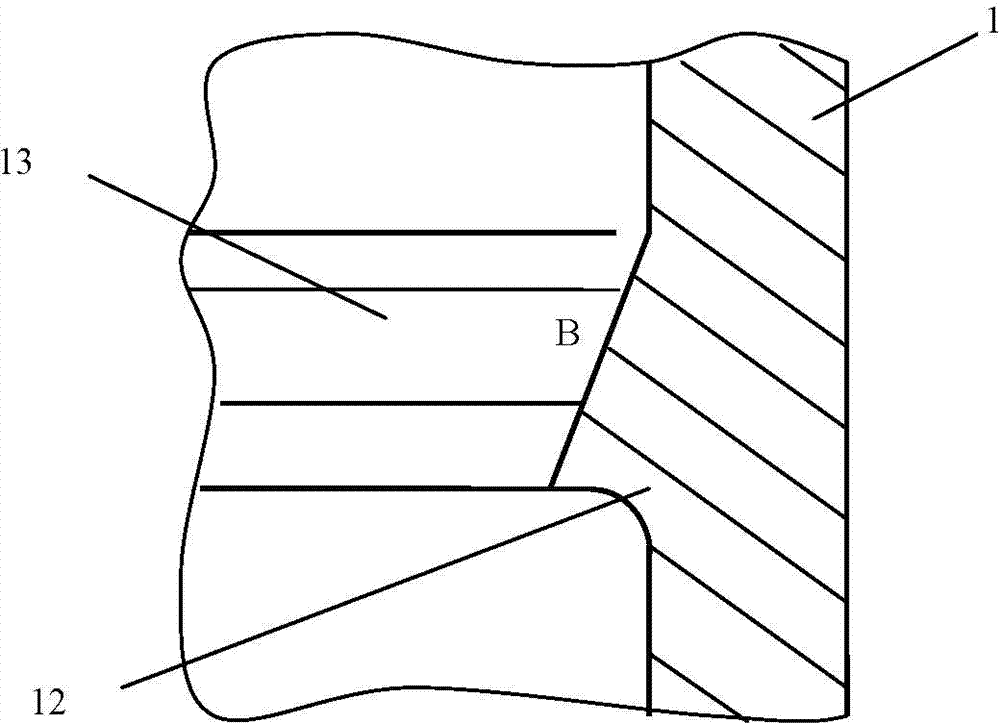

Connection method of cathode carbon blocks and cathode steel bars of aluminum electrolytic cells and construction thereof

The invention belongs to the technical field of aluminum production, wherein the key technology aims at developing a connection method of cathode carbon blocks and cathode steel bars of aluminum electrolytic cells by means of multi-grooves inserting and a construction thereof. The bottoms of the cathode carbon blocks (piece 1) are provided with a plurality of grooves; the cathode steel bars (piece2) consist of base plates and a plurality of rib plates welded thereon; the grooves of the cathode carbon blocks are correspondingly inserted with the rib plates of the cathode steel bars to completethe assembly of cathode carbon blocks. Compared with the existing cathode carbon blocks, the invention improves the utilization rate of the cathode carbon blocks, reduces the invalid usage amount ofthe cathode carbon blocks, reduces the mechanical machining quantity for forming steel bar grooves on the cathode carbon blocks, reduces the waste residue quantity of the cathode carbon blocks when overhauling the electrolytic cells, reduces the horizontal current in the cathode carbon blocks, removes the existing asphalt damage caused by carbon element paste when assembling the cathode carbon blocks and roasting the electrolytic cells, increases the iron carbon contact area between the cathode carbon blocks and the cathode steel bars, and prolongs the service life of the electrolytic cells.

Owner:郭龙

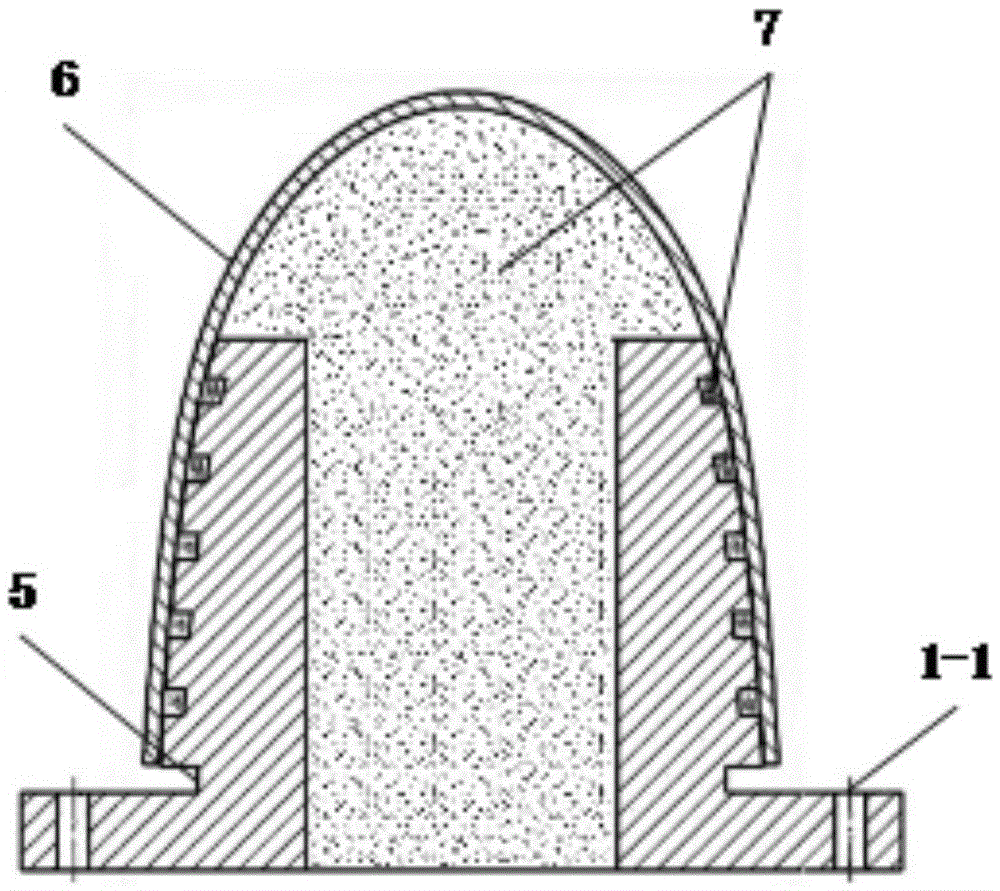

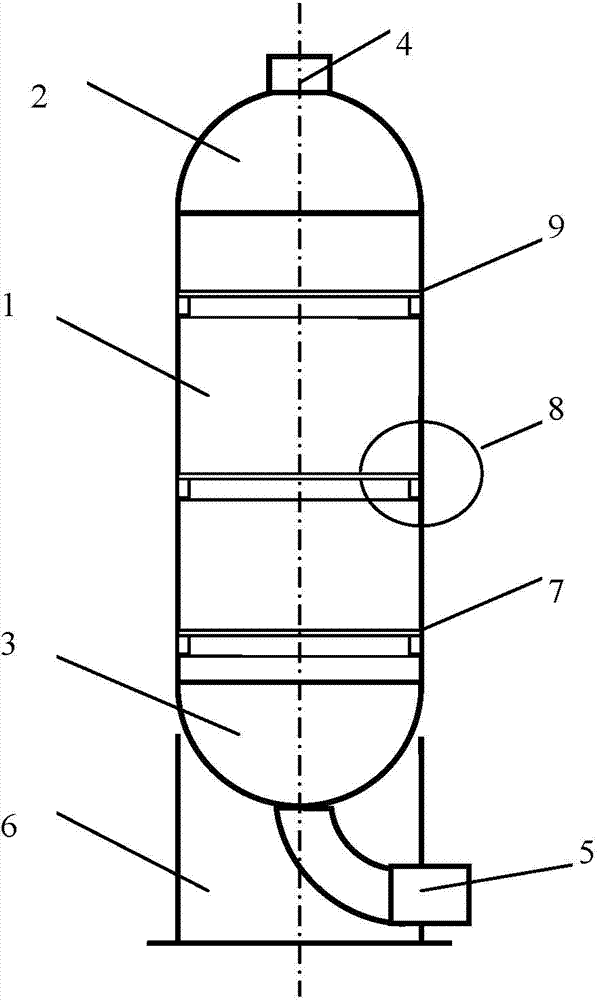

Reactor with inner supporting structure

InactiveCN104772091AExtended service lifeReduce local stress concentrationChemical/physical/physico-chemical processesCorrosion resistantEngineering

The invention provides a reactor with an inner supporting structure. The reactor comprises a barrel, material entering and exiting openings arranged on the barrel and the inner supporting structure arranged on the inner wall of the barrel, wherein the inner supporting structure comprises a supporting flange and a supporting rack and the flange surface of the supporting fits the supporting rack and is used for supporting the supporting rack. According to the invention, supporting is realized in the manner that the supporting flange fits the supporting rack through the flange surface of the supporting flange; compared with direct welding of a supporting plate and the inner wall of a barrel of a traditional supporting structure, such a manner has the advantages that strength difference between the supporting flange and the barrel is reduced, local stress concentration between the supporting flange and the inner wall of the reactor is lowered and the supporting flange can bear internal pressure, high temperature and gravitational load at one time, is easy to weld and has low cost; and through usage of the improved inner supporting structure, the reactor can resist corrosion and fatigue and does not crack in operation of the reactor, and has longer service life.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

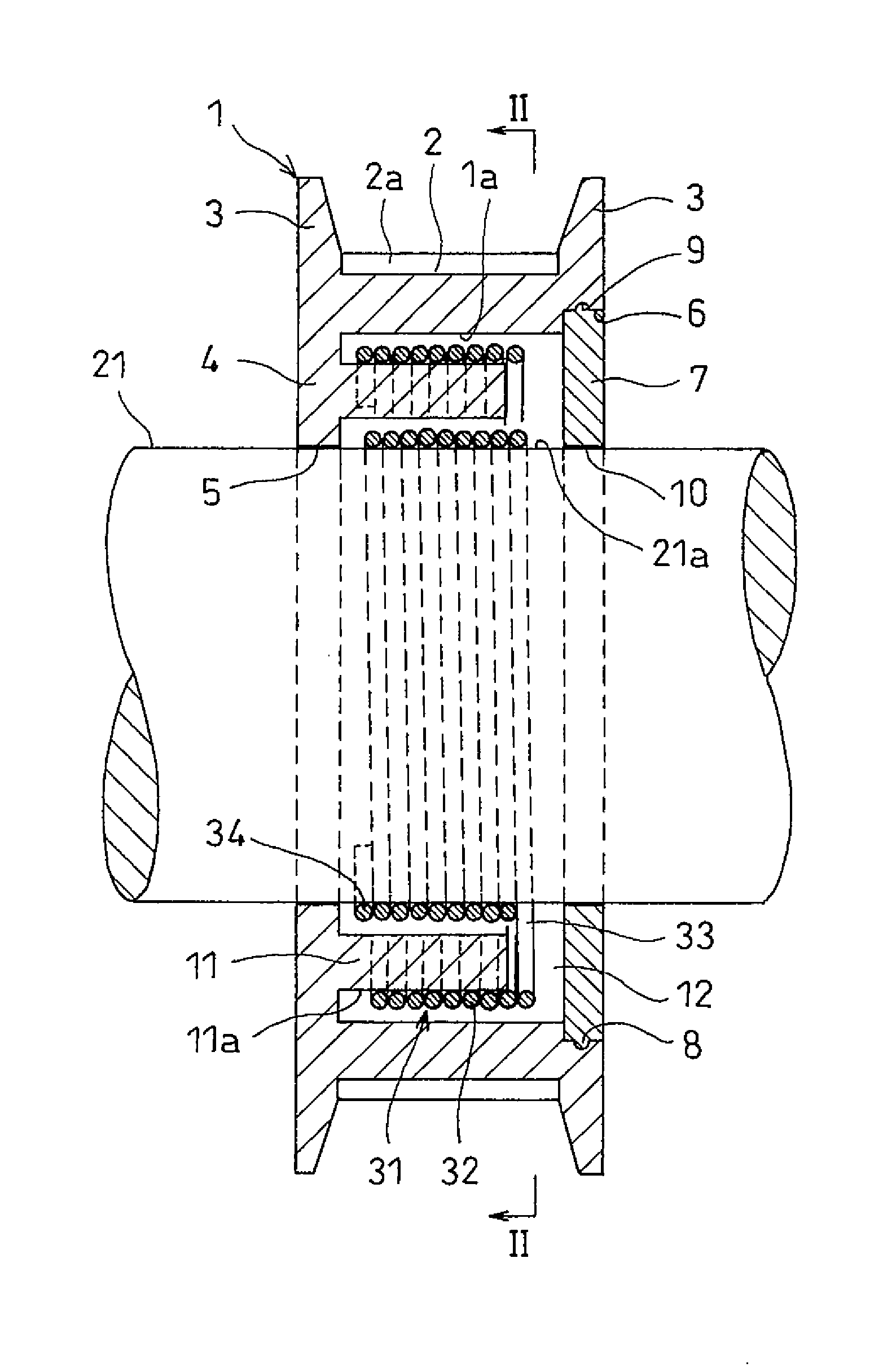

Spring type one-way clutch

InactiveUS20130313060A1Reduce local stress concentrationMinimize damageFriction clutchesInterengaging clutchesCoil springEngineering

A spring type one-way clutch includes an outer ring rotatable about a rotary shaft and having an inner tubular portion, and a clutch spring mounted in the outer ring. The clutch spring includes a large-diameter coil spring portion, a transition portion connected to the winding end of the large-diameter coil spring portion, and a small-diameter coil spring portion connected to the radially inner end of the transition portion and wound in the opposite direction from the large-diameter coil spring portion. When the outer ring is rotated in the direction opposite the winding direction of the large-diameter coil spring portion, the large and small-diameter coil spring portions are radially compressed and pressed against the inner tubular portion and the rotary shaft, allowing the rotary shaft to rotate together with the outer ring. The transition portion spirals radially inwardly in the winding direction of the large-diameter coil spring portion.

Owner:NTN CORP

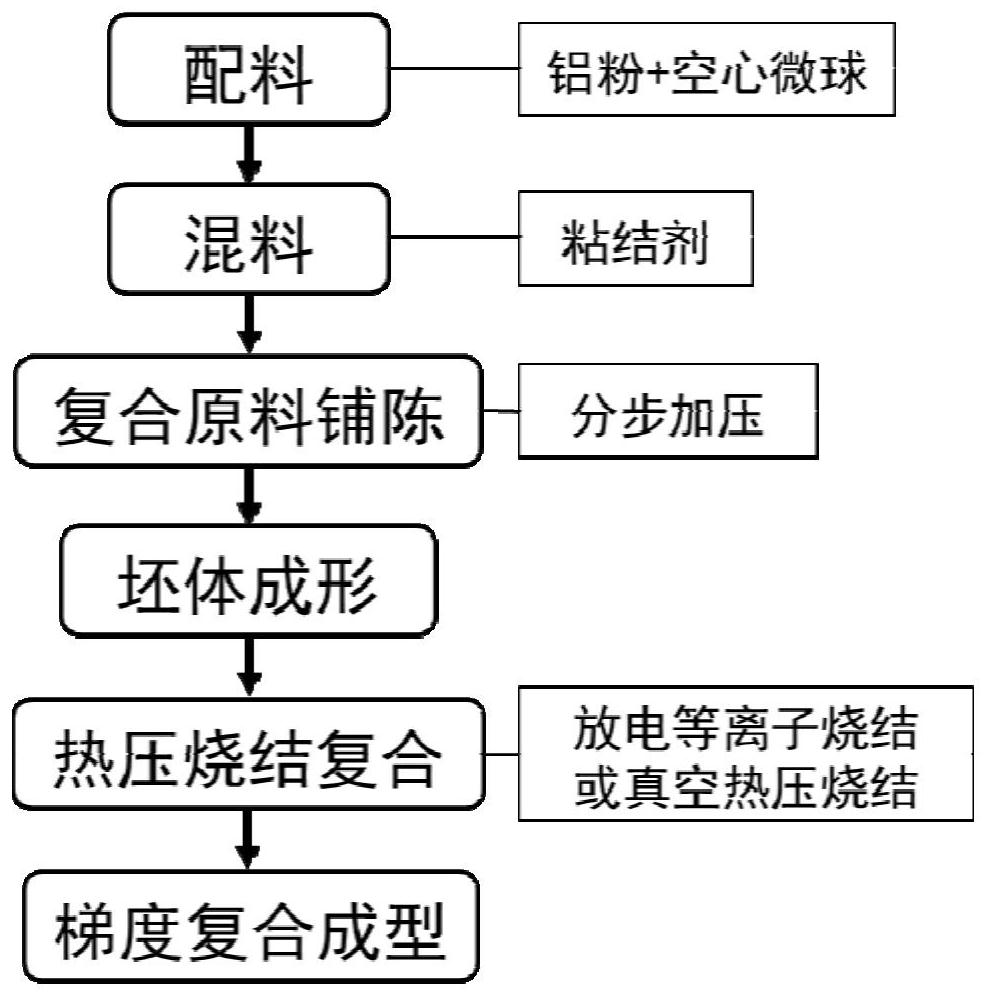

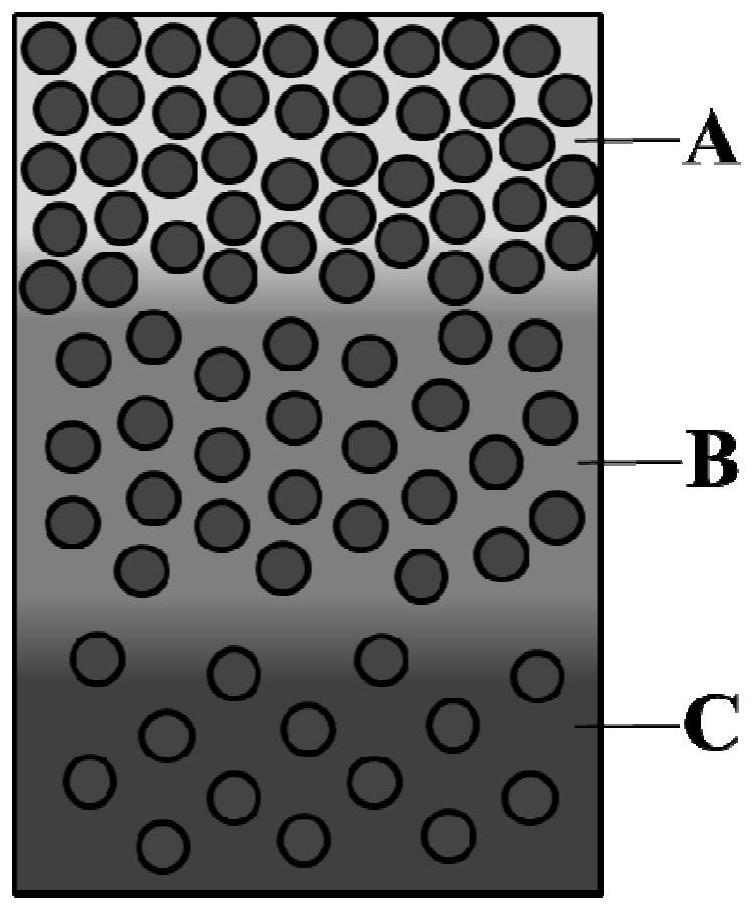

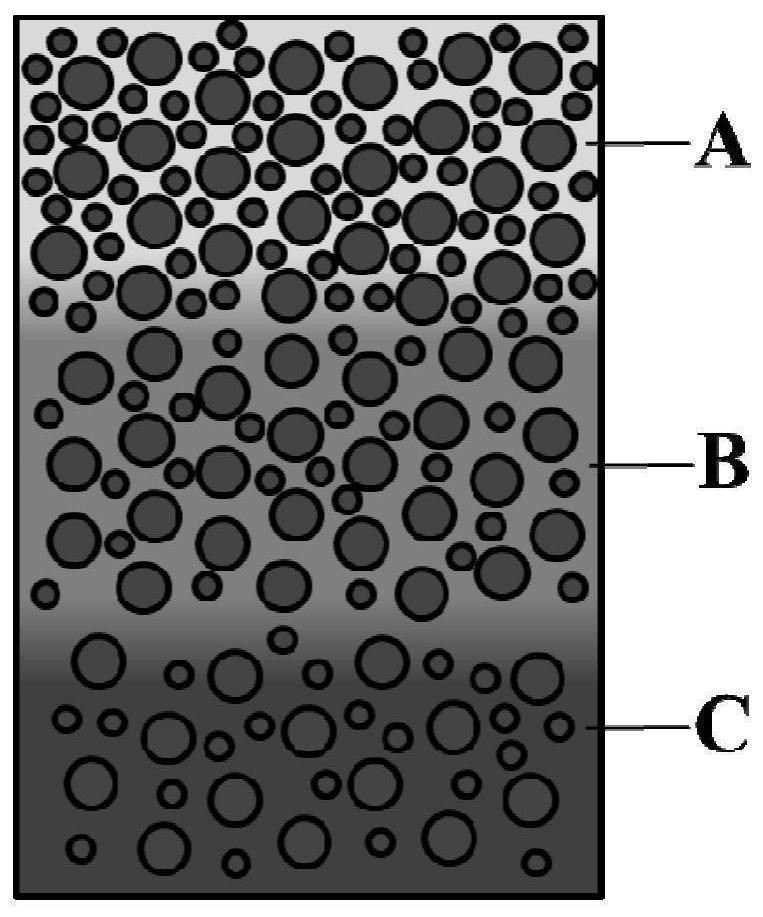

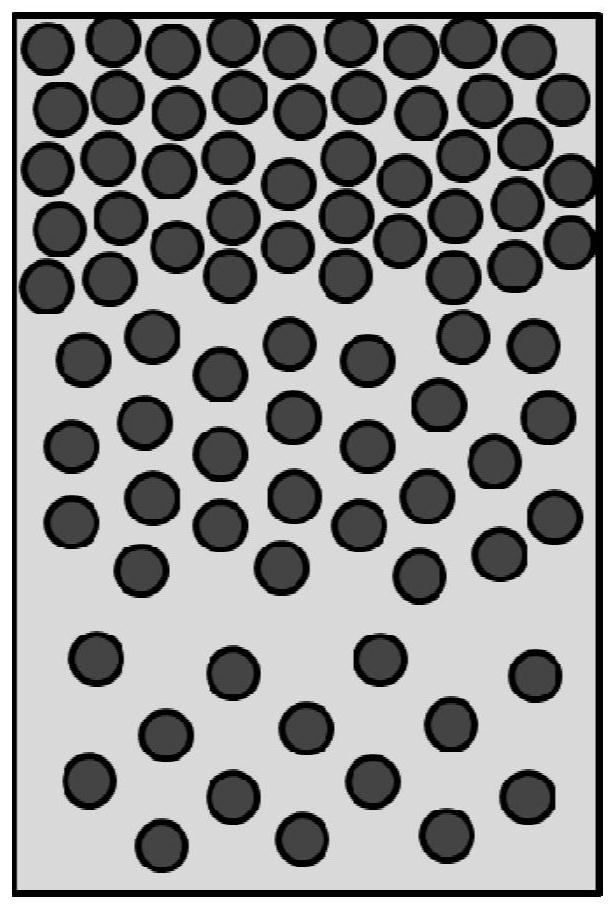

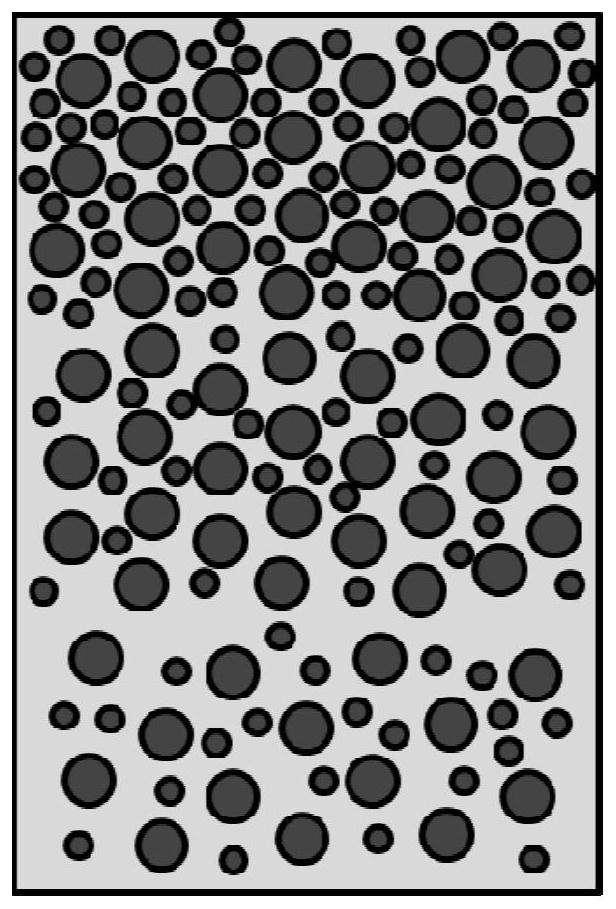

Aluminum-based porous composite material as well as preparation method and application thereof

ActiveCN113061770AStrong designabilityExcellent cushioning and energy absorption performanceEnergy absorbingPorous composite

The invention discloses an aluminum-based porous composite material as well as a preparation method and application thereof, and relates to the technical field of gradient composite materials. The preparation method comprises the following steps that a plurality of groups of composite raw materials are laid in a mold layer by layer, and cold pressing forming is carried out to obtain a prefabricated blank; hot pressed sintering is carried out on the prefabricated blank; and each group of composite raw materials comprises aluminum alloy powder and hollow microspheres, at least one parameter index of two adjacent layers of composite raw materials is different, and the parameter indexes comprise the volume fraction of the hollow microspheres, the grain size distribution of the aluminum alloy powder, the grain size distribution of the hollow microspheres, the components of aluminum alloy powder and the components of the hollow microspheres. The preparation method of the composite material is extremely high in designability, and the prepared composite material can form a functional gradient, so that excellent buffering and energy absorbing performance is obtained.

Owner:GUANGDONG INST OF NEW MATERIALS +1

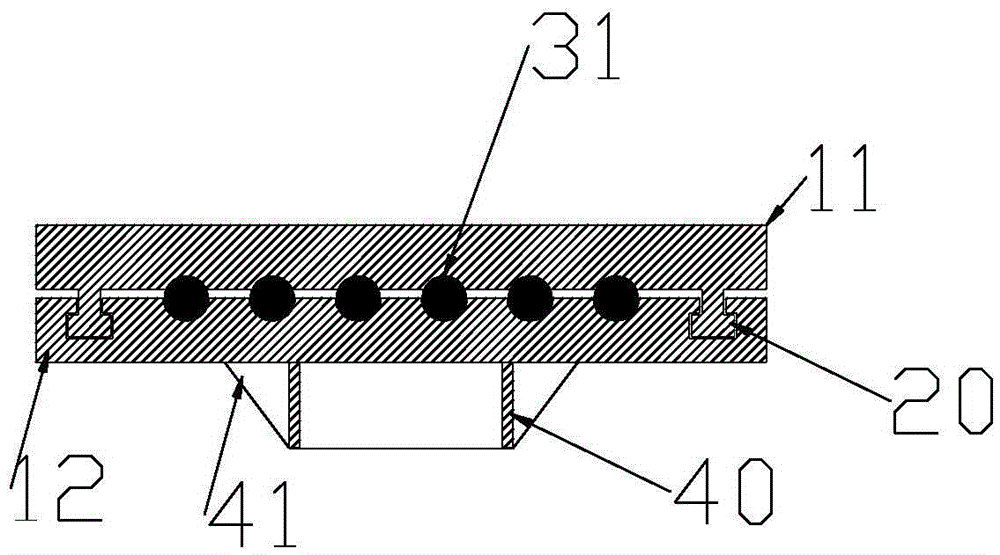

Horizontally slidable device and application method in jack lifting and unloading construction

ActiveCN105604335AEasy to assemble and disassembleAvoid local stress concentrationsBridge erection/assemblyBuilding material handlingMechanical engineeringBuilding construction

The invention relates to a horizontally slidable device and an application method in jack lifting and unloading construction, belongs to the technical field of building construction, and is used for solving the problem that in construction, a jack overturns due to horizontal displacement of a lifted object. The horizontally slidable device comprises a top plate, a bottom plate, balls between the top plate and the bottom plate, a steel sleeve arranged on the lower surface of the bottom plate and a limiting device positioned at the end part of the bottom plate, wherein a gap is formed between the top plate and the bottom plate; the top plate can slide horizontally relative to the bottom plate through the balls. The application method comprises the following steps: firstly, adjusting limiting rods of the bottom plate to position the top plate in a central position and lock the horizontal freedom degree of the top plate; secondly, sleeving the top end of the jack with the steel sleeve to connect the horizontally slidable device and the jack; thirdly, putting the jack at a preset position, and adjusting the elongation of the jack to tightly press the upper surface of the top plate against the lifted object; and finally, at the beginning of the construction, unlocking the limiting rods to ensure that the top plate can slide horizontally during the construction process.

Owner:SHANGHAI CONSTRUCTION GROUP

Aluminum-based porous composite material as well as preparation method and application thereof

ActiveCN113070464AExcellent cushioning and energy absorption performanceThe interface between the layers is well bondedLow internal friction springsMicrosphereInterface bonding

The invention discloses an aluminum-based porous composite material as well as a preparation method and application thereof, and relates to the technical field of composite materials. The preparation method of the aluminum-based porous composite material comprises the steps that multiple sets of composite blank raw materials are laid in a mold layer by layer and subjected to cold press molding, and a prefabricated blank is obtained; pressure infiltration is performed on the prefabricated blank by adopting an aluminum melt; the multiple sets of composite blank raw materials comprise aluminum material powder and hollow microspheres; and the proportions of the aluminum material powder and the hollow microspheres in every two adjacent sets of composite blank raw materials are different. The composite material with gradient distribution or periodic distribution of the hollow microspheres can be prepared through the preparation method, interlayer interface bonding is good, continuous transmission of impact loads is facilitated, and the material has more excellent buffering and energy absorbing performance.

Owner:GUANGDONG INST OF NEW MATERIALS +1

Concrete uniaxial tensile test fixture and test method

PendingCN111413203AAvoid damageEnsure tensile fracture surfaceMaterial strength using tensile/compressive forcesStress concentrationMortise and tenon

The invention discloses a concrete uniaxial tensile test fixture and a test method. The concrete uniaxial tensile test fixture comprises two fixture bodies with the same structure, each fixture body comprises a jaw connecting piece and a test piece clamping piece, one end of each jaw connecting piece is connected with a jaw of a tensile test machine in a matched mode, and the other end is connected with the corresponding test piece clamping piece; the jaw connecting piece is connected with the test piece clamping piece through a mortise and tenon joint; the clamping end of the concrete test piece is embedded into the test piece clamping piece, and the clamping end of the concrete test piece and the test piece clamping piece are connected in a surface contact close fit manner. The clampingend of the concrete test piece is connected with the test piece clamping piece in a surface contact fit manner, so that local stress concentration is effectively eliminated, the damage to the test piece is reduced, the tensile fracture surface of the concrete test piece is ensured to occur in the middle of the test piece, and a positive promoting effect is achieved for improving the test precision; the jaw connecting piece and the test piece clamping piece are connected in a mortise and tenon joint mode, the structural stability is improved, mounting and dismounting are easy, and the tensile test efficiency and the measurement precision are effectively improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

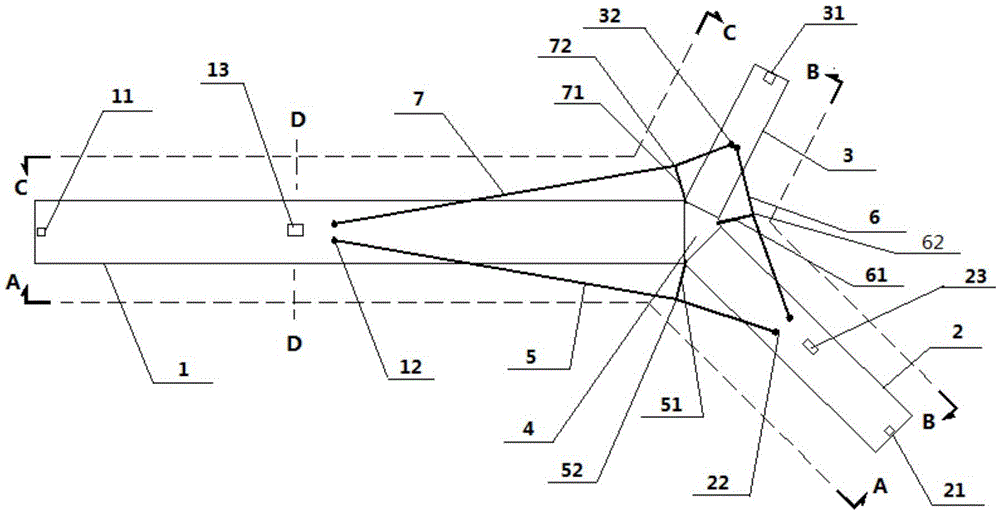

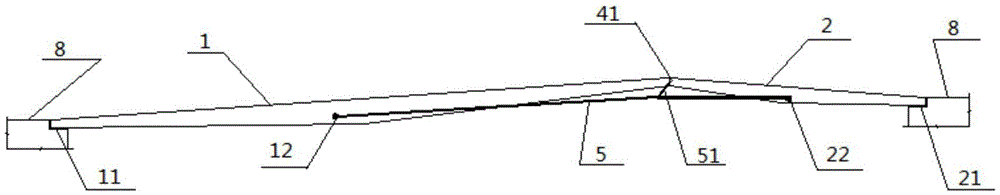

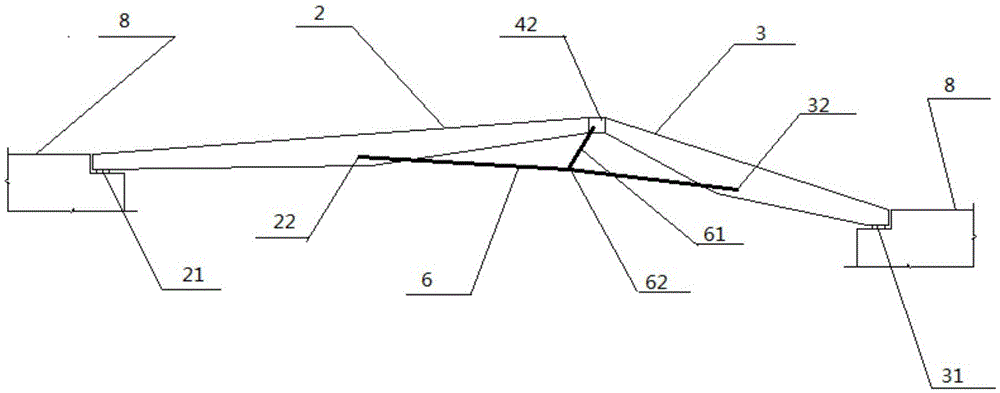

Spatial three-branch beam string structure footbridge

ActiveCN105463979AIncrease stiffnessIncrease vertical stiffnessBridge structural detailsStress concentrationAbutment

The invention discloses a spatial three-branch beam string structure footbridge which comprises a first main beam, a second main beam and a third main beam, wherein one ends of the three main beams are converged on a convergence node, and the other ends of the three main beams are supported on a bridge abutment through fixed supports; a first dragline is arranged between the middle part of the first main beam and the middle part of the second main beam, a second dragline is arranged between the middle part of the second main beam and the middle part of the third main beam, and a third dragline is arranged between the middle part of the third main beam and the middle part of the first main beam; and three anchorage plates are arranged on the side wall of the convergence node, a first connecting rod is arranged between the first anchorage plate and the first dragline, a second connecting rod is arranged between the second anchorage plate and the second dragline, and a third connecting rod is arranged between the third anchorage plate and the third dragline. According to the spatial three-branch beam string structure footbridge disclosed by the invention, the horizontal displacement of the structure under the action of vertical load can be limited, the integral rigidity of the three-branch beam string structure bridge can be increased, the local stress concentration degree of the convergence node of the three main beams can be reduced, and the vibration comfort can be improved when pedestrians cross the bridge.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

Preparation method of polyethylene glycol repaired graphene reinforced aluminum-based composite material

The invention discloses a preparation method of polyethylene glycol repaired graphene reinforced aluminum-based composite material, and relates to the preparation method of graphene reinforced aluminum-based composite material. The preparation method aims to solve a problem that grinding aid is residual in an aluminum alloy matrix, and realize self-repairing of the graphene. The preparation methodcomprises the step 1 of weighing the graphene, the polyethylene glycol and aluminum metal powder; the step 2 of putting the material obtained in the step 1 into a ball milling tank for ball milling;the step 3 of cold pressing; and the step 4 of preparing the composite material after the cold pressing. The grinding aid, polyethylene glycol is subjected to thermal decomposition to generate activeC atoms, and the C atoms can adsorb on the pits of the graphene, so that integrity of the graphene structure is greatly improved, good interface connection is formed, and overall performance of the material is greatly improved; the polyethylene glycol is beneficial to flake formation of the aluminum metal powder, so that a problem of high dispersion difficulty of the single-layer or few-layer graphene in the aluminum-based composite material is solved, and cold welding between the aluminum metal powders is reduced; polyethylene glycol is easy to remove, and the prepared few-layer graphene reinforced aluminum-based composite material is excellent in comprehensive performance. The method is suitable for preparing the graphene reinforced aluminum-based composite material.

Owner:HARBIN INST OF TECH

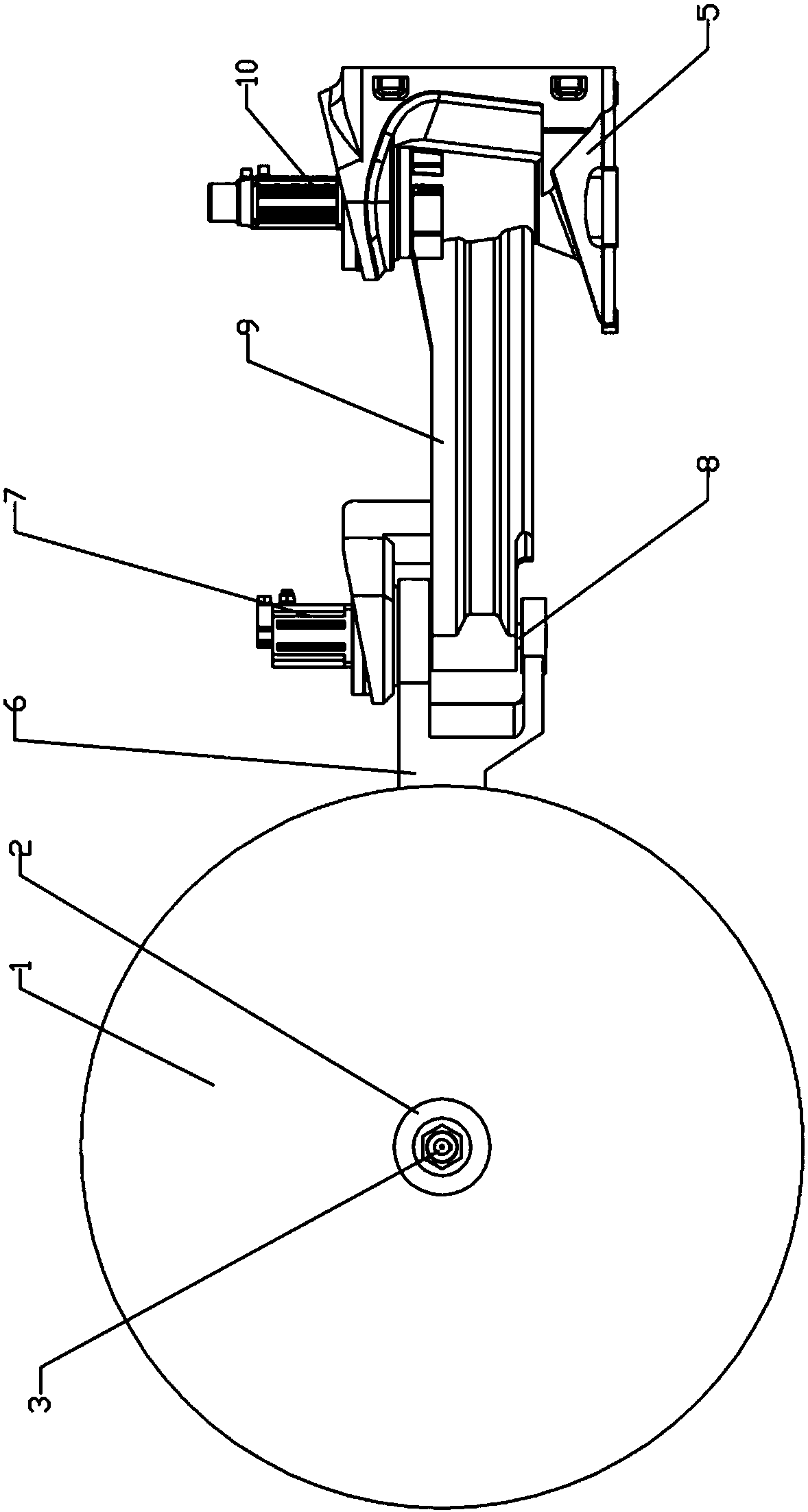

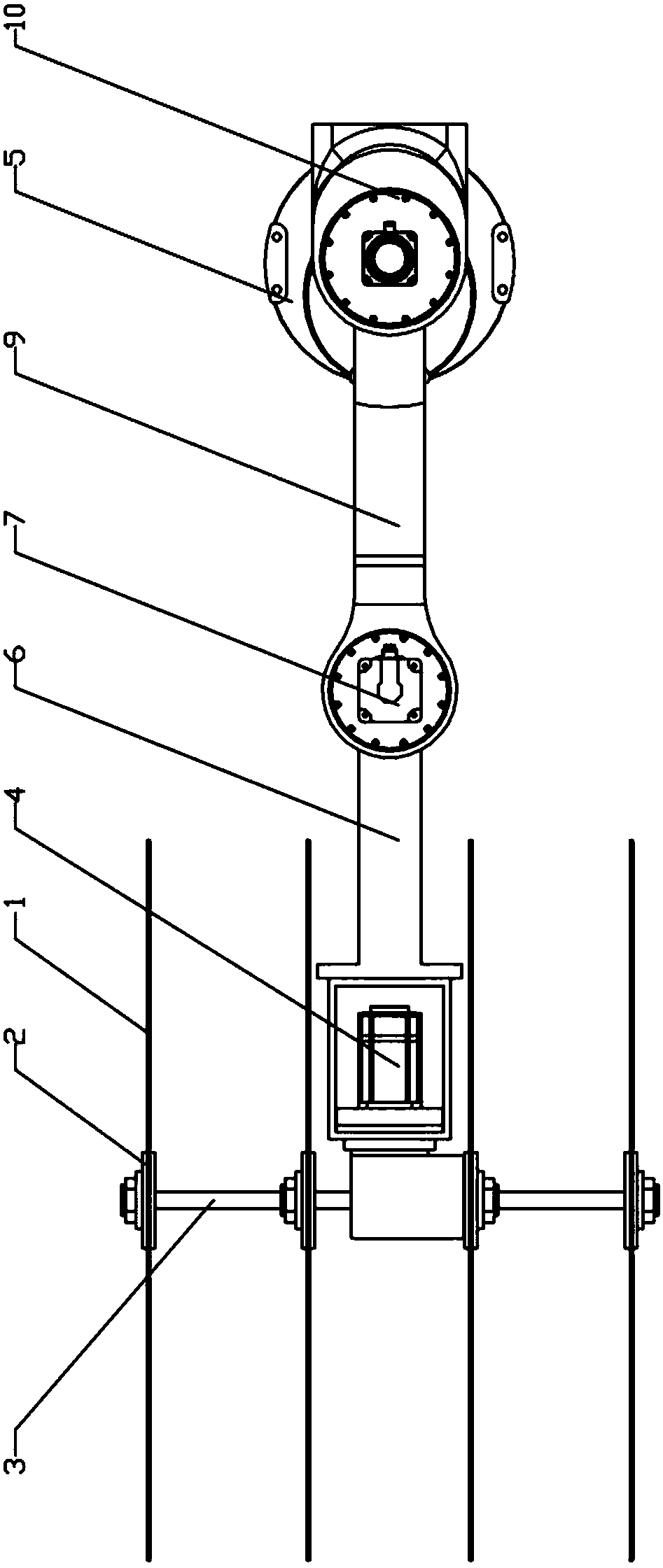

Cutting device for digging robot

InactiveCN108127649AExpand the scope of workAvoid destructionProgramme-controlled manipulatorTunnelsSingle degree of freedomEngineering

The invention discloses a cutting device for a digging robot. The device comprises a mechanical arm and a cutting machine which is driven by the mechanical arm to move in the space; the mechanical armcomprises a machine base, an inner arm which is rotatably connected to the machine base at the single degree of freedom in the vertical direction, an outer arm which is rotatably connected to the inner arm at the single degree of freedom in the vertical direction, a first driving device for driving the outer arm to rotate relative to the inner arm and a second driving device for driving the innerarm to rotate relative to the machine base. Therefore, the mechanical arm with high length and weight can be adopted for the cutting device for the digging robot, the bending moment generated under the gravity of the mechanical arm is prevented from damaging the driving devices (usually gear motors), and accordingly the operation range of the cutting device for the digging robot is greatly enlarged.

Owner:CHONGQING PENG TECH

Method for machining and manufacturing oil tank supporting frame

InactiveCN104289562AExtended service lifeEven by forceShaping toolsVehicle componentsStress concentrationSheet steel

The invention discloses a method for machining and manufacturing an oil tank supporting frame. According to the method for machining and manufacturing the oil tank supporting frame, two mutually connected inclined surfaces enable a steel plate to be stressed overall, the steel plate is evenly stressed during machining, local stress concentration appearing on a bent portion of a formed supporting frame blank is reduced, the situation that a fatigue source is formed by fine cracks generated on the welded portion of the bent portion of the supporting frame in the user process after the supporting frame is welded to an oil tank is avoided, and the service life of the supporting frame is prolonged.

Owner:CHENGDU XINGBODA PRECISION MACHINERY

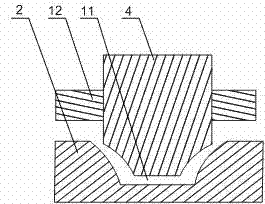

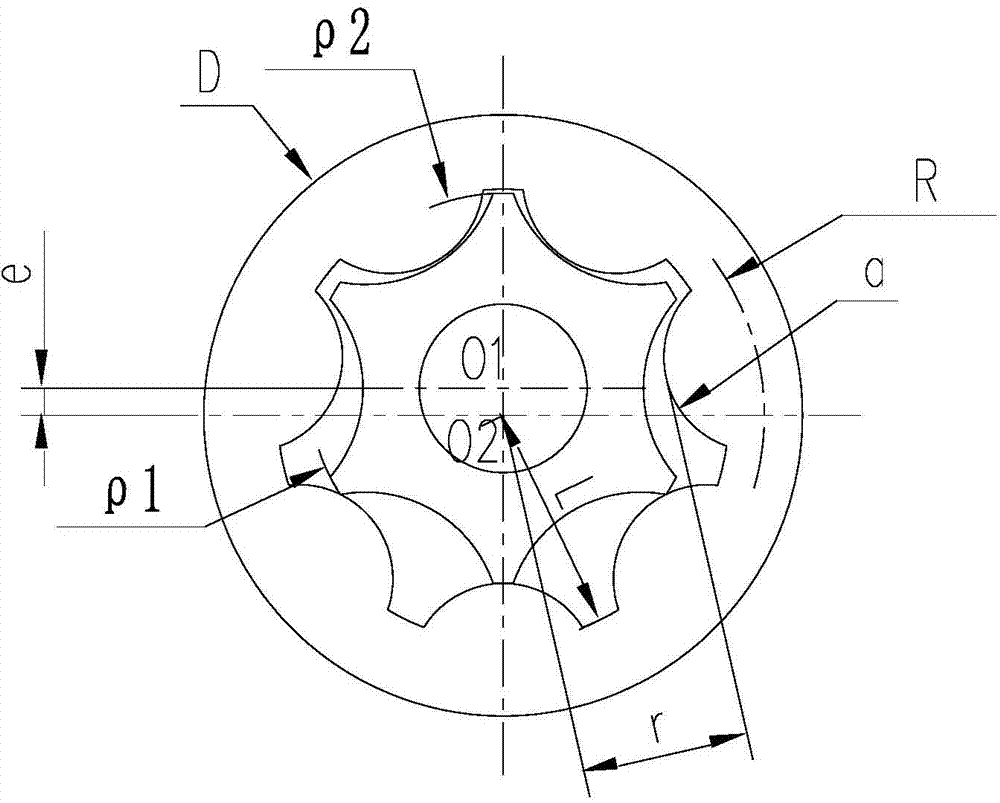

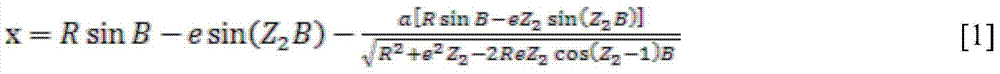

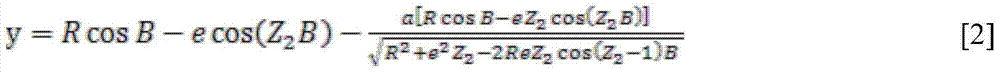

Method for designing and manufacturing cycloid rotor pump

ActiveCN104500388AHigh strengthReduce manufacturing precisionPump componentsRotary piston pumpsAviationEngineering

The invention relates to a method for designing and manufacturing a cycloid rotor pump and practical significance thereof in actual production. The method is successfully applied to the cycloid rotor pump in a certain aviation vehicle-mounted finished product, namely a hydraulic constant speed transmission device. The cycloid rotor pump provided by the invention is an internal engagement type cycloid rotor pump and is shown in the accompanying drawing. The meshed endpoint circle of the cycloid pump refers to a circle concentric to a restricted circle on an outer rotor, and the radius of the circle is smaller than that of the restricted circle. Accurate solution of the meshed endpoint circle has important guiding significance on production, and outside the meshed endpoint circle, because an inner rotor and the outer rotor are not meshed, the manufacturing precision can be properly reduced, and the manufacturing cost can be greatly saved. In addition, an arc angle is formed between a circular-arc fillet of the rotor outside the meshed endpoint circle and the restricted circle, the strength of the outer rotor can be greatly improved, and the service life is prolonged.

Owner:JINCHENG NANJING ELECTROMECHANICAL HYDRAULIC PRESSURE ENG RES CENT AVIATION IND OF CHINA

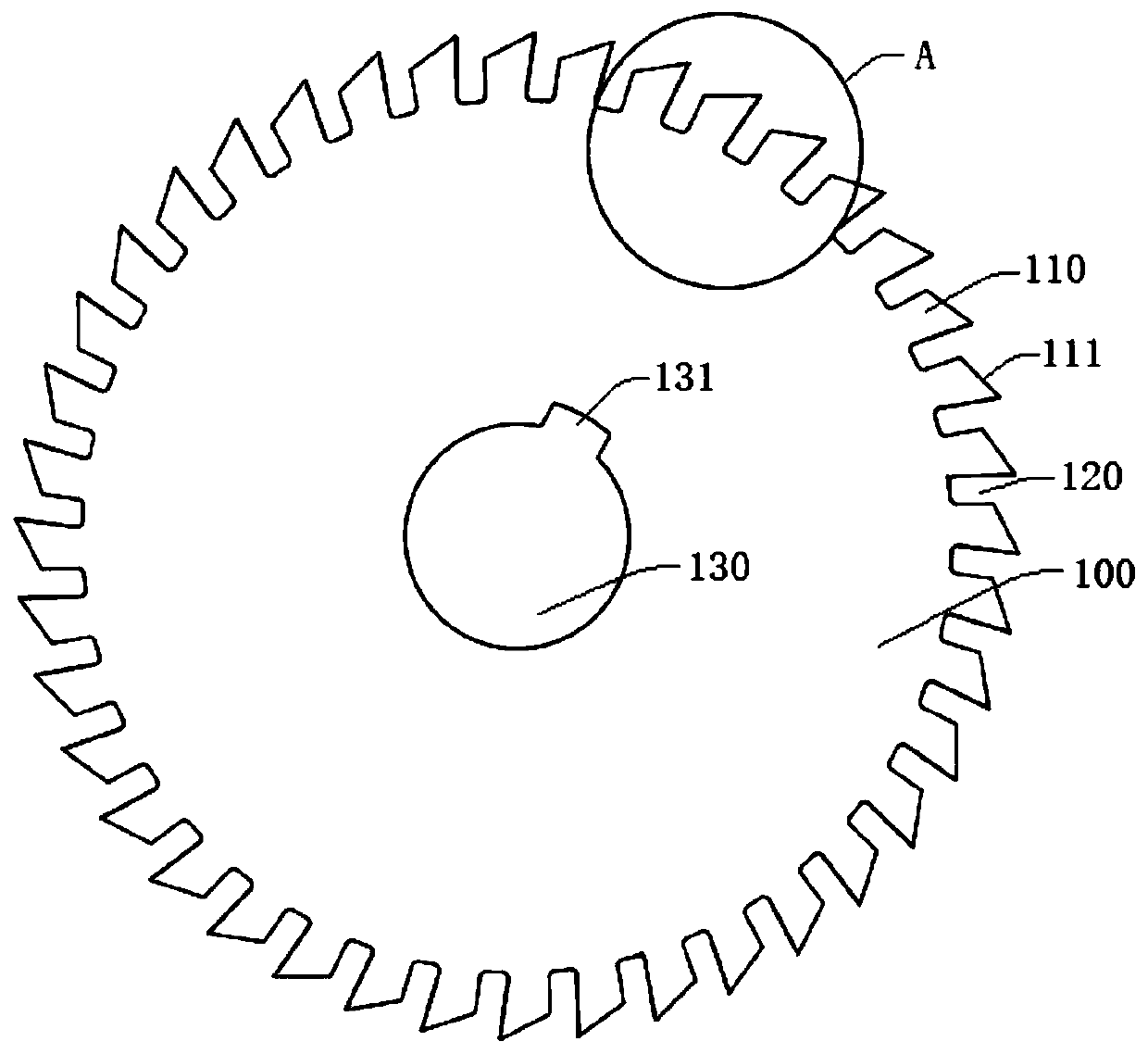

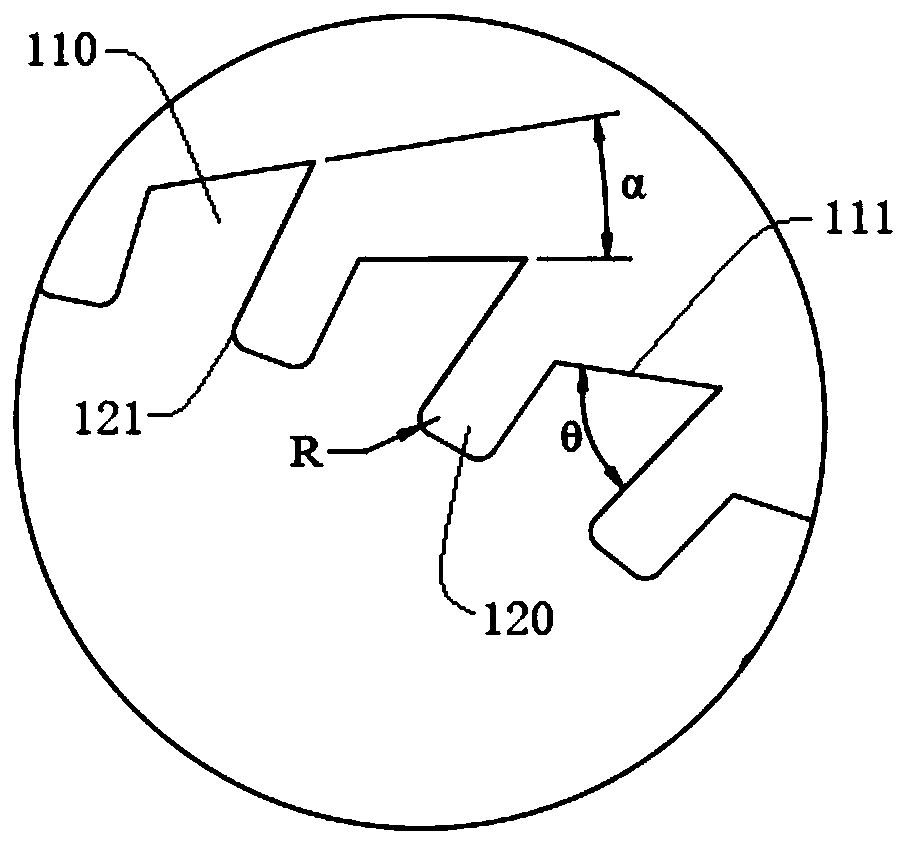

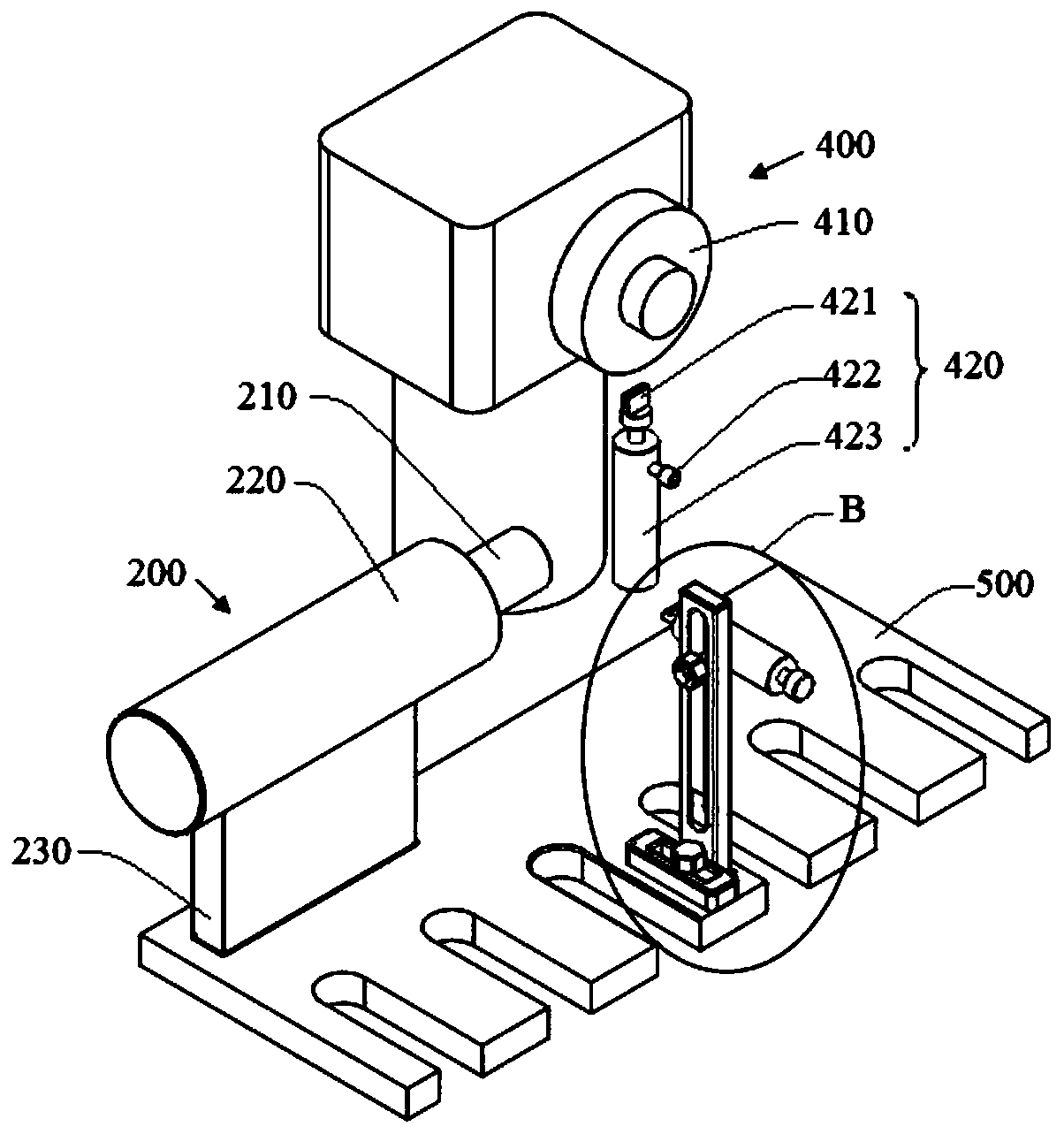

Circular tooth knife for plastic pulverizer and grinding tool and processing technology thereof

ActiveCN110238716AReduce damage rateAffect speedOther manufacturing equipments/toolsGrain treatmentsMechanical engineeringPulverizer

The invention discloses a circular tooth knife for a plastic pulverizer and a grinding tool and a processing technology thereof, and belongs to the technical field of mechanical cutters. The circular tooth knife comprises a cylindrical knife body, n knife teeth are uniformly distributed in the length direction of the periphery of the knife body, n is larger than or equal to 30 and smaller than or equal to 50, a tooth groove is formed between every two adjacent knife teeth, and arc faces are arranged at the edges in the length directions of the groove bottoms of the tooth grooves. The grinding tool comprises a mounting unit, a positioning unit and a grinding unit, the mounting unit is used for supporting the knife body to be processed, the positioning unit is used for limiting rotation of the knife body on the mounting unit, and the grinding unit is used for polishing cutting edge faces of the knife teeth; and the mounting unit is located between the positioning unit and the grinding unit. The processing technology of a round blade is that after linear cutting is carried out, the grinding tool is used for grinding and machining the cutting edge faces. By means of the circular tooth knife, the sharpness of the circular tooth knife can be ensured, the service life can be prolonged, and the cutting edge faces of the knife can be conveniently and accurately ground.

Owner:ANHUI FENGLIRUI BLADE MFG CO LTD

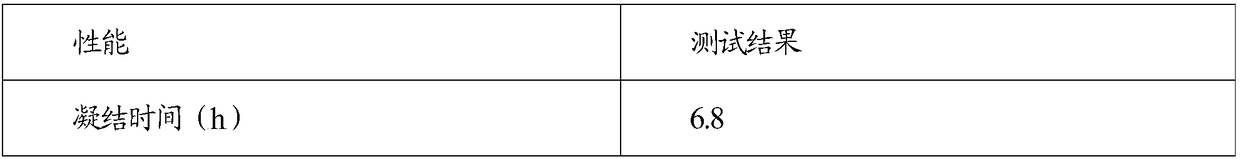

Stalk fiber toughening mortar and preparation method thereof

The invention discloses stalk fiber toughening mortar. The stalk fiber toughening mortar is prepared from the following ingredients in parts by weight: 20 to 40 parts of ordinary portland cement, 50 to 70 parts of perlite, 15 to 35 parts of iron tailings, 15 to 30 parts of waste porcelain powder, 15 to 20 parts of slag powder, 8 to 20 parts of straw fiber, 1 to 1.5 parts of starch ether, 0.5 to 2parts of hydroxy propyl cellulose, 3 to 8 parts of polyvinyl alcohol, 1 to 6 parts of styrene-acrylic emulsion and 2 to 4 parts of methyl cellulose ether. The method comprises the following steps of uniformly mixing the ordinary portland cement, the perlite, the iron tailings, the waste porcelain powder and the starch ether; then, adding the stalk fiber, the hydroxy propyl cellulose, the polyvinylalcohol, the styrene-acrylic emulsion and the methyl cellulose ether; finally adding water; performing mixing to obtain a finished product. The stalk fiber toughening mortar solves the problems of low tensile intensity, easy cracking and the like of the existing mortar due to poor toughness.

Owner:河南胜泽建筑保温工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com