Aluminum-based porous composite material as well as preparation method and application thereof

A composite material and aluminum-based porous technology, which is applied in the field of gradient composite materials, can solve problems such as the collapse of micro-region components, unsatisfactory energy absorption capacity of aluminum-based porous composite materials, and failure to fully exert the performance of components, etc., to achieve Strong designability and excellent cushioning and energy-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

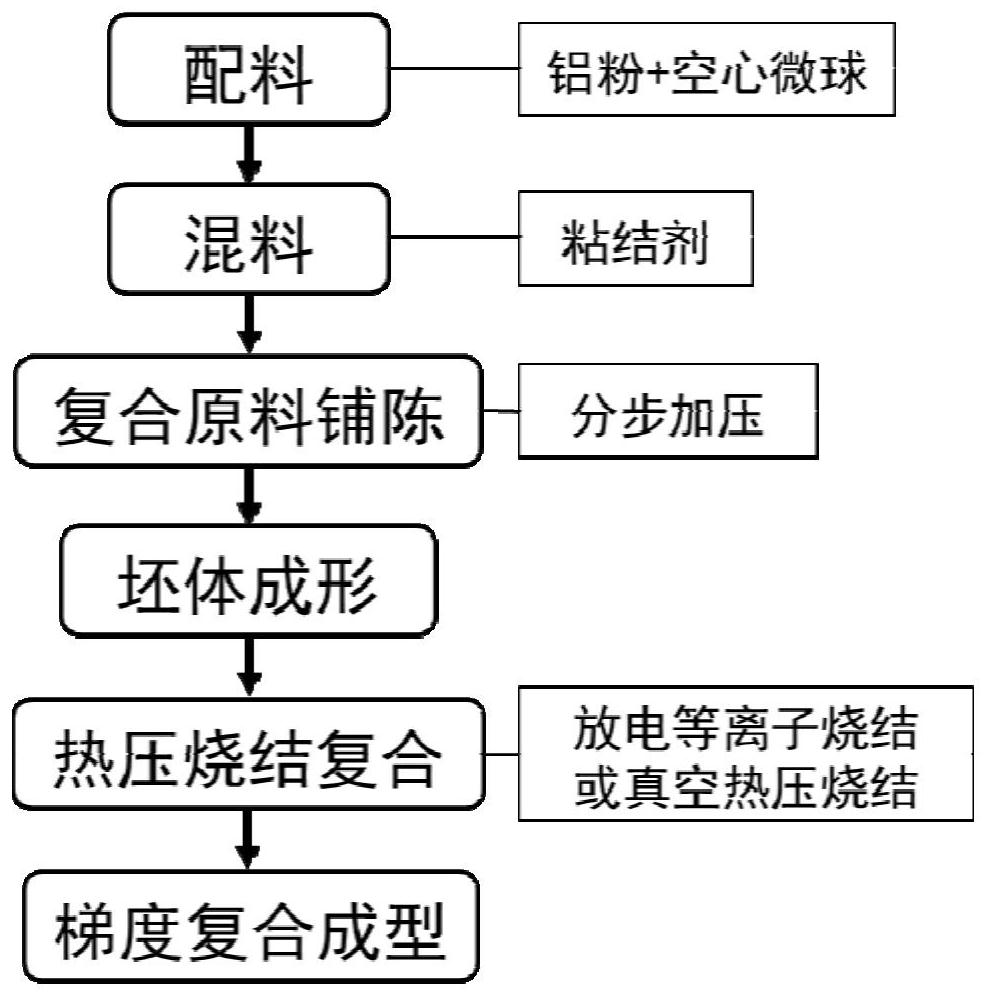

[0024] The embodiment of the present invention provides a method for preparing an aluminum-based porous composite material, please refer to figure 1 , including the following steps:

[0025] (1) Preparation of composite raw materials

[0026] Multiple groups of composite raw materials are prepared according to the pre-gradient design, and each group of composite raw materials includes aluminum alloy powder and hollow microspheres. Gradient design is to make the parameters of multiple groups of composite materials different. The parameters include volume fraction of hollow microspheres, particle size distribution of aluminum alloy powder, particle size distribution of hollow microspheres, composition of aluminum alloy powder and hollow microspheres. The composition of the ball. In the actual gradient design, at least one of the above indicators may be different, or two or more indicators may be different, and targeted design can be carried out according to the application env...

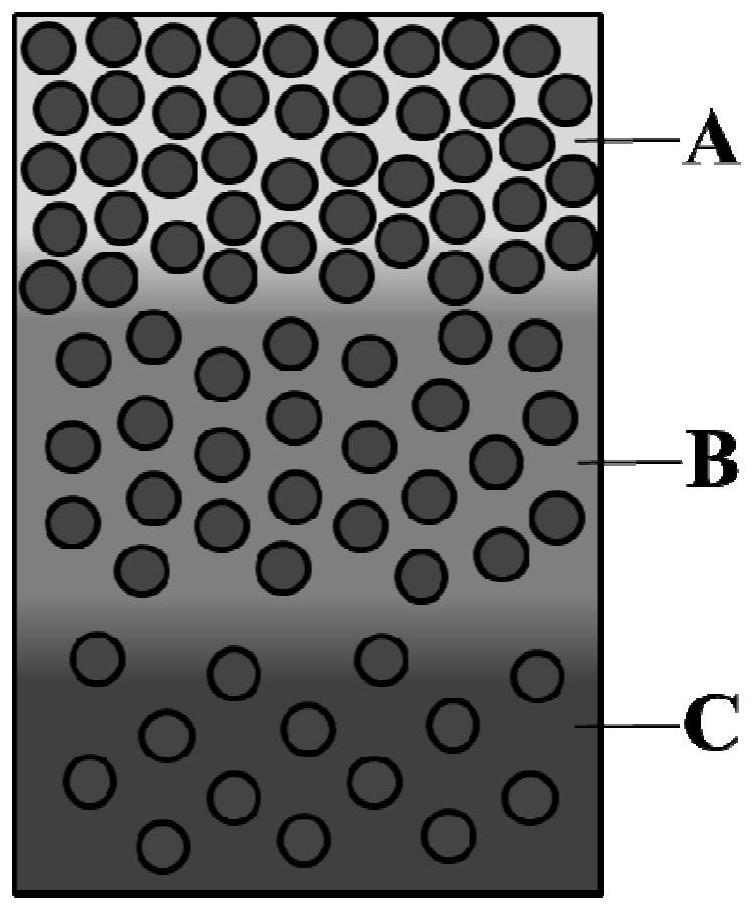

Embodiment 1

[0056] This embodiment provides a method for preparing an aluminum-based porous composite material, including:

[0057] (1) Preparation of composite raw materials: According to the volume fraction of hollow microspheres of 20%, 40% and 60%, the mesh particle size is 60-150 mesh Al 2 o 3 Ceramic hollow microspheres, respectively mixed with 200-400 mesh 1100 aluminum powder, 6061 aluminum powder and 6063 aluminum powder, the volume fraction of hollow microspheres corresponding to 6061 aluminum powder is 20%, and the volume fraction of hollow microspheres corresponding to 6063 aluminum powder is 40% %, the volume fraction of hollow microspheres corresponding to 1100 aluminum powder is 60%; each group of raw materials is put into the blender and mixed for 2h, and then adding mass fraction is 5% dehydrated alcohol (that is, accounting for the total volume of hollow microspheres and aluminum powder 5% of the mass) mixed for 4h.

[0058] (2) Cold press forming of the prefabricated ...

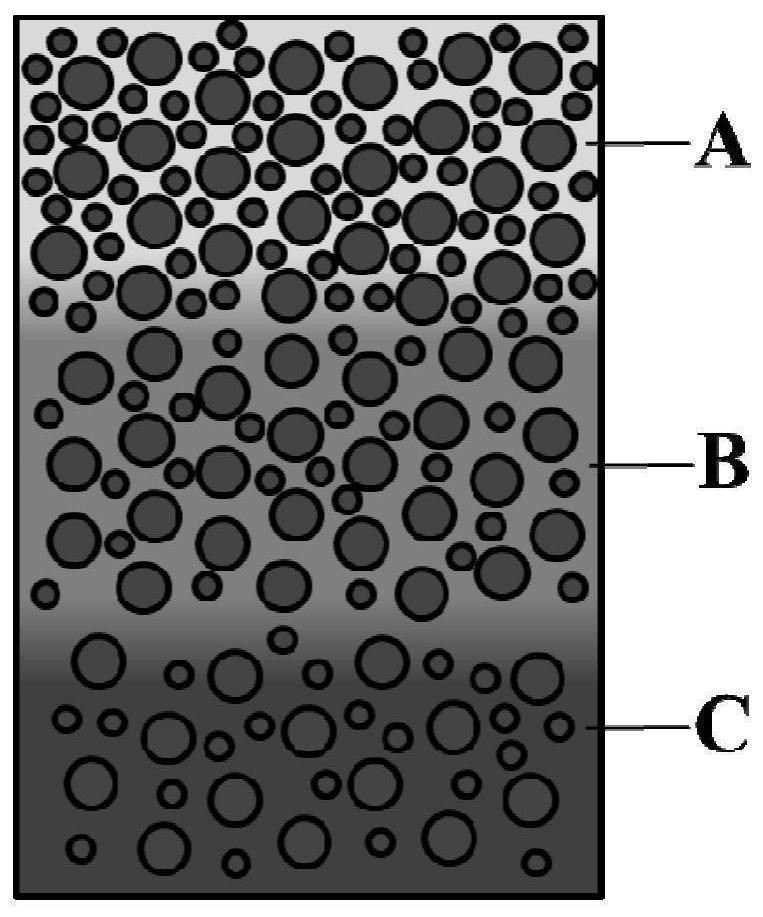

Embodiment 2

[0063] This embodiment provides a method for preparing an aluminum-based porous composite material, including:

[0064] (1) Preparation of composite raw materials: According to the volume fraction of hollow microspheres of 35%, 55% and 75%, take the glass hollow microspheres with a mesh particle size of 150-400 mesh and 500-1000 mesh, respectively, with a mesh particle size of 800-1000 mesh Purpose 1100 aluminum powder, 5A03 aluminum powder and 5A06 aluminum powder are mixed.

[0065] The specific ingredients are: control the volume fraction of hollow microspheres to be 35% and mix with 5A06 aluminum powder, control the volume fraction of hollow microspheres to be 55% and mix with 5A03 aluminum powder, control the volume fraction of hollow microspheres to be 75% and mix with 1100 aluminum powder, wherein , the volume fraction of hollow microspheres is 35% of the composite material, the volume fraction ratio of 150-400 mesh and 500-1000 mesh is 2:1; the volume fraction of hollo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com