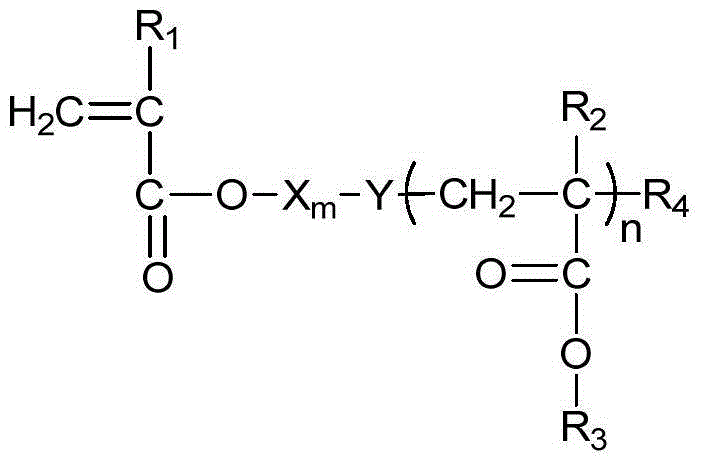

Reactive group-contained comb-type graft copolymer, and preparation method and application thereof

A technology of graft copolymer and reactive group, applied in the field of comb-shaped polymethyl acrylate containing reactive group and preparation thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0066] Under a nitrogen atmosphere, 90 g of methyl methacrylate (0.9 mol), 10 g of glycidyl methacrylate (0.07 mol), 4 g of mercaptoethanol (0.05 mol), 2.5 g of 4,4' as polymerization initiator-6 - Azobis(4-cyanopentanol) and 100 g of tetrahydrofuran as a solvent were uniformly mixed, and the temperature of the reactor was raised to 70° C. for 5 hours. Then the reaction device was cooled to 0°C, 10g triethylamine (0.1mol), 8g methacryloyl chloride (0.08mol) were added to the reaction system, reacted at 0°C for 4 hours, and the solvent was removed under reduced pressure to obtain a large Molecular monomer B is denoted as M-2000 (E-0.1), the molecular weight of macromolecular monomer B is 2000, and the mass fraction of epoxy is 10%.

Embodiment 1-2

[0068] Under a nitrogen atmosphere, 70 g methyl methacrylate (0.7 mol), 30 g glycidyl methacrylate (0.21 mol), 3.6 g mercaptoethanol (0.21 mol), 2.4 g of 4,4 as polymerization initiator-6 '-Azobis(4-cyanopentanol) and 100 g of tetrahydrofuran as a solvent were uniformly mixed, and the temperature of the reactor was raised to 70° C. for 5 hours. Then the reaction device was cooled to 0°C, 10g triethylamine (0.1mol) and 8g methacryloyl chloride (0.08mol) were added to the reaction system, reacted at 0°C for 4 hours, and then the solvent was removed under reduced pressure to obtain The macromonomer B is denoted as M-2000 (E-0.3), the molecular weight of the macromonomer B is 2000, and the mass fraction of epoxy is 30%.

Embodiment 1-3

[0070] Under a nitrogen atmosphere, 40 g methyl methacrylate (0.4 mol), 60 g glycidyl methacrylate (0.42 mol), 3.2 g mercaptoethanol (0.04 mol), 1.9 g of 4,4 as polymerization initiator-6 '-Azobis(4-cyanopentanol) and 100 g of tetrahydrofuran as a solvent were uniformly mixed, and the temperature of the reactor was raised to 70° C. for 5 hours. Then the reaction device was cooled to 0°C, 10g triethylamine (0.1mol) and 8g methacryloyl chloride (0.08mol) were added to the reaction system, reacted at 0°C for 4 hours, and then the solvent was removed under reduced pressure to obtain The macromonomer B is denoted as M-2000 (E-0.6), the molecular weight of the macromonomer B is 2000, and the mass fraction of epoxy is 60%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com