Patents

Literature

134results about How to "Good capacity increase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

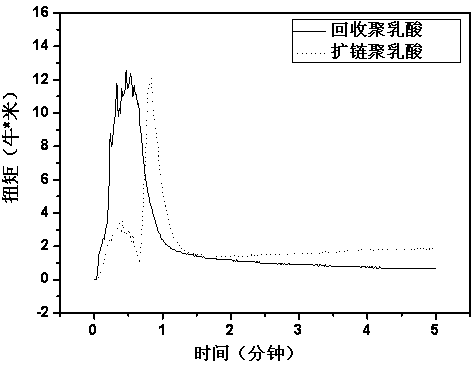

Method for manufacturing biologically degradable polyester composite material with capacity increasing function

The invention belongs to the technical field of polymer materials, which more particularly relates to a preparation method of a biological decomposable polyester composite material with compatibilization function. The specific steps are that: a method of small molecular diol hydroxyl end capping is adopted for preparing polylactic acid and biological decomposable polyester diol, a diisocyanate series chain extender is used for preparing the block copolymer of the polylactic acid and the decomposable polyester by a method of fusion chain extension, and the block copolymer is used in a blend system of the polylactic acid and the corresponding polyester to play the role of compatibilization function. The preparation method of the biological decomposable polyester composite material is simple in method and technique, easy in industrial production and the prepared block copolymer can increase the compatibility of the polylactic acid and the biological decomposable polyester blend system effectively and play the role of a compatibilizer.

Owner:TONGJI UNIV

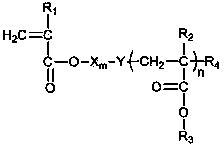

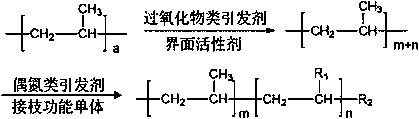

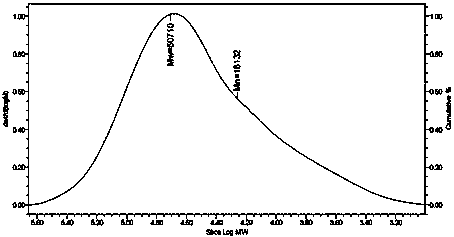

Comb-shaped stem grafting copolymer containing reactive group and preparation method and application thereof

The invention discloses a comb-shaped stem grafting copolymer containing reactive group and a preparation method and application thereof. The copolymer is a comb-shaped stem grafting copolymer by taking small molecule monomer B as the main chain, and giant molecule monomer A as the side chain. According to the method, the giant molecule monomer A and the small molecule monomer B are copolymerized to form the comb-shaped stem grafting copolymer of which the main chain is the small molecule monomer B and the side chain is the giant molecule monomer A. The comb-shaped stem grafting copolymer disclosed by the invention can serve as the chain extender of a polymer or a polymer blend, the compatibilizer of the polymer blend, the hydrolytic stabilizer, adhesive and anti-leakage agent of the polymer blend, and is used for coatings of wood, metal or plastic. The reactive group in the copolymer has very high reaction activity, and can react with various end groups of polyamide and polyester. Methacrylate monomers have thermodynamics compatibility with various polymers. The reactive group can react with the end hydroxyl group or the end carboxy group of polyester, so that the comb-shaped stem grafting copolymer can serve as the chain extender, and the processing and application properties of the material are improved.

Owner:HANGZHOU NORMAL UNIVERSITY

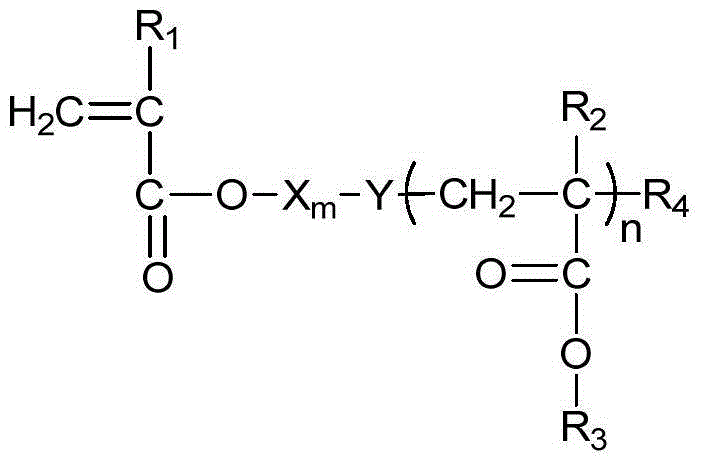

Reactive group-contained comb-type graft copolymer, and preparation method and application thereof

ActiveCN104610515AHigh reactivityThermodynamically compatibleCoatingsGraft polymer adhesivesBackbone chainOrganic chemistry

The invention discloses a reactive group-contained comb-type graft copolymer, and a preparation method and application thereof. A small molecular monomer A and a macromolecular monomer B are copolymerized to form the comb-type graft copolymer with the small molecular monomer A as a main chain and the macromolecular monomer B as a side chain; the weight of the macromolecular monomer B accounts for 0.1-80wt% of the mass of the comb-type graft copolymer; the weight of the small molecular monomer A accounts for 99.9-20wt% of the mass of the comb-type graft copolymer. The reactive group-contained comb-type graft copolymer is the comb-type graft copolymer containing a reactive group on the side chain, and can be used as a compatibilizer and a chain extender.

Owner:HANGZHOU NORMAL UNIVERSITY

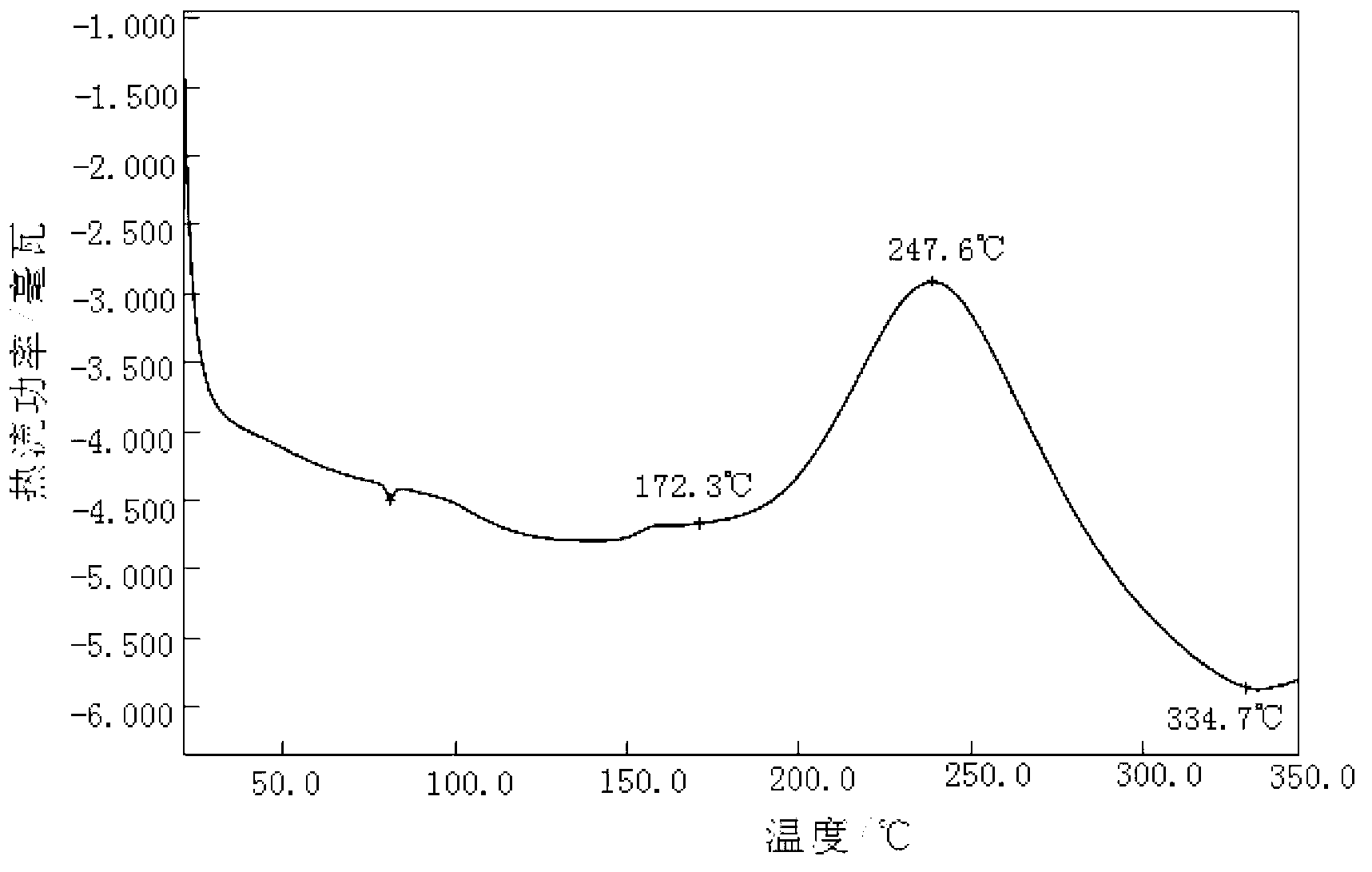

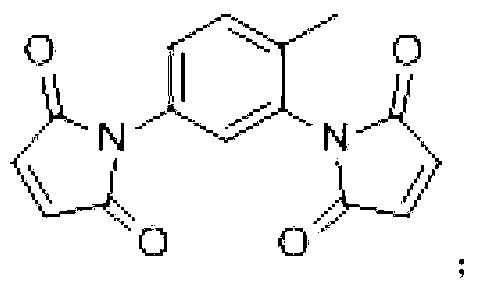

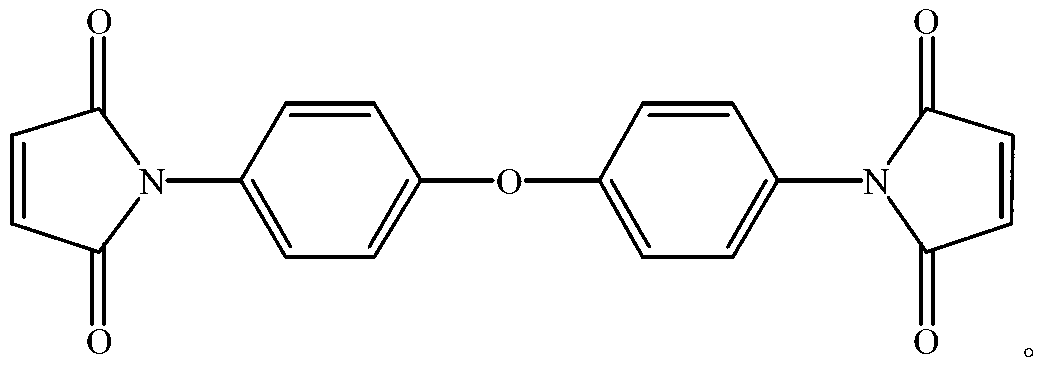

High-temperature-resistant bismaleimide resin carrier structure adhesive film and preparation method thereof

ActiveCN103242767AImprove bond reliabilityHigh temperature resistance hasNon-macromolecular adhesive additivesFilm/foil adhesivesTemperature resistanceGlass transition

The invention provides a high-temperature-resistant bismaleimide resin carrier structure adhesive film and a preparation method thereof, and relates to a high-temperature curing high-temperature-resistant structure adhesive. The invention aims to solve the problems that the conventional bismaleimide adhesive film does not have high temperature-resistant grade and high toughness. The adhesive film consists of bismaleimide resin, a technical modifier, a toughening modifier, a compatibilizer and a thixotropic agent. The preparation method comprises the following steps of: performing prepolymerization on the bismaleimide resin and the technical modifier to obtain a bismaleimide resin prepolymer; mixing the bismaleimide resin prepolymer, the toughening modifier, the compatibilizer and the thixotropic agent uniformly by a mechanical blending method to prepare an adhesive material; and preparing the adhesive by using a three-roller coating film-making machine under the film-forming assistance of the carrier. The adhesive has the characteristics of high-temperature resistance and high toughness, wherein the glass-transition temperature reaches above 280 DEG C and the honeycomb roller peeling strength reaches about 75.0 N.m / m. The adhesive is applied to adhesion of metal or composite material high-temperature-resistant structure members in the field of aerospace.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Toughening modifying method for polyphenyl ether/nylon 6 alloy

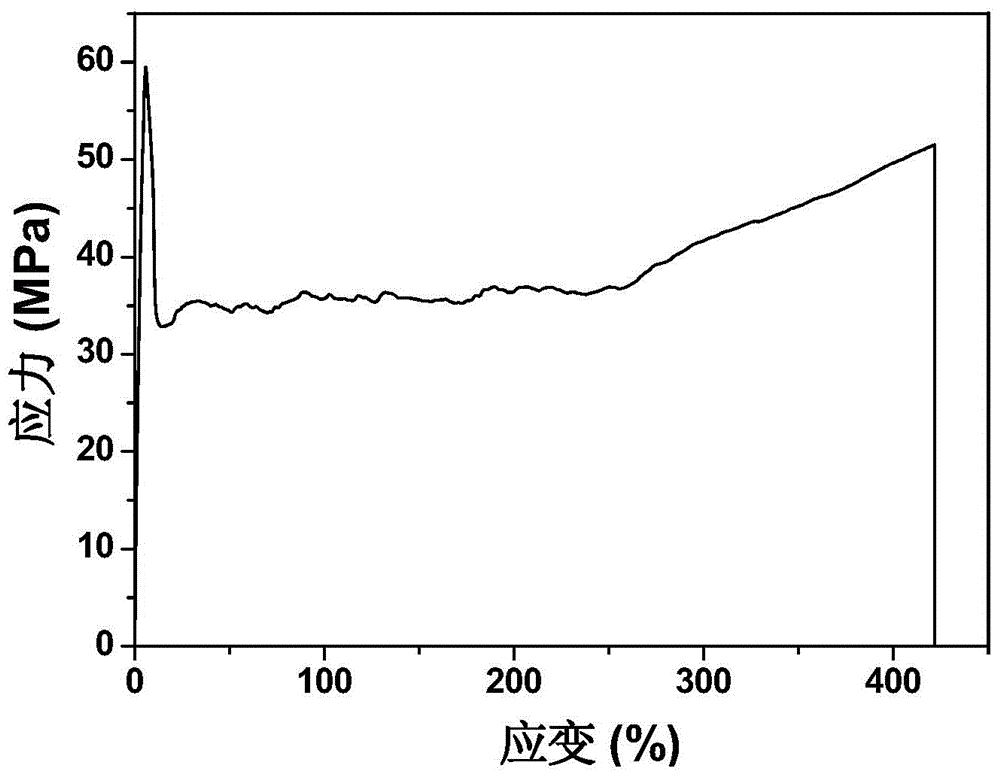

The invention discloses a toughening modifying method of polyphenylether / nylon 6 alloy. The polyphenylether grafted maleic anhydride is taken as the compatibilizer, which is made by melting grafted method. The mixture of the segmented copolymer of styrene- (ethylene-butylene)-styrene grafted maleic anhydride and the daiamidelastic body is taken as the toughener. The two above are mixed with the polyphenylether and nylon 6 in melting state and the polyphenylether / nylon 6 alloy can be obtained. The notch impact strength of the modified material can reach 1065 J / m, the elongation at break can reach 177 percent, the tensile strength can reach 43 MPa, the bending strength can reach 66.1 MPa and the flexural modulus can reach 1641 MPa.

Owner:SHANGHAI JIAO TONG UNIV

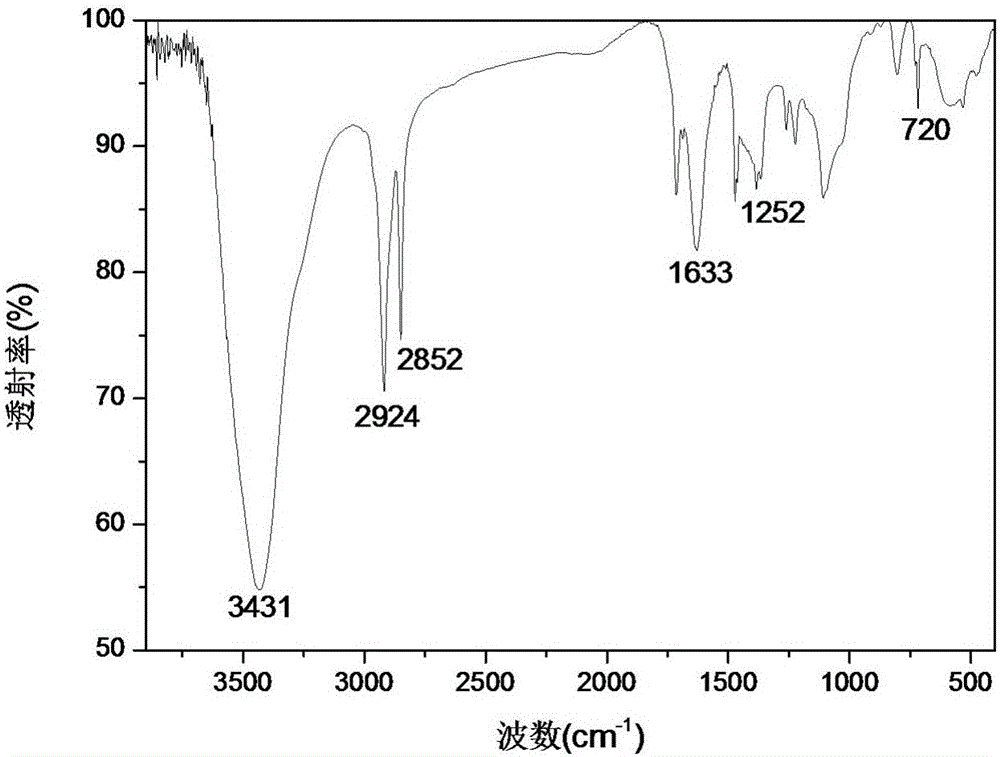

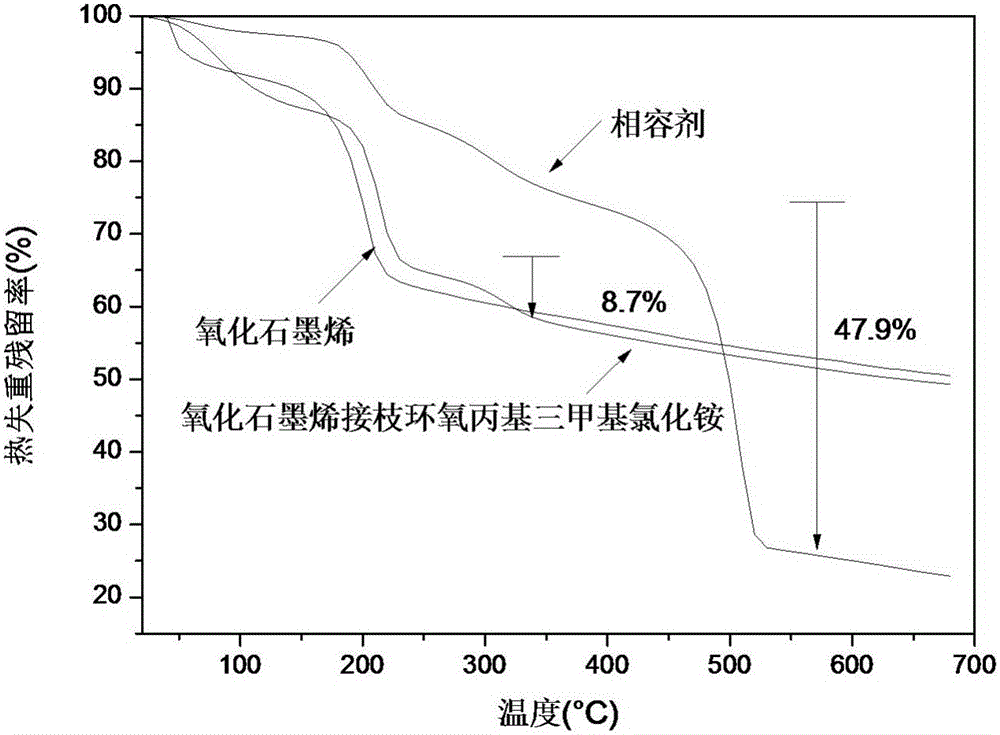

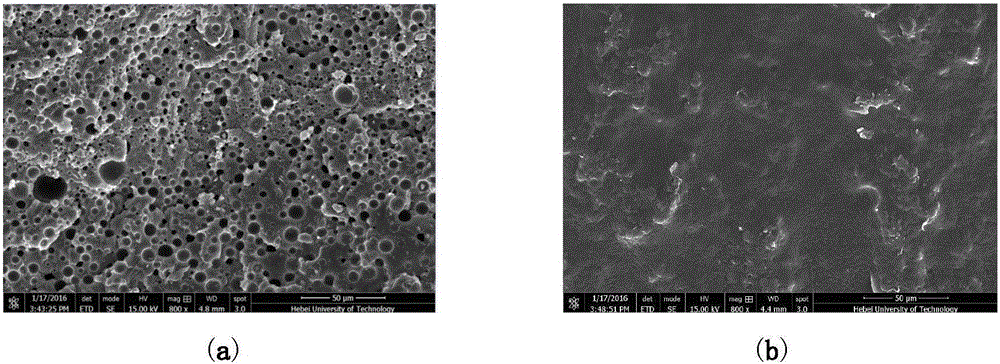

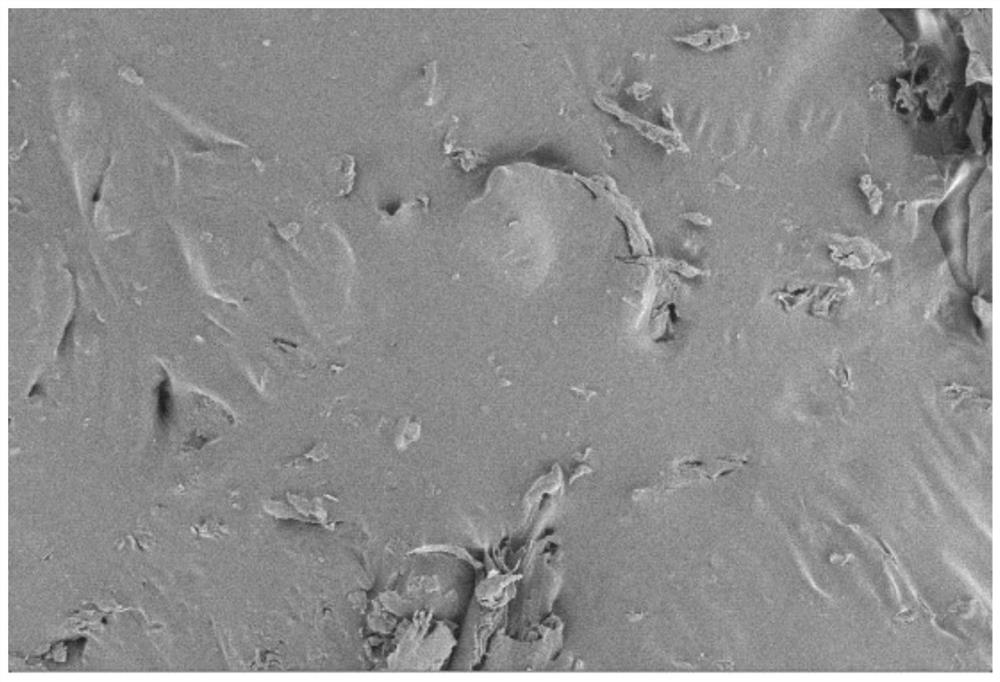

Polymer compatibilizers based on graphene oxide

The invention belongs to the technical field of polymer blends and carbon materials, and specifically relates to an application and an implementation method for blend compatibilizers based on graphene oxide. By virtue of the characteristic that the graphene oxide (or modified graphene oxide) can form different interactions with two components of the blend respectively, compatibilizers for some incompatible blending systems by using the graphene oxide (or modified graphene oxide) are developed. A specific implementation means of the graphene oxide for compatibilization is a two-step method. Firstly, solutions are mixed to obtain graphene oxide-containing polymer masterbatches or special materials; and secondly, the blending material compatibilized by the graphene oxide is obtained by a melting or solution processing means. Results show that the compatibilizers based on graphene oxide not only can increase the compatibility between the two components of the blend but also can significantly increase specific properties including mechanical strength, heat stability and the like of the blend material. The compatibilizers developed by the invention are cheap in cost of the raw materials, simple in preparation and suitable for large-scale production, and have good industrial production foundations and wide application prospects.

Owner:FUDAN UNIV

Dynamic vulcanization thermoplastic polyurethane/polysiloxane elastomer and preparation method thereof

ActiveCN108587123AGood dispersionAvoids problems associated with direct addition of high-viscosity polysiloxanesCross-linkPolymer science

The invention discloses a preparation method of a dynamic vulcanization thermoplastic polyurethane / polysiloxane elastomer. The preparation method comprises the following steps: firstly premixing thermoplastic polyurethane, methyl vinyl siloxane, a reinforcing filler and a chain extender, then carrying out melt extrusion pelletization inside an internal mixer or a double screw extrusion machine together with a catalyst to prepare a polyorganosiloxane master batch, then uniformly mixing thermoplastic polyurethane, the polyorganosiloxane master batch, a compatilizer and a polymerization inhibitor, and then adding a cross-linking agent and the catalyst for dynamic vulcanization. The methyl vinyl siloxane used for preparing the master batch is relatively low in viscosity and easy for good dispersion, and simultaneously chain growth can also be realized under the effect of the catalyst, and the viscosity and molecular weight of polyorganosiloxane are improved, so that the obtained elastomercan be of preferable mechanical property and sooth hand feeling, is easy for machining, and can be used in the application fields with high requirements such as buildings, automobile spare parts, electric wires and cables, medical apparatus and instruments and wearable equipment.

Owner:CHENGDU SILIKE TECH

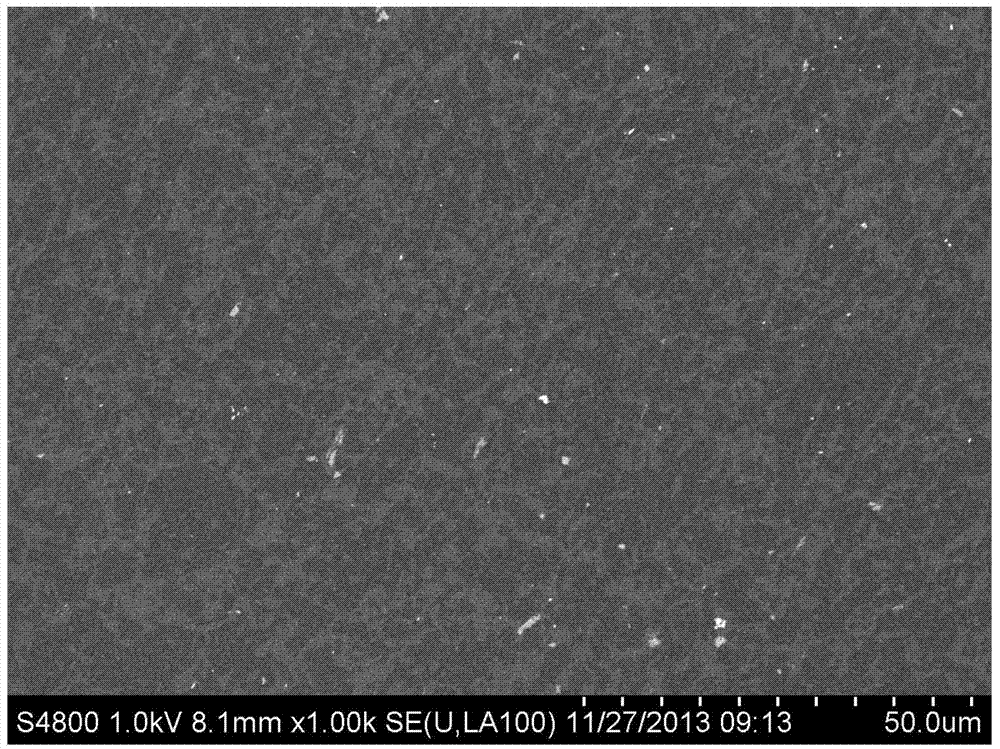

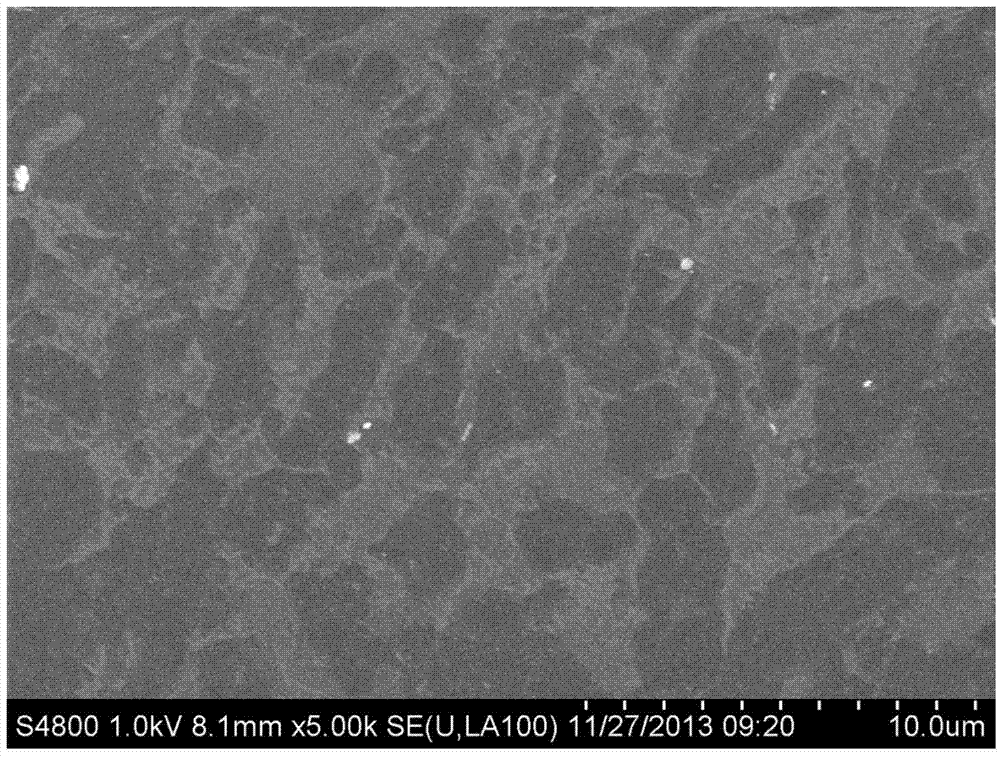

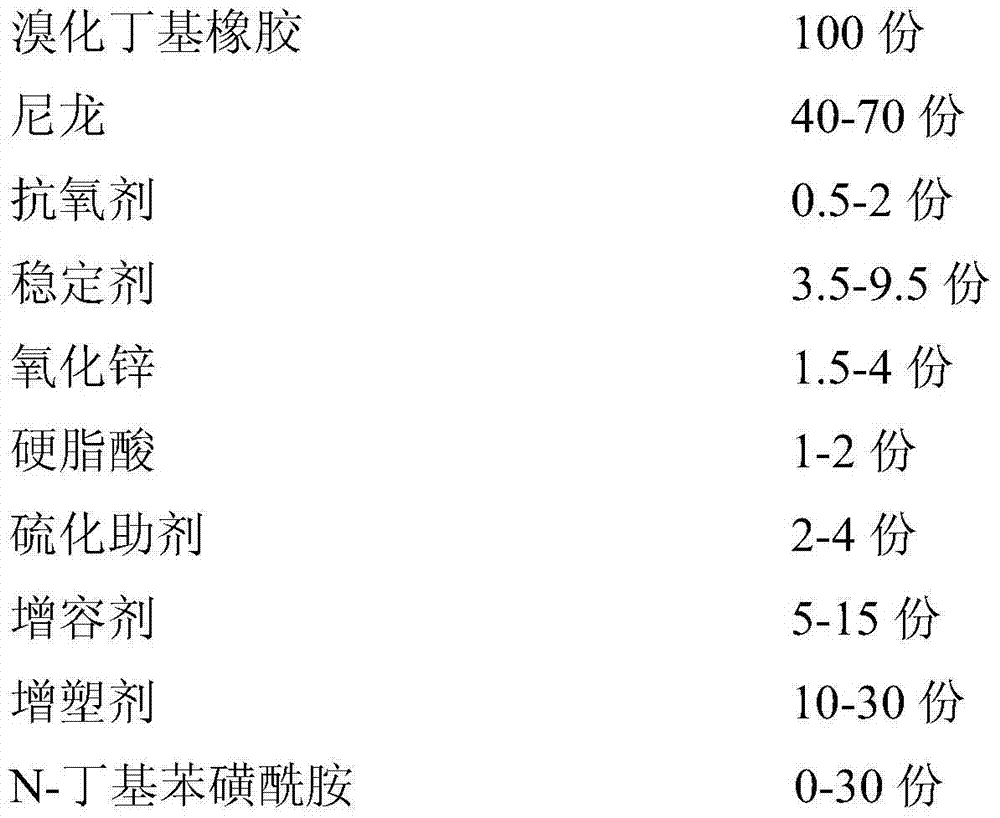

Thermoplastic vulcanizate having high gas barrier property and preparation method of thermoplastic vulcanizate

The invention relates to a thermoplastic vulcanizate having high gas barrier property and a preparation method of the thermoplastic vulcanizate, and belongs to the technical field of high molecular materials. The thermoplastic vulcanizate is prepared by dynamically vulcanizing a rubber-plastic mixture which is composed of nylon blended and grafted with a compatibilizer previously and butyl rubber; the interfacial compatibility between the nylon and the rubber is enhanced, and the thermoplastic vulcanizate is enabled to meet the requirements of a tyre airtight liner material in gas barrier property, mechanical properties, quality, hardness and the like.

Owner:BEIJING UNIV OF CHEM TECH +1

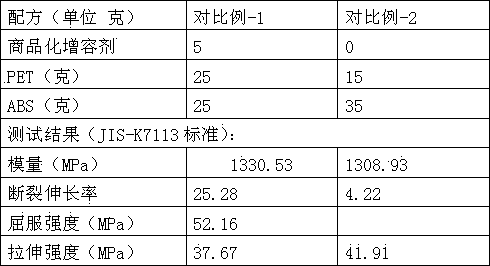

Polyethylene glycol terephthalate composite material and preparation method thereof

The embodiment of the invention discloses a polyethylene glycol terephthalate composite material, comprising the following raw materials in parts by weight: 60-80 parts of polyethylene glycol terephthalate, 10-20 parts of functionalized polyolefin elastomers, 15-30 parts of fibers, 1-5 parts of polyfunctional vinyl monomers and 2-10 parts of composite auxiliaries. The functionalized polyolefin elastomer comprises the block polymer and / or graft polymer of the polyolefin elastomer. The invention also provides a preparation method of the polyethylene glycol terephthalate composite material. The functionalized polyolefin elastomers self adopted by the invention have good compatibility with PET, therefore, the polyethylene glycol terephthalate composite material with high strength and high toughness is prepared by a composite method of enhanced radiation and reactive blending.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

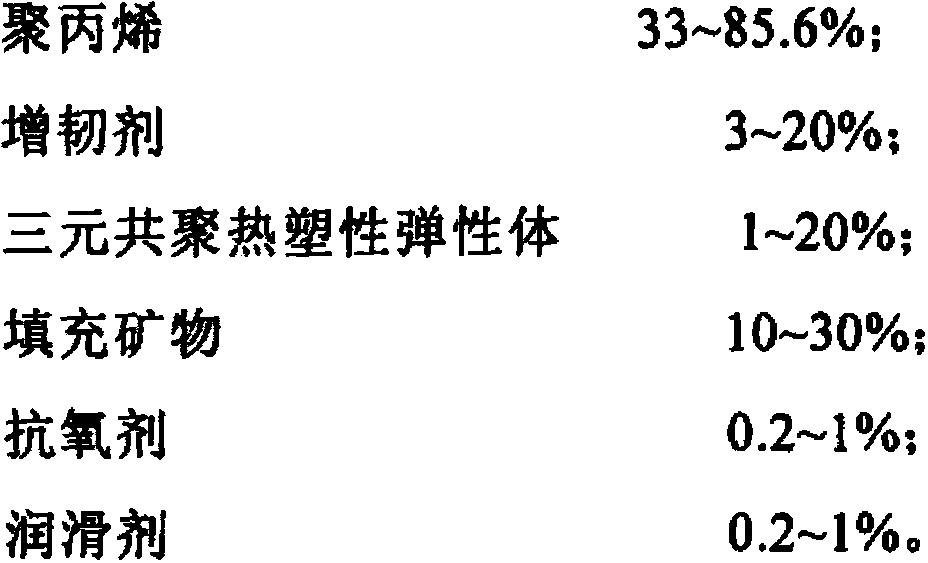

Polypropylene composite material with good appearance and preparation method thereof

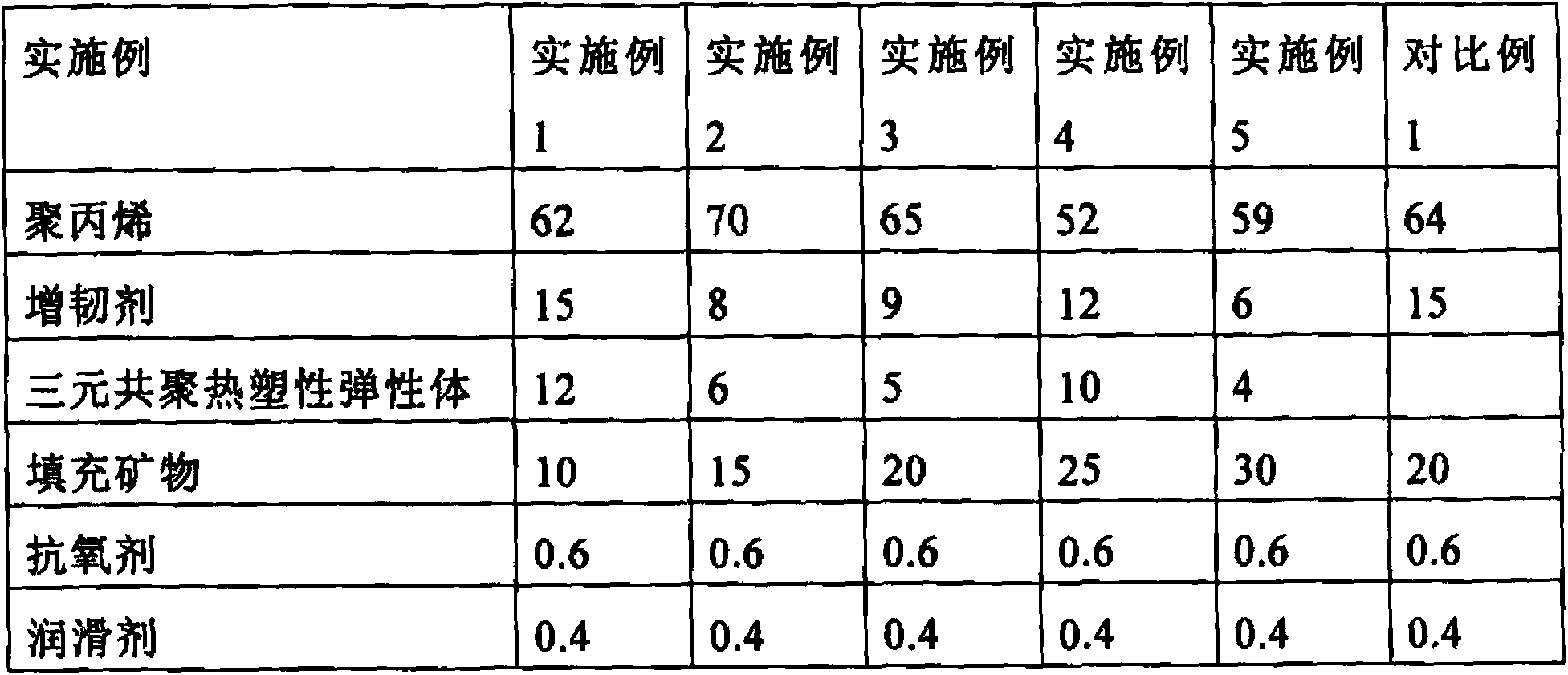

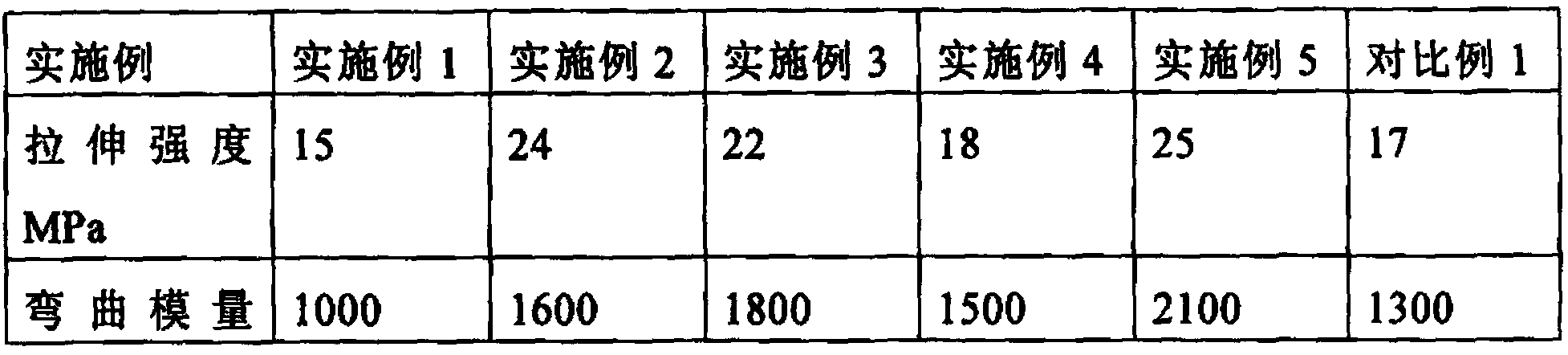

The invention relates to a polypropylene composite material with good appearance and a preparation method thereof. The preparation method comprises the following steps: (1) weighing the following components by weight percent: 33%-85.6% of polypropylene, 3-20% of flexibilizer, 1-20% of ternary polymerization thermoplastic elastomer, 10-30% of filling mineral, 0.2-1% of antioxygen, and 0.2-1% of lubricant; (2) putting the raw materials of the step (1) into a high-speed mixer and mixing for 2-5 minutes, and discharging; (3) putting the materials mixed in the step (2) into a twin screw extruder and pelleting through extrusion so as to prepare the polypropylene composite material with good appearance, wherein the rotation speed of the twin screw extruder is 200-400 rpm (revolutions per minute), and the temperature is 180-220 DEG C. Compared with the prior art, the polypropylene composite material has good mechanical property, has no defects such as marks and tiger skin left on the surface, is environment-friendly, and can be widely used in the fields of automobiles, household appliances, sports goods and the like.

Owner:SHANGHAI SUNNY

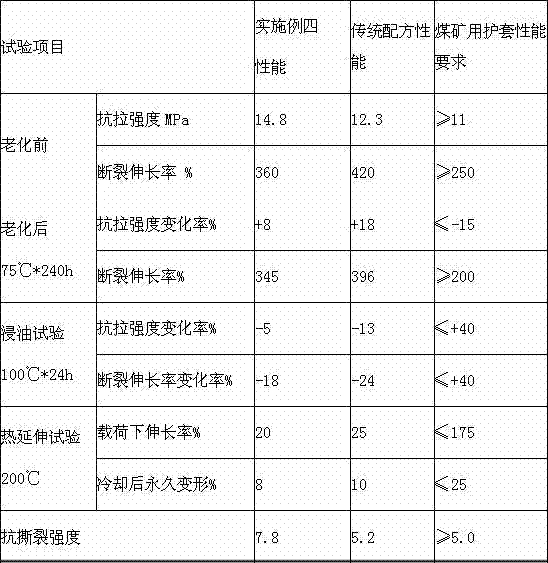

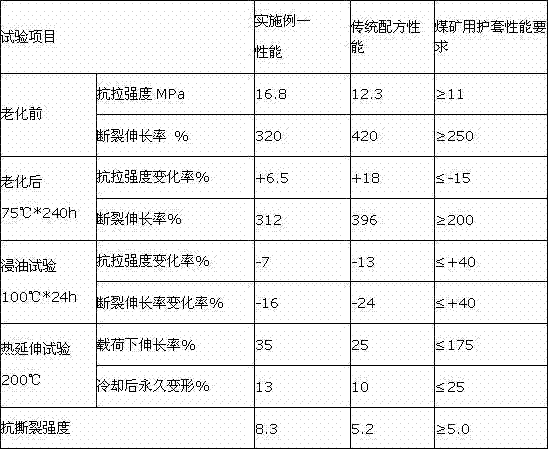

Cable sheath material

ActiveCN102344615AImprove mechanical propertiesGood compatibilityPlastic/resin/waxes insulatorsInsulated cablesPolymer scienceChlorinated polyethylene

The invention discloses a cable sheath material and a preparation method thereof, belonging to a cable sheath material. The invention is mainly applicable to coal mine cables. The cable sheath material comprises chlorinated polyethylene, nylon, compatibilizer CPE-g-MAH (chlorinated polyethylene-graft-maleic anhydride), high-performance composite flame retardant, composite stabilizer, anti-aging agent, thiadiazole vulcanizing agent and aldehyde-amine condensate accelerator. The preparation method comprises the following steps: plasticating, blending on a hot roll compounding mill, sulfurizing and the like. The invention has the advantages of high tearing strength, low hardness, high softness, wide application range, simple formula and simplified technique.

Owner:SICHUAN MINGXING CABLE

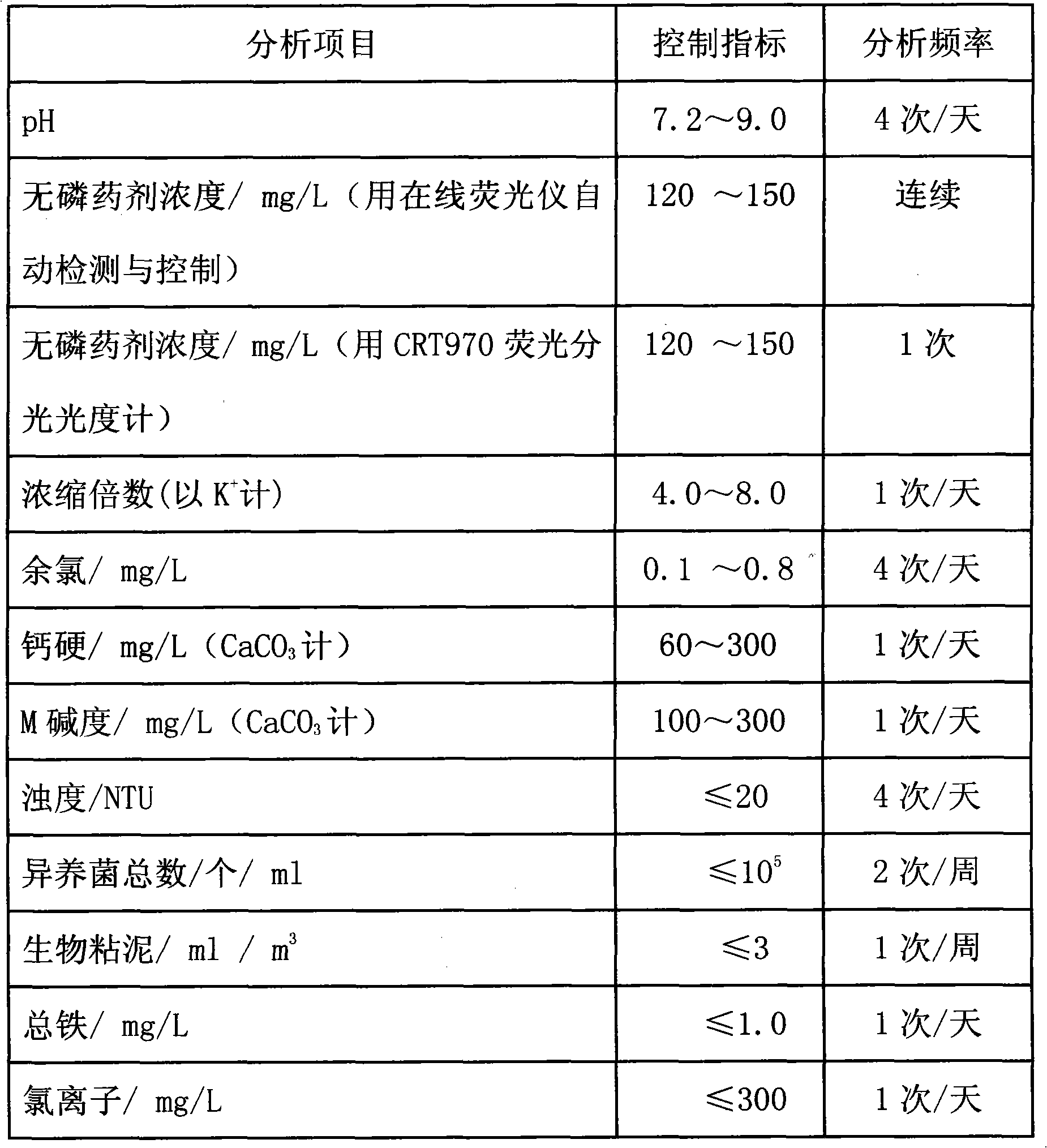

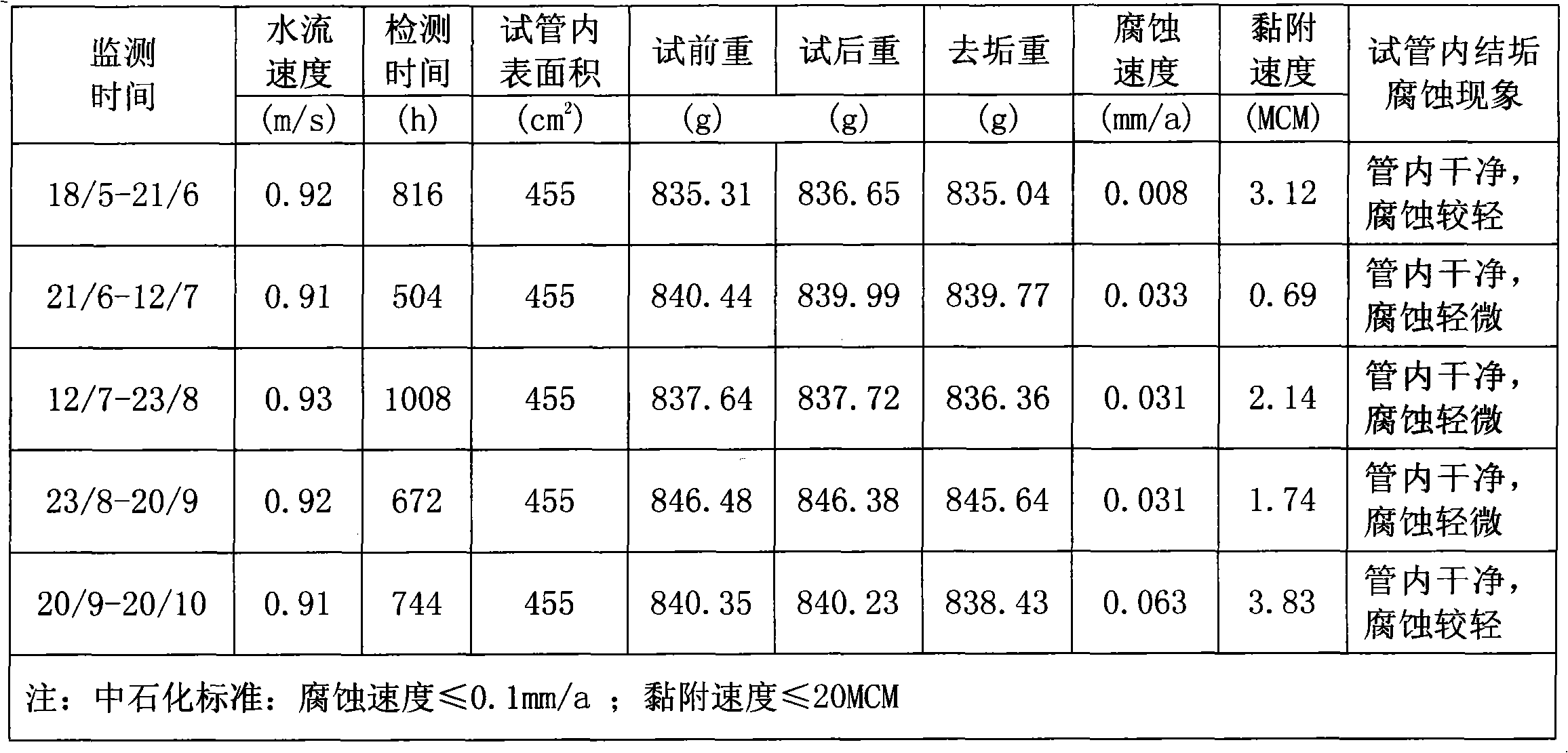

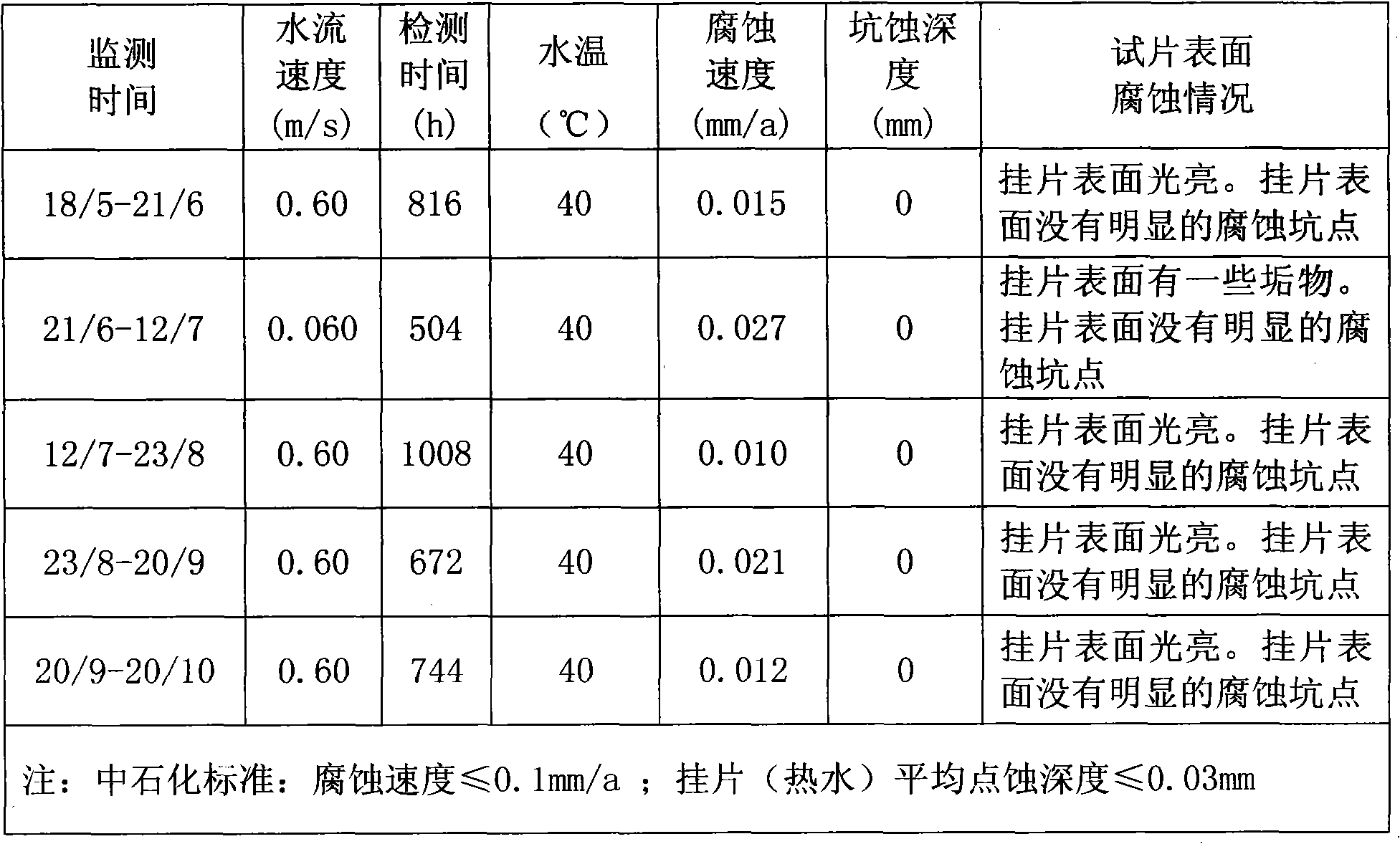

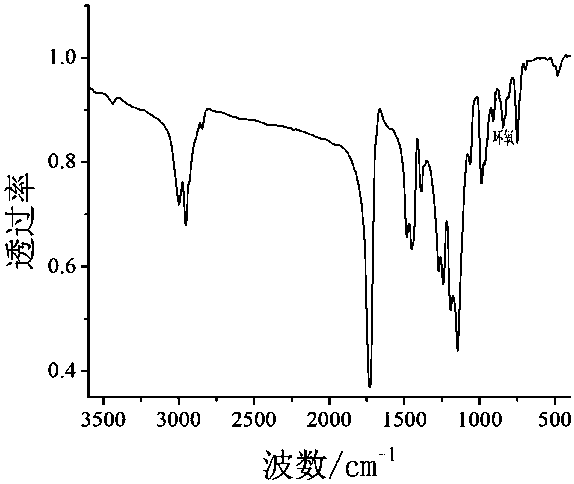

Phosphorus-free corrosion and scale inhibitor for treating strong corrosive water and use concentration detection method thereof

ActiveCN102092863AStable storageStrong corrosion inhibitionScale removal and water softeningFluorescence/phosphorescenceFluorescenceWater quality

The invention provides a phosphorus-free corrosion and scale inhibitor for treating strong corrosive water and application and a use concentration detection method thereof. The phosphorus-free corrosion and scale inhibitor for treating strong corrosive water comprises 20-60% by weight of polyepoxysuccinic acid, 5.5-25% by weight of S-carboxyethyl thiodisuccinic acid, 5-43% by weight of long-chain alkyl polyether amide, 10-35% by weight of quadripolymer containing AMPS (1-Acrylanmido-2-Methylpropanesulfonic Acid), 0.2-1% by weight of benzotriazole, 0.5-5% by weight of water soluble fluorescent compound, 1.5-3% by weight of pH value regulator, 0-15% by weight of zinc salt and 10-40% by weight of deionized water. The phosphorus-free corrosion and scale inhibitor has remarkable corrosion inhibition property. The concentration of the phosphorus-free corrosion and scale inhibitor can be detected by a fluorescent analysis method, and the phosphorus-free corrosion and scale inhibitor is particularly suitable for treating strong corrosive water. The phosphorus-free corrosion and scale inhibitor for treating strong corrosive water is used in industrial circulating cooling water and combined with the use concentration detection method, so that the successful application of the phosphorus-free corrosion and scale inhibitor for treating strong corrosive water in the industrial circulating cooling water becomes possible.

Owner:MAOMING SUNION GUOSONG FINE CHEM

Polyoxymethylene (POM) encapsulation material and preparation method thereof

ActiveCN102702664AEnhanced Interfacial InteractionGood capacity increasePolyoxymethyleneThermoplastic elastomer

The invention belongs to the field of composite materials, and discloses a polyoxymethylene (POM) encapsulation material and a preparation method thereof. The POM encapsulation material comprises the following components in part by weight: 50 to 60 parts of thermoplastic elastomer (TPE), 30 to 40 parts of plasticizer, 10 to 15 parts of propene polymer (PP), 5 to 10 parts of compatibilizer, and 0.5 to 1 part of other aid. A twin-screw extruder is used for pelleting and extrusion, and the temperature range is 180 to 200 DEG C. Compared with that of the prior art, the cohesiveness between a product and POM is obviously improved, so that by a multi-component injection method, the encapsulation material is widely applied to POM / TPE combination, mechanical anchoring such as expensive undercutting is not needed, the process is simplified, the development period of the product is shortened, and cost is reduced.

Owner:昆山聚威工程塑料有限公司

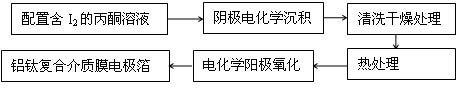

Method for improving specific volume of an aluminum electrode foil by electrochemical deposition method

ActiveCN102360955AControl nucleation densityPrecise control of deposition thicknessCapacitor electrodesDielectricElectroless deposition

The invention relates to an aluminum electrolytic capacitor, in particular to a method for improving specific volume of an aluminum electrode foil by an electrochemical deposition method. In the invention, an Al2O3 / TiO2 composite dielectric film is prepared on the surface of the electrode foil by adopting a cathodic electrochemical deposition technology. The preparation process of the composite dielectric film comprises the following steps: taking metallic titanium as an anode, taking an aluminum etched foil as a cathode, and carrying out electro-deposition in an organic solvent-acetone containing halogen-iodine; depositing a titanium-containing compound layer on the surface of the etched foil, and then carrying out heat treatment; and finally carrying out anodic oxidation treatment so asto obtain the aluminum-titanium composite dielectric film with high dielectric constant on the surface of the etched foil. Compared with the traditional dielectric film, the composite dielectric filmon the surface of the aluminum electrode foil obtained by the technological process has higher dielectric constant under the condition of equal thickness so as to more effectively improve the specific capacity of the aluminum electrode foil. The method has the advantages of simple process and lower cost, and is convenient for operation and easy to control.

Owner:南通东湖国际商务服务有限公司

Preparation of water phase suspended swelling graft polypropylene

A preparation method for graft polypropylene polymer by water phase Suspension and Swelling involves: polypropylene powder; graft monomer; water; coated dosage; initiator; and sweller. The process is carried out by: having the temperature of the reactor with uniform mixture of polypropylene powder, water dispersing medium, graft monomer, sweller, coated dosage raised to 80-100deg.C ; stirring it for 1-6 hours after the initiator putted in; then cooling, filtering, washing with clean water and drying. It features: temperate reacting conditions; easily controlling; high rate and high efficiency of grafting; environmental protection. And the polymer is extensive for compatible assistant of high molecular material blend, compound high molecular material for filling, covering material, and printing ink.

Owner:ZHEJIANG UNIV OF TECH

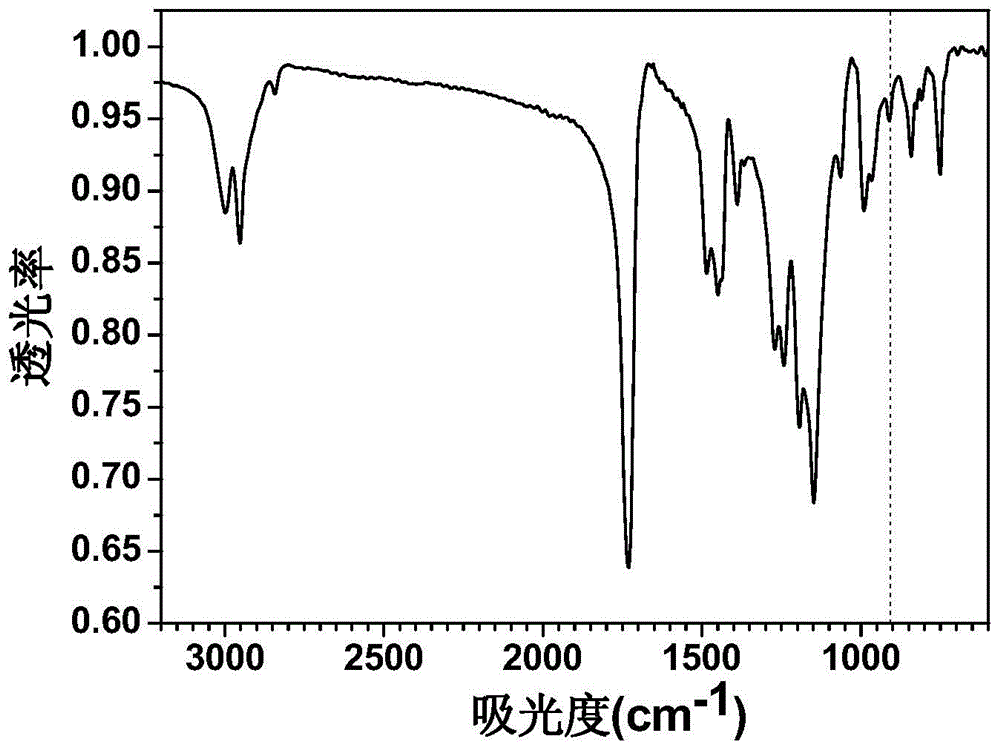

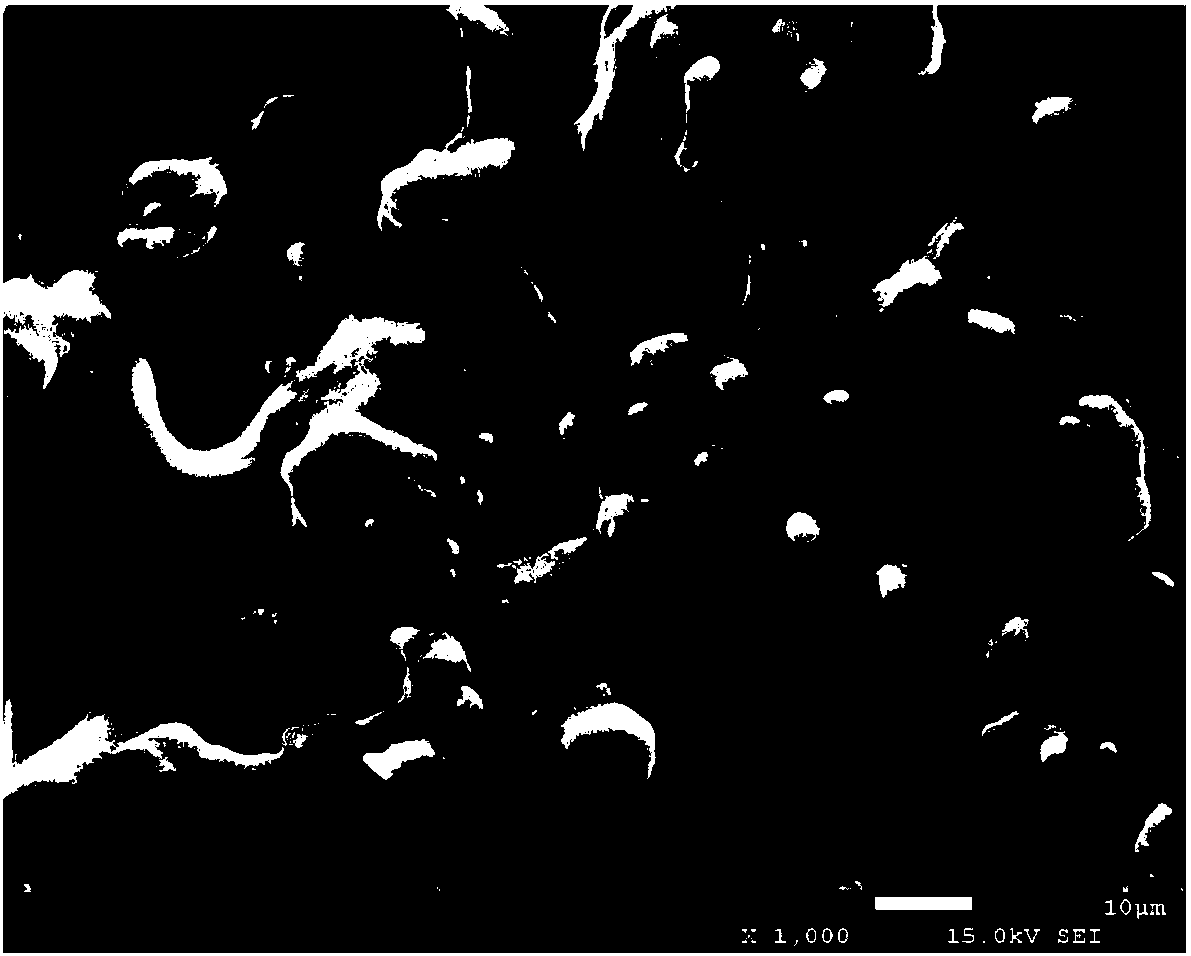

Polylactic acid/polyethylene glycol terephthalate-1, 4-cyclohexanedimethanol blend and preparation method thereof

ActiveCN103131148AImprove performanceGood capacity increaseCyclohexanedimethanolPolyethylene terephthalate glycol

The invention discloses polylactic acid / polyethylene glycol terephthalate-1, 4-cyclohexanedimethanol blend. The polylactic acid / polyethylene glycol terephthalate-1, 4-cyclohexanedimethanol blend is composed of 55 wt%-90 wt% of polylactic acid, 5 wt%-40 wt% of polyethylene glycol terephthalate-1, 4-cyclohexanedimethanol, and polylactic acid graft maleic anhydride less than 5 wt%. The invention further provides a preparation method of the polylactic acid / polyethylene glycol terephthalate-1, 4-cyclohexanedimethanol blend. Polylactic acid (PLA)-g-maleic anhydride (MAH) compatibilizer adopted by the polylactic acid / polyethylene glycol terephthalate-1, 4-cyclohexanedimethanol blend is self-made compatibilizer, and in the processing procedure, operation is easy, and cost is low while compatibilizing effect is remarkable. Compared with pure PLA material, compatibility between the PLA and polyethylene terephthalate glycol (PETG) is remarkably improved, elongation at break of products is remarkably increased, but tensile strength and modulus changes are small.

Owner:SICHUAN UNIV

Method for preparing polyfunctional group containing compatilizer with controllable polarity

InactiveCN106046647AHigh grafting rateLow molecular weightBulk chemical productionEvaporationHigh activity

The invention discloses a method for preparing polyfunctional group containing compatilizer with controllable polarity. The method comprises the following steps that 1, after a glycidyl alkyl salt compound is added into an aqueous solution containing nano particles to react for 1 h to 3 h, an intermediate 1 is obtained; 2, epoxy chloropropane is dropwise added into polyethylene polyamine, reacting is carried out for 6 h to 12 h at the temperature of 90 DEG C to 100 DEG C, rotary evaporation is carried out, and an intermediate 2 is obtained; 3, non-polar polymer graft and the intermediate 2 are mixed in a solvent, a phase transfer catalyst is added, reacting is carried out for 5-12 hours at the temperature of 100 DEG C to 160 DEG C, and an intermediate 3 is obtained; 4, the intermediate 1 and the intermediate 3 are mixed in a solvent, a phase transfer catalyst is added, reacting is carried out for 4-12 hours at the temperature of 80 DEG C to 130 DEG C, and the product is obtained. The obtained compatilizer contains a polar part with high activity, the grafting rate of the compatilizer is high, the characteristic that a large number of reaction activity points are provided for two incompatible phases in the blending process is guaranteed through rich polar functional groups on the solvent, and the interface bonding force is improved.

Owner:HEBEI UNIV OF TECH

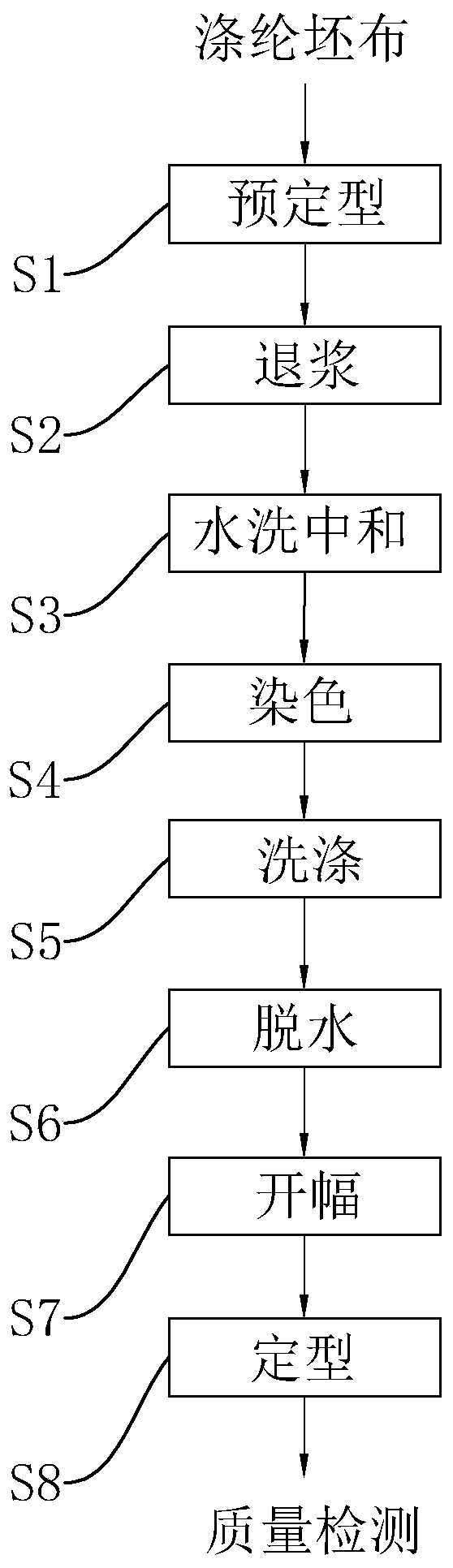

Dyeing process for polyester fabric

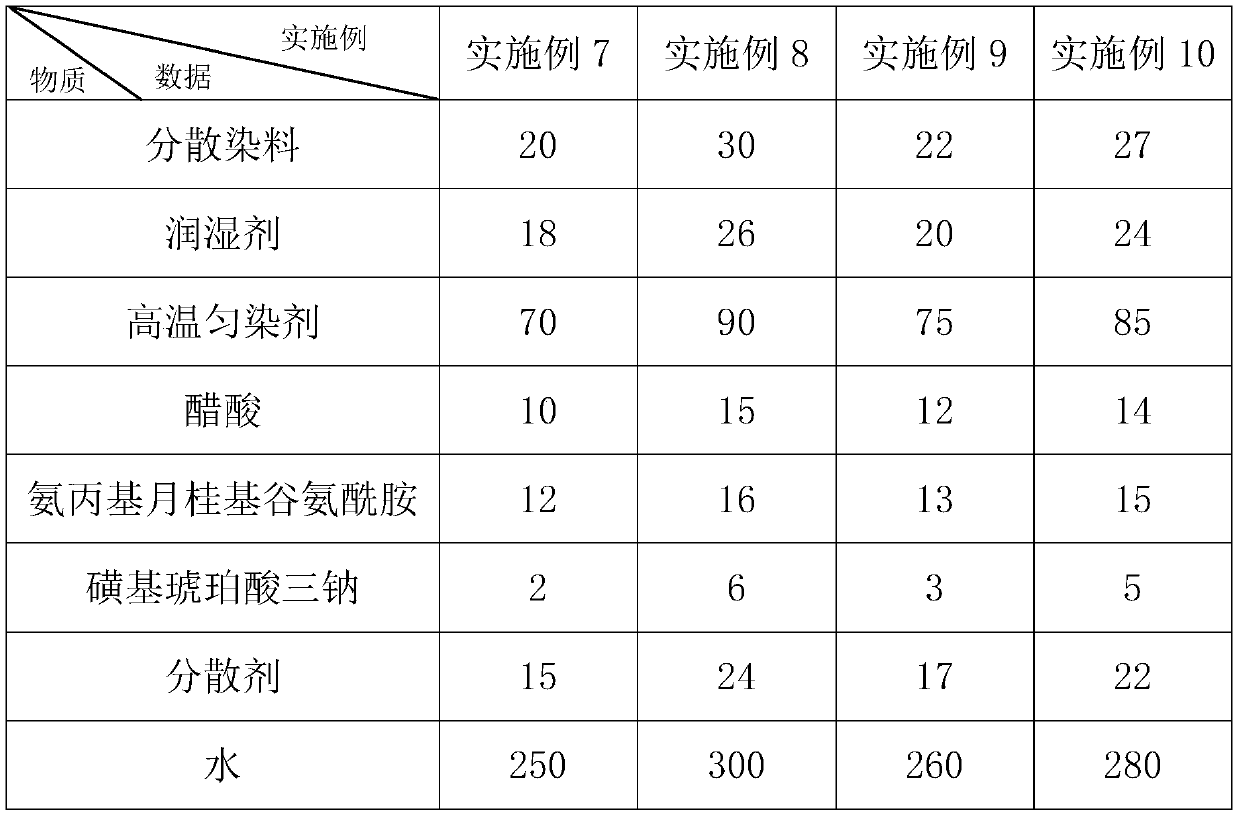

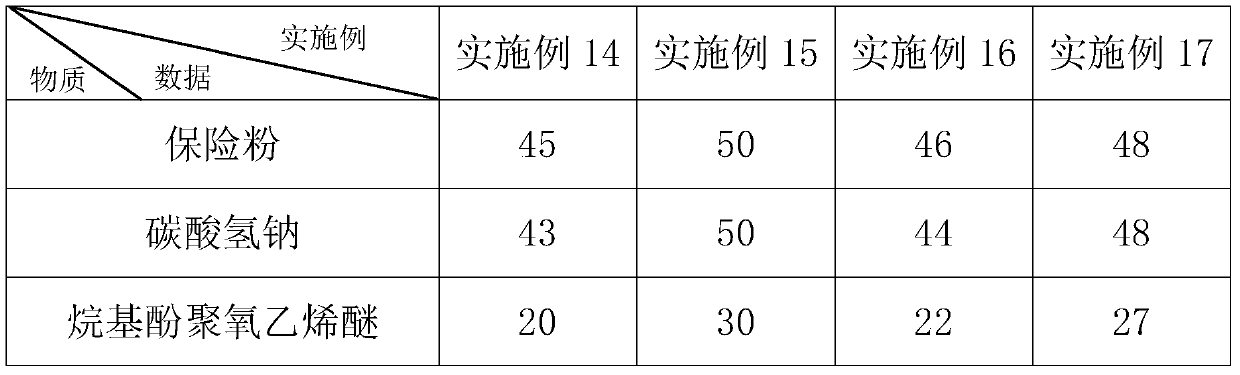

The invention relates to the technical field of textile processing, and discloses a dyeing process for polyester fabric. The unrolled polyester fabric is processed by the steps of S1, presetting greycloth; S2, desizing the grey cloth after presetting; S3, rinsing to neutralize the desized grey cloth; S4, dyeing the grey cloth which is neutralized by rinsing, wherein dyestuff comprises chemical components: by weight, 20-30 parts of disperse dyes, 18-26 parts of wetting agents, 70-90 parts of high temperature levelling agents, 10-15 parts of ethylic acid, 12-16 parts of aminopropyl laurylglutamine, 2-6 parts of trisodium sulfosuccinate and 250-300 parts of water, and dyeing temperature is controlled within 100-130 DEG C; S5, washing; S6, dewatering; S7, scutching; S8, sizing to obtain the dyed polyester fabric. With application of aminopropyl laurylglutamine and trisodium sulfosuccinate, the dye-uptake rate of the polyester fabric is increased.

Owner:HANGZHOU XINSHENG PRINTING & DYEING

Polypropylene-based composite material and preparation method thereof

The invention discloses a polypropylene-based composite material and a preparation method thereof. The polypropylene-based composite material is prepared from the following materials by taking the weight part of polypropylene as 100 parts: 10 to 100 parts of polyamide, 2 to 30 parts of functionalized polypropylene compatilizer, 0.5 to 5 parts of lubricant, 0.5 to 5 parts of plasticizer and 0.01 to1 part of stabilizing agent. The novel functionalized polypropylene compatilizer is added so that mutual mixing of the polypropylene and the polyamide can be promoted very well and the compatibilization effect is remarkable; an original shape of polypropylene powder can be kept through synthesis of the functionalized polypropylene compatilizer and the step of reprocessing and molding a subsequentmaterial is reduced; when the polypropylene-based composite material is blended and extruded, the temperature of each heating section and the rotary speed of a screw rod are regulated and controlled,and the dispersion of the functionalized polypropylene compatilizer in the polypropylene and the polyamide can be promoted to the extremely great extent, so that the compatibilization effect of the functionalized polypropylene compatilizer is displayed very well; a preparation process is simple and convenient and is suitable for large-scale industrial production.

Owner:义乌斌泰工艺品有限公司

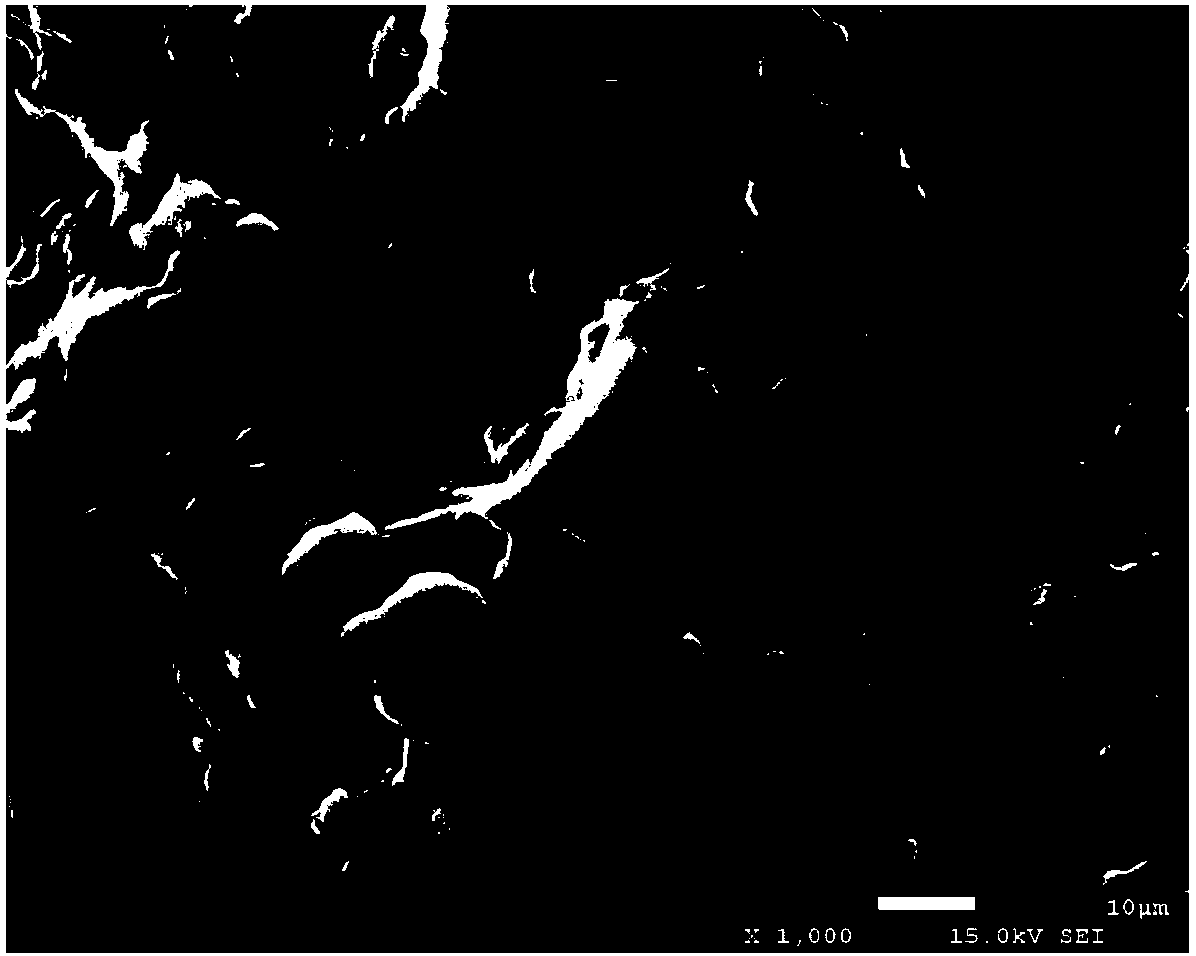

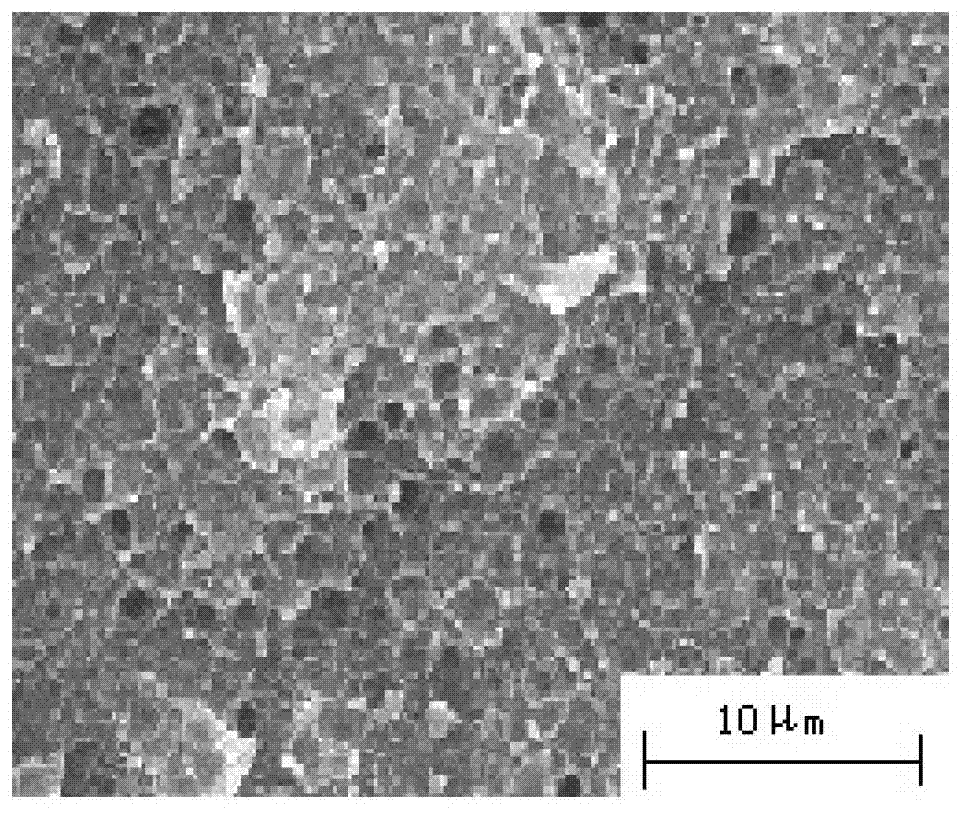

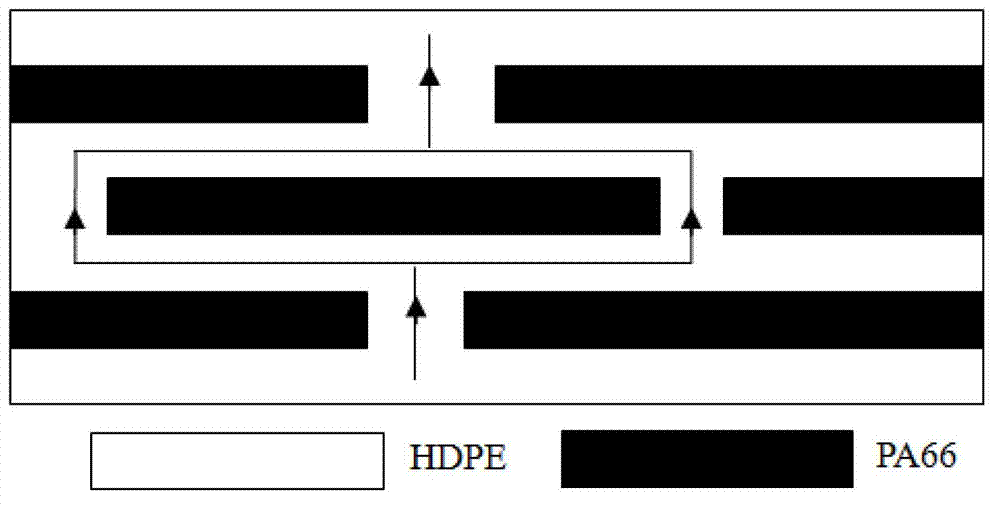

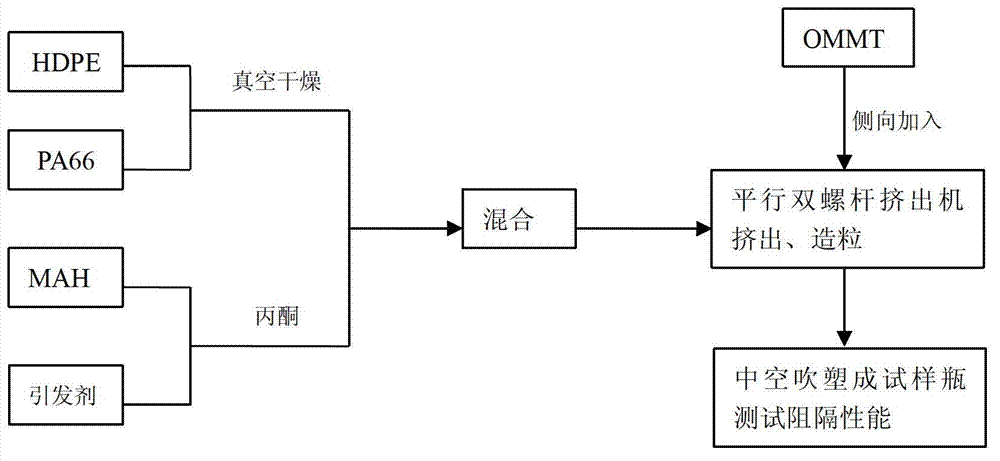

Preparation method of high-density polyethylene/polyamide 66 laminar barrier materials using in-situ reactive compatibilization method

ActiveCN102786633AGood capacity increaseImprove interfacial adhesionLow-density polyethylenePolyamide

The invention discloses a preparation method of high-density polyethylene / polyamide 66 laminar barrier materials using an in-situ reactive compatibilization method. By the preparation method, compatibility between the high-density polyethylene and the polyamide 66 is improved. The high-density polyethylene / polyamide 66 laminar barrier materials comprise, by weight, 65-95 parts of high-density polyethylene, 5-35 parts of polyamide 66, 0.01-1 part of initiator, 0.1-4 parts of maleic anhydride, and 1-7 parts of montmorillonite. The high-density polyethylene / polyamide 66 laminar barrier materials are evident in compatibilization, high in interface adhesion, excellent in barrier performance, applicable to hose packing of pesticide bottle production, paint bucket and diluent bottle production, and cosmetic production or to packing films or hose packing of food production.

Owner:SINOPLAST NEW MATERIAL

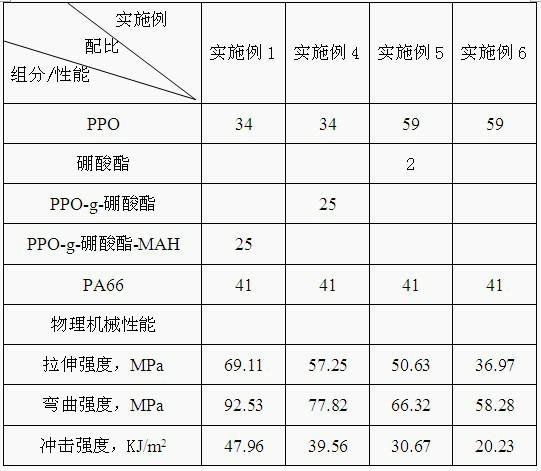

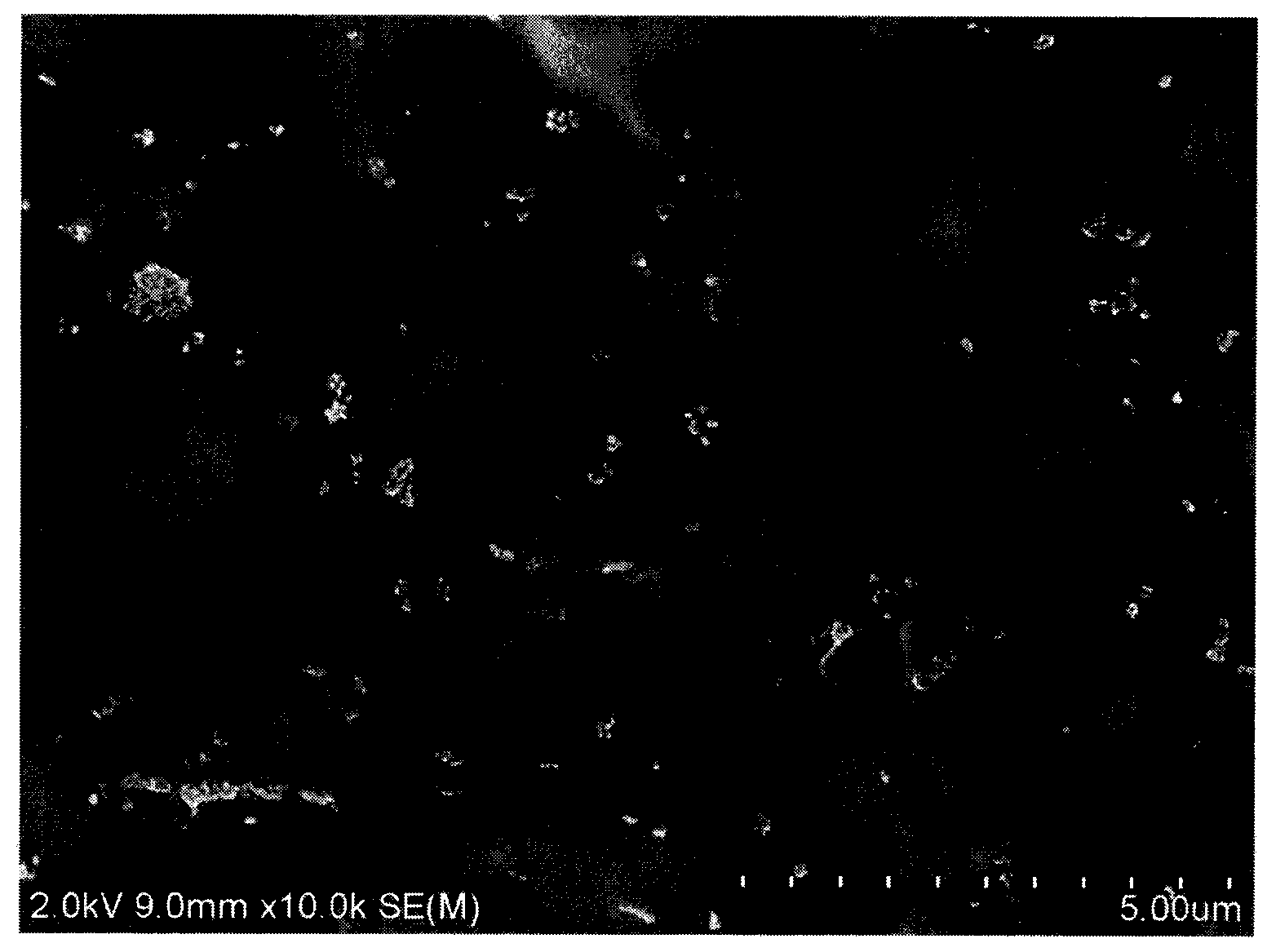

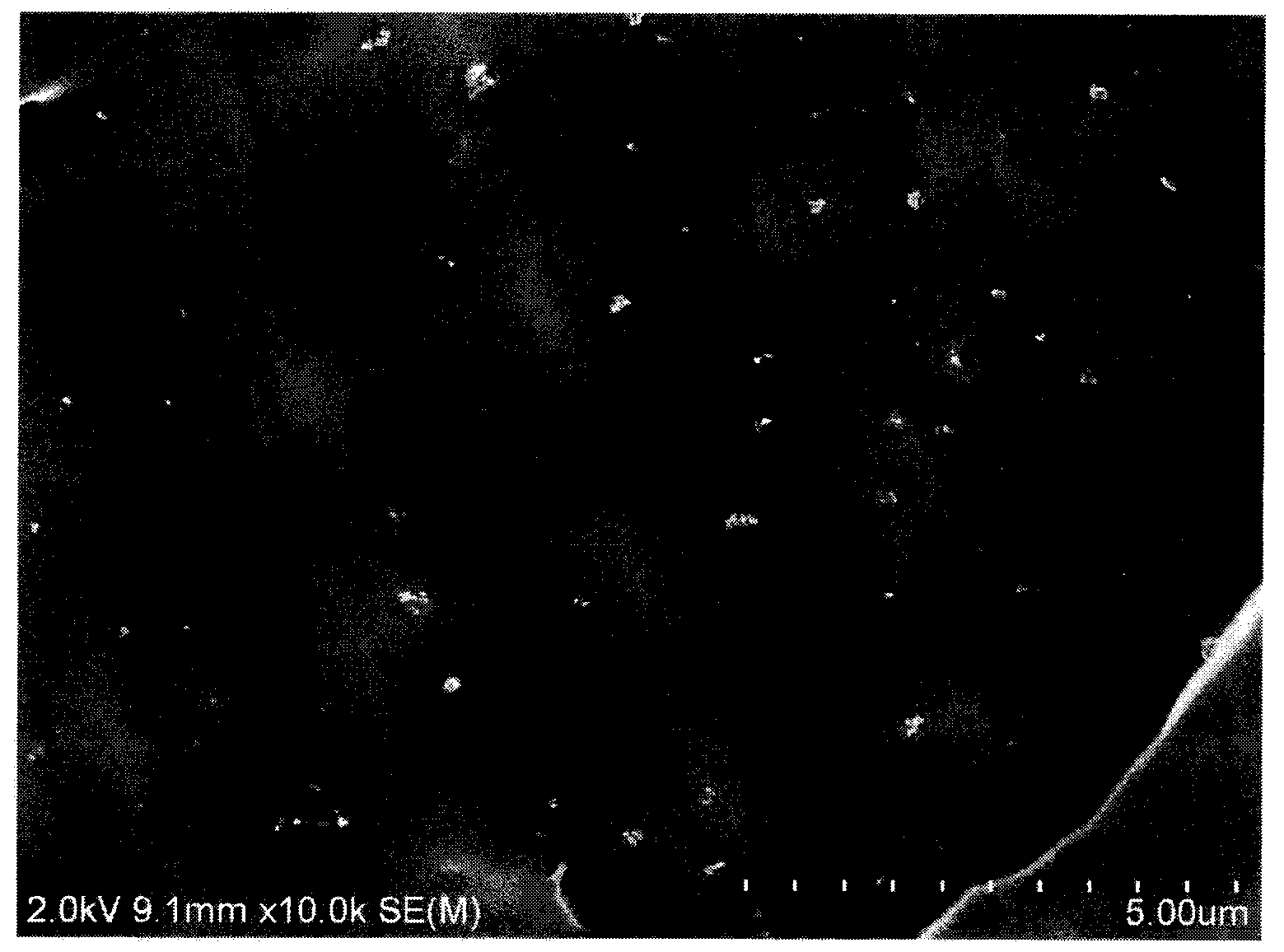

Compatilizer, application thereof in polyphenyleneoxide/nylon alloy and preparation method of polyphenyleneoxide/nylon alloy

ActiveCN102020785AGood compatibilityReduce interfacial tensionGroup 3/13 element organic compoundsBoronic acidAlloy

The invention relates to a compatilizer, an application of the compatilizer in a polyphenyleneoxide / nylon alloy and a preparation method of the polyphenyleneoxide / nylon alloy. The compatilizer provided by the invention is boronic acid ester prepared from boronic acid and substances containing hydroxy groups and carboxyl groups, can be directly used for preparing the polyphenyleneoxide / nylon alloy, and also can be subjected to melt extrusion with polyphenyleneoxide to be prepared into a polyphenyleneoxide blending compatibilization system which is used for preparing the polyphenyleneoxide / nylon alloy. The preparation method of the polyphenyleneoxide / nylon alloy is implemented as follows: drying and evenly stirring the compatilizer or the polyphenyleneoxide blending compatibilization system, polyphenyleneoxide and nylon; and feeding the mixture in a double screw extruder for extrusion to obtain the compatibilization modified polyphenyleneoxide / nylon alloy, wherein the screw temperature is 170-295 DEG C and the screw revolving speed is 70-120 revolutions / minute. The invention has the advantages of being convenient in processing, having simple process, notable compatibilization effect, remarkably improved tensile property and bending property, favorable and stable comprehensive property and wide industrial application prospect, and satisfying strength requirements of common applications.

Owner:山东三岭汽车内饰有限公司

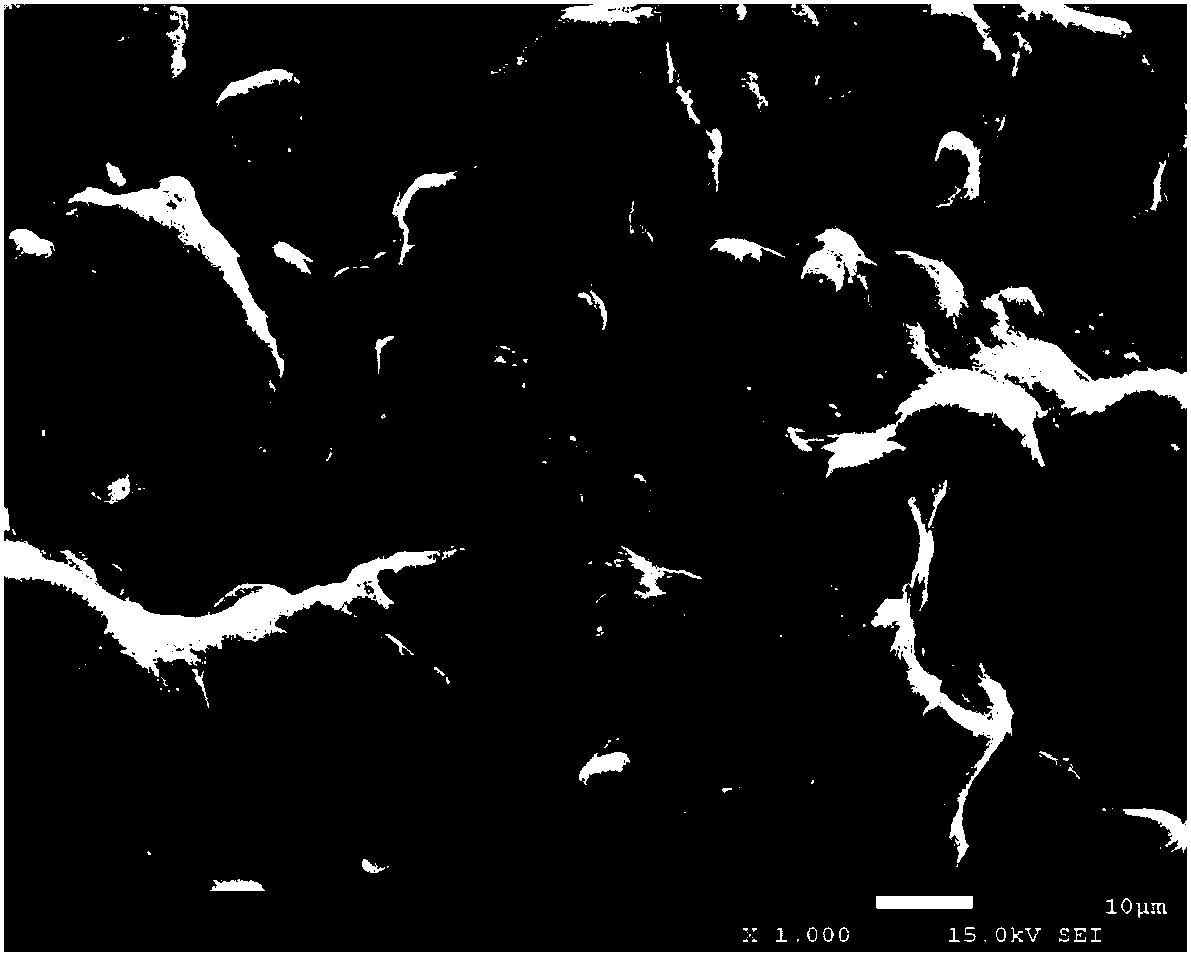

Biodegradable polyester/cellulose nanocomposite and preparation method thereof

The invention provides a biodegradable polyester / cellulose nanocomposite and a preparation method thereof and in particular provides a compatibilizer modified polycaprolactone (PCL) / cellulose nanocomposite and a preparation method thereof. The compatibilizer can obviously improve dispersion of cellulose in PCL, thus improving the mechanical properties of the nanocomposite. The compatibilizer has biocompatibility and biodegradability, thus being favorable for the nanocomposite to be applied in the biomedicine. The method for preparing the nanocomposite by adopting melt blending is simple and convenient to operate, is simple in production process and easily achieves large-scale production.

Owner:JIANGNAN UNIV

Wood-plastic composite material and preparation method thereof

The invention discloses a wood-plastic composite material and a preparation method thereof. The wood-plastic composite material comprises the following raw materials in part by weight: 30 to 50 percent of saw dust, 30 to 50 percent of waste polyethylene, 5 to 20 percent of waste polypropylene, 5 to 10 percent of aluminate, 0.5 to 1 percent of modifier, 4 to 5 percent of stearic acid, 0.5 to 1 percent of zinc stearate and 4 to 5 percent of ethylene wax. The preparation method comprises: weighing raw material; drying the saw dust; mixing, filling the waste polyethylene and waste polypropylene in an open mill, adding the modifier, stearic acid, zinc stearate and ethylene wax, plasticizing and sheeting to obtain a plasticized blank; and shearing the plasticized blank into small thin sheets, subjecting the small thin sheets to hot-forming, preparing a standard sample, removing flashing, and performing secondary hot-forming to obtain wood-plastic composite material. The wood-plastic composite material has high compatibility, interface compatibility and good mechanical properties and brings great convenience for production and life.

Owner:HUNAN FUXIANG WOOD

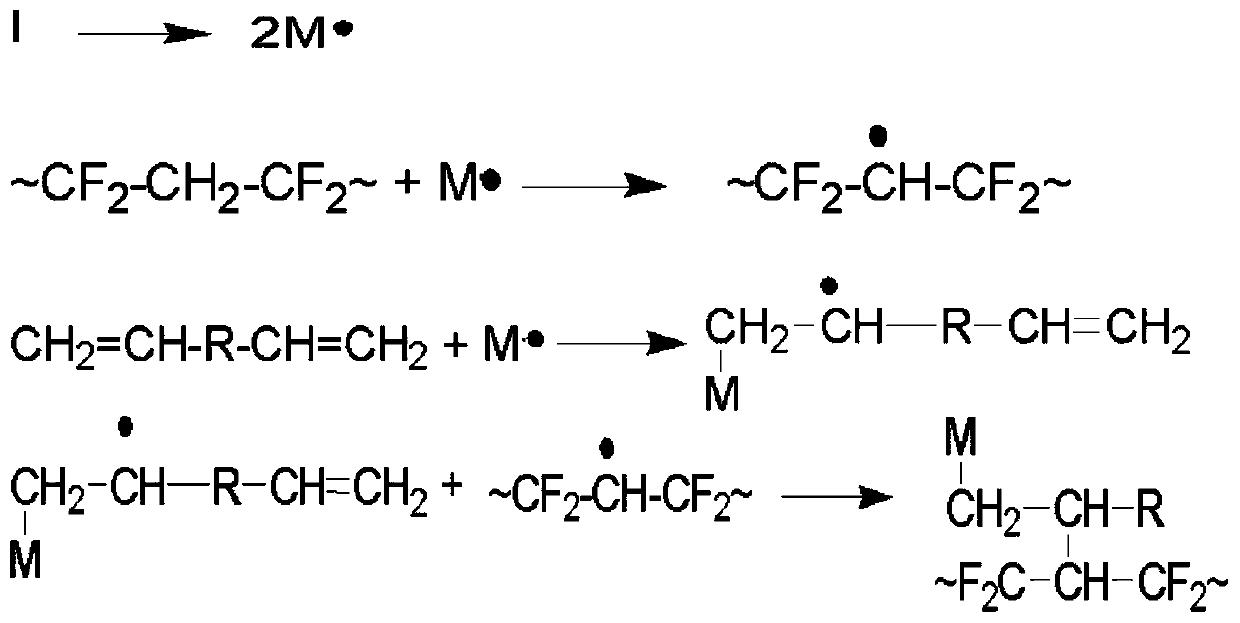

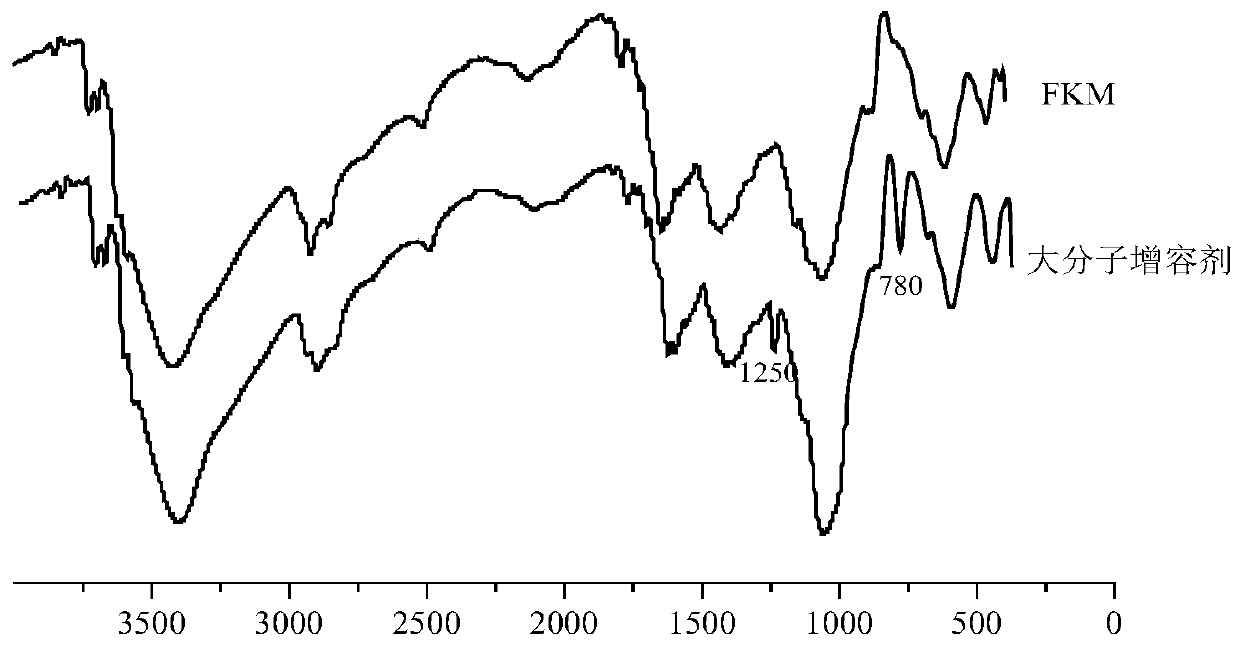

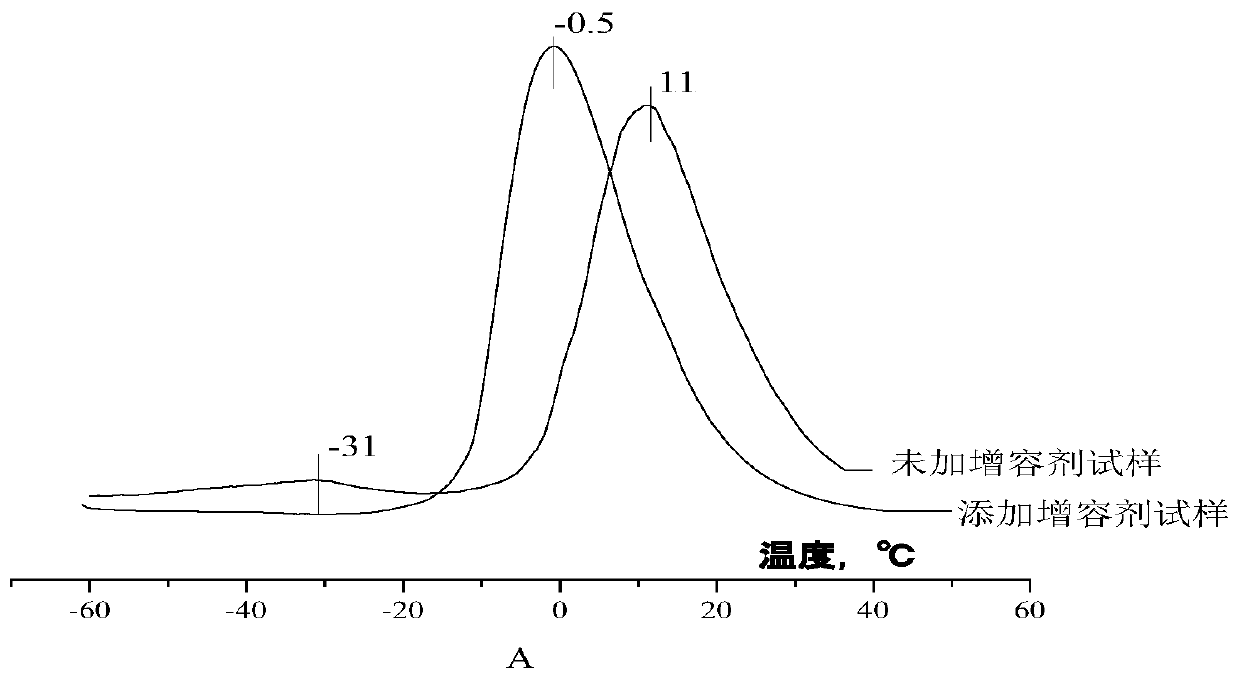

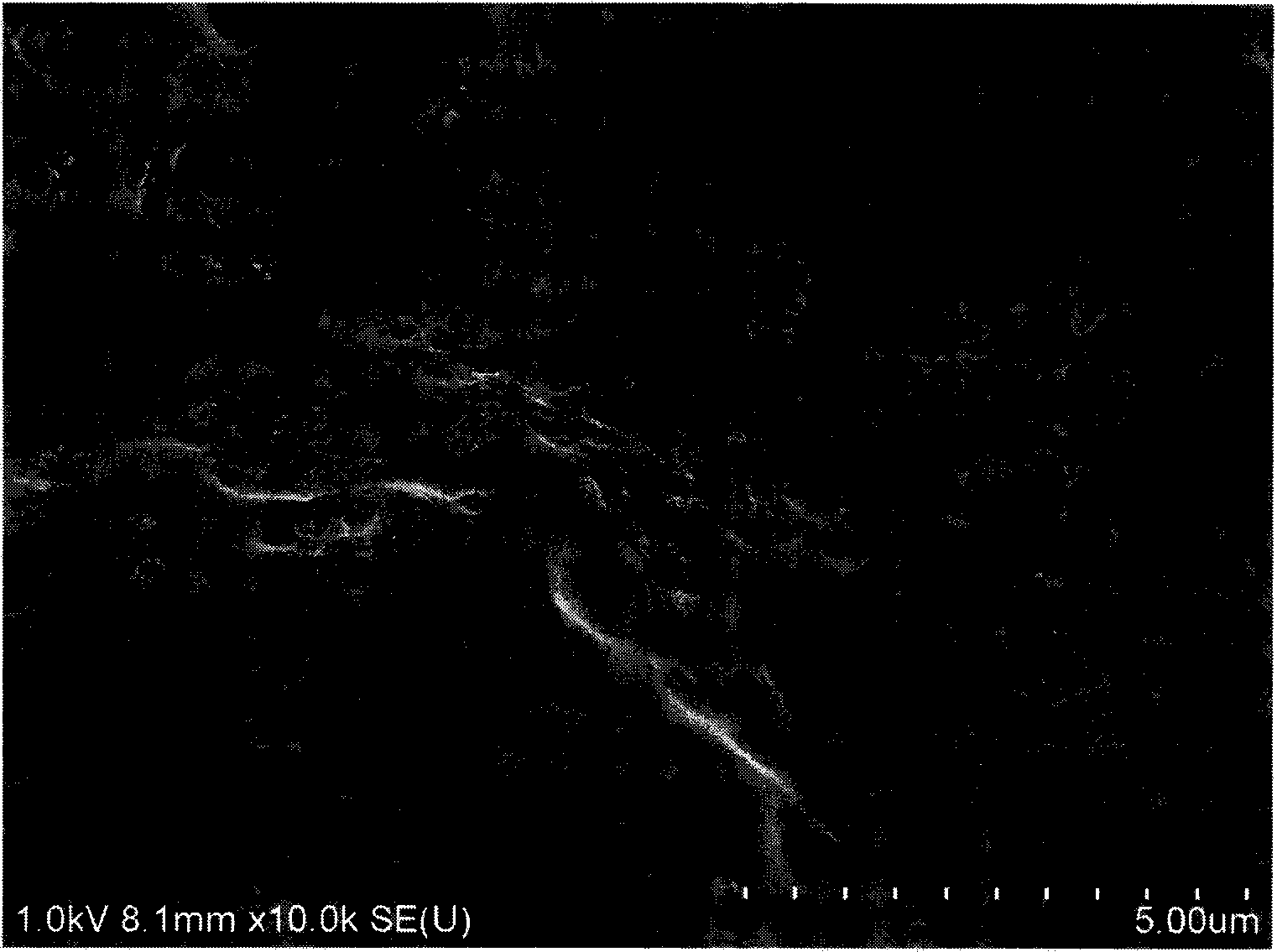

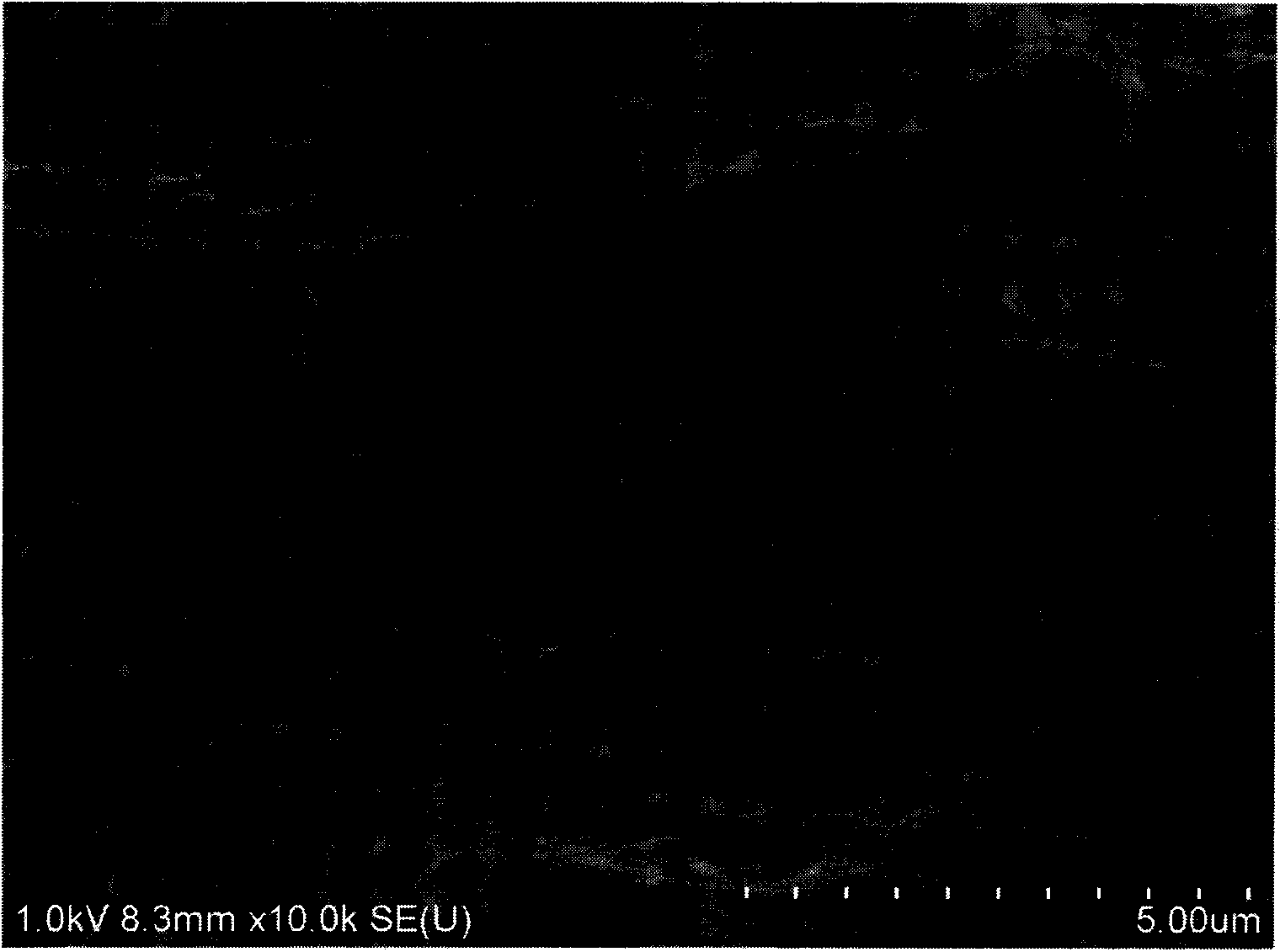

Rubber-blended macromolecular compatibilizer, preparation method and application thereof

The invention discloses a rubber-blended macromolecular compatibilizer, a preparation method and an application thereof. The rubber-blended macromolecular compatibilizer is a macromolecular compatibilizer FKM-g-(SiR)n acquired by taking fluororubber as a main chain and grafting with long-chain vinyl silicone oil through a high-temperature thermodynamic grafting process. The rubber-blended macromolecular compatibilizer disclosed by the invention can be used as the compatibilizer for blending fluororubber and silicone rubber, has a compatibilization effect on the blending of fluororubber and silicone rubber, and can be used for preparing vulcanized products with excellent physical and mechanical properties and oil resistance.

Owner:ANHUI UNIVERSITY

Biodegradable polyester nanocomposite and preparation method thereof

The invention provides a biodegradable polyester nanocomposite and a preparation method thereof and in particular provides a compatibilizer modified polycaprolactone (PCL) / hydroxyapatite nanocomposite and a preparation method thereof. The compatibilizer can obviously improve dispersion of nano-hydroxyapatite in PCL, thus improving the mechanical properties of the nanocomposite. The compatibilizer has biocompatibility and biodegradability, thus being favorable for the nanocomposite to be applied in the biomedicine. The method for preparing the nanocomposite by adopting melt blending is simple and convenient to operate, is simple in production process and easily achieves large-scale production.

Owner:JIANGNAN UNIV

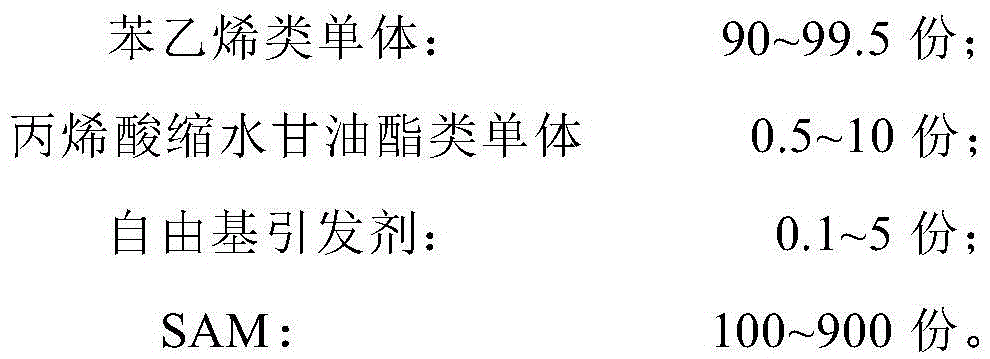

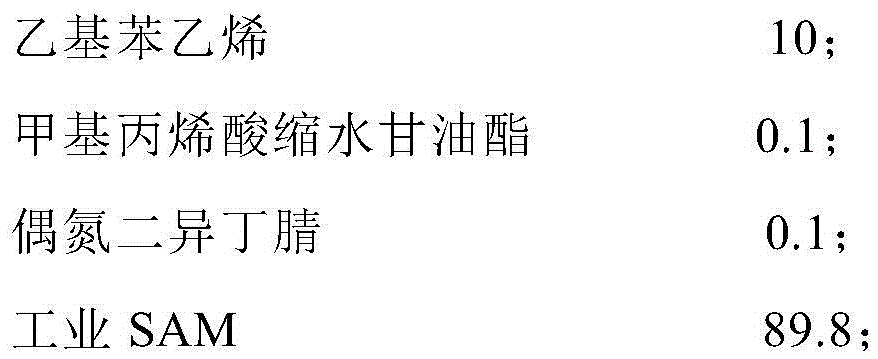

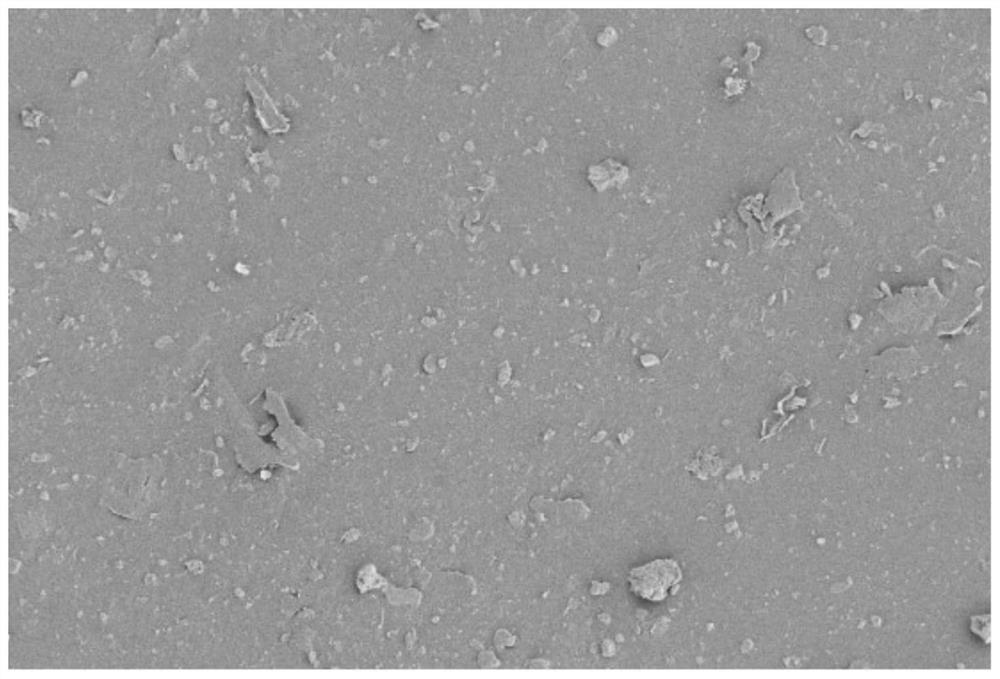

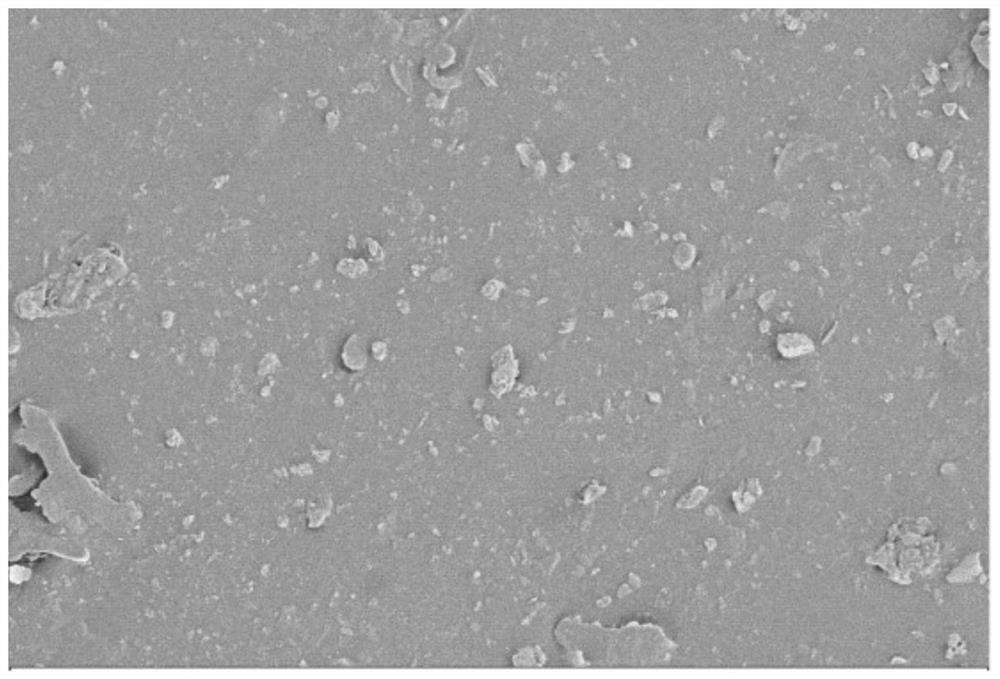

Macromolecular compatilizer for ABS (acrylonitrile-butadiene-styrene)-HIPS (high impact polystyrene) alloys and preparation method of macromolecular compatilizer

The invention provides a macromolecular compatilizer for ABS (acrylonitrile-butadiene-styrene)-HIPS (high impact polystyrene) alloys and a preparation method of the macromolecular compatilizer. The compatilizer comprises components in percentage by weight as follows: styrene monomers, glycidyl acrylate monomers, a free radical initiator and SAM (styrene-maleic anhydride-acrylonitrile). The preparation method comprises steps as follows: the styrene monomers, the glycidyl acrylate monomers and the free radical initiator react with a polymerization method, and a copolymer is obtained; the copolymer is uniformly mixed with SAM, and the macromolecular compatilizer for the ABS-HIPS alloys is obtained with a melt blending method. The macromolecular compatilizer has the benefits as follows: the amphipathic macromolecular compatilizer is obtained through one-step reaction and melt blending, a preparation process is simple, the proportion of polystyrene chain segments to SAM chain segments in the compatilizer is better adjusted, and the macromolecular compatilizer is suitable for blending systems of ABS and HIPS in various proportions. Experiment results show that the compatilizer has a remarkable compatibilization effect.

Owner:FINE BLEND COMPATILIZER JIANGSU CO LTD

High-temperature-resistant modified asphalt pavement repairing material and preparation method thereof

InactiveCN111808433AHigh softening pointReduce dosageBuilding insulationsPolymer sciencePhosphoric acid

The invention relates to a high-temperature-resistant modified asphalt pavement repairing material and a preparation method thereof. The material is prepared from the following substances in parts bymass: 76-96 parts of matrix asphalt, 15-20 parts of a grafted SBS modifier, 1-5 parts of polyphosphoric acid, 4-9 parts of a tackifier, 3-6 parts of a stabilizer and 4-6 parts of an anti-aging agent,wherein the grafted SBS modifier is prepared from SBS and a coupling agent through a coupling reaction. The preparation method comprises the following steps of: burning the solid matrix asphalt into aliquid state, weighing the liquid matrix asphalt, the grafted SBS modifier and the polyphosphoric acid according to the parts by mass, mixing liquid matrix asphalt, the grafted SBS modifier and the polyphosphoric acid in a modification system, and stirring at the speed of 800-1000r / min for 15 minutes at the temperature of 180 DEG C; then increasing the stirring speed of the modification system to1500-2000r / min, and adding the tackifier, the stabilizer and the anti-aging agent at the same time; finally, increasing the temperature of the modification system to 240 DEG C, and conducting stirring development for 2h to obtain the modified asphalt pavement repairing material which is resistant to high temperature and long in service life.

Owner:QUANZHOU INST OF INFORMATION ENG

Emulsifier suitable for glufosinate ammonium.fluoroglycofen-ethyl microemulsion, and application method of emulsifier

The invention relates to an emulsifier suitable for glufosinate ammonium.fluoroglycofen-ethyl microemulsion. The emulsifier is prepared from the following raw materials in percentage by mass: 1-70% ofstyrylphenol polyoxyethylene ether, 1-70% of modified alkyl glycoside, 1-70% of alkylphenol polyoxyethylene ether polyoxypropylene ether and 1-70% of of dodecyl hydroxysulfobetaine. The emulsifier prepared by the invention has good emulsifying function and compatibilizing effect. The invention also discloses an application method of the emulsifier suitable for glufosinate ammonium.fluoroglycofen-ethyl microemulsion, wherein the emulsifier is suitable for preparing a microemulsion product with glufosinate-ammonium mass percent of 5-20% and fluoroglycofen-ethyl mass percent of 0.1-1%, so that the glufosinate ammonium.fluoroglycofen-ethyl microemulsion is stable in quality, simple in process, convenient to operate and high in production efficiency.

Owner:NANJING KEYI NEW MATERIALS

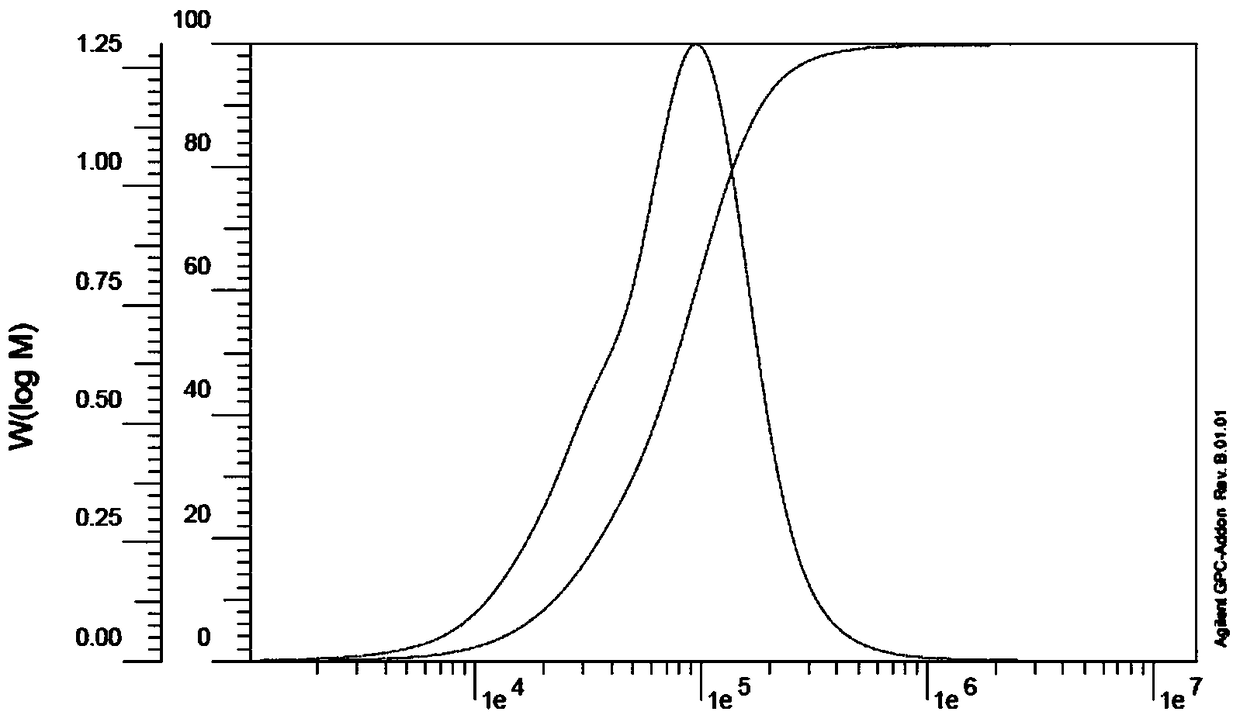

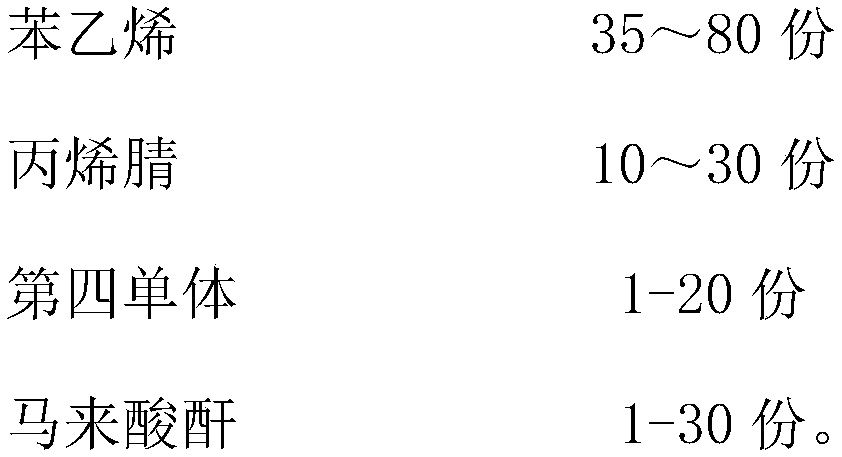

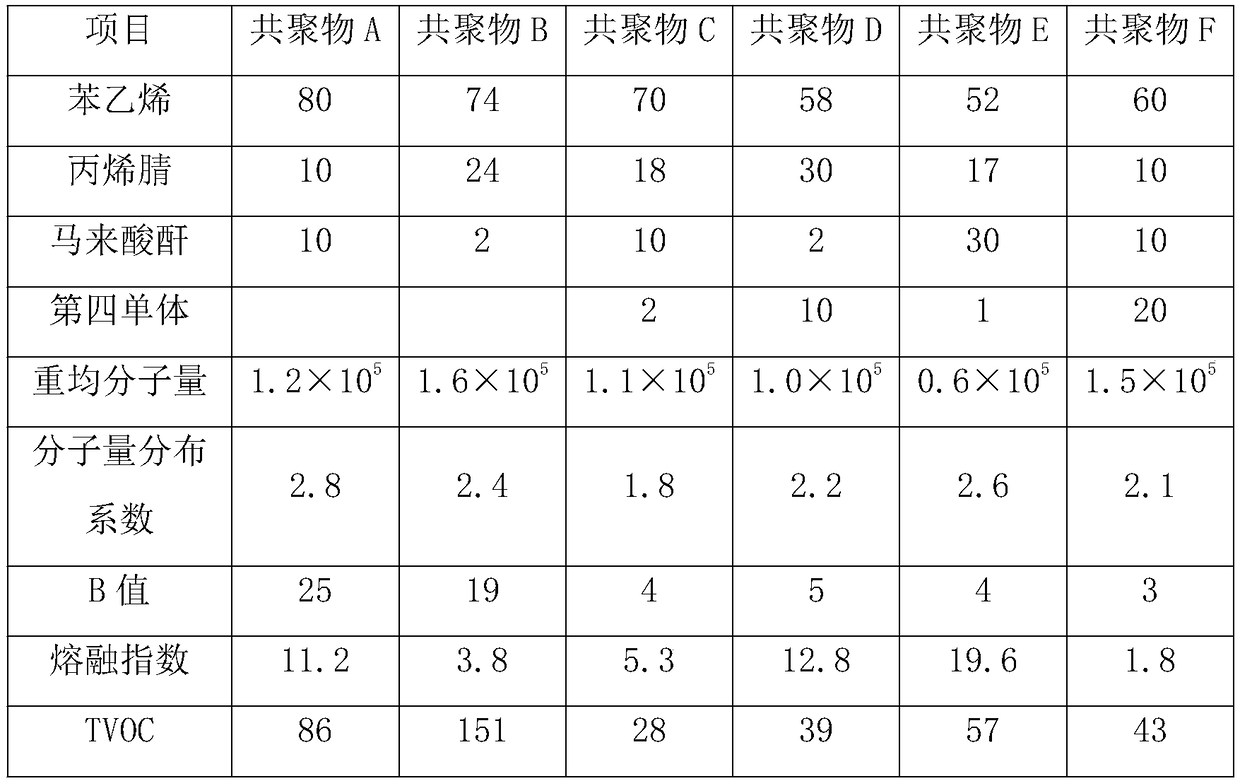

Low yellowness styrene-acrylonitrile-maleic anhydride copolymer and preparation method thereof

The invention discloses a low yellowness styrene-acrylonitrile-maleic anhydride copolymer and a preparation method thereof. The copolymer comprises the following components: 35-80 parts of styrene, 10-30 parts of acrylonitrile, 1-30 parts of maleic anhydride, and 1-20 parts of a fourth monomer. The bulk polymerization process is employed for production, and solves the problems of too yellow appearance, affected product appearance and the like in styrene-acrylonitrile-maleic anhydride copolymers produced by previous technologies. According to the invention, an oil-soluble initiator is employedto produce free radicals, and reaction is carried out under a low temperature condition so as to obtain the low yellowness terpolymer with low molecular weight distribution coefficient, the terpolymeris suitable for use as a compatibilizer of plastic alloys (PC / ABS, ABS / PET, PA / ABS, etc.), and does not affect the appearance of downstream modified products.

Owner:嘉兴华雯化工股份有限公司

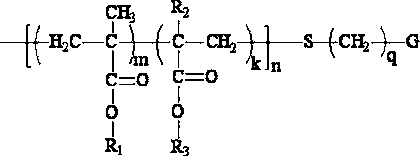

Grafted copolymer containing epoxy groups and application of grafted copolymer

The invention discloses a grafted copolymer containing epoxy groups and application of the grafted copolymer. The grafted copolymer is a polymer containing the epoxy groups and high-molecular copolymer side chains and is mainly prepared from 40wt%-90wt% of a monomer A containing carbon-carbon double bonds, 5wt%-30wt% of an unsaturated monomer B containing the epoxy groups and 5wt%-30wt% of a high-molecular polymer C containing the carbon-carbon double bonds through free radical polymerization copolymerization. The grafted copolymer is prepared by the following steps: firstly carrying out freeradical copolymerization so as to obtain a high-molecular polymer D, and preparing the high-molecular polymer C containing the carbon-carbon double bonds through reaction among the groups; and finallycarrying out free radical polymerization on the obtained high-molecular polymer C, the monomer A and the monomer B, drying, and carrying out devolatilization, so as to obtain the grafted copolymer containing the epoxy groups. The grafted copolymer containing the epoxy groups can be used as a compatibilizer for polymer blends and a chain extender for polymers.

Owner:KINGFA SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com