Preparation method of high-density polyethylene/polyamide 66 laminar barrier materials using in-situ reactive compatibilization method

A high-density polyethylene, in-situ reaction technology, applied in the field of polymer materials, can solve the problems of toxicity of fluorinating agents or sulfonating agents, adverse effects on human body and environment, difficulty in recycling scraps, etc., and achieves excellent barrier properties and compatibilization. Effective and easy to promote and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

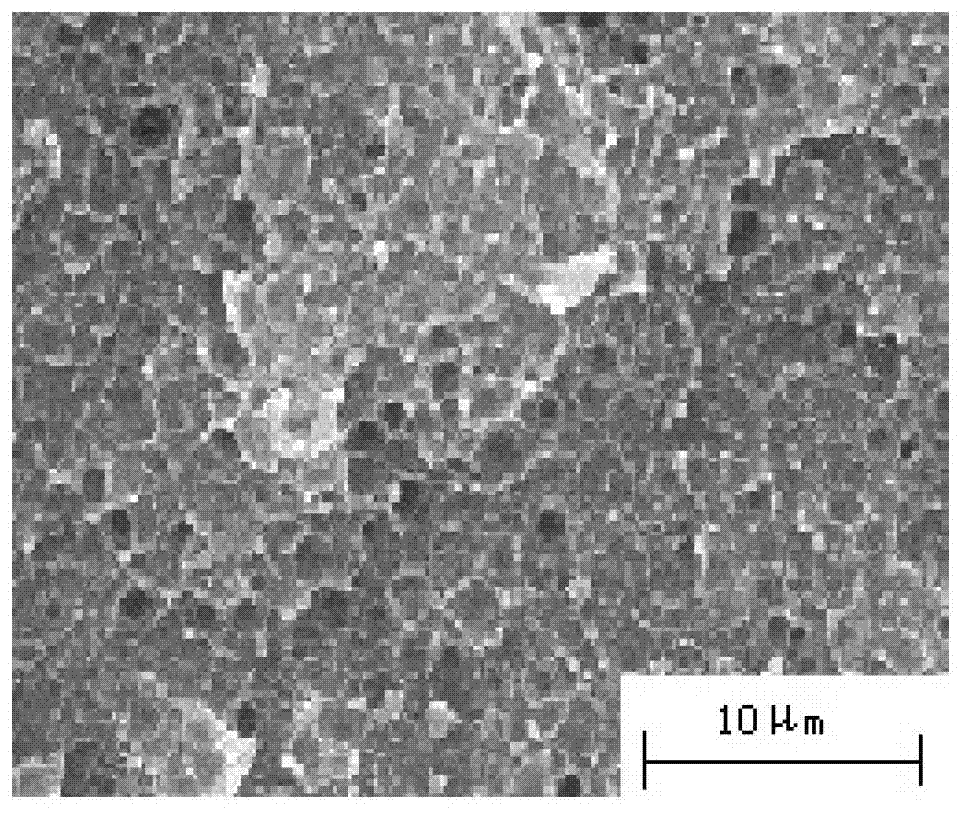

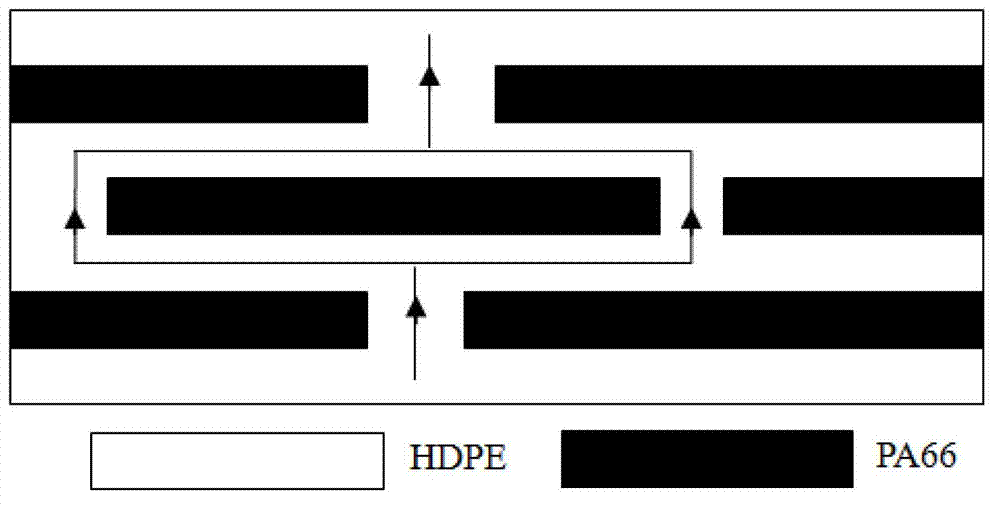

[0060] The high-density polyethylene / polyamide 66 laminate barrier material prepared by in-situ reaction compatibilization method is composed of the following raw materials in parts by weight: 95 parts of high-density polyethylene (HDPE), 5 parts of polyamide 66 (PA66), peroxidized Dicumyl benzene (DCP) 0.1 part, maleic anhydride (MAH) 1 part, organic montmorillonite (OMMT) 3 parts.

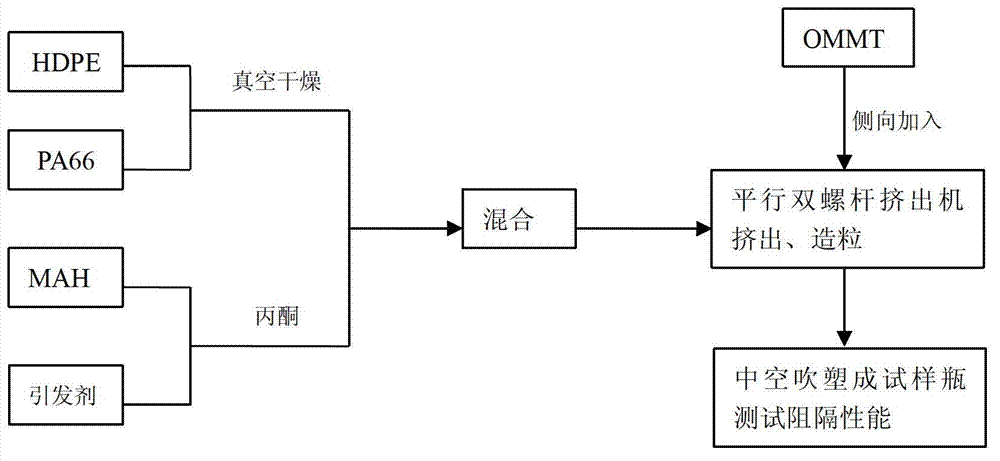

[0061] The method for preparing high-density polyethylene / polyamide 66 laminated barrier material by in-situ reaction compatibilization method comprises the following steps:

[0062] (1) Dissolving the DCP and MAH of the weight portion in the diluent butanone to obtain a mixed solution, which is placed for subsequent use;

[0063] (2) Put the HDPE and PA66 in parts by weight in a vacuum oven for drying treatment, adjust the oven temperature to 90°C, dry for 6 hours, then cool to room temperature, mix HDPE and PA66 uniformly in proportion to obtain a blend;

[0064] (3) Pour the mixed solution in...

Embodiment 2

[0069] The high-density polyethylene / polyamide 66 laminated barrier material prepared by in-situ reaction compatibilization method is composed of the following raw materials in parts by weight: 90 parts of high-density polyethylene (HDPE), 10 parts of polyamide 66 (PA66), peroxide Dicumyl benzene (DCP) 0.1 part, maleic anhydride (MAH) 1 part, organic montmorillonite (OMMT) 3 parts.

[0070] The method for preparing high-density polyethylene / polyamide 66 laminated barrier material by in-situ reaction compatibilization method comprises the following steps:

[0071] (1) Dissolving the DCP and MAH of the weight portion in the diluent butanone to obtain a mixed solution, which is placed for subsequent use;

[0072] (2) Put the HDPE and PA66 in parts by weight in a vacuum oven for drying treatment, adjust the oven temperature to 90°C, dry for 6 hours, then cool to room temperature, mix HDPE and PA66 uniformly in proportion to obtain a blend;

[0073] (3) Pour the mixed solution in ...

Embodiment 3

[0078] The high-density polyethylene / polyamide 66 laminate barrier material prepared by in-situ reaction compatibilization method is composed of the following raw materials in parts by weight: 85 parts of high-density polyethylene (HDPE), 15 parts of polyamide 66 (PA66), 2, 0.1 part of 5-dimethyl-2,5-di-tert-butylperoxyhexane (L-101), 1 part of maleic anhydride (MAH), 3 parts of organic montmorillonite (OMMT).

[0079] The method for preparing high-density polyethylene / polyamide 66 laminated barrier material by in-situ reaction compatibilization method comprises the following steps:

[0080] (1) Dissolve the L-101 and MAH of the weight portion in diluent acetone to obtain a mixed solution, which is placed for subsequent use;

[0081] (2) Put the HDPE and PA66 in parts by weight in a vacuum oven for drying treatment, adjust the oven temperature to 90°C, dry for 6 hours, then cool to room temperature, and mix HDPE and PA66 uniformly in proportion to obtain a blend;

[0082] (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com