Macromolecular compatilizer for ABS (acrylonitrile-butadiene-styrene)-HIPS (high impact polystyrene) alloys and preparation method of macromolecular compatilizer

A technology of macromolecules and compatibilizers, applied in the field of macromolecular compatibilizers and their preparation, can solve problems such as poor compatibility, deterioration of physical properties, peeling, etc., achieve compatibilization effect, simple preparation process and obvious effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

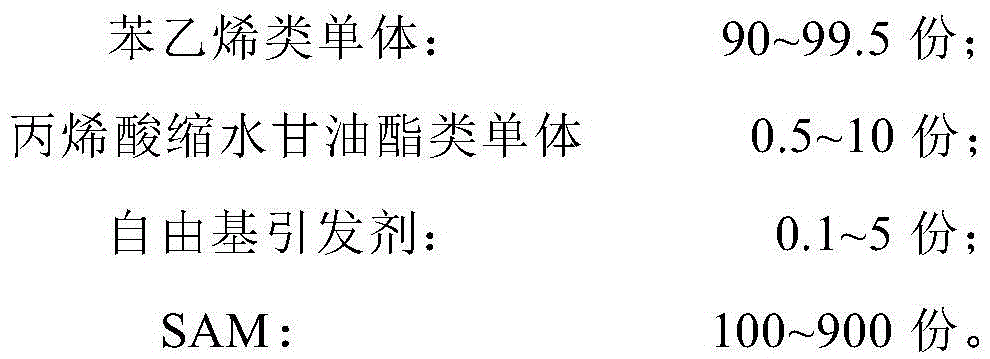

Method used

Image

Examples

Embodiment 1

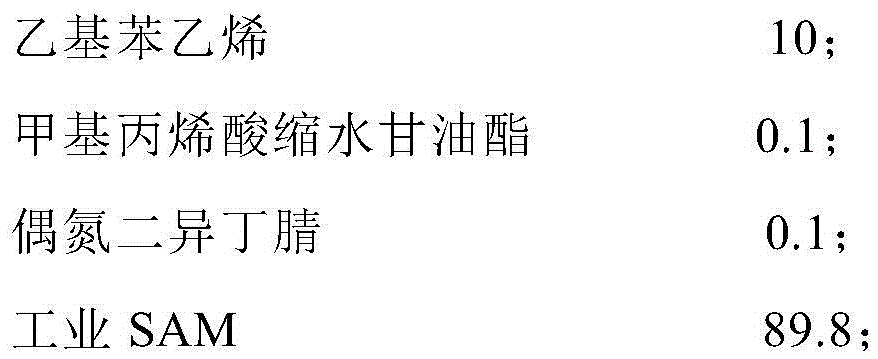

[0022] Prepare raw materials according to the following proportions, and the polymerization method is solution polymerization

[0023]

[0024] Dissolve azobisisobutyronitrile in styrene, then add glycidyl methacrylate, mix evenly and introduce it into the flask, then pour 45ml of dried toluene, add a magnet, connect a spherical condenser, vacuumize, nitrogen Protect. The reaction temperature was controlled at 90°C, condensed water was introduced, and the reaction time was 12 hours. Take 80ml of ethanol for precipitation, and after the precipitation is allowed to stand still, remove the upper layer liquid to obtain the bottom layer precipitation, and add 50ml of dichloromethane for secondary dissolution. After the solution is completely dissolved, slowly drop the solution into 80ml of methanol to obtain a white powdery precipitate and pour it into a Buchner funnel for vacuum filtration. After the white precipitate is obtained, put it into a watch glass, and put the product...

Embodiment 2

[0027] Prepare the raw materials according to the following proportions, and the polymerization method is suspension polymerization

[0028]

[0029]

[0030] Add 1200ml of desalted water into a 3000ml three-necked bottle, raise the temperature to 85°C, add 6g of polyvinyl alcohol, and start stirring until the polyvinyl alcohol is completely dissolved. Measure methyl styrene, glycidyl acrylate, and dibenzoyl peroxide in proportion, mix them evenly, add them into a three-necked bottle, and stop the reaction after 7 hours of reaction. Wash thoroughly with hot desalinated water to remove dispersants and monomers attached to the surface, and then dry for use.

[0031] Mix the obtained copolymer with industrial SAM in a high-speed mixer and add it to a twin-screw extruder. The temperature of the extruder is set between 180°C and 220°C, and the mixture melts and reacts at this temperature. The required compatibilizer is obtained by extruding strands, cooling and granulating, ...

Embodiment 3

[0033] Prepare the raw materials according to the following proportions, and the polymerization method is bulk polymerization

[0034]

[0035] Styrene, glycidyl methacrylate, and dibenzoyl peroxide were weighed in proportion, mixed evenly and poured into a three-necked bottle, vacuumed, nitrogen protection, condensed water, heated to 80°C in an oil bath, and reacted After 1 hour, react in a water bath at 60°C for 12 hours to obtain a polymer.

[0036] Mix the obtained copolymer with industrial SAM in a high-speed mixer and add it to a twin-screw extruder. The temperature of the extruder is set between 180°C and 220°C, and the mixture melts and reacts at this temperature. The required compatibilizer is obtained by extruding strands, cooling and granulating, and drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com