Low yellowness styrene-acrylonitrile-maleic anhydride copolymer and preparation method thereof

A technology of maleic anhydride and styrene, which is applied in the field of low-yellow styrene-acrylonitrile-maleic anhydride copolymer and its preparation, can solve the problem of low-yellowness, which can only reach up to 10% by mass fraction, two-phase Adhesive phase state dispersion improvement effect is not obvious, affecting alloy product odor, residual sheet and other problems, to achieve the effect of improving two-phase adhesiveness, less color change, and improved thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

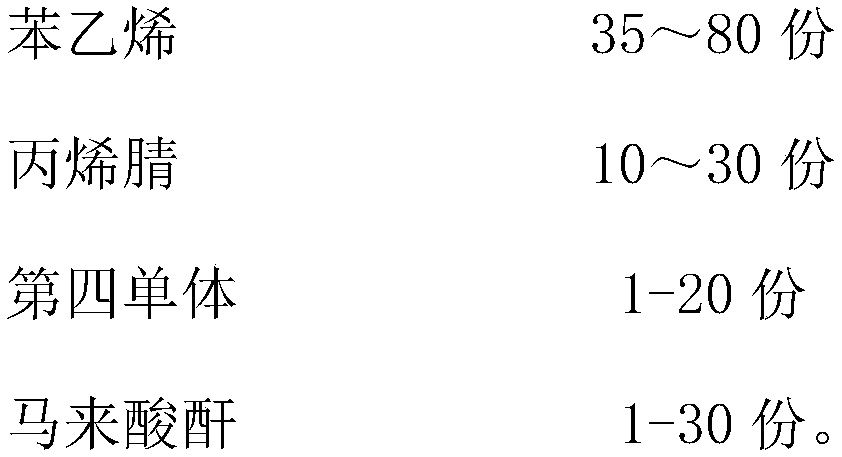

Method used

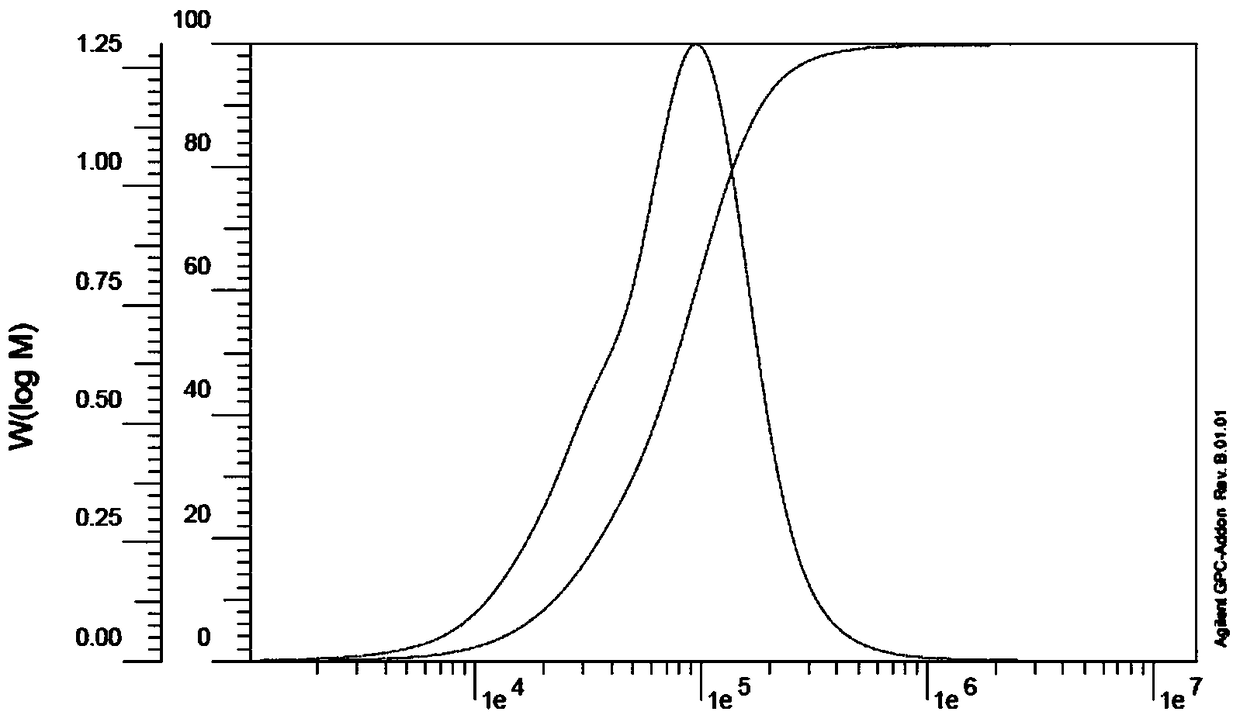

Image

Examples

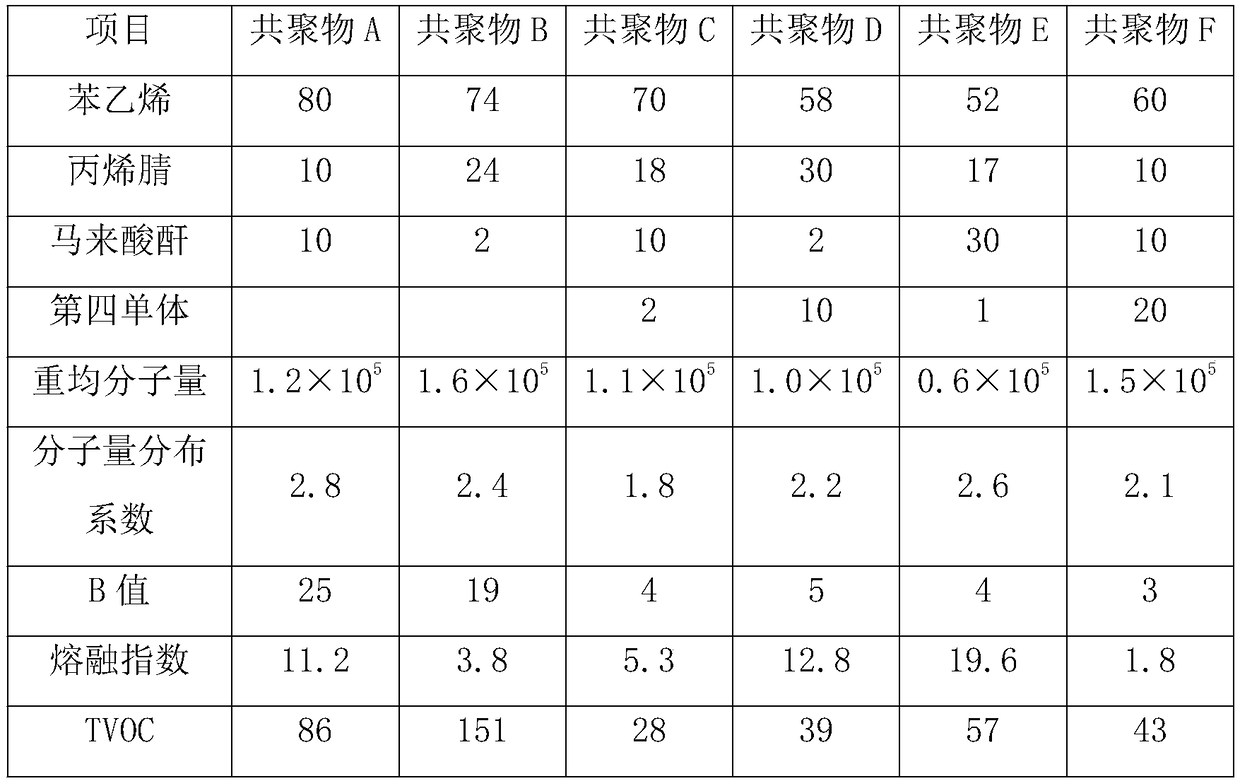

Embodiment 1

[0027] Add 0.1 part of DCP, 0.1 part of dodecyl mercaptan, 15 parts of styrene, 5 parts of acrylonitrile, and 1 part of methyl methacrylate into the reactor, stir evenly, the temperature of the reactor is 100°C, and the pressure is 1.2MPa 5 parts of maleic anhydride are dissolved in the remaining 59 parts of styrene and 14 parts of acrylonitrile, and the dissolved solution is dropped into the reactor to control the conversion rate to 50%; the solution obtained by the reaction is injected into the vacuum devolatilizer, Under the conditions of 250° C. and 30 KPa, unreacted monomers were removed to obtain a low-yellowness styrene-acrylonitrile-maleic anhydride copolymer C. The unreacted monomer is cooled and recycled by the condenser.

[0028] Then 65 parts of polycarbonate (Lotte PC1001), 35 parts of ABS (Takahashi Petrochemical ABS8391), and 0.5 parts of copolymer C were extruded and granulated at 240-260°C to obtain PC / ABS alloy 3. In addition, 65 parts of polycarbonate (Lott...

Embodiment 2

[0030] Add 1 part of azobisisobutyronitrile, 0.1 part of dodecyl mercaptan, 15 parts of styrene, and 5 parts of acrylonitrile into the reactor, and stir evenly. The temperature of the reactor is 60 ° C, the pressure is 0.6 MPa, and 0.8 Parts of maleic anhydride are dissolved in remaining 47.2 parts of styrene, 28 parts of acrylonitrile, 4 parts of methyl acrylate, and the dissolved solution is dripped into the reactor to control the conversion rate to 40%; The unreacted monomer was removed under the conditions of 180°C and 4KPa to obtain low yellowness styrene-acrylonitrile-maleic anhydride copolymer D. The unreacted monomer is cooled and recycled by the condenser.

[0031] Then 65 parts of polycarbonate (Lotte PC1001), 35 parts of ABS (Takahashi Petrochemical ABS8391), and 3 parts of copolymer D were extruded and pelletized at 240-260°C to obtain PC / ABS alloy 5. Copolymer D and The performance data of Alloy 5 are shown in Table 1 and Table 2, respectively.

Embodiment 3

[0033] Add 0.3 parts of BPO, 1 part of dodecyl mercaptan, 9 parts of styrene, 3 parts of acrylonitrile, and 0.4 parts of tert-butyl trimethylhexanoate into the reactor, stir evenly, and the temperature of the reactor is 80°C. The pressure is 0.1MPa, dissolve 12 parts of maleic anhydride in the remaining 57 parts of styrene and 19 parts of acrylonitrile, drop the dissolved solution into the reactor, and control the conversion rate to 40%; inject the solution obtained by the reaction into a vacuum The devolatilizer removes unreacted monomers under the conditions of 250°C and 100KPa to obtain low yellowness styrene-acrylonitrile-maleic anhydride copolymer E. The unreacted monomer is cooled and recycled by the condenser.

[0034] Then 65 parts of polycarbonate (Lotte PC1001), 35 parts of ABS (Takahashi Petrochemical ABS8391), and 3 parts of copolymer E were extruded and pelletized at 240-260°C to obtain PC / ABS alloy 6. Copolymer E and The performance data of Alloy 6 are shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com