Biodegradable polyester nanocomposite and preparation method thereof

A nanocomposite material and technology of biodegradable polyester are applied in the fields of polycaprolactone/hydroxyapatite nanocomposite material and its preparation, biodegradable polyester nanocomposite material and its preparation field. Polymer properties and other issues, to achieve the effect of improving mechanical properties, improving dispersion, and good compatibilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

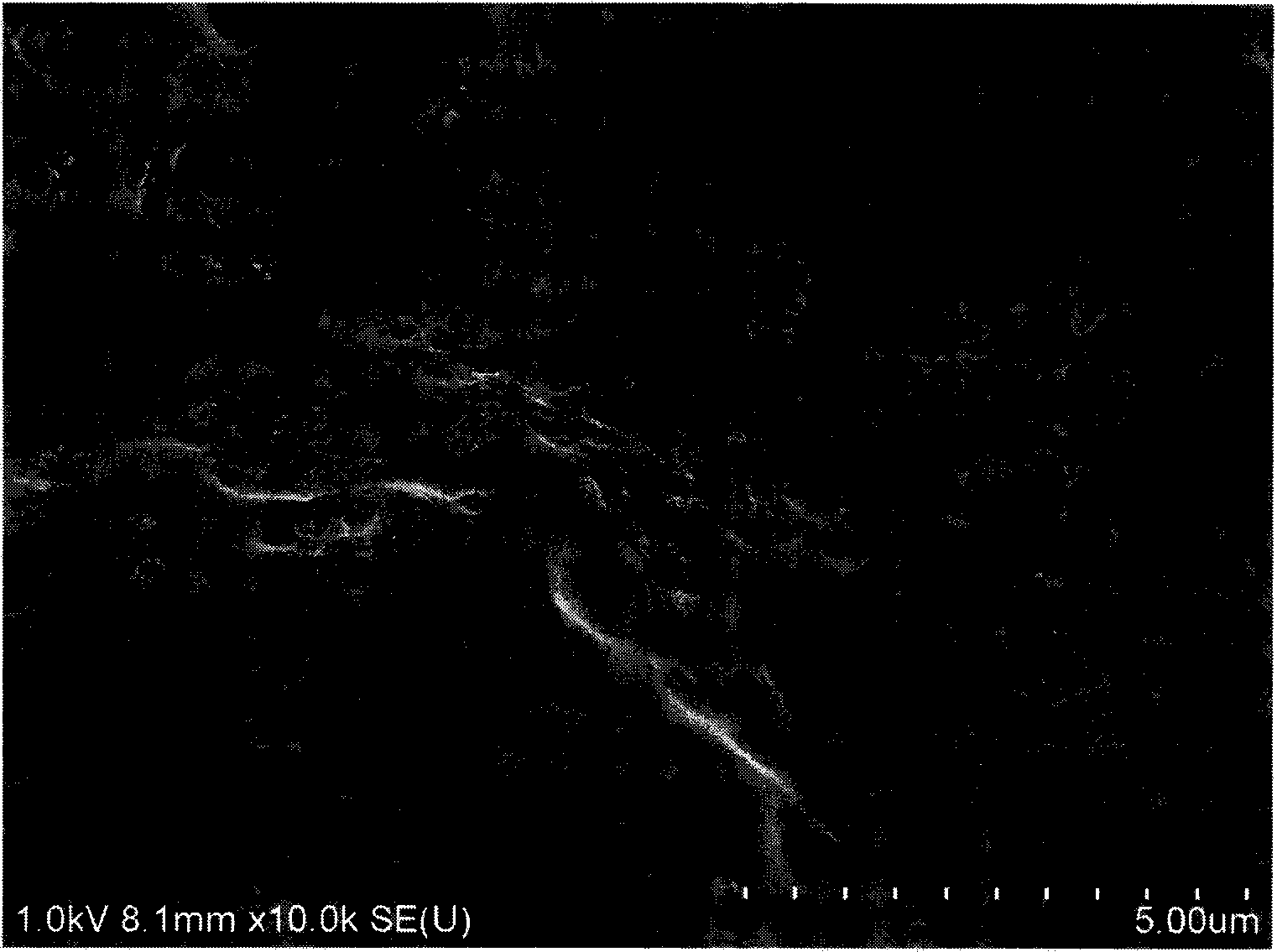

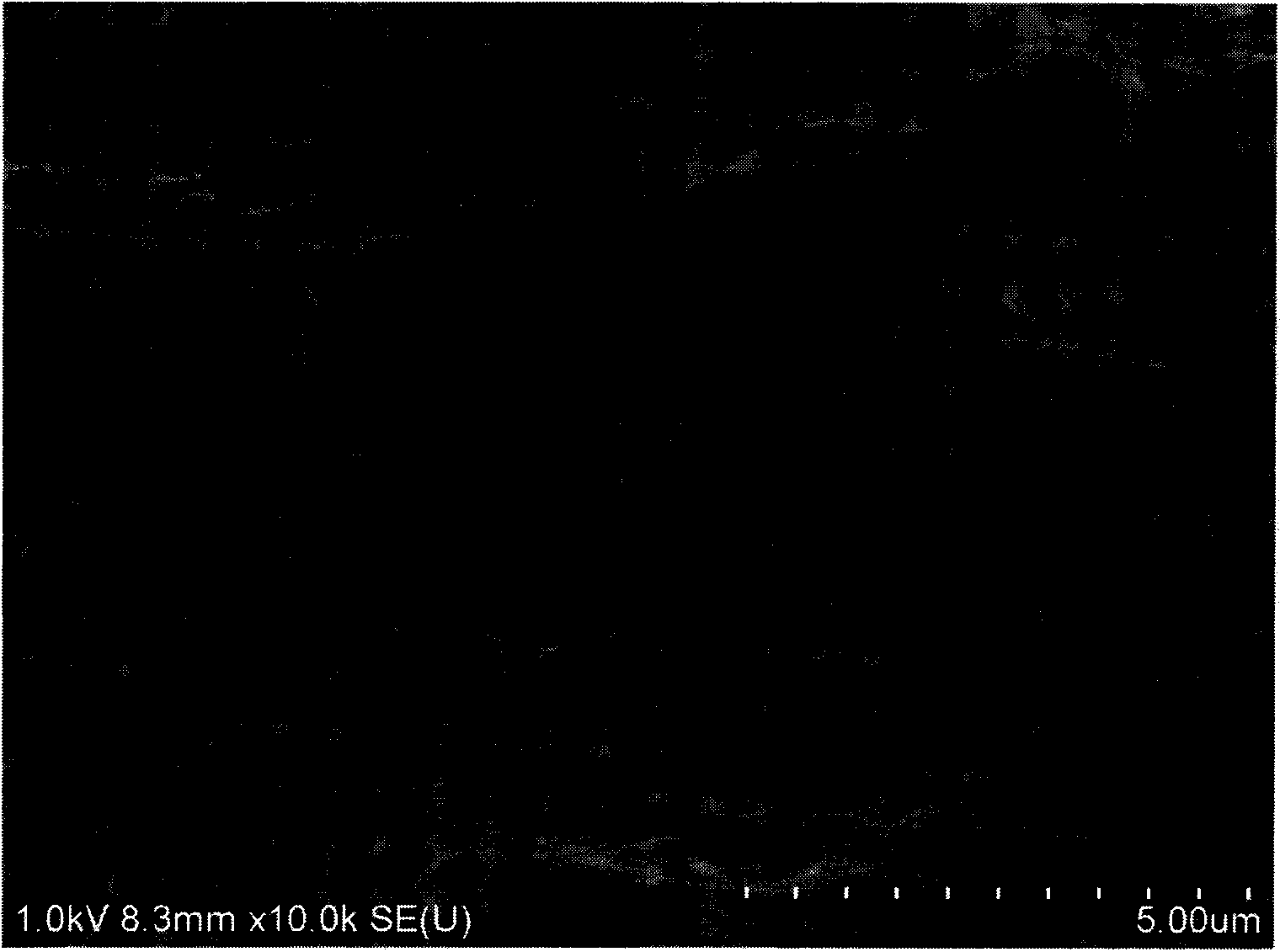

Image

Examples

preparation example Construction

[0019] Preparation of compatibilizer:

[0020] 1. Weigh 24g of dehydrated and dried caprolactone (moisture content<0.05‰), add it to a three-necked flask, ventilate nitrogen, add 0.5g of macromolecular initiator polyethylene glycol-2000, and then add 0.025g of methanesulfonic acid as Catalyst, the reaction temperature is 140°C, the temperature is raised and stirred, and the reaction is carried out for 24 hours to obtain the compatibilizer PCEC-2K; the molar ratio of polyethylene glycol-2000 to caprolactone is 1:840.

[0021] 2. Weigh 22g of dehydrated and dried caprolactone (moisture content<0.05‰), add it to a three-necked flask, ventilate nitrogen, add 1.5g of macromolecular initiator polyethylene glycol-6000, and then add 0.023g of stannous octoate to make Catalyst, the reaction temperature is 140 ° C, the temperature is raised and stirred, and the reaction is carried out for 24 hours to obtain the compatibilizer PCEC-6K; the molar ratio of polyethylene glycol-6000 to capro...

Embodiment 1

[0025] After mixing 2000g of polycaprolactone (PCL), 20g of nano-hydroxyapatite and 2g of compatibilizer PCEC-2K, melt blending was carried out to obtain a biodegradable polyester nanocomposite. Made a standard sample, the properties of the composite material obtained through testing are shown in Table 1.

Embodiment 2

[0029] After mixing 2000g of polycaprolactone (PCL), 200g of nano-hydroxyapatite and 40g of compatibilizer PCEC-2K, melt blending was carried out to obtain a biodegradable polyester nanocomposite. Made a standard sample, the properties of the composite material obtained through testing are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com