Patents

Literature

743 results about "Biodegradable polyester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

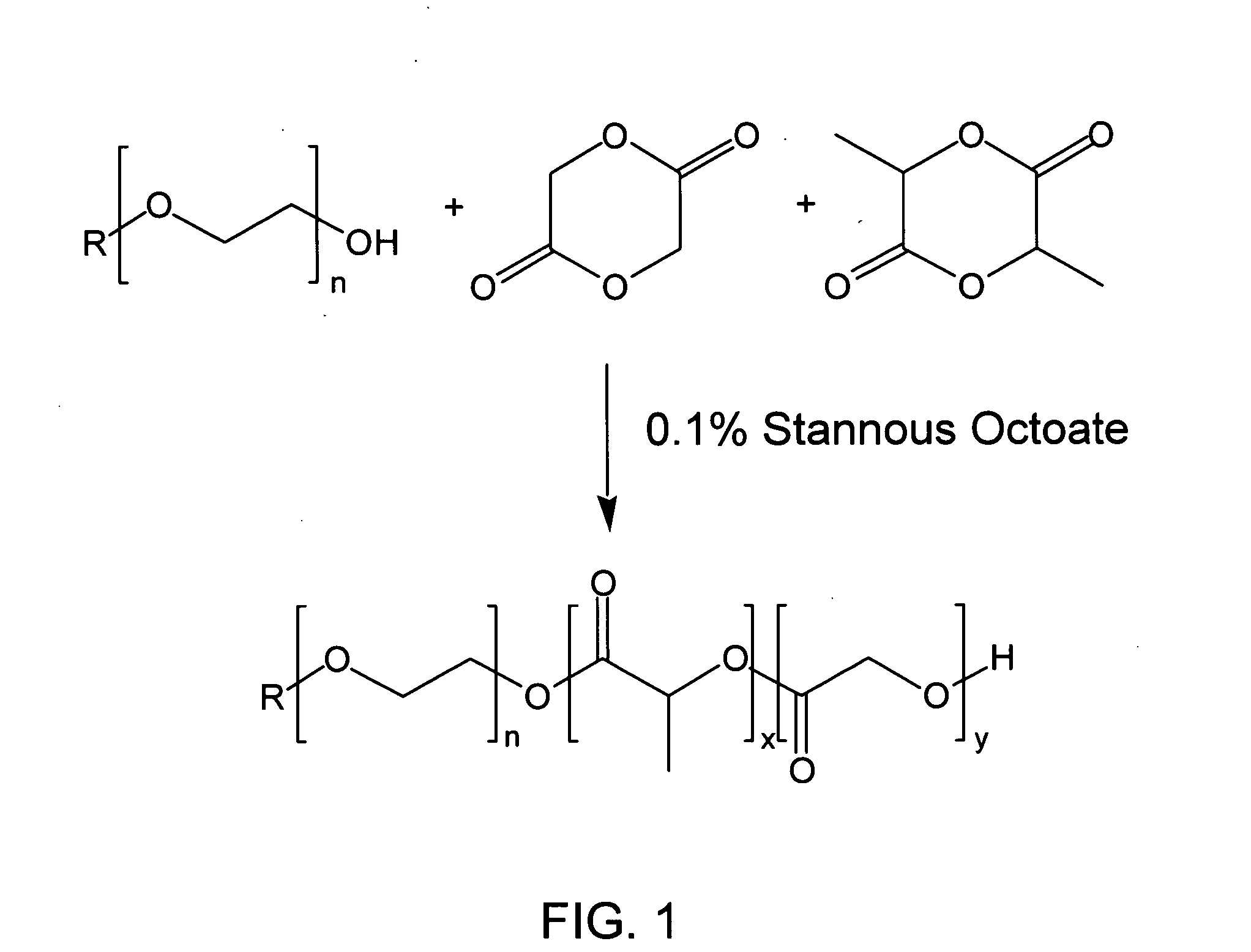

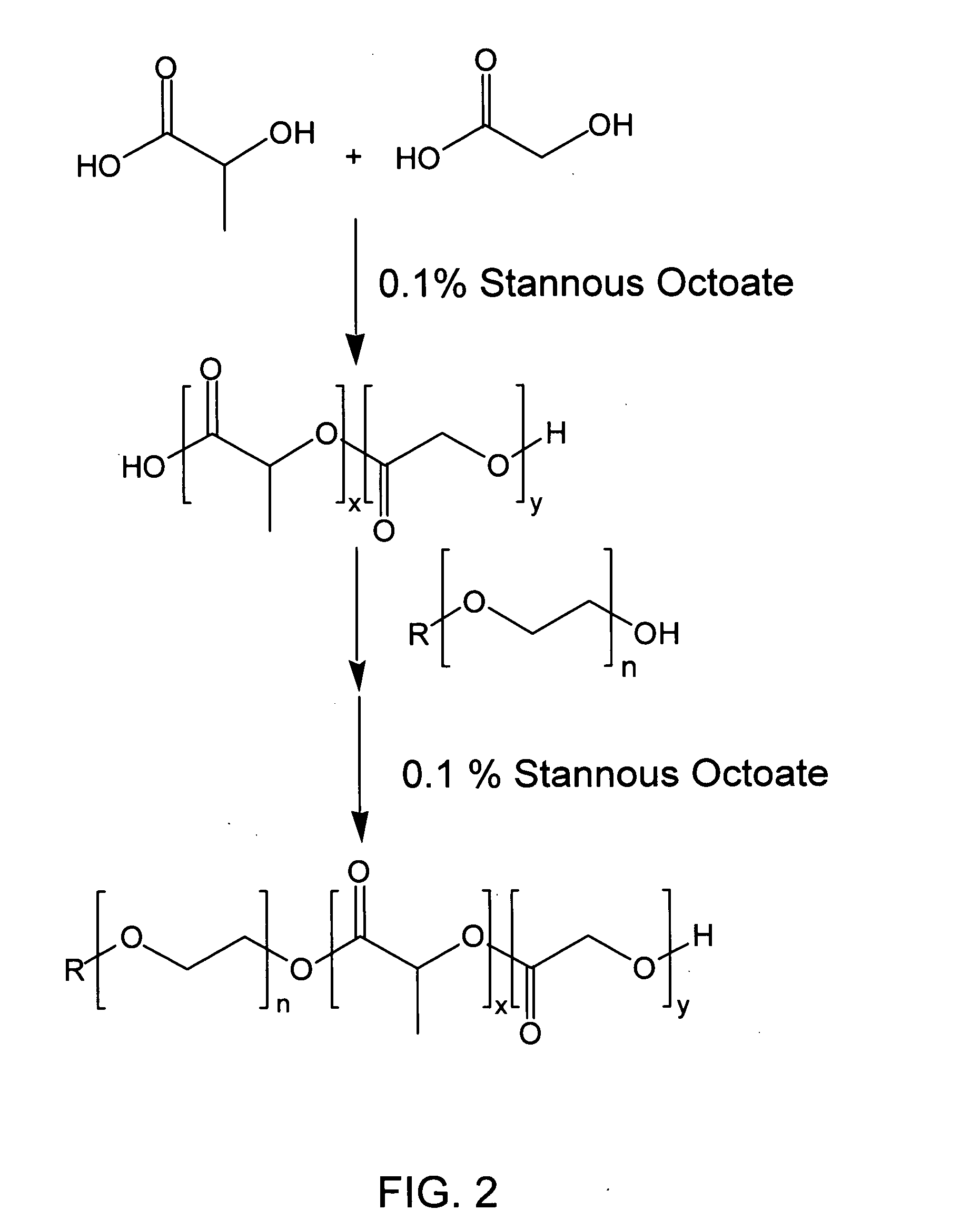

Biodegradable low molecular weight triblock poly(lactide-co- glycolide) polyethylene glycol copolymers having reverse thermal gelation properties

InactiveUS6201072B1Difficult to formulateDifficult to administerOrganic active ingredientsPowder deliverySolubilityPolymer science

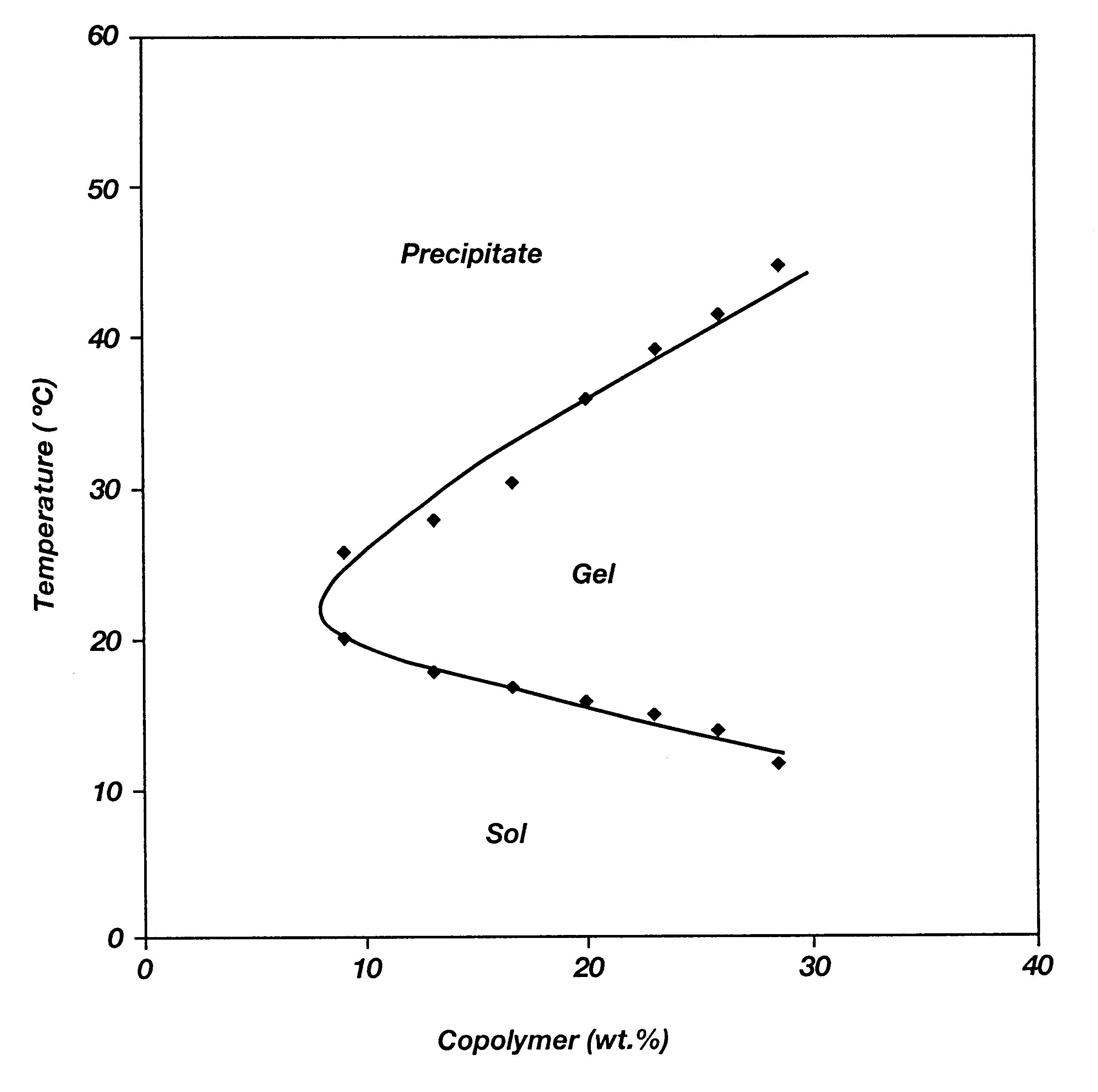

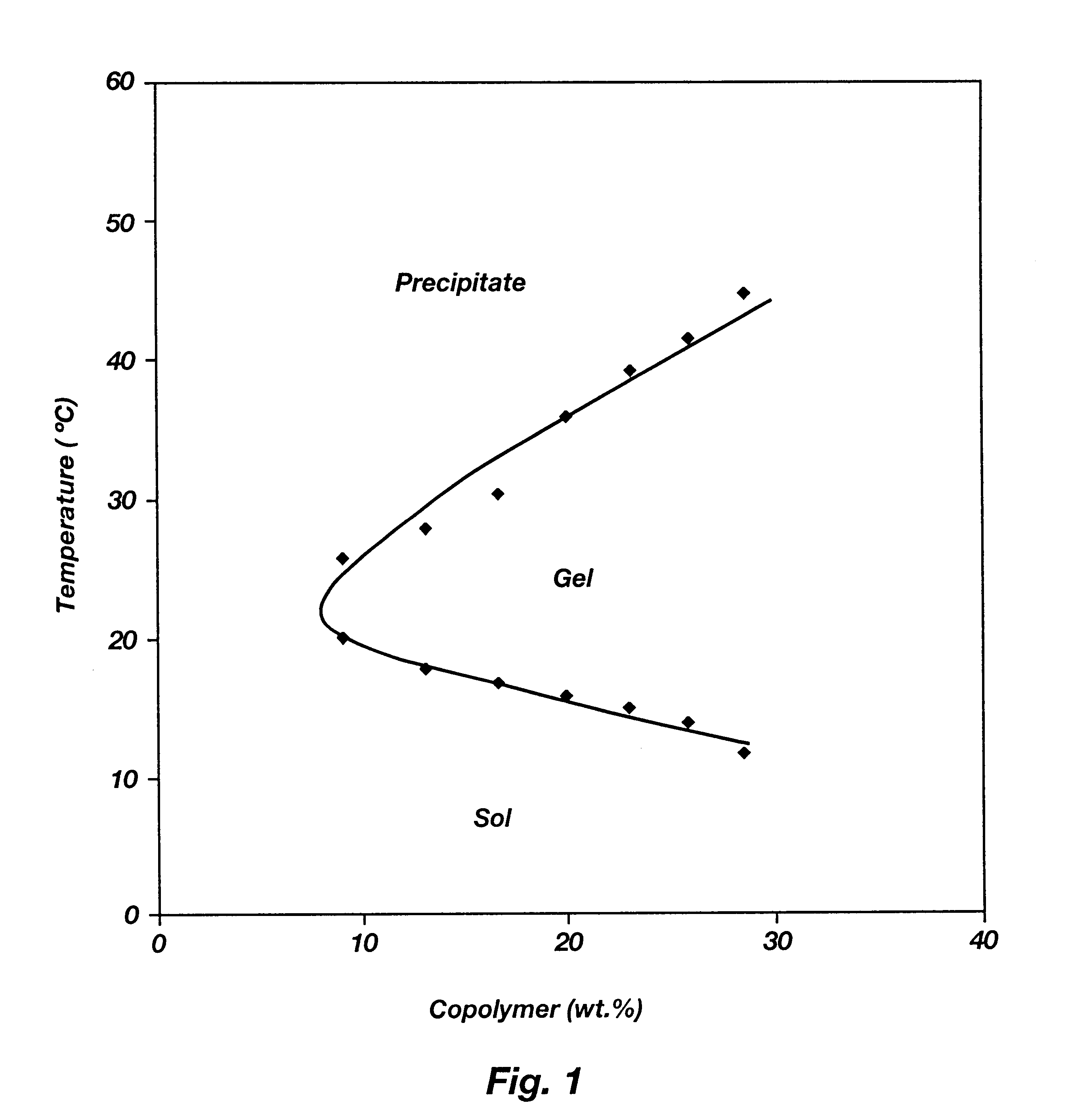

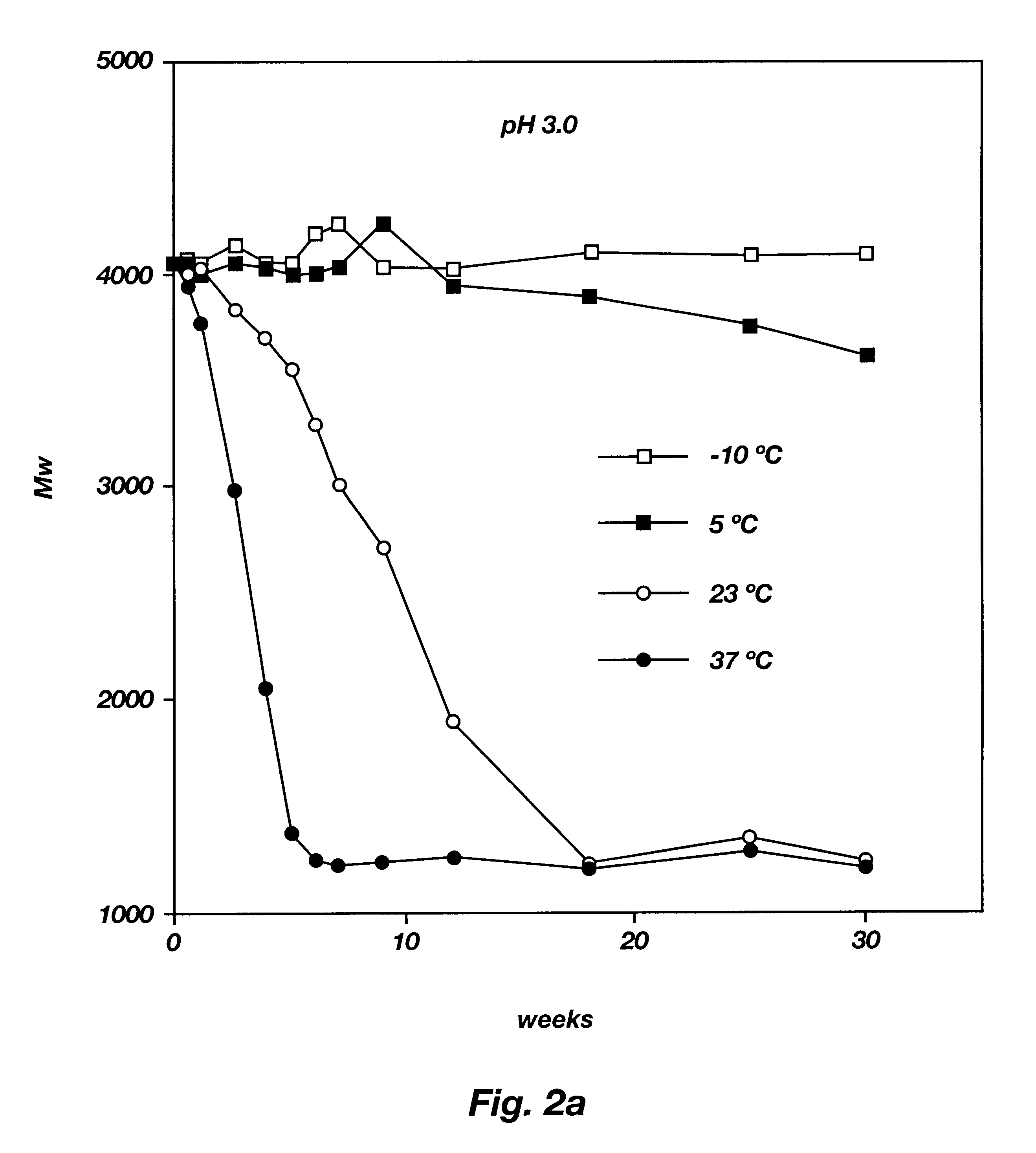

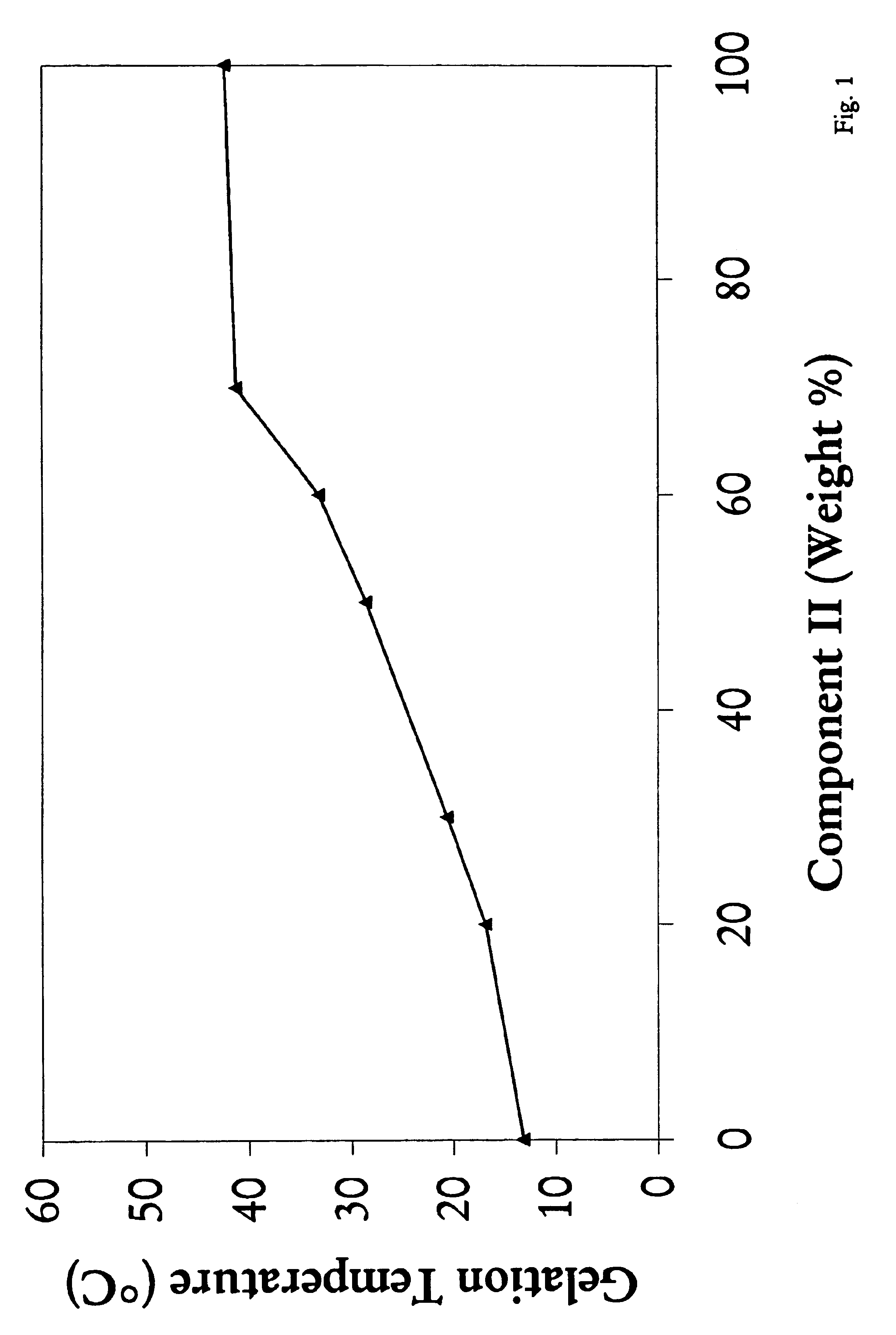

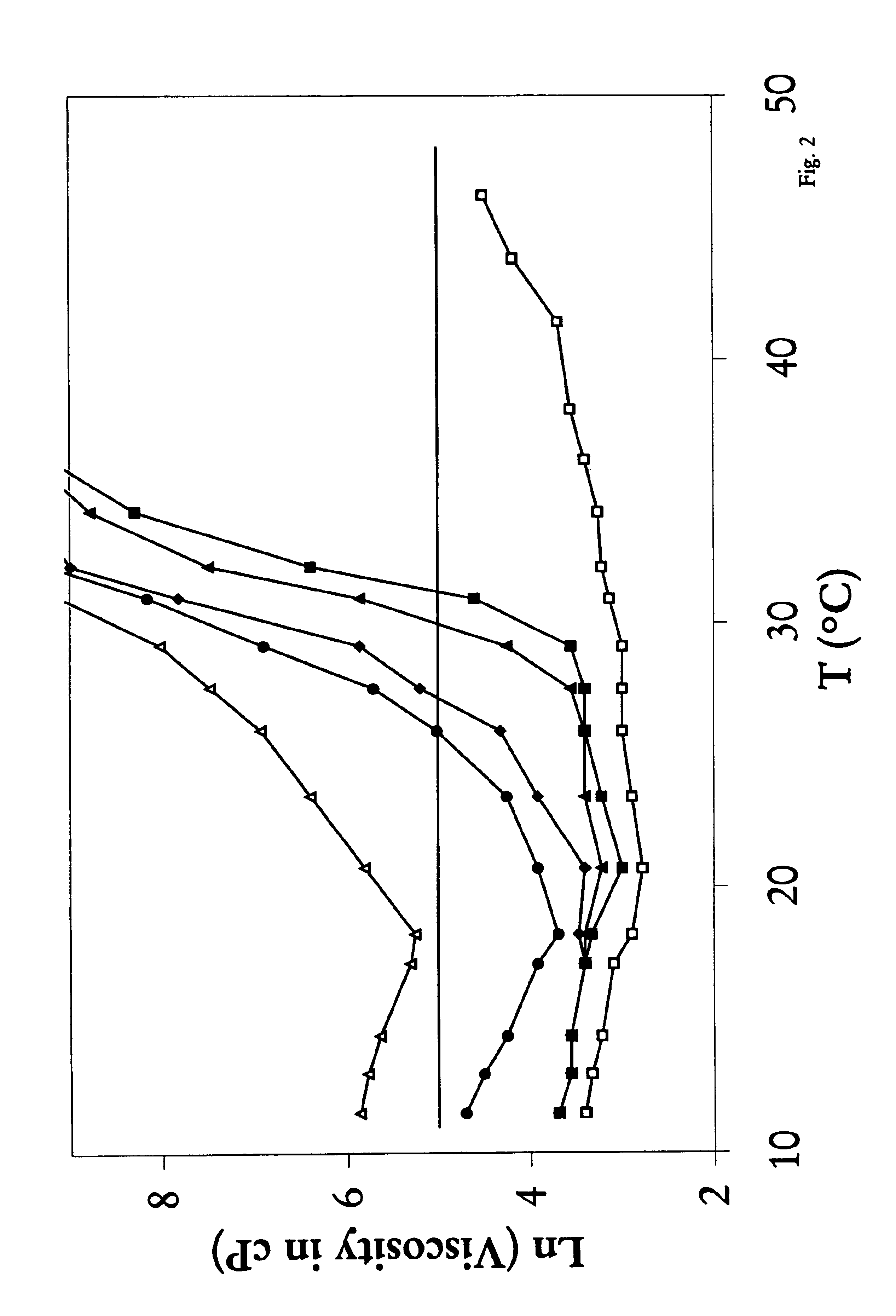

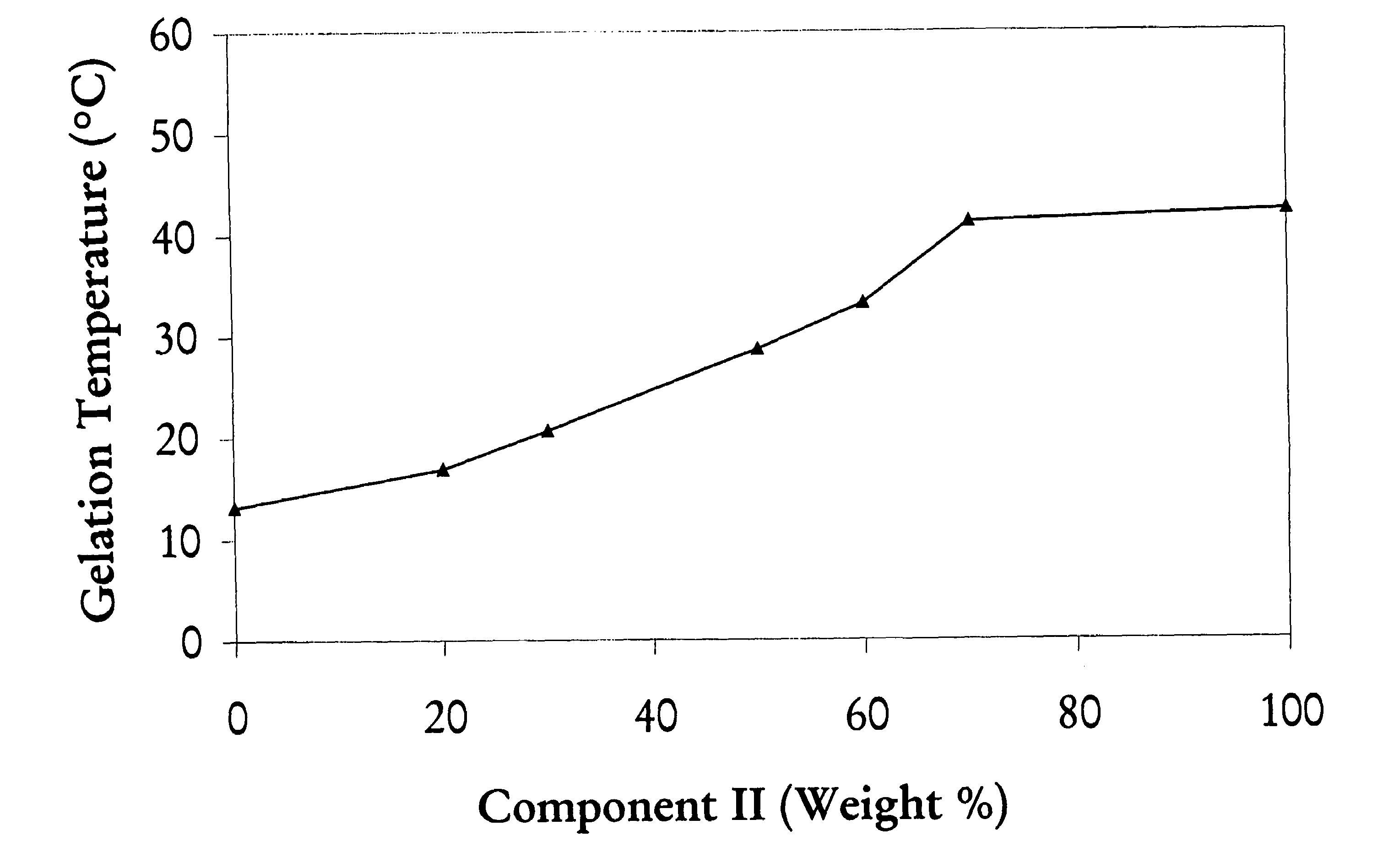

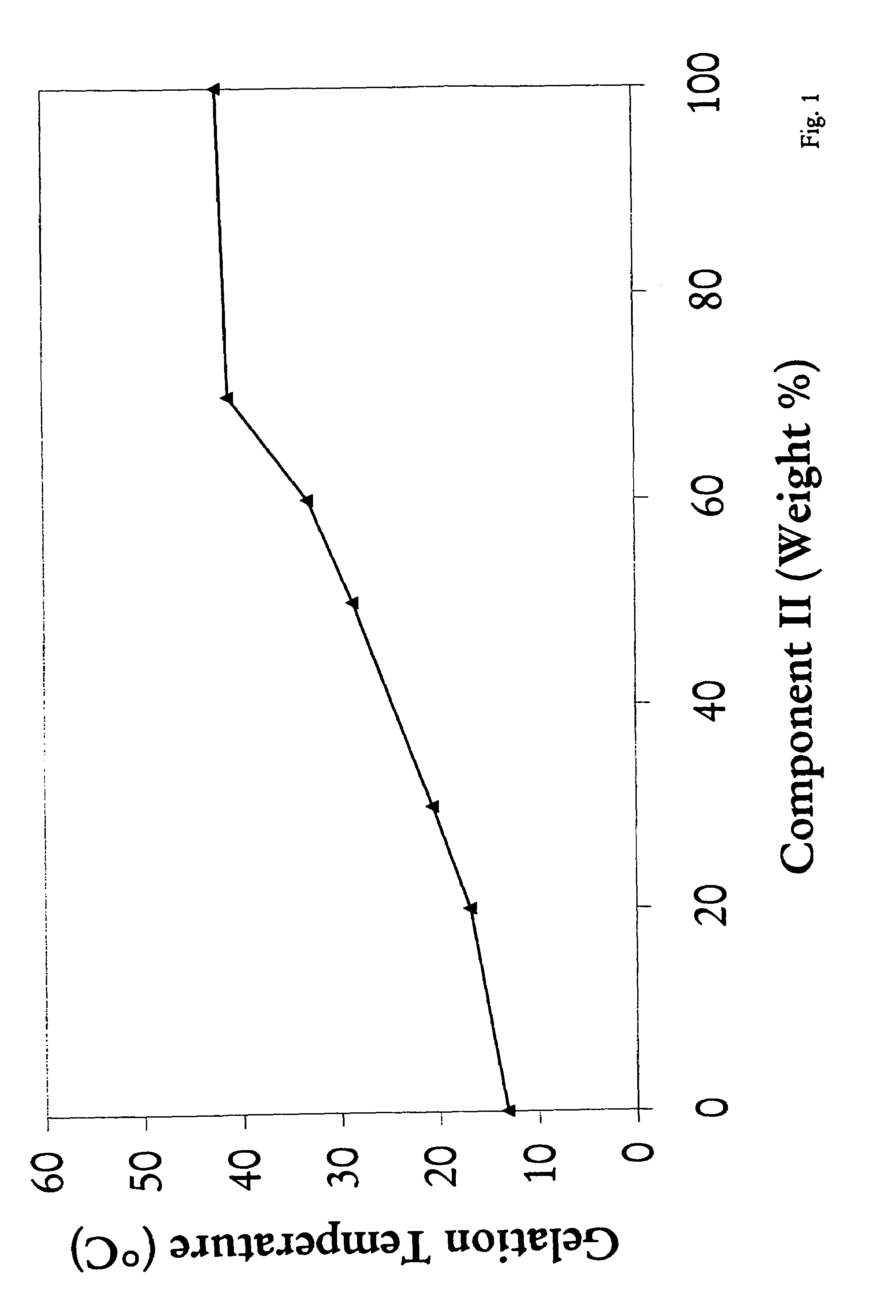

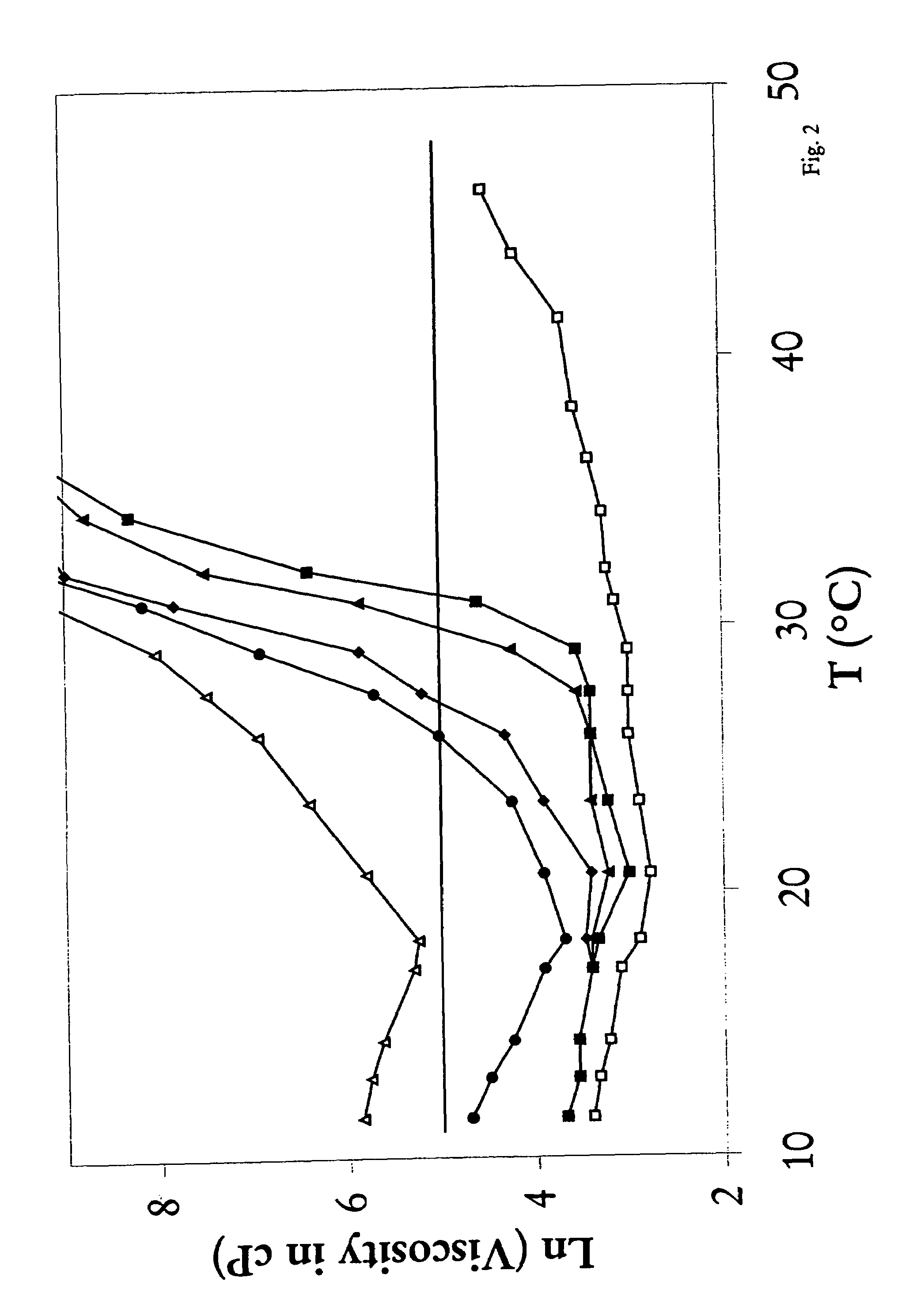

A water soluble, biodegradable ABA- or BAB-type tri-block polymer is disclosed that is made up of a major amount of a hydrophobic A polymer block made of a biodegradable polyester and a minor amount of a hydrophilic polyethylene glycol(PEG) B polymer block, having an overall average molecular weight of between about 2000 and 4990, and that possesses reverse thermal gelation properties. Effective concentrations of the tri-block polymer and a drug may be uniformly contained in an aqueous phase to form a drug delivery composition. At temperatures below the gelation temperature of the tri-block polymer the composition is a liquid and at temperatures at or above the gelation temperature the composition is a gel or semi-solid. The composition may be administered to a warm-blooded animal as a liquid by parenteral, ocular, topical, inhalation, transdermal, vaginal, transurethral, rectal, nasal, oral, pulmonary or aural delivery means and is a gel at body temperature. The composition may also be administered as a gel. The drug is released at a controlled rate from the gel which biodegrades into non-toxic products. The release rate of the drug may be adjusted by changing various parameters such as hydrophobic / hydrophilic component content, polymer concentration, molecular weight and polydispersity of the tri-block polymer. Because the tri-block polymer is amphiphilic, it functions to increase the solubility and / or stability of drugs in the composition.

Owner:KIM PH D SUNG WAN +2

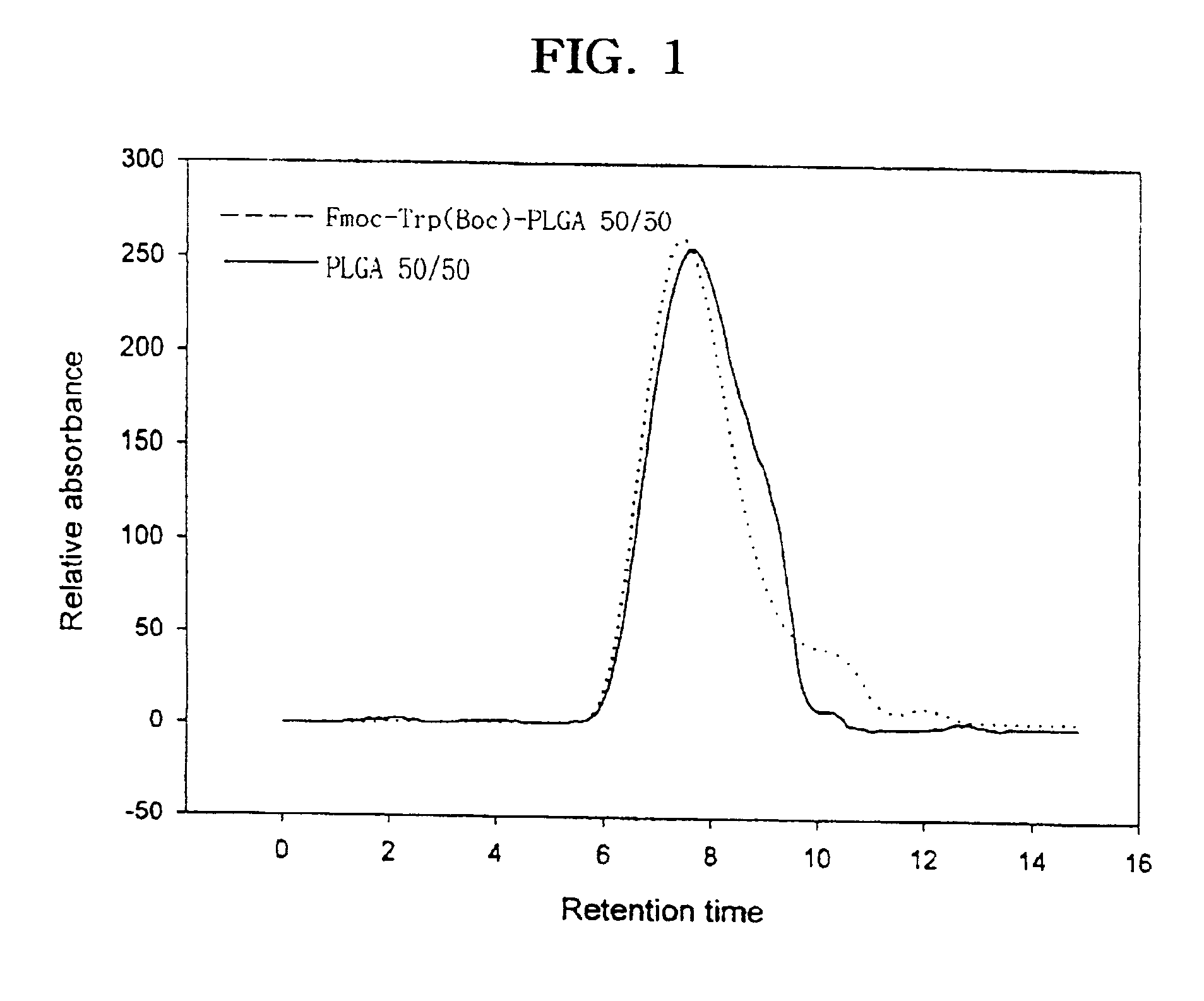

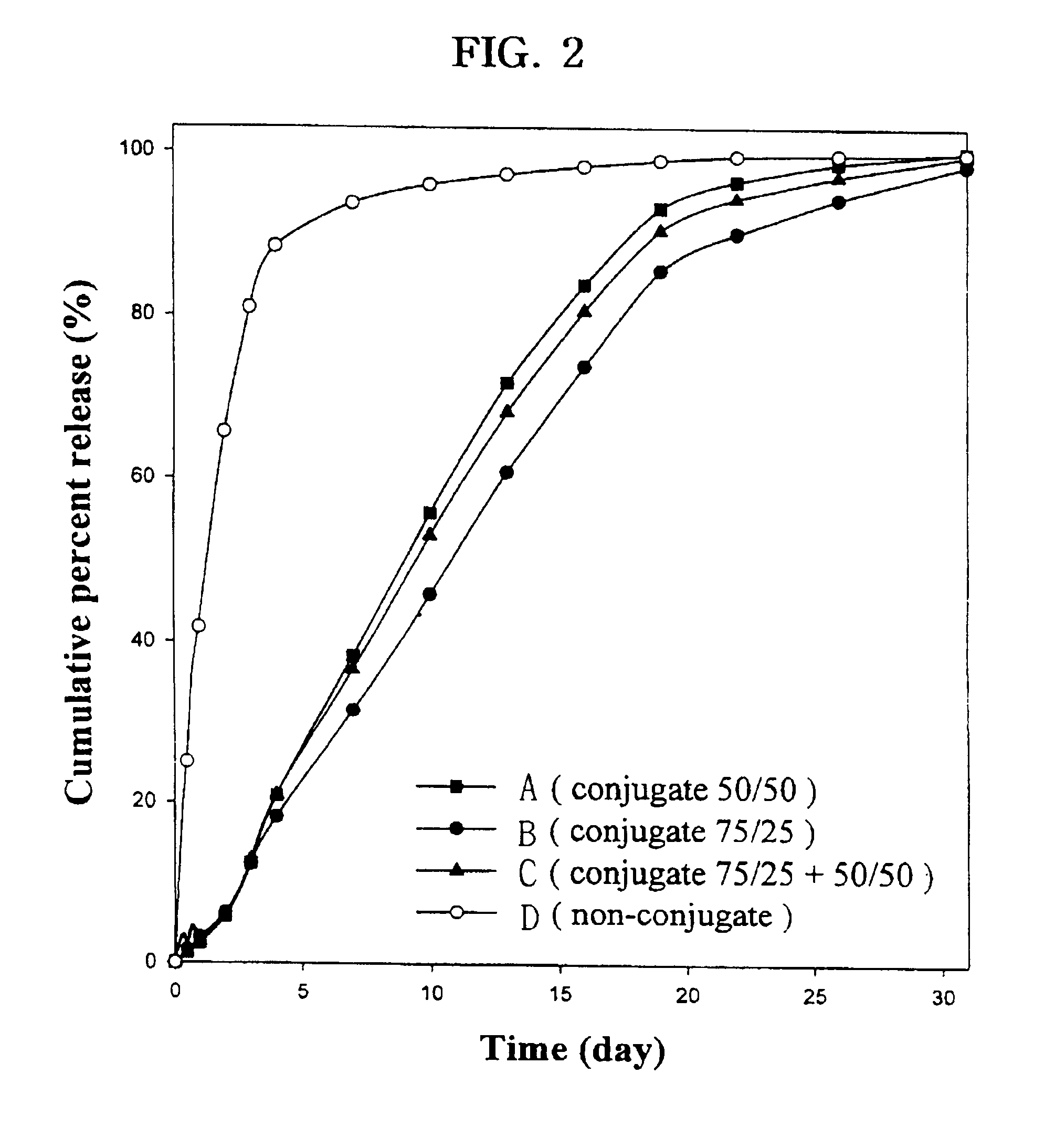

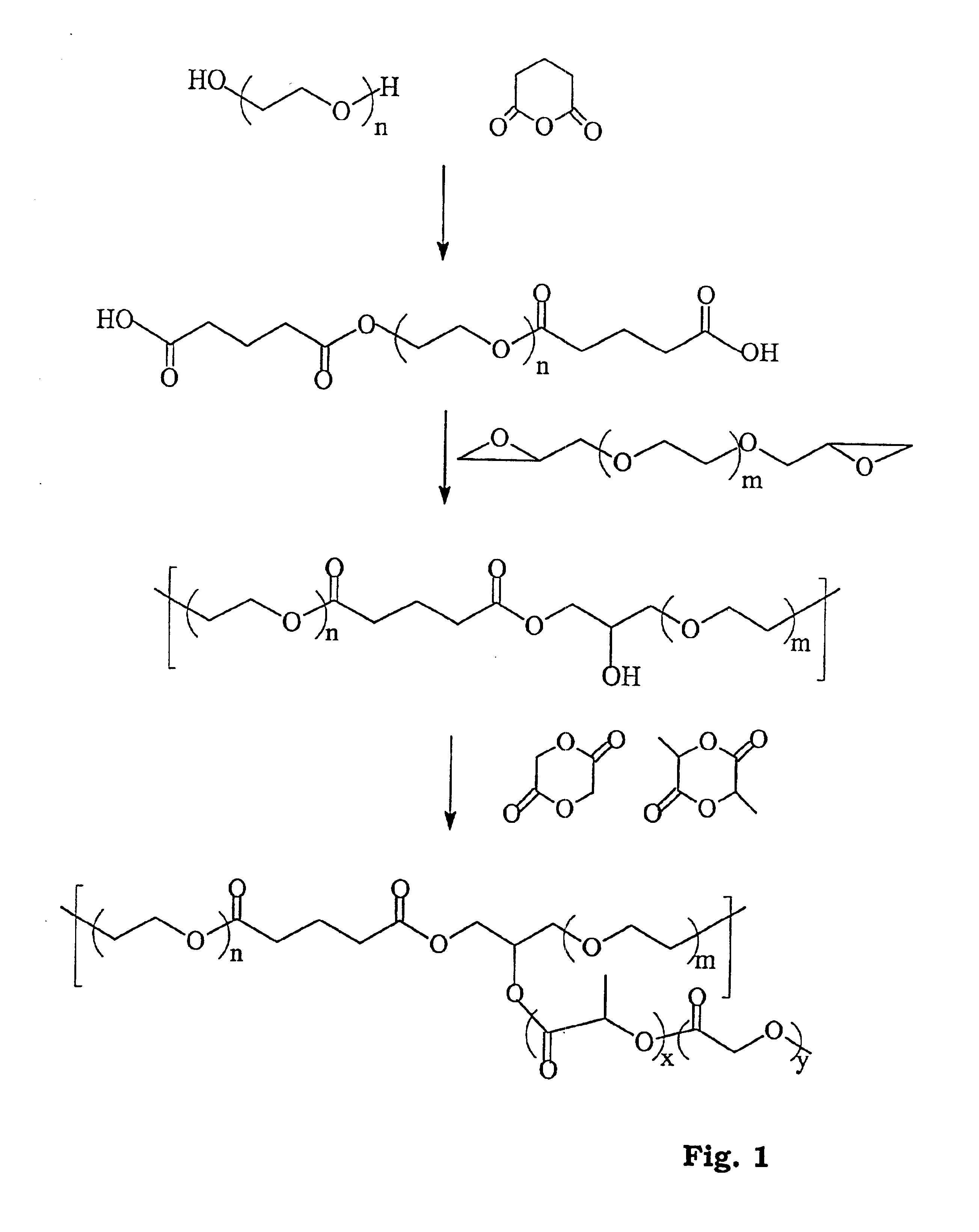

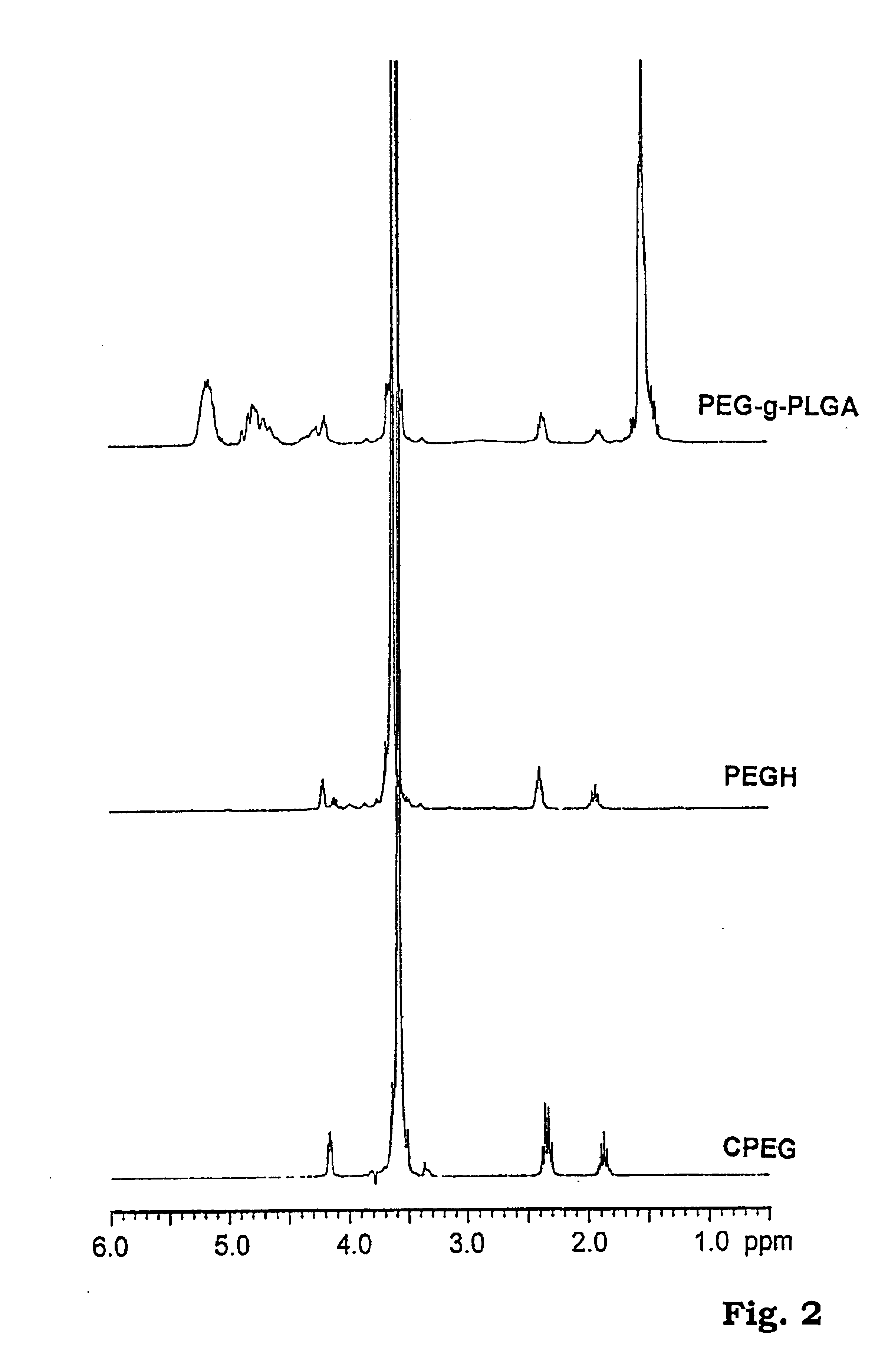

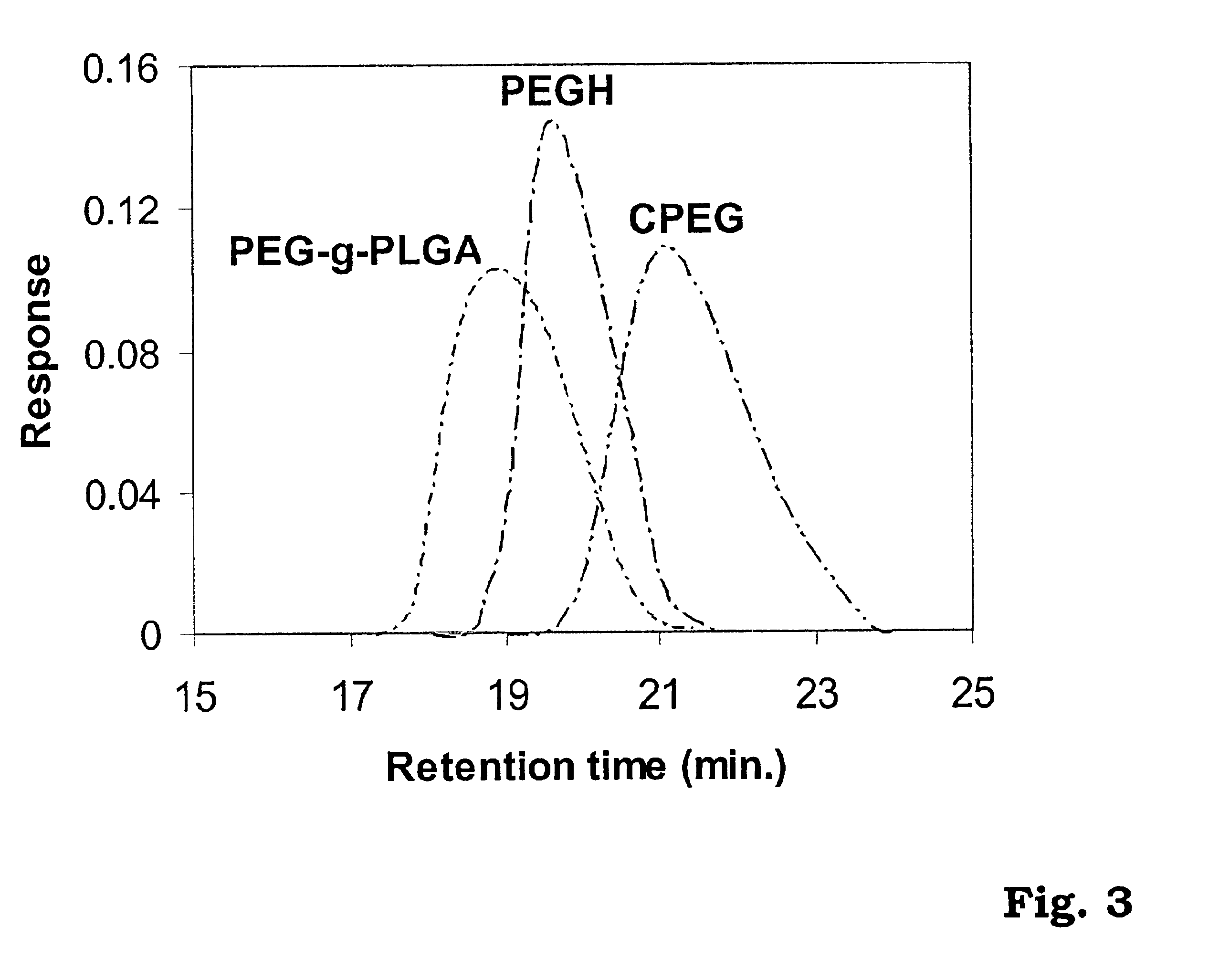

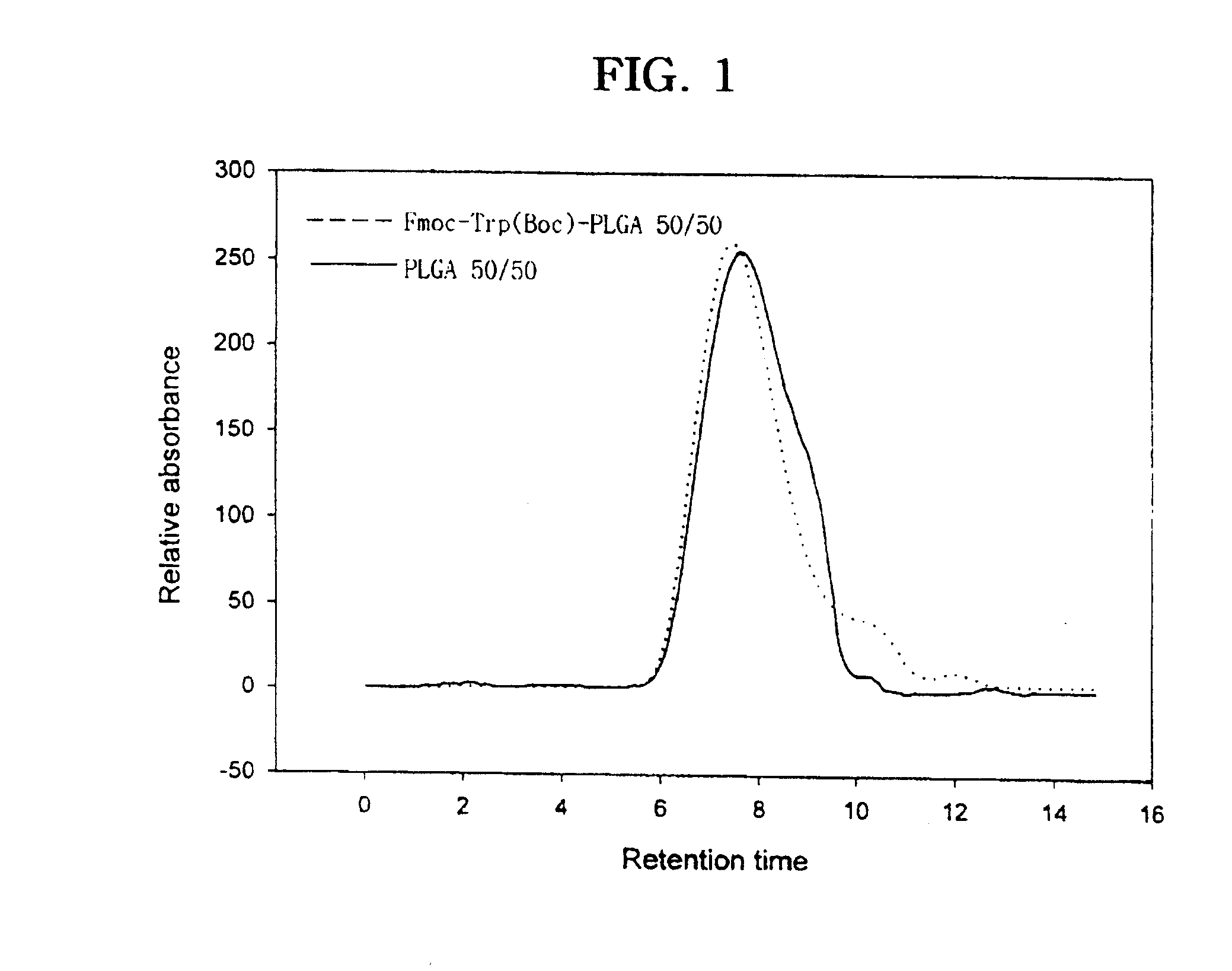

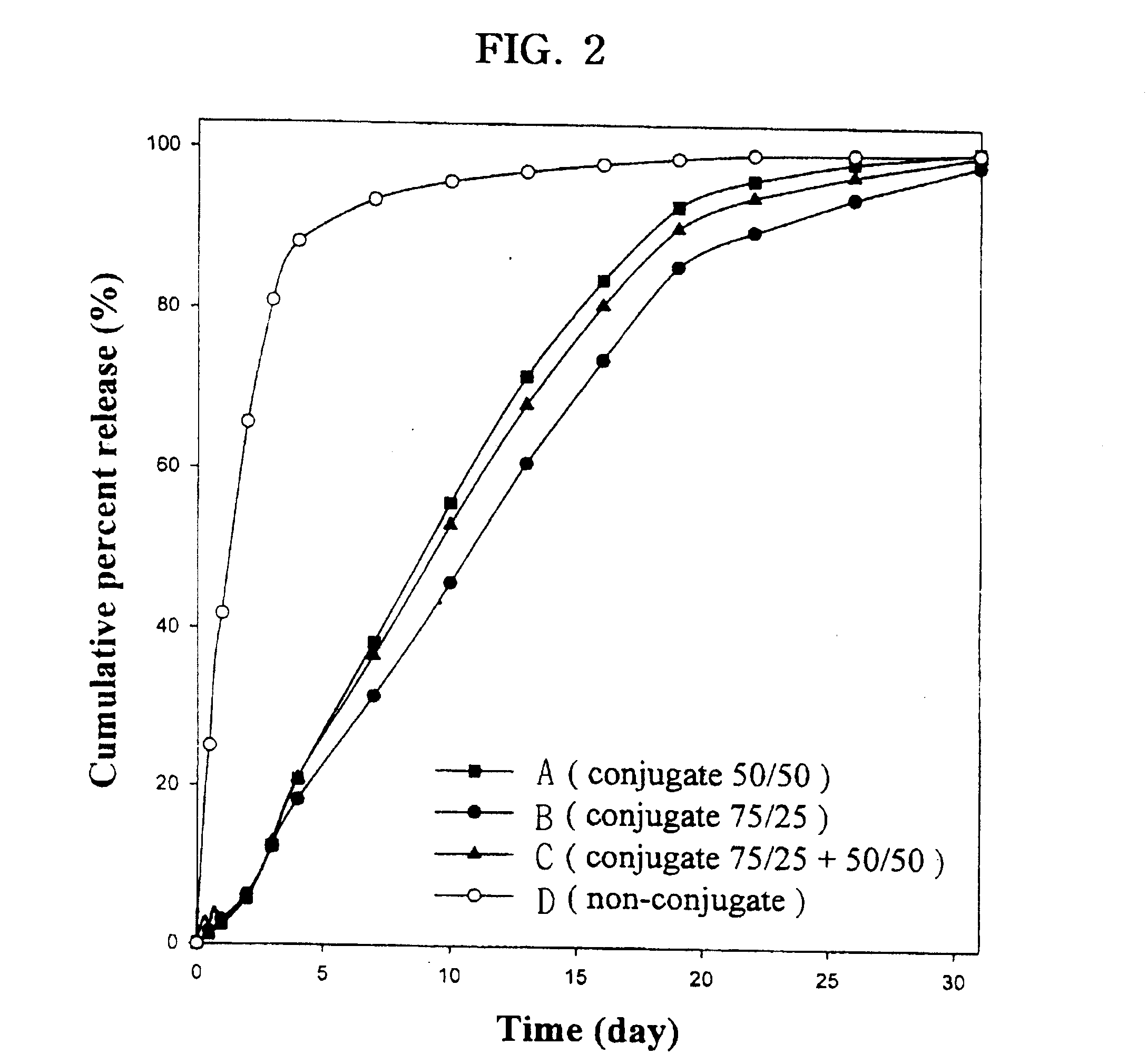

Controlled drug delivery system using the conjugation of drug to biodegradable polyester

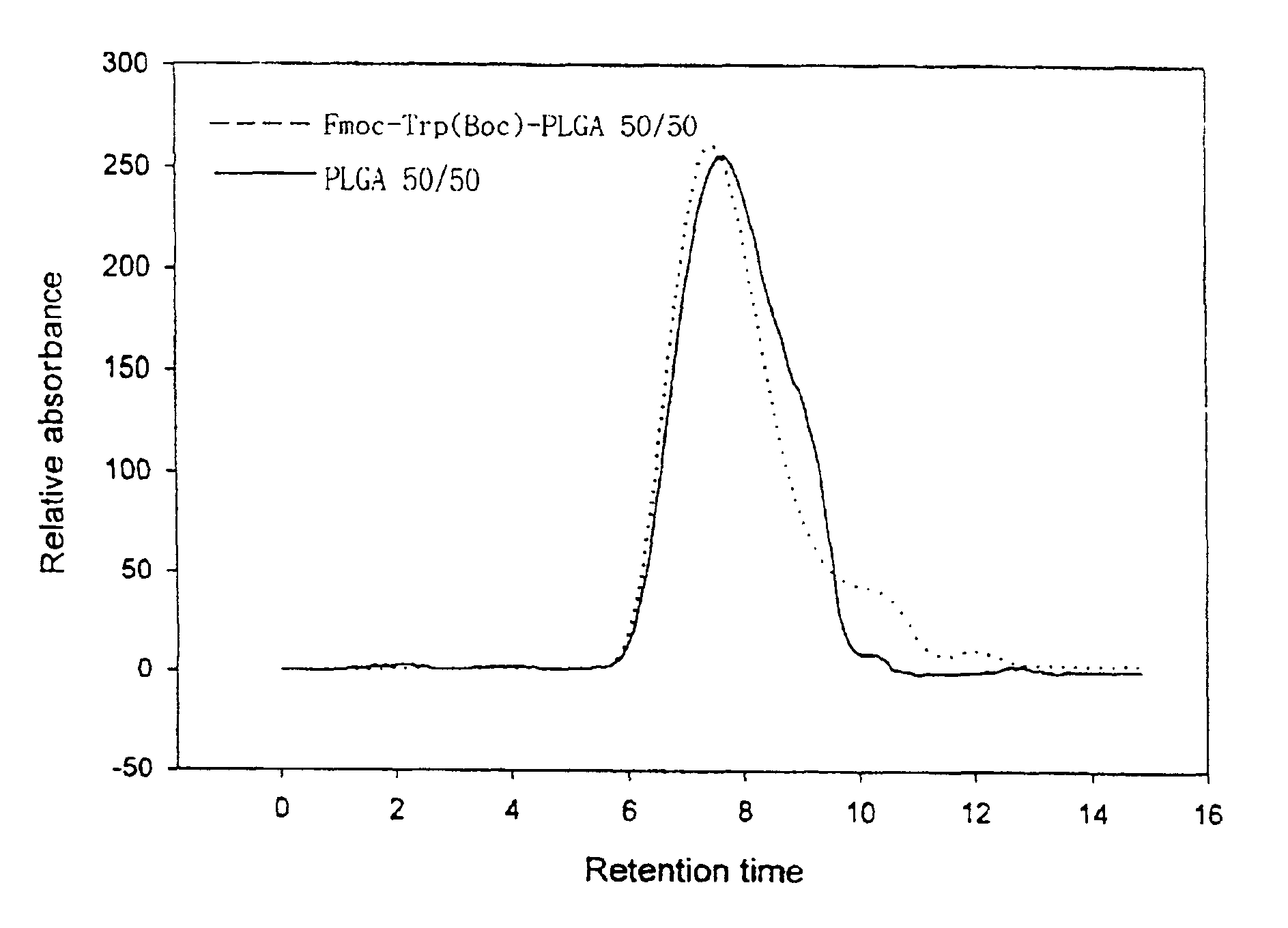

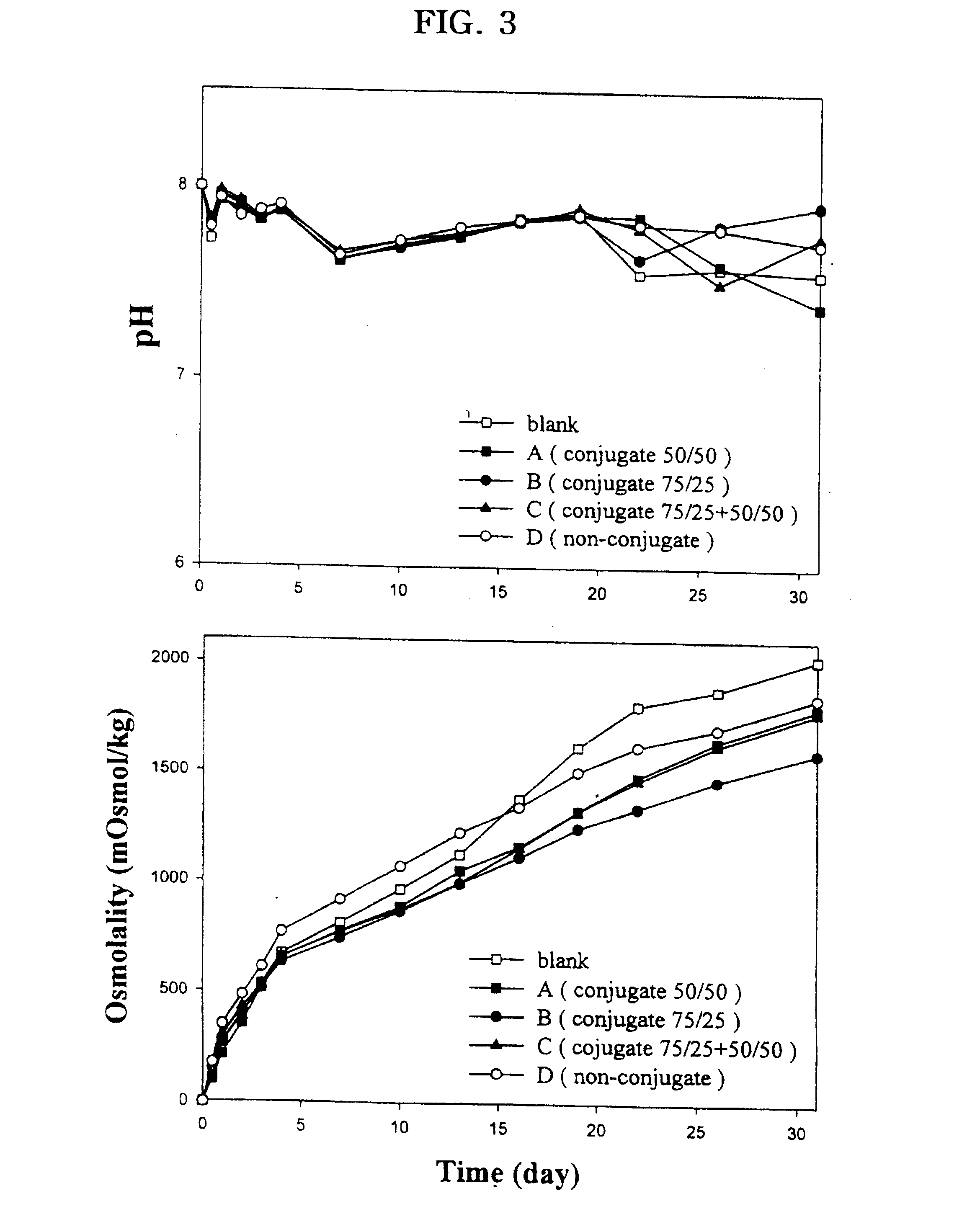

The present invention relates to a molecular sustained controlled release system constructed by the conjugation of molecules to be released with biodegradable polyester polymer via covalent bond and method for preparation thereof. In accordance with the present invention, the system may be formulated into microspheres, nanoparticles, or films. The molecular release rate from the above system can be regulated to be proportional to the chemical degradation rate of the biodegradable polyester polymers, resulting in near zero order kinetics profile of release without showing a burst effect, Moreover, a high loading efficiency of hydrophilic drugs can be achieved.

Owner:MOGAM BIOTECH RES INST +1

Biodegradable diblock copolymers having reverse thermal gelation properties and methods of use thereof

InactiveUS20060034889A1Good drug release propertiesPowder deliveryPharmaceutical non-active ingredientsPolymer sciencePolyethylene glycol

A water soluble, biodegradable AB type diblock copolymer which comprises 61 to 85% by weight of a biodegradable, hydrophobic A block comprising a biodegradable polyester, and 15 to 39% by weight of a biocompatible, hydrophilic B block comprising a monofunctional polyethylene glycol(PEG) having a number average molecular weight less than 5000, and wherein said diblock copolymer has a number average molecular weight less than 15000 and possesses reverse thermal gelation properties.

Owner:PROTHERICS SALTLAKE CITY INC

Biodegradable polyesters

InactiveUS6120895AMonocomponent copolyesters artificial filamentPolyurea/polyurethane coatingsFiberPolymer science

PCT No. PCT / EP97 / 04908 Sec. 371 Date Mar. 17, 1999 Sec. 102(e) Date Mar. 17, 1999 PCT Filed Sep. 19, 1997 PCT Pub. No. WO98 / 12242 PCT Pub. Date Mar. 20, 1998Biodegradable polyesters based on A) 95-99.99 mol % of at least one polyester A containing as monomeric building blocks of an acid component comprising a11) 20-95 mol % of at least one aliphatic or cycloaliphatic dicarboxylic acid or its ester-forming derivative and a12) 5-80 mol % of at least one aromatic dicarboxylic acid or its ester-forming derivative and at least one dihydroxy compound or at least one amino alcohol or their mixtures, and B) 0.01-5 mol % of a mixture comprising mono-, bi-, tri-, tetra- and higher-nuclear isocyanurates or corresponding compounds containing two, three or four functional groups capable of reacting with the end groups of polyester A, or mixtures of the isocyanurates and the corresponding compounds, as well as molding compositions comprising said polyesters, their manufacture and their use in the manufacture of moldings, filsm, fibers and coatings.

Owner:BASF AG

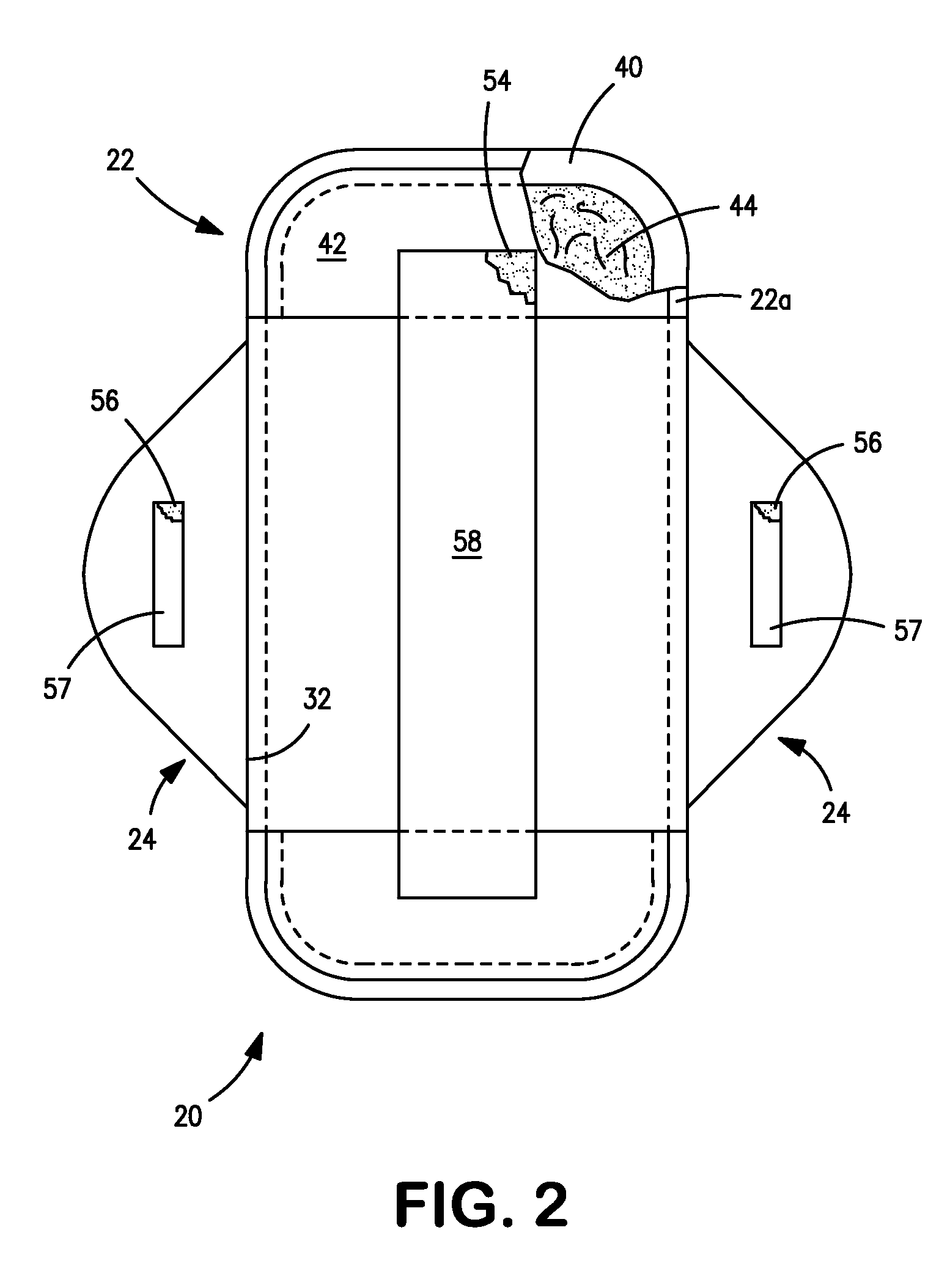

Mixtures of various triblock polyester polyethylene glycol copolymers having improved gel properties

InactiveUS7018645B1Good curative effectMinimize side effectsPowder deliveryPeptide/protein ingredientsPolymer scienceErosion rate

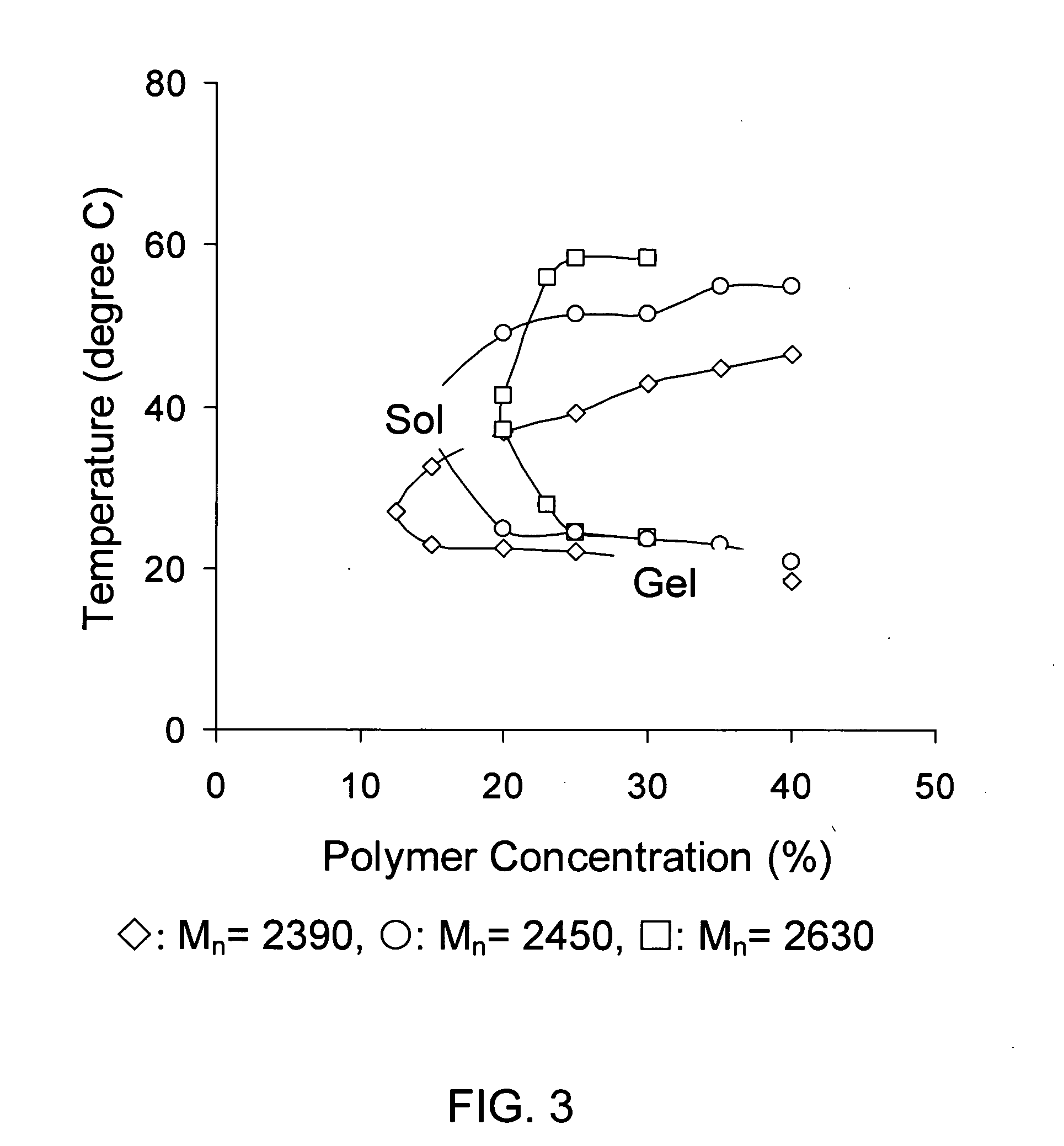

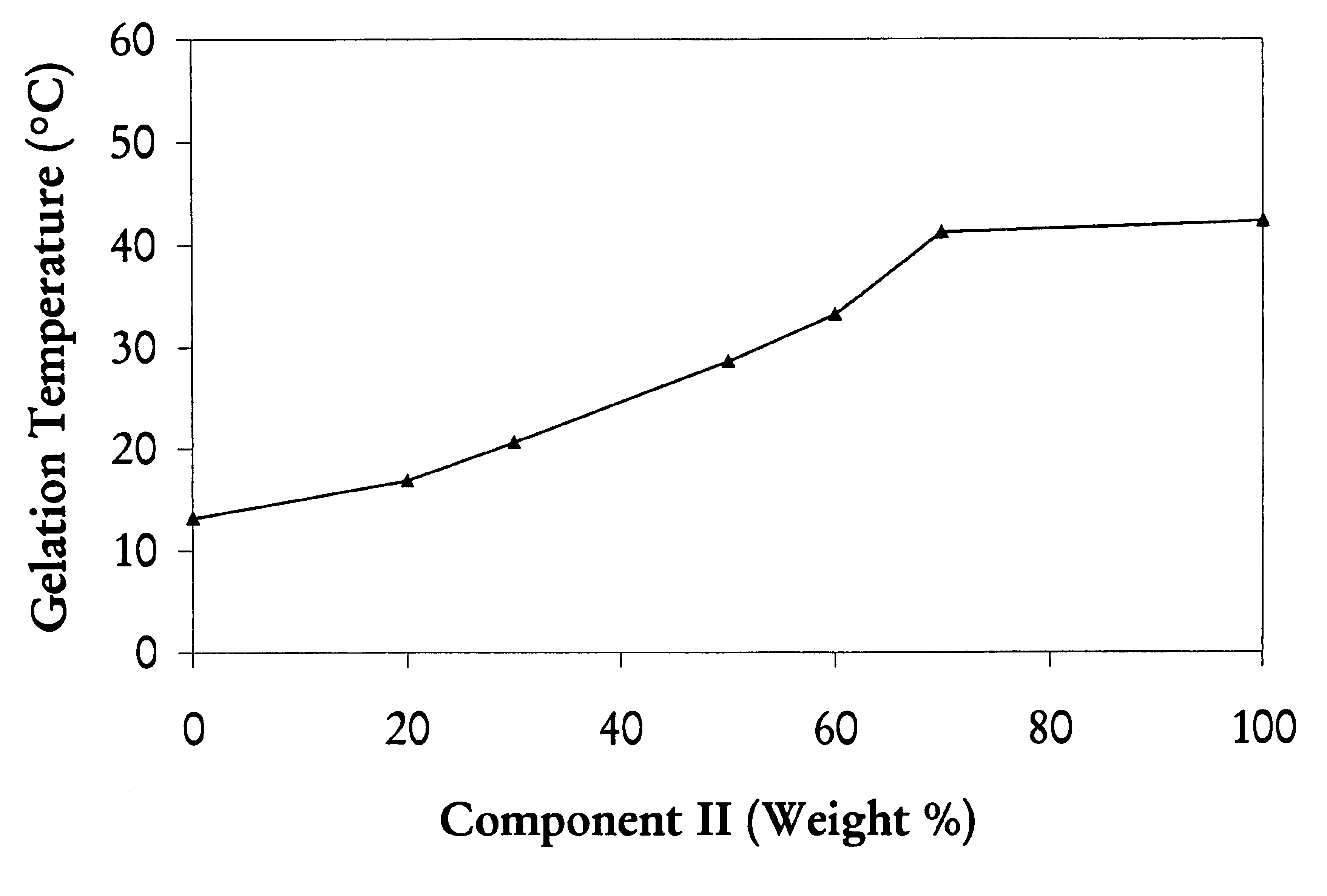

A water soluble, biodegradable reverse thermal gelation system comprising a mixture of at least two types of tri-block copolymer components is disclosed. The tri-block copolymer components are made of a hydrophobic biodegradable polyester A-polymer block and a hydrophilic polyethylene glycol B-polymer block. The drug release and gel matrix erosion rates of the biodegradable reverse thermal gelation system may be modulated by various parameters such as the hydrophobic / hydrophilic component contents, polymer block concentrations, molecular weights and gelation temperatures, and weight ratios of the tri-block copolymer components in the mixture.

Owner:BTG INT LTD

Biodegradable polyester resin composition, preparation method therefor, and foamed article and molded article produced therefrom

A biodegradable polyester resin composition which comprises a thermoplastic polymer comprising 100 parts by mass of an aliphatic polyester (A) and 0.01 to 5 parts by mass of a (meth)acrylic ester (B1) and / or a glycidyl ether (B2, and has a gelation index (1) of not lower than 0.1% and a gelation index (2) of not higher than 0.5%.

Owner:UNITIKA LTD

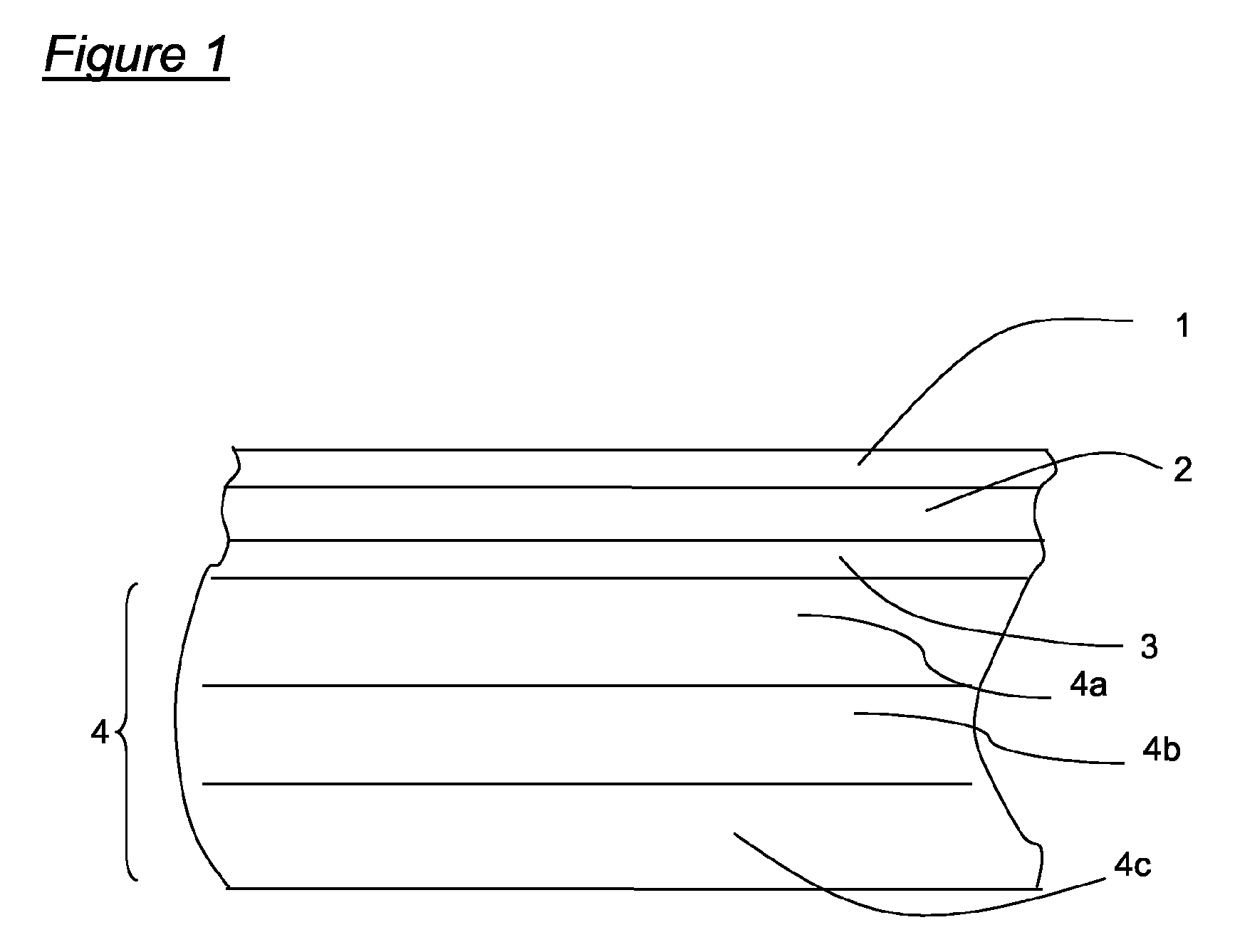

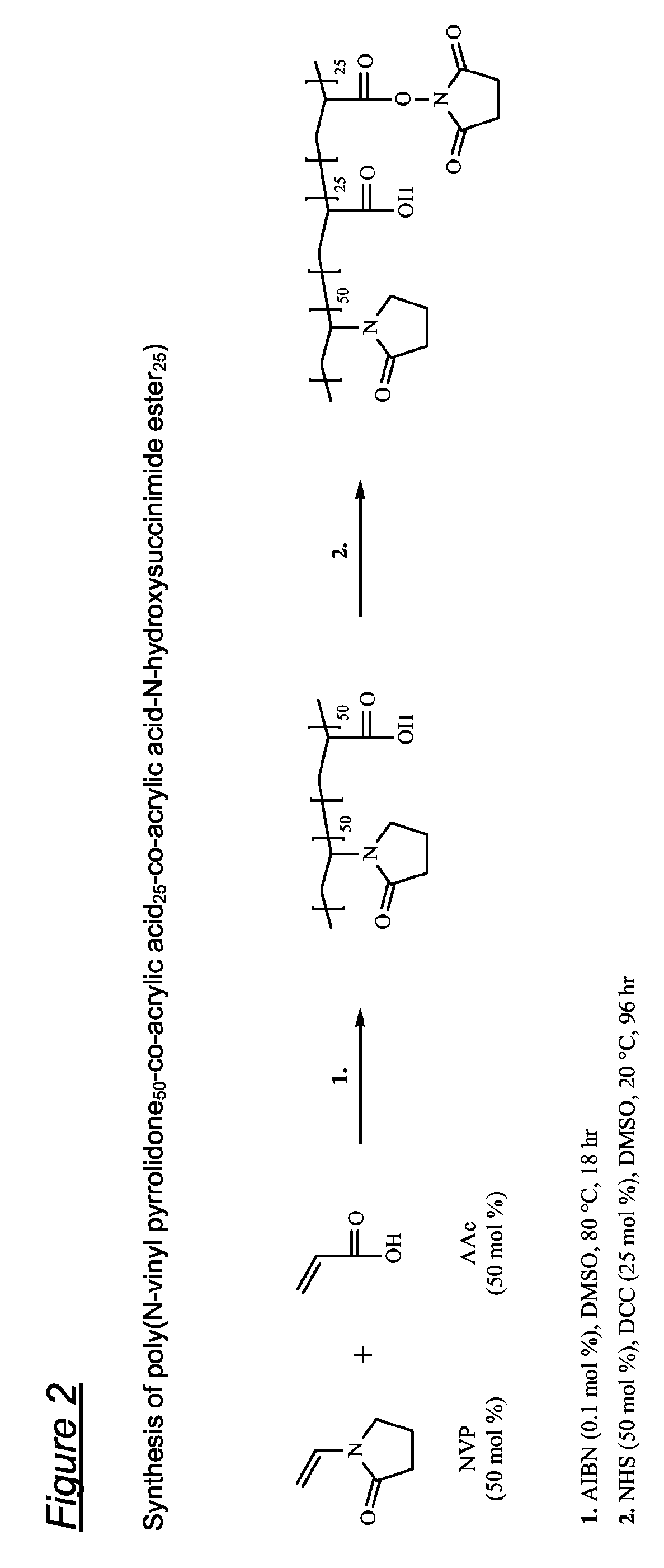

Tissue-adhesive materials

A multi-lamellar tissue-adhesive sheet comprises a structural layer or laminate conjoined to a tissue-contacting layer. The structural layer or laminate comprises one or more synthetic polymers having film-forming properties, and the tissue-contacting layer of material contains tissue-reactive groups. The synthetic polymers having film-forming properties are preferably biodegradable polyesters, and the tissue-reactive groups are most preferably NHS-ester groups.

Owner:TISSUEMED LTD

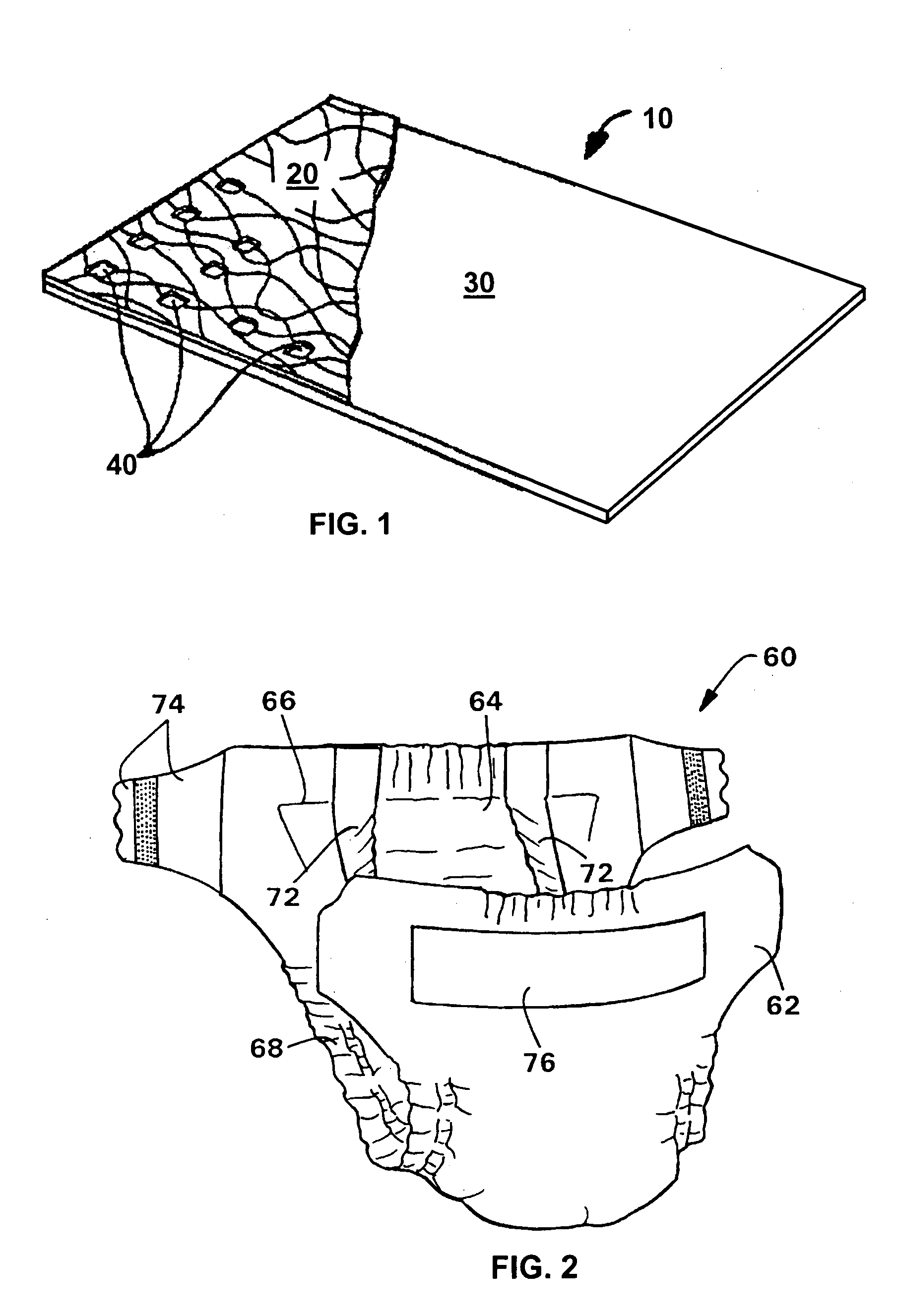

Water-sensitive biodegradable film

ActiveUS20080147034A1Film/foil adhesivesSynthetic resin layered productsWater dispersiblePolymer science

A film that is biodegradable and water-sensitive (e.g., water-soluble, water-dispersible, etc.) in that it loses its integrity over time in the presence of water is provided. More specifically, the film contains a combination of a biodegradable polyester and a water-sensitive thermoplastic starch. The desired water-sensitive attributes of film may be achieved in the present invention by selectively controlling a variety of aspects of the film construction, such as the nature of the components employed, the relative amount of each component, the manner in which the film is formed, and so forth.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Mixtures of various triblock polyester polyethylene glycol copolymers having improved gel properties

InactiveUS7135190B2Improve gelationGood drug release propertiesPowder deliveryGogglesPolymer scienceErosion rate

A water soluble, biodegradable reverse thermal gelation system comprising a mixture of at least two types of tri-block copolymer components is disclosed. The tri-block copolymer components are made of a hydrophobic biodegradable polyester A-polymer block and a hydrophilic polyethylene glycol B-polymer block. The drug release and gel matrix erosion rates of the biodegradable reverse thermal gelation system may be modulated by various parameters such as the hydrophobic / hydrophilic component contents, polymer block concentrations, molecular weights and gelation temperatures, and weight ratios of the tri-block copolymer components in the mixture.

Owner:BTG INT LTD

Thermogelling biodegradable aqueous polymer solution

InactiveUS6841617B2Low viscosityEasily manipulatedPowder deliveryPeptide/protein ingredientsPolymer sciencePolyethylene glycol

Disclosed is a thermogelling biodegradable aqueous polymer solution useful in providing a bioactive agent delivery system. The present invention provides a thermogelling biodegradable aqueous polymer solution with a polyethylene glycol (PEG) block and a biodegradable polyester block, where the blocks are linked to form a polymer of a general structure comprising the formula of An(B), where n is greater than 2 and A is selected from the group consisting of a polyethylene glycol block and a biodegradable polyester block, B is selected from the group consisting of a polyethylene glycol block and a biodegradable polyester block, and A is different from B.

Owner:BATTELLE MEMORIAL INST

Biodegradable polymer compositions for a breathable film

The invention provides a biodegradable polymer composition for a breathable film which comprises a biodegradable polyester such as polylactic acid, a biodegradable copolyester such as an aliphatic / aromatic copolyester, and a filler such as calcium carbonate. These compounds are melt blended and film formed and the film is then stretched in a monoaxial or biaxial direction to enhance pore formation and hence also enhance the breathability of the film. The water vapor transmission rate (WVTR) of the film is typically greater than 3,000 grams per square meter per day so that the film is suitable for use in disposable articles such as wipes, diapers, training pants, absorbent underpants, adult incontinence garments, feminine hygiene products, medical garments, bandages and the like.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Biodegradable resin composition for molding and object molded or formed from the same

Owner:UNITIKA LTD

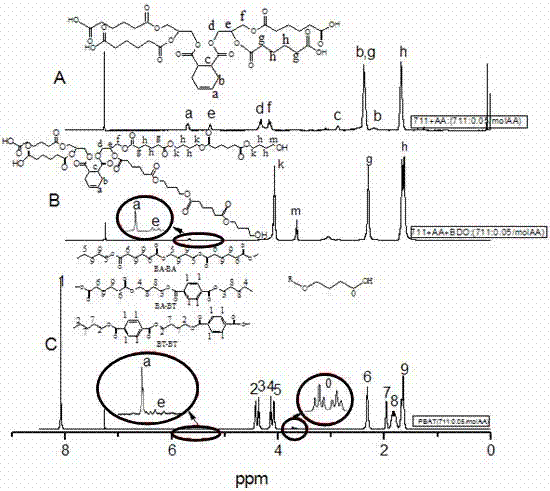

Controlled drug delivery system using the conjugation of drug to biodegradable polyester

The present invention relates to the molecular sustained controlled release system constructed by the conjugation of molecules to be released with biodegradable polyester polymer via covalent bond and method for preparation thereof. In accordance with the present invention, the system may be formulated into microspheres, nanoparticles, or films. The molecular release rate from the above system can be regulated to be proportional to the chemical degradation rate of the biodegradable polyester polymers, resulting in near zero order kinetics profile of release without showing a burst effect. Moreover, the high loading efficiency of hydrophilic drugs can be achieved.

Owner:OH JONG EUN +3

Ternary mixture of biodegradable polyesters and products obtained therefrom

InactiveUS6841597B2RapidityImproves UV stabilitySynthetic resin layered productsPaper coatingPolymer scienceBiodegradable polyester

The invention relates to a mixture of biodegradable polyesters comprising: (A) a polyhydroxy acid of the poly-ε-caprolactone type and its copolymers, (B) aliphatic polyester, and (C) a polymer of polylactic acid, in which the concentration of (A) varies with respect to (A+B) in the range between 40 and 70% by weight, and the concentration of (C) with respects to (A+B+C) lies between 2 and 30%.

Owner:NOVAMONT SPA

Biodegradable resin composition for molding and molded object obtained by molding the same

InactiveUS20050043462A1Improve heat resistanceHigh mechanical strengthDyeing processPhosphoniumPhosphonium salt

A biodegradable resin composition and an object molded or formed from the composition. The resin composition comprises: 100 parts by weight of a biodegradable polyester resin comprising not smaller than 50% by weight of polylactic acid having a melting point of not lower than 160° C., the biodegradable polyester resin having a melt flow rate of 0.1 to 50 g / 10 min as measured under a load of 21.2 N at 190° C.; and 0.1 to 20 parts by weight of a phyllosilicate containing a primary, secondary or tertiary amine salt, a quaternary ammonium salt or a phosphonium salt ionically bonded between layers thereof.

Owner:UNITIKA LTD

Ternary mixture of biodegradable polyesters and products obtained therefrom

InactiveUS20040092672A1RapidityMaintain transparencyFlexible coversWrappersPolymer scienceBiodegradable polyester

The invention relates to a mixture of biodegradable polyesters comprising: (A) a polyhydroxy acid of the poly-epsilon-caprolactone type and its copolymers, (B) aliphatic polyester, and (C) a polymer of polylactic acid, in which the concentration of (A) varies with respect to (A+B) in the range between 40 and 70% by weight, and the concentration of (C) with respects to (A+B+C) lies between 2 and 30%.

Owner:NOVAMONT SPA

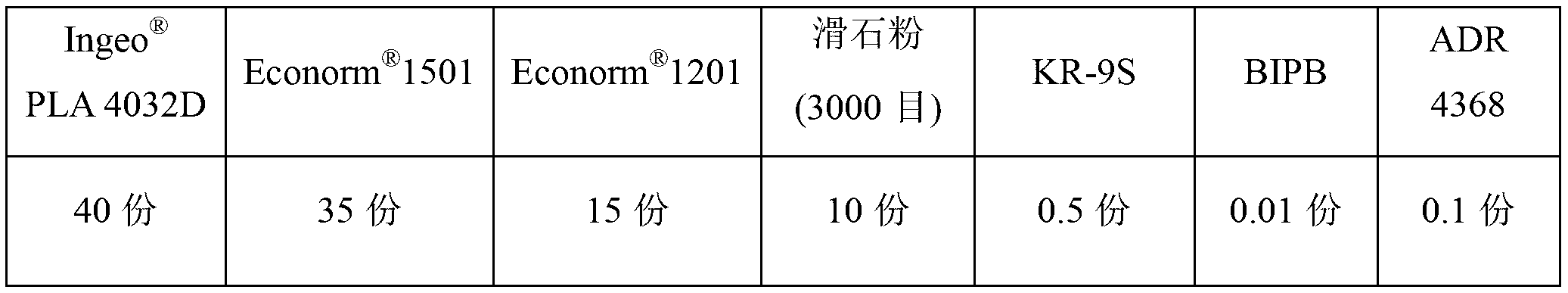

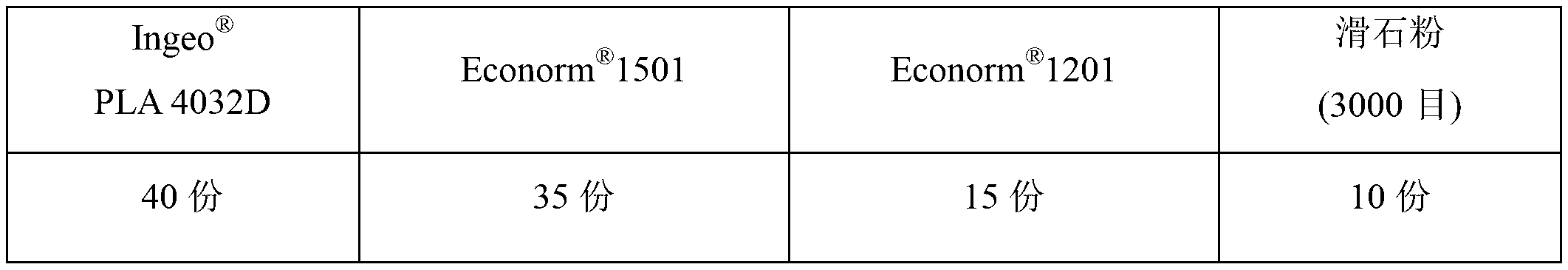

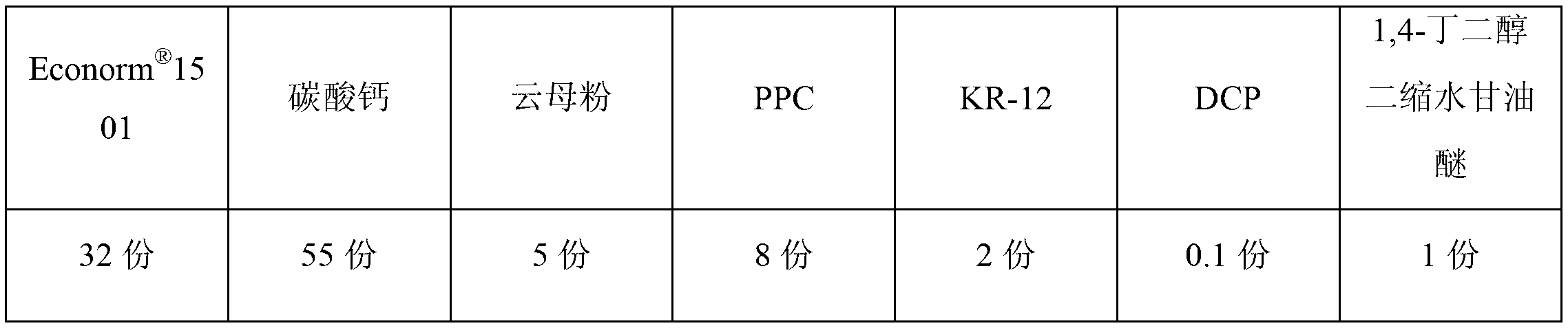

Method for increasing capacity of biodegradable polyester blend film

The invention relates to a biodegradable polyester blend film, and in particular relates to a method for increasing the capacity of a biodegradable polyester blend film. The method for increasing the capacity of the biodegradable polyester blend film comprises the steps of: adding a high-activity titanate coupling agent, a free radical cross-linking agent and a multi-epoxy group compound into a blending compound system of two or more than two biodegradable polyesters and an inorganic or organic filler; initiating and promoting transesterification, proper intermolecular cross-linking reaction and end-group chain extension in a double-screw extruder with the length-diameter ratio of more than or equal to 48 and the total kneading blocks of more than or equal to 16 under the action of high temperature and high shear strength, thus increasing the capacity of blending polyester. Through utilizing the double-screw extruder with the high length-diameter ratio and high shear strength and introducing the titanate coupling agent, the free radical cross-linking agent and the multi-epoxy group compound are introduced, on-line capacity increasing of a biodegradable polyester / filler blend compound system is carried out, so that the anisotropy of the mechanical property of the film is greatly improved.

Owner:山东悦泰生物新材料有限公司

Biodegradable Polyester Compositions

InactiveUS20090162683A1High impact strengthHigh transparencySynthetic resin layered productsThin material handlingMasterbatchBiodegradable polyester

The present invention relates to a biodegradable polyester composition having excellent transparency and impact strength, in particular to a biodegradable polyester composition comprising polylactic acid and a metal alkyl sulfonate as impact modifier as well as to a masterbatch composition useful in the preparation of the biodegradable polyester composition, and to films, sheets, profiles or moulded articles made thereof.

Owner:SUKANO FINANCE AG

Biodegradable water-sensitive films

A film that is biodegradable and water-sensitive (e.g., water-soluble, water-dispersible, etc.) in that it loses its integrity over time in the presence of water is provided. The film contains a biodegradable polyester, starch, water-soluble polymer, and plasticizer. The desired water-sensitive attributes of film may be achieved in the present invention by selectively controlling a variety of aspects of the film construction, such as the nature of the components employed, the relative amount of each component, the manner in which the film is formed, and so forth.

Owner:KIMBERLY-CLARK WORLDWIDE INC

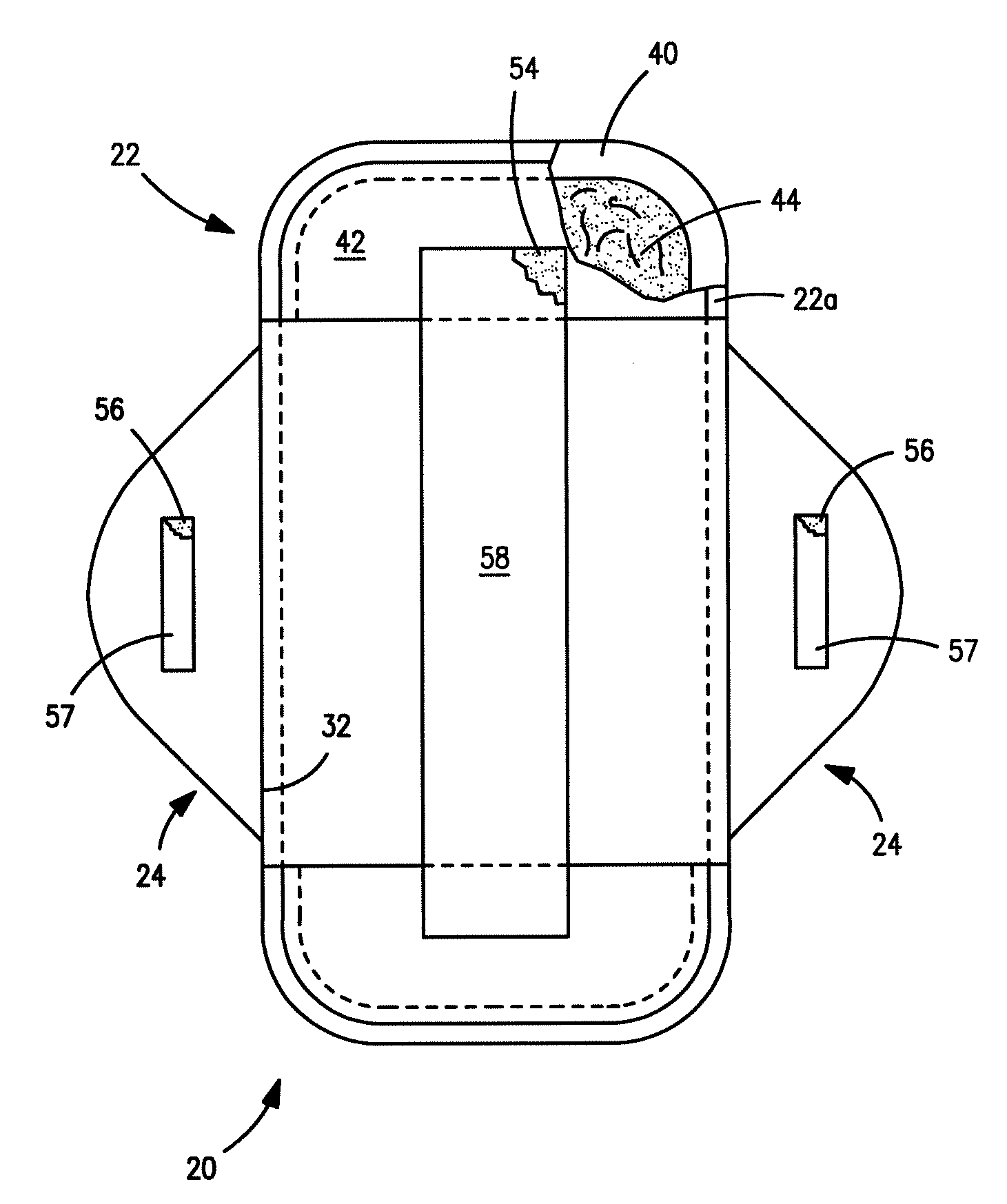

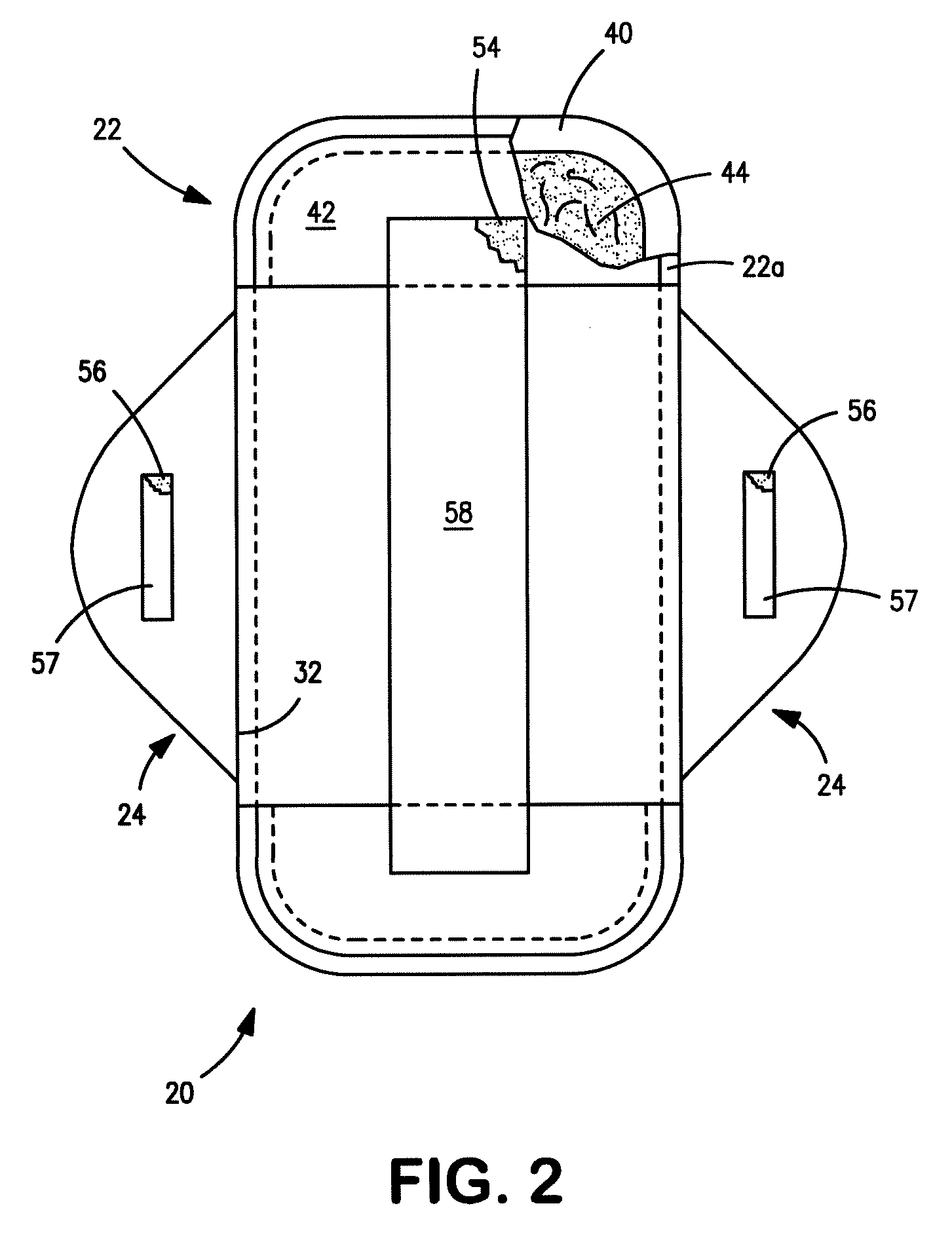

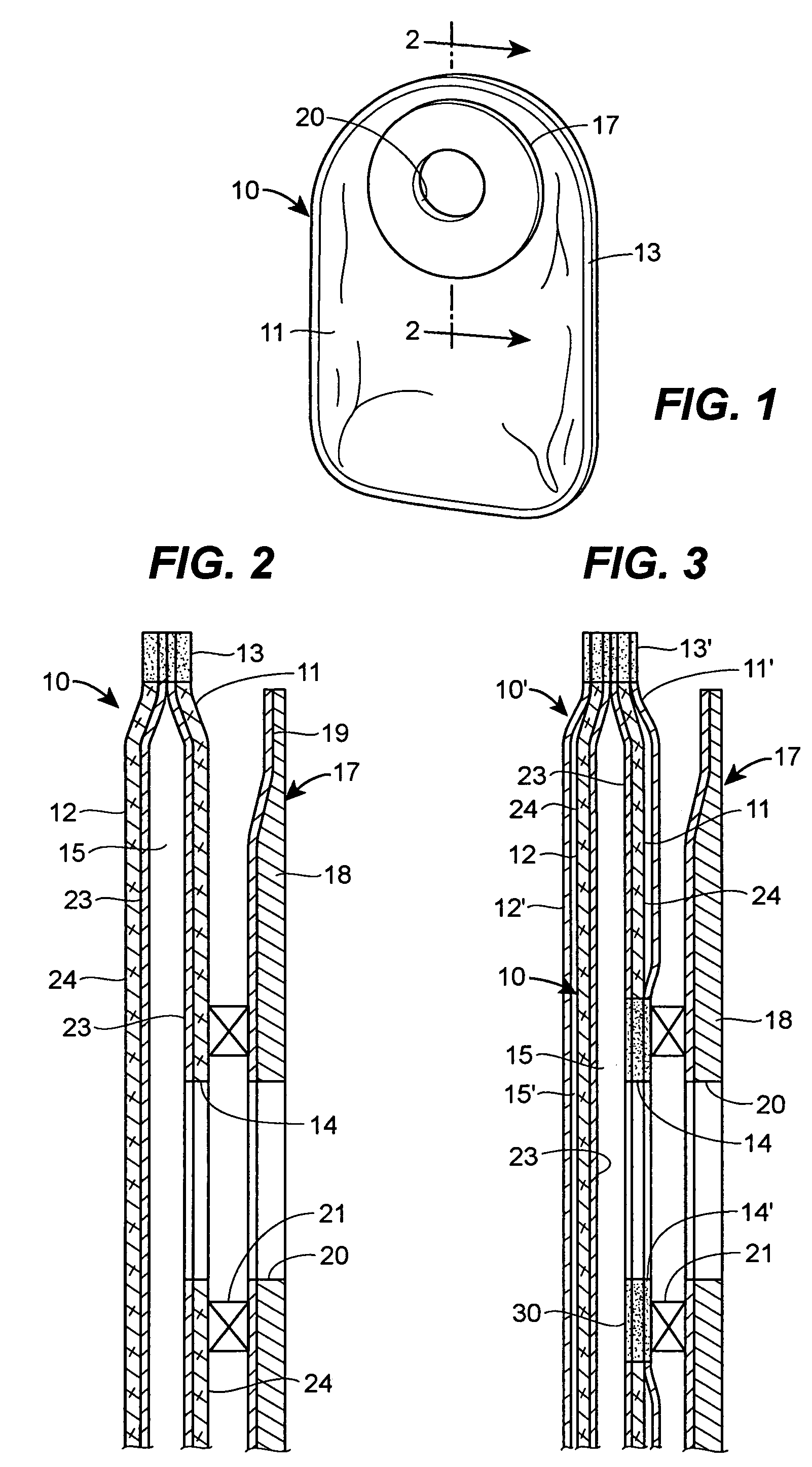

Flushable body waste collection pouch, pouch-in-pouch appliance using the same, and method relating thereto

InactiveUS7179245B2Limited biodegradabilityReduce noiseSynthetic resin layered productsNon-surgical orthopedic devicesFiberPolymer science

A biodegradable and toilet-flushable body waste collection pouch, and an appliance in which such pouch constitutes the inner pouch of a peelably separable pouch-in- pouch system, are disclosed. The walls of the inner pouch are composed of an ultra-thin, heat-sealable film impermeable to body wastes comprising a plasticized biodegradable polyester or copolyester externally covered by a soft, porous, water-disintegratable cover layer of biodegradable and water-dispersible fibers.

Owner:HOLLISTER INCORPORAED

Biodegradable nanometer filling function master batch and preparation method and application thereof

The invention relates to a biodegradable nanometer filling function master batch and a preparation method and application thereof, and belongs to the technical field of biodegradable plastic master batch preparation.The master batch is prepared from, by weight, 10-50 parts of biodegradable polyester, 40-80 parts of nanometer filler, 1-5 parts of dispersing agent, 1-5 parts of lubricant, 0.5-2.5 parts of coupling agent and 0.1-0.5 part of antioxidant.Mixing and plasticizing are conducted through an internal mixer, and extruding and die surface hot cutting are conducted through a single-screw extruder to obtain the biodegradable nanometer filling function master batch.The master batch is prepared with biodegradable polyester as the carrier and nanoscale powder as the filler and with the aid of various additives; on one hand, the compatibility and dispersity of the master batch and biodegradable plastic are improved, and the processing performance and processing environment of the material are improved; on the other hand, by introducing nanometer filler and adding the master batch to biodegradable plastic, the mechanical property of biodegradable plastic products can be improved, production cost can be reduced, and environment pollution is reduced.

Owner:JIANGXI PINGXIANG XUANPIN PLASTIC PROD CO LTD

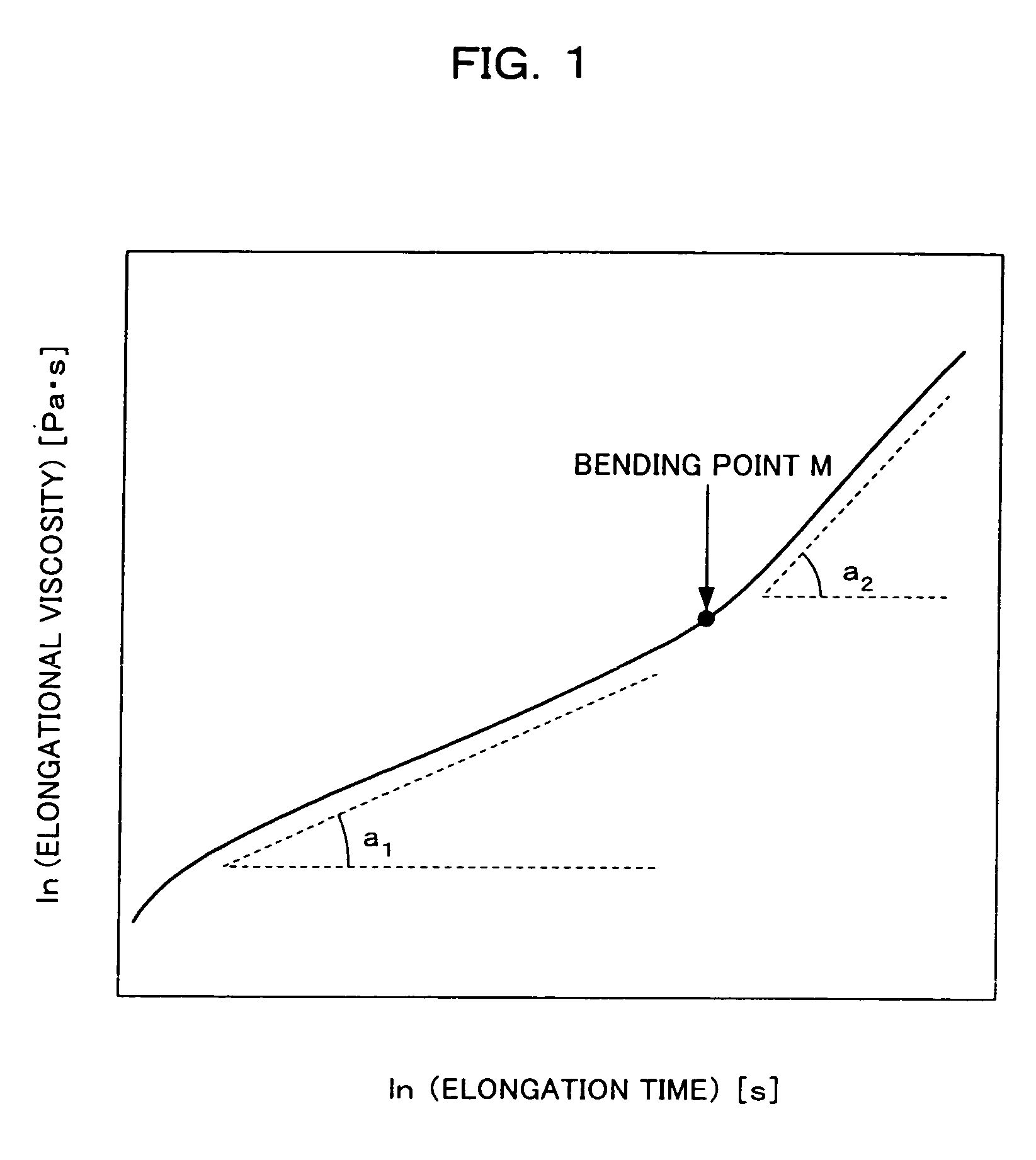

Biodegradable polyester resin composition, process for producing the same and formed article and molded and molded article using the same

It is intended to provide a biodegradable polyester resin composition which is excellent in gas barrier properties, mechanical strength and heat resistance and has Theological characteristics advantageously usable in molding a foamed article, etc., a process for producing the same, and a foamed article and a molded article using the same. The biodegradable polyester resin composition contains 100 parts by mass of a biodegradable polyester resin containing 59% mole or more of a hydroxycarboxylic acid unit, 0.01 to 10 parts by mass of a (meth)acrylic acid ester compound and 0.05 to 20 parts by mass of a layered silicate.

Owner:UNITIKA LTD

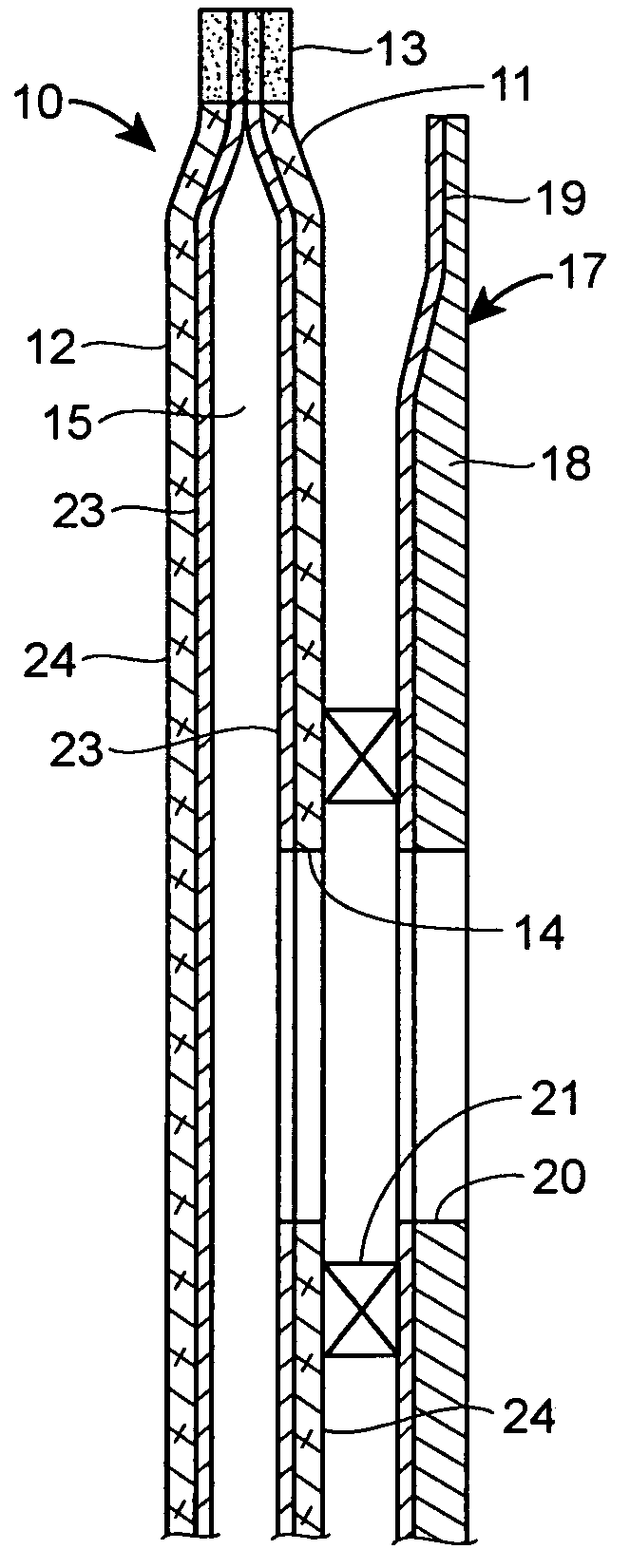

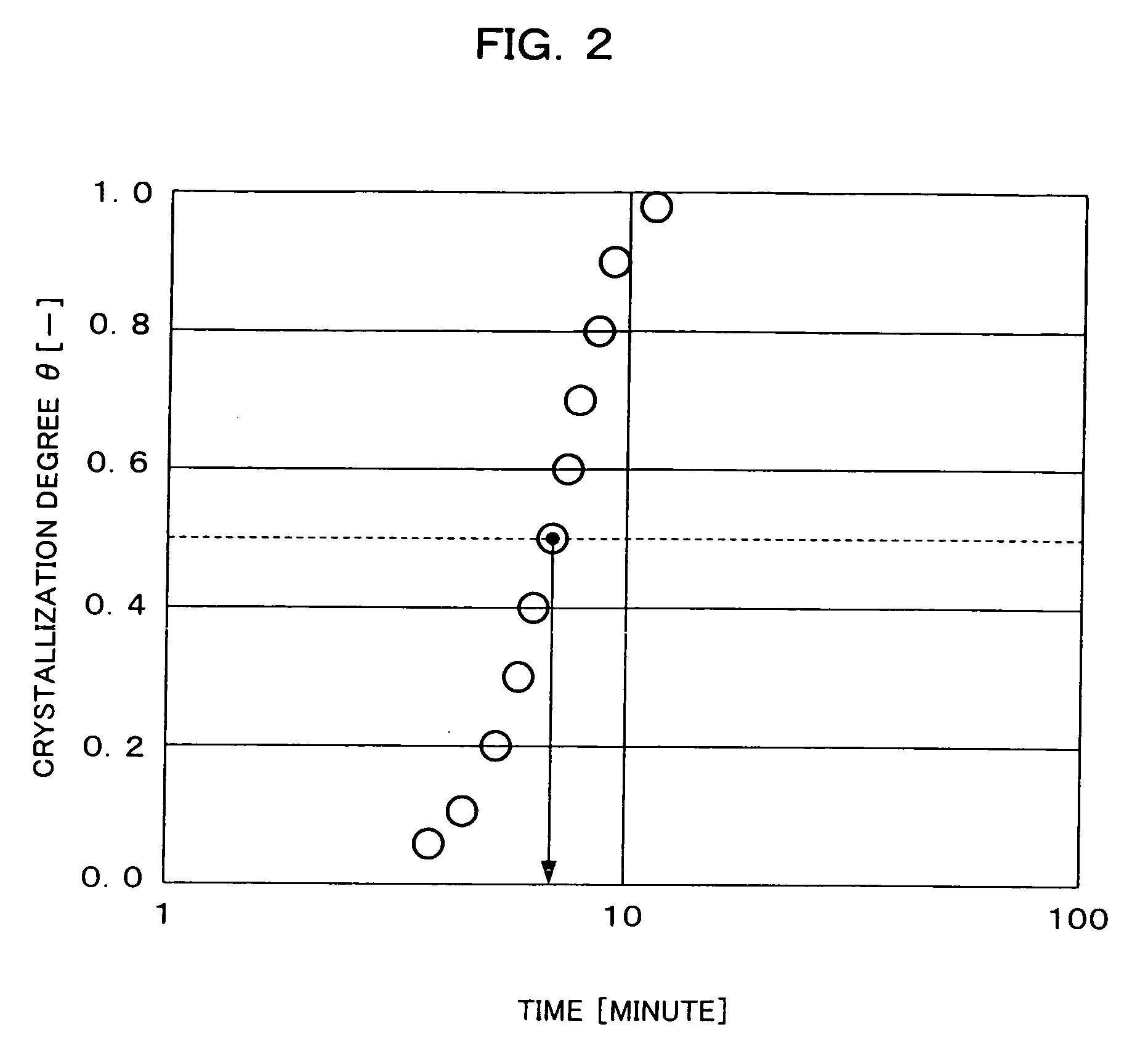

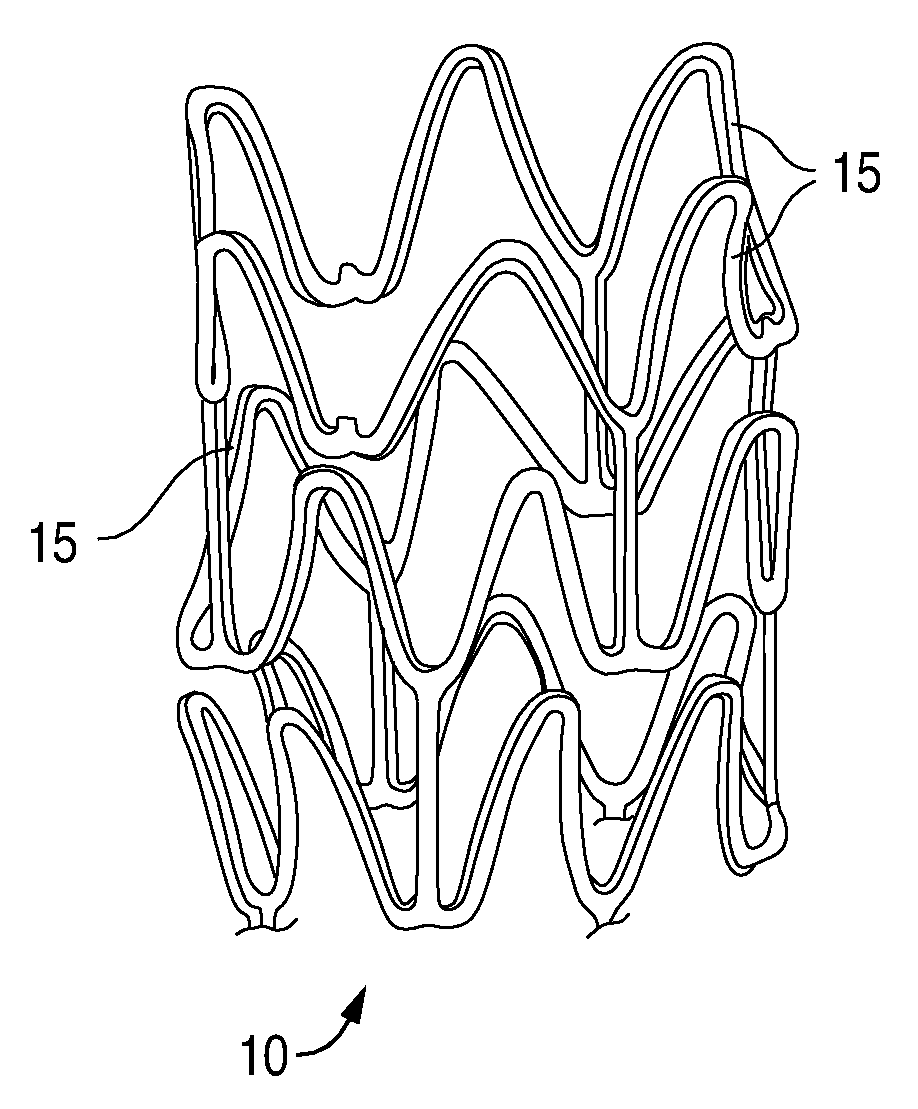

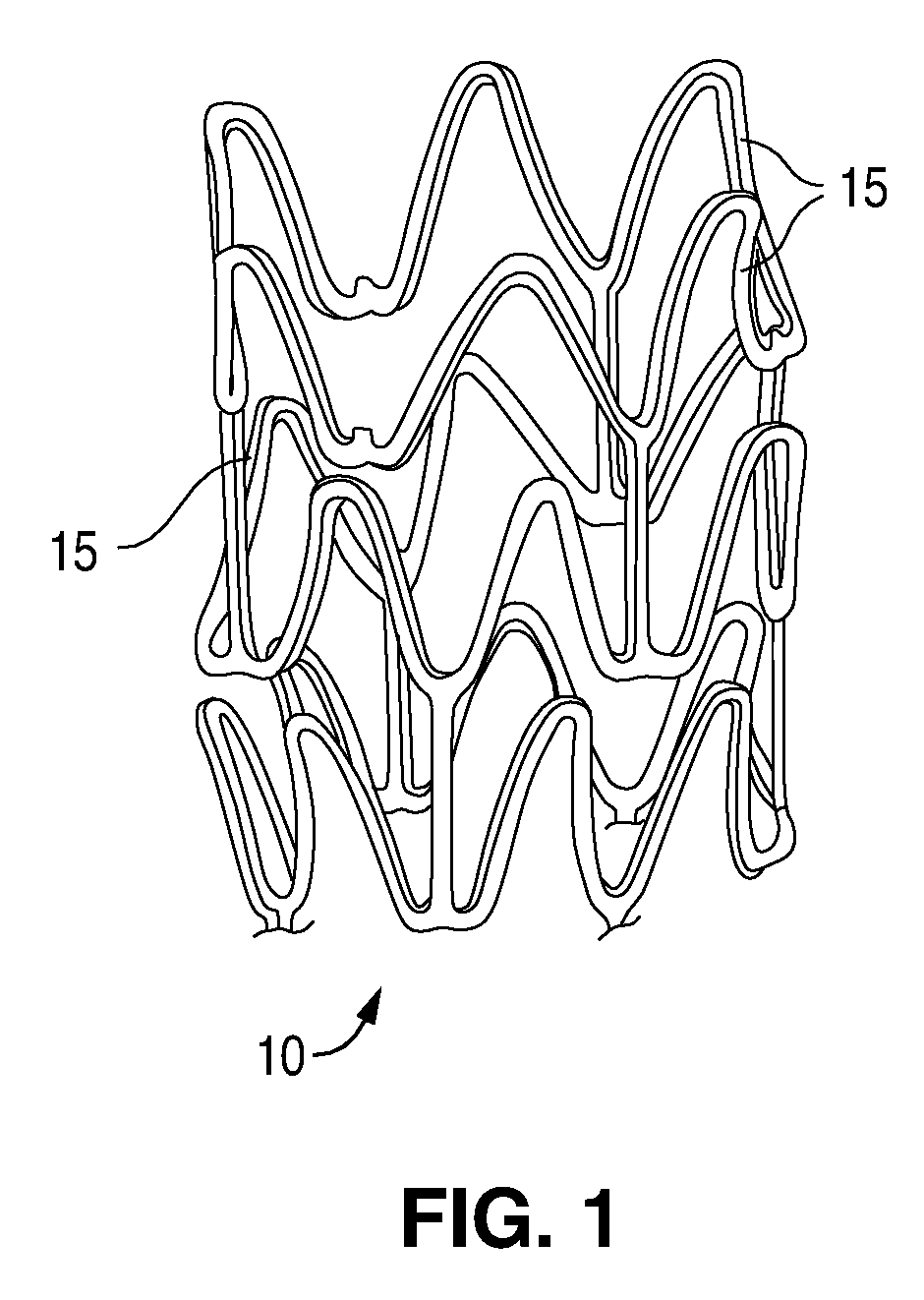

Bioabsorbable Polymeric Stent With Improved Structural And Molecular Weight Integrity

InactiveUS20090319031A1Reduces and inhibits polymer degradationPrevent degradationStentsSurgical adhesivesBiodegradable polyesterMedical device

Various embodiments of the present invention include implantable medical devices such as stents manufactured from polymers, and more particularly, biodegradable polymers including biodegradable polyesters. Other embodiments include methods of fabricating implantable medical devices from polymers. The devices and methods utilize one or more stabilizers, where each stabilizer may be chosen from the following categories: free radical scavengers, peroxide decomposers, catalyst deactivators, water scavengers, and metal scavengers.

Owner:ABBOTT CARDIOVASCULAR

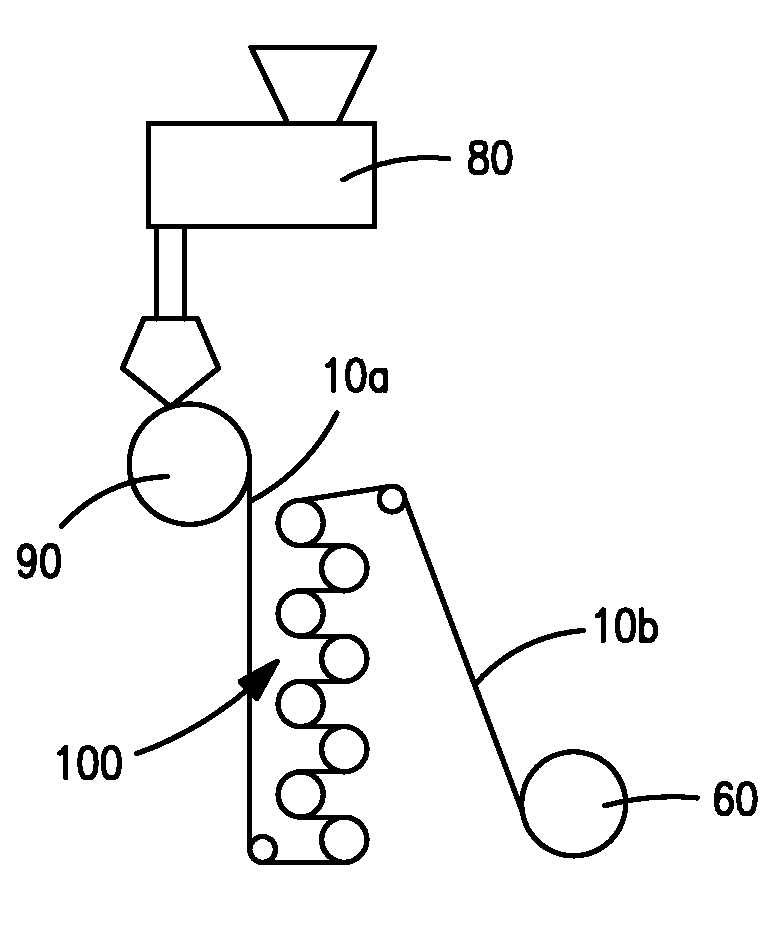

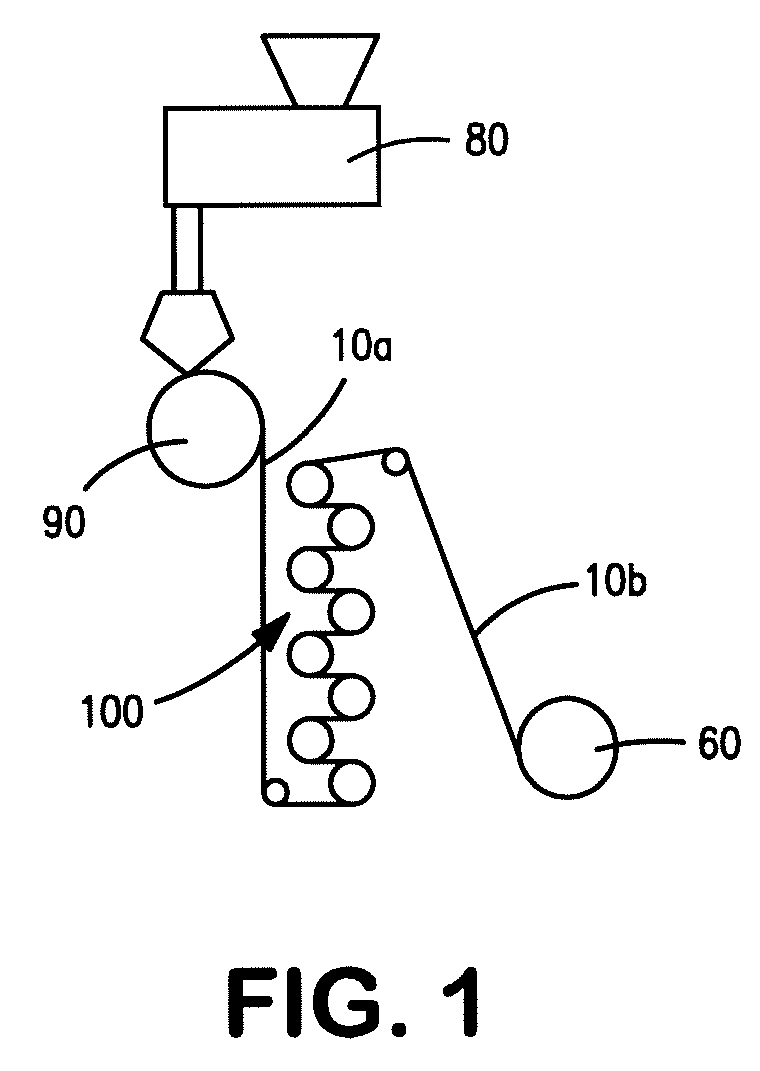

Process for calendering of polyesters

Disclosed is a process for a film or sheet by calendering a polyester composition, comprising one or more semicrystalline polyesters and a release additive, at a maximum temperature below the upper temperature of the melting point range of each of the polyesters in the composition. The polyester composition may comprise one or more biodegradable polyesters such as, for example, aliphatic-aromatic polyesters. The calendered polyesters can form tough, flexible films without the addition of a plasticizer. The film and sheet can have optical and physical properties that make them suitable as a replacement for some plasticized PVC films. Also disclosed is a polyester composition for calendering comprising an aliphatic-aromatic polyester.

Owner:STRAND MARC ALAN +2

Method for preparing biodegradable polyester from consumed polyester

The invention discloses a method for preparing biodegradable polyester from consumed polyester. The method comprises the following steps of: reacting the consumed polyester and divalent alcohol under the action of a catalyst at the temperature of between 190 and 250 DEG C to decompose the polyester to a corresponding oligomer by the alcohol; adding aliphatic dibasic acid or esterification derivative of the aliphatic dibasic acid and acid or alcohol of multifunctional groups into the oligomer, and performing esterification reaction at the temperature of between 180 and 240 DEG C to obtain corresponding esterification products; and performing condensation polymerization reaction on the esterification products to obtain biodegradable aliphatic-aromatic copolyester. By the method, the consumed and reclaimed polyester material can be directly converted into a biodegradable polyester material, and a virtuous circle channel is provided for reclamation and utilization of non-degradable polyester white pollutants; and the biodegradable polyester material has excellent mechanical and processing properties.

Owner:KINGFA SCI & TECH CO LTD +2

Starch-base fully biodegradable resin with steady hydrophobic property and preparation method thereof

The invention discloses a starch-base fully biodegradable resin with steady hydrophobic property and a preparation method thereof, belonging to the technical field of biodegradable materials. The resin comprises the following raw materials in parts by weight: 20-50 parts of modified starch, 50-80 parts of fully biodegradable polyester, 0.1-5 parts of a lubricant, and 0.1-0.5 parts of an antioxidant. The starch-base fully biodegradable resin with steady hydrophobic property is rational in design, so that the dispersity of the starch is improved greatly through pre-treatment of the starch; the moisture content is relatively low, so that degradation reaction of the resin in the processing process is also reduced. Through rational micronization function, the performance of the starch-base fully biodegradable resin is improved obviously.

Owner:YIFAN XINFU PHARMA CO LTD +1

Method for preparing polylactic acid degradable material

The invention relates to a method for preparing a degradable material, in particular to a method for preparing a polylactic acid degradable material, which comprises the following steps: 1, preparing 50 to 80 weight percent of polylactic acid, 10 to 40 weight percent of acetyl cellulose, 1 to 10 weight percent of biodegradable polyester, 1 to 10 weight percent of plasticizer and 1 to 5 weight percent of nano organic modified montmorillonite; 2, filling the polylactic acid, acetyl cellulose, biodegradable polyester, plasticizer and nano organic modified montmorillonite into a high-speed mixer,and stirring uniformly; and 3, filling the uniformly mixed raw material into a granulator for blending, melting, extruding, cooling and granulating and thus, obtaining the degradable material. The preparation method has the advantages that: the process is simple; the raw materials are mixed by a one-step process; and the prepared material can be obtained by granulation in a double-screw extruder.The product made of the degradable material prepared by the method has high rigidity and excellent performance indexes.

Owner:祝光富

Long chain branched polyester and preparation method thereof

The invention discloses long-chain branched polyester and a preparation method thereof. The long-chain branched polyester is obtained by carrying out esterification and polycondensation on a diacid component A, a diacid component B and a bifunctional branching agent component C such as biglycidyl ester, diglycidyl ether or glycidol and the like. According to the invention, a non-toxic bifunctional branching agent is directly adopted to in situ generate branching points; the preparation method is unique, preparation process is simple and environmentally-friendly, branching reaction is uniform,branching degree is easy to regulate and control, and the high molecular weight long-chain branched polyester can be prepared; and the preparation method can be used for preparation of non-degradablepolyester and preparation of biodegradable polyester, thereby being beneficial to the realization of commercialization. The long-chain branched polyester has the characteristics of long-chain branching and large molecular weight in structure and is beneficial to increase of melt strength and improvements of blow molding and foaming processing performance.

Owner:ZHEJIANG UNIV

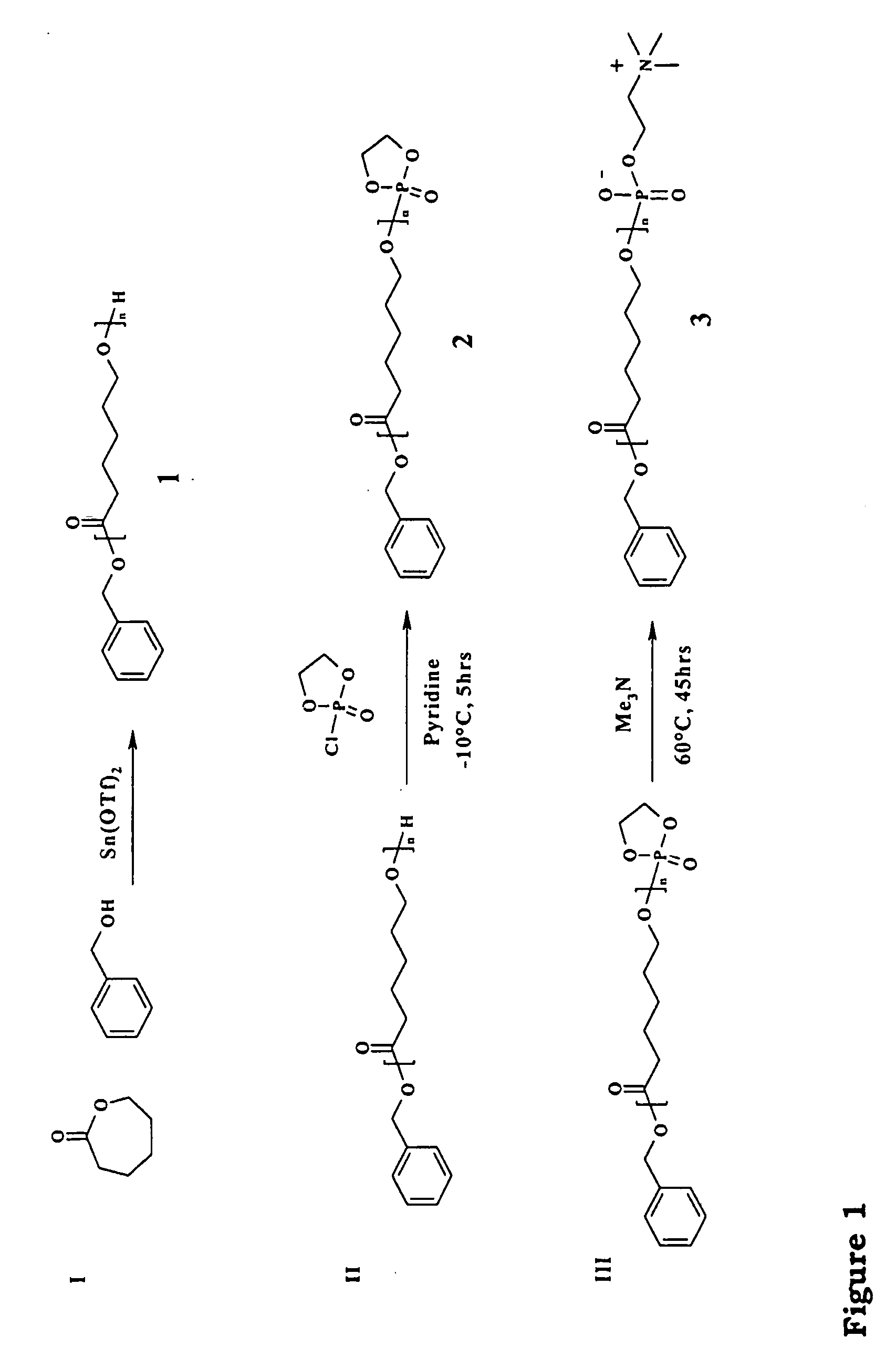

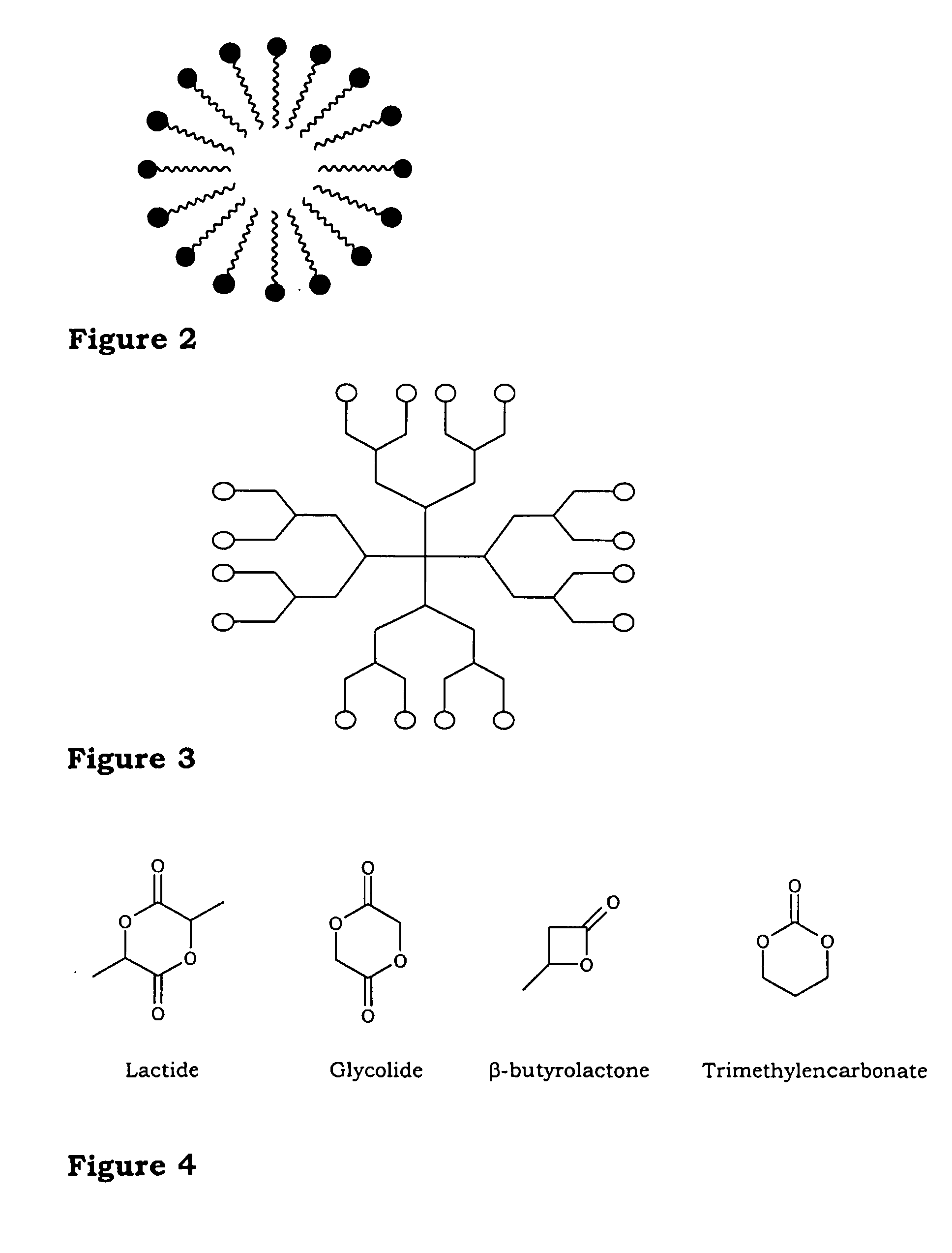

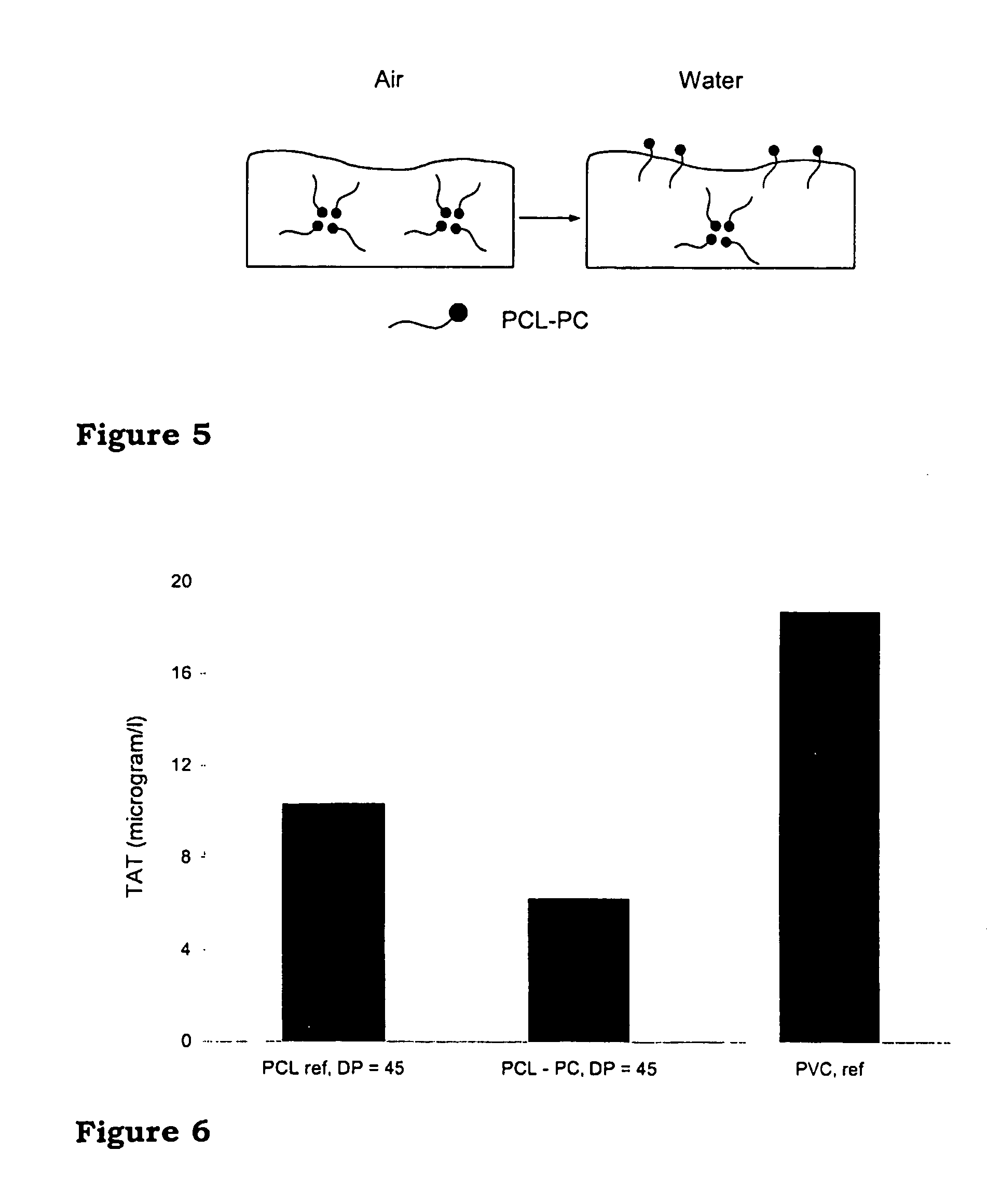

New polymers and applications

InactiveUS20060147490A1Good blood compatibilityHigh precisionEmulsion deliveryCoatingsPolymer scienceActive agent

The present invention provides a biodegradable, biocompatible polymer that is capable of forming particles (micelles), vesicles, surfaces and membranes, and other structures in which a biologically active agent, e.g. a drug, can be incorporated in such a way that its release to the host can be controlled to a high degree of accuracy, or in where surfaces of the formed polymers can be used to increase the hemeo compatibility of biomaterials. The present invention provides polymer compounds comprising at least one biodegradable polyester having a terminal functional group based on hydrophilic moieties from a phospholipid.

Owner:BOWDEN TIM +2

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com