Thermoplastic starch (TPS), biodegradable polyester/starch composite material and preparation thereof

A technology for biodegrading polyester and thermoplastic starch, applied in the field of biodegradable composite materials, can solve problems such as the influence of the stability of composite materials and the reduction of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

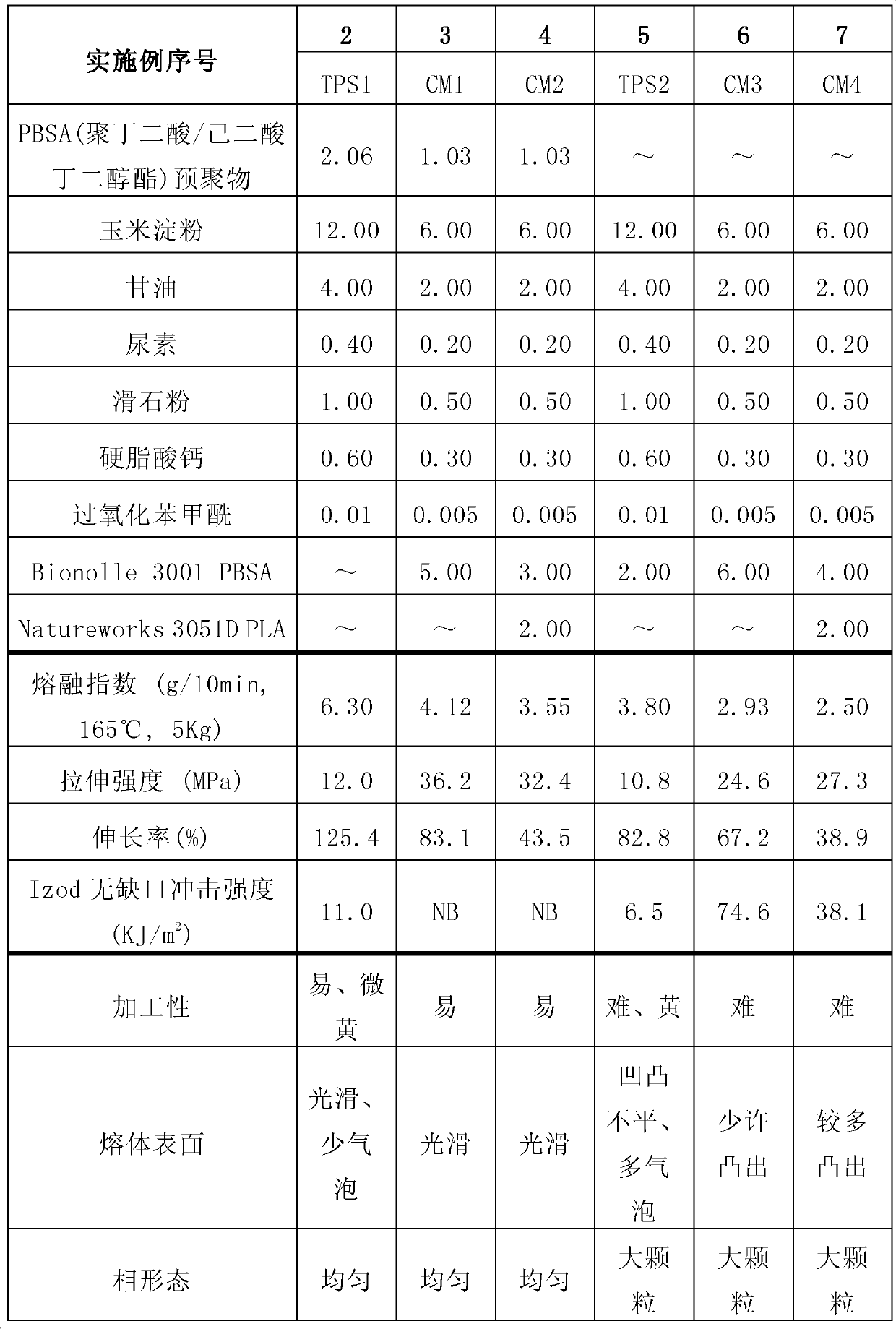

Examples

preparation example Construction

[0095] Preparation of TPS

[0096] In the process of the present invention, the components for preparing TPS include, for example: 20 to 80 parts of starch, 0.01 to 10 parts of reaction activator, 5 to 40 parts of polyester prepolymer carrier, 0.01 to 10 parts of catalytic deactivator , 5 to 50 parts of more than one plasticizer. The processing temperature is between 50 and 150 degrees Celsius.

[0097] Described thermoplastic starch is prepared by following method:

[0098] Condensation polymerize biodegradable polyester monomers, and form biodegradable polymer prepolymers with active end groups with reaction activators;

[0099] The starch is reacted with the active end group of the prepolymer of the biodegradable polymer to form a polyester-TPS graft copolymer; that is, the thermoplastic starch.

[0100] In a specific embodiment, the polycondensation synthesis conditions of the biodegradable prepolymer are: the temperature is from 80 to 220 degrees Celsius, and the rea...

Embodiment 1

[0120] Preparation of Prepolymers of Biodegradable Polyesters with Active Functional Groups by Direct Condensation Polymerization

[0121] Add 16.4 kg of 1,4-butanediol (99%), 17.7 kg of succinic acid and 4.3 kg of adipic acid in a 50L reactor with a heating and stirring reactor, add 194.0 g of tetratitanate after mixing Butyl ester (99%) was added as reaction catalyst. The temperature of the mixed reaction was set at 120 degrees Celsius, and the temperature was raised to 180 degrees Celsius at a rate of 30 degrees Celsius per hour, and kept at each temperature point for 5 hours, and kept stirring. While heating up, turn on the vacuum system and reduce to a vacuum of 50 mbar at a speed of 100 mbar / hour. Then, increase the temperature to 220 degrees Celsius and keep it for 5 hours. Thereafter, the vacuum was released and 963.0 grams of a commercially available ADR 4368C model was added to the reactor and the prepolymer was allowed to react for 30 minutes from the side feed po...

Embodiment 2

[0122] [embodiment 2] utilize prepolymer to prepare thermoplastic starch (TPS)

[0123] 12.0 kilograms of cornstarch, 4.0 kilograms of glycerol, 2.06 kilograms of prepolymers of biodegradable polyester (prepared in Example 1), 400 grams of urea, 1.0 kilograms of talcum powder, 600 grams of calcium stearate and 10.0 grams of benzoyl peroxide first in Mixed with a high-speed mixer, and then extruded with a co-rotating twin-screw extruder. Typical extrusion stage settings for TPS preparation are: 60··140°C, screw speed 150rpm. After the extruded TPS strips are cooled by the conveyor belt and wind, they are granulated for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com