Preparation method of disk tool with dustproof function

A technology of function and plate tools, applied in the field of plate preparation, can solve the problems of cumbersome processing, influence of electrical conductivity, increase of resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

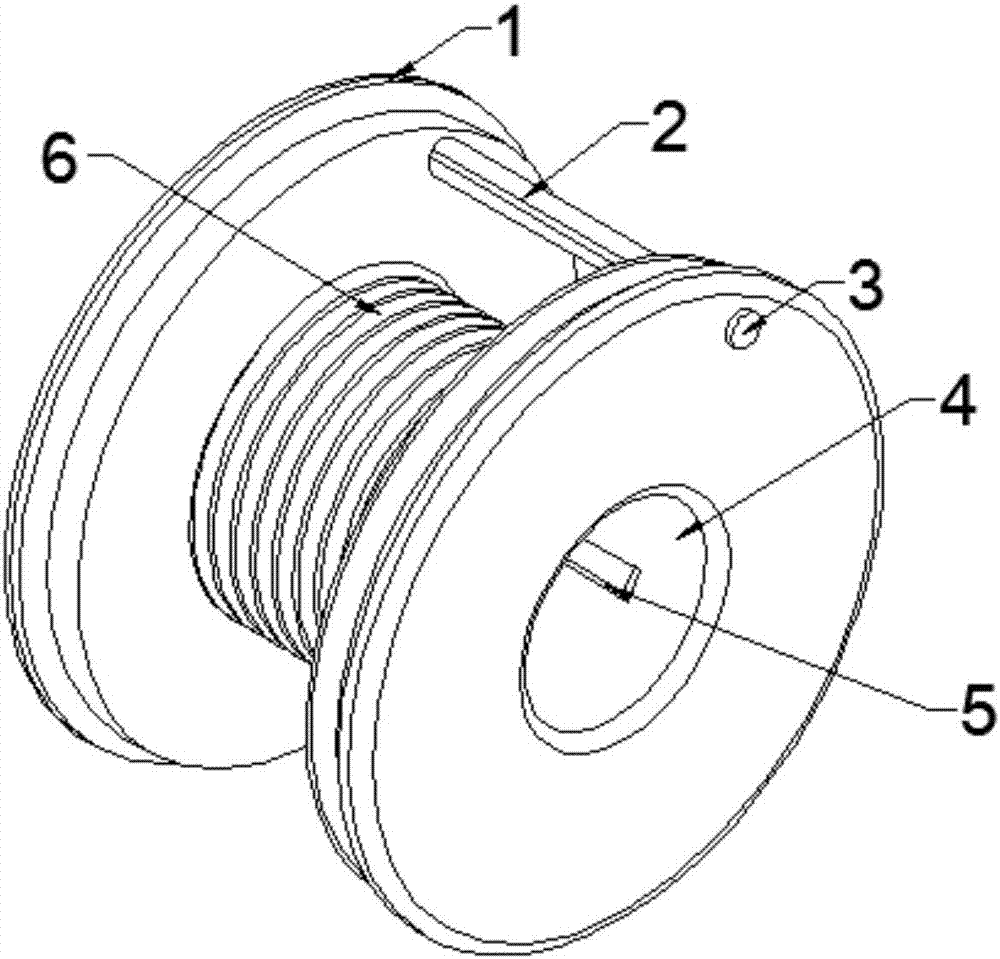

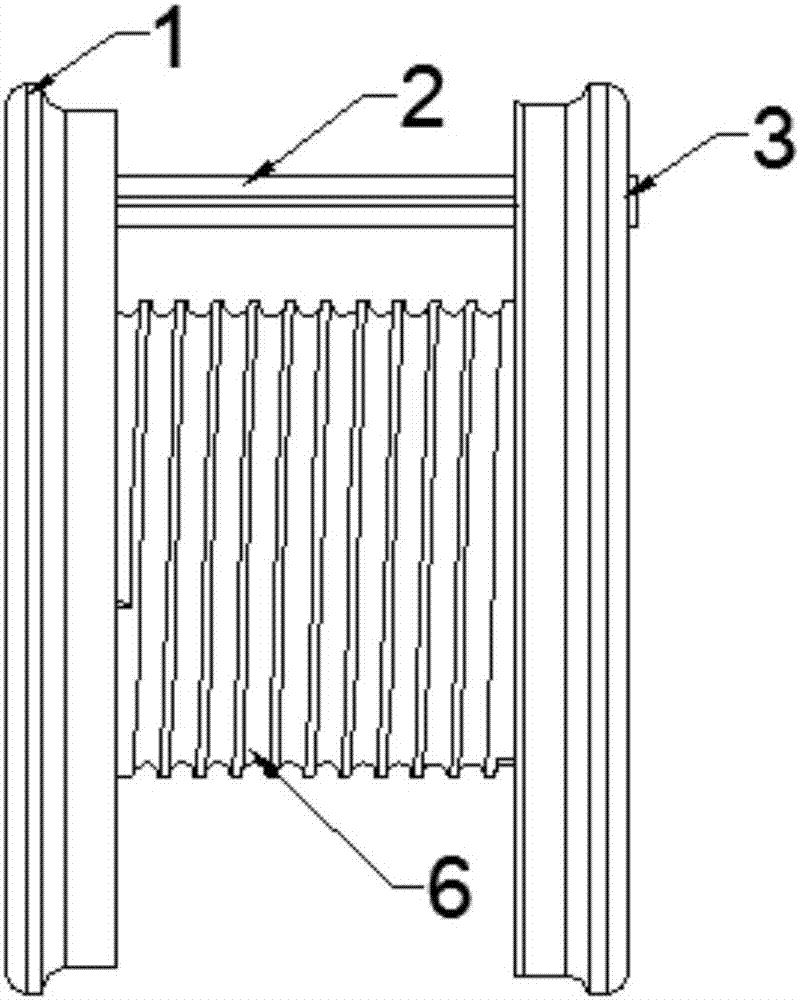

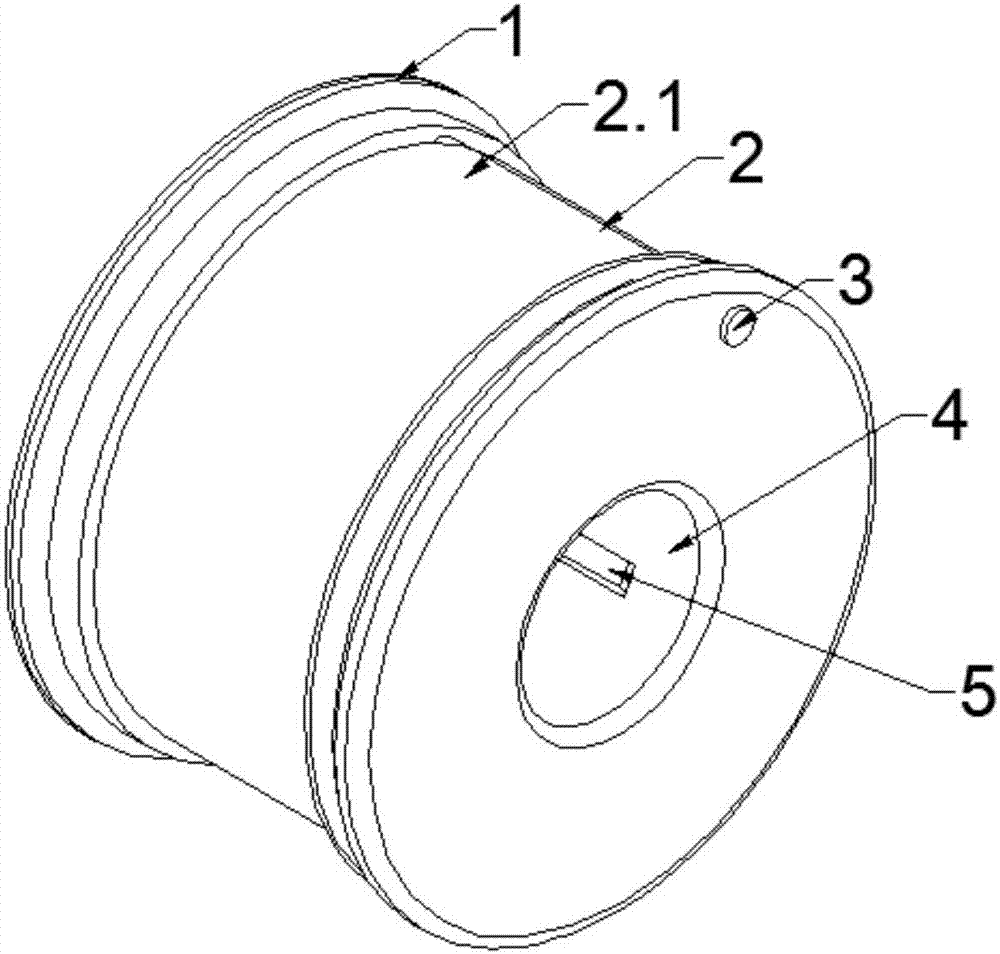

[0024] Such as Figure 1-3 As shown, a method for preparing a tray with a dustproof function includes a main shaft 6 and baffles 1 located at both ends of the main shaft 6, and a storage device 2 for storing a dustproof cloth 2.1 is installed on the baffle 1. The storage device 2 is cylindrical and parallel to the main shaft 6. In order to make the main shaft 6 have a larger space and capacity for taking up wires, the installation position of the storage device 2 is designed to be close to the at the outer edge of the baffle 1. One end of the storage device 2 is inserted and fixed with the baffle 1 , and the other end is fixed with the baffle 1 through a fixing member 3 . When the storage device 2 is in the protection mode, the dust-proof cloth 2.1 in the storage device 2 is pulled out, surroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com