Cable sheath material

A technology of cable sheath material and chlorinated polyethylene, which is applied in the direction of insulating cables, cables, circuits, etc., can solve the problems that are not conducive to ensuring the flexibility of cable sheath materials, affecting wide application, and high hardness of materials, so as to achieve capacity increase Excellent effect, improved compatibility, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

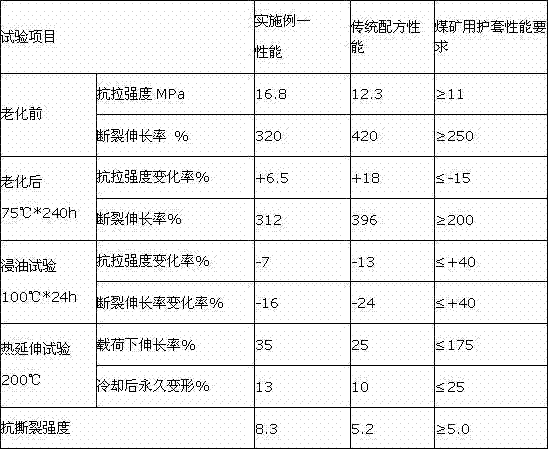

Embodiment 1

[0056] A cable sheathing material, which is added according to the components of the traditional cable sheathing material: magnesium oxide; stearic acid; plasticizer; nanometer highly active white carbon black; activated calcium carbonate; quantity:

[0057] 60 parts of chlorinated polyethylene;

[0058] 40 parts of nylon;

[0059] Compatibilizer CPE-g-MAH 6 parts;

[0060] 25 parts of high-performance composite flame retardant;

[0061] Composite stabilizer 4 parts;

[0062] Anti-aging agent 1 part;

[0063] 1 part of thiadiazole vulcanizing agent;

[0064] Aldehyde condensation accelerator 1.5 parts.

[0065] The compatibilizer CPE-g-MAH is mixed uniformly by 100 parts of chlorinated polyethylene, 4 parts of maleic anhydride, and 0.3 part of dicumyl peroxide on a double-roll mill, and the chlorinated polyethylene blend Put it into a torque rheometer with a temperature of 150° C. and a rotational speed of 30 r / min to carry out a melt-grafting reaction to obtain CPE-...

Embodiment 2

[0075] A cable sheathing material, which is added according to the components of the traditional cable sheathing material: magnesium oxide; stearic acid; plasticizer; nanometer highly active white carbon black; activated calcium carbonate; quantity:

[0076] 90 parts of chlorinated polyethylene;

[0077] 10 parts of nylon;

[0078] Compatibilizer CPE-g-MAH 10 parts;

[0079] 30 parts of high-performance composite flame retardant;

[0080] Composite stabilizer 7 parts;

[0081] Anti-aging agent 2.5 parts;

[0082] Thiadiazole vulcanizing agent 4 parts;

[0083] Aldehyde condensation accelerator 3 parts.

[0084] The compatibilizer CPE-g-MAH is mixed uniformly by 100 parts of chlorinated polyethylene, 10 parts of maleic anhydride, and 0.7 part of dicumyl peroxide on a double-roll mill, and the chlorinated polyethylene blend Put it into a torque rheometer with a temperature of 150° C. and a rotational speed of 30 r / min to carry out a melt-grafting reaction to obtain CPE-g-...

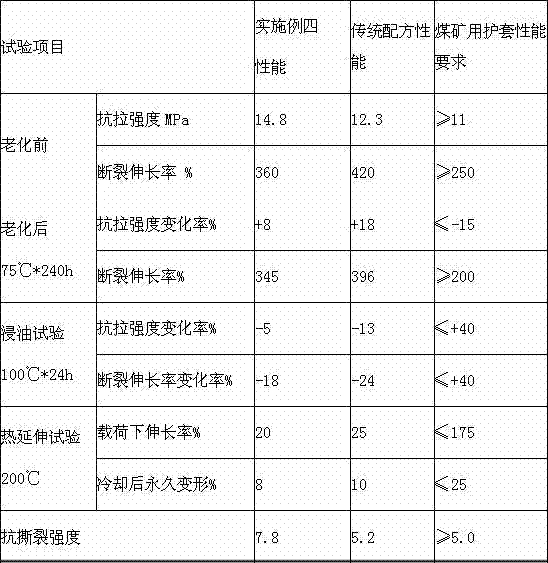

Embodiment 3

[0092] A cable sheathing material, which is added according to the components of the traditional cable sheathing material: magnesium oxide; stearic acid; plasticizer; nanometer highly active white carbon black; activated calcium carbonate; quantity:

[0093] 75 parts of chlorinated polyethylene;

[0094] 25 parts of nylon;

[0095] Compatibilizer CPE-g-MAH 8 parts;

[0096] 28 parts of high-performance composite flame retardant;

[0097] Composite stabilizer 5 parts;

[0098] Anti-aging agent 2 parts;

[0099] Thiadiazole vulcanizing agent 3 parts;

[0100] Aldehyde condensation accelerator 2 parts.

[0101] The compatibilizer CPE-g-MAH is mixed uniformly by 100 parts of chlorinated polyethylene, 7 parts of maleic anhydride, and 0.5 part of dicumyl peroxide on a double-roll mill, and the chlorinated polyethylene blend Put it into a torque rheometer with a temperature of 150° C. and a rotational speed of 30 r / min to carry out a melt-grafting reaction to obtain CPE-g-MAH....

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com