Thermoplastic vulcanizate having high gas barrier property and preparation method of thermoplastic vulcanizate

A thermoplastic vulcanizate and gas barrier technology, applied in the field of polymer materials, can solve the problems of manpower and material resources consumption, environmental pollution, and unsatisfactory expansion effect, and achieve the effect of reducing degradation and good stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

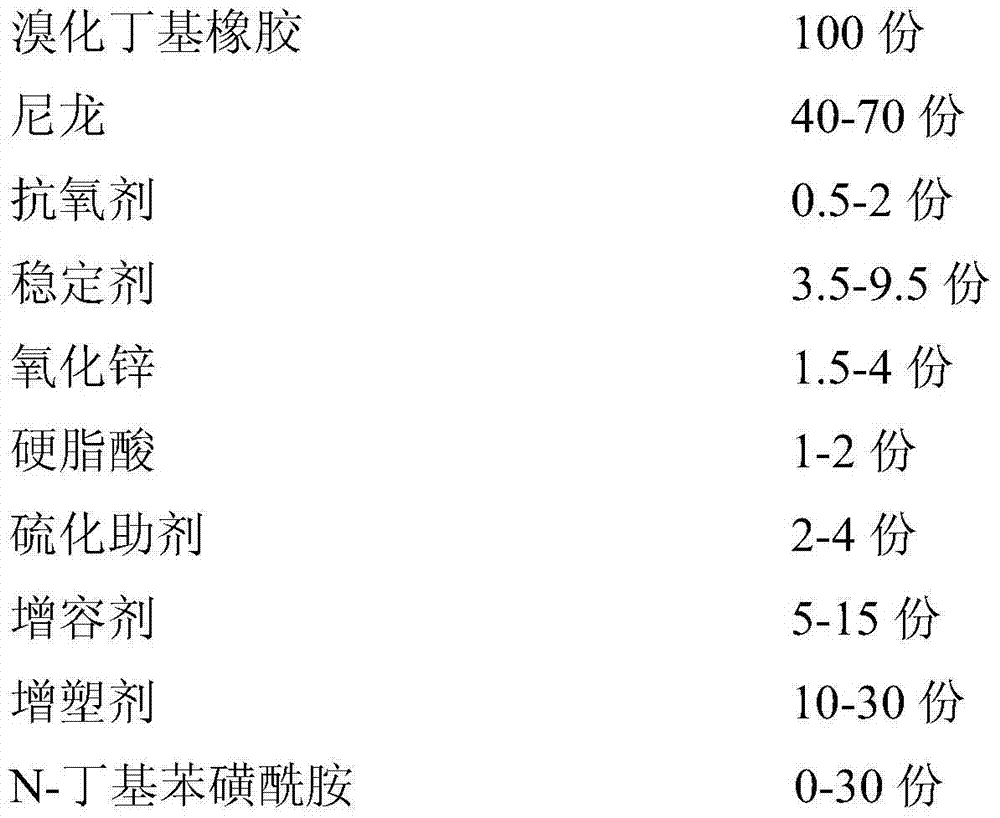

[0028] Embodiment 1: (the parts described in the embodiment are parts by mass)

[0029] Nylon 12 (melt index 230°C 2.16kg, 3.5g / 10min) was dried at 120°C for 5 hours, nylon 12 (54 parts) and compatibilizer polyisobutylene succinic anhydride PIBSA (10 parts) were melted at 185°C Grafting for 10 minutes; Add the stabilization system (epoxidized soybean oil: calcium stearate: antioxidant 1010=2:2:1) (5 parts) to BIIR (Mooney viscosity ML (1+8) 125°C: 32 ) (100 parts), the mixture of BIIR and stabilizer, the grafted blend, and antioxidant 1010 (1 part), were mixed uniformly in an internal mixer at 185°C. The temperature was lowered to room temperature, and zinc oxide (2 parts), vulcanization aid HVA-2 (4 parts), stearic acid (1.2 parts) and paraffin oil (15 parts) were added to the above mixture.

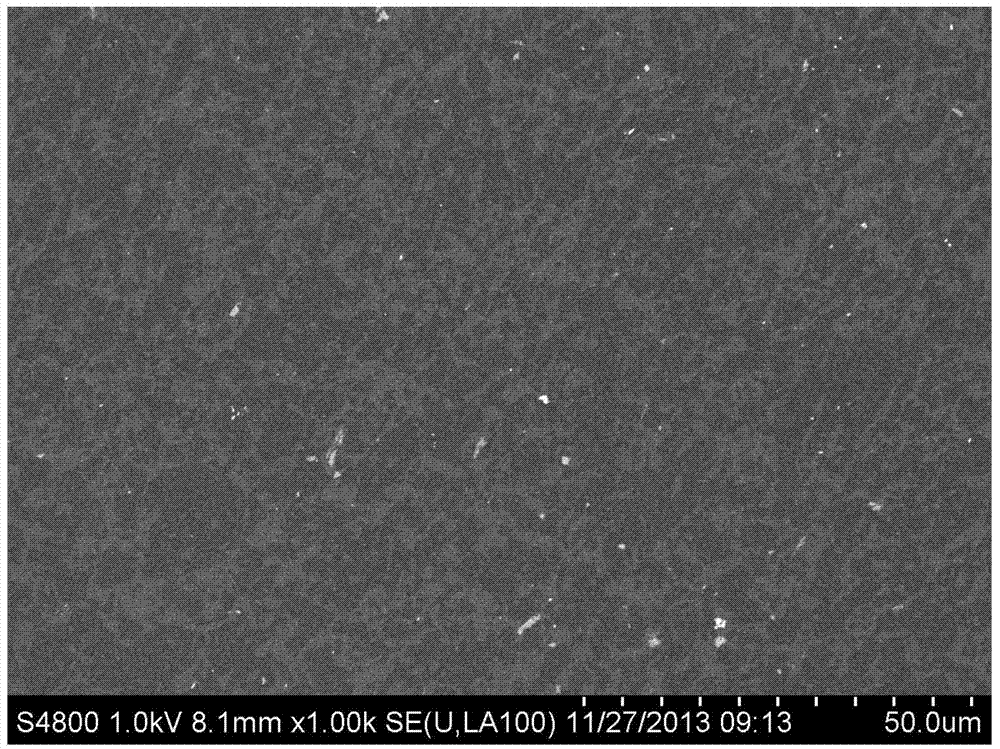

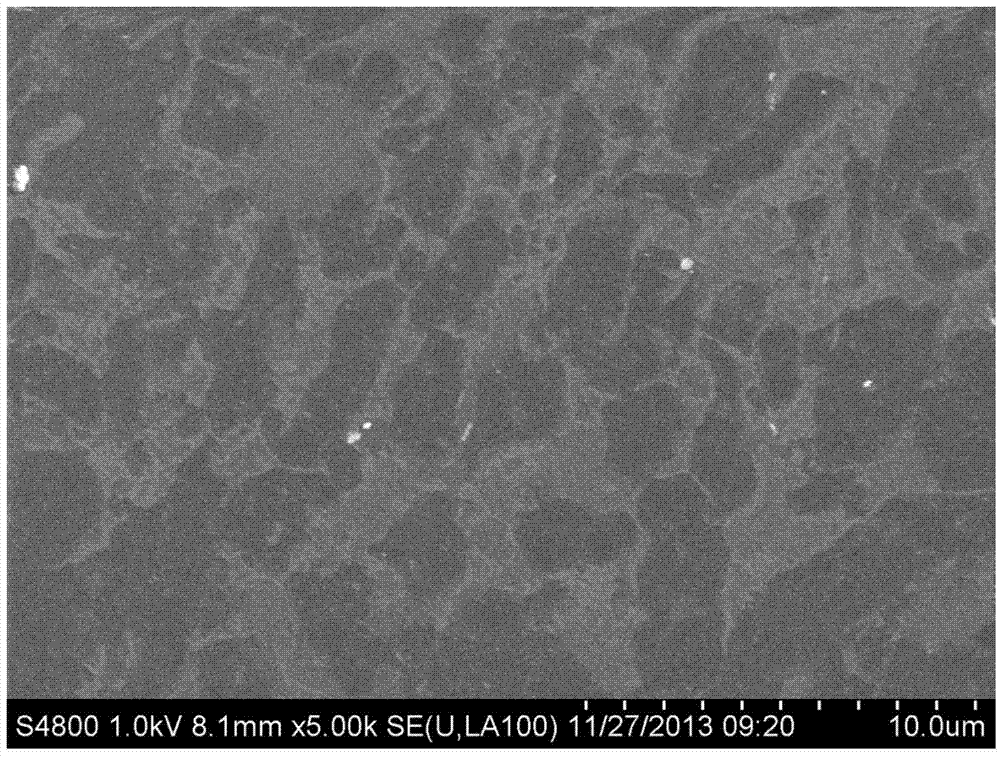

[0030] Dynamic crosslinking was performed in a twin-screw extruder (HTS-40, Nanjing Rubber and Plastic Machinery Factory). Set the temperature of each section of screw / head to 185 185...

Embodiment 2

[0032] Polypropylene grafted with maleic anhydride PP-g-MAH was used as a compatibilizer, and other preparation processes were the same as in Example 1.

Embodiment 3

[0039] Nylon 12 (same as Example 1) was dried at 120°C for 5 hours, nylon 12 (43 parts) and PIBSA compatibilizer (5 parts) were melt grafted at 190°C for 7.5min; the stabilizer (epoxidized soybean oil : calcium stearate: antioxidant 1010=3:2.5:1.5) (7 parts) joins in BIIR (with embodiment 1) (100 parts), weighs the mixture and graft blend of BIIR and stabilizing agent 1. Antioxidant 1010 (1.5 parts), mixed uniformly in an internal mixer at 190°C. The temperature was lowered to room temperature, and zinc oxide (3 parts), vulcanization aid HVA-2 (3 parts), stearic acid (1.5 parts) and paraffin oil (20 parts) were added to the above mixture.

[0040] Dynamic cross-linking was carried out in the twin-screw extruder described in Example 1, and the temperature of each section of the screw / head was set to 185 185 185 185 185 185 185 185 185 185 185 185 / 185, and the twin-screw speed was 480 rpm. After completing the dynamic cross-linking, add N-BBSA to adjust the hardness and measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com