Compatilizer, application thereof in polyphenyleneoxide/nylon alloy and preparation method of polyphenyleneoxide/nylon alloy

A polyphenylene ether and compatibilizer technology, applied in chemical instruments and methods, compounds containing elements of group 3/13 of the periodic table, organic chemistry, etc. Insufficient compatibility and other problems, to achieve excellent compatibilization effect, improve compatibility, and improve system compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

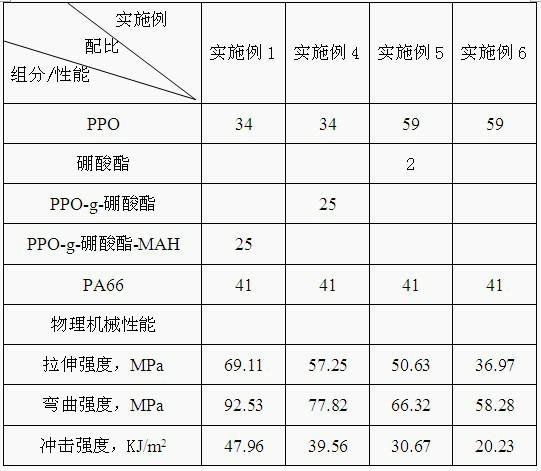

Examples

Embodiment 1

[0025] (1) Preparation of borate esters with dual active functional groups

[0026] Add 100 parts of boric acid and 50 parts of gluconic acid into a three-necked glass flask with a stirrer, thermometer and water separation and reflux device, and add 10 parts of toluene as a solvent, heat in an oil bath, and stir the reaction at 90 ° C. Toluene and The water generated by the reaction forms an azeotrope and gradually evaporates, and the generated water is separated through the water separation and reflux device. After reacting for 8 hours, distill under reduced pressure at 88 kPa for 40 minutes to remove the remaining toluene, a small amount of water and excess polyhydric acid. Carboxylic acid or its derivatives are used to obtain borate ester products with dual active functional groups, which are sealed and dried.

[0027] (2) Mix 100 parts of dried polyphenylene ether, 1 part of boric acid ester, 1 part of maleic anhydride, and 0.2 part of dicumyl peroxide at 60°C, and then ad...

Embodiment 2

[0030] (1) Preparation of borate esters with dual active functional groups

[0031]Add 100 parts of boric acid and 150 parts of tartaric acid into a three-neck glass flask with a stirrer, thermometer and water separation and reflux device, and add 50 parts of toluene as a solvent, heat in an oil bath, and stir the reaction at 60 ° C. Toluene and The water generated by the reaction forms an azeotrope and gradually evaporates, and the water generated is separated by a water separation and reflux device. After reacting for 9 hours, it is distilled under reduced pressure at 60 kPa for 40 minutes to remove the remaining toluene, a small amount of water and excess polyhydric acid. Carboxylic acid or its derivatives are used to obtain borate ester products with dual active functional groups, which are sealed and dried.

[0032] (2) Mix 100 parts of dried polyphenylene ether, 5 parts of borate ester and 0.1 part of dicumyl peroxide uniformly at 60°C, and then add them into a twin-scre...

Embodiment 3

[0035] (1) Preparation of borate esters with dual active functional groups

[0036] Add 100 parts of boric acid and 300 parts of citric acid into a three-neck glass flask equipped with a stirrer, thermometer and water separation and reflux device, and add 100 parts of toluene as a solvent, heat in an oil bath, and stir at 120°C. Toluene Form an azeotrope with the water generated by the reaction and gradually distill it out, and separate the generated water through a water separation and reflux device. After reacting for 8 hours, distill under reduced pressure at 90 kPa for 40 minutes to remove the remaining toluene, a small amount of water and excess Polybasic carboxylic acid or its derivatives are used to obtain borate ester products with dual active functional groups, which are sealed and dried for storage.

[0037] (2) Mix 100 parts of dried polyphenylene ether, 2 parts of boric acid ester, 5 parts of maleic anhydride, and 0.5 parts of dicumyl peroxide at 60°C, and then ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com