Patents

Literature

33results about How to "Good thermodynamic compatibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

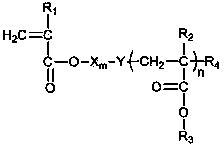

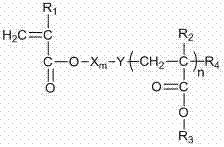

Comb-shaped stem grafting copolymer containing reactive group and preparation method and application thereof

The invention discloses a comb-shaped stem grafting copolymer containing reactive group and a preparation method and application thereof. The copolymer is a comb-shaped stem grafting copolymer by taking small molecule monomer B as the main chain, and giant molecule monomer A as the side chain. According to the method, the giant molecule monomer A and the small molecule monomer B are copolymerized to form the comb-shaped stem grafting copolymer of which the main chain is the small molecule monomer B and the side chain is the giant molecule monomer A. The comb-shaped stem grafting copolymer disclosed by the invention can serve as the chain extender of a polymer or a polymer blend, the compatibilizer of the polymer blend, the hydrolytic stabilizer, adhesive and anti-leakage agent of the polymer blend, and is used for coatings of wood, metal or plastic. The reactive group in the copolymer has very high reaction activity, and can react with various end groups of polyamide and polyester. Methacrylate monomers have thermodynamics compatibility with various polymers. The reactive group can react with the end hydroxyl group or the end carboxy group of polyester, so that the comb-shaped stem grafting copolymer can serve as the chain extender, and the processing and application properties of the material are improved.

Owner:HANGZHOU NORMAL UNIVERSITY

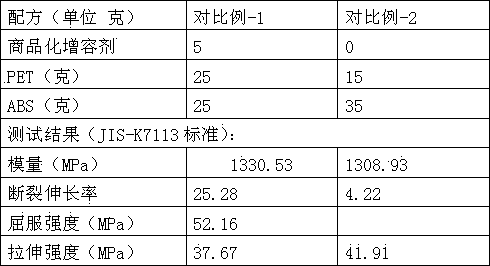

High-toughness high-modulus polypropylene composite material and preparation method thereof

The invention discloses a high-toughness high-modulus polypropylene composite material and a preparation method thereof. The high-toughness high-modulus polypropylene composite material consists of 50-62.5 parts of a polypropylene base body, 10-12 parts of high-density polyethylene, 12-15 parts of a polyolefin elastomer, 6-9 parts of modified wollastonite, 0.5-2 parts of nano modified particles, 1-2 parts of modified boron nitride, 5-6 parts of a compatibilizer, 1-1.5 parts of an antioxidant and 2-2.5 parts of a lubricating agent, wherein the nano modified particles are obtained by mixing a silane coupling agent and nano titanium dioxide in a weight ratio of 1 to 100. The preparation process is simple and convenient, the adopted materials are cheap, the comprehensive cost is lower than that of conventional toughness-modified polypropylene, and the produced high-toughness high-strength high-modulus polypropylene is excellent in performance. A composite system disclosed by the invention forms a polymer / flexible interface layer / inorganic particle three-phase composite system.

Owner:HENAN UNIV OF SCI & TECH

Three-dimensional curled elastic fiber and preparation method thereof

ActiveCN107574507ANo peelingGood thermodynamic compatibilityFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterPolymer science

Owner:JIANGSU DESAI CHEM FIBER

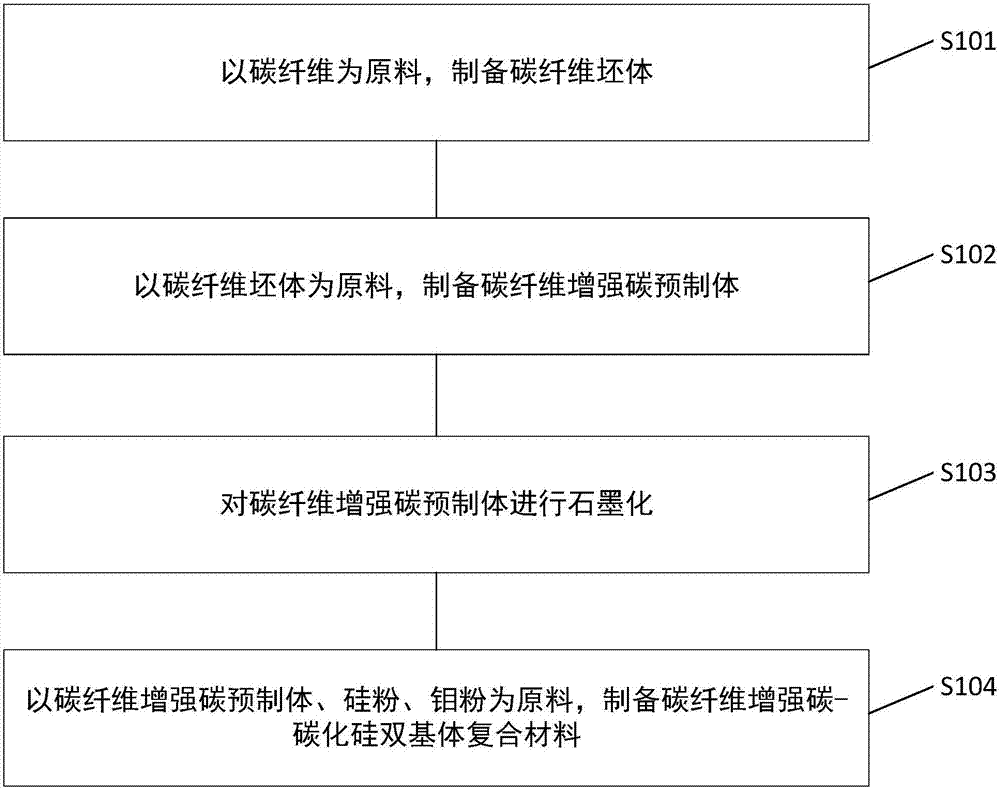

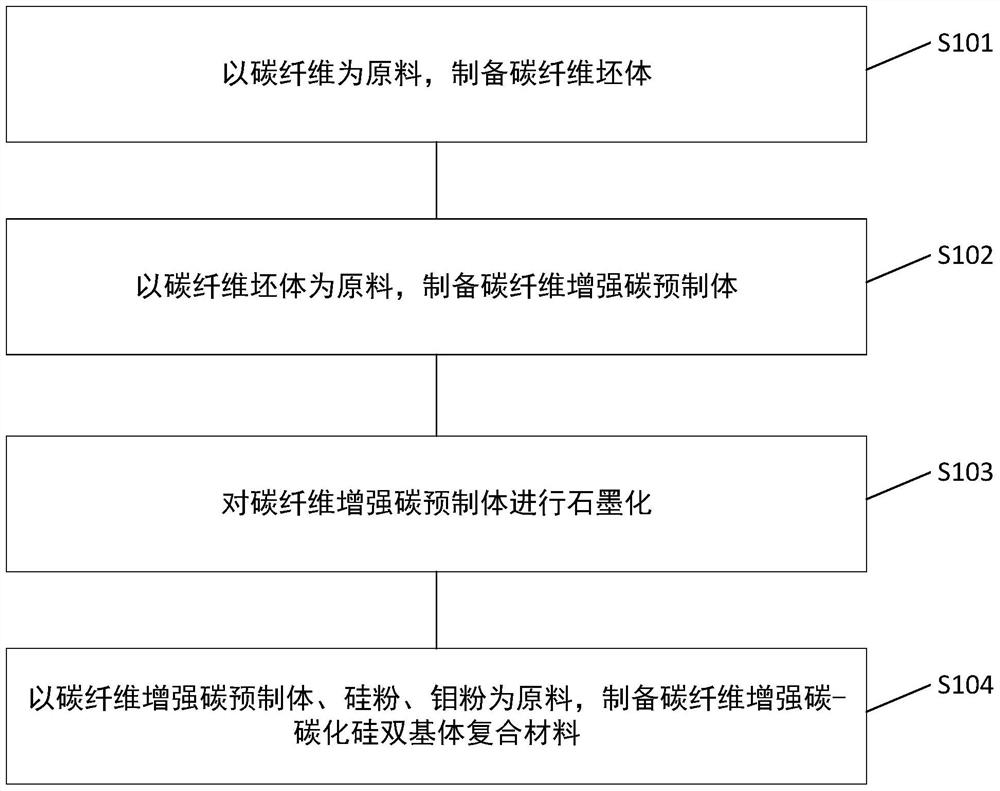

Preparation method of carbon fiber reinforced carbon-silicon carbide double-matrix composite material

The invention provides a preparation method of a carbon fiber reinforced carbon-silicon carbide double-matrix composite material. According to the present invention, through silicon-molybdenum alloy infiltration, a molybdenum disilicide phase is introduced into a composite material matrix so as to reduce the residual silicon element and reduce the brittleness of the composite material; molybdenum disilicide has characteristics of moderate density, high melting point and good oxidation resistance, and can be converted from the brittleness to the plasticity within a certain temperature range, wherein molybdenum disilicide has a plastic deformation behavior and shows metal-like ductility when the temperature exceeds the temperature range so as to improve the fracture toughness of the composite material; molybdenum disilicide has a low thermal expansion coefficient and has good thermodynamic compatibility to silicon carbide so as to easily reduce the crack generation; and the process is simple, and the operation is easy.

Owner:BEIHANG UNIV

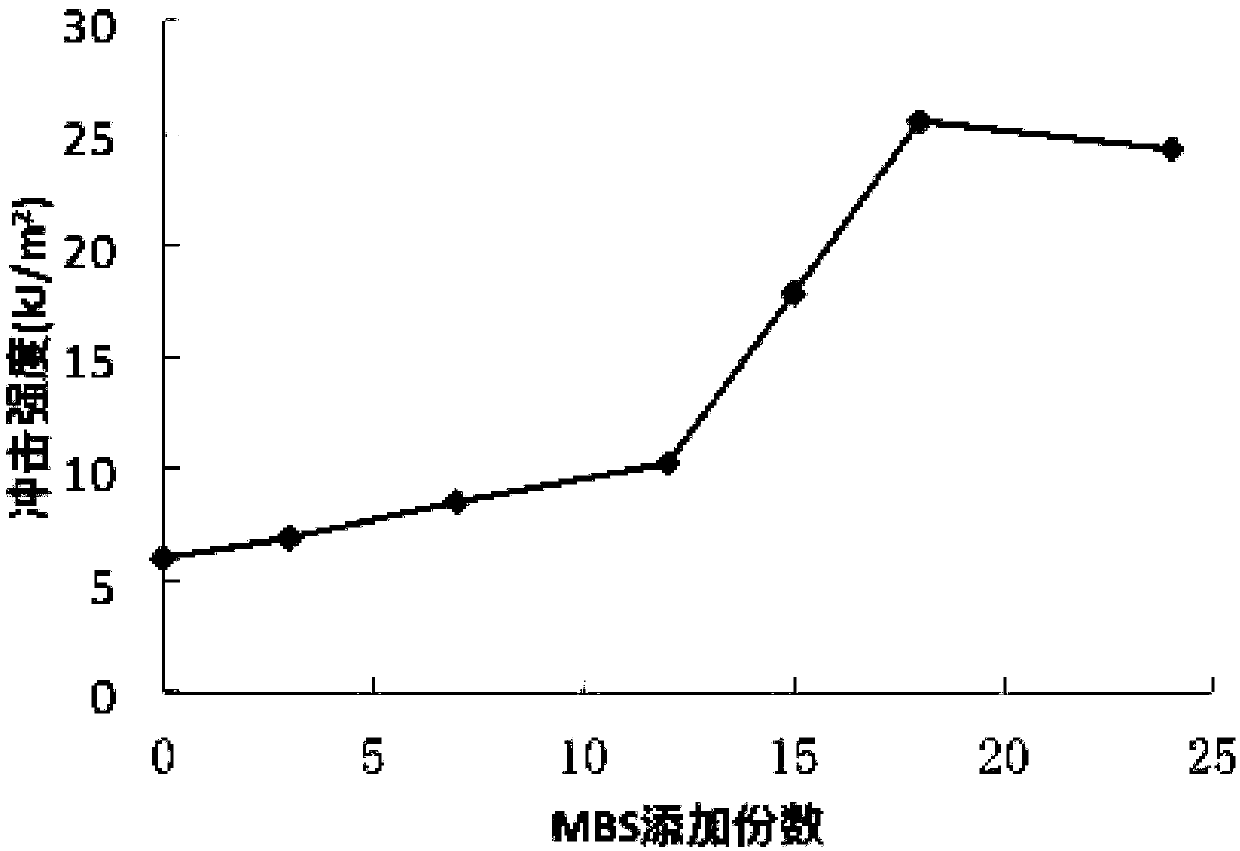

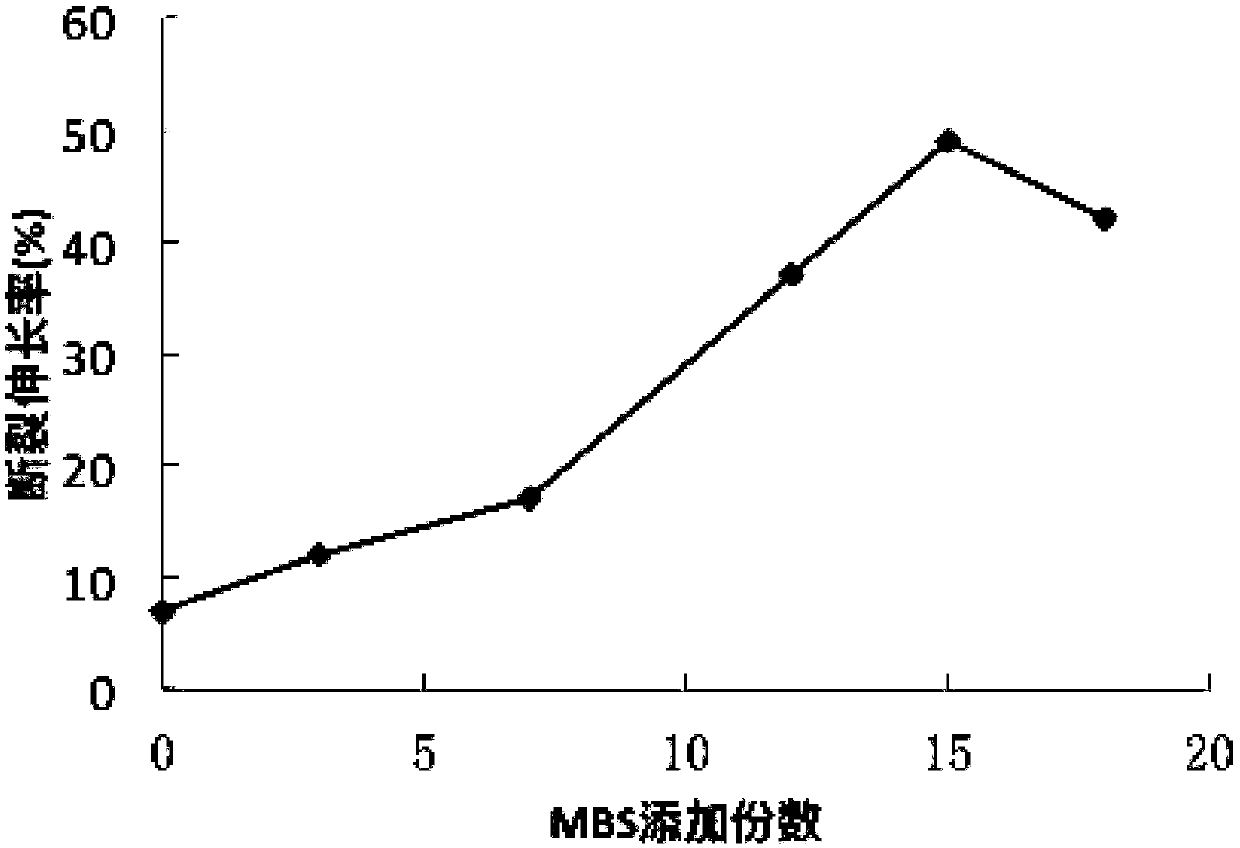

High-strength environment-friendly PVC shrink film and preparation process thereof

The invention discloses a high-strength environment-friendly PVC shrink film and a preparation process thereof. The PVC shrink film is prepared from the following raw materials in parts by weight: 88-100 parts of polyvinyl chloride, 6-10 parts of ethylaniline, 10-15 parts of dioctyl phthalate, 5-10 parts of MBS resin, 1-3 parts of a plasticizer, 2-4 parts of a heat stabilizer, 1-3 parts of an internal lubricant, 1-2 parts of an external lubricant and 3-5 parts of a processing aid. The PVC raw material is modified by virtue of an anti-impact enhancer, the plasticizer, the heat stabilizer, the internal lubricant, the external lubricant and the like through a polymer blending modification technique, and after being mechanically mixed with PVC, a modifier is well dispersed in a PVC matrix, sothat the heat stability of PVC is improved, the processing performance is improved, and meanwhile, the tenacity and impact resistance of PVC can be substantially improved.

Owner:厦门市瀚邦包装制品有限公司

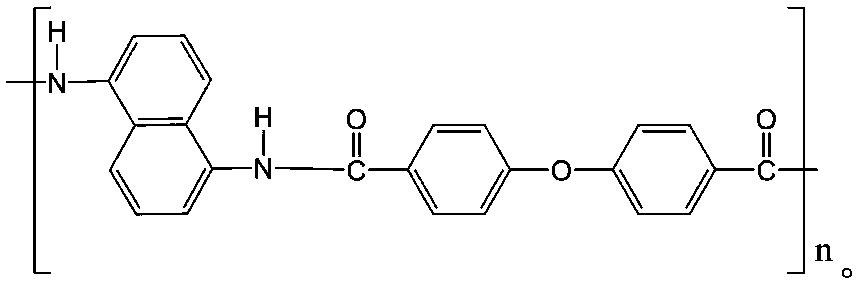

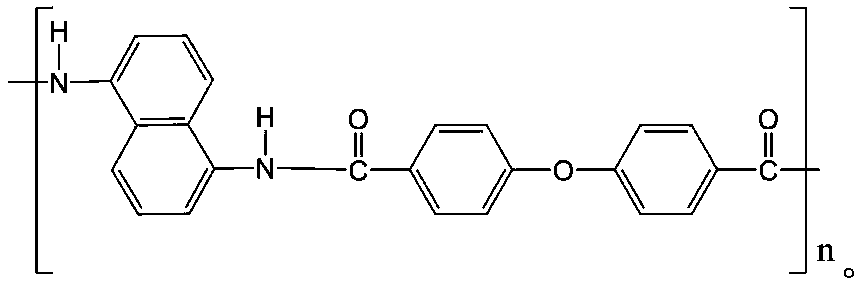

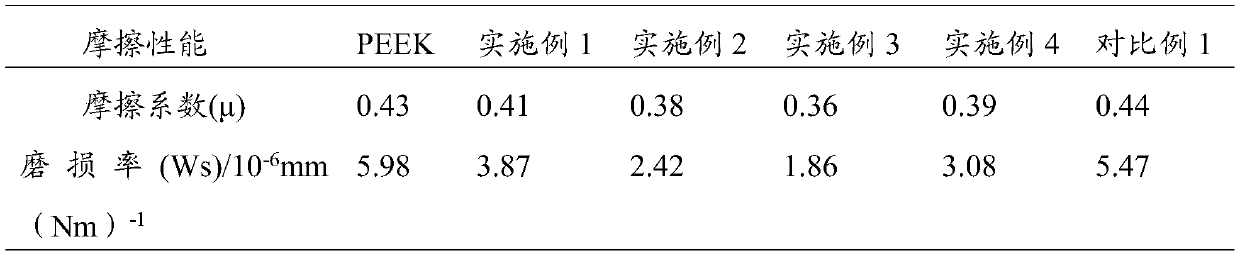

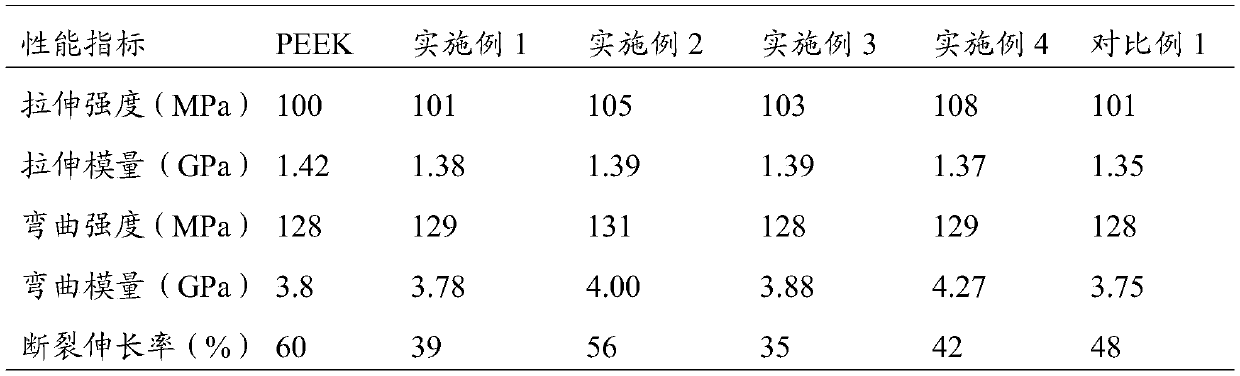

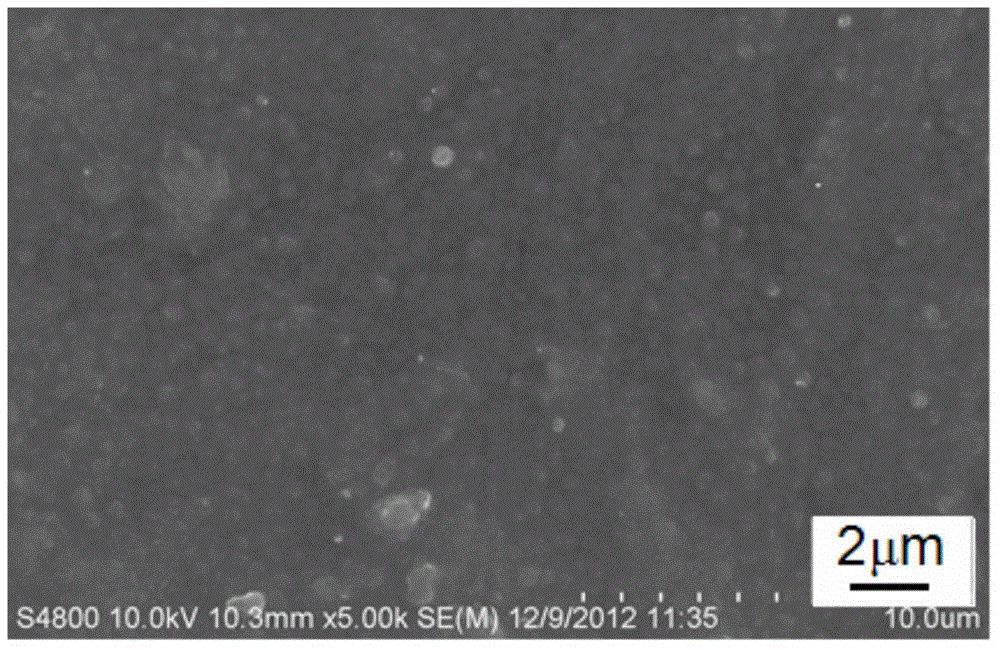

Aromatic polyamide-contained ternary alloy and preparation method thereof

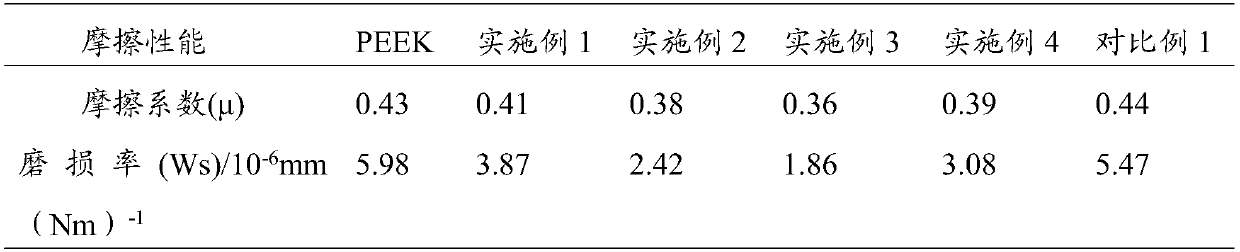

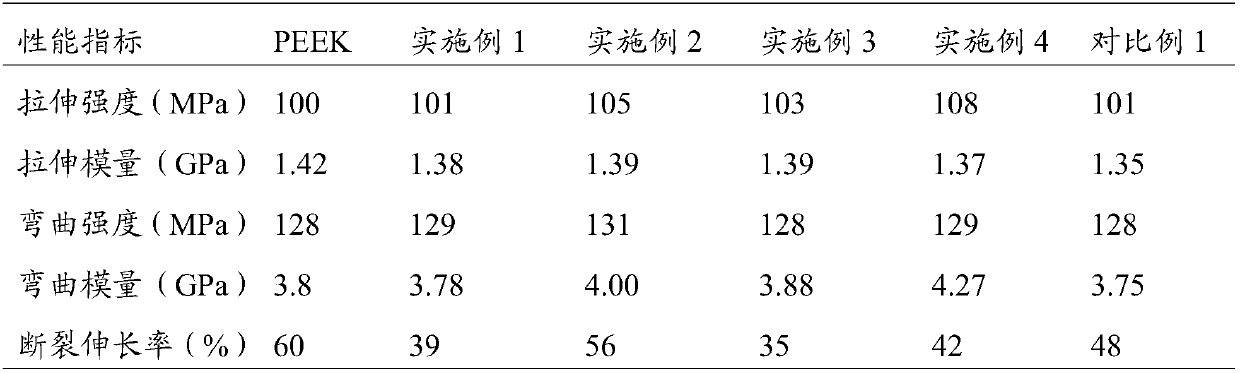

The invention relates to the technical field of polymer materials, in particular to an aromatic polyamide-contained ternary alloy and a preparation method thereof. The provided aromatic polyamide-contained ternary alloy is prepared from, by weight, 70-94 parts of polyether ether ketone, 3-20 parts of polyetherimide and 3-10 parts of aromatic polyamide; aromatic polyamide contains an ether ketone structure or naphthalene. According to records of the embodiment, the friction coefficient of the ternary alloy is reduced by 4.7% or above in comparison with that of pure-phase PEEK, the wear rate isreduced by 35.3% or above, and the mechanical property of the ternary alloy is greatly improved in comparison with that of the pure-phase PEEK.

Owner:JILIN UNIV

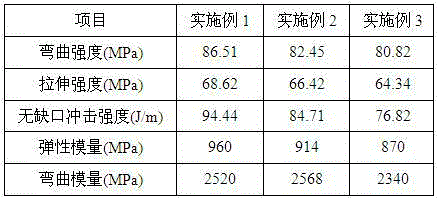

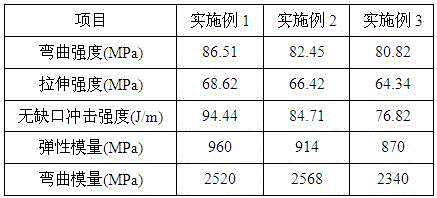

Fiber-enhanced polypropylene material and preparation method thereof

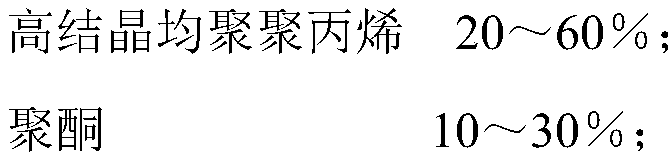

The invention belongs to the technical field of modification of high molecular composite materials and in particular relates to a fiber-enhanced polypropylene material and a preparation method thereof. The polypropylene material takes high-crystallinity homopolymerized polypropylene as a basic component and polyketone resin is added to improve the wear resistance and mechanical properties of the material; compound fibers composed of chopped carbon fibers and aluminum fibers are added, and graphene is added to improve the mechanical strength and heat and electricity conductivity of the material; a compatibilizer is added to improve the binding force between raw materials, so that the mechanical properties of the material are improved; and an antioxidant is added to improve the anti-ageing performance of the material and a lubricant is used for reducing the friction generated in a material processing process. The material has the advantages of high strength and high modulus, heat conduction and electricity conduction, high temperature resistance, excellent size stability and the like, and can completely meet the functional requirements of automobiles, machines and chemical heat exchange parts on the material under a severe environment.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

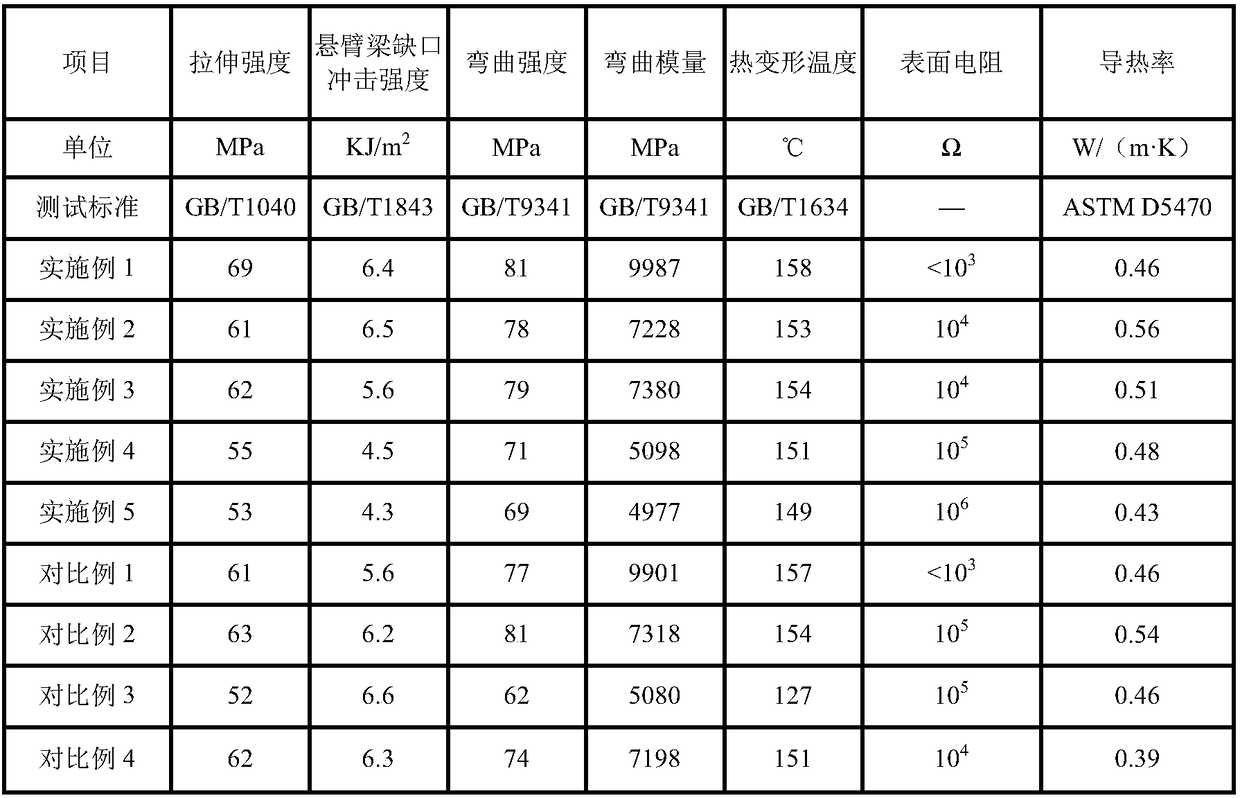

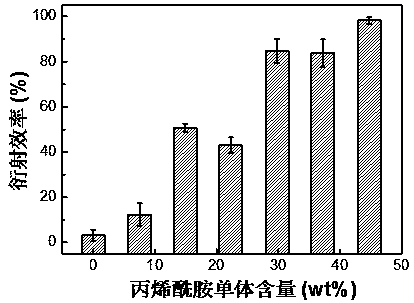

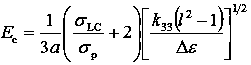

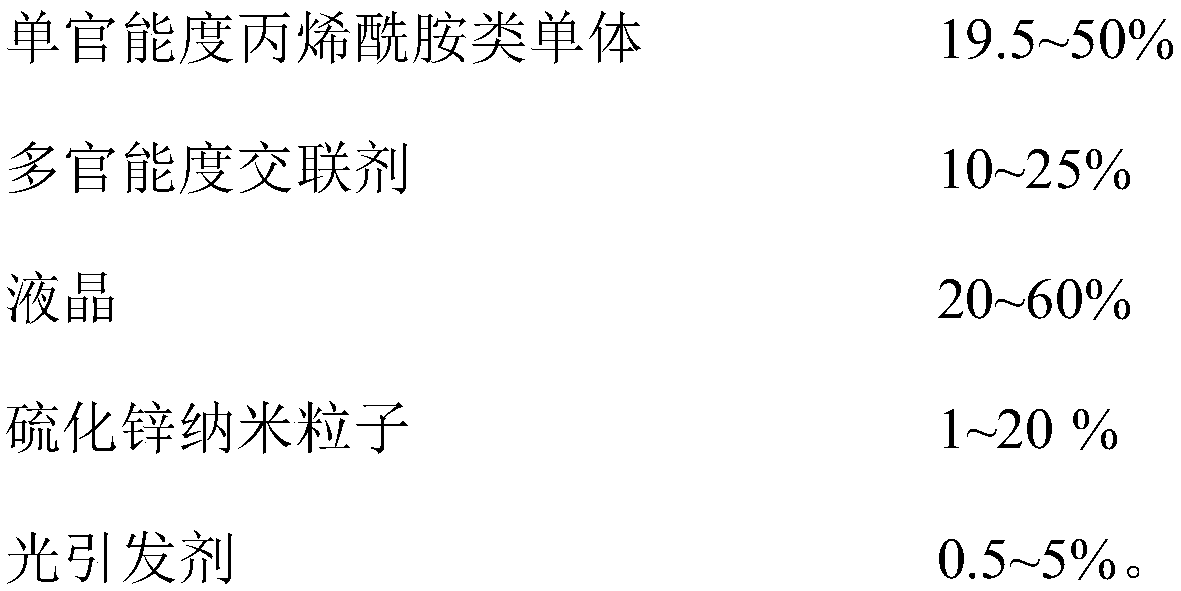

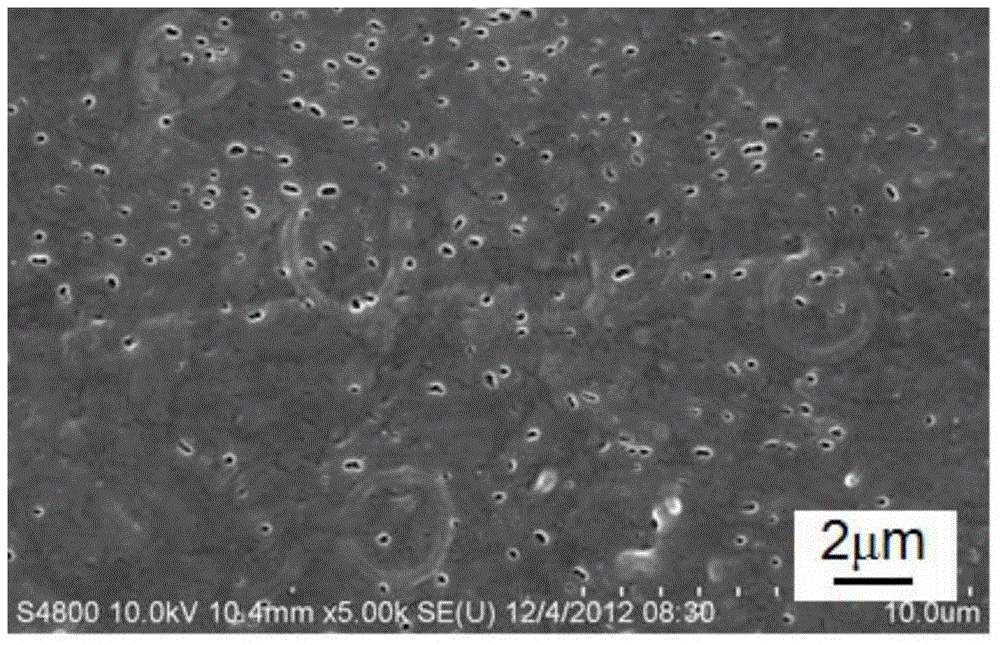

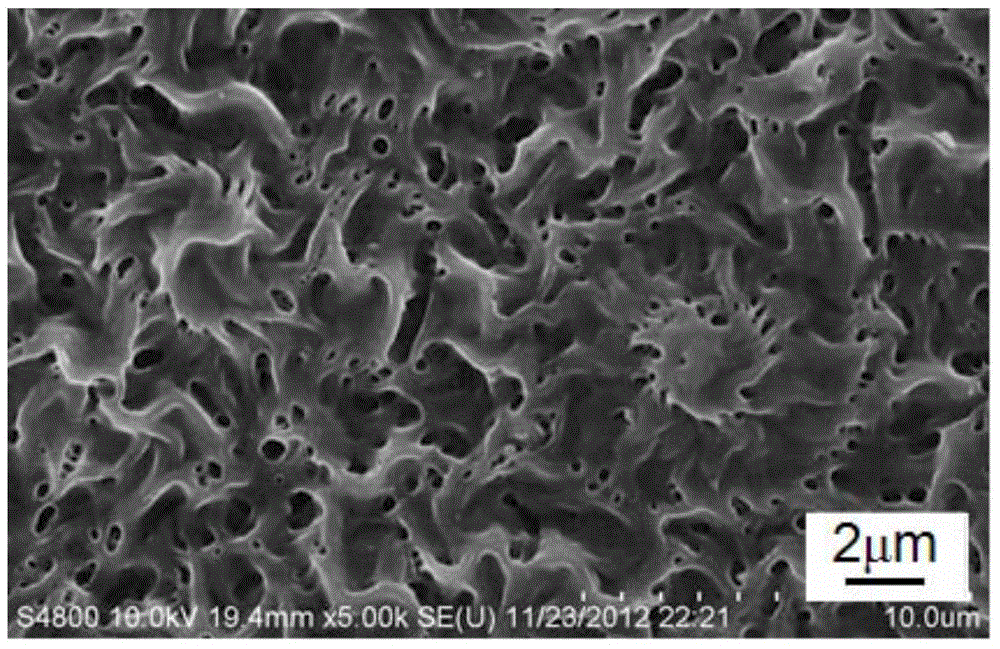

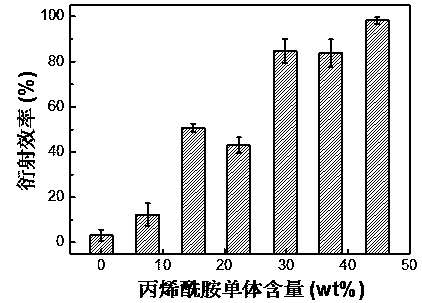

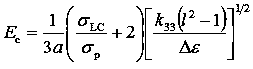

Photopolymer/liquid crystal/zinc sulfide nano-composite holographic grating and preparation method therefor

The invention belongs to the field of function materials, and specifically relates to a photopolymer / liquid crystal / zinc sulfide nano-composite holographic grating and a preparation method therefor. The method comprises the steps: employing a single-functionality acrylamide monomer, a multi-functionality cross-linking agent, liquid crystal, zinc sulfide nano-particles and photoinitiator as raw materials, mixing the raw materials to form mixed solution, pouring the mixed solution into a liquid crystal box, and carrying out exposure through the interference light, thereby obtaining the photopolymer / liquid crystal / zinc sulfide nano-composite holographic grating. The diffraction efficiency of the photopolymer / liquid crystal / zinc sulfide nano-composite holographic grating is higher than 90%, and a drive voltage is less than 2.5V / micron. Meanwhile, the photopolymer / liquid crystal / zinc sulfide nano-composite holographic grating is high in diffraction efficiency, and is low in drive voltage. The photopolymer / liquid crystal / zinc sulfide nano-composite holographic grating is good in application prospects in the fields of 3D display, laser modulation, pohotonic crystal fibers, data storage, environment monitoring, and biosensing.

Owner:HUAZHONG UNIV OF SCI & TECH

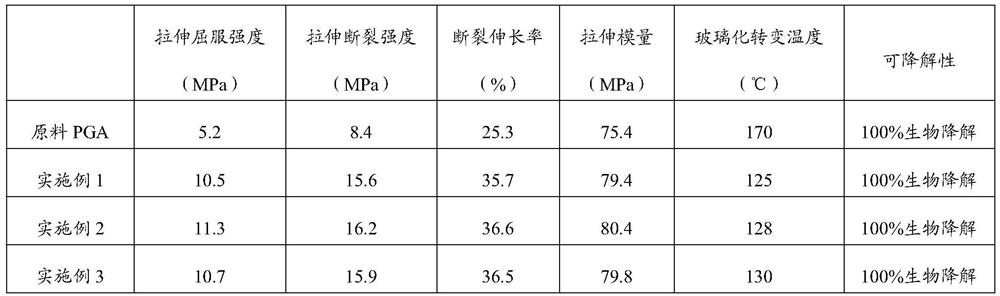

Modified PGA material and preparation method thereof, and modified PGA film

The invention provides a modified PGA material and a preparation method thereof, and a modified PGA film. The invention provides a modified PGA material. The modified PGA material is prepared from the following raw materials in parts by mass: 70-80 parts of PGA; 5-15 parts of an ionic liquid; and 5 to 25 parts of a filler; The ionic liquid is 1-pentyl-3-methylimidazolium tetrafluoroborate. The PGA material is modified by adopting the specific ionic liquid and the filler, so that the tensile strength, the elongation at break and the tensile modulus of the material can be effectively improved, the processability is improved, and good biodegradability is kept.

Owner:HAINAN SHINER IND

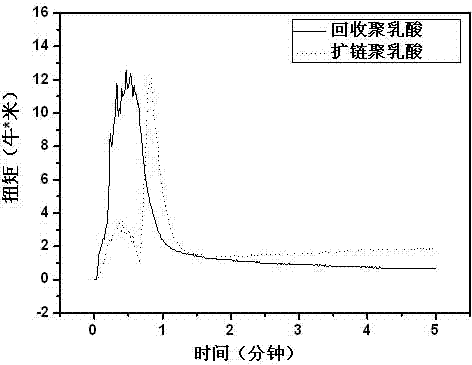

Modified polylactic acid adhesive and preparation method thereof

InactiveCN107216841AImprove plasticityImprove mechanical propertiesNon-macromolecular adhesive additivesStarch derivtive adhesivesAdhesivePolyethylene glycol

The invention discloses a modified polylactic acid adhesive and a preparation method thereof. The modified polylactic acid adhesive comprises the following components in parts by weight: 13-26 parts of starch, 8-20 parts of maleic anhydride, 3-15 parts of polyethylene glycol, 8-19 parts of nano calcium carbonate, 3-11 parts of sodium hydroxide, 8-19 parts of hydroxymethyl cellulose, 1-5 parts of a dispersing agent, 3-8 parts of a defoaming agent, 8-16 parts of an L-lactide monomer and 22-45 parts of polylactic acid. Firstly, the starch in the modified polylactic acid adhesive is good in thermodynamic compatibility with polylactic acid, so that the breaking strength of interfaces is relatively high; and secondly, the adhesive disclosed by the invention is high in plasticity and good in mechanical property and physical property.

Owner:苏州奥宇包装科技有限公司

Highly-wear-resistant plastic sheave liner and preparation method thereof

ActiveCN105482447AGood thermodynamic compatibilityImprove impact resistanceCrack resistanceWear resistant

The invention discloses a highly-wear-resistant plastic sheave liner and a preparation method thereof. The liner consists of the following components in parts by weight: 100 parts of nylon, 10-20 parts of aramid fiber, 15-20 parts of hollow glass beads, 5-15 parts of bauxite, 5-15 parts of barite, 1-3 parts of magnesium stearate, 0.5-1.5 parts of a titanate coupling agent, 10-15 parts of dioctyl phthalate, 1-3 parts of antimony trioxide, 5-10 parts of decabromodiphenyl ether, 10-15 parts of conductive carbon black and 0.5-1.5 parts of an antioxidant. The preparation process is simple, and the prepared plastic liner has good antistatic and flame-retardant properties, can keep relatively high tensile property, and is long in service life; and the sheave liner is good in seasoning crack resistance and moisture resistance, and is particularly suitable for use in severe environments with sprinkling water, strong corrosivity and the like in mines.

Owner:中实洛阳机械工程科技有限公司

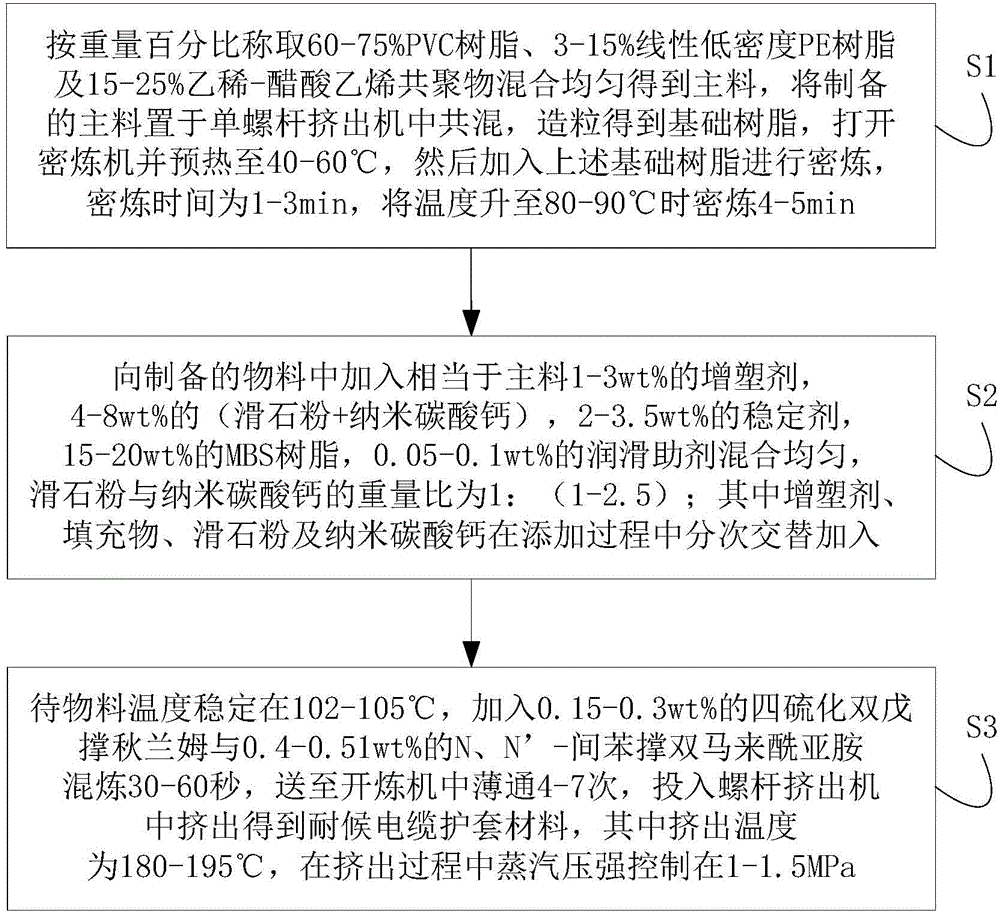

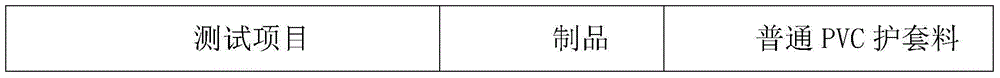

Method for preparing weather-resistant cable sheath material

InactiveCN103951905APrevent debonding and agglomerationEliminate internal stressPlastic/resin/waxes insulatorsInsulated cablesMethacrylateCrack resistance

The invention discloses a method for preparing a weather-resistant cable sheath material. The method comprises the following steps: weighing a PVC (Polyvinyl Chloride) resin, a linear low-density PE (Poly Ethylene) resin and an ethylene-vinyl acetate copolymer, uniformly mixing to obtain a main material, putting the prepared main material into a single screw rod extruder for commixing, pelleting to obtain a basic resin, adding the basic resin into an internal mixer, mixing, subsequently adding a plasticizer, talcum powder, nano calcium carbonate, an MBS (Methacrylate-Butadiene-Styrene) resin, a filler and a lubrication additive, uniformly mixing, adding dipentamethy lene thiuram hexasulfide and N,N'-m-phenylene bismaleimide when the temperature of the material is kept at 102-105 DEG C, mixing for 30-60 minutes, thinning, and extruding to obtain the weather-resistant cable sheath material, wherein the extrusion temperature is 180-195 DEG C, and the pressure intensity of the steam is controlled at 1-1.5MPa in the extrusion process. The weather-resistant cable sheath material is high in hardness, is abrasion-resistant, good in environment crack resistance, excellent in weather resistance and simple in preparation method.

Owner:ANHUI HAIRONG CABLE

Aromatic polyamide hollow fiber membrane and its preparation method and application

Owner:TIANJIN MOTIMO MEMBRANE TECH

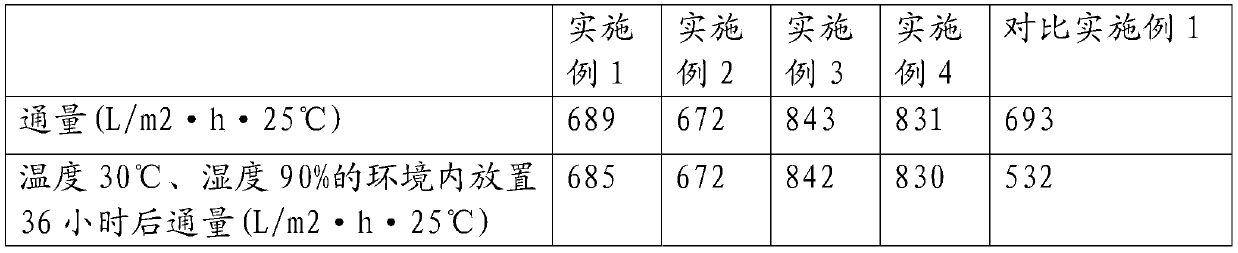

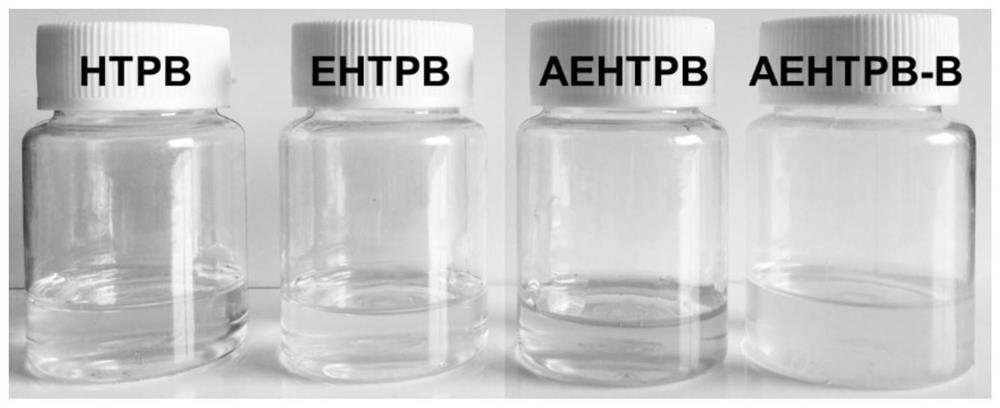

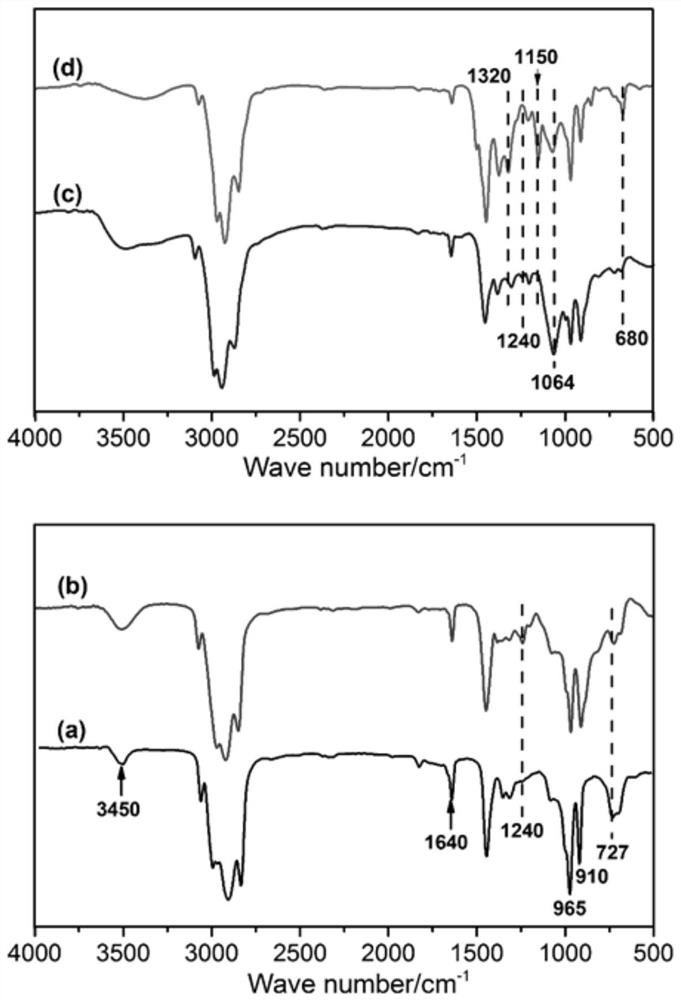

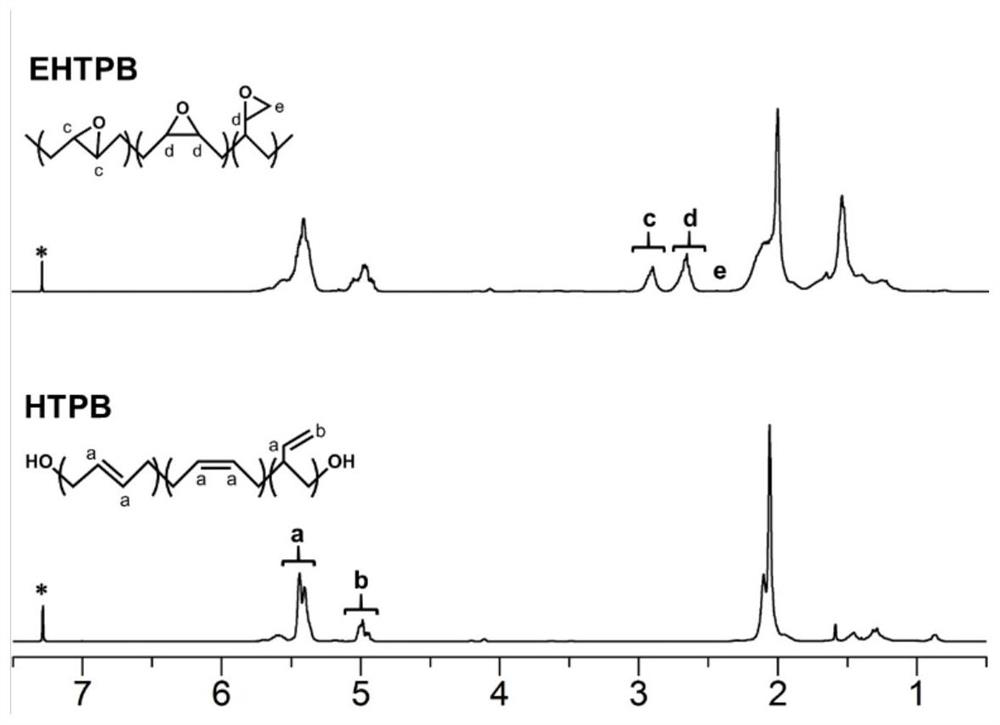

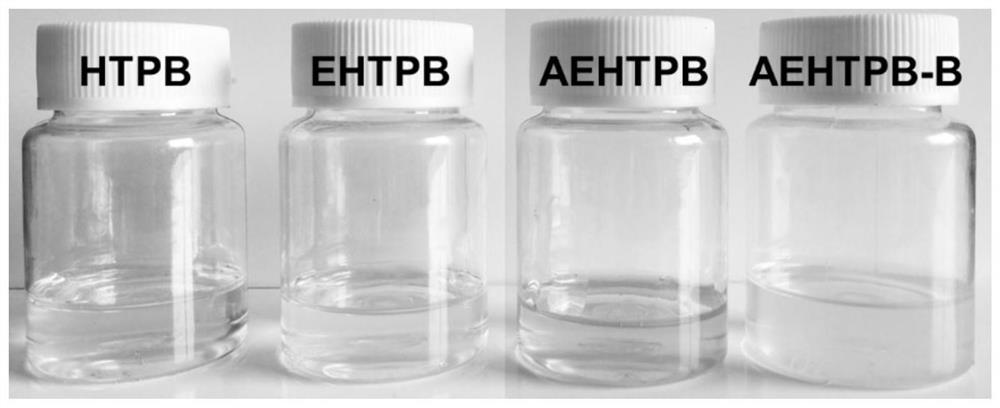

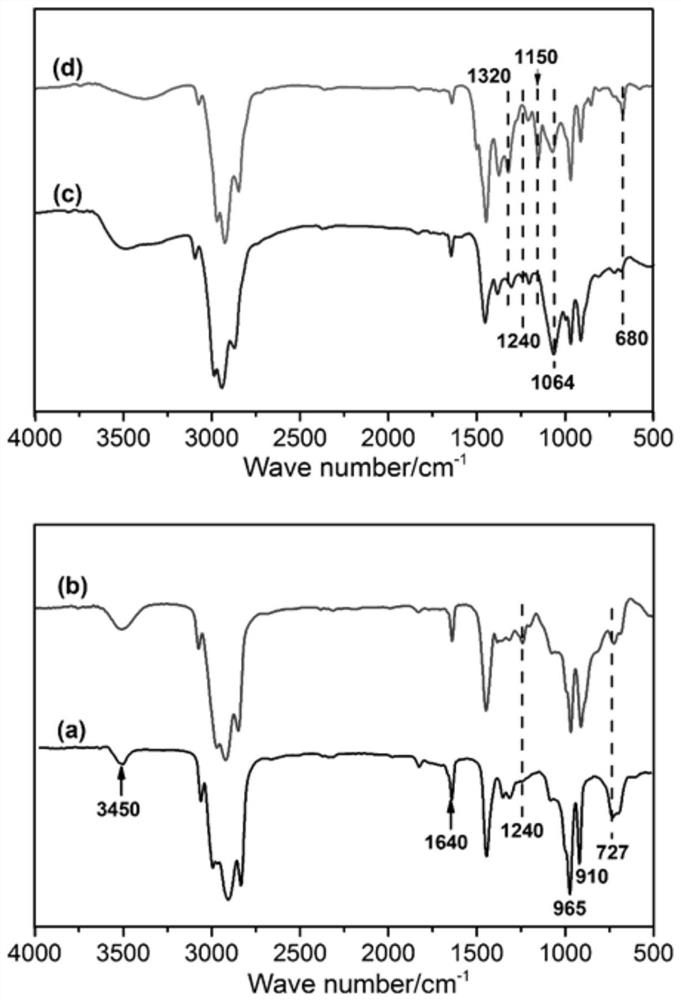

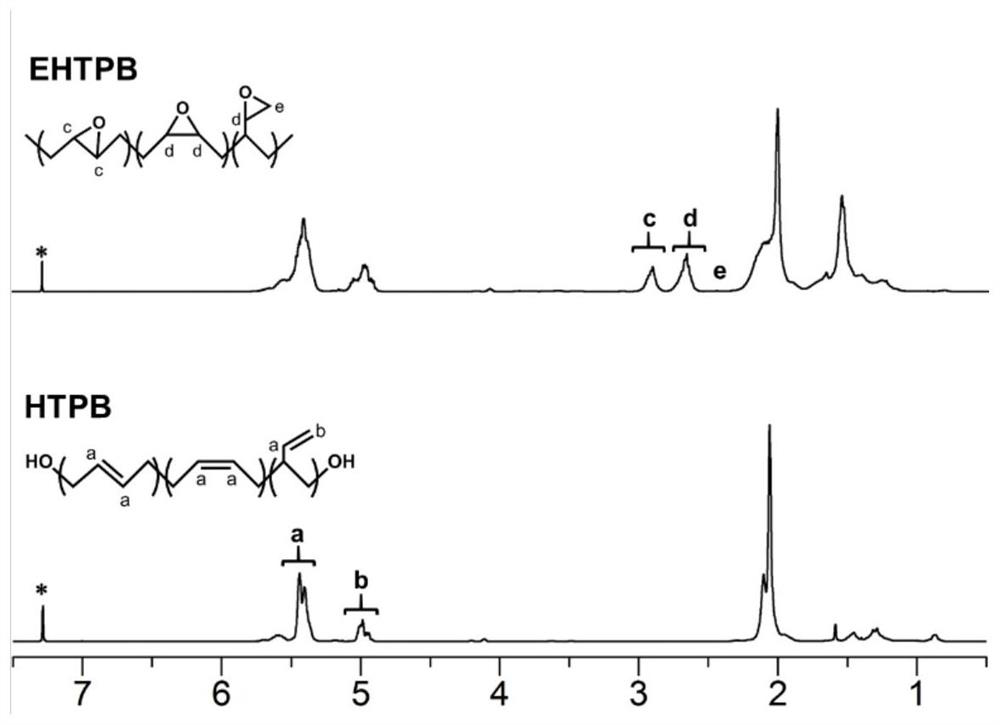

Modified hydroxyl-terminated polybutadiene as well as preparation method and application thereof

ActiveCN112574335AOptimized formulaSimple preparation processNon-explosive/non-thermic compositionsPressure gas generationPolymer scienceBoronic acid

The invention relates to modified hydroxyl-terminated polybutadiene as well as a preparation method and application thereof; the modified hydroxyl-terminated polybutadiene has the following structure:HTPB is used as a starting material for chemical modification of the modified hydroxyl-terminated polybutadiene to prepare modified HTPB containing hydroxyl, tertiary amine group and borate group orcyano group at the same time; then the modified product partially replaces HTPB and is added into the formula of the hydroxyl-terminated polybutadiene propellant, wherein the borate group or cyano group in the molecular structure has the function of interfacial bonding of the nitramine filler, the tertiary amine group has the function of interfacial bonding of the ammonium perchlorate and also hasa function of inhibiting decomposition of the ammonium perchlorate, and the hydroxyl group has the function of in cross-linking enhancement in the curing stage. Besides, the modified HTPB integratingthe functions of crosslinking enhancement, interface bonding, combustion speed adjustment and the like has excellent compatibility with a traditional HTPB adhesive, and after the modified HTPB and the traditional HTPB adhesive are mixed, the overall polarity of a propellant adhesive matrix can be improved, and the thermodynamic compatibility with other functional auxiliaries is enhanced.

Owner:HUNAN UNIV

Manufacturing technique of automobile engine seal gasket

InactiveCN106832462ADoes not affect low temperature resistanceImprove cold resistanceEngine sealsEngineeringSolvent

The invention discloses a manufacturing process of an automobile engine sealing gasket. The invention uses raw nitrile rubber as a raw material, modifies the nitrile rubber with a small amount of acrylate rubber, firstly swells and dissolves it in a solvent, and then under the condition of mechanical stirring, successively Add reinforcing filler, active agent, anti-aging agent, vulcanizing agent, plasticizer and other additives, stir and mix evenly, and dilute with a solvent to a suitable viscosity, and apply it to the surface-treated metal plate by dip coating On, vulcanization molding, the preparation of nitrile and acrylic compound sealing gasket with rubber metal.

Owner:ANHUI MENGLING PRECISION ELECTRONICS

Preparation method of carbon fiber reinforced carbon-silicon carbide double matrix composites

The invention provides a preparation method of a carbon fiber reinforced carbon-silicon carbide double-matrix composite material. According to the present invention, through silicon-molybdenum alloy infiltration, a molybdenum disilicide phase is introduced into a composite material matrix so as to reduce the residual silicon element and reduce the brittleness of the composite material; molybdenum disilicide has characteristics of moderate density, high melting point and good oxidation resistance, and can be converted from the brittleness to the plasticity within a certain temperature range, wherein molybdenum disilicide has a plastic deformation behavior and shows metal-like ductility when the temperature exceeds the temperature range so as to improve the fracture toughness of the composite material; molybdenum disilicide has a low thermal expansion coefficient and has good thermodynamic compatibility to silicon carbide so as to easily reduce the crack generation; and the process is simple, and the operation is easy.

Owner:BEIHANG UNIV

A kind of preparation method of high wear-resistant plastic sky wheel liner

ActiveCN105482447BGood thermodynamic compatibilityImprove impact resistanceCrack resistanceWear resistant

Owner:中实洛阳机械工程科技有限公司

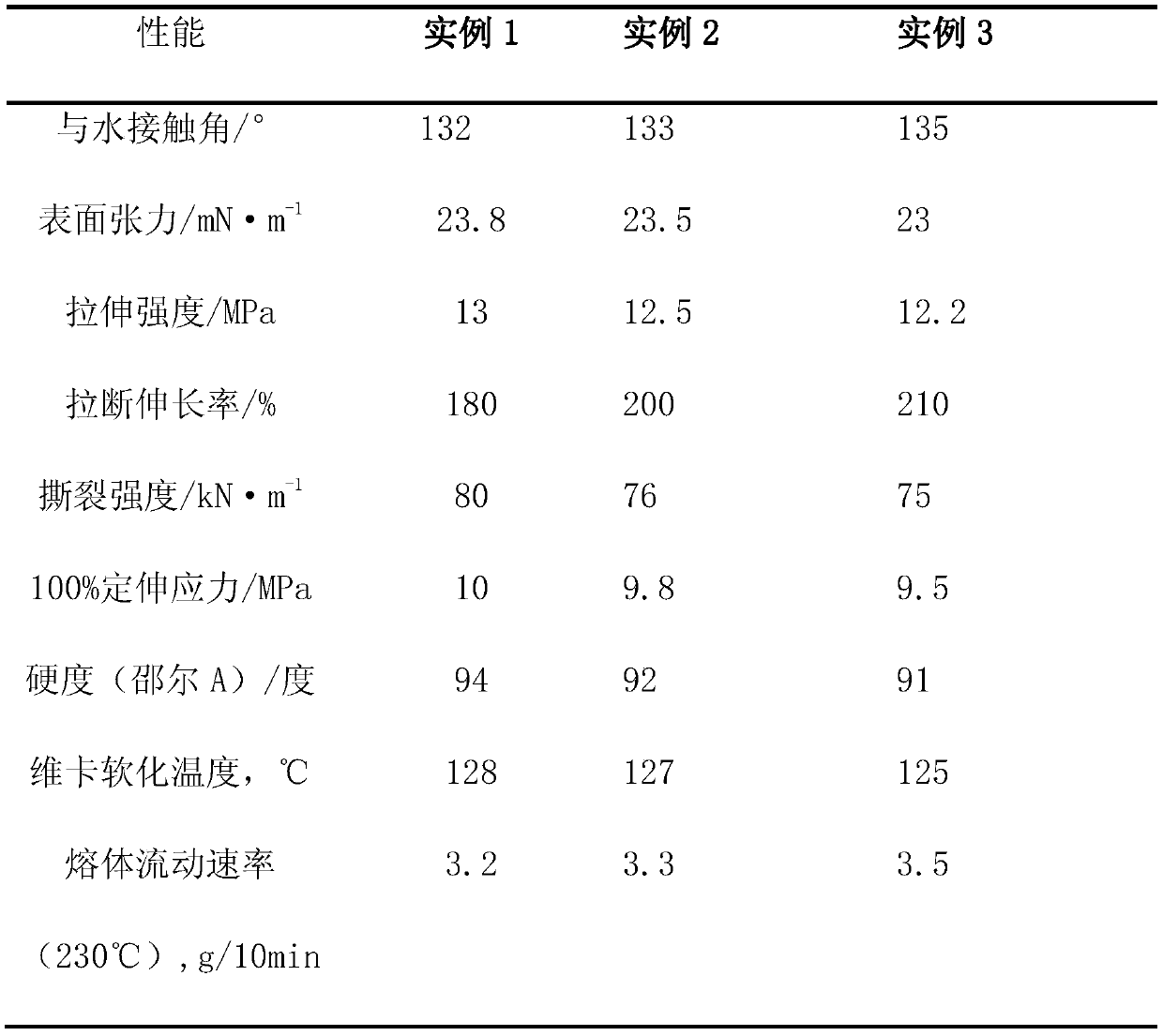

A kind of hydrophobic and heat-resistant thermoplastic elastomer and its preparation method

ActiveCN107325404BSolve the problem of degrading PPReduce surface tensionPlastic/resin/waxes insulatorsElastomerVulcanization

The invention relates to a lyophobic and thermal-resistant type thermoplastic elastomer and a preparation method thereof. The preparation method comprises the following steps: by taking polypropylene (PP) as a base material, performing dynamic vulcanization on methyl vinyl silicone rubber (MVQ) and a polyethylene-octylene elastomer (POE) to prepare the thermoplastic elastomer, performing commixing modification on PP and the thermoplastic elastomer by using a double-screw extruder, and further adding polytetrafluoroethylene micro powder of 200 meshes, thereby obtaining a novel thermoplastic material which is good in self-cleaning property, excellent in mechanical property and good in high temperature resistance and can be recycled.

Owner:QINGDAO UNIV OF SCI & TECH +1

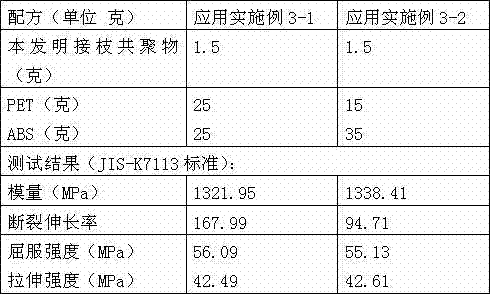

Comb-shaped stem grafting copolymer containing reactive group and preparation method and application thereof

The invention discloses a comb-shaped stem grafting copolymer containing reactive group and a preparation method and application thereof. The copolymer is a comb-shaped stem grafting copolymer by taking small molecule monomer B as the main chain, and giant molecule monomer A as the side chain. According to the method, the giant molecule monomer A and the small molecule monomer B are copolymerized to form the comb-shaped stem grafting copolymer of which the main chain is the small molecule monomer B and the side chain is the giant molecule monomer A. The comb-shaped stem grafting copolymer disclosed by the invention can serve as the chain extender of a polymer or a polymer blend, the compatibilizer of the polymer blend, the hydrolytic stabilizer, adhesive and anti-leakage agent of the polymer blend, and is used for coatings of wood, metal or plastic. The reactive group in the copolymer has very high reaction activity, and can react with various end groups of polyamide and polyester. Methacrylate monomers have thermodynamics compatibility with various polymers. The reactive group can react with the end hydroxyl group or the end carboxy group of polyester, so that the comb-shaped stem grafting copolymer can serve as the chain extender, and the processing and application properties of the material are improved.

Owner:HANGZHOU NORMAL UNIVERSITY

Preparation method of low-melting-point composite polyester fiber with porous structure

PendingCN114775106AHigh mechanical strengthResolve stiffnessFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterSpinning

The invention discloses a preparation method of a low-melting-point composite polyester fiber with a porous structure, a composite fiber is prepared from low-melting-point polyester and fiber-grade polyester through a skin-core composite spinning method, a skin layer in the composite fiber comprises the low-melting-point polyester and a pre-activator, and a core layer is the fiber-grade polyester; and activating the composite fibers to prepare the porous-structure low-melting-point composite polyester fibers, and forming the porous-structure low-melting-point composite polyester fibers through hot air. The composite fiber is activated by a certain water solution, and micropores with the diameter of 0.1-1.0 micron are formed on the surface of the activated composite fiber. The porous composite low-melting-point polyester fiber is excellent in mechanical property, the surface porous structure endows a high specific surface area, the fiber water absorption rate is remarkably improved, meanwhile, when the porous composite low-melting-point polyester fiber is used as a hot melting bonding material, the bonding strength between fibers is high, high resilience under the action of strong external force can be achieved, and the application requirement of high-grade three-dimensional structure non-woven fabric is met.

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

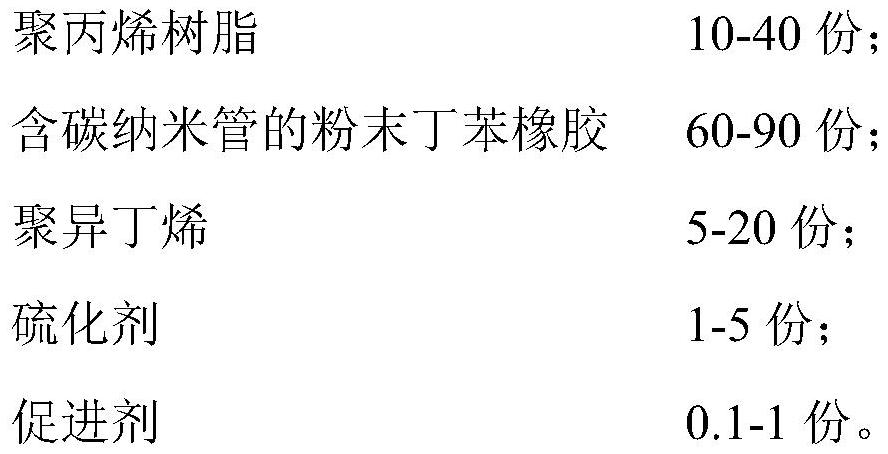

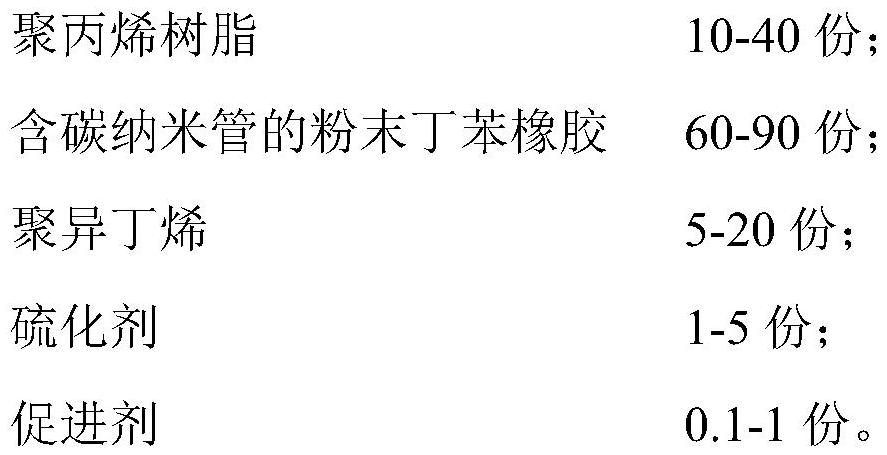

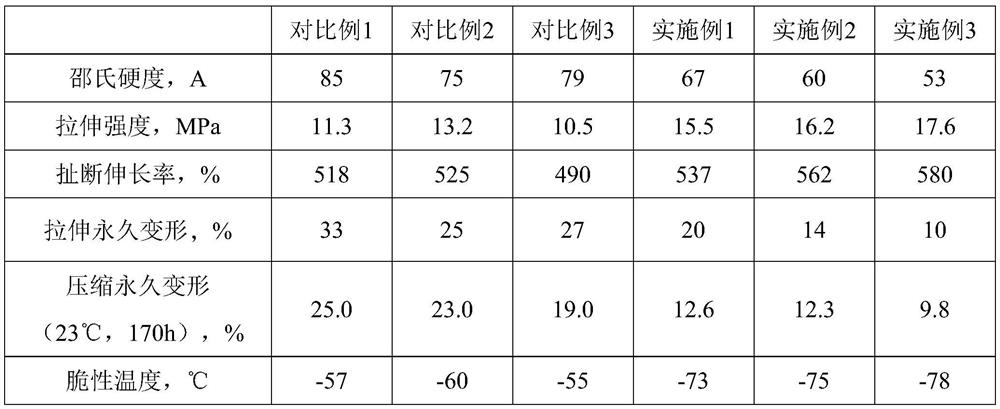

Low-temperature-resistant low-hardness thermoplastic elastomer and preparation method thereof

The invention relates to a low-temperature-resistant low-hardness thermoplastic elastomer and a preparation method thereof, and belongs to the field of high-molecular elastomers. The low-temperature-resistant low-hardness thermoplastic elastomer is prepared from the following raw materials in parts by mass: 10-40 parts of polypropylene resin, 60-90 parts of powdered styrene-butadiene rubber containing carbon nanotubes, 5-20 parts of polyisobutene, 1-5 parts of a vulcanizing agent, and 0.1-1 part of an accelerant. According to the invention, styrene-butadiene rubber and polypropylene resin are taken as basic raw materials, a dynamic vulcanization technology is adopted, the powdered styrene-butadiene rubber containing carbon nanotubes is prepared by a co-flocculation process of a carbon nanotube emulsion and a styrene-butadiene rubber emulsion, the powdered styrene-butadiene rubber is blended with polypropylene resin, and low-molecular-weight polyisobutene is used for oil-filled softening to prepare the low-temperature-resistant low-hardness thermoplastic elastomer. The problem of large permanent deformation caused by poor dispersibility of the filler is solved by using the co-flocculation process of the carbon nanotube emulsion and the styrene-butadiene rubber emulsion, the hardness of the TPV product is reduced by filling the low-molecular-weight polyisobutene, and the TPV has excellent low-temperature resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of ternary alloy containing aromatic polyamide and preparation method thereof

Disclosed are a ternary alloy containing an aromatic polyamide and a preparation method therefor. The ternary alloy containing an aromatic polyamide is prepared from the following raw materials in parts by weight: 70-94 parts of polyether ether ketone, 3-20 parts of polyetherimide, and 3-10 parts of an aromatic polyamide, wherein the aromatic polyamide is an aromatic polyamide containing an ether ketone structure or naphthalene. According to the disclosure in the embodiments, the ternary alloy has a friction coefficient reduced by ≥4.7%, a wear rate reduced by ≥35.3%, and significantly improved mechanical properties compared with those of a pure PEEK phase.

Owner:JILIN UNIV

A kind of three-dimensional crimped elastic fiber and its preparation method

ActiveCN107574507BNo peelingGood thermodynamic compatibilityFilament/thread formingConjugated synthetic polymer artificial filamentsPolymer sciencePolyethylene terephthalate glycol

The invention relates to a three-dimensional curled elastic fiber and a preparation method thereof, and especially relates to an elastic fiber proto-filament, which is prepared by the following steps:taking modified co-polyester and polyethylene glycol tere-phthalate as raw materials and then subjecting raw materials to parallelly compounded asymmetric melt spinning, circular blow cooling, oiling, reeling, and bucket falling. The elastic short fiber with a three dimensional curling property is prepared by subjecting the proto-filament to following steps: bundling, drawing, oiling, tightened thermoforming, and cutting. The modified co-polyester is prepared by adding a modifying component (tween) in the synthesis process of polyethylene glycol tere-phthalate to carry out ester exchange andpolycondensation. The modifying component (tween) is an aliphatic hydrophilic flexible chain macromolecule, can form modified block co-polyester with polyester hard sections, and can obviously enhancethe water moistening property of polyethylene glycol tere-phthalate. The prepared three-dimensional curled elastic fiber has the advantages of high fluffiness and high elastic recovery rate, has a normal pressure boiling dyeing effect, and is widely used in fields such as home textile, clothes, and the like.

Owner:JIANGSU DESAI CHEM FIBER

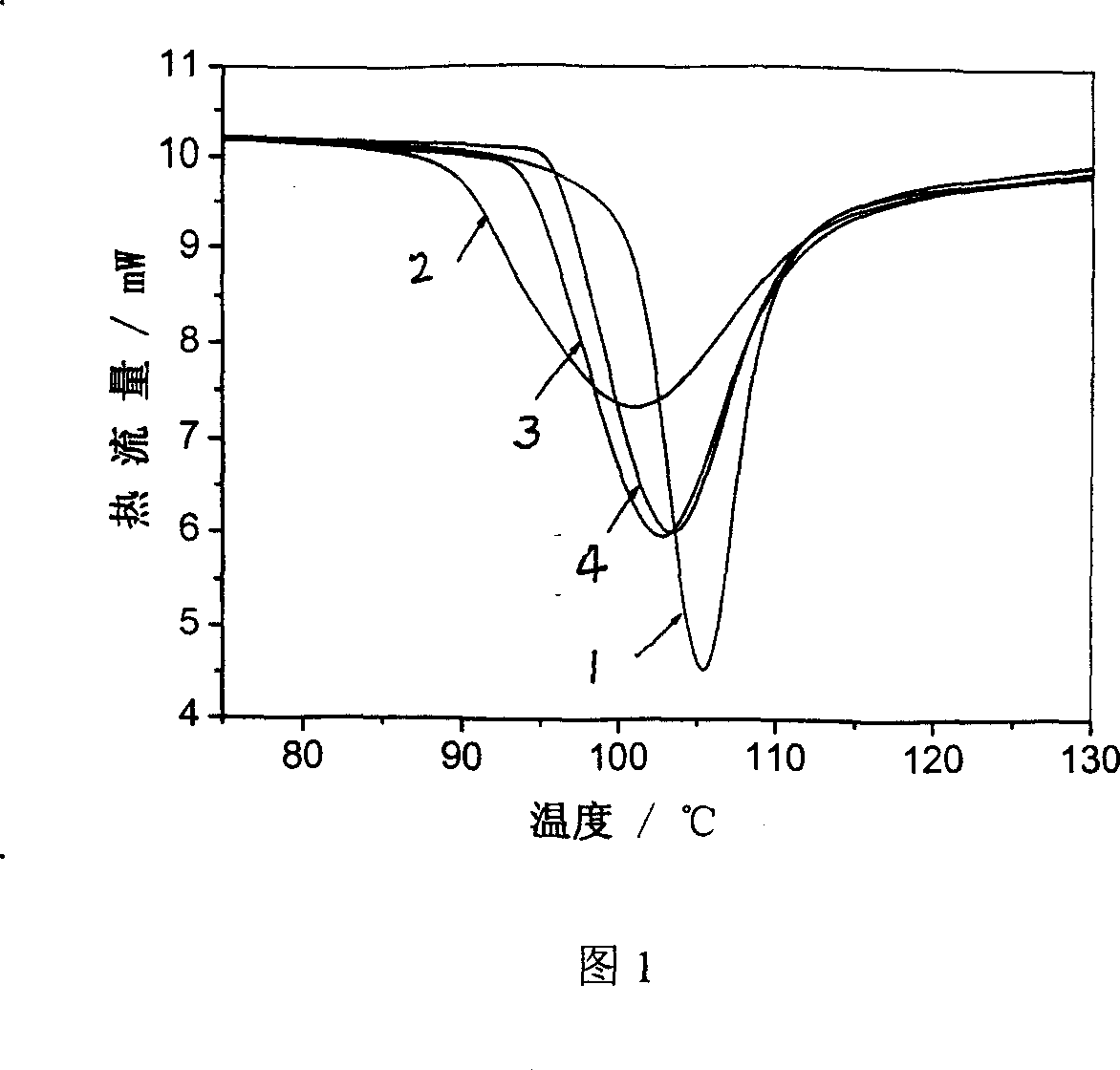

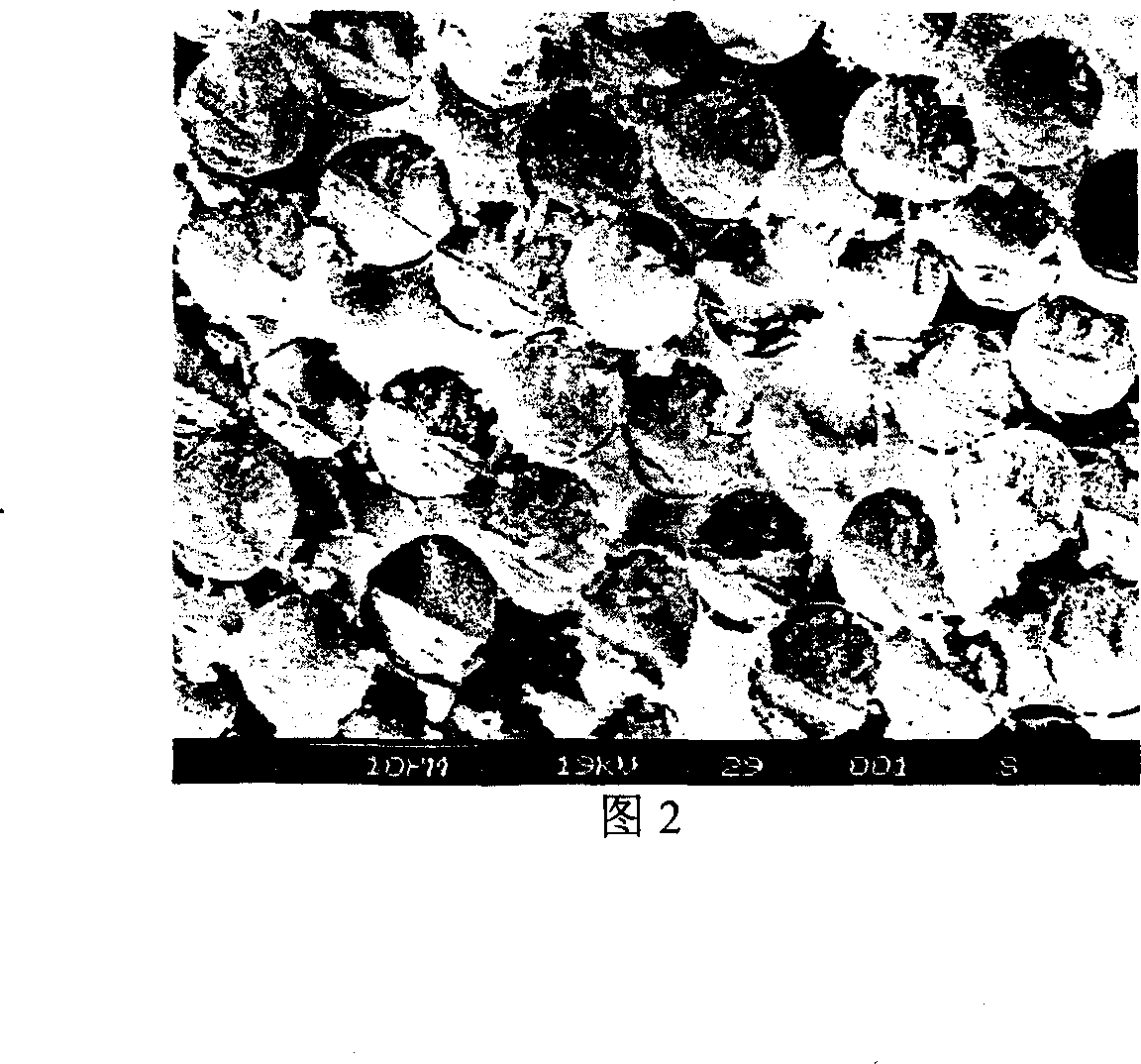

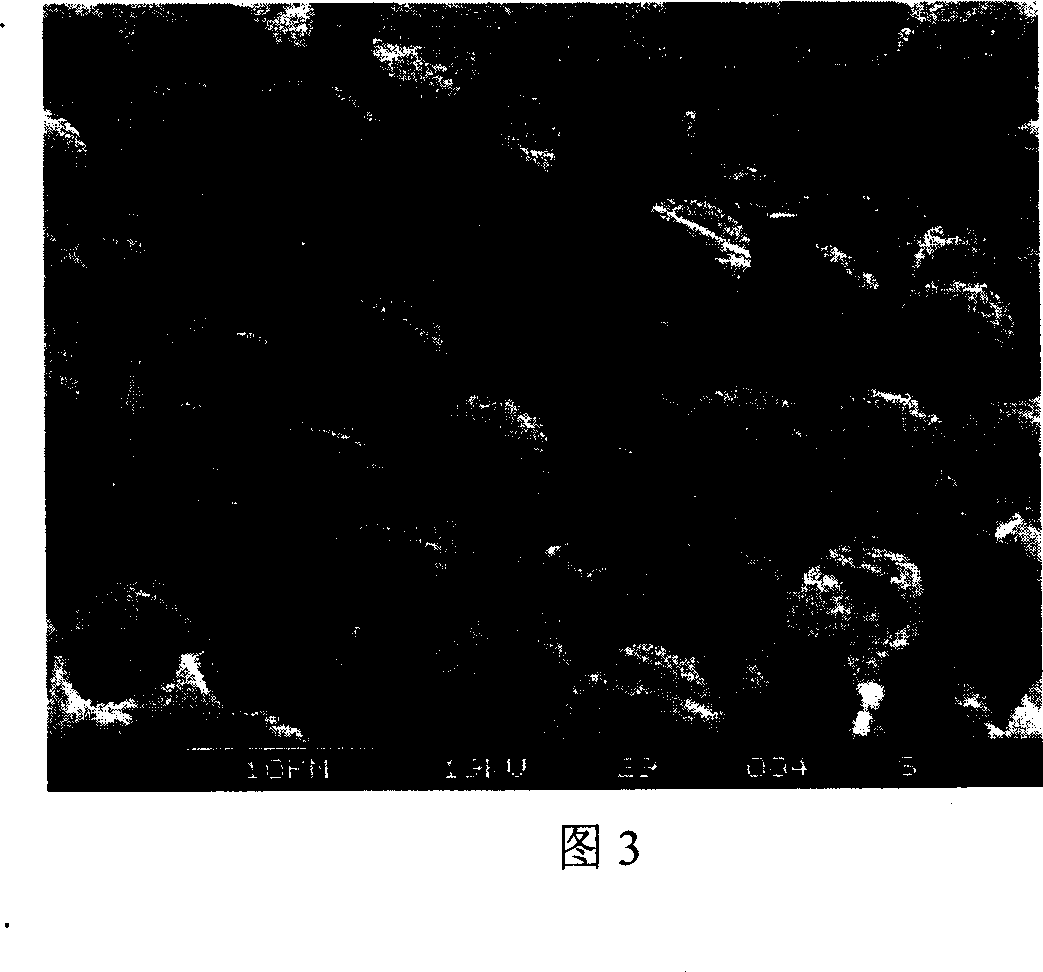

A polyoxymethylene nanoporous film with micro-nano double continuous porous structure and preparation method thereof

The invention discloses a polyformaldehyde nanopore film with a micro-nano bicontinuous porous structure and a preparation method of the polyformaldehyde nanopore film. The film is 1-300mu m thick, has a nano bicontinuous porous structure and is made of polyformaldehyde. The method comprises the steps: drying polylactic acid and polyformaldehyde, adding the dried polylactic acid and polyformaldehyde into melting and mixing equipment for melting and mixing for 5-10min, discharging, cooling, then, melting and tabletting to prepare a film with the thickness of 1-300mu m, soaking the film into an alkaline solution of polylactic acid with the temperature of 65 DEG C for 120h to obtain the polyformaldehyde nanopore film; or extracting the film by using a Soxhlet extraction method to obtain the polyformaldehyde nanopore film, wherein a good solvent for the polylactic acid is used as an extraction solution, the heating temperature is controlled so that the extraction solution can reflow once every 6-8min, and the extraction time is 6-12h. The melt of polyformaldehyde can crystallize in the polyformaldehyde nanopore film to form double continuous support networks which are communicated with each other; and the film has favorable ductility and mechanical strength, high water flux and porosity and the arrangement of pores in the film is controllable.

Owner:HANGZHOU NORMAL UNIVERSITY

A photopolymer/liquid crystal/zinc sulfide nanocomposite holographic grating and its preparation method

ActiveCN107255840BHigh diffraction efficiencyGood thermodynamic compatibilityDiffraction gratingsMaterials scienceLiquid crystal cell

Owner:HUAZHONG UNIV OF SCI & TECH

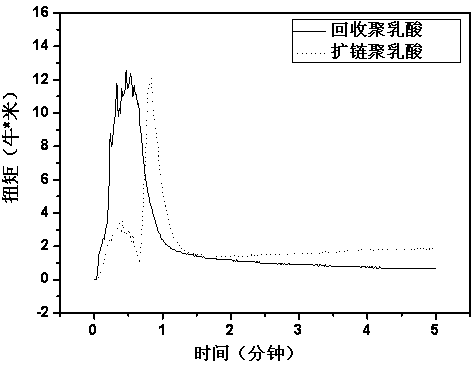

Nitrile rubber-modified polylactic acid composite material and preparation method thereof

The invention discloses a nitrile rubber-modified polylactic acid composite material and a preparation method thereof. The composite material comprises, by weight, 12 to 29 parts of Manila hemp fibers, 3 to 15 parts of China hemp fibers, 5 to 16 parts of banana leaf fibers, 12 to 26 parts of nitrile rubber, 8 to 17 parts of polycaprolactone, 3 to 11 parts of polyurethane, 1 to 9 parts of dicumyl peroxide, 3 to 8 parts of a L-lactide monomer, 1 to 7 parts of maleic anhydride and 25 to 55 parts of polylactic acid. The nitrile rubber-modified polylactic acid composite material flexibilizer has good thermodynamical compatibility with polylactic acid. The composite material has obvious toughening effects.

Owner:苏州奥宇包装科技有限公司

Preparation method of isomeric polyester sheath-core composite fiber

PendingCN114775105AGood thermodynamic compatibilityHigh mechanical strengthFilament/thread formingArtificial filament heat treatmentFiberPolymer science

The invention discloses a preparation method of an isomeric polyester sheath-core composite fiber, which comprises the following steps: carrying out sheath-core composite spinning on low-melting-point polyester and block copolyester to prepare a composite fiber, a sheath layer in the composite fiber comprises the low-melting-point polyester and a pre-activated polymer, and a core layer is the block copolyester; activating the composite fiber to prepare an isomeric polyester sheath-core composite fiber; and carrying out hot air forming on the isomeric polyester sheath-core composite fiber. The main components of the skin layer and the core layer are polyesters, and have good interfacial compatibility. The composite fiber is activated by a certain alkaline aqueous solution, and a microporous structure with the diameter of 0.1-1.0 micron and rich reactive groups are formed on the surface of the activated composite fiber. In hot air bonding of the isomeric polyester sheath-core composite fibers, the contact area between the fibers is increased, meanwhile, the reactive groups further react with the surfaces of the fibers, and the bonding strength is comprehensively improved. The method can be applied to non-woven high-resilience textiles.

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

High toughness and high modulus polypropylene composite material and preparation method thereof

The invention discloses a high-toughness high-modulus polypropylene composite material and a preparation method thereof. The high-toughness high-modulus polypropylene composite material consists of 50-62.5 parts of a polypropylene base body, 10-12 parts of high-density polyethylene, 12-15 parts of a polyolefin elastomer, 6-9 parts of modified wollastonite, 0.5-2 parts of nano modified particles, 1-2 parts of modified boron nitride, 5-6 parts of a compatibilizer, 1-1.5 parts of an antioxidant and 2-2.5 parts of a lubricating agent, wherein the nano modified particles are obtained by mixing a silane coupling agent and nano titanium dioxide in a weight ratio of 1 to 100. The preparation process is simple and convenient, the adopted materials are cheap, the comprehensive cost is lower than that of conventional toughness-modified polypropylene, and the produced high-toughness high-strength high-modulus polypropylene is excellent in performance. A composite system disclosed by the invention forms a polymer / flexible interface layer / inorganic particle three-phase composite system.

Owner:HENAN UNIV OF SCI & TECH

Fibre reinforced vinyl ester resin base pultrusion composite

A fibre reinforced vinylester-resin composition with high toughness, strength and high-temp resistance is prepared from the refractory vinylester-resin composition prepared from phenolic vinylester resin, biphenol-A vinylester resin, solidifying agent and additive, and the reinforcing fibres chosen from carbon fibres, glass fibres, aramide fibres and their mixture through pulling and extruding.

Owner:胜利油田孚瑞特石油装备有限责任公司 +1

A modified hydroxyl-terminated polybutadiene and its preparation method and application

ActiveCN112574335BOptimized formulaSimple preparation processNon-explosive/non-thermic compositionsPressure gas generationPolymer scienceBoronic acid

The invention relates to a modified hydroxyl-terminated polybutadiene and its preparation method and application. The modified hydroxyl-terminated polybutadiene has the following structure: the modified hydroxyl-terminated polybutadiene uses HTPB as a starting material, and Chemical modification is used to prepare modified HTPB containing both hydroxyl groups, tertiary amine groups, and borate ester groups or cyano groups; the modified product is partially replaced by HTPB and added to the butyl hydroxyl propellant formula, and the borate ester group or cyano group in its molecular structure is The tertiary amine group can play an interfacial bonding role with nitramine filler, the tertiary amine group can play an interfacial bonding role with ammonium perchlorate, and can inhibit the decomposition of ammonium perchlorate, and the hydroxyl group can play a cross-linking enhancement role during the curing stage. In addition, this modified HTPB, which integrates cross-linking enhancement, interfacial bonding, burning rate adjustment and other functions, has excellent compatibility with traditional HTPB adhesives. Mixing the two can improve the overall propellant adhesive matrix. Polarity, enhances thermodynamic compatibility with other functional additives.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com