Preparation method of carbon fiber reinforced carbon-silicon carbide double-matrix composite material

A silicon carbide dual-composite material technology, applied in the field of composite materials, can solve the problems of limiting the service temperature of composite materials, insufficient fracture toughness, damage to mechanical properties, etc., and achieves good oxidation resistance, reducing cracks and reducing brittleness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

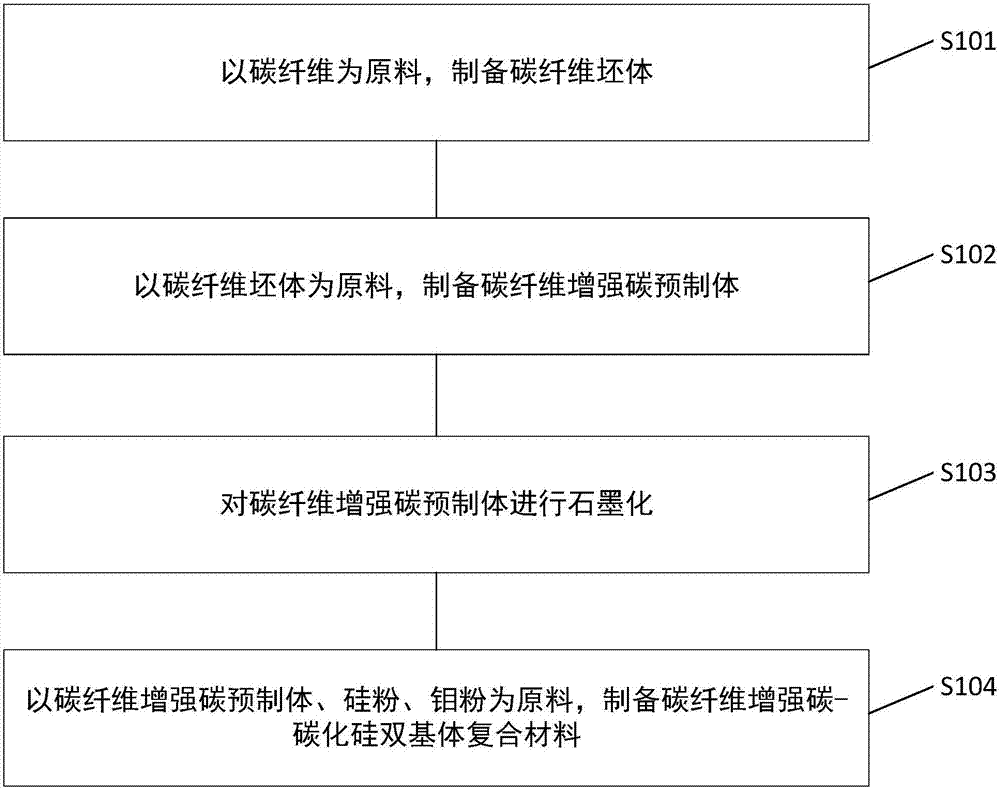

[0030] Such as figure 1 As shown, the embodiment of the present invention provides a method for preparing a carbon fiber reinforced carbon-silicon carbide double-matrix composite material, including:

[0031] Step S101, using carbon fiber as a raw material to prepare a carbon fiber green body;

[0032] Step S102, using the carbon fiber green body as a raw material to prepare a carbon fiber reinforced carbon prefabricated body;

[0033] Step S103, graphitizing the carbon fiber reinforced carbon preform;

[0034] Step S104, using carbon fiber reinforced carbon prefabricated body, silicon powder, and molybdenum powder as raw materials to prepare carbon fiber reinforced carbon-silicon carbide double-matrix composite material.

[0035] The embodiment of the present invention introduces the molybdenum disilicide phase into the composite material matrix to reduce the residual silicon element and the brittleness of the composite material through the co-infiltration of silicon-molybd...

specific Embodiment 2

[0055] An embodiment of the present invention provides a method for preparing a carbon fiber reinforced carbon-silicon carbide double-matrix composite material, including:

[0056] Step 1, preparing a carbon fiber green body; the carbon fiber green body is a two-dimensional 0° / 90° laminate, or a three-dimensional acupuncture or three-dimensional weaving;

[0057] Step 2, prepare C / C composite material preform:

[0058] The prepared carbon fiber three-dimensional needle-punched braided body was loaded into a chemical vapor deposition furnace for deposition. The deposition temperature is 950-1050°C, the deposition gas is natural gas and propane, the flow rate of natural gas is 3.5-6.5L / min., the flow rate of propane is 0.2-0.5L / min., the furnace pressure is 1000Pa, and the deposition time is 10h-30h , the C / C composite material prefabricated body can be obtained;

[0059] Step 3, graphitization treatment:

[0060] Put the obtained C / C composite material into a high-temperatur...

specific Embodiment 3

[0072] An embodiment of the present invention provides a method for preparing a carbon fiber reinforced carbon-silicon carbide double-matrix composite material, the method comprising:

[0073] Step 1, weaving T700 carbon fiber into a two-dimensional 0° / 90° carbon fiber fabric laminate;

[0074] Step 2, prepare C / C composite material preform:

[0075] The prepared two-dimensional carbon fiber fabric stack was loaded into a chemical vapor deposition furnace for deposition. The deposition temperature is 1005°C, the deposition gas is natural gas and propane, the flow rate of natural gas is 4.0L / min., the flow rate of propane is 0.4L / min., the furnace pressure is 1000Pa, and the deposition time is 20h, the C / C can be obtained. Composite preforms;

[0076] Step 3, graphitization treatment:

[0077] Put the obtained C / C composite material into a high-temperature heat treatment furnace for graphitization treatment, the specific process is as follows:

[0078] Vacuumize the high te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com