Patents

Literature

360 results about "Molybdenum disilicide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

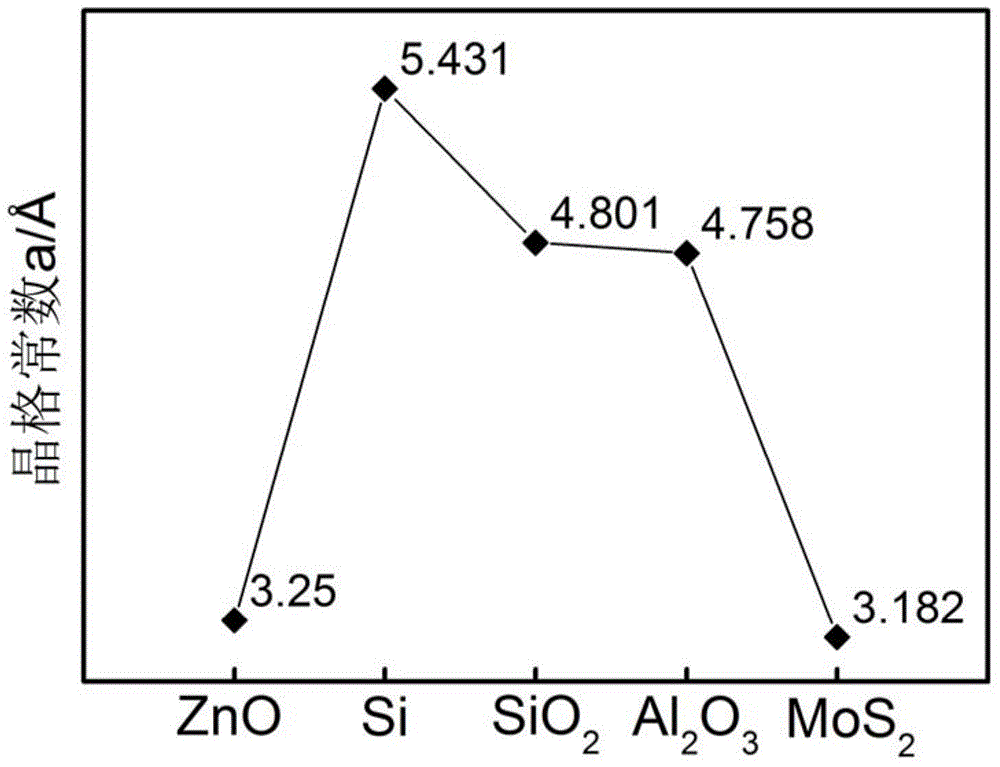

Molybdenum disilicide (MoSi₂, or molybdenum silicide), an intermetallic compound, a silicide of molybdenum, is a refractory ceramic with primary use in heating elements. It has moderate density, melting point 2030 °C, and is electrically conductive. At high temperatures it forms a passivation layer of silicon dioxide, protecting it from further oxidation. The thermal stability of MoSi₂ alongside its high emissivity make this material, alongside WSi₂ attractive for applications as a high emissivity coatings in heat shields for atmospheric entry. MoSi₂ is a gray metallic-looking material with tetragonal crystal structure (alpha-modification); its beta-modification is hexagonal and unstable. It is insoluble in most acids but soluble in nitric acid and hydrofluoric acid.

Thermal protective coating for ceramic surfaces

ActiveUS6921431B2Extended shelf lifeConvenience to workFireproof paintsOther chemical processesColloidal silicaSodium Bentonite

A coating admixture, method of coating and substrates coated thereby, wherein the coating contains colloidal silica, colloidal alumina, or combinations thereof; a filler such as silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides, copper chromium oxides, cerium oxides, terbium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide is also added.

Owner:WESSEX

Thermal protective coating for ceramic surfaces

ActiveUS20050051057A1Extend working lifeReduce surface temperatureFireproof paintsOther chemical processesColloidal silicaSodium Bentonite

A coating admixture, method of coating and substrates coated thereby, wherein the coating contains colloidal silica, colloidal alumina, or combinations thereof; a filler such as silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides, copper chromium oxides, cerium oxides, terbium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide is also added.

Owner:WESSEX

Thermal protective coating

ActiveUS7105047B2Extended shelf lifeReduce weightAlkali metal silicate coatingsPretreated surfacesCalcium silicateSodium Bentonite

A coating, method of coating and substrates coated thereby, wherein the coating contains an inorganic adhesive such as an alkali / alkaline earth metal silicate such as sodium silicate, potassium silicate, calcium silicate, and magnesium silicate; a filler such as a metal oxide for example silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides and copper chromium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide may be added.

Owner:WESSEX

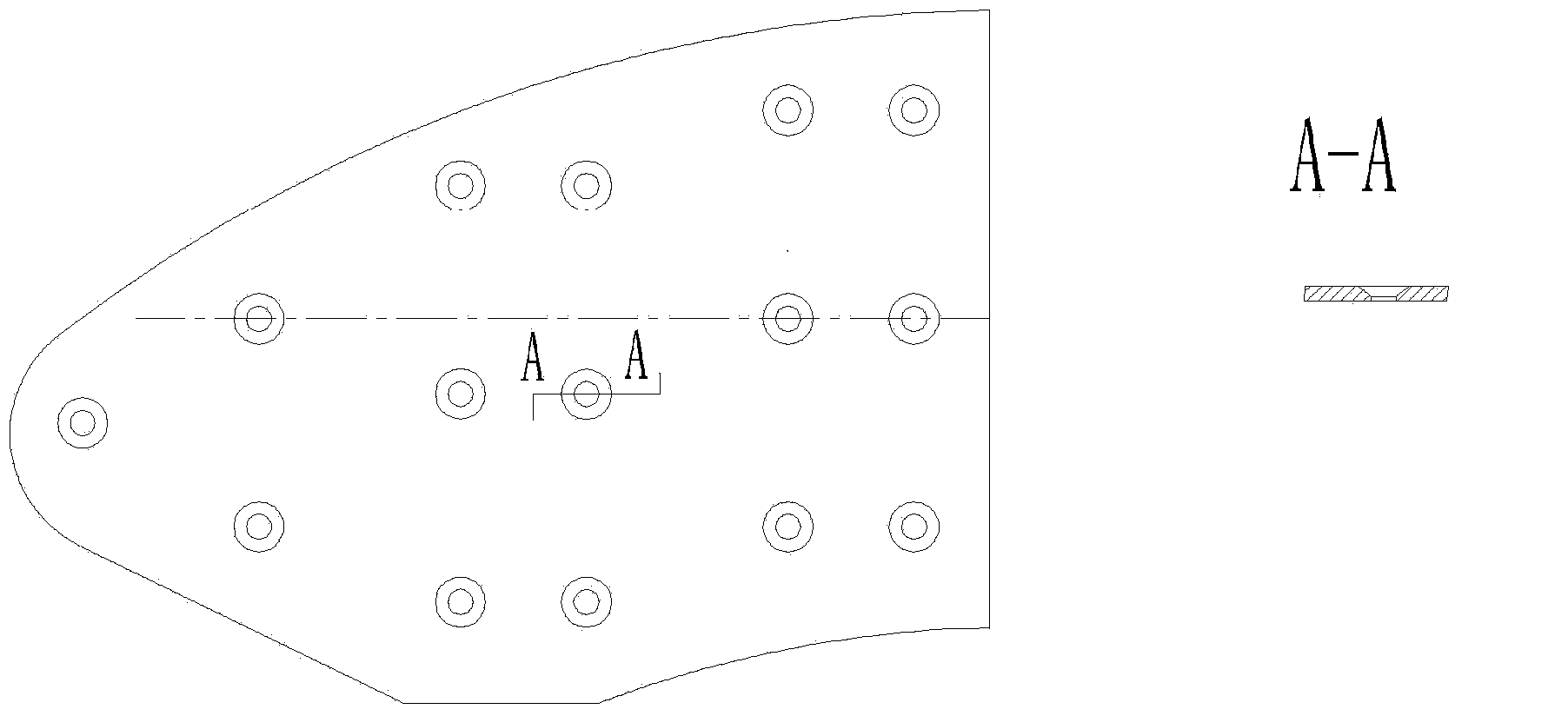

Diamond/cubic boron nitride saw blade for cutting metal and fabricating method therefor

ActiveCN1669708ANo harmHuman and Environmental HazardsMetal sawing toolsSawing tools dressing arrangementsBoron carbideBoron nitride

This invention relates to a saw bit belonging to mechanical working field, which comprises metal base being alloy steel or carbon steel, with Phi8-Phi10mm radiating holes equispaced on its surface; Carcass including alumina, zircite, quartz, tungsten carbide, zirconium diboride, molybdenum disilicide; common abradant including brown fused alumina, carbofrax, green silicon carbide, cubic carbofrax, boron carbide; superhard abradant including diamond and cubic boron nitride. The produce process includes mixing carcass flour, working layered material batching-mixing process, welding layered material batching-mixing process, koldflo, thermal pressing-sintering formation, arc milling, welding, dressing and making edge. The invention has improved working efficiency, lowered product cost, and is suitable for cutting metal tube, plate such as this materials.

Owner:SF DIAMOND CO LTD

Additive for lubricant for improving the tribologic properties, a method for its production and application

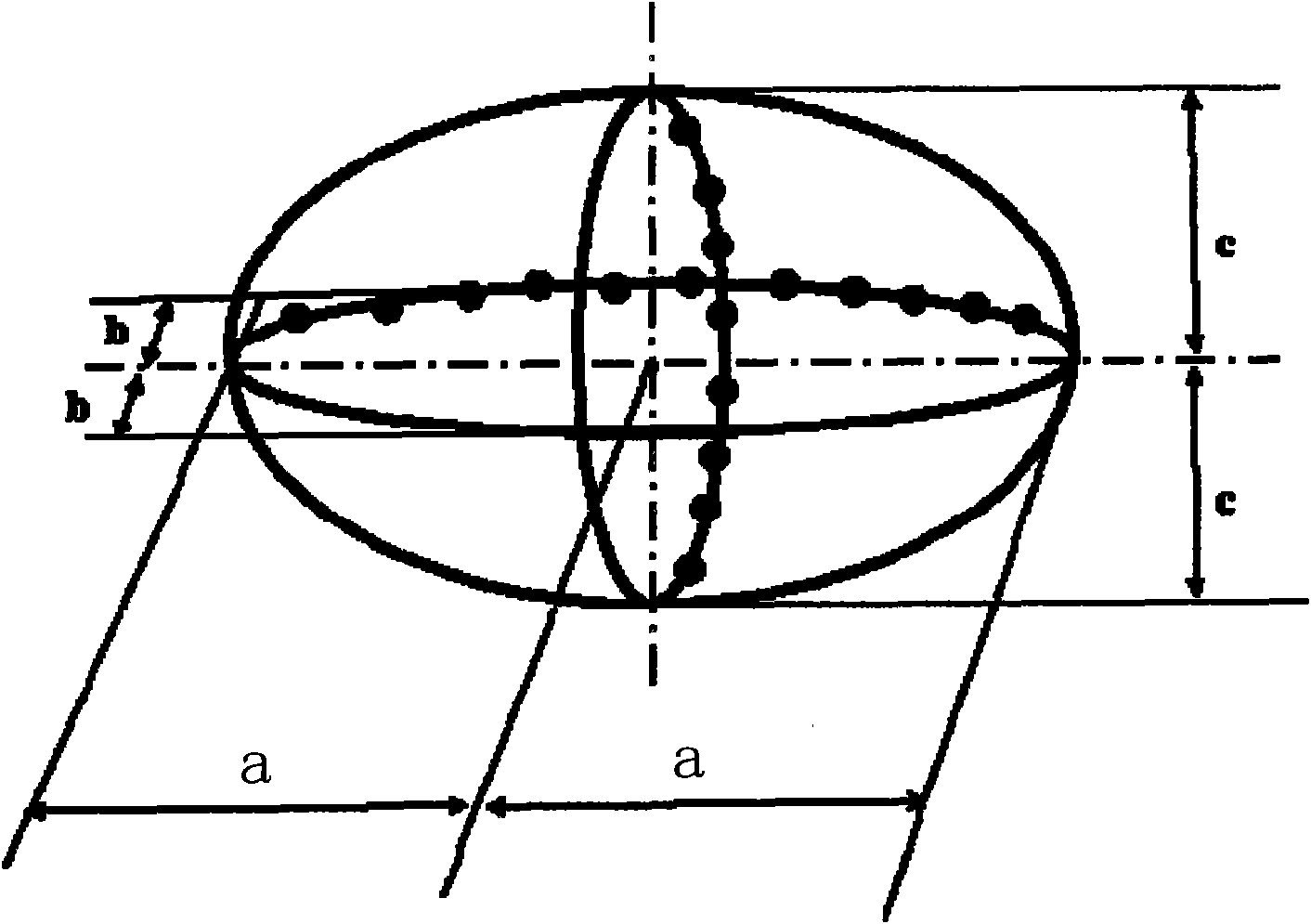

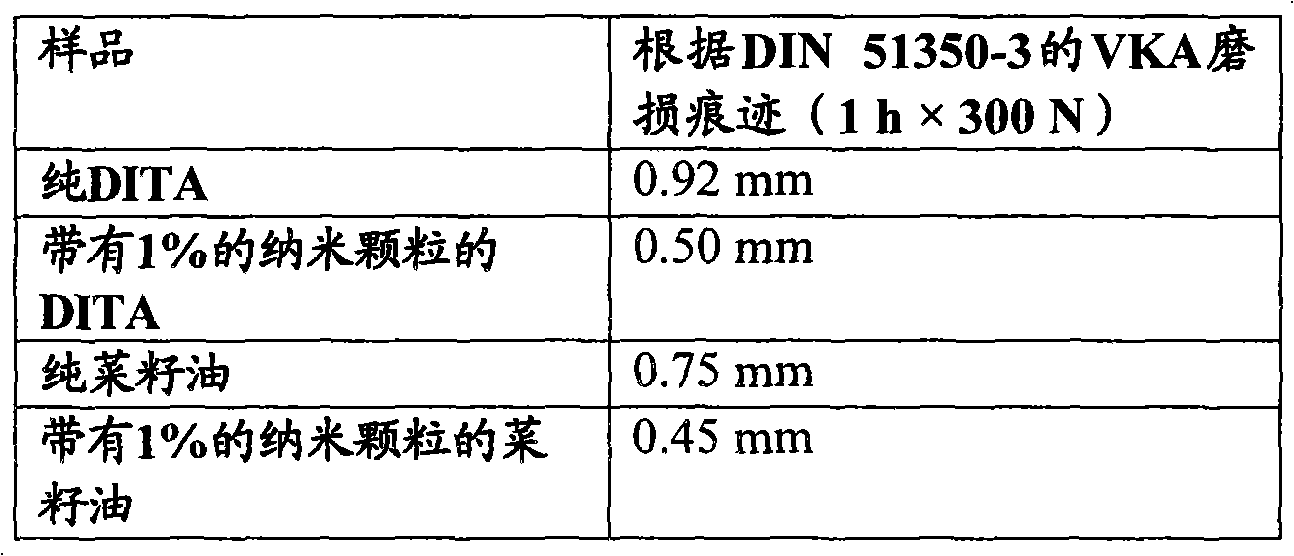

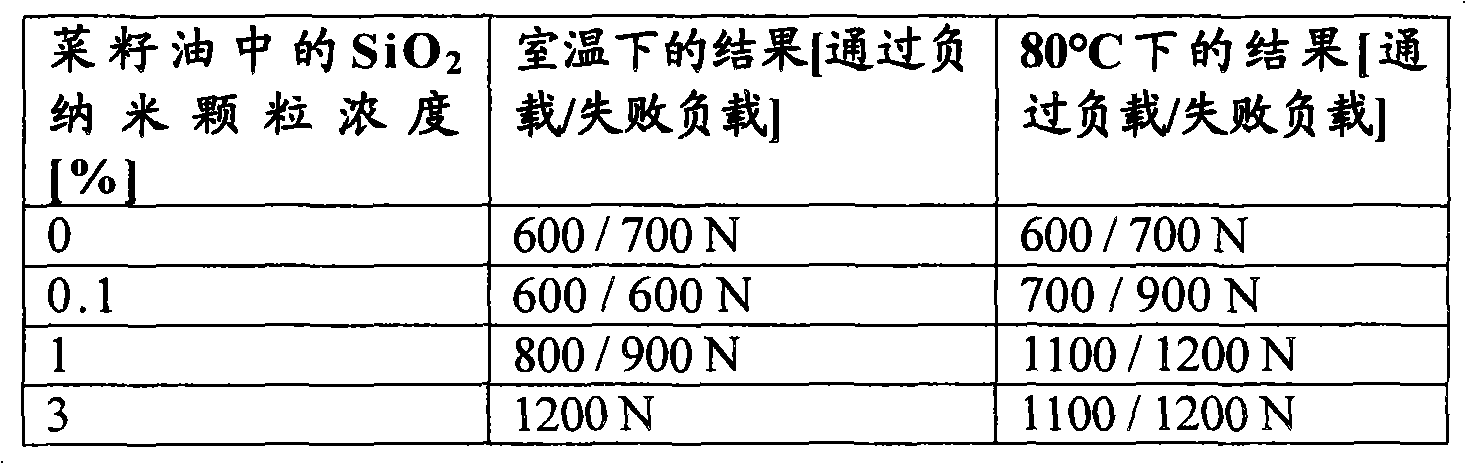

The present invention relates to novel lubricant additives for improving the tribological properties, novel lubricants containing these additives, processes for the preparation thereof and the use thereof. Lubricant comprises ceramic nanoparticles as additives comprising aluminum oxide, aluminum nitride, silicon dioxide, titanium dioxide, zirconium oxide, yttrium oxide, tungsten oxide, tantalum pentoxide, vanadium pentoxide, niobium pentoxide, cerium dioxide, boron carbide, aluminum titanate, boron nitride, molybdenum disilicide, silicon carbide, silicon nitride, titanium carbide, titanium nitride, zirconium diboride and / or clay minerals, and thermally stable carbonates and / or sulfates. The nanoparticles represent an ellipsoid with three semi-axes a, b and c, which are not equal to each other, or equal to each other. The ratio of a and b is 1-100, a and c is 1-1000, and b and c is 1:100.

Owner:แลนด์เซสส์ ดอยช์แลนด์ จีเอ็มบีเอช

Thermal protective coating

ActiveUS20060156958A1Extended shelf lifeExcellent optical propertiesAlkali metal silicate coatingsPretreated surfacesCalcium silicateSodium Bentonite

A coating, method of coating and substrates coated thereby, wherein the coating contains an inorganic adhesive such as an alkali / alkaline earth metal silicate such as sodium silicate, potassium silicate, calcium silicate, and magnesium silicate; a filler such as a metal oxide for example silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides and copper chromium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide may be added.

Owner:WESSEX

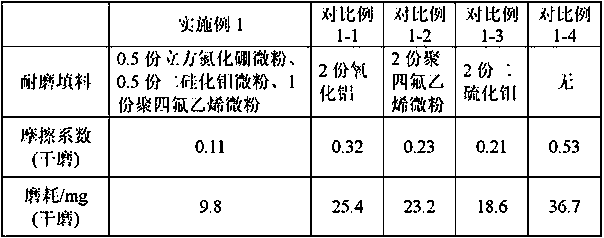

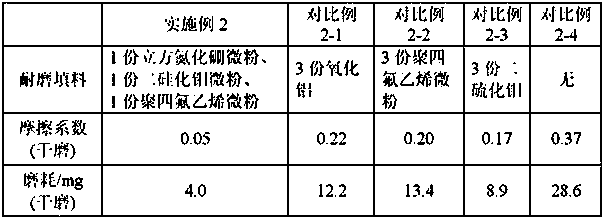

Wear-resistant filling material, wear-resistant composite material prepared from same and preparation method for composite material

The invention discloses a wear-resistant filling material, a wear-resistant composite material prepared from the same and a preparation method for the composite material. The wear-resistant filling material is prepared from the following components by weight: 0.15 to 7.5 parts of cubic boron nitride micro powder, 0.15 to 7.5 parts of molybdenum disilicide micro powder and 0.2 to 10 parts of polytetrafluoroethylene micro powder. The wear-resistant composite material is prepared from the following components by weight: 100 parts of a plastic resin, 0.5 to 25 parts of the wear-resistant filling material, 0 to 2 parts of a coupling agent and 0 to 2 parts of a processing aid. The preparation method for the wear-resistant composite material comprises the following steps: mixing the above-mentioned components at a high speed and carrying out extrusion with an extruder. According to the invention, cubic boron nitride micro powder, molybdenum disilicide micro powder and polytetrafluoroethylene micro powder are compounded to prepare the wear-resistant filling material which is applied to a plastic matrix, so the wear-resistant composite material with good wear resistance, a low friction coefficient and low dry grinding abrasion is prepared; and the application scopes of cubic boron nitride and molybdenum disilicide are broadened at the same time.

Owner:HEFEI GENIUS NEW MATERIALS

Carbon ceramic braking pad for high-speed train and preparation method of carbon ceramic braking pad

ActiveCN103511525ALess impact on friction and wear propertiesHigh and stable coefficient of frictionFriction liningFiberCeramic composite

The invention relates to a carbon ceramic braking pad for a high-speed train and a preparation method of the carbon ceramic braking pad. The carbon ceramic braking pad is made of carbon ceramic composite material; the carbon ceramic composite material comprises the following components in percentage by mass: 16-30 percent of carbon fibers, 20-36 percent of pyrolytic carbon, 28-46 percent of silicon carbide, 6-12 percent of molybdenum disilicide and 2-6 percent of simple substance silicon; the density of the carbon ceramic composite material is 1.8-2.4g / cm<3>; the carbon fibers are uniformly distributed in the carbon ceramic composite material in a three-dimensional network structure. According to the invention, after the high-temperature heat treatment is performed on a carbon fiber felt with the density of 0.20-0.65g / cm<3>, the pyrolytic carbon is generated in the carbon fiber felt through the thermal-gradient chemical vapor deposition carburizing treatment, then the catalytic graphitization treatment, non-immersion type melting infiltration and assembly are performed, so that the carbon ceramic braking pad for the high-speed train is obtained.The carbon ceramic braking pad is simple in preparation technology, moderate in friction coefficient, good in abrasion performance, stable in braking and strong in environmental suitability and can meet braking requirements of the high-speed train with the speed of 200Km / h.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

Molybdenum disilicide heating element and its production method

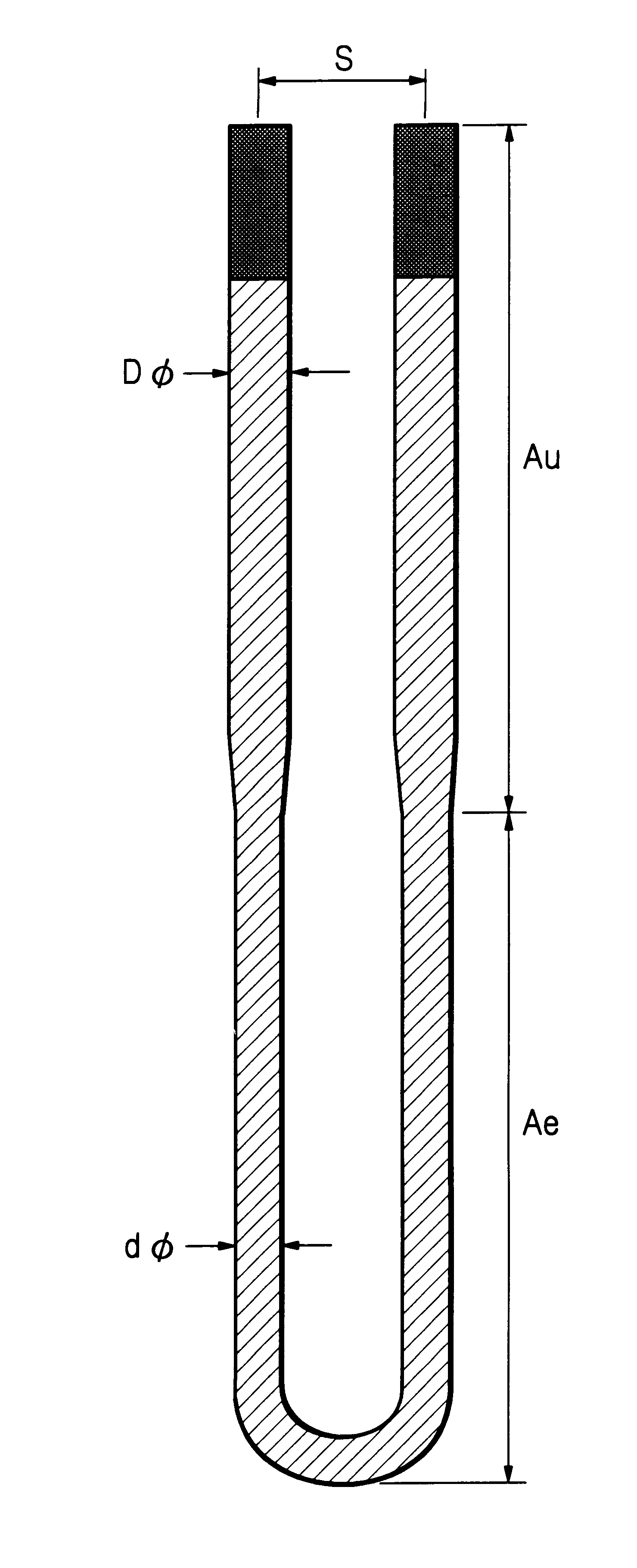

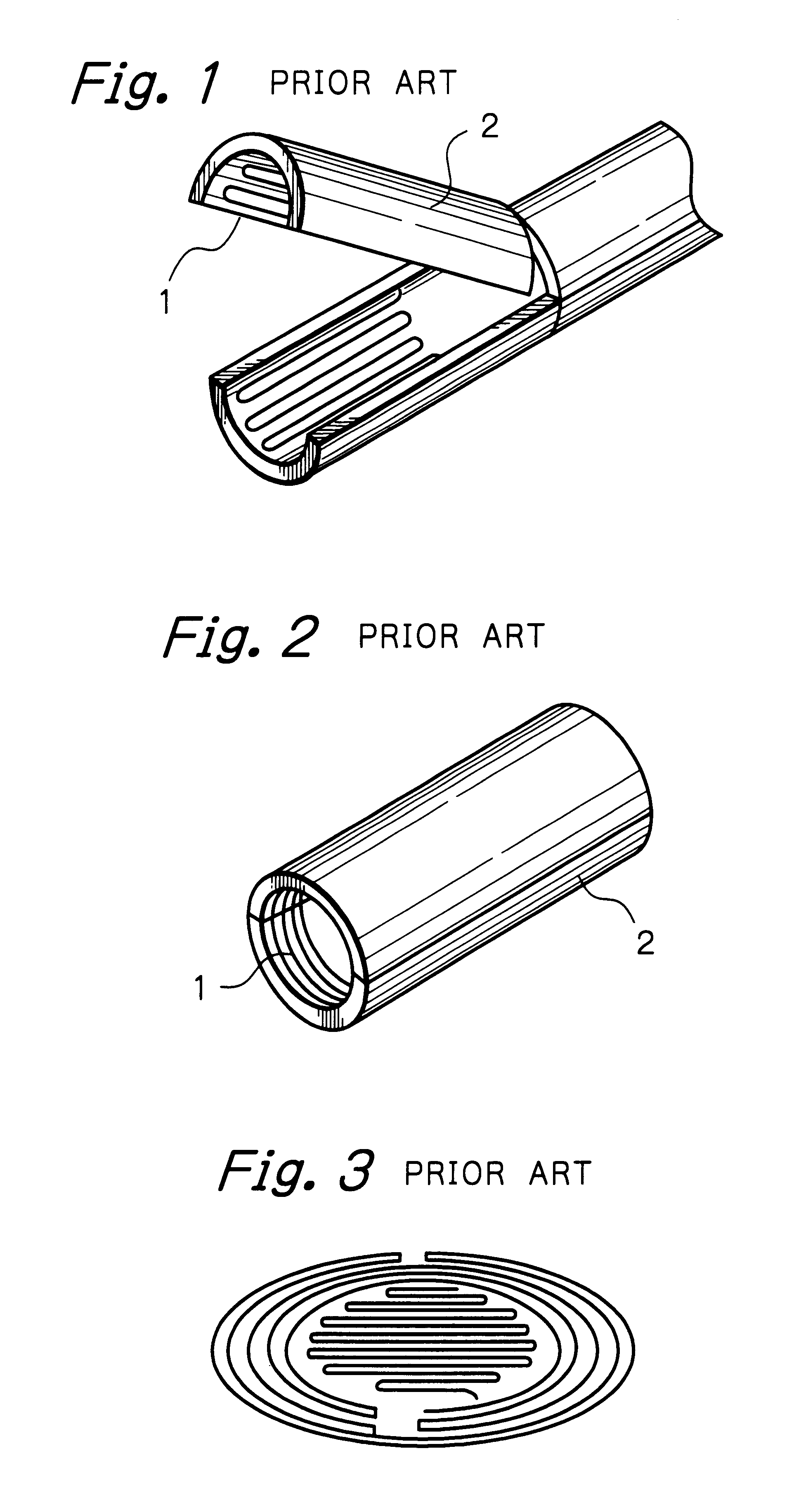

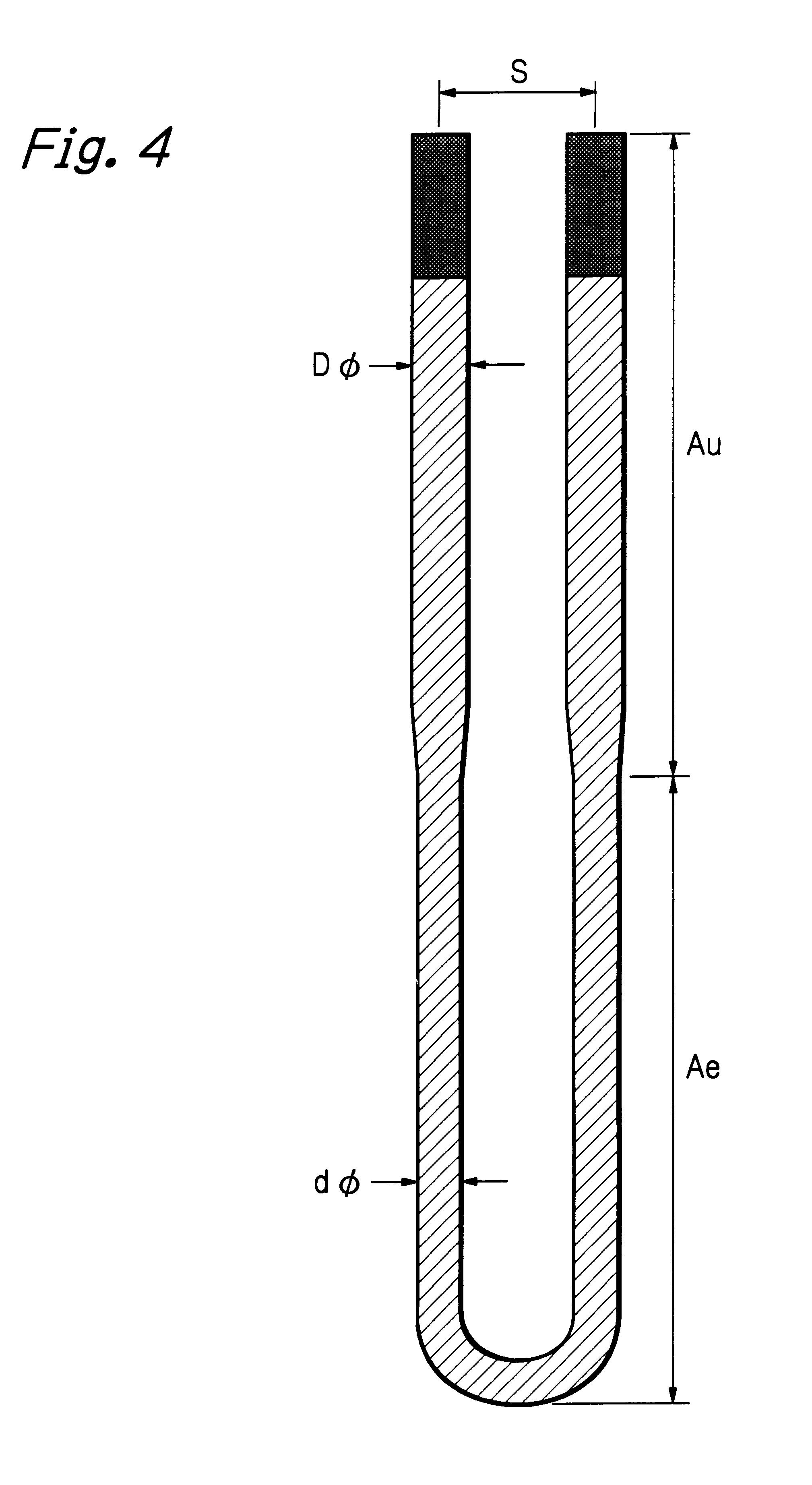

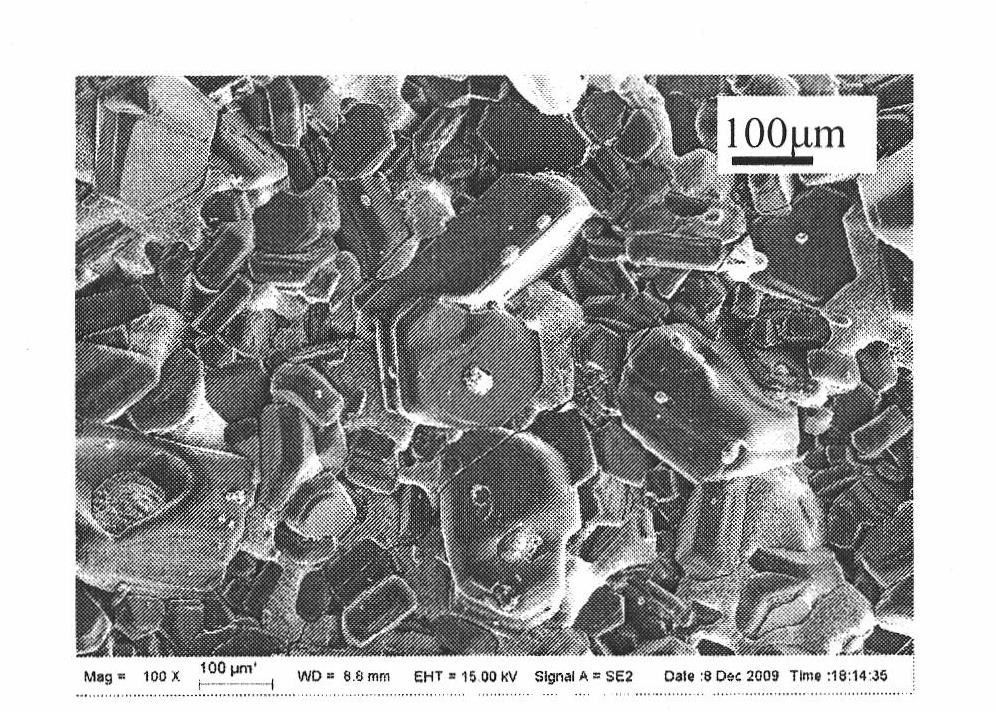

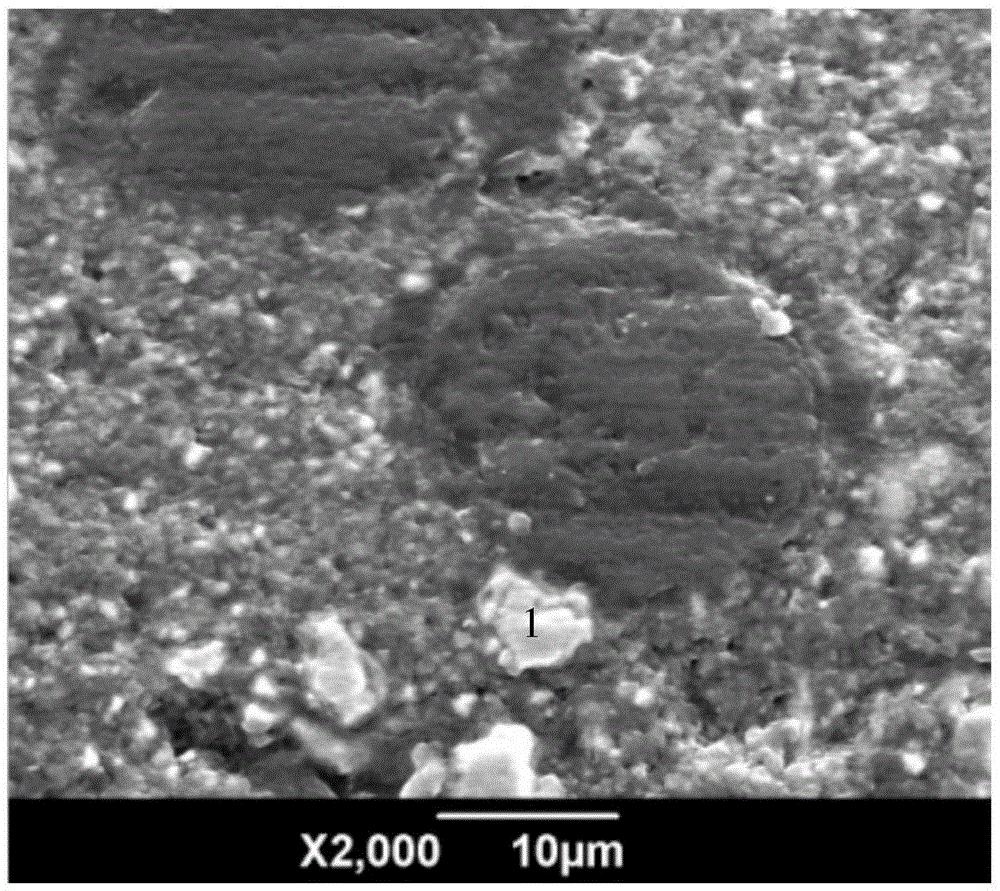

InactiveUS6211496B1Prolong lifeReduce areaHeating element materialsNon-adjustable resistorsNetwork structureEngineering

The MoSi2 heating element has not been so resistant under the low-temperature heating, because the low-temperature oxidation, which is attributable to the grain boundary oxidation, occurred. In the present invention, long life under the low-temperature heating is attained by the following two structures. (1) The MoSi2 grains have a network structure and are linked three dimensionally. (2) The secondary, silica-bearing oxide or glass phase forms a net-like structure around the MoSi2 grains.

Owner:RIKEN CO LTD

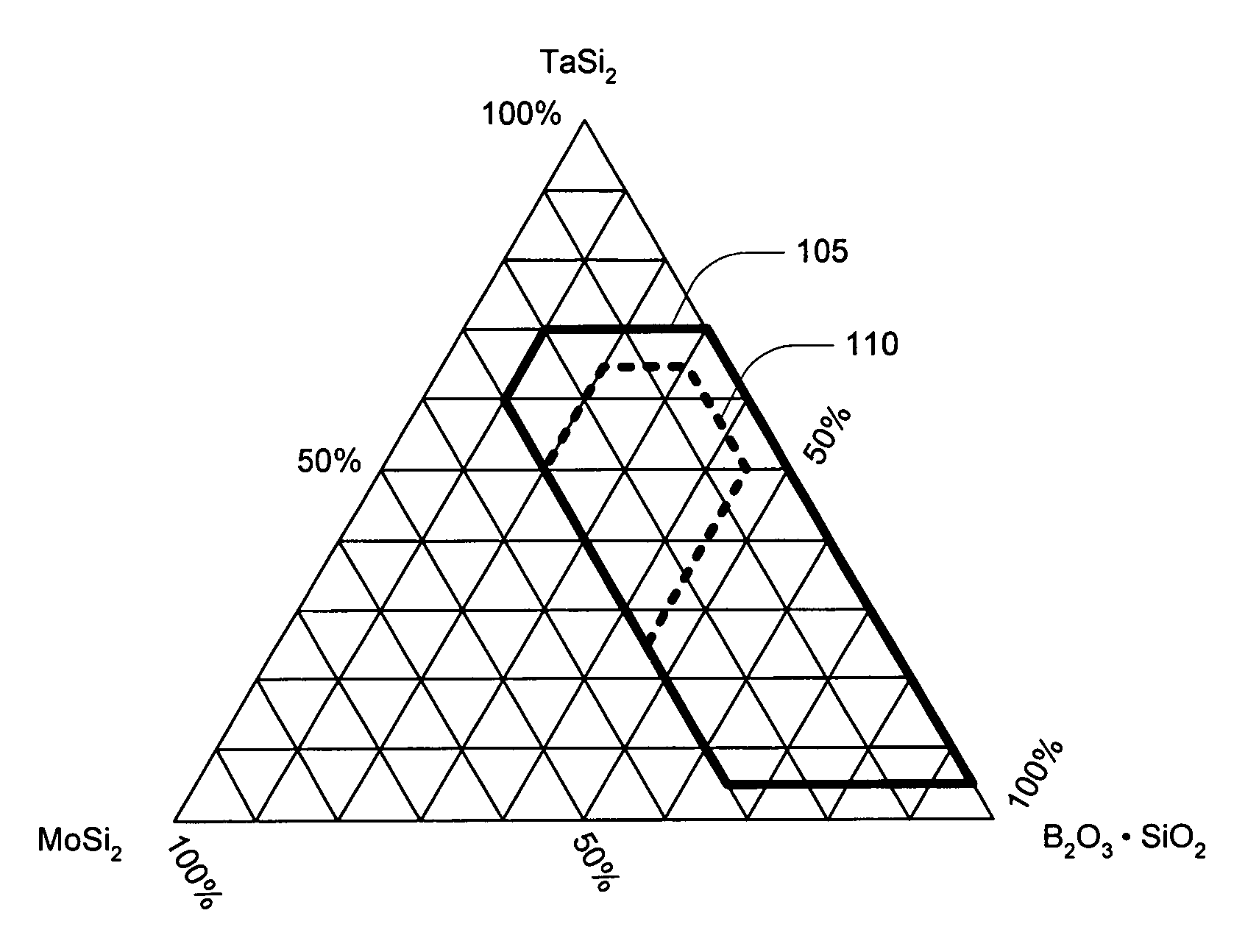

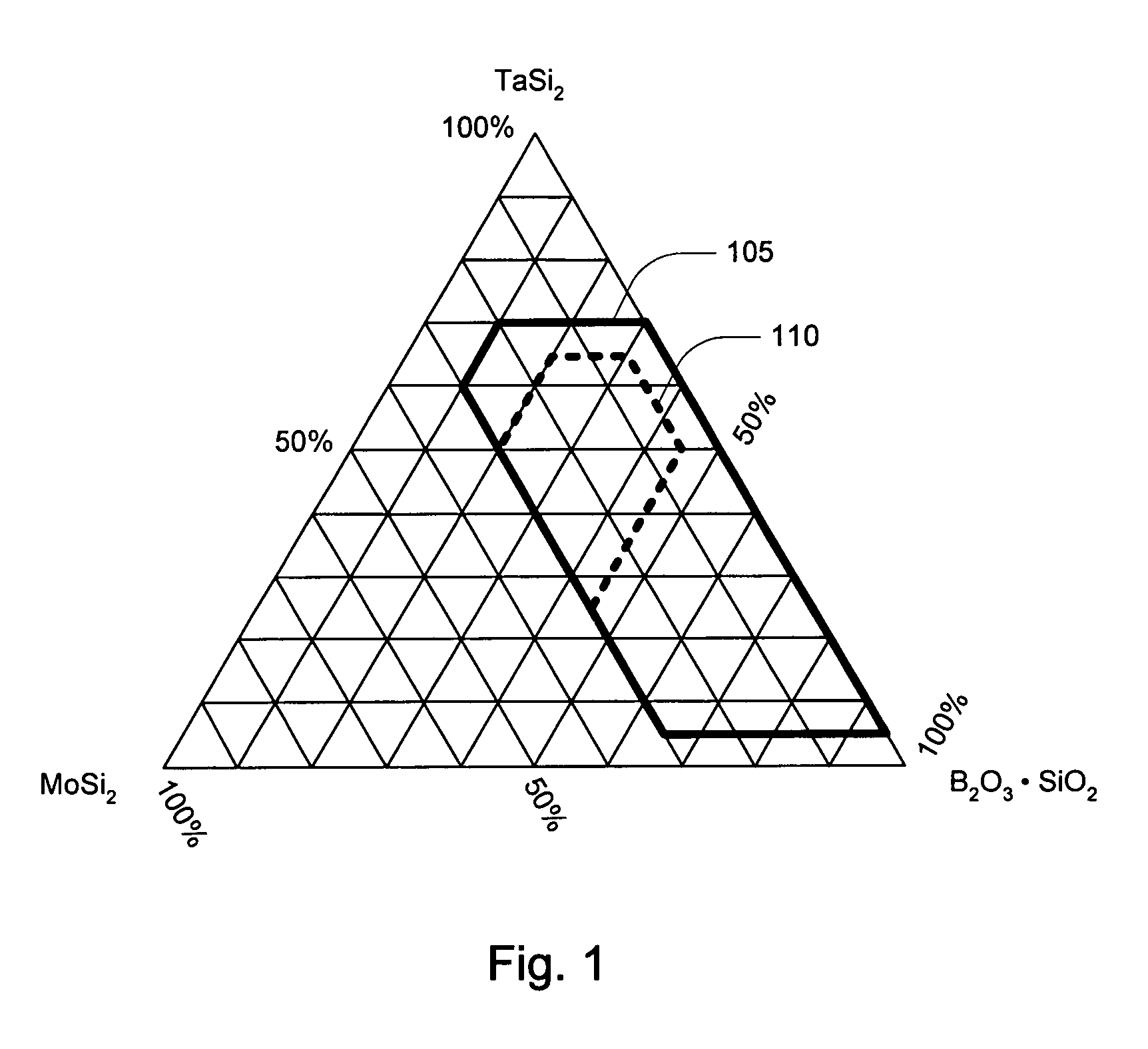

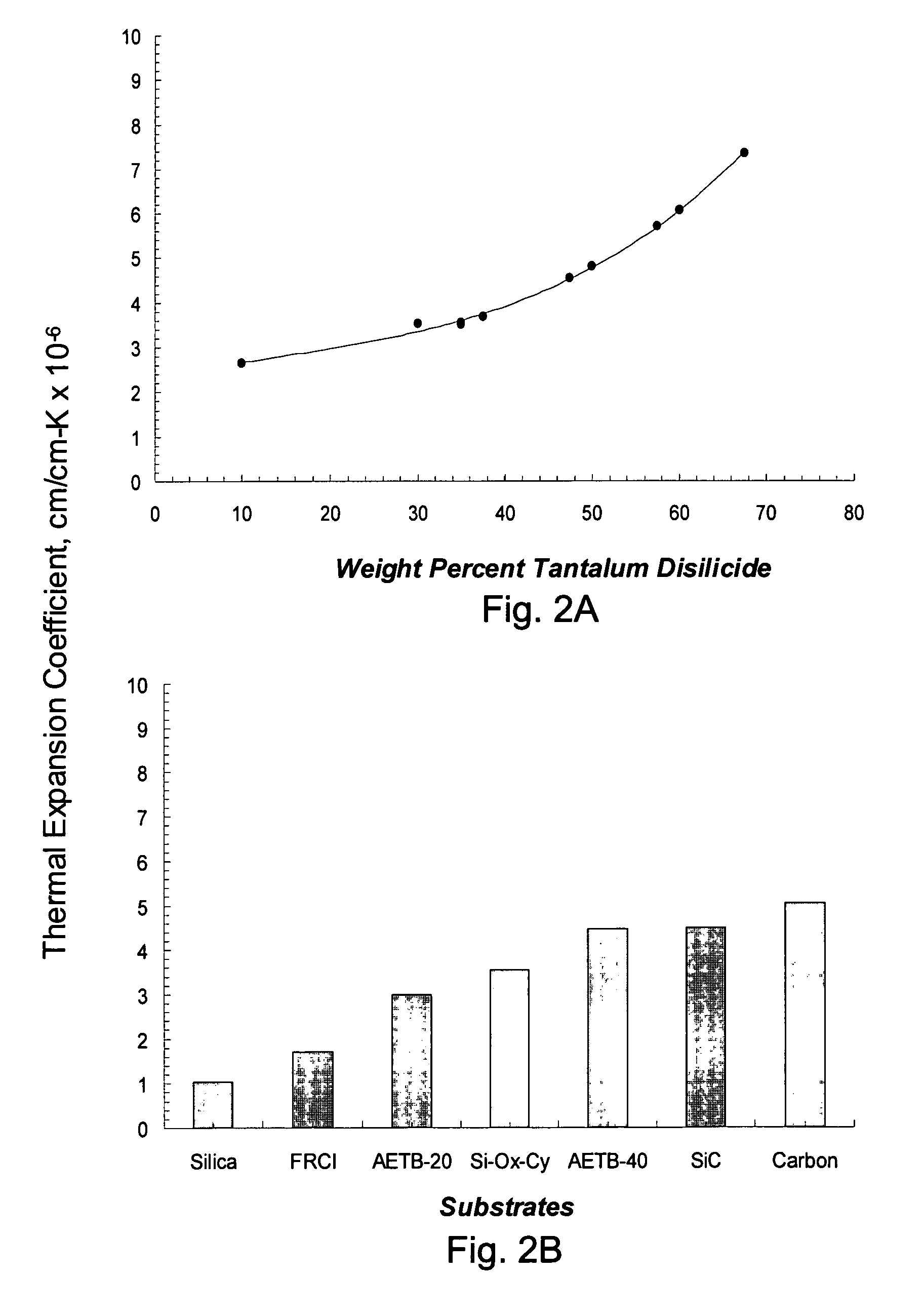

High efficiency tantalum-based ceramic composite structures

ActiveUS7767305B1Improve abilitiesLow catalytic efficiencySynthetic resin layered productsCosmonautic thermal protectionPorous substrateRe entry

Tantalum-based ceramics are suitable for use in thermal protection systems. These composite structures have high efficiency surfaces (low catalytic efficiency and high emittance), thereby reducing heat flux to a spacecraft during planetary re-entry. These ceramics contain tantalum disilicide, molybdenum disilicide and borosilicate glass. The components are milled, along with a processing aid, then applied to a surface of a porous substrate, such as a fibrous silica or carbon substrate. Following application, the coating is then sintered on the substrate. The composite structure is substantially impervious to hot gas penetration and capable of surviving high heat fluxes at temperatures approaching 3000° F. and above.

Owner:NASA

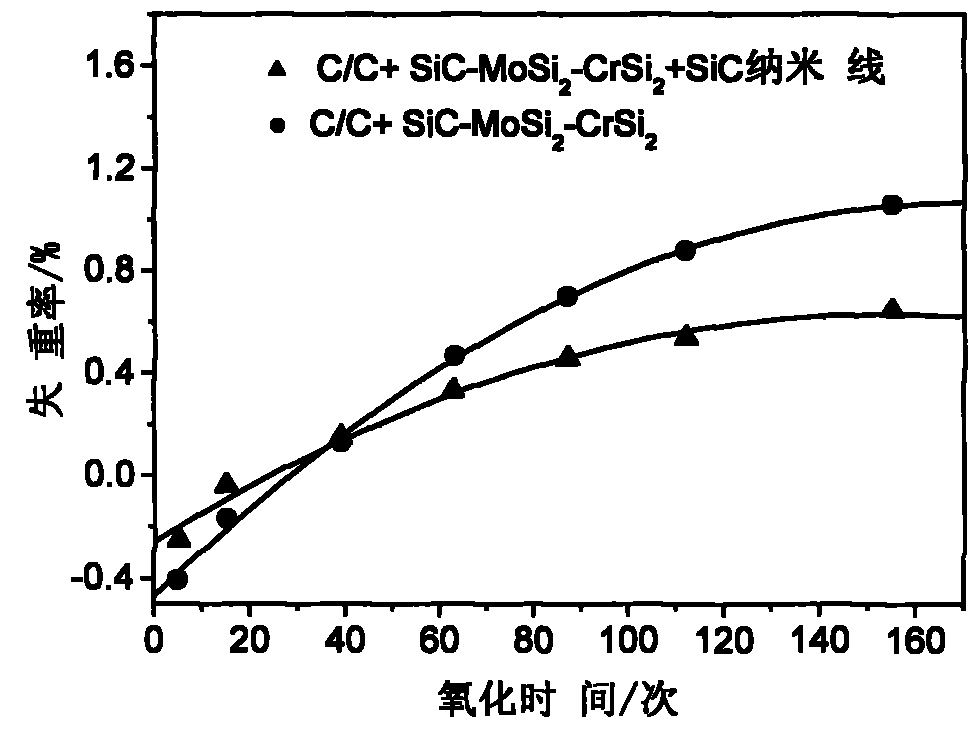

Method for preparing nanowire-toughened carbon/carbon composite material ceramic coating

The invention discloses a method for preparing a nanowire-toughened carbon / carbon composite material ceramic coating. The method aims to solve the technical problem that the ceramic coating prepared by a conventional method has poor denseness. The method adopts the following technical scheme that: the nanowire-toughened carborundum (SiC)-molybdenum disilicide (MoSi2)-chromium silicide (CrSi2) ceramic coating is prepared by chemical vapor deposition, the cracking trend of the coating is reduced, and the ceramic coating with a dense structure is prepared by means of the toughening effect of nanowires. The effective anti-oxidization time of the prepared ceramic coating in atmosphere at the temperature of 1,500 DEG C is improved to 140 and 155 hours from 50 hours in background technology.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

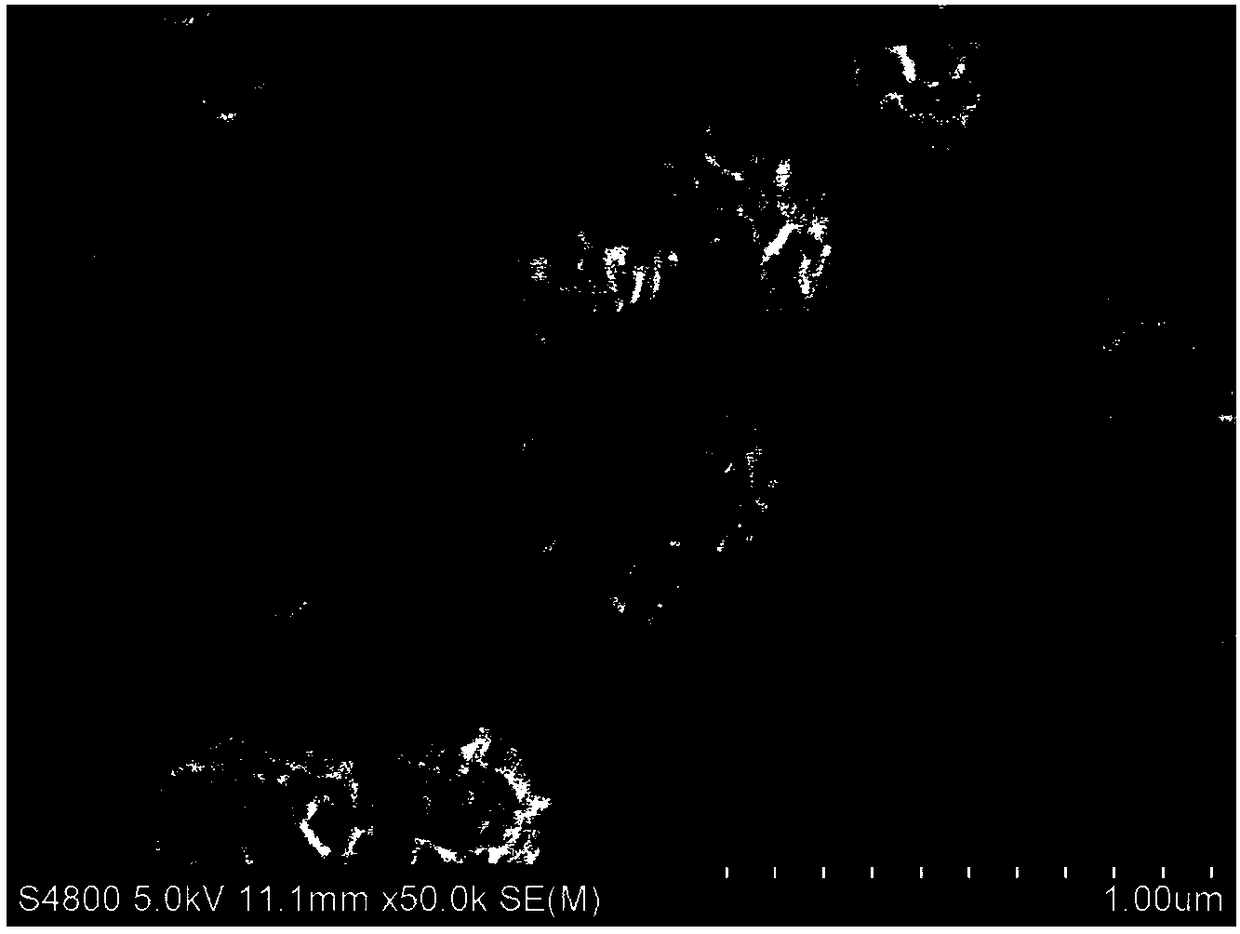

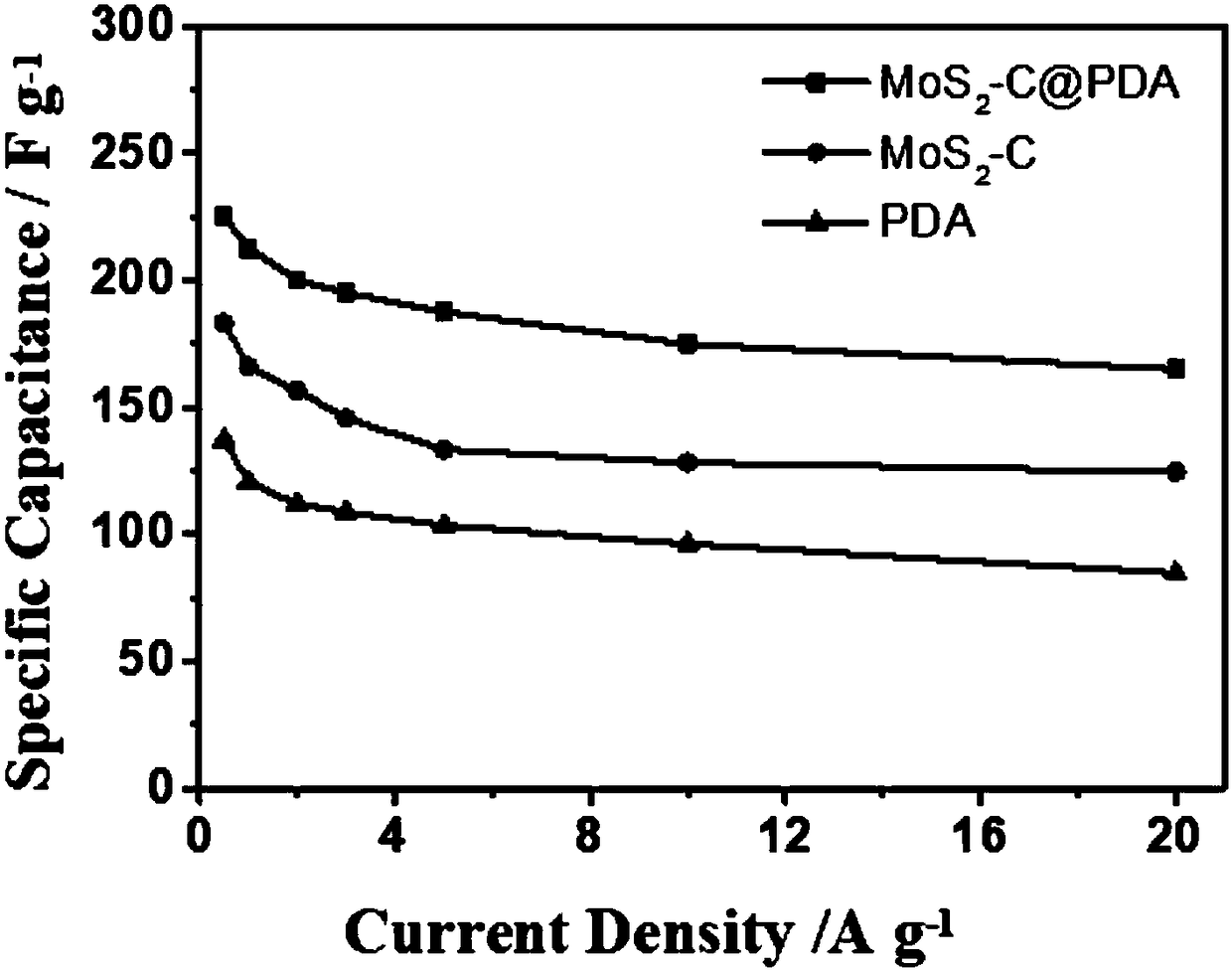

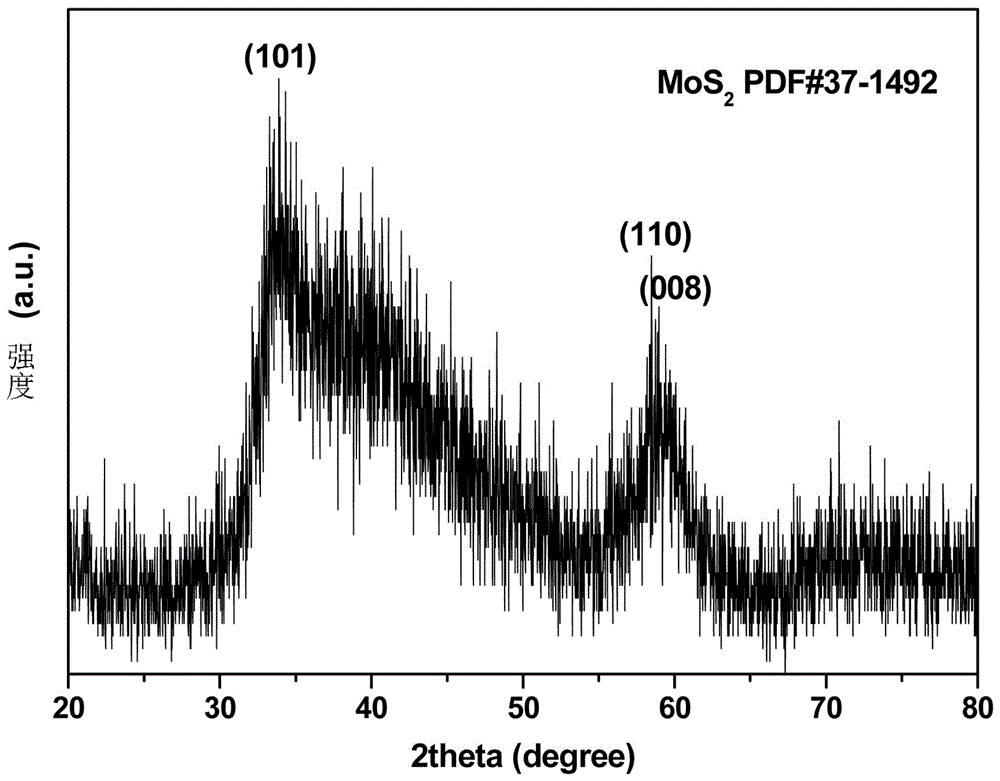

Molybdenum disulfide/porous carbon nanosphere composite material and preparation method thereof

ActiveCN108231426AImprove conductivityLarge specific surface areaHybrid capacitor electrodesSodium molybdatePorous carbon

The invention provides a molybdenum disulfide / porous carbon nanosphere composite material and a preparation method thereof and belongs to the technical field of composite materials. The diameter of the composite spheres of the molybdenum disulfide / porous carbon nanosphere composite material of a core-layer structure taking porous nitrogen doped carbon spheres as cores and molybdenum disulfide as shell layers is 500-600 nanometers. Molybdenum disulfide is uniformly coated to the surfaces of porous nitrogen doped carbon spheres and is pedal like. The composition is prepared by the following steps: dissolving porous polydopamine spheres in deionized water; then successively adding sodium molybdate, thiourea, anhydrous oxalic acid and anhydrous glucose; uniformly mixing and ultrasonically treating the solution; and then annealing the solution at a high temperature of 700-900 DEG C for 2-3 hour. The composite material prepared by the method for preparing a cathode material of a capacitor not only has a relatively high specific surface area, but also has a relatively high specific capacity and an excellent cyclic characteristic. The composite material is simple in preparation method andsuitable for industrial production.

Owner:BEIJING UNIV OF CHEM TECH

Large casting-molding self-combined silicon carbide product

The invention relates to a large casting-molding self-combined silicon carbide product. The method comprises the following steps: taking silicon carbon particulates and fine powder, silicon carbon powder, silica powder, silicon powder, carbon black, molybdenum disilicide micro powder, active magnesium oxide and a water reducer as powder; by taking ludox as a binding agent, molding by adopting a vibrating casting manner; sintering the molded green body under a protective atmosphere after conserving and baking, wherein the highest sintering temperature is 1300-1500 DEG C; sintering and cooling to room temperature along with a furnace, so as to prepare the self-combined silicon carbide product. The large and profile self-combined silicon carbide product can be prepared, and has the advantages that the size and the shape of the product are not limited, performance is excellent, and the like, and the prepared self-combined silicon carbide product can be applied to the fields such as a blast-furnace tuyere and a cooling wall tile in the iron and steel industry and an aluminum electrolytic cell in the non-ferrous industry.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

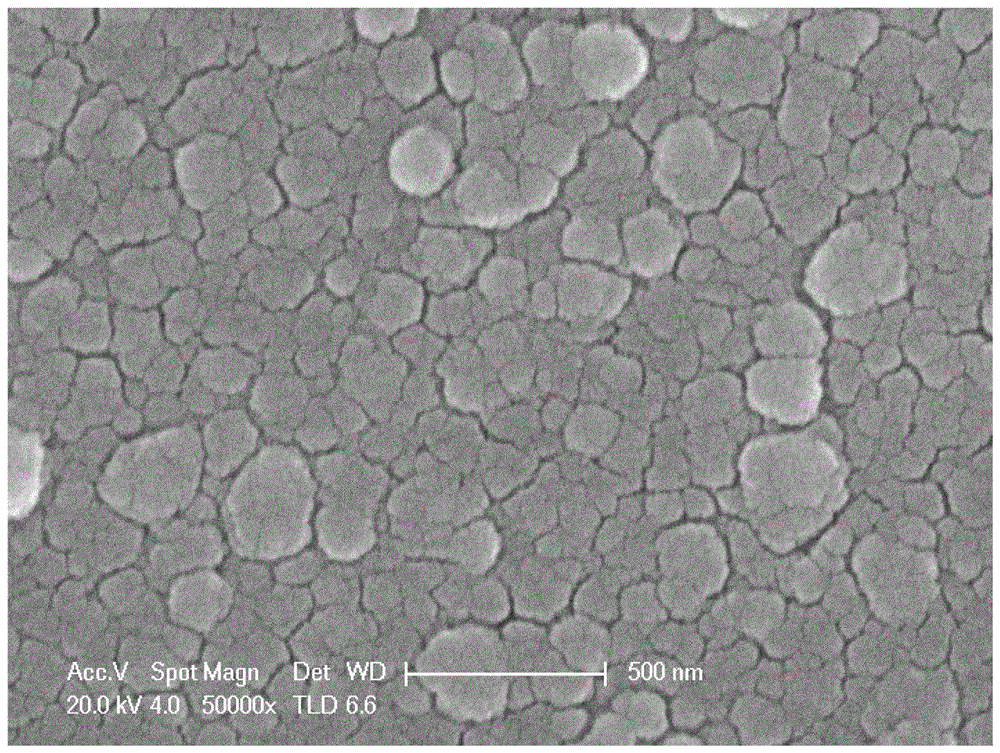

Preparation method of molybdenum disulfide thin film and molybdenum disulfide thin film

ActiveCN104947070AQuality improvementReduce defectsChemical vapor deposition coatingChemical vapor depositionMolybdenum disulfide

The invention discloses a preparation method of a molybdenum disulfide thin film and the molybdenum disulfide thin film. A chemical vapor deposition method (CVD) is used for directly growing a large-area high-voltage low-defect molybdenum sulfide (MoS2) thin film on a silicon substrate plated with an oxide buffer layer, and rapid transferring of the MoS2 thin film can be creatively achieved.

Owner:贵溪穿越光电科技有限公司

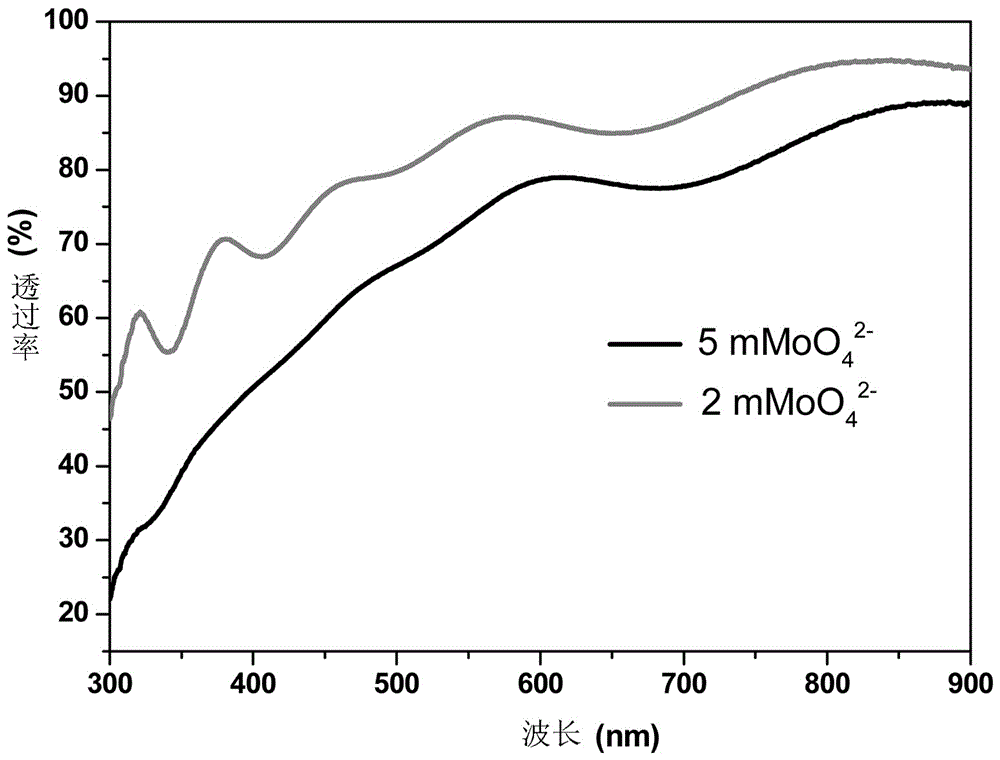

Solvothermal preparation method of in-situ molybdenum disulfide electrode

The invention discloses a solvothermal preparation method of an in-situ molybdenum disulfide electrode. The preparation method comprises the following steps: dissolving molybdenum-containing salts (sodium molybdate, etc.) into an alcohol solution containing a sulfur source (thiourea, etc.), adding a substrate material, then filling the mixture into a hydrothermal kettle, carrying out solvothermal reactions for 6 to 24 hours at a temperature of 180 to 230 DEG C; taking out the substrate, and cleaning and drying the substrate. If people want to improve the crystallization property of molybdenum disulfide, the substrate can be annealed in an atmosphere of N2 for one hour at a temperature of 500 DEG C. The prepared in-situ molybdenum disulfide electrode has the advantages of high transparency and uniformity, and strong adhesion force on substrate. The dye-sensitized solar cell prepared from the provided in-situ molybdenum disulfide electrode has a higher photoelectric conversion efficiency, compared with the cells prepared from a conventional pyrolytic Pt electrode, and the result shows that the prepared molybdenum disulfide electrode has an extremely good electro-catalytic activity.

Owner:CHINA THREE GORGES UNIV

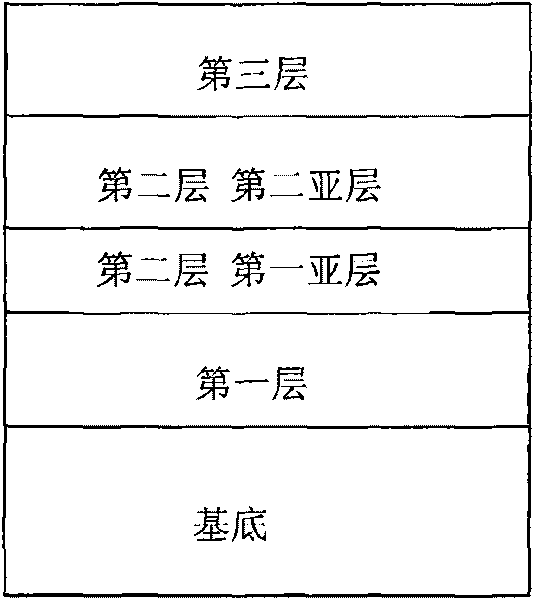

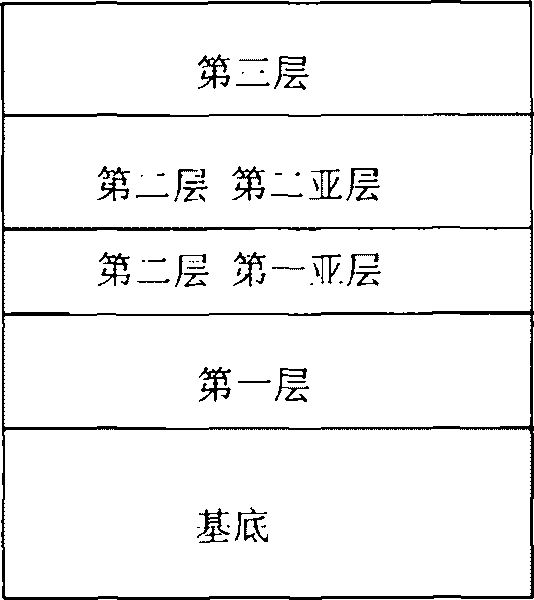

Solar selectively absorbing coating and preparation method thereof

ActiveCN101737982ASimple preparation processEasy to operateSolar heat devicesLayered productsCeramic compositeWorking temperature

The invention relates to a solar selectively absorbing coating. A three-layer film structure is formed on a substrate from bottom to top, an infrared reflective layer, an absorbing layer and an antireflection layer are arranged on the substrate in turn; the first layer is the infrared reflective layer which is formed from metal copper layer prepared by magnetron sputtering, if a polished stainless steel substrate or a copper substrate is adopted, the substrate can be directly used as the infrared reflective layer; the second layer is the absorbing layer which is an alloy-ceramic composite layer which is formed by dispersing molybdenum disilicide particles in aluminium oxide ceramic medium according to a definite proportion through sputtering, the structure has two sub-layers with different thicknesses and MoSi2 volume percentages so as to form the interference and absorption effect; and the third layer is the Al2O3 antireflection layer which is prepared by magnetron sputtering of Al2O3 ceramic target or DC magnetron reactive sputtering of aluminum target. The coating has good medium-high temperature thermal stability, and when the air quality factor AM is 1.5, the absorption rate is 0.90-0.94, and the emissivity is 0.06-0.14. The solar selectively absorbing coating is suitable for the solar vacuum collector tube with medium-high work temperature (300-500 DEG C).

Owner:安徽科鑫光热技术有限公司

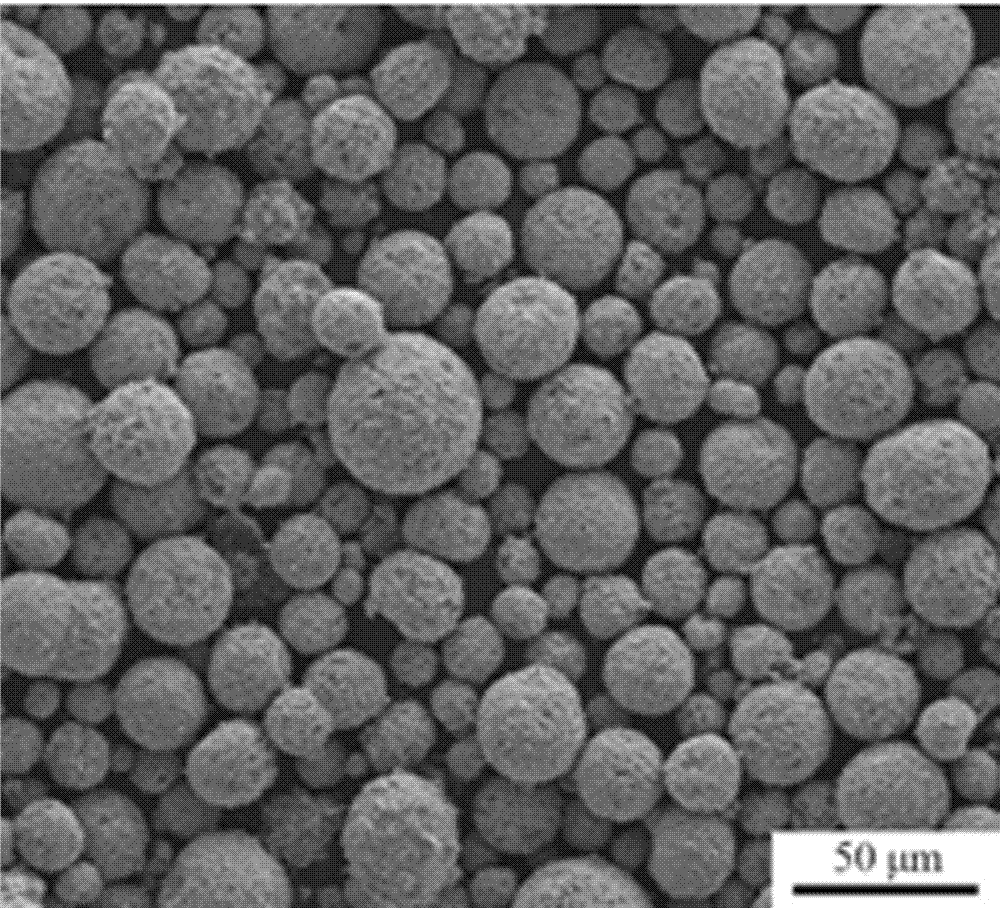

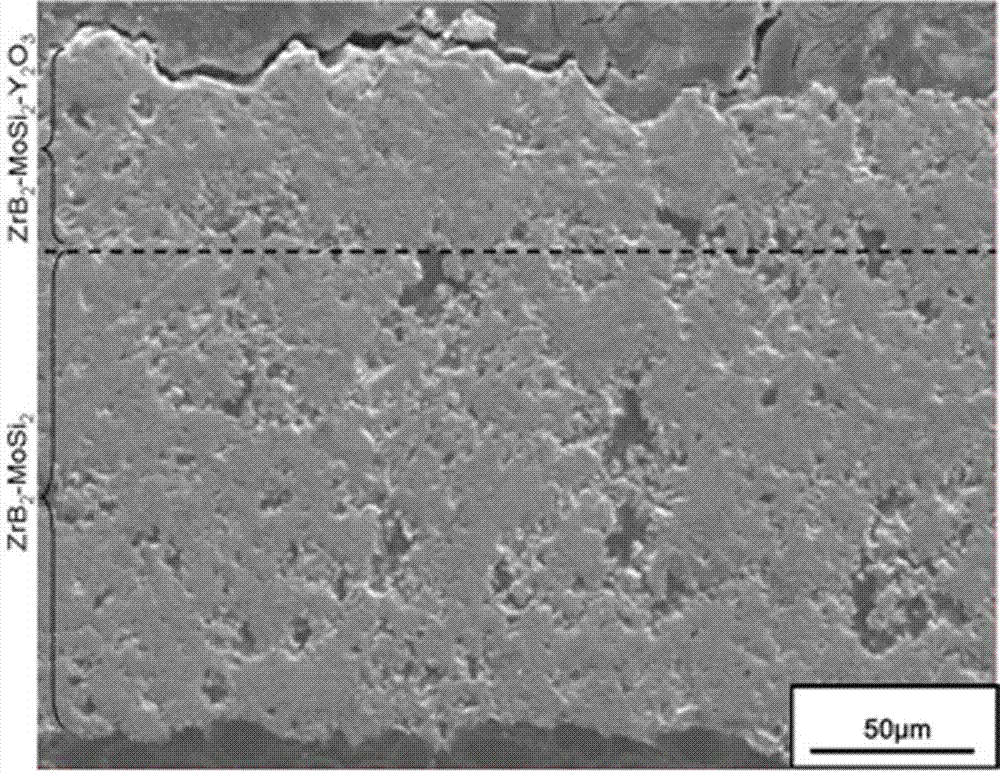

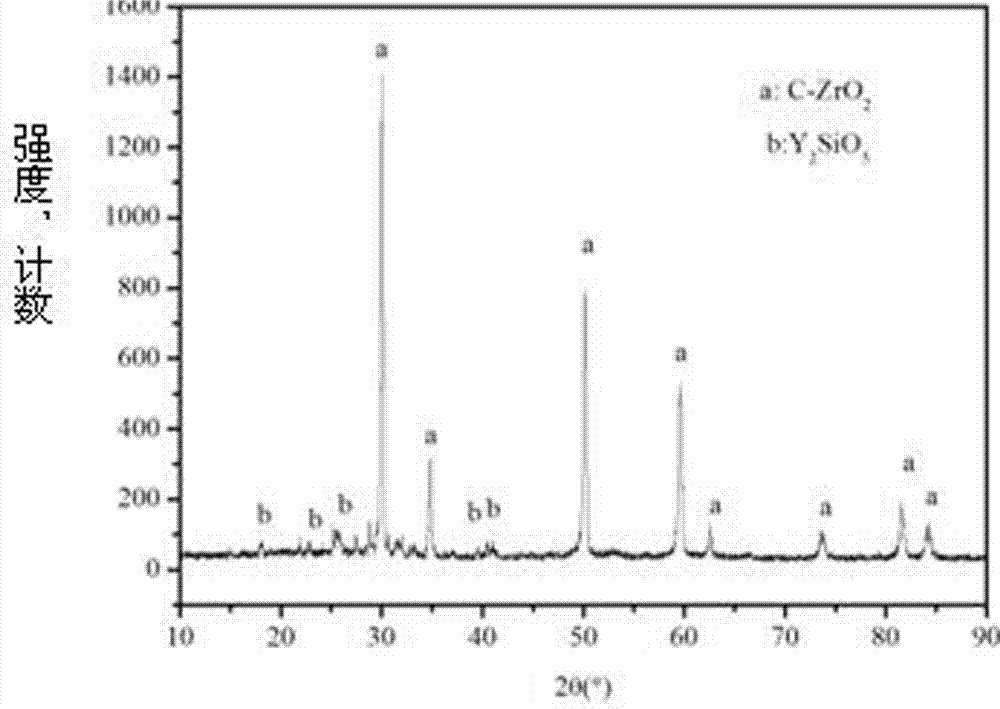

Method for preparing ablation-resistant coating

InactiveCN107021787AImprove liquidityImprove high temperature ablation resistanceCarbon compositesSlurry

The invention relates to a method for preparing an ablation-resistant coating. The method comprises the following steps: mixing zirconium diboride and molybdenum disilicide or silicon carbide and yttrium oxide with the particle size of 1 to 3 microns, then, mixing the mixture with a binder so as to obtain a mixture, blending the mixture with deionized water, and then, carrying out ball milling, so as to obtain slurry; preparing spherical powder at the temperature of 110 DEG C to 130 DEG C; carrying out sintering for 1 to 2 hours at the temperature of 1,200 DEG C to 1,600 DEG C; carrying out sieving, so as to obtain zirconium diboride-molybdenum disilicide or silicon carbide-yttrium oxide powder for spraying; spraying a zirconium diboride-molybdenum disilicide or silicon carbide undercoat to the surface of a carbon / carbon composite material by a plasma spraying method, and then, spraying the zirconium diboride-molybdenum disilicide or silicon carbide-yttrium oxide powder to the undercoat by the same method, thereby preparing the ablation-resistant coating. The yttrium oxide modified zirconium diboride-molybdenum disilicide or silicon carbide coating prepared by the method can be used for remarkably improving the high-temperature ablation resistance of the carbon / carbon composite material.

Owner:GUANGDONG INST OF NEW MATERIALS

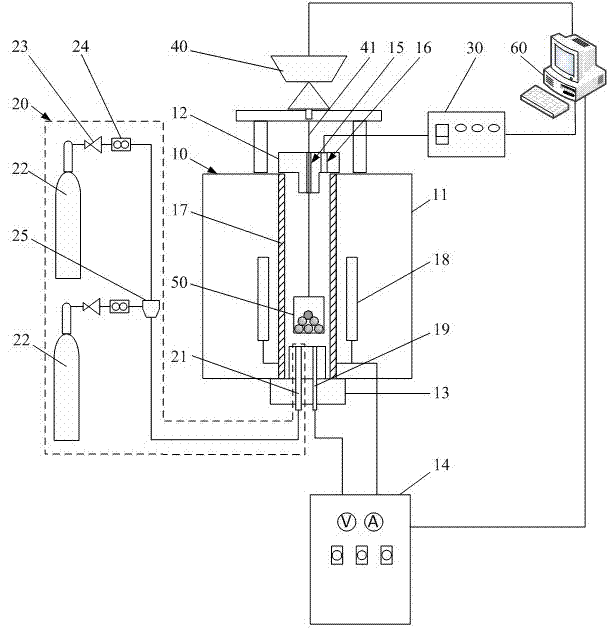

Experimental device and method for performing on-line monitoring on lump coal splitting decomposition

InactiveCN102768161ARealize simulationEasy extractionFuel testingMaterial weighingFlue gasElemental analysis

The invention provides an experimental device and method for performing on-line monitoring on lump coal splitting decomposition. The experimental device is mainly formed by a molybdenum disilicide furnace, a protective gas supplying device, a flue gas analyzer, an electronic balance, a corundum crucible and a monitoring computer. The experimental device is simple, practical and capable of performing on-line monitoring on quality changes and a gas generation rule in the fast decomposition process when the lump coal instantly enters high temperature from normal temperature. The obtained monitoring data can provide important theoretical foundation and technical basis for research directions such as how to optimize a blending structure, reduce bed pressure damage or reduce fuel consumption in the COREX process. By means of the experimental device and method for performing on-line monitoring on the lump coal splitting decomposition, carbocoal products of a lump coal splitting decomposition experiment can be conveniently extracted and can be further used for carbocoal industrial analysis and elemental analysis after being subjected to dry quenching of coke, and detection to strength and changes of coal rock structures, particle sizes, porosity, shapes, functional group structures and the like. Therefore, the experimental device and method for performing on-line monitoring on the lump coal splitting decomposition have wide application prospects.

Owner:CHONGQING UNIV

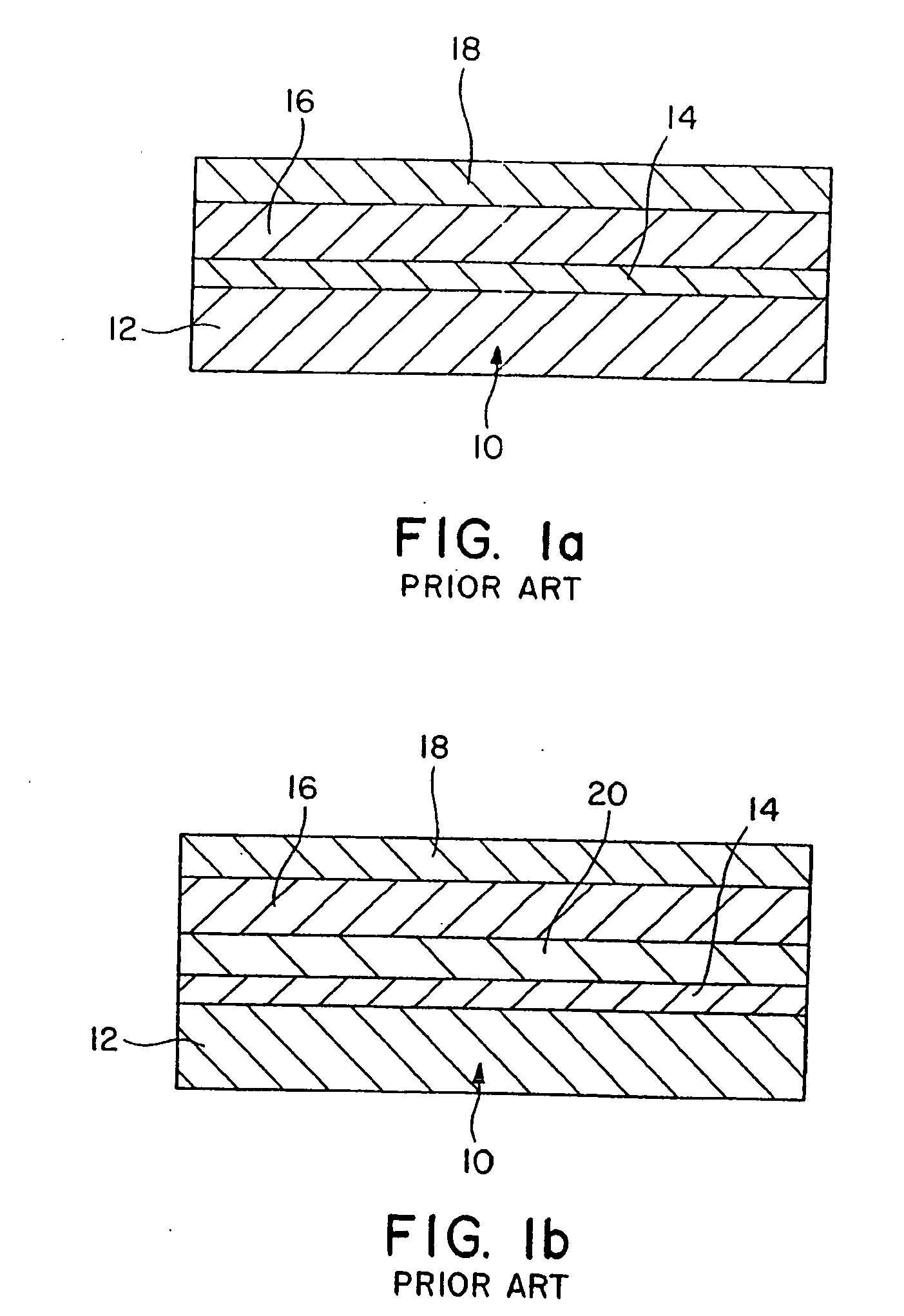

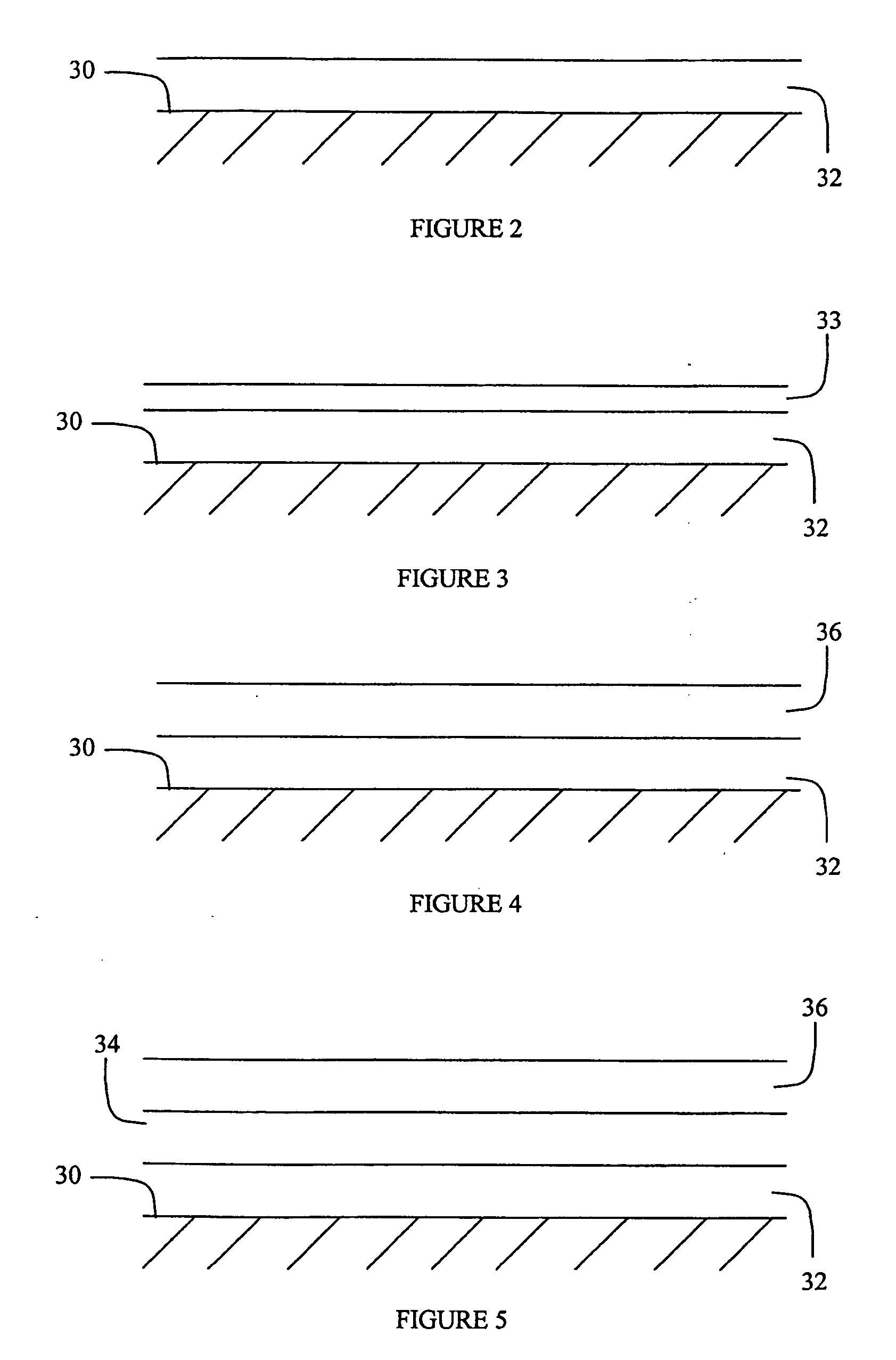

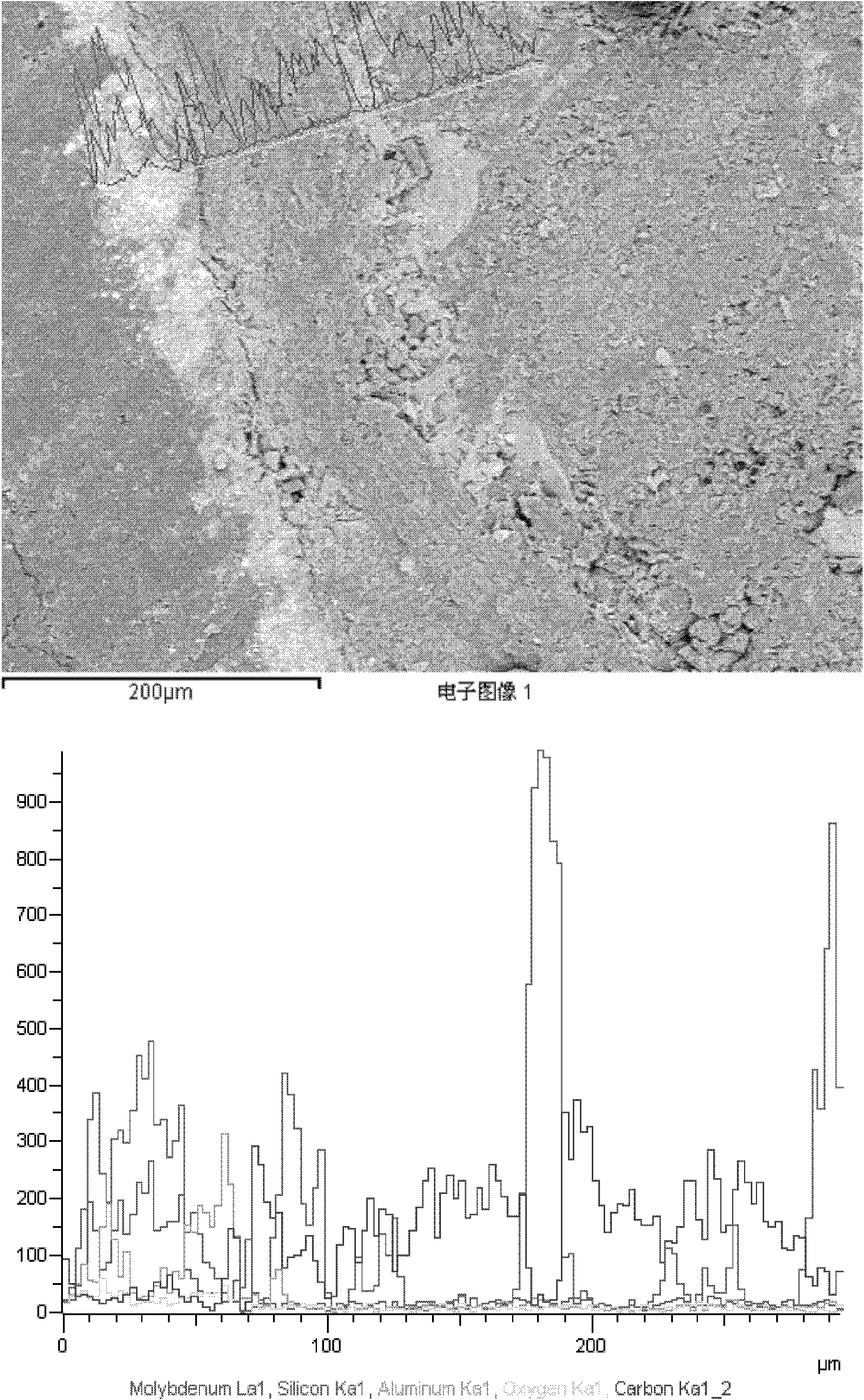

Bond coating and thermal barrier compositions, processes for applying both, and their coated articles

A coated article includes an article having at least one surface and composed of a molybdenum based refractory metal alloy base substrate, a niobium based refractory metal alloy base substrate or a silicon base substrate. A bond coat layer is disposed upon the surface. The bond coat layer includes a molybdenum disilicide base compound and at least one of the following: silicon nitride, silicon carbide or tantalum oxide. A process for coating the article includes the steps of applying upon the article's surface the aforementioned bond coat layer. A functionally graded material layer is applied upon the bond coat layer. The functionally graded material layer comprising molybdenum disilicide, mullite and at least one of the following: silicon nitride, silicon carbide or tantalum oxide. A thermal barrier coating layer is then applied upon the functionally graded material layer.

Owner:RTX CORP

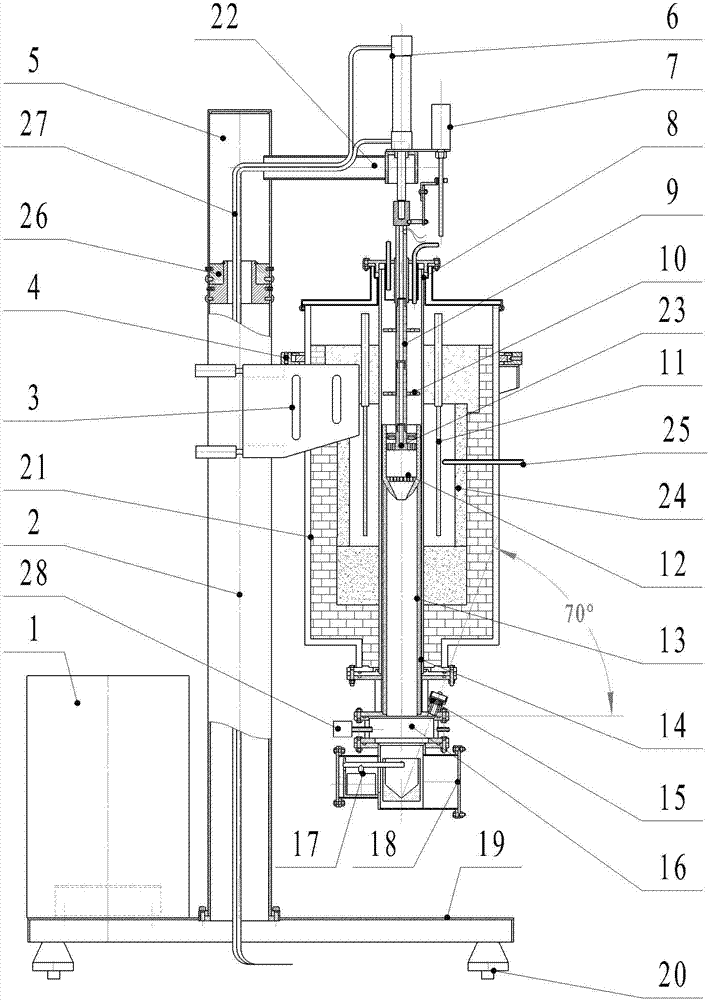

Experiment device for testing softening and dropping point of sinter

ActiveCN103713007AEasy to operateMeet testing needsInvestigating phase/state changeFurnace temperatureGas cylinder

The invention relates to an experiment device for testing a softening and dropping point of a sinter. The device is composed of a large current transformer, a furnace body fixing column, a tray, a furnace body adjusting frame, a rotary column, a pressurized gas cylinder, a displacement sensor, a furnace top sealing furnace cover, a pressurized graphite compression strut, an anti-radiation graphite cover, a molybdenum disilicide heater, a graphite crucible, a high pure graphite sleeve, a sealed alundum tube, a pinhole camera, an air inlet channel fixing sleeve, a dropping crucible weighing device, a dropping crucible device, a furnace body chassis, furnace body castors, a heating furnace body, a cantilever beam, a sample temperature thermocouple, a alumina hollow ball member, a furnace temperature control thermocouple, a rotary column circular sleeve, a pressurized gas cylinder pipeline and a pressure transmitter. The large current transformer is adopted to supply power for the molybdenum disilicide heater; the pinhole camera is used to observe a dropping process of high temperature liquid slag iron; the dropping crucible weighing device is arranged; the crucible is assembled and disassembled in a manner of laterally opening the door; and the position of the heating furnace body is adjusted by the furnace body adjusting frame, so that the device is flexible, accurate and convenient for operations.

Owner:NORTHEASTERN UNIV

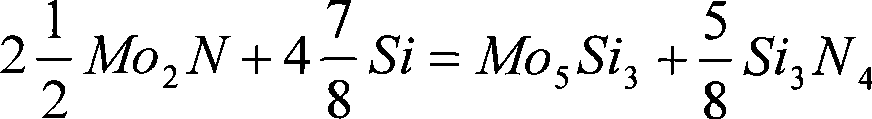

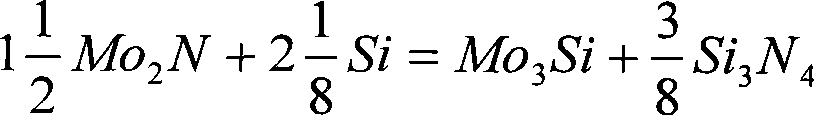

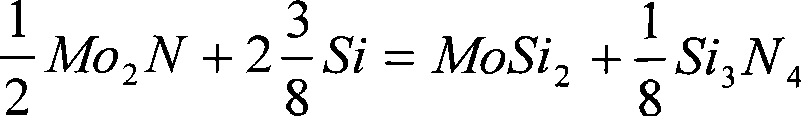

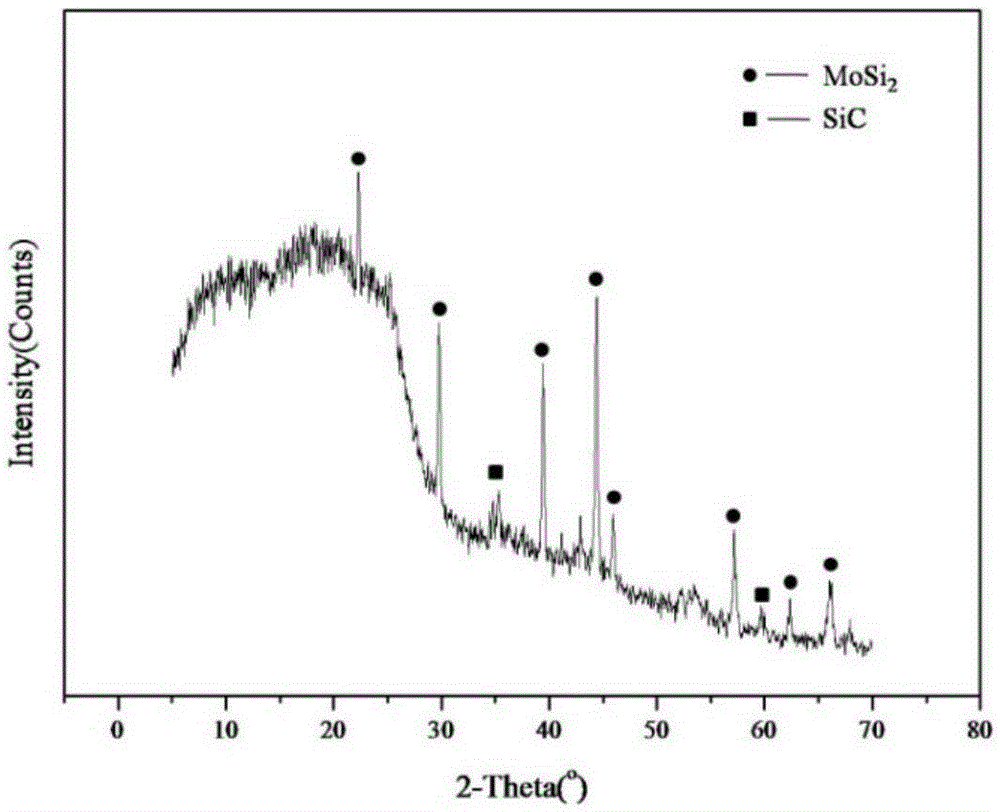

Composite high-temperature molybdenum disilicide-base material and preparation method thereof

InactiveCN101531519AImprove antioxidant capacityAdjust the coefficient of thermal expansionComposite substrateRoom temperature

The invention relates to a composite high-temperature molybdenum disilicide-base material and a preparation method thereof. The method can prepare the composite high-temperature material under lower production cost, which has the highest room temperature toughness equivalent to that of high-temperature alloys, higher high temperature intensity, high temperature creep resistant performance and certain plastic processing performance; the substrate of the composite high-temperature material is a composite substrate composed of MoSi2 and Si3N4, wherein the average crystal grain size of the MoSi2 is smaller than 2 microns, and the average grain diameter of the Si3N4 particulates is smaller than 1 microns. The method adopts the following technical proposal: Mo2N powder or powder of Mo5Si3 or Mo3Si are used as initial powder to obtain composite powder Mo3Si-Mo5Si3-Si3N4 or Mo5Si3-MoSi2-Si3N4 after being processed by siliconization or nitridation-siliconization, the composite powder is further enhanced and mixed with materials such as Si powder, SiC powder and the like, and is pressing molded, and then a blank is sintered under the temperature of 1415 to 1550 DEG C, and finally the sintered blank is plastic deformed, thus obtaining a required dense article of the composite high-temperature material.

Owner:李琎 +1

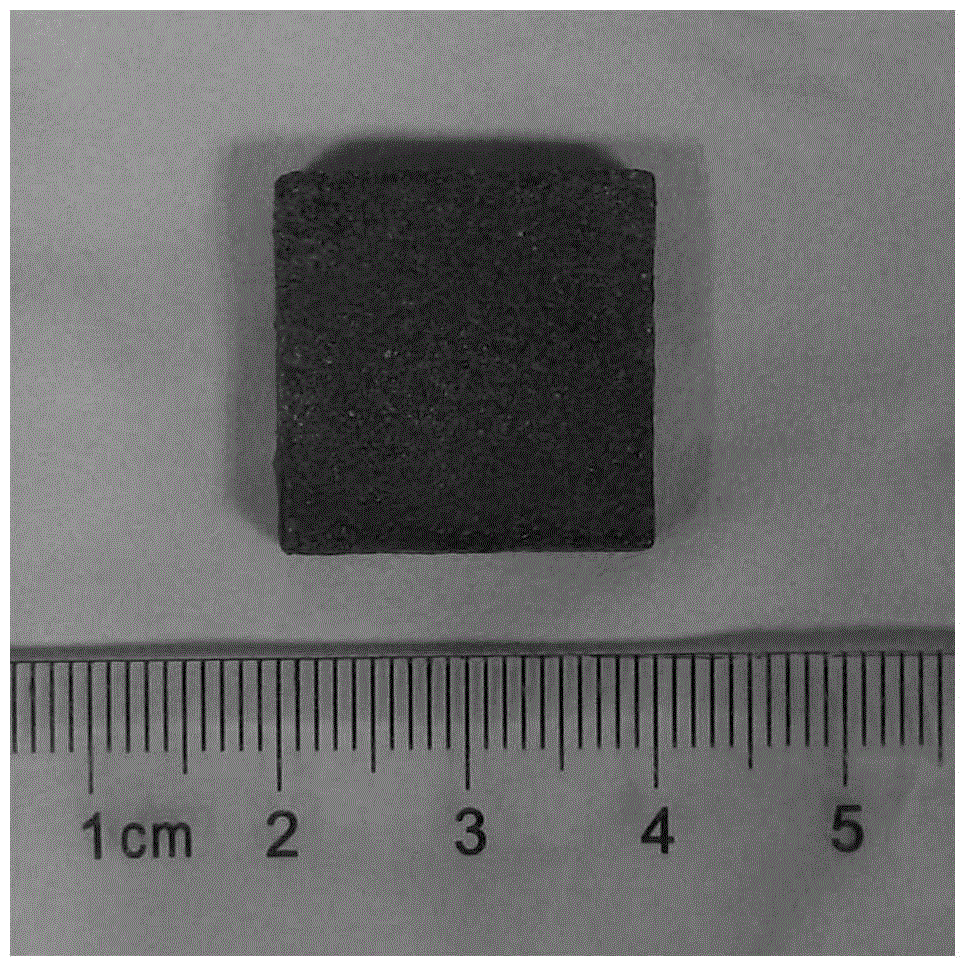

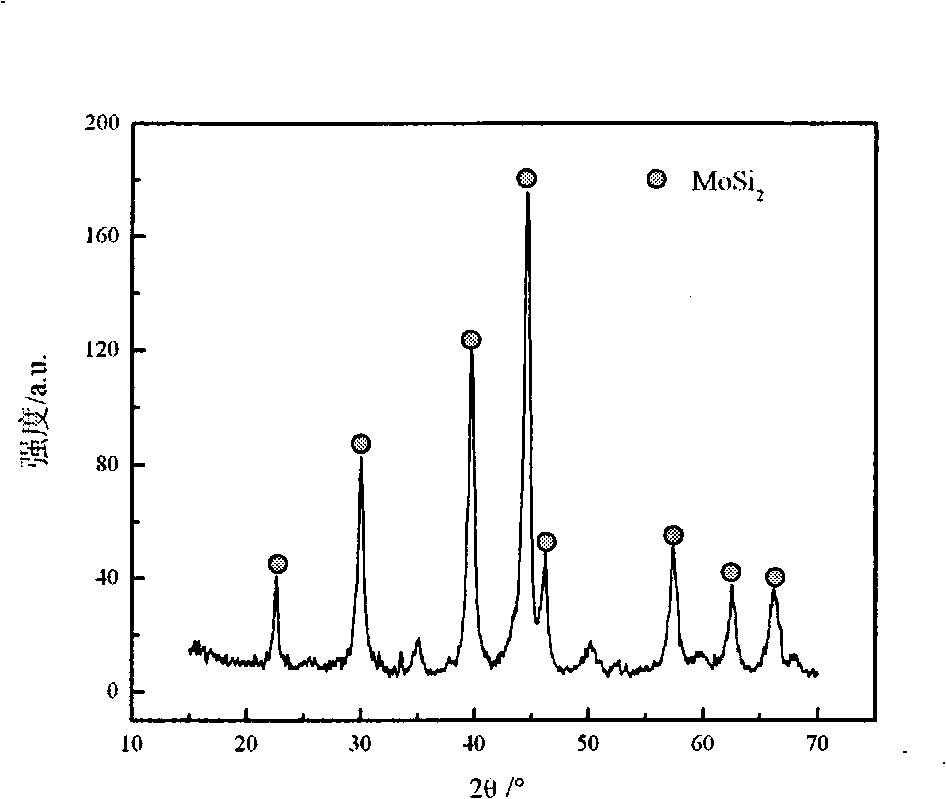

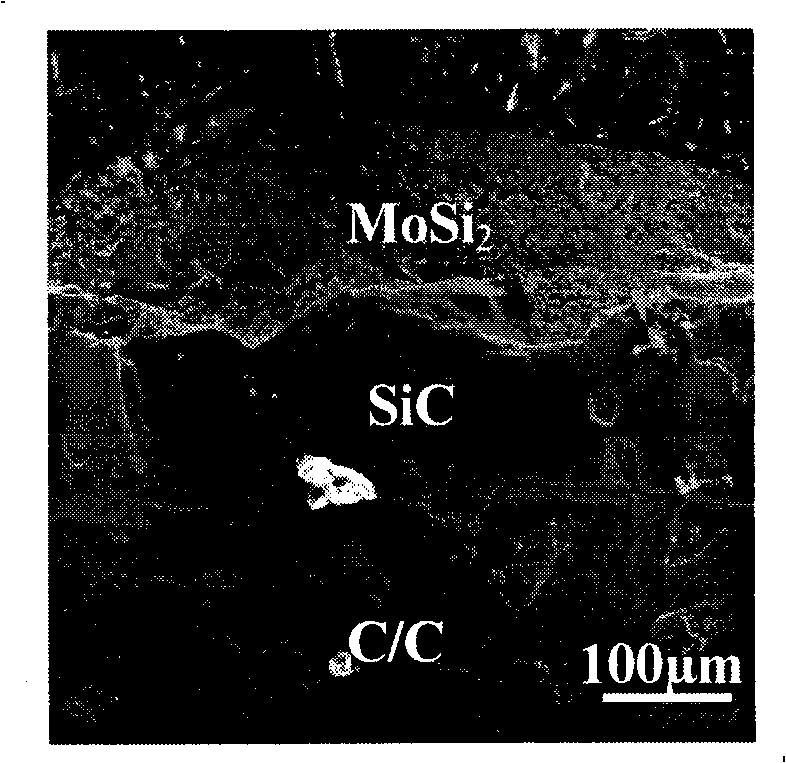

Preparation method of C/C-SiC-MoSi2 ceramic-based composite material

A preparation method of a C / C-SiC-MoSi2 ceramic-based composite material includes the following steps: 1) dispersing silicon carbide powder and molybdenum disilicide powder in isopropyl alcohol, and performing ultrasound vibration and stirring to obtain a suspension liquid A and a suspension liquid B: 2) increasing the density of a low-density carbon fiber stereo fabric in a manner of hydrothermal permeation of glucose, and placing the fabric in a suction filtration device having a glass sand core; 3) pouring the suspension liquid A and the suspension liquid B successively into a suction filtration flat-bottom funnel to enable the suspension liquids to pass the C / C composite material completely; 4) performing a homogeneous phase hydrothermal reaction until the density is 1.2-1.5 g / cm<3>; and 5) performing thermal treatment to obtain the C / C-SiC-MoSi2 ceramic-based composite material. The composite material is moderated in density, is compact in structure, and is excellent in interface binding between a C / C interface and a SiC interface, the SiC interface and a MoSi2 interface and the C / C interface and the MoSi2 interface. The raw materials are easy to obtain. The preparation method is simple in operation, is low in cost, is environment-friendly and is pollution-free.

Owner:浙江领崎科技有限责任公司

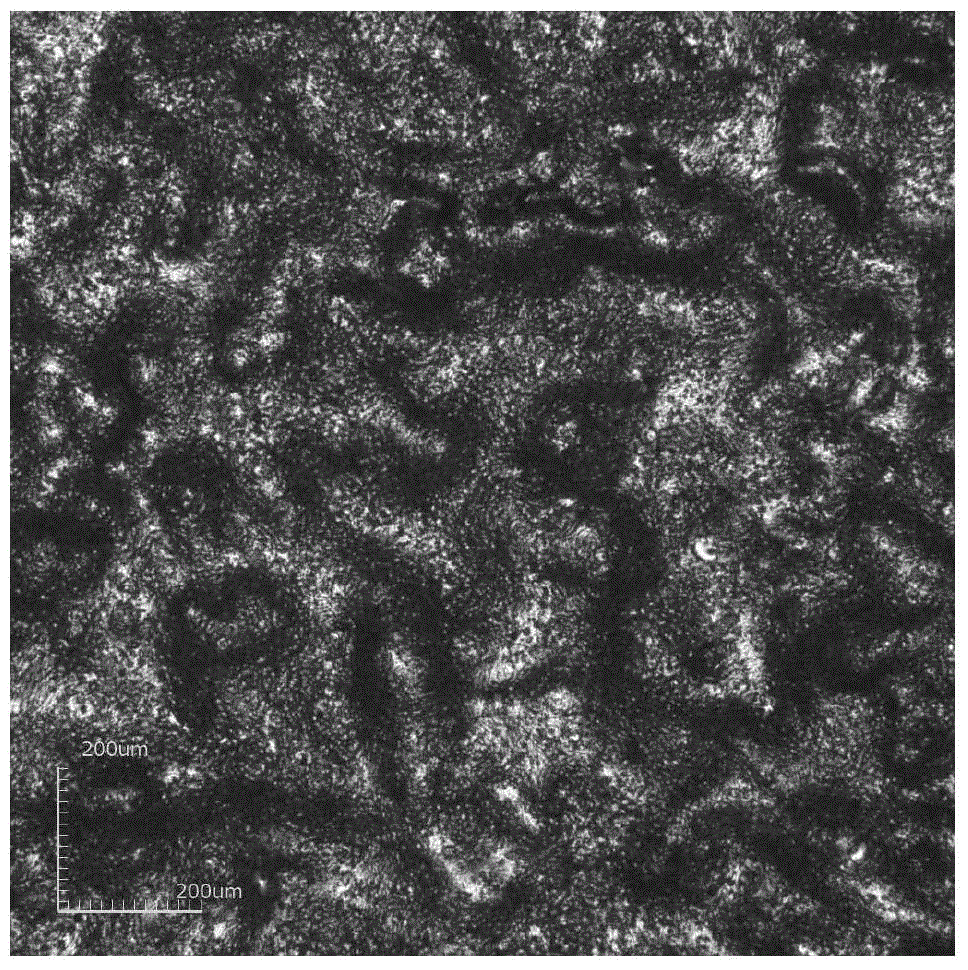

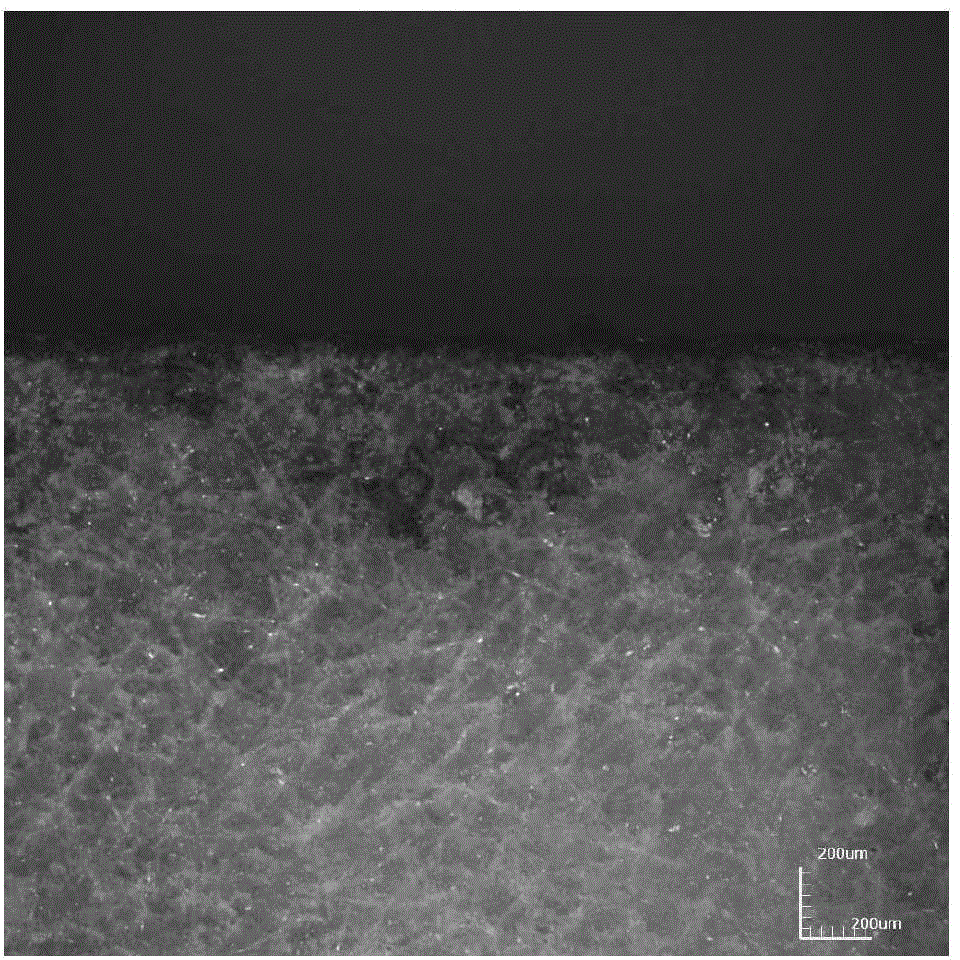

MoSi2-BSG coated zirconium oxide fiberboard integrated heat insulating material and preparation method thereof

The invention belongs to the field of preparation of heat insulating materials, and relates to a MoSi2-BSG coated zirconium oxide fiberboard integrated heat insulating material and a preparation method thereof. The preparation method comprises the following steps: preparing borosilicate glass by taking silicon dioxide and borax as raw materials; then preparing a MoSi2-BSG coating on the surface of a zirconium oxide fiberboard by taking molybdenum disilicide as a radiation agent, the borosilicate glass as a bonding agent, silicon hexaboride as a sintering aid and ethanol as a dispersant through a slurry immersion method, thereby finally obtaining the MoSi2-BSG coated zirconium oxide fiberboard integrated heat insulating material. The surface coating of the integrated heat insulating material infiltrates into a substrate material for 0.5-2mm, the emissivity is more than 0.8, and the temperature resistance at least can reach more than 1400 DEG C, so that the integrated heat insulating material has excellent heat insulating property, thermal shock resistance and bonding property.

Owner:NANJING UNIV OF TECH

Fiber-enhanced integrated material with high-temperature resistance property and high emissivity and preparation method thereof

The invention discloses a fiber-enhanced integrated material with high-temperature resistance property and high emissivity and a preparation method thereof. The preparation method comprises the following steps of using a carbon fiber felt as a framework support; filling the framework with a C-SiO2 (carbon-silicon dioxide) composite aerogel, so as to obtain the carbon fiber-enhanced C-SiO2 aerogel;coating a high-emissivity heat prevention coating layer to the surface of the carbon fiber-enhanced C-SiO2 aerogel; filling a C-SiO2 aerogel with high-temperature resistance property and low heat conductivity into the carbon fiber felt by a sol-gel method, a carbon dioxide super-critical drying technique and high-temperature heat treatment process, so as to form a heat isolation material with light weight, high-temperature resistance property and scouring resistance property; preparing a molybdenum disilicide-B2O3(boron oxide)-SiO2 glass coating layer at the surface of the heat isolation material by a slurry impregnating method and a quick heat treatment method, so as to form the fiber-enhanced integrated material with high-temperature resistance property and high emissivity. The fiber-enhanced integrated material has the advantages that the high temperature of 1500 DEG C can be resisted; the internal carbon fiber-enhanced C-SiO2 aerogel has lower heat conductivity of 0.035 to 0.045W.m<-1>.K<-1>; the emissivity of the surface heat protection coating layer at room temperature is greater than 0.85.

Owner:NANJING UNIV OF TECH

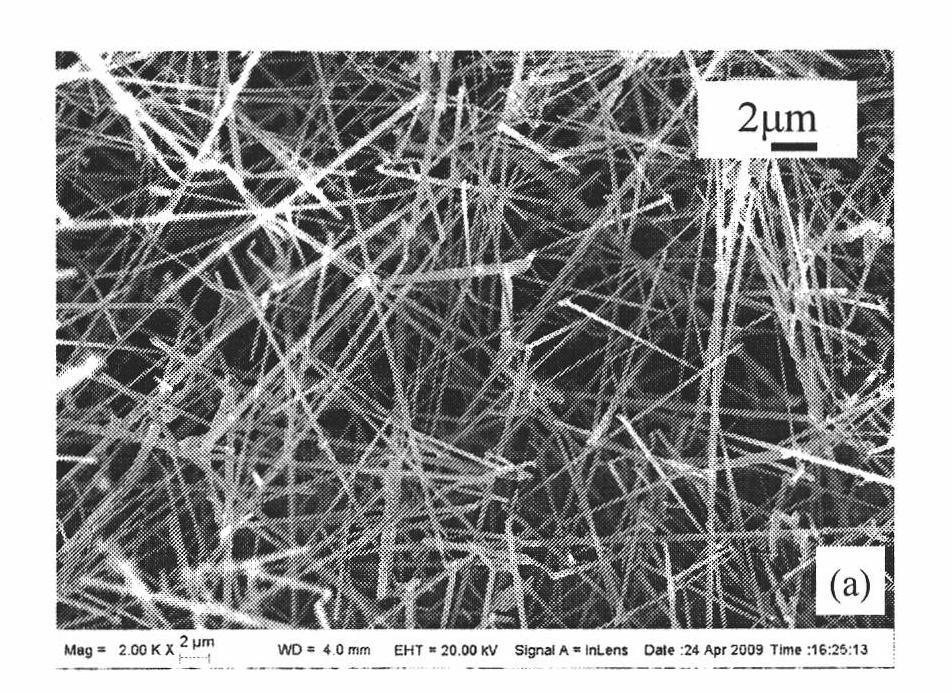

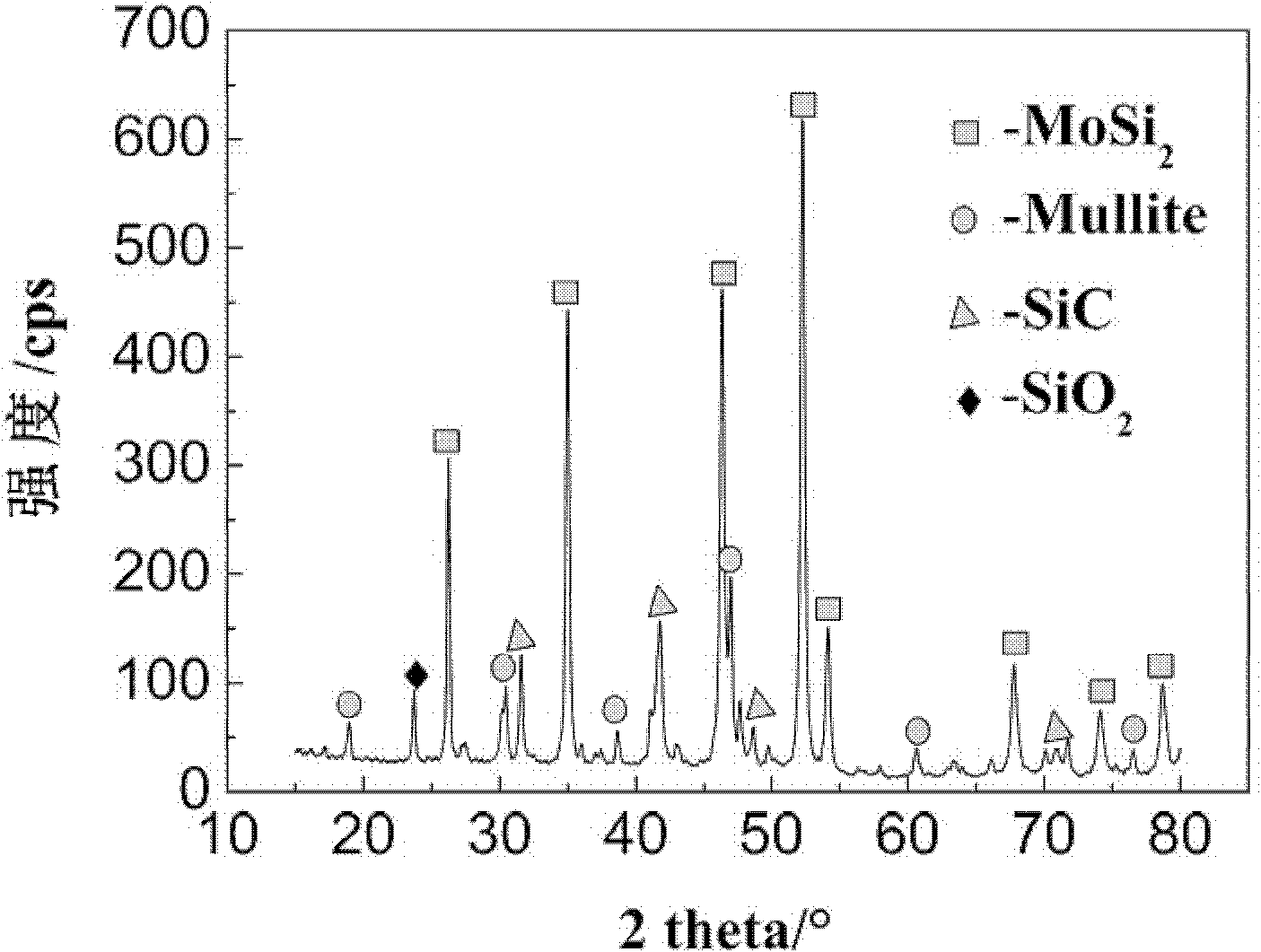

Method for preparing C/C composite material nanometer silicon carbide-mullite-molybdenum disilicide composite external coating

InactiveCN101844936AImprove toughnessImproved high temperature oxidation protectionCarbon compositesMullite

The invention relates to a method for preparing a C / C composite material nanometer silicon carbide-mullite-molybdenum disilicide composite external coating, which comprises the following steps of: adding mullite powder, nanometer silicon carbide powder and molybdenum disilicide powder into isopropanol and performing ultrasonic oscillation to obtain suspension A; adding an iodine simple substance into the suspension A and performing ultrasonic oscillation to obtain solution B; and pouring the solution B into a hydrothermal reaction kettle, clamping a C / C composite material sample with a SiC internal coating on a cathode clamp in the hydrothermal reaction kettle, performing hydrothermal electrophoresis reaction, naturally cooling to room temperature, taking the sample out and drying the sample to obtain the nanometer silicon carbide-mullite-molybdenum disilicide composite external coating. The reaction is finished in the hydrothermal reaction kettle at one time without subsequent heat treatment, wherein the nanometer silicon carbide powder can fill cracks, micropores and other defects in the coating; and the rodlike mullite whisker has good toughening effect so as to greatly improve the high-temperature oxidation protective capability of the composite coating.

Owner:SHAANXI UNIV OF SCI & TECH

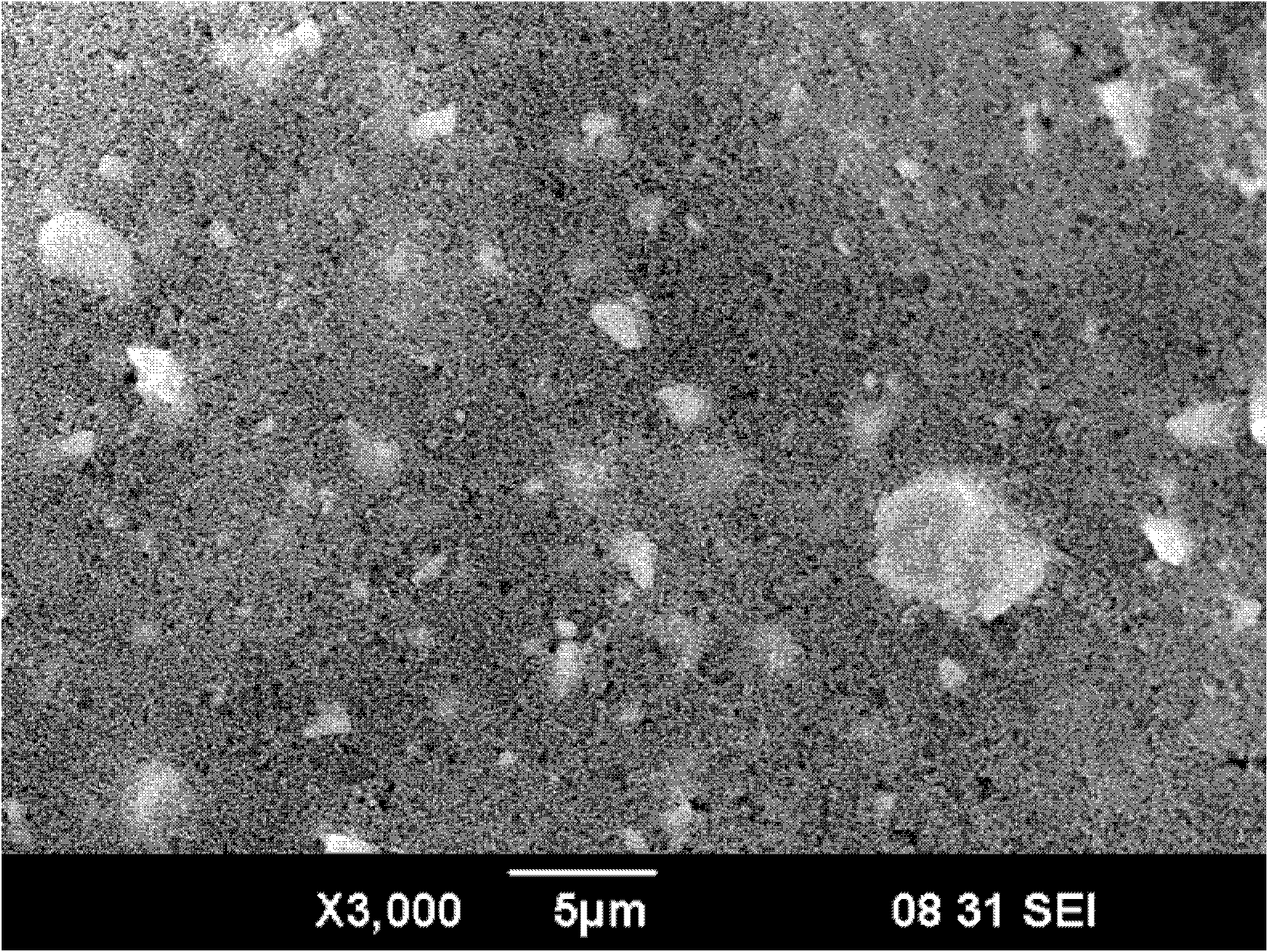

Preparation of carbon/carbon composite material molybdenum disilicide outer coating

The invention relates to a preparation method of a carbon / carbon composite material molybdenum disilicide external coating, which comprises the following steps: the ball-milled molybdenum disilicide powder and isopropanol are mixed in a supersonic generator and vibrated; suspending liquid A is obtained after magnetic stirring; iodine is added to the suspending liquid A and vibrated in the supersonic generator; solution B is obtained after magnetic stirring; the solution B is poured into a hydro-thermal reaction kettle; a carbon / carbon composite material sample with a SiC internal coating is clamped on a cathode clamp inside the hydro-thermal kettle; the hydro-thermal kettle is put in an oven; after the hydrothermal electrophoresis is finished, the sample is cooled to room temperature; and the sample is taken out and dried to obtain the final product, i.e., the carbon / carbon composite material with the protection of the molybdenum disilicide external coating and a carborundum internal coating. The adoption of the hydrothermal electrophoresis precipitation method can prepare the external coating with uniform thickness and without penetrating crackles and millipores. As the reaction is finished in the hydro-thermal kettle once without post heat treatment and carried out at low temperature, the base material is not damaged, the obtained molybdenum disilicide external coating has small internal stress and compact and uniform structure.

Owner:SHAANXI UNIV OF SCI & TECH

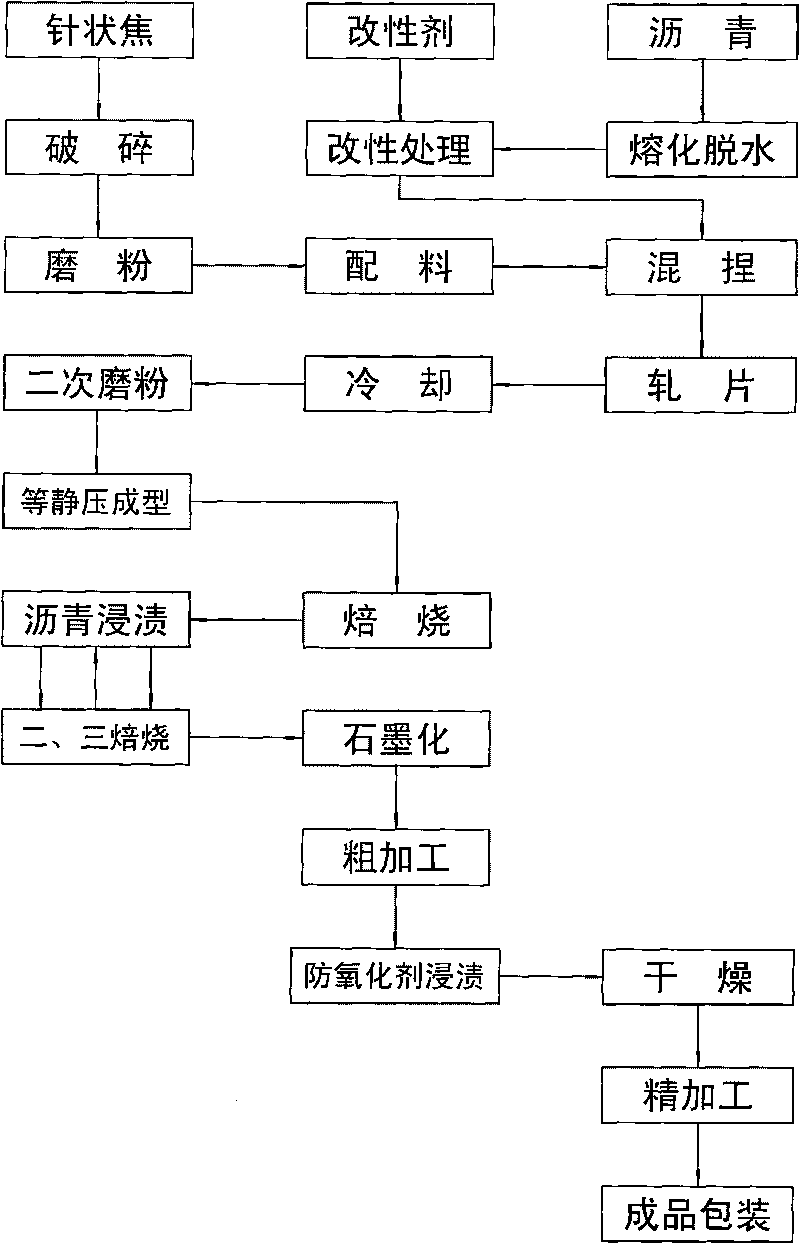

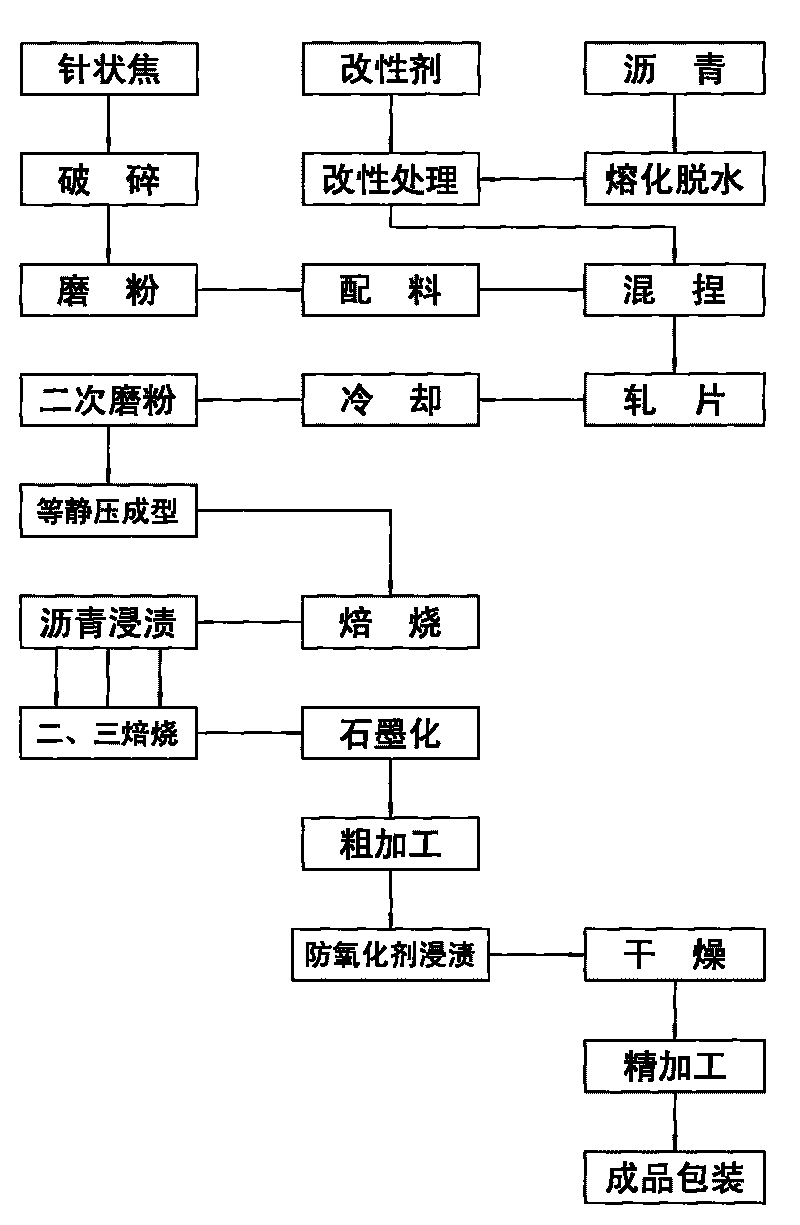

High-temperature graphite carbon bush and production method

ActiveCN101696121AImprove adhesionGood kneadingFurnace typesHeat treatment furnacesAntioxidantTitanium nitride

The invention discloses a high-temperature graphite carbon bush and a production method, wherein the high-temperature graphite carbon bush is suitable for carrying out heat treatment on a high-trademark cold rolling silicon steel sheet under the condition of high temperature (950-1,050 DEG C). The method comprises the following steps: mixing and kneading raw materials; molding; and dipping the raw materials by an antioxidant, wherein the raw materials comprise the following components in percentage by weight: 65-70 percent of powder with the grain diameter of 300-400 meshes and 30-35 percent of modified asphalt; the powder comprises the following components in percentage by weight: 99.5-99.8 percent of needle coke, 0.3-0.5 percent of titanium nitride and 0.2-0.3 percent of molybdenum disilicide; the modified asphalt is prepared by melting and dewatering high-temperature coal tar pitch and then adding phenolic resin to modify the coal tar pitch, and the weight ratio of the high-temperature coal tar pitch to the phenolic resin is 100:(3-5). The manufactured graphite carbon bush has the characteristics of high strength, wear resistance, good thermal shock resistance and good beading resistance and oxidation resistance; in addition, the working temperature can reach more than 1,050 DEG C.

Owner:DALIAN JINGYI CARBON

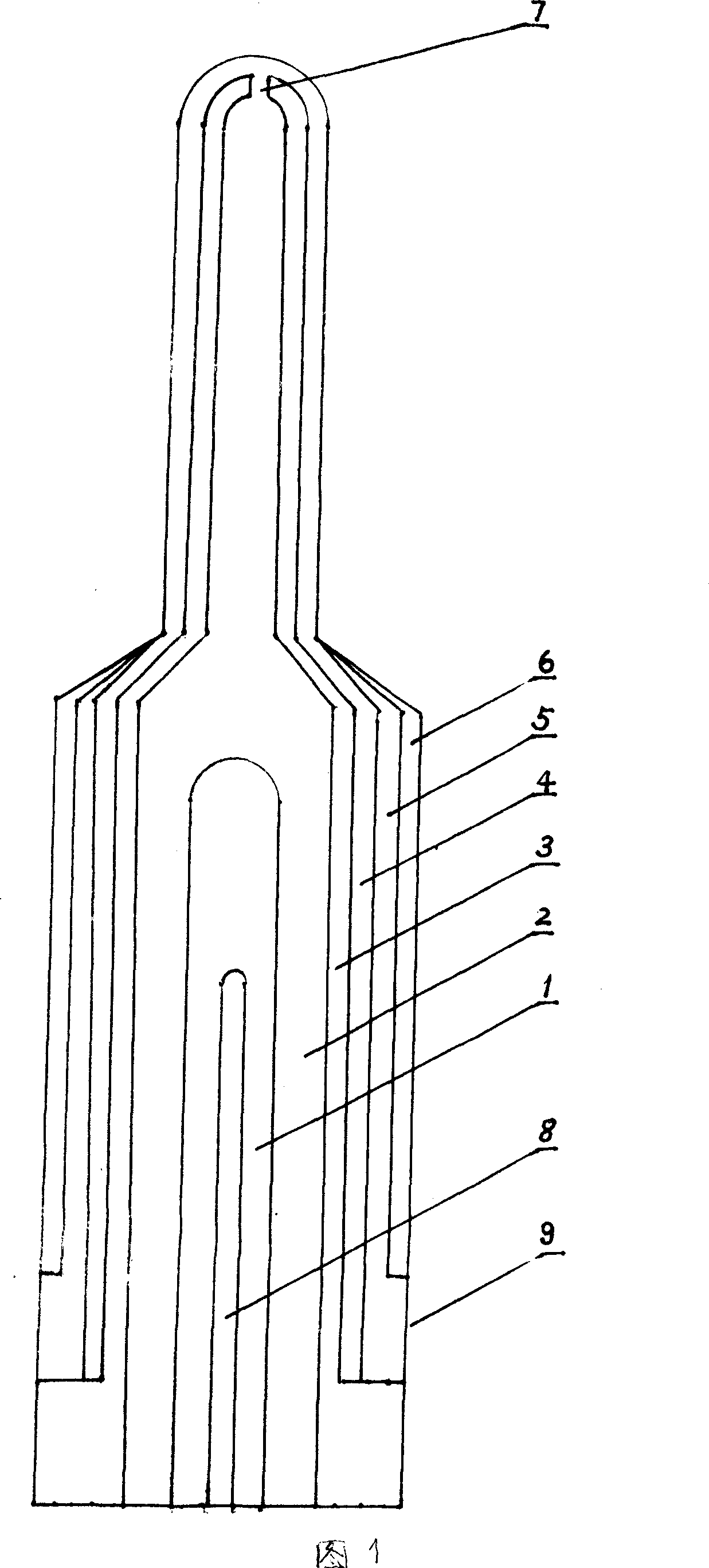

Ceramic six-layered electric heater

ActiveCN101031168AFast heating and ignitionIncrease temperatureLayered productsHeating element materialsElectrical resistance and conductanceInsulation layer

Owner:CHONGQING LE MARK CERAMIC TECH CO LTD

Electroplating liquid used for forming nickel molybdenum rare earth-molybdenum disilicide composite plating, and preparation method and application thereof

InactiveCN103436930ASmall coefficient of thermal expansionHigh electrical and thermal conductivityNickel saltChloride

The invention discloses electroplating liquid used for forming nickel molybdenum rare earth-molybdenum disilicide composite plating and a preparation method of the electroplating liquid. The per liter of the electroplating liquid used for forming the nickel molybdenum rare earth-molybdenum disilicide composite plating comprises the following components by mass: 10 to 400 g nickel salt, 10 to 800 g molybdenum polyoxometallate, 5 to 100 g complexing agent, 10 to 300 g chloride, 0.5 to 6 g rare earth, 5 to 60 g molybdenum disilicide, 0.01 to 0.9 g surfactant and water in balancing amount. The preparation method of the electroplating liquid comprises the following four steps: preparing a rare earth salt solution, pre-treating molybdenum disilicide particles, preparing nickel salt-molybdenum polyoxometallate-complexing agent-chloride-rare earth salt mixed liquor, and preparing the electroplating liquid of the nickel molybdenum rare earth-molybdenum disilicide composite plating, and the obtained electroplating liquid used for forming nickel molybdenum rare earth-molybdenum disilicide composite plating is used for performing electroplating on to-be-plated pieces to form the nickel molybdenum rare earth-molybdenum disilicide composite plating.

Owner:SHANGHAI INST OF TECH

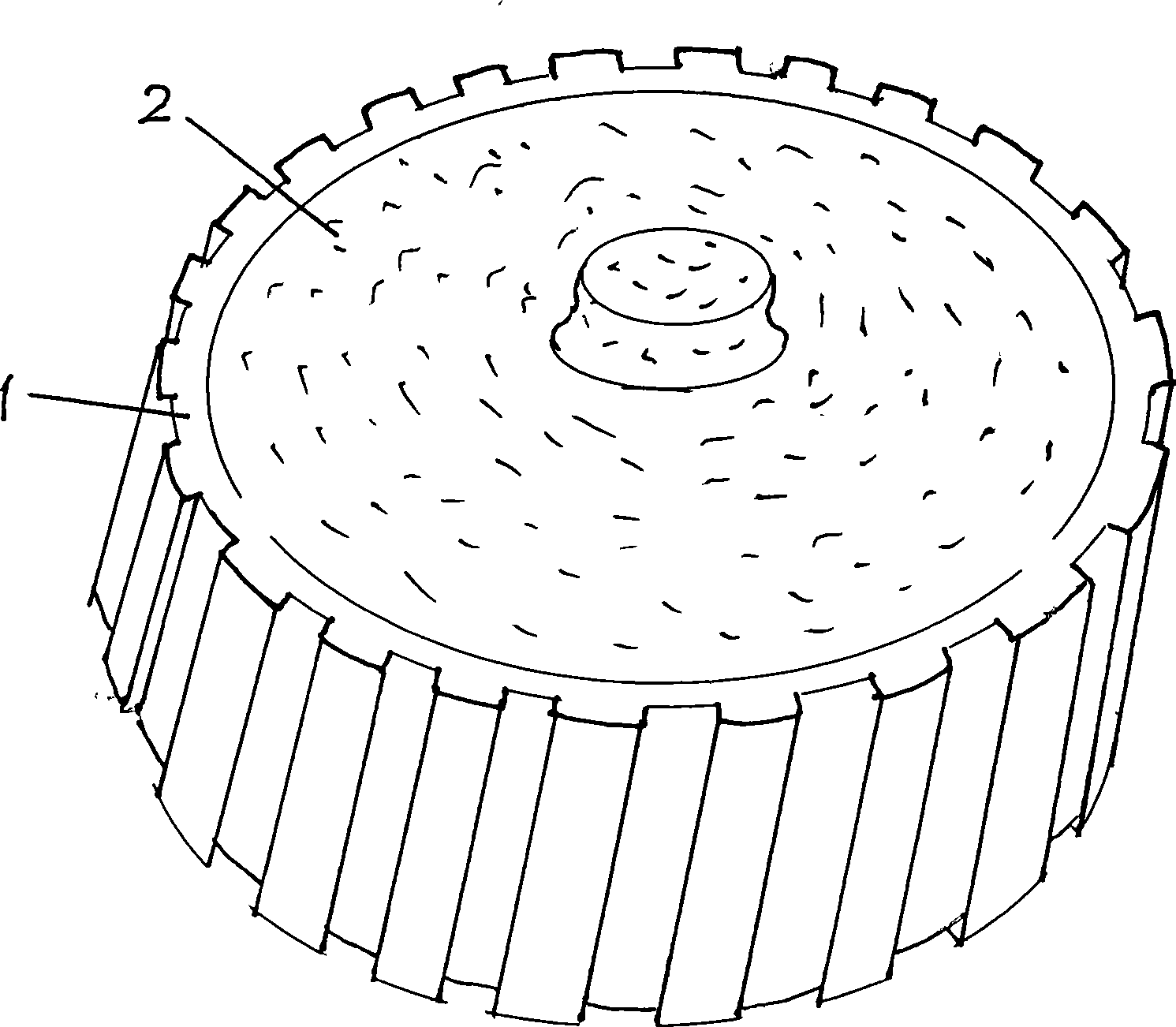

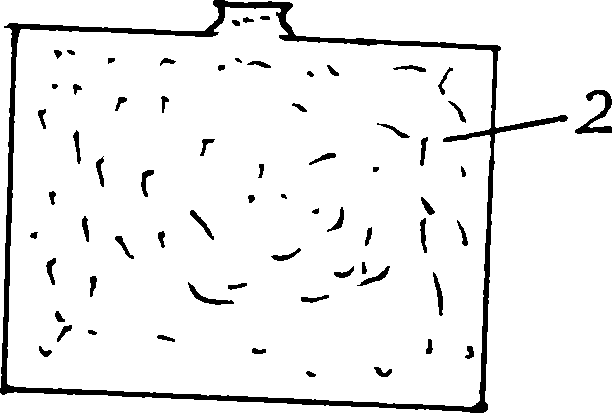

High speed disc type brake pad pottery friction body and method for producing same

InactiveCN101382173AExtended service lifeIncrease coefficient of frictionFriction liningIron powderLead oxide

The invention belongs to a compounding technique of a high-speed disc-typed brake ceramic typed friction body and comprises a pipe which is provided with a plurality of concave troughs on the external surface and an anti-friction body that is pressed and sintered by various wearable powder-shaped materials is arranged in the pipe which is provided with a plurality of concave troughs on the external surface; according to the weight percentage, all wearable powder-shaped material compounding in the anti-friction body comprises chromium iron powders, ferromolybdenum powders, Copper powders, graphite powders, supramoly powders, molybdenum disilicide powders, lead oxide powders, lead powders, mullite, carborundum powders and iron powders; the compounding technique comprises the preparation steps as follows: (1) selecting materials; (2) pre-mixing small materials of mullite adding with carborundum powders; (3) pre-mixing middle materials; (4) mixing all materials; (5) shape pressing and sintering; (6) embedding the materials into a heat dissipation sleeve. The compounding technique has the advantages that the mullite is added with the carborundum powders, the mullite has high wearability, the Fe powders are used as mainbody to replace the Cu powders, thus greatly saving the cost, with the friction coefficient still being: Mu equal to 0.32-0.57.

Owner:向兴碧

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com