Solvothermal preparation method of in-situ molybdenum disulfide electrode

A technology of molybdenum disulfide and in-situ electrodes, applied in the direction of coating, etc., to achieve the effect of preventing oxidation, improving purity and electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Dissolve 2mM molybdenum chloride and 7mM thiourea in ethylene glycol solution, add a piece of fluorine-doped tin oxide conductive glass with an area of 1.5cm*7cm, and then put it into a hydrothermal kettle and heat it in a solvent at 200°C for 6h, in which molybdenum The atomic ratio of atoms and sulfur atoms is 1:3.5. The molybdenum disulfide in-situ electrode can be obtained by taking out the substrate, cleaning it, and drying it.

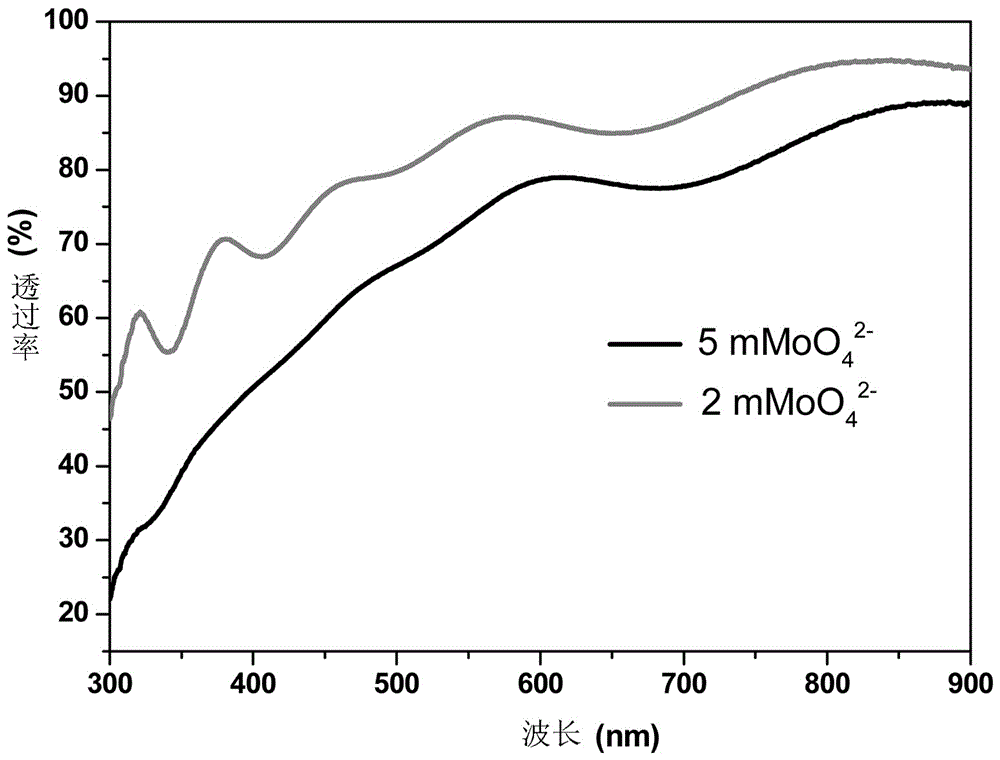

[0020] figure 1 The molybdenum disulfide in-situ electrode (2mMMoO 4 2- ) light transmittance. It can be seen from the figure that the molybdenum disulfide electrode has high transparency, and about 85% of ultraviolet-visible-near-infrared light can pass through the molybdenum disulfide film.

Embodiment 2

[0022] Dissolve 5mM sodium molybdate and 25mM thiourea in ethylene glycol solution, and add a piece of fluorine-doped tin oxide conductive glass with an area of 1.5cm*7cm, and then put it into a hydrothermal kettle and heat it at 200°C for 6 hours, in which molybdenum The atomic ratio of atoms to sulfur atoms is 1:5. Take out the substrate, wash it, dry it and put it in N 2 Annealing at 500°C for 1 h in the atmosphere can obtain molybdenum disulfide in-situ electrodes.

[0023] figure 1 The molybdenum disulfide in-situ electrode (5mMMoO 4 2- ) light transmittance. It can be seen from the figure that the molybdenum disulfide electrode has high transparency, and about 75% of ultraviolet-visible-near-infrared light can pass through the molybdenum disulfide film.

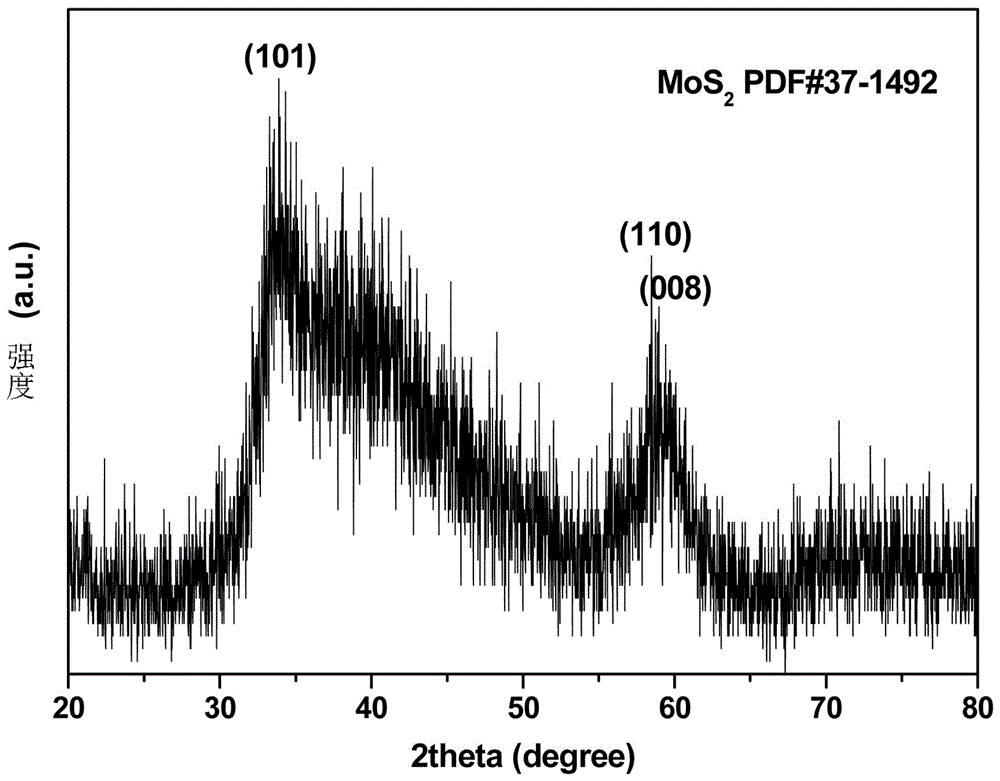

[0024] figure 2 Powder XRD of the sample prepared for this implementation example. The comparison with the standard PDF card shows that the prepared sample is molybdenum disulfide.

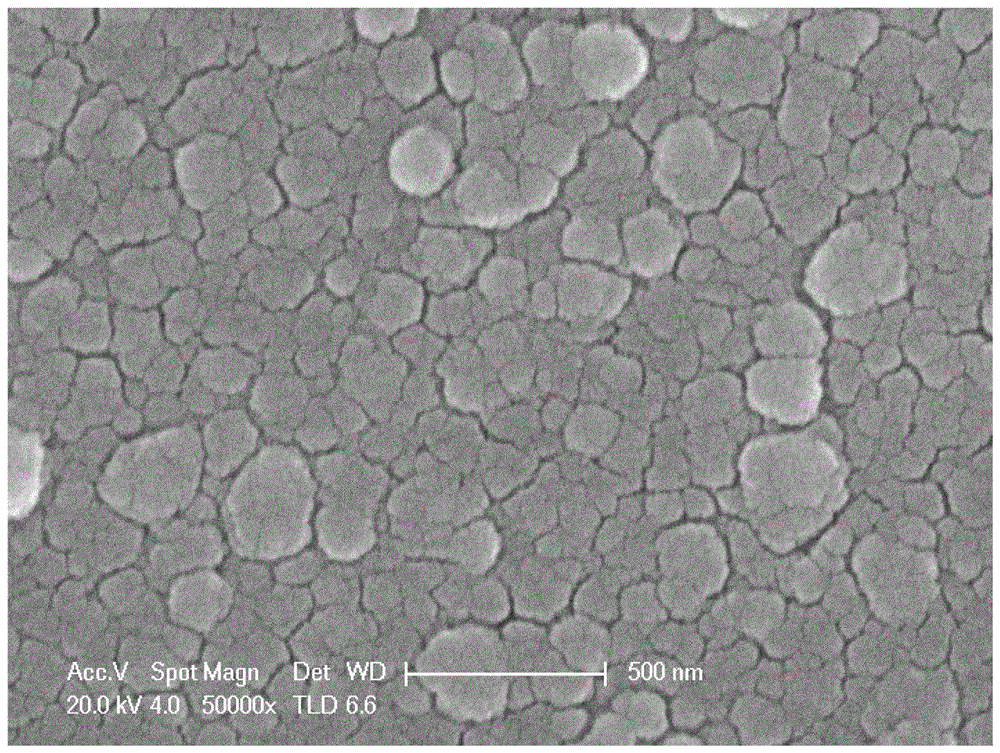

[0025] image 3 SEM imag...

Embodiment 3

[0027] Dissolve 5mM sodium molybdate and 35mM thioacetamide in ethylene glycol solution, and add a piece of fluorine-doped tin oxide conductive glass with an area of 1.5cm*7cm, then put it into a hydrothermal kettle and heat it in a solvent at 200°C for 12h , where the atomic ratio of molybdenum atoms to sulfur atoms is 1:7. Take out the substrate, wash it, dry it and put it in N 2 Annealing at 500°C for 1 h in the atmosphere can obtain molybdenum disulfide in-situ electrodes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com