Patents

Literature

65 results about "Molybdenum chloride" patented technology

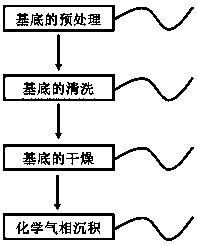

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molybdenum(V) chloride is the inorganic compound with the formula [MoCl5]2. This dark volatile solid is used in research to prepare other molybdenum compounds. it is moisture-sensitive and soluble in chlorinated solvents. Usually called molybdenum pentachloride, it is in fact a dimer with the formula Mo2Cl10.

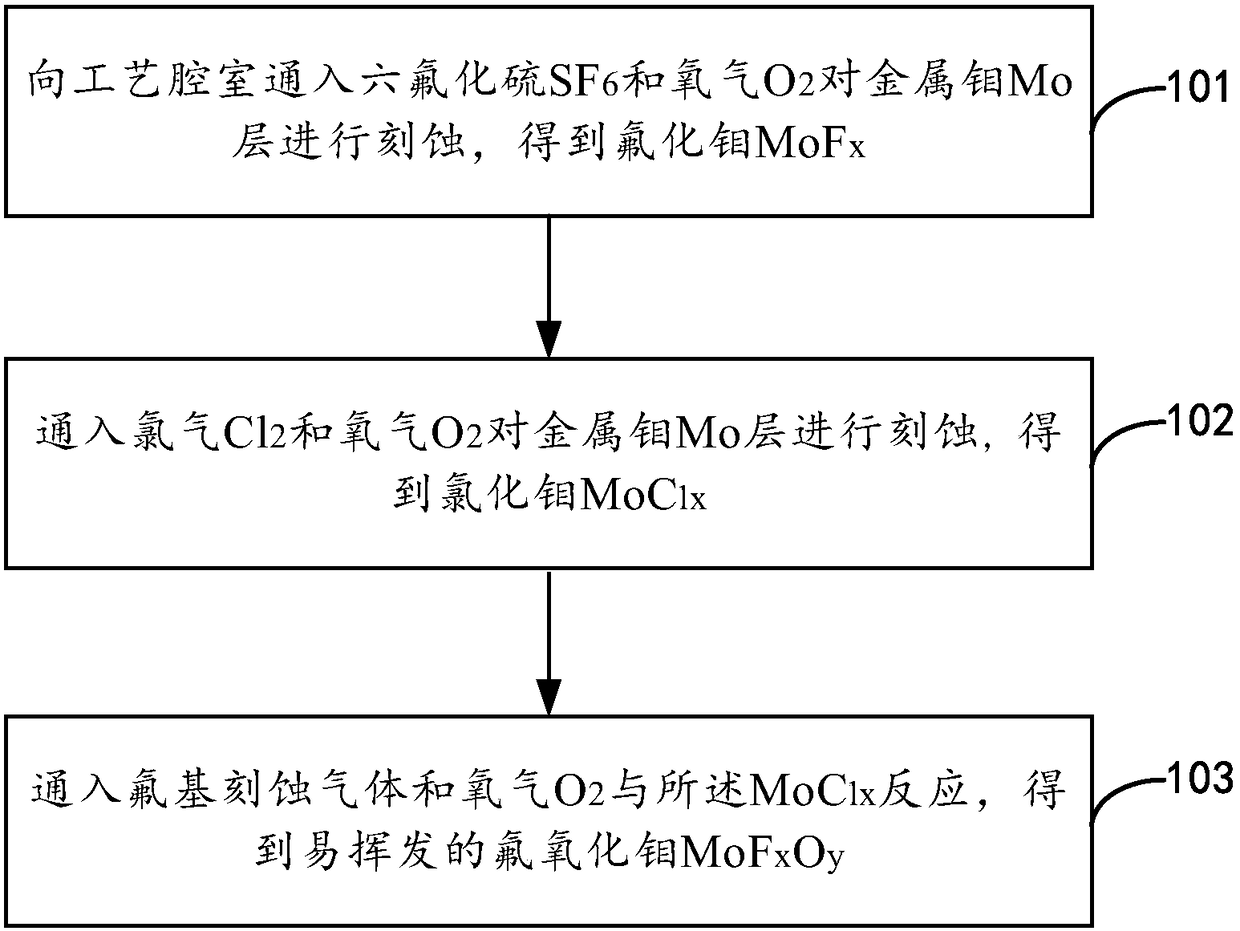

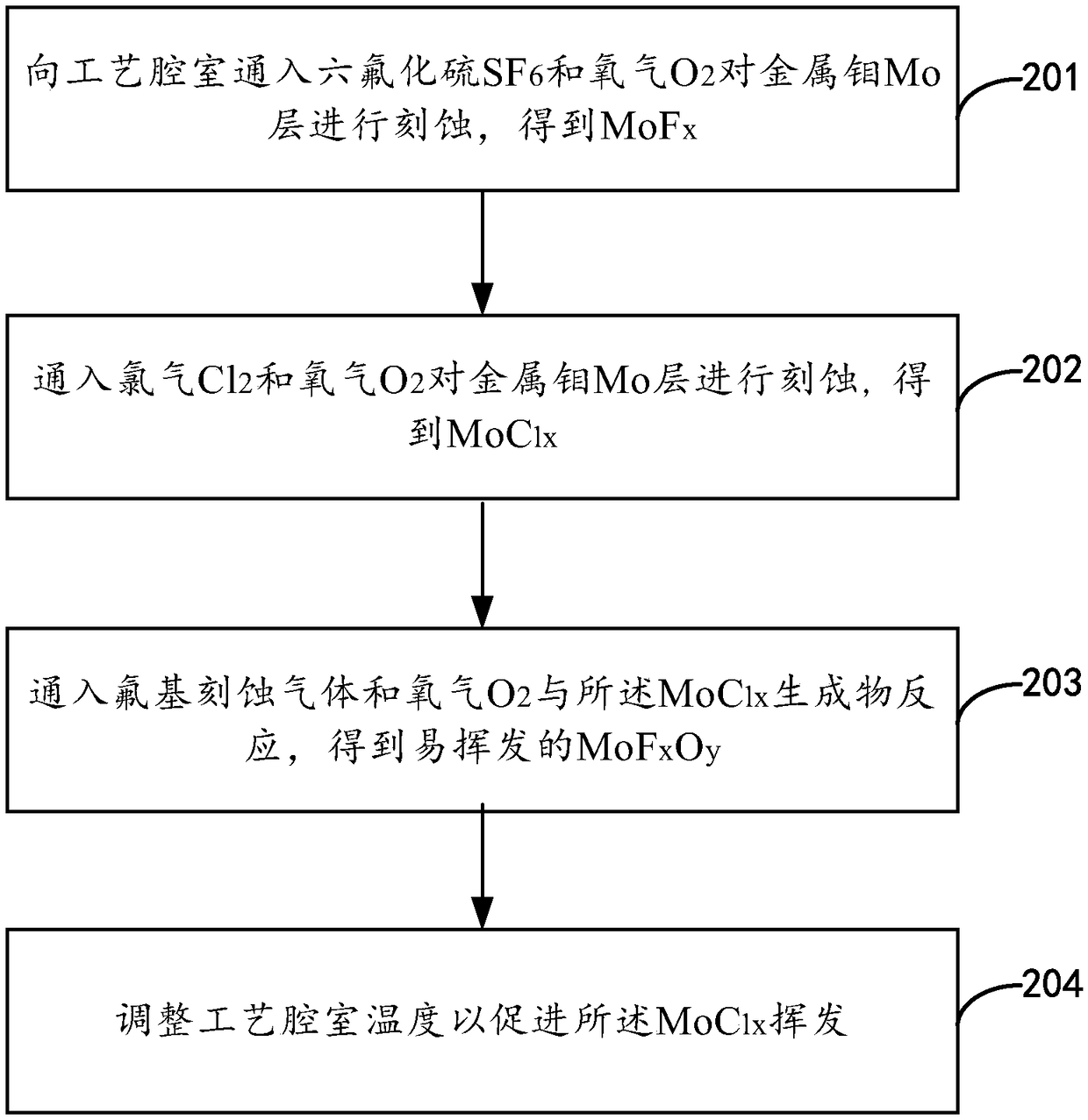

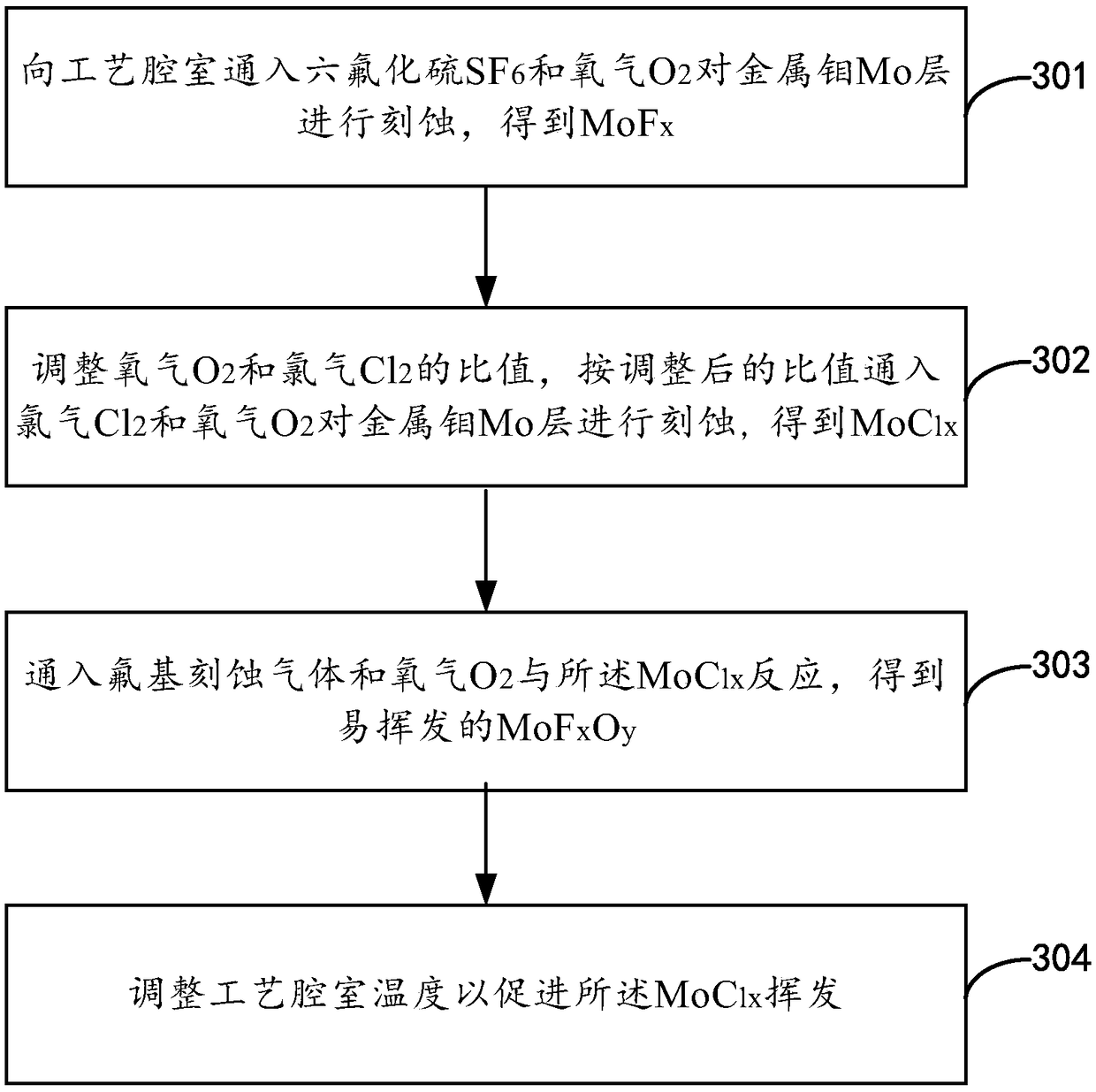

Etching method, low-temperature polysilicon thin film transistor and AMOLED panel

ActiveCN108389798AEasy to handlePrevent dark spotsTransistorSolid-state devicesSulfur hexafluorideOxygen

Owner:TRULY HUIZHOU SMART DISPLAY

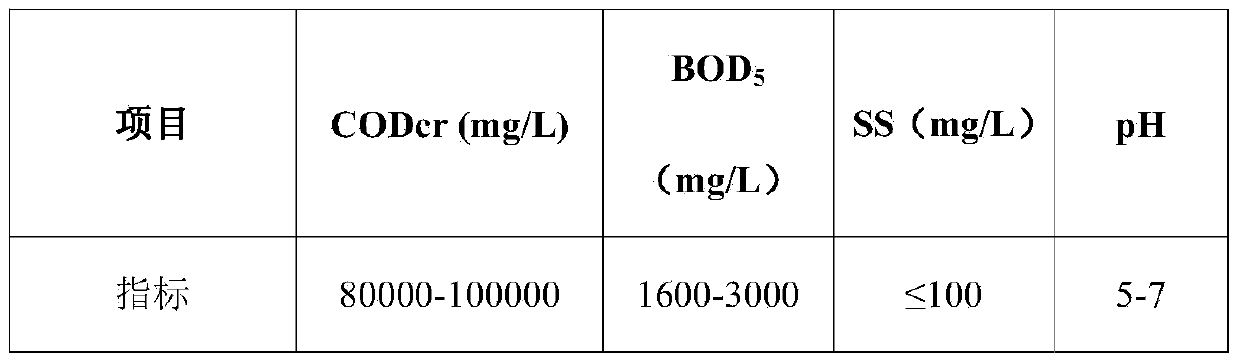

Sewage flocculant

InactiveCN104843841APromote degradationLow ecotoxicityWater/sewage treatment by flocculation/precipitationSludgeMolybdenum chloride

The invention relates to the technical field of sewage treatment, in particular to a sewage flocculant. The flocculant consists of the following components in parts by weight: 12-25 parts of poly-aluminum calcium chloride, 5-15 parts of ferric chloride, 2-10 parts of aluminum potassium sulfate, 2-8 parts of sodium carboxymethylcellulose, 1-6 parts of sodium hypochlorite, 10-30 parts of poly-molybdenum chloride, 10-20 parts of diatomite, 10-20 parts of zeolite and 0.01-0.05 part of additives. The sewage flocculant has the beneficial effects that the obtained flocculant is good in degradability, low in ecotoxicity, free of stimulation on human bodies, obvious in flocculation effect on the treatment of various complex sewage and high in cost performance for dehydration of sludge; the sewage flocculant has the characteristics of no toxicity and residue for human bodies, good flocculation effect and wide application range.

Owner:ZHANGJIAGANG SHANMU NEW MATERIAL TECH DEV

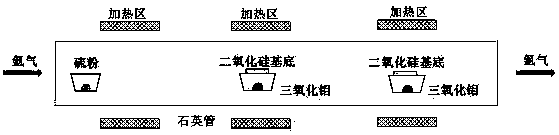

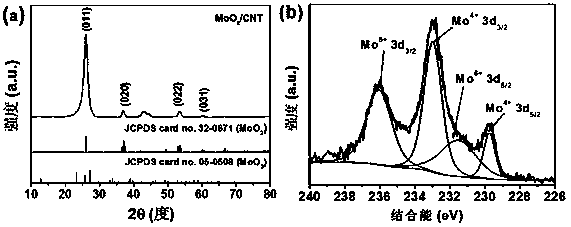

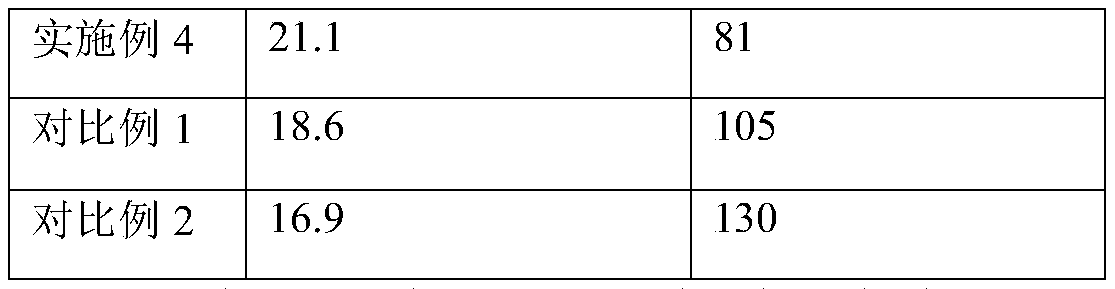

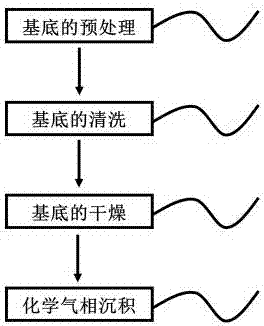

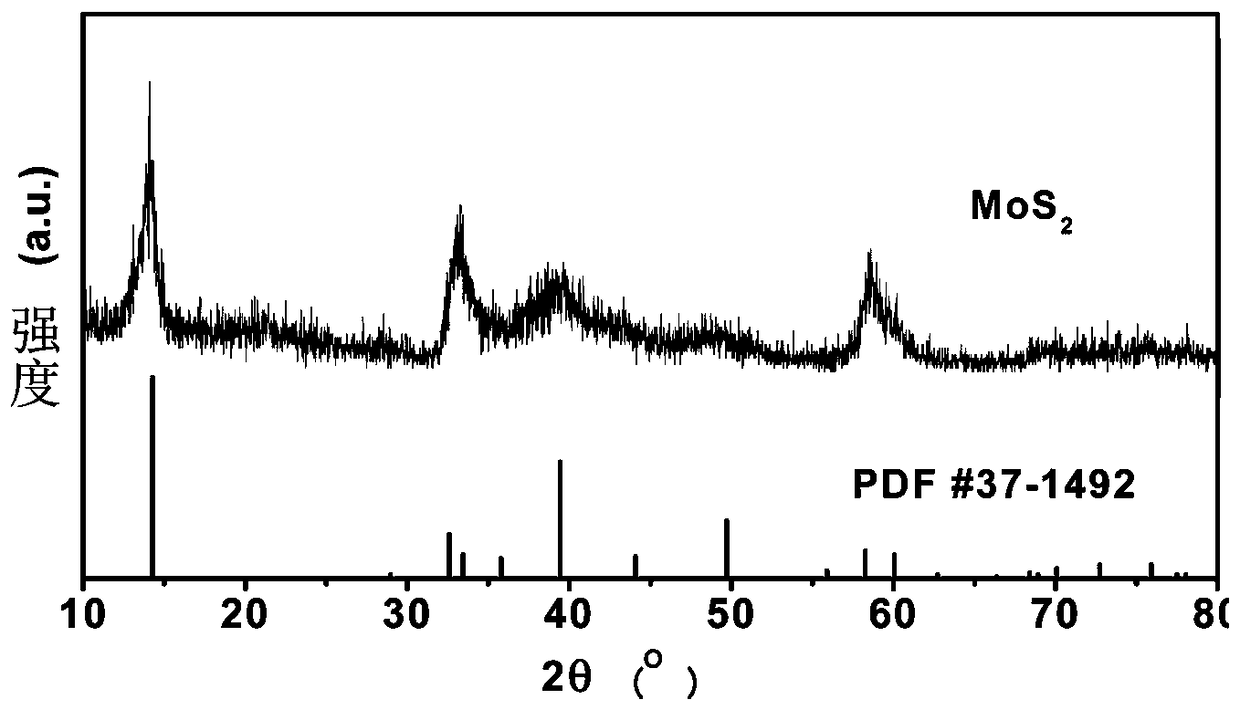

High-density boundary double-layer molybdenum disulfide nano sheet and preparation method thereof

ActiveCN108017090AUniform sizeHigh density boundaryMaterial nanotechnologyHydrogen productionChemical vapor depositionMolybdenum trioxide

The invention relates to a high-density boundary double-layer molybdenum disulfide nano sheet and a preparation method thereof. The preparation method comprises the following steps: S1, placing a glass slide as a substrate into a hydrofluoric acid for soaking for 5-10 minutes, then cleaning and removing the silicate reaction product on the surface, and carrying out drying for later use; and S2, using a chemical vapor deposition method, using sublimated sulfur as a sulfur source, and molybdenum trioxide, molybdenum chloride and ammonium tathiomolybdate as molybdenym sources, and using a three-temperature-zone tube furnace to make molybdenum disulfide to grow on the substrate. The double-layer molybdenum disulfide nano sheet provided by the invention has uniform size, higher density boundary, and good conductivity and catalytic performance, and the preparation method is simple in operation, less in process flow and low in cost.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

Preparation method for graphene/molybdenum disulfide composite material

The invention aims to provide a novel method for preparing a lot of graphene / molybdenum disulfide composite materials. The method comprises the specific steps: (1) preparing commercially-purchased glucose and melamine taken as raw materials into graphene by a high-temperature cracking method; (2) dispersing the graphene prepared by the step (1) and commercially-purchased molybdenum chloride (MoCl5) into absolute ethyl alcohol; carrying out ultrasonic treatment, agitating and drying in vacuum; then grinding to obtain a mixed raw material; putting the mixed raw material into a square ceramic boat and putting the ceramic boat into a middle part of a horizontal pipe type furnace with the length of 90cm; weighing a certain amount of sulfur powder and putting the sulfur powder into the other square ceramic boat; putting the square boat into a 18cm part of an argon inlet of the horizontal pipe type furnace; sealing the horizontal pipe type furnace and vacuumizing to 10<-4>MPa; introducing argon with a certain flow speed and keeping a low-pressure condition; raising the temperature to a pre-set temperature and keeping the heat for 30 minutes; and finally, naturally cooling to the room temperature under the protection of the argon and collecting an obtained product in the ceramic boat for containing the mixed raw material.

Owner:XINJIANG UNIVERSITY

Milk cattle feedstuff and manufacturing technique

InactiveCN101081062AIncrease milk productionImprove absorption rateAnimal feeding stuffAccessory food factorsSodium bicarbonateVegetable oil

The present invention discloses one kind of milk cow feed. Pre-mixed material is first produced with zinc sulfate, ferrous sulfate, anhydrous cupric sulfate, potassium iodide, sodium selenite, cobalt chloride, manganese sulfate, molybdenum chloride, vitamin A, vitamin D3 and vitamin E and through mixing; and then mixed with slow released non-protein nitrogen, calcium biphosphate, feather powder, cotton seed dregs, tree leaf powder, calcium carbonate, table salt, anhydrous sodium sulfate, sodium bicarbonate, yeast and vegetable oil through stirring homogeneously to produce the milk cow feed. The milk cow feed has balanced nutrients, protein capable of being decomposed directly in the rumen of milk cow, high absorption rate and capacity of raising milk yield.

Owner:齐庆文

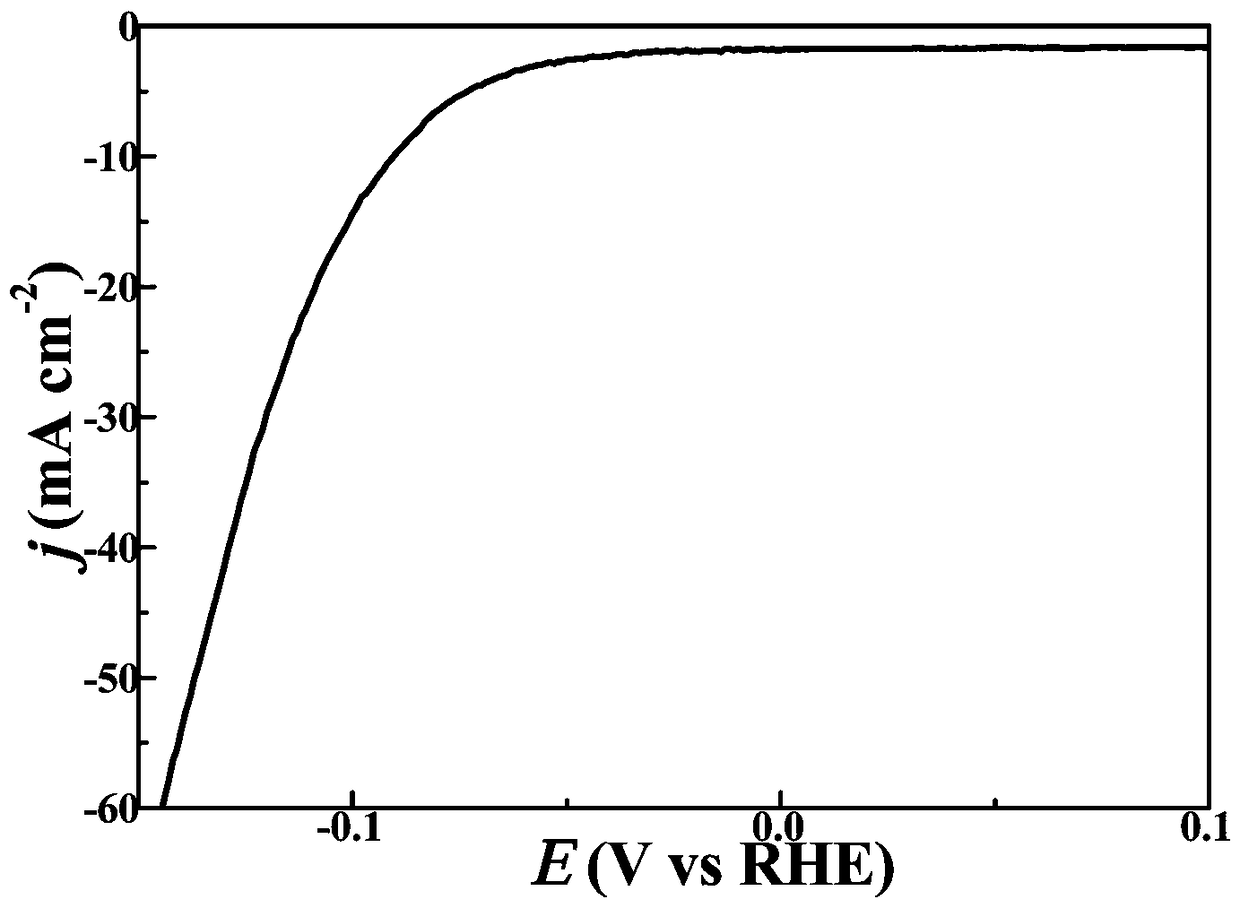

CVD preparation method of Co-doped MoS2 array in-situ electrodes

ActiveCN108385132ALow costReduce pollutionLight-sensitive devicesFinal product manufactureVulcanizationReaction temperature

The invention provides a CVD preparation method of Co-doped MoS2 array in-situ electrodes. The preparation method specifically comprises the steps that cobalt salt and molybdenum chloride are dissolved in a volatilized non-aqueous solvent to obtain a Co-Mo precursor solution, a substrate is coated with the precursor solution, and CVD vulcanization is carried out in the atmosphere of Ar and S or inthe atmosphere of N2 and S, specifically, the vulcanization reaction temperature is 600-800 DEG C, and the vulcanization reaction time is from 10 min to 2 h. According to the technical scheme, the CVD preparation method can be applied to electrolytic hydrogen making and dye sensitization solar cells and has a great significance on batch production of the in-situ electrodes.

Owner:CHINA THREE GORGES UNIV

Method for separating molybdenum and tungsten from molybdenum-tungsten concentrate

ActiveCN102864300AReduce consumptionSimple methodProcess efficiency improvementNitrogenMolybdenum chloride

A method for separating molybdenum and tungsten from molybdenum-tungsten concentrate is characterized by including well mixing molybdenum-tungsten concentrate with reducing agent; introducing nitrogen for chloridizing roasting; allowing molybdenum and tungsten to volatilize in chloride form; collecting molybdenum and tungsten chlorides and adding the chlorides into water or dilute hydrochloric acid solution to form tungsten chloride precipitate and molybdenum chloride solution; filtering and cleaning to separate the molybdenum and tungsten. The molybdenum-tungsten concentrate is decomposed by one-step chlorination process, and molybdenum and tungsten are separated by taking the advantage of property difference between the molybdenum chloride and the tungsten chloride. The method can be used to process concentrates different in molybdenum and tungsten content, and has the advantages of simplicity, low reagent consumption and the like.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

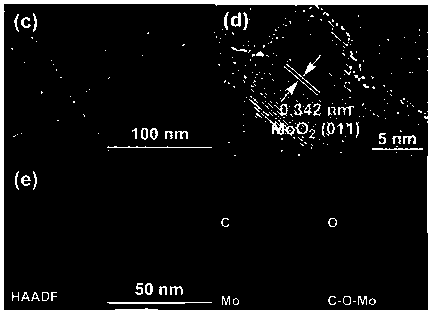

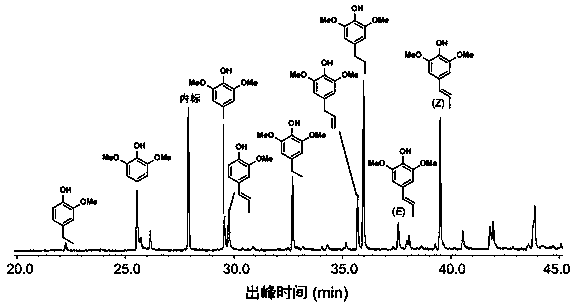

Preparation method for supported molybdenum oxide catalyst and application thereof

ActiveCN107597097AFacilitated DiffusionIncrease exposureMolecular sieve catalystsOrganic compound preparationDepolymerizationEvaporation

The invention discloses a preparation method for a supported molybdenum oxide catalyst and an application thereof. The preparation method comprises the following steps: firstly preparing a molybdenumdichloride hydrate precursor, dissolving the obtained molybdenum dichloride hydrate precursor into methanol or ethanol, slowly adding the obtained liquid into a carrier dropwise after the precursor iscompletely dissolved, allowing the obtained mixture to stand, performing evaporation, and performing roasting under an inert gas atmosphere to obtain the supported molybdenum oxide catalyst. The application of the supported molybdenum oxide catalyst including that the supported molybdenum oxide catalyst is used for hydrogenation depolymerization of lignin, is used for preparing aniline from nitrobenzene and is used as a composite electrode material. The catalyst provided by the invention has the advantages of having small particles and a large specific surface area, being beneficial for reactant diffusion and active site exposure and the like, and meanwhile the catalyst has similar noble-metal catalytic performance, and can be widely applied to the fields such as biomass catalytic conversion and electrode materials.

Owner:BEIJING FORESTRY UNIVERSITY

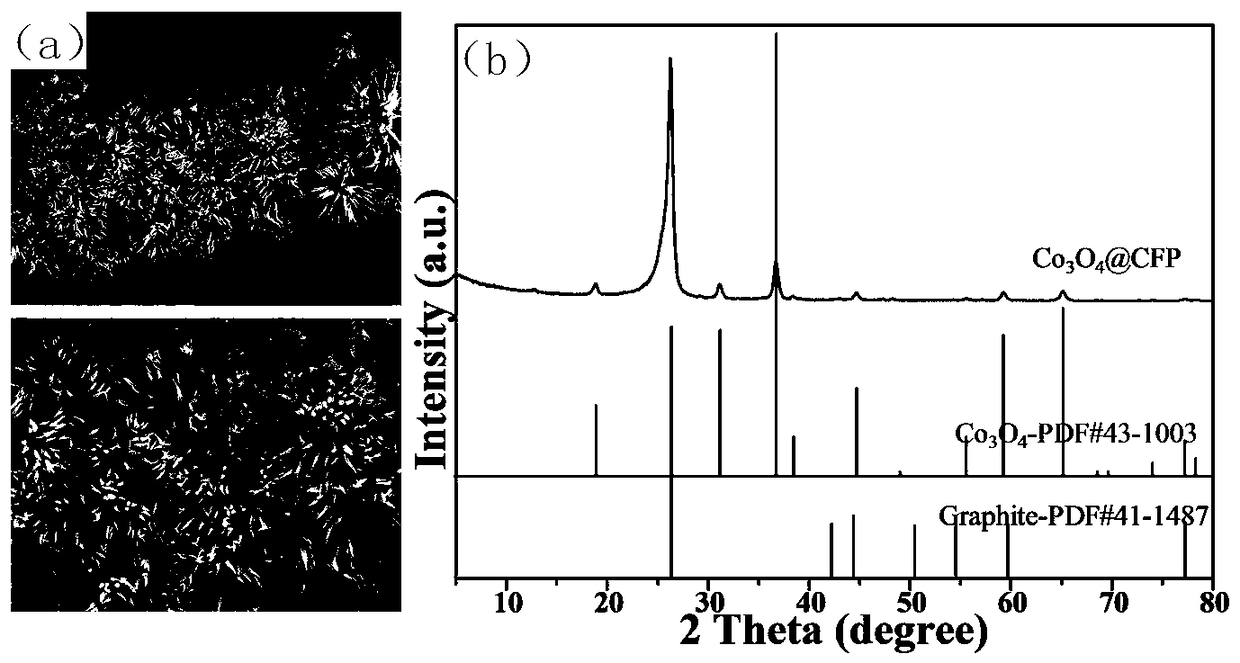

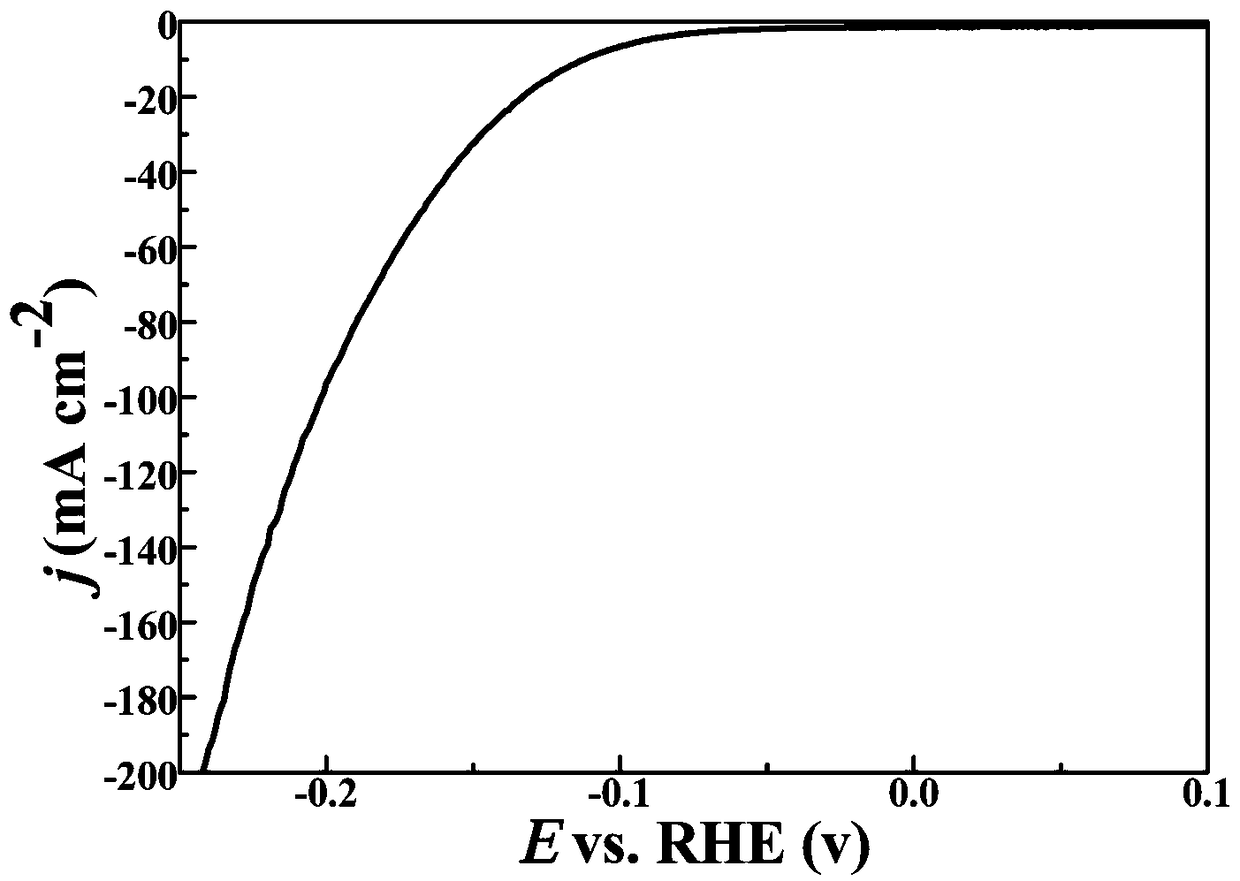

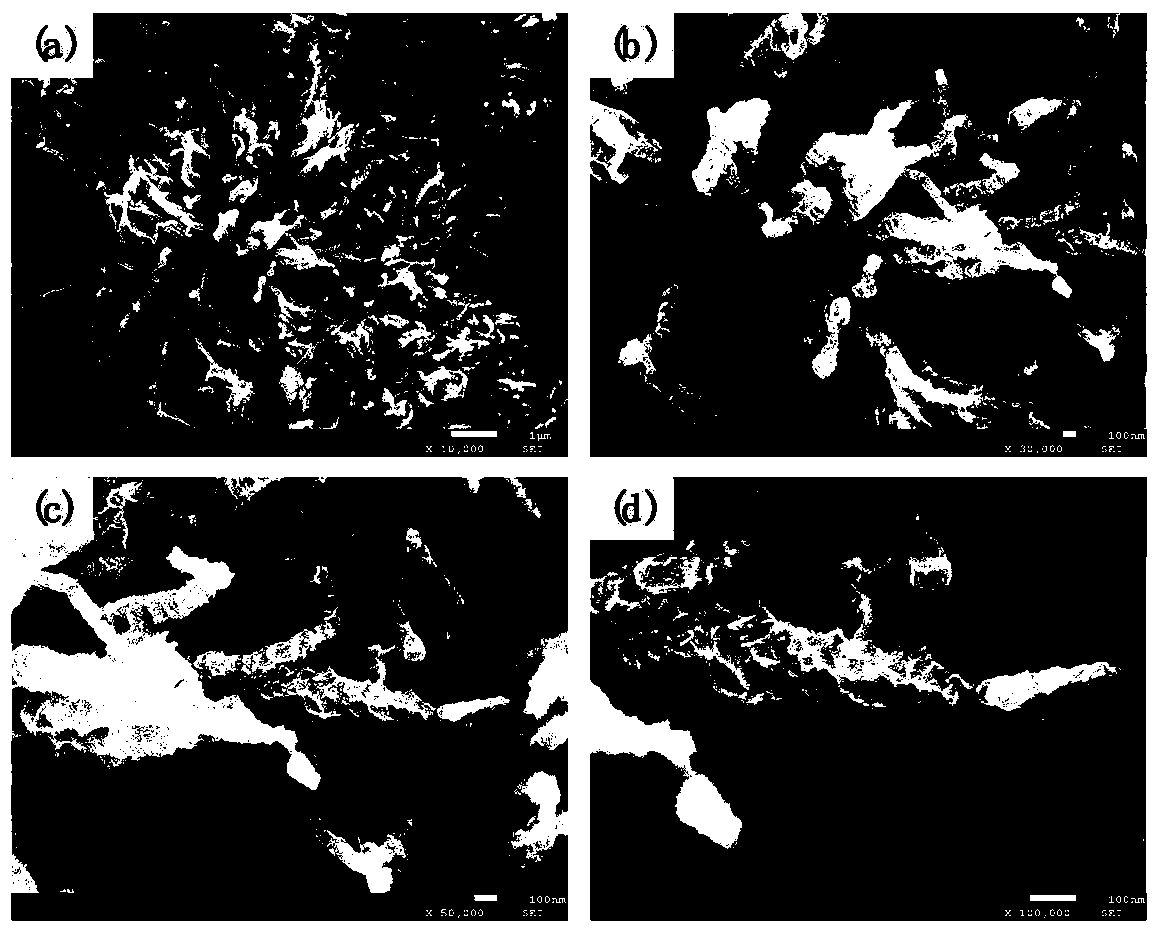

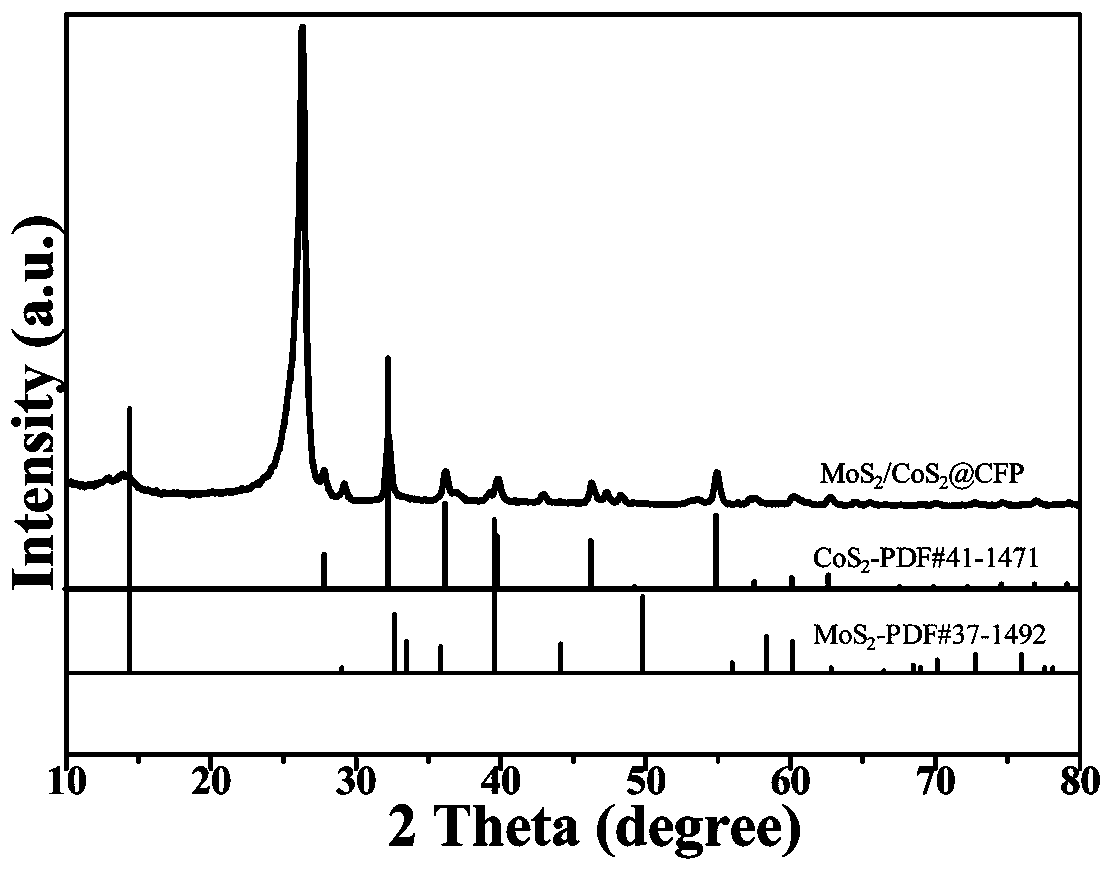

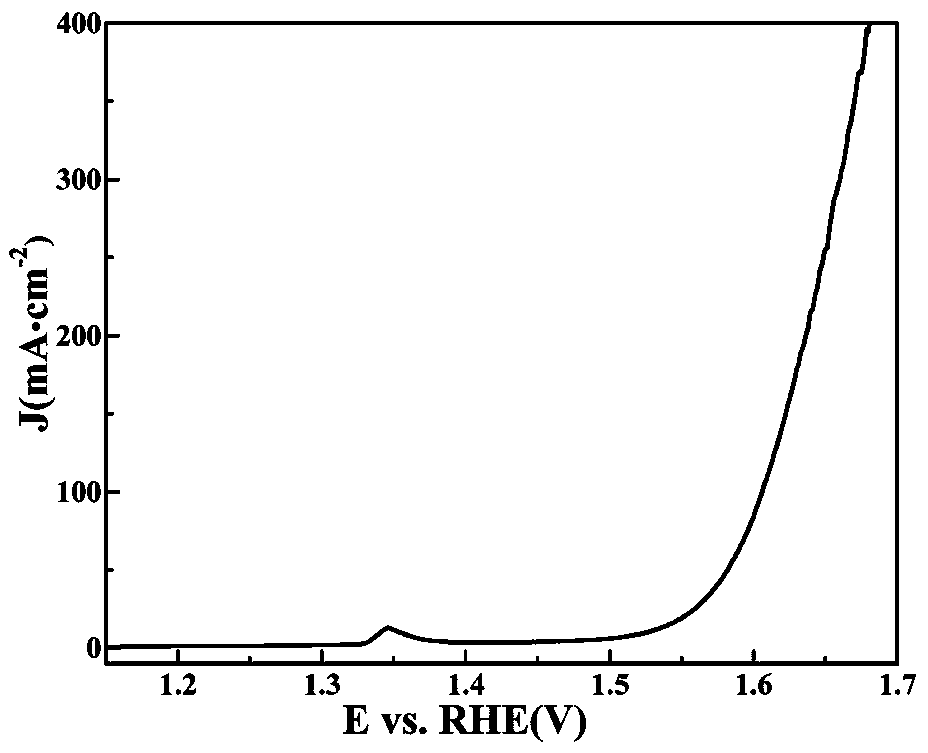

Preparation method for cobalt sulfide and molybdenum disulfide in-situ composite electrode and application of cobalt sulfide and molybdenum disulfide in-situ composite electrode in hydrogen production by water electrolysis

The invention provides a preparation method for a cobalt sulfide and molybdenum disulfide in-situ composite electrode. The preparation method particularly comprises the following steps that molybdenumchloride is dissolved in ethanol under the condition of stirring at room temperature, and a precursor solution is obtained; and a substrate on which a cobaltosic oxide array grows is coated with theprecursor solution, the substrate coated with the precursor solution is subjected to high-temperature one-step vulcanization in an Ar+S atmosphere or N2+S atmosphere after being dried and is cooled with a furnace and taken out, and the molybdenum disulfide / molybdenum disulfide composite in-situ electrode is obtained. According to the technical scheme of the preparation method, cobaltosic oxide reacts with sulfur at the high temperature to generate nano-sized cobalt sulfide, and molybdenum disulfide generated by the molybdenum chloride and sulfurization gas phase reaction is deposited around the nano-sized cobalt sulfide to form a heterogeneous interface which has a synergistic and high catalytic effect, is in close contact between cobalt sulfide and molybdenum disulfide and has a large contact area between cobalt sulfide and molybdenum disulfide while a nano-sized pore passageway is left.

Owner:CHINA THREE GORGES UNIV

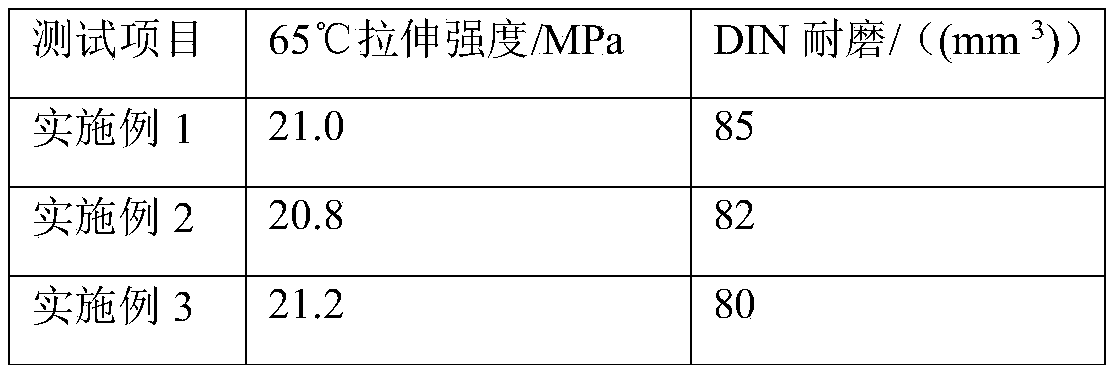

Special composite wear-resistant rubber for inorganic enhanced driving belt and preparation method

ActiveCN110054818AImprove wear resistanceSignificant improvement in tensile strengthWear resistantPolybutadiene

The invention relates to the technical field of functional rubber and preparation thereof, in particular to special composite wear-resistant rubber for an inorganic enhanced driving belt and a preparation method. The special composite wear-resistant rubber comprises butadiene styrene rubber, butadiene rubber, ethylene propylene diene monomer, wear-resistant fillers, sulfur, coupling agents, filling reinforcing agents, anti-aging agents, softening agents and vulcanizing agents, wherein the wear-resistant fillers are layered silicate wear-resistant fillers of molybdenum disulfide coated graphene. The method includes the steps: spraying precursor liquid prepared from molybdenum chloride and nickel chloride to the surface of graphene loaded layered silicate, drying the layered silicate, sintering the layered silicate in a calcining furnace with sulfur-containing nitrogen atmosphere and cooling the layered silicate to obtain the wear-resistant fillers; performing mixing, heat treatment andmilling on rubber raw materials to obtain the special composite wear-resistant rubber. The special composite wear-resistant rubber for the inorganic enhanced driving belt has the advantages of good wear resistance and obvious tensile strength improvement effects, the added graphene does not easily fall off and is high in stability, and the service time of the special composite wear-resistant rubber for the inorganic enhanced driving belt is prolonged.

Owner:TAIZHOU BAIHUA RUBBER BELT

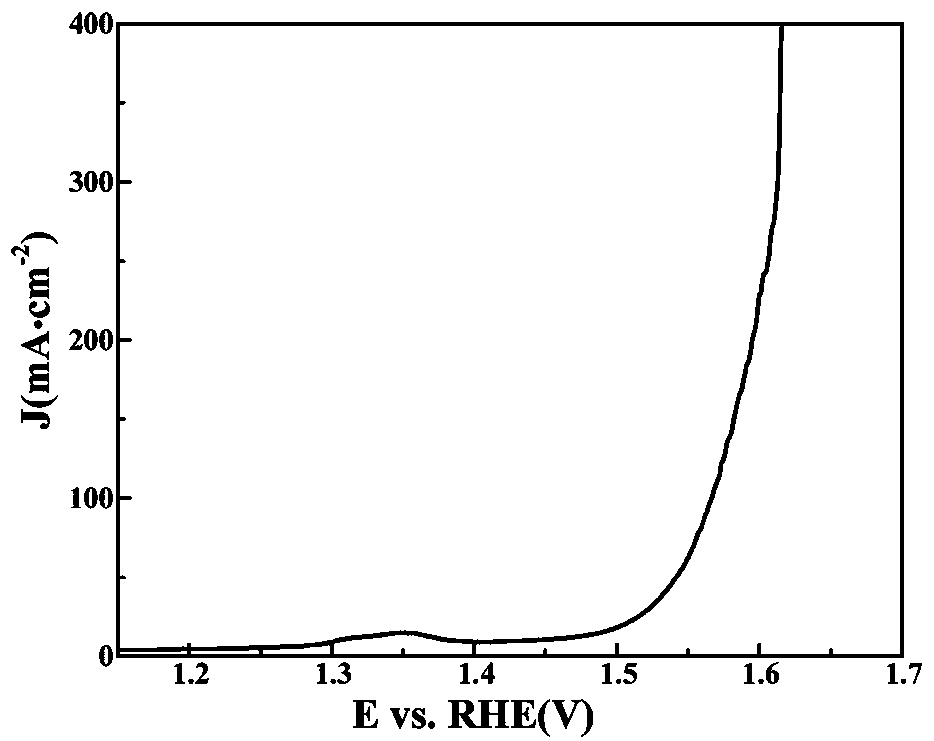

Preparation method of molybdenum disulfide nanosheet @ cobalt sulfide nanoneedle in-situ array electrode

ActiveCN108396330ALower surface energyMaterial nanotechnologyCobalt sulfidesCobalt(II,III) oxideSolvent

The invention provides a preparation method of a molybdenum disulfide nanosheet @ cobalt sulfide nanoneedle in-situ array electrode. The preparation method comprises the steps of conducting sulfuration on a substrate where an cobaltosic oxide array grows in Ar+S atmosphere or N2+S atmosphere the first time, so that an cobalt sulfide nanoneedle array electrode is obtained; dissolving molybdenum chloride into volatile nonaqueous solvent, coating the surface of the cobalt sulfide nanoneedle array electrode with an obtained solution, and drying the cobalt sulfide nanoneedle array electrode for use; and then, putting a sample in the Ar+S atmosphere or the N2+S atmosphere, conducting sulfuration the second time, conducting furnace cooling, and taking the sample out, so that the molybdenum disulfide nanosheet @ cobalt sulfide nanoneedle in-situ array electrode is obtained.

Owner:CHINA THREE GORGES UNIV

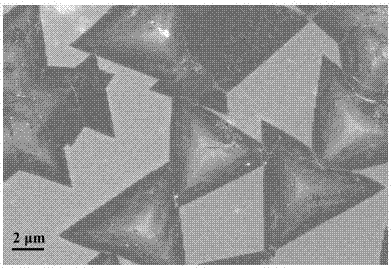

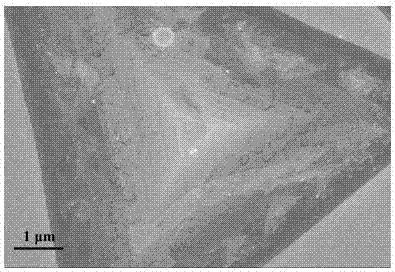

Pyramidal molybdenum disulfide nanosheet and preparation method and application thereof

InactiveCN107961799AUniform sizeHigh density boundaryPhysical/chemical process catalystsHydrofluoric acidHigh density

The invention relates to a pyramidal molybdenum disulfide nanosheet and a preparation method and an application thereof. The method comprises the following steps: S1) taking a slide glass as a substrate and placing the slide glass in hydrofluoric acid for immersion for 3-5 min, then performing cleaning and removing silicate on a surface to generate a product, drying the product for standby; S2) using a chemical vapor deposition method, taking sublimed sulfur and molybdenum trioxide, molybdenum chloride or ammonium tetrathiomolybdate as a sulfur source and a molybdenum source, and growing molybdenum disulfide on a substrate of a three-temperature zone tubular furnace. The pyramidal molybdenum disulfide nanosheet has an uniform size, has higher density boundary, and has good conductive performance and catalysis performance.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

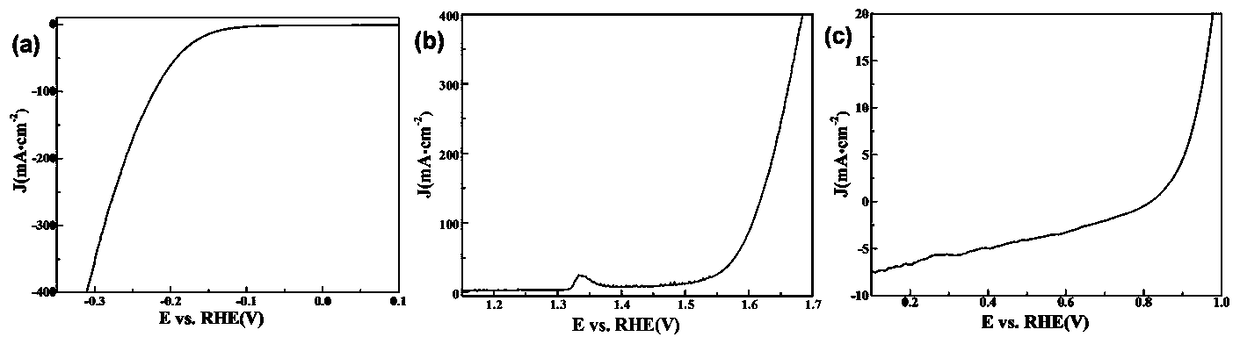

Method for preparing multifunctional nickel-doped molybdenum disulfide in situ electrode by CVD (Chemical Vapor Deposition) method

The invention provides a method for preparing a multifunctional nickel-doped molybdenum disulfide in situ electrode by CVD (Chemical Vapor Deposition) method. The method comprises the following steps:dissolving nickel salt and molybdenum chloride in a volatile non-aqueous solvent to obtain Ni-Mo precursor liquid; coating a substrate with the precursor liquid; and drying the substrate, and then, putting the dried substrate in an Ar+S atmosphere or in an N2+S atmosphere so as to be subjected to CVD vulcanization. The product obtained by the method provided by the invention has the advantages oflow equipment requirements, low required raw material cost, easy control on reaction conditions, simple production processes, good formed product uniformity, little environmental pollution and the like, and can be used for multifunctional electro-catalysts for HER (Hydrogen Evolution Reaction), OER (Oxygen Evolution Reaction) and ORR (Oxygen Reduction Reaction).

Owner:CHINA THREE GORGES UNIV

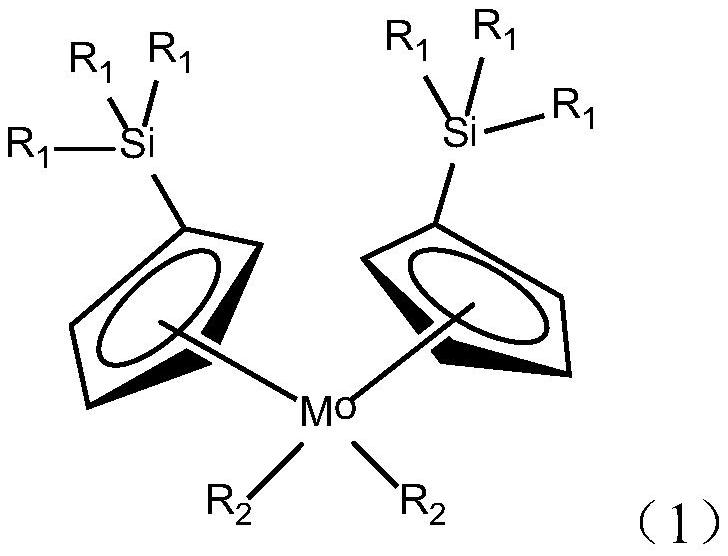

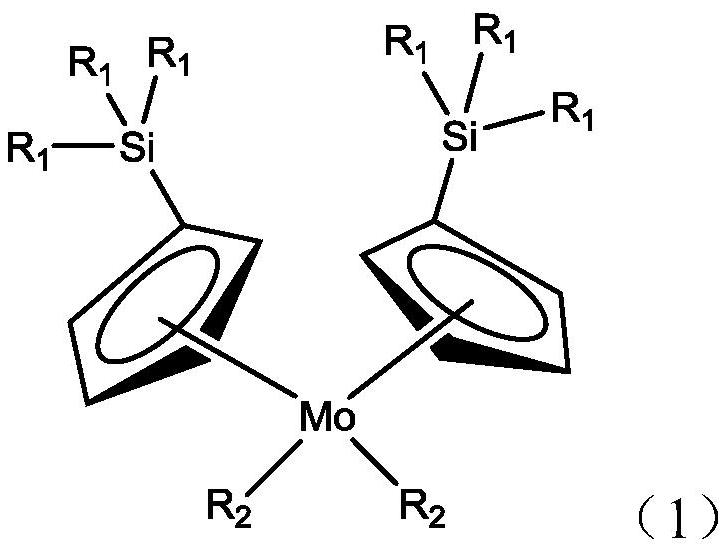

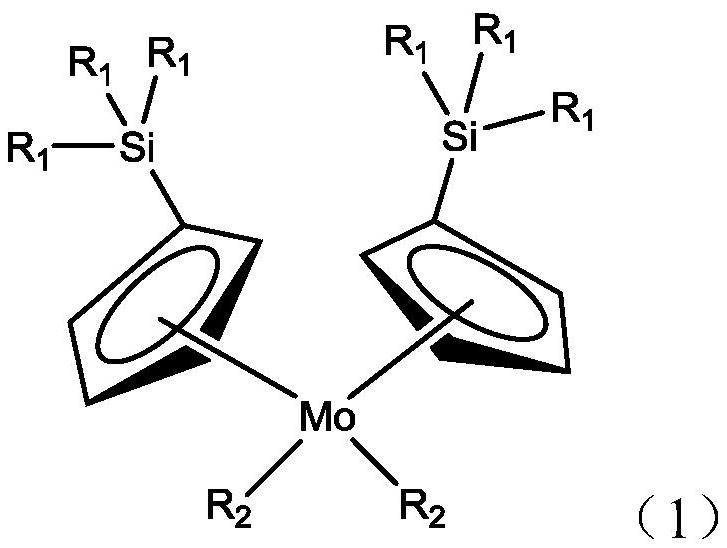

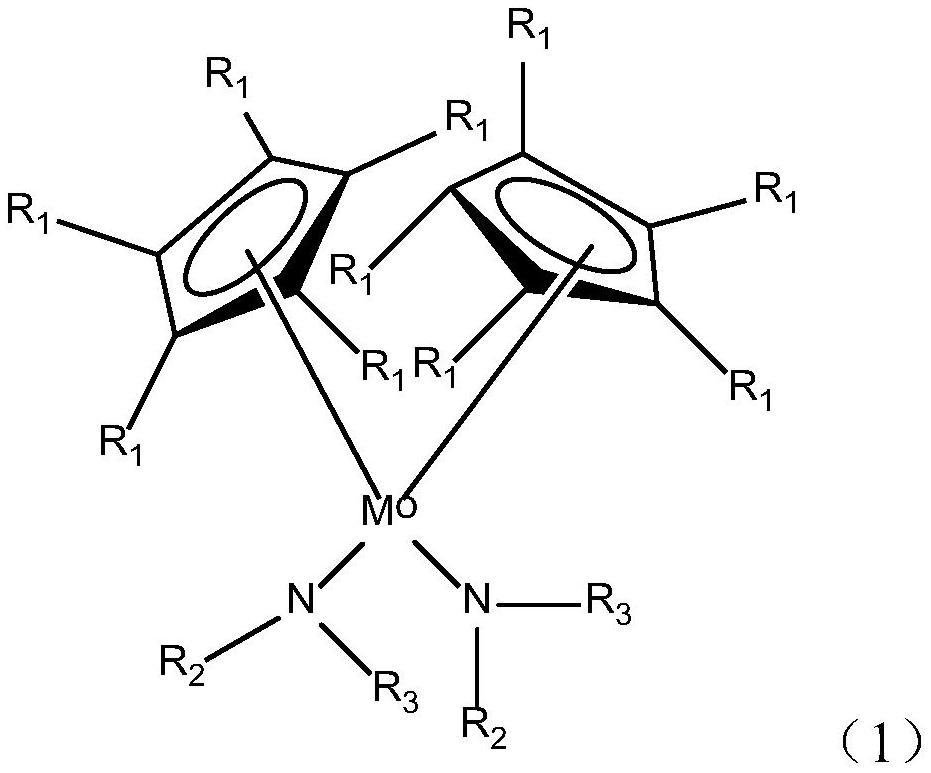

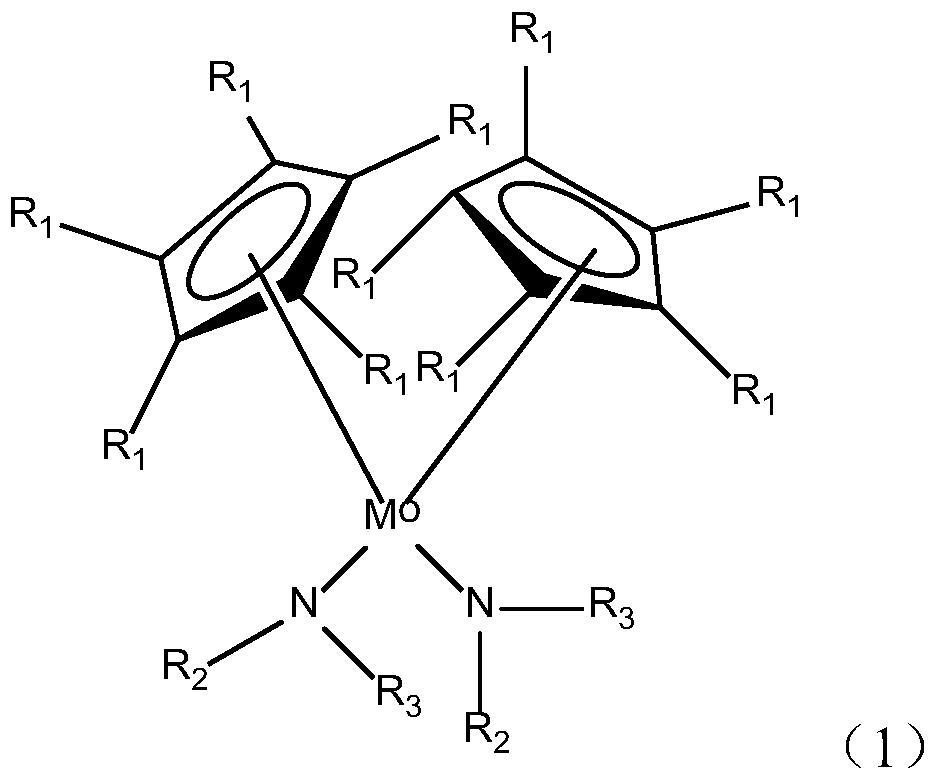

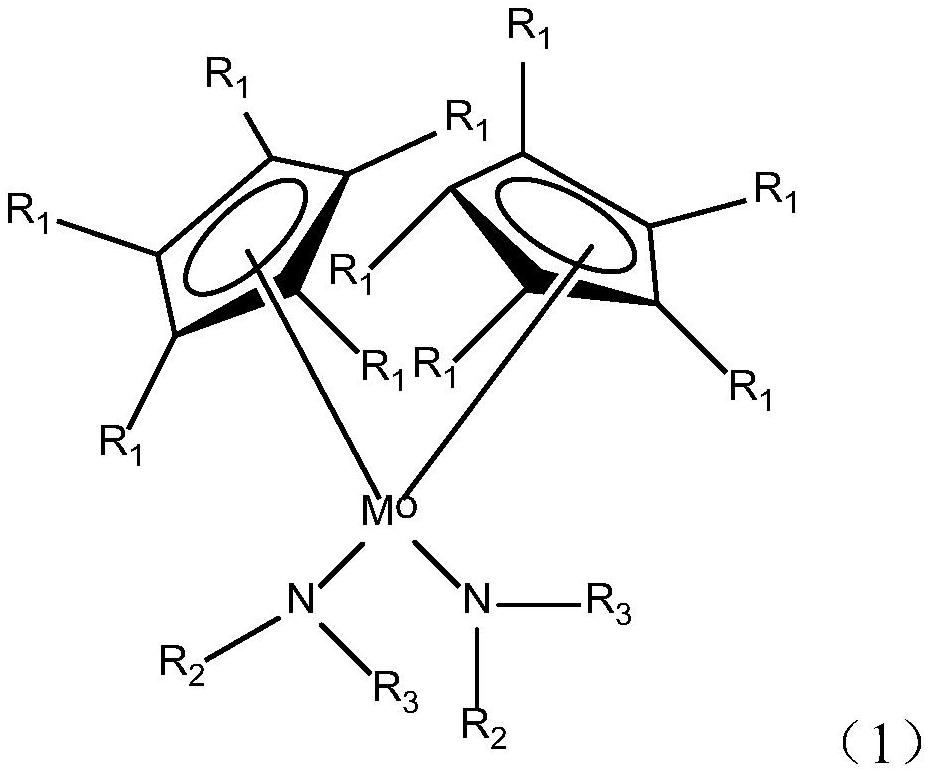

Dialkyl dicyclopentadienyl molybdenum complex as well as preparation method and application thereof

PendingCN111777649AStable in natureStable storageChemical vapor deposition coatingMetallocenesAlkanePhysical chemistry

The invention relates to a dialkyl dicyclopentadienyl molybdenum complex as well as a preparation method and application thereof. The preparation method comprises the following steps: dissolving molybdenum penta-chloride in a first solvent, cooling for the first time to prepare a first solution; dissolving trialkyl silicon cyclopentadiene lithium and sodium borohydride in a second solvent, coolingfor the second time to prepare a second solution; mixing the first solution and the second solution, stirring for 2-4 hours, heating to 55-75 DEG C, reacting for 20-18 hours, adding alkane into the reaction product, extracting, collecting the water phase, filtering, adding chloroform into the filtrate, stirring for 8-12 hours to prepare bis(trialkylsilylcyclopentadienyl) molybdenum dichloride; and reacting bis(trialkylsilylcyclopentadienyl) molybdenum dichloride with alkyl lithium. According to the preparation method, a dicyclopentadienyl molybdenum dichloride complex is synthesized in one step and then reacts with alkyl lithium to prepare the dialkyl dicyclopentadienyl molybdenum complex, so that the reaction steps are shortened, the production cost is reduced, the high yield is maintained, and the industrial production is facilitated.

Owner:苏州欣溪源新材料科技有限公司

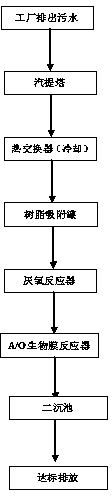

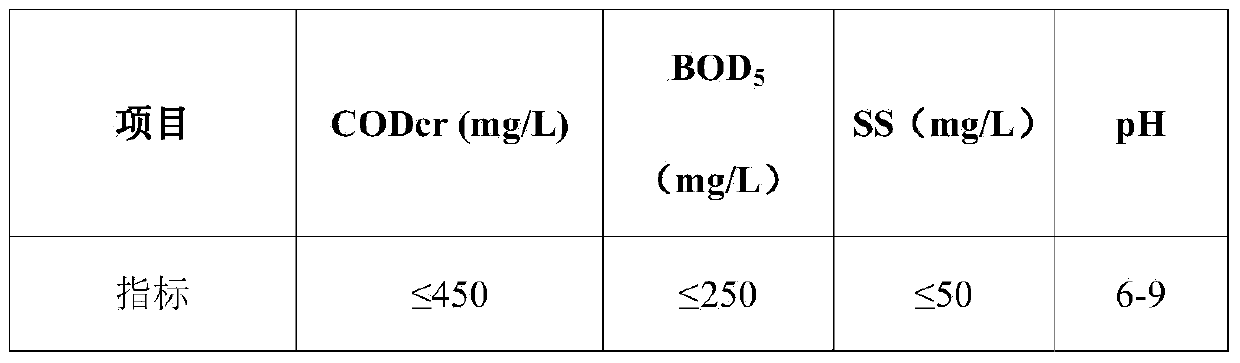

Sewage treatment method

InactiveCN103739170AEasy to handleIncrease concentrationMultistage water/sewage treatmentNature of treatment waterPhosphateWater quality

The invention provides a process for treating neopentyl glycol production sewage by hydrocondensation. The process is characterized in that neopentyl glycol production sewage is sequentially subjected to steam stripping, cooling, ion exchange, anaerobic biological treatment, and treatment through an A / O biological membrane. The process specifically comprises the following steps: feeding production sewage into a steam stripping column; heating to reach 95 DEG C; recovering materials from the sewage; cooling to reach 30 to 40 DEG C; transferring into an ion exchanger; adsorbing organic matters from sewage; then adding phosphate, cobalt chloride and molybdenum chloride to the sewage; performing anaerobic biological treatment; treating sewage through an EGSB (Expanded Granular Sludge Bed); transferring the water from the EGSB reactor into an anaerobic sludge recovery tank; feeding into an A / O bio-membrane reactor; denitriding and degrading the organic matters in the sewage; transferring the outlet water into a secondary precipitating tank to precipitate sludge until the water quality meets nationally specified drainage standard; and then draining up to standard.

Owner:NANJING CLEAR STREAM ENVIRONMENTAL PROTECTION TECH CO LTD

Diamino molybdenum dicyclopentadienyl complex as well as preparation method and application thereof

PendingCN111747994AStable in natureStable storageChemical vapor deposition coatingMetallocenesAlkaneMolybdenum pentachloride

The invention relates to a diamino molybdenum dicyclopentadienyl complex as well as a preparation method and application thereof. The preparation method comprises the following steps of: dissolving molybdenum pentachloride in a first solvent, and performing cooling to prepare a first solution; dissolving substituted cyclopentadiene lithium and sodium borohydride in a second solvent, and performingcooling to prepare a second solution; mixing the first solution and the second solution, performing stirring for 2-4 hours, performing heating for 55-75 hours, performing a reaction for 20-18 hours,adding alkane into a reaction product, performing extraction, collecting a water phase, performing filtering, adding chloroform into a filtrate, and stirring for 8-12 hours to prepare bis (substitutedcyclopentadiene lithium) molybdenum dichloride; and making the bis (substituted cyclopentadiene lithium) molybdenum dichloride with dialkylamine lithium. According to the preparation method, the dichloro-molybdenum dicyclopentadienyl complex is synthesized in one step and then reacts with the lithium dialkylamine, so that the diamino-molybdenum dicyclopentadienyl complex can be prepared, so thatreaction steps are shortened, production cost is reduced, the higher yield is maintained, and the industrial production is better facilitated.

Owner:苏州欣溪源新材料科技有限公司

Bio-based organic fertilizer utilizing livestock and poultry died of illness and preparation method thereof

InactiveCN111269064AGood moisturizing effectHigh nitrogen contentAmmonium salt fertilisersFertilizer mixturesCelluloseHydrolysate

The invention relates to a bio-based organic fertilizer utilizing livestock and poultry died of illness. The fertilizer comprises the following raw material components: amino acid hydrolysate, modified lignin and a biological fertilizer, wherein the amino acid hydrolysate is prepared by reacting livestock and poultry died of illness, water and solid superacid; the solid superacid is prepared by reacting zirconium n-propoxide, tetrabutyl titanate, aluminum isopropoxide, nano cellulose, isopropanol, nano ferroferric oxide and dilute sulfuric acid; the modified lignin is prepared by reacting sodium lignin sulfonate, ferric chloride, manganese chloride, copper chloride, zinc chloride, molybdenum chloride, boron chloride, urea and an ammonium sulfate aqueous solution; and the biological fertilizer is prepared by reacting earthworm secreta, snail secreta, soybean straw, crab shells, lobster shells and yeast fermentation residues. The bio-based organic fertilizer has excellent effects of increasing crop yield and improving soil hardening.

Owner:JIANGSU BIG DIPPER ENVIRONMENTAL PROTECTION CO LTD

Synthesis method of mesalazine drug intermediate 5-aminosalicylic acid

ActiveCN106008249AShort reaction timeHigh reaction yieldOrganic compound preparationAmino-carboxyl compound preparationSulfite saltSynthesis methods

The invention discloses a synthesis method of a mesalazine drug intermediate 5-aminosalicylic acid. The method includes: in a mixed solution of sodium sulfite and 2-hydroxy-5-methyl-3-nitropyridine, subjecting azobenzene salicylic acid and molybdenum chloride to heating reflux reaction, then adding a xylene solution, conducting cooling, solid precipitation and recrystallization, using an oxalic acid solution to perform dissolving, and carrying out molecular sieve decoloration, filtration, cooling filtration and dehydration, thus obtaining 5-aminosalicylic acid. Compared with the synthesis method of the background technology, the method provided by the invention has obviously shortened reaction time and greatly improved reaction yield. Also, the invention provides a new synthetic route, and lays a good foundation for further improving reaction yield.

Owner:海宁经开产业园区开发建设有限公司

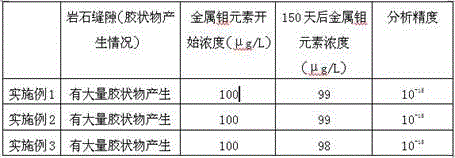

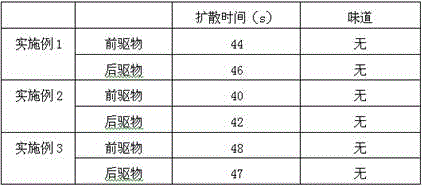

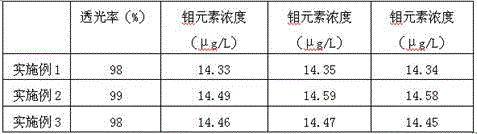

Microelement tracer agent used for offshore oilfield and use method thereof

ActiveCN106368679ANo radioactivityNo pollution in the processConstructionsMolybdenum chloridePollution

The invention provides a microelement tracer agent special for an offshore oilfield. The tracer agent is made from raw materials of a precursor and a post-cursor. The precursor and the post-cursor each contain microelement chloride. A microelement mixture is a praseodymium-molybdenum chloride mixture. The invention further provides a use method of the microelement tracer agent. The use method comprises the step that a prepared precursor solution and a prepared post-cursor solution are sequentially injected into a monitoring well, wherein the volume ratio of the precursor solution to the post-cursor solution is 1:(0.8-1), and the time interval for injection of the precursor solution and injection of the post-cursor solution is 80-120 min. The prepared microelement tracer agent is free of radiation and pollution and good in safety and stability; an HR-ICP-MS instrument is used for detecting, the minimum detection limit can be up to 10-15 (ppq grade) grade; and the microelement tracer agent can be fast disintegrated in water, and evenly diffused and dissolved with the diffusion time no longer than 48 seconds.

Owner:潍坊华诺生物科技有限公司

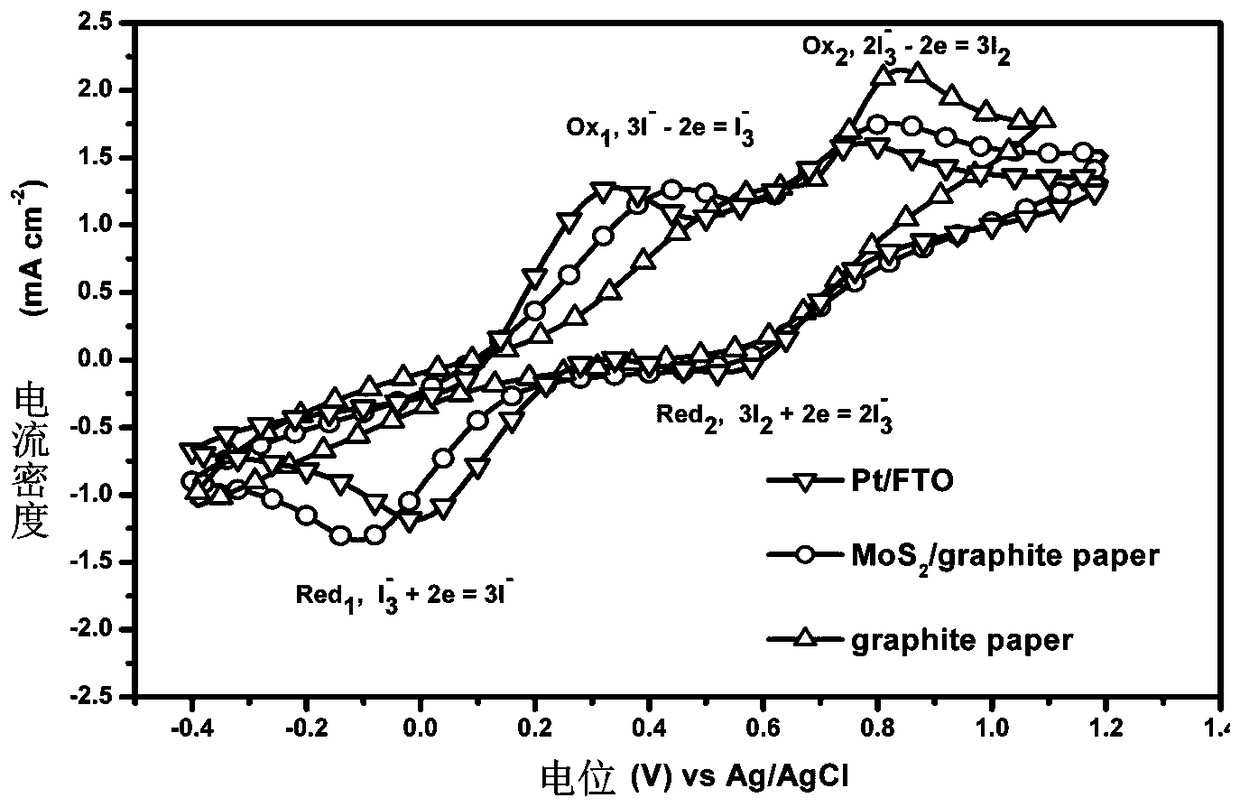

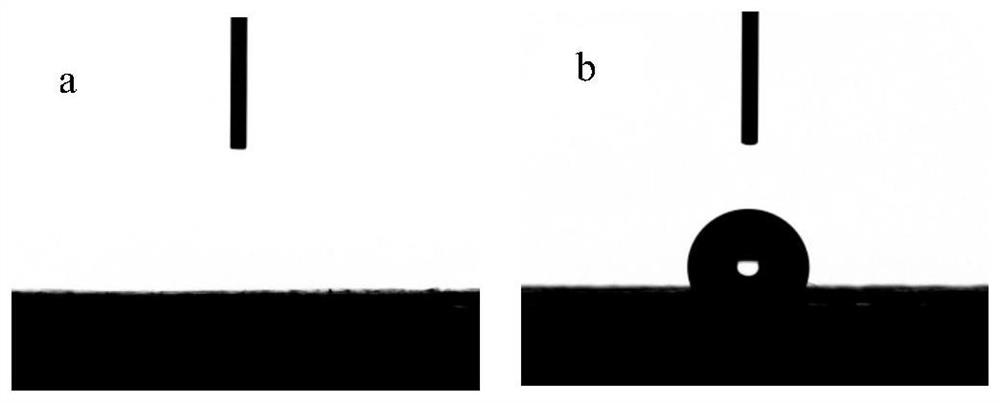

Solution method for in-situ preparation of molybdenum disulfide/graphite paper electrode

The invention discloses a solution method for in-situ preparation of a molybdenum disulfide / graphite paper electrode in particular, an ethanol solution containing molybdenum chloride and thiourea is dropwisely added to the surface of a hydrophilic treated graphite paper, sintered under an inert atmosphere at a high temperature after drying, and taken out after cooling to obtain the molybdenum disulfide / graphite paper electrode. The reagent used in the invention is low in cost and simple in preparation. The prepared molybdenum disulfide / graphite paper electrode is closely bonded with graphite paper without falling off. SEM results show that molybdenum disulfide is uniformly coated on the surface of graphite paper. Relevant electrochemical tests show that the molybdenum disulfide / graphite paper electrode has extremely high conductivity and good electrocatalytic activity.

Owner:CHINA THREE GORGES UNIV

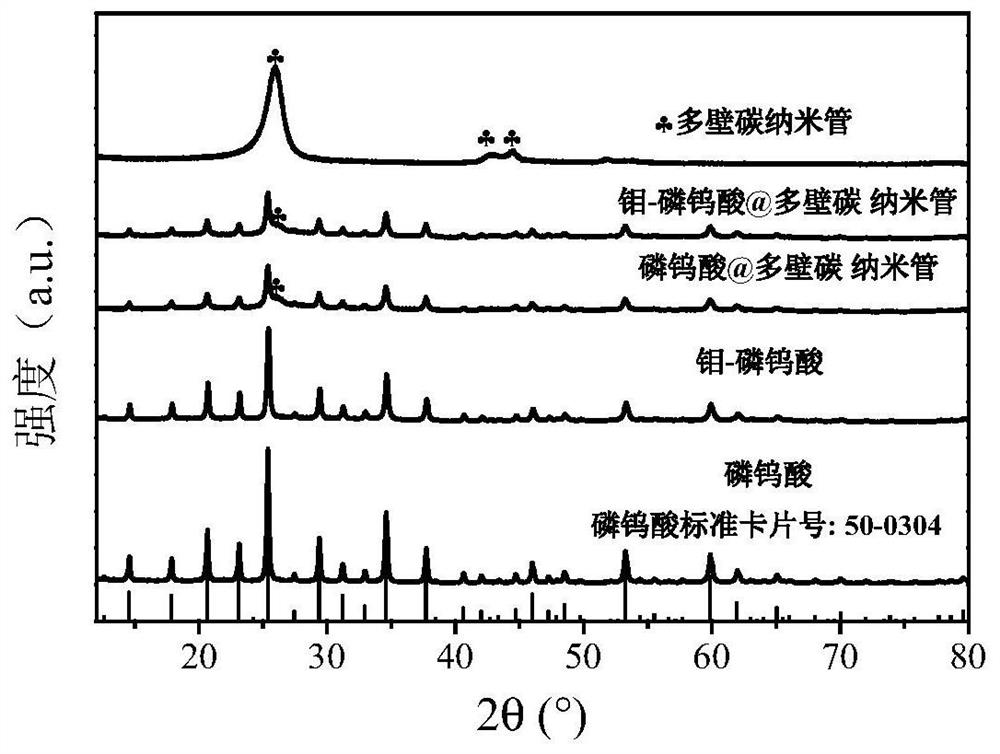

Super-hydrophobic molybdenum-loaded catalyst as well as preparation method and application thereof

ActiveCN113058658AImprove mass transfer efficiencySimple preparation conditionsCatalyst carriersOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystPhysical chemistry

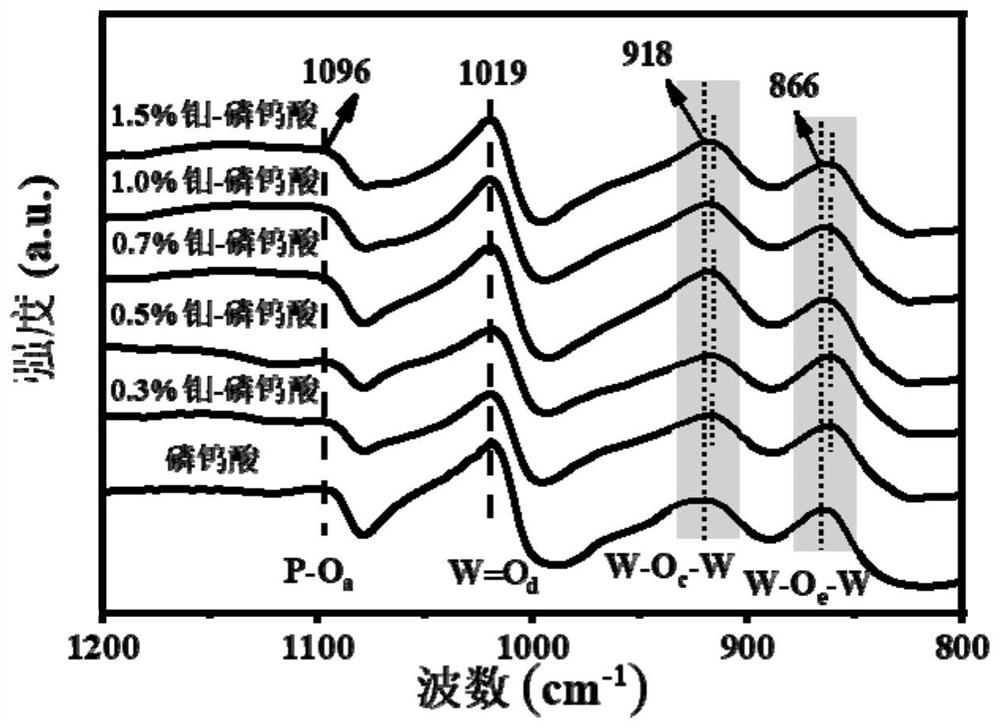

The invention discloses a preparation method and application of a super-hydrophobic molybdenum-loaded catalyst, and belongs to the technical field of material preparation, electro-catalysis and fine chemical engineering. The high-performance super-hydrophobic molybdenum-loaded phosphotungstic acid electrocatalyst for electrocatalytic nitrogen fixation is developed by using commercial phosphotungstic acid PTA and molybdenum pentachloride as raw materials, feeding in batches, heating and stirring under mild conditions, using phosphotungstic acid with rich oxygen coordination sites as a carrier and using molybdenum chloride pentahydrate as a precursor of a modification species. The prepared electrocatalyst has good stability and electrocatalytic performance, and can effectively solve the problems that in current normal-temperature normal-pressure electrocatalytic synthesis of ammonia, nitrogen is difficult to adsorb and activate, and hydrogen evolution competitive reaction is dominant. And the catalyst has the advantages of simple preparation process, low cost, green and environment-friendly production process and great application potential.

Owner:FUZHOU UNIV

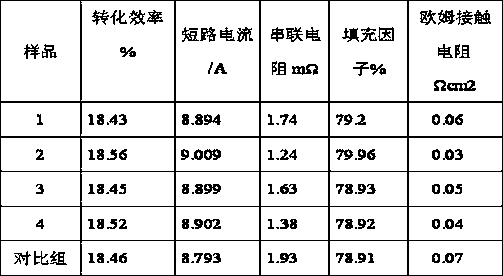

Silver electrode paste

InactiveCN108665994AImprove conversion efficiencySpeed up the flowOxide conductorsNon-conductive material with dispersed conductive materialFine lineCobalt

The invention discloses silver electrode paste. The conductive paste consists of the following components, by weight: 75-92 parts of silver powder, 5-12 parts of an organic solvent, 2-3 parts of an organic carrier, 0.5-1 part of alkyl phenol polyoxyethylene ether, and 0.8-5.3 parts of metal microcrystalline glass powder. The particle size D50 of the metal microcrystalline glass powder is 0.3-2 mum. The metal microcrystalline glass powder consists of the following components: 10-50 parts of tellurium dioxide, 15-70 parts of lead oxide, 2-10 parts of zinc oxide, 1-15 parts of molybdenum oxide,5-20 parts of lithium oxide, 0.4-2 parts of tungsten dioxide, 1-6 parts of molybdenum dioxide, 1-4 parts of cobalt monoxide, 1-2 parts of molybdenum chloride, and 0.4-1 part of indium chloride. The conductive paste effectively improves the conversion efficiency of cells, and has the characteristics of high temperature viscosity and large surface tension. Molten glass cannot not flow easily duringa paste sintering process, thereby maintaining a fine line shape.

Owner:SUZHOU ISILVER MATERIALS

Papermaking wastewater flocculating agent and preparation method of papermaking wastewater flocculating agent

InactiveCN105540802AImprove the coagulation effectSettling fastWaste water treatment from plant processingWater/sewage treatment by flocculation/precipitationWater vaporTurbidity

The invention discloses a papermaking wastewater flocculating agent and a preparation method of the papermaking wastewater flocculating agent. The papermaking wastewater flocculating agent is prepared from the following raw materials in parts by weight: 12 to 16 parts of polysilicate, 1 to 4 parts of sodium polyacrylate, 10 to 16 parts of aluminum sulfate, 10 to 15 parts of ferric citrate, 8 to 13 parts of calcium hydroxide, 1 to 4 parts of aluminum oxide, 3 to 10 parts of aluminum trichloride, 18 to 25 parts of zeolite, 12 to 18 parts of sodium carboxymethylcellulose, 3 to 8 parts of polymerized molybdenum chloride, 20 to 28 parts of ferric magnesium polysilicate and 40 to 50 parts of water. The preparation method comprises the following steps: putting the polysilicate, the sodium polyacrylate, the aluminum sulfate, the ferric citrate, and the ferric magnesium polysilicate into high-pressure water steam and treating to prepare a mixture A; mixing the calcium hydroxide, the sodium carboxymethylcellulose, the aluminum oxide, the zeolite, polymerized molybdenum chloride and the aluminum trichloride with the water and carrying out ultrasonic treatment to prepare a mixture B; putting the mixture A into the mixture B and treating to obtain the product. The papermaking wastewater flocculating agent provided by the invention has a good coagulation performance and a rapid sedimentation speed; the papermaking wastewater flocculating agent has remarkable effects of removing turbidity, de-coloring, removing oil, dehydrating, removing bacteria, deodorizing, removing algae, removing COD (Chemical Oxygen Demand), BOD (Biochemical Oxygen Demand) and heavy metal ions in the water and the like.

Owner:范洲卫

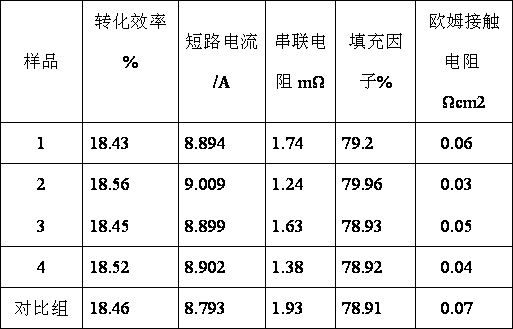

Conductive slurry used for solar energy battery

InactiveCN108666008AImprove conversion efficiencySpeed up the flowNon-conductive material with dispersed conductive materialPhotovoltaic energy generationFine lineSlurry

The invention discloses a conductive slurry used for a solar energy battery. The conductive slurry is prepared from the following components, by weight: 75-92 parts of silver powder, 5-12 parts of anorganic solvent, 2-3 parts of an organic carrier, 0.5-1 part of alkyl phenol polyoxyethylene ether, and 0.8-5.3 parts of metal microcrystalline glass powder. The particle size D50 of the metal microcrystalline glass powder is 0.3-2 [mu]m. The metal microcrystalline glass powder is prepared from the following components: 10-50 parts of tellurium dioxide, 15-70 parts of bismuth oxide, 2-10 parts ofzinc oxide, 1-15 parts of tungsten oxide, 5-20 parts of lithium oxide, 0.4-2 parts of boric acid, 1-6 parts of molybdenum chloride, 1-4 parts of silicon oxide, and 1-2 parts of barium carbonate. The battery conversion efficiency is effectively improved, the conductive slurry has characteristics of large viscosity and large surface tension at high temperature, the molten glass does not flow easilyduring a slurry sintering process, and the fine line is maintained.

Owner:SUZHOU ISILVER MATERIALS

Ammonium thiosulfate desulfurization catalyst from coking wastewater and preparation and implementation methods therefor

ActiveCN104998685AOrganic-compounds/hydrides/coordination-complexes catalystsAmmonia compoundsPtru catalystCobalt phthalocyanine

The present invention discloses an ammonium persulfate catalyst extracted from coking wastewater and an implementation method therefor. The catalyst comprises the following components in percentage by mass: 85-95% of binuclear cobalt phthalocyanine ammonium sulphonate, 1-5% of molybdenum pentachloride, and 4-15% of disodium EDTA. The bath temperature of the coking wastewater is 65 DEG C. The amount of the catalyst to be added is 1%. The reaction can be performed by blowing air with 12-hour reaction time and a pH range of 7-8.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

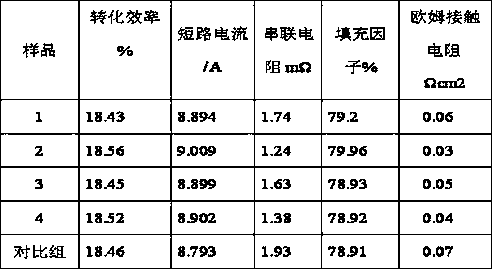

Photovoltaic electrode silver paste

InactiveCN108666007AImprove conversion efficiencyImprove solubilityNon-conductive material with dispersed conductive materialPhotovoltaic energy generationFine lineMolybdenum chloride

The invention discloses photovoltaic electrode silver paste. The conductive paste consists of the following components, by weight: 75-92 parts of silver powder, 5-12 parts of an organic solvent, 2-3 parts of an organic carrier, 0.5-1 part of alkyl phenol polyoxyethylene ether, and 0.8-5.3 parts of metal microcrystalline glass powder. The particle size D50 of the metal microcrystalline glass powderis 0.3-2 mu m. The metal microcrystalline glass powder consists of the following components: 10-50 parts of tellurium dioxide, 15-70 parts of lead oxide, 2-10 parts of zinc oxide, 1-15 parts of molybdenum oxide, 5-20 parts of lithium oxide, 0.4-2 parts of aluminium oxide, 1-6 parts of bismuth oxide, 1-4 parts of calcium carbonate, and 1-2 parts of molybdenum chloride. The conductive paste effectively improves the conversion efficiency of cells, and has the characteristics of high temperature viscosity and large surface tension. Molten glass cannot not flow easily during a paste sintering process, thereby maintaining a fine line shape.

Owner:SUZHOU ISILVER MATERIALS

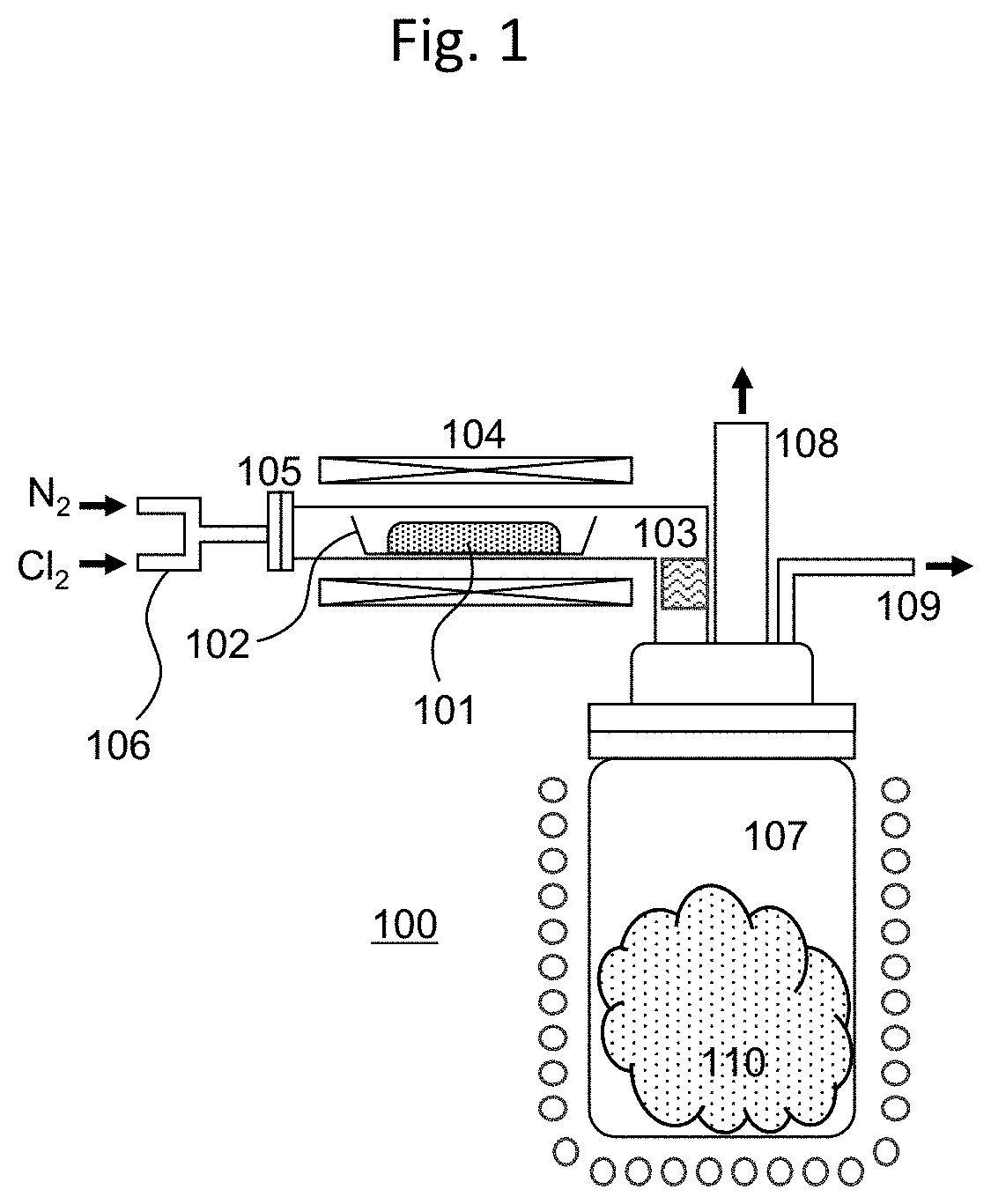

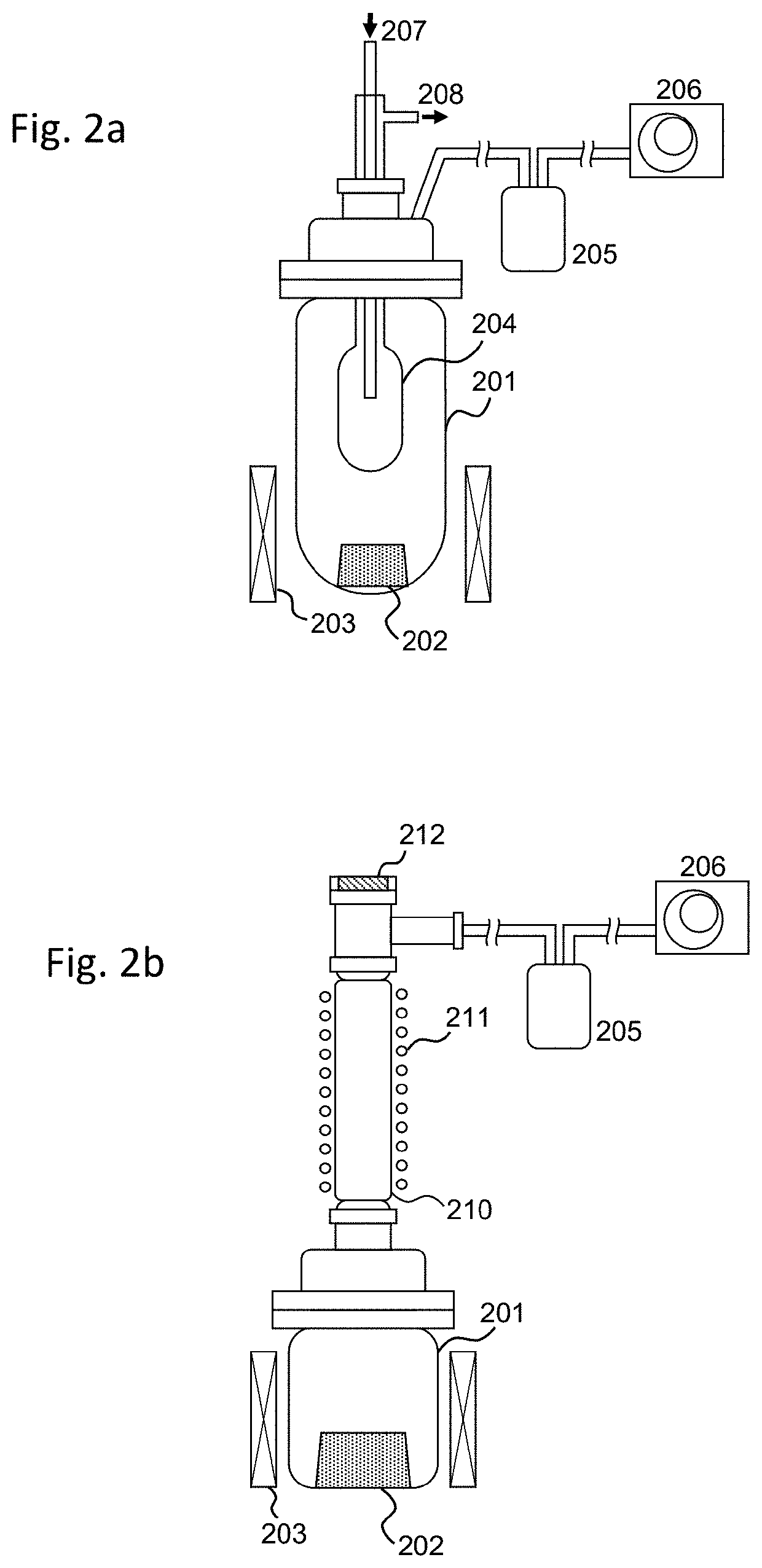

Method of producing high bulk density molybdenum oxychloride

PendingUS20210009436A1High bulk densityEasy to handleMolybdeum compoundsFrom chemically reactive gasesPhysical chemistryVapor phase

Provided is a method of producing a high purity molybdenum oxychloride by including means of sublimating and reaggregating a raw material molybdenum oxychloride in a reduced-pressure atmosphere, or means of retaining a gaseous raw material molybdenum oxychloride, which was synthesized in a vapor phase, in a certain temperature range, and thereby growing crystals to obtain a higher purity molybdenum oxychloride having a high bulk density and high hygroscopicity resistance.

Owner:JX NIPPON MINING& METALS CORP

Highly-active high vinyl butadiene rubber catalyst as well as preparation and application thereof

The invention discloses a highly-active high vinyl butadiene rubber catalyst, as well as a preparation and application of the highly-active high vinyl butadiene rubber catalyst, and belongs to technical field of high polymer synthesis. The highly-active high vinyl butadiene rubber catalyst comprises a main catalyst and a cocatalyst; the main catalyst is a mixture obtained by mixing and reacting molybdenum chloride or / and a molybdenum oxide, an anti-oxidant with an antioxidant function, a compound with active hydrogen and a solvent oil at room temperature; the molybdenum chloride or / and molybdenum oxide, the anti-oxidant with the antioxidant function and the compound with the active hydrogen are added in a molar ratio of 1:(0.5-10):(0.3-5); the compound with the active hydrogen is one or a mixture selected from the group of alcohol ROH, water and carboxylic acid RCOOH; the cocatalyst is a product obtained by a reaction of cresol or m-cresol and an organic aluminum compound in a molar ratio of (1-6):1 at the room temperature. The highly-active high vinyl butadiene rubber catalyst disclosed by the invention has relatively high polymerization activity, and further improves physical and mechanical properties of aging resistance and the like of butadiene rubber.

Owner:CHINA PETROLEUM & CHEM CORP

Method for preparing methacrylic acid catalyst for iso-butane production

InactiveCN106076413AOvercome the disadvantages of easy breakage and blockageExtended service lifeOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsTitanium chlorideLithium chloride

The invention relates to a method for preparing a methacrylic acid catalyst for iso-butane production. According to the invention, in a reaction vessel, 100 crosslinking polystyrene microsphere, titanium chloride, zinc chloride, molybdenum chloride, palladium chloride, lithium chloride, cerium chloride, tetrahydrofuran, bisindolylmaleimide, and 2,5-dimethyl pyrrole are added, and the materials are subjected to a reaction under proper temperature, the obtained products are filtered and dried to obtain the catalyst product.

Owner:王金明

Cleaning and smelting process for low-grade complex nickel-molybdenum ore

A cleaning and smelting process for low-grade complex nickel-molybdenum ore comprises the steps that the nickel-molybdenum ore, a chlorinating agent and water are evenly mixed in a certain proportionand granulated, granulated pellets are directly put into a volatilization furnace without drying, and chlorination and volatilization smelting is carried out under a certain heat preservation and heating mechanism and the reducing atmosphere; and arsenic chloride, molybdenum chloride, zinc chloride and other products are recovered from flue gas generated by volatilization in a flue gas collectiondevice. By the adoption of the cleaning and smelting process, all kinds of low-grade complex nickel-molybdenum ore can be treated, molybdenum, zinc, arsenic and other valuable components can be separated in one step, and the volatile slag obtained by volatilization can be sold directly if the requirement of low nickel matte is met. Compared with an existing nickel-molybdenum ore treatment method,the method has the beneficial effects of the low energy consumption, high efficiency, cleanness and environmental protection.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com