Pyramidal molybdenum disulfide nanosheet and preparation method and application thereof

A molybdenum disulfide, pyramid-shaped technology, applied in the field of pyramid-shaped molybdenum disulfide nanosheets and its preparation, can solve the problems of reducing catalytic efficiency and affecting the conductivity of molybdenum disulfide, and achieve less process flow, good electrical conductivity and catalytic performance. Performance, Effects of High Density Borders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

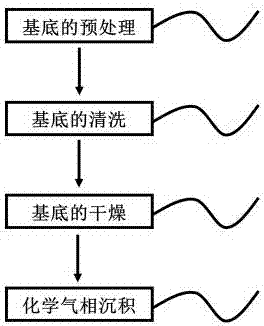

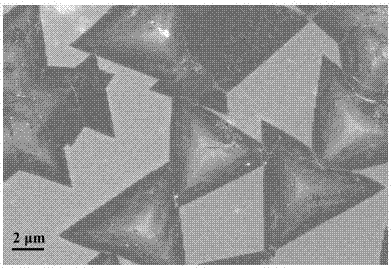

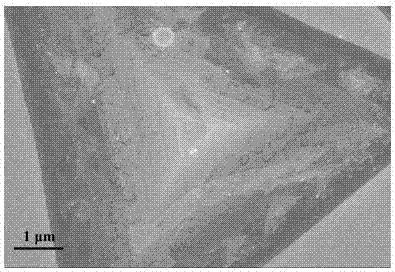

[0040] Such as figure 1 Shown is a flow chart of a method for preparing a pyramidal molybdenum disulfide with a high-density border in an embodiment of the present invention, figure 2 It is a schematic diagram and a physical picture of the preparation method. The pyramidal molybdenum disulfide method of the high-density boundary includes:

[0041] Step 101, pretreatment of the substrate;

[0042] Step 102, cleaning of the substrate;

[0043] Step 103, drying of the substrate;

[0044] Step 104, growing pyramidal molybdenum disulfide on the substrate by chemical vapor deposition;

[0045] In the processing of the step base: the commercial slides are cut into 2.5cm long and 1.5cm wide pieces, then soaked in hydrofluoric acid solution for 5 min, the concentration of hydrofluoric acid is 40% (Tianjin University Mao Chemical Reagent Factory).

[0046] In the cleaning of the substrate in the above step: Remove the products generated by the surface silicate reaction on the soa...

Embodiment 2

[0062] In this embodiment, the mass concentration of hydrofluoric acid in step 101 is 35%, and the cleaning time is 5 minutes.

[0063] In step 104, the temperature control of the three temperature zones during the growth process is as follows: increase from 30°C to 300°C after 5 minutes, hold for 5 minutes, then raise the temperature to 750°C after 10 minutes and hold for 5 minutes, cool down to 650°C after 3 minutes and open The tube furnace cools down quickly.

[0064] During the growth process, the gas flow was adjusted to 200 sccm before the temperature was raised to 650°C and after the tube furnace was turned on for rapid cooling, and the gas flow was 25 sccm during the period.

Embodiment 3

[0066] In this embodiment, the mass concentration of hydrofluoric acid in step 101 is 30%, and the cleaning time is 5 minutes.

[0067] In step 104, the temperature control of the three temperature zones during the growth process is as follows: increase from 30°C to 400°C after 15 minutes, hold for 8 minutes, then raise the temperature to 740°C after 9 minutes and hold for 8 minutes, cool down to 680°C after 5 minutes and Turn on the tube furnace to cool down quickly.

[0068] During the growth process, the gas flow was adjusted to 200 sccm before the temperature was raised to 700°C and after the tube furnace was turned on for rapid cooling, and the gas flow was 40 sccm during the period.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com