Preparation method for cobalt sulfide and molybdenum disulfide in-situ composite electrode and application of cobalt sulfide and molybdenum disulfide in-situ composite electrode in hydrogen production by water electrolysis

A technology of molybdenum disulfide and in-situ compounding, which is applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., and can solve problems such as complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

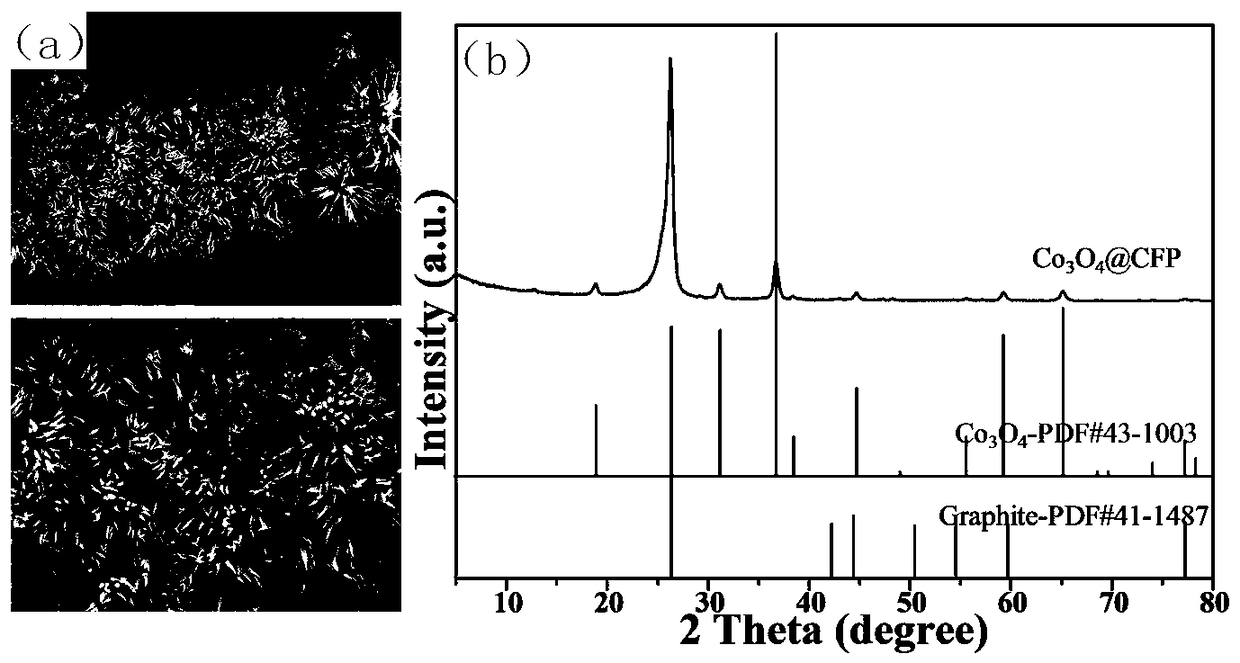

[0024] Dissolve molybdenum chloride in ethanol solution at room temperature, stir to dissolve, and obtain 450 mM molybdenum chloride ethanol solution. will grow with Co 3 o 4 The carbon paper substrate of the array was soaked in molybdenum chloride solution, and dried on a hot stage at 80°C for 10 min after taking it out. Put the coated substrate into the tube furnace, and repeatedly discharge the residual air in the tube furnace with Ar gas and vacuumize it three times, and then pass Ar gas at a flow rate of 2 SCCM. As the temperature in the tube furnace rises, the sulfur powder evaporates to form sulfur vapor, react in an Ar+S atmosphere at 600°C for 30 minutes, and take it out after natural cooling. figure 1 for the growth of Co 3 o 4 (a) SEM and (b) XRD patterns of the arrayed carbon paper, Co 3 o 4 The array adopts the method reported by Kuo-Chuan Ho et al. (ACS nano, 2012, 6, 7016.), specifically 10.6667g urea, 5.7108g CoCl 2 ·6H 2 O was dissolved in 160mL water,...

Embodiment 2

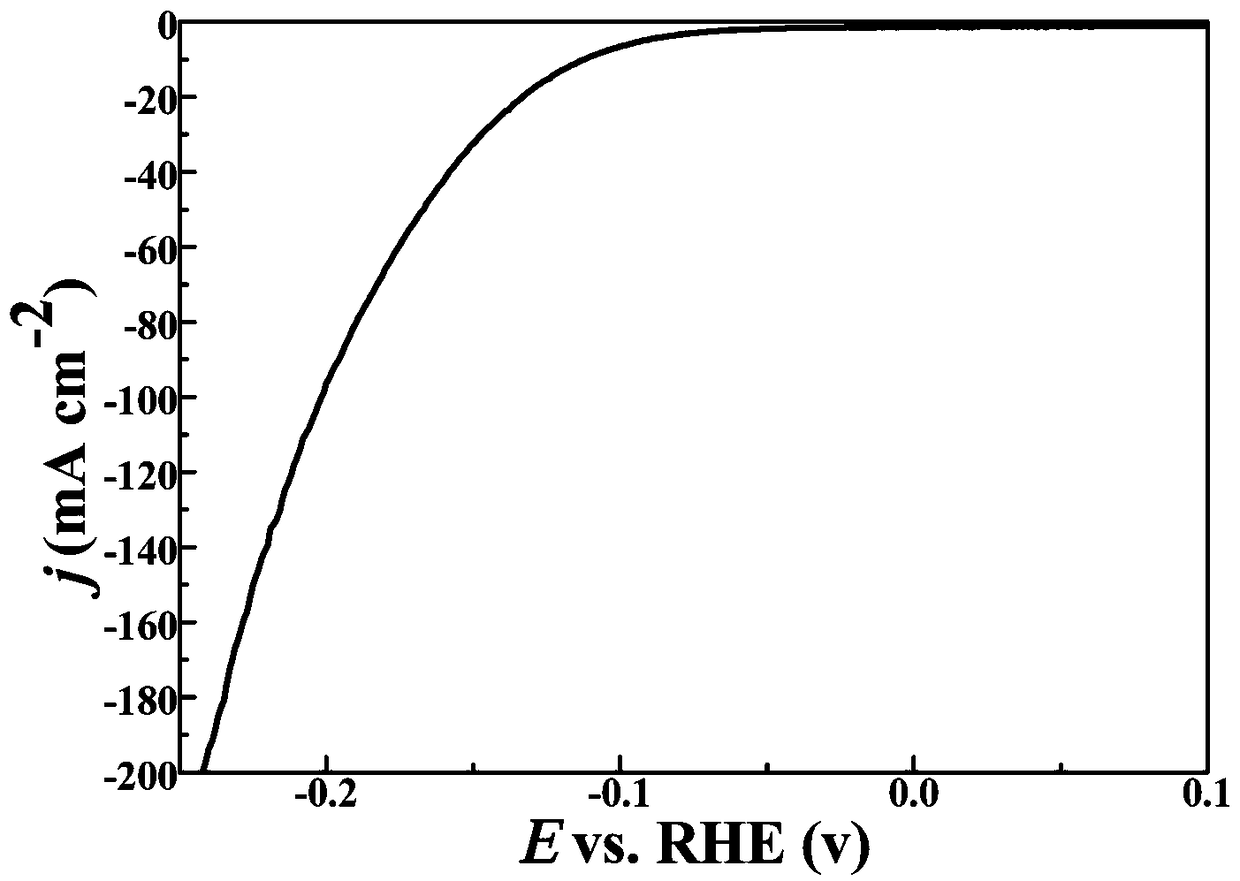

[0026] Dissolve molybdenum chloride in ethanol solution at room temperature, stir to dissolve, and obtain 450 mM molybdenum chloride ethanol solution. will grow with Co 3 o 4 The carbon paper substrate of the array was soaked in molybdenum chloride solution, and dried on a hot table at 90°C for 10 min after taking it out. Put the coated substrate into the tube furnace, ventilate Ar gas to vacuumize repeatedly three times to discharge the residual air in the tube furnace, and then ventilate Ar gas with a flow rate of 1 SCCM. The temperature in the tube furnace rises, the sulfur powder evaporates to form sulfur vapor, and reacts at 600°C for 1 hour in an Ar+S atmosphere, and takes it out after natural cooling. Figure 4(a) SEM image and (b) linear voltammetry scanning performance in 1M KOH of the in-situ composite electrode of cobalt sulfide and molybdenum disulfide prepared in Example 2. It can be seen from the figure that when the hydrogen-producing electrode passes through...

Embodiment 3

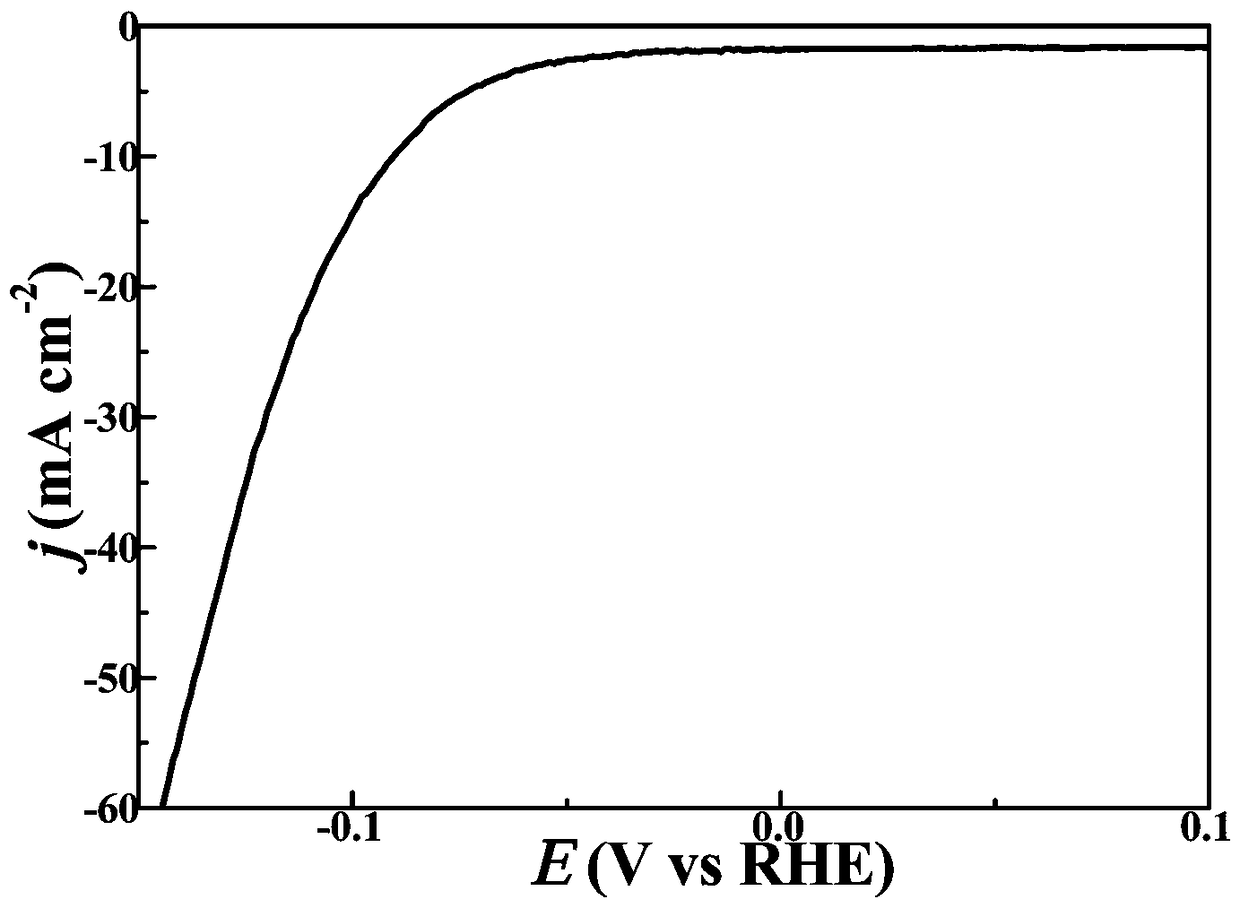

[0028] Dissolve molybdenum chloride in ethanol solution at room temperature, stir to dissolve, and obtain 570 mM molybdenum chloride ethanol solution. will grow with Co 3 o 4 The carbon paper substrate of the array was soaked in molybdenum chloride solution, and dried on a hot stage at 80°C for 10 min after taking it out. Put the coated substrate into the tube furnace, ventilate Ar gas to vacuumize repeatedly three times to discharge the residual air in the tube furnace, and then ventilate Ar gas with a flow rate of 1 SCCM. The temperature in the tube furnace rises, the sulfur powder evaporates to form sulfur vapor, and reacts at 600°C for 2 hours in an Ar+S atmosphere, and takes it out after natural cooling. Figure 5 (a) in 0.5M H 2 SO 4 The linear voltammetric scanning performance in (b) the linear voltammetric scanning performance in 1M PBS solution (PH=7.17), Image 6 is its linear voltammetry sweep performance in 1M KOH. It can be seen from the figure that when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com