Photovoltaic electrode silver paste

A technology of electrode and silver paste, applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as adverse effects, achieve the effects of improving wettability, improving battery conversion efficiency, and promoting dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0033] Embodiment 1~4: a kind of photovoltaic electrode silver paste, described conductive paste is made up of the following components by weight:

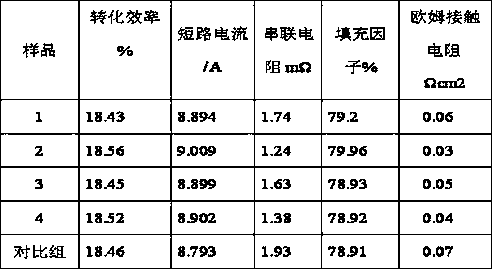

[0034] Table 1

[0035] ;

[0036] The above-mentioned organic carrier is formed by mixing butyl carbitol acetate, ethyl cellulose, acrylate, oleic acid, polypropylene glycol, and polyamide wax in a weight ratio of 75:7:6:4:3:5.

[0037] The above-mentioned organic carrier is formed by heating, stirring and mixing at a temperature of 90 degrees.

[0038] Note: embodiment 1 organic solvent is at least one in terpineol, butyl carbitol, propylene glycol phenyl ether, propylene glycol methyl ether, dimethyl glutarate, dimethyl succinate; embodiment 2 organic solvent It is a mixed solvent formed by butyl carbitol and propylene glycol phenyl ether; the organic solvent of embodiment 3 is propylene glycol phenyl ether; the organic solvent of embodiment 4 is a mixed solvent formed by terpineol and dimethyl glutarate.

[0039] The meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com