Microelement tracer agent used for offshore oilfield and use method thereof

A trace element and offshore oilfield technology, applied in construction and other fields, can solve the problems of long tracer diffusion time, insufficient analysis accuracy, and low oil recovery efficiency, and achieve the prevention and control of large pores, good safety and stability, and advanced detection technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

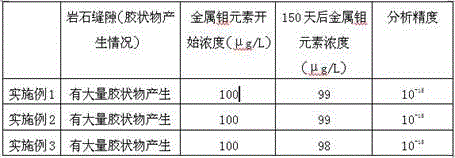

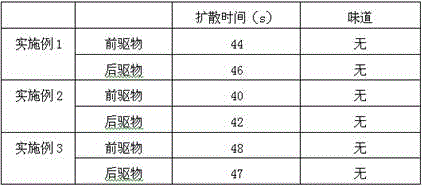

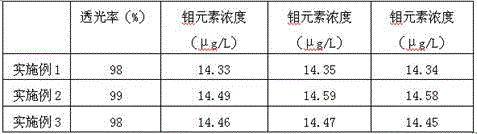

Embodiment 1

[0034] Example 1 A trace element tracer, in parts by weight, including the following components:

[0035] Precursors: 4 parts of trace element chloride, 1 part of precursor, 0.1 part of sodium bicarbonate, 0.2 part of citric acid, 0.08 part of sulfonated phenolic resin, 0.12 part of PAM;

[0036] The trace element chloride in the precursor is a mixture of praseodymium-molybdenum chloride; the precursor is sodium ethylenediamine tetramethylene phosphate;

[0037] After-drive: 2-parts of trace element chloride, 0.6-parts of after-drive agent, 0.3 parts of calcium chloride, 0.25 parts of sodium dodecylbenzene sulfonate, 0.05 parts of polyacrylamide;

[0038] In the after-drive, the trace element chloride is a mixture of praseodymium-molybdenum chloride;

[0039] The molar mass ratio of praseodymium chloride to molybdenum chloride in the trace element chloride is 0.6;

[0040] The after-drive agent calcium lignosulfonate;

Embodiment 2

[0041] Example 2 A trace element tracer, using the raw materials described in Example 1, only the ratio of the raw materials was changed to:

[0042] Precursors: 4.5 parts of trace element chloride, 1.1 parts of precursors, 0.12 parts of sodium bicarbonate, 0.25 parts of citric acid, 0.09 parts of sulfonated phenolic resin, 0.13 parts of PAM;

[0043] The trace element chloride in the precursor is a mixture of praseodymium-molybdenum chloride; the precursor is sodium ethylenediamine tetramethylene phosphate;

[0044] After-drive: 2.3 parts of trace element chloride, 0.7 parts of after-drive agent, 0.35 parts of calcium chloride, 0.27 parts of sodium dodecylbenzene sulfonate, 0.07 parts of polyacrylamide;

[0045] In the after-drive, the trace element chloride is a mixture of praseodymium-molybdenum chloride;

[0046] Among the trace element chlorides of the precursor and the follower, the molar mass ratio of praseodymium chloride to molybdenum chloride is 0.8;

[0047] The after-drive ag...

Embodiment 3

[0048] Example 3 A trace element tracer, using the raw materials described in Example 1, only the ratio of the raw materials was changed to:

[0049] Precursors: 5 parts of trace element chloride, 1.2 parts of precursors, 0.15 parts of sodium bicarbonate, 0.3 parts of citric acid, 0.1 parts of sulfonated phenolic resin, 0.14 parts of PAM;

[0050] The trace element chloride in the precursor is a mixture of praseodymium-molybdenum chloride; the precursor is sodium ethylenediamine tetramethylene phosphate;

[0051] After-drive: 2.5 parts of trace element chloride, 0.8 parts of after-drive agent, 0.4 parts of calcium chloride, 0.3 parts of sodium dodecylbenzene sulfonate, 0.08 parts of polyacrylamide;

[0052] In the after-drive, the trace element chloride is a mixture of praseodymium-molybdenum chloride;

[0053] Among the trace element chlorides of the precursor and the follower, the molar mass ratio of praseodymium chloride to molybdenum chloride is 1.1;

[0054] The after-drive agent ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com