Patents

Literature

57results about How to "Detection Technology Improvement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

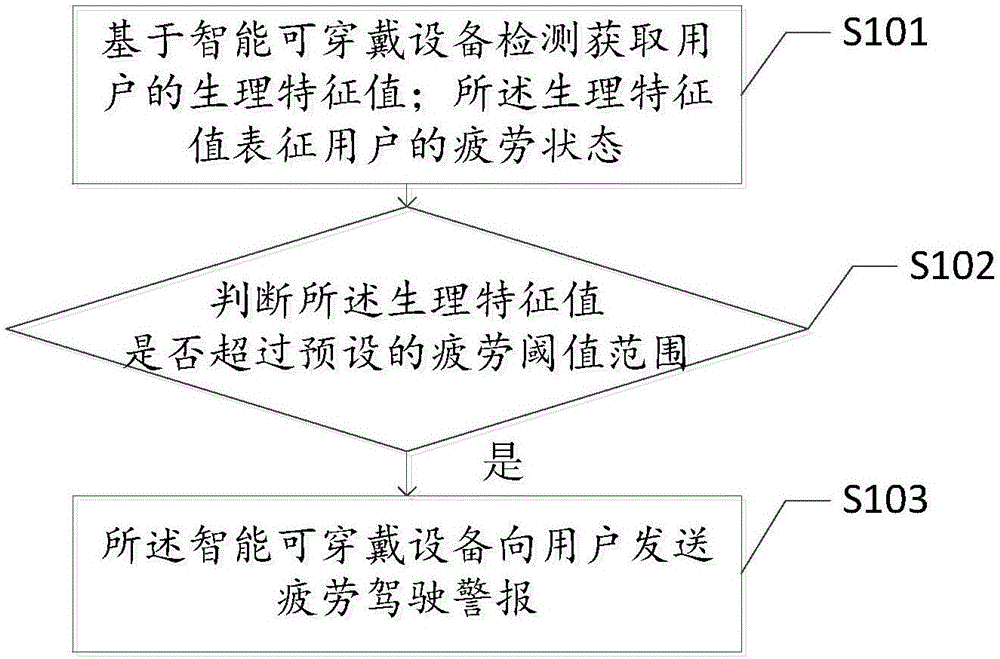

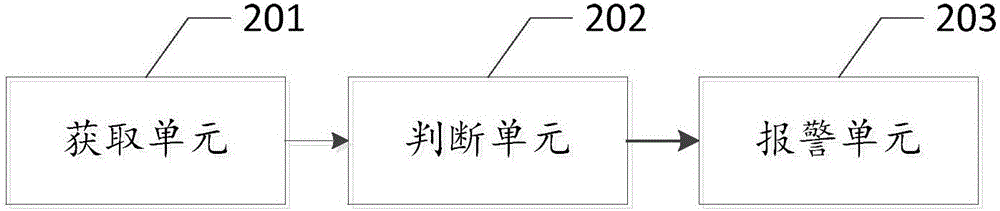

Safe driving method and apparatus based on smart wearable equipment

InactiveCN106530621APreventing dangerous situations of drowsy drivingEnsure safetyAlarmsEmbedded systemDriving safety

The invention discloses a safe driving method and apparatus based on smart wearable equipment. The method includes the steps of detecting and obtaining physiological characteristic values, of a user, indicating the fatigue state of the user, based on the smart wearable equipment, determining whether the physiological characteristic values exceeds a preset fatigue threshold scope, and if yes, the smart wearable equipment sending a fatigue driving alarm to the user. When the method is adopted, fatigue driving of a user can be prevented, and an alarm is given to remind the user to drive safely, thereby ensuring the driving safety of the user. The method realizes safe driving prompting in combination with smart wearable equipment. Whether a user is driving safely or dangerously can be determined based on the body state detected by the smart wearable equipment worn by the user, and whether the user is fatigue and whether an alarm has to be given off can be determined according to the detection result.

Owner:HANGZHOU LIANLUO INTERACTIVE INFORMATION TECH CO LTD

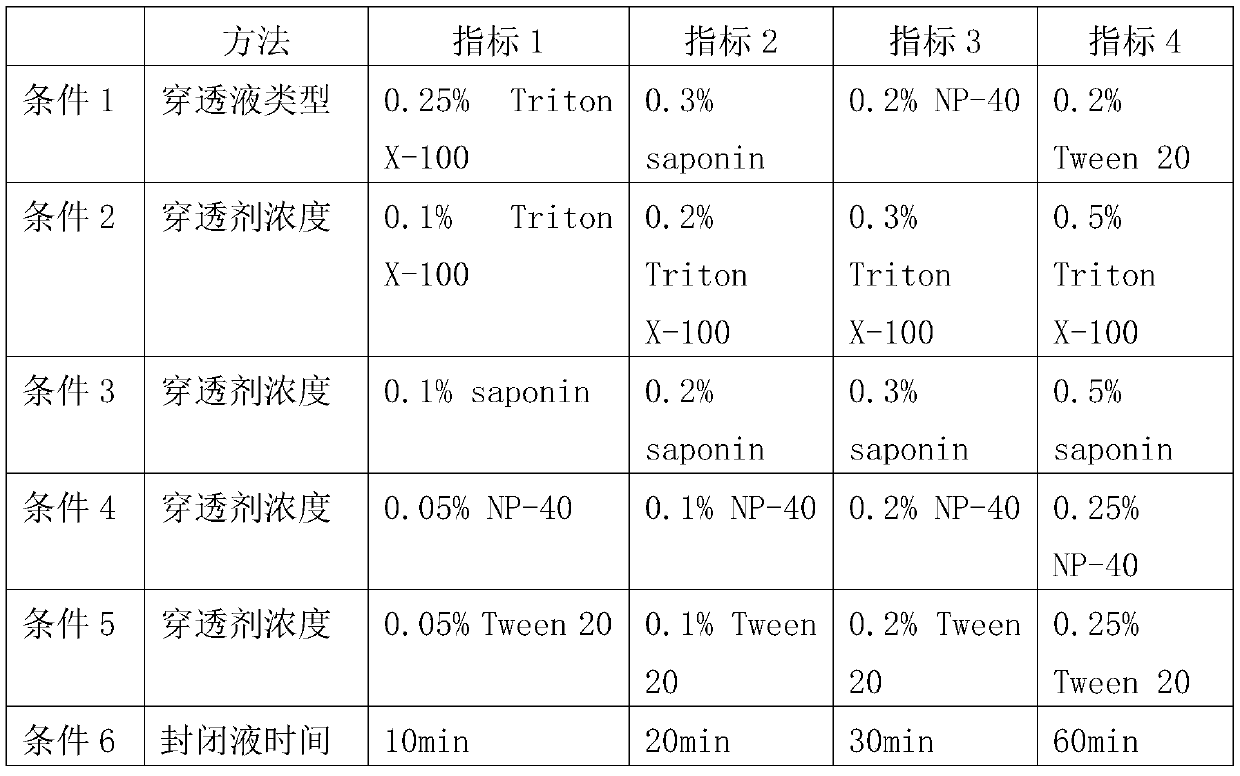

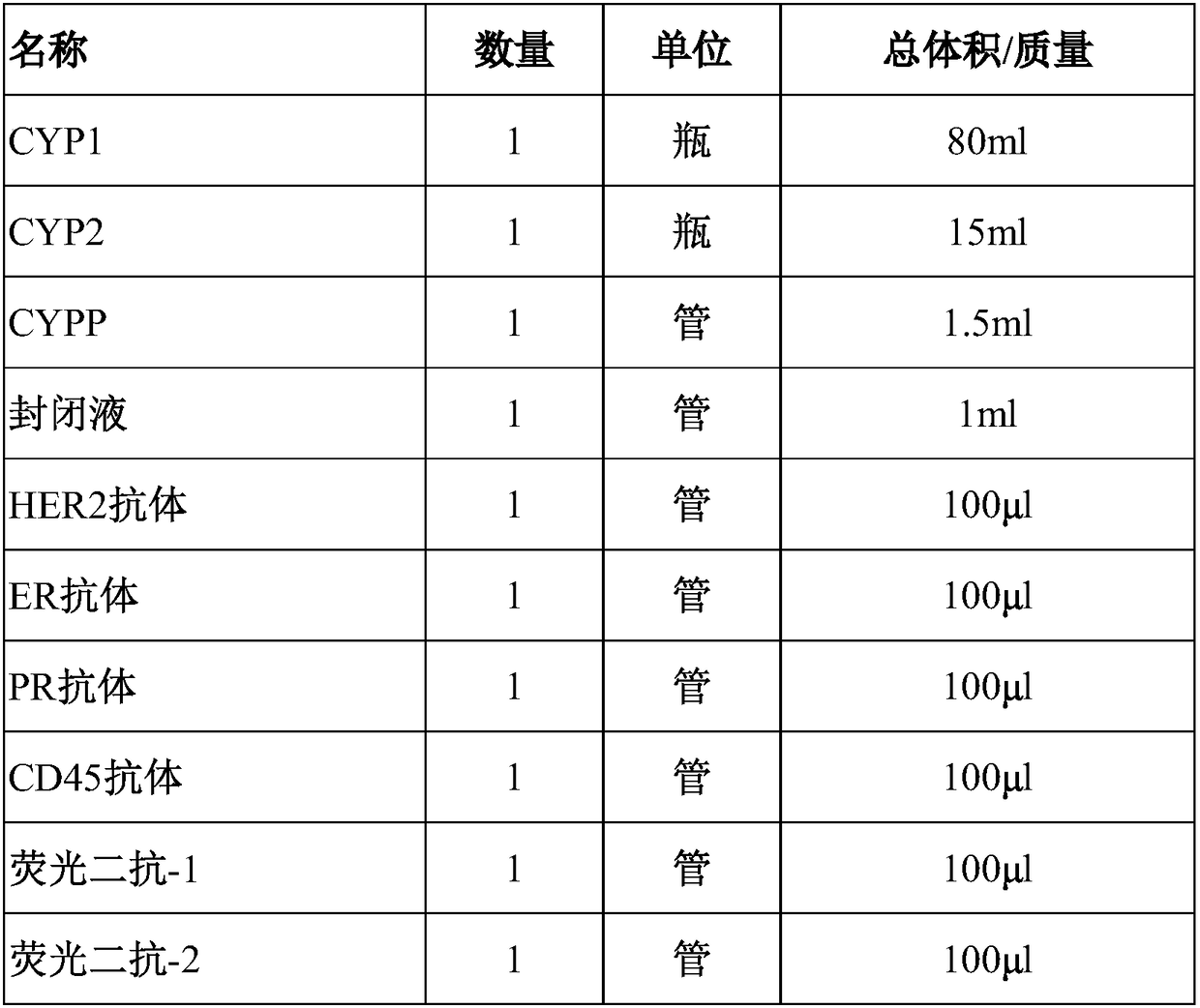

Immunofluorescence kit for detecting PD-L1 and CD8 antigens and application method

PendingCN110632292AAccurately reflectEasy to get materialsMaterial analysisLymphatic SpreadAntigen testing

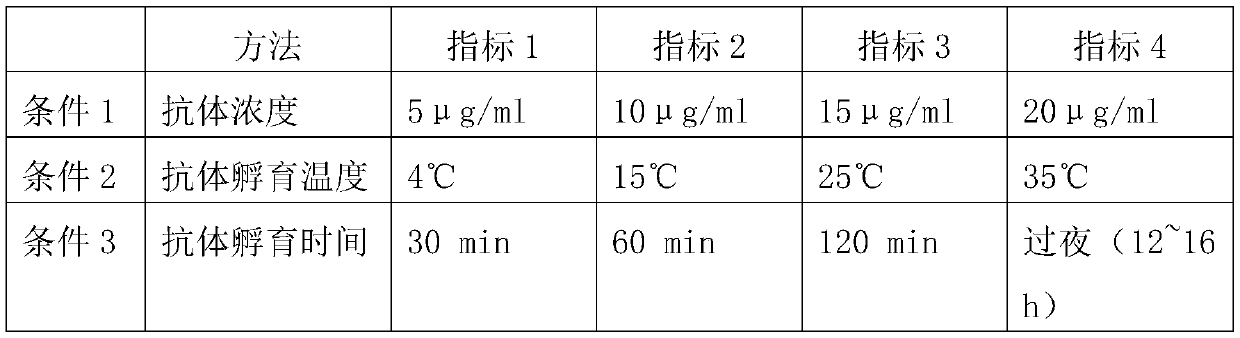

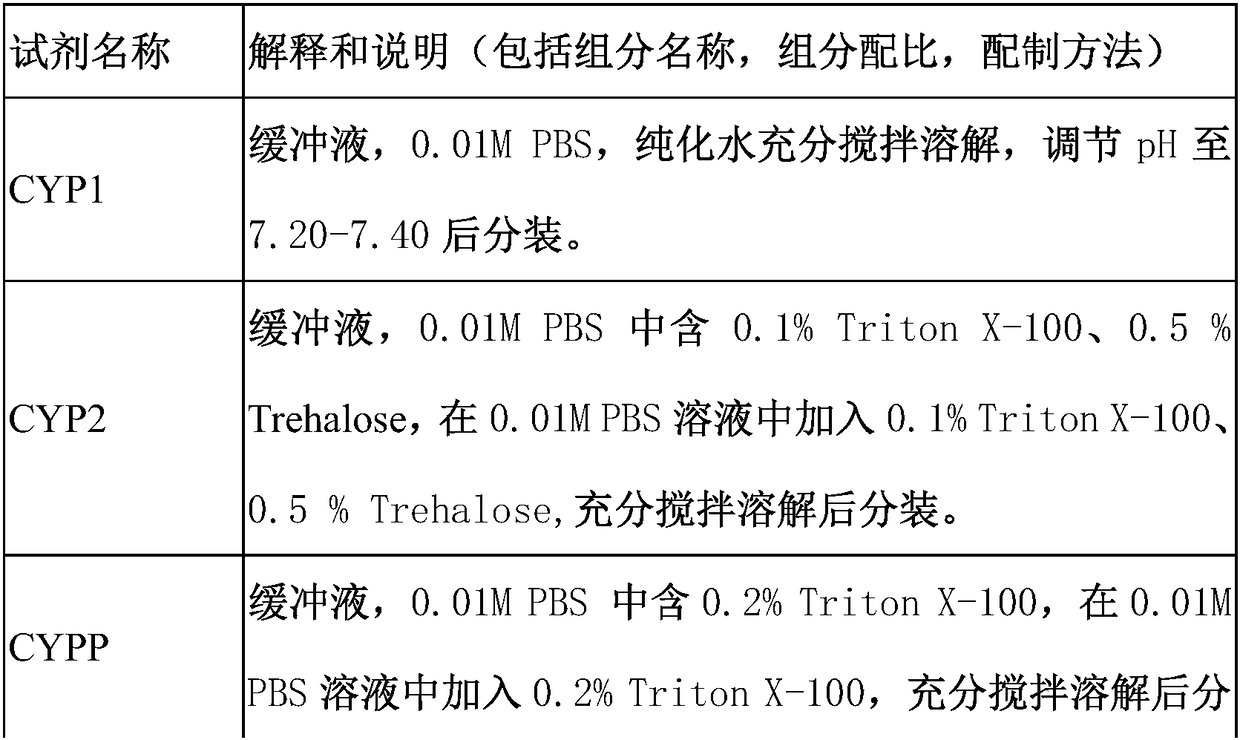

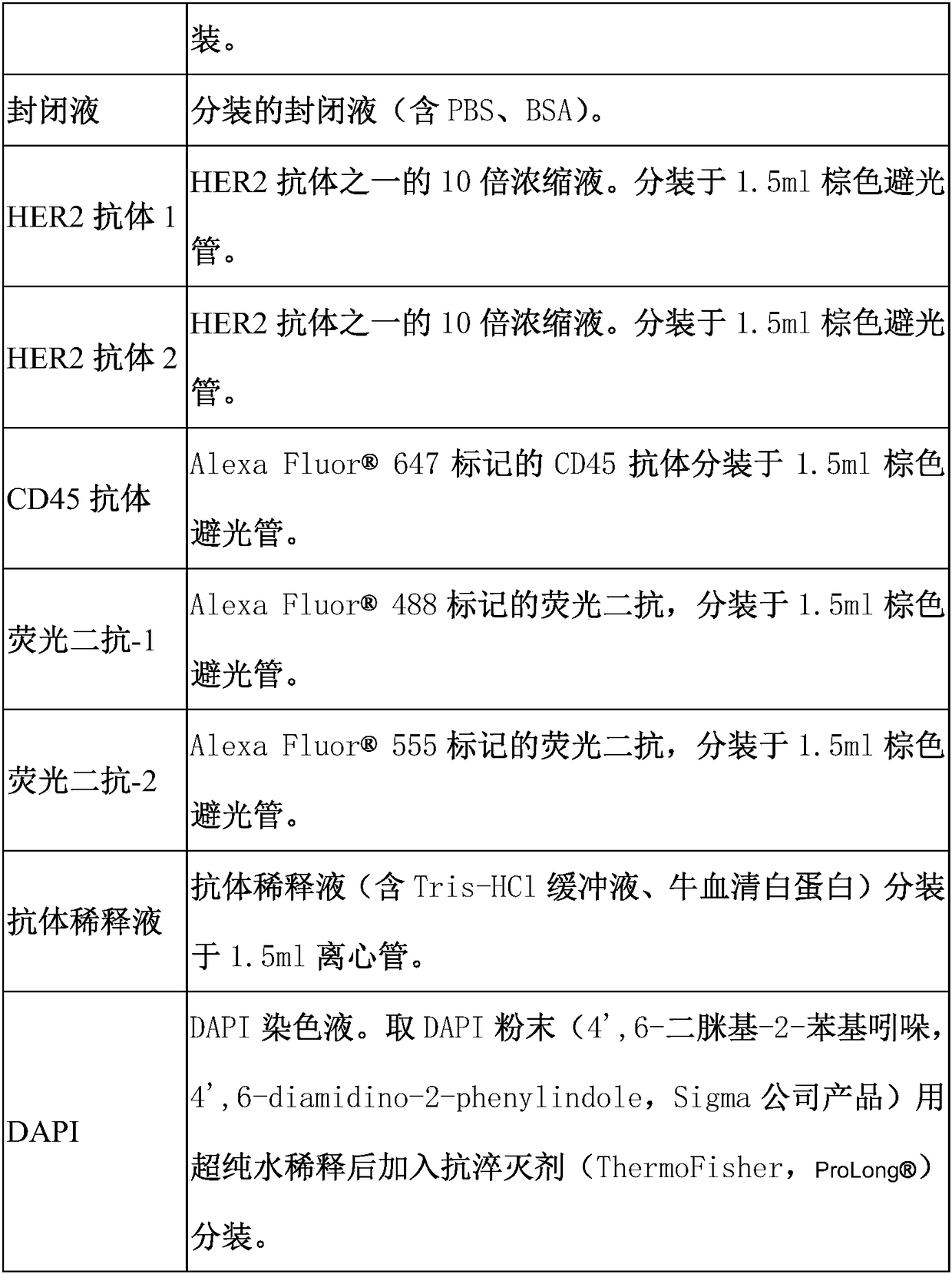

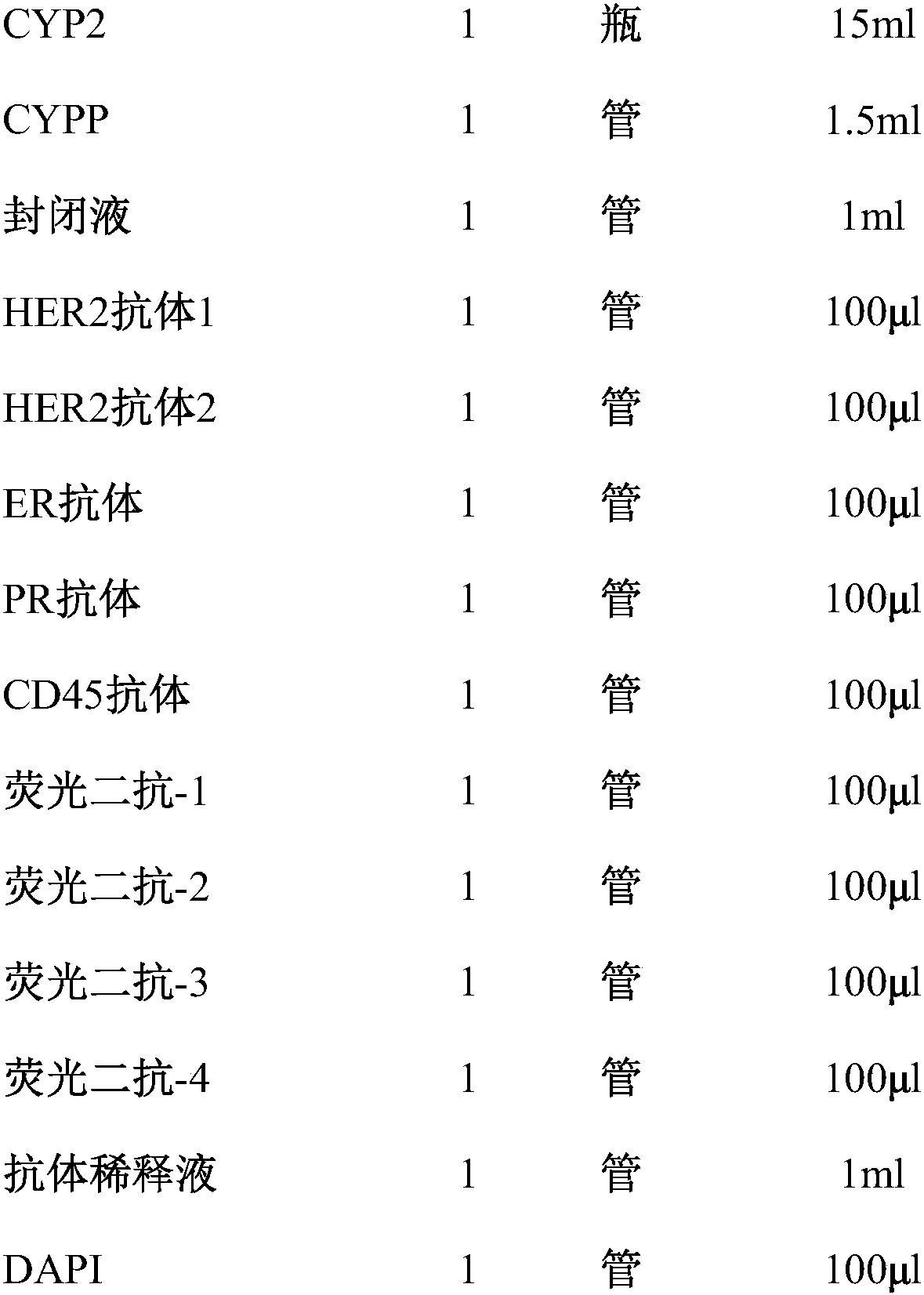

The present invention relates to an immunofluorescence kit for detecting PD-L1 and CD8 antigens and a detection method using the kit. The kit comprises the following reagents: buffer solutions CYP1, CYP2 and CYPP, a blocking solution, a specific antibody for detecting PD-L1, a corresponding fluorescent second antibody, a fluorescently labeled CD45 antibody, a fluorescently labeled CD8 antibody, anantibody dilution solution and a nuclear staining solution. The invention also provides a method for carrying out antigen detection by using the kit. A detection result of the kit can guide actual drug use, and not only can reflect the whole tumor comprising carcinoma in situ and possibly existent invisible micro-metastasis load, but also can reflect the expression condition of the PD-L1 in CTC;a reference can be provided for precise selection of therapeutic drugs according to the proportion of PD-L1 and CD8 positive cells in PBMC; and the kit is more convenient than a detection technology based on tumor tissues in material acquisition.

Owner:CYTTEL BIOSCI BEIJING

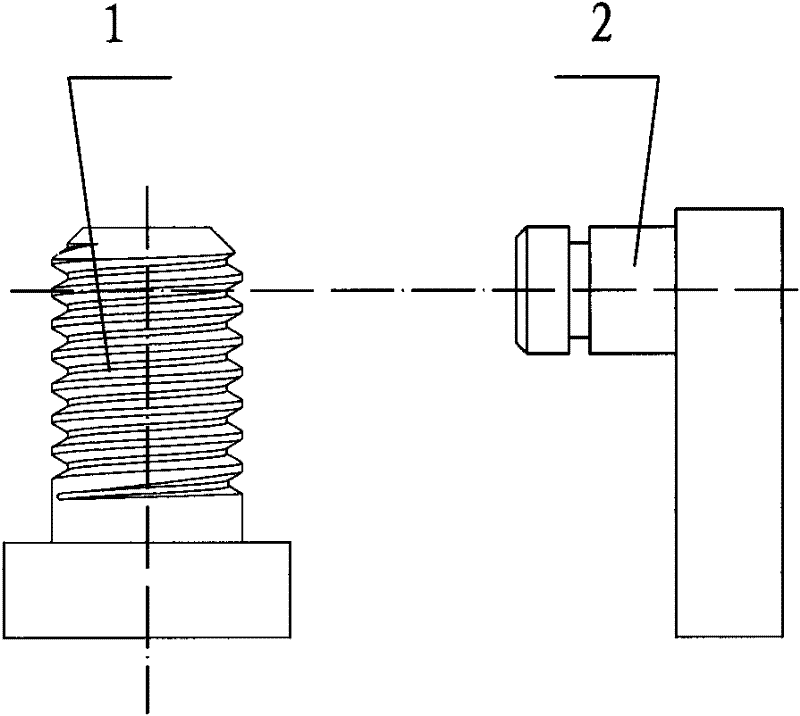

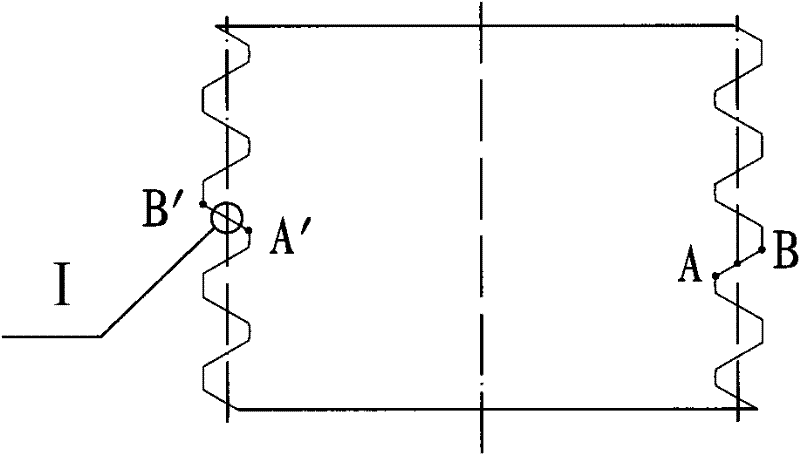

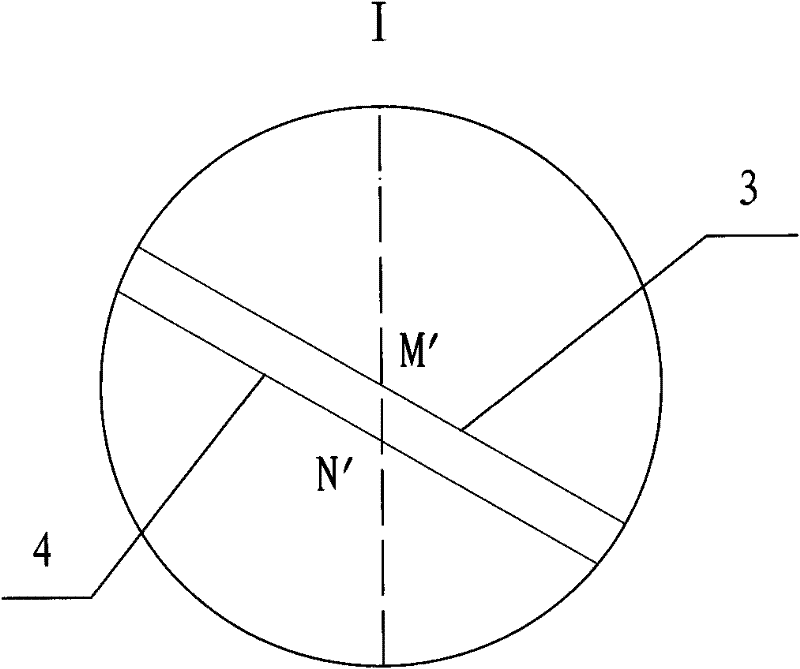

Method for eliminating error of cylinder screw thread non-contact measurement

InactiveCN102221349AAvoid measurement errorsAvoid quality problemsUsing optical meansBoundary equationCcd camera

The invention discloses a method for eliminating error of cylinder screw thread non-contact measurement. The method comprises the following steps: presenting a concept of projection boundary, establishing projection boundary equation, obtaining difference relation of screw thread intersection line and projection boundary and correcting cylinder screw thread parameter. By employing the above method, spatial position relation is formed according to the screw thread projection boundary, the projection boundary equation is creatively established, the difference relation of the screw thread intersection line and the projection boundary is deduced on the former base, and extracted coordinates of points on cylinder screw thread image shot by a CCD camera are repeatedly corrected until the obtaining of cylinder screw thread parameter which satisfies precision requirement. The method is concise, visual, easy to grasp and easy to realize automatic detection. The non-contact detection method can avoid measurement error of high precision cylinder screw thread, and eradicate screw thread product quality problem caused by screw thread non-contact detection error.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

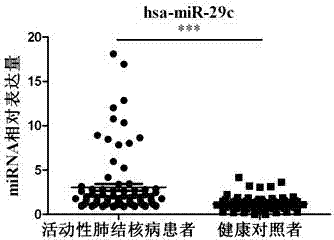

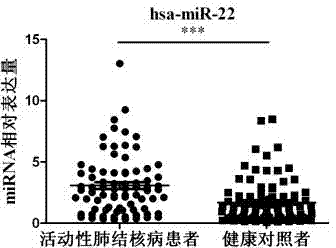

Kit for detecting active pulmonary tuberculosis

ActiveCN103045723AEarly Detection ImprovesEarly detection to improve the early diagnosis of active tuberculosisMicrobiological testing/measurementMicroorganism based processesSerum mirnaPulmonary tb

The invention provides a diagnostic kit for detecting active pulmonary tuberculosis. The kit consists of an RNA extract buffer solution, a specific serum miRNA composition for the active pulmonary tuberculosis, internal reference reverse transcription primers, polymerase chain reaction (PCR) primers and a fluorescent quantitative reverse transcription-polymerase chain reaction (RT-PCR) reaction solution, wherein the specific serum miRNA composition for the active pulmonary tuberculosis consists of four differential expression serum miRNAs, namely hsa-miR-29c, hsa-miR-22, hsa-miR-320b and hsa-miR-101. By using the specific serum miRNAs composition for the active pulmonary tuberculosis to detect the active pulmonary tuberculosis on the serum miRNAs level, the sensitivity is 90.2 percent, and the specificity is 75.0 percent; and the kit has early-stage diagnostic value for the active pulmonary tuberculosis, and can realize early warning and early diagnosis of the active pulmonary tuberculosis.

Owner:ZHEJIANG UNIV

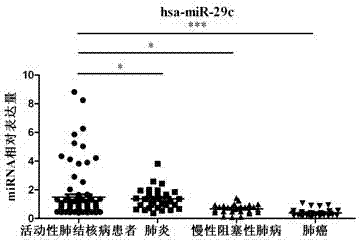

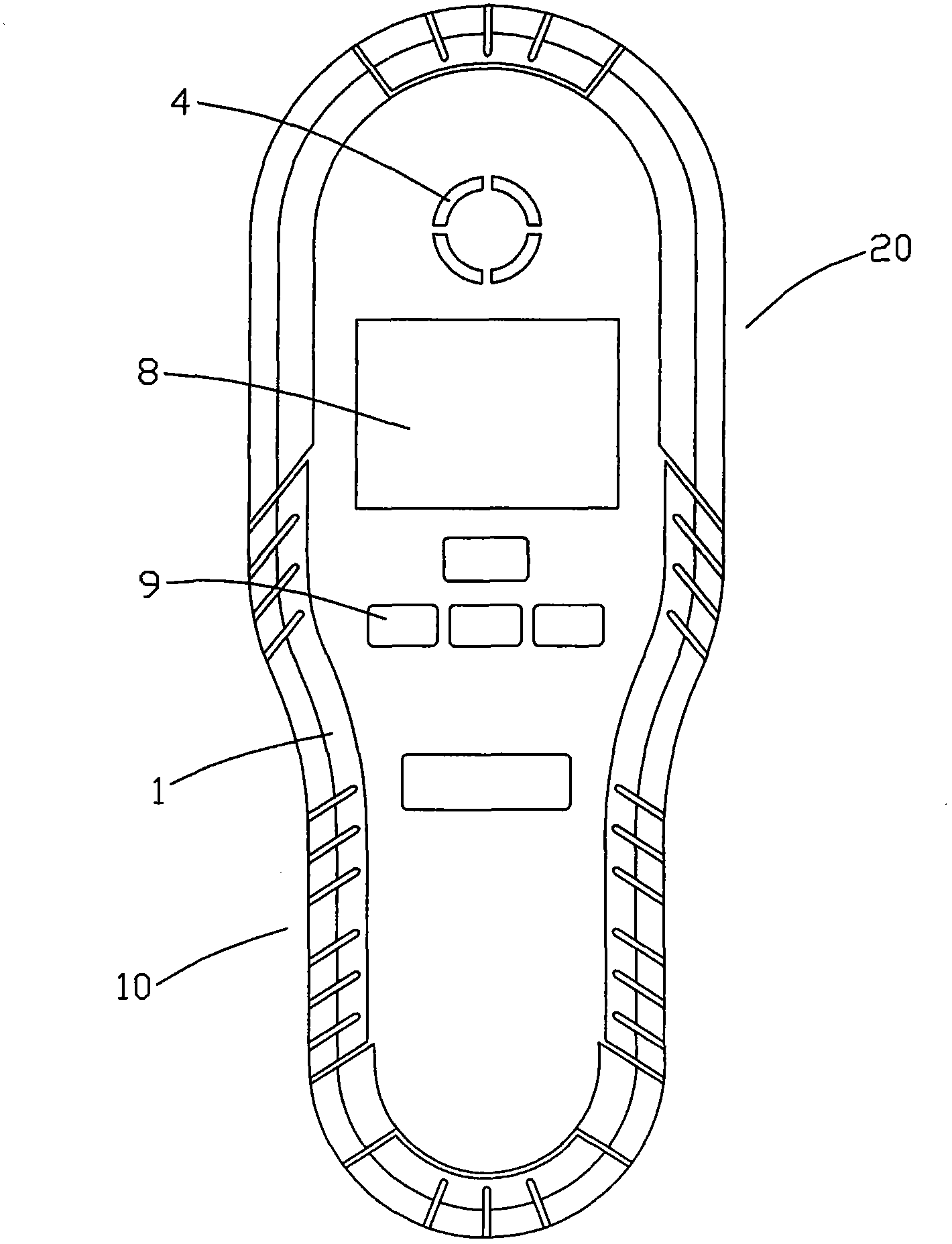

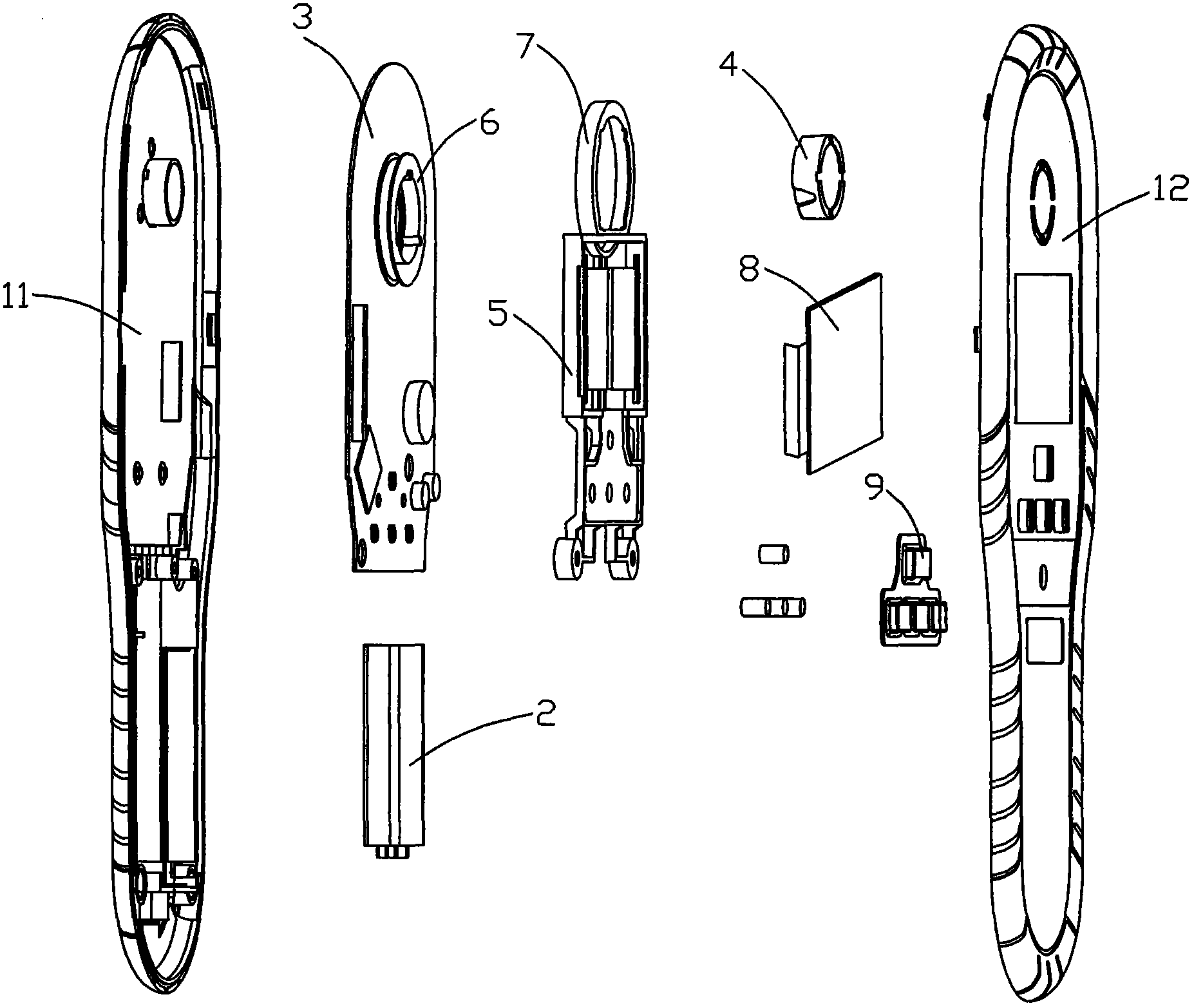

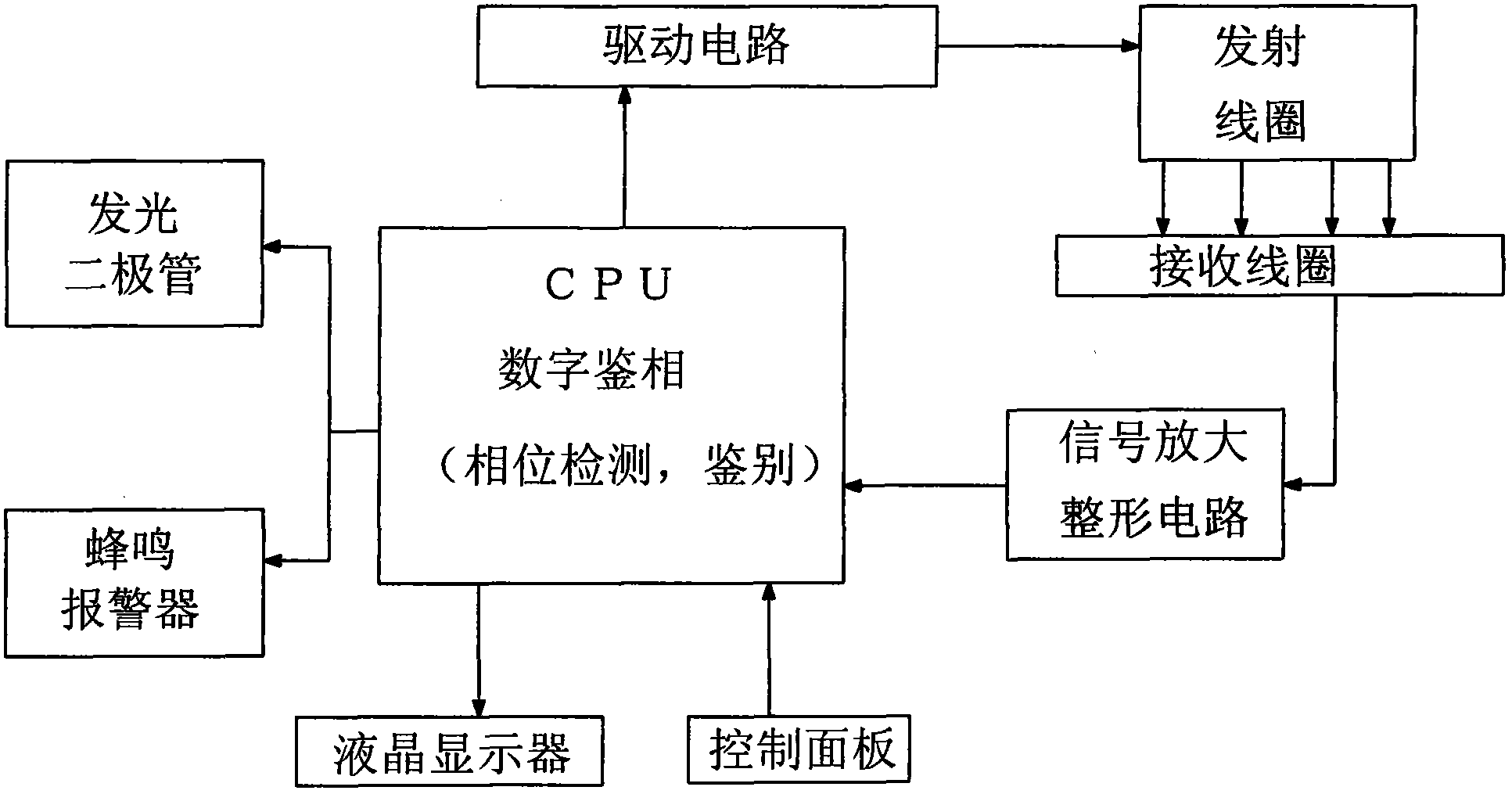

Handheld detecting instrument

InactiveCN103424779AHigh sensitivityImprove anti-interference abilityElectric/magnetic detectionAcoustic wave reradiationLiquid-crystal displayLight guide

The invention relates to a handheld detecting instrument which comprises a casing. One end of the casing forms a handheld portion, and the other end of the casing is provided with a detecting portion; a battery is arranged in the handheld portion of the casing; a circuit board, a light guiding column and a fixing support are arranged in the detecting portion of the casing; a central processing unit (CPU), an emitting coil, a receiving coil, a light-emitting diode and a buzzing alarm are installed on the circuit board; a liquid crystal display and a control panel are arranged on the outer surface of the detecting portion of the casing; the CPU is a processor with phase detecting and identifying functions; the control panel is electrically connected with the input end of the CPU; the light-emitting diode, the buzzing alarm and the liquid crystal display are electrically connected with the output end of the CPU respectively; the emitting coil is electrically connected with the output end of the CPU through a driving circuit; and the receiving coil is electrically connected with the input end of the CPU through a signal amplifying and shaping circuit. The handheld detecting instrument is precise and reliable in detecting, good in anti-interference capacity, complete in functions, capable of being used for detecting objects such as metal, alternating current, wood beams, plastics and the like.

Owner:JINHUA MAKA TECH

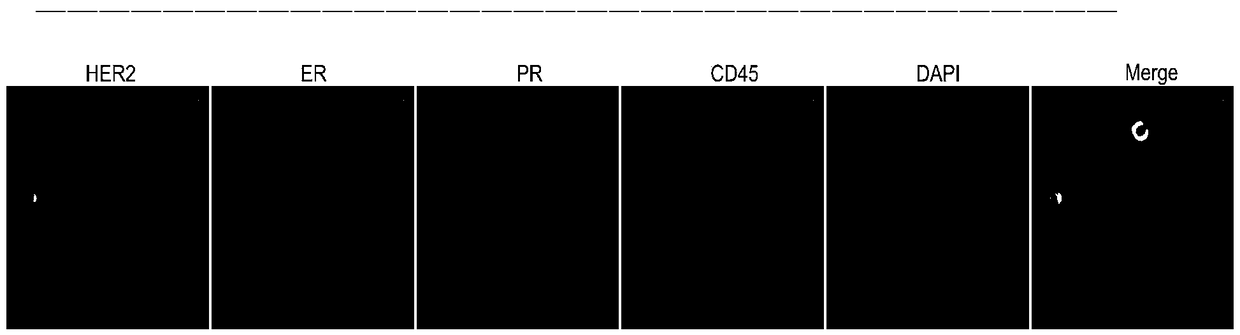

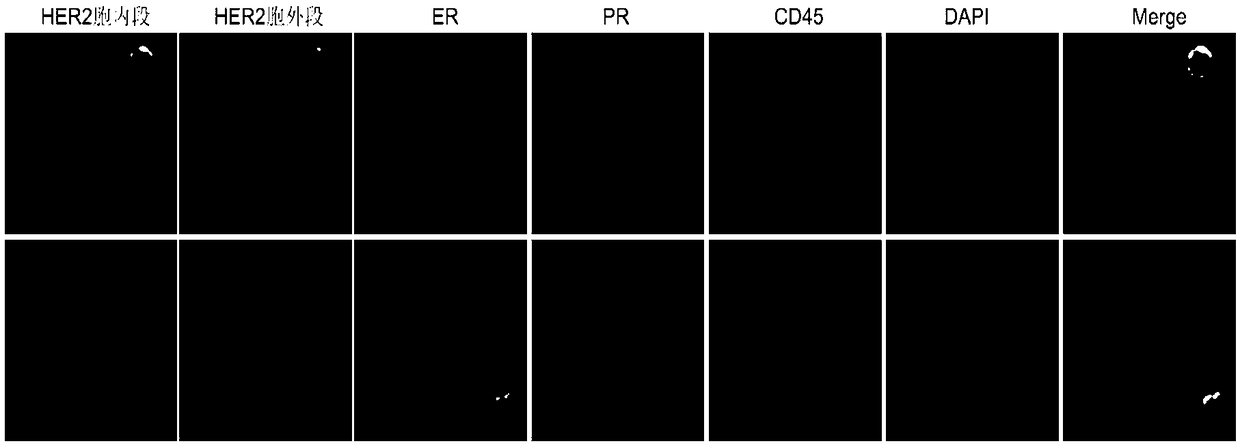

Immunofluorescent kit for detecting circulating tumor cells HER2, ER and PR and application of immunofluorescent kit

InactiveCN109187978APrecise Medication GuidanceGood choiceDisease diagnosisBiological testingProtein targetImmunofluorescence

The invention relates to an immunofluorescent kit for detecting circulating tumor cells HER2, ER and PR and an application of the immunofluorescent kit. A detection principle of a method disclosed bythe invention is as follows: firstly, enriching circulating tumor cells and other rare cells, and then, detecting the expression of target proteins in the enriched cells in cells by using an immunofluorescene detection method according to an antigen-antibody reaction principle. According to the kit, a common antigen CD45 of a target cell and a leukocyte is fluorescently labeled, and the cells withpositive target proteins and negative CD45 are screened, so that the circulating tumor cells with positive specific proteins in the blood are interpreted and counted.

Owner:北京莱尔生物医药科技有限公司

Immunofluorescent kit for detecting different loci of HER2 antigen and application of immunofluorescent kit

InactiveCN109187977AAccurately reflectEasy to get materialsDisease diagnosisBiological testingProtein targetImmunofluorescence

The invention relates to an immunofluorescent kit for detecting different loci of an HER2 antigen and an application of the immunofluorescent kit. A detection principle of the method disclosed by theinvention is as follows: firstly, enriching non-humoral rare nucleated cells, and then, detecting the expression of target proteins in the enriched cells in cells by using an immunofluorescene detection method according to an antigen-antibody reaction principle. According to the kit, a common antigen CD45 of a target cell and a leukocyte is fluorescently labeled, and the cells with positive targetproteins and negative CD45 are screened, so that the non-humoral rare nucleated cells with positive specific proteins in the blood are interpreted and counted.

Owner:北京莱尔生物医药科技有限公司

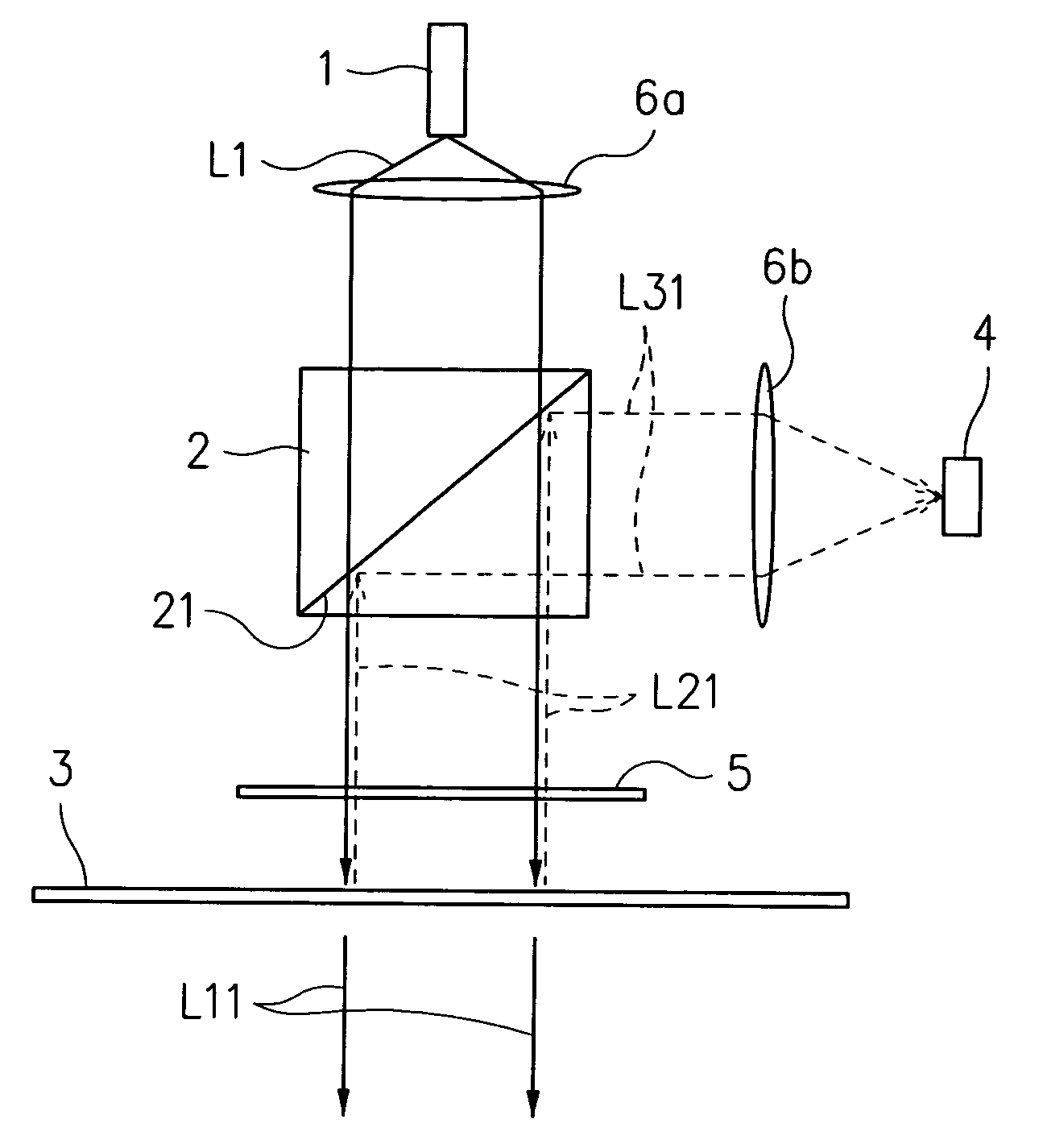

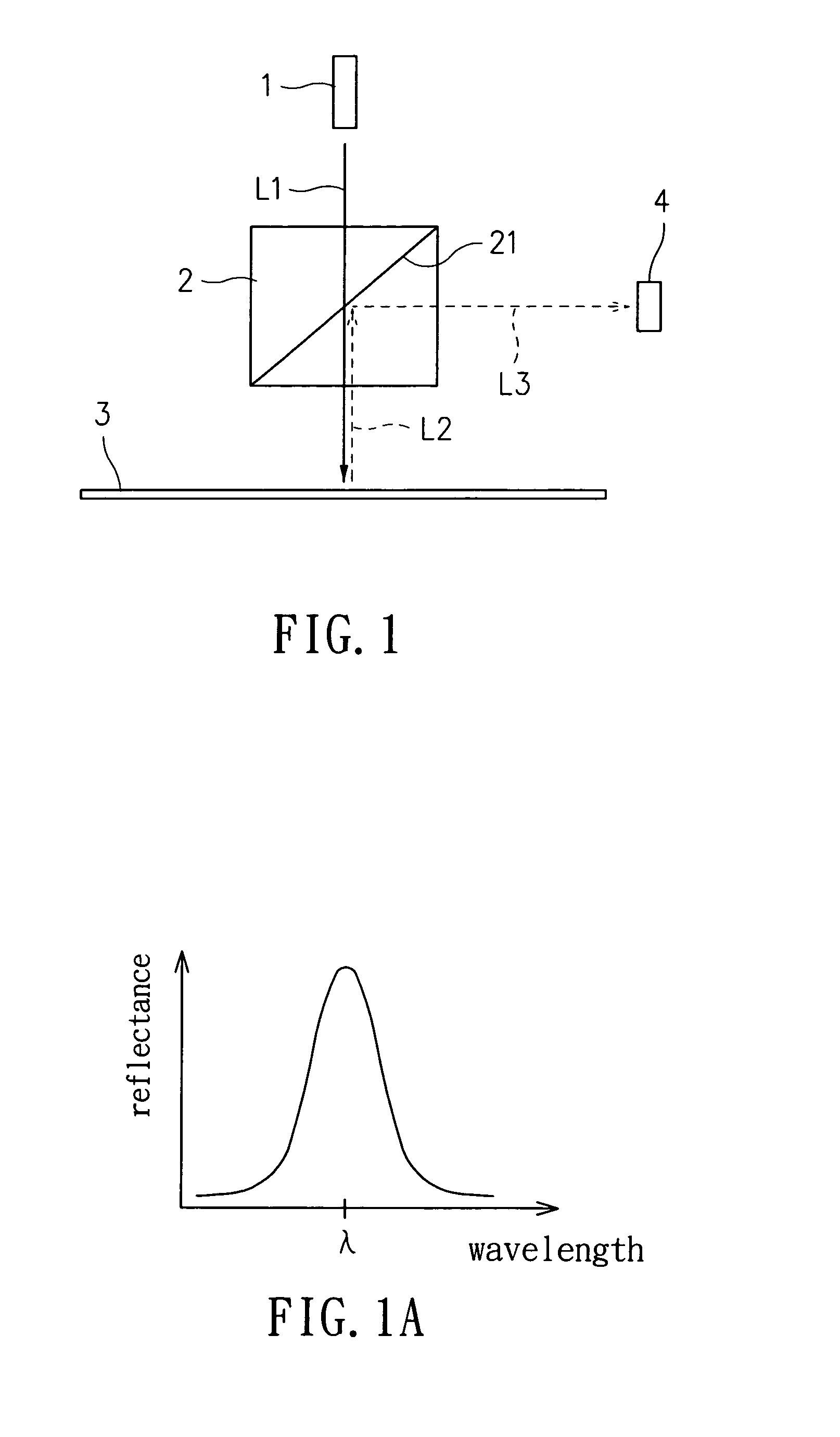

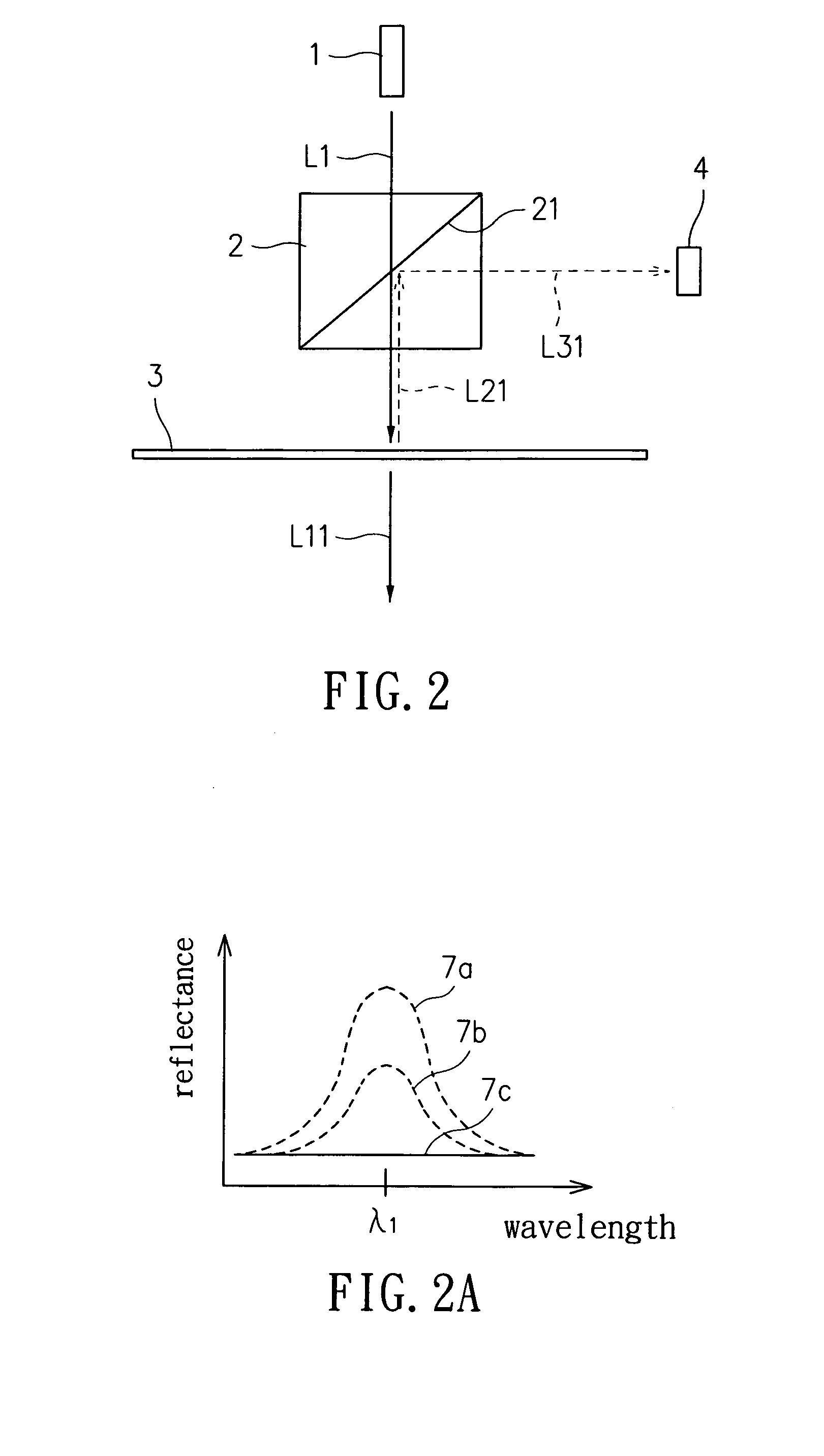

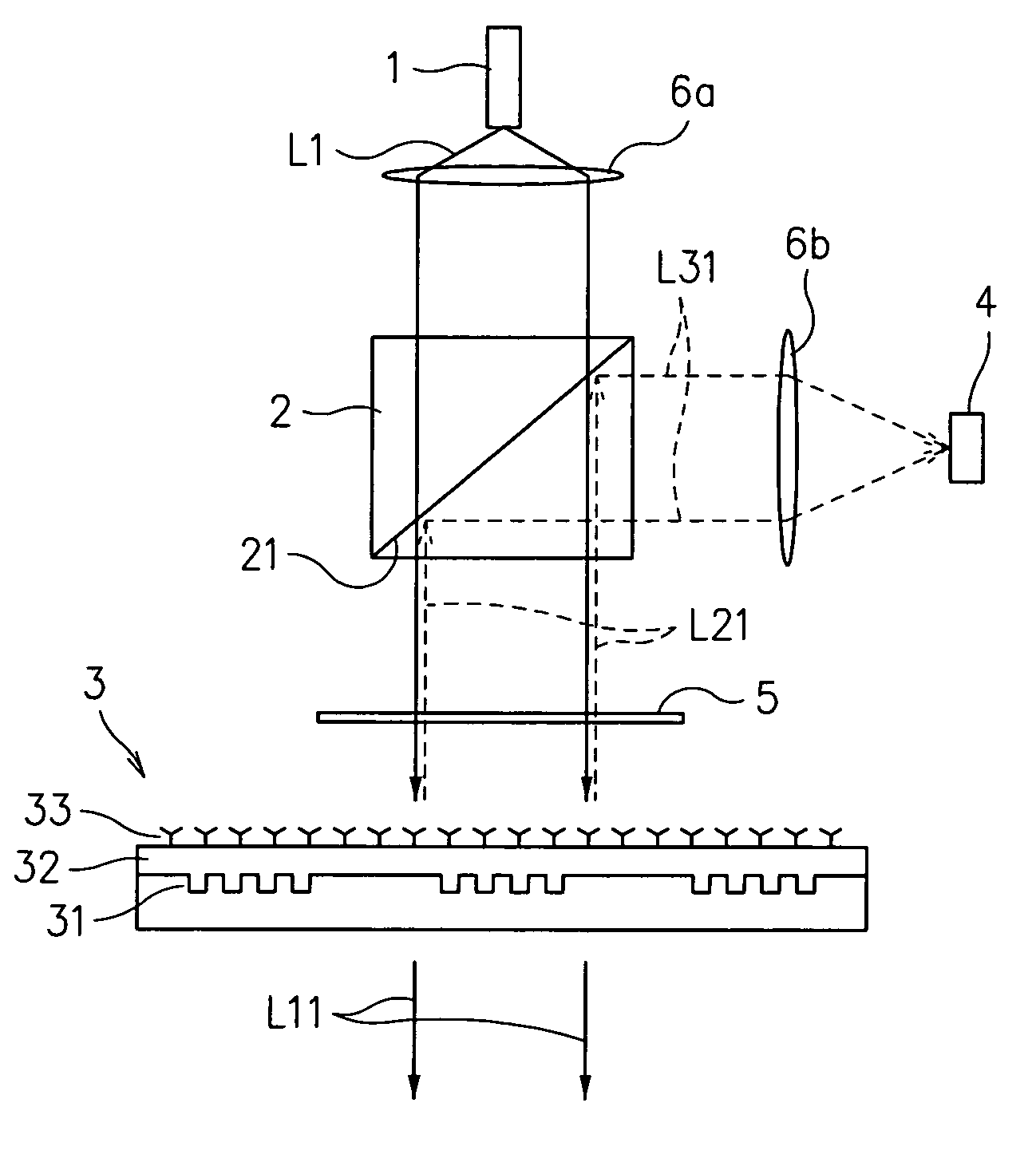

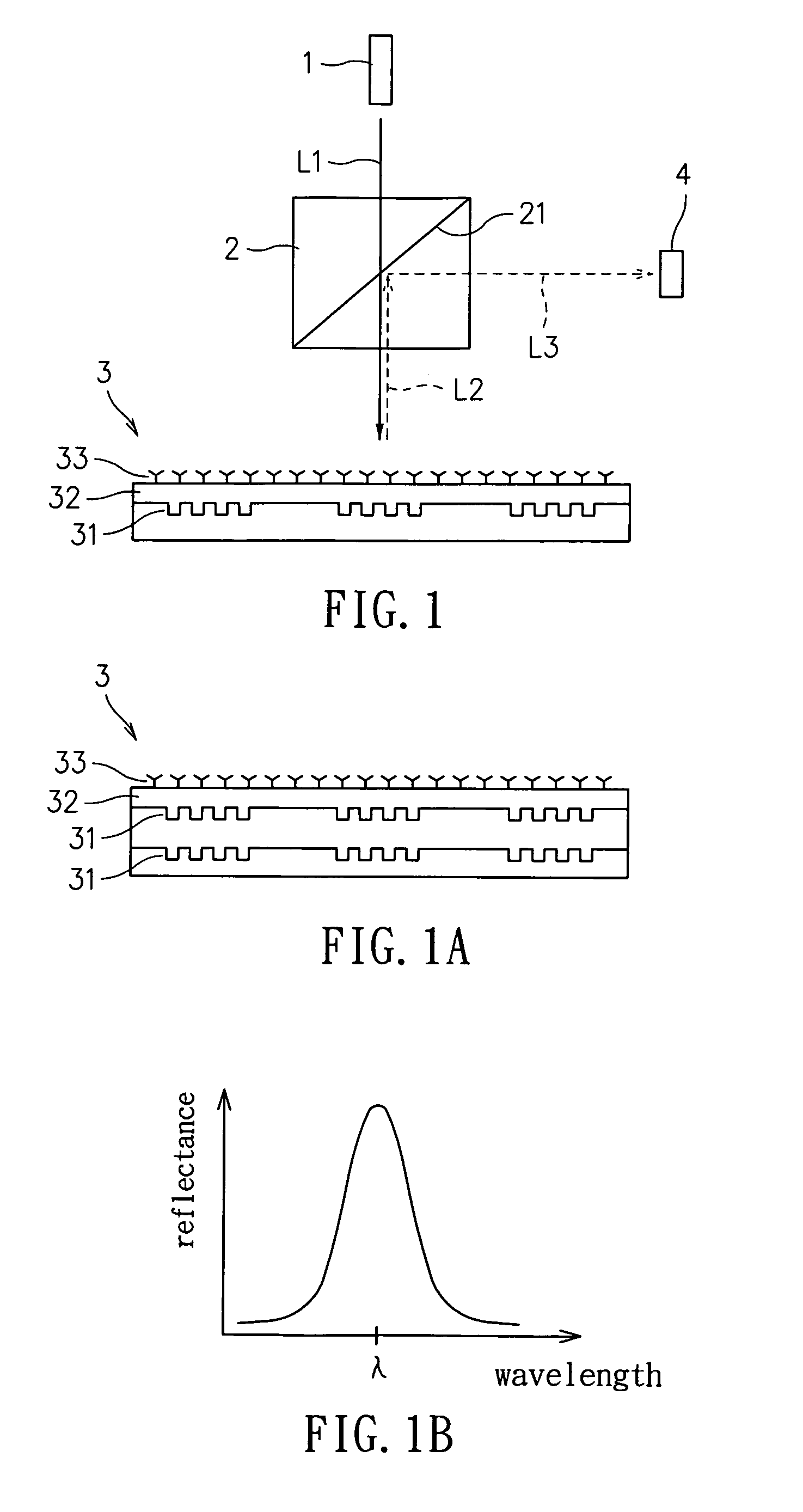

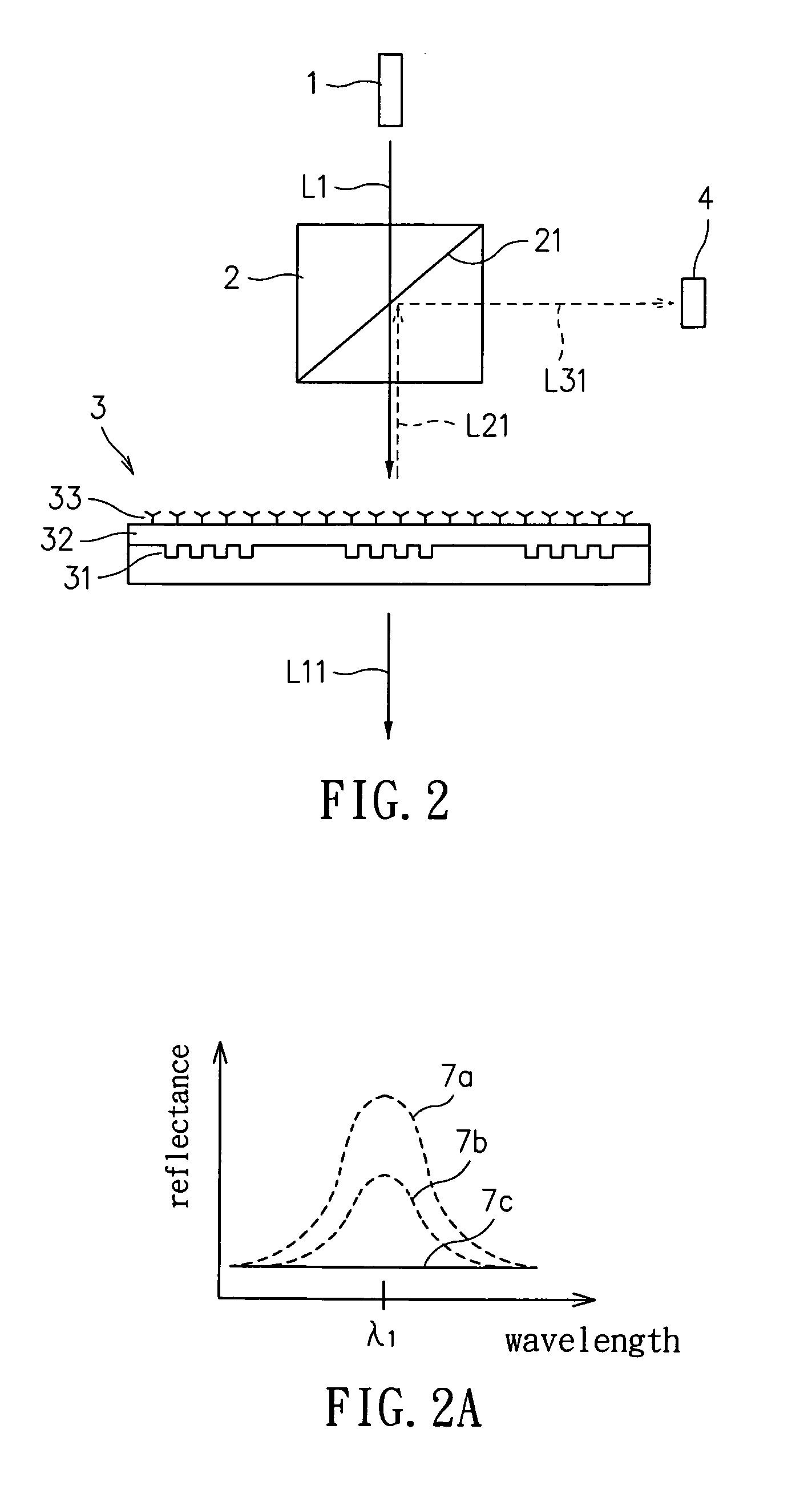

Optical waveguide bio-sensing device

InactiveUS20070147727A1High sensitivity detection techniqueInvention is simpleMaterial analysis by optical meansCoupling light guidesGratingBeam splitter

An optical waveguide bio-sensing device, comprising: a monochromatic light source, a beam splitter, a grating chip with a sub-wavelength grating structure and a sensor. Moreover, in order to enhance the sensitivity of the system using the optical waveguide bio-sensing device, a light concentrating element or a quarter waveplate (¼λ) is arranged in the optical path during detection. When the grating chip is not coated with a layer of biochemical substance corresponding to a monochrome light emitted from the monochromatic light source, a reflected light of a specific narrow wavelength is reflected by a specific angle as a surface plasmon resonant effect caused by waveguide coupling is excited by the incidence of the monochrome light to the grating chip through the beam splitter; otherwise, there will be little or no reflection. Accordingly, the optical waveguide bio-sensing device can detect bio-molecular interactions, reaction rate and / or molecular dynamics without any labeling in real time. Optical systems using the present invention are simplified and capable of being portable. Thus a high sensitivity detection technique is achieved.

Owner:IND TECH RES INST

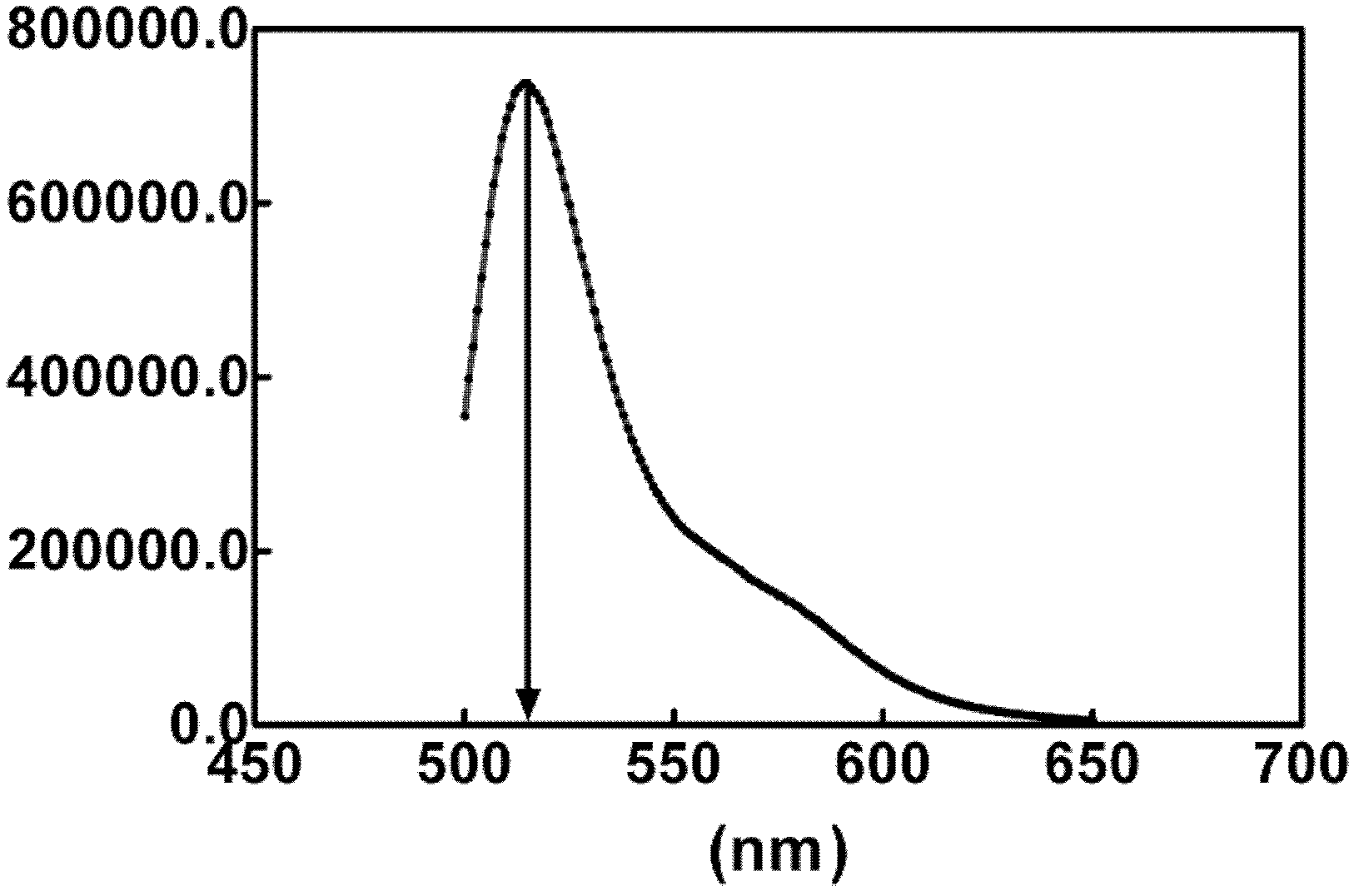

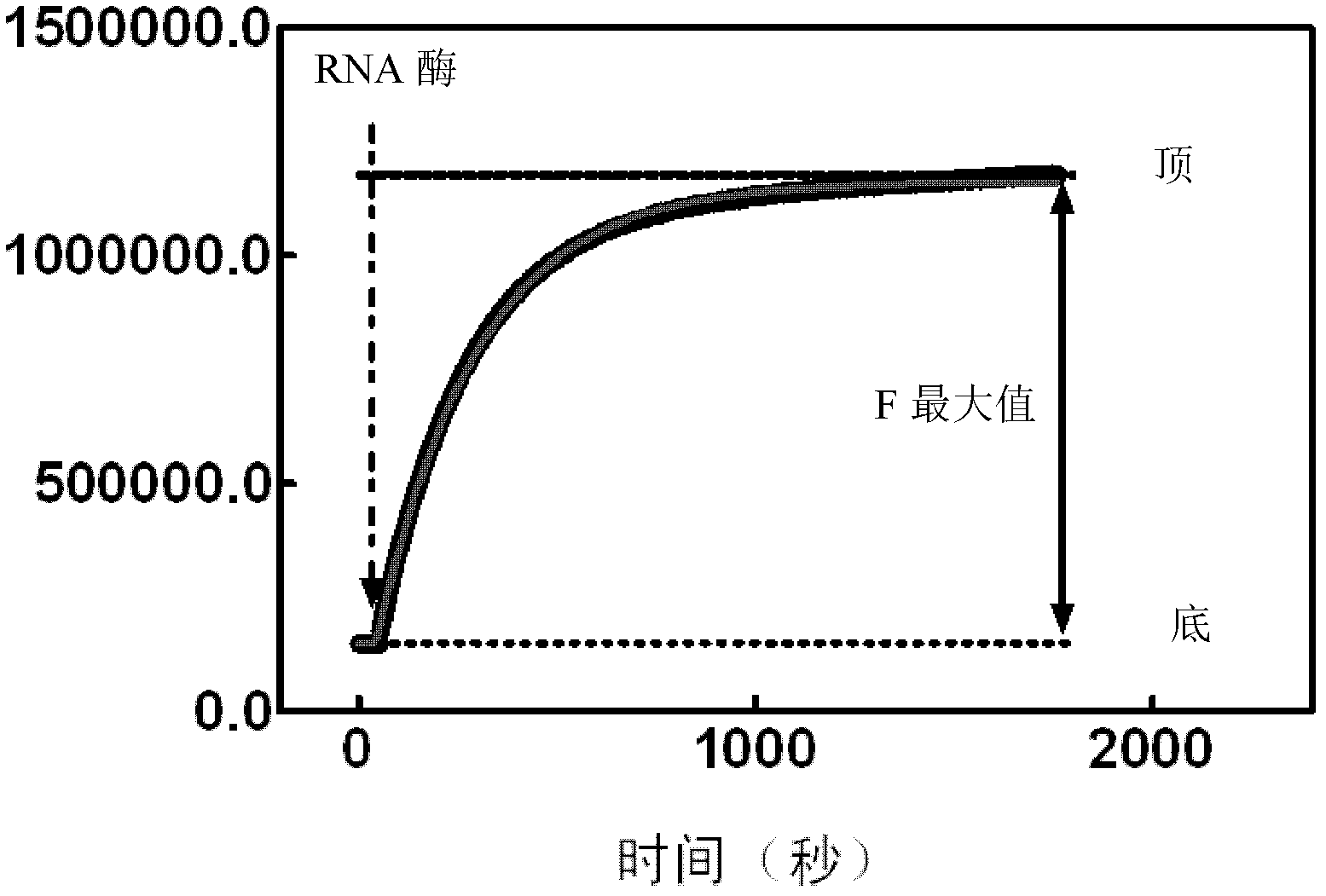

Double-stranded nucleic acid and application thereof, and ribonuclease detection method

InactiveCN103013987ASimple and efficient operationLow detection costMicrobiological testing/measurementDNA/RNA fragmentationDouble strandSubstrate degradation

The present invention provides a double-stranded nucleic acid, a ribonuclease detection method, and applications of the double-stranded nucleic acid and the ribonuclease detection method in ribonuclease detection. Specifically the double-stranded nucleic acid substrate contains at least one ribonuclease-sensitive site, wherein double-stranded nucleic acid substrate degradation by the ribonuclease is analyzed to detect activity and content of the ribonuclease in a sample. The present invention further provides applications of the double-stranded nucleic acid substrate and the detection method in sample ribonuclease detection.

Owner:SUZHOU RIBO LIFE SCIENCE CO LTD

Optical waveguide bio-sensing device

InactiveUS7636502B2Invention is simpleDetection Technology ImprovementMaterial analysis by optical meansCoupling light guidesBeam splitterGrating

Owner:IND TECH RES INST

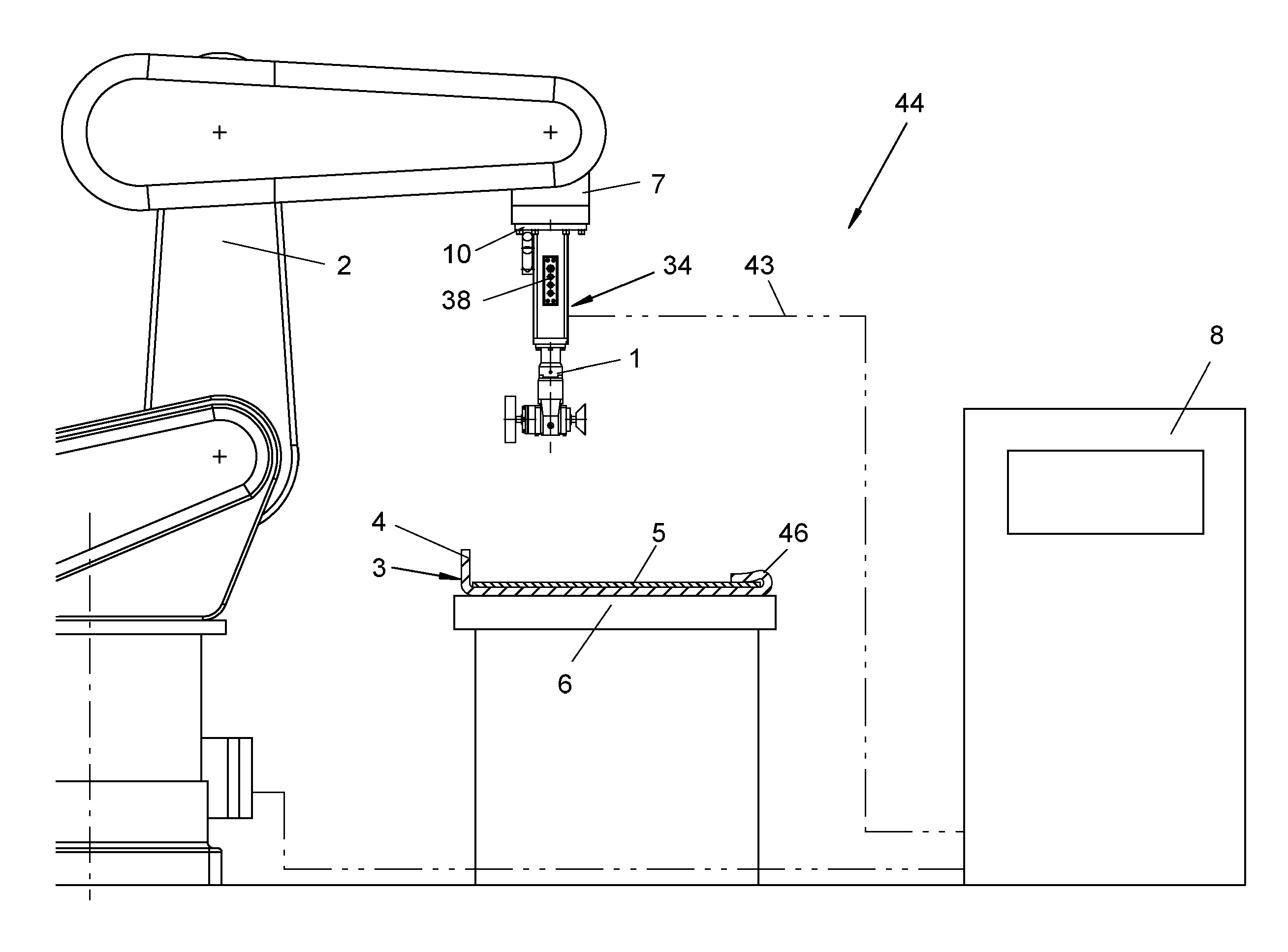

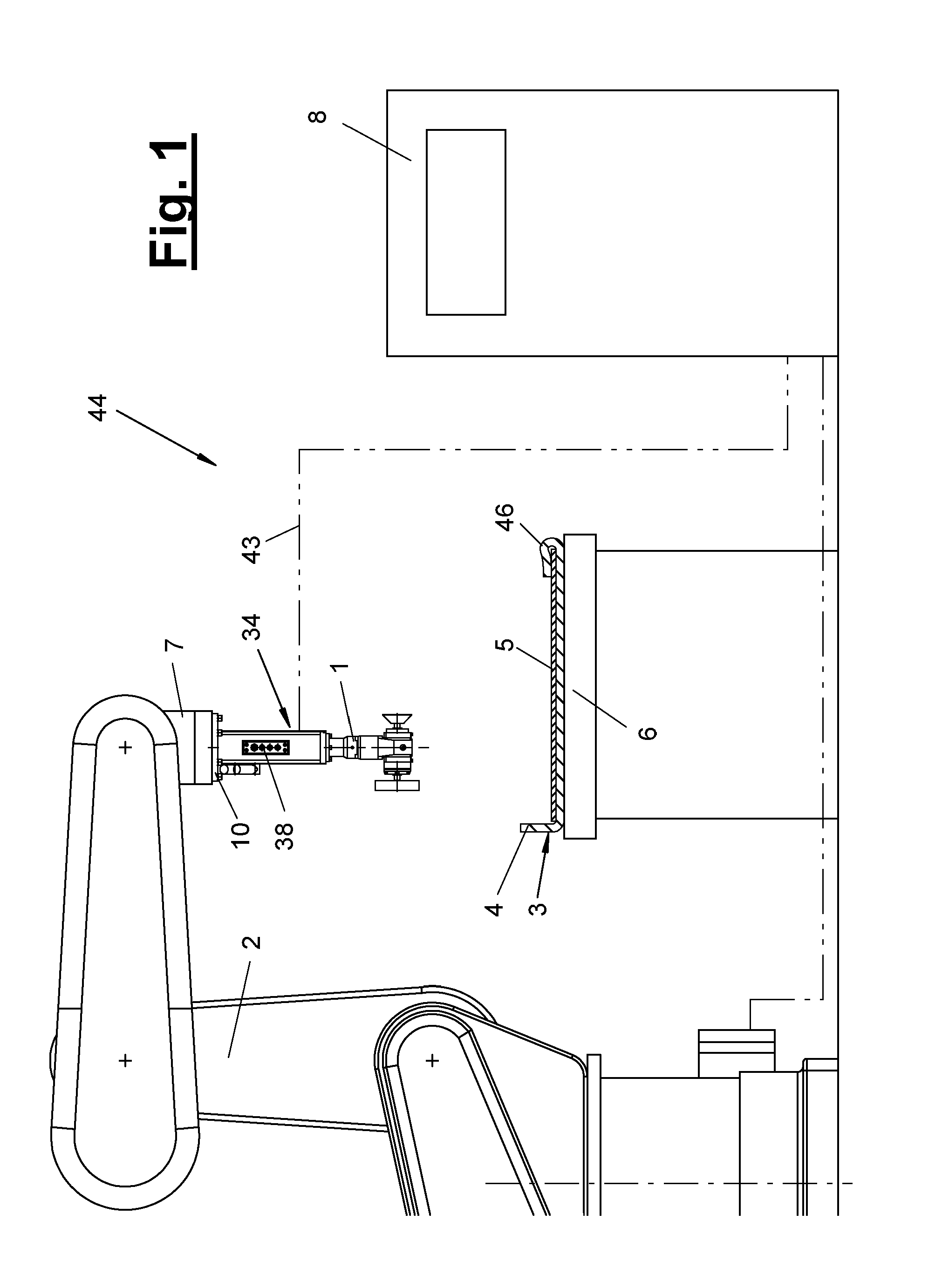

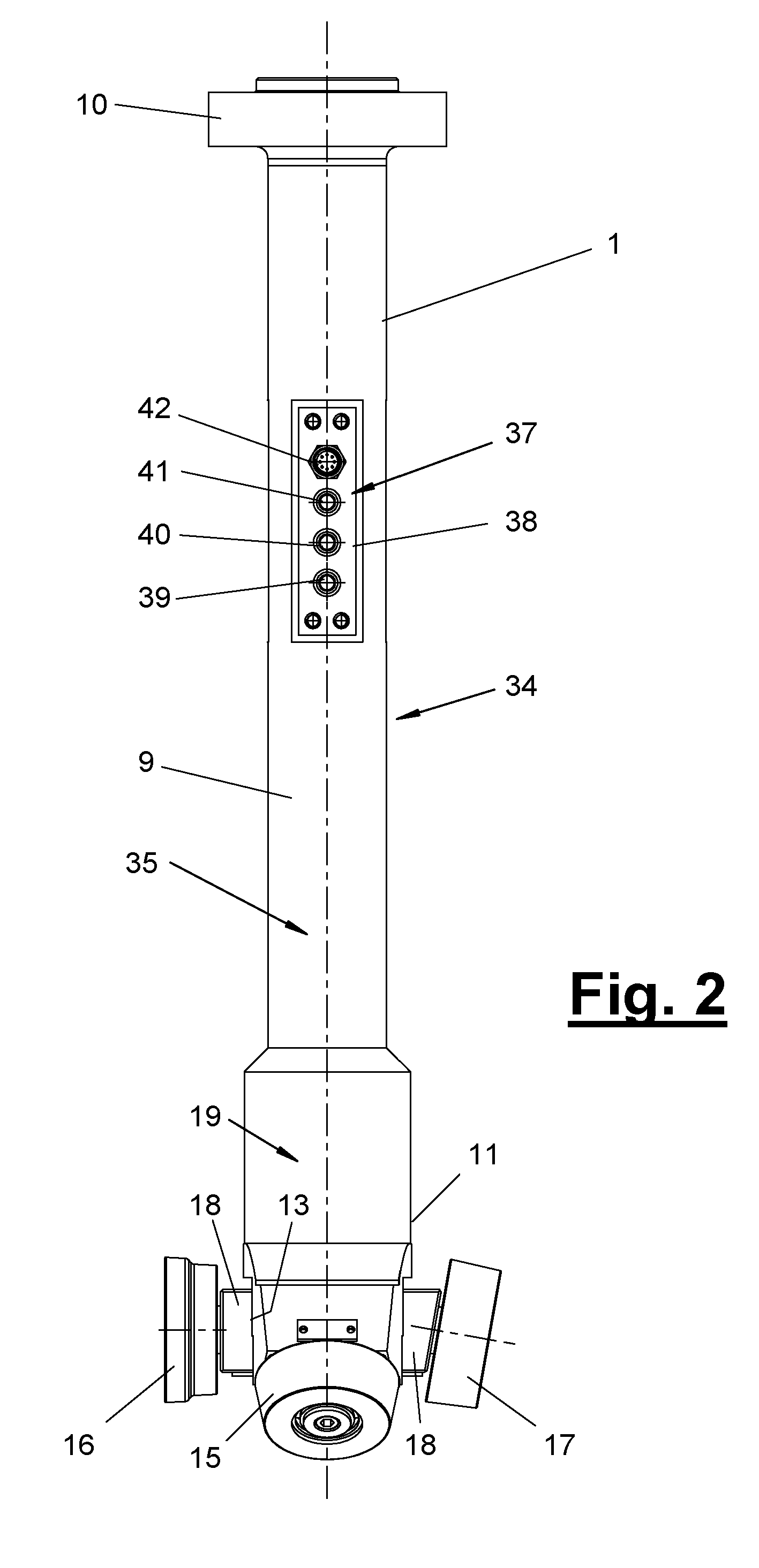

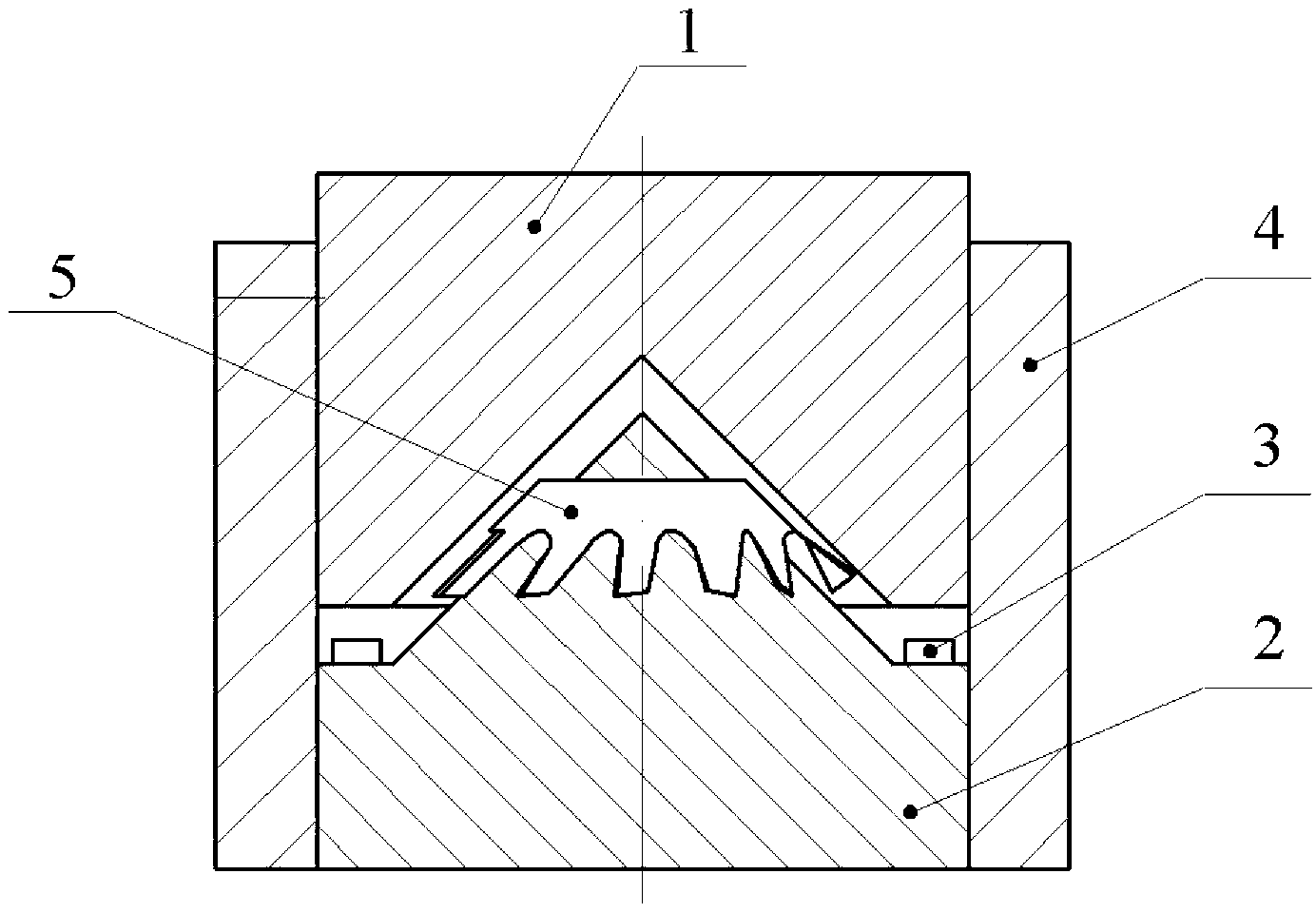

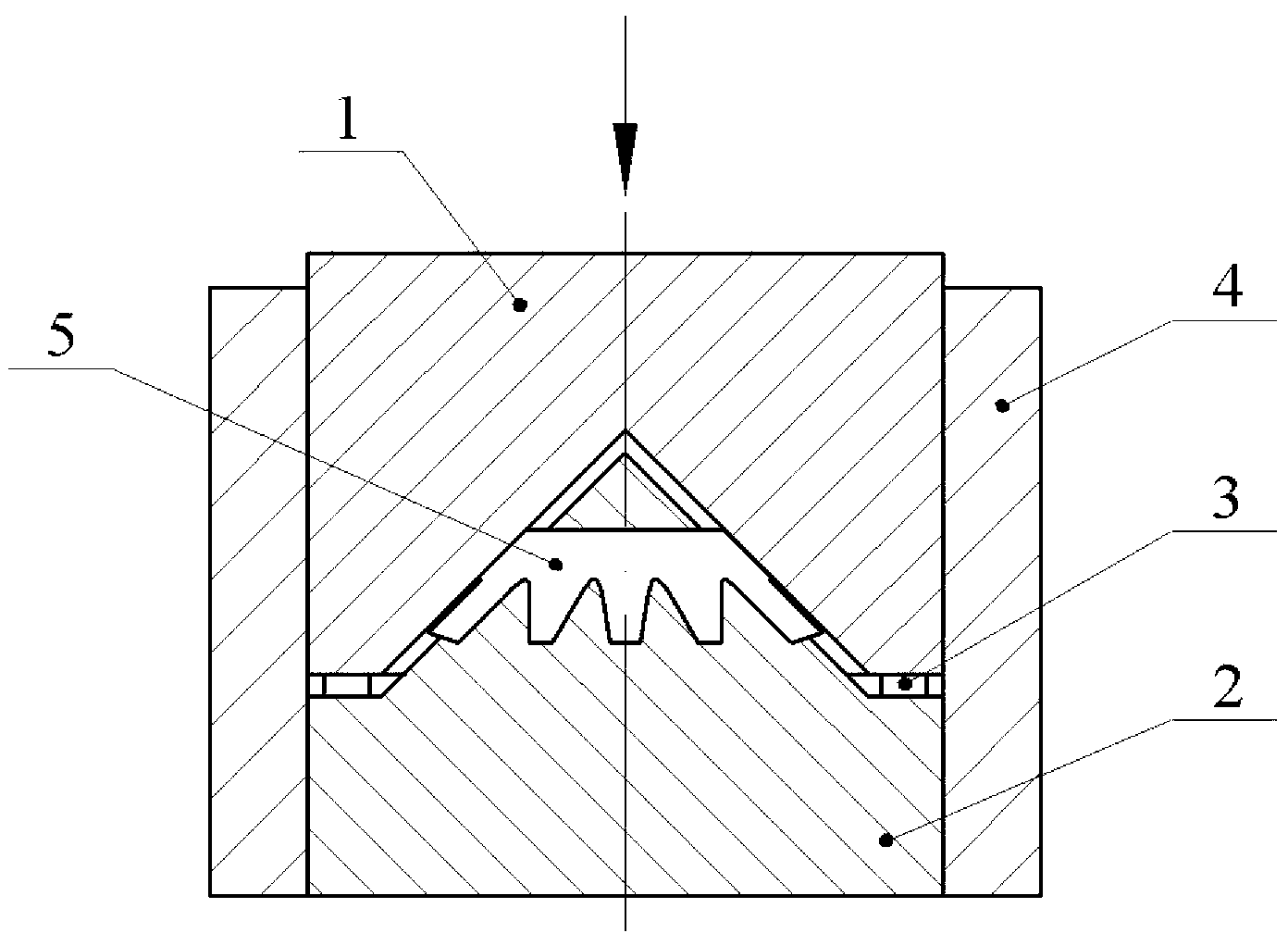

Folding device and folding method

ActiveUS20130312473A1Detection Technology ImprovementImprove abilitiesGripping headsShaping safety devicesEngineeringManipulator

A manipulator-guided folding (hemming) tool (1) includes a frame (9) having a preferably roller-shaped folding element (15, 16, 17, 17′) and a connection (10) for connecting to a manipulator (2), and a detecting device (34) for the loads that occur during folding. The detecting device (34) has an indicator (38) for the loads, which indicator is arranged on the folding tool (1). The indicator is preferably designed as an optical indicator and is arranged in a tool area that is visible during folding.

Owner:KUKA SYSTEMS

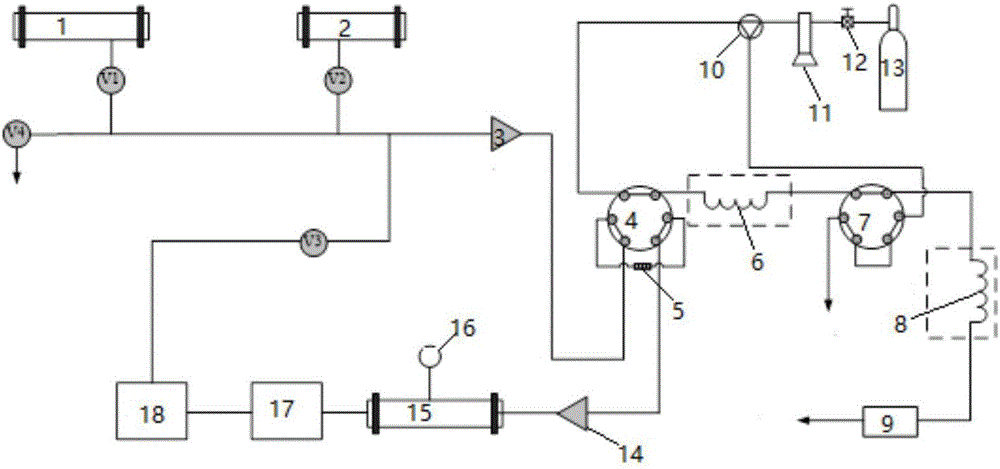

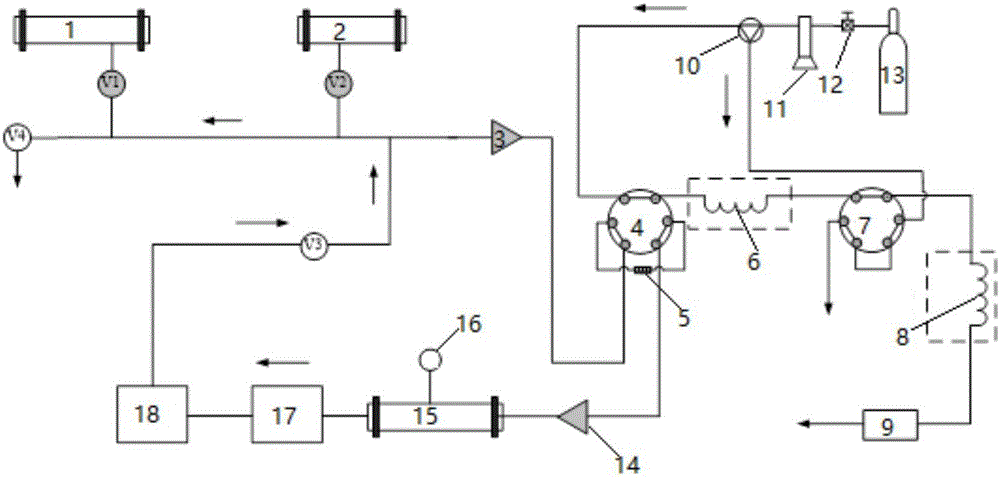

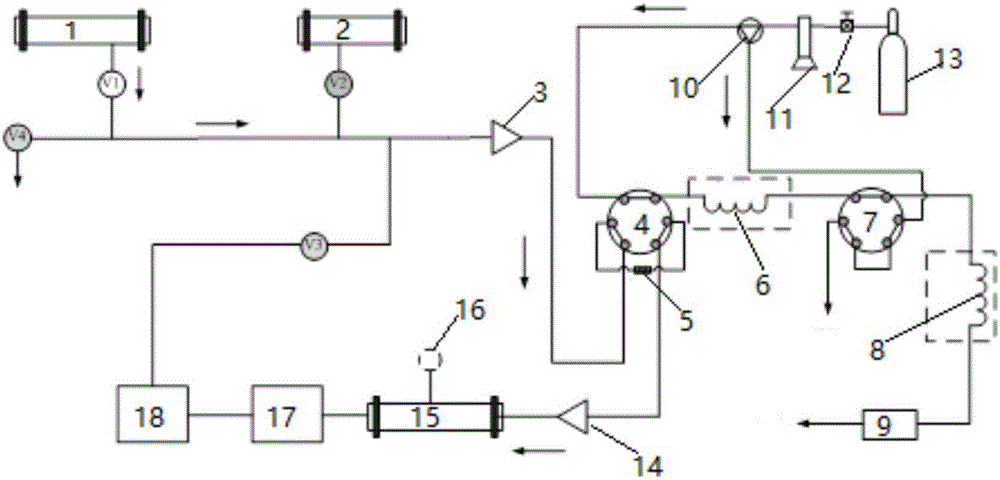

Refilling type sulfur hexafluoride decomposition product chromatography online detector

ActiveCN106370764ADetection Technology ImprovementLow detection limitComponent separationSulfur hexafluorideDecomposition

The embodiment of the invention discloses a refilling type sulfur hexafluoride decomposition product chromatography online detector. The refilling type chromatography detector is used for single-hole sulfur hexafluoride electrical equipment, achieves automatic online detection and analysis of insulating gas of the sulfur hexafluoride electrical equipment in the modes of vacuumizing, sample collection, sample analysis and sample refilling, has multiple detection components and high detection precision and can achieve automatic sampling, detection and refilling of sampling gas of the sulfur hexafluoride electrical equipment, so that harm caused by gas emission to personnel and environment is avoided, the insulativity of the electrical equipment cannot be affected by gas refilling, and the online detection frequency and timeliness of sulfur hexafluoride are greatly improved.

Owner:GUANGDONG POWER GRID CO LTD +1

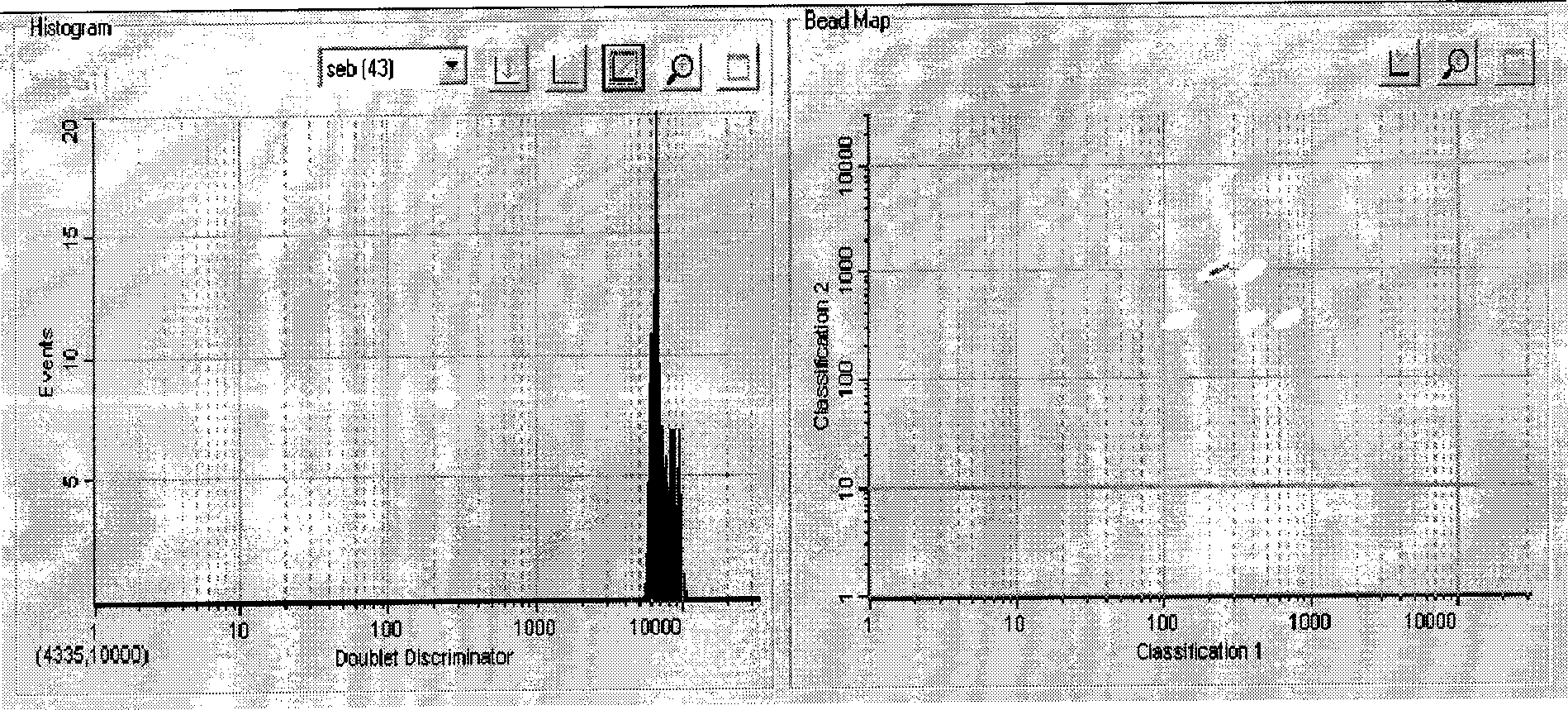

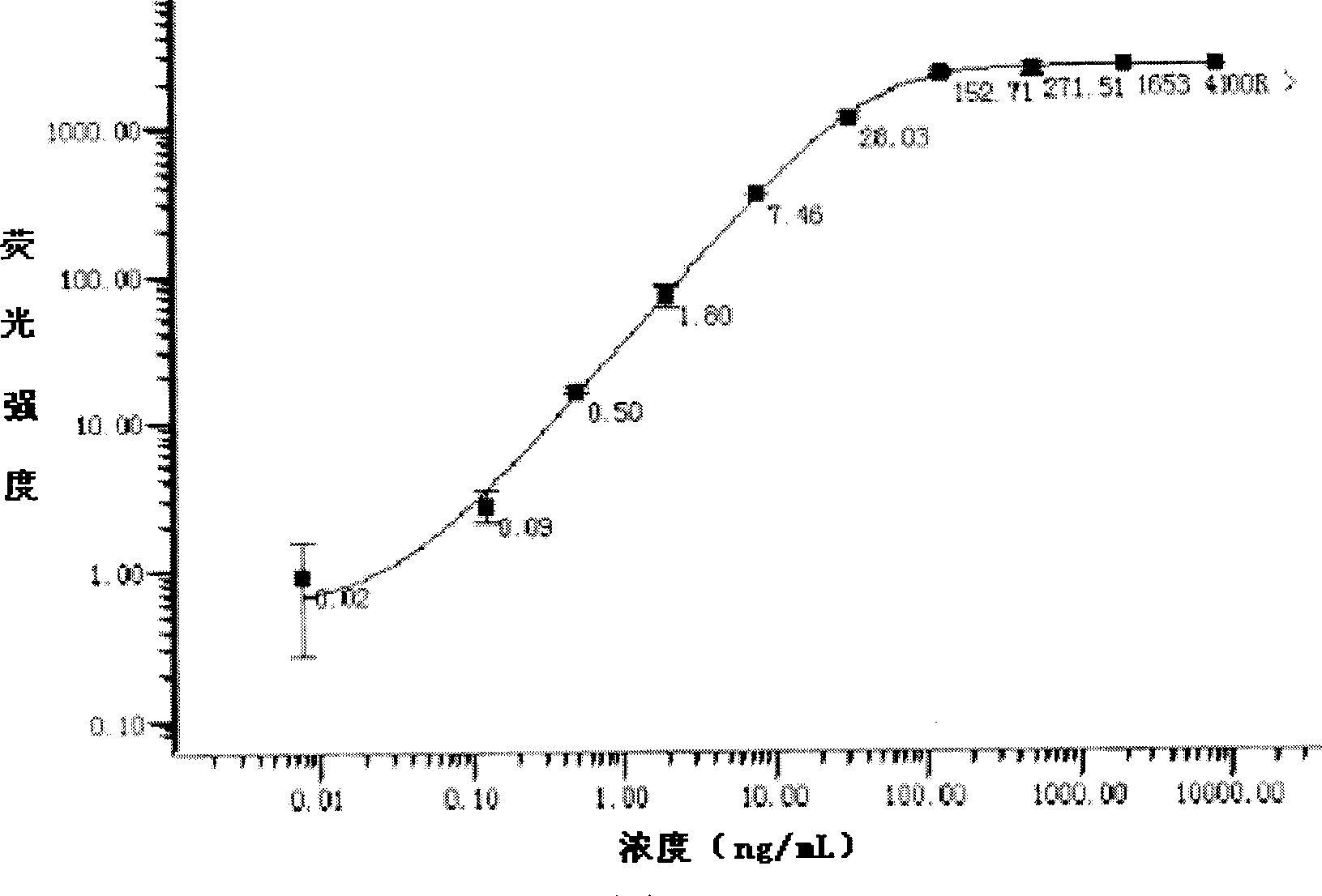

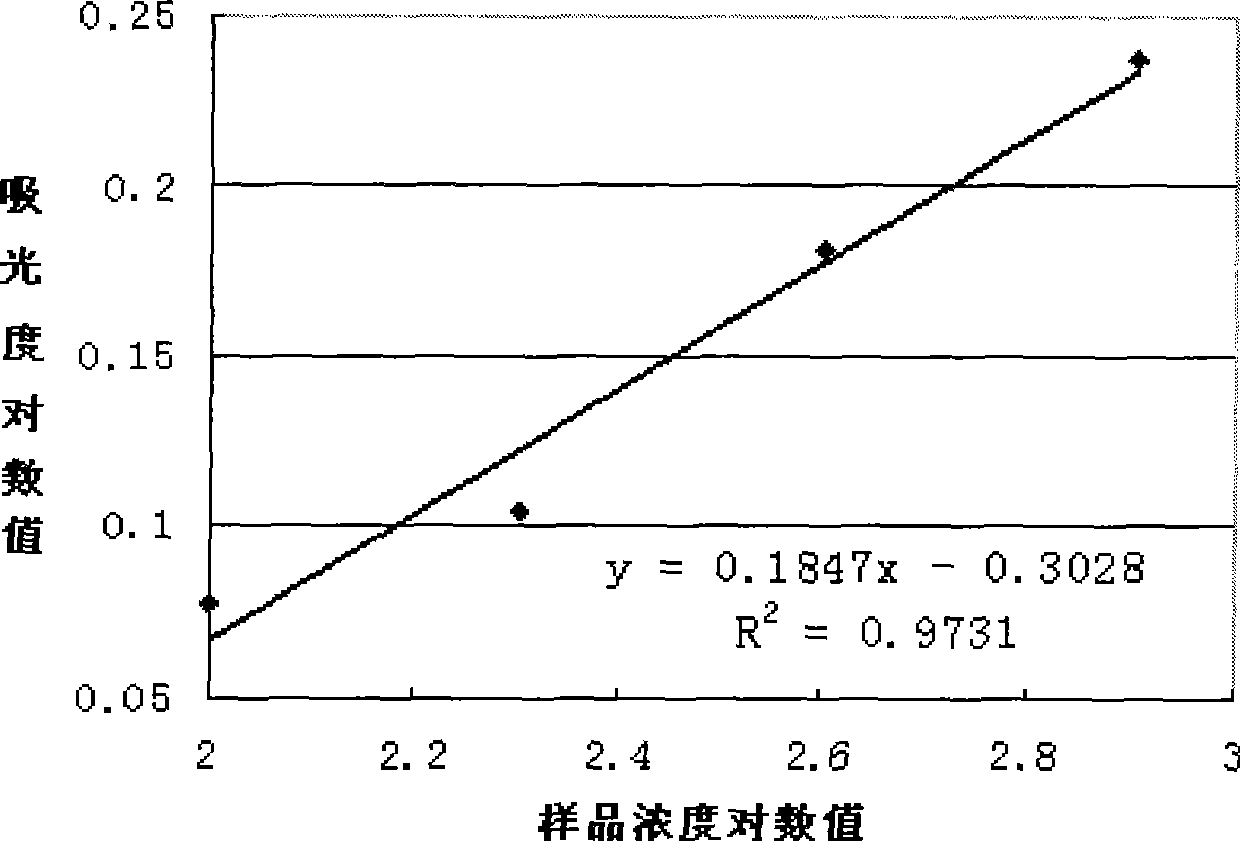

Protein suspending chip for quantitative detection of staphylococcal enterotoxin B and method for producing the same

InactiveCN101498720ACoating volume improvementQuick checkMaterial analysis by observing effect on chemical indicatorProtein insertionBacterium L

The invention aims to provide a protein suspension chip capable of quantificationally detecting bacterial toxin and the preparation method thereof, and particularly relates to a protein suspension chip which is suitable for quantificationally detecting and analyzing staphylococcal enterotoxin. The method has high sensitivity and high particularity, good detection capacity and wide dynamic range and builds a novel detection modularity platform.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

Kit for detecting HER2 different sites, ER, and PR of circulating tumor cells and application thereof

InactiveCN109239030AGood choiceAccurately reflectBiological material analysisFluorescence/phosphorescenceProtein targetLeukocyte Common Antigens

The invention relates to a kit for detecting HER2 different sites, ER, and PR of circulating tumor cells and an application thereof. The detection principle of the method of the invention is as follows: firstly, enriching circulating tumor cells and other rare cells, and then detecting expression of a target protein in cells in the enriched cells by an immunofluorescence detection method, according to the principle of antigen-antibody reaction. The kit is capable of fluorescently labeling target cells and leukocyte common antigen CD45, and screening target protein-positive and CD45-negative cells, thereby interpreting and counting specific protein-positive circulating tumor cells in the blood.

Owner:北京莱尔生物医药科技有限公司

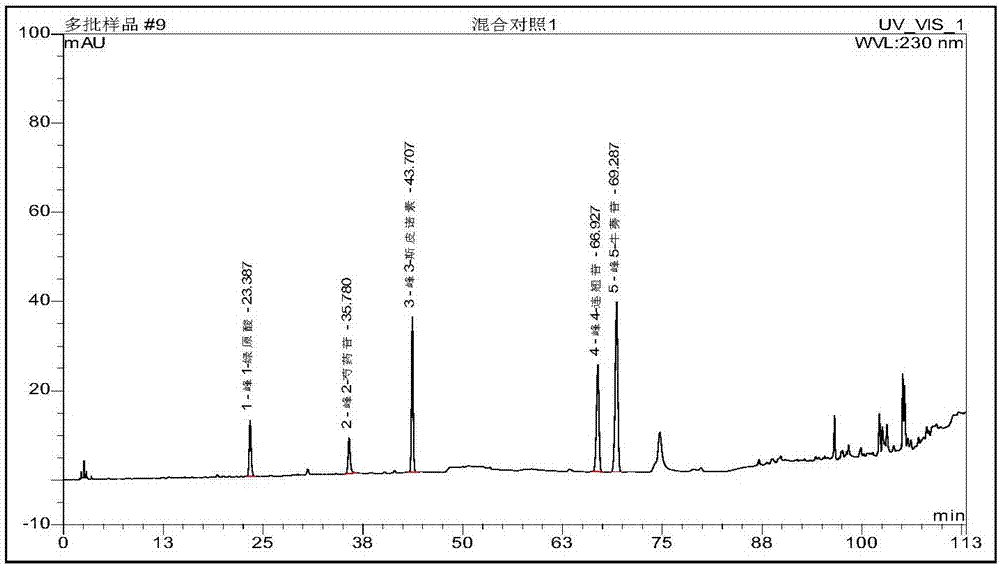

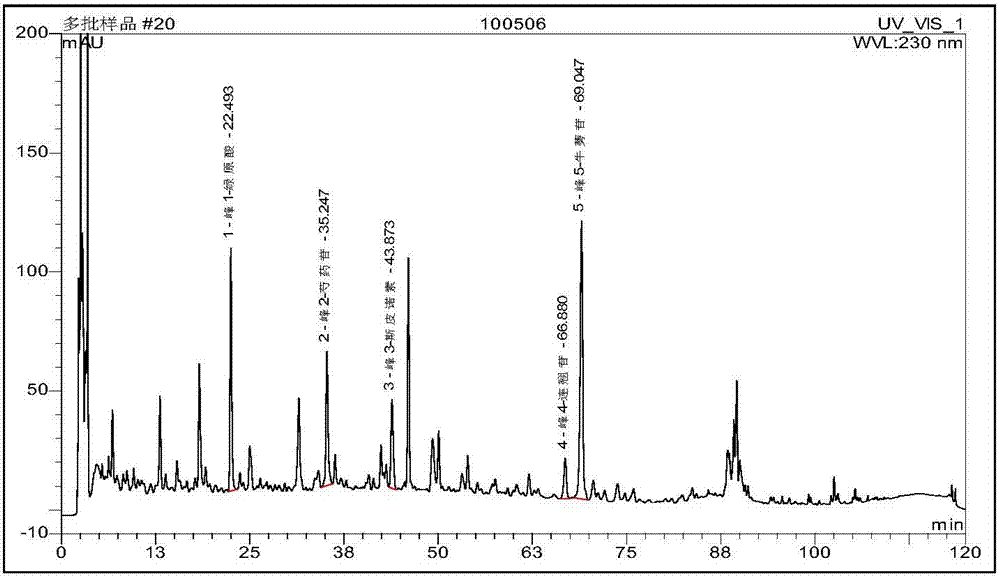

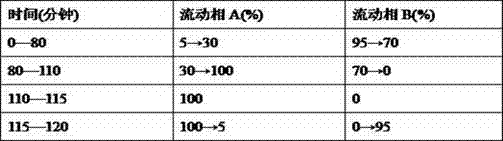

Detection method of traditional Chinese medicine composition capable of invigorating brain and tonifying kidney

InactiveCN108008023ADetection Technology ImprovementEfficient detectionComponent separationChlorogenic acidMedicine

The invention discloses a detection method of a traditional Chinese medicine composition capable of invigorating brain and tonifying kidney, and belongs to the technical field of traditional Chinese medicine quality detection. According to the detection method, high performance liquid chromatography is adopted, under the same chromatographic conditions, paeoniflorin is taken as a reference, and characteristic qualitative analysis on chlorogenic acid, spinosin, forsythin, and arctiin in samples is carried out. The detection method is simple and rapid, and is high in sensitivity and stability; acomposition characteristic spectrum is obtained; and comprehensive detection of all contents of the composition is realized.

Owner:王荔强

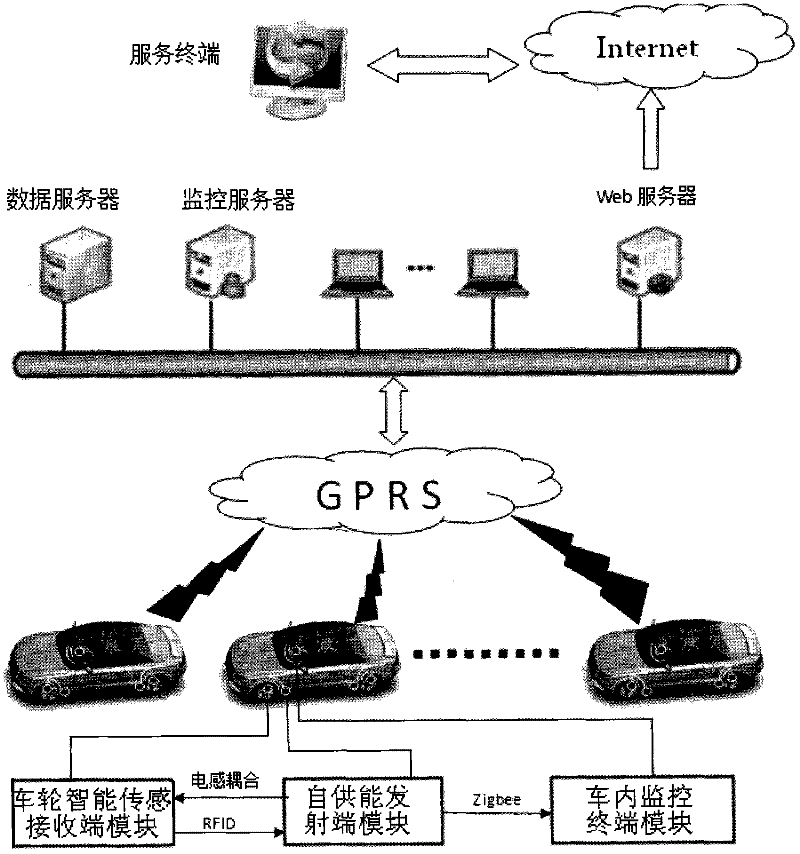

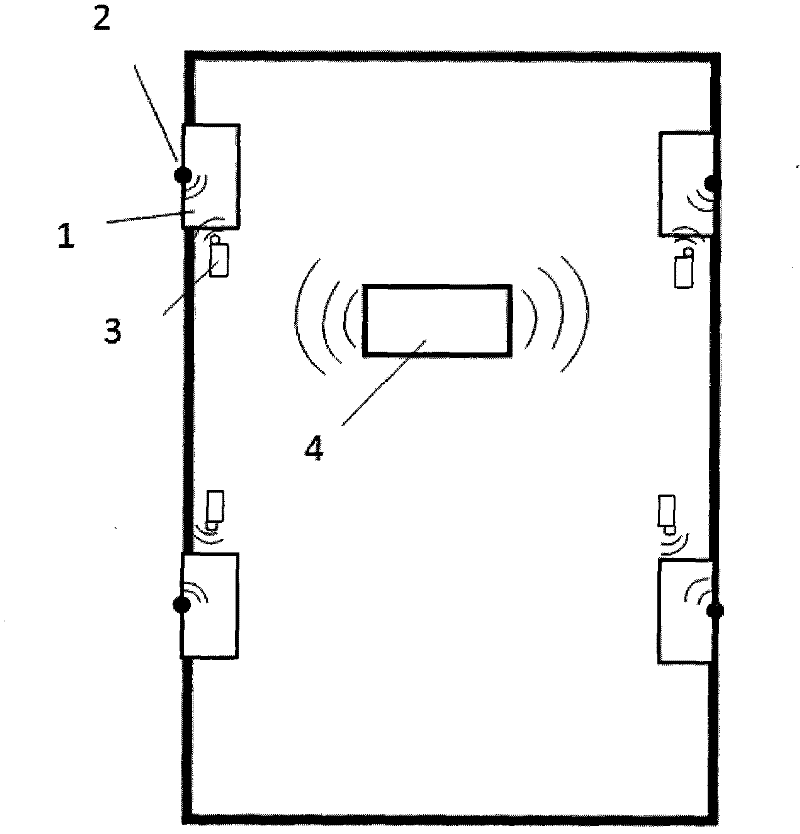

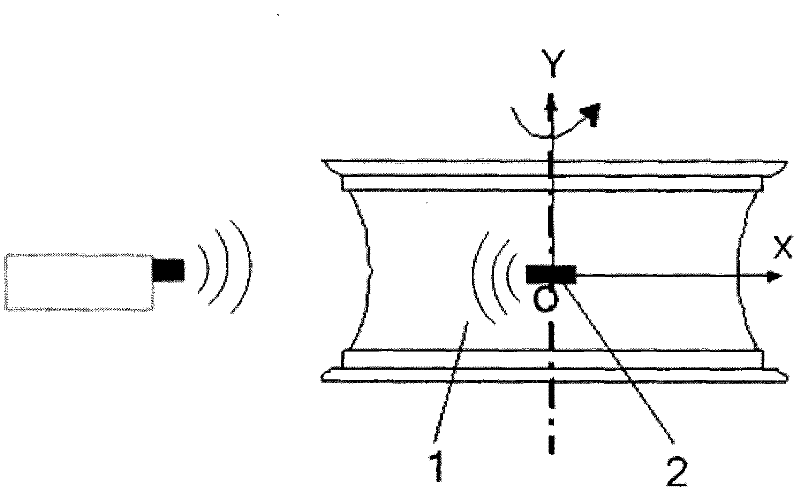

Wheel load sensing system and wheel load sensing method of vehicle network interconnection based on RFID (Radio Frequency Identification Device) self energy supply

InactiveCN102407742ADetection Technology ImprovementLow-level detection technology improvementTyre measurementsRecord carriers used with machinesCapacitanceSensing system

The invention discloses a wheel load sensing system and a wheel load sensing method of vehicle network interconnection based on RFID (Radio Frequency Identification Device) self energy supply. The system comprises a car inside monitoring terminal module, a wheel intelligent sensing receiving end module for receiving activated label power signal, acquiring wheel safety related dynamic data and capacitance electric quantity data information, and wirelessly feeding back received data to a self energy supply transmitting end module, and the self energy supply transmitting end module which performs inductance matching and coupling by electromagnetic coil and inductance coil of the wheel intelligent sensing receiving end module to realize wireless power supply, and can read, analyze and judge data transmitted from the wheel intelligent sensing receiving end module. Based on this, the self energy supply transmitting end module transmits detection data to a cab monitoring terminal through Zigbee mode, and overall monitoring mode of vehicle network interconnection is realized based on GPRS finally. The mode of wheel load real-time accurate detection on motor vehicle safety running parameters is perfected and the bottom layer detection technique of the vehicle network interconnection is further improved.

Owner:SOUTH CHINA UNIV OF TECH

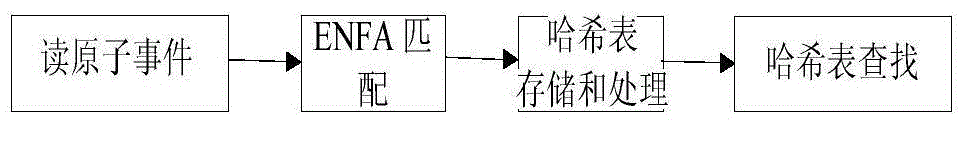

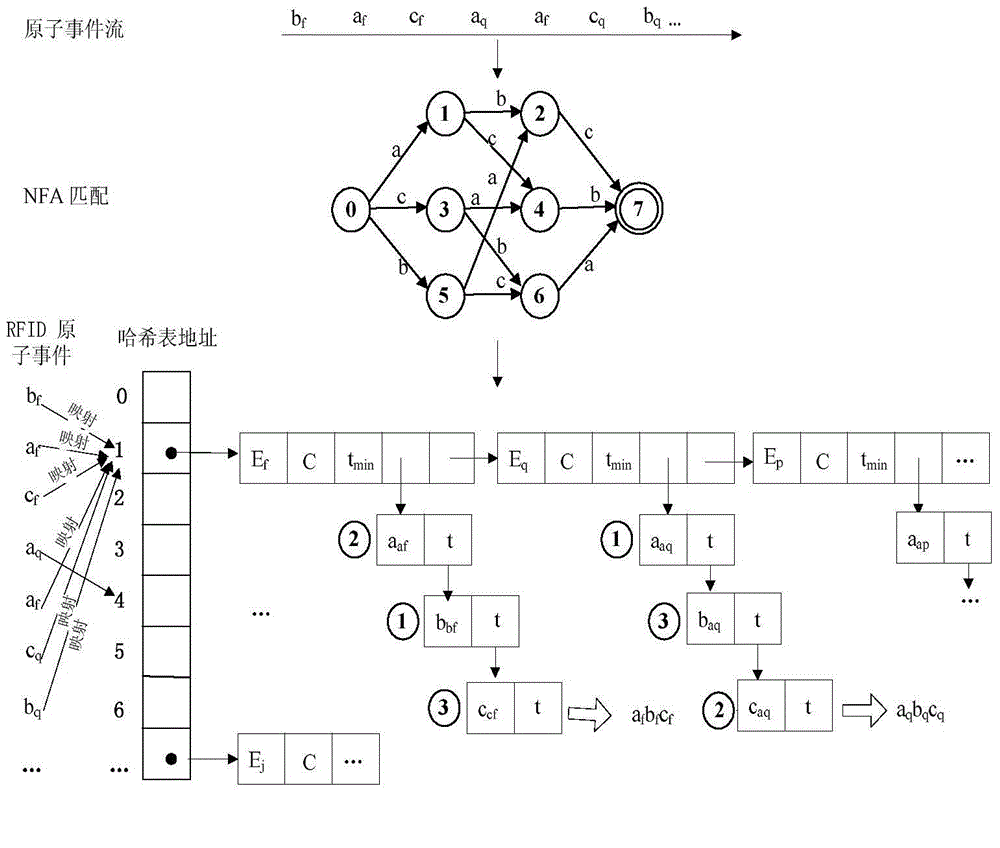

Detection method for complex events in mass disordered data streams of Internet of Things Manufacturing

InactiveCN104408142ADetection Technology ImprovementImprove incident detection capabilitiesSpecial data processing applicationsData streamPattern detection

The invention discloses a detection method for complex events in mass disordered data streams of Internet of Things Manufacturing, and aims at solving the problem of low efficiency on detecting the events in mass disordered data streams in the Internet of Things Manufacturing. The method is characterized in that ENFA (Extended Nondeterministic Finite Automaton) is utilized for selecting events in mass disordered data streams, and the storage relationship of a hash table structure is utilized to handle events in the mass disordered data streams, so as to realize the detection of the complex events in mass disordered data streams. The method has the advantages that the existing automaton-based complex event mode detection method is improved, the existing complex event detection technology is expanded to be able to efficiently detect the complex events in the mass disordered data streams, and therefore, the detection efficiency is raised.

Owner:GUANGDONG UNIV OF TECH

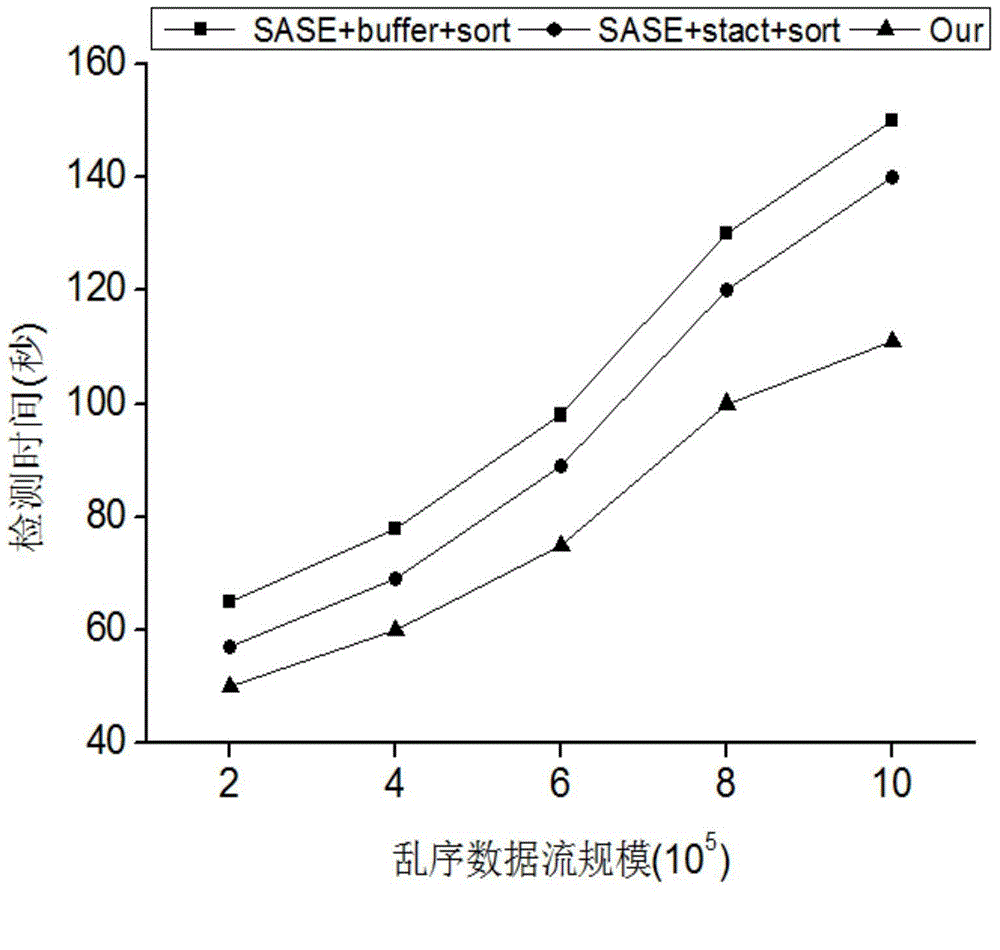

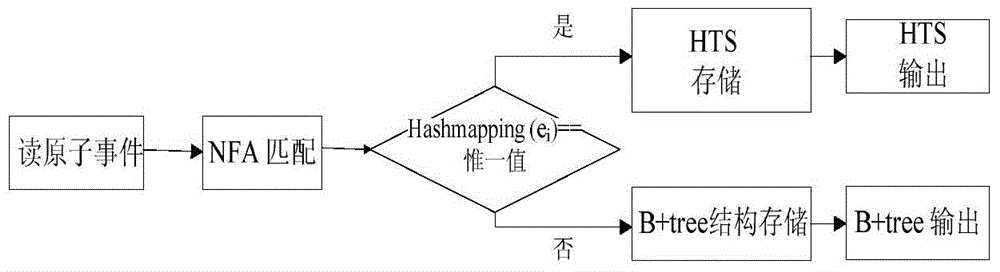

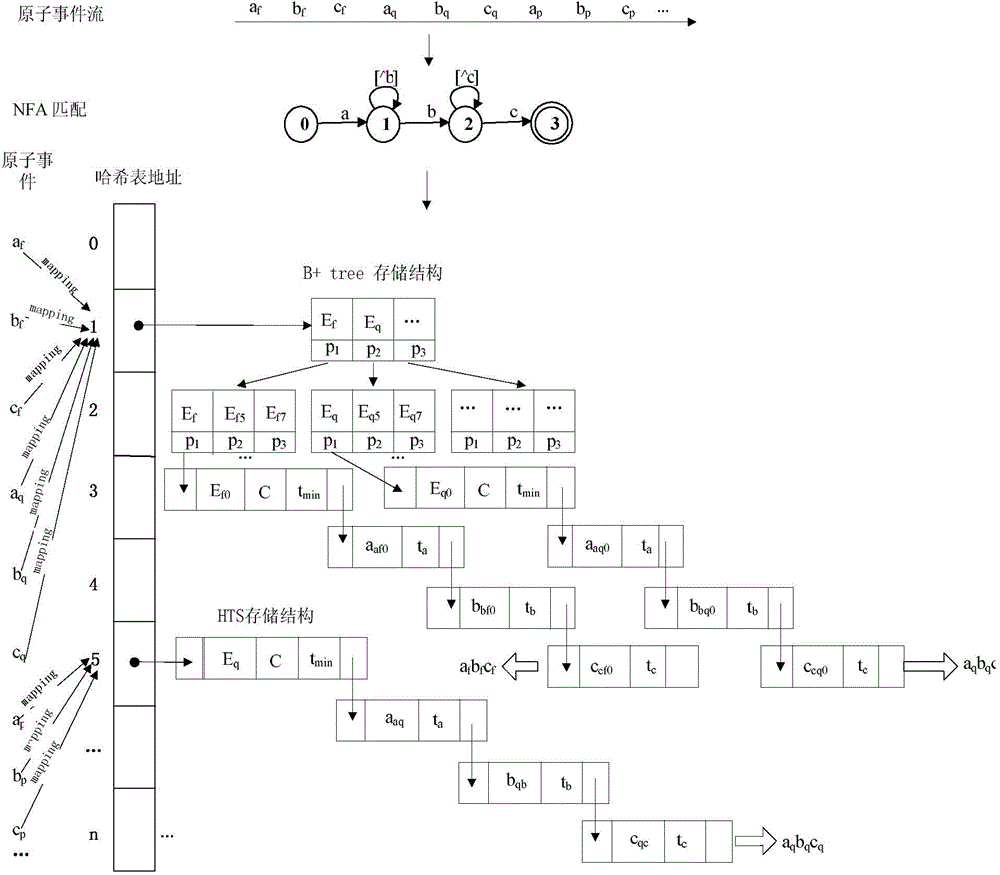

Method for using hash B + tree structure to detect complex events in manufacturing Internet of Things massive data streams

InactiveCN104391950ADetection Technology ImprovementEasy to detectSpecial data processing applicationsData streamPattern detection

The invention discloses a method using a hash B + tree structure to detect complex events in manufacturing Internet of Things massive data streams and aims to the solve the problems that current methods for detecting the complex events in the manufacturing Internet of Things massive data streams are long in detecting time, slow in response, low in detecting efficiency, and the like. The method has the advantages that an nondeterministic finite automata (NFA) is used in combination with the hash table B + tree technology to detect the complex events, the detecting capability of the complex events in the manufacturing Internet of Things massive data streams is increased greatly, current complex event mode detecting methods based on the NFA are improved, existing complex event detecting technologies are expanded, and detecting of the complex events in the manufacturing Internet of Things massive data streams can be completed efficiently.

Owner:GUANGDONG UNIV OF TECH

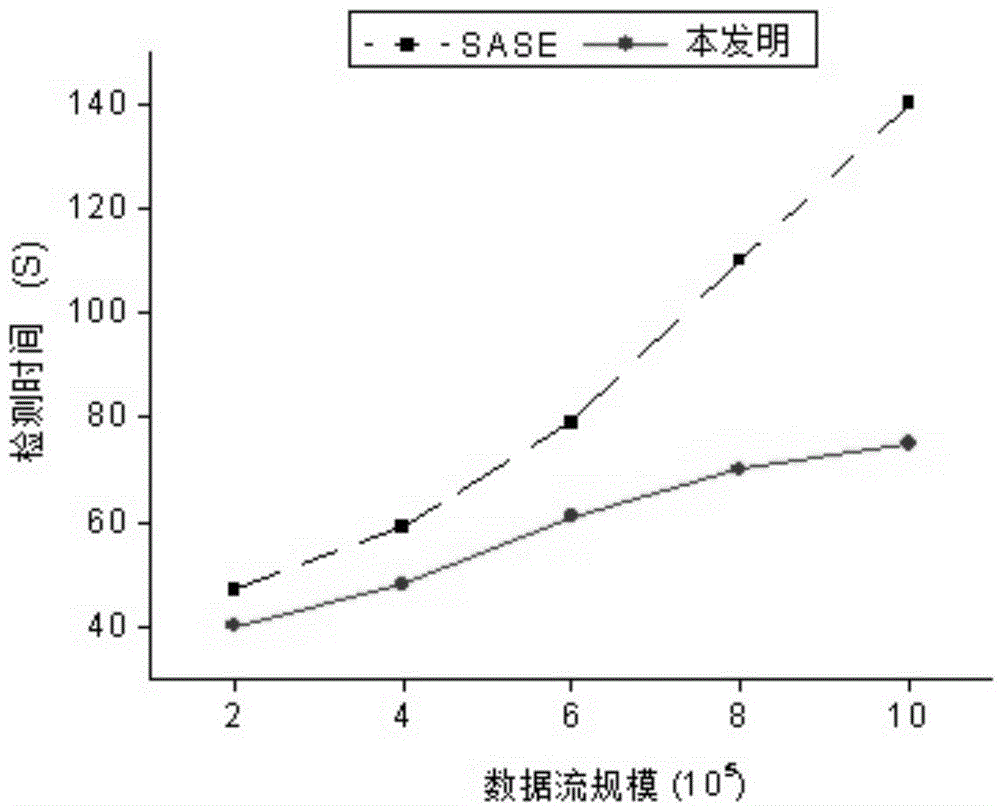

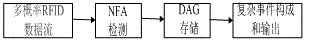

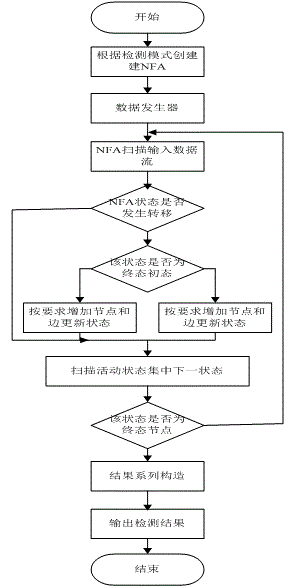

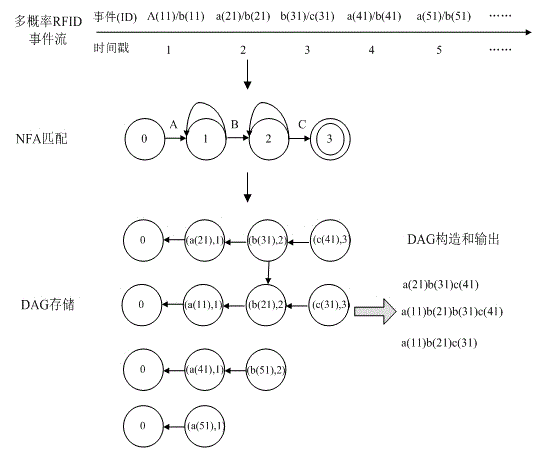

Method for detecting complex events on multi-probability RFID event flows

InactiveCN104700055AEasy to detectDetection Technology ImprovementSensing record carriersAutomatonData mining

The invention discloses a method for detecting complex events on multi-probability RFID event flows. The method aims at solving the problem that an existing commonly-used Naive method is long in detection time, large in memory expenditure and low in detection efficiency when being used for detecting the complex events on the probability RFID event flows, uses NFA (Nondeterministic Finite Automation) and DAG (Directed Acyclic Graph) to detect complex events on the probability RFID event flows and can greatly solve the problems existing in the Naive method. A current automaton based complex event detection mode is improved, an existing complex event detection technology is expanded, detection of the complex events on the probability event flows can be completed by means of the method, and the capacity of detecting the events on uncertain event flows is improved.

Owner:GUANGDONG UNIV OF TECH

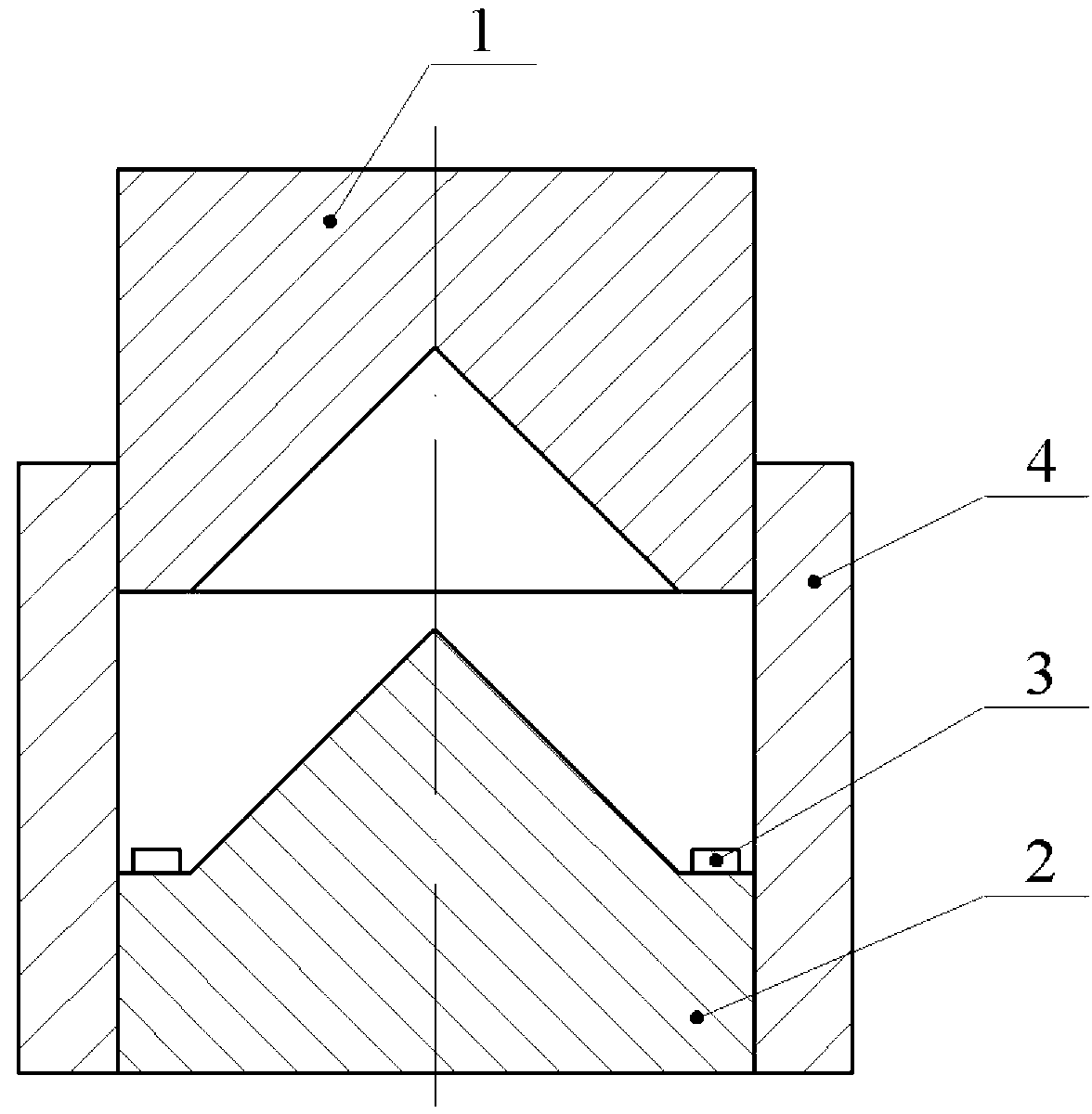

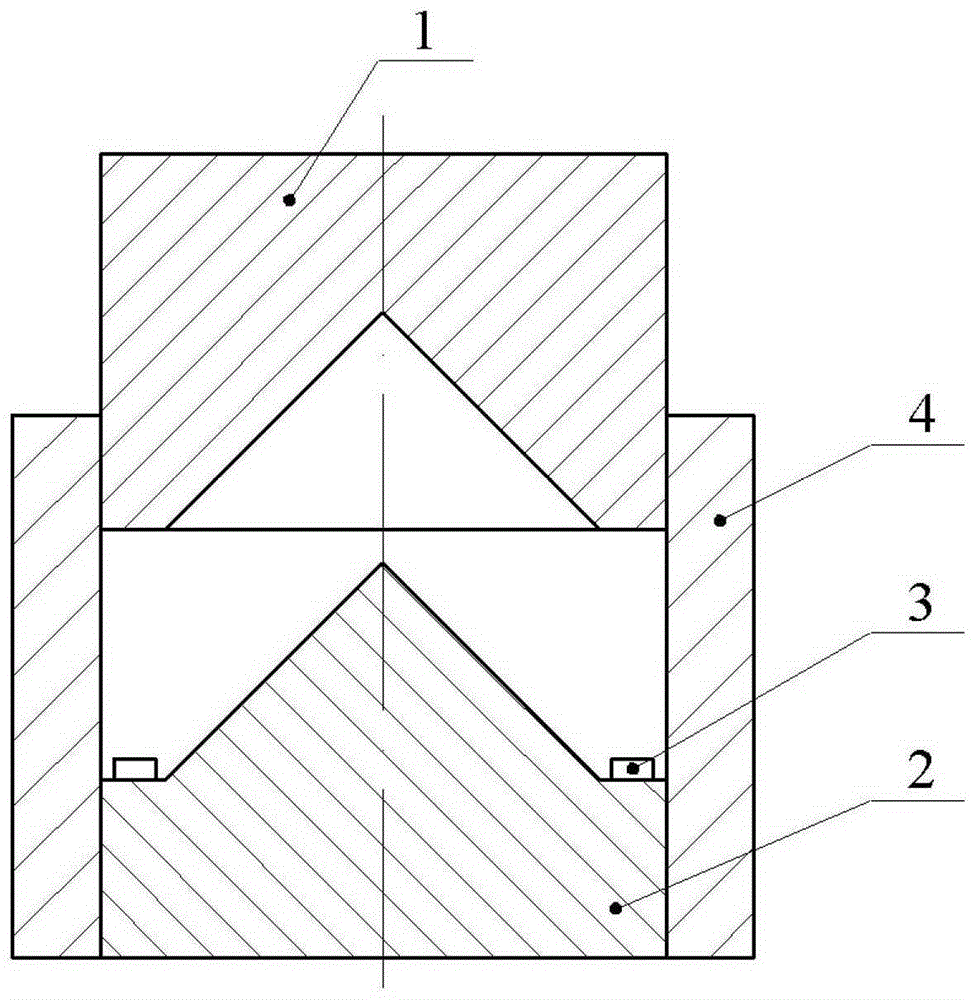

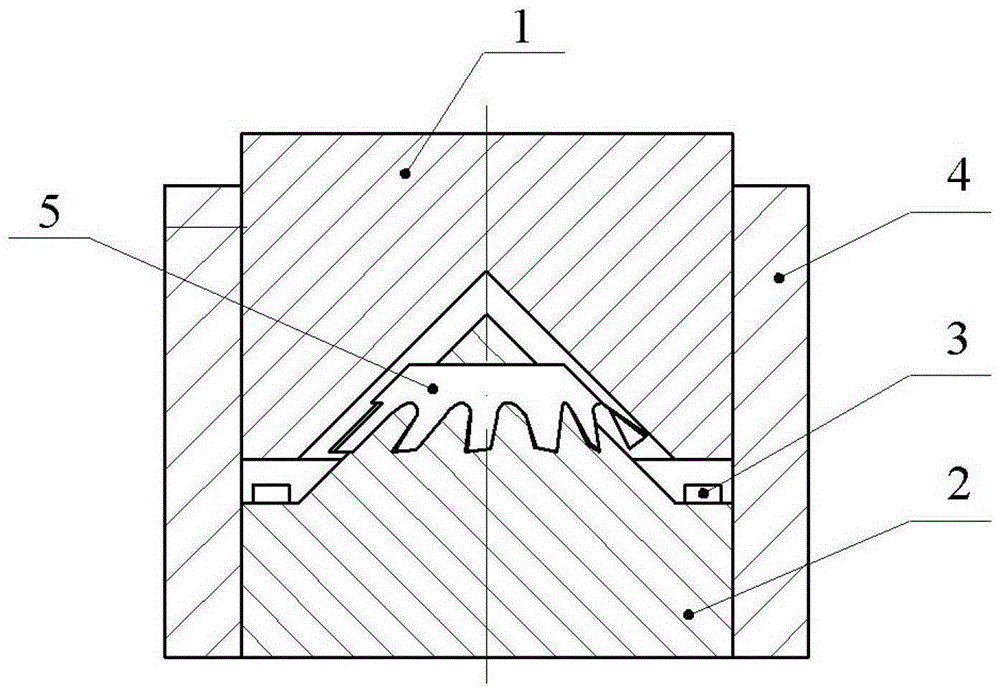

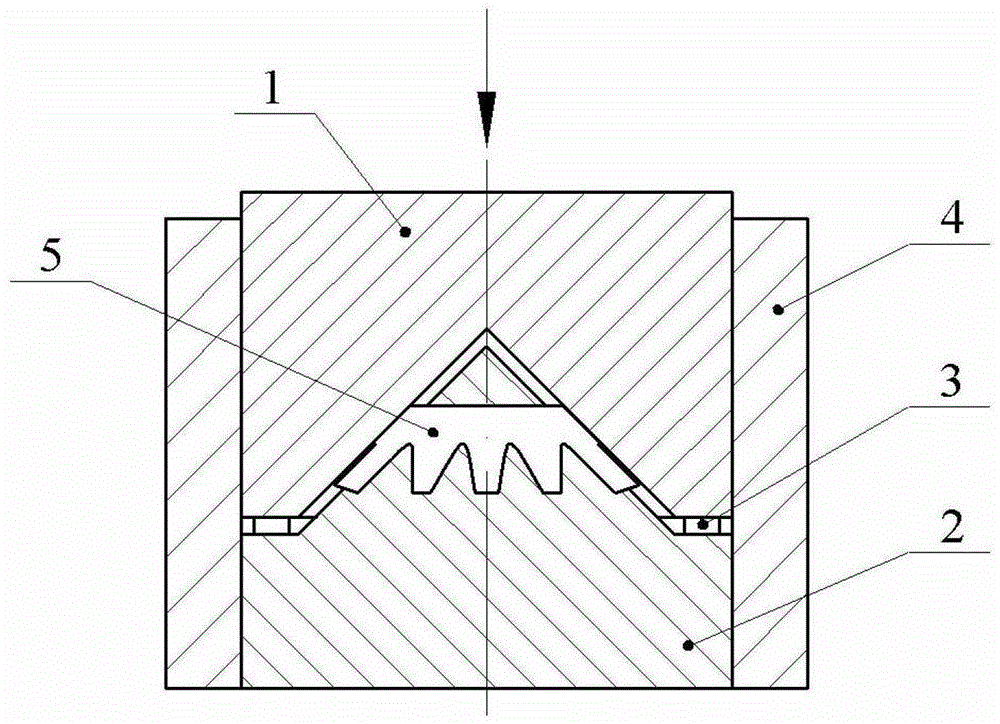

Elasticity test tool for taper washers

ActiveCN103234719ASolve the technical problem that the height dimension is not easy to determineSimple structureElasticity measurementEngineeringGreek letter alpha

The invention discloses an elasticity test tool for taper washers. The elasticity test tool for taper washers comprises an inner cone with an inner conical surface, and an outer cone with an outer conical surface, wherein the inner cone and the outer cone are opposite in the vertical direction. The conical surfaces of the inner and outer cones match with each other while the inner and outer cones have superposing axes. The inner and outer conical surfaces are provided with set taper angles equal to a taper angle of a taper washer to be tested. The inner and outer conical surfaces are peripherally provided with upper and lower positioning planes facing to each other respectively. The upper and lower positioning planes are perpendicular to the axes. A block for limiting the distance between the inner and outer conical surfaces is disposed between the upper and lower positioning planes. The vertical thickness of the block is L+(S+0.12)*sin(alpha / 2), the alpha is the taper angle of the taper washer to be tested, the S is the thickness of the taper washer to be tested, and the L is spacing of the upper and lower positioning planes when the inner and outer conical surfaces are fitted. When the upper and lower positioning planes contact with the upper and lower ends of the block respectively during test, the taper washer can be exactly compressed to be S+0.12mm high.

Owner:河南航天精工制造有限公司

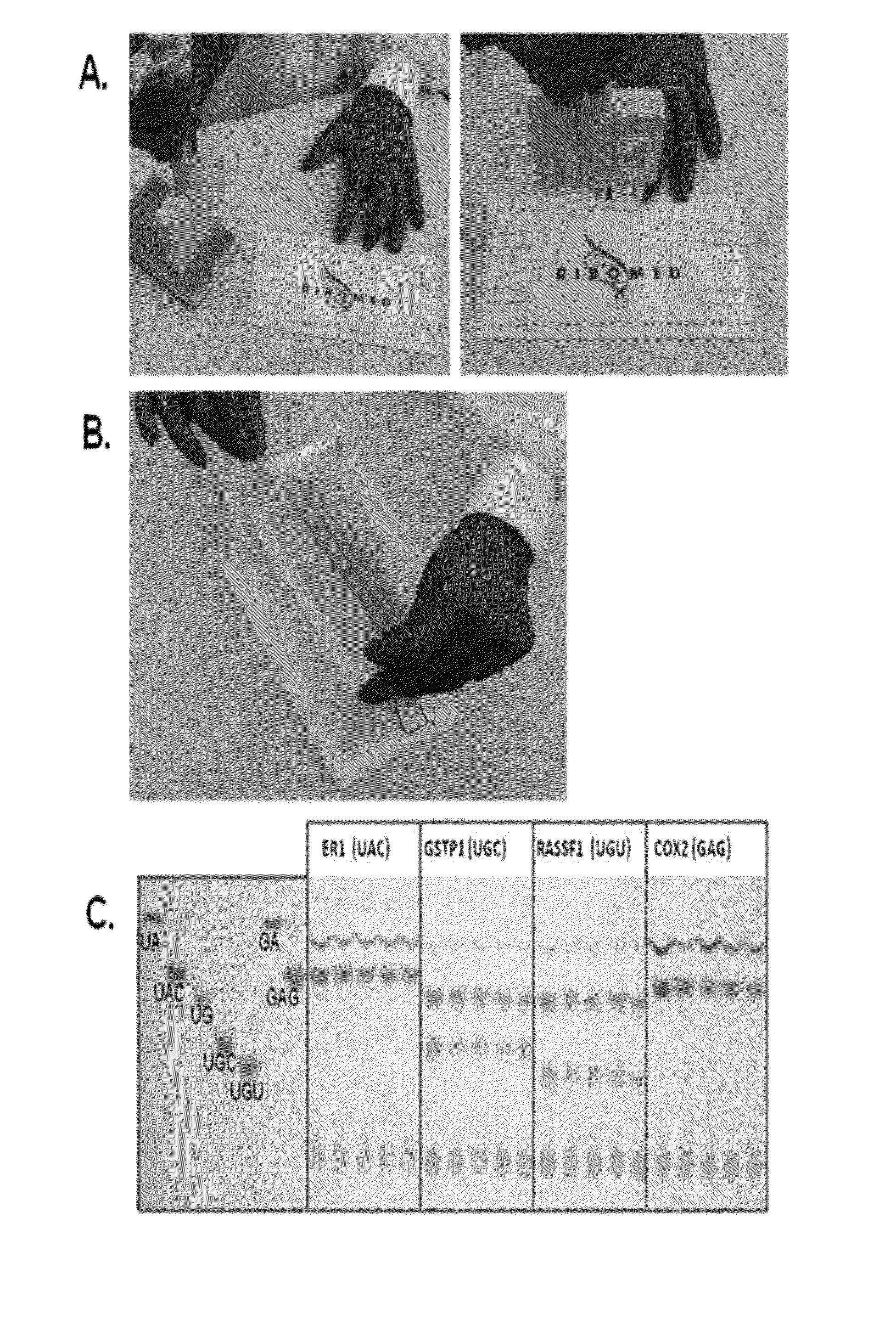

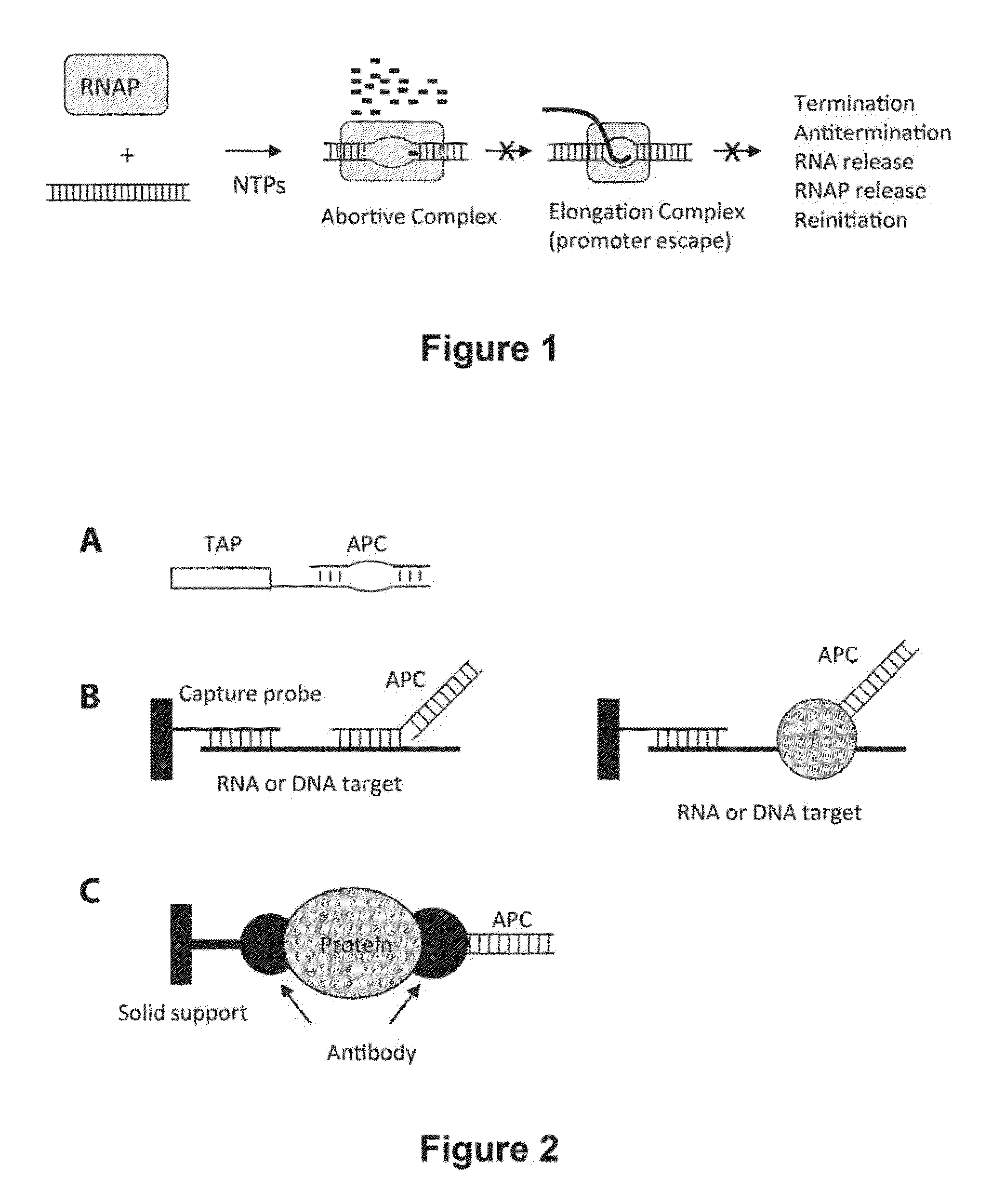

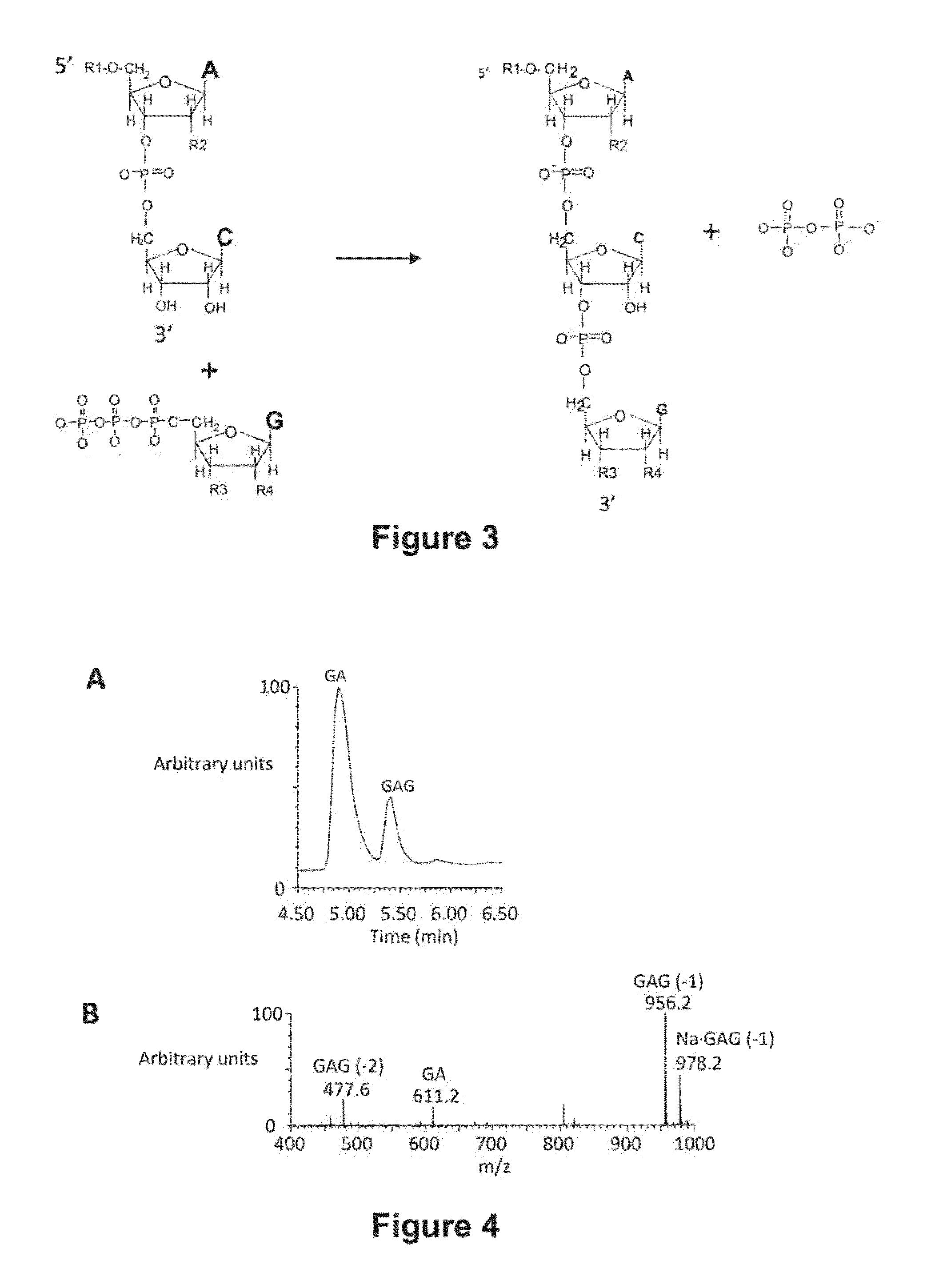

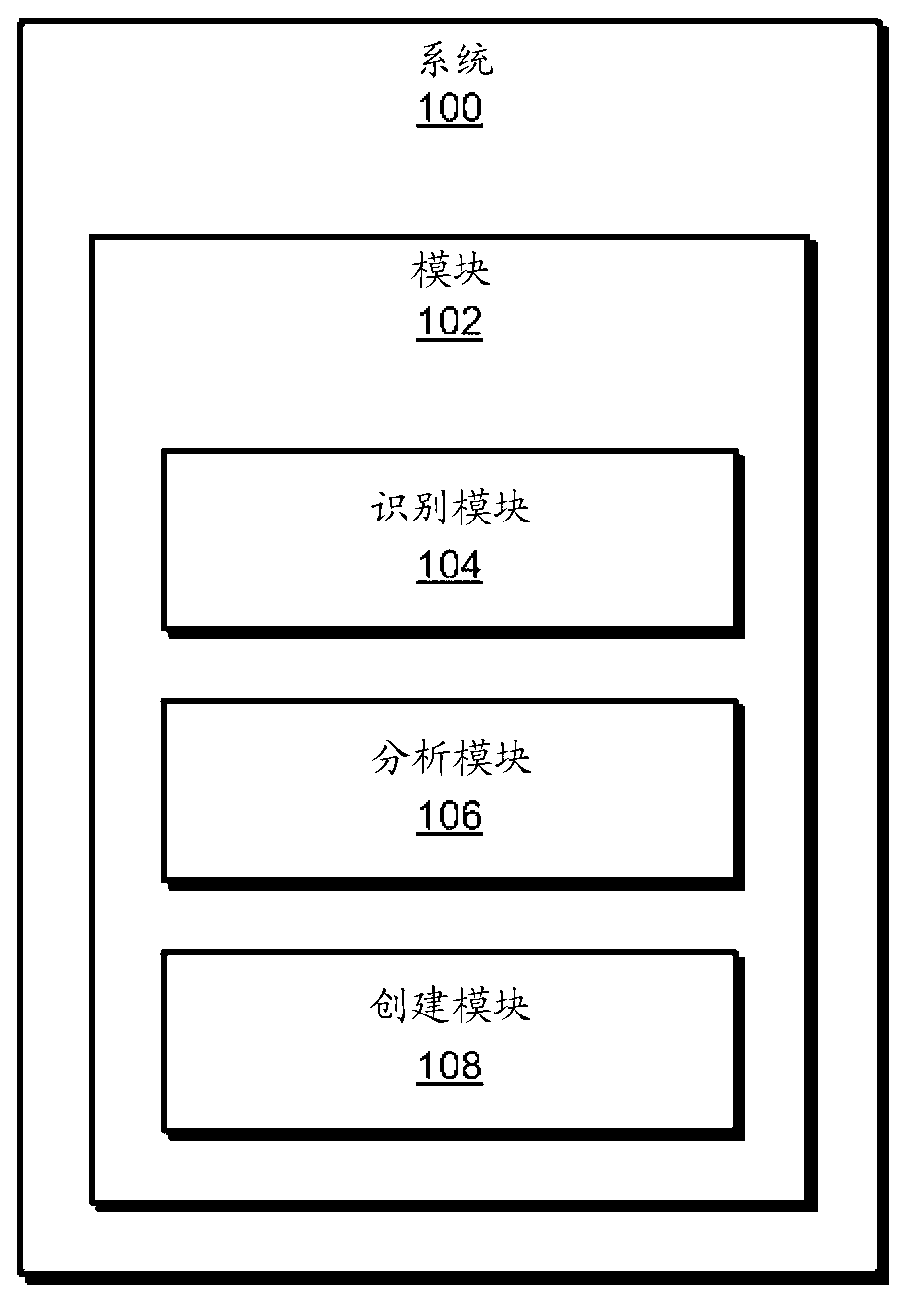

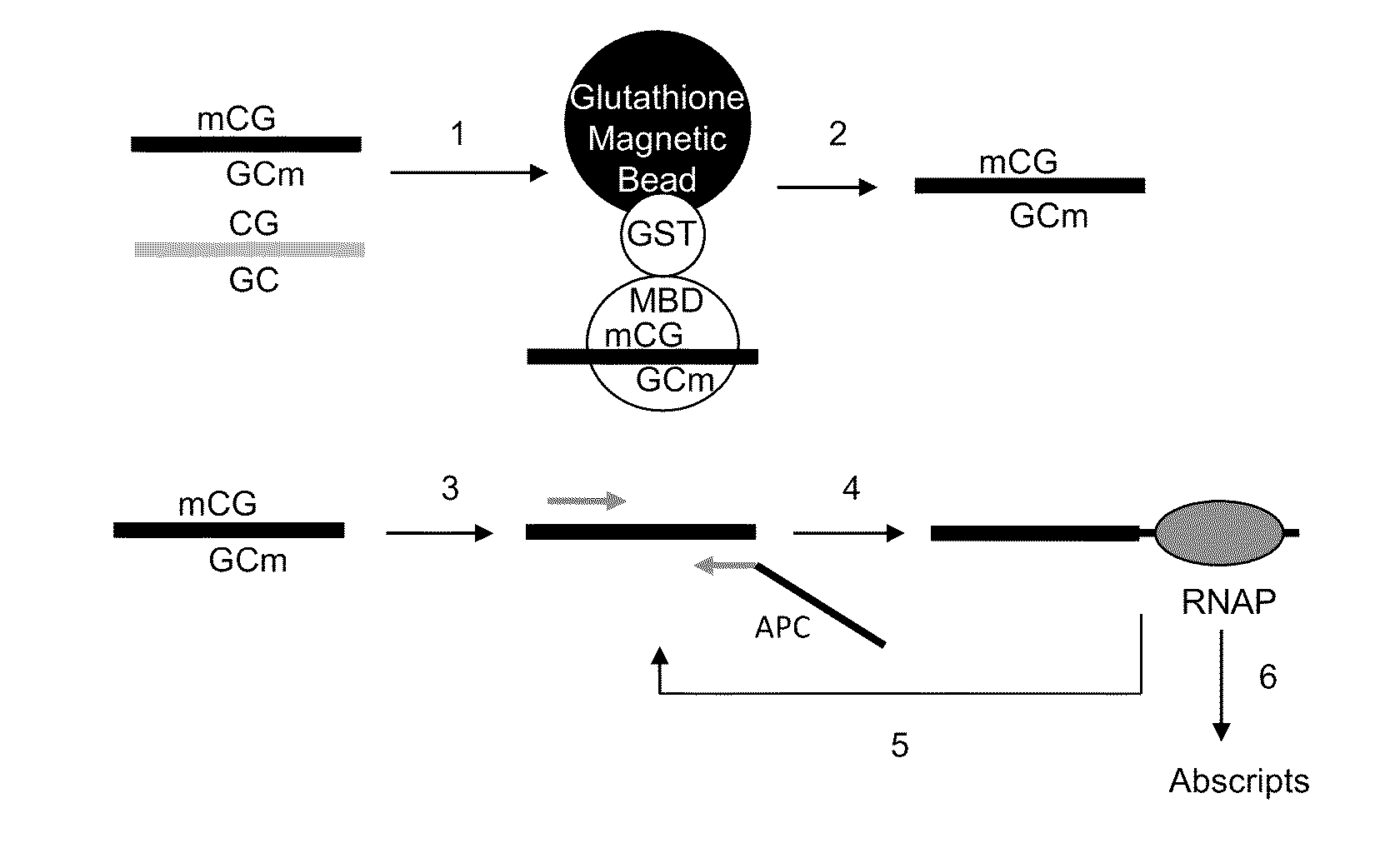

Abscription based molecular detection of DNA methylation

InactiveUS20130157266A1Easy to mergeEasy to separateMicrobiological testing/measurementDNA methylationSingle sample

The present invention provides methods for detecting biomarkers based on Abscription®, abortive transcription technology. Particularly, the present invention provides bisulfate free methods for detecting methylation of CpG islands from small samples containing DNA, including formalin fixed, paraffin embedded samples. The methods are suitable for multiplexing and can be used to analyze multiple CpG islands from a single sample in a short time.

Owner:RIBOMED BIOTECHNOLOGIES INC

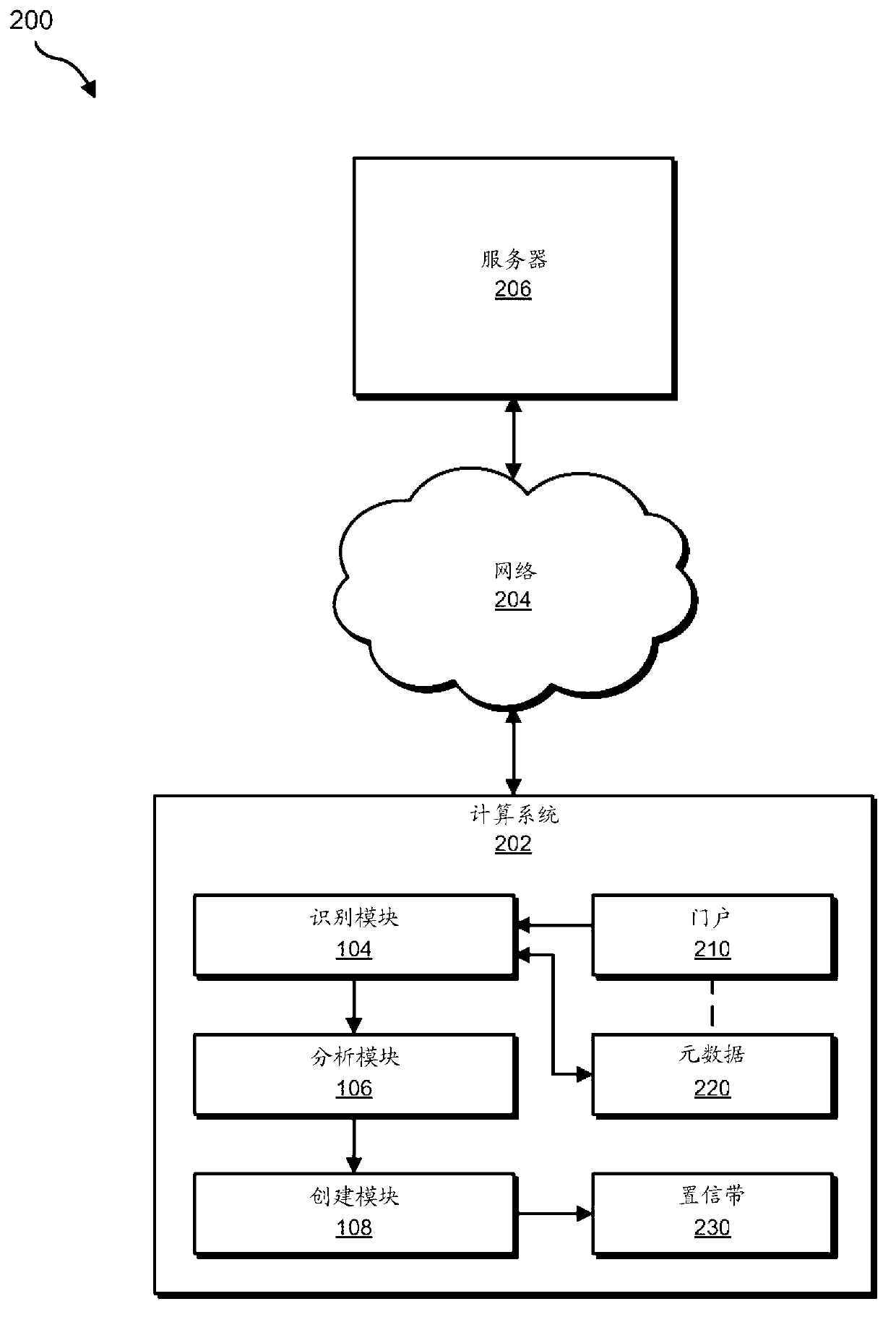

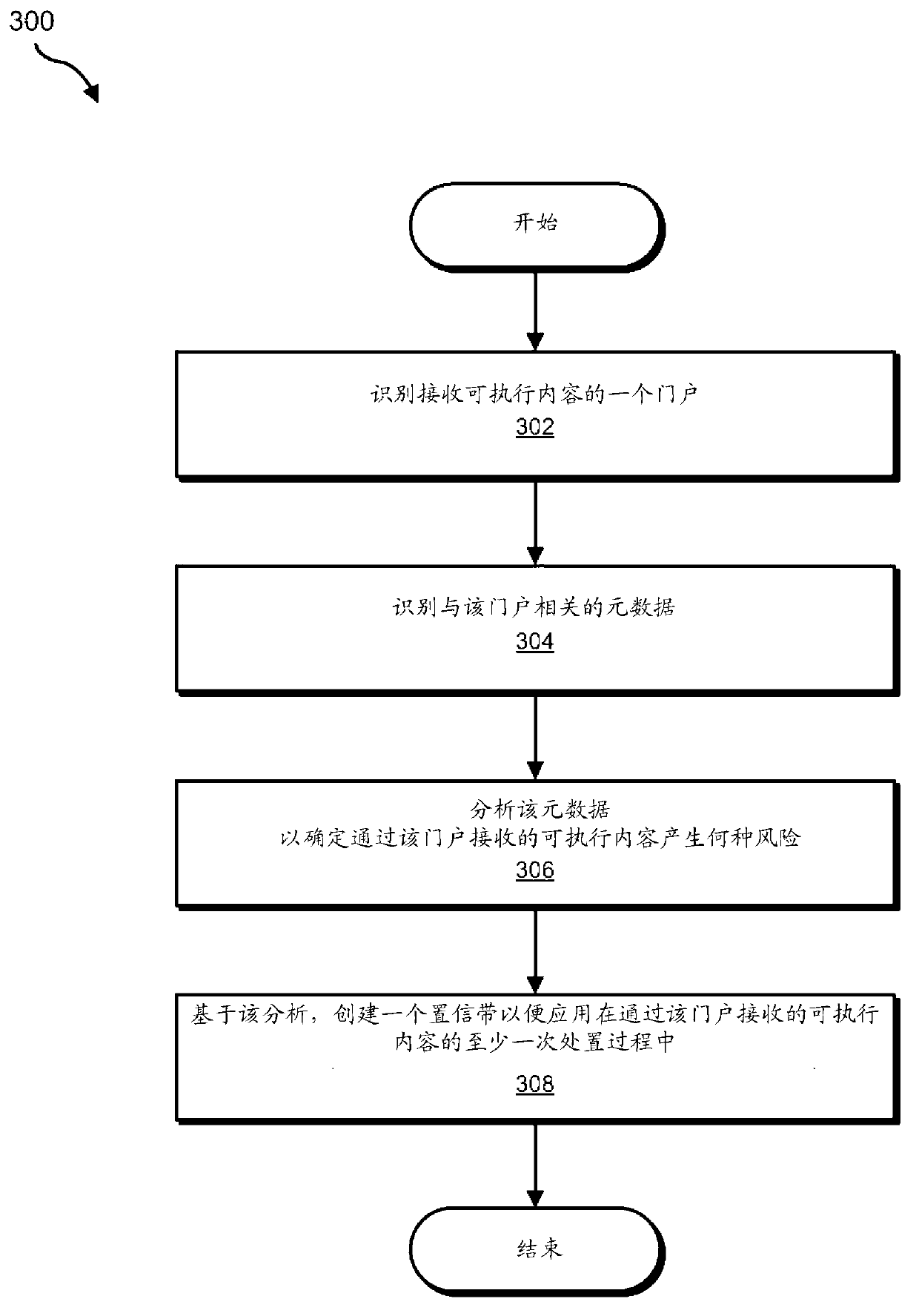

Systems and methods for creating customized confidence bands for use in malware detection

ActiveCN103109295ADetection Technology ImprovementImprove physical examinationPlatform integrity maintainanceTransmissionMalwareDatabase

A computer-implemented method for creating customized confidence bands for use in malware detection may include 1) identifying a portal for receiving executable content, 2) identifying metadata relating to the portal, 3) analyzing the metadata to determine what risk executable content received via the portal poses, and then 4) creating, based on the analysis, a confidence band to apply during at least one disposition of executable content received via the portal. Various other methods, systems, and computer-readable media are also disclosed.

Owner:CA TECH INC

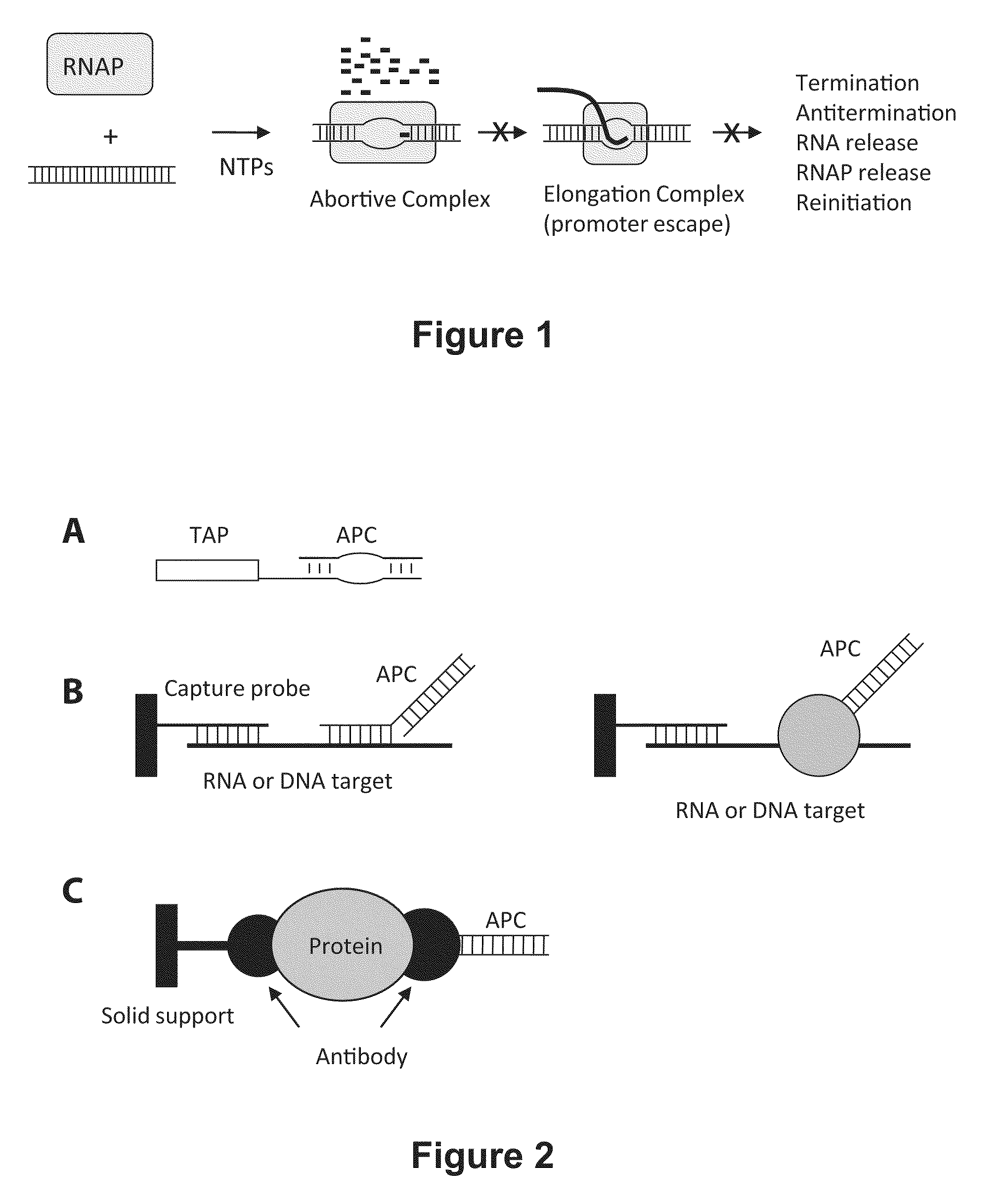

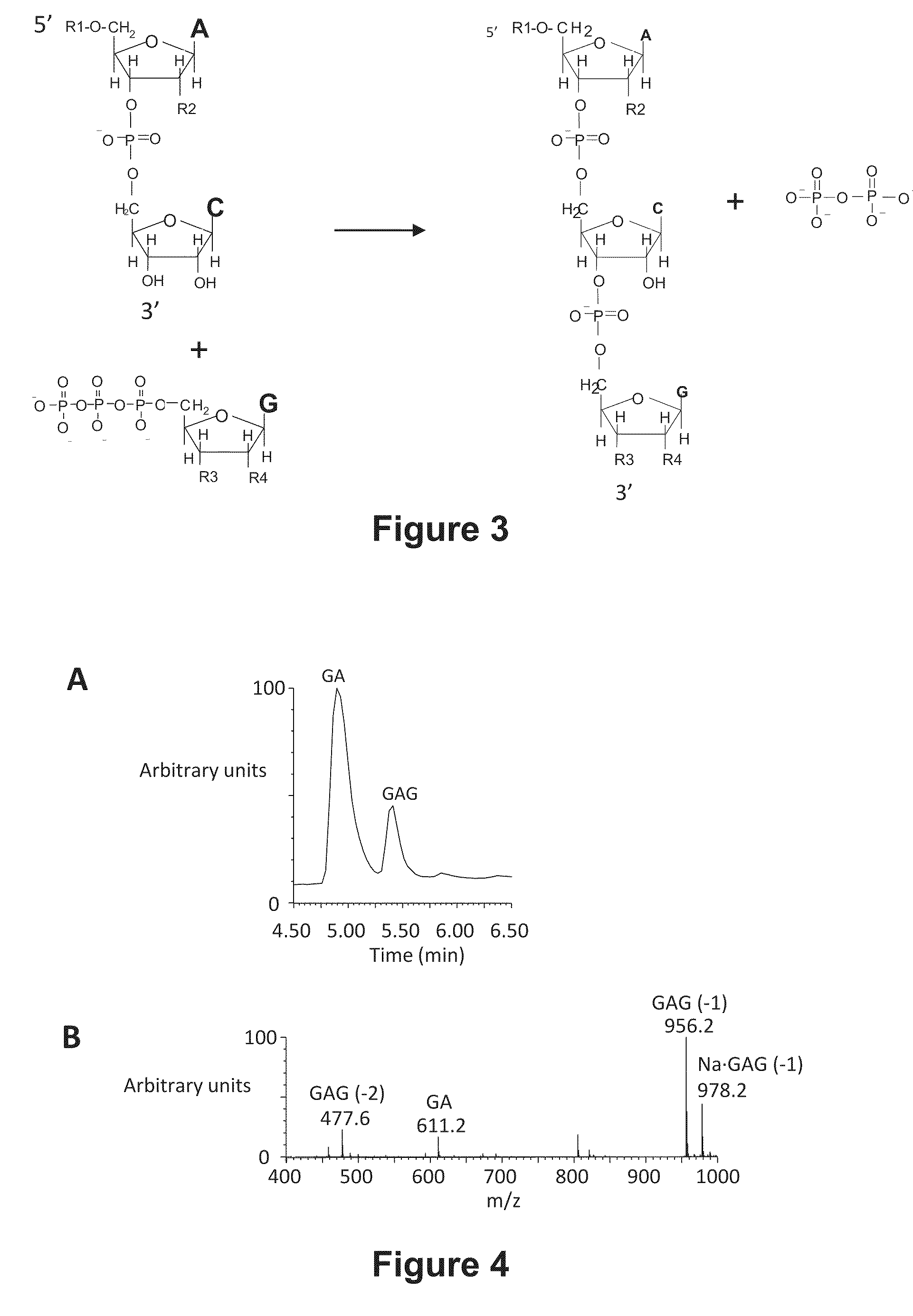

Abscription based molecular detection

InactiveUS8263339B2Easy to mergeEasy to separateMicrobiological testing/measurementFermentationSingle sampleMultiplexing

The present invention provides methods for detecting biomarkers based on Abscription®, abortive transcription technology. Particularly, the present invention provides bisulfate free methods for detecting methylation of CpG islands from small samples of DNA. The methods are suitable for multiplexing and can be used to analyze multiple CpG islands from a single sample in a short time.

Owner:RIBOMED BIOTECHNOLOGIES INC

Primer composition for LAMP (loop-mediated isothermal amplification) rapid detection of pomegranate fusarium sulphureum and application of primer composition

ActiveCN108315391AHigh sensitivityStrong specificityMicrobiological testing/measurementDNA/RNA fragmentationLoop-mediated isothermal amplificationBiology

The invention discloses a primer composition for LAMP (loop-mediated isothermal amplification) rapid detection of pomegranate fusarium sulphureum and application of the primer composition. The primercomposition disclosed by the invention is prepared from the following primers: F3, B3, BIP and FIP. The primer composition is used for carrying out the LAMP rapid detection on the pomegranate fusariumsulphureum and has strong specificity and high sensitivity, so that the primer composition disclosed by the invention can be used for detecting and / or identifying the pomegranate fusarium sulphureum;a simple, rapid and low-cost detection technology is provided for scientific researches and production practice and theoretical foundation and technical guidance are also provided for early warning and reasonable application of the pomegranate fusarium sulphureum; the primer composition has realistic and profound significances of increasing ecological social and economic benefits.

Owner:PLANT PROTECTION & QUALITY & SAFETY OF AGRI PRODS INST ANHUI ACAD OF AGRI SCI

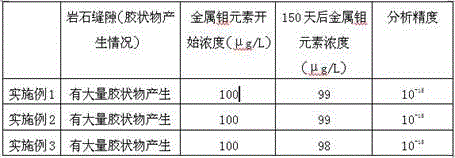

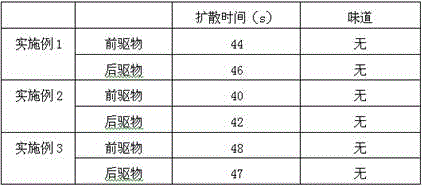

Microelement tracer agent used for offshore oilfield and use method thereof

ActiveCN106368679ANo radioactivityNo pollution in the processConstructionsMolybdenum chloridePollution

The invention provides a microelement tracer agent special for an offshore oilfield. The tracer agent is made from raw materials of a precursor and a post-cursor. The precursor and the post-cursor each contain microelement chloride. A microelement mixture is a praseodymium-molybdenum chloride mixture. The invention further provides a use method of the microelement tracer agent. The use method comprises the step that a prepared precursor solution and a prepared post-cursor solution are sequentially injected into a monitoring well, wherein the volume ratio of the precursor solution to the post-cursor solution is 1:(0.8-1), and the time interval for injection of the precursor solution and injection of the post-cursor solution is 80-120 min. The prepared microelement tracer agent is free of radiation and pollution and good in safety and stability; an HR-ICP-MS instrument is used for detecting, the minimum detection limit can be up to 10-15 (ppq grade) grade; and the microelement tracer agent can be fast disintegrated in water, and evenly diffused and dissolved with the diffusion time no longer than 48 seconds.

Owner:潍坊华诺生物科技有限公司

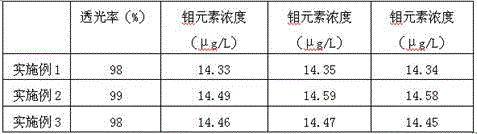

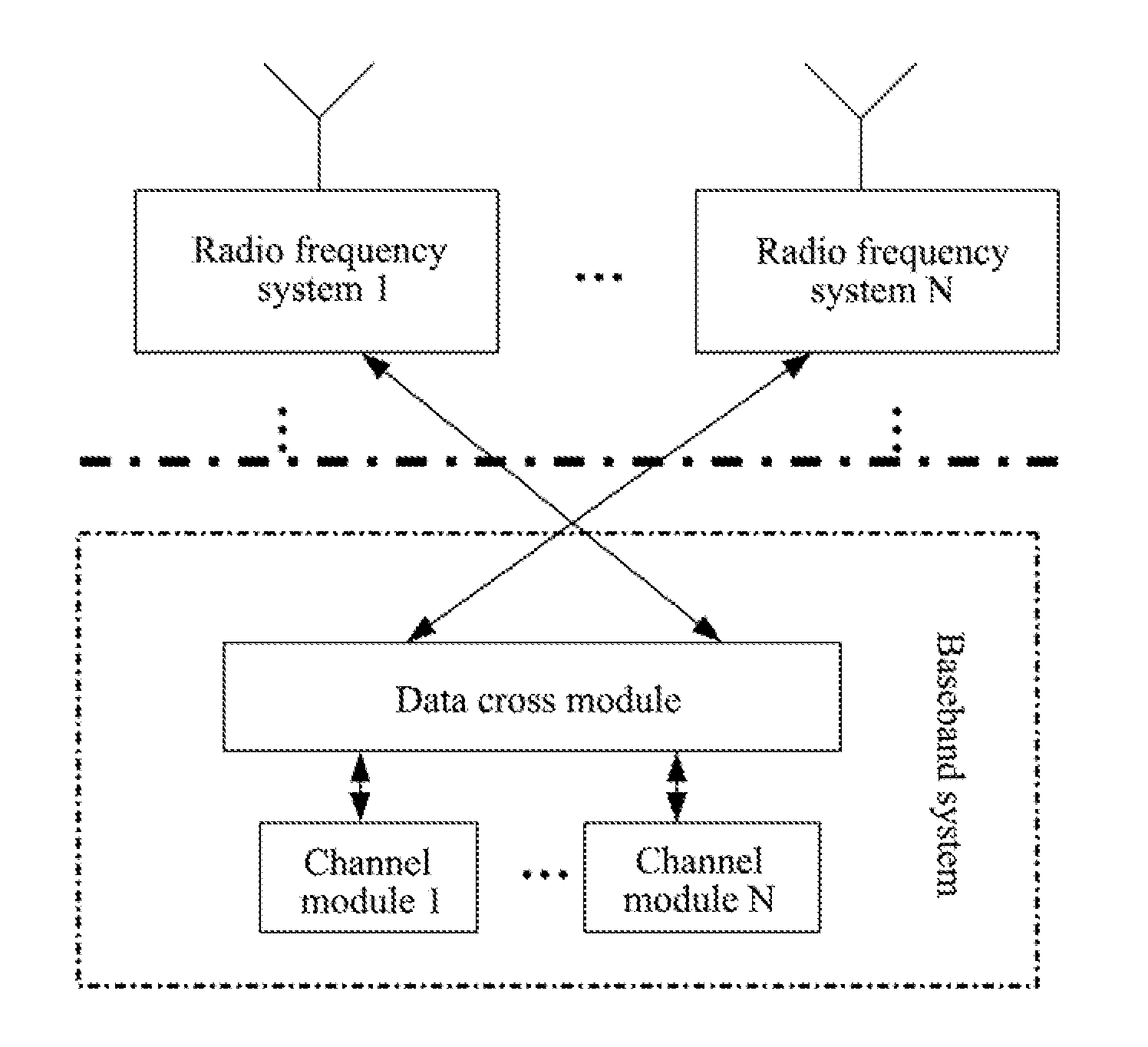

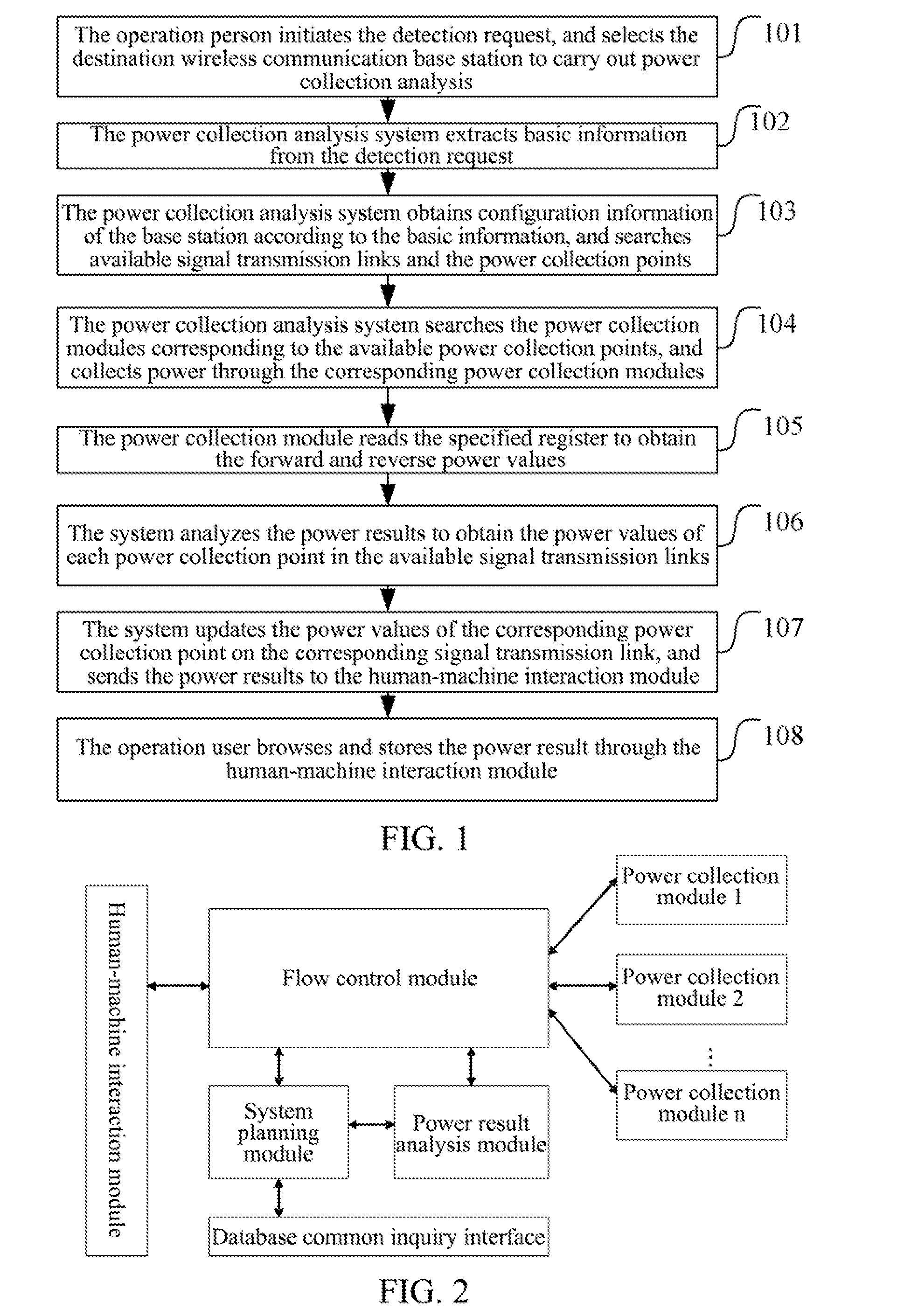

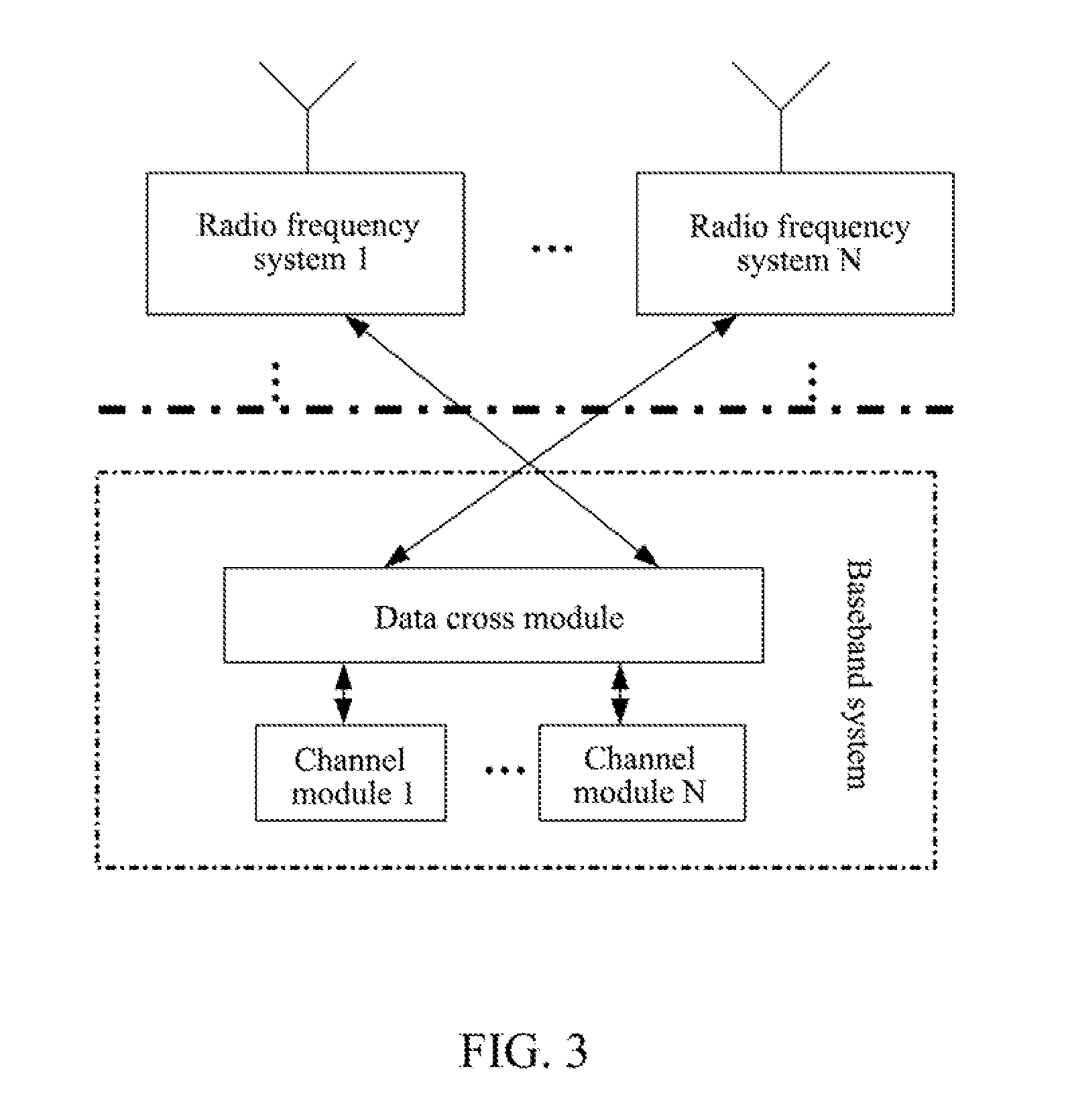

Method and System for Implementing Power Detection

ActiveUS20120231748A1High effectivenessImprove unityPower managementEnergy efficient ICTMaintainabilityBase station

The present invention discloses a method and system for implementing power detection, wherein said method includes: extracting basic information of a destination base station from a detection request, obtaining configuration information of said destination base station from a database according to the basic information, and searching available signal transmission links and power collection points of said destination base station according to the configuration information; carrying out power collection, and analyzing power values of each available power collection point on the available signal transmission link, and updating the power values of corresponding power collection points. With the present invention, power detection can be carried out on the device from a perspective of the system, and the maintainability and operability are improved.

Owner:ZTE CORP

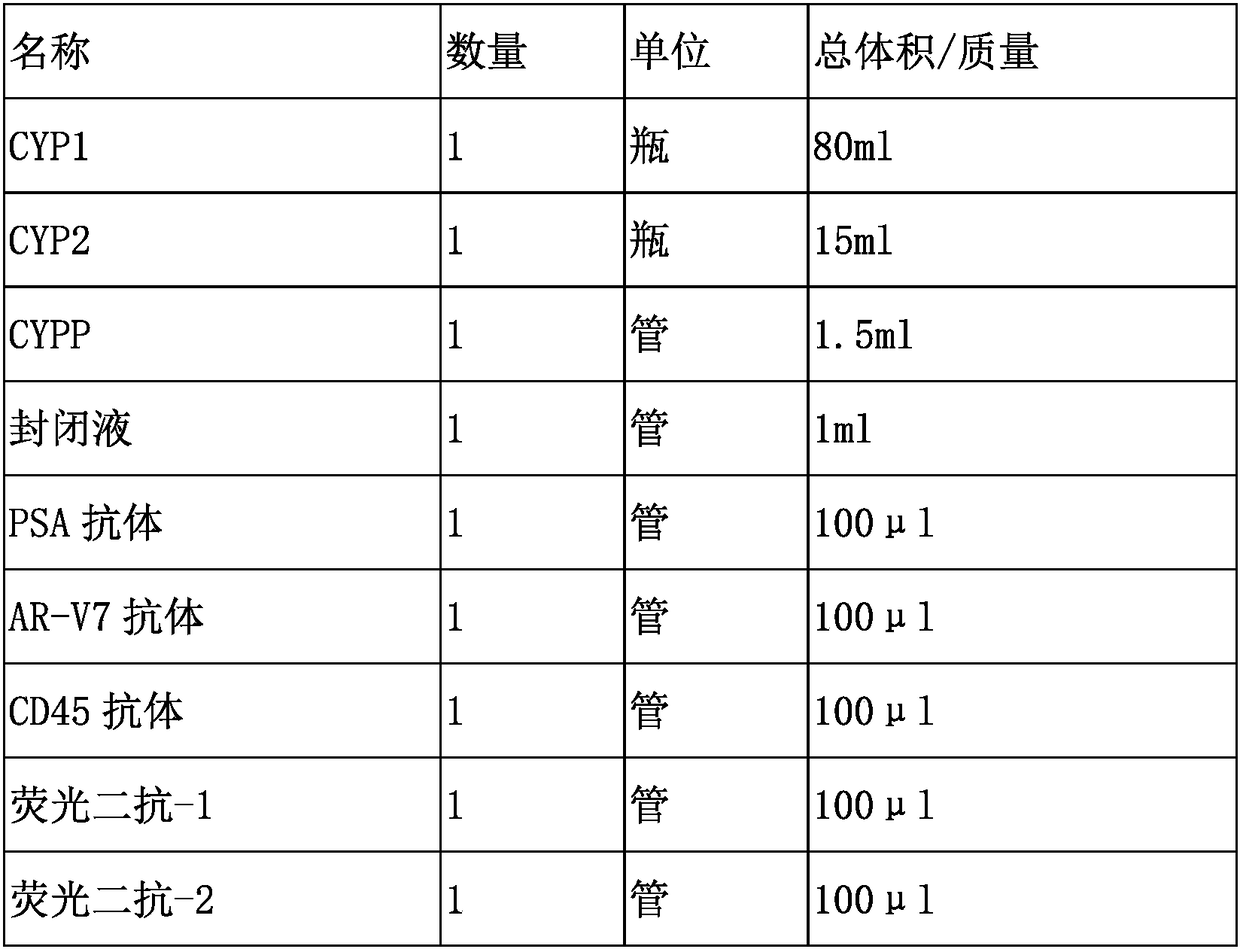

Immunofluorescence kit for detecting human prostate cancer antigens PSA and AR-V7 and application

InactiveCN108982874AGuidance on precise medicationAccurately reflectBiological testingFluorescence/phosphorescenceProtein targetImmunofluorescence

The invention relates to an immunofluorescence kit for detecting human prostate cancer antigens PSA and AR-V7 and application. According to a method provided by the invention, a detection principle comprises the following steps: firstly, enriching non-body-fluid rare karyocytes; the detecting expression of target protein in enriched cells in the cells by adopting an immunofluorescence detection method according to an antigen and antibody reaction principle. The kit provided by the invention is used for carrying out fluorescence labeling on a common antigen CD45 of targeting cells and white blood cells, and positive and CD45 negative cells of the target protein are screened, so that the positive non-body-fluid rare karyocytes of specific protein in blood are judged and counted.

Owner:北京莱尔生物医药科技有限公司

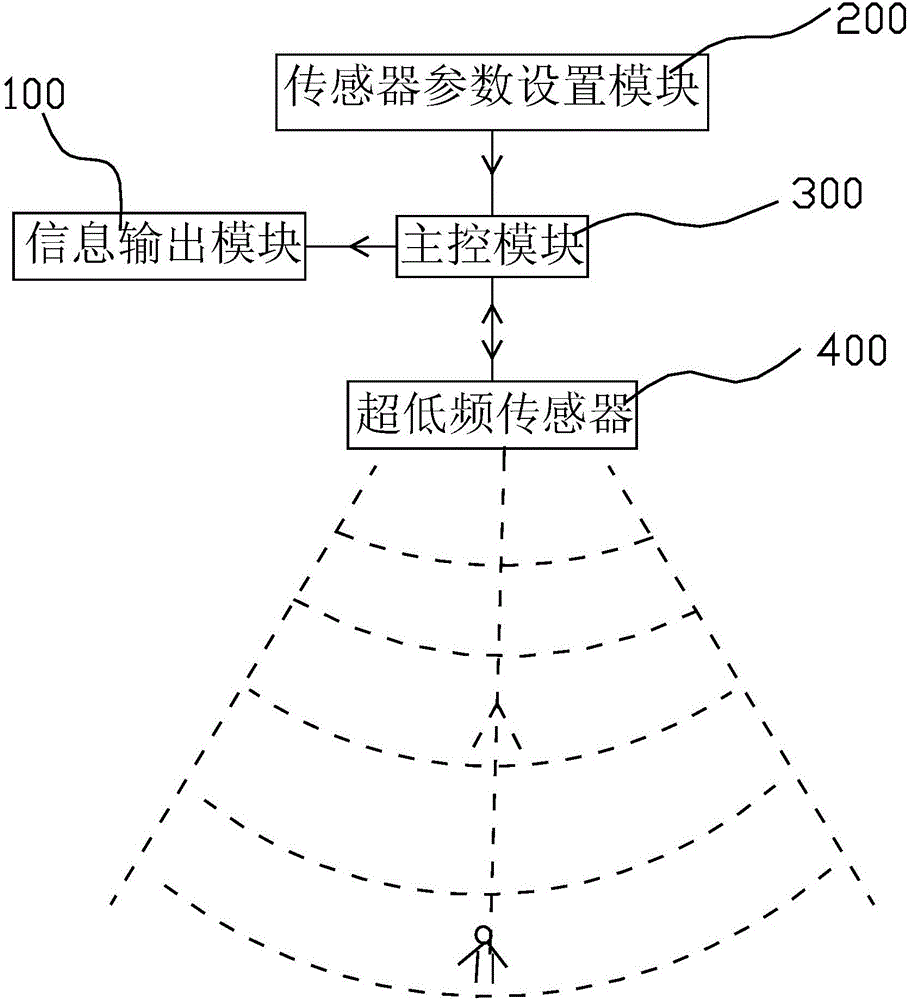

Pedestrian detection system and detection method based on human body electric waves

PendingCN106611154AImproving Pedestrian Detection TechnologyEasy image analysis and processingCharacter and pattern recognitionTransportation FacilityHeart beat

The invention discloses a pedestrian detection system based on human body electric waves. The system comprises a master control module arranged on a transportation facility and an ultralow frequency sensor and an information output module electrically connected with the master control module; and the ultralow frequency sensor can receive the biological waves of the human body heart beating. The invention further discloses a pedestrian detection method based on the human body electric waves. The system disclosed by the invention has the advantages of being simple in analysis and processing method, capable of improving the timeliness, the accuracy and the reliability of the pedestrian detection.

Owner:SHENZHEN PROTRULY ELECTRONICS CO LTD

Elasticity test fixture for conical washers

ActiveCN103234719BSolve the technical problem that the height dimension is not easy to determineSimple structureElasticity measurementEngineeringConical surface

Owner:河南航天精工制造有限公司

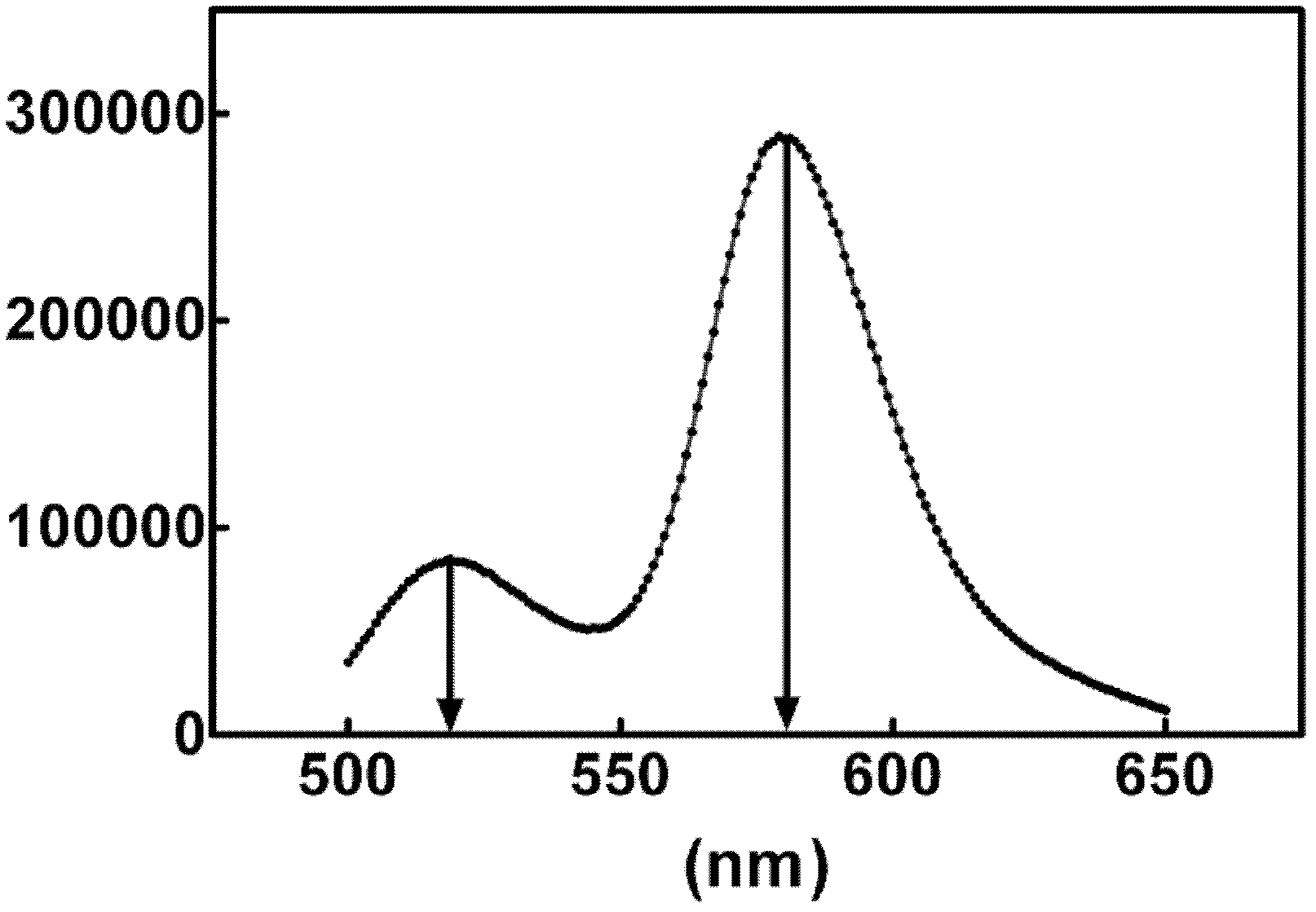

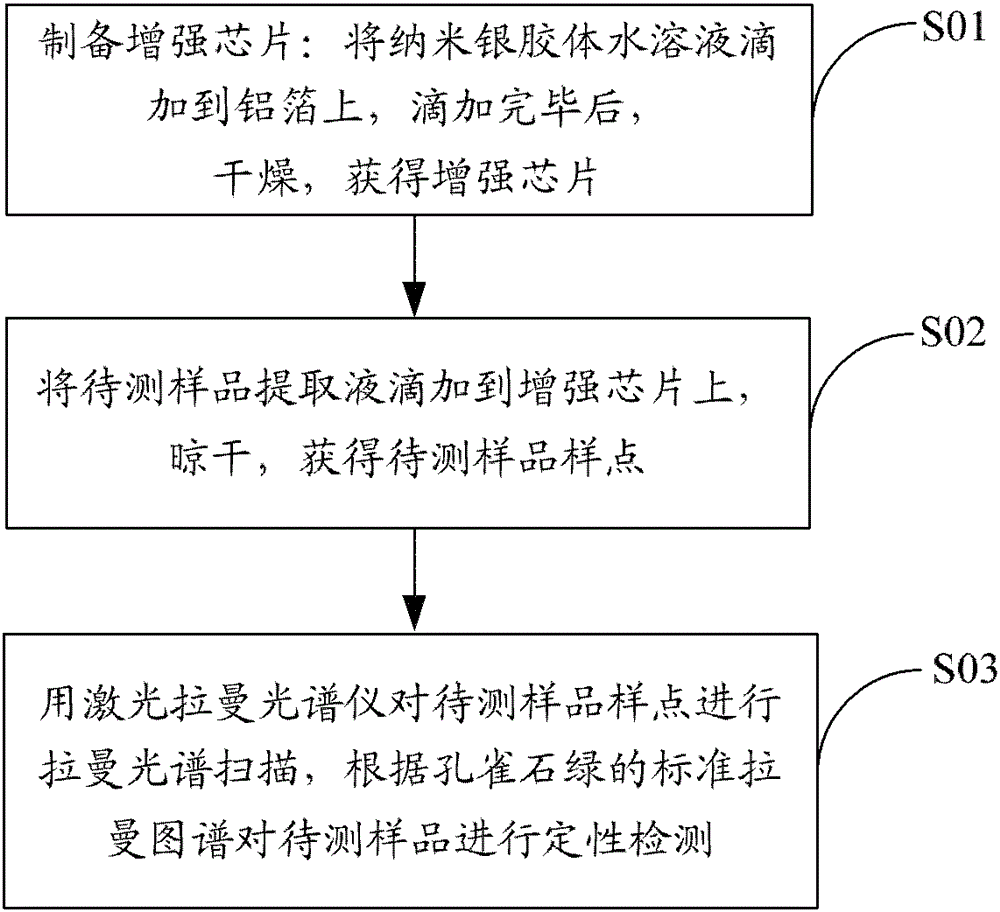

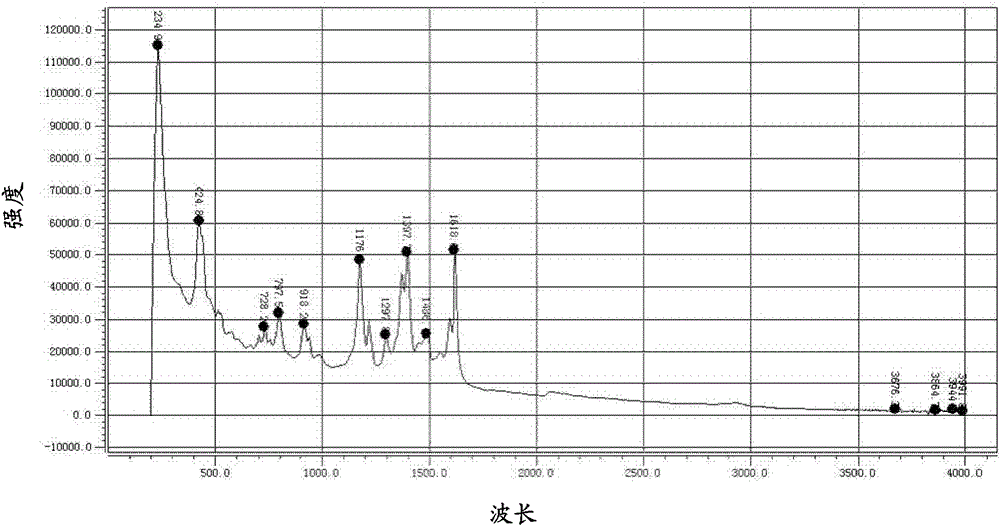

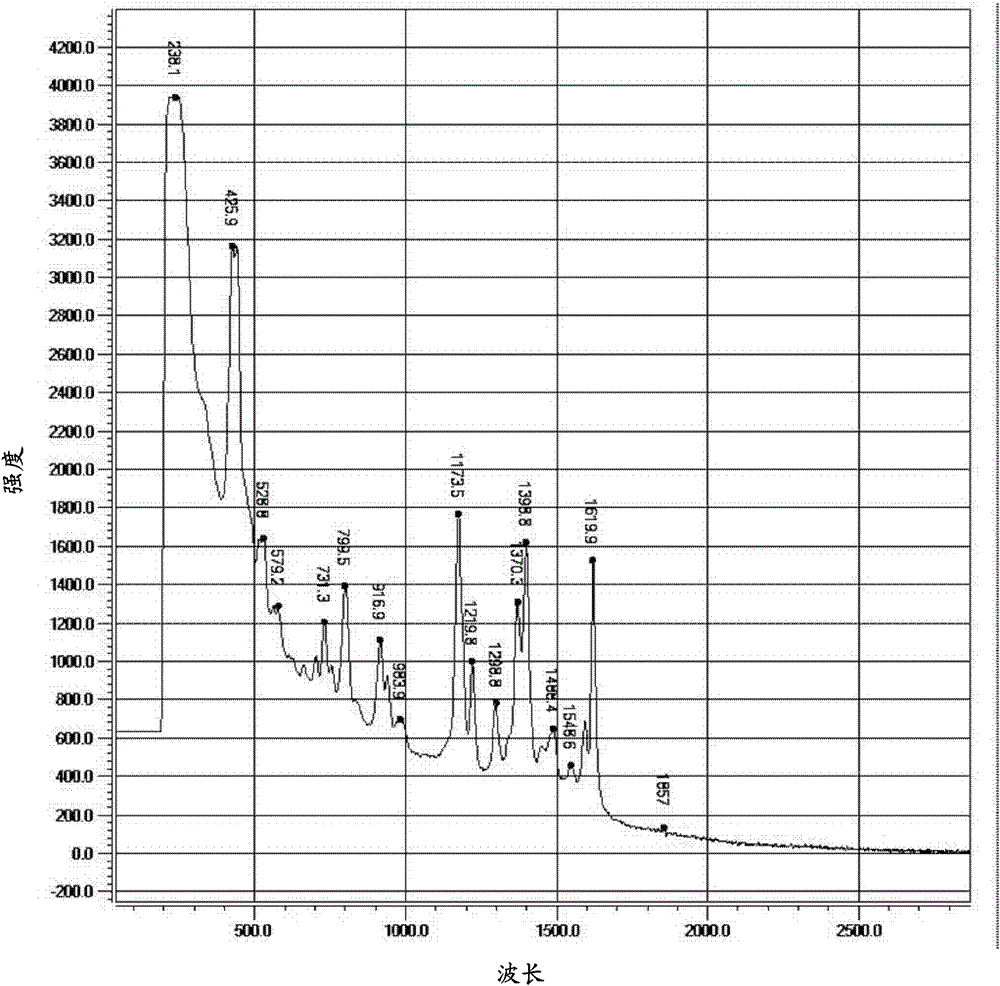

A kind of laser Raman detection method of malachite green

Owner:SHENZHEN YU CHI TESTING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com