Method for eliminating error of cylinder screw thread non-contact measurement

A non-contact thread thread technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of thread tooth angle error and the inability to obtain the real parameters of thread tooth angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0052] attached by Figure 8 Shown the present invention is used for eliminating the schematic flow chart of the method for non-contact measuring cylindrical thread profile error as known, it comprises the following steps:

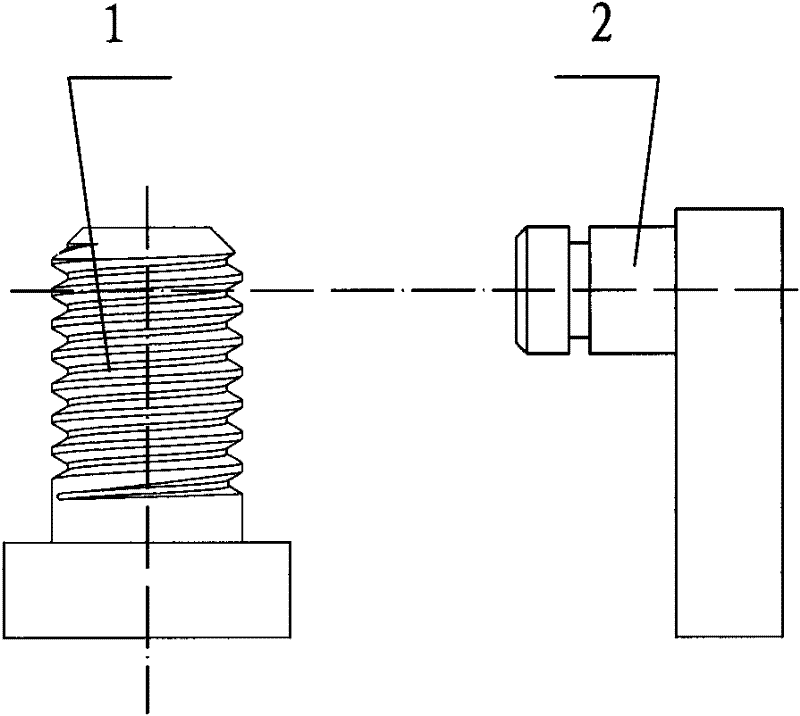

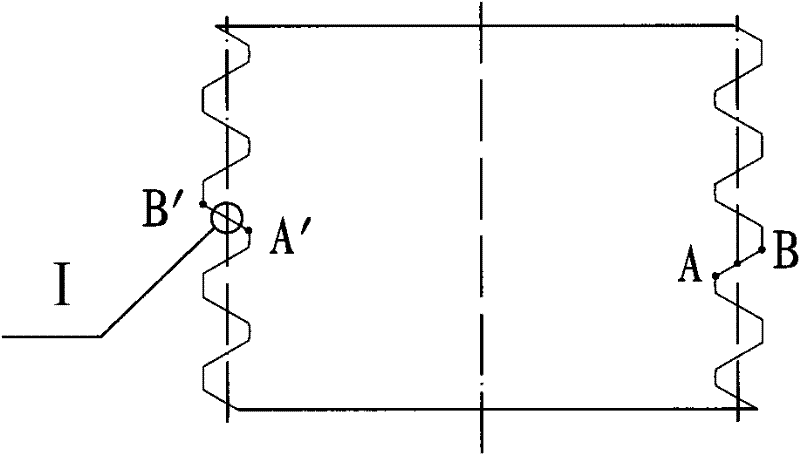

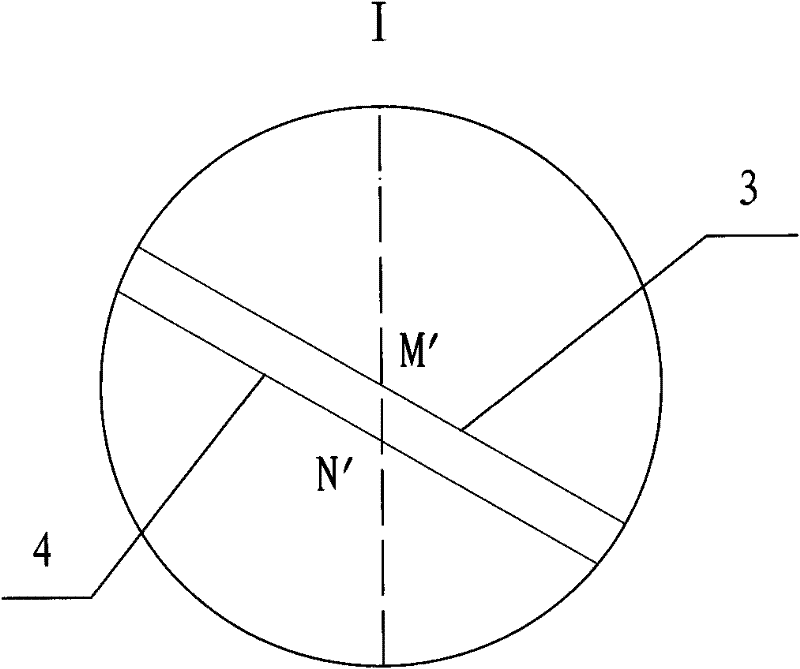

[0053] (1) Propose the concept of projection boundary

[0054] The cross-sectional profile of the thread obtained after cutting along the axis of the bolt, AB is a tooth-shaped intersection line of the cylindrical thread profile on the cross-section, such as Figure 5 , Figure 6 and Figure 7 As shown, after AB rotates half a circle according to the helix of the thread, the helicoid is obtained, and another tooth-type intersection line A'B' is formed on the other side of the section. There is a point M on the intersection line AB, which reaches the central axis of the thread The distance is r, the point M rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com