Difference measurement method for MEMS gyroscopes

A differential measurement, gyroscope technology, applied in the gyro effect for speed measurement, measuring device, speed/acceleration/shock measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

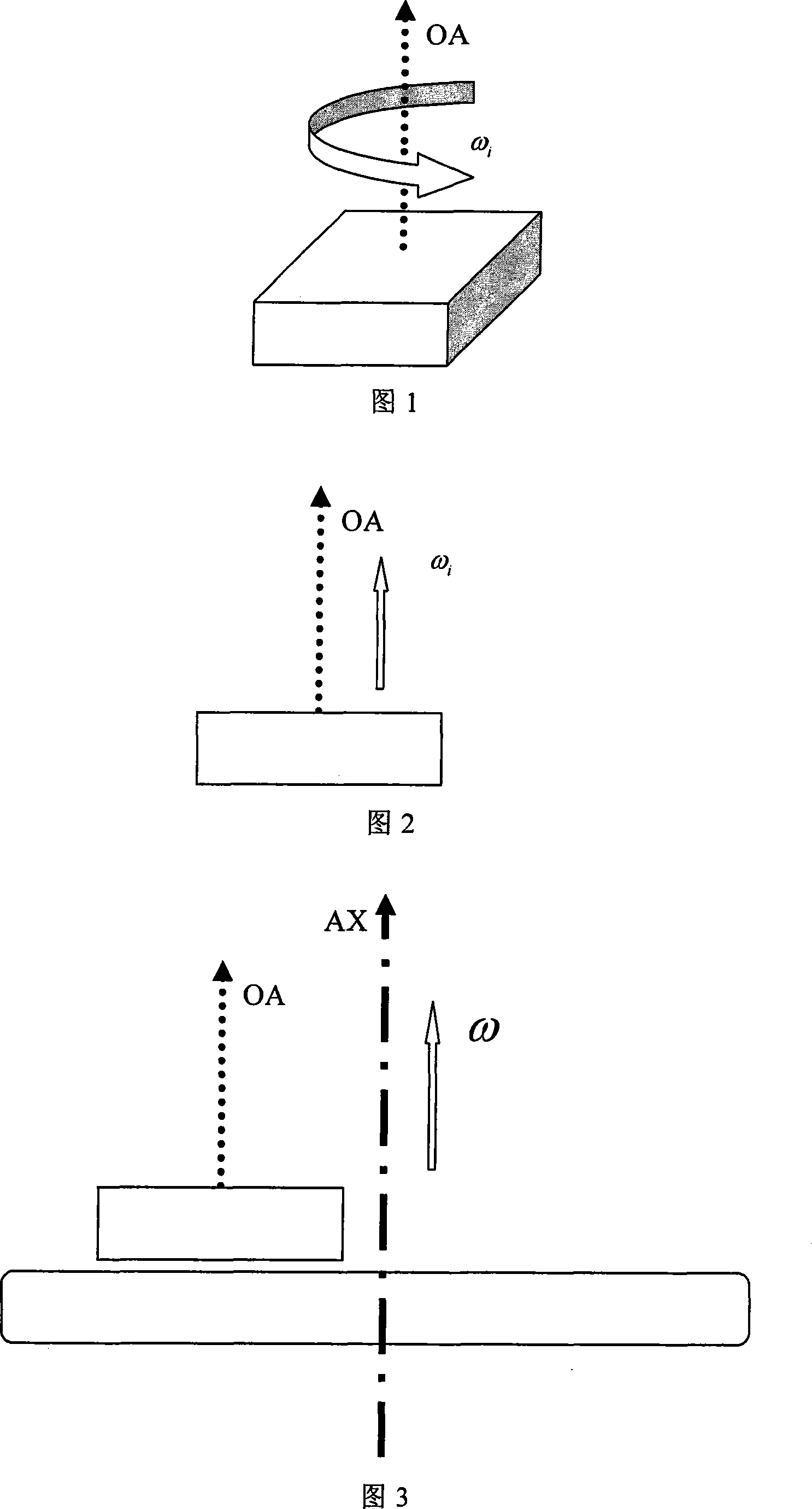

Method used

Image

Examples

Embodiment Construction

[0087] The MEMS gyroscope in the first embodiment of the present invention takes the silicon MEMS gyroscope CRS03 as an example.

[0088] First, take a batch of silicon MEMS gyroscopes CRS03, 20 in this embodiment, and conduct test experiments according to the commonly used gyroscope test standards. Test and calibrate each important parameter of MEMS gyroscope, including various deterministic error items and their coefficients, usually including zero bias, zero bias stability, zero bias repeatability, scale factor, scale factor asymmetry, scale Factor repeatability, maximum input angular velocity, threshold, resolution, random walk coefficient, input axis misalignment angle, frequency bandwidth and other parameters.

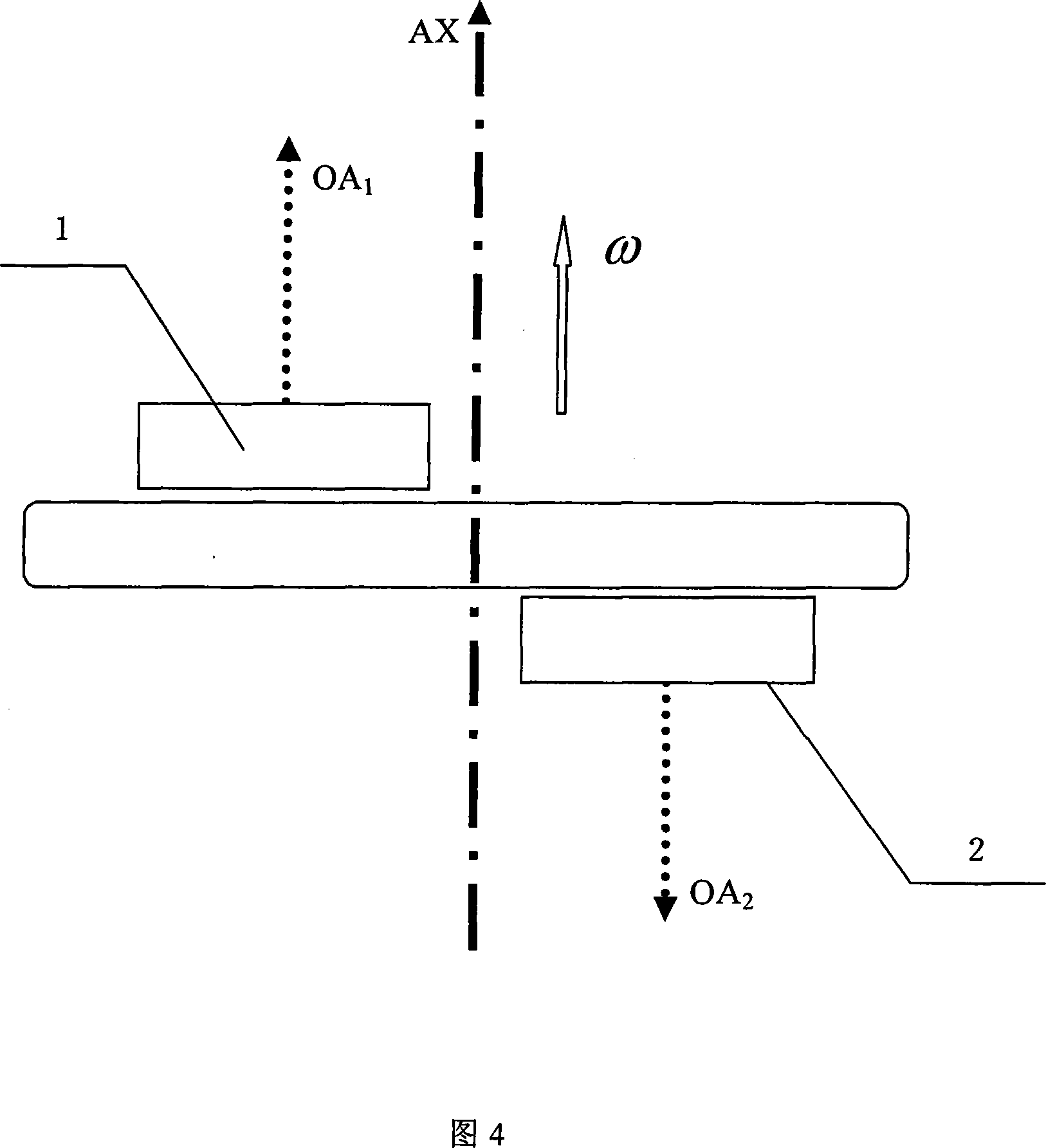

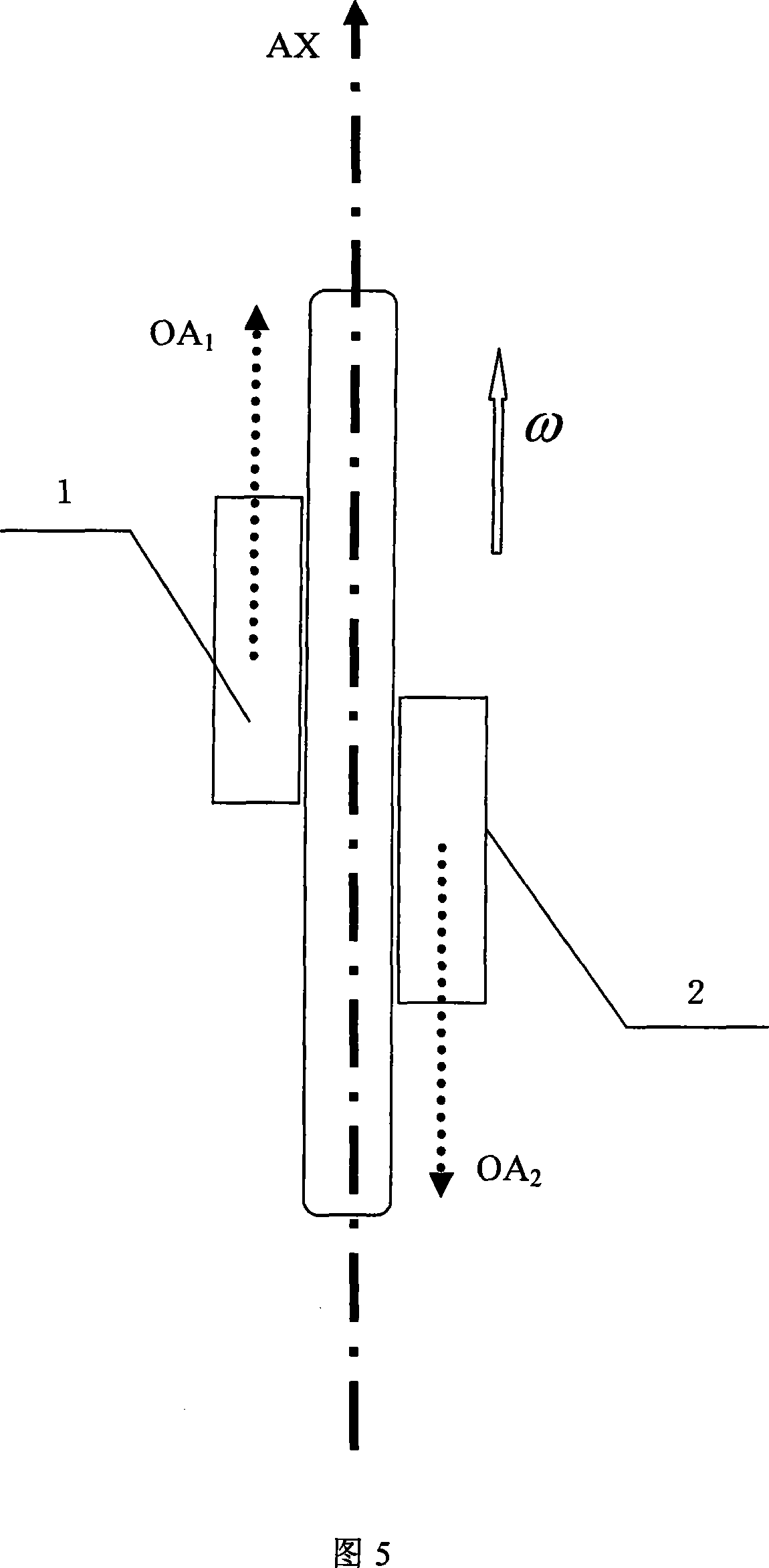

[0089] Secondly, divide this batch of MEMS gyroscopes CRS03 into two groups, 10 in each group. Turntable tests were performed using a uniaxial rate turntable. Fix the sensitive axis of one group of MEMS gyroscopes parallel to the rotation axis of the turntable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com