Elasticity test fixture for conical washers

A conical washer and elastic test technology, which is applied in the field of mechanical fasteners, can solve the problems that it is not easy to determine the conical washer, the distance is difficult to measure and control, and the elastic test of the conical washer is inconvenient, so as to solve the problem that the height dimension is not easy to determine , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

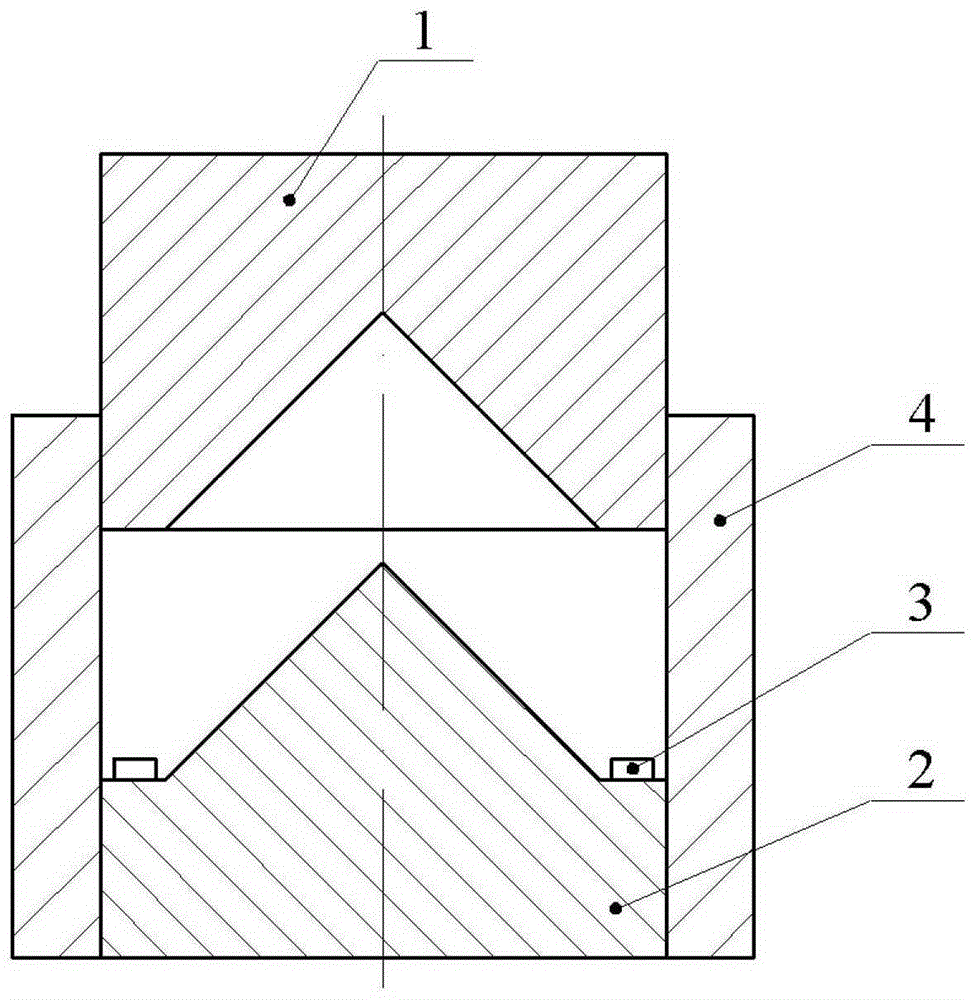

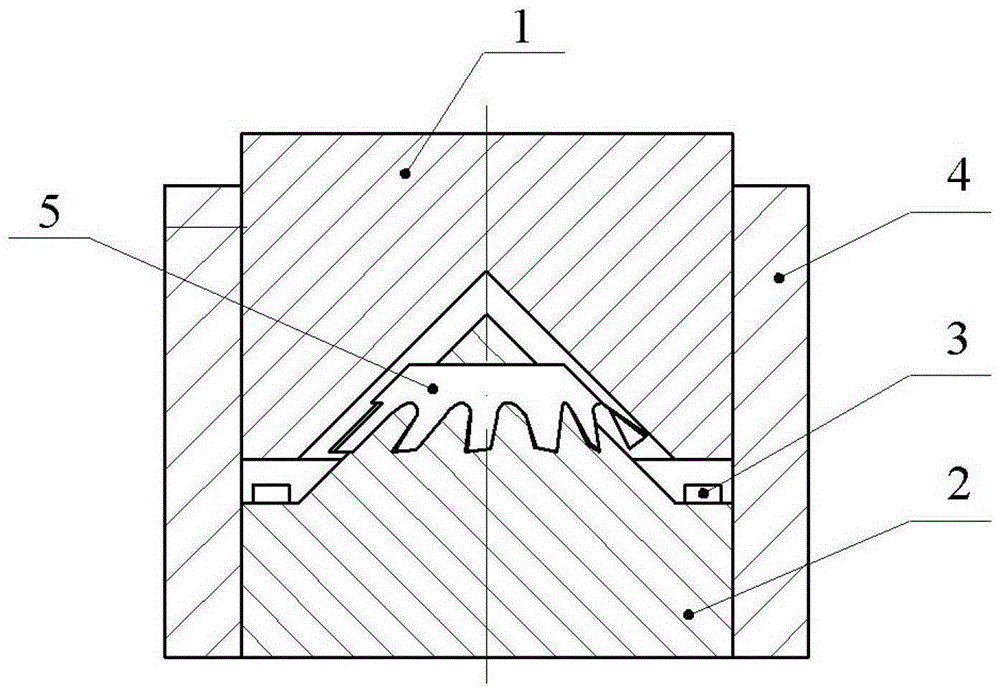

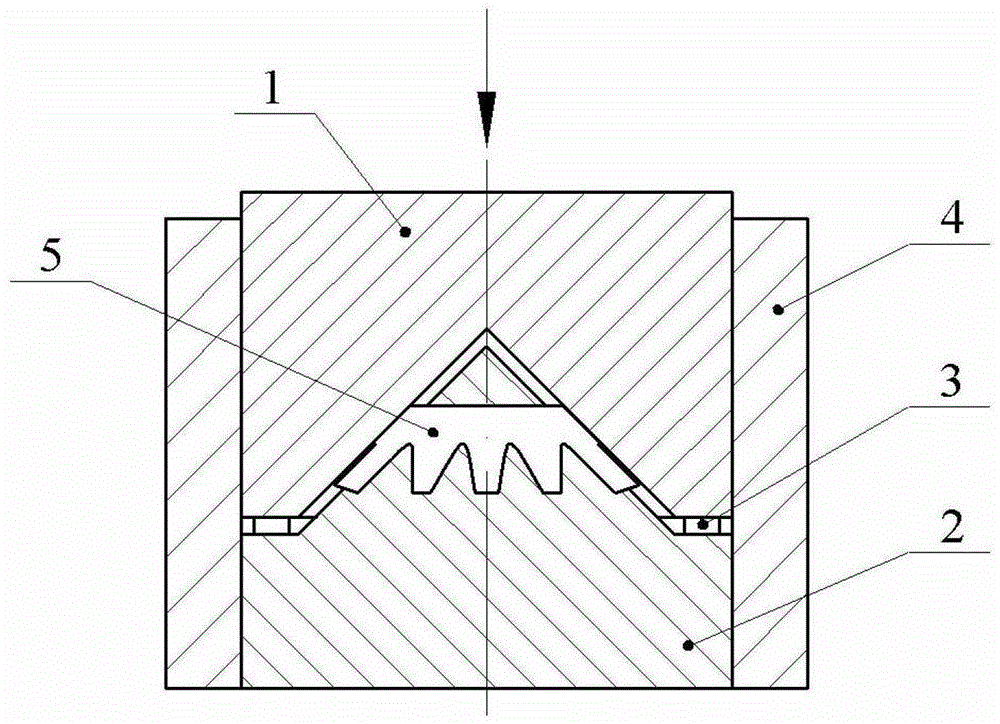

[0017] A kind of embodiment of tapered washer elasticity test tooling of the present invention is for example Figure 1 to Figure 3 As shown, it includes an outer cone 2 with an outer cone and an inner cone 1 with an inner cone, the inner and outer cones are arranged correspondingly up and down, and the cones of the inner and outer cones are in the same shape and have coincident axes. The cone angle angles of the inner and outer cone surfaces of the present embodiment are 90°, which are equal to the cone angle angles of the conical gasket 5 to be tested. Positioning plane, the upper and lower positioning planes are perpendicular to the axis of the cone surface. The upper and lower positioning planes of the present embodiment also fit together when the inner cone surface and the outer cone surface are in an anastomotic state, that is, the inner and outer cone surfaces When fitting, the distance between the upper and lower positioning planes is 0. This embodiment also includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com