Patents

Literature

519 results about "Thermocouple Wire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

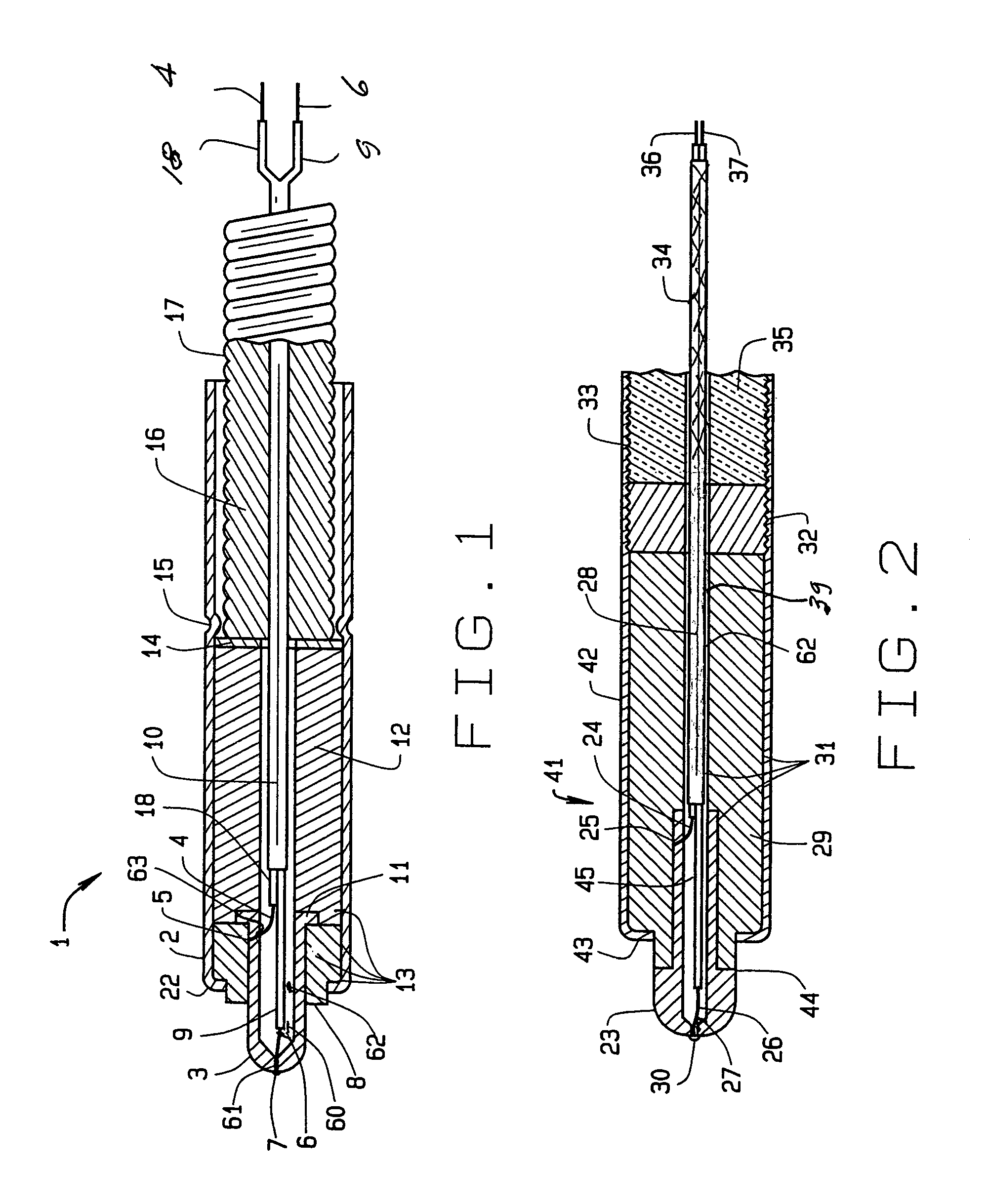

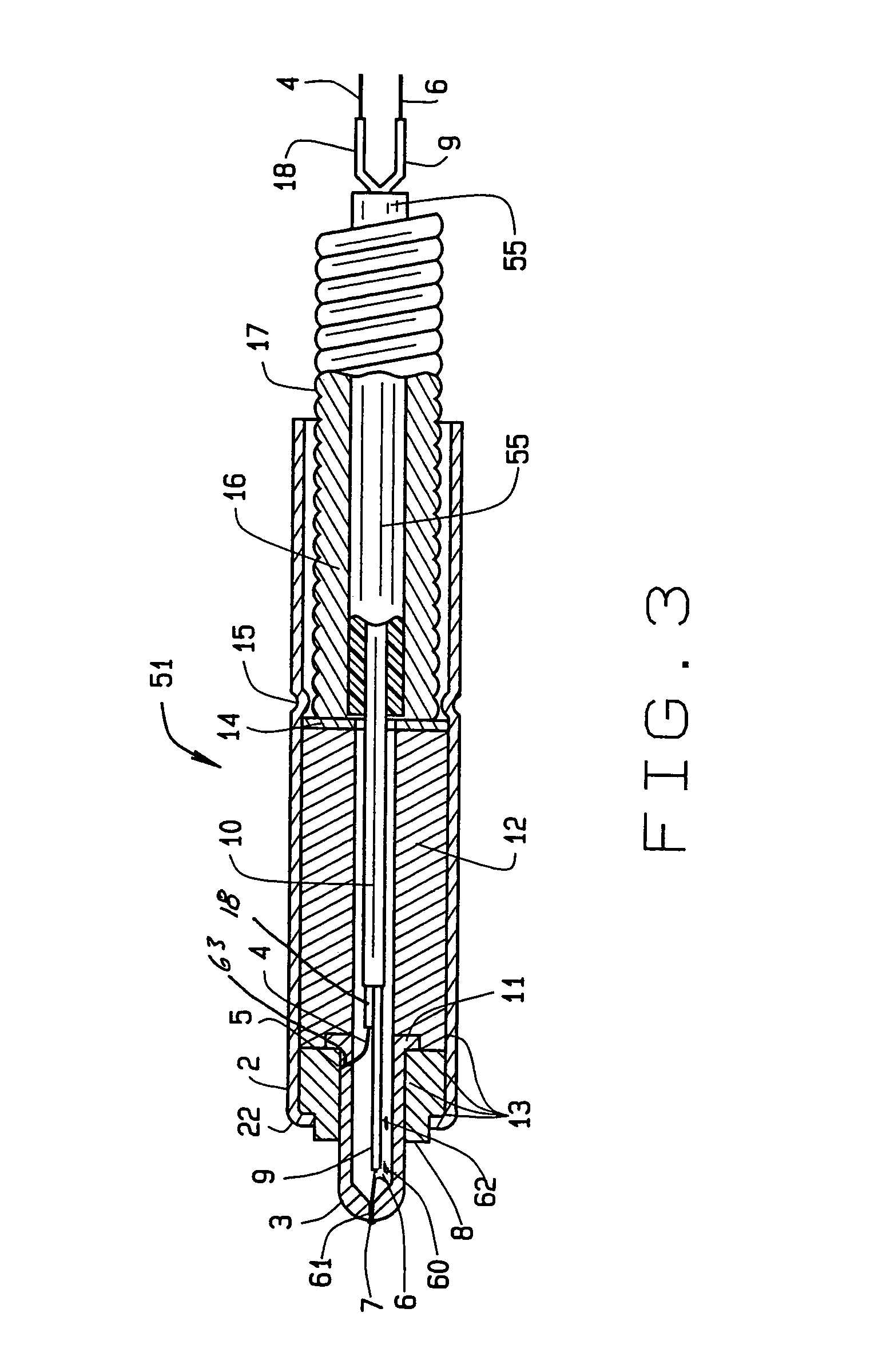

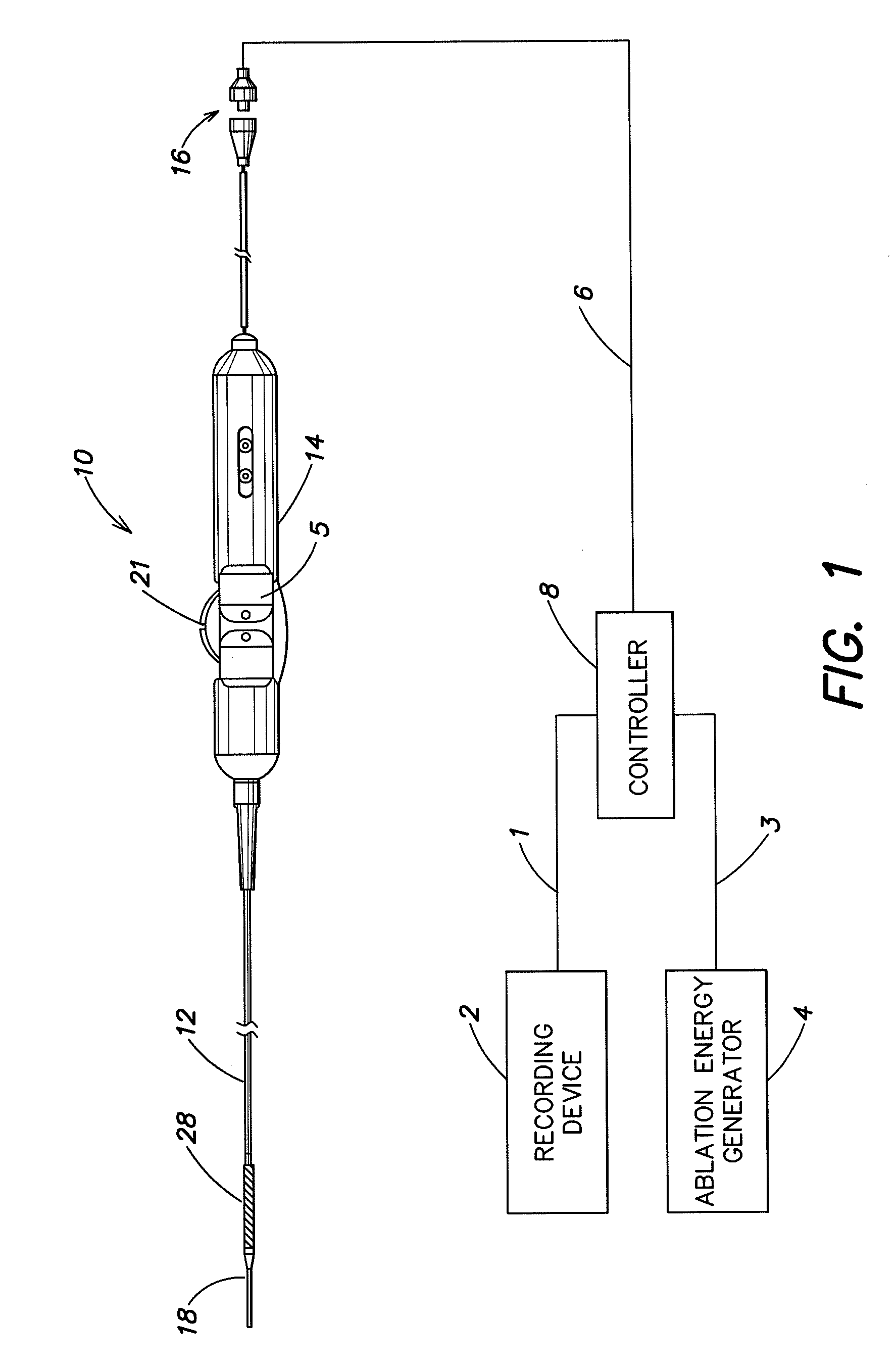

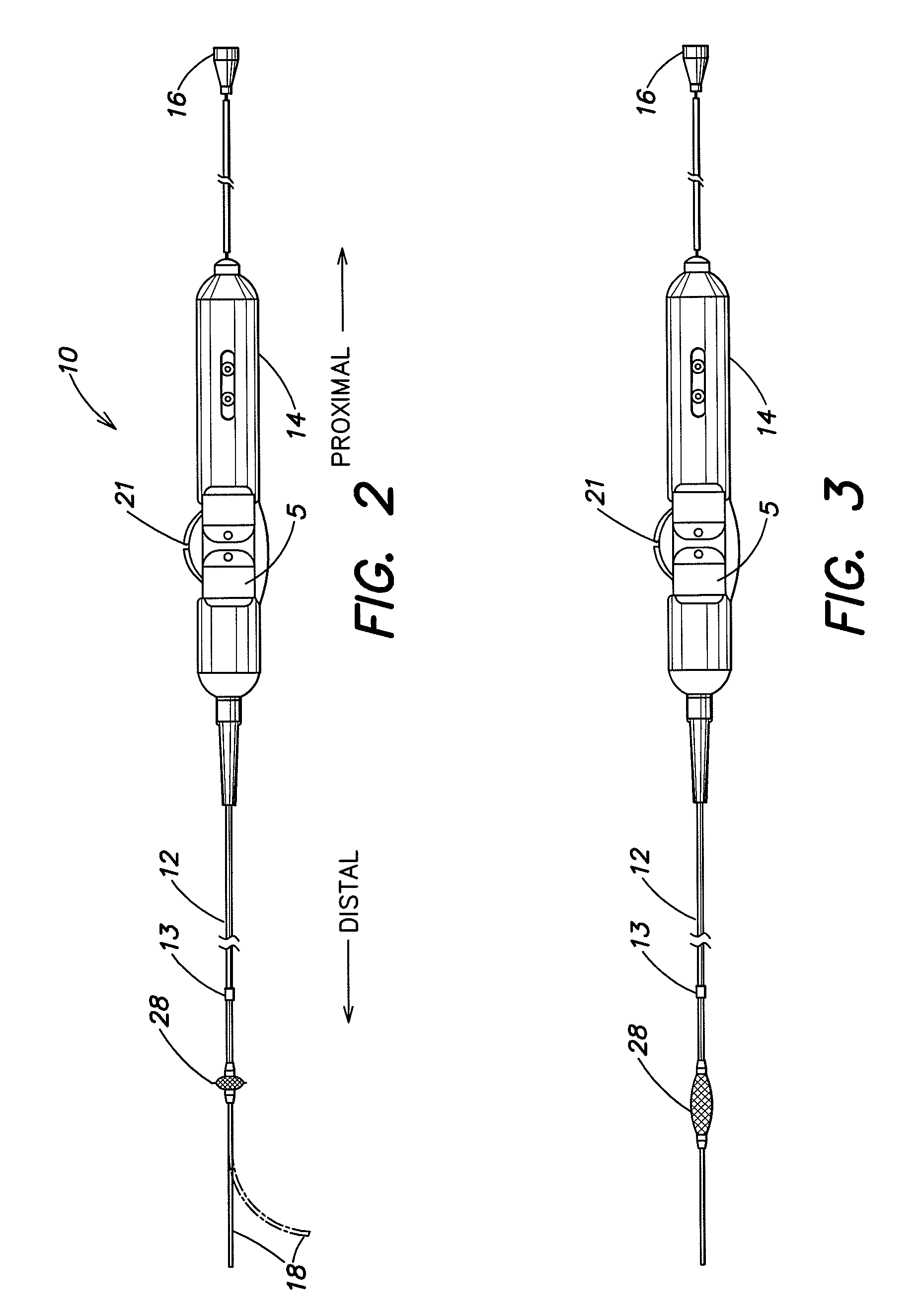

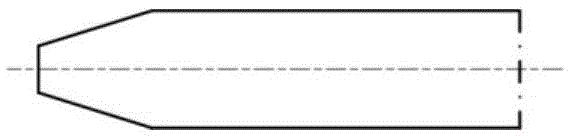

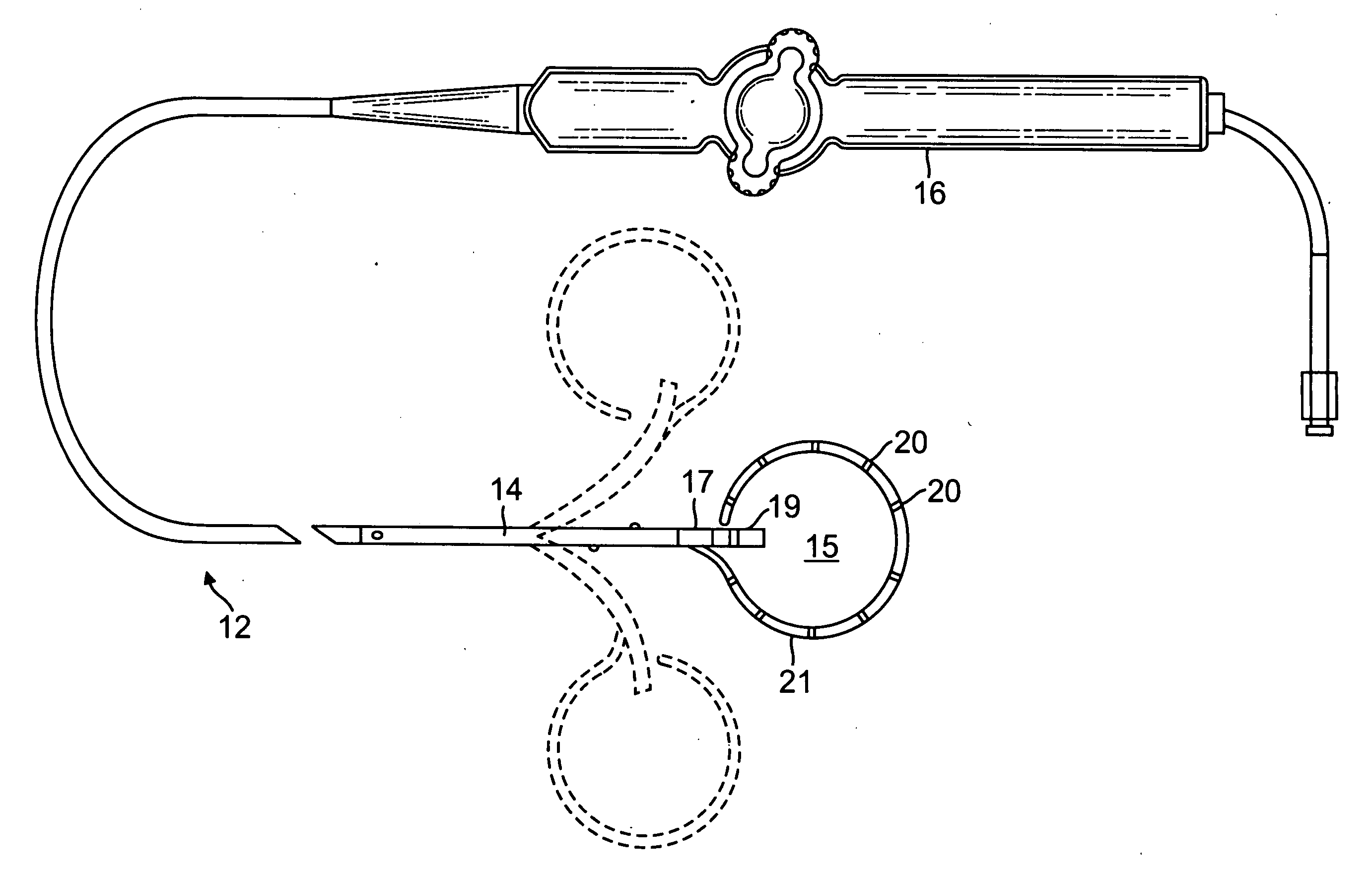

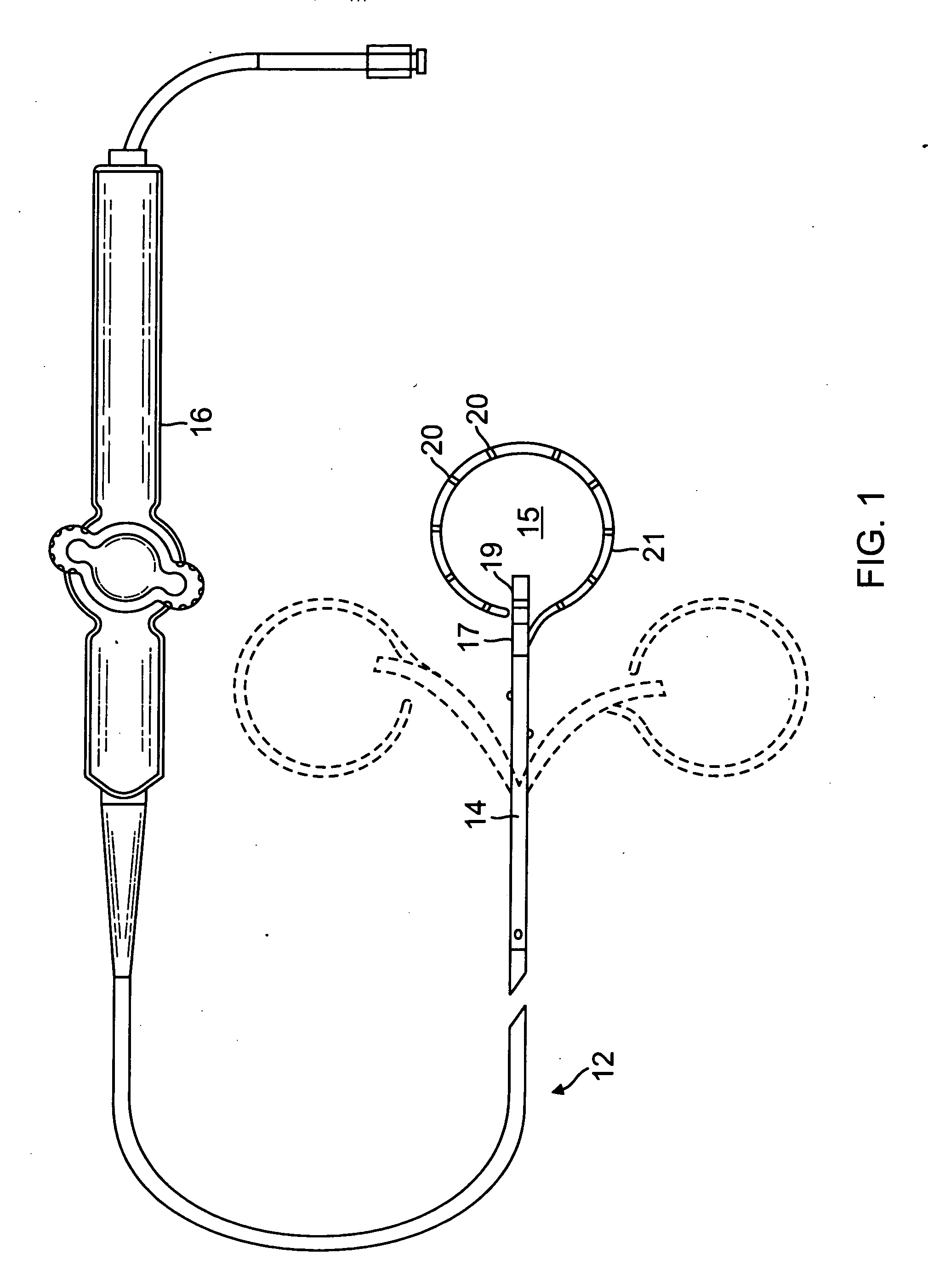

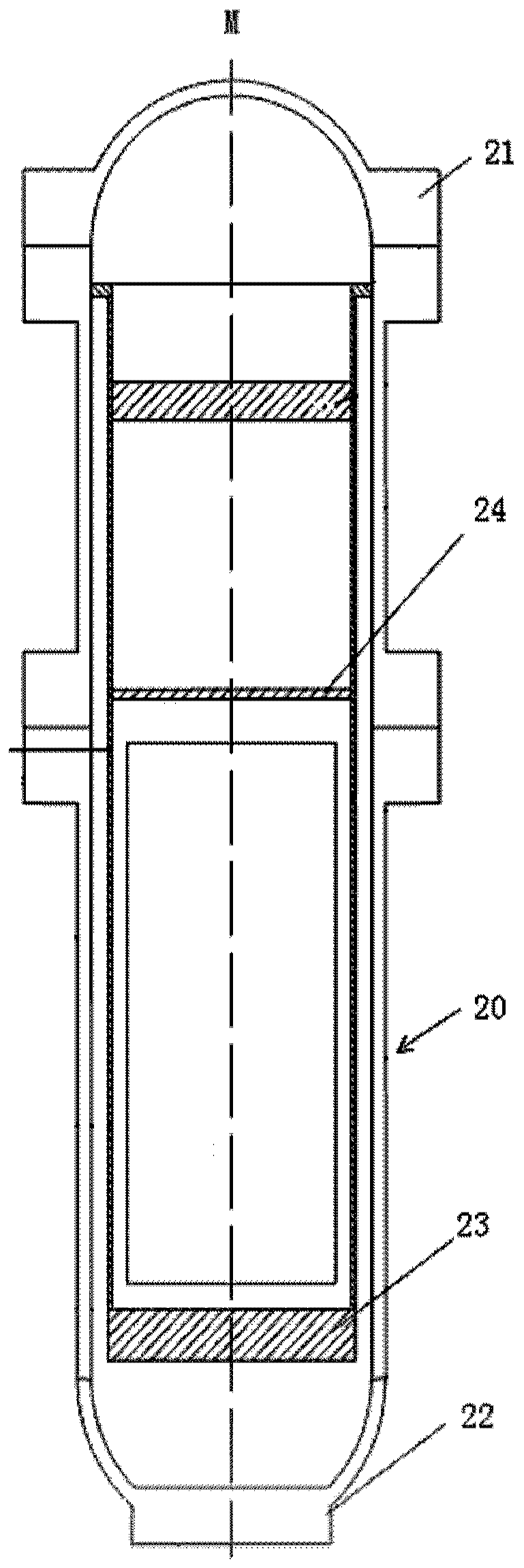

Epicardial mapping and ablation catheter

ActiveUS8287532B2Safely maneuverReliable contactBioelectric signal measurementCatheterEpicardial mappingThermocouple Wire

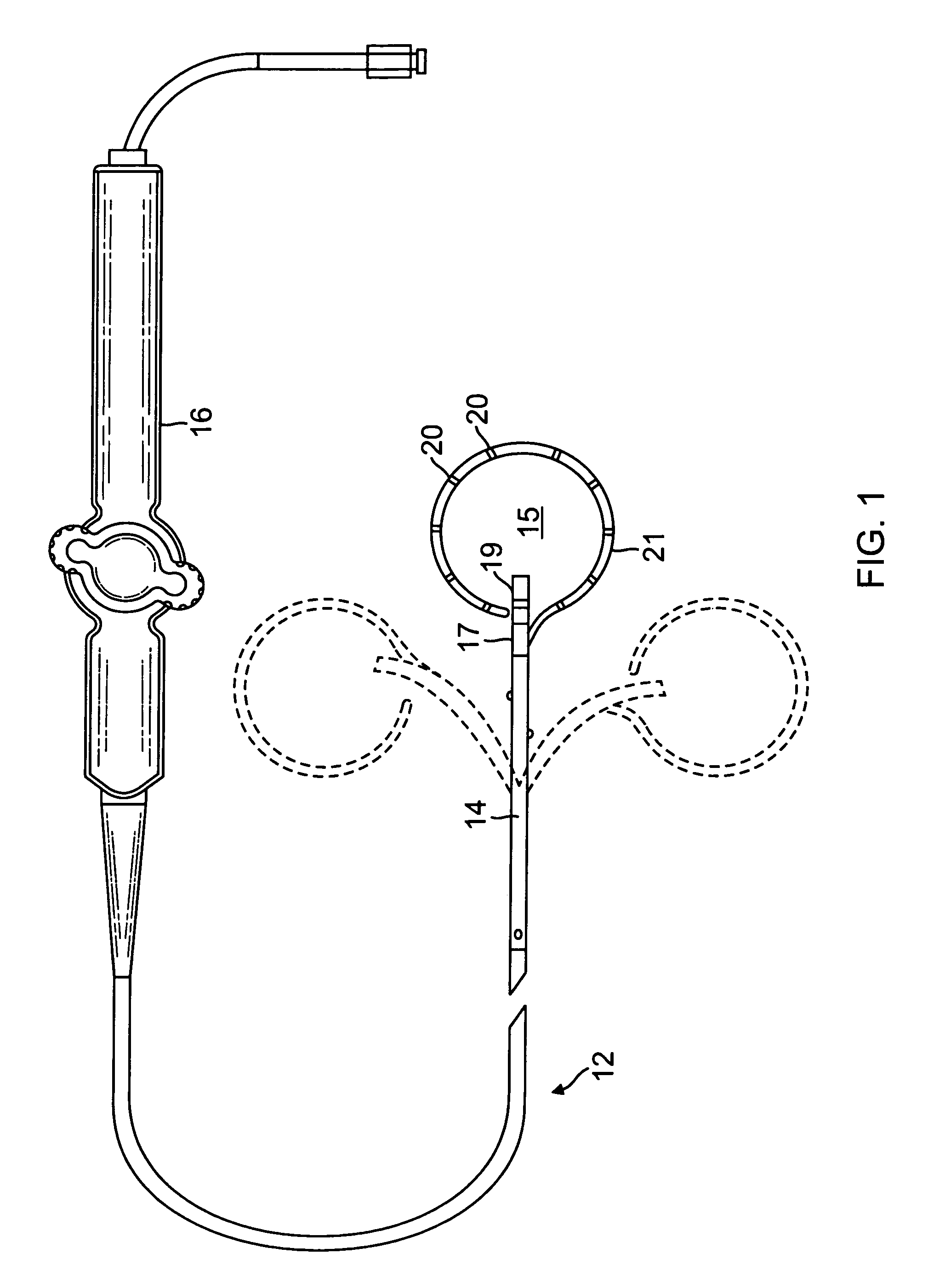

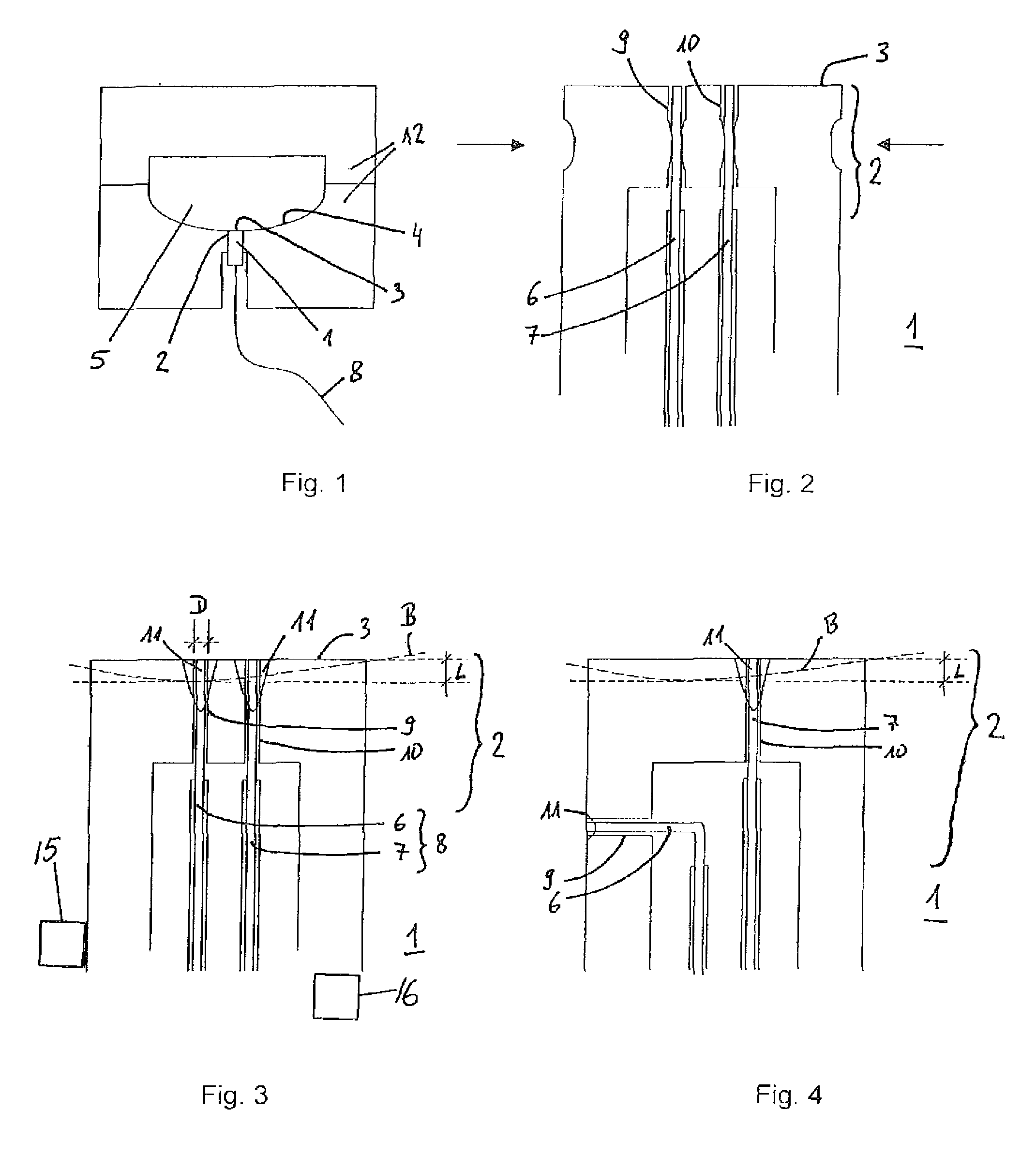

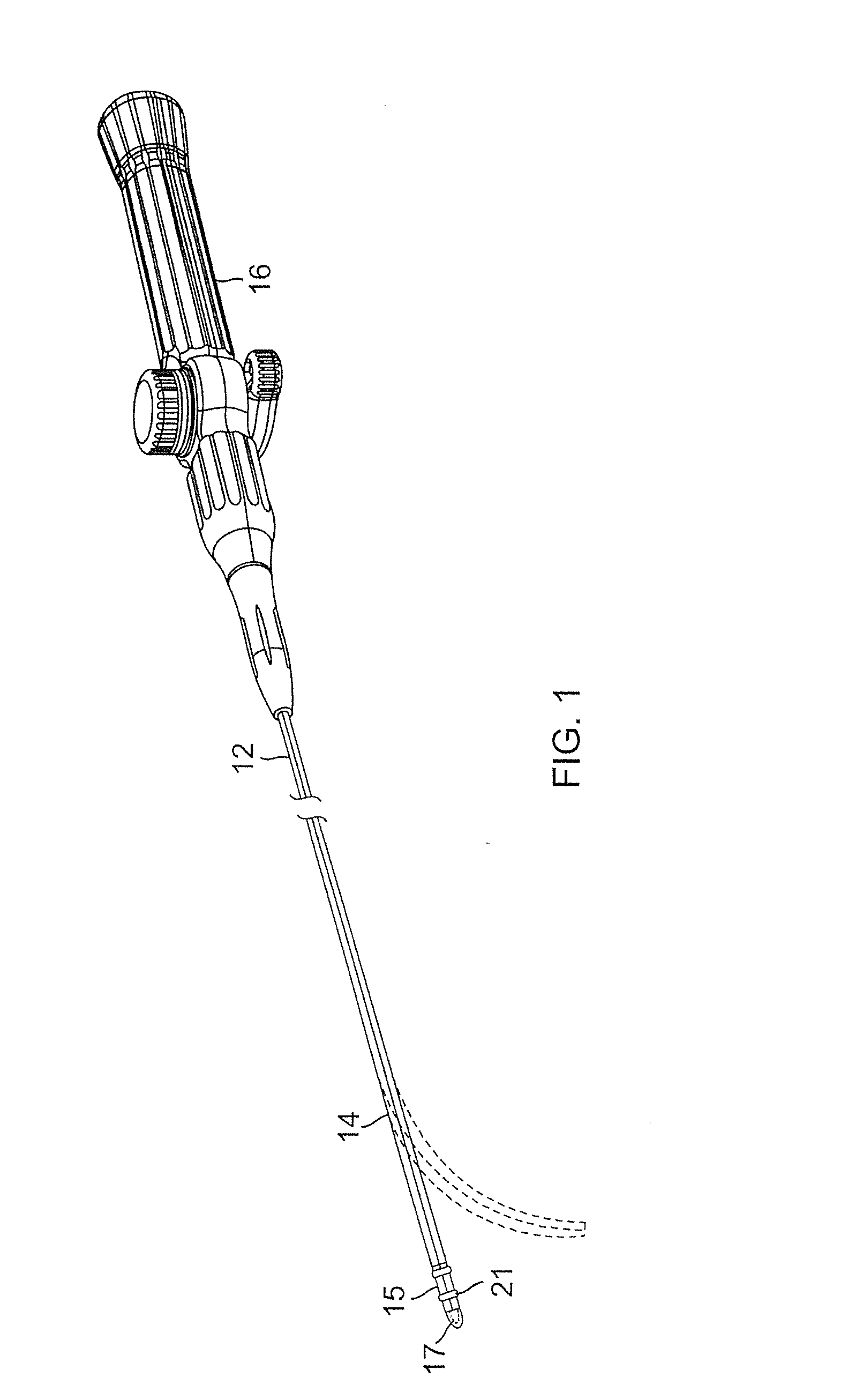

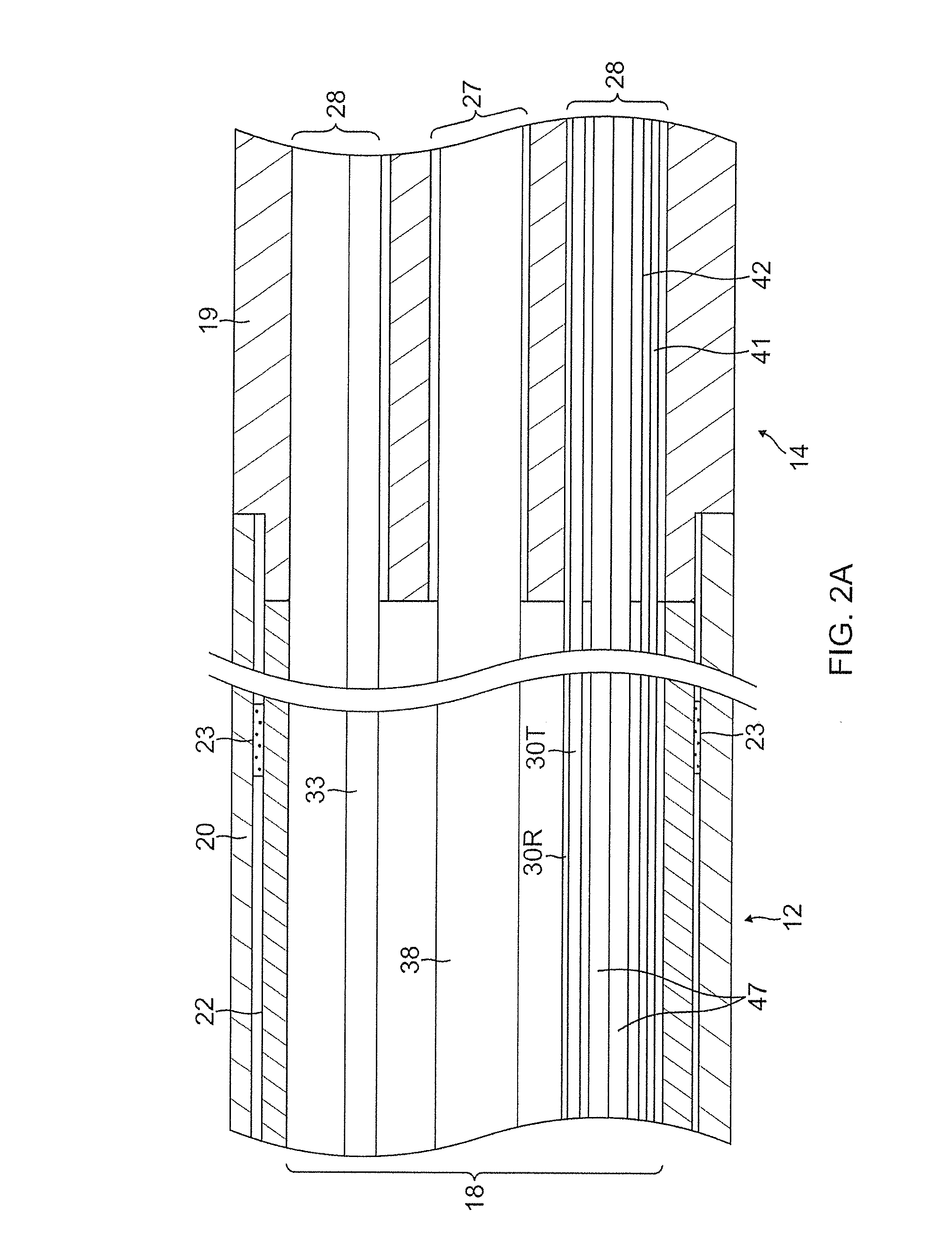

A catheter adapted for mapping and ablating epicardial tissue from the pericardial cavity includes a catheter body and an electrode assembly that has a tip section and a loop member lying generally within a plane, wherein the tip section includes an ablation electrode exposed on one side of the loop member and an insulation member exposed on an opposite side of the loop member. The catheter also includes a intermediate section between the catheter body and the electrode assembly, wherein the intermediate deflects the loop member and the tip section bi-directionally within the same plane. So arranged, the catheter can be safely maneuvered in the pericardial sac and swept in a side to side motion over the epicardium with the ablation electrode reliably facing and making contact with the epicardium. The tip section can include a balloon that is inflatable to push away surrounding pericardial tissue. The catheter may further include an injection needle whose distal end can extend outside of the tip section to puncture epicardial tissue. A lumen in the injection needle allows for delivery to agents directly to the punctured tissue and thermocouple wires can be carried in the lumen for temperature sensing at the treatment site.

Owner:BIOSENSE WEBSTER INC

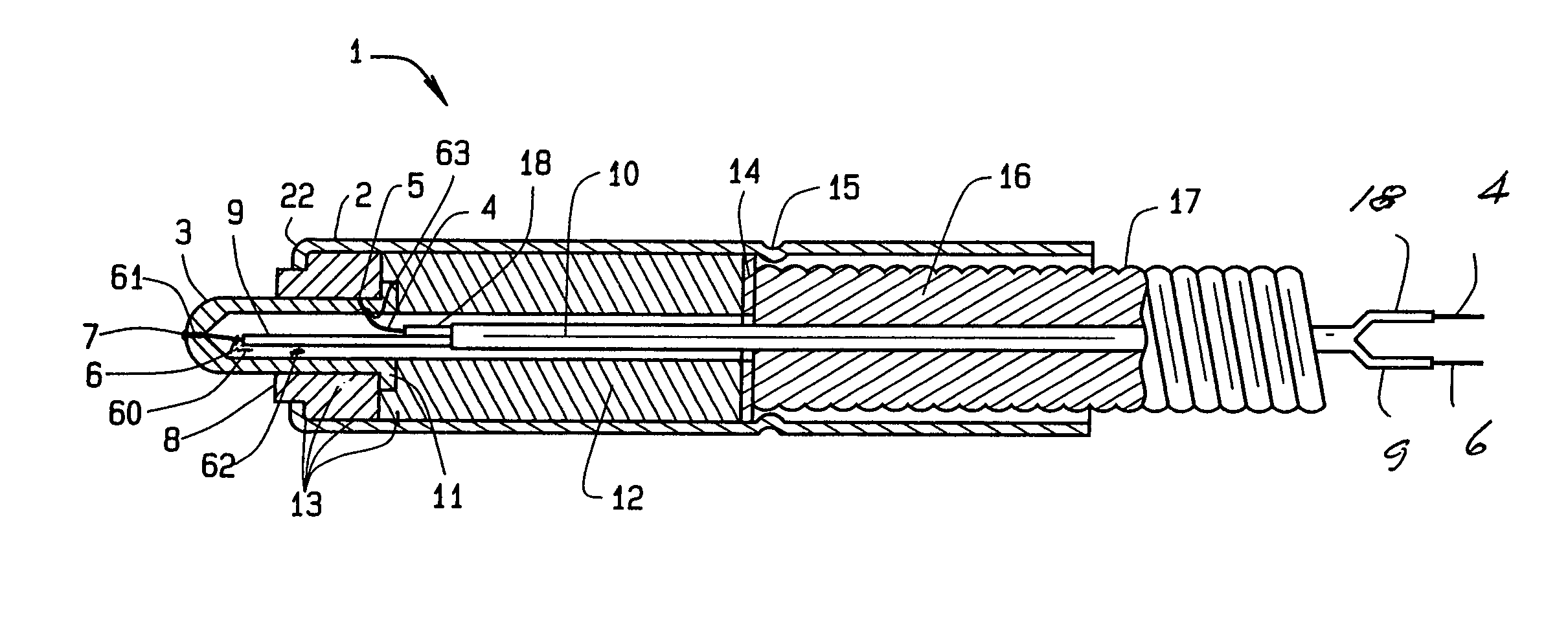

Temperature sensor with processable front

ActiveUS7789559B2Thermometer detailsThermometers using electric/magnetic elementsThermocouple WireBiomedical engineering

A temperature sensor has a sensor tip and a front for measuring the temperature of the inner walls of tools, particularly inner walls of injection molding tools. The tip of the temperature sensor has two thermocouple wires of a thermocouple. Each thermocouple wire of the thermocouple guided to the front is welded to the sensor tip up to a depth which is larger than the total processing depth behind the front. The sensor tip is processable by removing of material at the front up to that processing depth.

Owner:KISTLER HLDG AG

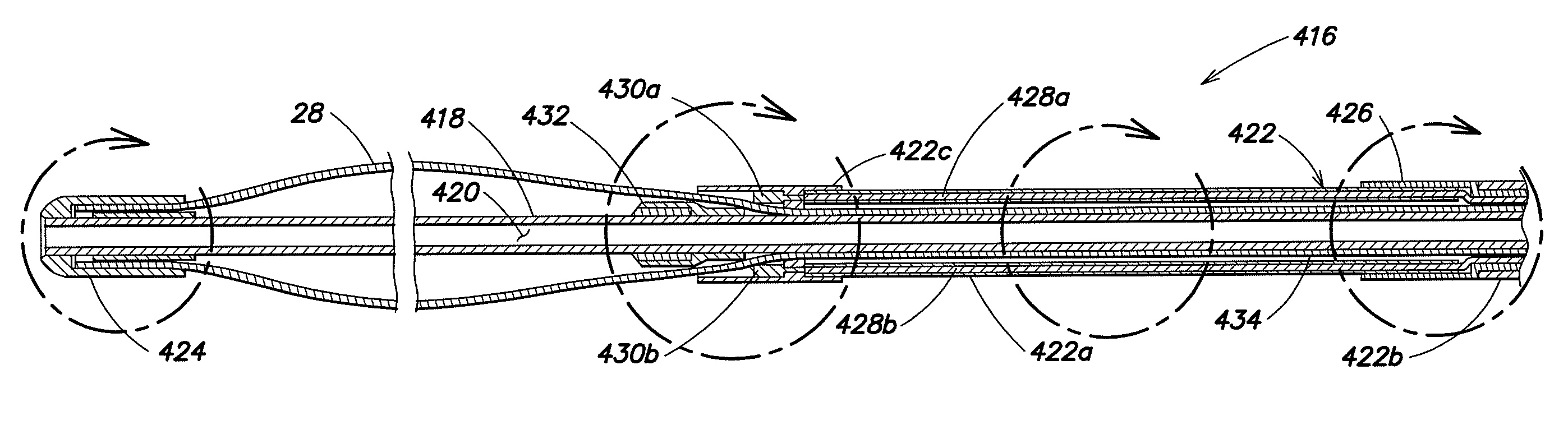

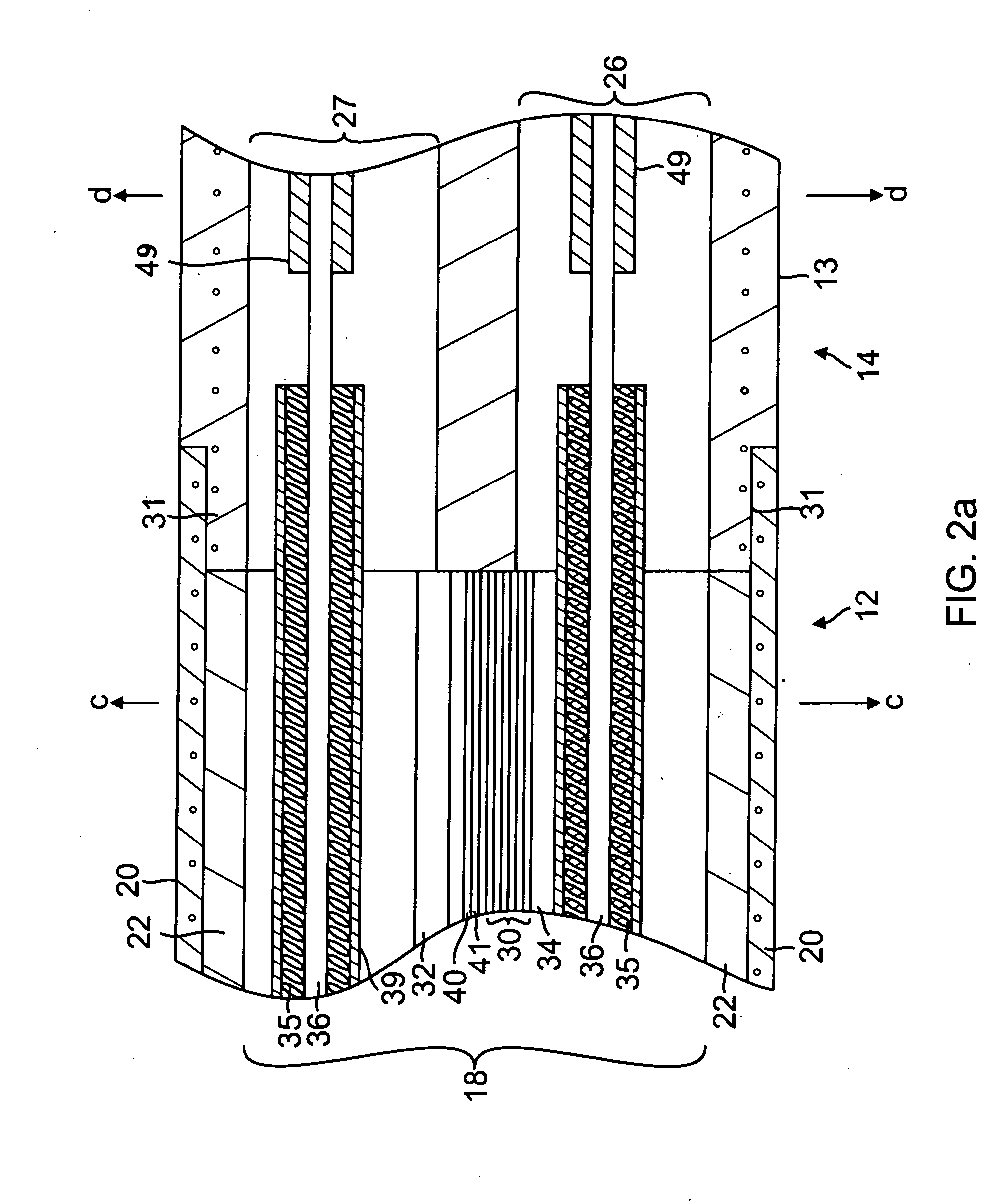

Braided mesh catheter

InactiveUS20070129717A1Increase rotational frictionEasy to compressElectrocardiographyCatheterThermocouple WireBiomedical engineering

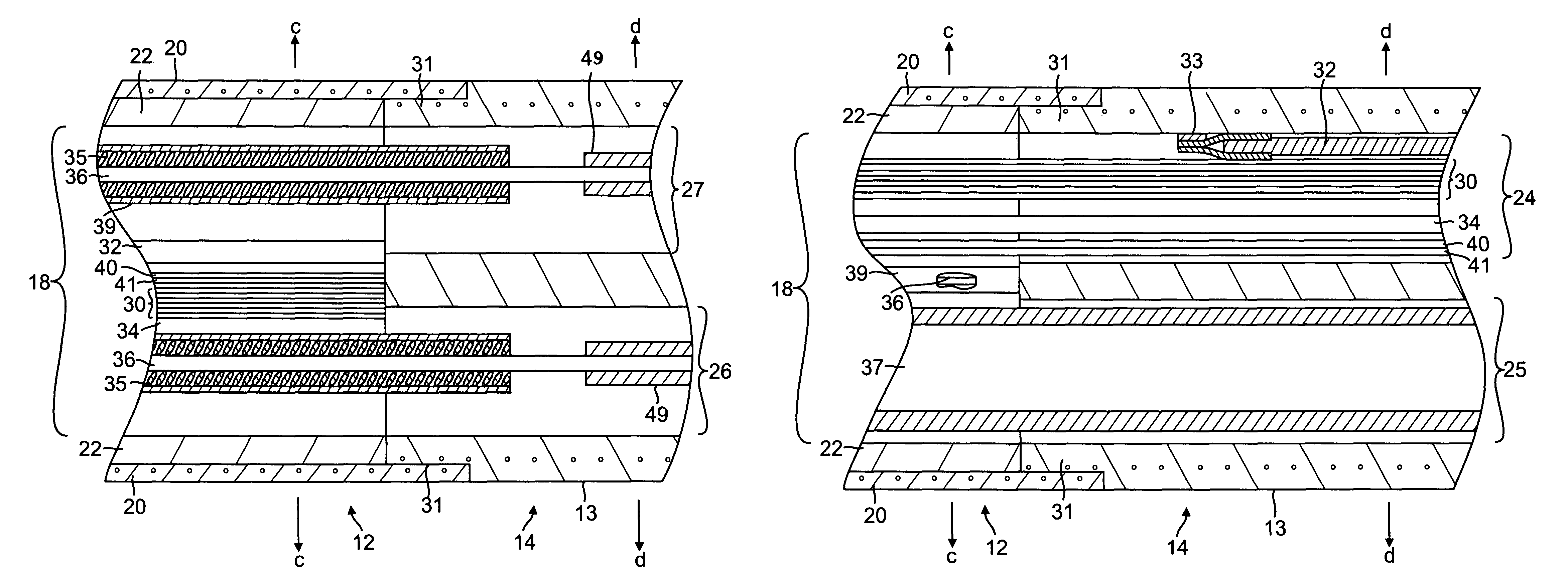

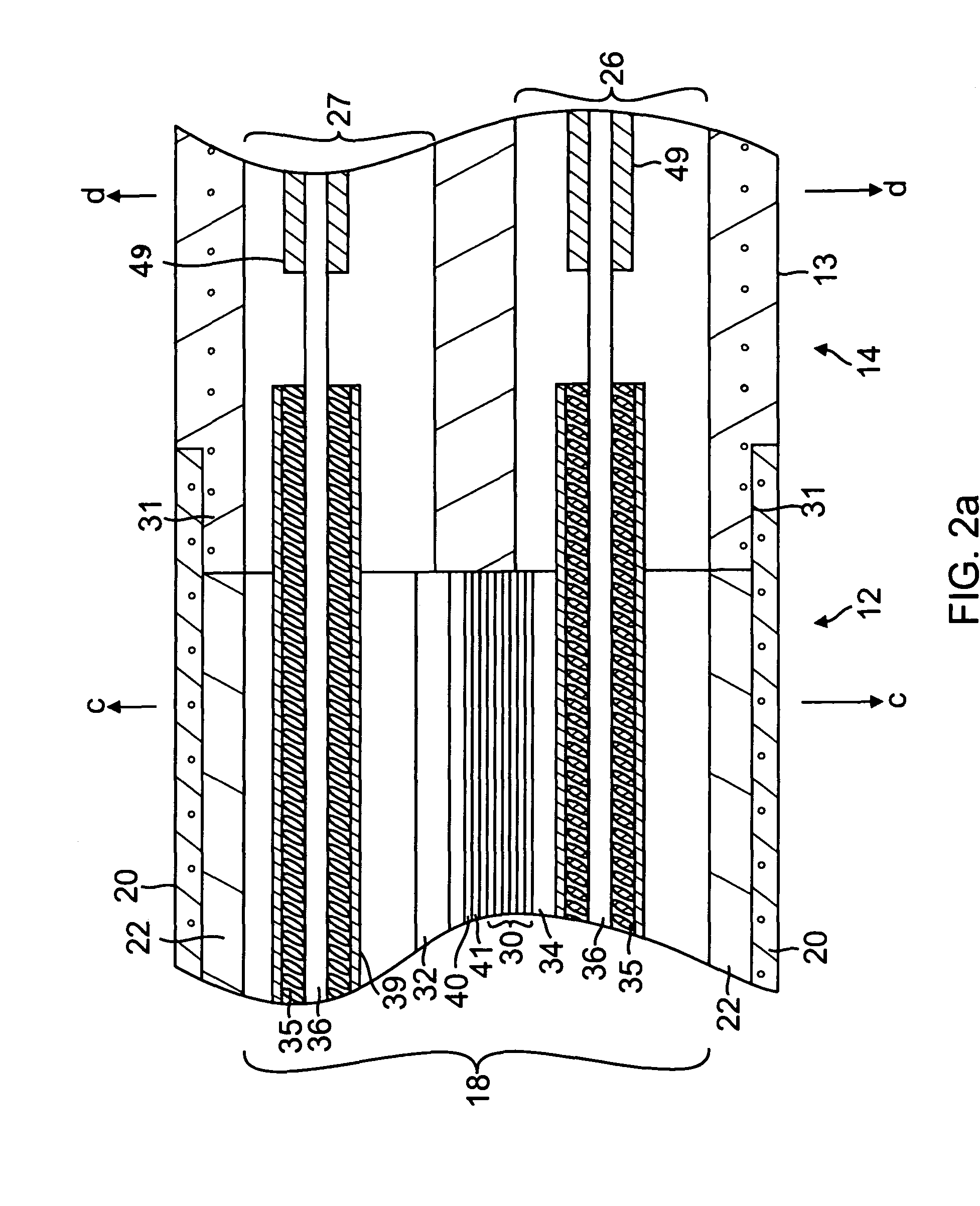

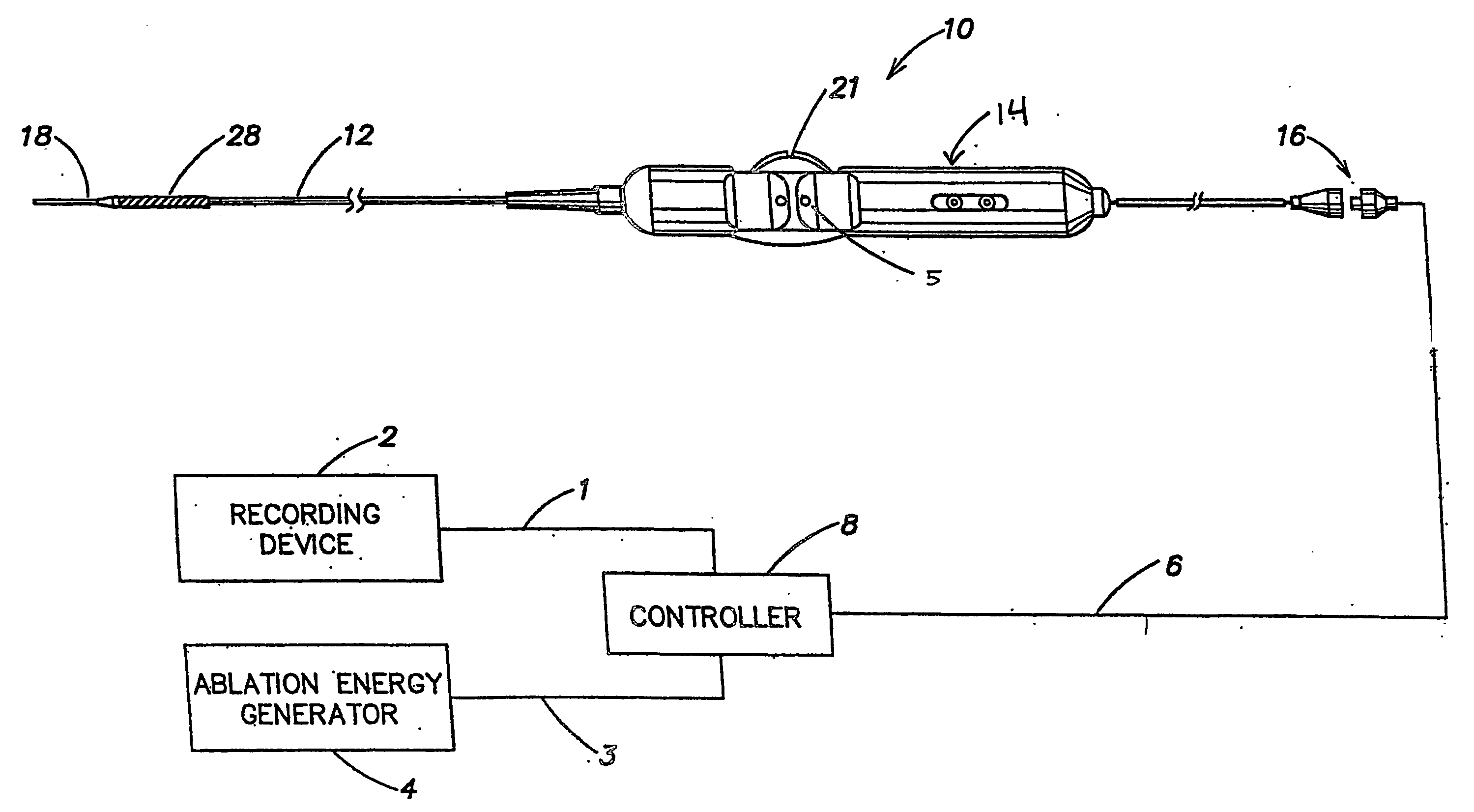

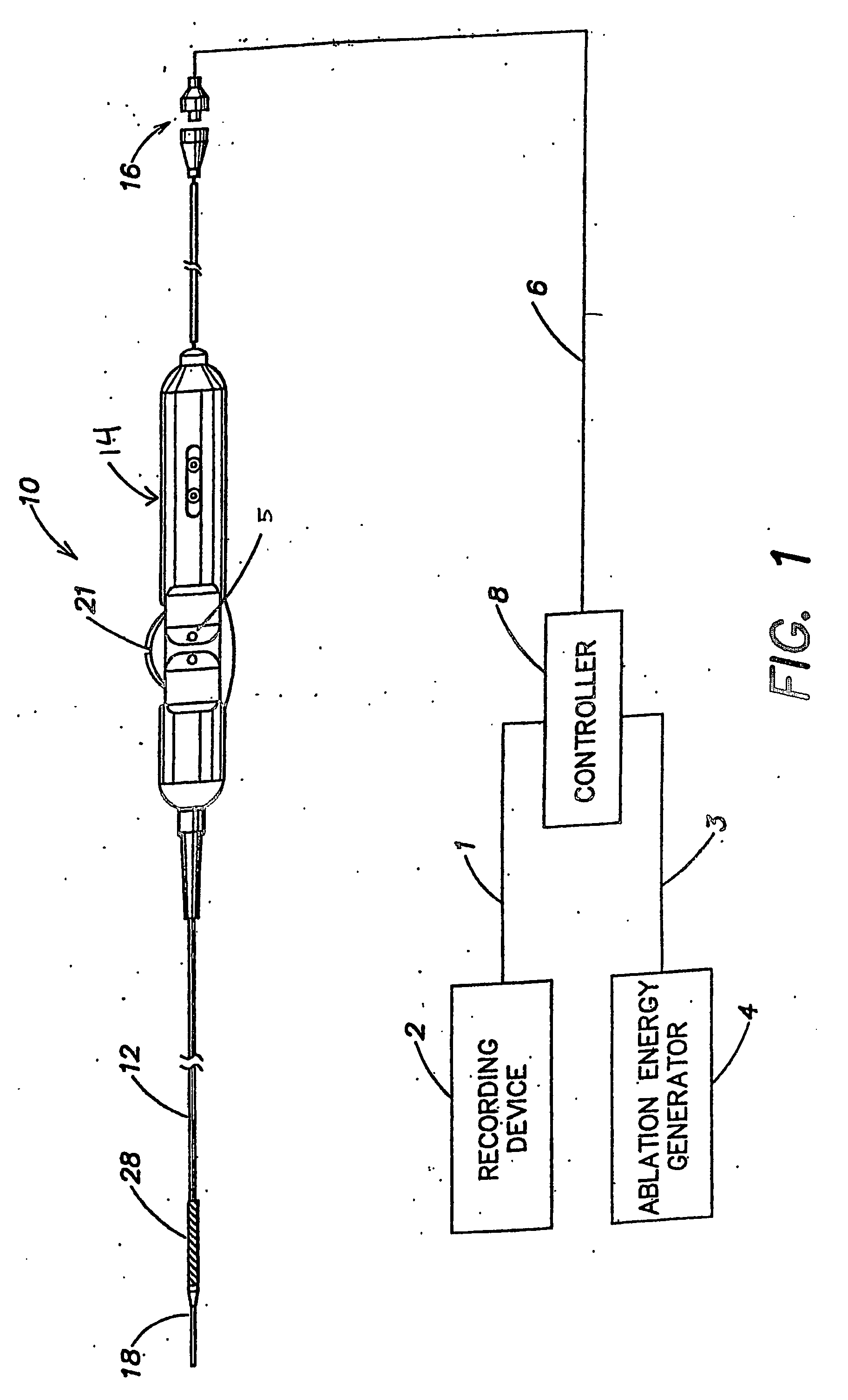

Embodiments of the invention relate to electrophysiology catheters and methods of using the same. According to one embodiment, the catheter includes a braided conductive member at its distal end that can be radially expanded, for example using a mandrel slidably disposed within a shaft of the catheter. According to another embodiment, the catheter comprises a tip portion constructed of an elastomeric material. According to a further embodiment, the catheter includes a braided conductive member wherein a thermocouple is formed using one filament of the braided conductive member and one thermocouple wire. Other embodiments of the invention relate to a handle for use with a catheter and methods of using the same. According to one embodiment, the handle comprises a thumbwheel coupled to a housing, a spring disposed within the housing in contact with the thumbwheel, and means for increasing compression of the spring to increase rotational friction on the thumbwheel.

Owner:BOSTON SCI SCIMED INC

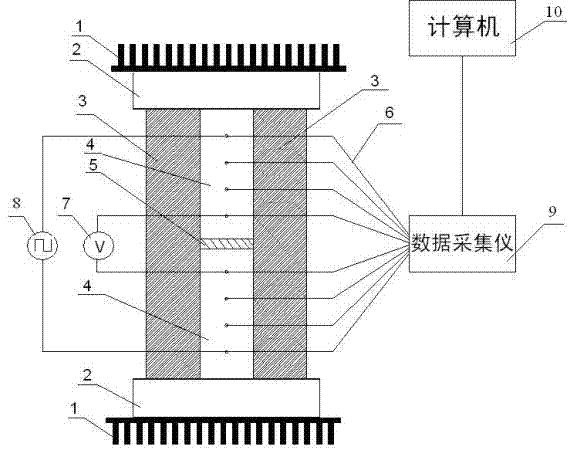

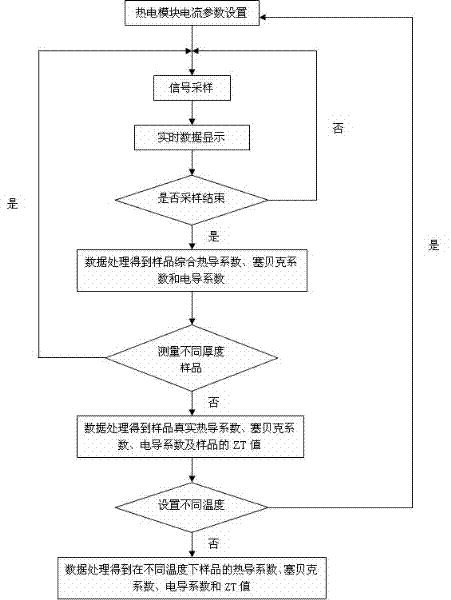

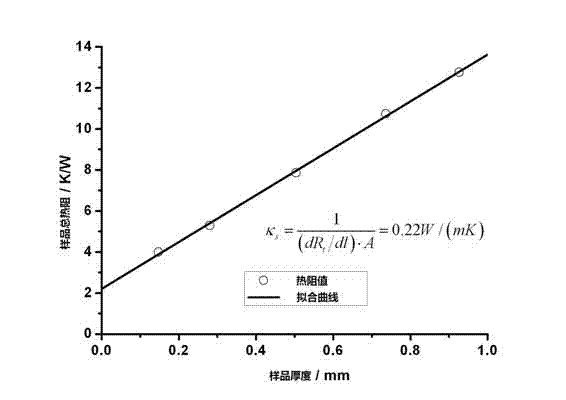

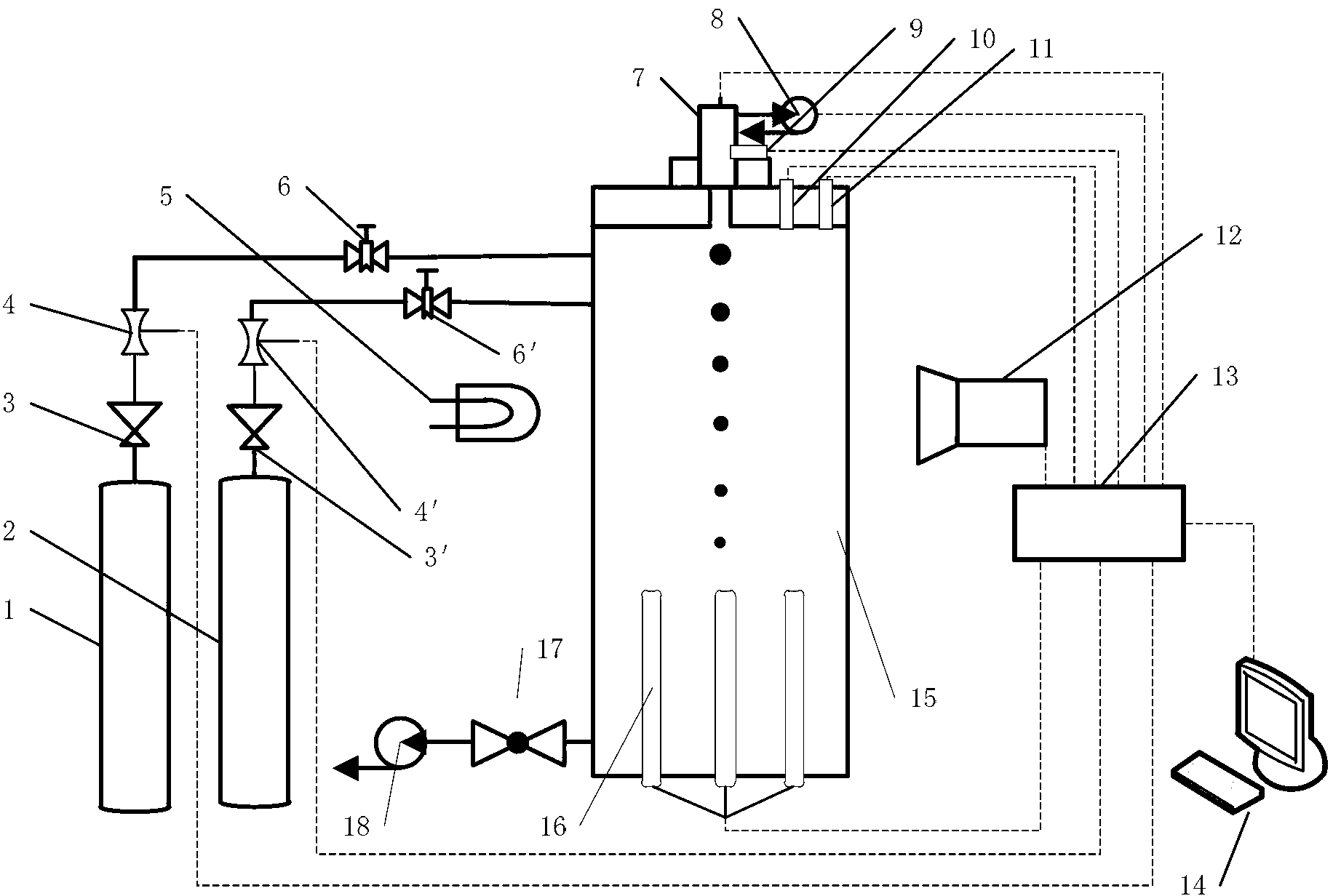

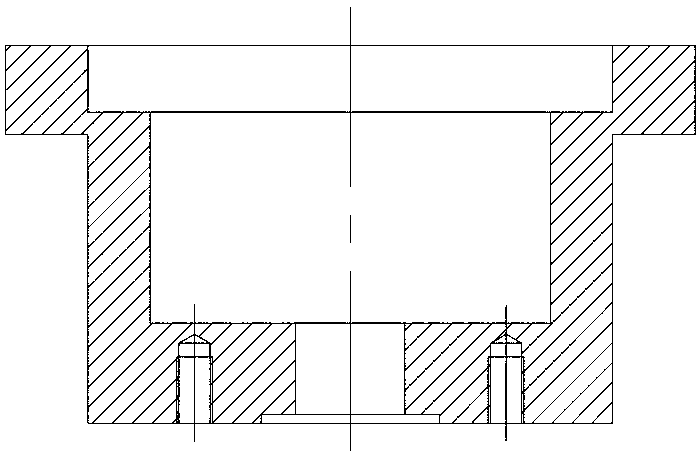

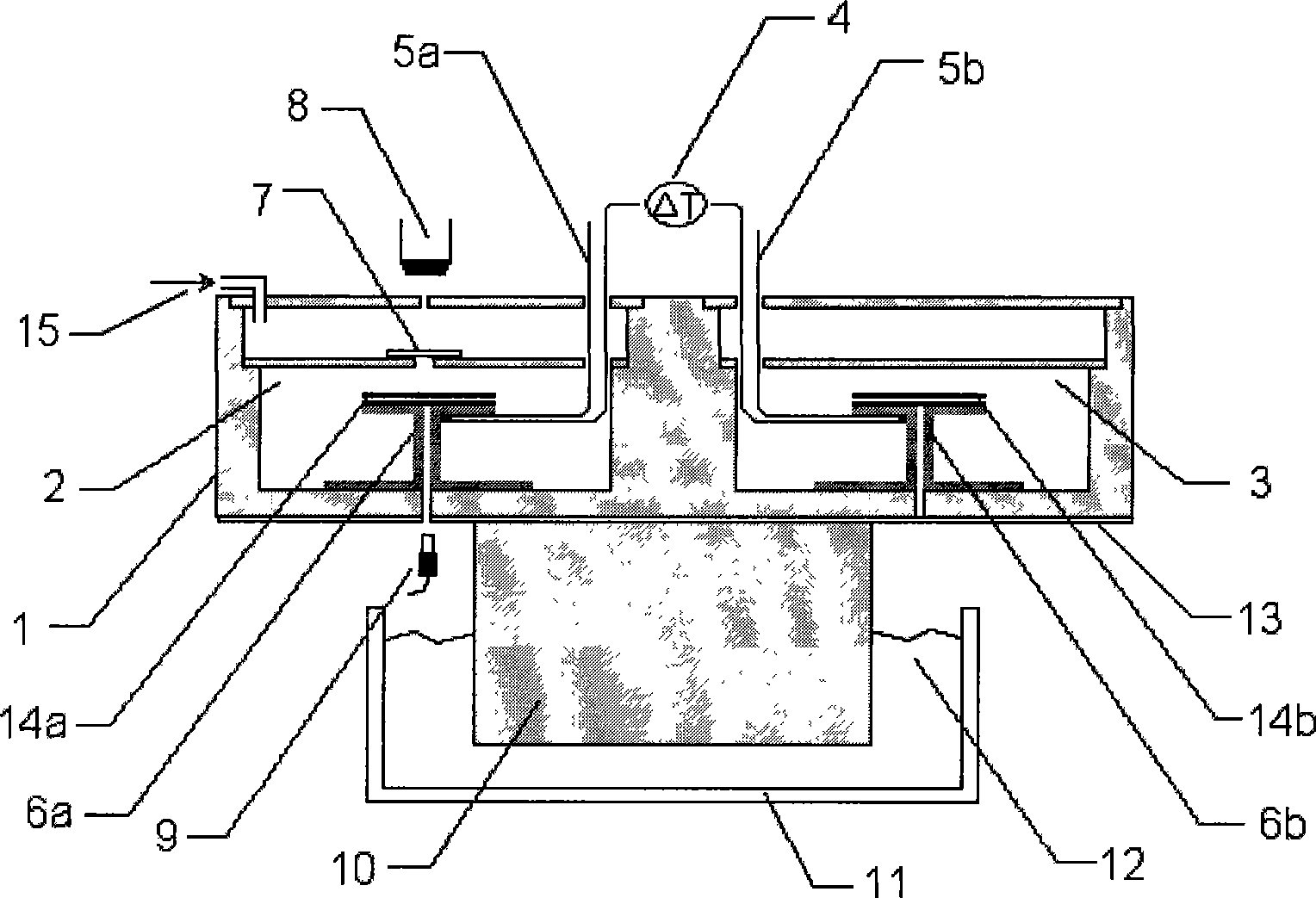

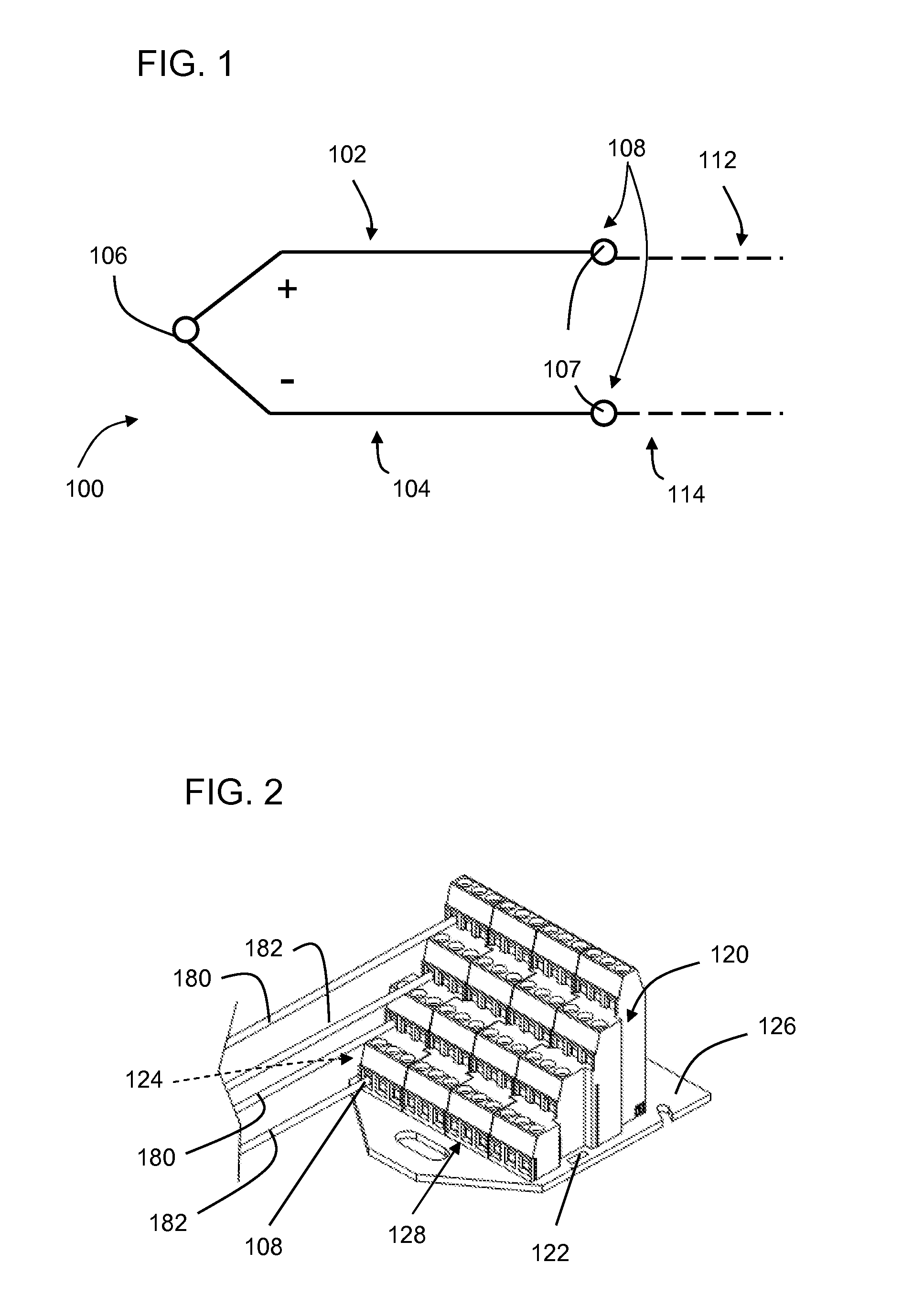

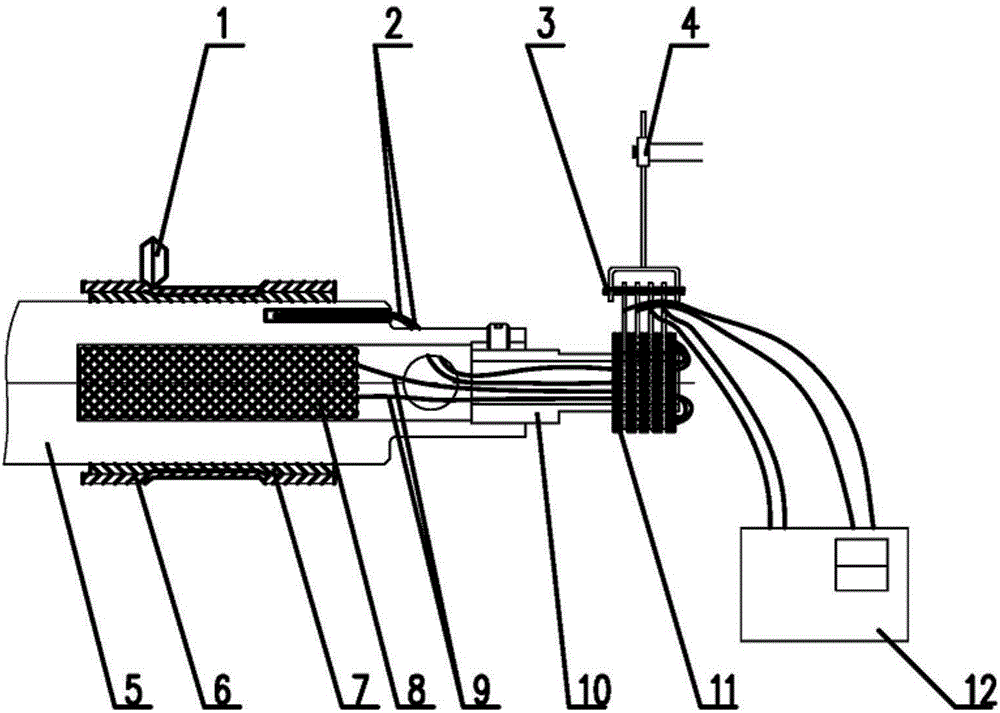

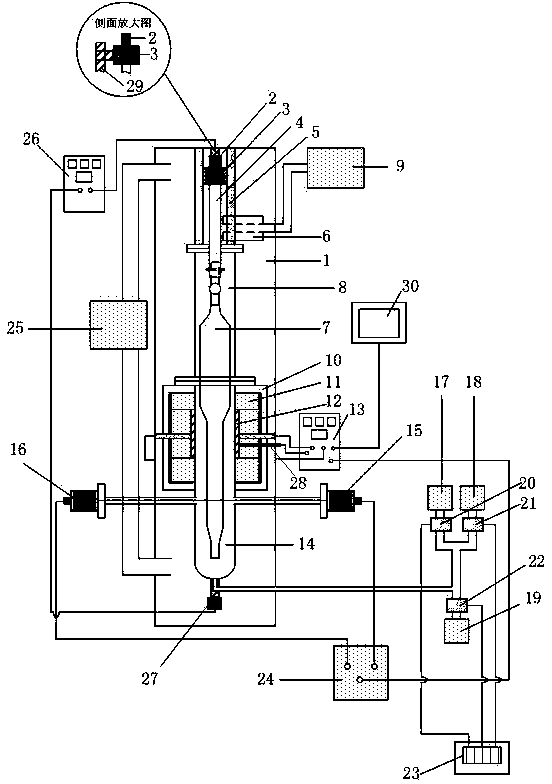

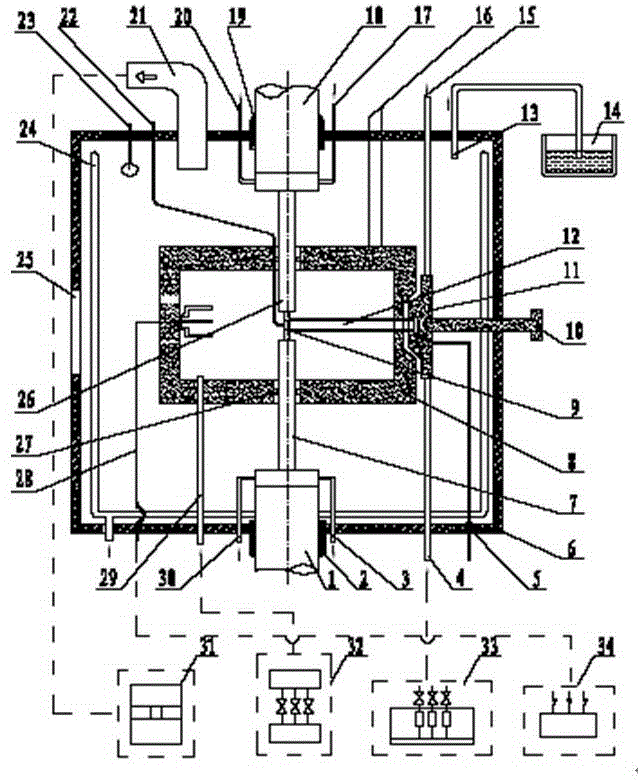

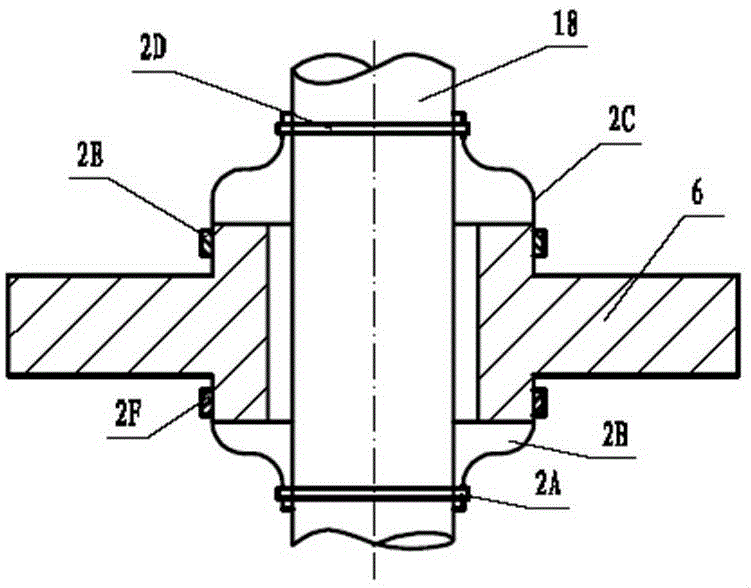

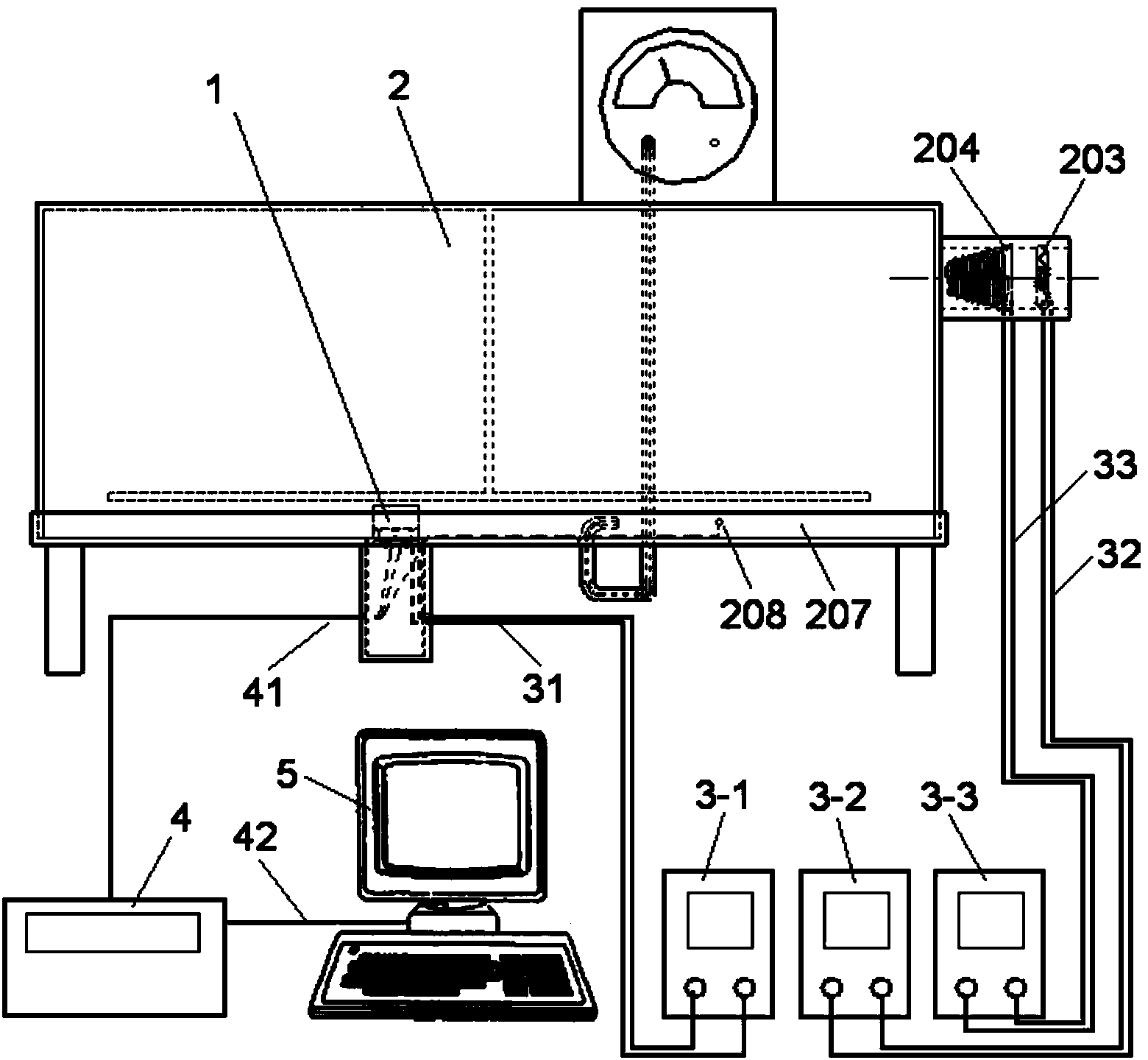

A kind of measuring device and method of thin film thermoelectric performance parameters

InactiveCN102297877AHigh temperature control accuracySave resourcesResistance/reactance/impedenceMaterial heat developmentThermoelectric materialsMeasurement device

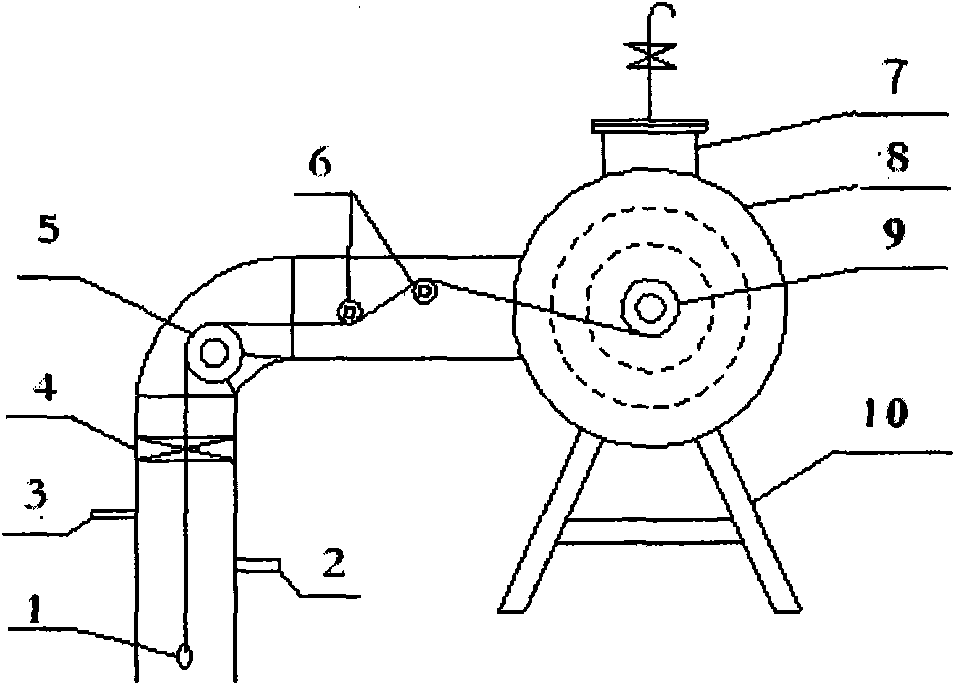

The invention provides a device and a method for measuring thermoelectric parameters of a film. The measuring device, which has a symmetric structure, comprises a radiating fin, a thermoelectric module, a heat insulation material, metal round rods, a thermocouple wire, a voltmeter, a power supply, a data acquisition instrument and a computer. The measuring method provided by the invention comprises the following steps of: clamping a film to be measured between two upper and lower metal round rods which are completely same while the area of the film sample is the same as the cross-sectional area of the metal round rods, controlling the ambient temperature of the measuring device and the heat flow of the film sample by the use of the thermoelectric module, detecting and recording each performance parameter of the film thermoelectric material at real time by the use of the data acquisition instrument. The invention has the following advantages: the performance of the film thermoelectric material at different temperatures can be measured, that is to say, the same device can be utilized to simultaneously measure the thermal conductivity coefficient, Seebeck coefficient and conductance coefficient of the film thermoelectric material so as to calculate ZT values of the film thermoelectric material at different temperatures. According to the invention, the measuring device has a simple principle, is convenient to operate, is small in size, has many test functions and has high measuring precision.

Owner:SHANGHAI UNIV

Fast acting thermocouple

InactiveUS7004626B1Improve insulation effectImprove protectionThermometer detailsThermometers using electric/magnetic elementsEngineeringThermocouple Wire

In a two wire thermocouple, a hollow tip is formed of the material of one of the thermocouple wires, the tip being adapted to extend into a medium the temperature of which is to be measured, both wires extending into a passage in the tip through an open outer end of the passage toward an inner end of the passage, one of the two thermocouple wires, of a material different from said tip, extending entirely through the passage and being welded at the outside of said tip to form a thermocouple junction and the other of the wires, of the same material as the tip, being welded to the tip at a place spaced from the junction.

Owner:TURBO RES

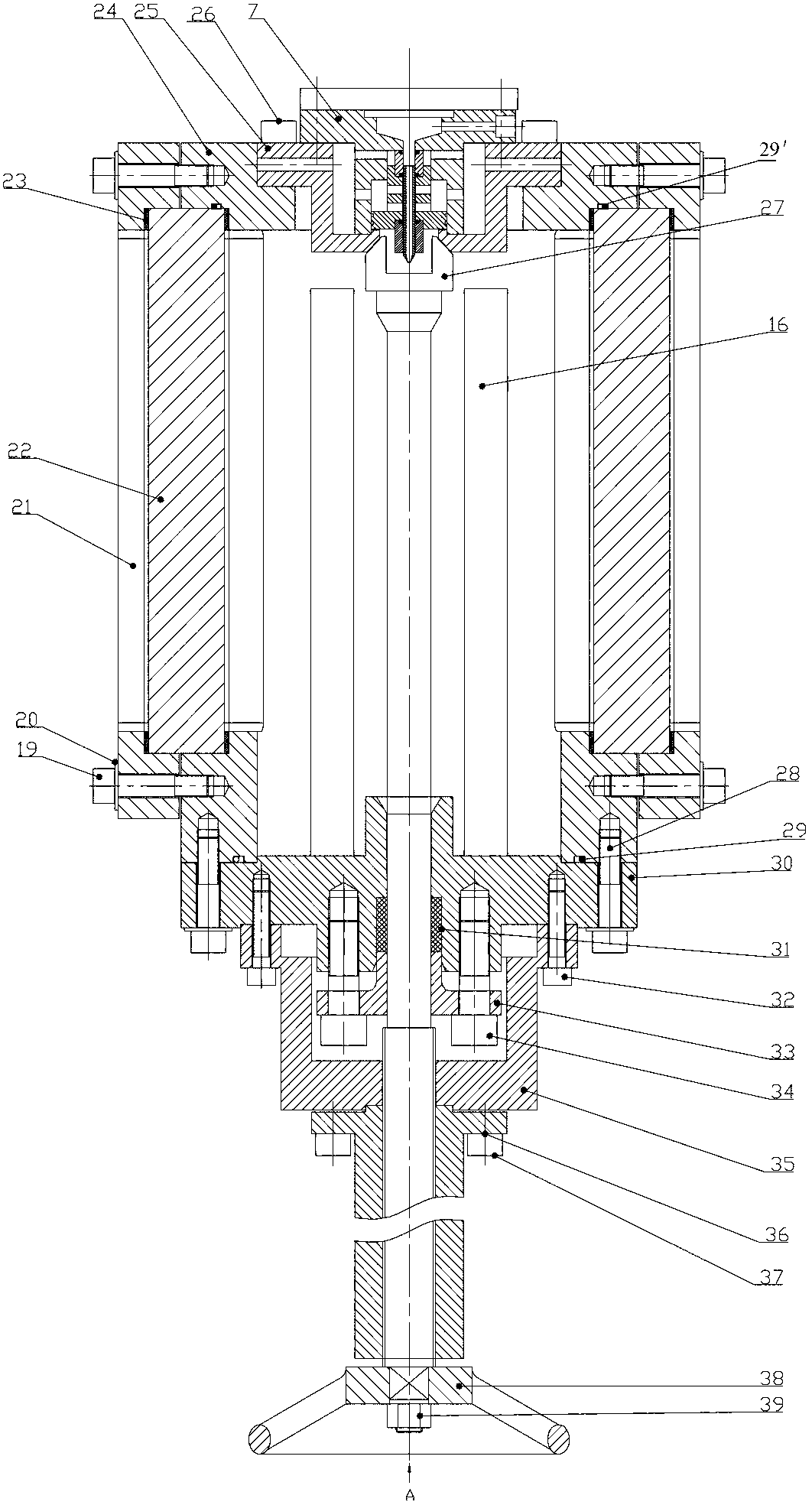

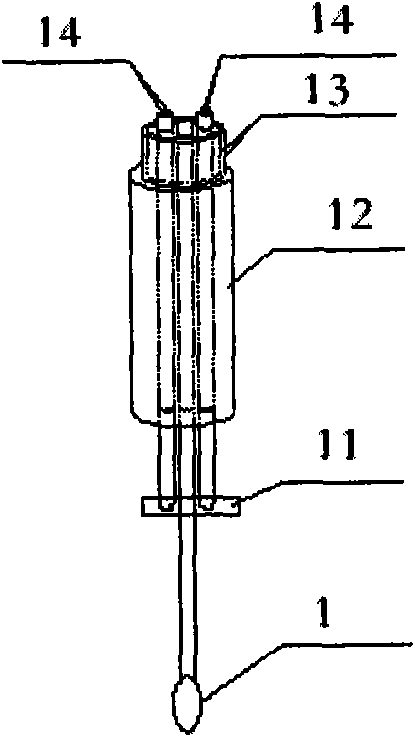

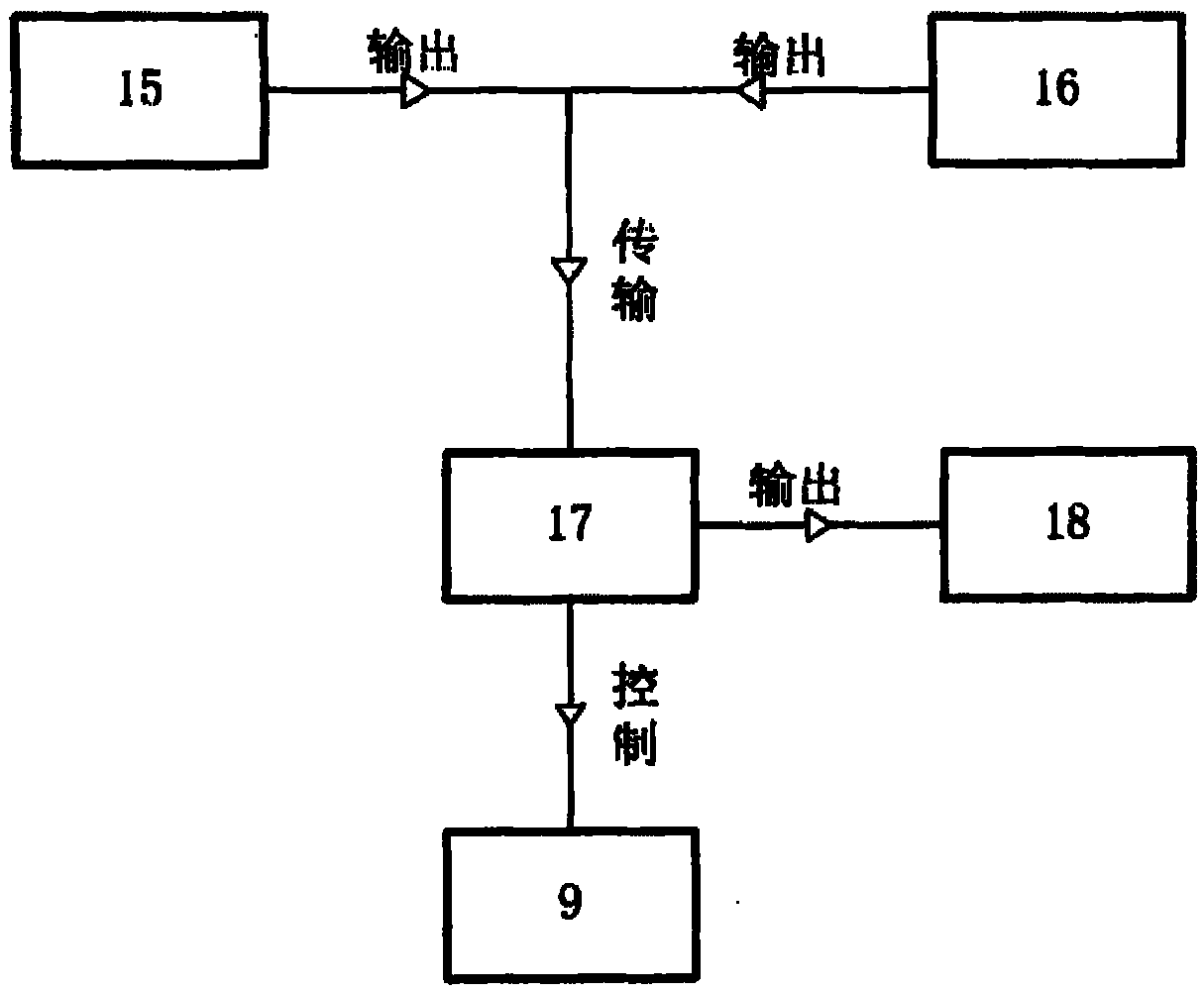

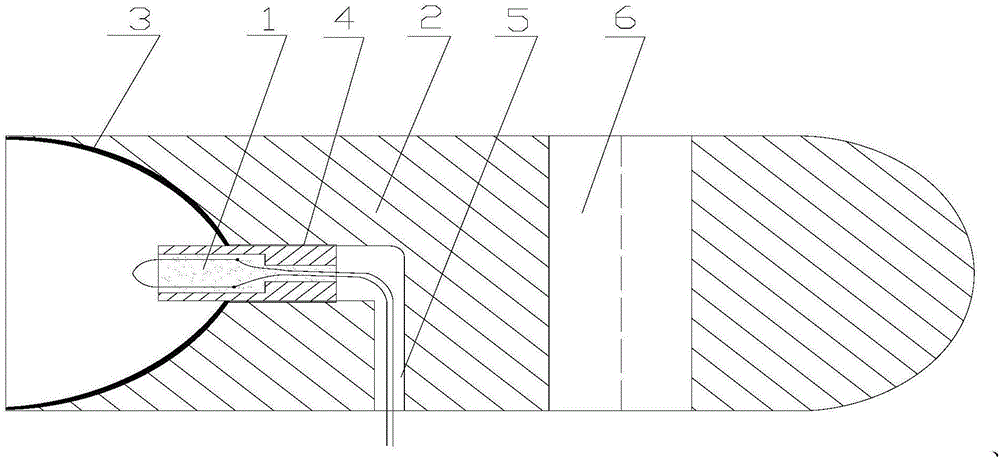

High-temperature and high-pressure single-drop evaporating and burning device

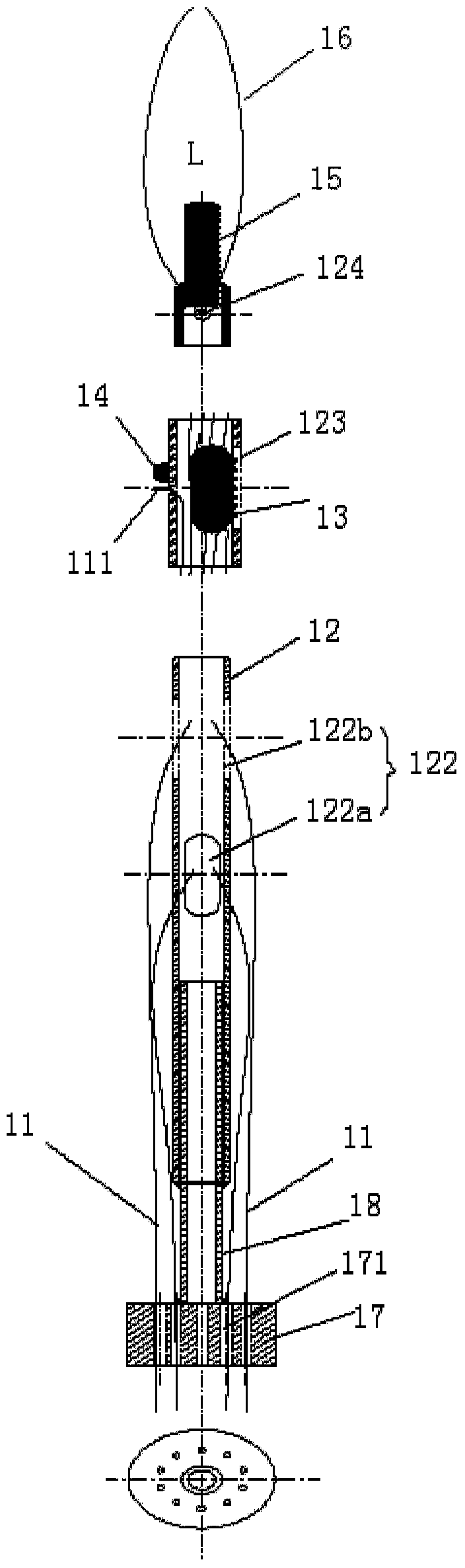

InactiveCN103308662AGuaranteed initial temperatureSolving the Difficulty of Changing Fuel FluidsFuel testingEngineeringThermocouple Wire

The invention provides a high-temperature and high-pressure single-drop evaporating and burning device. The high-temperature and high-pressure single-drop evaporating and burning device comprises a gas supplying device, a burning and evaporating projectile body (15), a single-drop generator (7), a single-drop generator cooling device and a control unit (13), wherein the burning and evaporating projectile body (15) is connected with the gas supplying device; the single-drop generator (7) and the single-drop generator cooling device are positioned at the upper part of the burning and evaporating projectile body (15); the control unit (13) is connected with the burning and evaporating projectile body (15) by a wire; the single-drop generator (7) comprises a piezoelectric piece type sprayer inside; the single-drop generator cooling device comprises a water pump (8) connected with the single-drop generator (7) and a thermocouple wire temperature sensor (9) positioned in the single-drop generator (7). The high-temperature and high-pressure single-drop evaporating and burning device provided by the invention has the advantage that the research for micro-drop evaporating and burning characteristics can be realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Braided mesh catheter

InactiveUS7722604B2Increase rotational frictionEasy to compressElectrocardiographyCatheterThermocouple WireElectrophysiology

Embodiments of the invention relate to electrophysiology catheters and methods of using the same. According to one embodiment, the catheter includes a braided conductive member at its distal end that can be radially expanded, for example using a mandrel slidably disposed within a shaft of the catheter. According to another embodiment, the catheter comprises a tip portion constructed of an elastomeric material. According to a further embodiment, the catheter includes a braided conductive member wherein a thermocouple is formed using one filament of the braided conductive member and one thermocouple wire. Other embodiments of the invention relate to a handle for use with a catheter and methods of using the same. According to one embodiment, the handle comprises a thumbwheel coupled to a housing, a spring disposed within the housing in contact with the thumbwheel, and means for increasing compression of the spring to increase rotational friction on the thumbwheel.

Owner:BOSTON SCI SCIMED INC

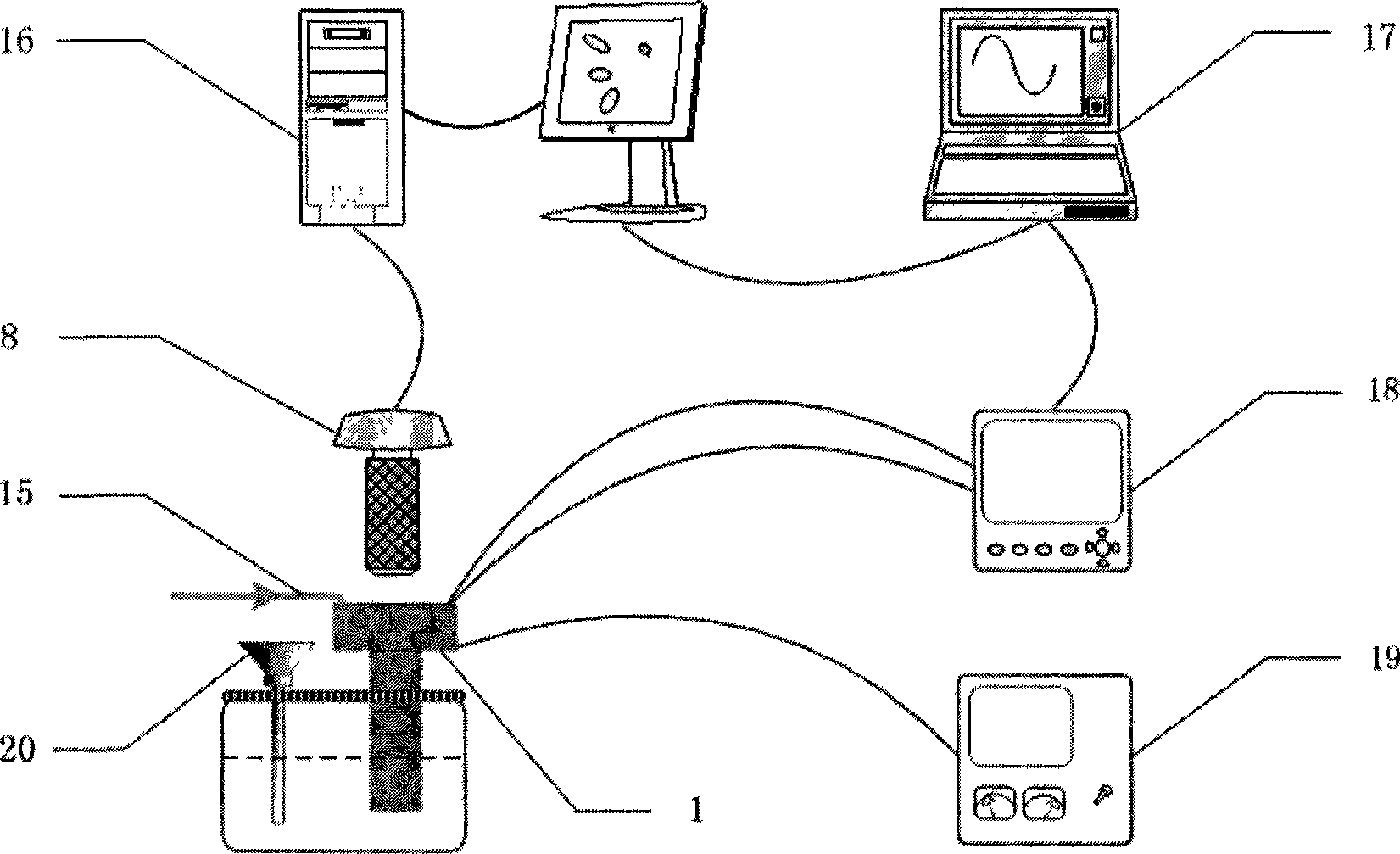

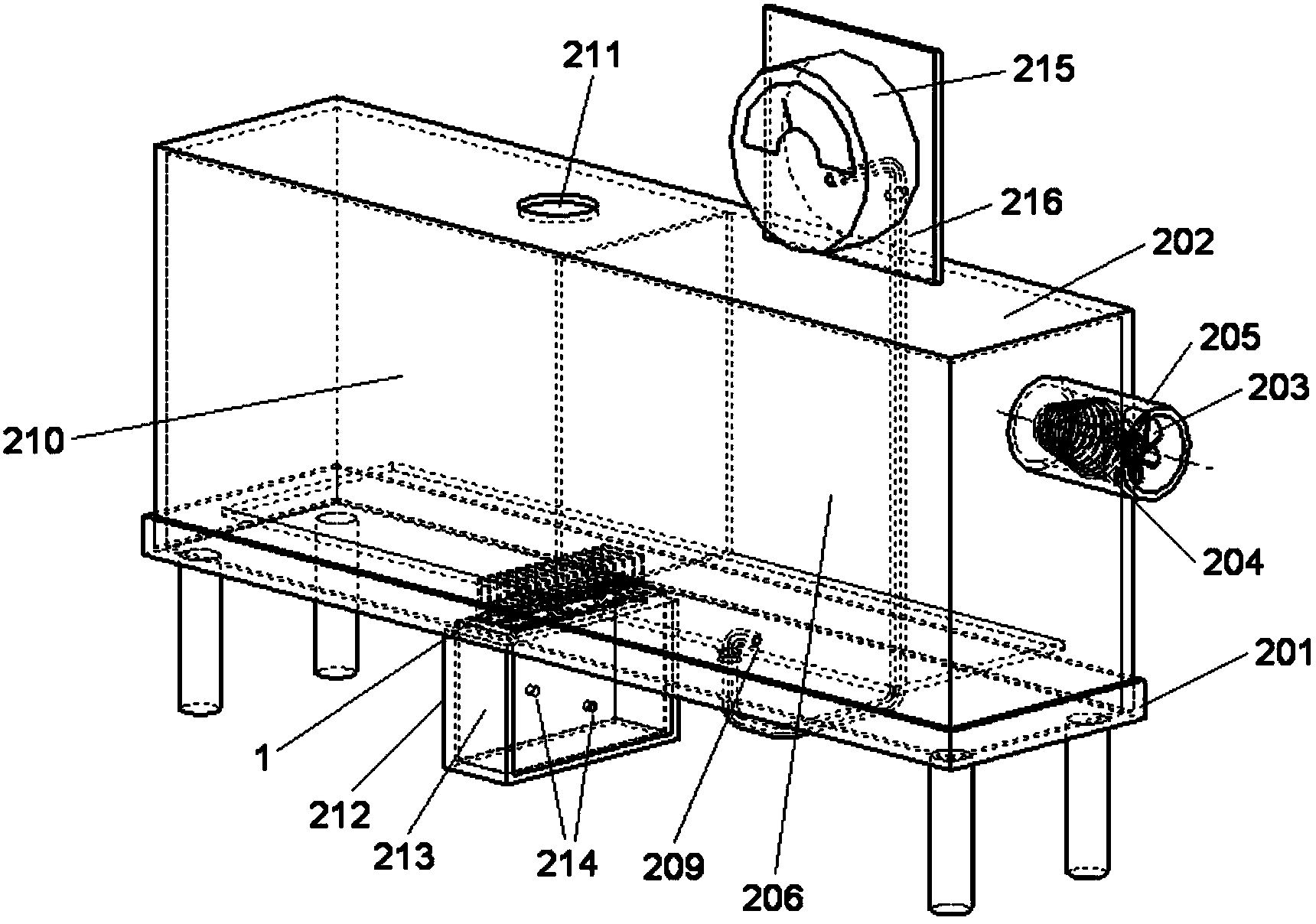

DSC meter with visualization function

InactiveCN101487806AFunction increaseEasy to assembleMaterial heat developmentMaterial analysis by optical meansReal time analysisHeat flux

The invention discloses a differential scanning calorimeter, which is compatible with visualization and comprises a worktable, a first heat current detection part, a second heat current detection part, temperature control equipment, a temperature-recording instrument, a microscope image pickup system and an image acquisition system; wherein, the worktable is provided with a sample cell and a reference cell. The first heat current detection part is arranged in the sample cell and used for bearing samples and transmitting heat flux with the samples. The second heat current detection part is arranged in the reference cell and is used for bearing reference compound and transmitting heat flux with the reference compound. The temperate control equipment respectively controls the heating up and temperature reduction of the two heat current detection parts. The temperature-recording instrument is respectively connected with the two heat current detection parts by a thermocouple wire. The microscope image pickup system observes the microstructure of the samples by a sample observation window arranged on the sample cell and acquires and records the microstructure variation of the sample by the image acquisition system. The differential scanning calorimeter can monitor and acquires the structure variation information of the sample while measuring the heat flow when the samples change phase, and increases the synchronicity and integrity of real-time analysis detecting of the samples.

Owner:SUN YAT SEN UNIV

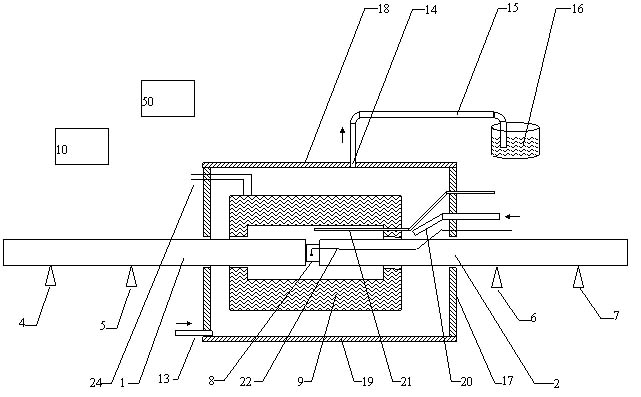

High-temperature Hopkinson pressure bar experimental system with atmosphere protection device

InactiveCN101893531AReduce the likelihood of a reactionReduce and avoid oxidationStrength propertiesFurnace temperatureExperimental methods

The invention discloses a high-temperature Hopkinson pressure bar experimental system with an atmosphere protection device. The whole system comprises an atmosphere protection device, a heating system and a loading system, wherein the atmosphere protection device comprises a protection box, an exhaust emission pipeline and an exhaust filtering device, wherein the protection box is provided with a protective gas inlet, an exhaust emission hole and a cooling gas inlet, and a seal suite is arranged between the protection box and a wave guide bar; the heating system comprises a heating furnace, an armoured thermocouple and a thermocouple wire, wherein the armoured thermocouple is used for monitoring furnace temperature, and the thermocouple wire is welded on a test piece by spots and is used for measuring the temperature of the test piece. The whole heating furnace, the armoured thermocouple for monitoring furnace temperature and bar ends of two wave guide bars are separately arranged in the protection box. The invention can adopt two experimental methods for firstly heating the test piece, and then assembling the test piece and the wave guide bars or heating the test piece and the wave guide bars simultaneously. The experimental system not only can conveniently carry out a high-temperature dynamic experiment of special materials in a protection atmosphere, but also can be used for a high-temperature dynamic experiment in common air.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

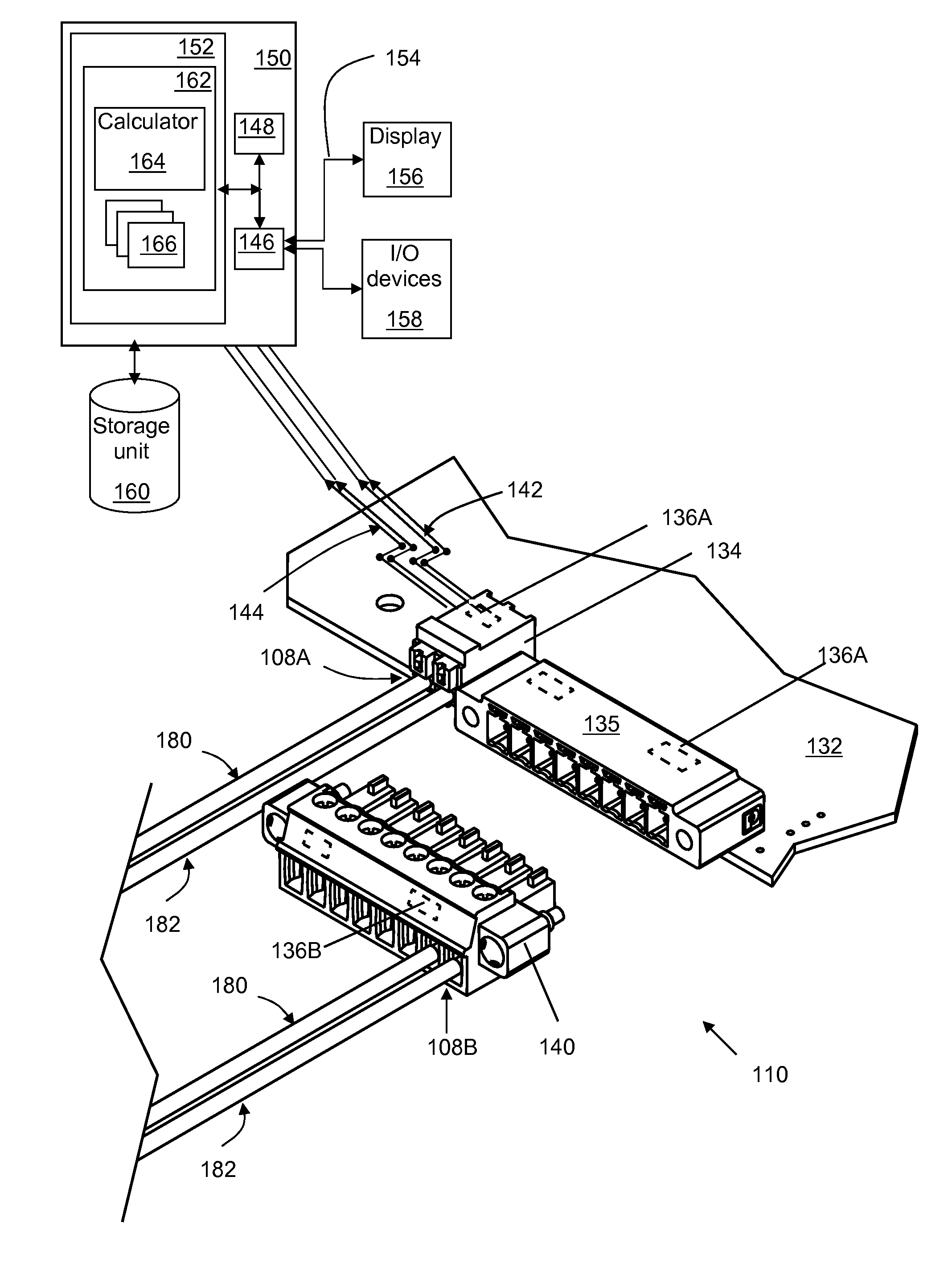

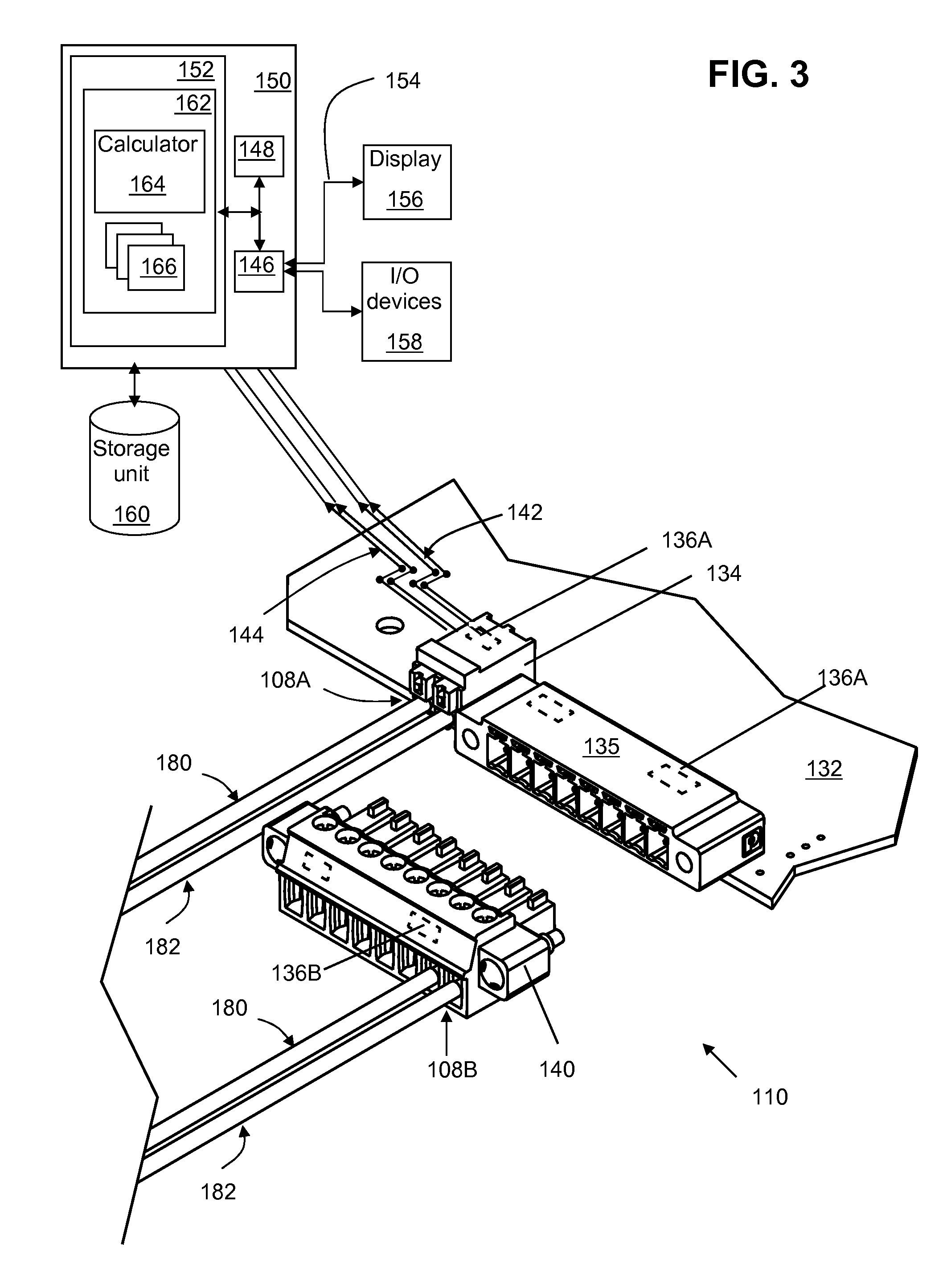

Integrated cold junction compensation circuit for thermocouple connections

InactiveUS20120065923A1Thermometer detailsThermometers using material expansion/contactionThermocouple WireElectric signal

An integrated cold junction compensation system for a thermocouple connection is disclosed. The system includes a temperature sensor integrated with a terminal at which the thermocouple wires terminate. The temperature sensor is integrated with the terminal proximal to a cold junction of a thermocouple, such that the temperature at the sensor location is substantially equal to that at the cold junction. The temperature sensor is further in electrical signal isolation from a circuit carrying voltage output by the thermocouple.

Owner:GENERAL ELECTRIC CO

Catheter with improved safety line for distal tip and related method

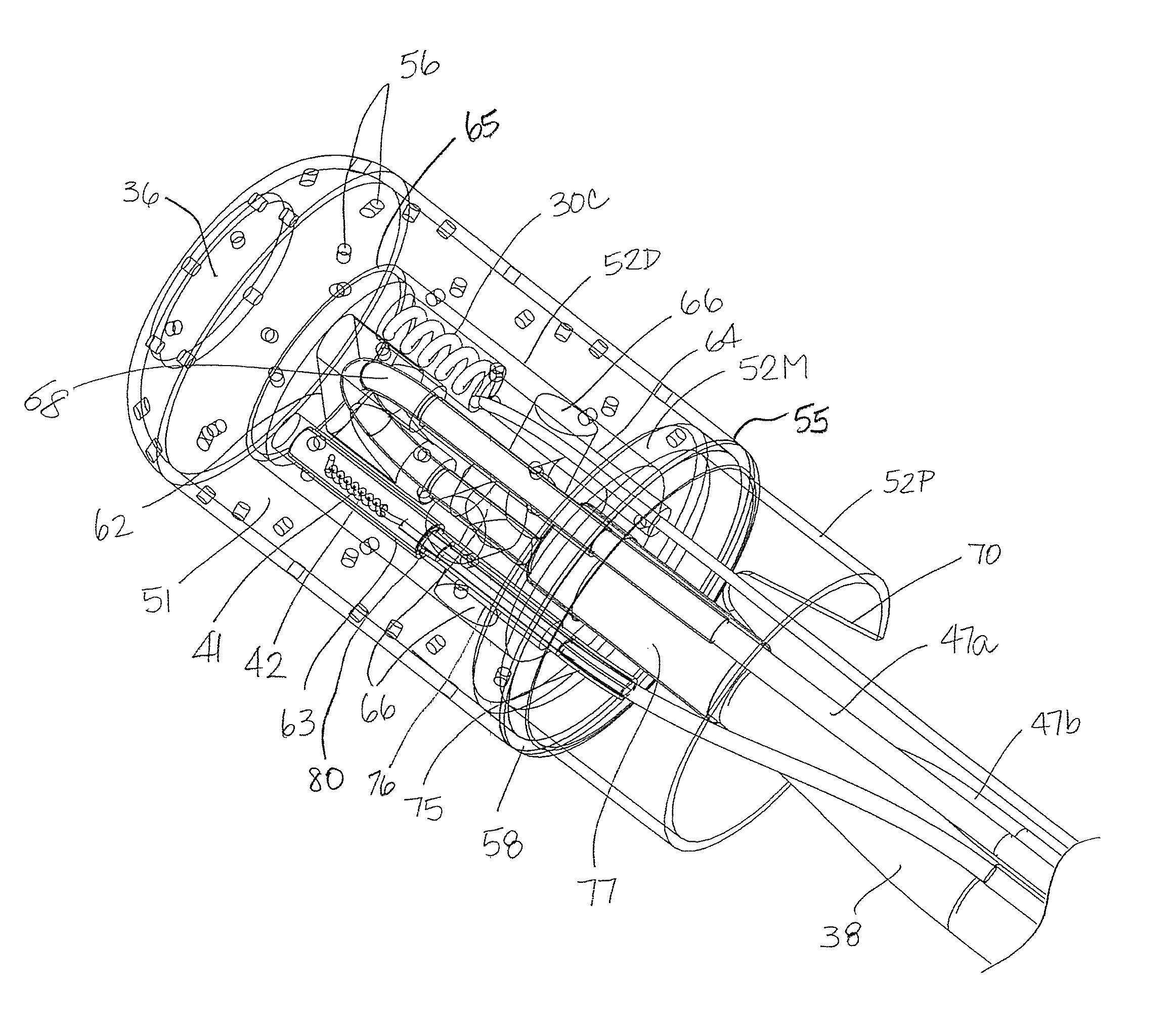

ActiveUS20140187893A1Reduce stress concentrationEffective load-carrying capacityLine/current collector detailsElectrocardiographyThermocouple WireCatheter

A catheter includes a tip electrode with a shell and a support member to provide a plenum chamber. The plug is formed with a U-shaped passage for a safety line to wrap around and secure the support member (with the shell affixed thereto) to the catheter. Additional passages are formed in the plug to accommodate components such as irrigation tubing, lead wire and thermocouple wire pair. A method of manufacture provides distal installation and / or anchoring of the safety line, lead wire and thermocouple wire pair in the support member prior to sealing the support member and mounting the shell.

Owner:BIOSENSE WEBSTER (ISRAEL) LTD

On-line underground temperature measurement system

ActiveCN101942990AAvoid short circuit problemsHigh strengthSurveyConstructionsThermocouple WireEngineering

The invention relates to an underground temperature measurement system. The system comprises a thermocouple, a compensating lead and a heavy hammer, wherein the compensating lead is positioned above the thermocouple, and the lower end of the compensating lead is connected with the upper end of the thermocouple; the heavy hammer is positioned below the thermocouple, connected with the lower end of the thermocouple and used for guiding the thermocouple to advance in a temperature measurement passage; and the thermocouple is a sheathed thermocouple manufactured by combined assembly of a thermocouple wire, an insulating material and a metal protective sleeve and stretching, and the length of the sheathed thermocouple corresponds to the thickness of a highest temperature interval in an underground high temperature layer to be measured. The temperature measurement system can greatly reduce the manufacturing cost of the thermocouple, effectively prolong the service life of the thermocouple and improve the automation degree of temperature measurement, and is convenient for repair and maintenance of the system per se.

Owner:ENN SCI & TECH DEV

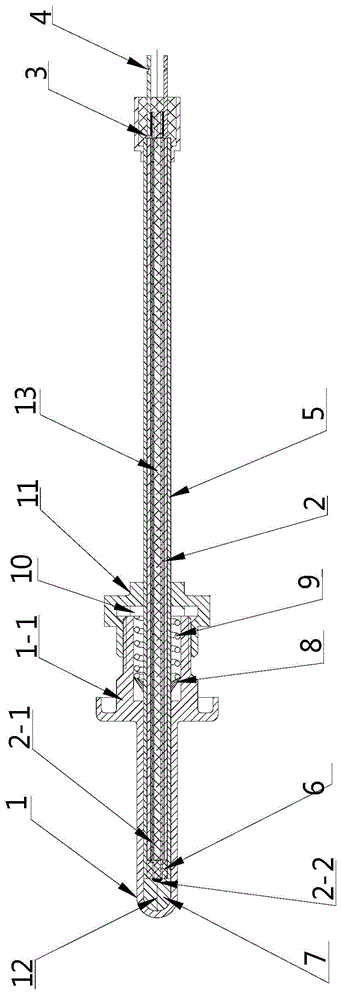

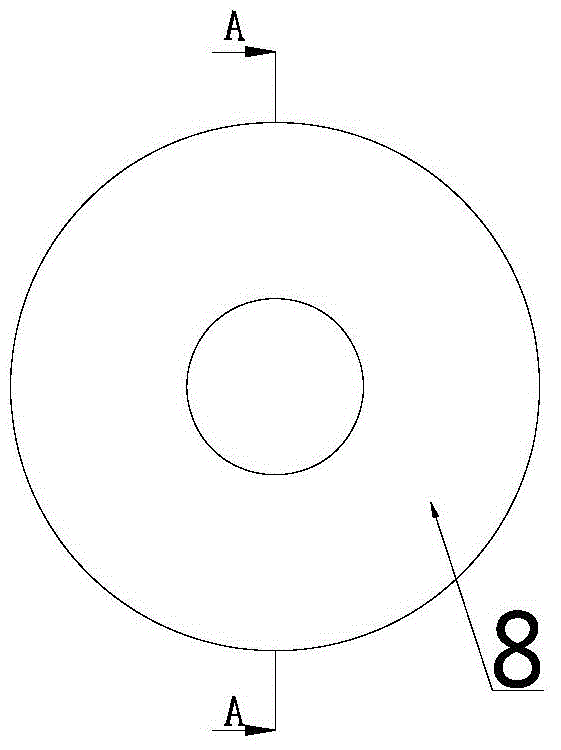

Temperature-measuring armored thermocouple

ActiveCN104596661AImprove temperature measurement accuracyEasy to assemble and disassembleThermometers using electric/magnetic elementsUsing electrical meansHeat conductingEngineering

The invention discloses a temperature-measuring armored thermocouple. A supporting pipe is arranged outside the armored thermocouple in a sleeved manner, the armored thermocouple is mounted in a protecting sleeve through the supporting pipe, multiple pairs of thermocouple wires are arranged in the armored thermocouple, a corundum pipe is arranged at a heat end of the armored thermocouple, extending ends of the thermocouple wires of the armored thermocouple penetrate a through hole of the corundum pipe respectively, a thermojunction is formed by welding and contacts with the protecting sleeve, heat-conducting filler is filled between the thermojunction and the protecting sleeve, cold ends of the thermocouple wires are connected with a compensation cable through a sealed connecting member, a compression nut connected with a mounting portion of the protecting sleeve sleeves above the supporting pipe, and a compression gasket is arranged between the compression nut and the mounting portion of the protecting sleeve. The temperature-measuring armored thermocouple is compact in structure, high in thermoelectric performance, high in radiation resistance, high in high-temperature resistance, high in reliability, safe and reliable to use and convenient for popularization.

Owner:CHONGQING MATERIALS RES INST

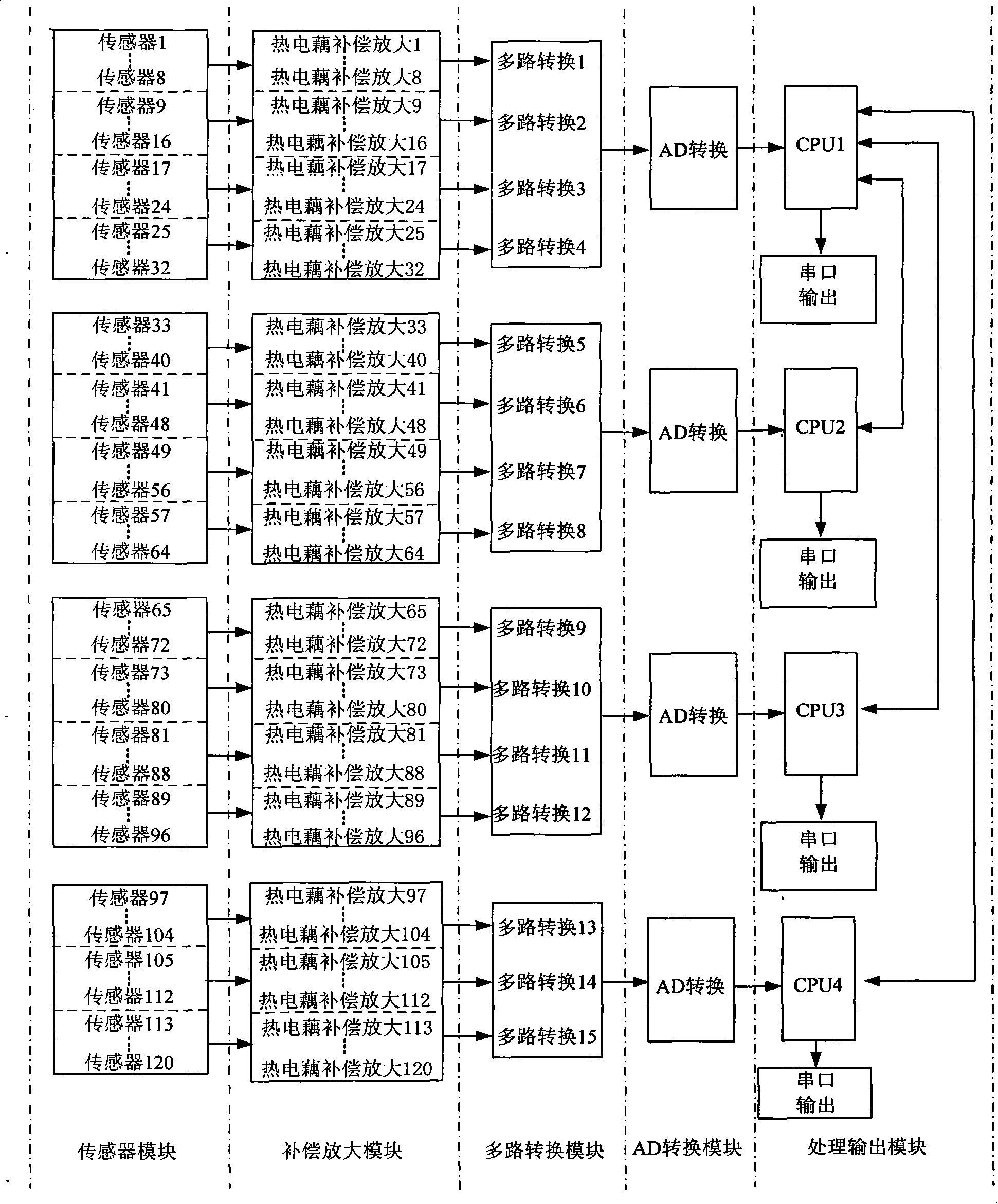

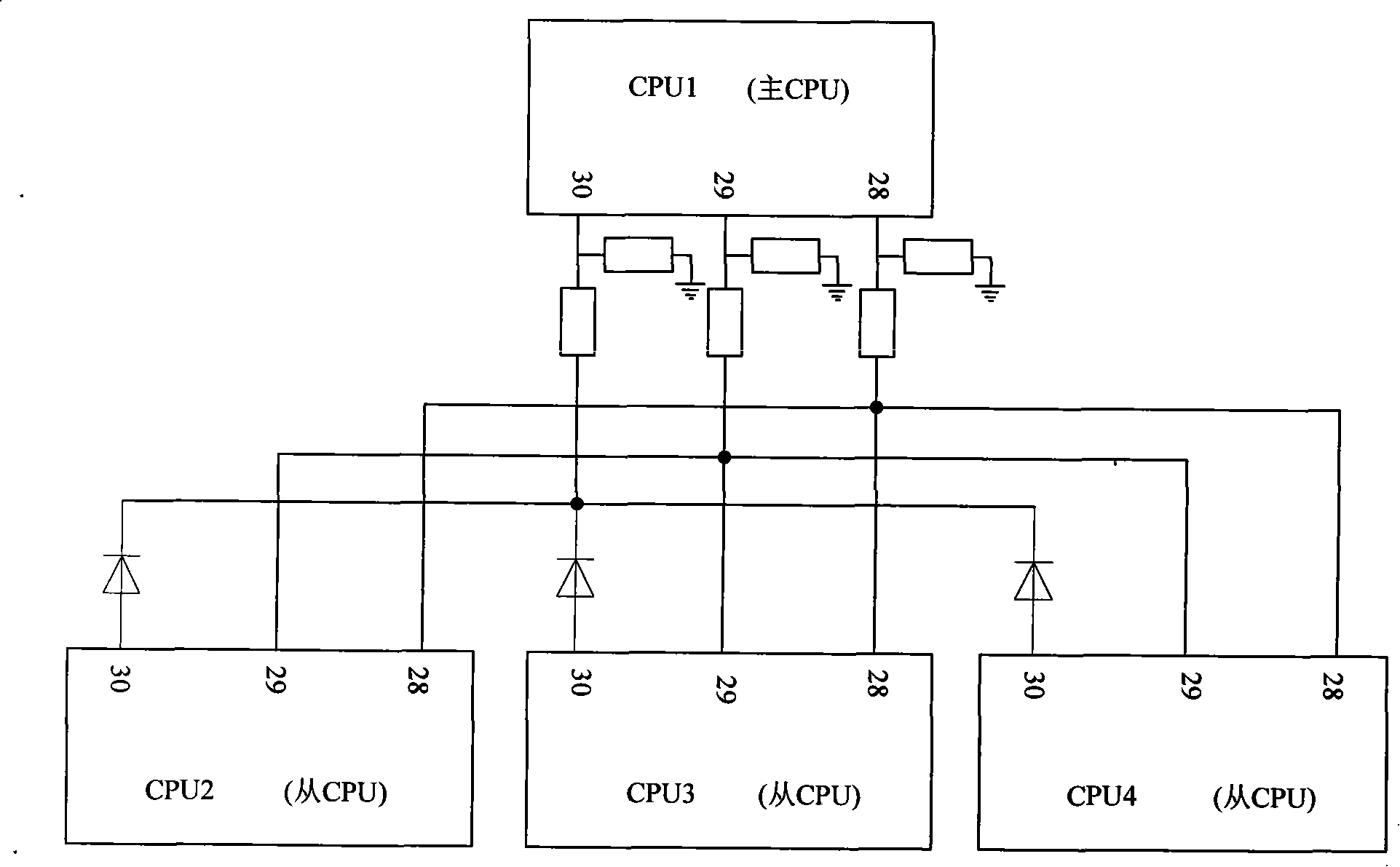

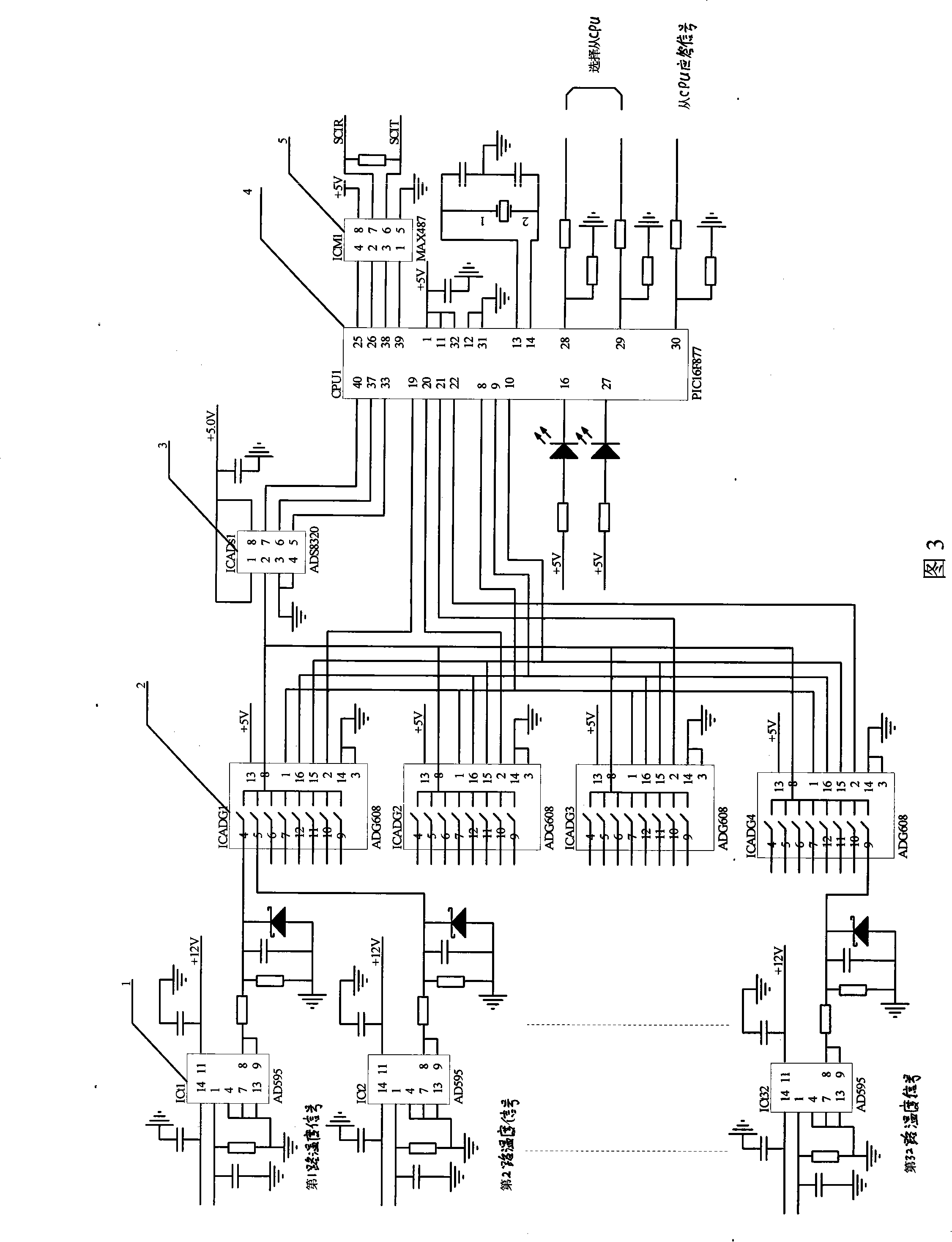

System for detecting temperature of dynamic battery set for hybrid power car

InactiveCN101251424AMonitor temperatureUniform temperatureThermometers using electric/magnetic elementsSecondary cellsSystems designElectrical battery

The invention provides a temperature detection system for a dynamic battery unit of a hybrid electric vehicle, which comprises a temperature collecting module, an A / D conversion module, a data processing and control module and a communication module. A temperature signal is transmitted out through a thermocouple wire, and control chips receive the temperature analog signal and output the signal through a serial port after carrying out corresponding A / D conversion. The system adopts the multi-path temperature collection of 120 paths with a temperature sensor on each battery sub-module, thereby accurately detecting the temperature distribution of each battery block, and consequently taking corresponding measures to enable the temperature distribution of the dynamic battery unit as even as possible. The system adopts 4 chips, wherein one serves as a master chip, and the other three serve as slave chips. The collected data is all transmitted out through the serial port. The system deserves generalization and application with simple design, low cost, small investment and convenient use.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD +1

Device and method for testing early thermal expansion coefficient of concrete based on suspension method

ActiveCN103293179ALongitudinal stiffness is smallReduce thicknessMaterial thermal coefficient of expansionTemperature controlMeasurement device

The invention relates to a device and a method for testing an early thermal expansion coefficient of concrete based on a suspension method. The device comprises a corrugated pipe test mould for pouring concrete to be tested to form a concrete corrugated pipe test piece, a plurality of rope rings for suspending the concrete corrugated pipe test piece, a device base for suspending the rope rings, a temperature measurement device used for measuring the temperature change of the concrete in the corrugated pipe test mould and having the measurement end of a first thermocouple wire buried in the corrugated pipe test mould, a deformation measurement device for measuring the deformation amount of the concrete corrugated pipe test piece, and a temperature control box used for adjusting the temperature of a test environment and in which a suspension position of the concrete corrugated pipe test piece is located. According to the method, the concrete corrugated pipe test piece is suspended by adopting the device to measure the early thermal expansion coefficient of the concrete. According to the test device and the test method, the friction between the test piece and the test device is effectively reduced, the test precision is improved, the operation is simple, and the using effect is good.

Owner:FUJIAN TONGLI BUILDING MATERIALS SCI & TECH

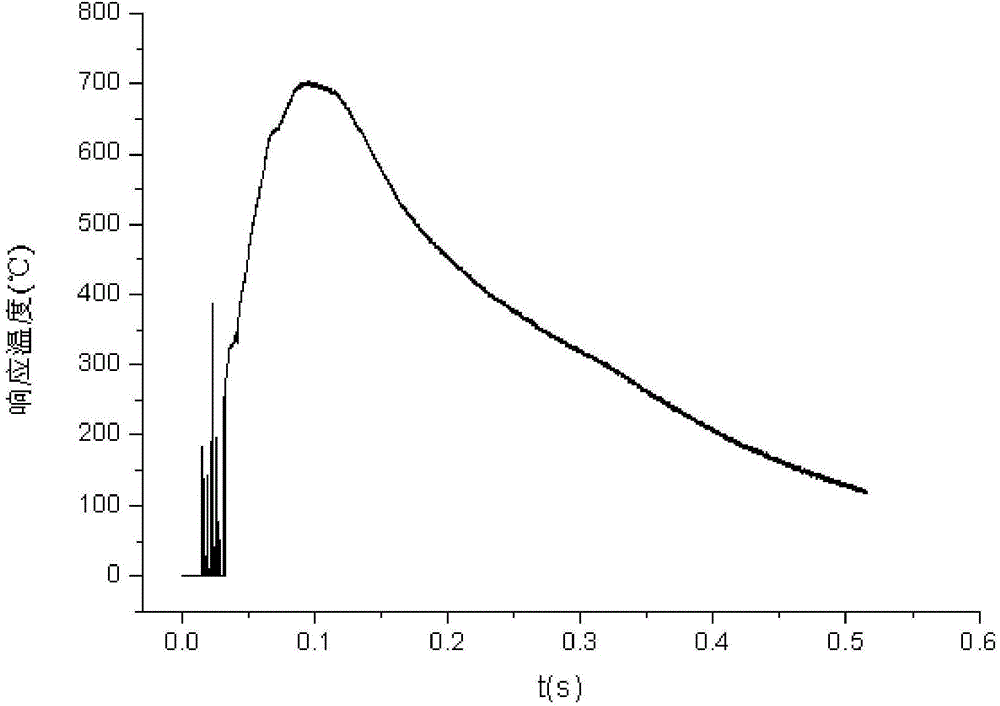

Thermocouple suitable for dynamic method flame temperature measurement and manufacturing method of thermocouple

ActiveCN104931148AIncrease the convective heat transfer areaReduce heat conduction loss errorThermometers using electric/magnetic elementsUsing electrical meansConduction lossThermocouple Wire

The invention discloses a thermocouple suitable for dynamic method flame temperature measurement. The thermocouple includes two thermocouple wires, a thermocouple wire node, an insulating busing, a protective busing and compensation conductors; the thermocouple wire node is formed by welding the two thermocouple wires; the thermocouple wire node is circular-sheet-shaped; the two thermocouple wires are an upper thermocouple wire and a lower thermocouple wire respectively; the included angle between the tangent line of a contact point of the upper thermocouple wire and the thermocouple wire node and the tangent line of a contact point of the lower thermocouple wire and the thermocouple wire node ranges from 30 degrees to 60 degrees; and the upper thermocouple wire and the lower thermocouple wire respectively pass through two wire entering holes of the insulating busing, and then are connected with the two compensation conductors on the protective busing. According to the thermocouple of the invention, the circular-sheet-shaped thermocouple wire node is adopted, so that the heat conduction loss of the thermocouple wires can be decreased, and the thermal inertia and temperature nonuniformity of the thermocouple wire node can be decreased, and interference of the thermocouple on flames and the deposition of particles in the flames on the surface of the thermocouple can be decreased, and the accuracy and sensitivity of temperature measurement can be improved, so that the temperature of the flames can be obtained quickly and accurately.

Owner:HUAZHONG UNIV OF SCI & TECH

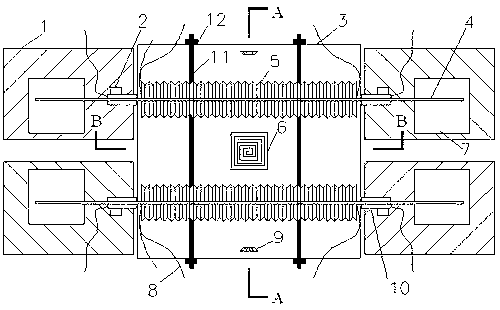

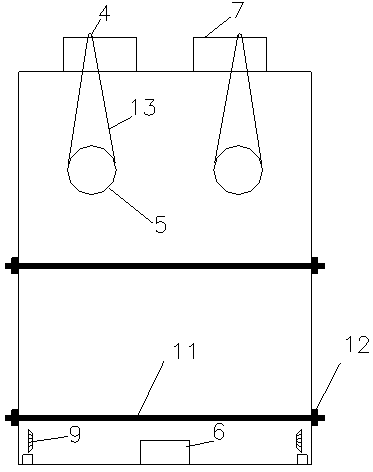

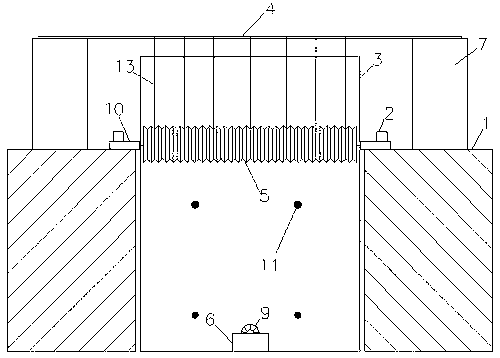

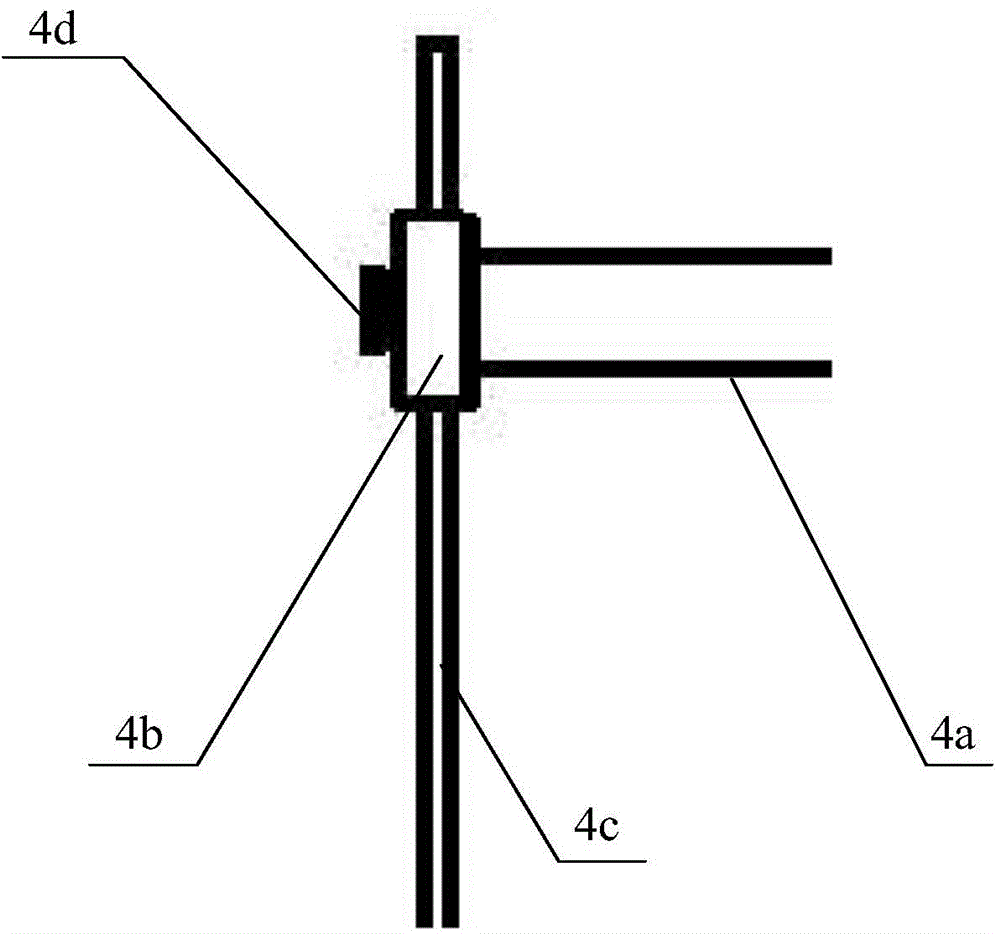

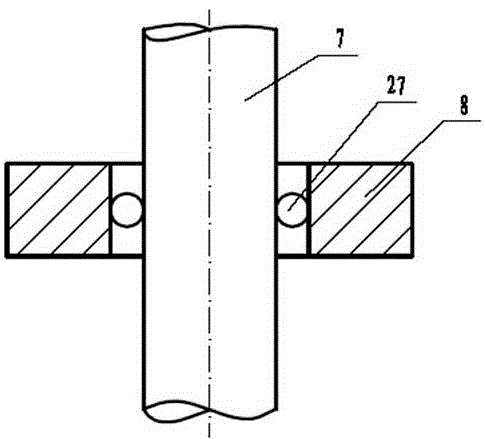

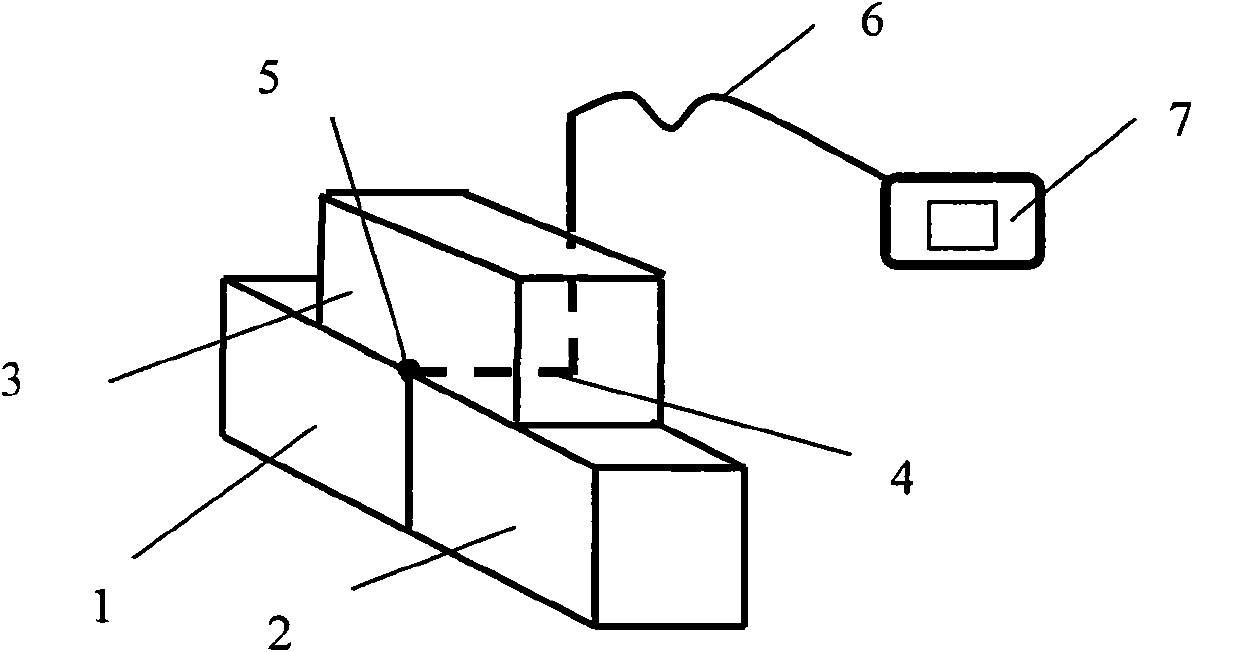

Rotary heating and temperature control device in combined spinning process of dissimilar metal

The invention discloses a rotary heating and temperature control device in the combined spinning process of dissimilar metal and relates to the field of plastic composite forming of dissimilar metal. The rotary heating and temperature control device solves the problem existing in accurate temperature control over a central spindle and a tube blank in the combined spinning process of the dissimilar metal. According to the scheme, one end of a central spindle is connected with a central spindle collecting ring connector through a connector lug; a through hole used for allowing thermocouple wires and heating rod power wires to be placed therein is formed in the central spindle collecting ring connector; four collecting rings are fixed to the other end of the central spindle collecting ring connector, two of the four connecting rings are connected with the heating rod power wires, and the remaining two of the four connecting rings are connected with the thermocouple wires led in through the central spindle; the central spindle collecting rings are connected with a carbon brush holder in a compressed mode through springs on carbon brushes, so that an electric conduction effect is achieved; two carbon brushes enable a heating rod to be connected to the current output end of an intelligent temperature controller, and the remaining two carbon brushes enable the thermocouple wires to be connected to the feedback input end of the intelligent temperature controller. The rotary heating and temperature control device is used for rotary heating and temperature control in the combined spinning process of the dissimilar metal.

Owner:HARBIN INST OF TECH +1

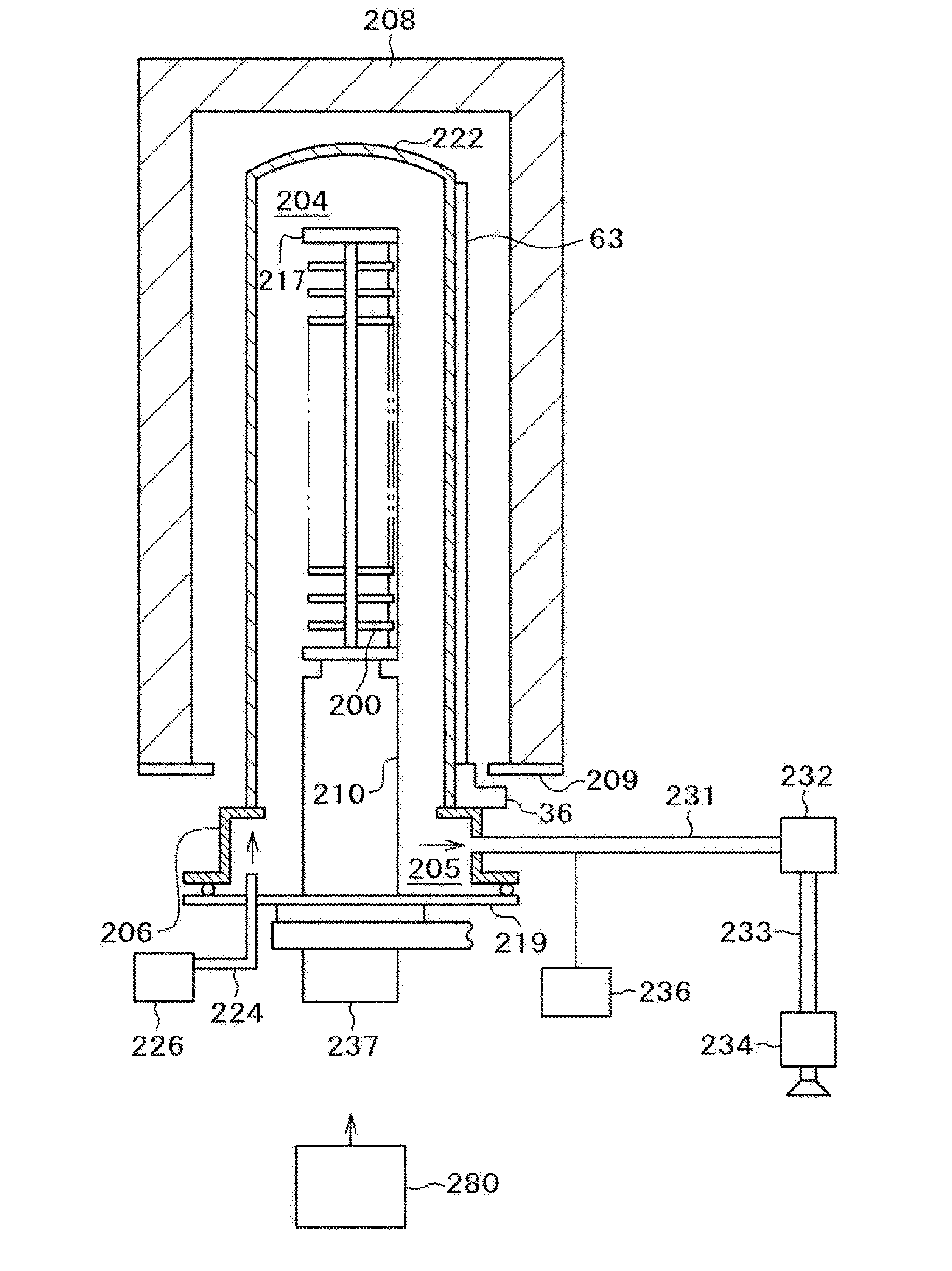

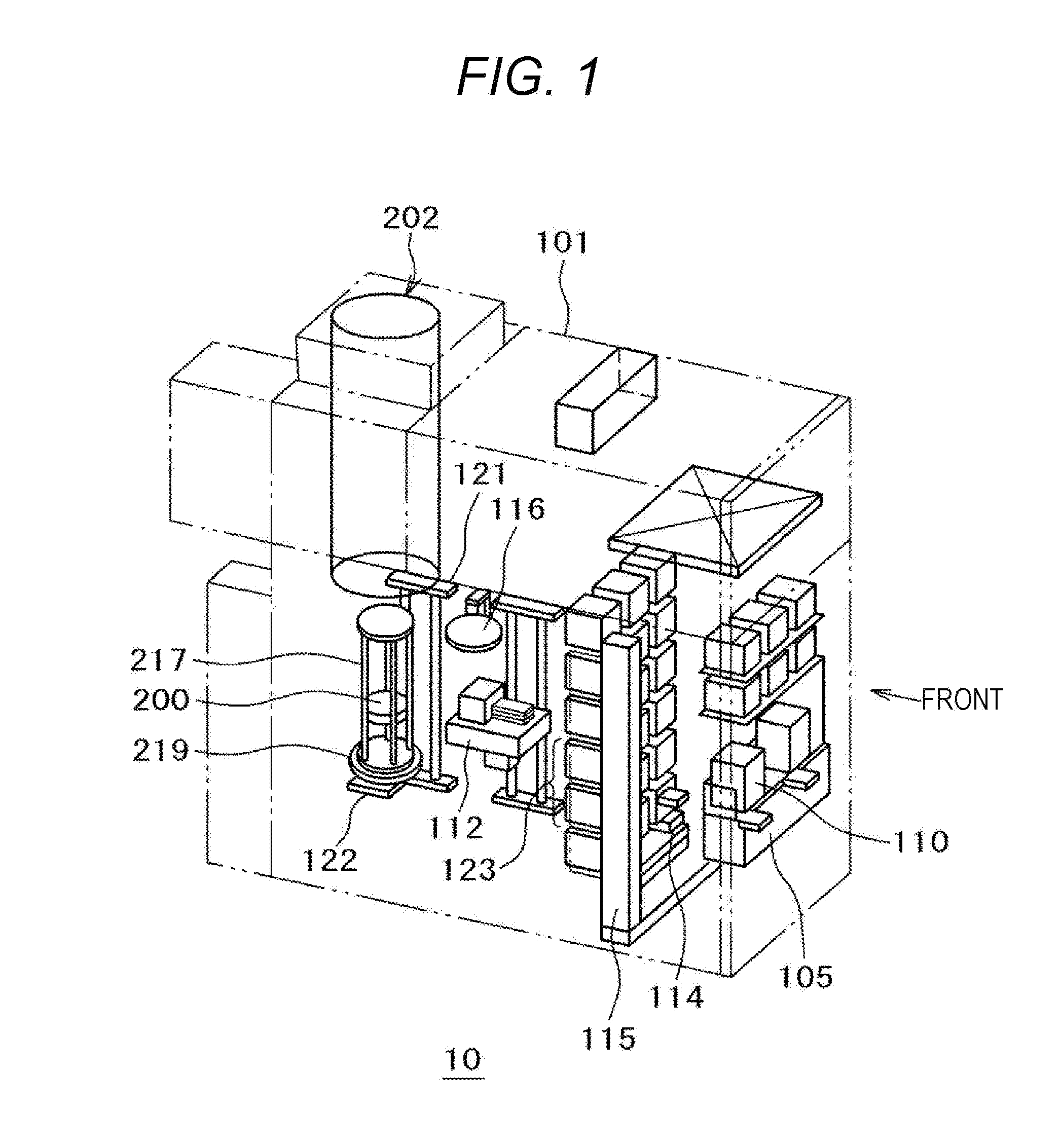

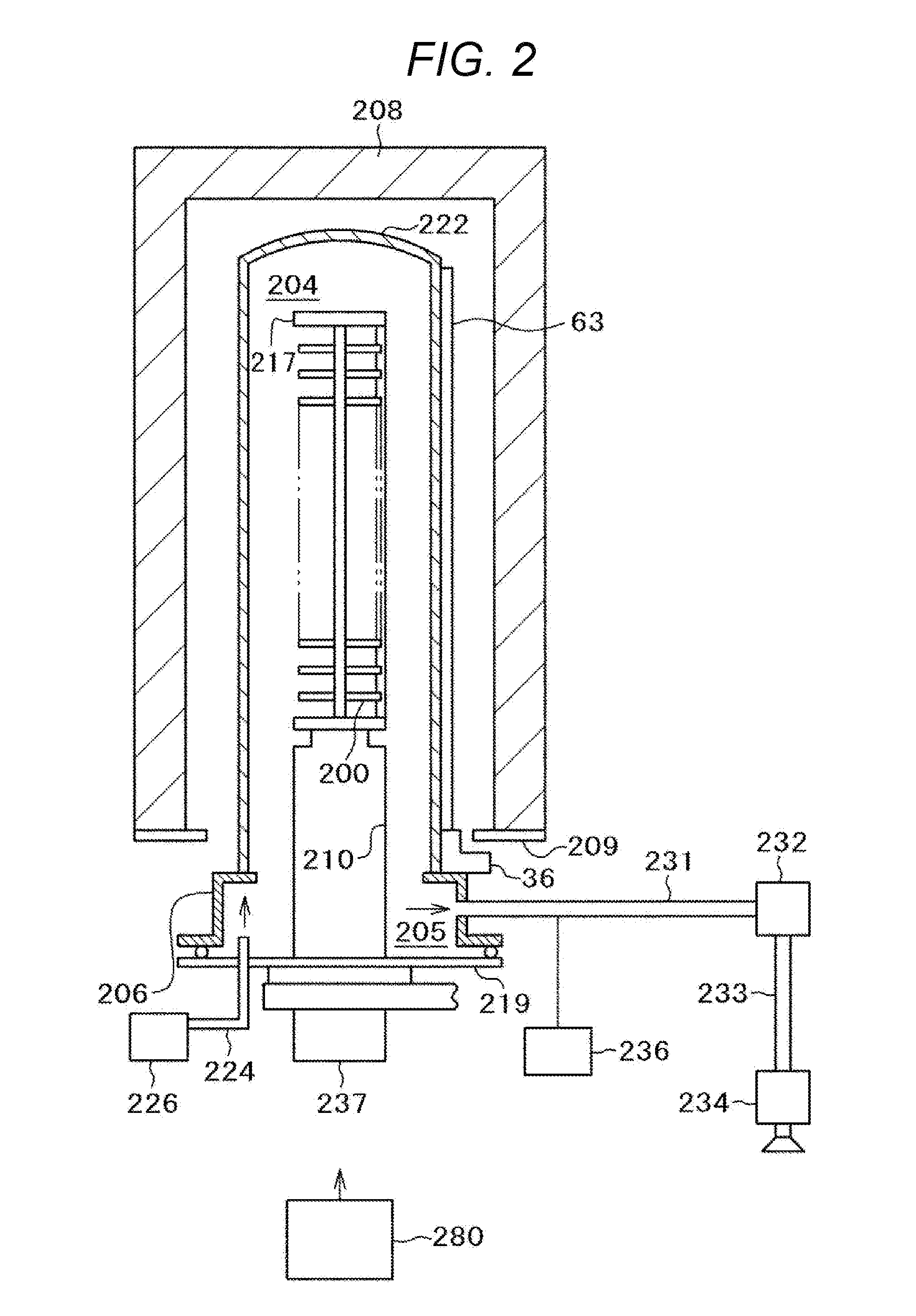

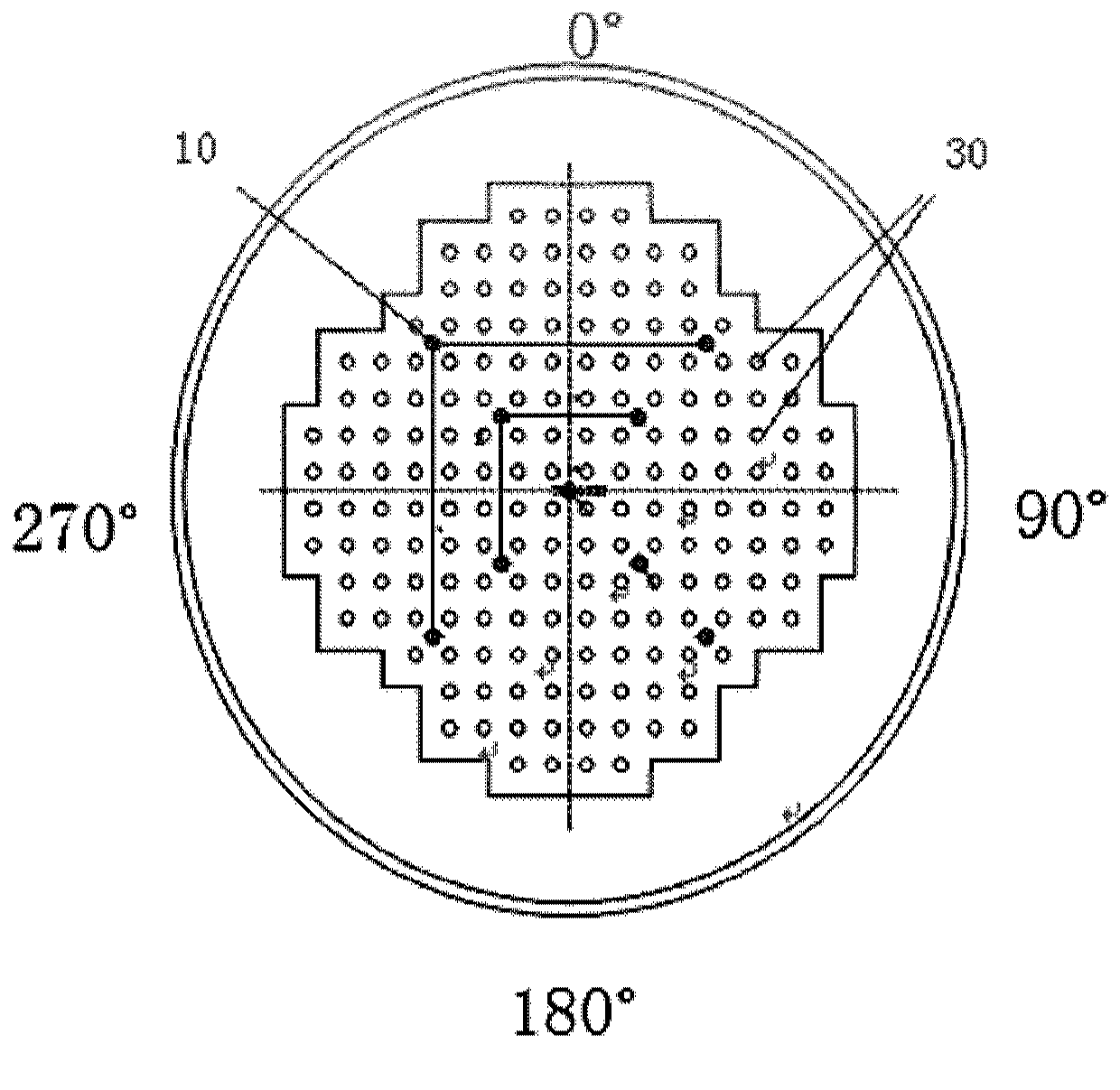

Substrate processing apparatus, method of manufacturing semiconductor device, and thermocouple support

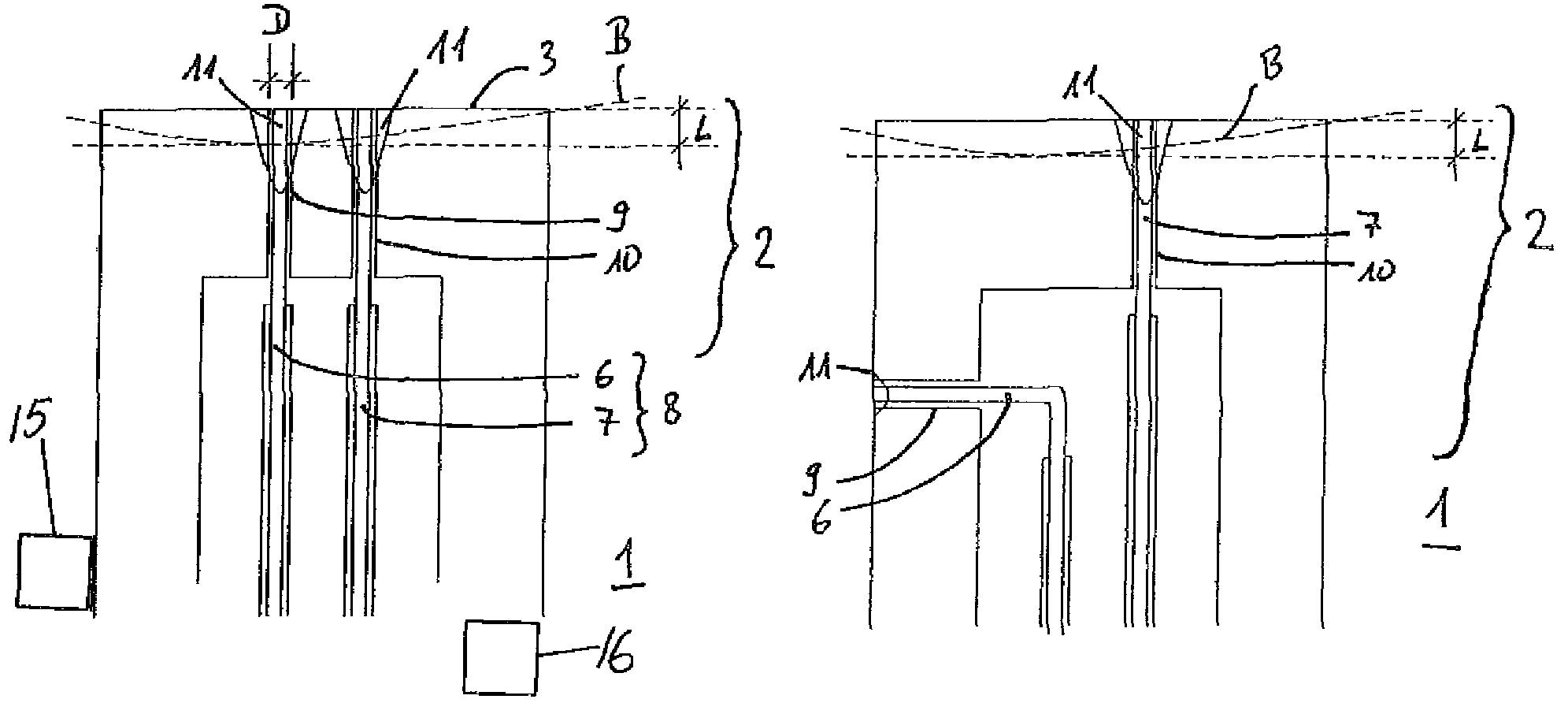

InactiveUS20140120636A1Reduce waiting timeThermometer detailsSemiconductor/solid-state device testing/measurementDevice materialEngineering

A substrate processing apparatus includes: a reaction tube configured to accommodate a substrate holder holding a plurality of substrates and process a substrate held on the substrate holder; a heating unit installed outside the reaction tube and configured to heat an inside of the reaction tube; a protection tube installed to extend in a vertical direction in contact with an outer wall of the reaction tube; an insulating tube disposed inside the protection tube and having through-holes extending in a vertical direction; a thermocouple having a thermocouple junction provided at an upper end thereof, and thermocouple wires joined at the thermocouple junction and inserted into the through-holes of the insulating tube; a gas supply unit configured to supply a gas, for processing a substrate accommodated in the reaction tube, into the reaction tube; and an exhaust unit configured to exhaust a gas from the reaction tube.

Owner:KOKUSA ELECTRIC CO LTD

Sintering method of optical fiber preform and equipment thereof

ActiveCN103739194AReal-time access to transparencyTransparency can be adjusted online in real timeGlass making apparatusLaser transmitterLoop control

The invention relates to a sintering method of optical fiber preform and equipment thereof. The invention relates to the field of optical fiber perform sintering, and particularly relates to a method and equipment which utilize a laser feedback control system for adjusting the temperature of a sintering furnace in a sintering process in real time so as to realize the closed-loop control over the sintering process. The equipment comprises a tower body, a motor I, a chuck, a quartz derrick, a guide rail, a gas suction port, powder perform, a quartz chamber, a washing tower, a furnace body, a heat insulation material, a heating body, a temperature control cabinet, a quartz furnace core pipe, a laser transmitter, a laser receiver, a Cl2 gas holder, a He gas holder, an N2 gas holder, a Cl2 mass flow controller, a He mass flow controller, an N2 mass flow controller, an MFC (Microfunction Circuit) flow control cabinet, a laser control cabinet, an air exhaust and supply controller, a motor control cabinet, a motor II, a thermocouple, a lead screw and a control computer.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD +2

Epicardial mapping and ablation catheter

ActiveUS20120130366A1Safely maneuverReliable contactBioelectric signal measurementCatheterEpicardial mappingThermocouple Wire

A catheter adapted for mapping and ablating epicardial tissue from the pericardial cavity includes a catheter body and an electrode assembly that has a tip section and a loop member lying generally within a plane, wherein the tip section includes an ablation electrode exposed on one side of the loop member and an insulation member exposed on an opposite side of the loop member. The catheter also includes a intermediate section between the catheter body and the electrode assembly, wherein the intermediate deflects the loop member and the tip section bi-directionally within the same plane. So arranged, the catheter can be safely maneuvered in the pericardial sac and swept in a side to side motion over the epicardium with the ablation electrode reliably facing and making contact with the epicardium. The tip section can include a balloon that is inflatable to push away surrounding pericardial tissue. The catheter may further include an injection needle whose distal end can extend outside of the tip section to puncture epicardial tissue. A lumen in the injection needle allows for delivery to agents directly to the punctured tissue and thermocouple wires can be carried in the lumen for temperature sensing at the treatment site.

Owner:BIOSENSE WEBSTER INC

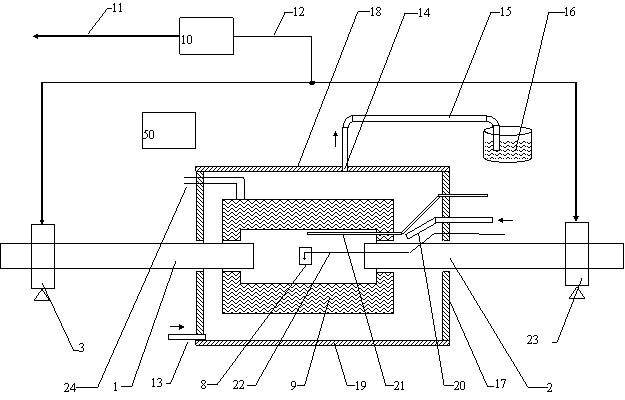

Metallic material tensile experiment system of multifunctional integration structure

InactiveCN104596863AReduce and avoid oxidationReduce and avoid releaseMaterial strength using tensile/compressive forcesMetallic materialsThermocouple Wire

The invention provides a metallic material tensile experiment system of a multifunctional integration structure. The metallic material tensile experiment system is characterized in that an atmosphere, heating and vacuum integration device is additionally arranged on the basis of a conventional metallic material tensile experiment system, so that the test for the high-temperature tensile mechanical properties of a metallic material under different environmental conditions can be satisfied. The metallic material tensile experiment system mainly includes the metallic material high-temperature tensile mechanical property test in an inert atmosphere protection environment, in a multi-component atmosphere environment and in a vacuum environment. The temperature of a test piece is measured by adopting a thermocouple wire, the thermocouple wire is connected with the test piece in a spot welding manner and is arranged in the integration device, parameters of the metallic material such as the elastic modulus and the tensile strength in a high-temperature environment and in the atmosphere environment can be accurately measured, and the test requirements of the tensile mechanical properties of a special material in the high-temperature environment or different environmental atmospheres can be met.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

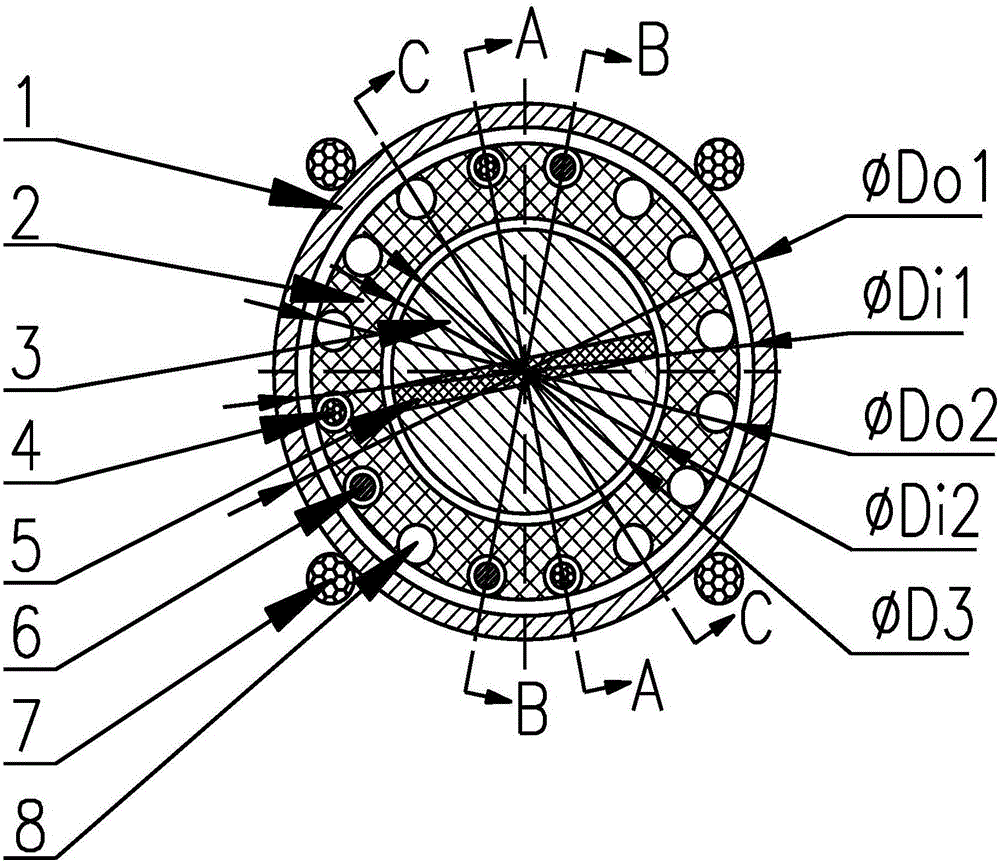

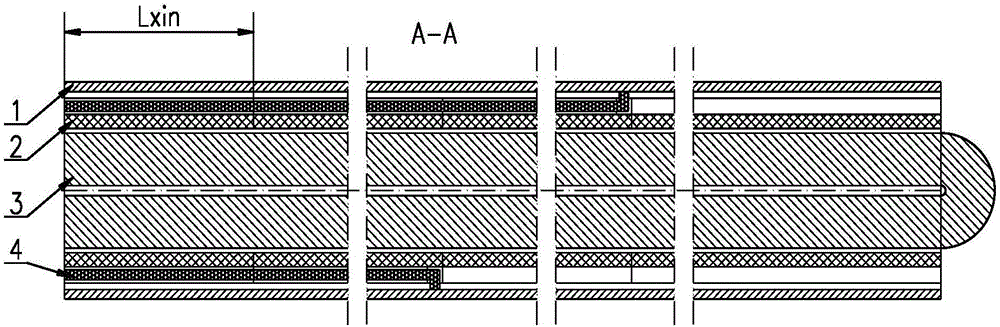

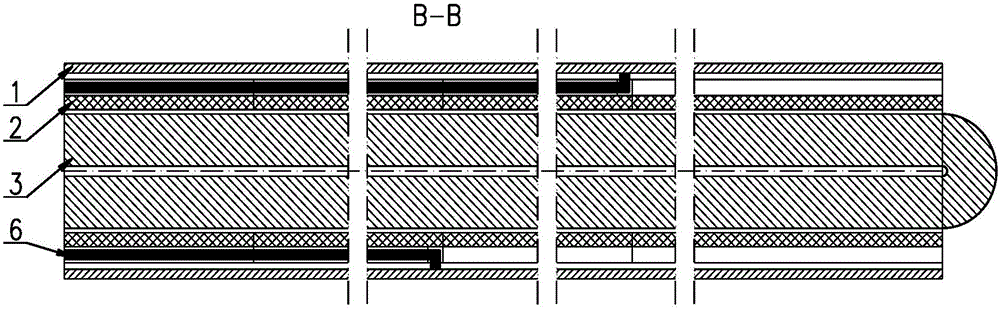

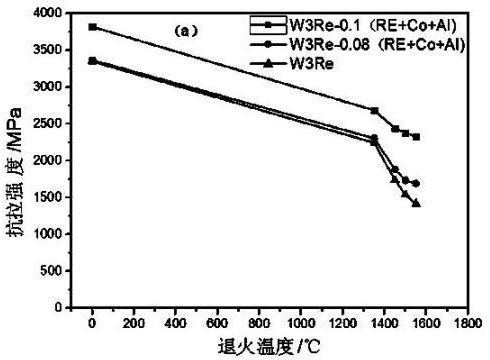

Nuclear reactor fuel rod simulating electric heating device and assembly process

ActiveCN106328226ASimulate Thermal PropertiesAccurate and controllable electric heating powerNuclear energy generationNuclear monitoringPressurized water reactorThermocouple Wire

The invention discloses a nuclear reactor fuel rod simulating electric heating device and an assembly process. The device comprises a simulation jacket and simulation fuel element pellets, each simulation fuel element pellet is provided with 16 through holes axially extending along the simulation fuel element pellet, thermocouple wire anodes are mounted in part of the through holes, thermocouple wire cathodes are mounted in part of the through holes, and inert gas is stored in the rest through holes. Electric heating rods are mounted in an inner cavity of each simulation fuel element pellet, and a plurality of external wall temperature thermocouples are mounted on the outer side of the simulation jacket. The electric heating device is used for laboratory simulation of nuclear reactor fuel rods to carry out high-temperature degradation and reflooding behavioral experiments of fuel rods for pressurized water reactors under severe accident conditions. A working medium is an aqueous medium, a steam medium or an inert gas medium, a working pressure is 5MPa, a long-term working temperature is 1800 DEG C, and a short-term working temperature is 2400 DEG C.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

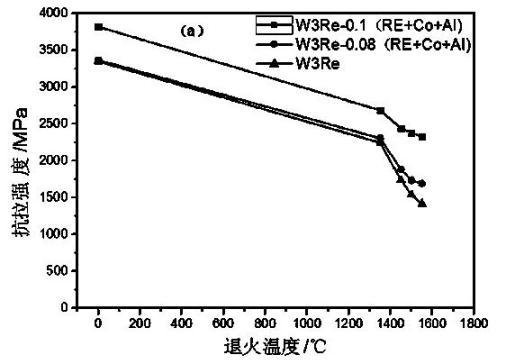

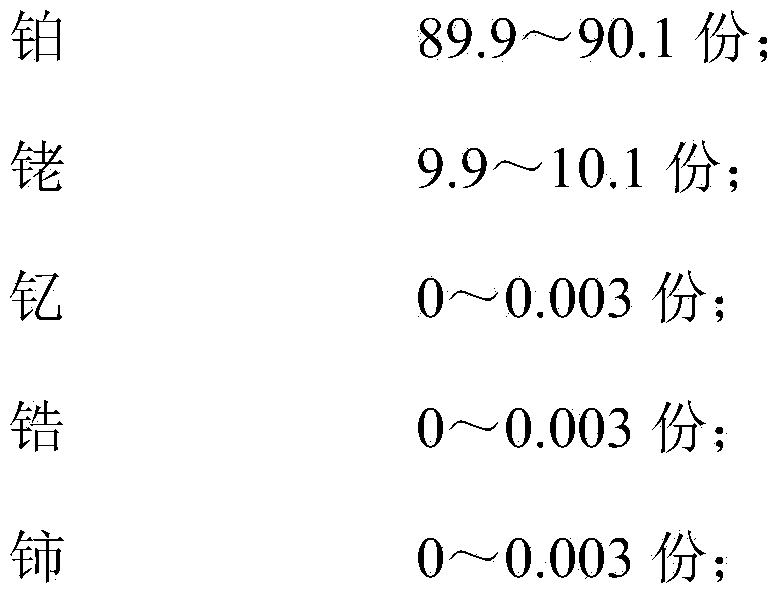

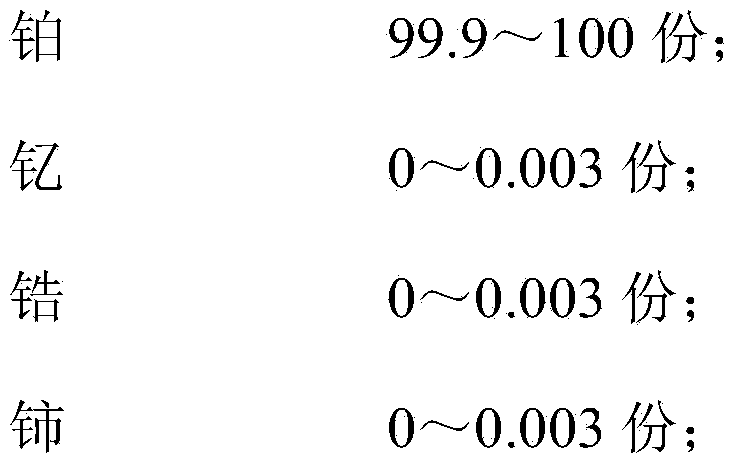

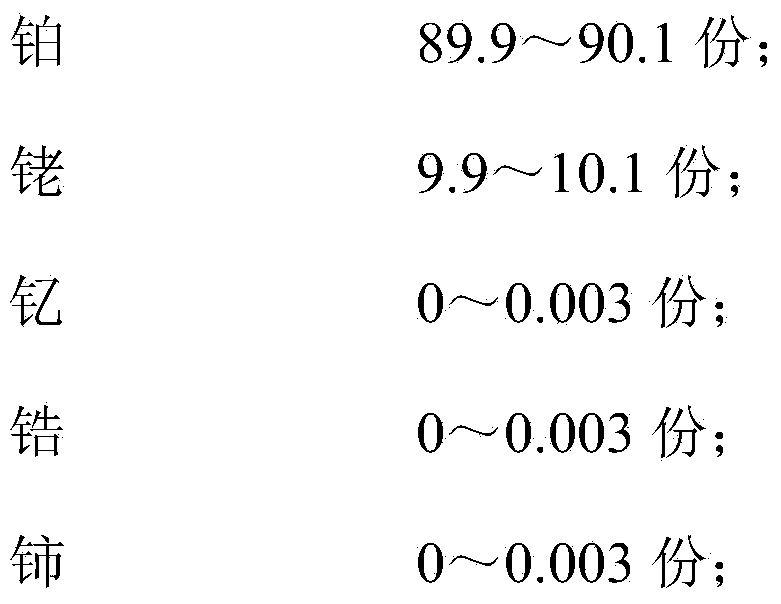

Method for preparing fine platinum powder used for negative electrode fine platinum wire in intensified thermocouple wires

The invention discloses a method for preparing fine platinum powder used for a negative electrode fine platinum wire in intensified thermocouple wires. According to the method, waste material of Pt-based material thermocouple wires PtRh or Pt is adopted, dissolution, impurity removal through sedimentation, revivification and other methods are carried out on the waste material to obtain the fine platinum powder, and the fine platinum powder prepared through the method is machined to be the fine platinum wire. The fine platinum powder is machined to be the Pt wire, therefore, tensile strength and elongation of the platinum wire can be increased, creep resistance of the platinum wire is improved, service life is prolonged, and the platinum wire is made to be easy to micronize.

Owner:CHONGQING MATERIALS RES INST

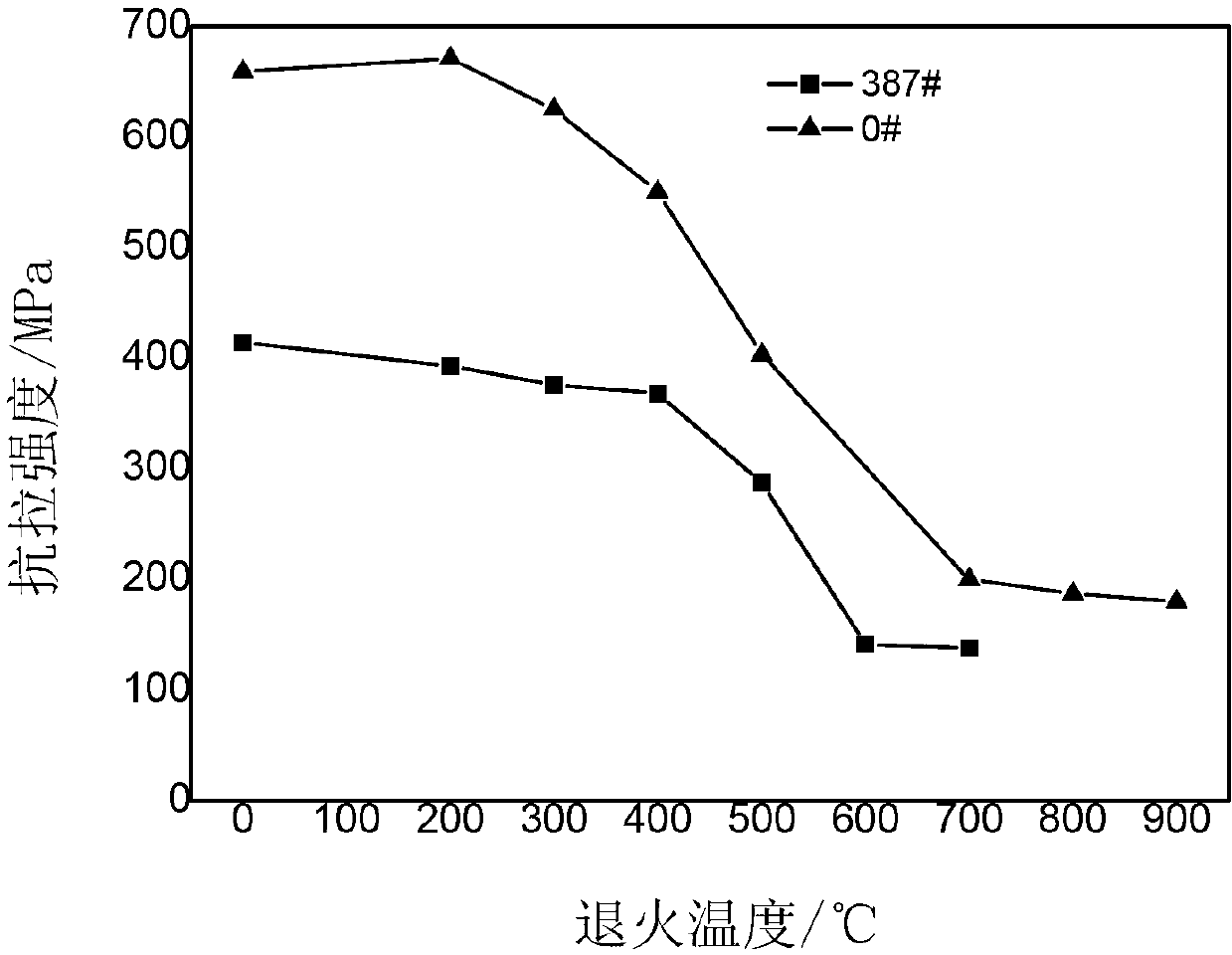

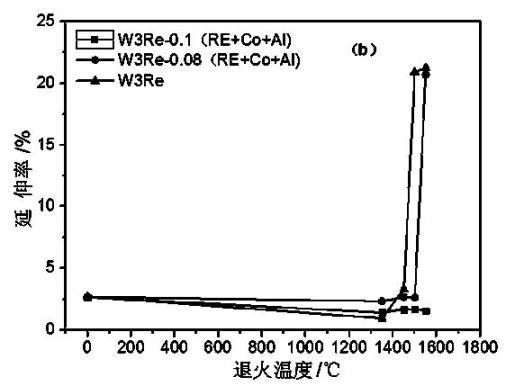

W3Re-W25Re thermocouple material and preparation method of thermocouple

The invention discloses a W3Re-W25Re thermocouple material and a preparation method of a thermocouple. A negative pole W25Re alloy material comprises the following components in percentage by weight: 74.2%-75.5% of W and 24.5-25.8% of Re, a positive pole material W3Re alloy material comprises the following components in percentage by weight: 96.0%-97.5% of W, 2.5%-3.5% of Re, 0-0.5% of Co, 0-0.5% of Al and 0-0.5% of rare earth. The preparation method of the thermocouple comprises the following steps of: (a) respectively weighing all the components of the negative pole W25Re alloy material and the positive pole material W3Re alloy material according to the percentage by weight; (b) preparing pre-alloy powder; (c) forming; (d) pre-sintering; (e) performing vertical melting; (f) swaging; (g) drawing; (h) cleaning; (i) annealing; and (k) performing performance test and indexing calibration. The W3Re-W25Re thermocouple material disclosed by the invention can achieve the level of a precious metal thermocouple wire and improve temperature measurement response speed, temperature measurement precision and stability.

Owner:CHONGQING MATERIALS RES INST

Thermocouple multi-point temperature measurement device and simulated pressure reactor comprising same

ActiveCN105509913AThermometers using electric/magnetic elementsUsing electrical meansElectricityHeater Rod

The invention discloses a thermocouple multi-point temperature measurement device comprising at least two thermocouple wires and a casing. The casing has a first end and a second end which face each other in the axial direction of the casing. The side wall of the casing is provided with at least two lead-out holes, and the at least two lead-out holes are spaced apart in the axial direction of the casing. One end of each thermocouple wire passes through the casing and is led out of the outer wall of the casing through the corresponding lead-out hole, the led-out thermocouple wire section is used as a temperature measurement section and extends in a direction roughly perpendicular to the axial direction of the casing, and the diameter of the thermocouple wires is slightly smaller than the inner diameter of the lead-out holes. The invention further relates to a simulated pressure reactor comprising a simulated pressure reactor vessel, multiple electric heating rods, and at least one thermocouple multi-point temperature measurement device, wherein the axial direction of the casing of each thermocouple multi-point temperature measurement device is parallel to the axial direction of the vessel, and the casing of each thermocouple multi-point temperature measurement device is disposed in the gap between adjacent electric heating rods.

Owner:STATE NUCLEAR POWER TECH +1

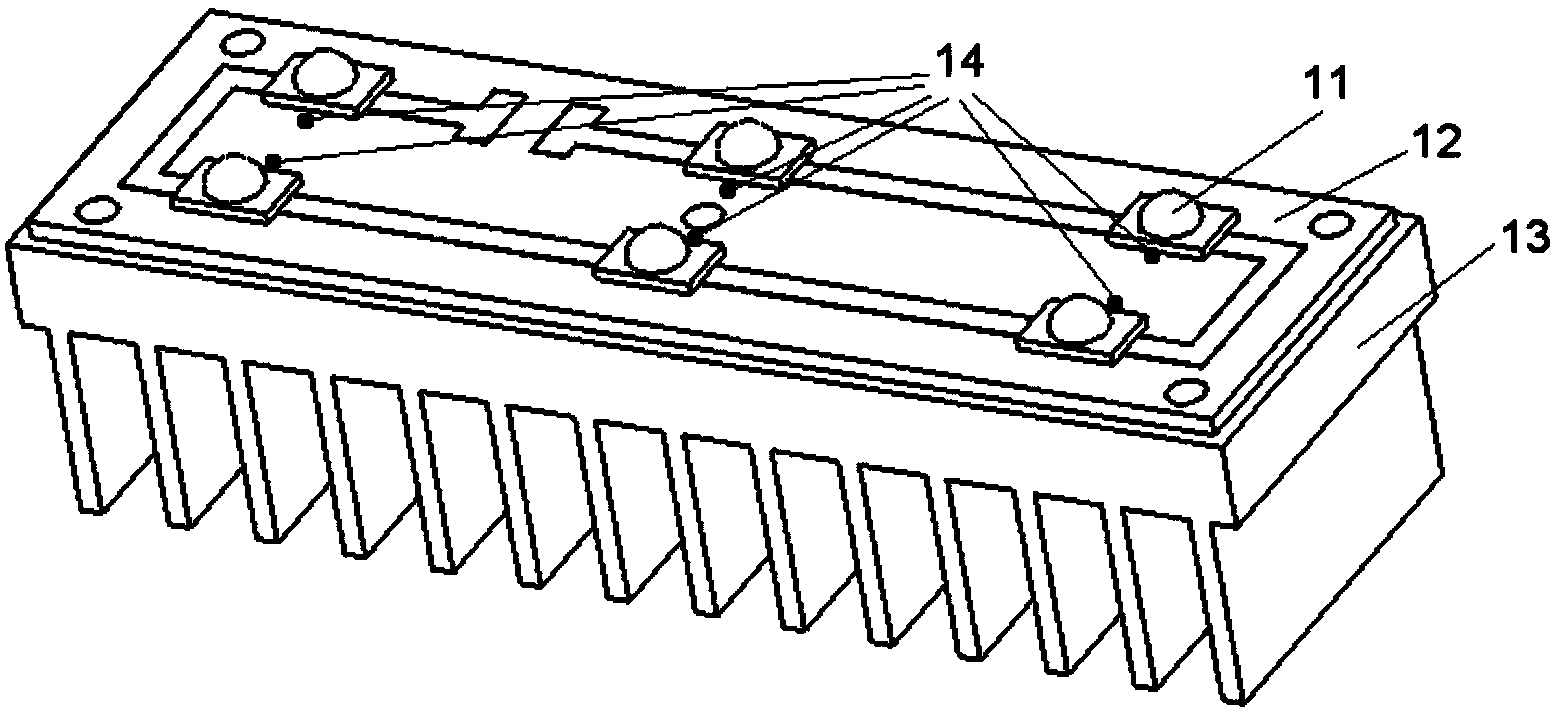

Method and system for measuring entire thermal resistance of LED (light emitting diode) radiating module

InactiveCN103630851AGuaranteed accuracyEasy to measureLamps testingThermocouple WireEnvironmental simulation

The invention discloses a method and a system for measuring the entire thermal resistance of an LED (light emitting diode) radiating module. The method is simple; and the method and the system are high in practicality. The system comprises an LED radiating module, an environmental simulation testing box, a temperature recorder and a power control system, wherein an inlet air pressure voltage-stabilizing chamber, a testing air duct and an outlet air pressure voltage-stabilizing chamber are formed in the environmental simulation testing box; the testing air dust is connected with the inlet air pressure voltage-stabilizing chamber and the outlet air pressure voltage-stabilizing chamber; an air inlet is formed in a box body and corresponds to the inlet air pressure voltage-stabilizing chamber; an air flow driving device and an air heating device are arranged at an air inlet; an air outlet is formed in the box body and corresponds to the outlet air pressure voltage-stabilizing chamber; an air temperature testing point is arranged in the testing air duct; the LED radiating module is arranged in the testing air duct; temperature measuring probes are arranged at a temperature measuring reference point and an air temperature testing point of the LED radiating module; and a temperature signal output end of each temperature measuring probe is connected with a thermocouple wire of the temperature recorder. The system is easy to operate; and obtained data are effective and reliable.

Owner:天津市易伸技术有限公司

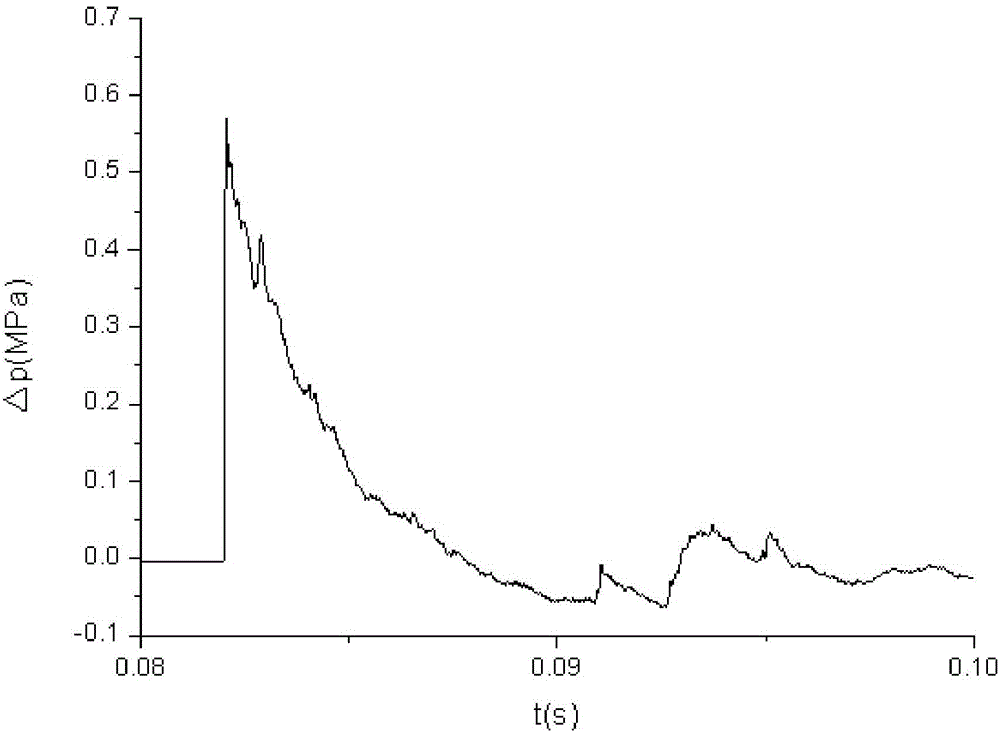

Thermocouple protecting device suitable for fireball response temperature testing in blast field

InactiveCN104535211AResist damageThe temperature measurement curve is validThermometers using electric/magnetic elementsUsing electrical meansMicrowaveEngineering

The invention discloses a thermocouple protecting device suitable for fireball response temperature testing in a blast field. The thermocouple protecting device suitable for fireball response temperature testing in the blast field is mainly composed of a thermocouple, a protective shell, a microwave absorbing coating, a thermocouple installation hole, a wire trough and a fixing hole. The thermocouple protecting device suitable for fireball response temperature testing in the blast field is characterized in that the thermocouple is connected with the protective shell through the thermocouple installation hole, a thermocouple wire is arranged in a concave structure of the protective shell, a thermocouple signal line is lead out from the wire trough, the microwave absorbing coating is arranged on the internal wall surface of the concave structure of the protective shell, the device is fixed to an installation structure through the fixing hole, and the tail portion of the protective shell is right opposite to a blast center when the thermocouple protecting device is used. The thermocouple protecting device suitable for fireball response temperature testing in the blast field has the remarkable advantages that on the premise that the response time of a rapid response thermocouple resisting to transient high pressure is not influenced, the environmental adapting ability of the thermocouple is improved, the damage of high-speed fragments, high-pressure impact and explosion products to a thermocouple wire can be effectively resisted, and testing data can be obtained.

Owner:XIAN MODERN CHEM RES INST

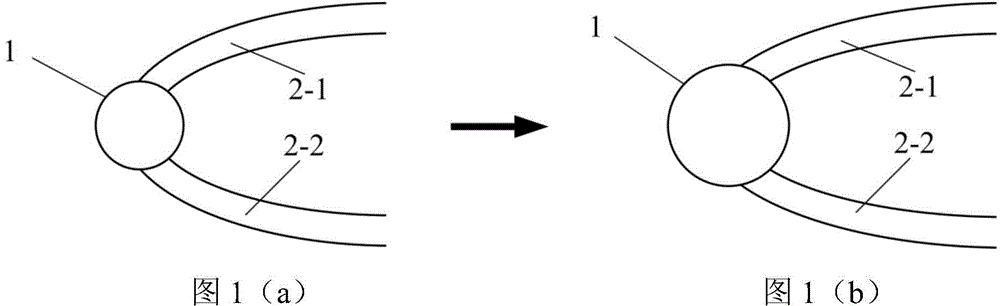

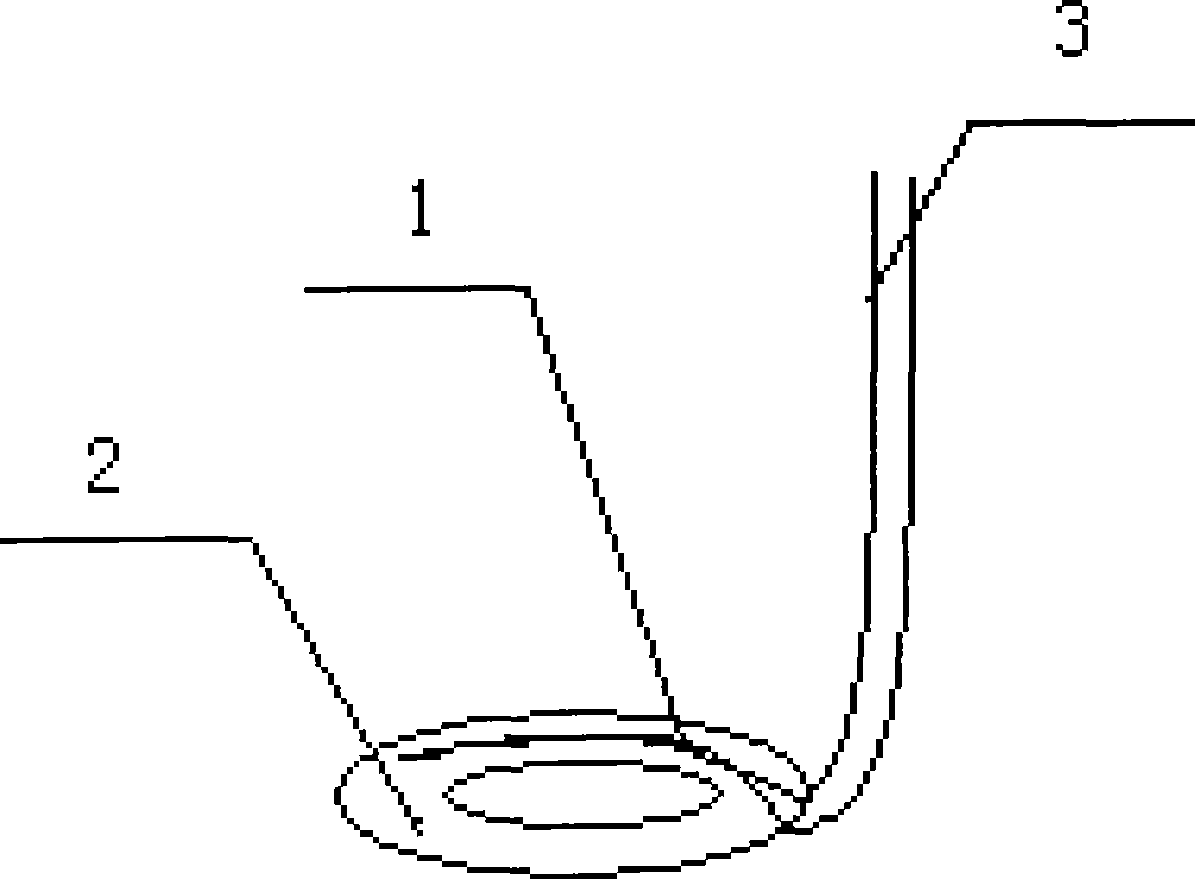

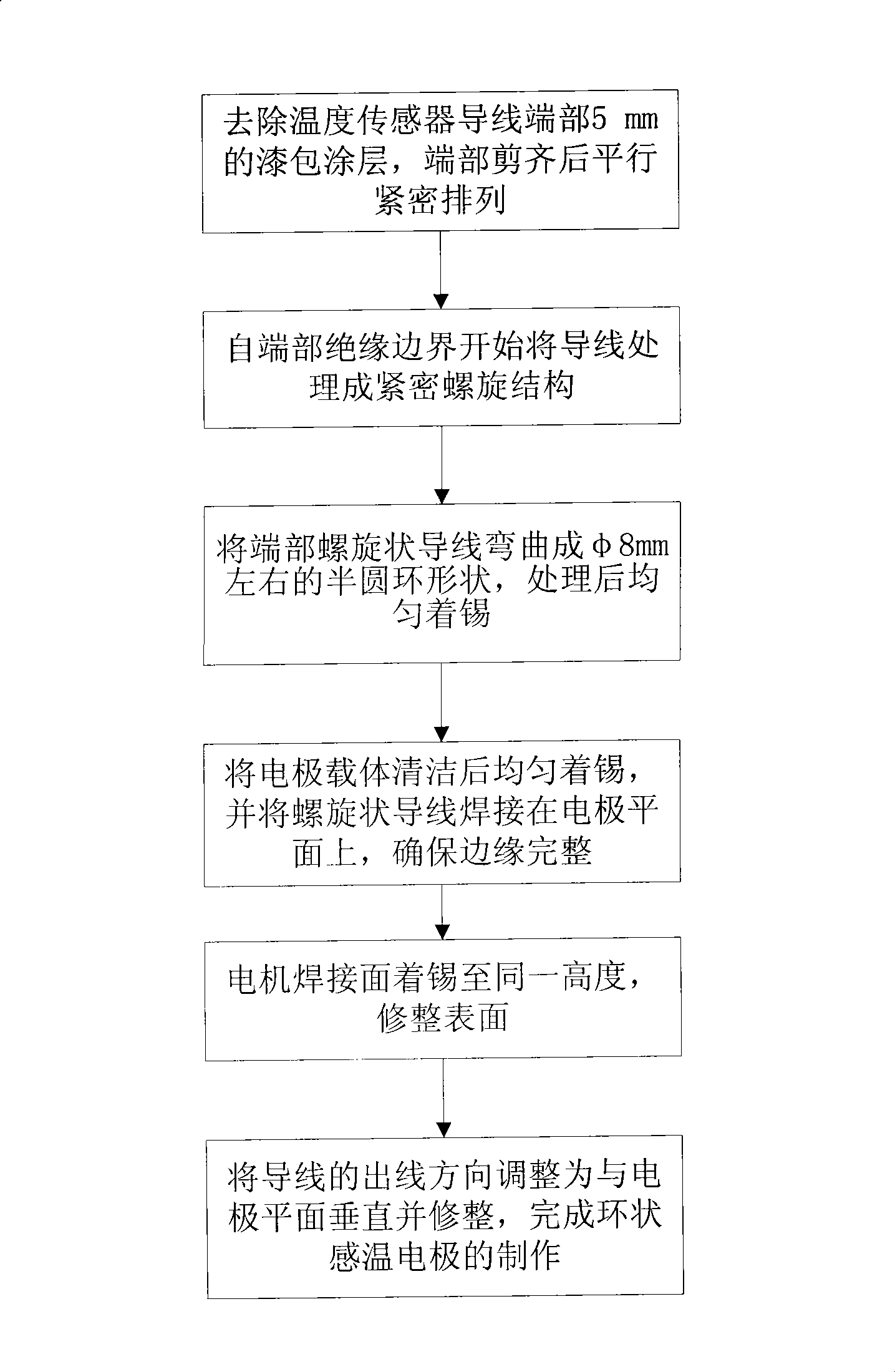

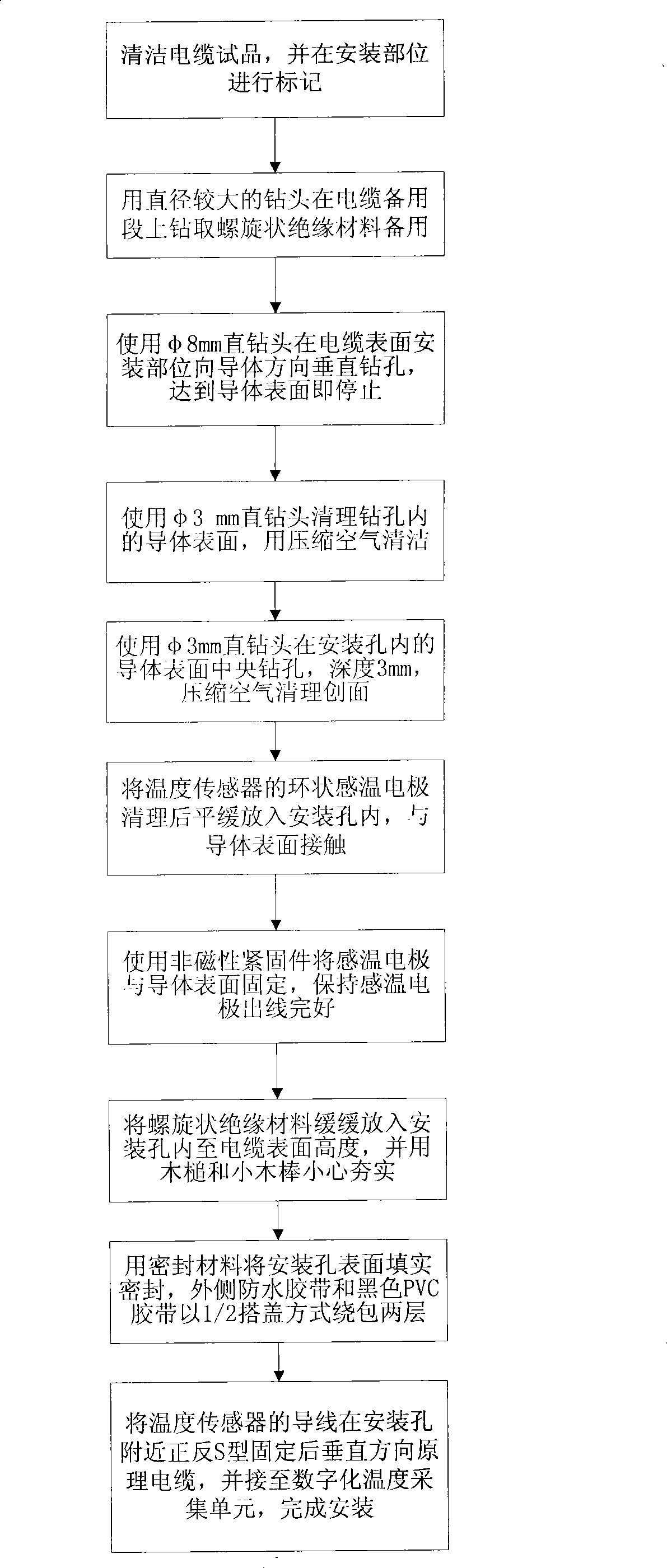

Loop sensor for temperature measurement of cable conductor and method for manufacturing same

InactiveCN101387558AAccurate measurementEffective monitoringThermometers using electric/magnetic elementsUsing electrical meansElectrical conductorThermocouple Wire

The invention relates to a loop sensor for measuring cable conductor temperature and a production method thereof, while the loop sensor is made of two thermocouple wires, which is characterized in that: the thermocouple wires have a semicircle temperature sensing end welded with a copper ring pad. The production method comprises: bending the ends of the two thermocouple wires into a semicircle shape and coating tin uniformly; welding the ends of the thermocouple wires in the tinned plane of a copper sheet; supplying solder tin for the non-welded part of the thermocouple wires in the tinned plane of the copper sheet to obtain a uniform annular solder tin layer at the upper part of the copper sheet, thereby completing the production of the loop temperature sensing electrode. The invention has the advantages that the annular sensor can accurately and real-timely measure the conductor temperature at any part of a cable in a narrow space, according to research demands, to effectively monitor the operation state and the conductor temperature of a cable circuit under different loads, thereby providing scientific and effectively technique information for the safe operation of cable circuits.

Owner:WUHAN HIGH VOLTAGE RESEARCH INSTITUTE OF STATE GRID

Reinforced platinum/rhodium 10-platinum fine thermocouple wire for quick temperature measurement and preparation method thereof

The invention relates to a reinforced platinum / rhodium 10-platinum fine thermocouple wire for quick temperature measurement and a preparation method thereof. The material comprises a positive pole PtRh10 material and a negative pole Pt material, wherein the positive pole PtRh10 material comprises the following components in parts by weight: 89.9-90.1 parts of platinum, 9.9-10.1 parts of rhodium, 0-0.003 part of yttrium, 0-0.003 part of zirconium, and 0-0.003 part of cerium; the negative pole Pt material comprises the following components in parts by weight: 99.9-100 parts of platinum, 0-0.003 part of yttrium, 0-0.003 part of zirconium and 0-0.003 part of cerium; and the yttrium, zirconium and cerium are distributed in the material matrix in a dispersed manner in the form of fine oxide. When the materials are prepared into the platinum / rhodium thermocouple wire, the minimum diameter is phi0.035mm, and the application range is phi0.035-0.07mm. The reinforced platinum / rhodium 10-platinum fine thermocouple wire has the properties of quick, accurate and stable temperature measurement, high reliability, high strength and the like.

Owner:CHONGQING MATERIALS RES INST

Testing method of baking temperature of steel ladle

ActiveCN101907496AControl operation timeControl bake timeThermometer detailsThermometers using electric/magnetic elementsFire brickRefractory

The invention relates to a testing method of baking temperature of a steel ladle, which belongs to the technical field of temperature tests. When firebricks of a working layer of the steel ladle are constructed, thermocouples are embedded into seams of the firebricks in advance; three to five thermocouples are respectively embedded into the bottom, the inner wall and residue lines of the steel ladle according to the height and the inner diameter of the steel ladle; a temperature testing point of the thermocouples is consistent with the inner vertical surface of the firebricks of the working layer; wires of the thermocouples are distributed between the working layer and a permanent layer; the wires are led out of the bottom of the steel ladle or the top of the wall of the steel ladle; and the tail wires of the thermocouples are connected with a temperature display meter. Special fine thermocouples can be customized; the outer diameter of protective sleeves of the thermocouples is 2 to 3 mm; the thermocouples are made of heat-resistant stainless steel by adopting a hot drawing process; insulating materials are filled between the thermocouple wires in the sleeves and the sleeves; the embedded firebricks do not affect the construction of the steel ladle; in the baking process of the steel ladle, the temperature of a fireproof material of the inner wall is measured and displayed in real time; the operation and the baking time of a baker can be accurately controlled; and after baking is finished, the temperature display meter is disconnected from the thermocouples so as to be convenient to be used in next on-line baking.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com