Temperature-measuring armored thermocouple

A technology of armored thermocouples and thermocouple wires, which is applied to measuring devices, measuring heat, thermometers, etc., can solve problems such as unstable thermoelectric potential output, damage to power supply coolant, and affecting power generation performance, so as to improve temperature measurement accuracy and The effects of thermal response time, easy disassembly and assembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

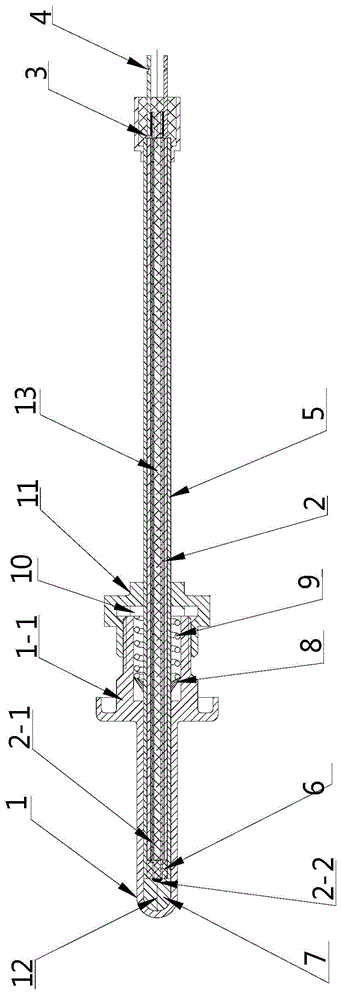

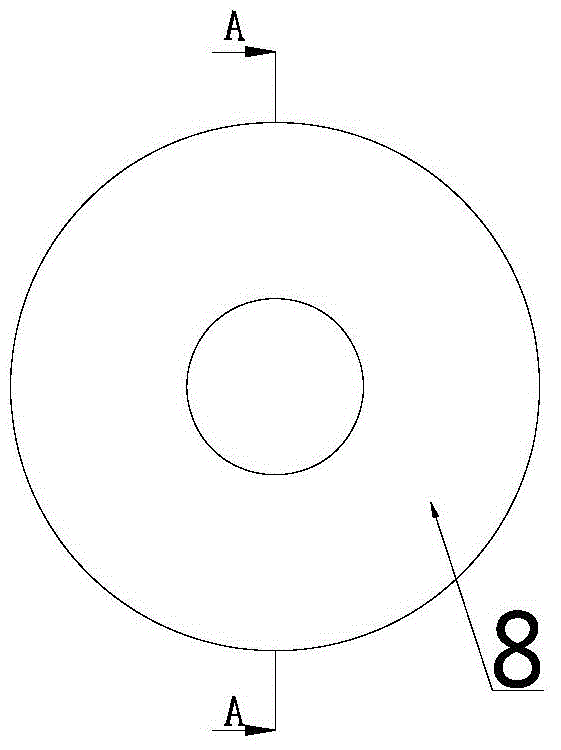

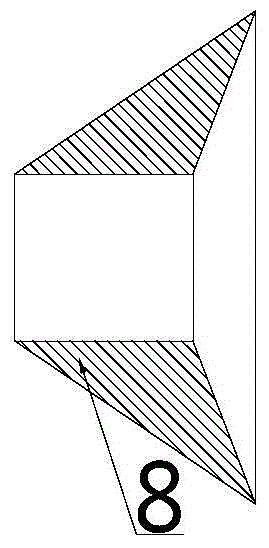

[0028] see Figure 1 to Figure 4 As shown, a temperature-measuring armored thermocouple includes a protective sleeve 1 and an armored thermocouple 2. One end of the protective sleeve 1 is processed into a seal, and the other end is a mounting part 1-1 provided with an insertion port. The installation part 1-1 is composed of a connecting boss arranged along the outer circumference of the protective sleeve 1 and an extension part extending in the axial direction, the extension part is cylindrical, the extension part is provided with an external thread, and an internal A spring installation cavity, the inner diameter of the spring installation cavity is larger than the outer diameter of the support tube 5 . The protective sleeve 1 is integrally processed by 316H stainless steel, and the installation part 1-1 is welded on the cooling pipeline for installing the protective sleeve 1 on the cooling pipeline. The installation part 1-1 of the protective sleeve 1- 1 Argon arc welding i...

specific Embodiment 2

[0050] Specific embodiment 2: see Figure 5 As shown, the characteristics of this embodiment are: there are multiple armored thermocouples installed on the flange, and the effect of using n (n>1) thermocouples is that when any 1 to n-1 thermocouples fail At least one thermocouple can still output the correct temperature signal to the control system. Other characteristics are identical with specific embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com