Patents

Literature

62results about How to "Guaranteed heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

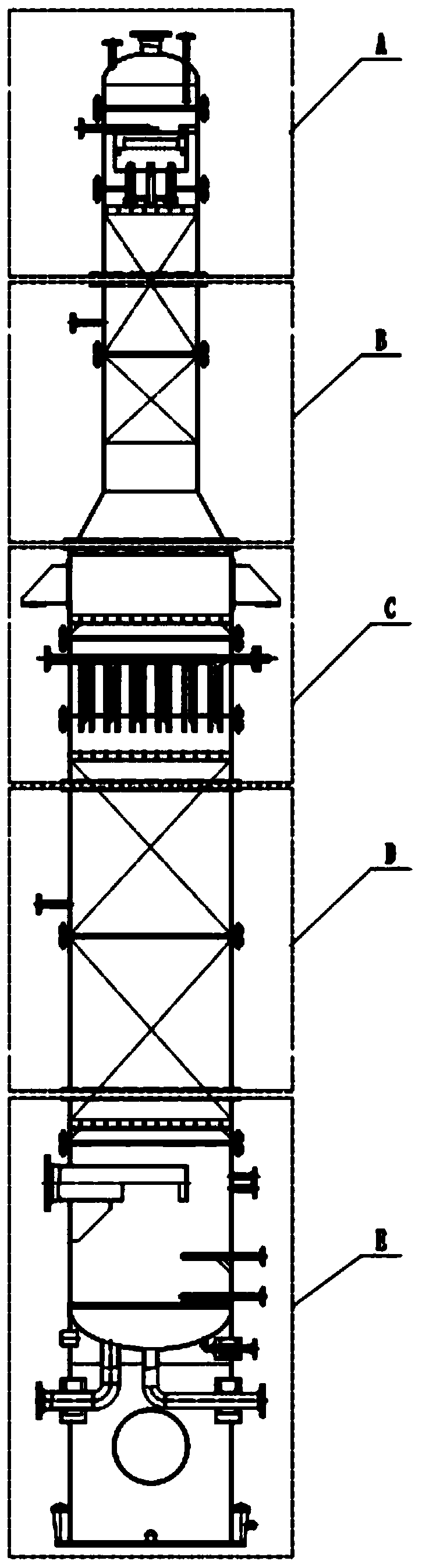

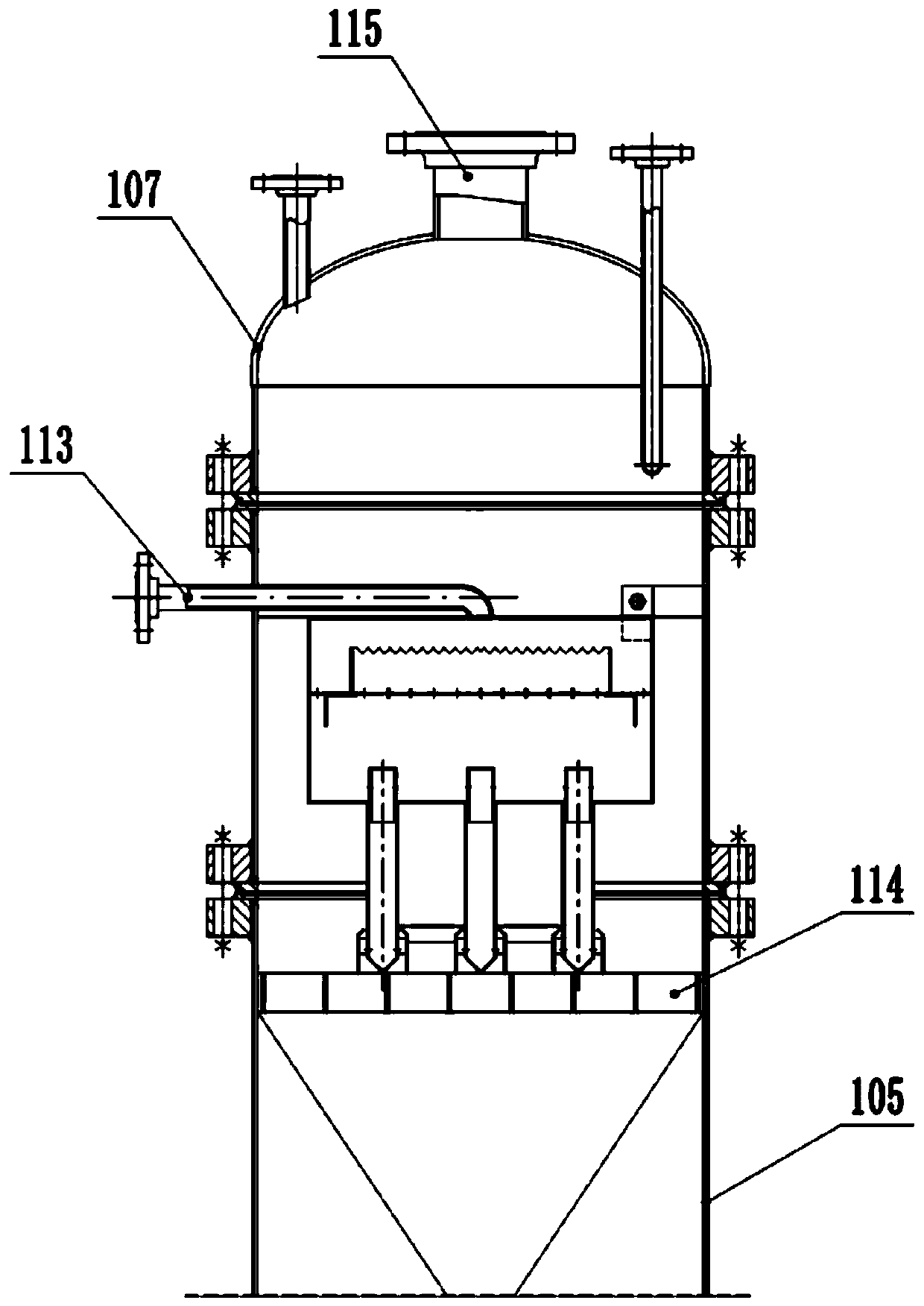

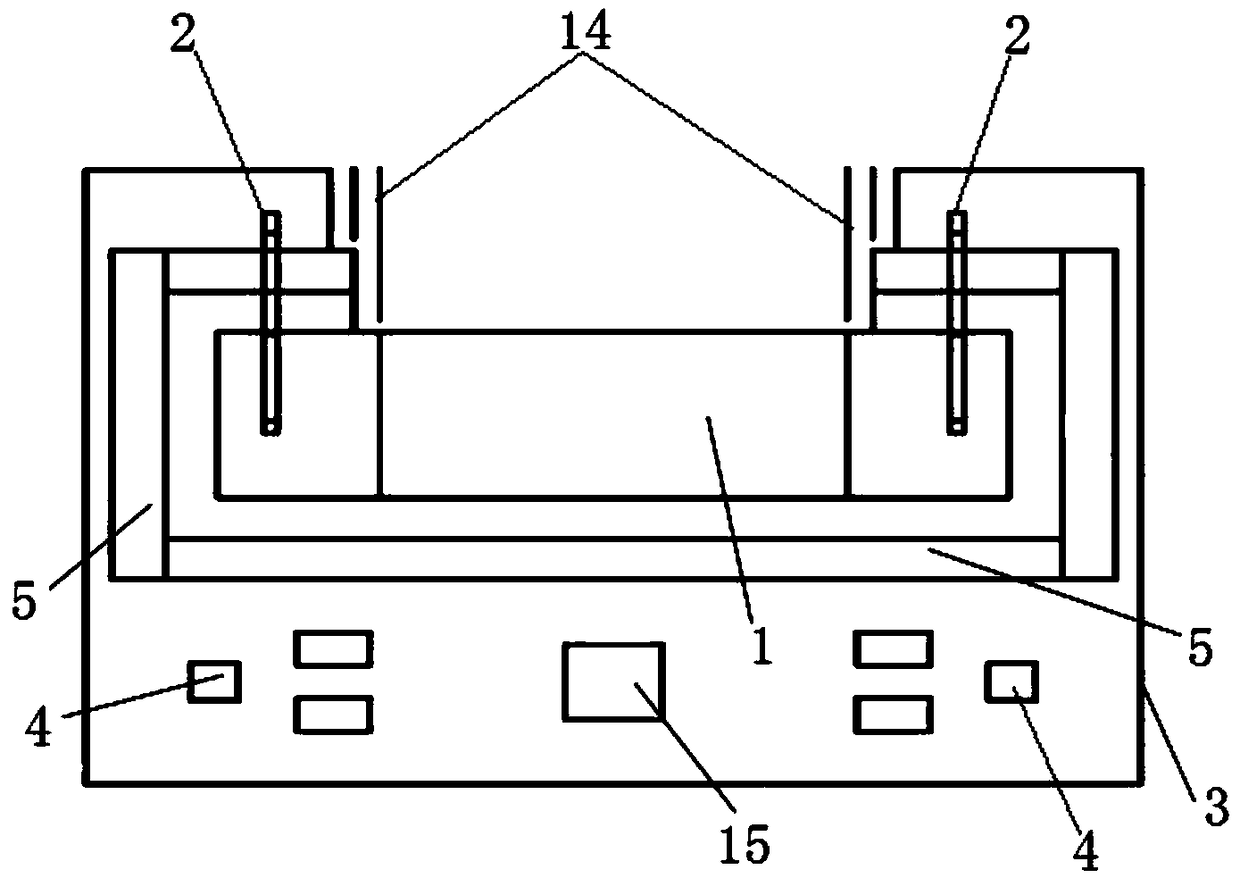

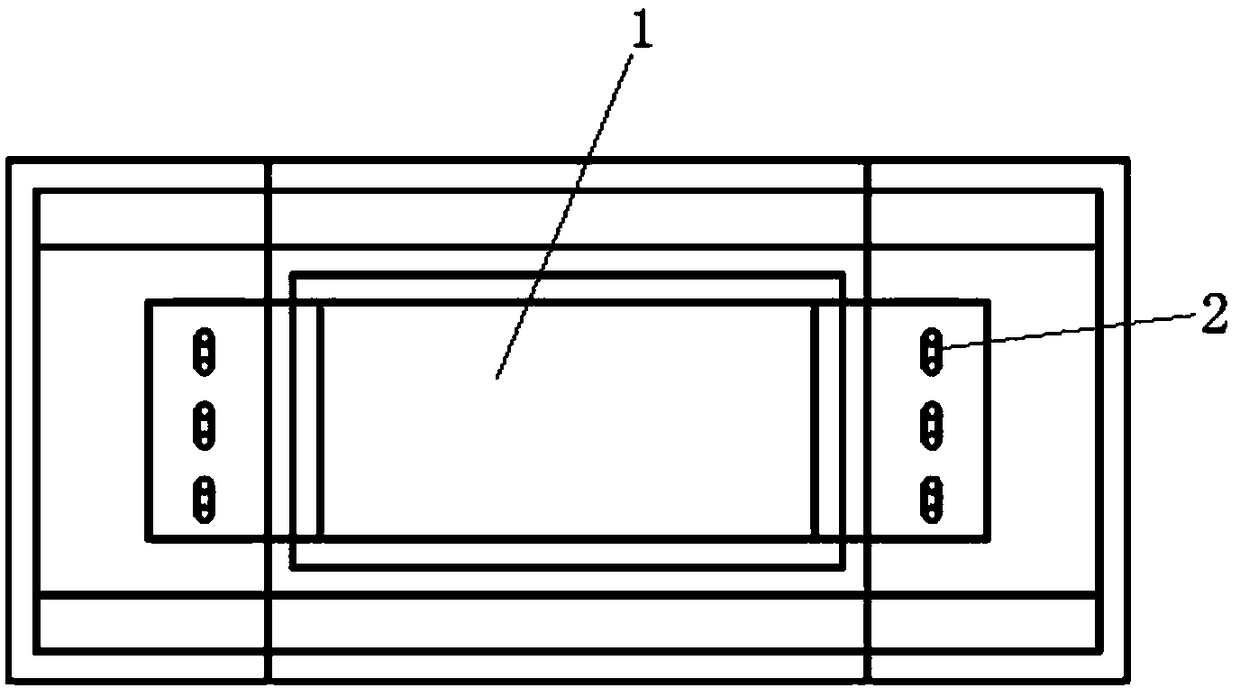

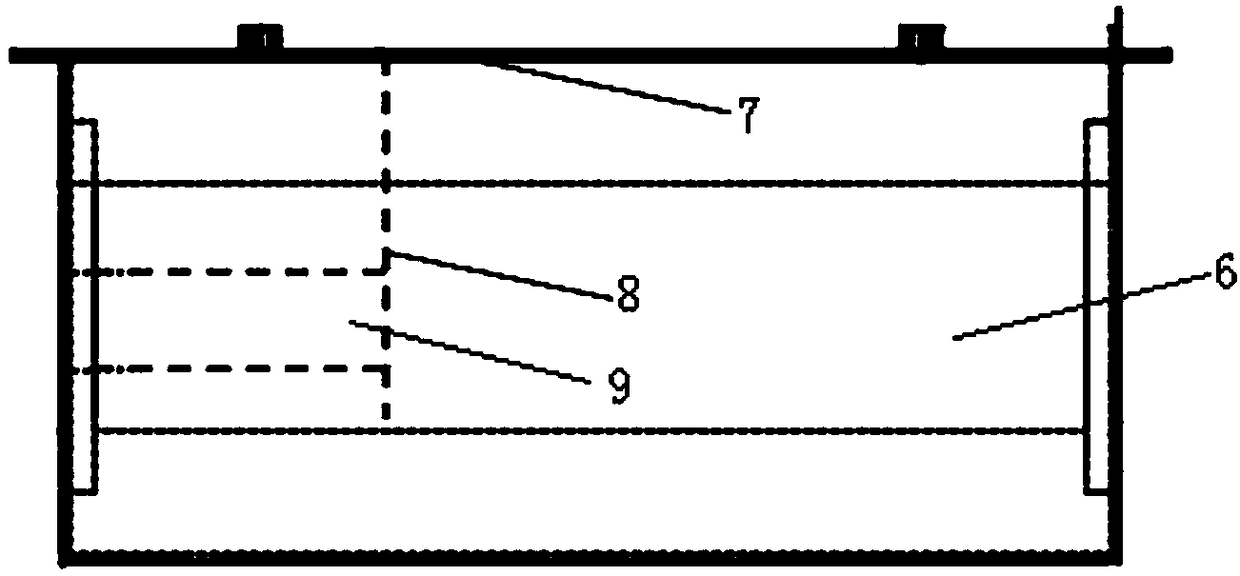

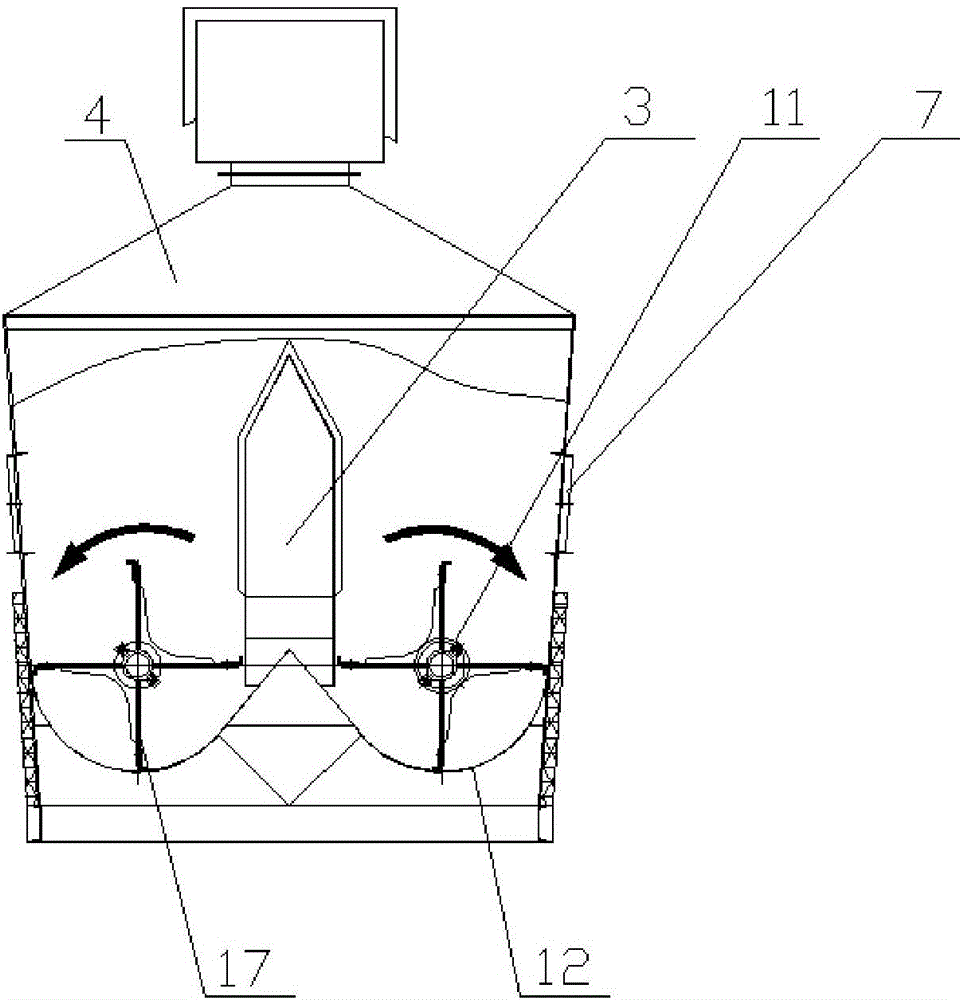

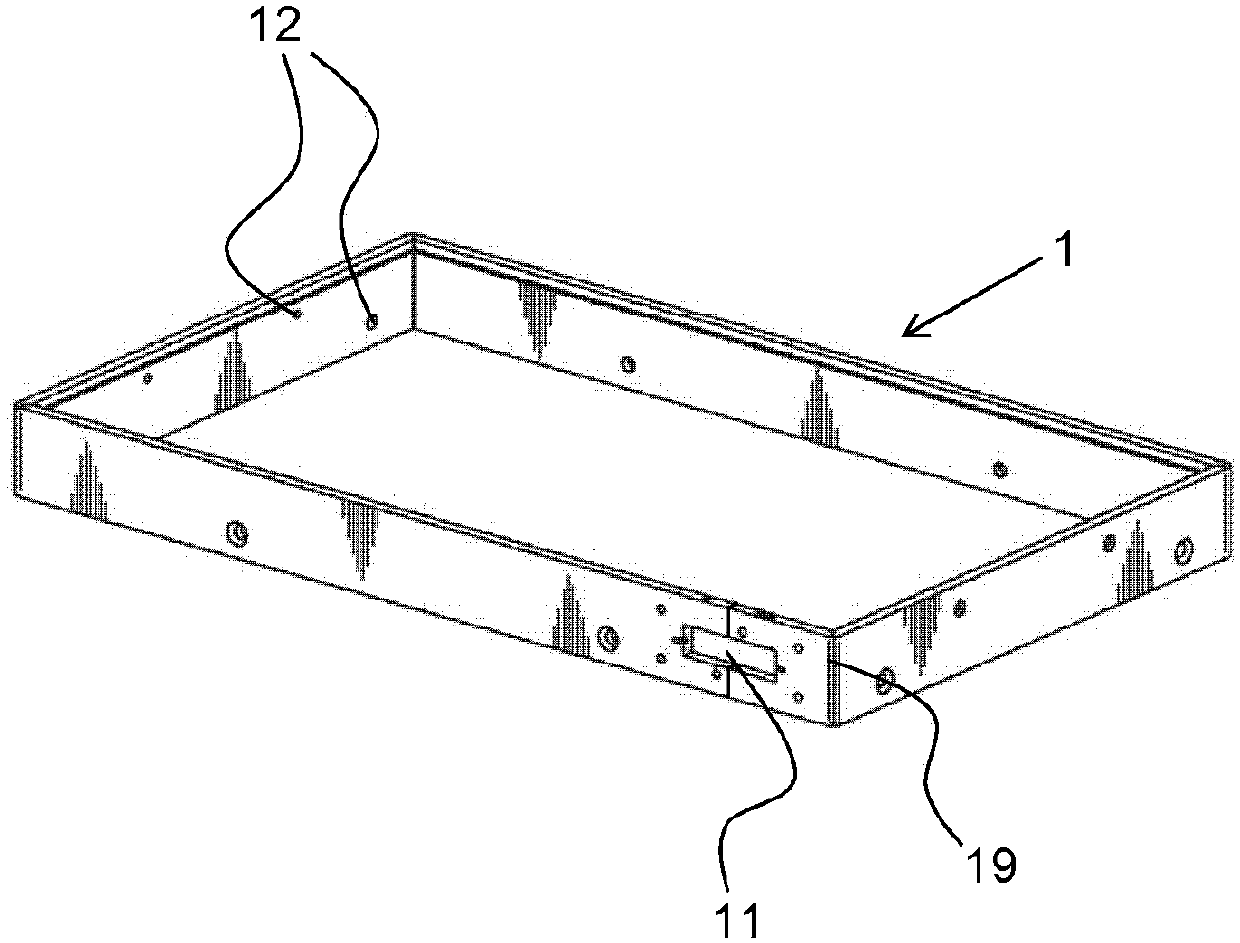

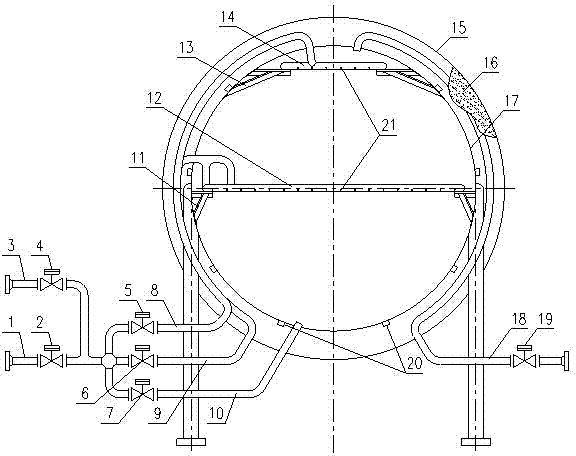

Solid fermentation bioreactor

InactiveCN102443535AAffect growthWell mixedBioreactor/fermenter combinationsBiological substance pretreatmentsBioreactorControl unit

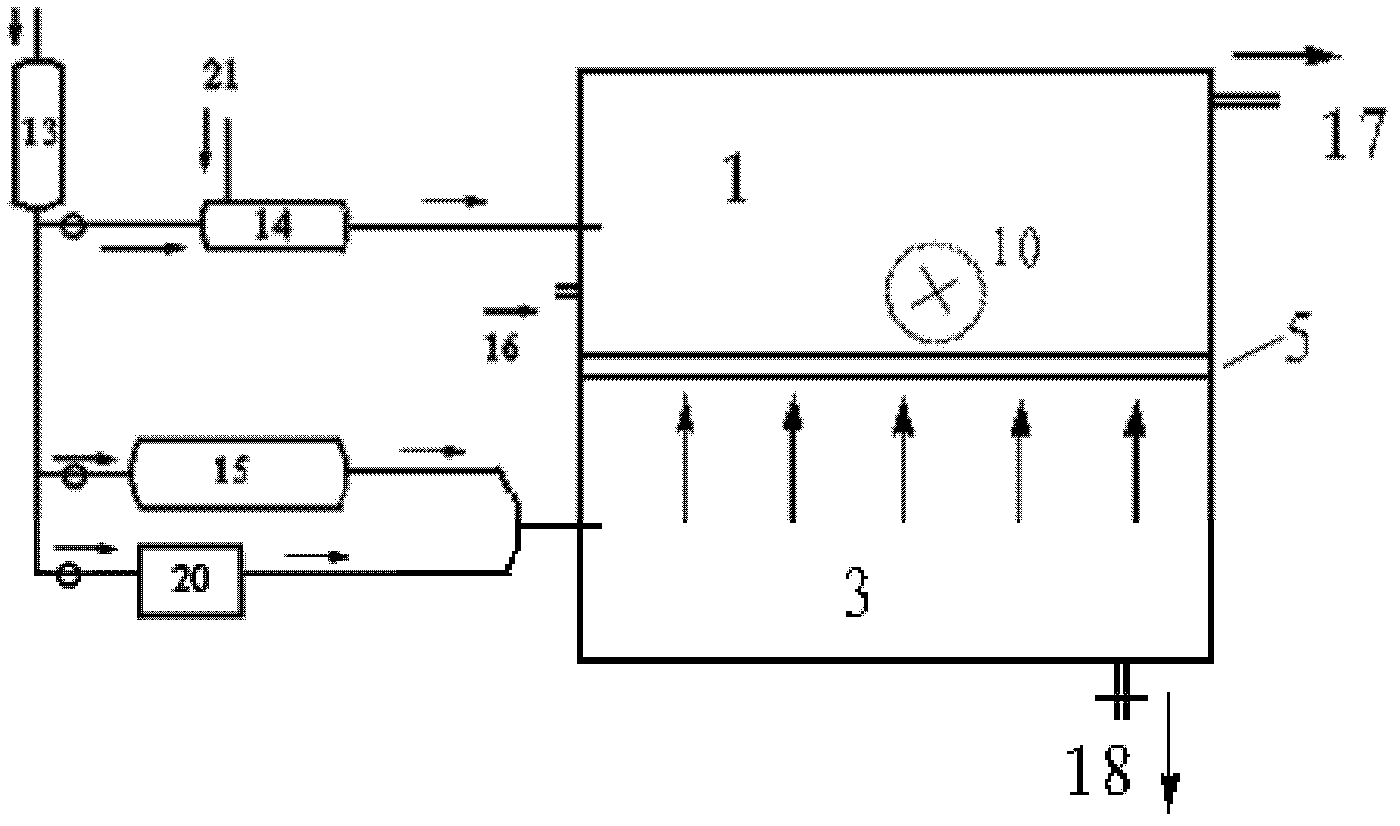

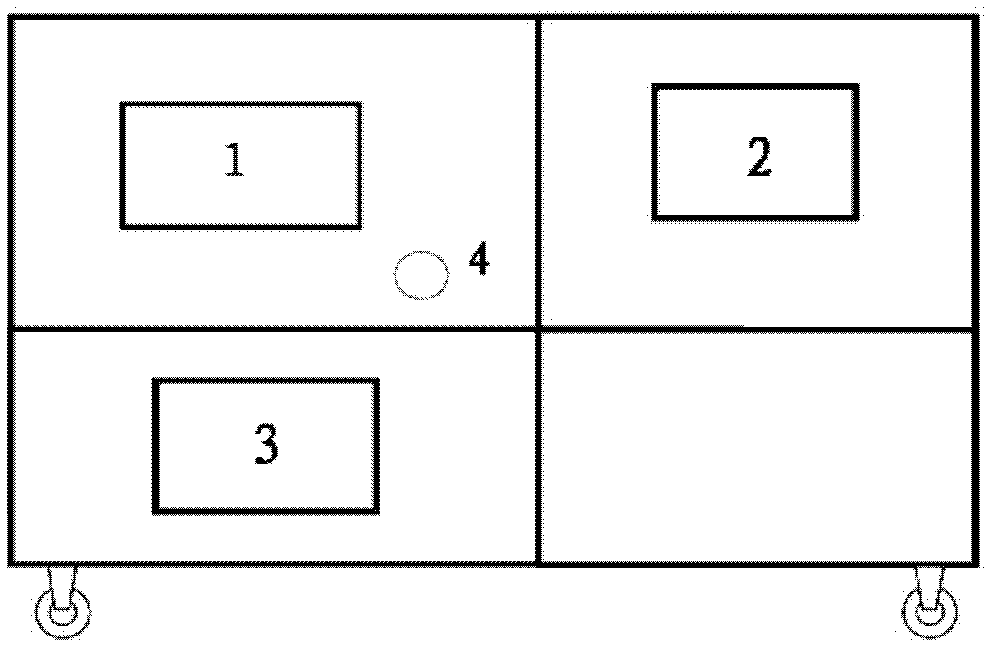

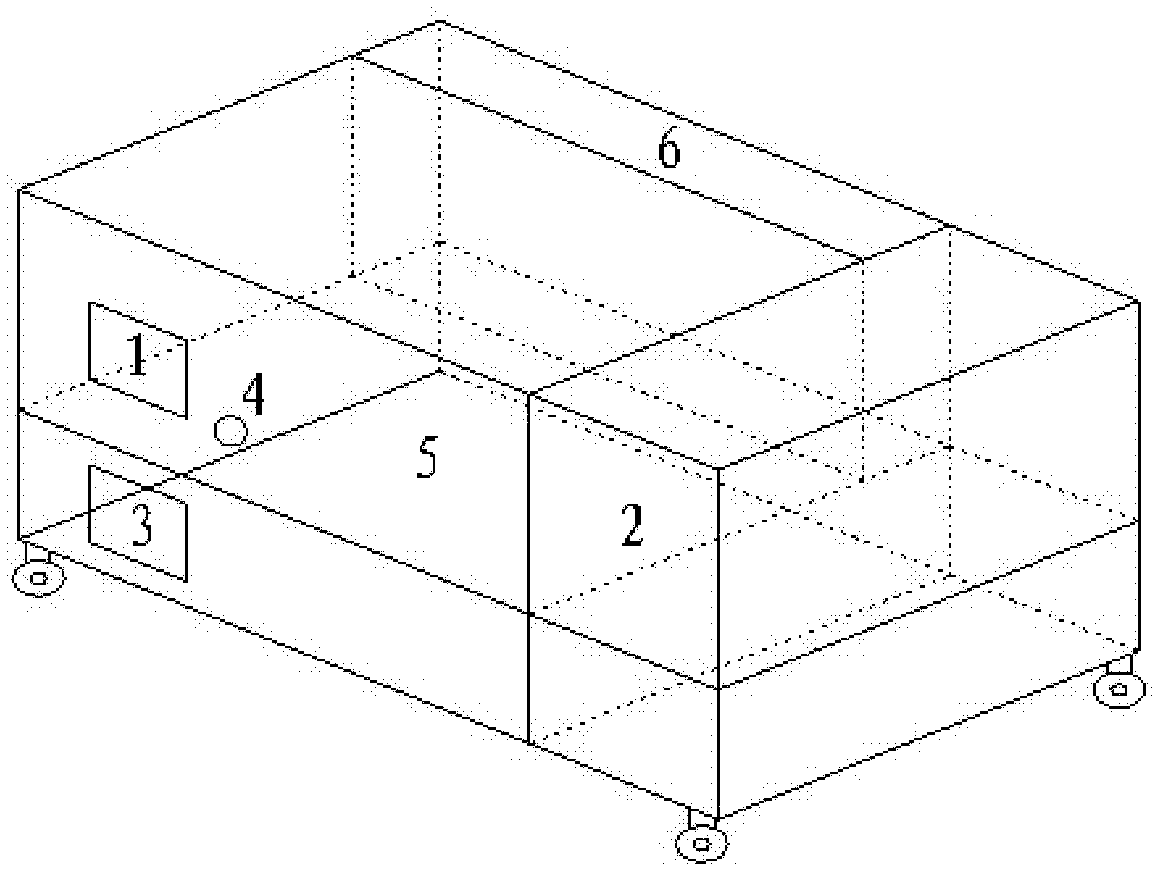

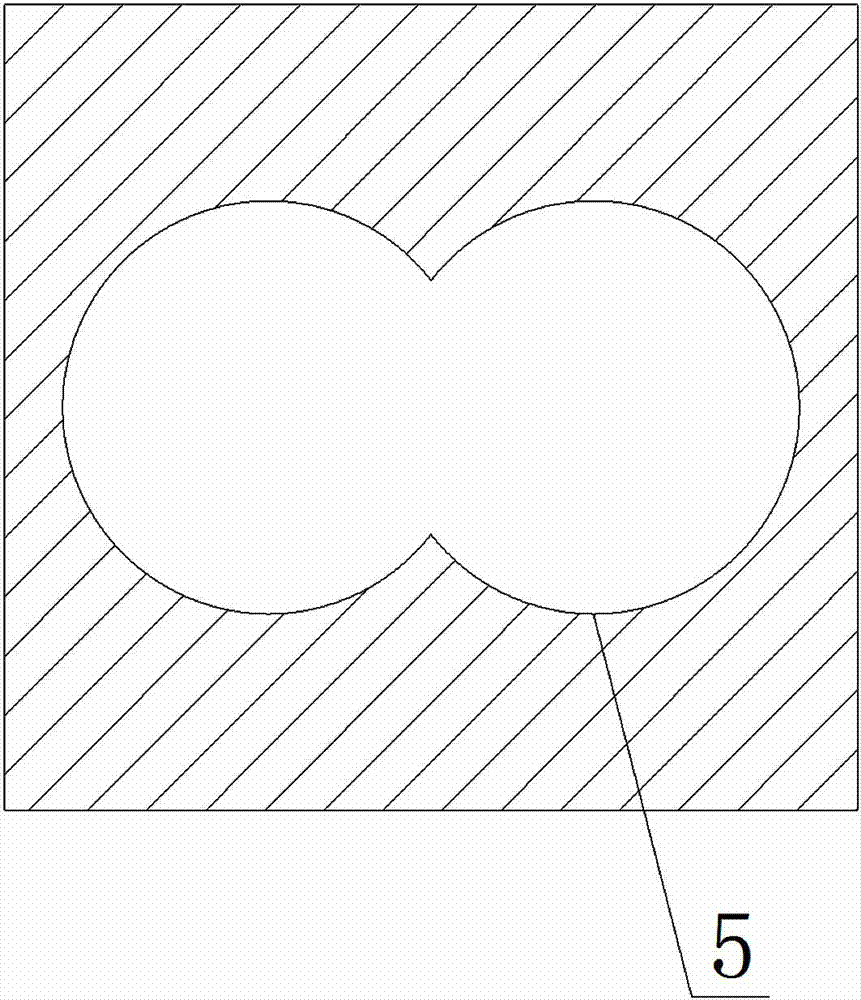

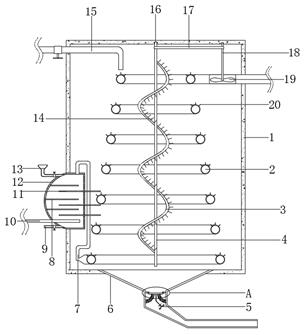

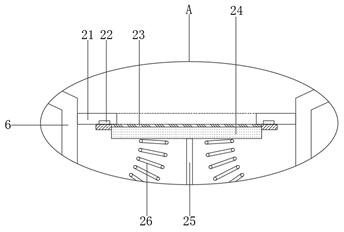

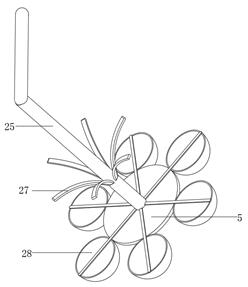

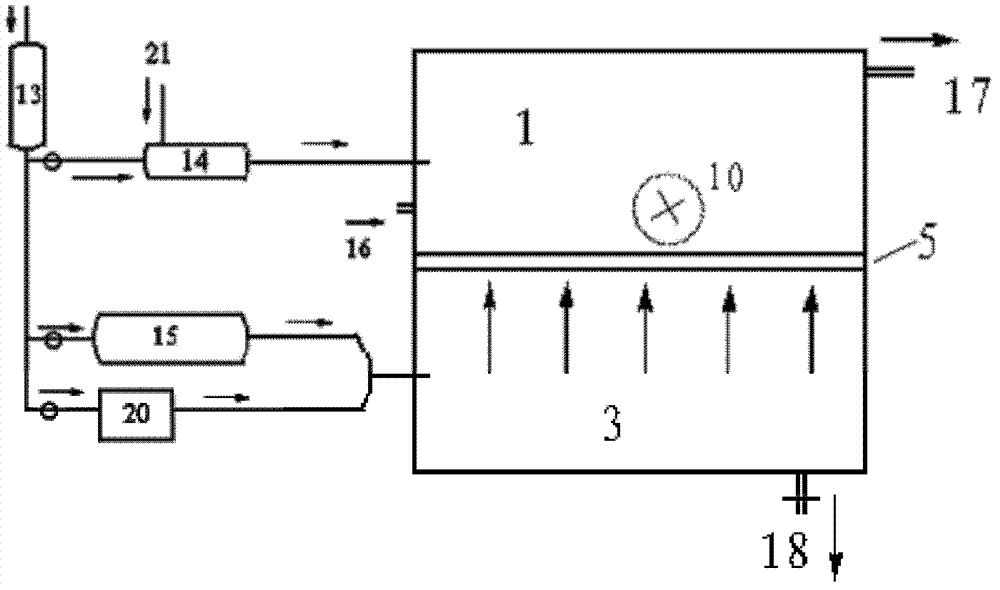

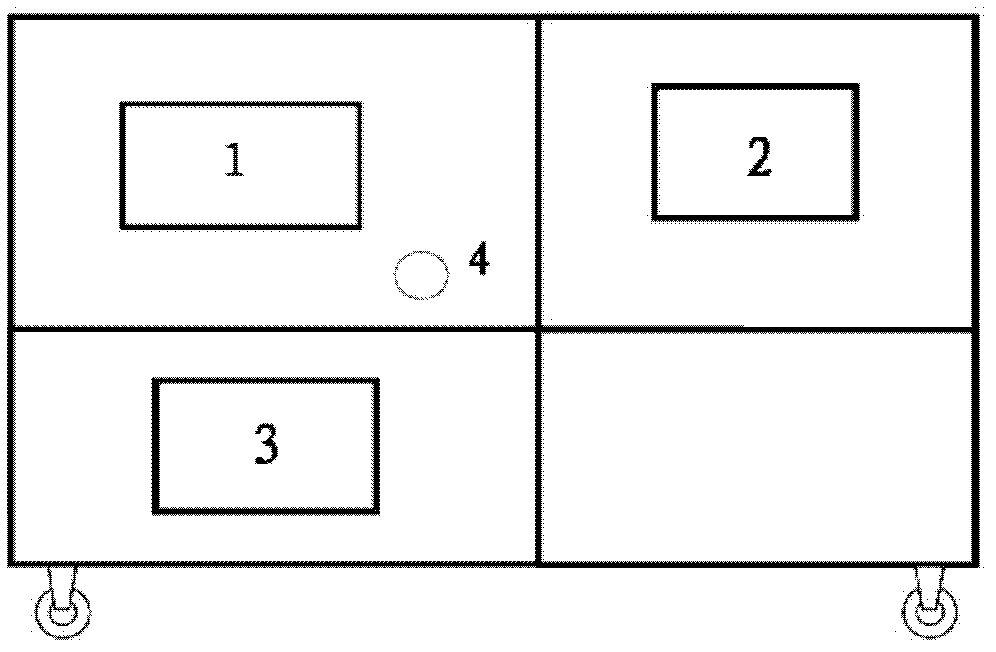

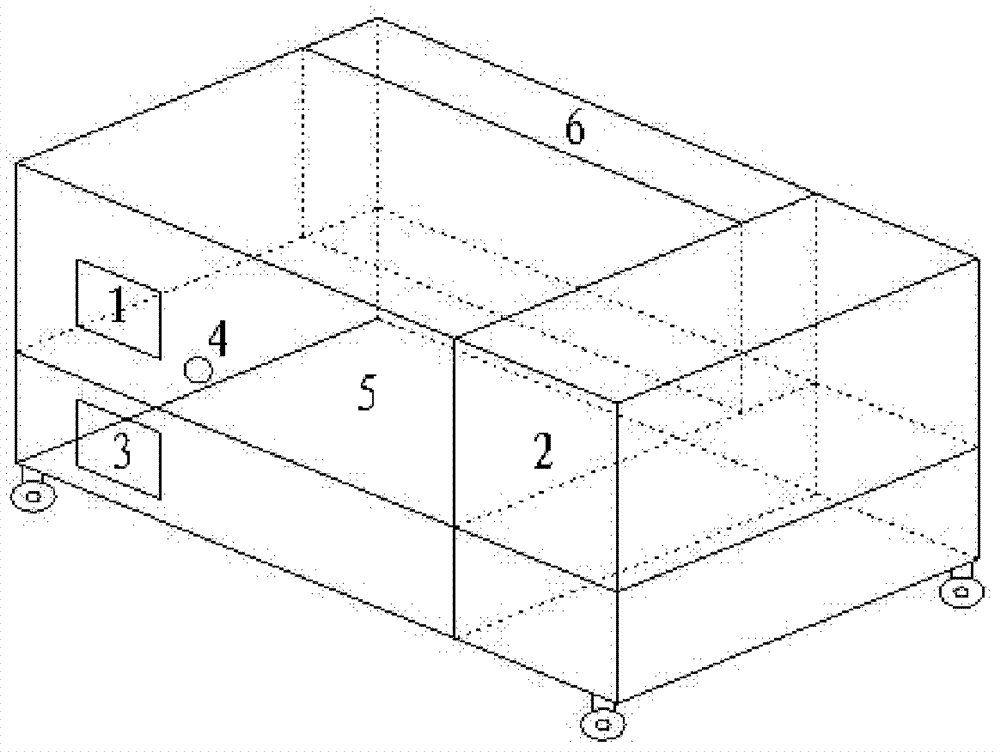

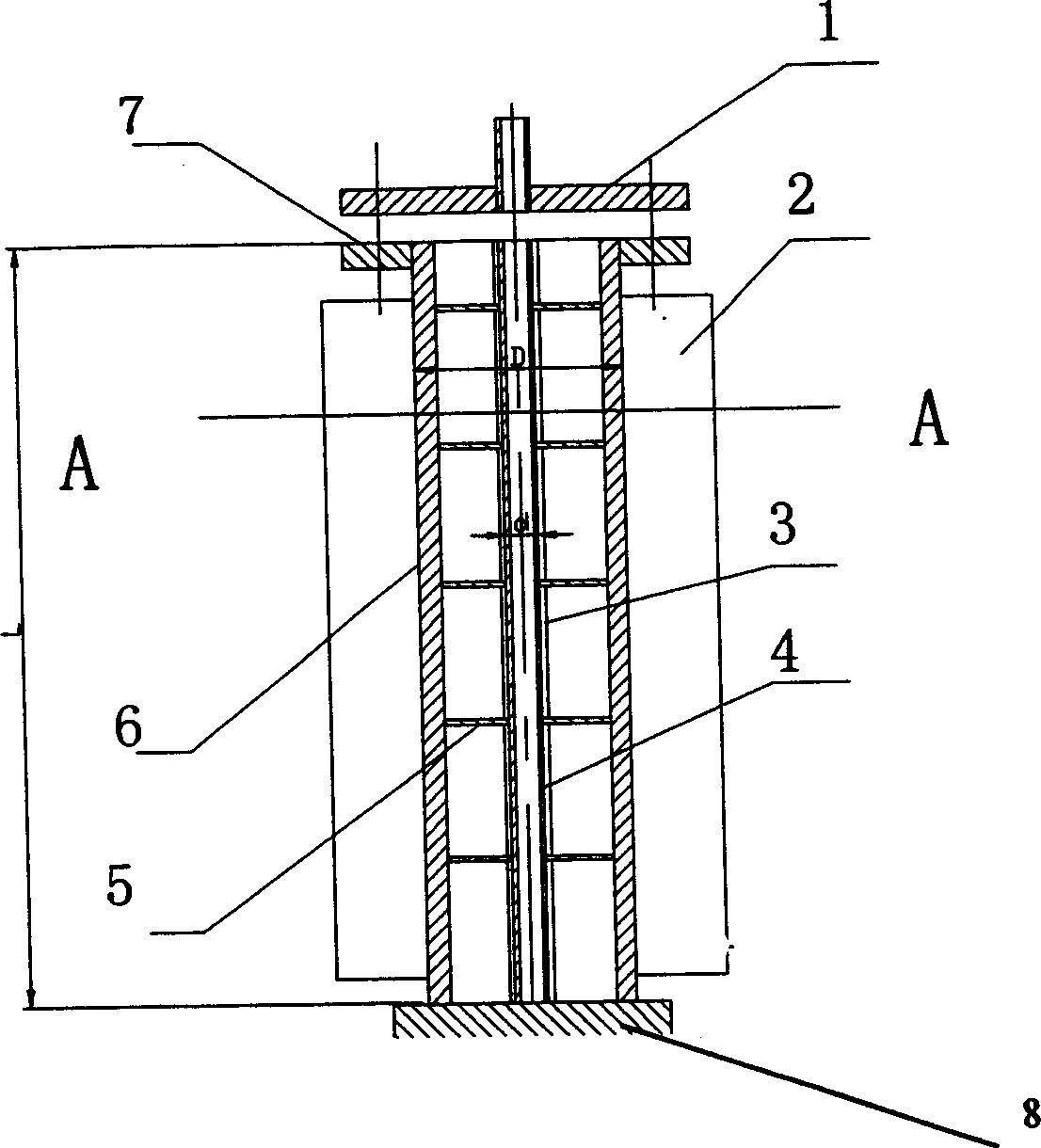

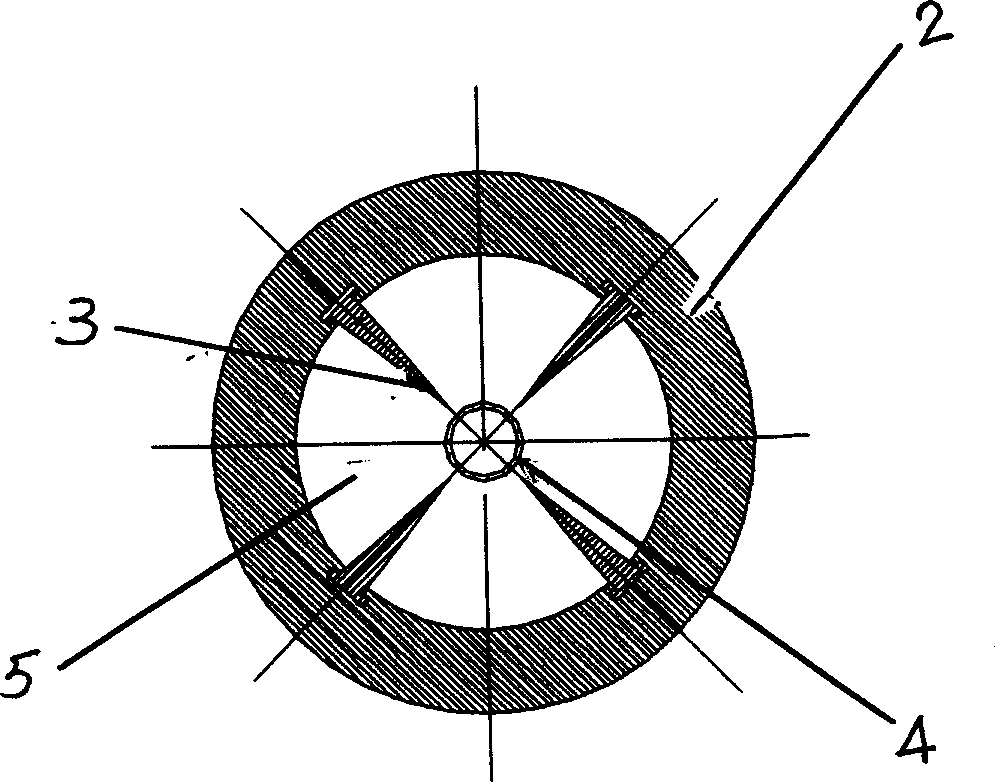

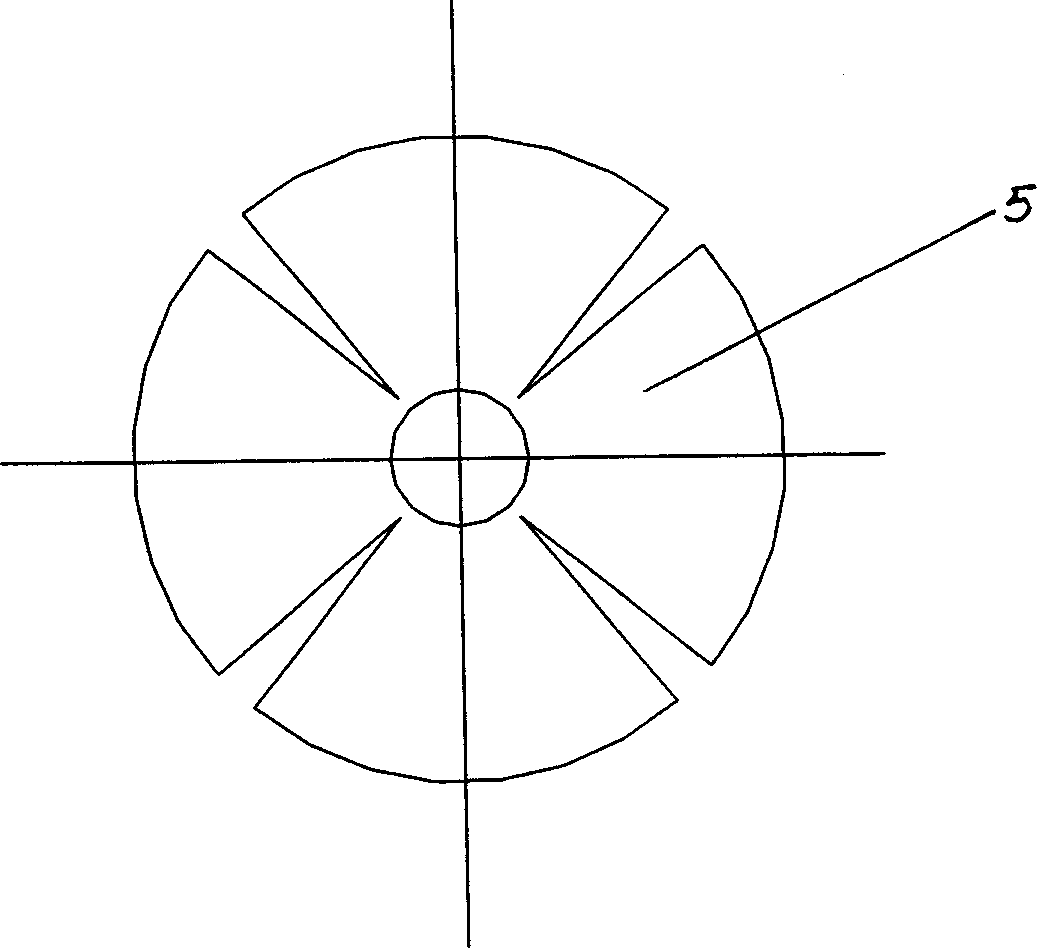

The invention relates to a solid fermentation bioreactor. The reactor comprises a reaction casing , and a porous material layer separator plate (5) is arranged in the reaction casing to divide the reaction casing into an upper fermentation chamber (1) and a lower layer air chamber (3); the reactor also comprises a fermentation control system for controlling a stirring unit, a temperature control unit, a humidity control unit, an air feed control unit and a fermentation tail gas detection and processing unit, so as to realize real time monitoring and control on temperature, humidity, ventilation, stirring and tail gas. The invention realizes totally enclosing on-line fermentation and prevents extraneous pollutants from entering; the tail gas detection system carries out real time on-line monitoring on fermentation gas, and tail gas is treated by tail gas recovery equipment to protect the environment, thereby realizing coupling operation of temperature, humidity, ventilation, stirring and tail gas control system and ensuring necessary essential factors for microbe growth.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

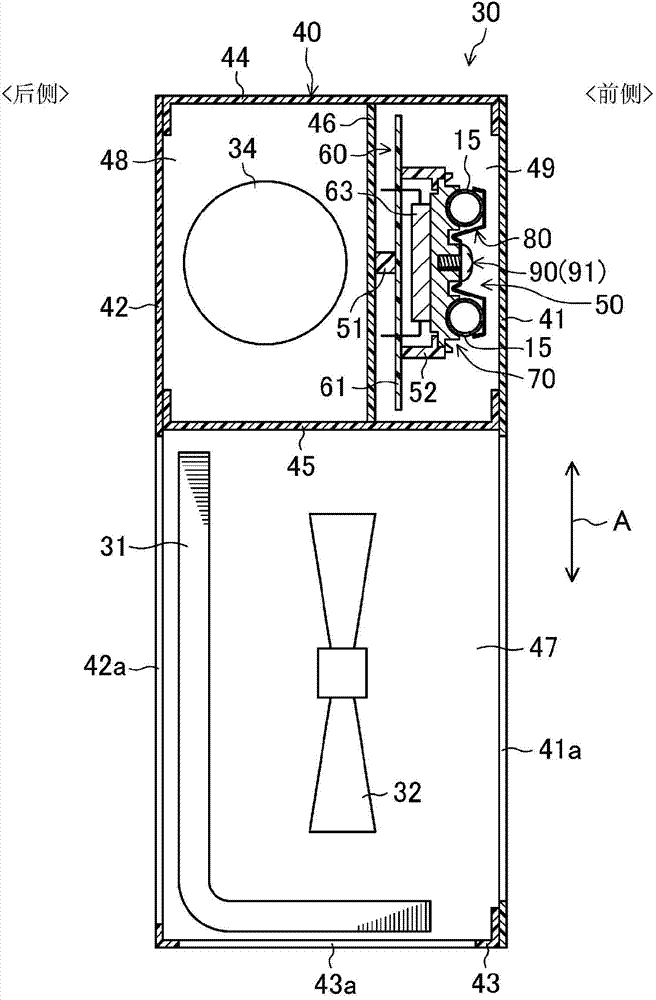

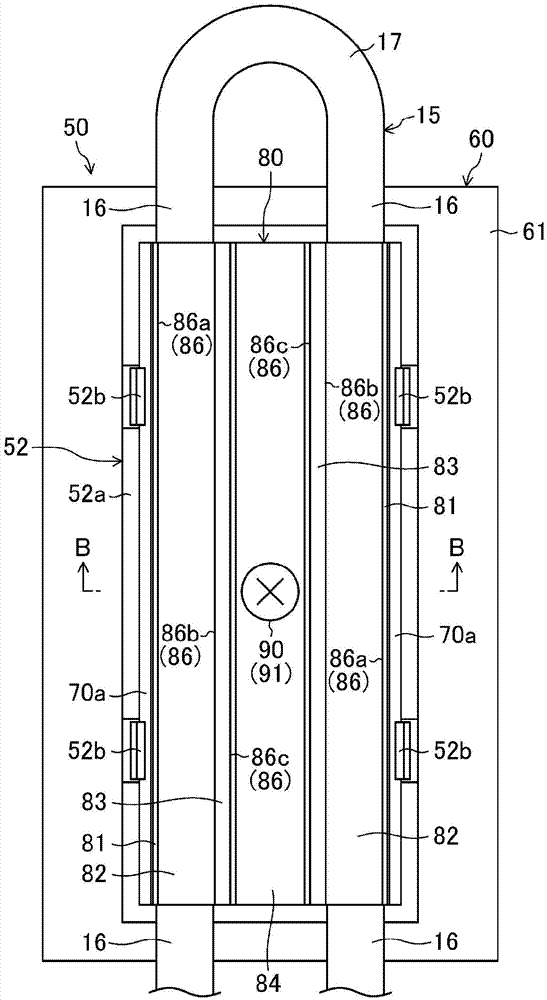

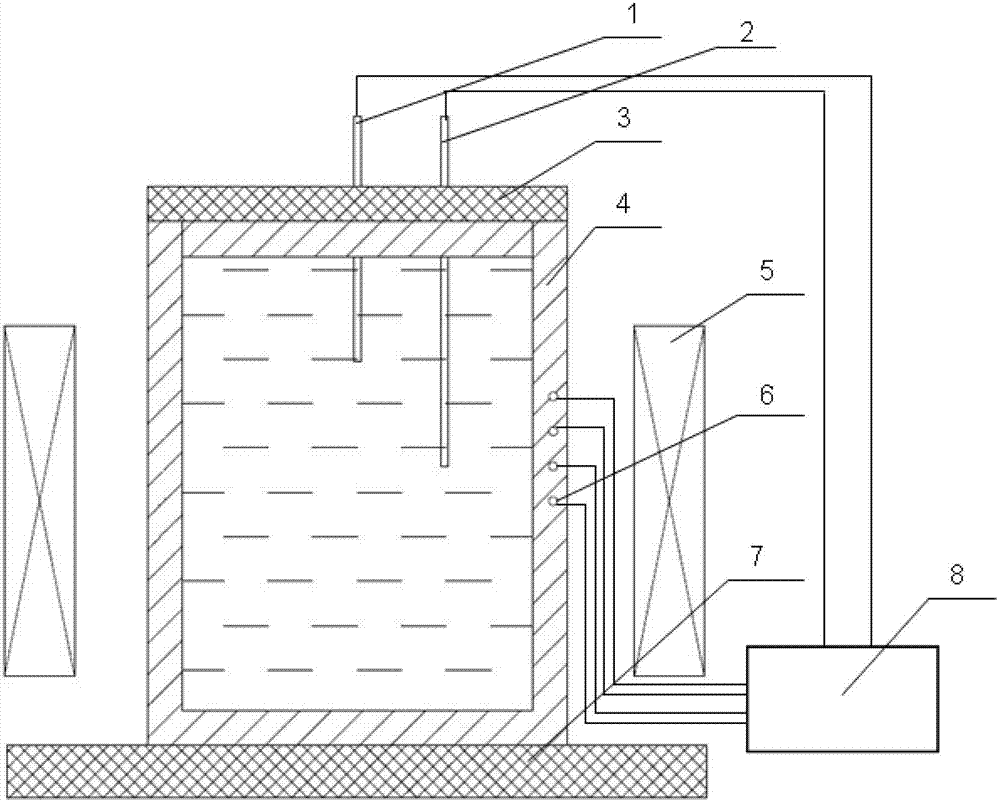

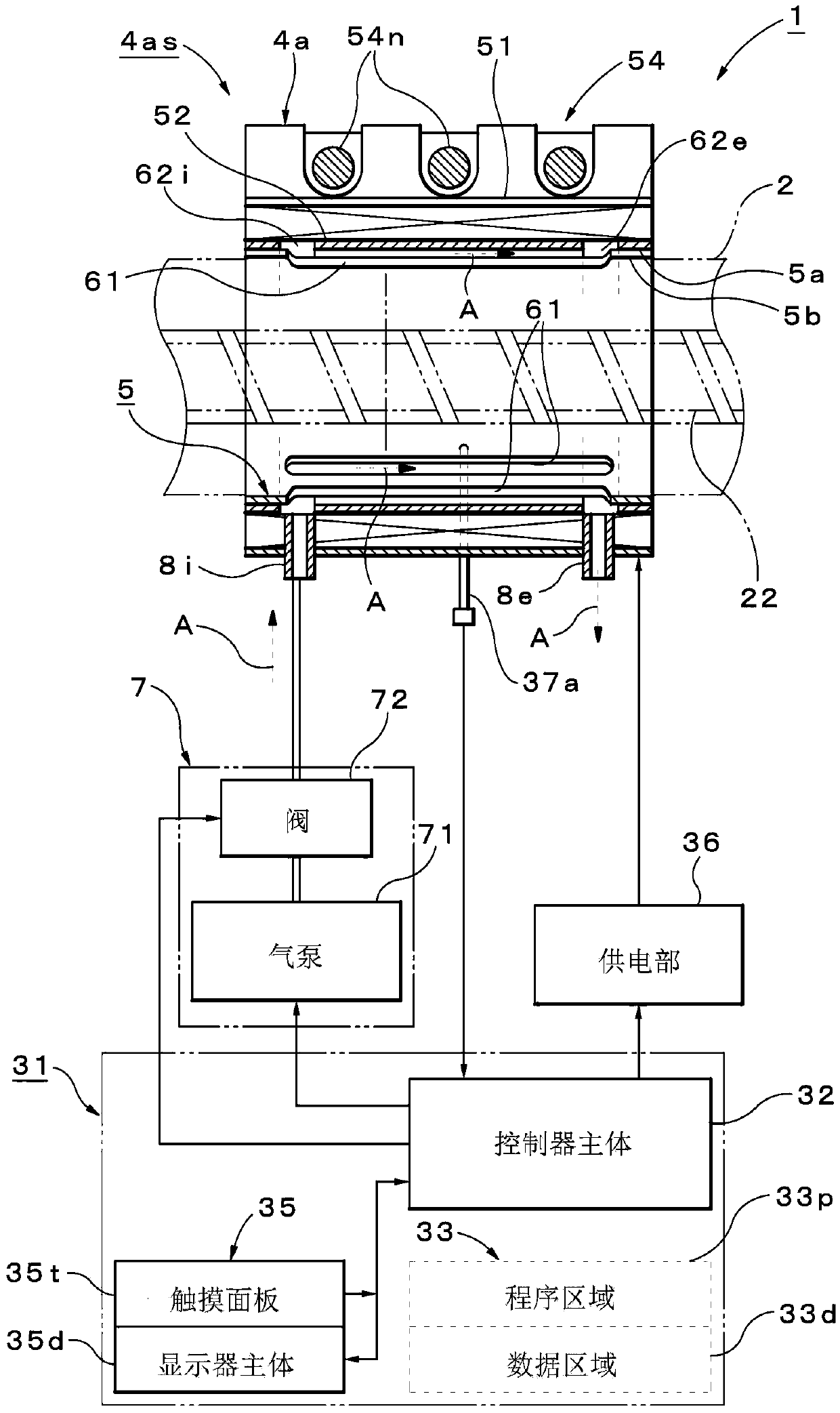

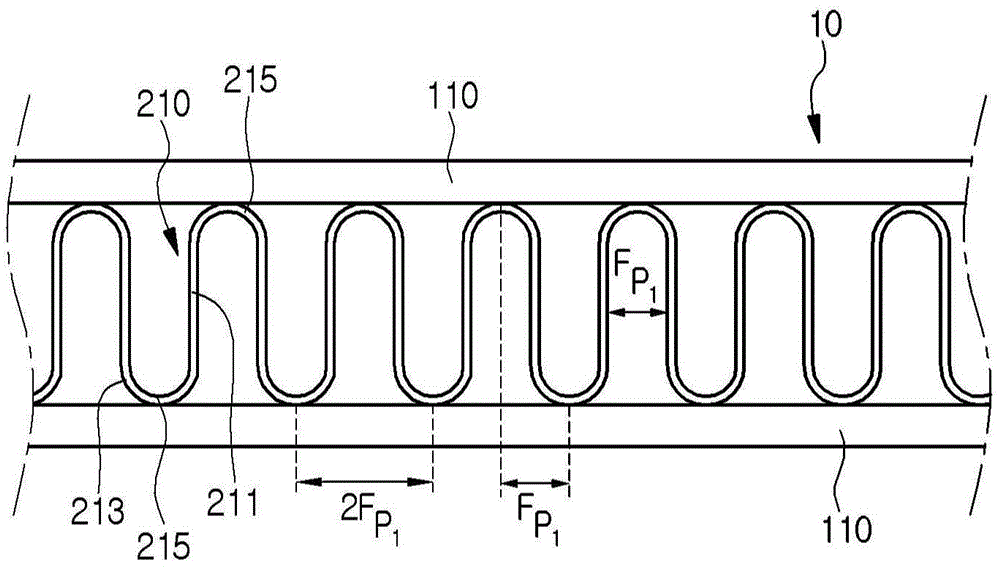

Installation structure for coolant pipe

ActiveCN103688605AIncrease contact areaReduce thermal resistanceCompressorSemiconductor/solid-state device detailsEngineeringRefrigerant

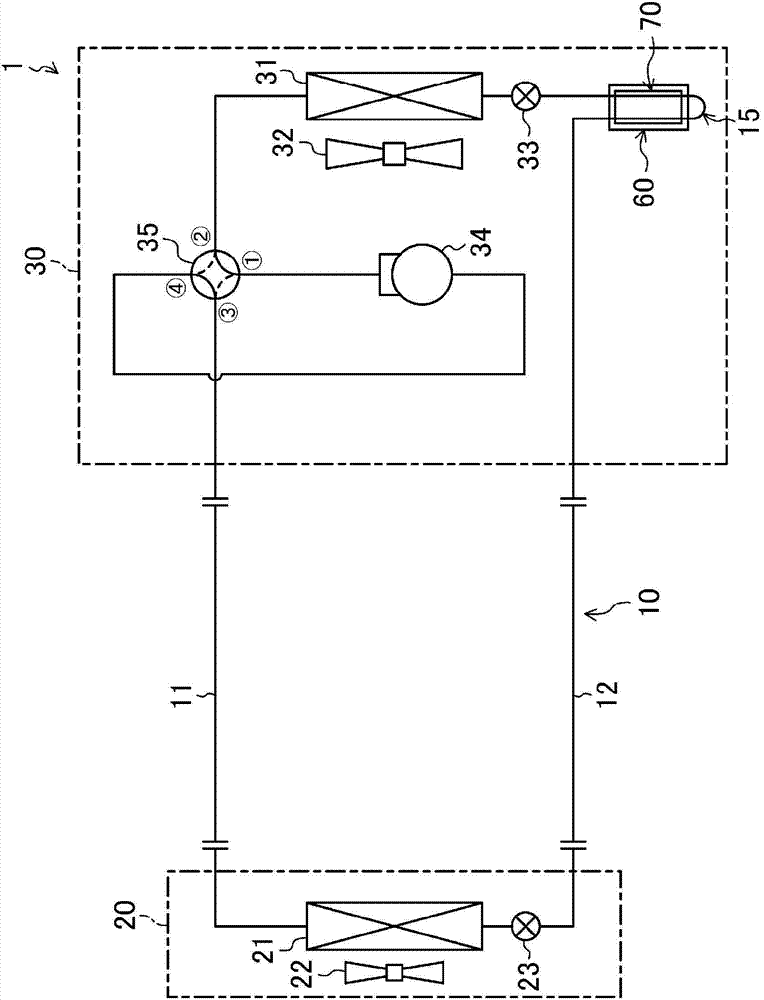

The present invention provides a coolant pipe installation structure which can reliably retain a coolant pipe and which can sufficiently decrease the thermal resistance between a coolant pipe and a heat-transmitting member. A heat-transmitting member (70) having a vertical groove part (72) into which a coolant pipe (15) fits, and which thermally contacts with a component to be cooled (63), is provided. An elastic member (80) formed in a long plate shape which extends in the extension direction of the coolant pipe (15), and having an opposing part (82) opposite the coolant pipe (15), is provided. A pushing structure (90) which pushes the elastic member (80) to the heat-transfer member (70) side is provided.

Owner:DAIKIN IND LTD

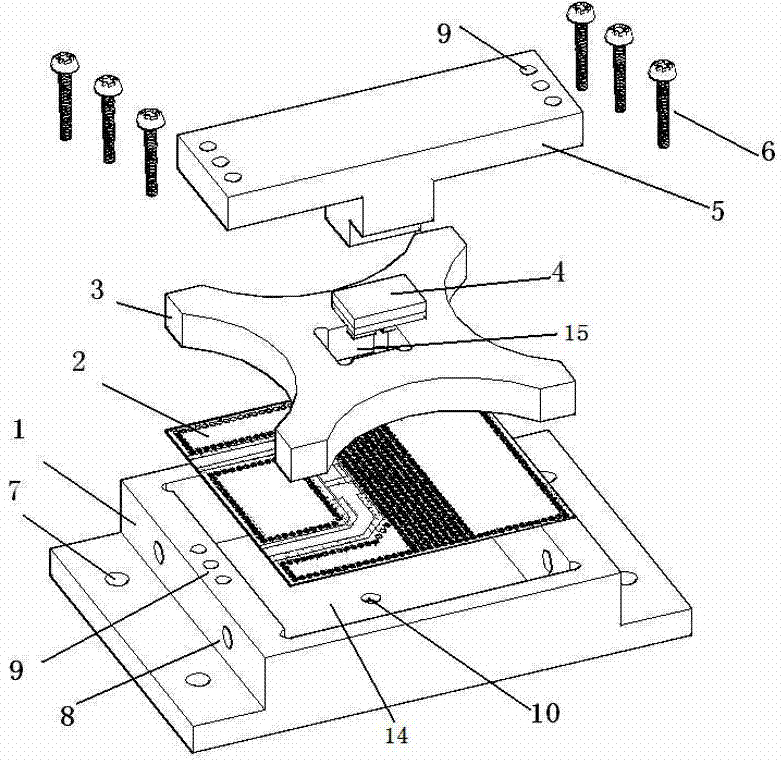

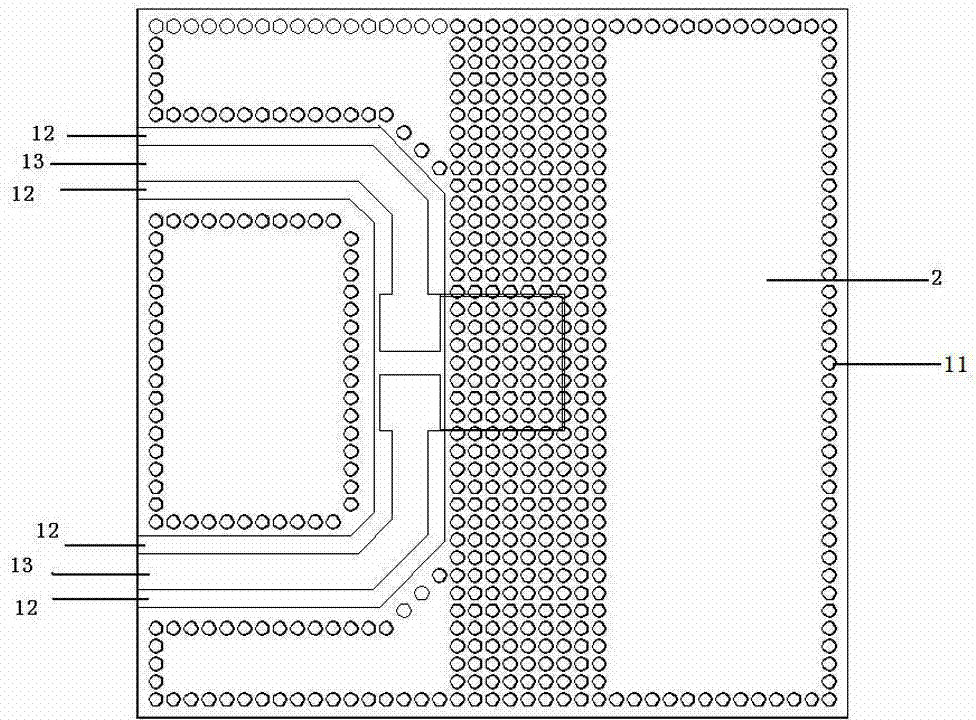

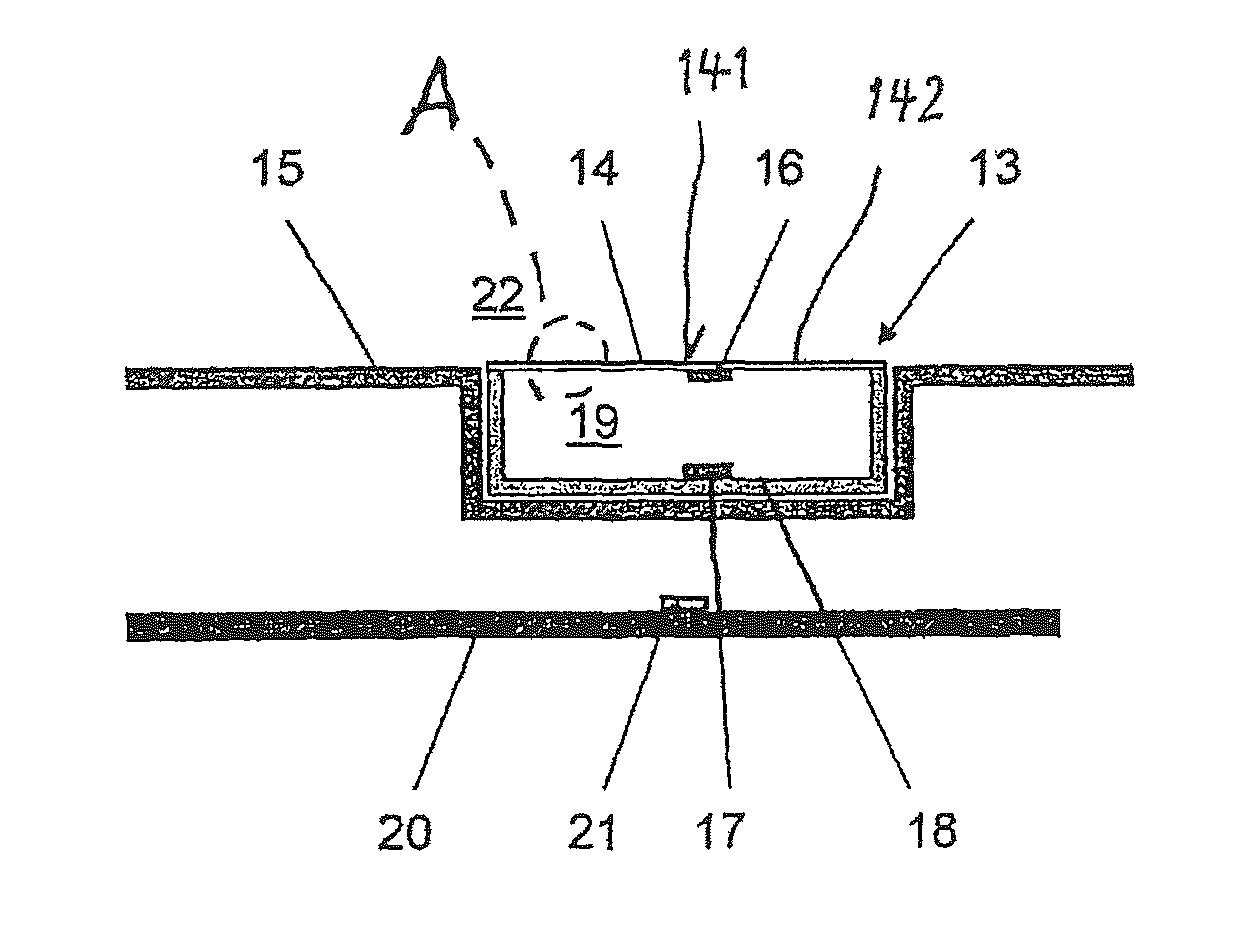

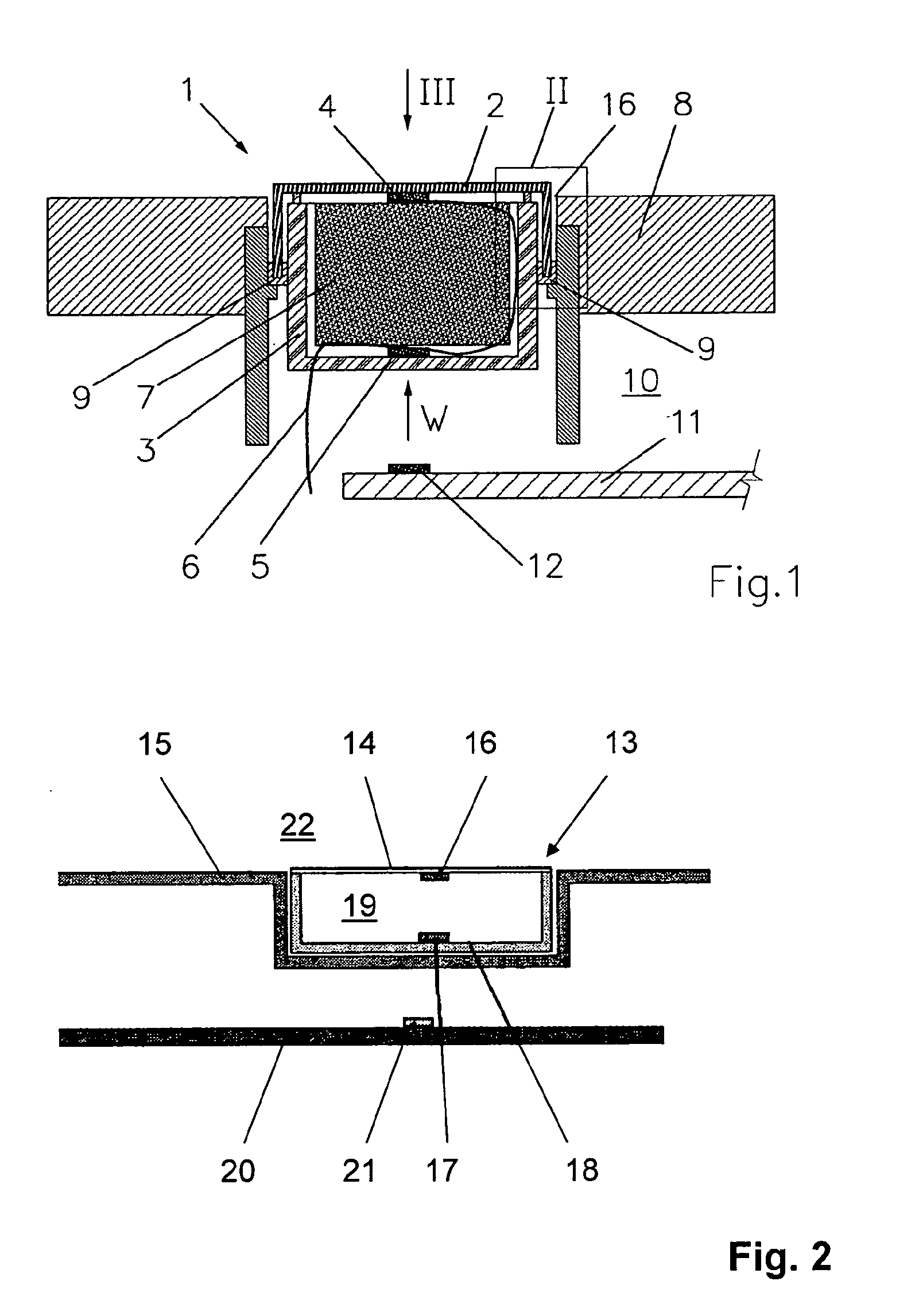

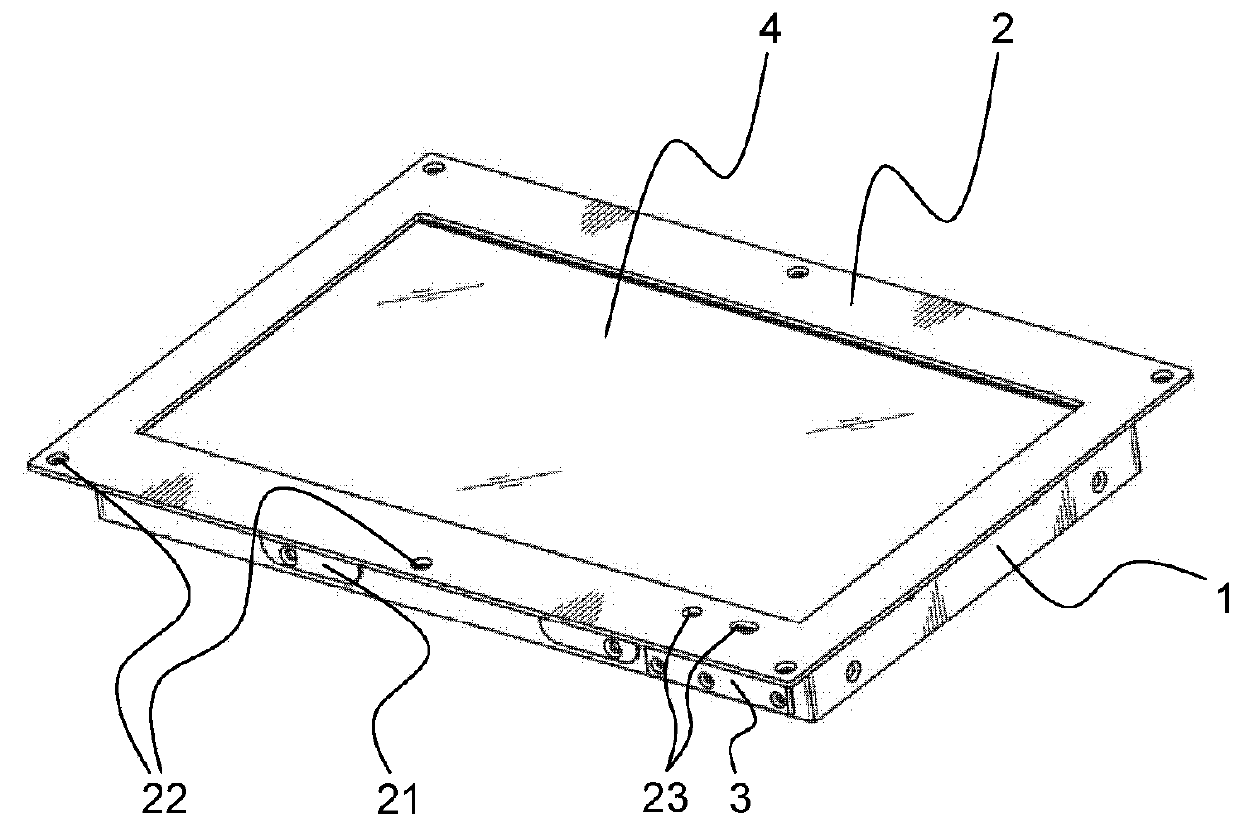

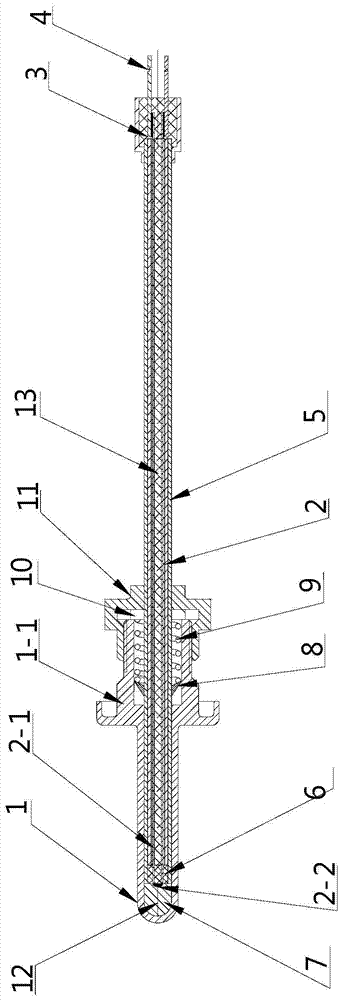

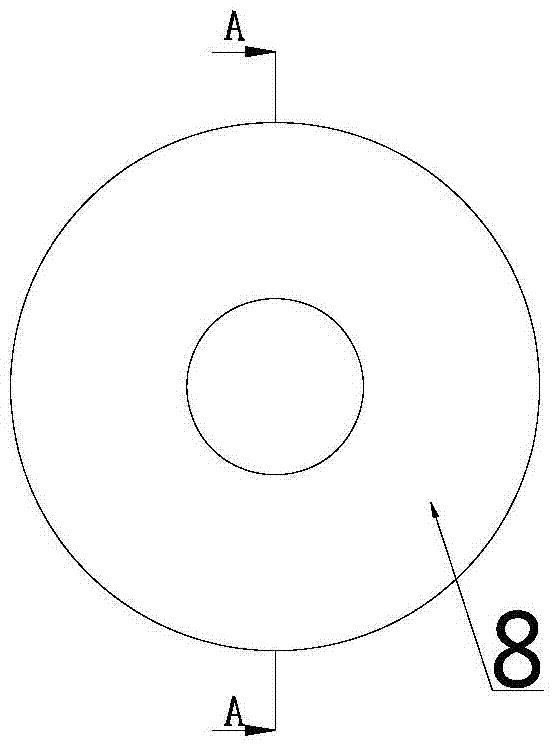

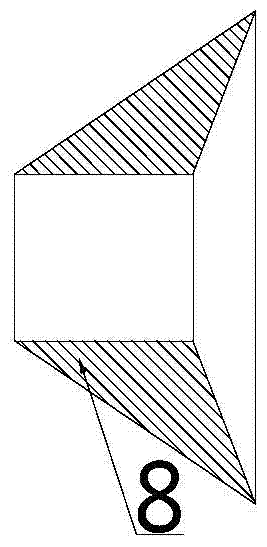

Clamp for thermal resistance test of SMD packaged semiconductor device

InactiveCN104730295AGuaranteed electrical contactGuaranteed heat transferMeasurement instrument housingIndividual semiconductor device testingThermal conductivitySemiconductor

The invention discloses a clamp for a thermal resistance test of a SMD packaged semiconductor device and relates to the technical field of semiconductor testing. The clamp comprises a metal base, a PCB, an insulated locating block and a compressing block. A groove is formed in the metal base. The PCB circuit is arranged in the groove. The insulated locating block is arranged on the PCB. The insulated locking block is provided with a locating containing hole matched with the tested SMD device. The compressing block capable of downwards compressing a tested SMD device is arranged on the insulated locating block. A thermocouple probe containing hole corresponding to the electrode of the tested SMD device in position is formed in the bottom of the groove. Two electrode wiring holes are formed in the side faces of the groove. Two electrodes enabling pins of the tested SMD device to be connected with electrode wiring holes are arranged on the PCB. The clamp can guarantee that the good thermal conductivity between the tested SMD device and a constant-temperature platform is achieved, the temperature of a shell can be easily controlled within a required range, it is also guaranteed that the electrodes of the tested SMD device are insulated from one another, and normal operation of the test is guaranteed.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

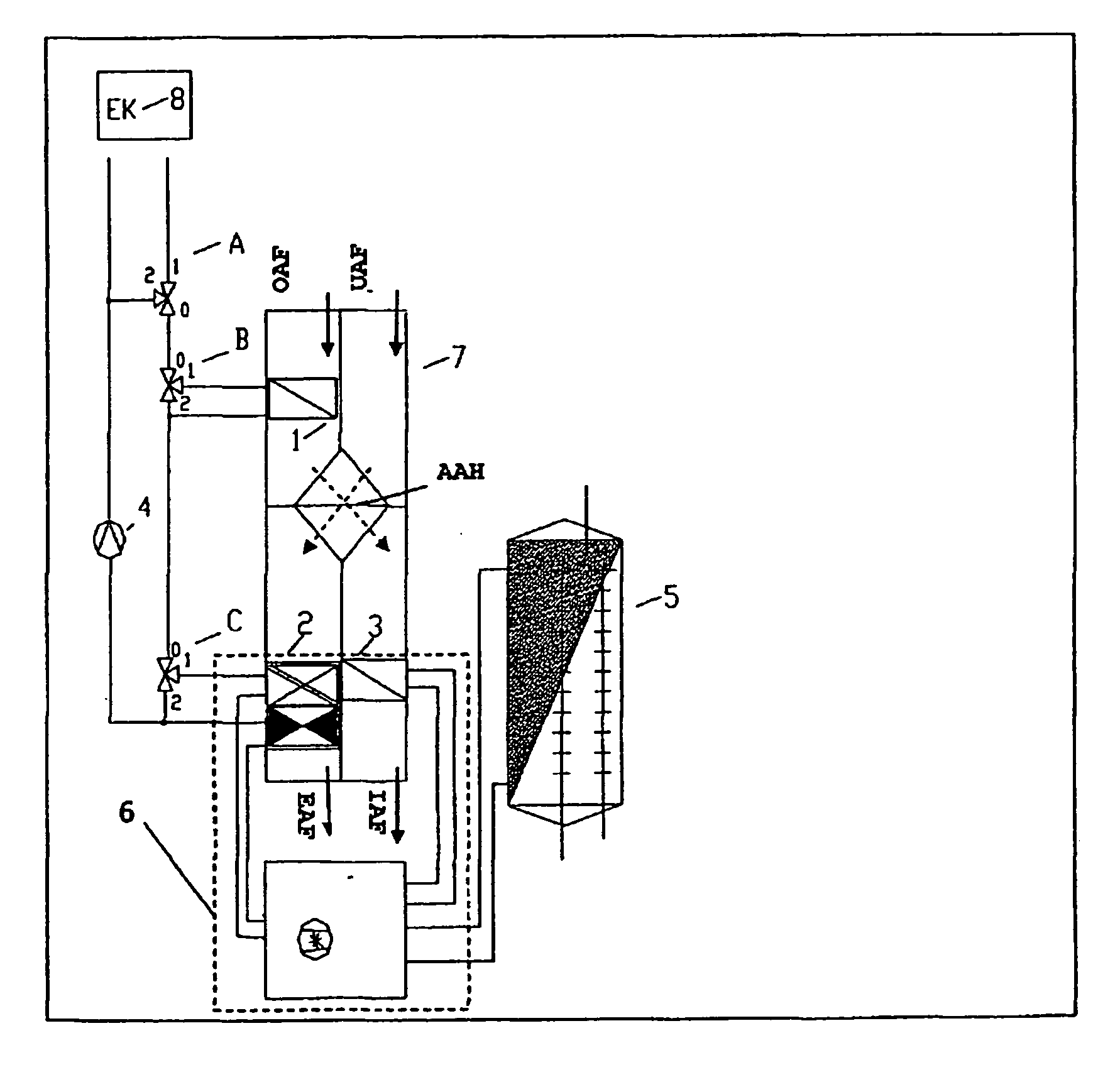

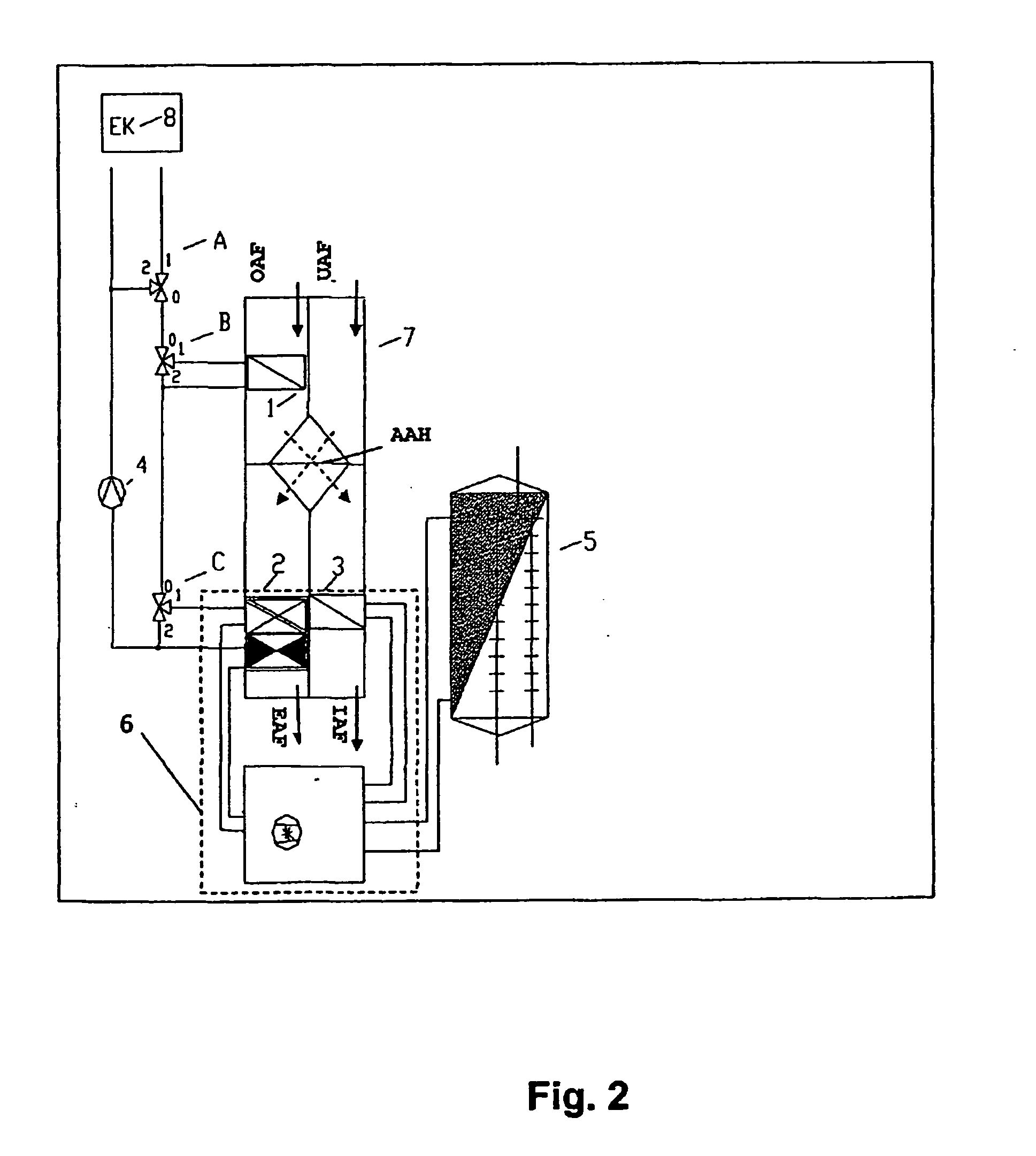

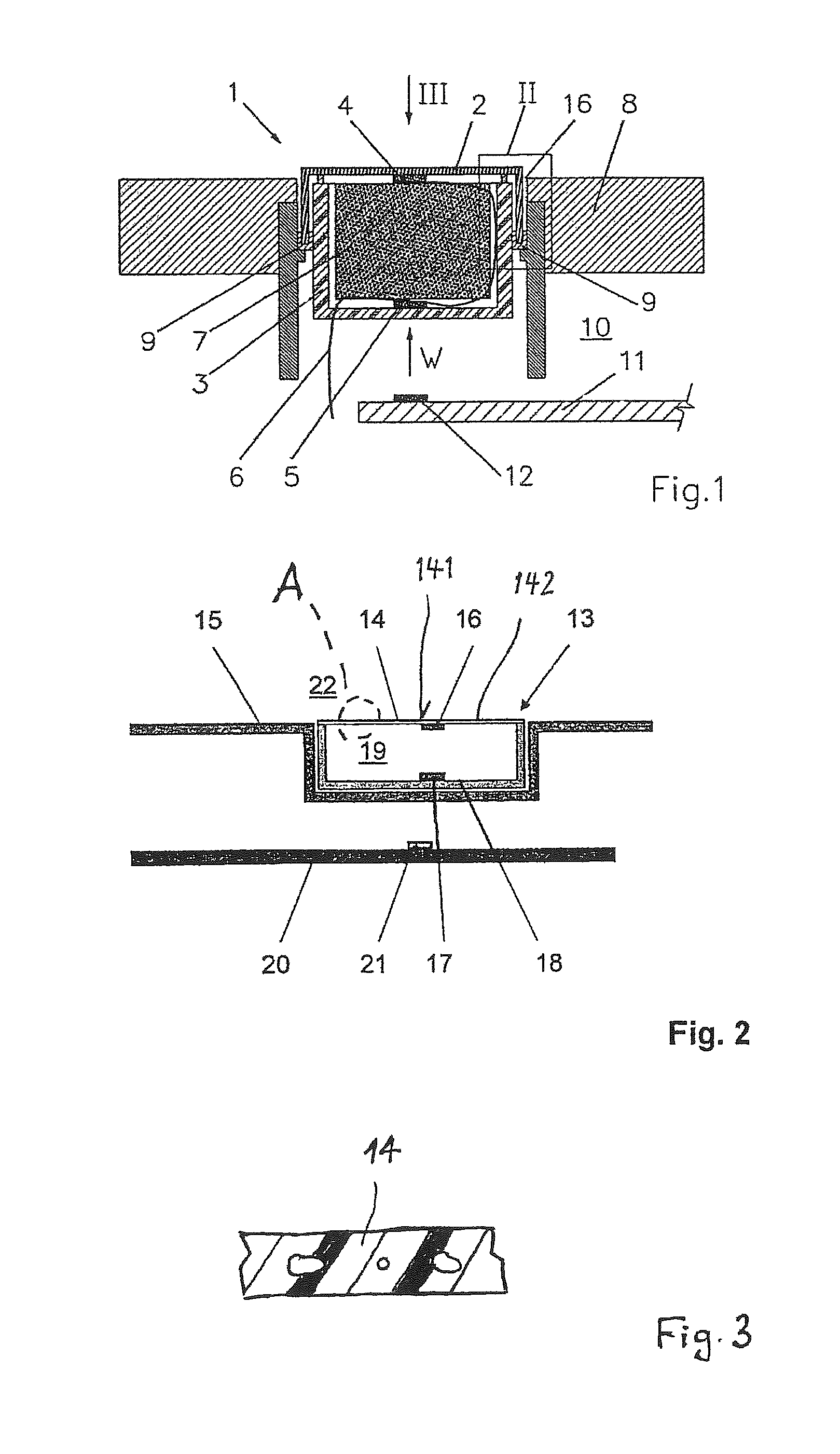

Combined Fluid-Air Evaporator And Novel Switching Concept For A Heat Pump In A Ventilating Apparatus

InactiveUS20070209780A1Efficient solutionTechnically simpleEnergy recovery in ventilation and heatingHeat recovery systemsEngineeringThermal contact

A combined fluid-air evaporator having at least two separate duct systems is described, through which separate material flows may be conducted, at least one of the two duct systems having a free surface which may be brought into thermal contact with an air flow, and the at least two duct systems being at least partially in thermal contact with one another. Furthermore, a ventilation arrangement for a building is described using the combined fluid-air evaporator, in which a used air flow directed out of the building, which is in thermal contact with an outside air flow via an air-air heat exchanger, comes into thermal contact with the combined fluid-air evaporator, through which a refrigerant and an exothermic fluid pass, the refrigerant circulating in the loop of a heat pump, whose condenser is connected downstream in the flow direction from the air-air heat exchanger in the heated outside air flow, and the exothermic fluid circulates in the loop of a heat accumulator system.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

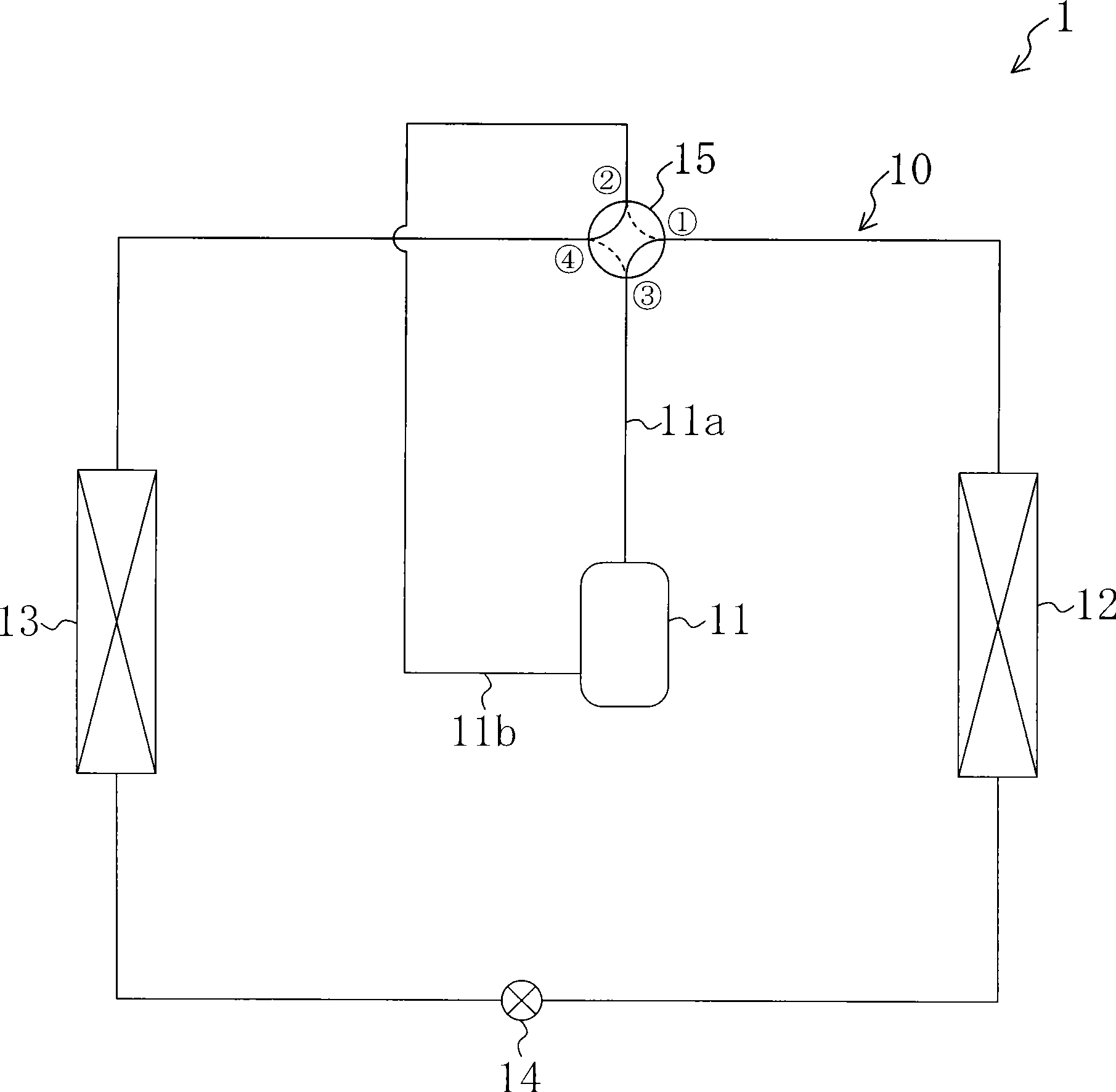

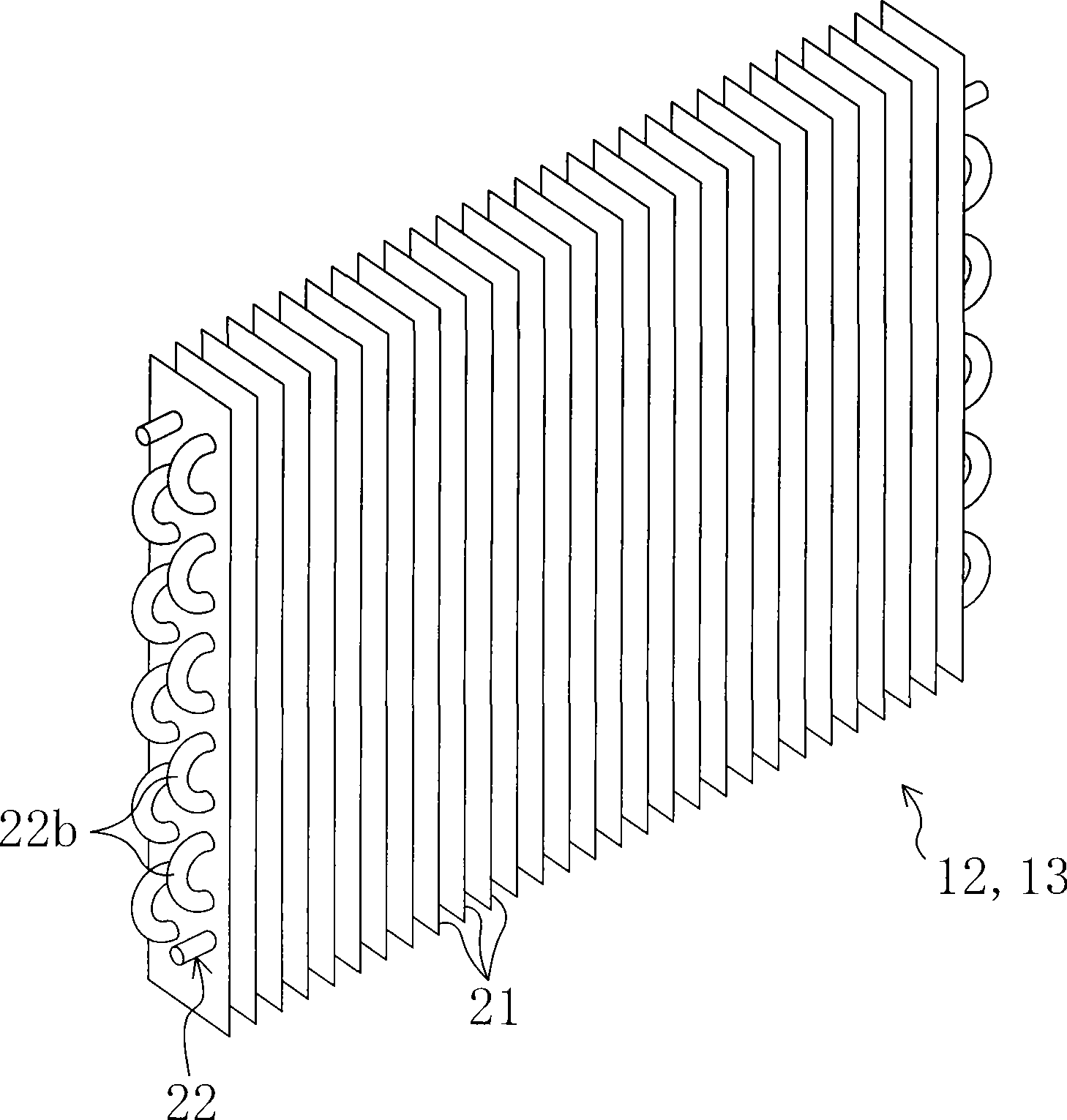

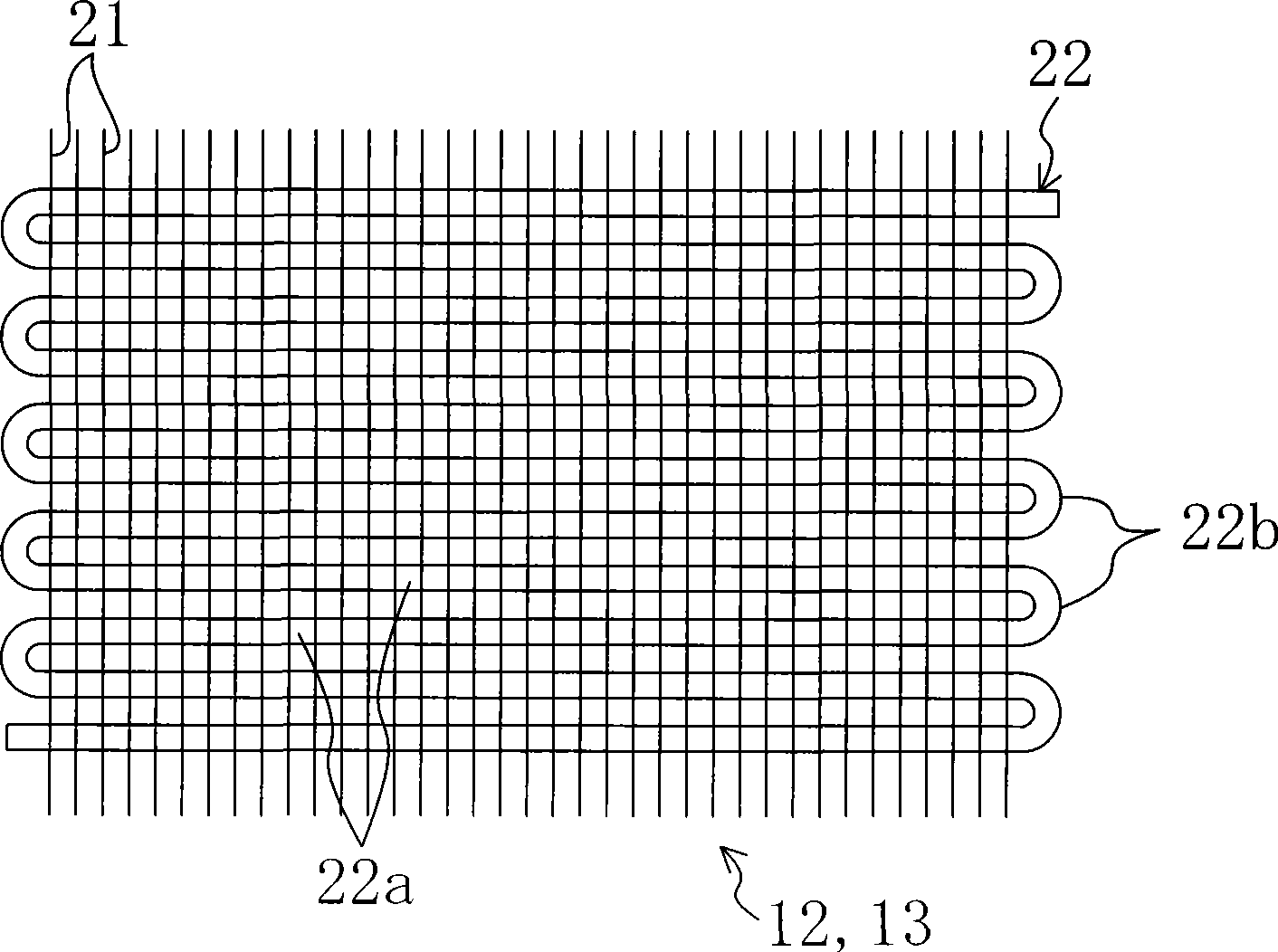

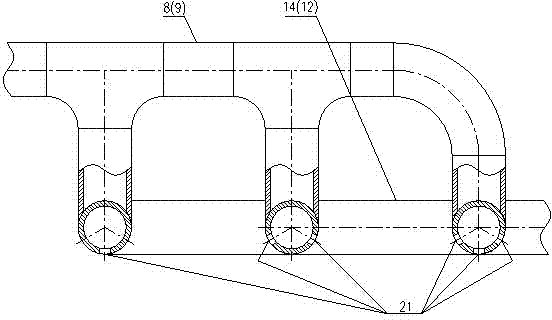

Heat exchanger and refrigeration device

InactiveCN101523149AIncreased pressure lossIncrease contact areaCompression machines with non-reversible cycleEvaporators/condensersHeat transmissionEngineering

The invention provides a heat exchanger and refrigeration device. An oil grooves (25) for collecting oil and causing it to flow are formed in the inner peripheral surface of a heat transmission tube (22) of heat exchangers (12, 13) so as to extend in the direction of the axis of the heat transmission tube (22).

Owner:DAIKIN IND LTD

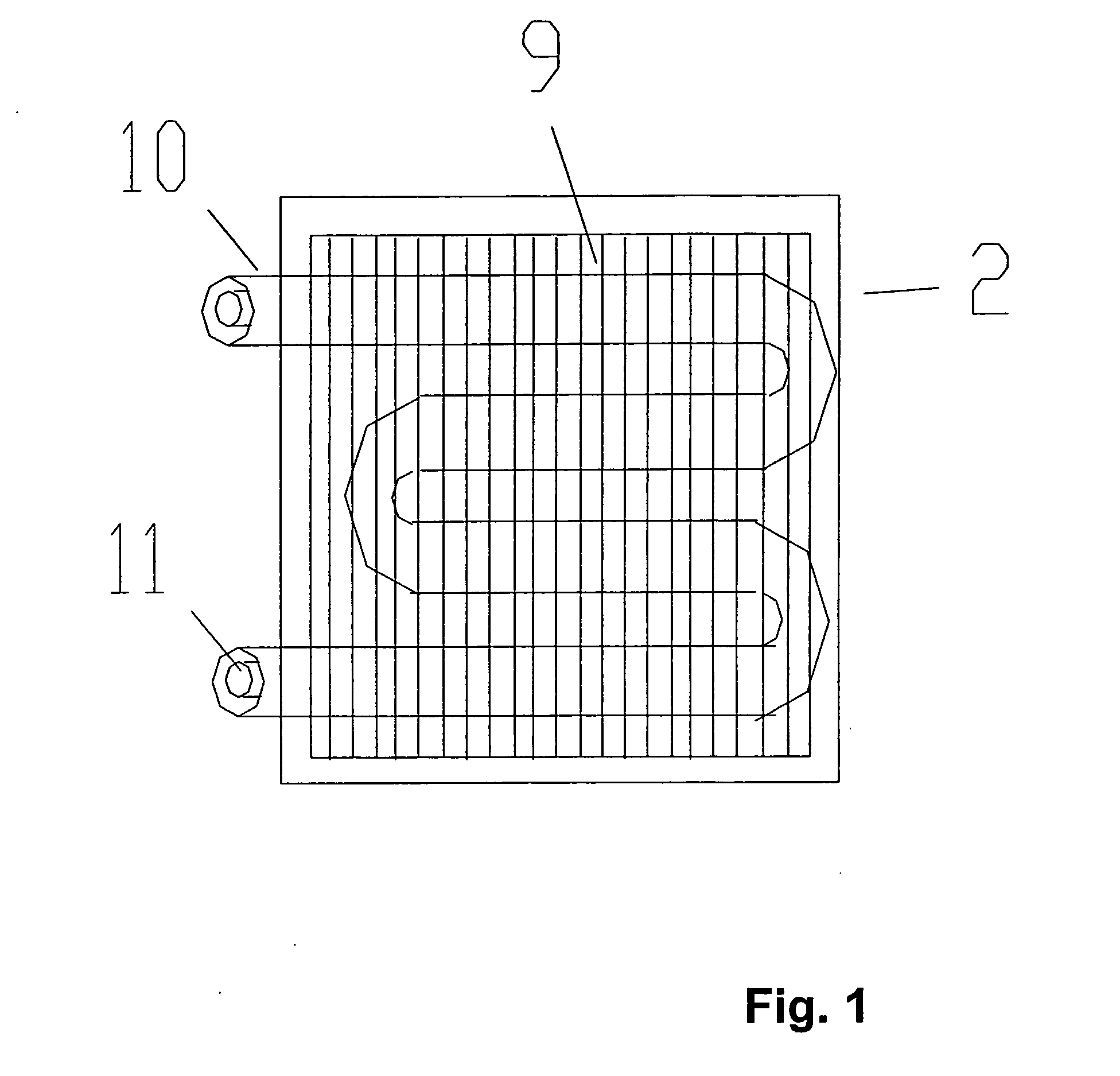

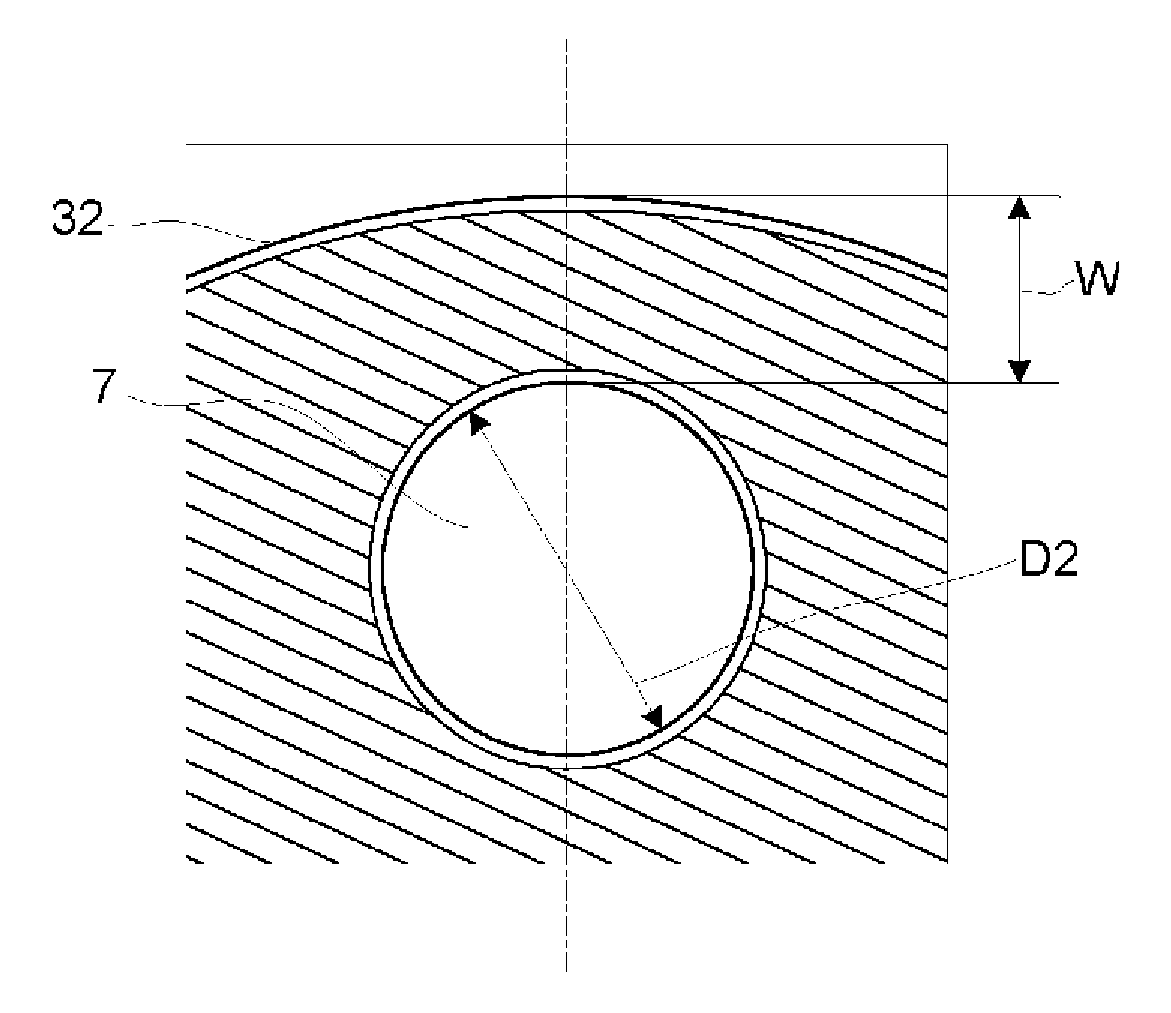

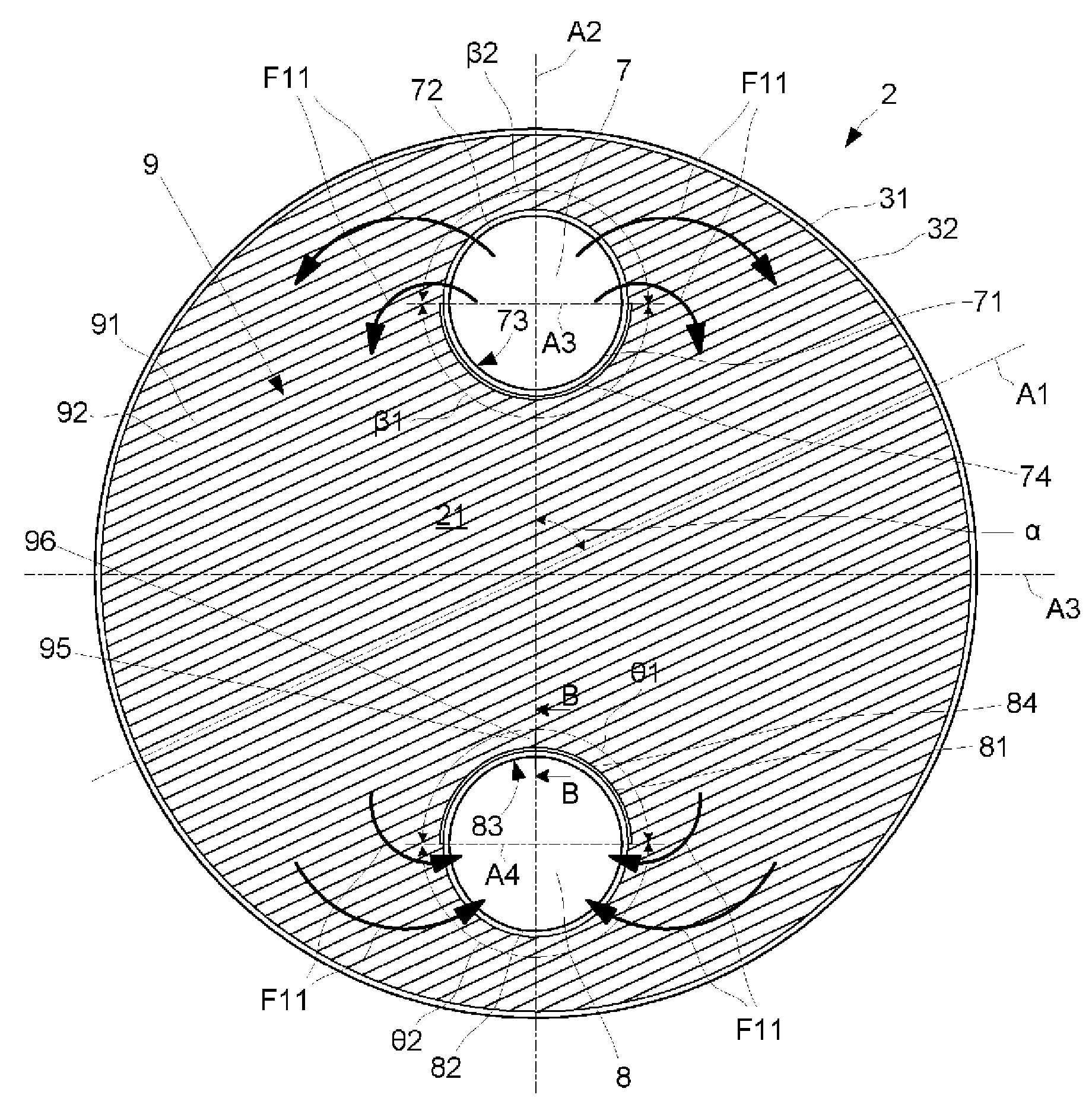

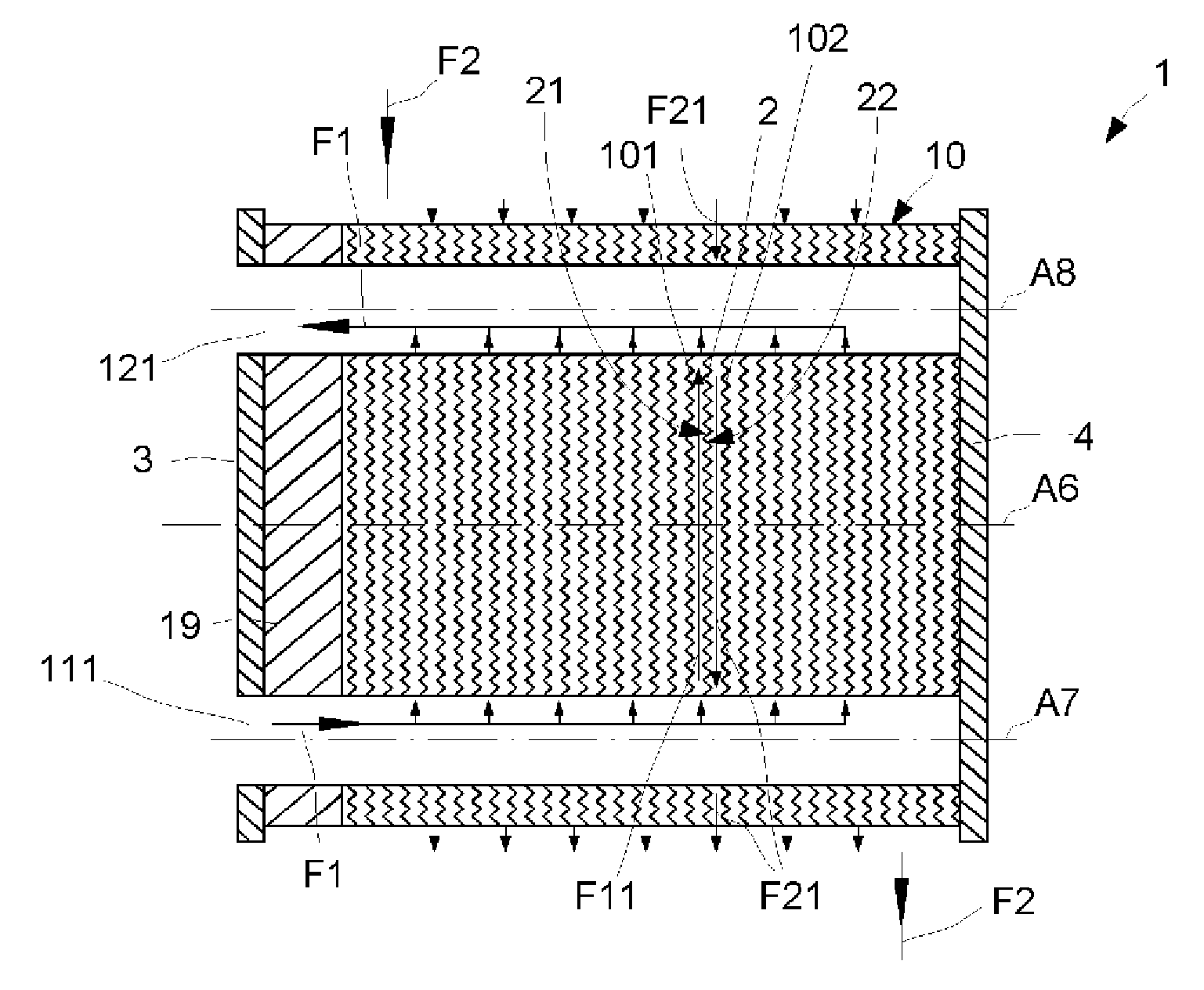

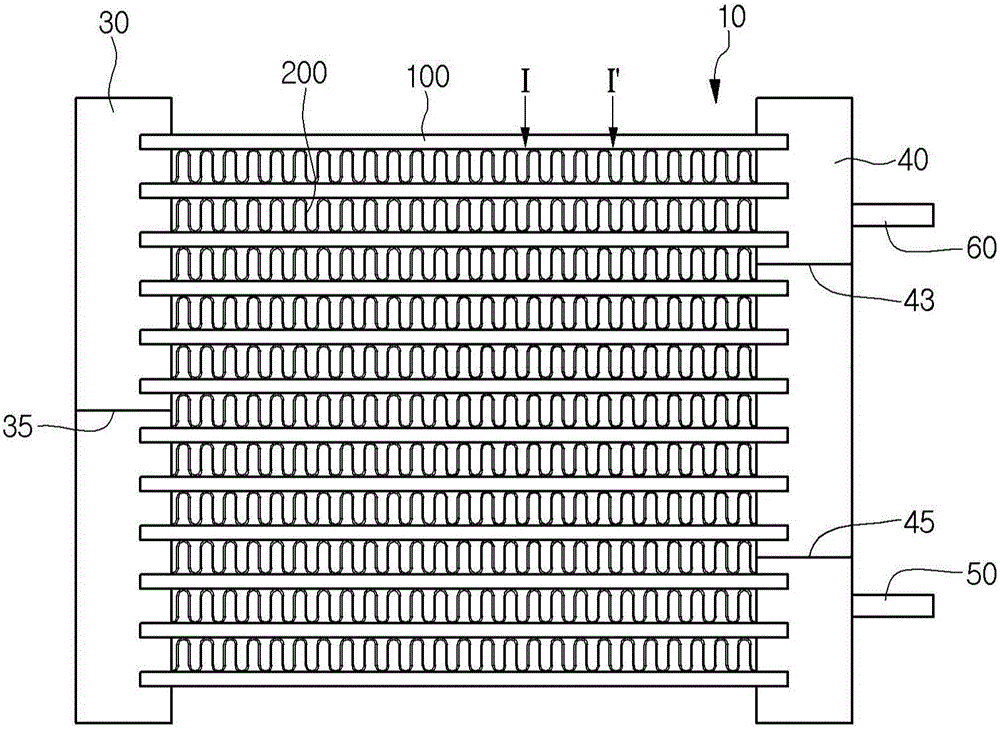

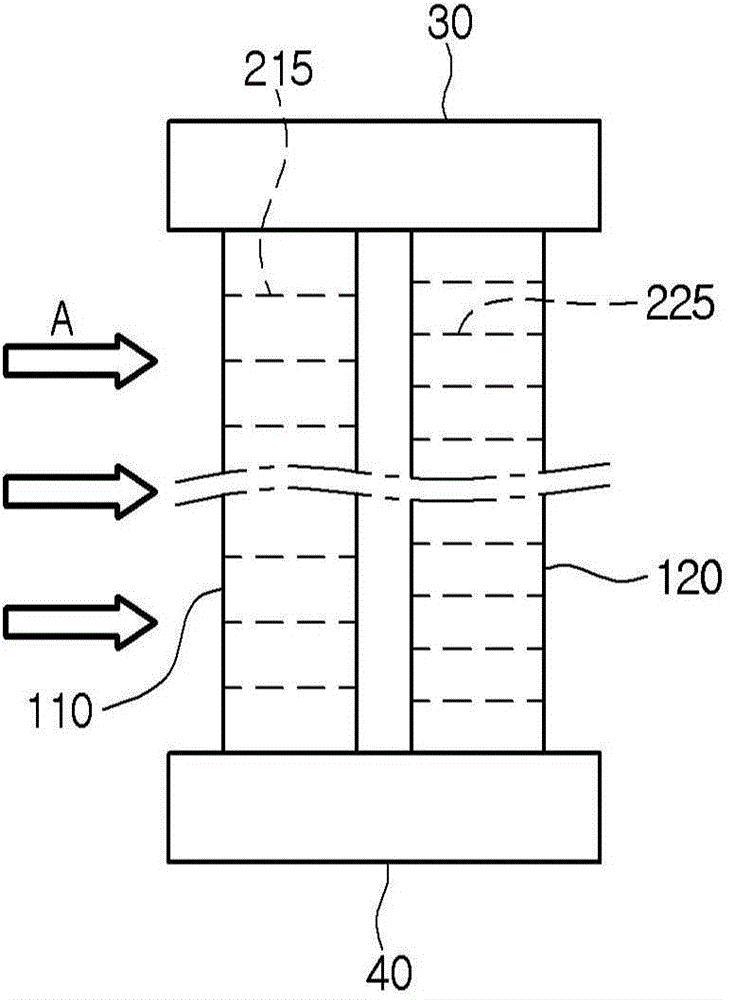

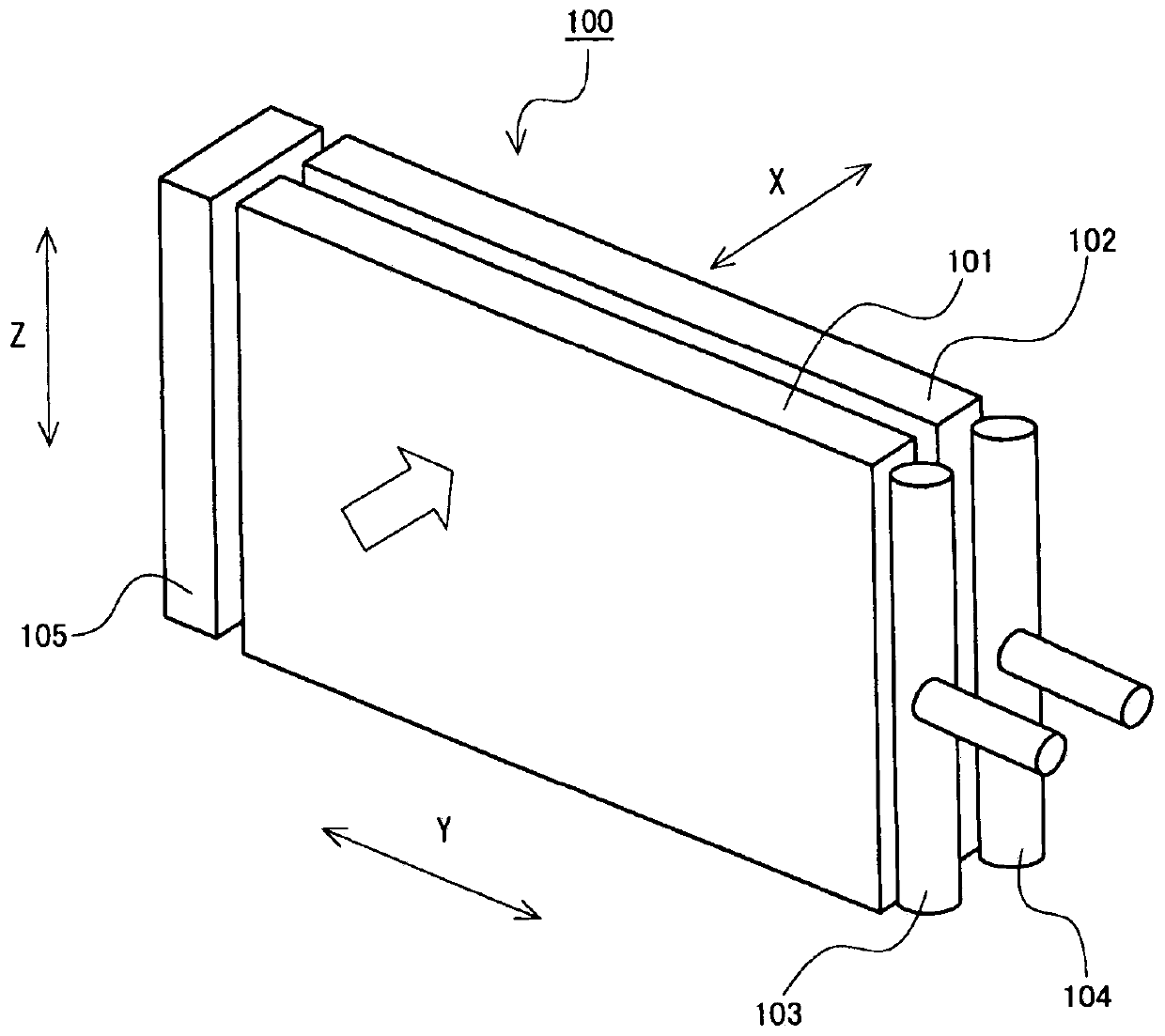

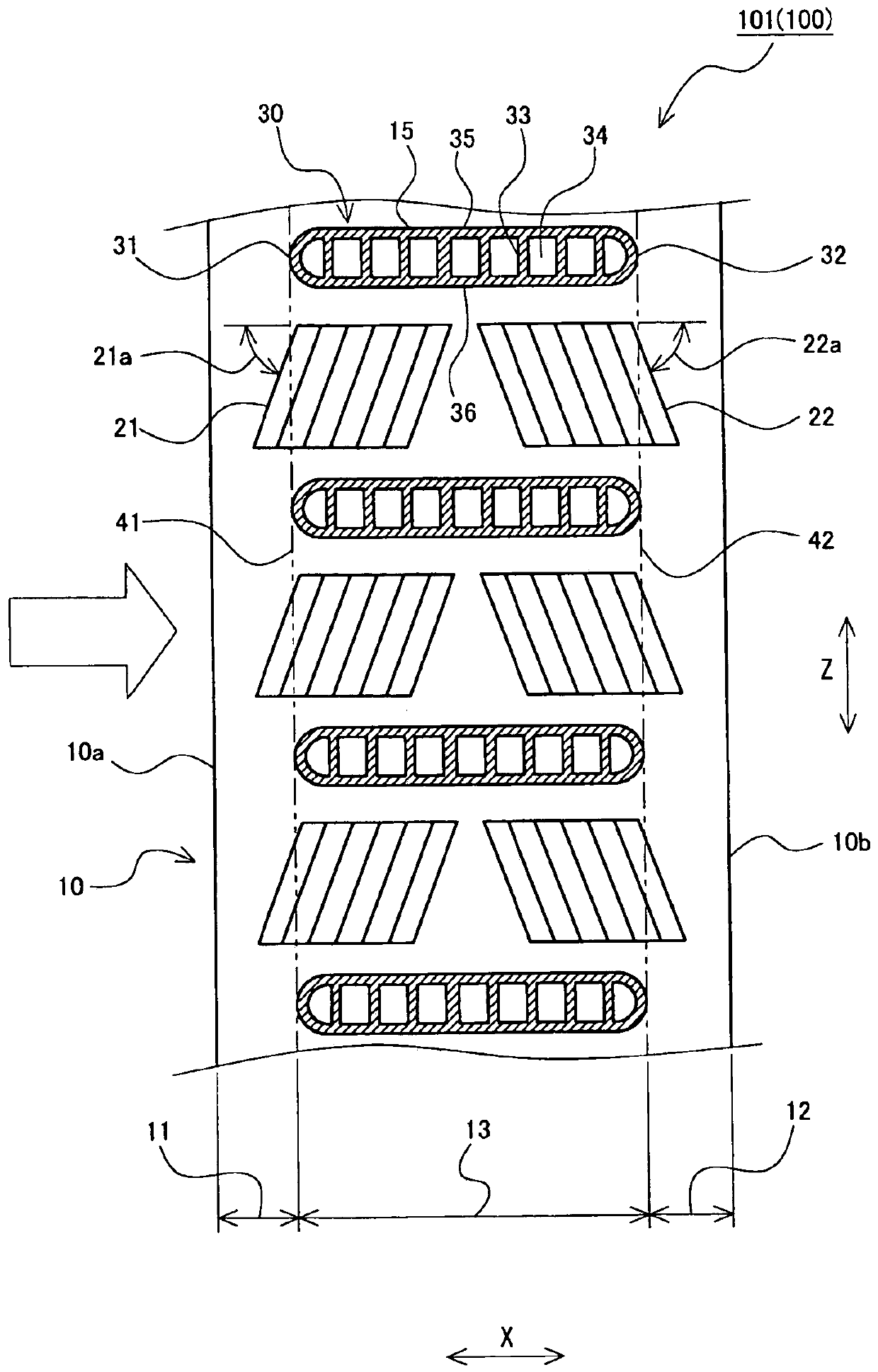

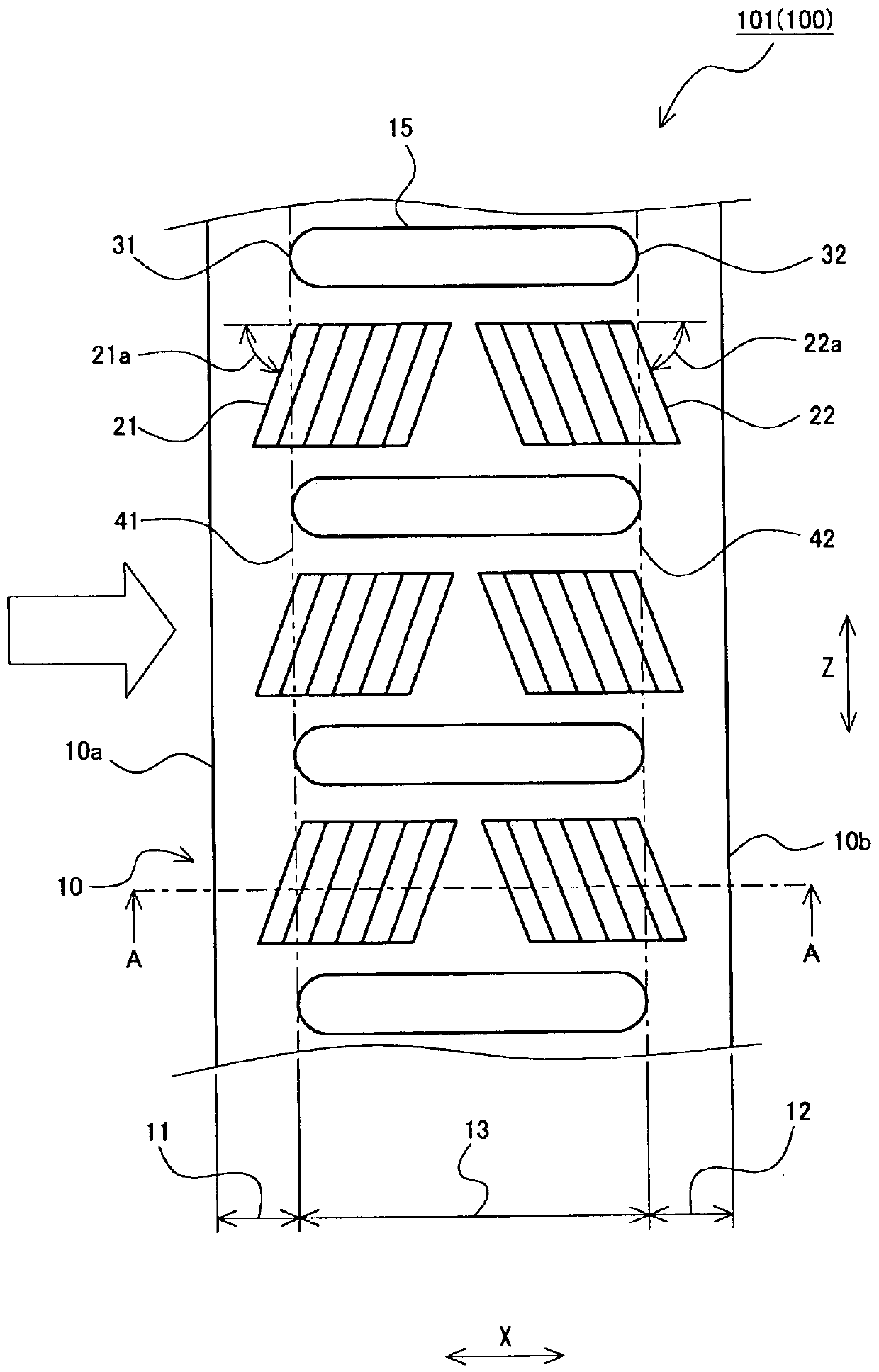

Heat transfer plate for a plate-and-shell heat exchanger

InactiveCN103547878AGuaranteed heat transferLaminated elementsStationary plate conduit assembliesPlate heat exchangerEngineering

A heat transfer plate configured to be arranged in a plate-and-shell type plate heat exchanger. The heat transfer plate comprises an inlet port (7) and an outlet port (8). The inlet port (7) has a first inlet section (71) that faces the outlet port (8) and comprises a first fluid blocker (74), for distribution of at least a part of a flow of fluid (F11) over a second inlet section (72) of the inlet port (7). The outlet port (8) has a first outlet section (81) that faces the inlet port (7) and comprises a second fluid blocker (84), for distribution of at least a part of the flow of fluid (F11) over a second outlet section (82) of the outlet port (8). Corrugations (9) are arranged intermediate the inlet port (7) and the outlet port (8).

Owner:ALFA LAVAL CORP AB

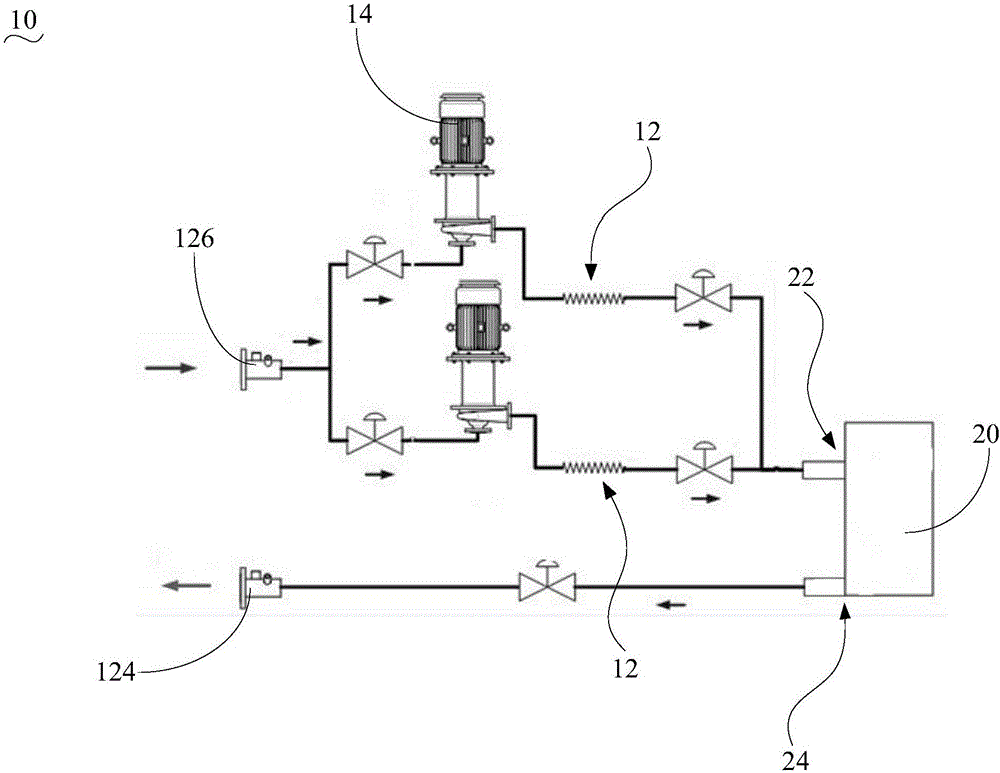

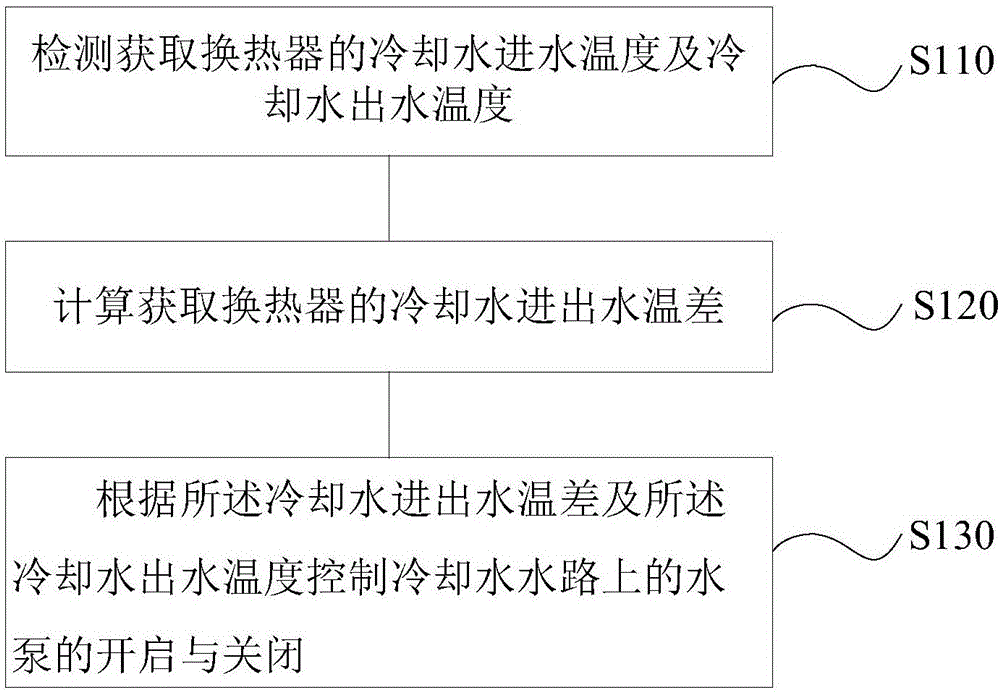

Chilled water way system, adjusting method of system, water chilling unit and air conditioner

ActiveCN106440546AGuaranteed heat transferGuaranteed service lifeMechanical apparatusFluid circulation arrangementEngineeringChilled water

The invention provides a chilled water way system. The system comprises a chilled water way and a water pump; a heat exchanger is connected in the chilled water way; the water pump is connected in the chilled water way and is used for driving chilled water to circulate in the chilled water way; the chilled water way comprises at least two chilled water inlet ways which are connected with a chilled water inlet of the heat exchanger in a converged manner; and the water pump is connected with the at least two chilled water inlet ways so as to control opening and closing of the chilled water inlet ways. Thus, according to the chilled water inlet and outlet temperature difference and the chilled water outlet temperature, opening and closing of the chilled water inlet ways are controlled, the flow of the chilled water is adjusted, the chilled water inlet and outlet temperature difference is matched with the indoor load, the degree of heat exchange between the chilled water and a refrigerant in the heat exchanger is guaranteed, and the refrigeration comfort is guaranteed. Besides, the chilled water outlet temperature is within the reasonable range, and the service life of a refrigeration component is guaranteed. The invention further provides an adjusting method of the chilled water way system, a water chilling unit and an air conditioner.

Owner:GREE ELECTRIC APPLIANCES INC

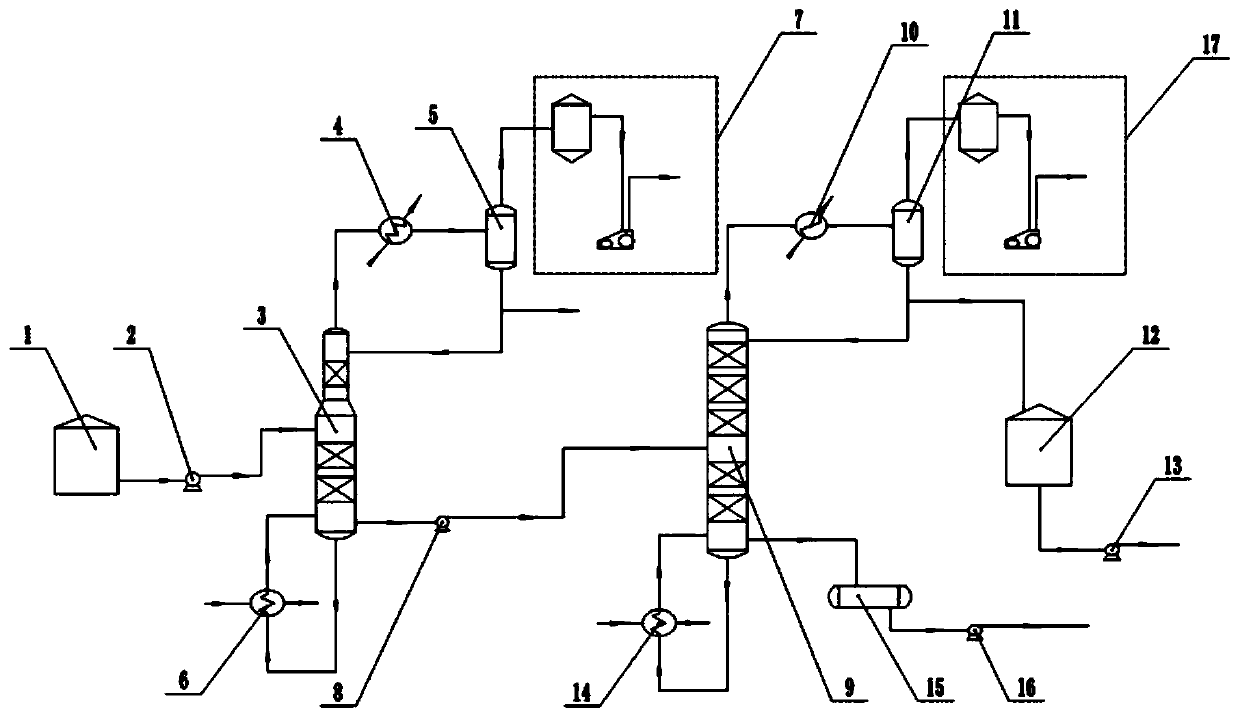

NMP waste liquid recovery process

ActiveCN111170919AThe production process is simplifiedLower energy costsOrganic chemistryThermodynamicsWastewater

The invention relates to the technical field of NMP purification, and particularly discloses an NMP waste liquid recovery process. The process comprises the following two steps: dehydration treatmentand heavy component removal treatment. In the step of the dehydration treatment, NMP waste liquid is pumped into a vacuum dehydration tower and subjected to negative-pressure rectification, then wateris discharged from the top of the vacuum dehydration tower and is condensed, one part of a formed condensate is discharged as wastewater, the other part of the condensate flows back to the vacuum dehydration tower, a reflux ratio is 0.60-0.65, and a crude NMP material is discharged from the bottom of the vacuum dehydration tower. In the step of the heavy component removal treatment, the crude NMPmaterial discharged from the bottom of the vacuum dehydration tower is fed into a finished product tower and undergoes negative-pressure heavy component removal, an obtained NMP gas phase is discharged from the top of the finished product tower and then condensed, a part of a formed condensate is conveyed out as a product, and the other part of the condensate flows back into a product tower at areflux ratio of 0.50-0.55. By the adoption of such a technical scheme, the problems that in the prior art, technological processes are redundant, and energy consumption and investment cost are high are solved.

Owner:重庆中润新材料股份有限公司

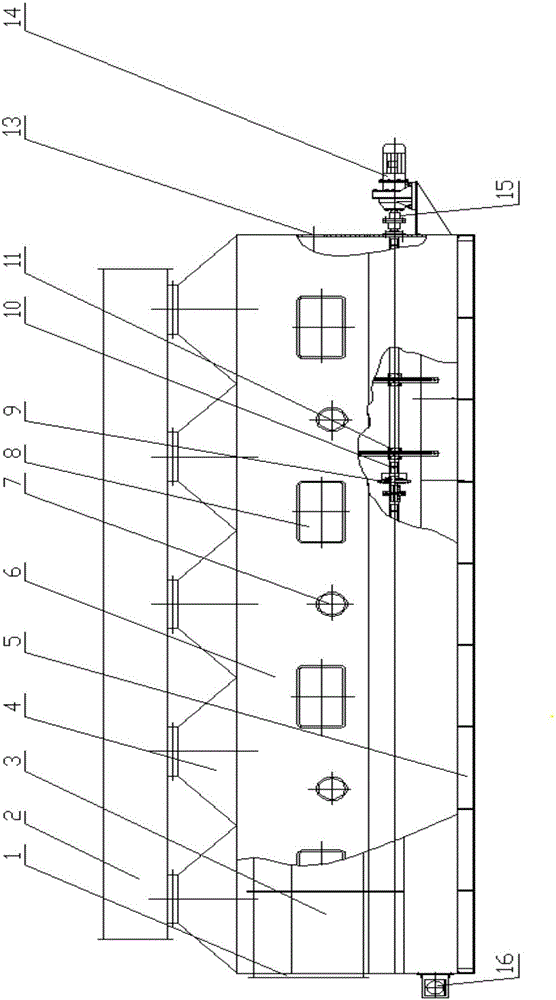

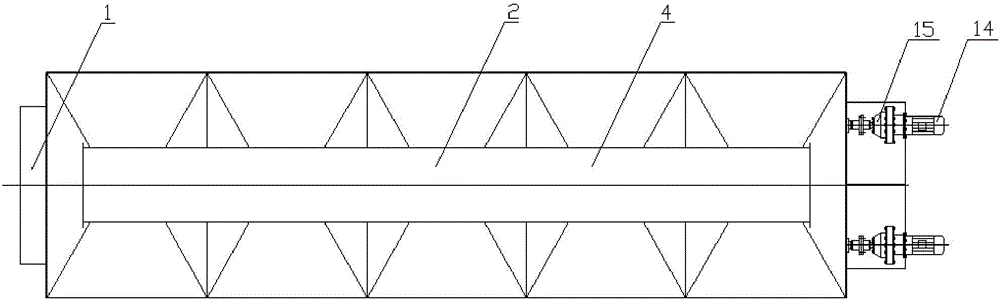

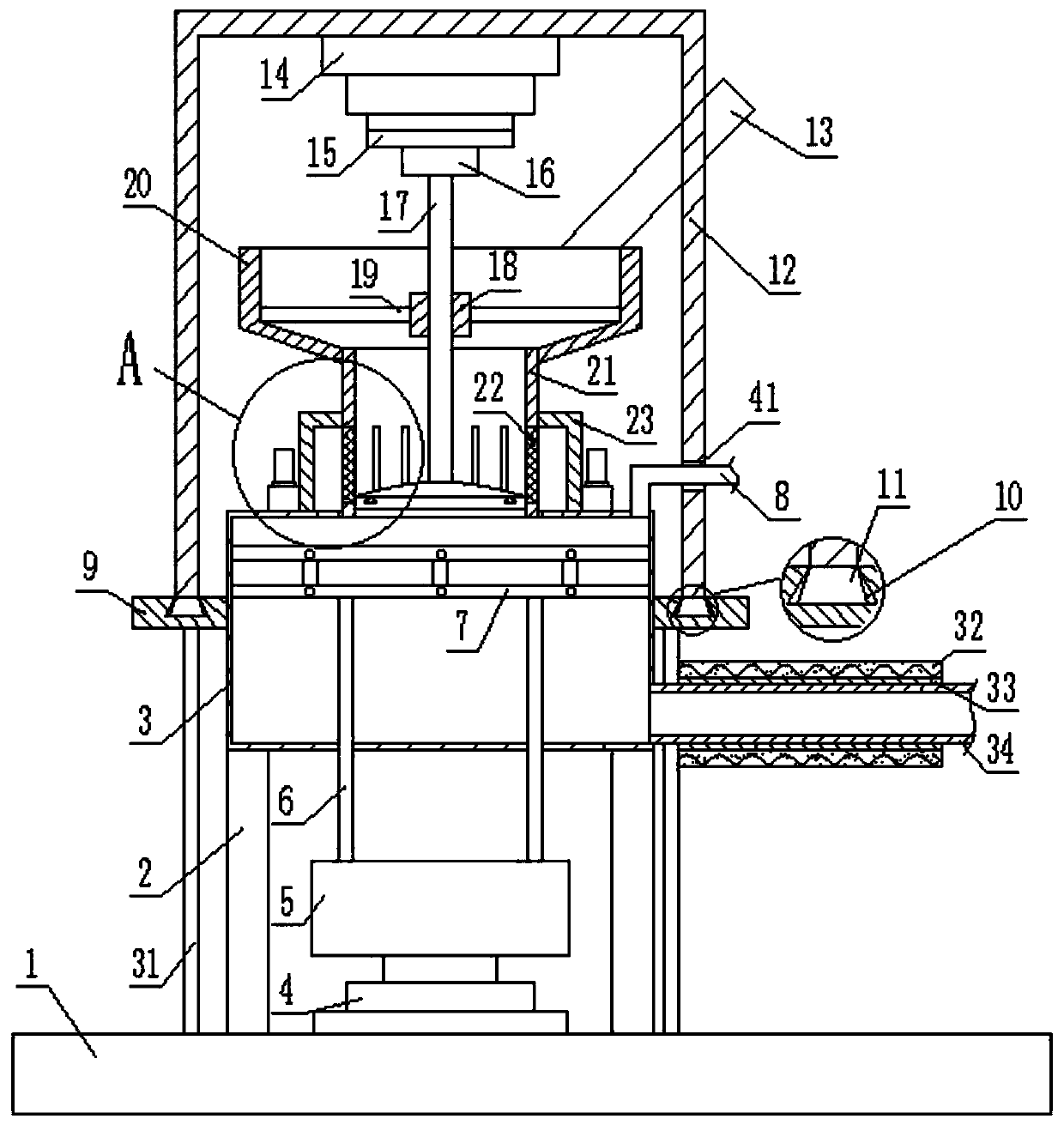

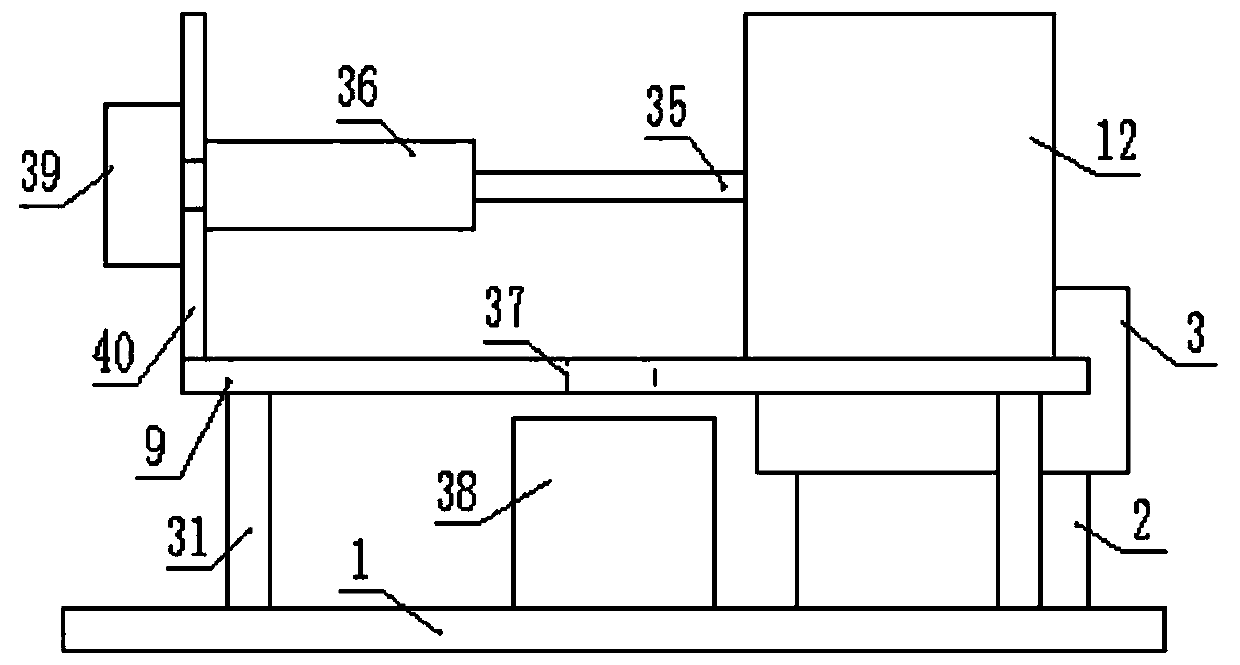

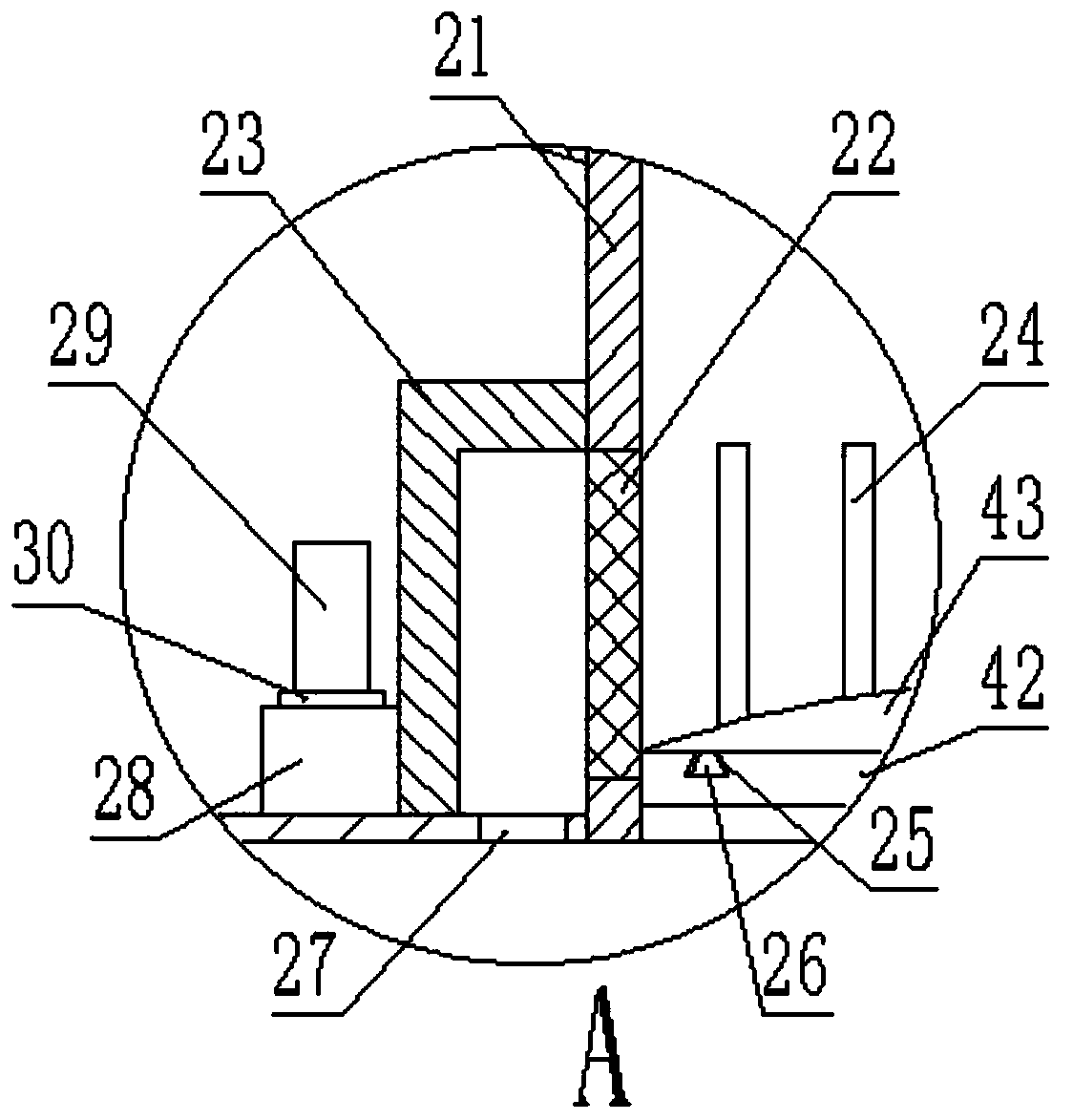

Experimental coke oven for small-scale production of coke and colloid layer samples and using method thereof

ActiveCN108398022ASimulation is accurateReal-time measurementCoke ovensFurnace typesCarbonizationColloid

The invention relates to an experimental coke oven for small-scale production of coke and colloid layer samples and a using method thereof. The experimental coke oven comprises a heating furnace, a reactor and a colloid layer sampler; the heating furnace is composed of a furnace shell, a heating furnace body, a carbonization chamber and a top split furnace door which are sequentially arranged fromoutside to inside; heating devices are arranged in the heating furnace body at the two ends of the carbonization chamber respectively; the reactor used for containing coal samples is arranged in thecarbonization chamber and is divided into a main reaction region and a colloid layer sampling region, and the main reaction region and the colloid layer sampling region are respectively close to two heating ends of the heating furnace body; and the colloid layer sampler is movably arranged in the colloid layer sampling region; and the top of the reactor is provided with a reactor upper cover, thereactor upper cover is provided with a gas outlet, a plurality of temperature sensors and a pressure sensor. The experimental coke oven can be used for accurately simulating the working conditions ofa large coke oven, and preparing the colloid layer samples and the coke samples for coking of single coal seed or coal blending; and meanwhile a colloid layer can be sampled at any time, and the experimental coke oven is simple in structure and convenient to operate.

Owner:UNIV OF SCI & TECH LIAONING

Method for measuring coefficient of heat transfer of solidification interface under action of alternating magnetic field

InactiveCN103115938AGuaranteed accuracyGuaranteed heat transferMaterial heat developmentMeasurement deviceElectromagnetic field

The invention discloses a method for measuring a coefficient of heat transfer of a solidification interface under the action of an alternating magnetic field. The device comprises a thermocouple for measuring the temperature change of a metal melt and the temperature change of a cylindrical mould, an induction coil, a heat insulation material and a data collecting and calculating system. Through measuring the temperature change of the metal melt and the mould under the action of the alternating magnetic field generated by the induction coil and using a reverse heat transfer calculation program, the coefficient of the heat transfer of the solidification interface in the metal solidification process is obtained. The device is capable of measuring the coefficient of heat transfer of the metal interface under the action of the alternating magnetic field, and provides a basis for applying the electromagnetic field in the solidification process.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

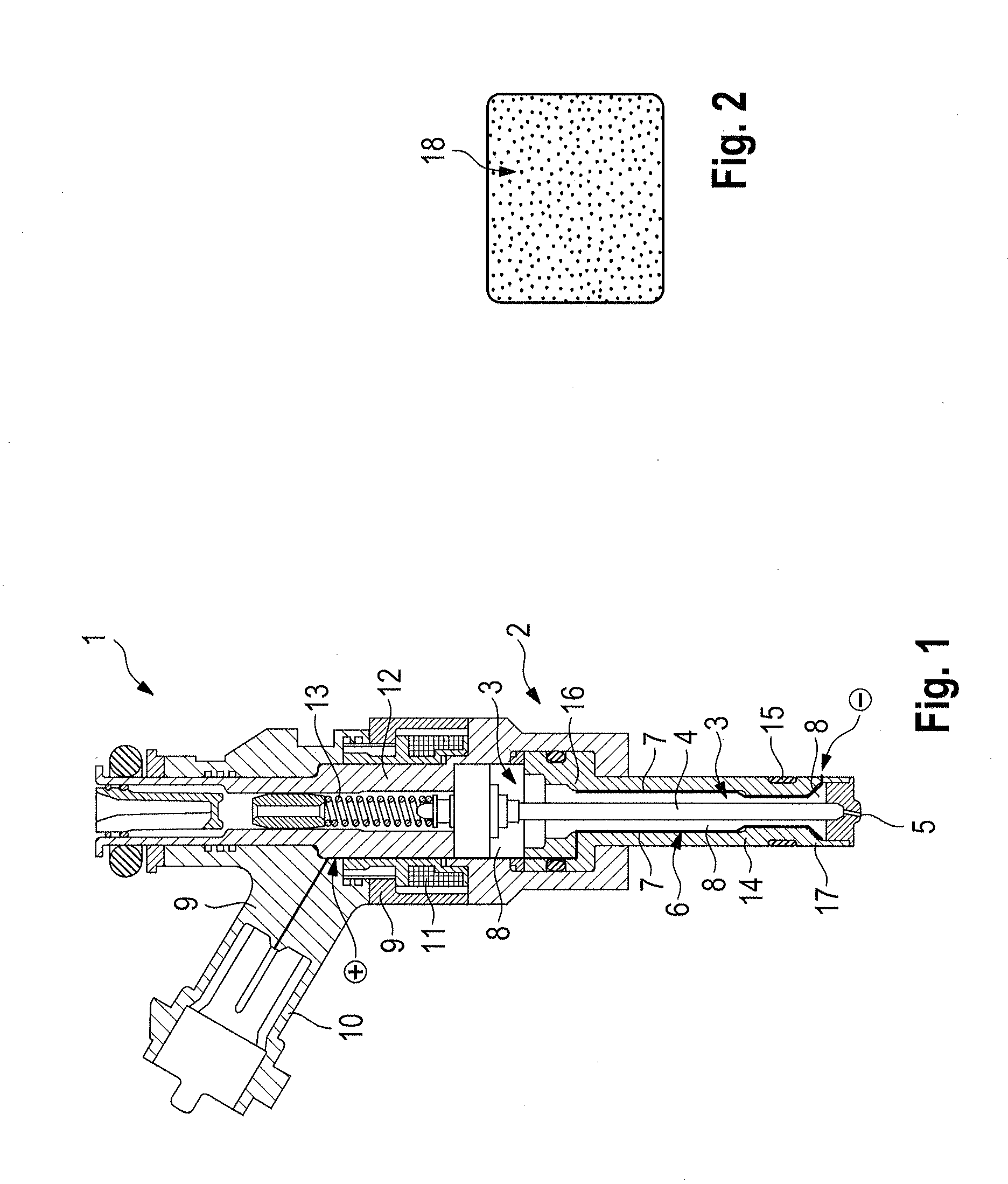

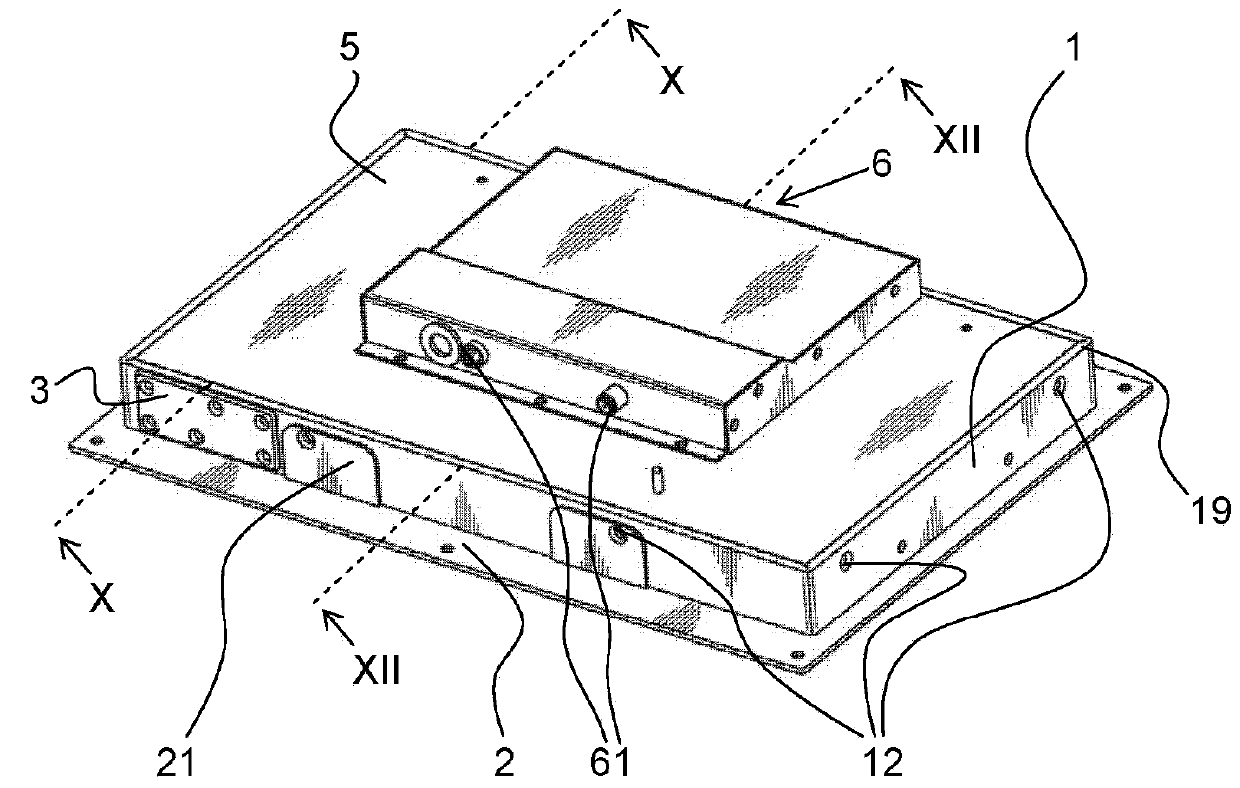

Sensor arrangement for determining an inside temperature in a motor vehicle

ActiveUS8651735B2Simple configurationGuaranteed heat transferThermometer detailsThermometer applicationsMotorized vehicle

Owner:PREH GMBH

Sensor arrangement for determining an inside temperature in a motor vehicle

ActiveUS20110128991A1Simple configurationGuaranteed heat transferThermometer detailsEngineeringMotorized vehicle

Owner:PREH GMBH

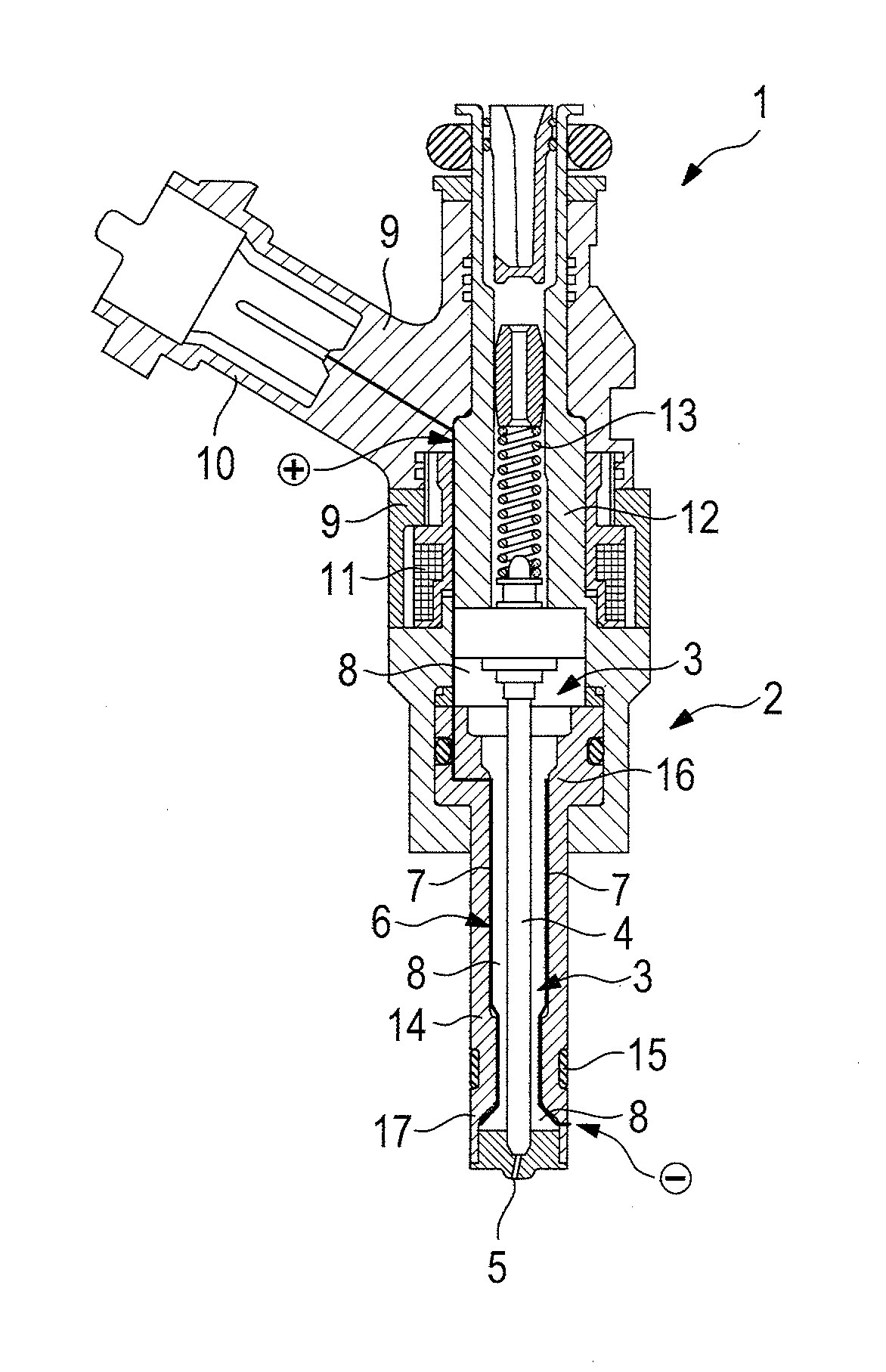

Heatable injector for fuel injection in an internal combustion engine

ActiveUS20140252122A1Satisfactory heating propertySimple designSpray nozzlesMachines/enginesInjectorCarbon Nanoparticles

A heatable injector for fuel injection in an internal combustion engine, the injector having an injector housing, a fuel space which is situated inside the injector housing, an adjustable injector needle which is arranged in the injector housing for opening and closing a fuel discharge opening of the injector housing, and a heating device which is arranged inside the injector housing with a heating element for heating the fuel which is situated in the fuel space. The heating element is configured as a coating of a boundary face of the injector with respect to its fuel space, the coating being composed of a carbon nanoparticle material.

Owner:DR ING H C F PORSCHE AG

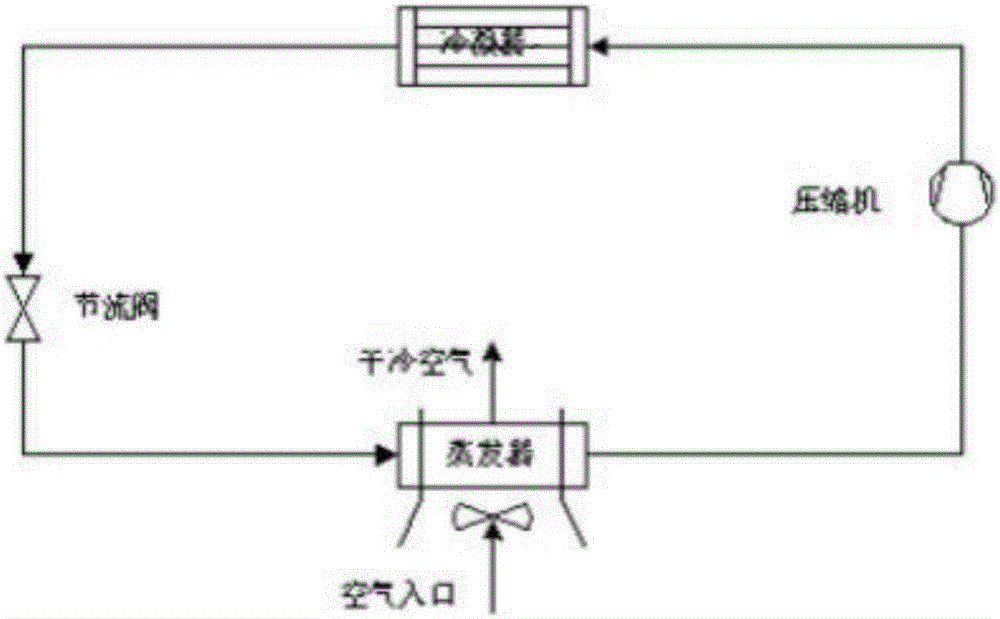

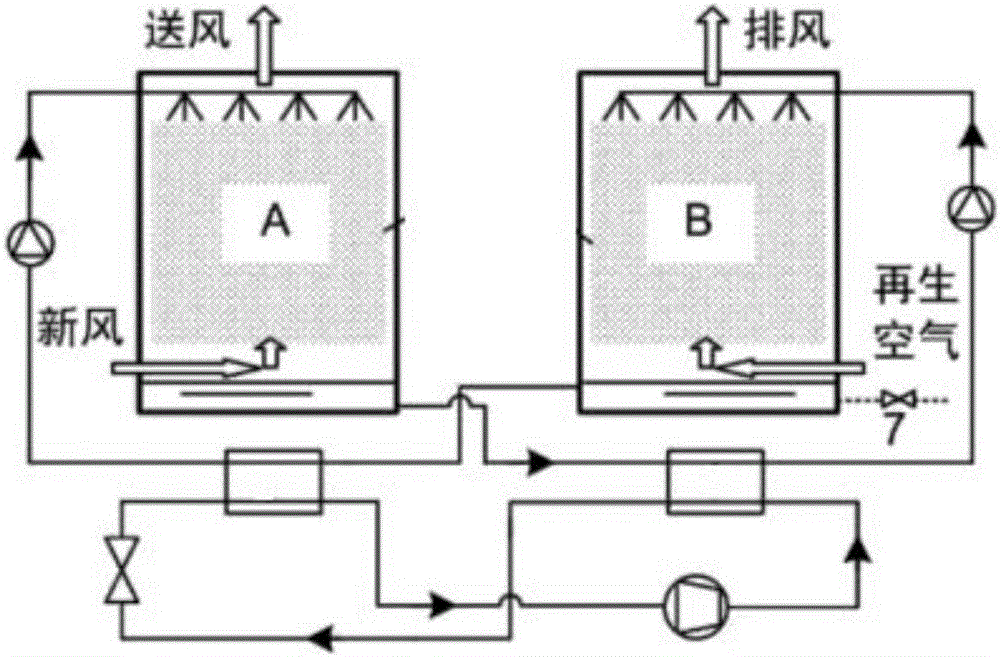

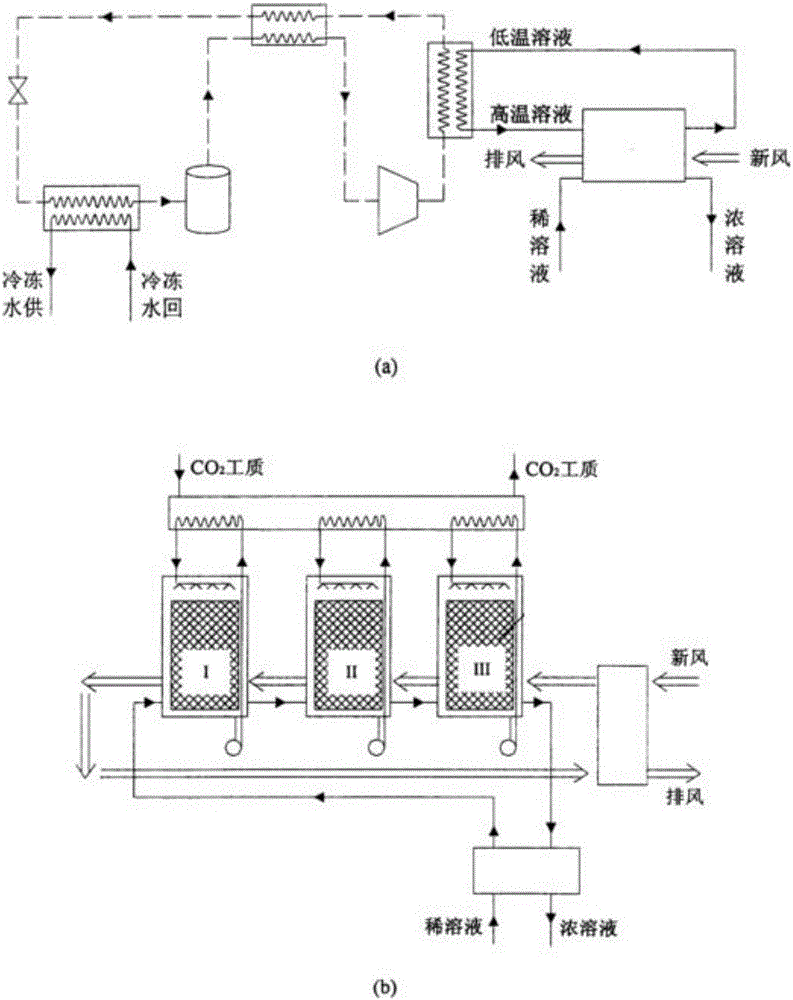

Transcritical carbon dioxide circulation and solution dehumidification air temperature and humidity regulation system

ActiveCN106440115AIncrease profitReduce energy consumptionAir conditioning systemsRefrigeration machinesDesorptionFresh air

The invention provides a transcritical carbon dioxide circulation and solution dehumidification air temperature and humidity regulation system, and belongs to the technical field of air conditioner system regulation. Heat cascade integration of a carbon dioxide transcritical refrigeration system and a liquid absorption type dehumidification system is achieved, the energy utilization rate is increased, and the energy consumption of an air conditioner refrigeration system is reduced. Fresh air is dehumidified and then cooled through a refrigeration system evaporator, independent step control of temperature and humidity is truly achieved, the cooling capacity of the evaporator is not consumed in the dehumidification process, and energy is saved to the maximum extent. A refrigeration unit inner cooler exchanges heat with desorption air, and the system performance is improved. Cooling water is used as the hot water resource used for life after being heated by the system in a cascade manner. A low-circulation-ration solution circulation system is adopted. By means of the unique structural design of an inner heat exchange type absorber and a regenerator, it is ensured that the heat transfer process and the mass transfer process are conducted in a container at the same time. By applying the nanometer technology to the inner surfaces of the absorber and the regenerator, the surface infiltration performance is improved, and the heat transfer and mass transfer effects are improved.

Owner:谷俊轻

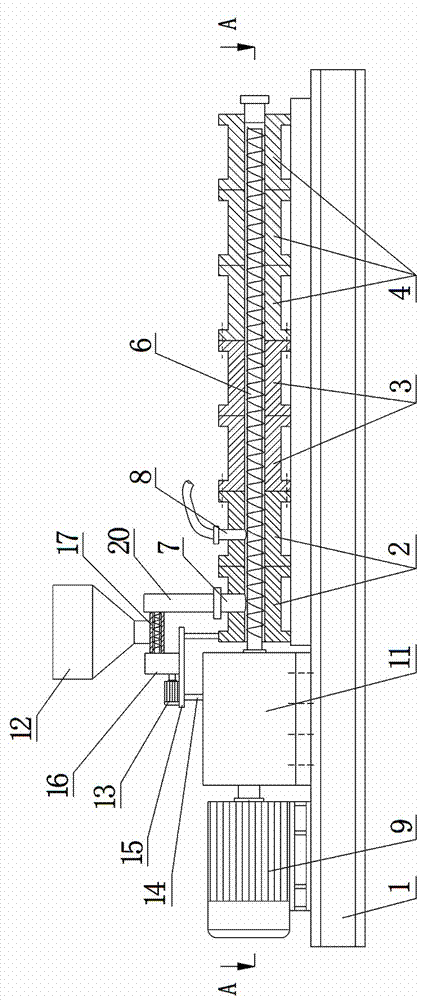

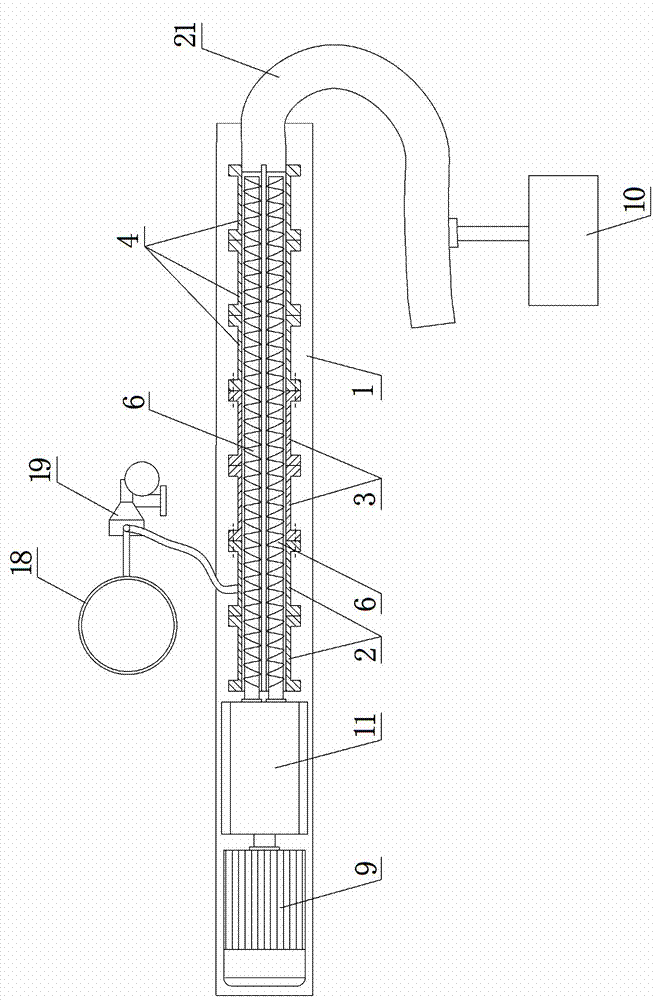

Device and method for preparing foam resin microspheres for physical sensitization of emulsified explosives

The invention discloses a device for preparing foam resin microspheres for physical sensitization of emulsified explosives. The device comprises a frame (1) and a conveying channel cylinder, wherein the conveying channel cylinder is composed of a charging cylinder section (2), a mixing cylinder section (3) and a foaming cylinder section (4) for foaming resin microspheres; the three sections are orderly connected by use of flanges, and a feeding hole A (7) and a feeding hole B (8) both communicated with a conveying channel (5) are formed in the top of the charging cylinder section (2); the device further comprises a charging system, a liquid adding system, a motor I (9), a nitrogen cooling device (10) and a reduction gearbox I (11) with two output ends, wherein the motor I (9), the reduction gearbox I (11) and the conveying channel cylinder are orderly arranged on the frame (1). The invention also discloses a method for preparing the foam resin microspheres. The device for preparing the foam resin microspheres for physical sensitization of the emulsified explosives has the beneficial effects that the production efficiency is high, the dust generated after the foaming of the foam resin microspheres for physical sensitization of the emulsified explosives is effectively reduced, and sticking of the foam resin microspheres for physical sensitization of the emulsified explosives at high temperatures is effectively prevented.

Owner:雅化集团三台化工有限公司

High-temperature flue gas waste heat utilization device

InactiveCN112414197AImprove occlusion effectIncrease forceRecuperative heat exchangersHeat recovery systemsThermodynamicsFlue gas

The invention belongs to the technical field of environmental protection, particularly relates to a high-temperature flue gas waste heat utilization device. Aiming at solving the problems that a traditional high-temperature flue gas heat recovery device is generally simple in structure, flue gas is directly introduced into the device for heat exchange, the wall surface of a heat exchange componentis prone to be attached with dust, and then the heat recovery effect is affected, the following scheme is provided. According to the scheme, the novel device comprises a heat exchange tank, a water outlet is formed in the bottom end of the heat exchange tank, and a water outlet hopper is welded to the inner wall of the water outlet. According to the novel device, by arranging an automatic drainage mechanism, when the temperature of water in the heat exchange tank continuously rises, and the internal pressure rises to a certain value, a sealing top plate is pressed to be separated from a fixing ring, so that the water flows out; and in the process of losing magnetic adsorption of magnetic blocks, the water flows out and impacts, along with the water outlet hopper, a flow dividing blockingpiece and a supporting plate with a semispherical plate, so that continuous pulling force is generated on the sealing top plate, and then it is guaranteed that the sealing top plate is far away from the fixing ring, and the automatic drainage is smoothly carried out.

Owner:潘勇

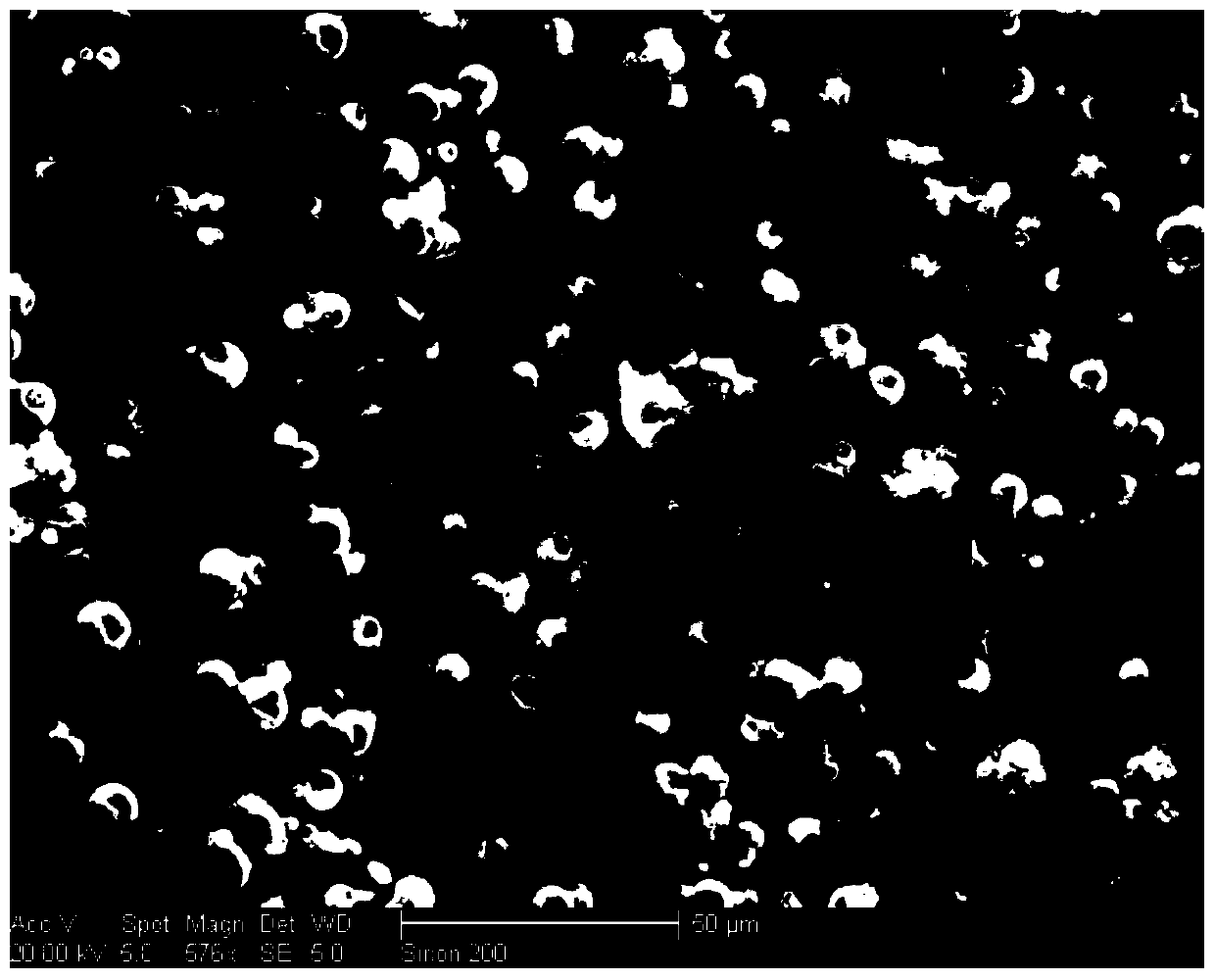

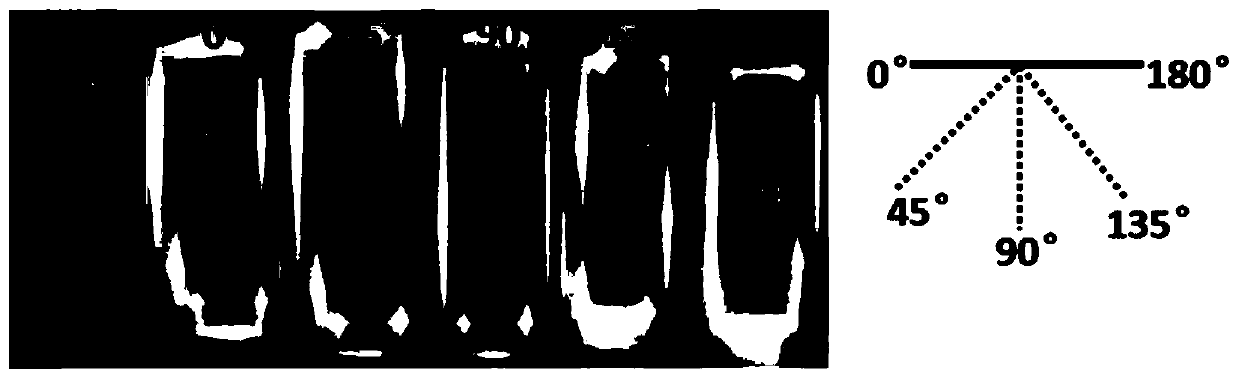

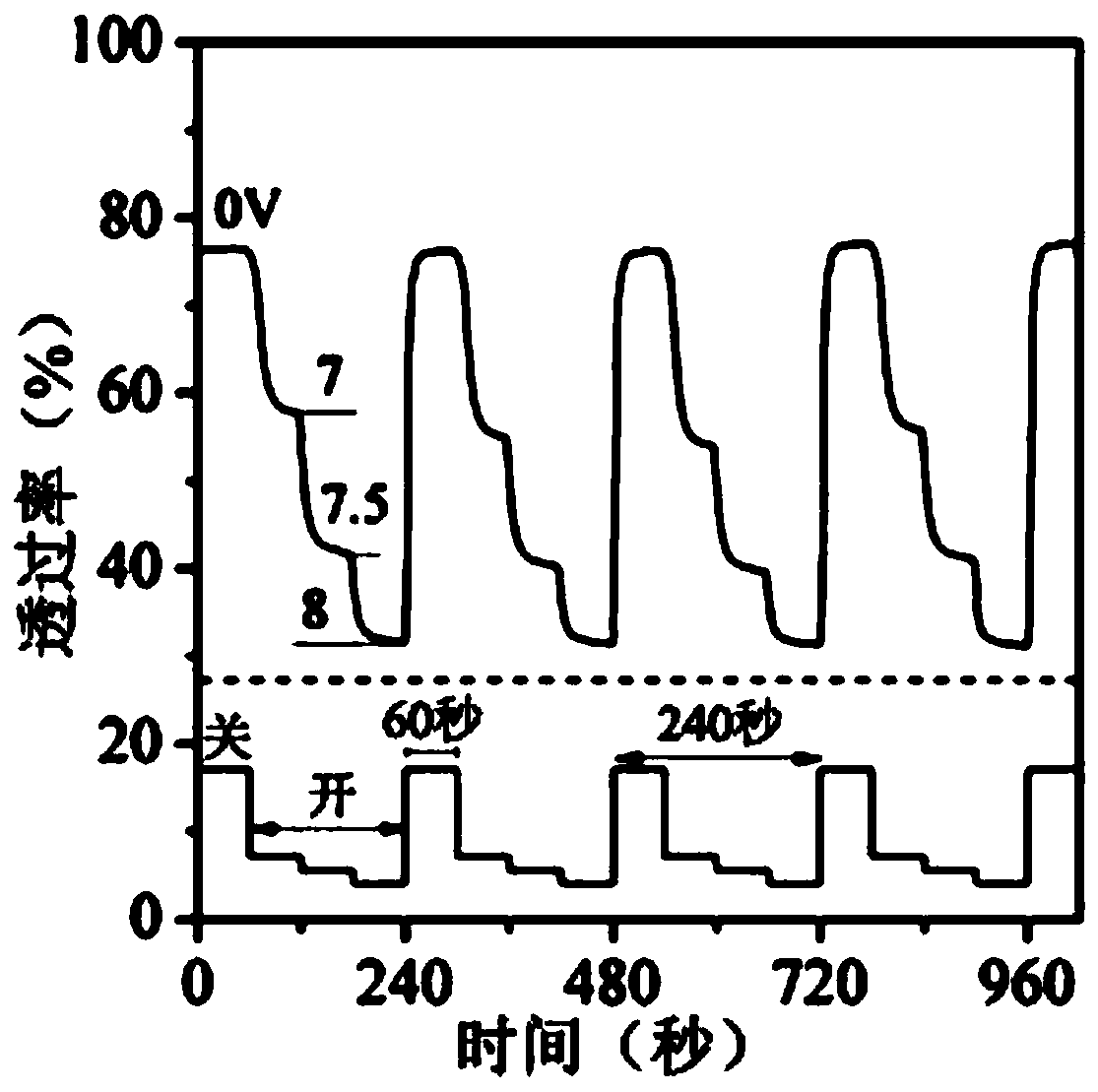

Preparation method of foldable thermochromic device based on nanowire film

PendingCN110109265AImprove flexibilityReduce the impact of volatilityDuplicating/marking methodsOther printing apparatusScreen printingOptical transmittance

The invention discloses a preparation method of a foldable thermochromic device based on a nanowire film. According to the preparation method of the foldable thermochromic device based on the nanowirefilm, when a metal nanowire film is located under a thermochromic display layer on a substrate, the metal nanowire film is prepared by automatic blade coating, and the hermochromic display layer is prepared by silk-screen printing; and when the thermochromic display layer is located under the metal nanowire film on the substrate, the hermochromic display layer is prepared by ink jet printing, andthe metal nanowire film is prepared by spray coating. The metal nanowire film has high optical transmittance, an ultralow resistance value and a high heat conductivity coefficient, has an invisibility function on the substrate, and can be located on the same side of the substrate with a thermochromic display object; and the quantity of heat is transmitted to a thermochromic material directly andrapidly, and the display object is not shielded.

Owner:NANJING SILVERNANO NEW MATERIALS TECH CO LTD

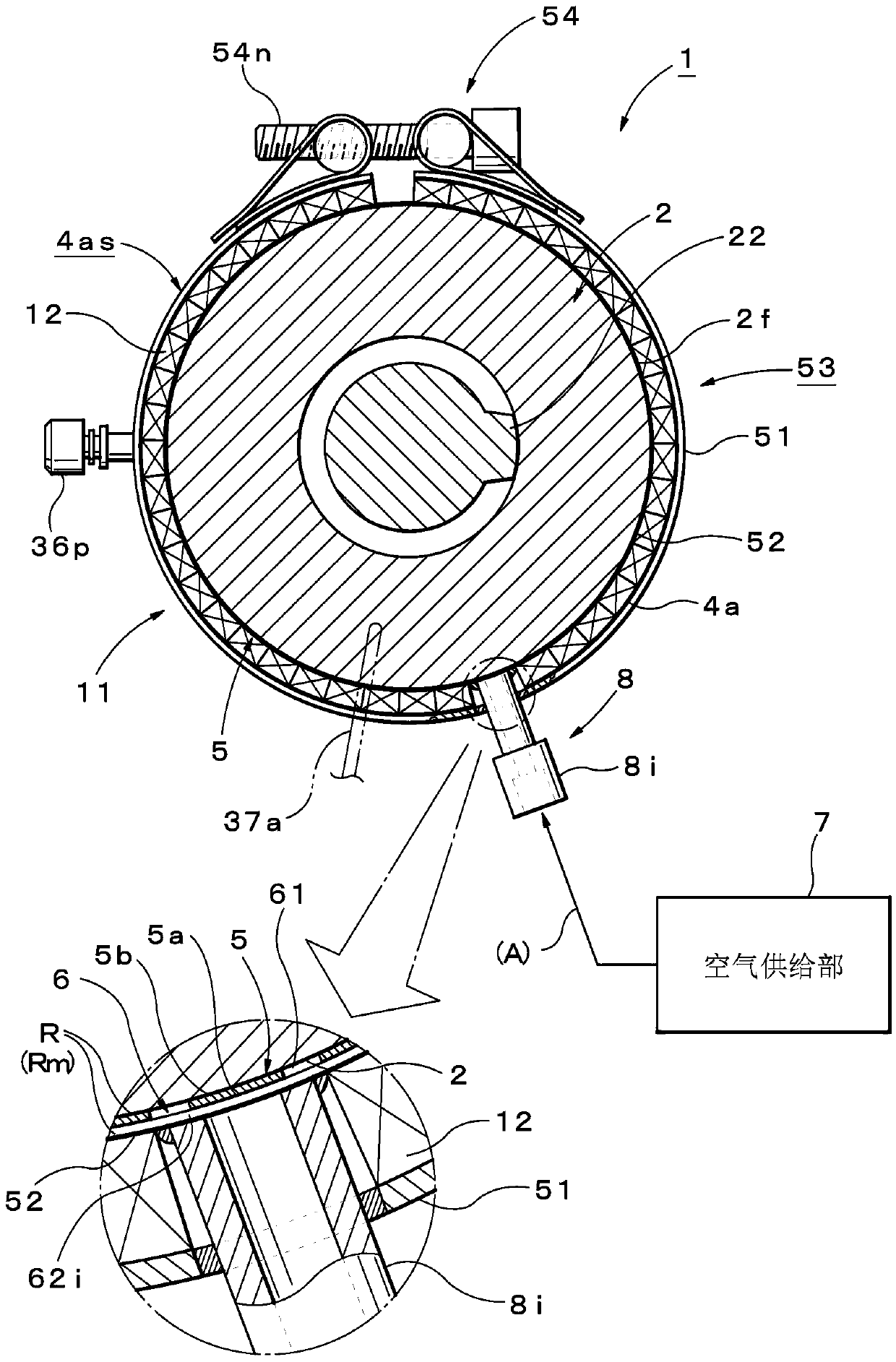

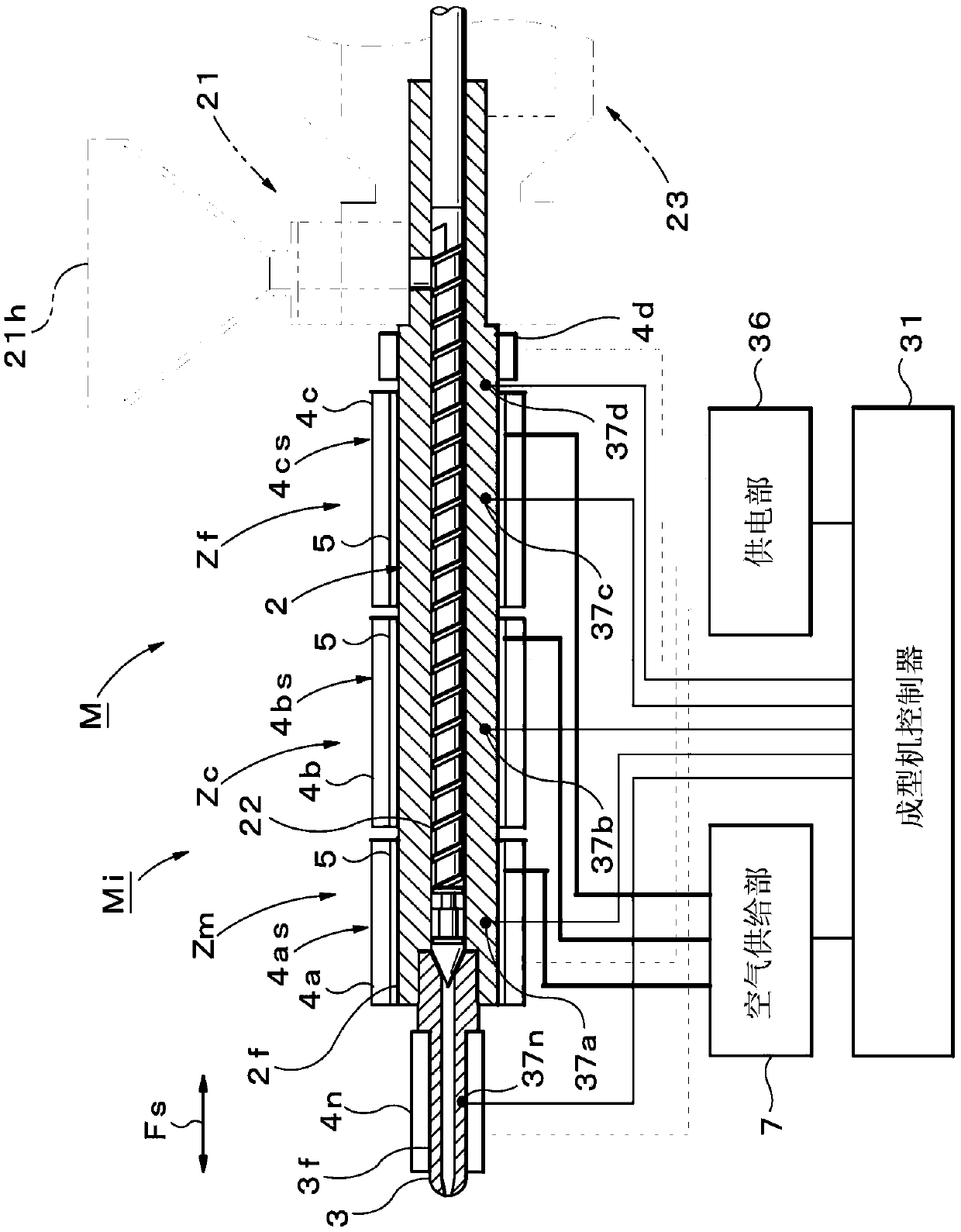

Heating device of injection molding machine

ActiveCN105538633AResponsive decline inhibitionControlled decline inhibitionThermal conductivityEngineering

The invention provides a heating device of an injection molding machine. When a heating device is formed which includes at least one or more heaters (4n, 4a, 4b, 4c and 4d) that are provided on the outer circumferential surfaces (2f and 3f) of at least one of a heating cylinder (2) and an injection nozzle (3) to heat at least one of the heating cylinder (2) and the injection nozzle (3), at least some heaters (4a, 4b, 4c, . . .) of all the heaters (4n, 4a, . . .) are formed with air cooling-capable heaters (4as, 4bs and 4cs) in which a panel member (5) formed of a material having thermal conductivity is interposed between the heaters (4a, 4b, 4c, . . .) and the outer circumferential surfaces of at least one of the heating cylinder and the injection nozzle, in which an air path (6) for air cooling is formed in the panel member (5) and in which an air outlet and inlet portion allowing air to be passed from an air supply portion is provided in the air path.

Owner:NISSEI PLASTICS IND CO LTD

Horizontal fluidized stirring dryer of beer grains

InactiveCN106766685AHave a crushing effectGuaranteed loosenessDrying solid materials with heatDrying gas arrangementsPulp and paper industry

The invention relates to a horizontal fluidized stirring dryer of beer grains. The horizontal fluidized stirring dryer of the beer grains comprises a machine frame and a housing installed on the machine frame. The central position in the housing is provided with a blast channel. The blast channel divides the housing to two drying chambers. A stirring shaft is respectively installed in each of two drying chambers. The stirring shafts are installed on a pair of bearing seats at two ends of the housing. The stirring shafts are driven to be rotated by a motor installed at the exterior of the housing through a transmission mechanism. A plurality of stirring blades is uniformly distributed on the stirring shafts. An arc plate is installed on the inner wall of the drying chambers below the stirring shafts. One end of each of two drying chamber housings is provided with a material inlet, and the other end of the housing is provided with a material outlet and an air inlet. The upper part of the housing is provided with an air inducing pipe. The end part of the blast channel is communicated with the air inlet. The bottom of the blast channel is provided with an air guiding plate. The top of the housing is provided with an air inducing cover. The structure design of the horizontal fluidized stirring dryer of the beer grains is scientific and reasonable. The material is stirred to be fluidized state by the stirring blades, and the thick beer grains are crushed, so the loose degree of the beer grains is guaranteed, the drying efficiency is improved, and the integrated drying treatment of the bear grains is realized.

Owner:宁波沪港食品机械制造有限公司

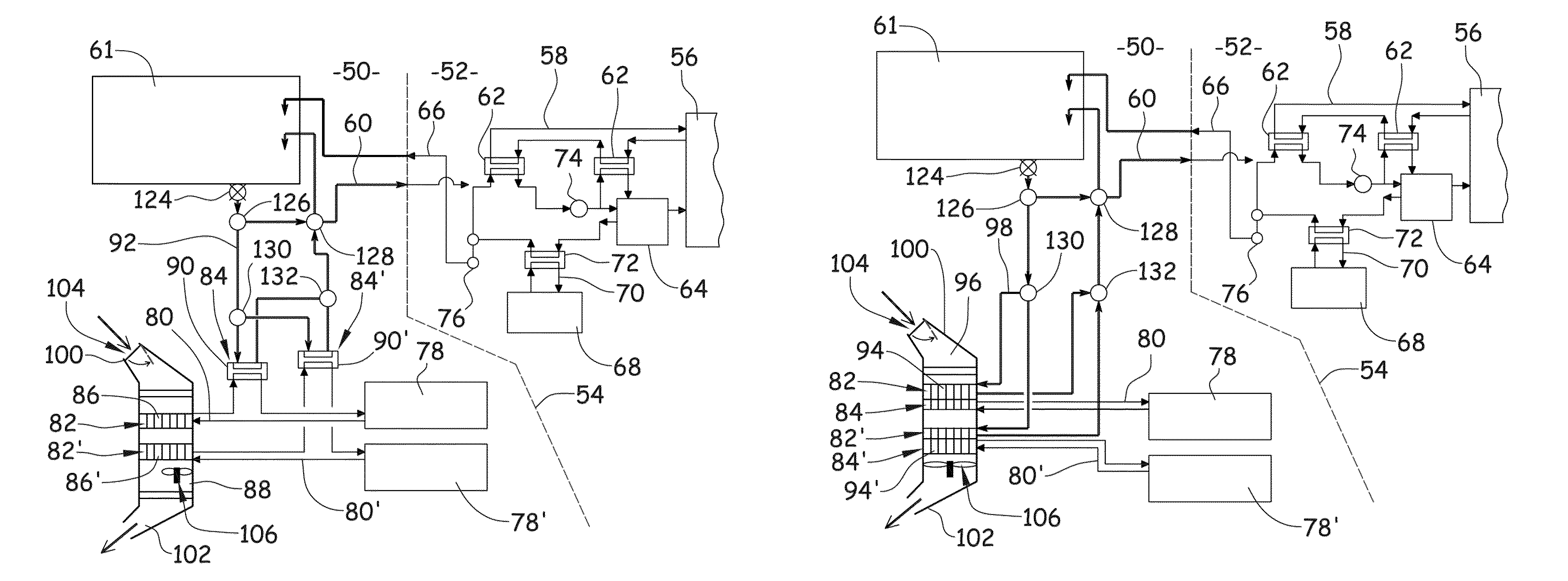

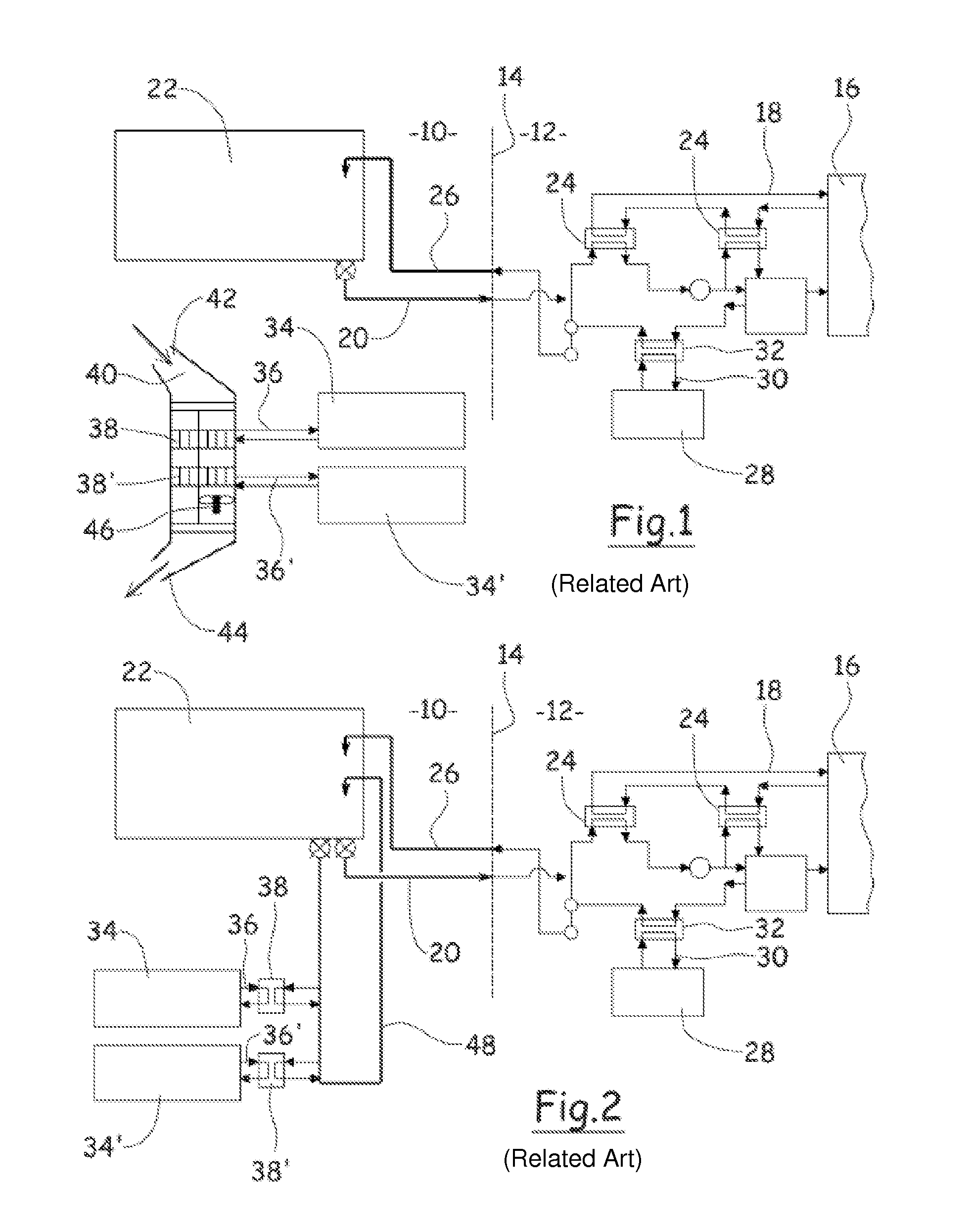

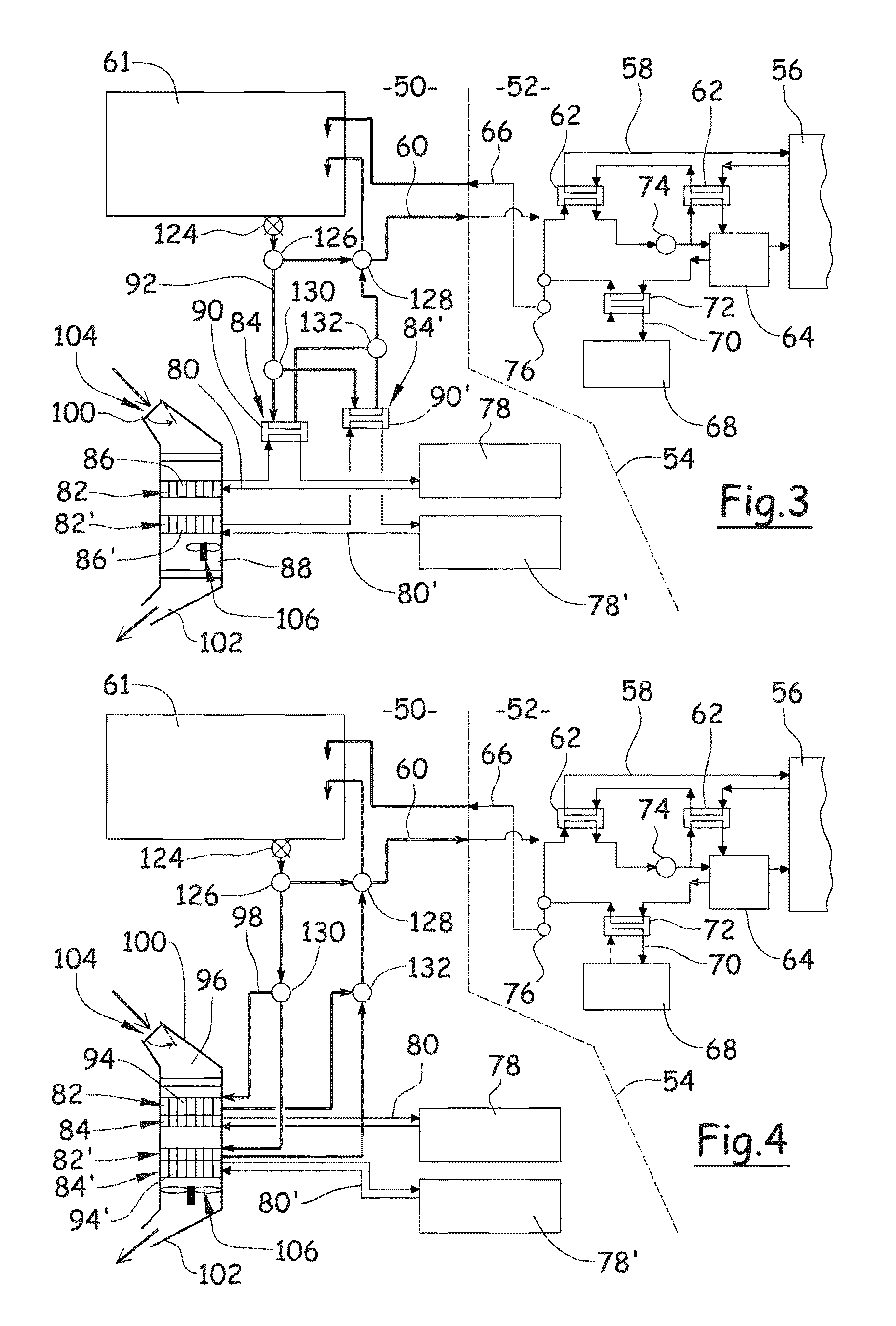

System for managing the heat fluxes of an aircraft

InactiveUS8516792B2Guaranteed heat transferControl impactCoolant flow controlAir coolingHeat fluxHeat flow

A system for managing heat fluxes of an aircraft is provided, including a fuel tank supplying a turbomachine with fuel via a fuel supply circuit; a cell cooling circuit connected to a thermal effluents source, which integrates a first heat exchanger ensuring heat transfer between a coolant circulating in the cell cooling circuit and air flow channeled into a cooling air channel extending from an air intake to an exhaust; and a second heat exchanger ensuring a heat transfer between the coolant circulating in the cell cooling circuit and the fuel. The air intake includes a blocker to open / close it. The system includes a fuel transfer circuit, which connects the fuel tank to the second heat exchanger and provides fuel to the second heat exchanger, including a valve selectively changing a fuel supply direction from the second heat exchanger between the directions of the tank and the fuel supply circuit.

Owner:AIRBUS OPERATIONS (SAS)

Solid fermentation bioreactor

InactiveCN102443535BNo side effectsIsolated entryBioreactor/fermenter combinationsBiological substance pretreatmentsBioreactorControl unit

The invention relates to a solid fermentation bioreactor. The reactor comprises a reaction casing , and a porous material layer separator plate (5) is arranged in the reaction casing to divide the reaction casing into an upper fermentation chamber (1) and a lower layer air chamber (3); the reactor also comprises a fermentation control system for controlling a stirring unit, a temperature control unit, a humidity control unit, an air feed control unit and a fermentation tail gas detection and processing unit, so as to realize real time monitoring and control on temperature, humidity, ventilation, stirring and tail gas. The invention realizes totally enclosing on-line fermentation and prevents extraneous pollutants from entering; the tail gas detection system carries out real time on-line monitoring on fermentation gas, and tail gas is treated by tail gas recovery equipment to protect the environment, thereby realizing coupling operation of temperature, humidity, ventilation, stirring and tail gas control system and ensuring necessary essential factors for microbe growth.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

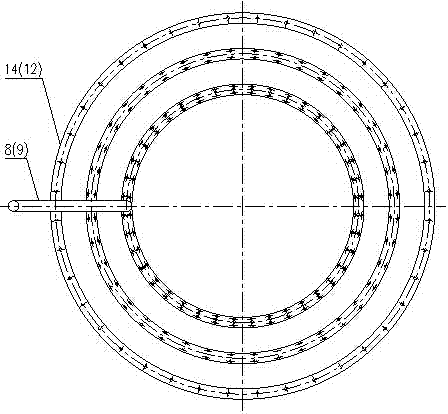

Reinforced heat transfer adsorption regenerator

InactiveCN1423102AImprove practicality and cooling powerReduce metal usageBoiler absorbersClimate change adaptationEngineeringSorbent

The invention refers to gas and solid reaction field of chemistry absorption cooling, sun energy thermal storage and large quantity heat transmitting, accurately it is absorbing regenerator which is used to strengthen heat transmitting, it sets a multi-hole pipe in the centre of gapless rail, radial and lengthways vanes are set between small pipe and seamless rail, it fills sorbent in space isolated by radial and lengthways vanes.

Owner:SOUTH CHINA UNIV OF TECH

Heat exchanger

InactiveCN104833137AReduce frostingGuaranteed heat transferEvaporators/condensersCorrosion preventionRefrigerantMechanical engineering

Provided is a heat exchanger. The heat exchanger includes a plurality of refrigerant tubes through which a refrigerant flows, the plurality of refrigerant tube being disposed to be spaced apart from each other in one direction and a plurality of fins disposed between the plurality of refrigerant tubes. A distance between the fins disposed on a front end-side of the plurality of refrigerant tubes is greater than that between the fins disposed on a rear end-side of the plurality of refrigerant tubes.

Owner:LG ELECTRONICS INC

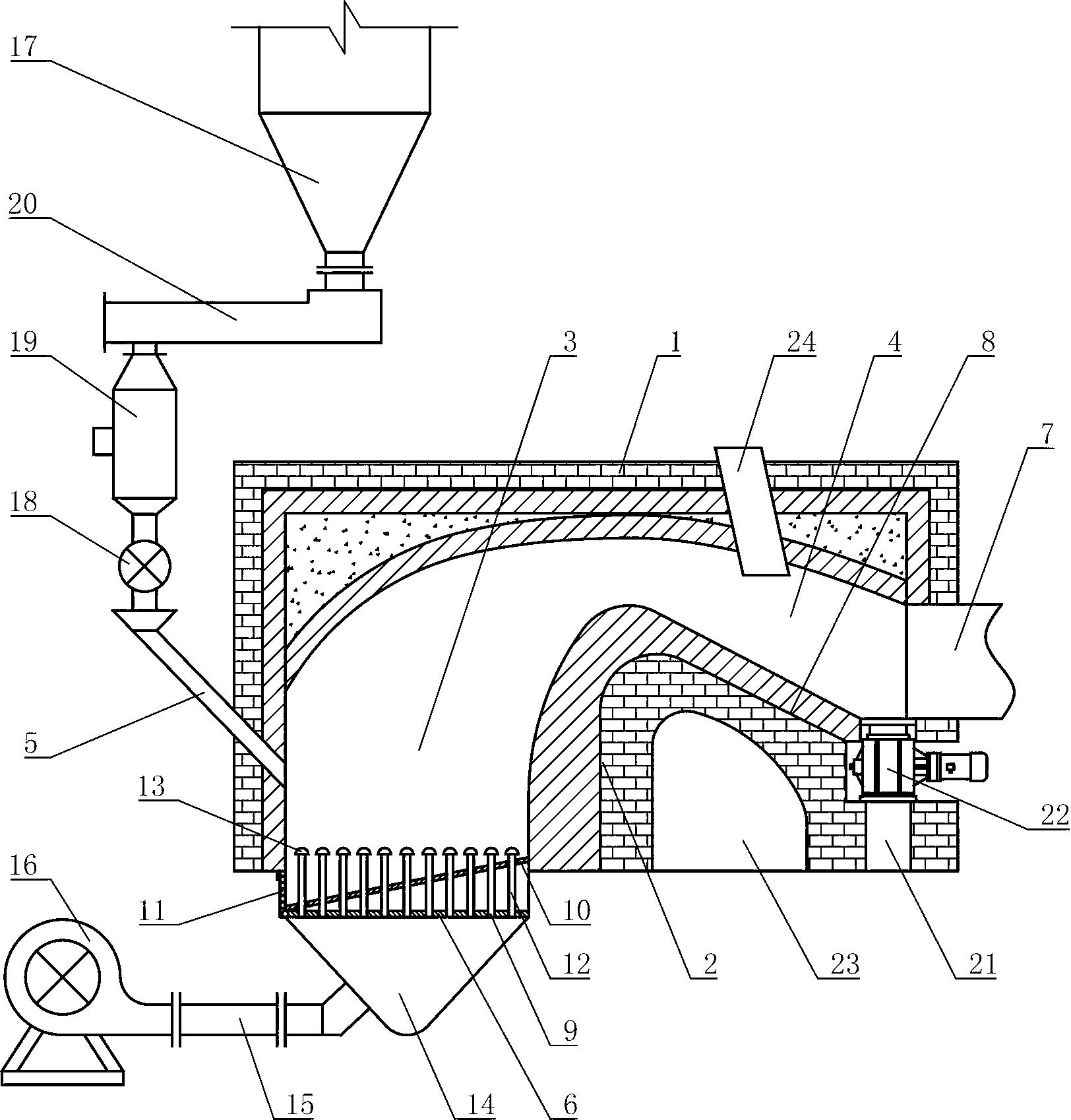

Novel high temperature smoke fluidized bed furnace

InactiveCN102840753AImprove stabilitySpeed up the flowAir heatersHeating arrangementCombustion chamberSlag

The invention relates to a fluidized bed furnace for drying in the industry, in particular to a novel high temperature smoke fluidized bed furnace which is thorough in slag discharging and long in service life, and a coking phenomenon cannot happen. The novel high temperature smoke fluidized bed furnace comprises a furnace body (1), a fire blocking wall (2) is arranged inside the furnace body, the inside of the furnace body (1) is separated by the fire blocking wall (1) into a combustion chamber (3) and a mixing chamber (4). A coal inlet pipe (5) is arranged on the lateral wall of the furnace body (1) of the combustion chamber (3) in inclination mode, a wind distribution plate (6) is arranged at the bottom of the furnace body (1), and an air outlet (7) is arranged on the lateral wall of the furnace body (1) of the mixing chamber (4). The novel high temperature smoke fluidized bed furnace is characterized in that the top of the furnace body (1) is in an arc shape protruding upwards, the fire blocking wall (2) is vertically located at the lower portion of one side of the mixing chamber (4), and the upper portion is in an arc shape curving to the mixing chamber (4). The fire blocking wall (2) is located on one side of the mixing chamber (4) to be connected with the bottom of the mixing chamber (4) to form an inclined face (8) with the same inclination, and the tail end of the inclined face (8) is connected with the bottom end of the air outlet (7).

Owner:张斌

Housing for holding a flat screen

InactiveCN103635041AAvoid accumulationImprove cooling effectDigital data processing detailsCasings/cabinets/drawers detailsClassical mechanicsEngineering

Owner:RUF TELEMATIK

Temperature measuring armored thermocouple

ActiveCN104596661BImprove sealingImprove reliabilityThermometers using electric/magnetic elementsUsing electrical meansEngineeringThermocouple Wire

The invention discloses a temperature-measuring armored thermocouple. The armored thermocouple is provided with a support tube, and the armored thermocouple is installed in the protective sleeve through the support tube. The armored thermocouple is provided with multiple pairs of thermocouple wires. The hot end of the thermocouple is equipped with a corundum tube, and the extension ends of the multiple pairs of thermocouple wires of the armored thermocouple pass through the through holes of the corundum tube respectively, and are welded into a hot junction, and the thermal junction and the protective sleeve are filled with thermally conductive fillers , the cold end of the thermocouple wire is connected to the compensation cable through a sealed connector; a compression nut connected to the installation part of the protective sleeve is sleeved above the support tube, and a compression pad is provided between the compression nut and the installation part of the protective sleeve piece. The invention has the advantages of compact structure, good thermoelectric performance, good radiation resistance performance, good high temperature resistance performance, high reliability, safe and reliable use, and easy popularization.

Owner:CHONGQING MATERIALS RES INST

Glass fiber drawing machine with uniform heating

ActiveCN111320378AGuaranteed heat transferReduce usageGlass making apparatusMagnetic separationGlass fiberMolten state

The invention discloses a glass fiber drawing machine with a uniform heating function. The machine comprises a wire drawing machine, a discharge pipe is fixedly connected to the input end of the wiredrawing machine; the input end of the discharge pipe is fixedly connected with the melting chamber; a heating device is fixedly mounted on the melting chamber; the input end of the melting chamber isfixedly connected with the impurity removal device; the outer side of the impurity removal device is covered with a charging box; the impurity removing device comprises a filtering device and a magnetic metal removing device; according to the glass fiber drawing machine, the wire drawing machine is directly connected with the melting chamber and the impurity removing device; the raw materials arecontinuously subjected to impurity removal and melting treatment, consumption of treatment equipment is reduced, consumption of cost resources is reduced, meanwhile, an asbestos heat preservation layer and a heat insulation sleeve are arranged on the outer side of the discharging pipe, heat preservation conveying of the molten raw materials is guaranteed, heat loss is prevented, and the raw materials are kept in a molten state all the time.

Owner:浙江得胜玻璃纤维有限公司

Low-temperature double-ball spherical tank liquid distribution system and precooling method

ActiveCN104747900AReduce stressIncrease temperatureContainer filling methodsPressure vesselsThermodynamicsDistribution system

The invention provides a low-temperature double-ball spherical tank liquid distribution system which comprises an upper inlet liquid distributor and a lower liquid inlet pipe, wherein the upper inlet liquid distributor and the lower liquid inlet pipe are arranged at the top and lower part of an inner spherical tank; the liquid distribution system comprises a middle inlet distributor arranged at the middle of the inner spherical tank; the middle inlet liquid distributor consists of a middle liquid inlet pipe and a middle liquid distributor; the middle liquid inlet pipe is guided from the bottom of an outer spherical tank, is guided to the middle of the inner spherical tank along an interlayer and penetrates through the inner spherical tank so as to be connected with the middle liquid distributor in an equatorial plane of the inner spherical tank. A precooling method of the low-temperature dual-ball spherical tank is realized by virtue of preparation before precoling, a front-stage precooling stage, a middle-stage precooling stage and a rear-stage precooling stage. By virtue of matched use of the upper inlet liquid distributor and the middle inlet liquid distributor, large-range uniform liquid distribution in a precooling process is realized, the wall temperature distribution of the inner spherical tank in the precooling process is effectively improved, the temperature stress is reduced, and the structural safety of the low-temperature dual-ball spherical tank in the precooling process is greatly improved.

Owner:GANSU LANPEC TECH +2

Heat exchanger and refrigeration cycle device

PendingCN110603419AImprove drainage capacityBig angleEvaporators/condensersStationary conduit assembliesEngineeringRefrigeration

A heat exchanger relating to the present invention is provided with: a fin, which has a first through hole and a second through hole formed therein, and a first end portion and a second end portion; afirst heat transfer tube inserted into the first through hole; and a second heat transfer tube inserted into the second through hole. When a virtual straight line passing end portions of the first heat transfer tube and the second heat transfer tube, said end portions being on the first end portion side, is defined as a first virtual straight line, a virtual straight line passing end portions ofthe first heat transfer tube and the second heat transfer tube, said end portions being on the second end portion side, is defined as a second virtual straight line, a region between the first end portion and the first virtual straight line is defined as a first drain region, a region between the second end portion and the second virtual straight line is defined as a second drain region, and a region surrounded by the first heat transfer tube, the second heat transfer tube, the first virtual straight line, and the second virtual straight line is defined as a water conducting region, a first trench inclined downward toward the first drain region, and a second trench tilted downward toward the second drain region are formed in the water conducting region.

Owner:MITSUBISHI ELECTRIC CORP

Method for preparing maleic anhydride-alkyl vinyl ether co-polymer

The invention relates to a solution copolymerization method for preparing a maleic anhydride-alkyl vinyl ether alternate copolymer. The method is characterized in that the method comprises the following steps: carrying out the solution copolymerization reaction of the maleic anhydride and the alkyl vinyl ether in the mol ratio of 1:1 in the mixed solvent through the initiation of an initiator, setting the polymerization temperature between 81 and 90 DEG C and the reaction time between 5 and 7 hours, obtaining slurry copolymer solution, filtrating and drying the solution in vacuum, and finally obtaining the white polymer powder.

Owner:锦西化工研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com