Patents

Literature

39results about How to "Have a crushing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

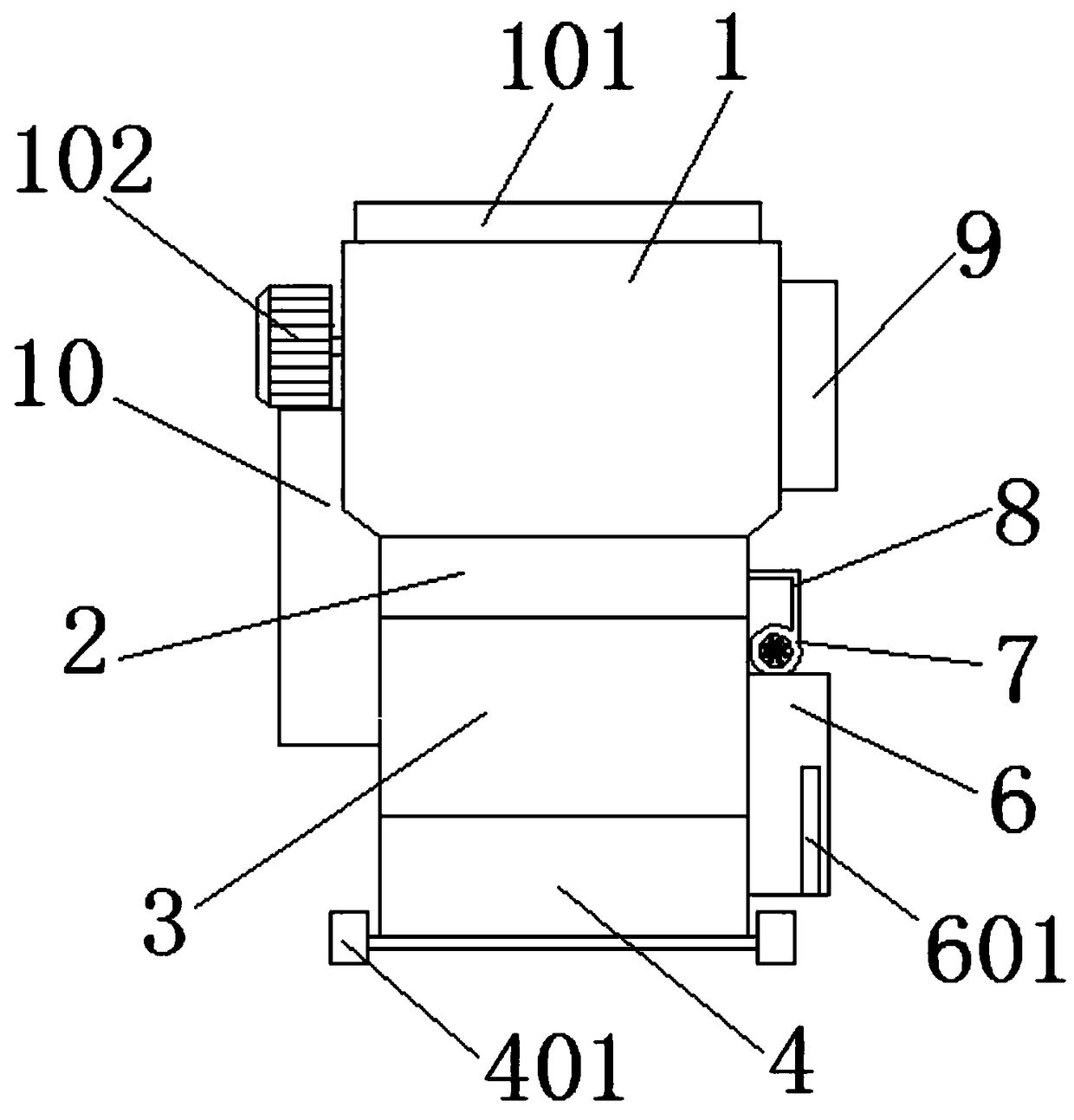

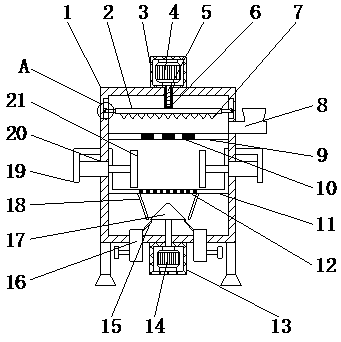

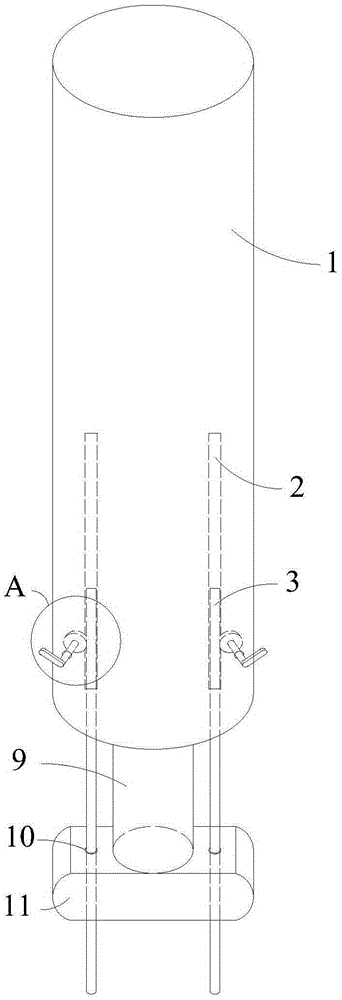

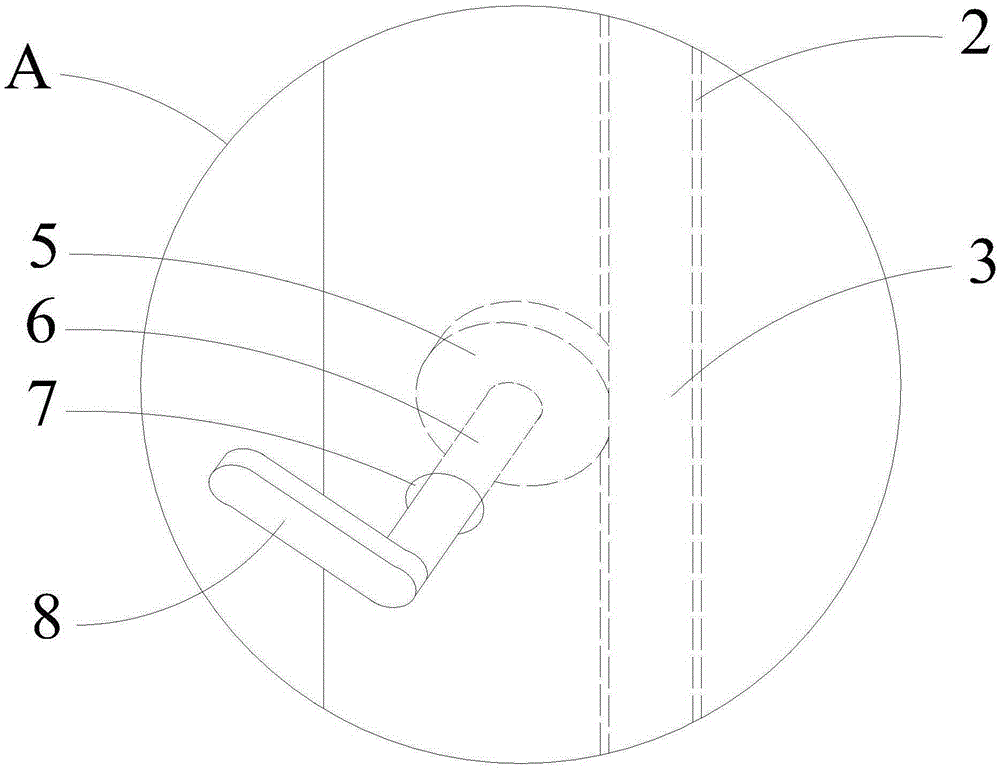

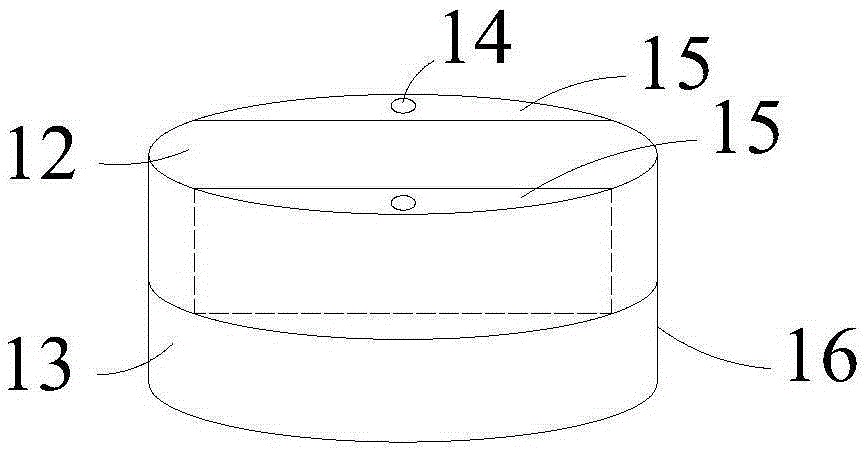

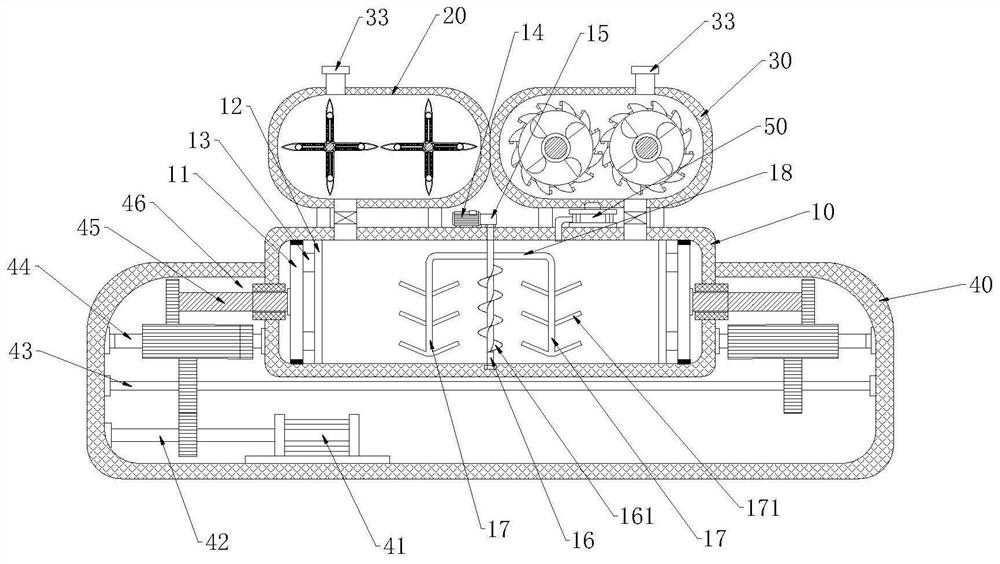

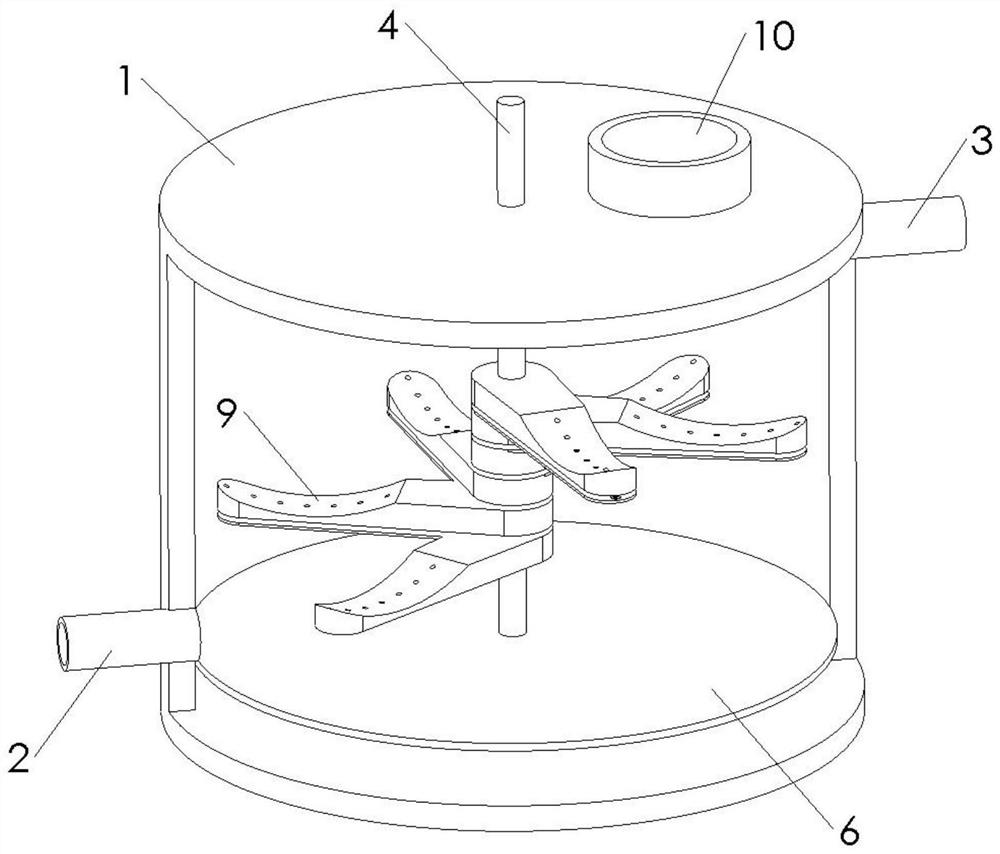

Calcium carbonate processing device for flame retardant cables

ActiveCN109551804AAutomatic entryImprove work efficiencyDrying solid materials without heatGrain treatmentsWater filterPulp and paper industry

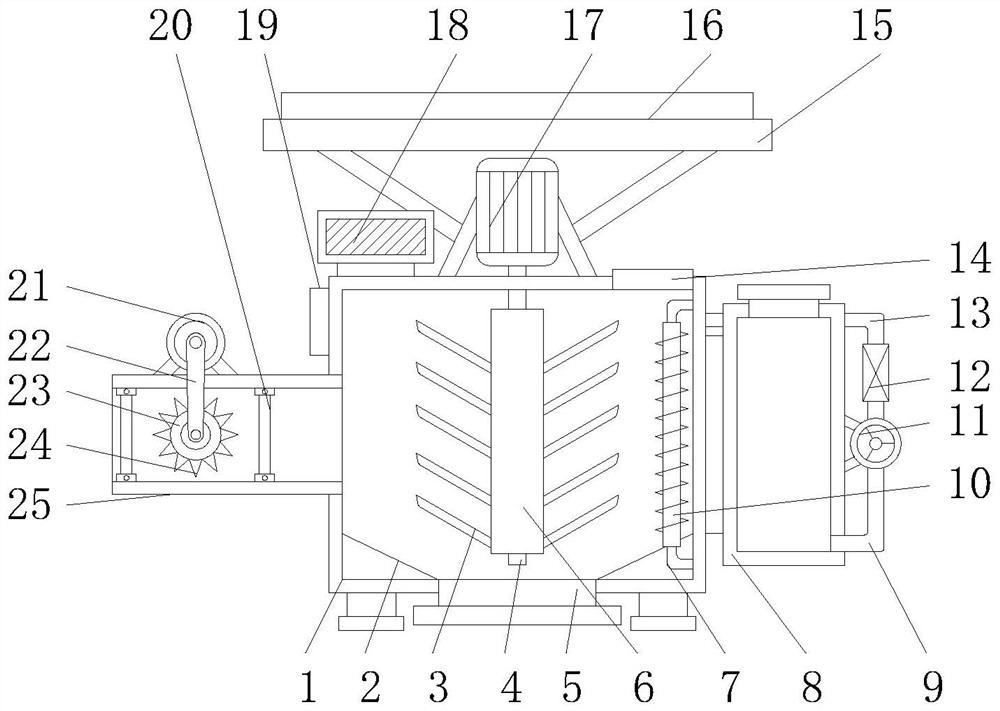

The invention provides a calcium carbonate processing device for flame retardant cables. The calcium carbonate processing device for the flame retardant cables comprises a processing box, a pluralityof supporting feet connected to the lower end of the processing box, two symmetrical discharging openings connected to the lower end of the processing box in a cutthrough mode, a motor connected to the bottom wall of the processing box through a first supporting frame and a rotary shaft connected to a rotating shaft of the motor. According to the calcium carbonate processing device for the flame retardant cables, deficiencies of the prior art are overcome, the design is reasonable, and the structure is compact; a pressure test of a mixed solution of calcium carbonate sediment and water is carried out through a pressing plate, the water in the solution is enabled to outflow through water filtering holes, and thus the dehydration process is achieved; the water in the calcium carbonate sediment is heated and evaporated by annular heating plates, and thus a good drying effect is achieved; and through the structural combination of touch rods and touch plates, a trapezoid circular table is driven to shake, and thus the smashing effect is realized; and the number of operation processes is reduced, and the working efficiency is improved.

Owner:天长市运成电缆辅料有限公司

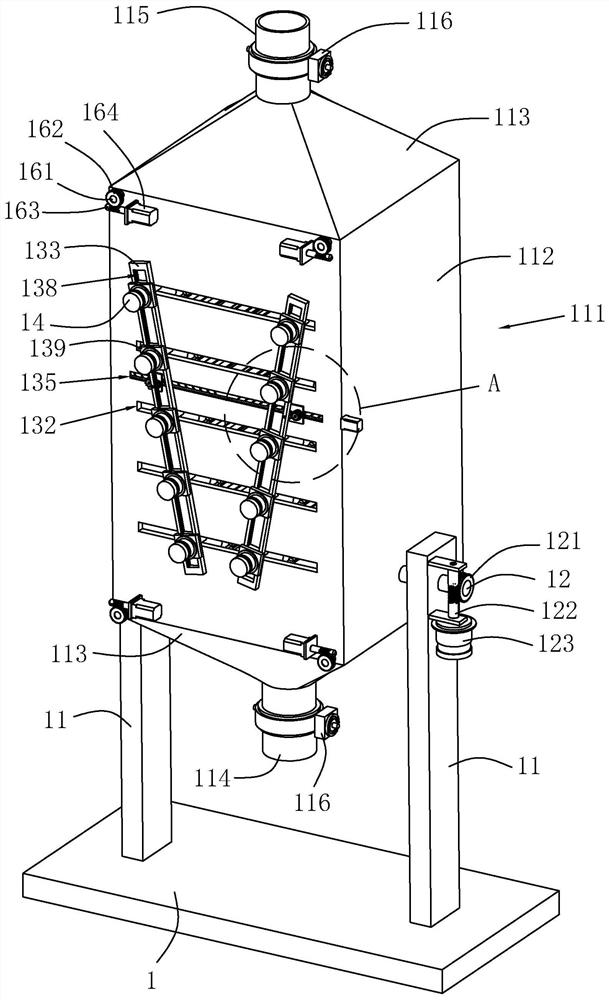

Corn flour production device with good dust-proof effect

InactiveCN109382181AHave the effect of suckingThe generation of solutionDirt cleaningGrain treatmentsElectricityCorn flour

The invention discloses a corn flour production device with good dust-proof effect, wherein the corn flour production device includes a body; a fixed plate is fixedly connected at the upper end of theleft side of the body; a motor box is fixedly connected at the top of the fixed plate; a first motor is fixed in an inner cavity of the motor box, an output shaft of the first motor is fixedly connected with a first rotating rod, and the upper end and the lower end of the first rotating rod are each fixedly connected with blades. The top of a support seat is fixedly provided with a dust collector, the input end of the dust collector passes through a support plate through a pipeline and is fixedly connected with a dust collection hood, and the output end of the dust collector communicates withthe left side of the top of a dust collection box through a pipeline, so that the effect of sucking away dust when the corn flour is discharged is played, and the problems that a lot of dust can be generated when conventional corn flour is produced, dust can float in air, enters respiratory tracts with people's breath and brings great hidden danger to people body safety, and the problem that explosion can be possible to occur due to too much dust is solved.

Owner:许昌泰禾农业科技发展有限公司

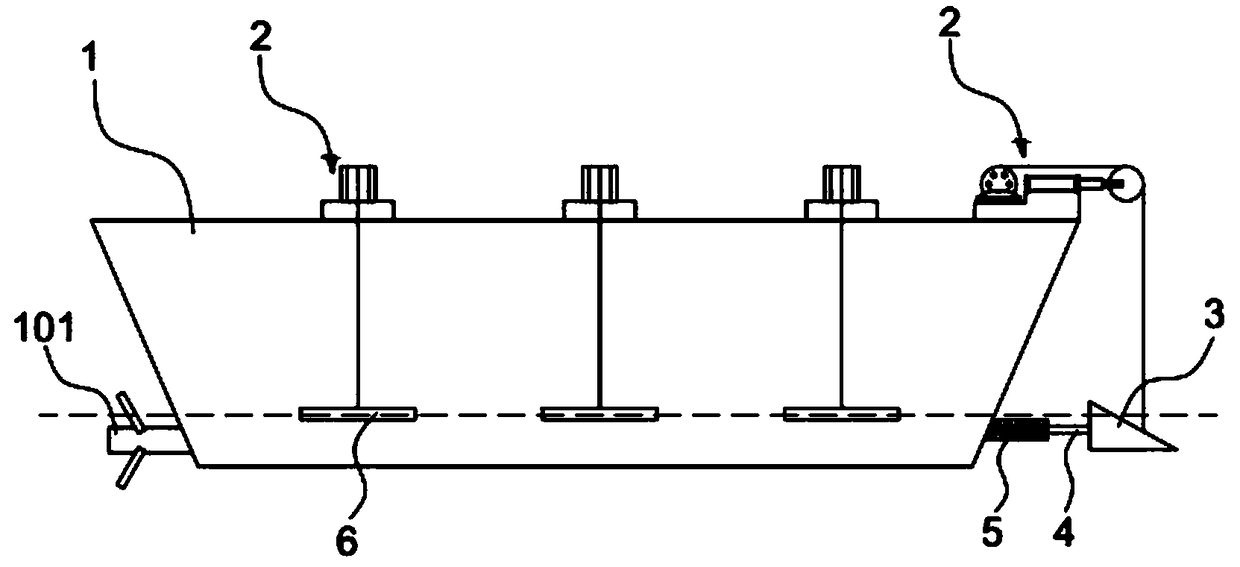

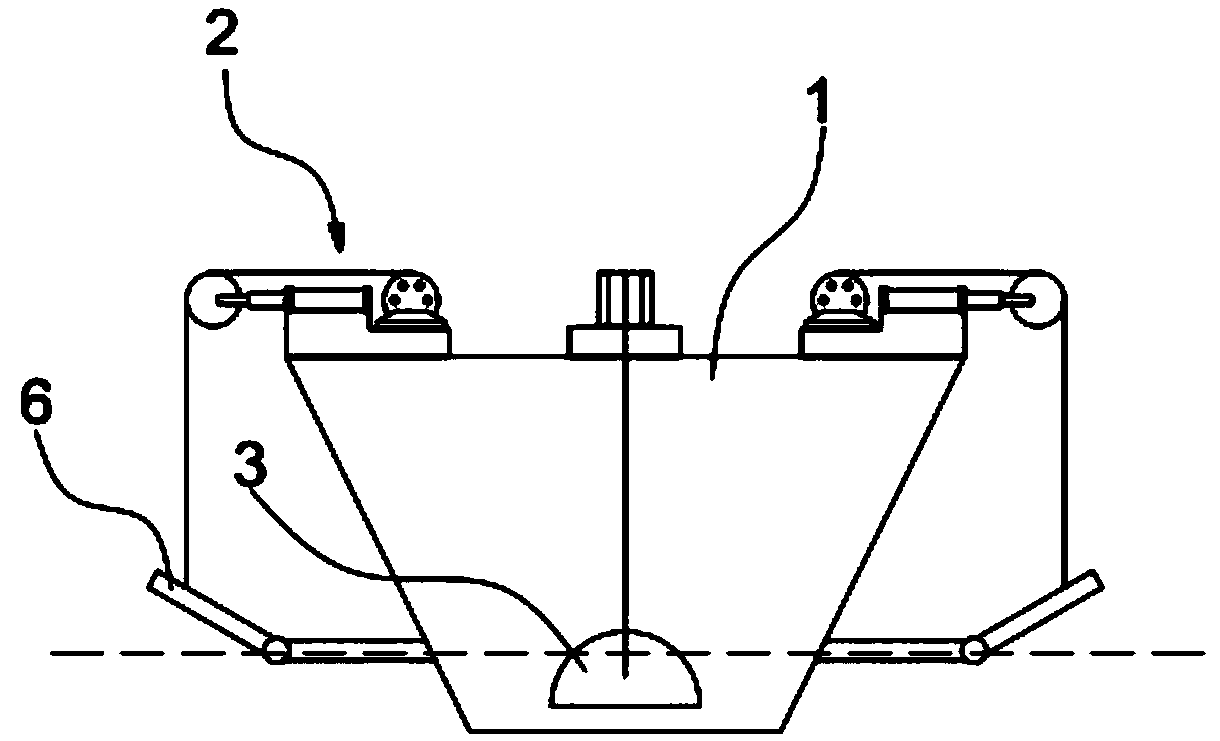

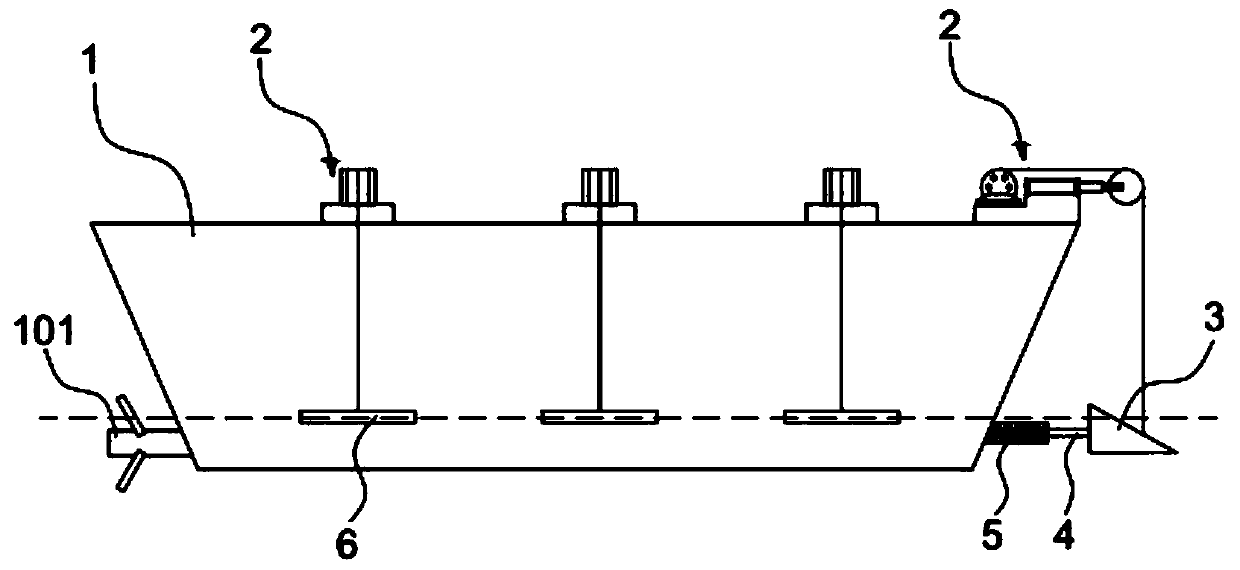

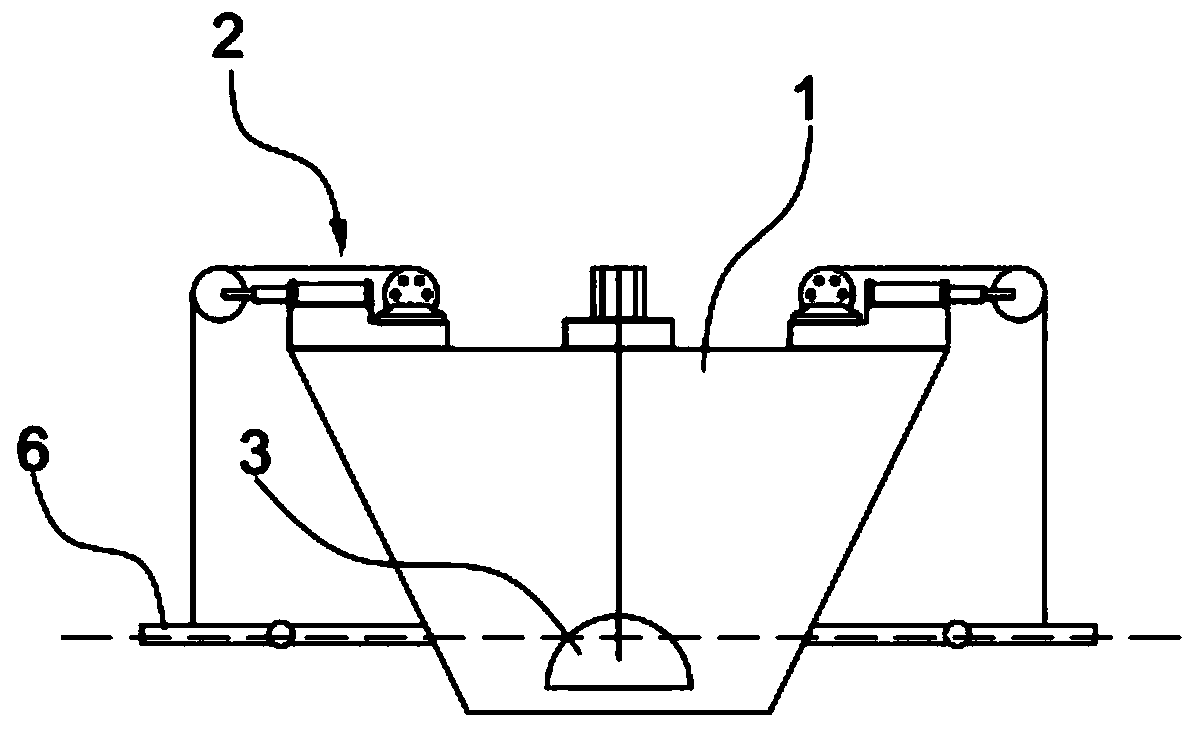

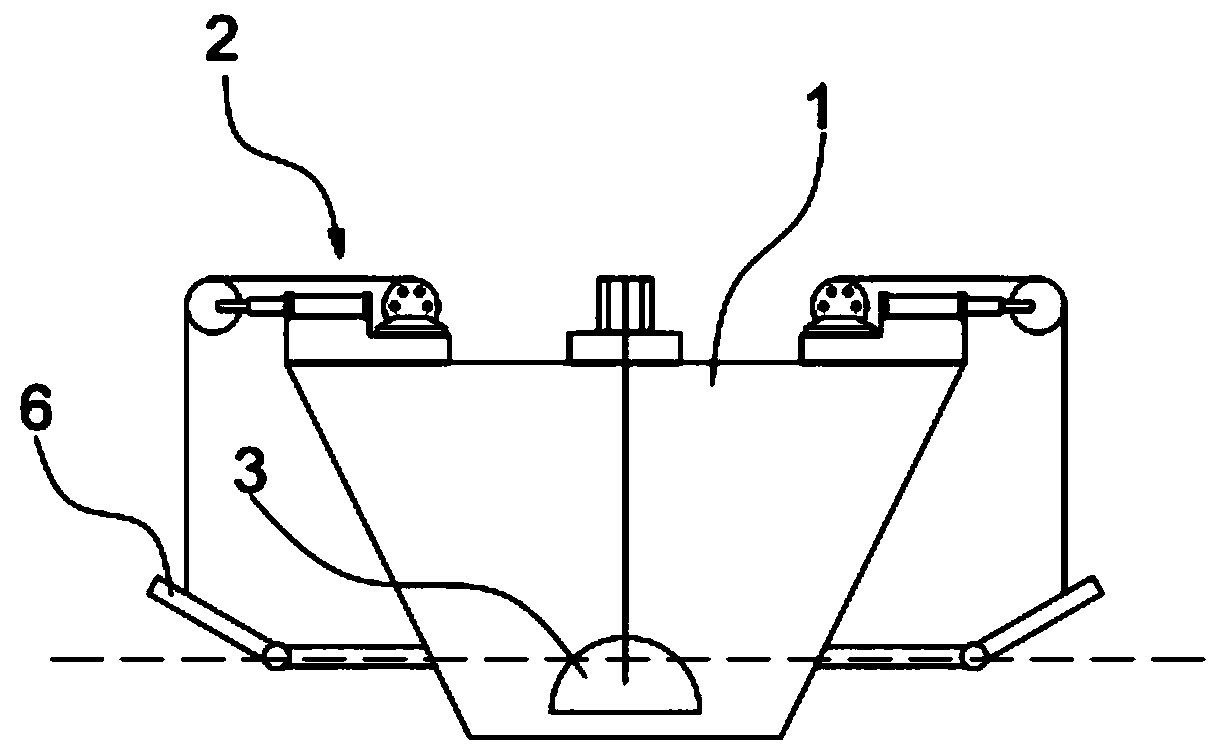

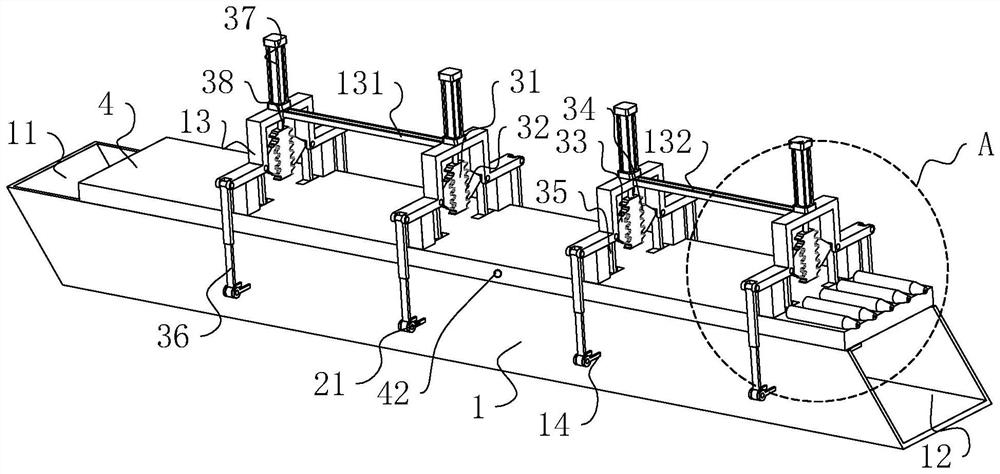

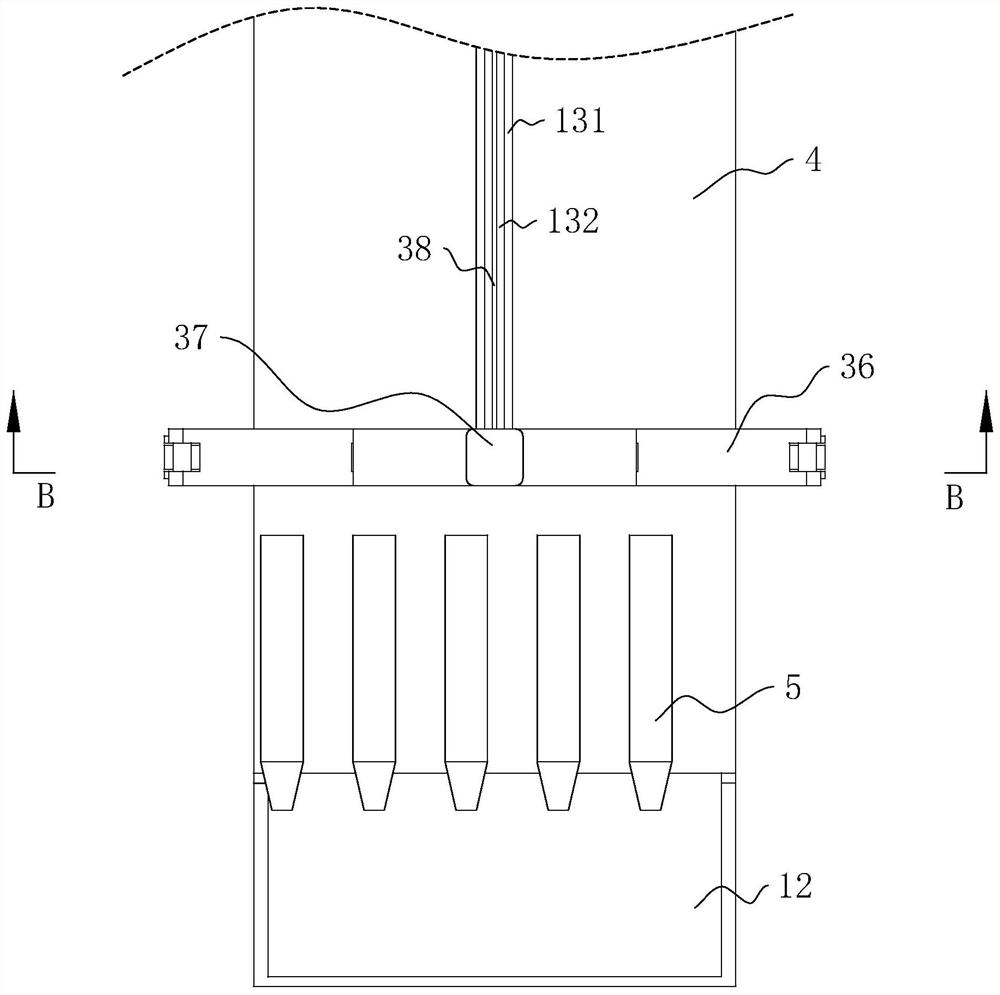

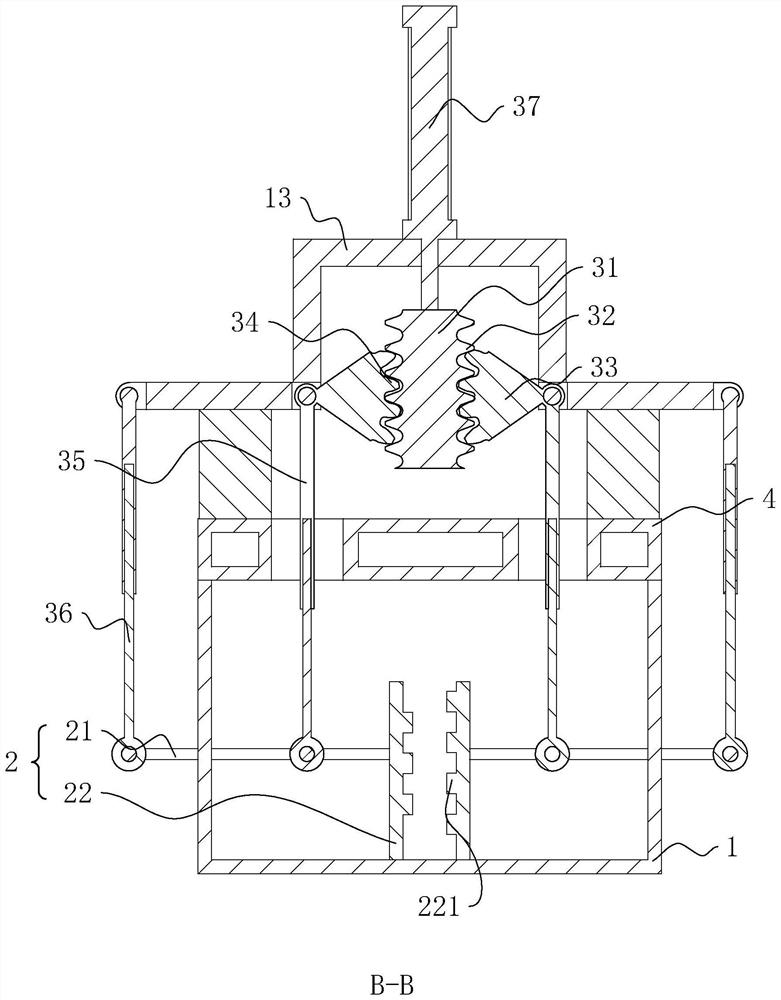

Unattended ship stabilizing device

ActiveCN109436233AImprove stabilityReduce hull contactVessel cleaningHullsMonitoring dataMarine engineering

The invention discloses an unattended ship stabilizing device, and belongs to the technical field of ship stabilizing. The unattended ship stabilizing device comprises a ship body. A flow breaking body is arranged at a stem position of the ship body and is in a conical shape. The rear end of the flow breaking body is connected with a connecting rod. The connecting rod is connected with the ship body through a damper. One end of the flow breaking body is connected with a rope body. The rope body is connected with a winding and unwinding mechanism on the ship body. The unattended ship stabilizing device has wave breaking, stabilizing and power generating functions and enhances the storing and balancing capacity and monitoring data precision of an unattended ship.

Owner:ZHEJIANG OCEAN UNIV

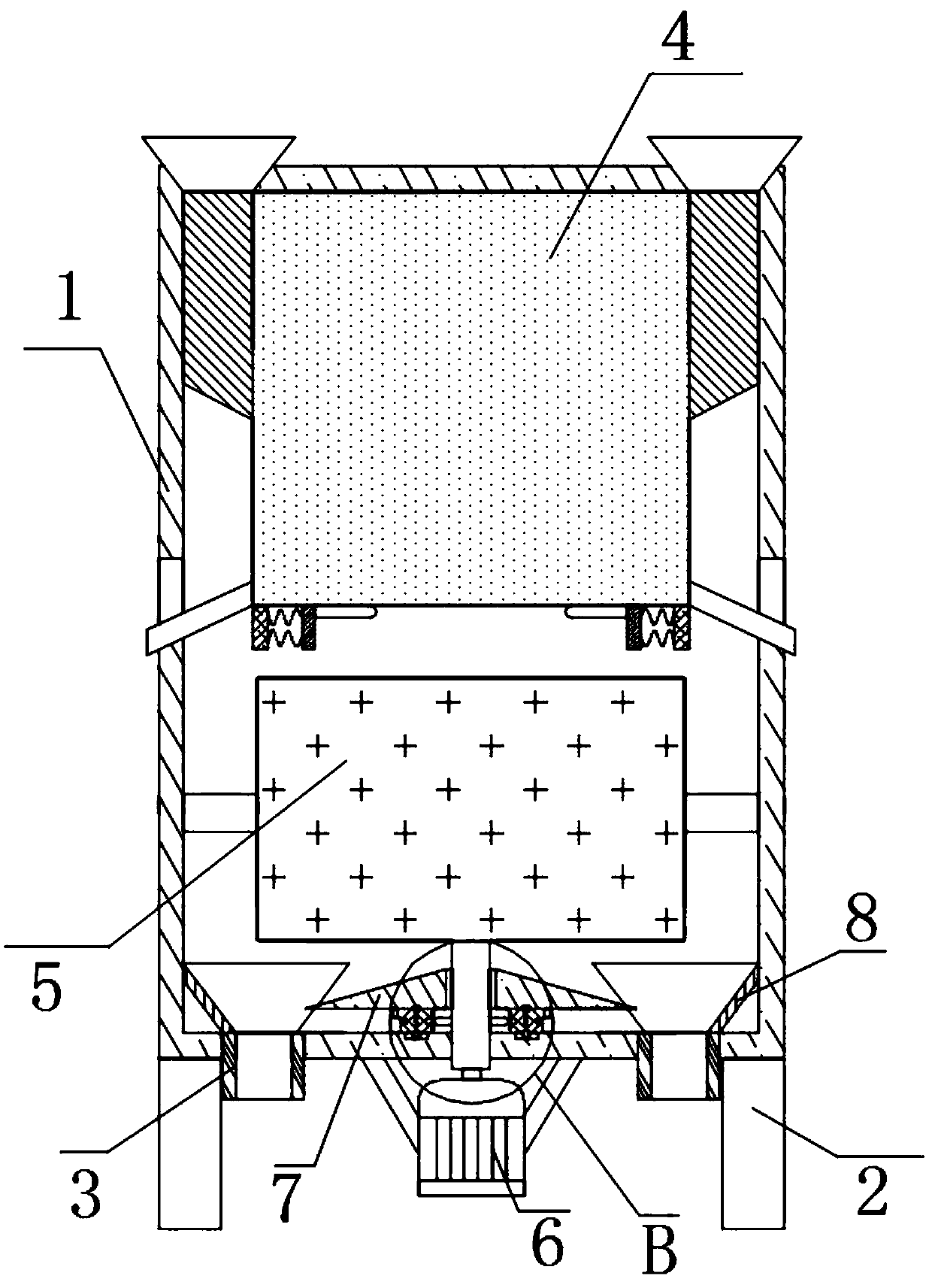

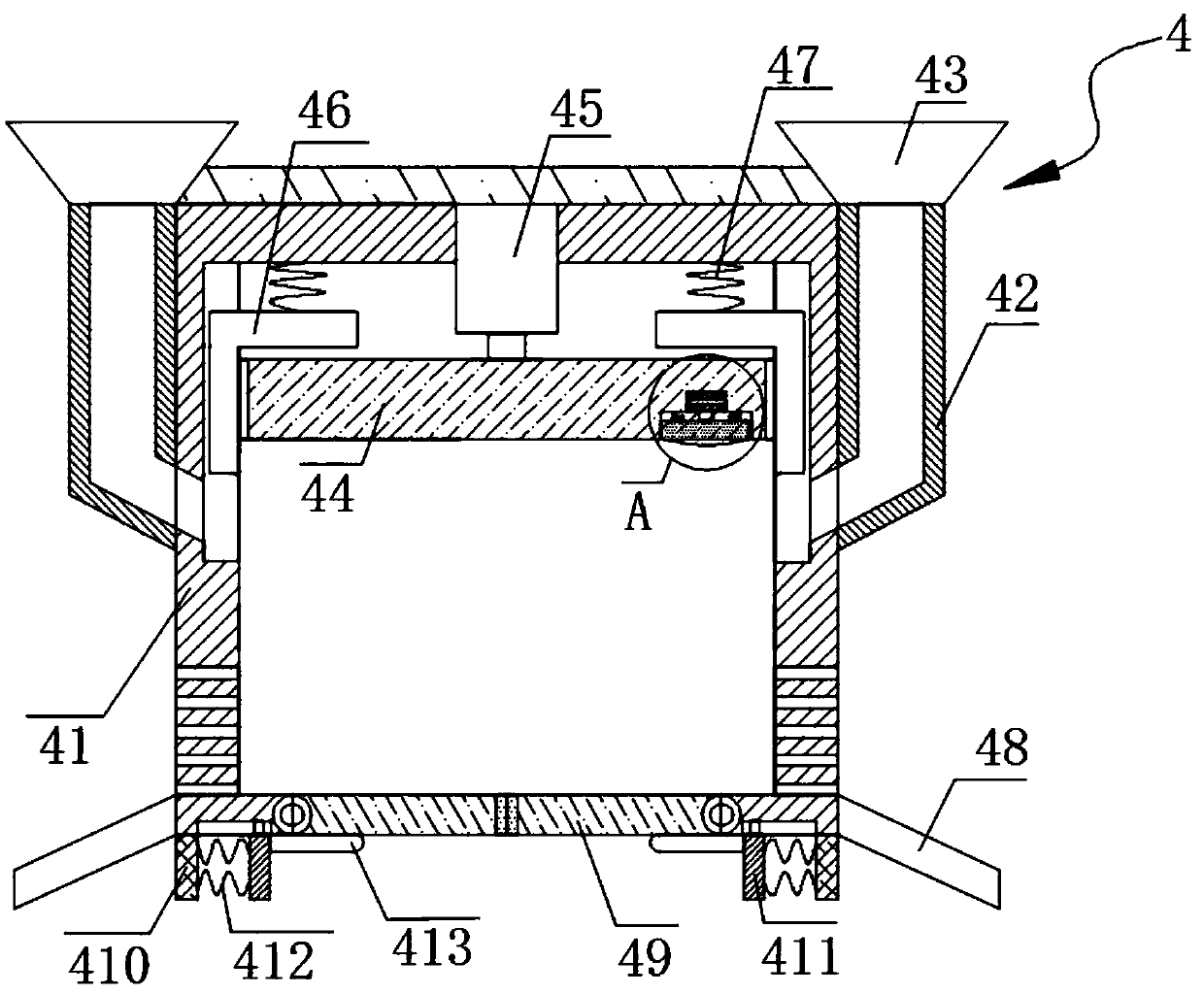

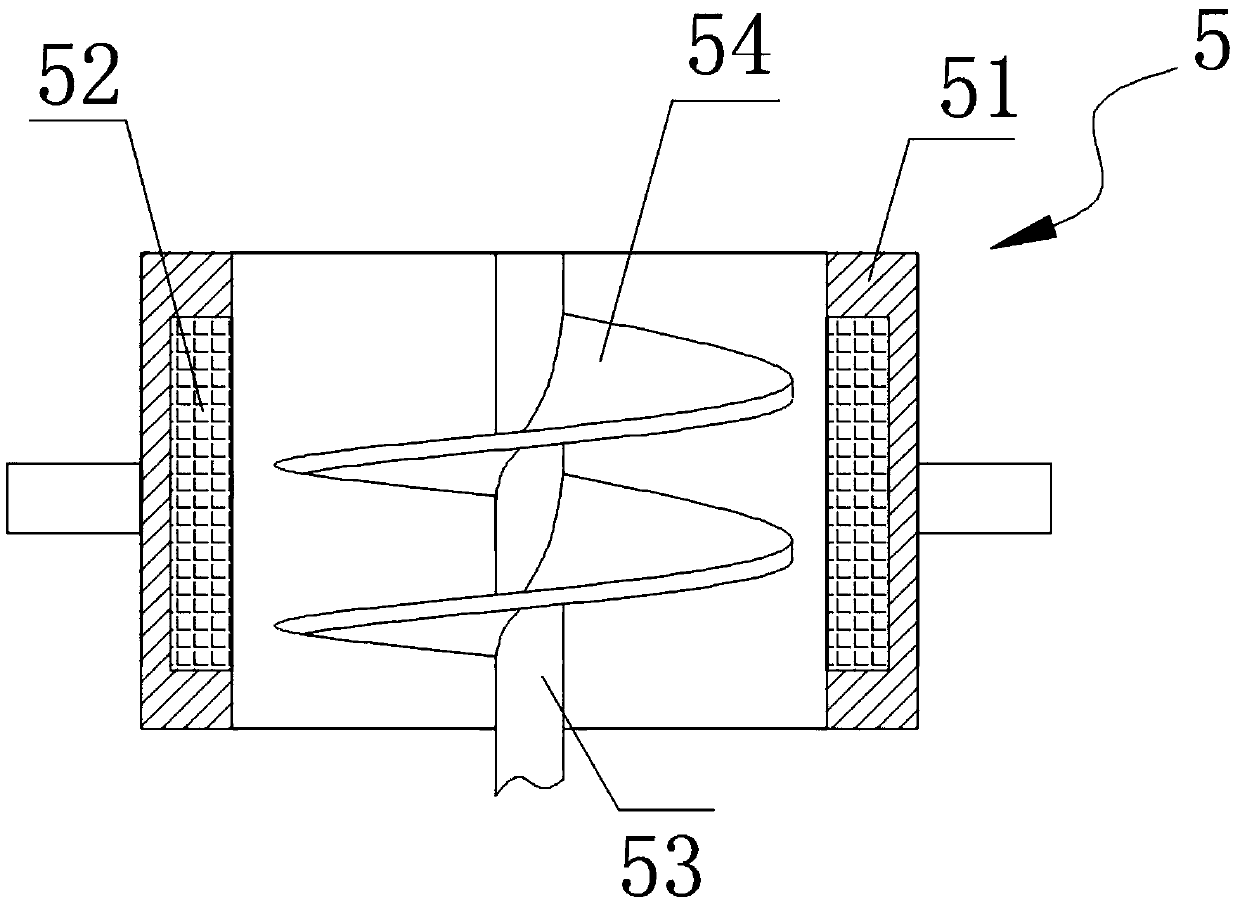

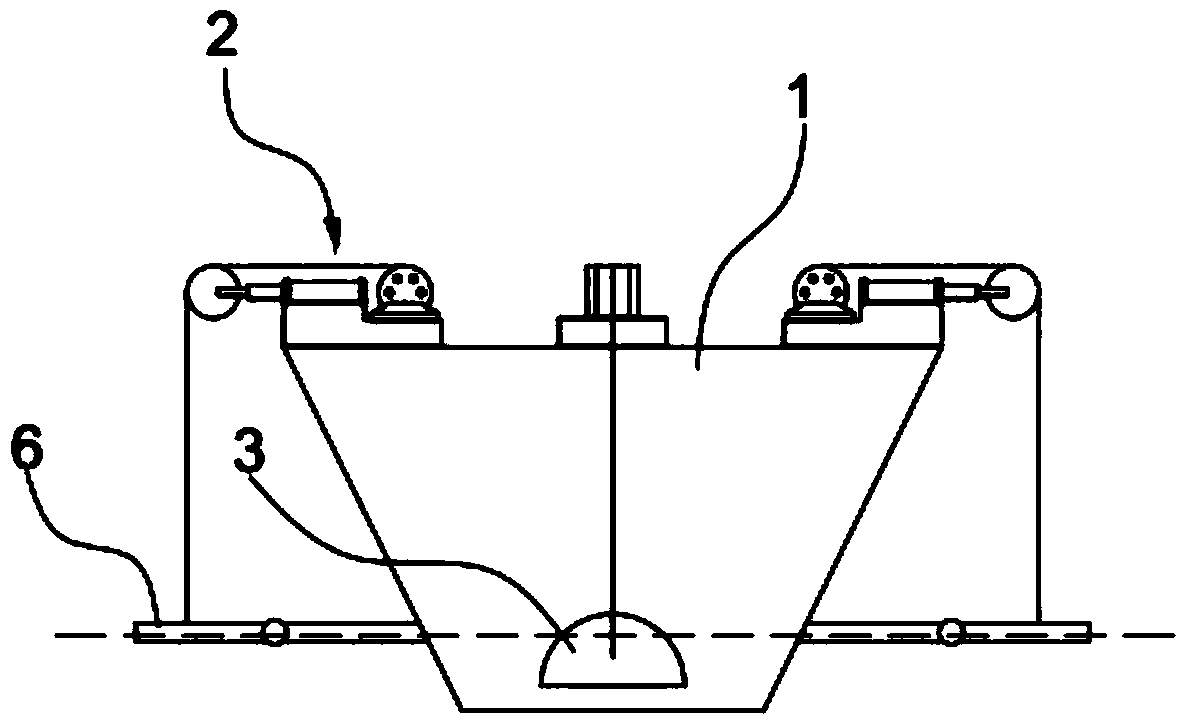

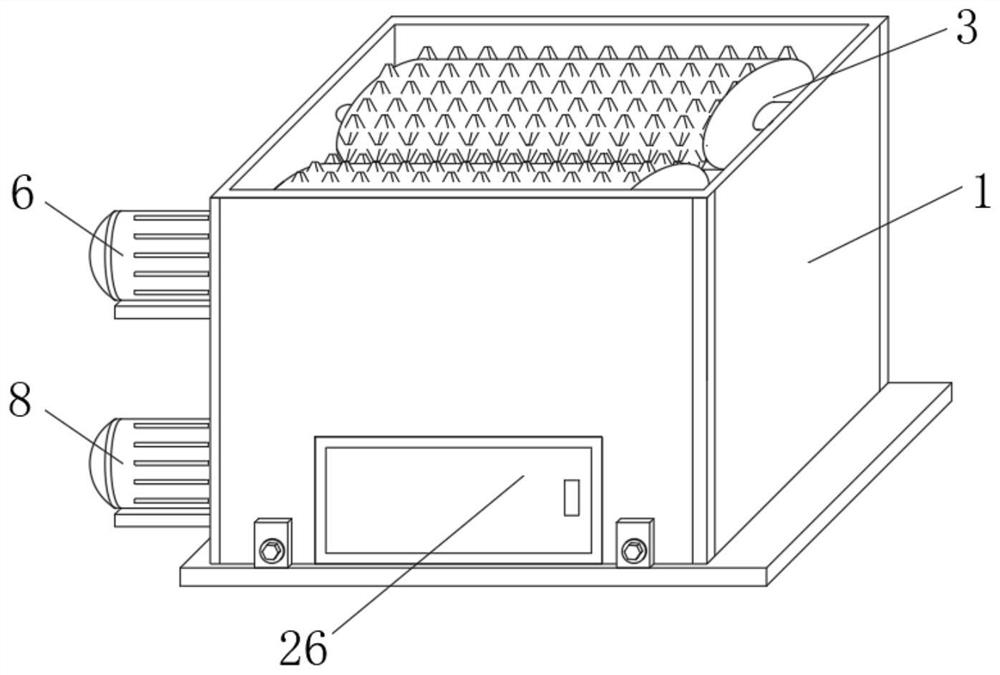

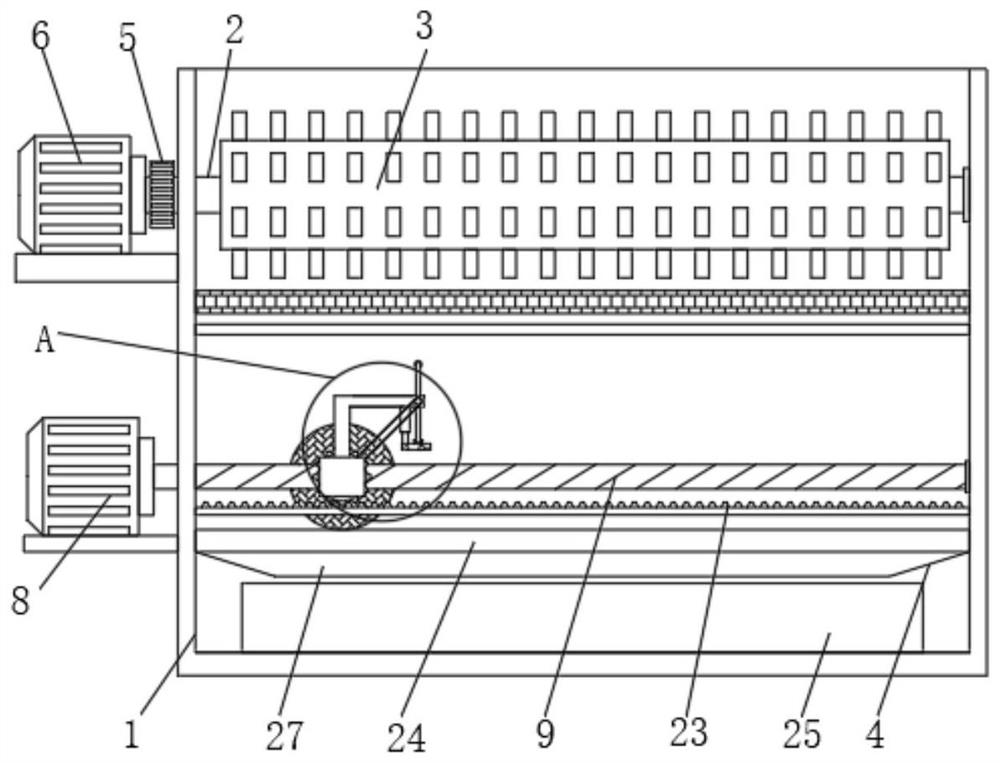

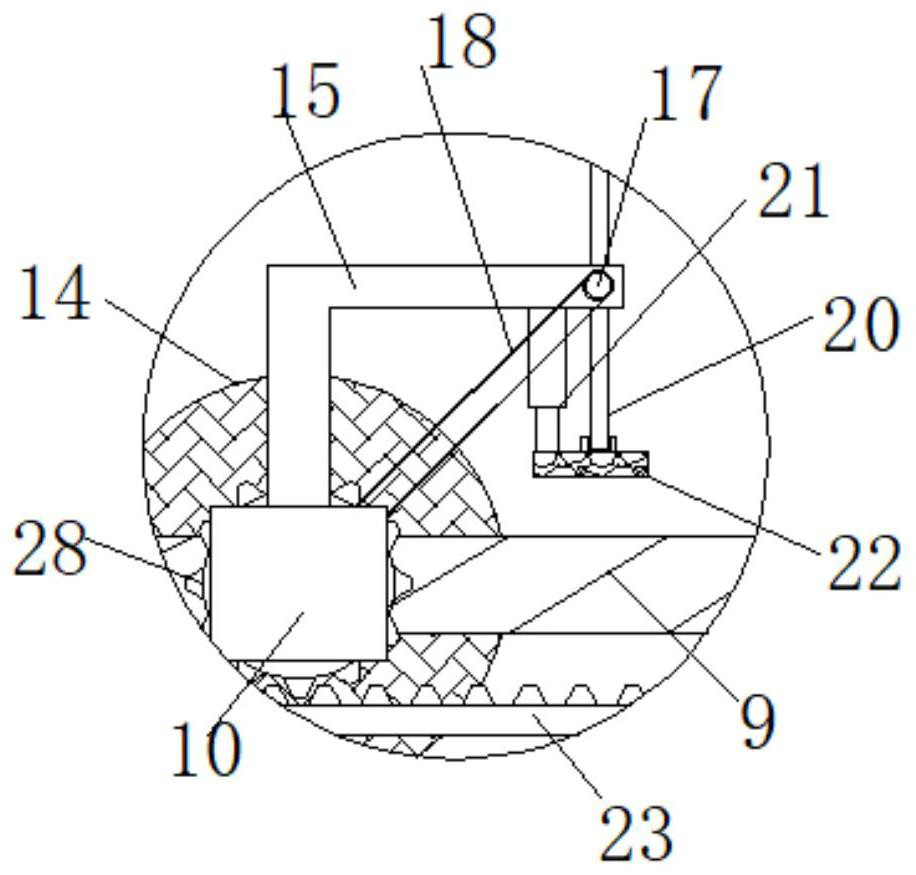

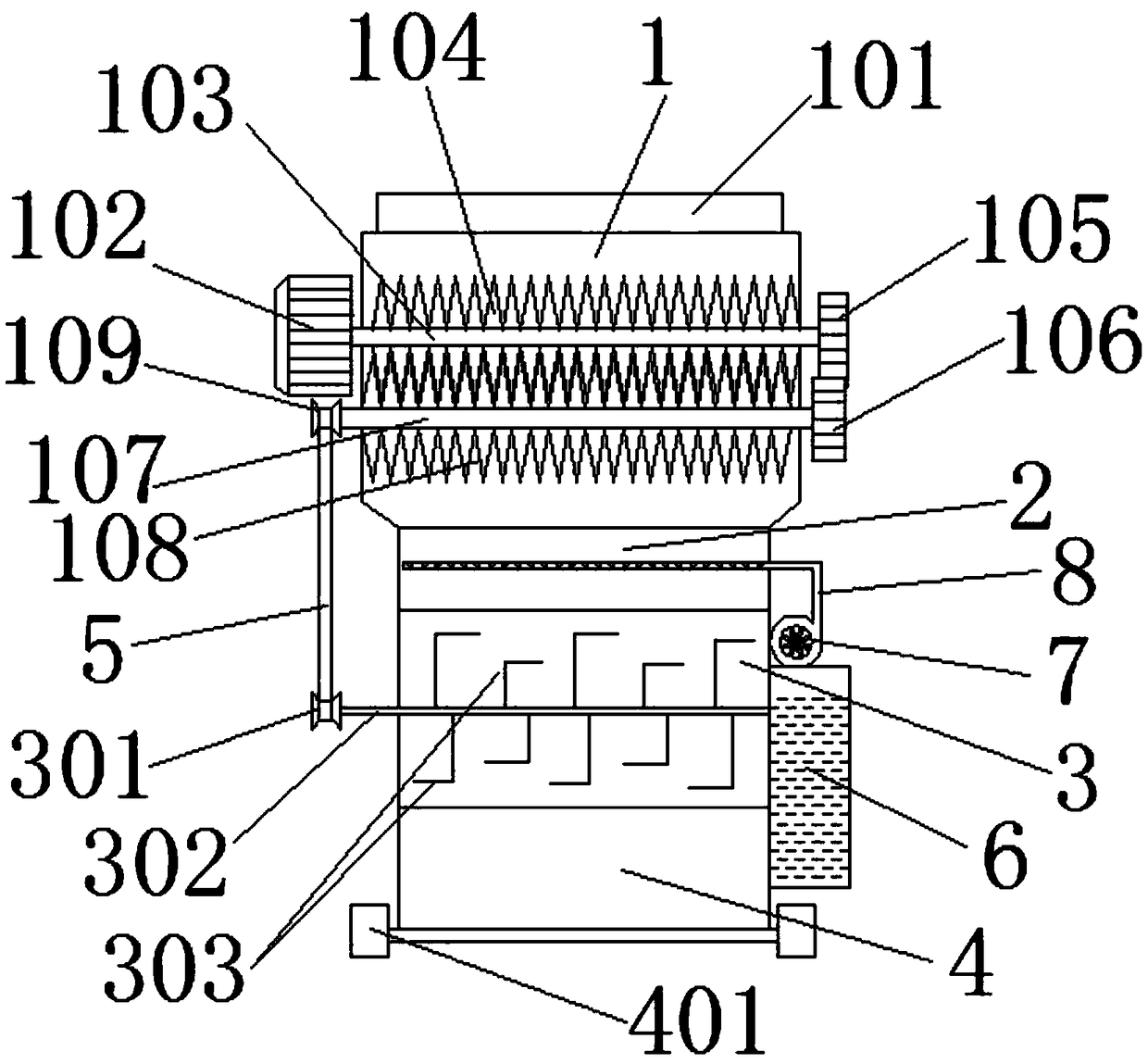

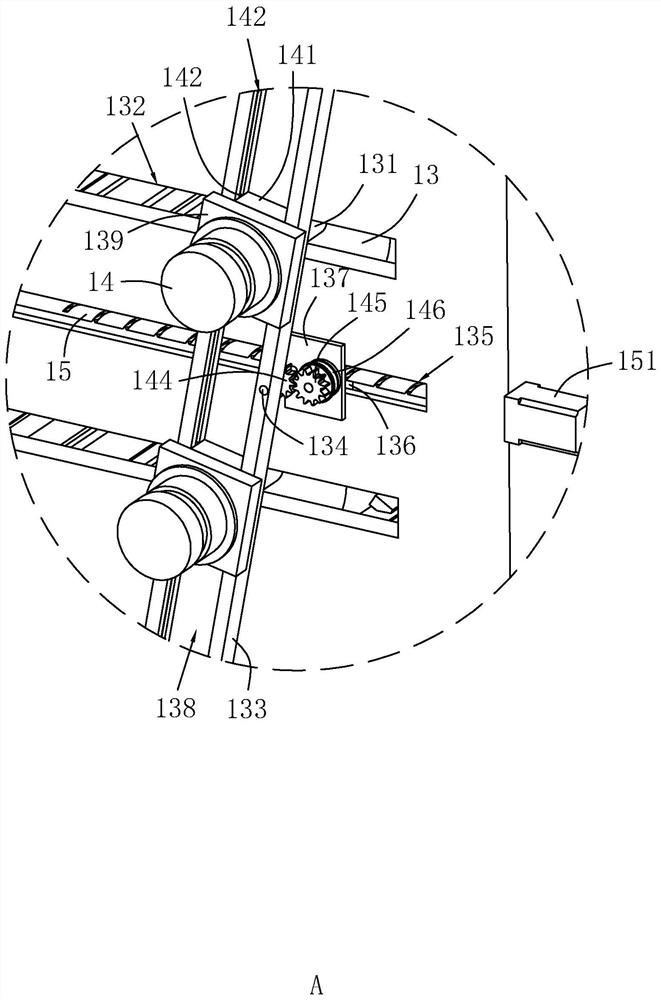

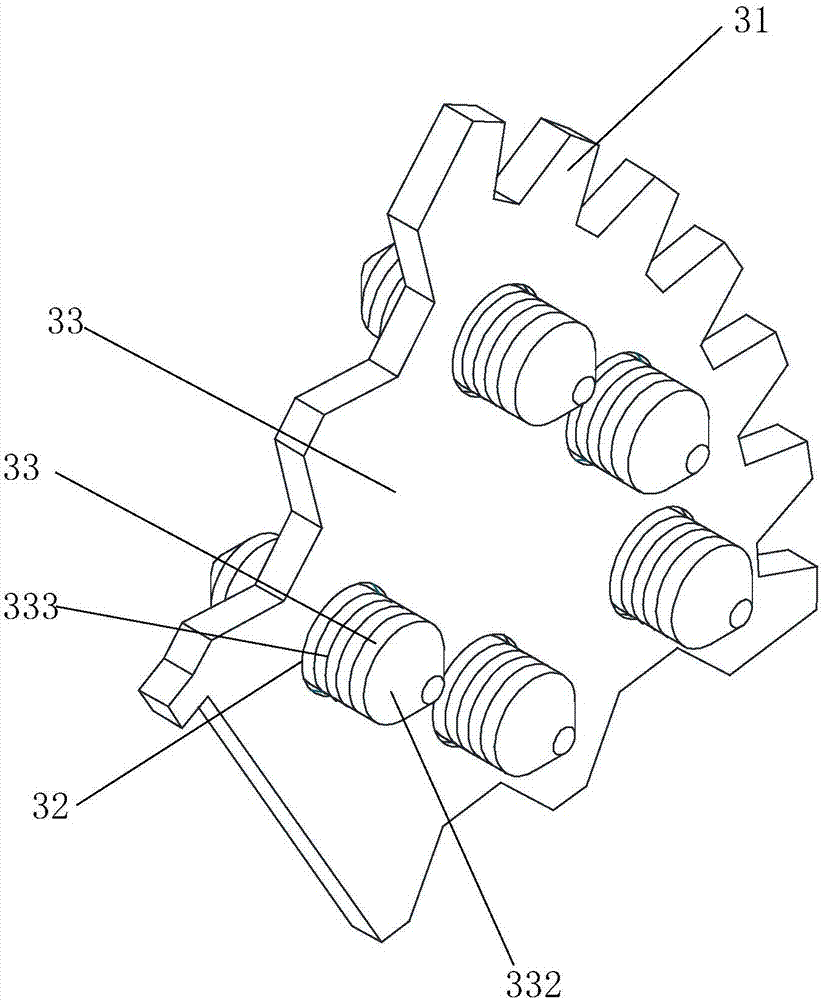

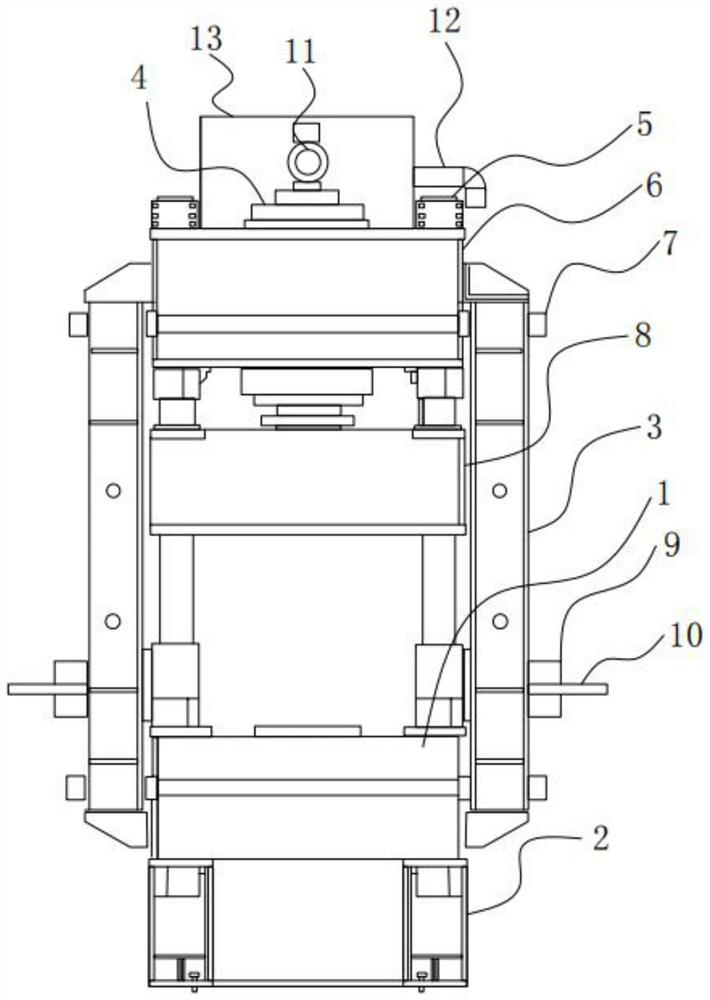

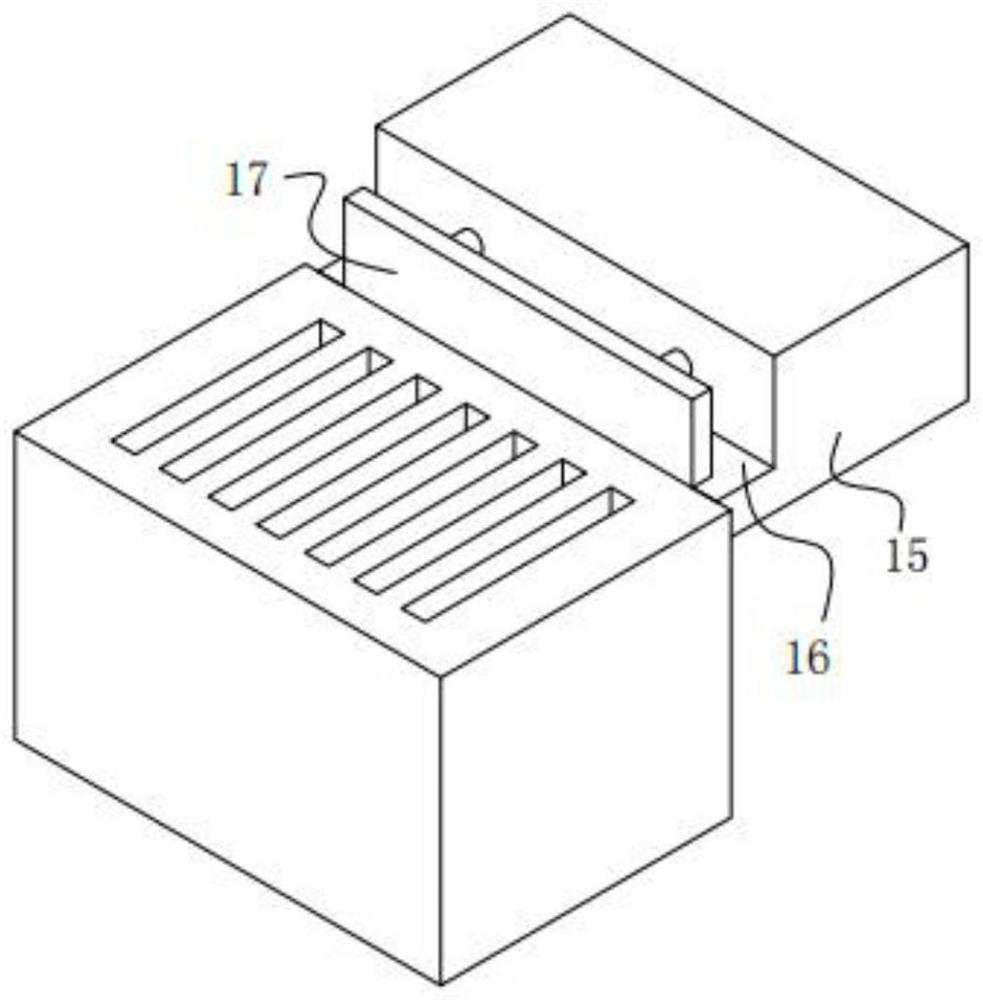

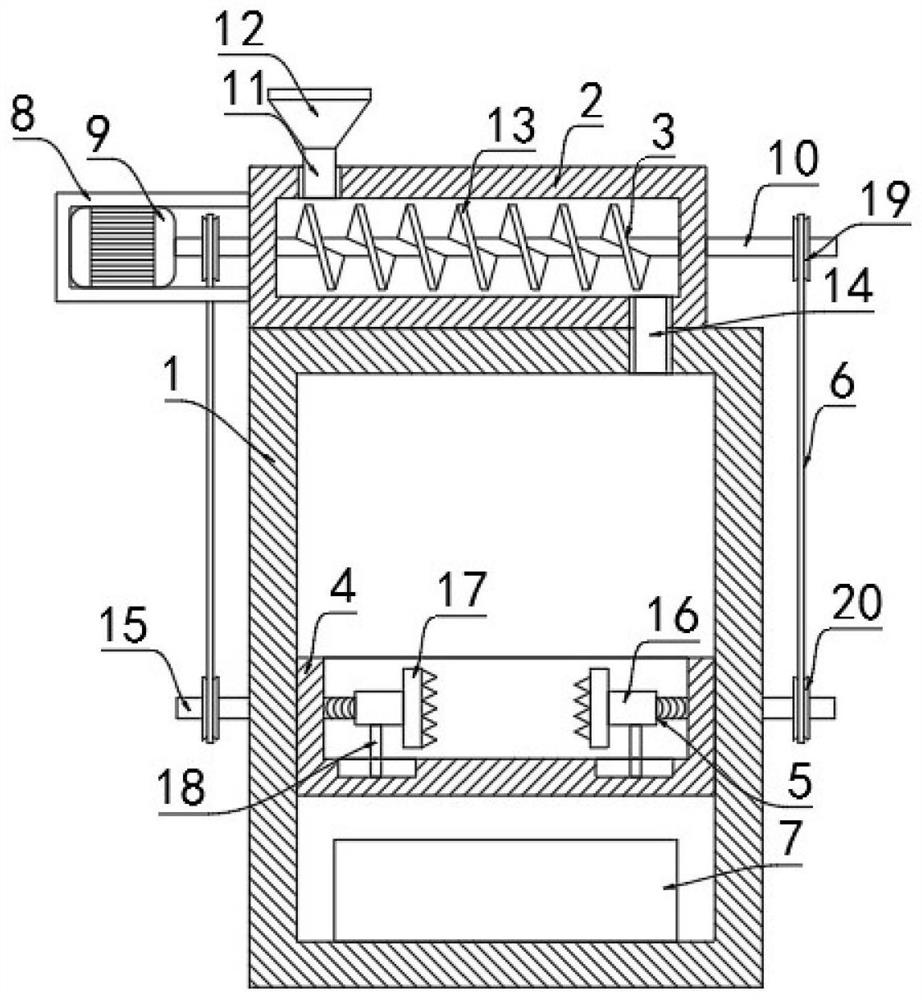

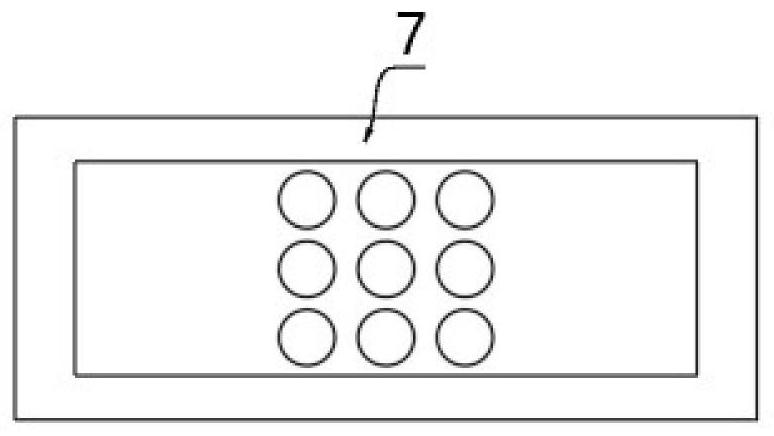

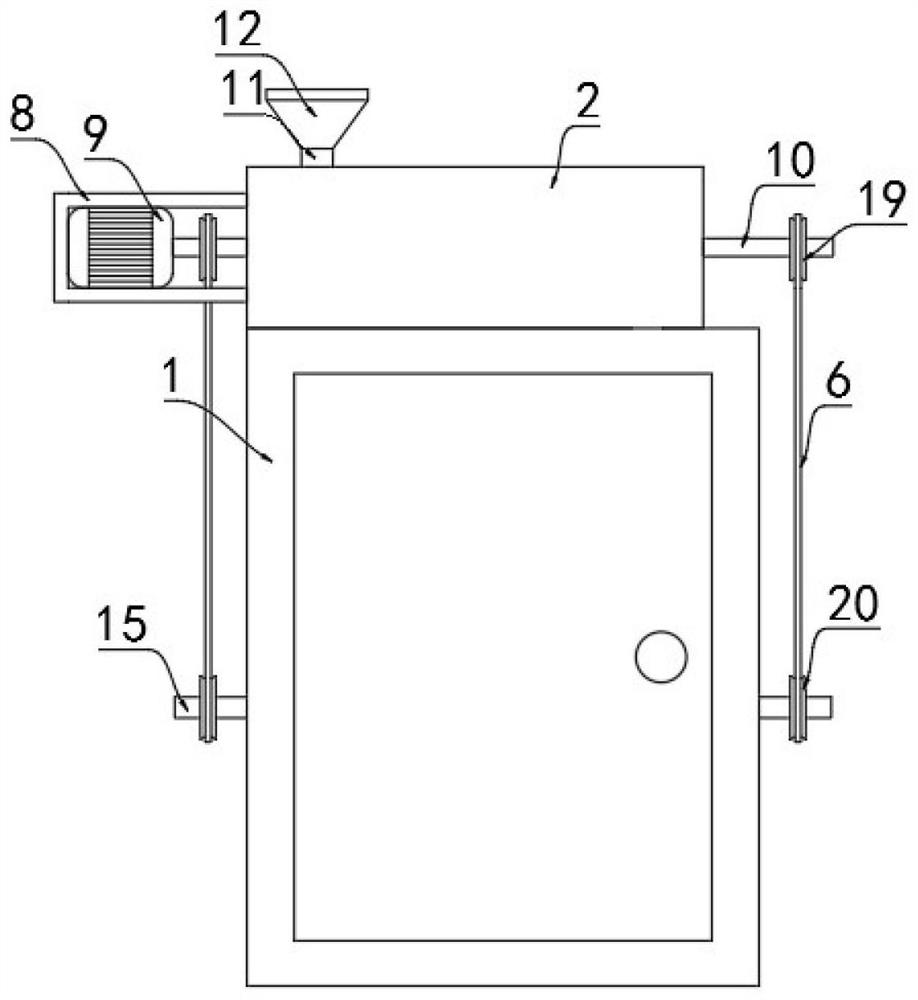

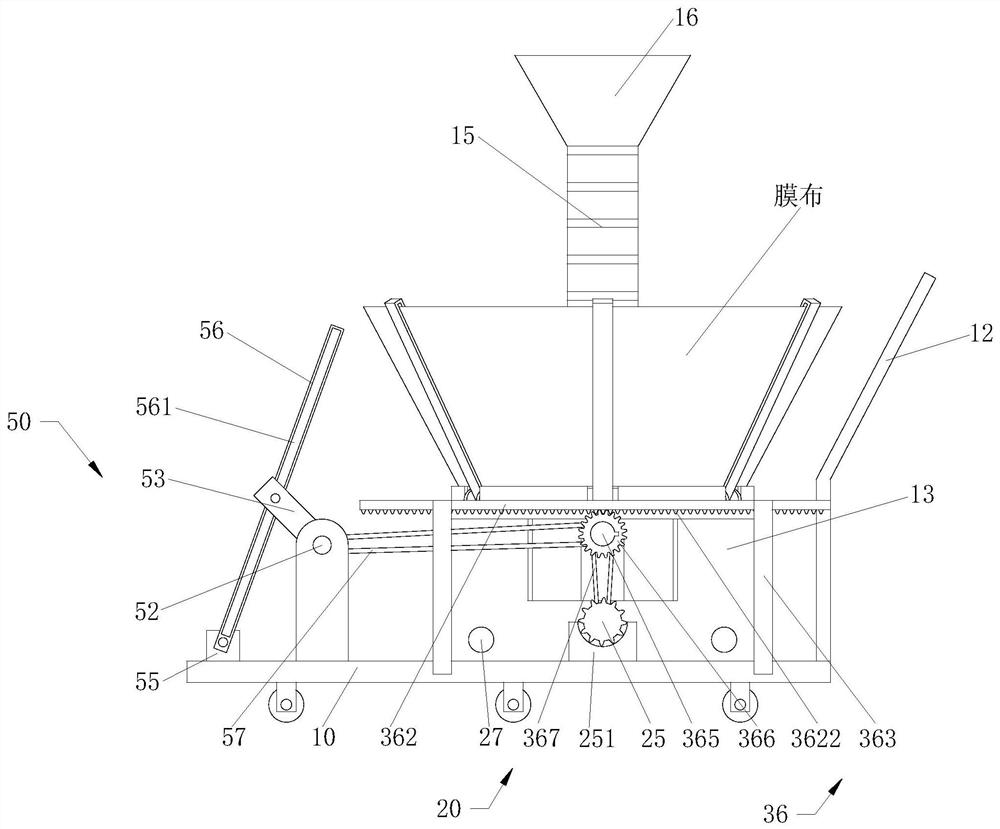

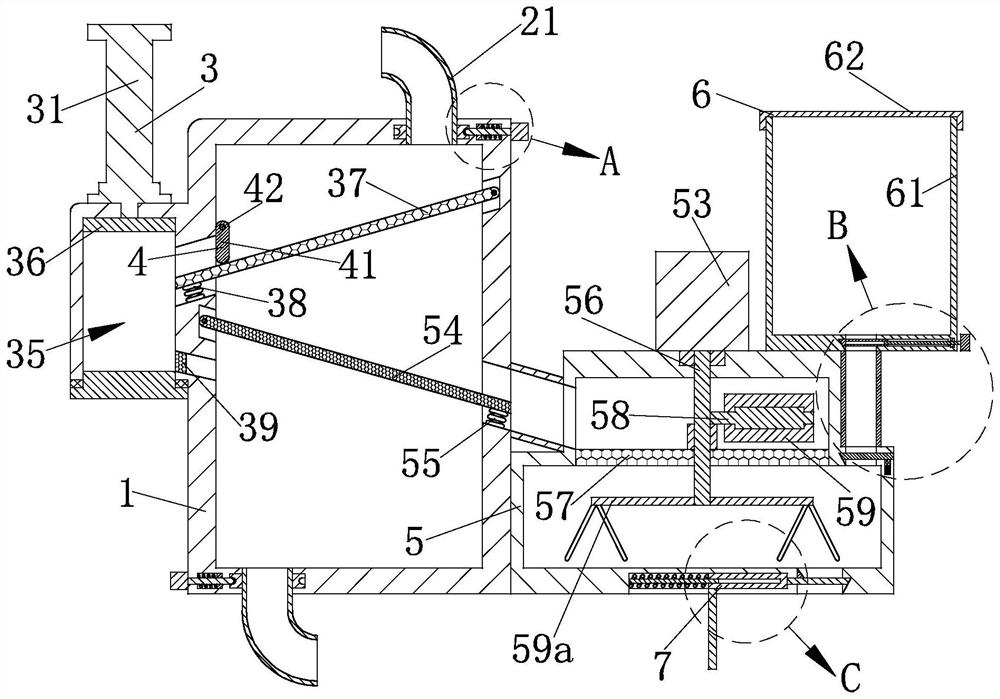

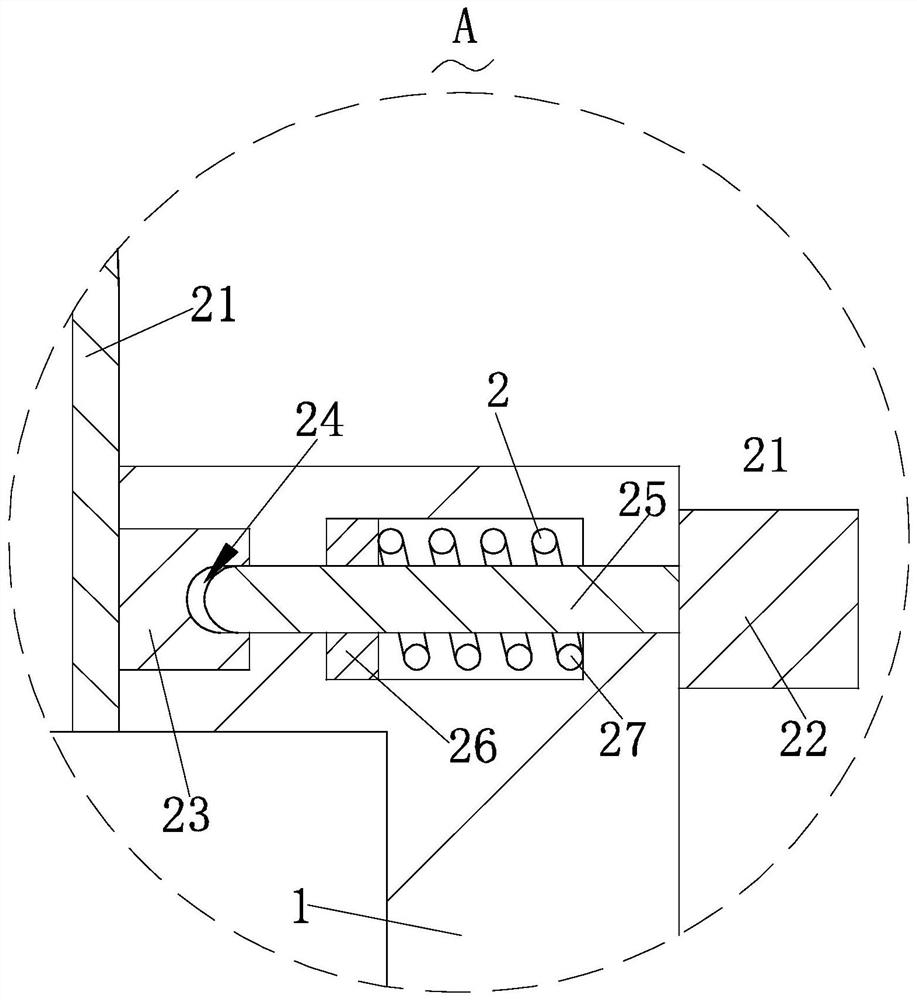

Composite manufacturing device for preparing recycled aggregate from construction waste and recycled aggregate preparation method

InactiveCN112691748AFacilitate subsequent processingHave a crushing effectGrain treatmentsAggregate (composite)Gear wheel

The invention relates to the technical field of construction waste regeneration, and discloses a method for preparing recycled aggregate from construction waste. A device comprises a shell, and further comprises two transverse rods which are respectively mounted between the left side wall and the right side wall of the interior of the shell and are arranged in parallel, crushing cutters are fixedly connected to the outer surfaces of the two transverse rods, and the left ends of the two transverse rods penetrate through and extend to the outer side of the shell and are fixedly connected with transmission gears, and the two transmission gears are meshed with each other; and the outer surface of the shell is fixedly connected with a first motor, and the output end of the first motor is fixedly connected with the left end of the transverse rod on the outer side. According to the manufacturing device for preparing the recycled aggregate from the construction waste, the waste is firstly crushed through the crushing cutters, then crushed through grinding of a grinding wheel and impacted by an impacting plate, the waste can be comprehensively crushed, aggregate particles are uniform, the particle size of the particles is small, the working requirement is met, repeated crushing is not needed, the working efficiency is high, and the working quality is good.

Owner:夏雪娟

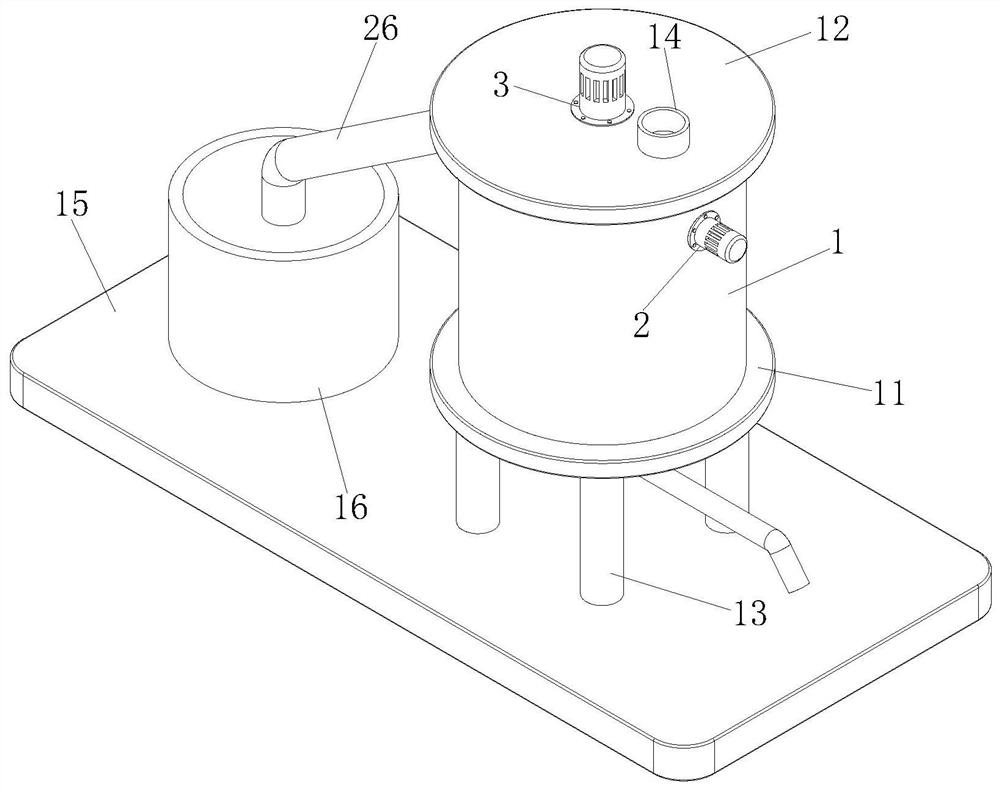

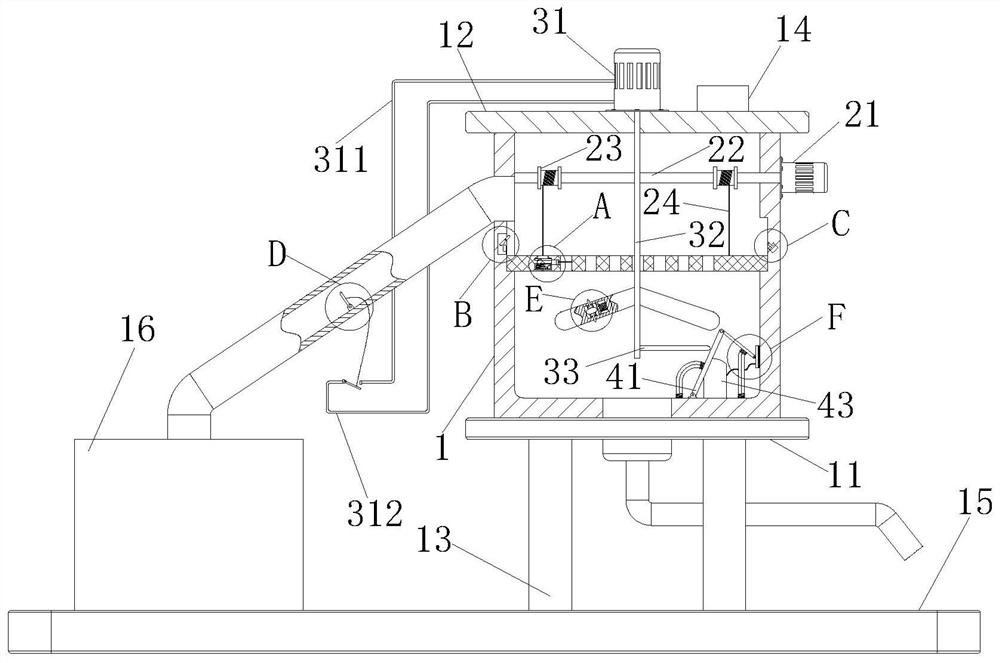

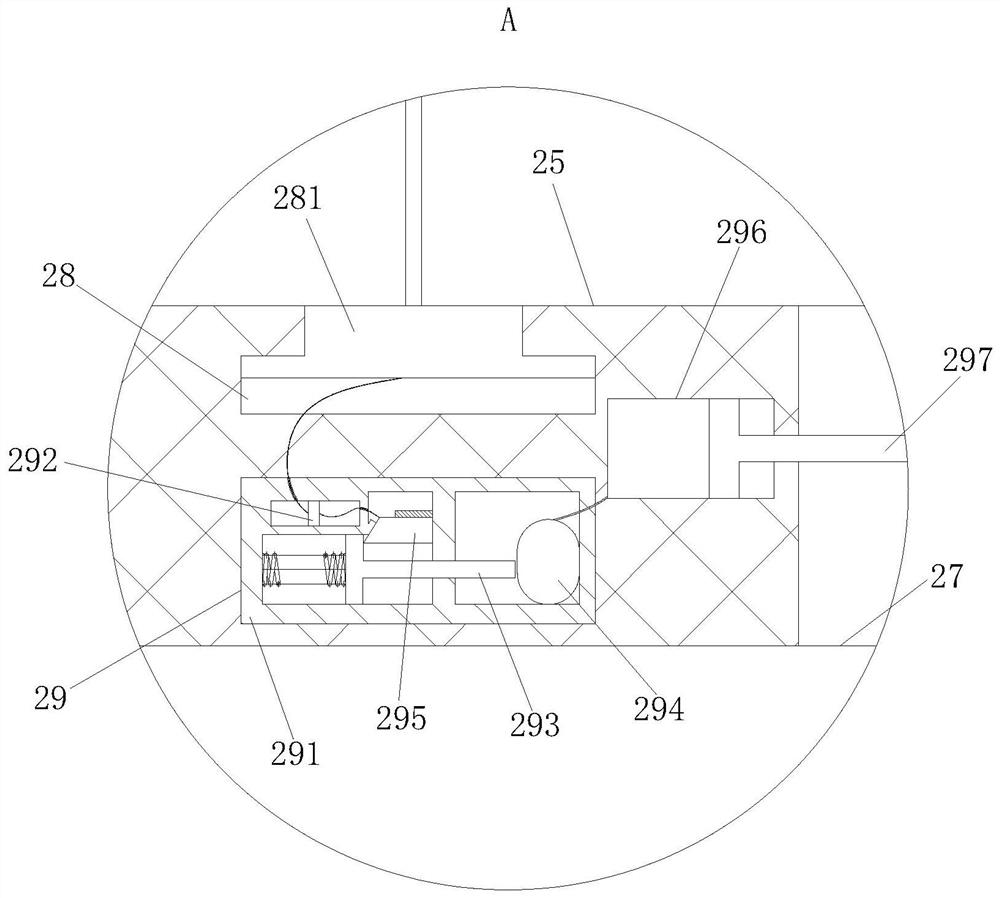

Sugarcane crushing and squeezing device used for agriculture

InactiveCN111660597AFacilitate pressing and discharge of waste residuePrevent slidingJuice extractionMetal working apparatusAgricultural engineeringAgricultural science

The invention belongs to the technical field of sugarcane production, and particularly relates to a sugarcane crushing and squeezing device used for agriculture. By aiming at the problem that in a squeezing process of an existing squeezing device, leakage holes are likely to be blocked by sugarcane slags so as to be unfavorable for discharging waste slags, the invention now puts forward the following scheme that the sugarcane crushing and squeezing device comprises a base of a flat square tube structure, wherein the middle of the upper surface of the base is provided with a round hole; a squeezing bucket is clamped in the round hole; the bucket bottom of the squeezing bucket is of a taper-shaped structure; and on the upper surface of the base, a C-shaped steel stand column of which the opening faces the middle is fixed near an edge. When the sugarcane crushing and squeezing device is used and sugarcanes need to be squeezed, blocked sugarcanes only need to be added into the squeezing bucket, and then, the rotation of a transmission rod is controlled to squeeze the sugarcanes. During squeezing, extruded juice can be discharged out of the squeezing bucket along a notch on the side surface of an end cap, and in addition, when waste slags need to be cleaned, the end cap only needs to be slightly raised to slowly discharge the waste slags from the bottom.

Owner:烟台增鲜农业科技有限公司

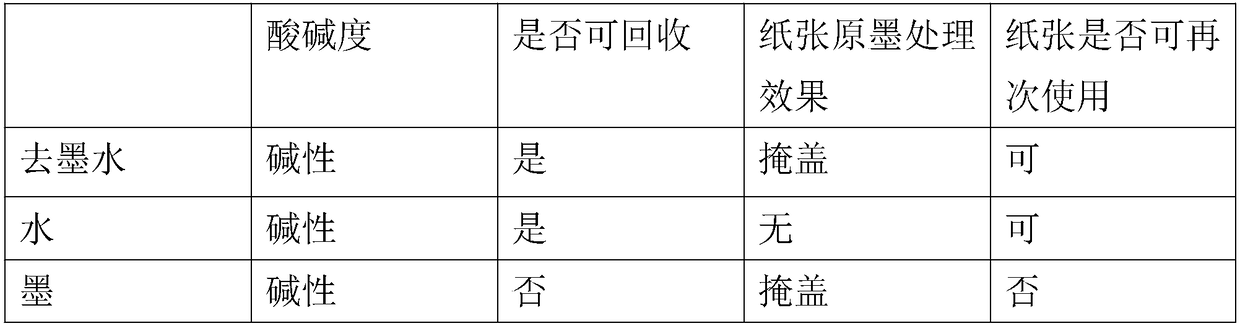

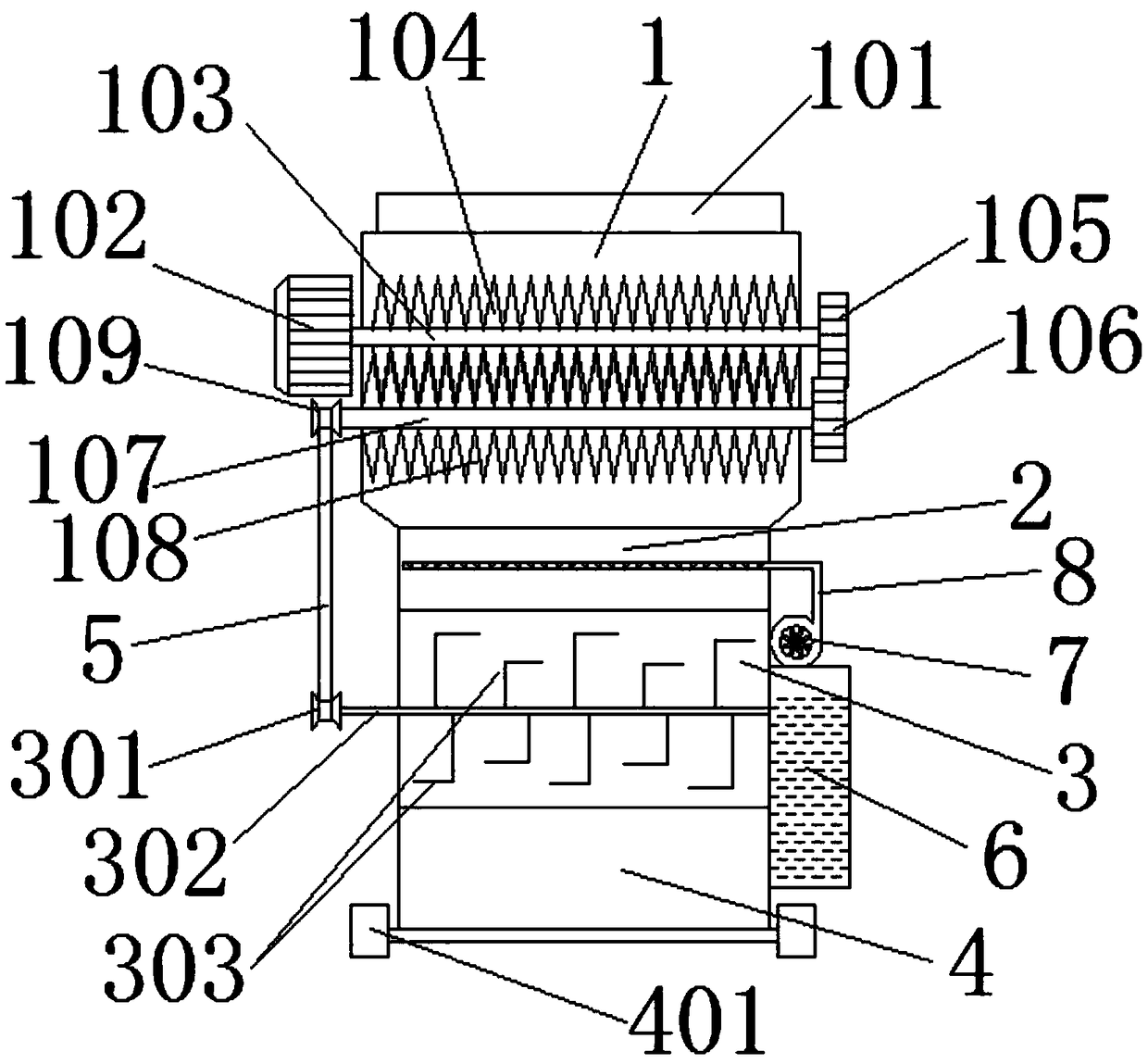

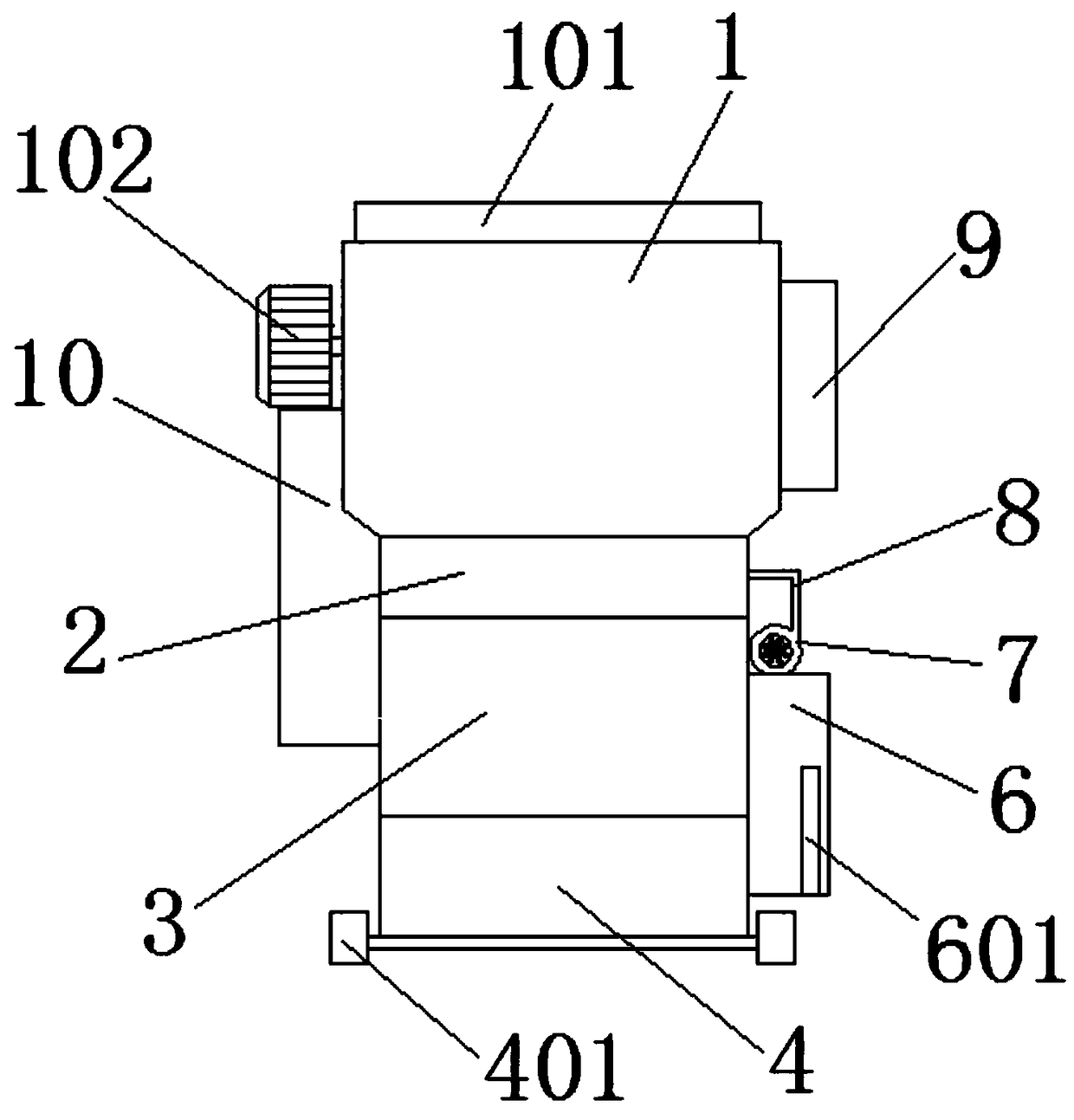

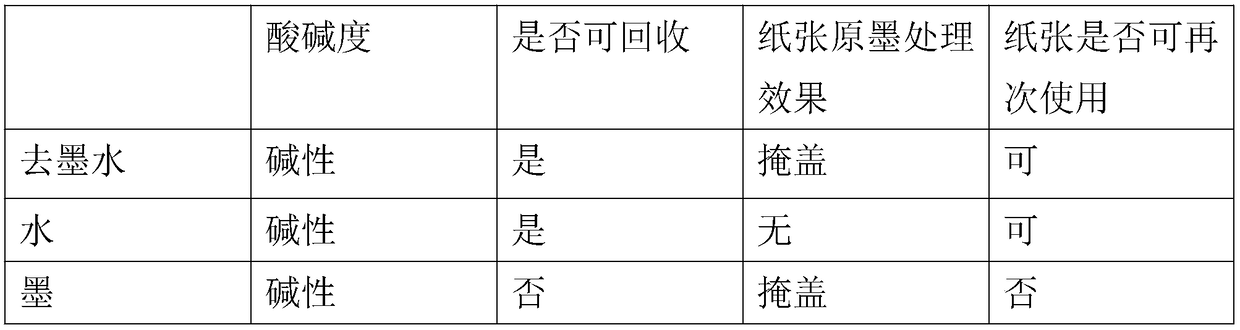

Anti-leakage document crushing equipment

The invention discloses anti-leakage document crushing equipment, and relates to the technical field of waste and abandoned document file destroy. The anti-leakage document crushing equipment comprises a crushing machine, wherein a spraying chamber is arranged inside the crushing machine and is filled with purpose-made ink removal liquid. The ink removal liquid is characterized in that basic nitrogen compound combining agents combined with basic nitrogen compounds in the ink removal liquid are combined with nitride combining agents in ink; when the ink removal liquid is in contact with ink onpaper, good decoloring dye is formed; the whole is basic; the paper is not damaged; the ink on the paper cannot be immediately removed, but the decoloring trends of the ink marks on the paper are reduced along with time, so that the covering and hiding functions are reached; meanwhile, when the liquid is sprayed onto the paper, a thin film is formed; the re-writing time can be reduced during the repeated utilization of paper; the diffusion of the ink removal liquid to the paper can also be reduced; the re-writing quality can be improved; no pollution is caused; the recovery and reutilization can be realized; the resources are saved.

Owner:靳月华

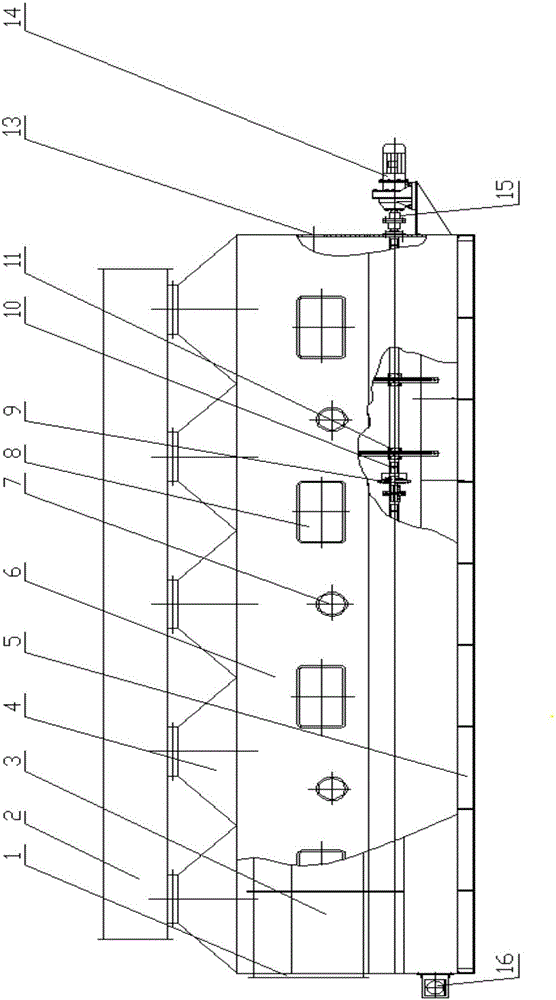

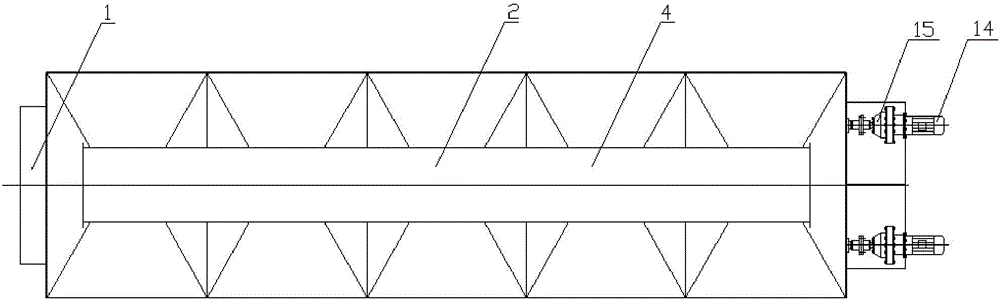

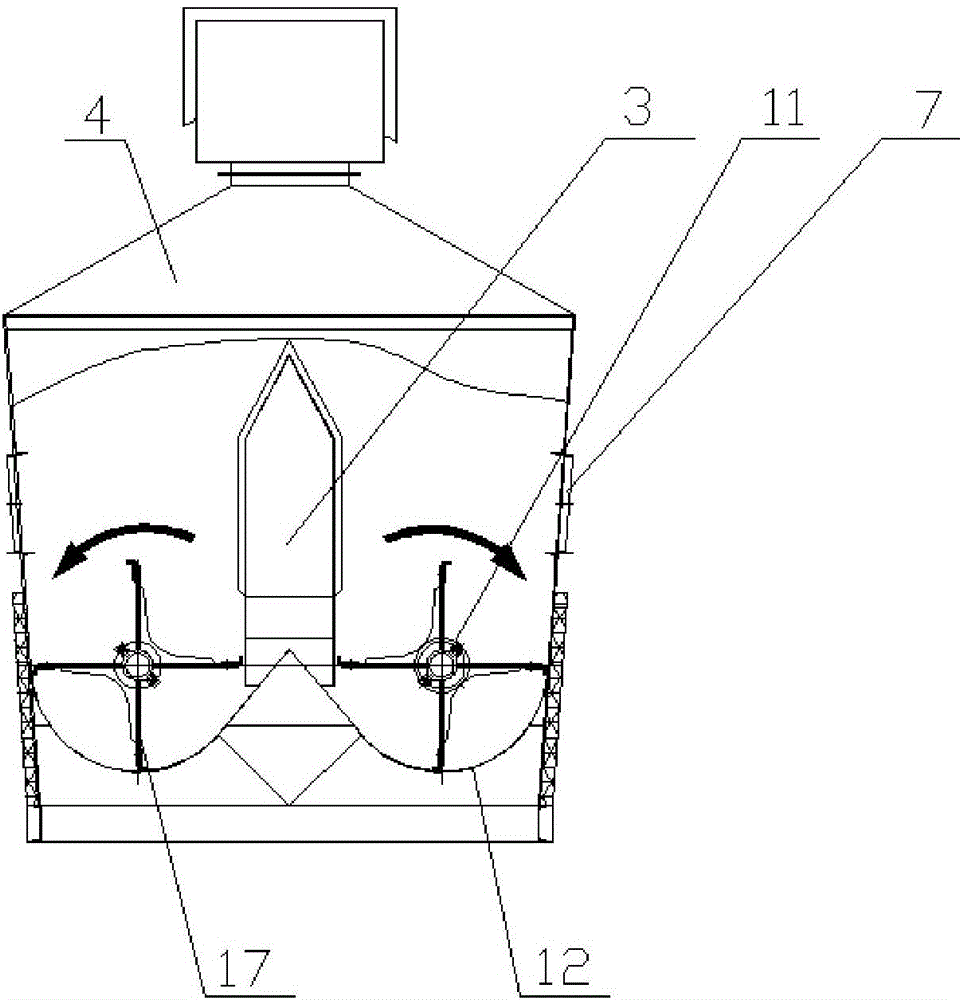

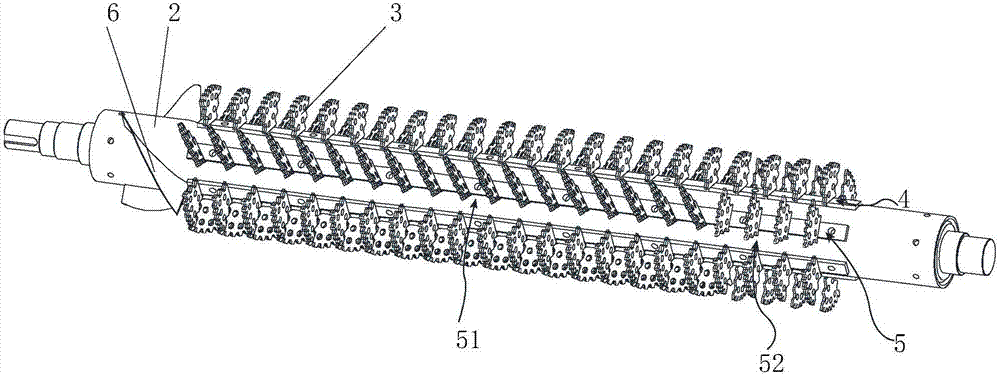

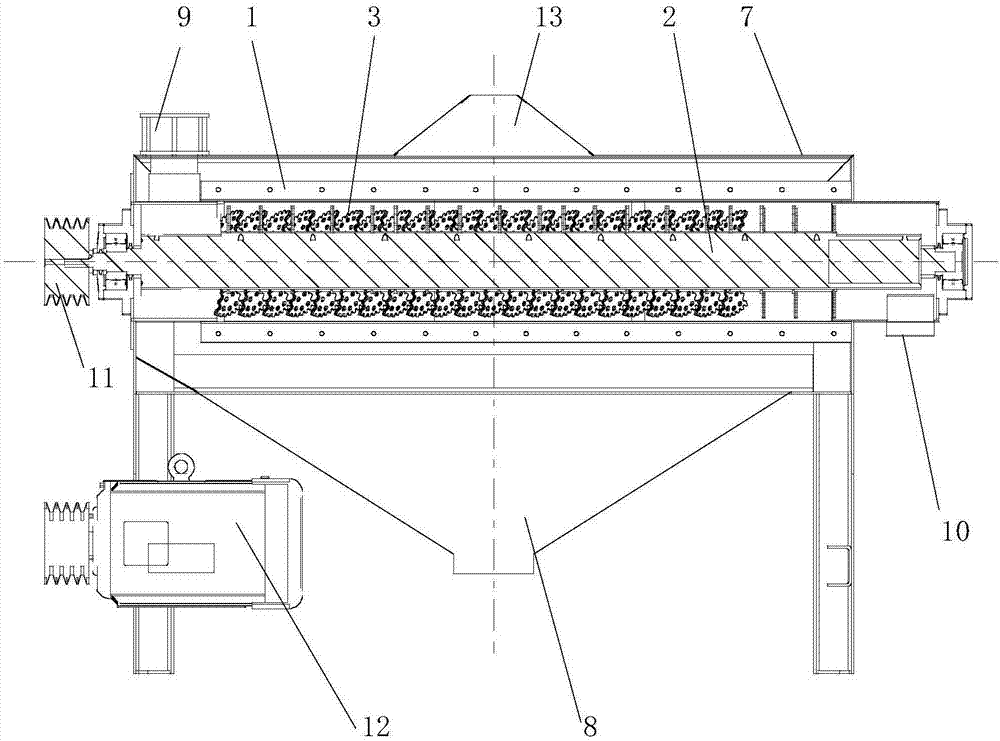

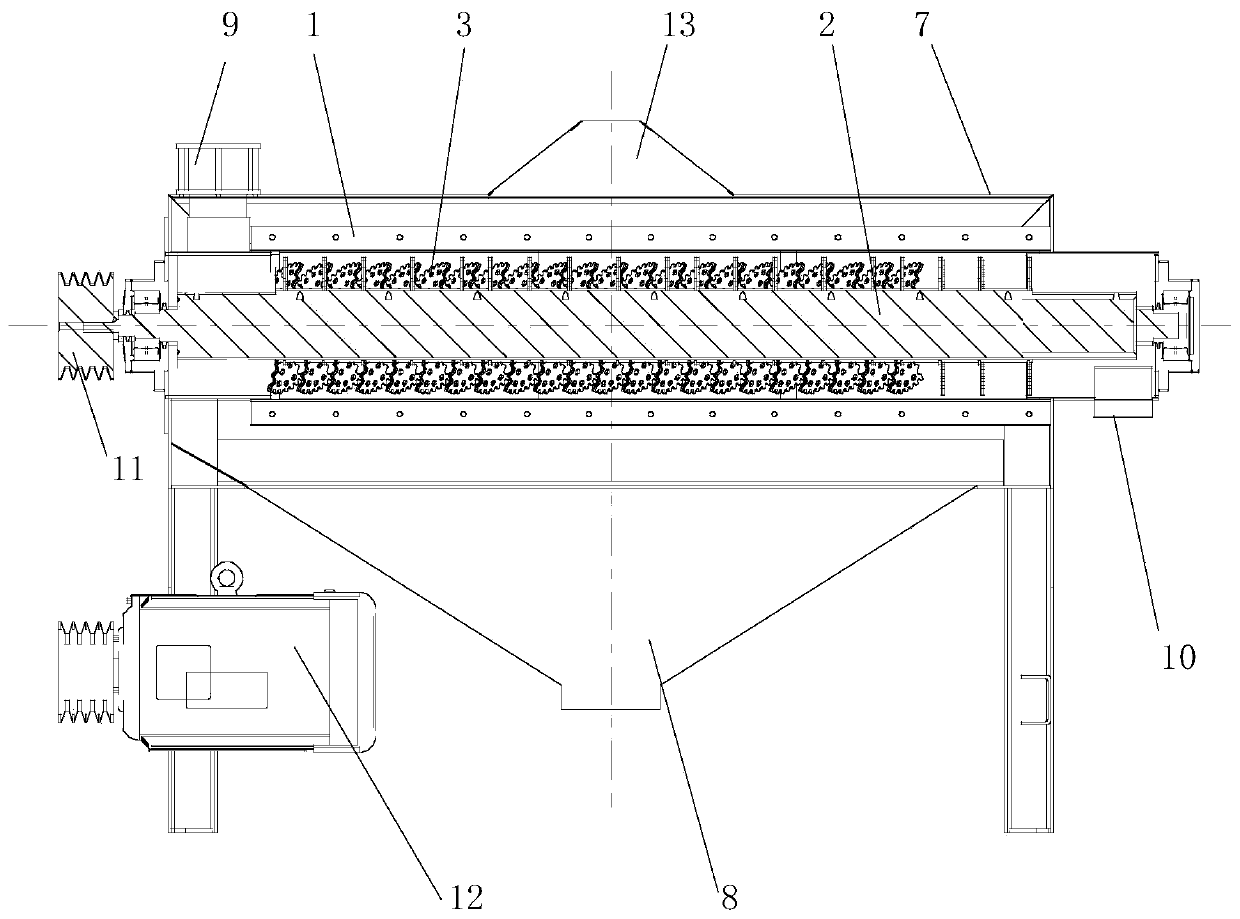

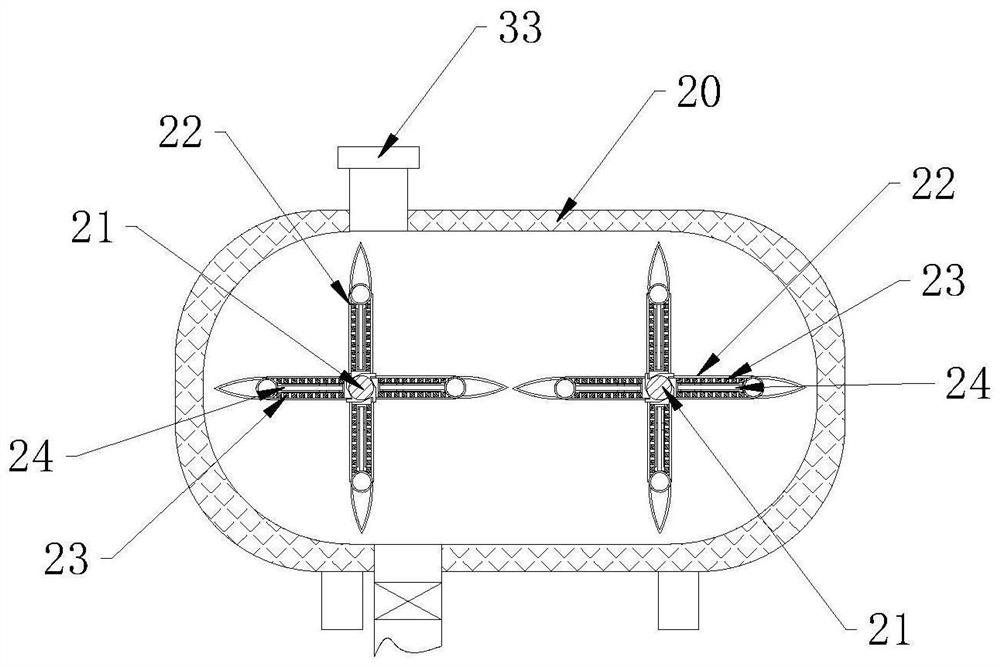

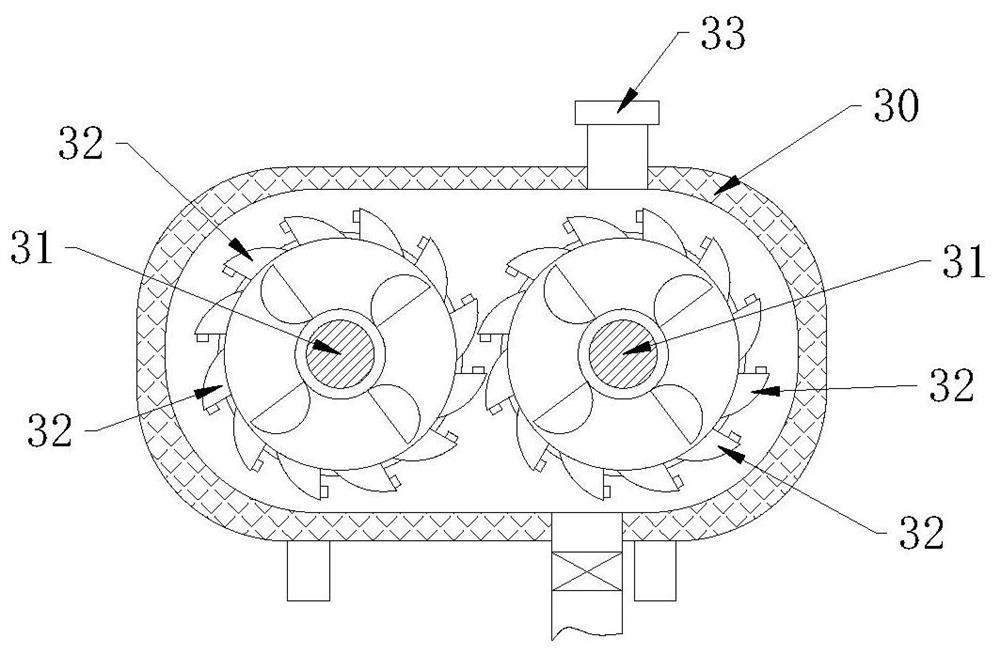

Horizontal fluidized stirring dryer of beer grains

InactiveCN106766685AHave a crushing effectGuaranteed loosenessDrying solid materials with heatDrying gas arrangementsPulp and paper industry

The invention relates to a horizontal fluidized stirring dryer of beer grains. The horizontal fluidized stirring dryer of the beer grains comprises a machine frame and a housing installed on the machine frame. The central position in the housing is provided with a blast channel. The blast channel divides the housing to two drying chambers. A stirring shaft is respectively installed in each of two drying chambers. The stirring shafts are installed on a pair of bearing seats at two ends of the housing. The stirring shafts are driven to be rotated by a motor installed at the exterior of the housing through a transmission mechanism. A plurality of stirring blades is uniformly distributed on the stirring shafts. An arc plate is installed on the inner wall of the drying chambers below the stirring shafts. One end of each of two drying chamber housings is provided with a material inlet, and the other end of the housing is provided with a material outlet and an air inlet. The upper part of the housing is provided with an air inducing pipe. The end part of the blast channel is communicated with the air inlet. The bottom of the blast channel is provided with an air guiding plate. The top of the housing is provided with an air inducing cover. The structure design of the horizontal fluidized stirring dryer of the beer grains is scientific and reasonable. The material is stirred to be fluidized state by the stirring blades, and the thick beer grains are crushed, so the loose degree of the beer grains is guaranteed, the drying efficiency is improved, and the integrated drying treatment of the bear grains is realized.

Owner:宁波沪港食品机械制造有限公司

File pulverizer

The invention discloses a file pulverizer and relates to the technical field of waste file data destruction. The file pulverizer comprises a pulverizer body. A spray chamber is arranged in the pulverizer body and filled with a special ink eradicator. According to the ink eradicator, a basic nitrogen compound bonding agent for basic nitrogen compounds of the ink eradicator is combined with a nitrogen compound bonding agent of ink, when the ink eradicator makes contact with ink on paper, good decolorizing dye is formed, is basic overall and does not damage paper and remove ink on paper immediately, but ink on paper tends to fade along with time, and thus the functions of covering and concealing are achieved; and meanwhile, a film is formed by spraying the ink eradicator on paper, time for secondary writing can be shortened when paper is recycled, diffustion of the ink eradicator to paper is reduced, the quality of secondary writing can be improved, pollution is avoided, recycling can beachieved, and resources are saved.

Owner:靳月华

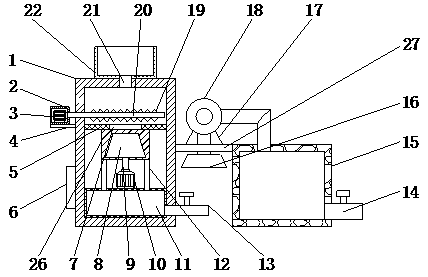

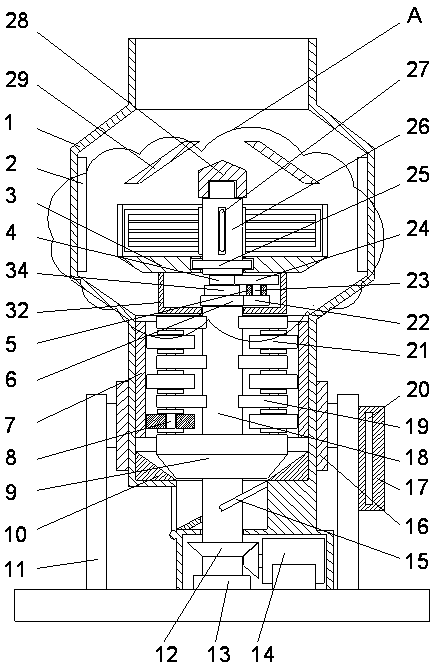

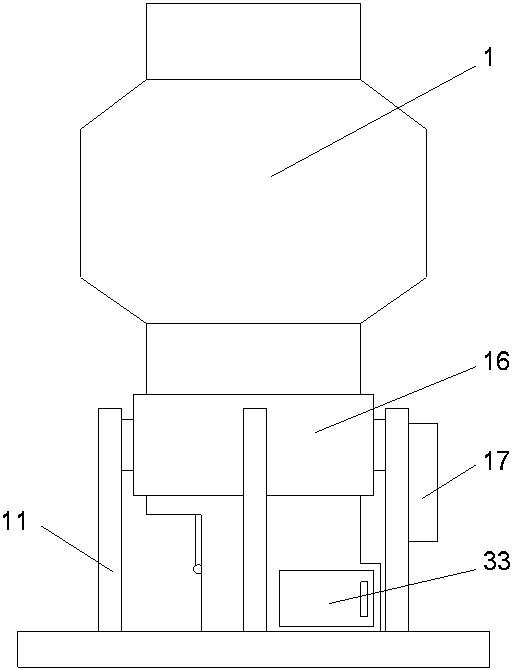

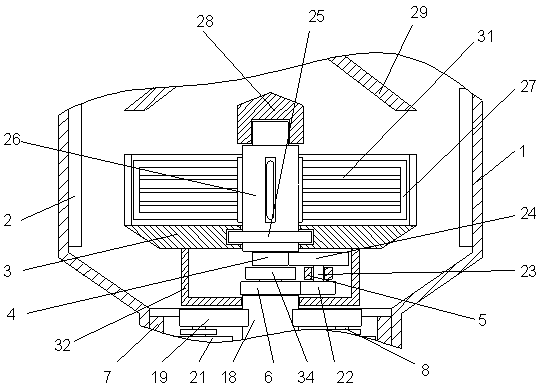

Raw material crushing device for mechanical processing

InactiveCN108554581AReasonable designGood crushing effectGrain treatmentsElectric machineryMotor shaft

The invention discloses a raw material crushing device for mechanical processing. The raw material crushing device comprises a box body, wherein the bottom end of the box body is provided with a bottom plate; a stabilizing rod is arranged at the edge part of the top end of the bottom plate; a connecting sleeve is arranged at the lower part of the outer side of the box body; the outer side of the connecting sleeve is fixedly connected with the stabilizing rod; the side wall, positioned inside the box body, of the top end of the bottom plate is fixedly connected with a rotating shaft seat; the inner side of the rotating shaft seat is rotationally connected with a rotating shaft; a bevel gear is arranged at the lower part of the outer side of the rotating shaft; a motor is arranged at the lower part of the inner side of the box body; a motor shaft of the motor is connected with a motor wheel through a shaft coupler; the motor wheel is matched with the bevel gear. The raw material crushingdevice has the advantages that the structure design is reasonable; a good crushing effect can be still well achieved by the crushing device when raw materials with great volume difference are processed; multilayer processing equipment is installed, so that the device discharging materials are finer; the crushing effect is better; the crushing device is used for performing collision crushing on the raw materials; the later-period grinding workload is reduced; the grinding efficiency is improved; the device structure is stable; the effect is obvious; the applicability is high.

Owner:德庆县智联机械科技有限公司

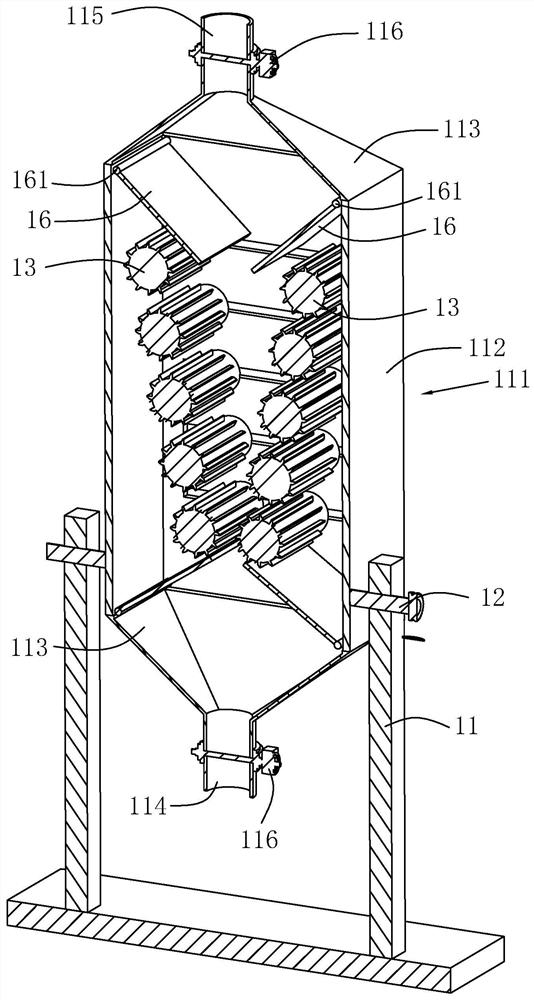

Coal slime sludge and raw coal mixed fuel crushing device

ActiveCN113926532AAchieve primary crushingImprove crushing effectBiofuelsWaste based fuelSludgeCrusher

The invention relates to a coal slime sludge and raw coal mixed fuel crushing device. The coal slime sludge and raw coal mixed fuel crushing device comprises a bottom plate, wherein rod bodies are arranged on the bottom plate and are located on two sides of the bottom plate; a crushing machine body is arranged between the rod bodies on the two sides; a discharging pipe is arranged on the side, facing towards the bottom plate, of the crushing machine body; a feeding pipe is arranged on the side, deviating from the bottom plate, of the crushing machine body; switches are arranged on the feeding pipe and the discharging pipe; a plurality of groups of crushing mechanisms are arranged in the machine body in a height direction of the machine body; each group of crushing mechanisms comprises two crushing rollers which are parallel to each other and are arranged at intervals and a driving mechanism used for driving the two crushing rollers to rotate; the machine body is provided with an adjusting mechanism used for driving the distance between the two crushing rollers of the multiple groups of crushing mechanisms to be gradually increased or decreased in a direction close to the discharging pipe; a rod body on one side is provided with a rotating mechanism used for driving the machine body to drive the discharging pipe to rotate to be in the state of facing towards the bottom plate or deviating from the bottom plate. The coal slime sludge and raw coal mixed fuel crushing device has the advantage that the crushing efficiency of repeated crushing of materials is improved.

Owner:杭州航民江东热电有限公司

Minitype broken glass piece collecting device

InactiveCN109513511AHave a crushing effectEffect of crushingGrain treatmentsArchitectural engineeringThreaded rod

The invention discloses a minitype broken glass piece collecting device. The minitype broken glass piece collecting device comprises a body, the middle end of the top of the body is fixedly connectedwith a first motor box, the inner cavity of the first motor box is fixedly provided with a first motor, an output shaft of the first motor is fixedly connected with a threaded rod, the outer surface of the threaded rod is in threaded connection with a threaded sleeve, the bottom of the threaded sleeve is fixedly connected with a crushing plate, and the bottom of the crushing plate is fixedly connected with teeth. According to the minitype broken glass piece collecting device, by means of coordination of the first motor, the threaded rod, the threaded sleeve, the crushing plate, the teeth and fixed plates, the effect of crushing is achieved; by means of the manner that the tail ends of electric stretching and contracting rods are fixedly connected with squeezing plates, the effect of squeezing crushing is achieved; by means of coordination of auxiliary plates, a grinding disc and a second motor, the effect of grinding into powder is achieved; and by means of the minitype broken glass piece collecting device, the problems that existing minitype broken glass pieces are concentrated in one place after being collected, in this way, land is occupied, and value generated by the broken glass pieces is further wasted are solved.

Owner:XUCHANG FUHUA GLASS

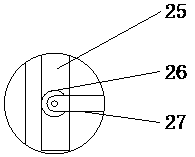

An unmanned monitoring ship anti-rolling device

ActiveCN109436233BAchieve conversionIncrease driving speedVessel cleaningHullsDamperMechanical engineering

Owner:ZHEJIANG OCEAN UNIV

Blueberry sparkling wine brewing device

PendingCN112024050AShorten screening timeIncrease productionAlcoholic beverage preparationGrain treatmentsYield (wine)Electric machinery

The invention relates to the technical field of brewing, in particular to a blueberry sparkling wine brewing device. The device comprises a stirring barrel, a screening mechanism, a crushing mechanismand a cleaning mechanism. The bottom end of the stirring barrel is fixedly connected with a bottom plate, and the top end of the stirring barrel is fixedly connected with a top plate; the crushing mechanism is mounted in the stirring barrel; the cleaning mechanism is mounted in the stirring barrel; the screening mechanism is mounted in the stirring barrel and comprises a first motor, a straight rod, a winding drum, a string, a screening plate and a slide way; the first motor is fixedly connected to the outer side wall of the stirring barrel; the straight rod is fixedly connected to an outputend of the first motor; the winding drum is fixedly connected to the side wall of the straight rod; the screening plate is connected to the inner side wall of the stirring barrel in a sliding manner;and one end of the string is wound on the winding drum, and the other end is fixedly connected to the top end of the screening plate. Through the screening mechanism and the crushing mechanism, the screening process is greatly shortened, the efficiency is improved, and the yield is increased.

Owner:YICHUN ZHONGZHI DASHANWANG WINERY

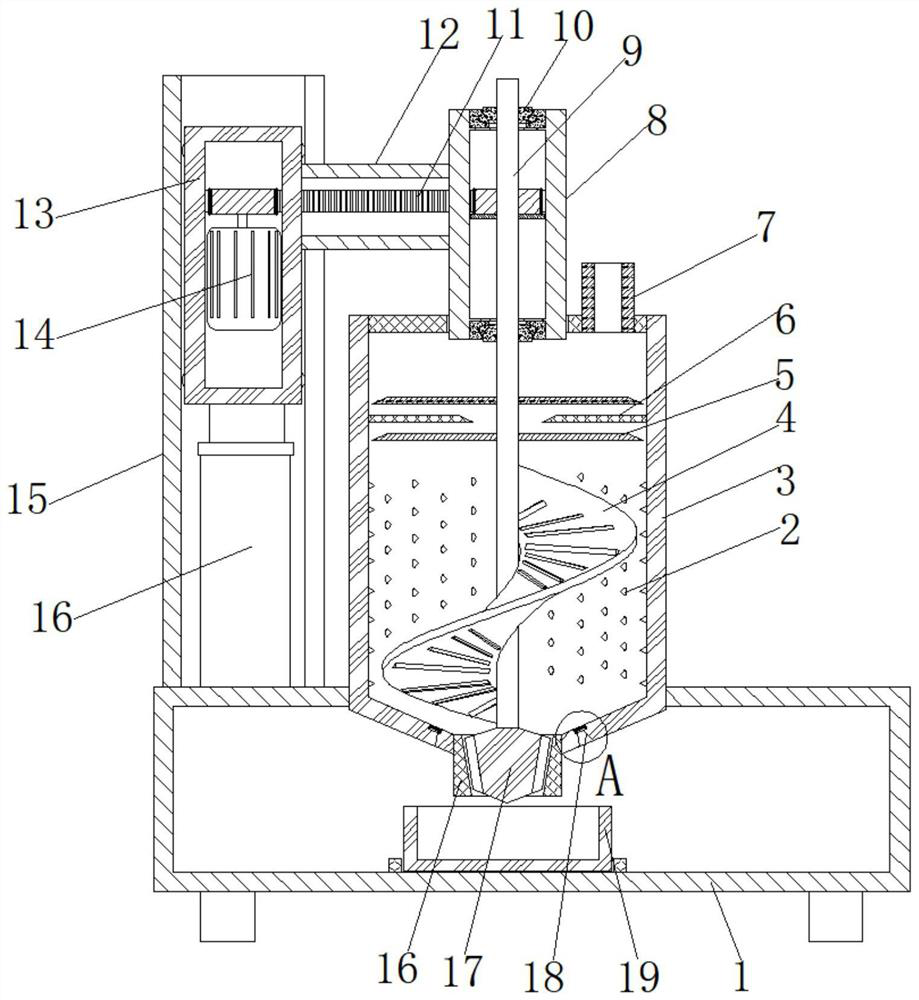

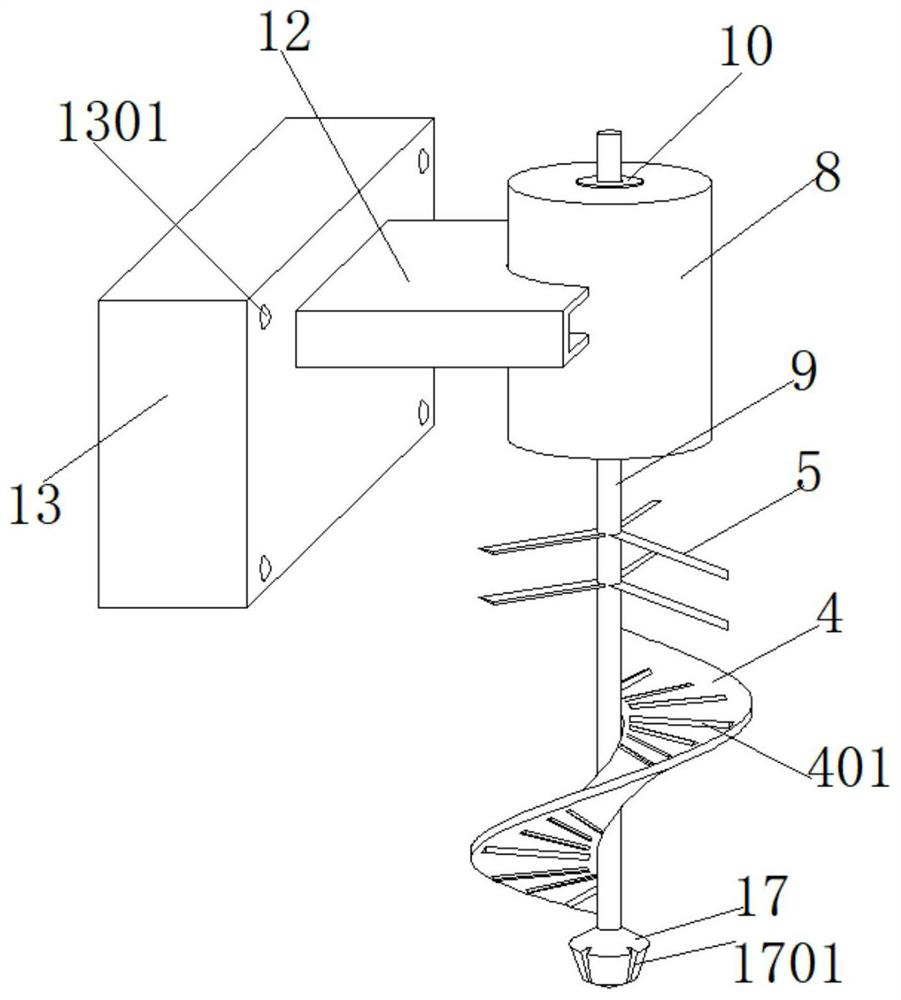

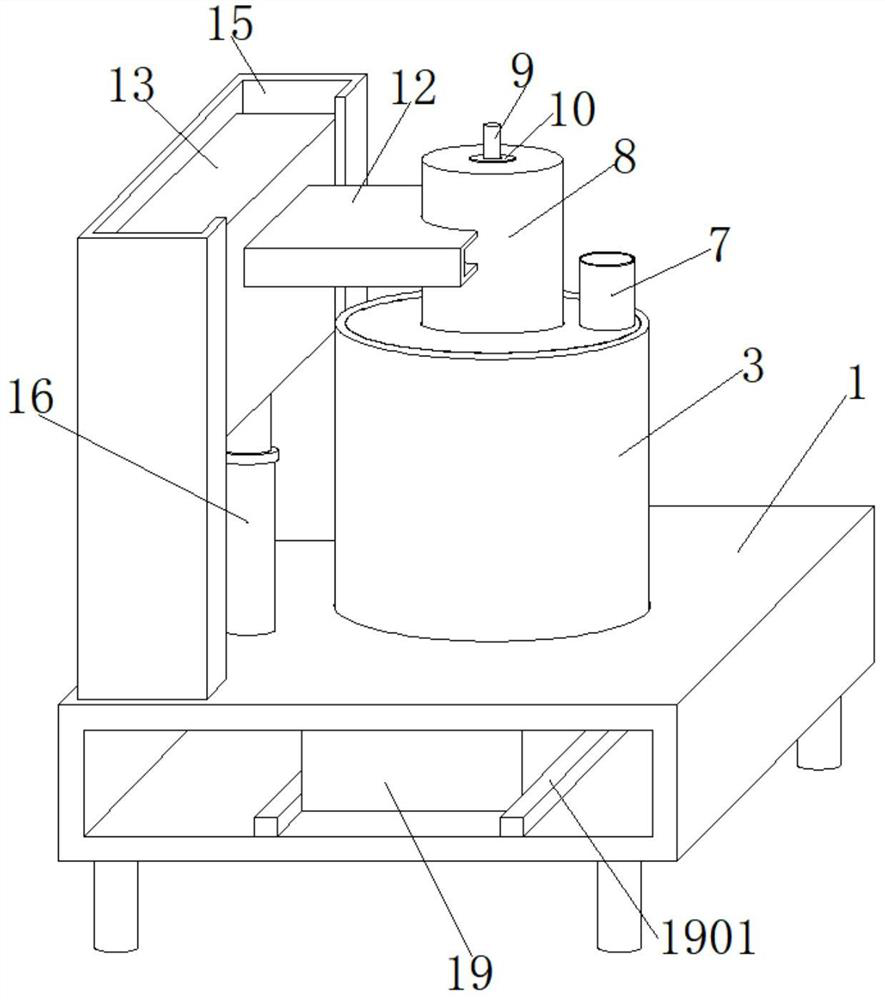

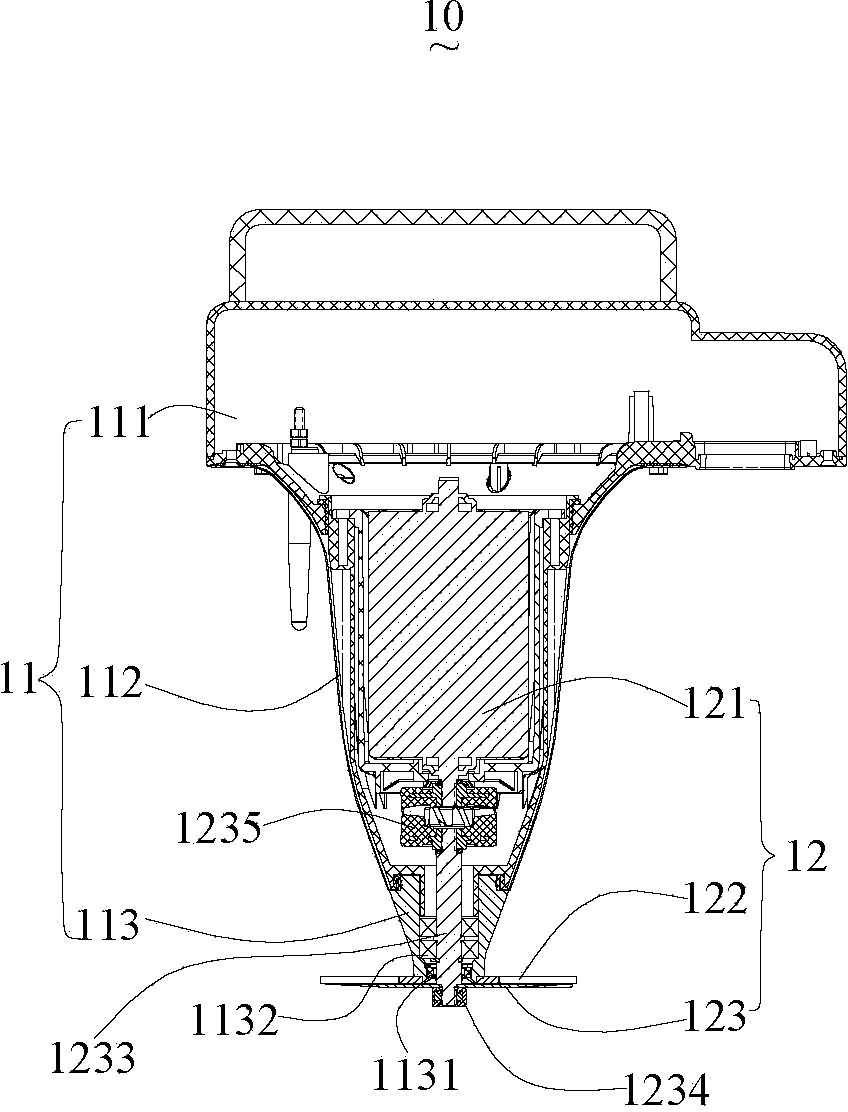

Soybean milk machine with efficient pulverization function

The invention relates to a soybean milk machine with the efficient pulverization function. The soybean milk machine with the efficient pulverization function comprises a motor, a fixed knife and a movable knife, wherein the motor is installed in a machine head, the fixed knife is fixed to the lower end of the machine head, the motor drives the movable knife to rotate, the fixed knife comprises a wing root and at least two shearing blades which are arranged on the same plane and are connected with the wing root of the fixed knife, the movable knife comprises a wing root and at least one shearing wing which is parallel to the shearing blades of the fixed knife and is connected with the wing root of the movable knife, the shearing wing is arranged below the shearing blades, a cutting edge is formed on the shearing wing, the cutting edge forming surface of the cutting edge faces the bottom of a cup body, the shearing wing and the shearing blades are used in cooperation to shear and pulverize materials, and the size of a gap between each shearing blade and the shearing wing ranges from 0.05 mm to 2 mm. According to the soybean milk machine with the efficient pulverization function, a traditional blade cutting type pulverization mode is changed, a shearing pair is formed by the fixed knife and the movable knife, and both large-grained materials and fine materials can be well sheared and pulverized.

Owner:JOYOUNG CO LTD

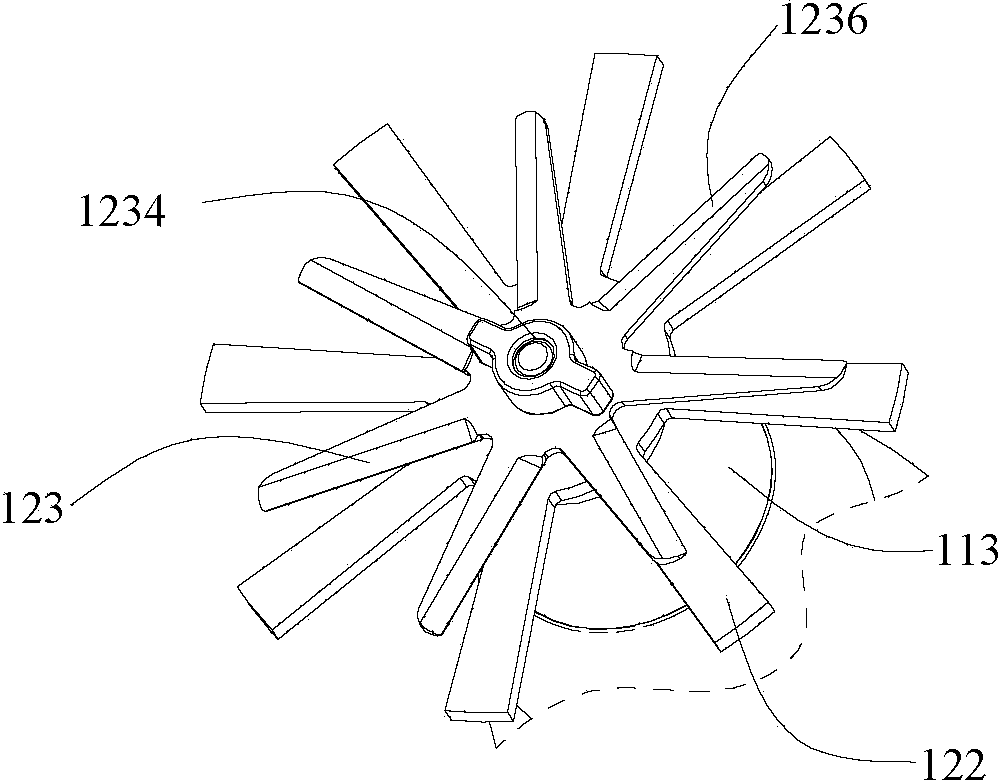

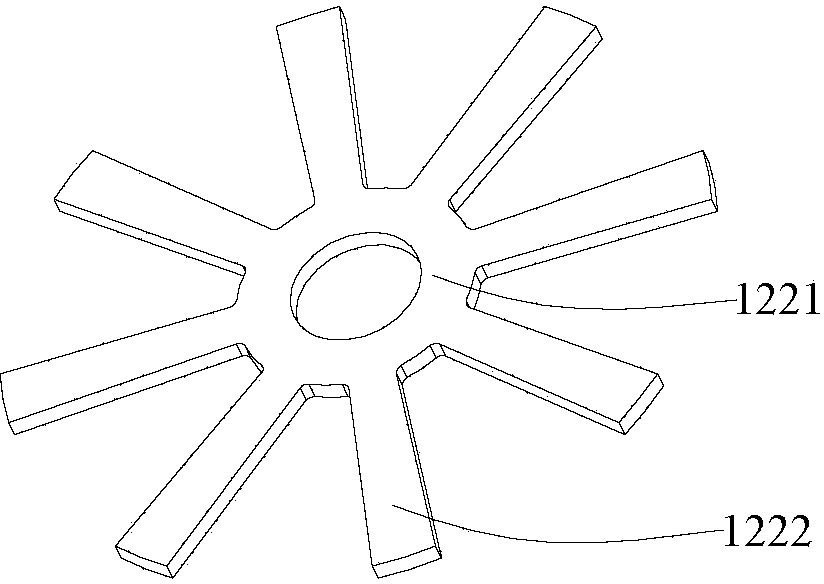

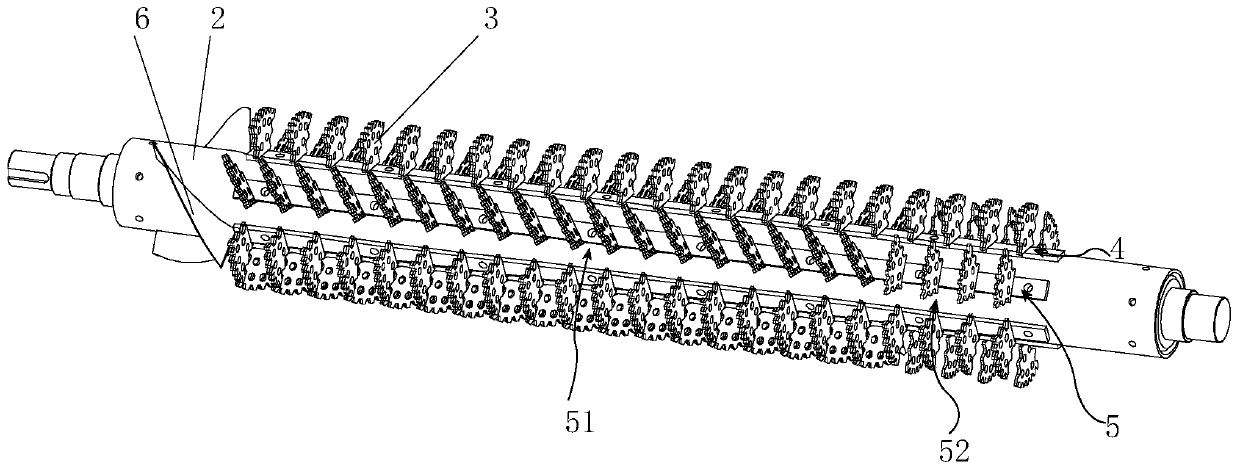

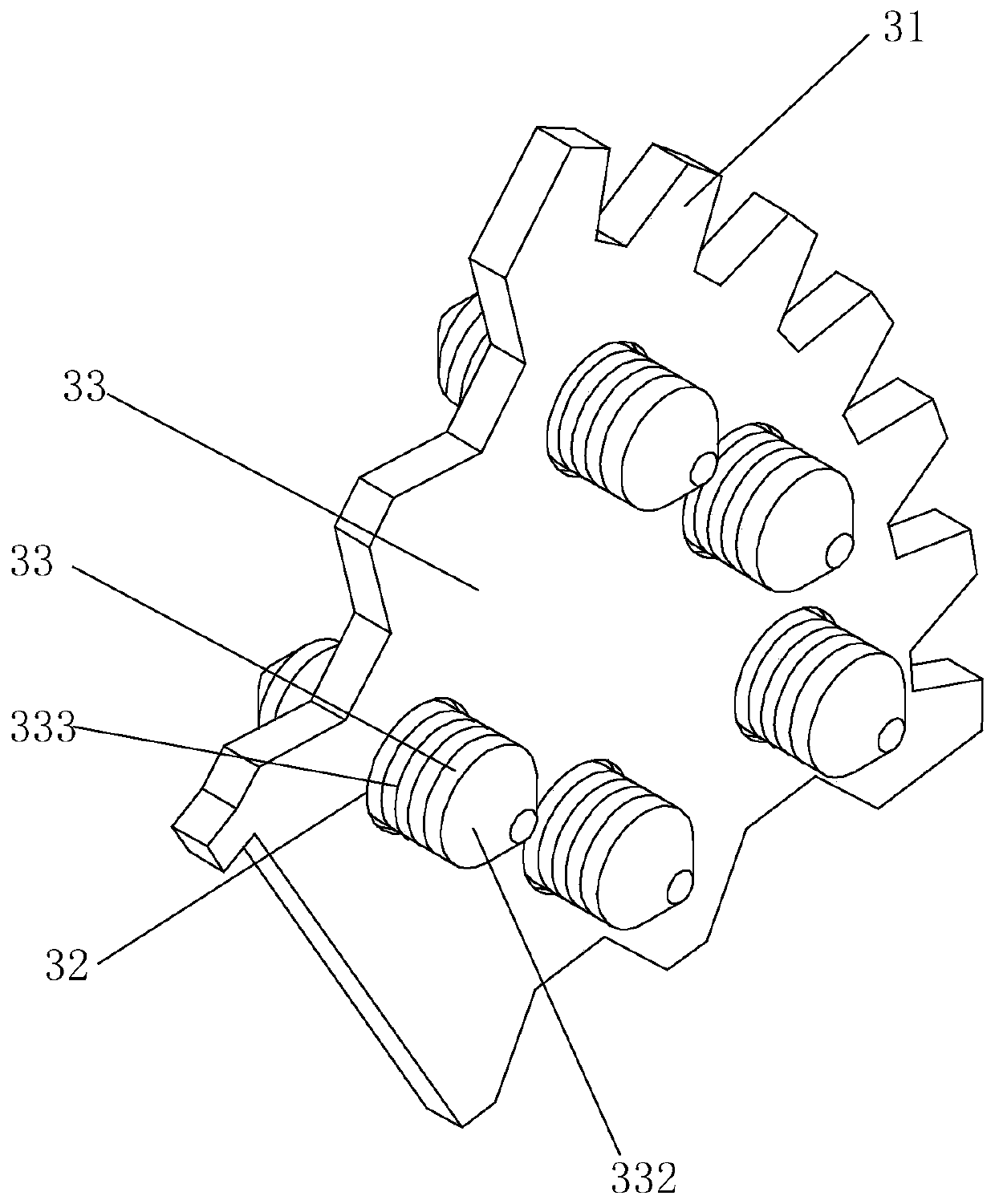

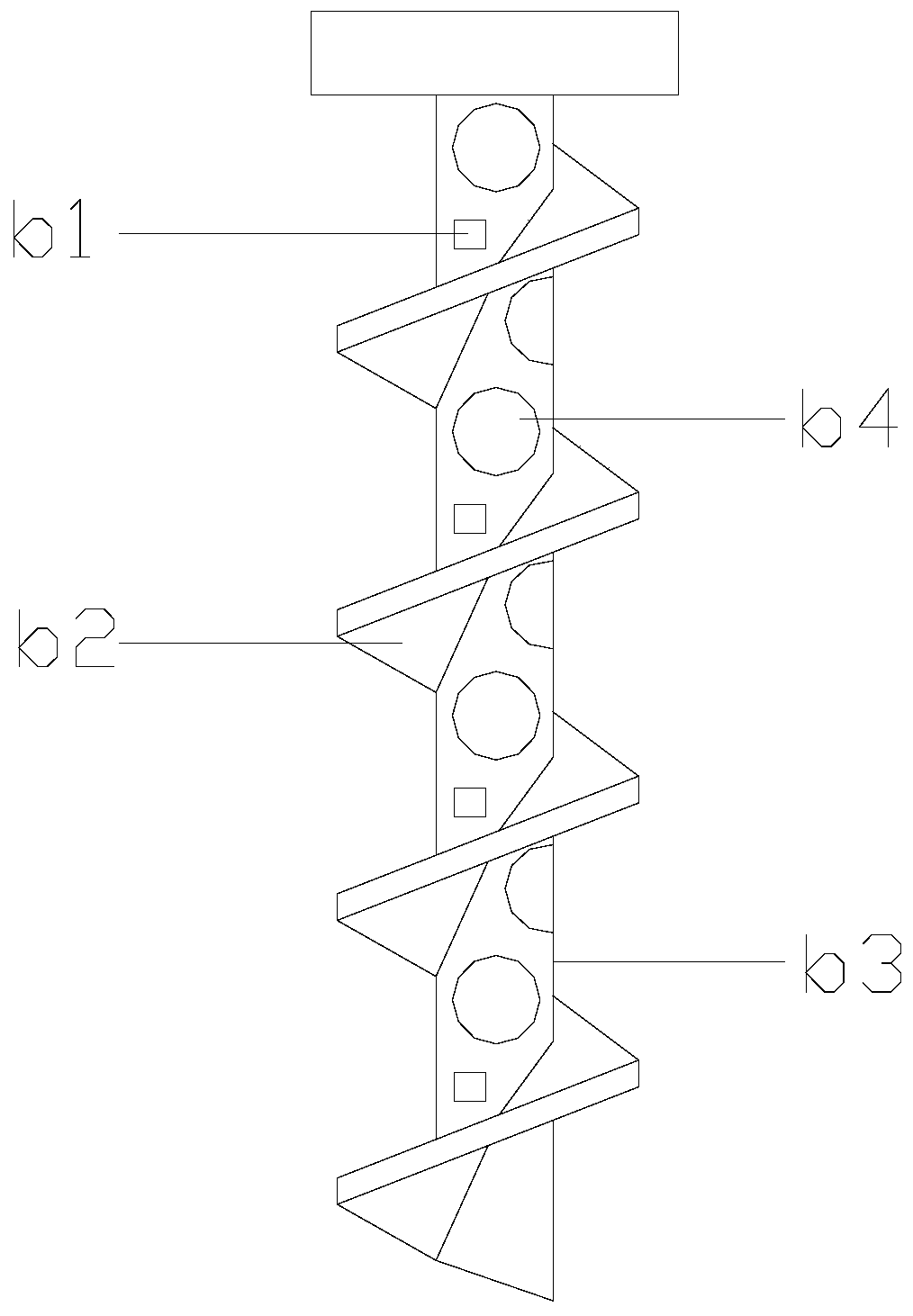

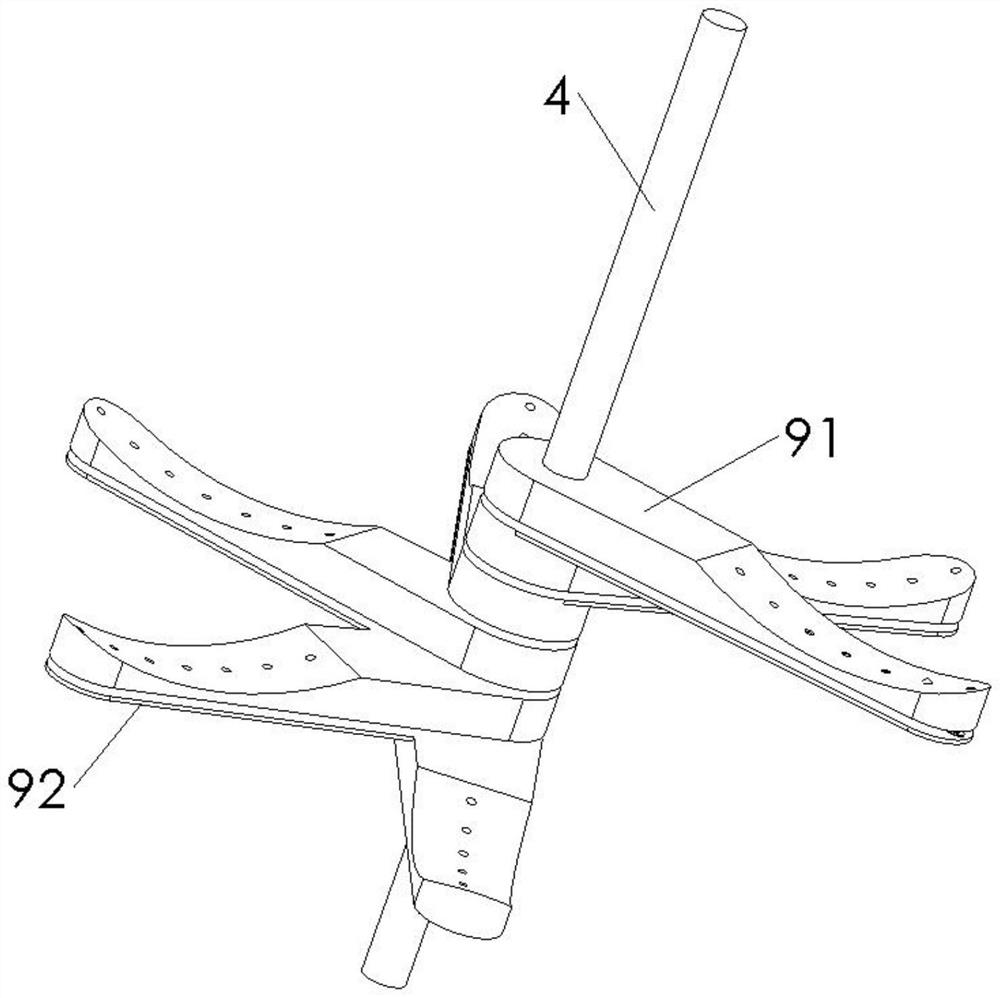

Shaft body structure and corn peeling and degerming slag-breaking machine

ActiveCN107321417AGood slag breaking effectImproved slag breaking efficiencyGrain huskingGrain polishingSlagAgricultural engineering

The invention belongs to the technical field of agricultural mechanical equipment, and provides a shaft body structure. The shaft body structure comprises a main shaft; a beating plate is arranged on the main shaft, teeth are arranged at the circumferential direction of the main shaft, and a beating rod is arranged on the beating plate. The invention further provides a corn peeling and degerming slag-breaking machine. The corn peeling and degerming slag breaking machine comprises the shaft body structure; and a screening drum is arranged outside the shaft body structure, a shell body is arranged outside the screening drum, a material collecting hopper is arranged at the lower part of the shell body, a feeding inlet and a discharging outlet are correspondingly formed in the two ends of the shell body, and the main shaft is connected with a motor through a main shaft belt wheel. According to the shaft body structure and the corn peeling and degerming slag-breaking machine, the technical problem of low slag-breaking efficiency of existing corn peeling and degerming slag-breaking machine is solved.

Owner:SHIJIAZHUANG HONGDEFA MACHINERY CO LTD

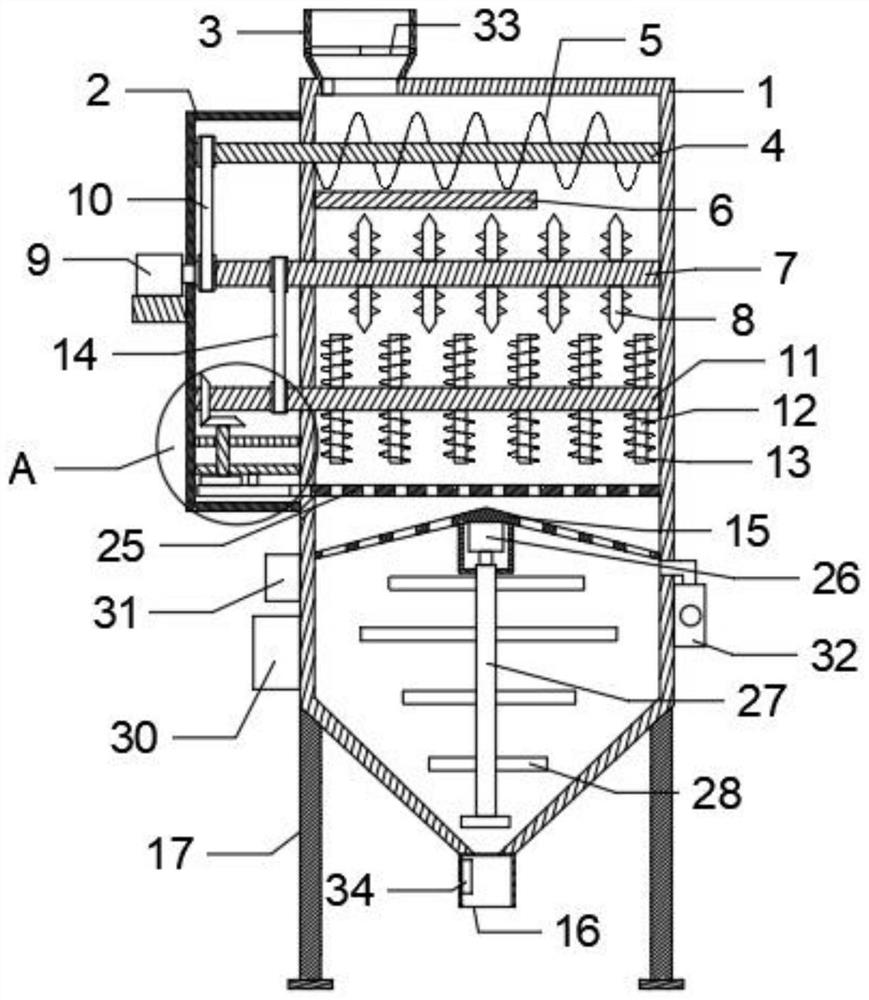

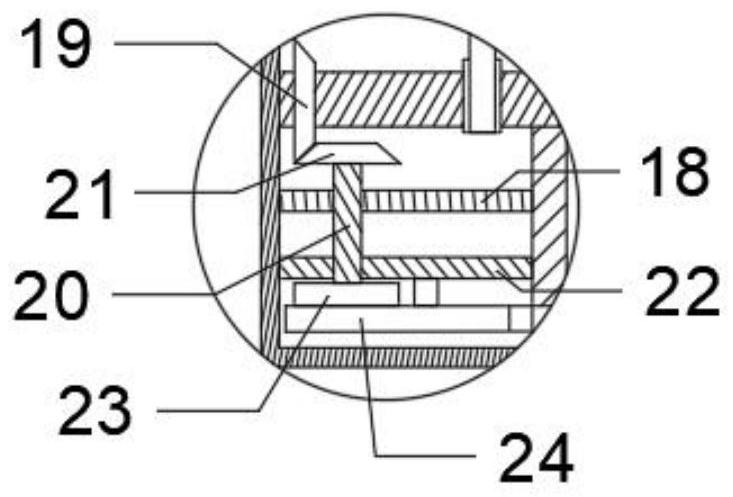

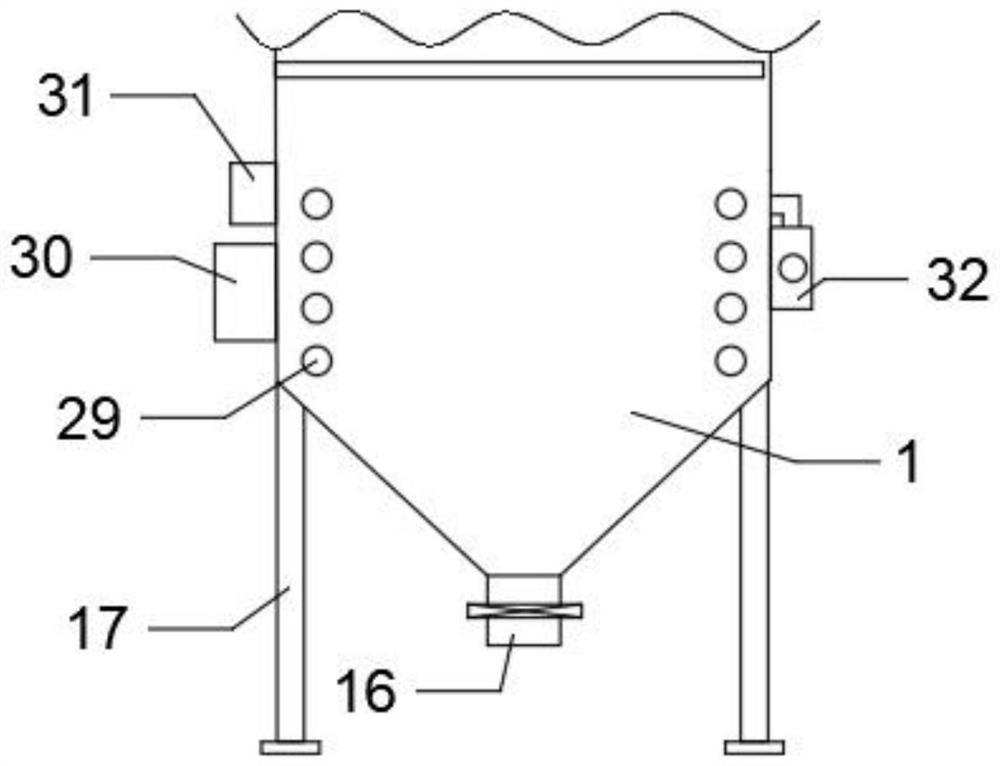

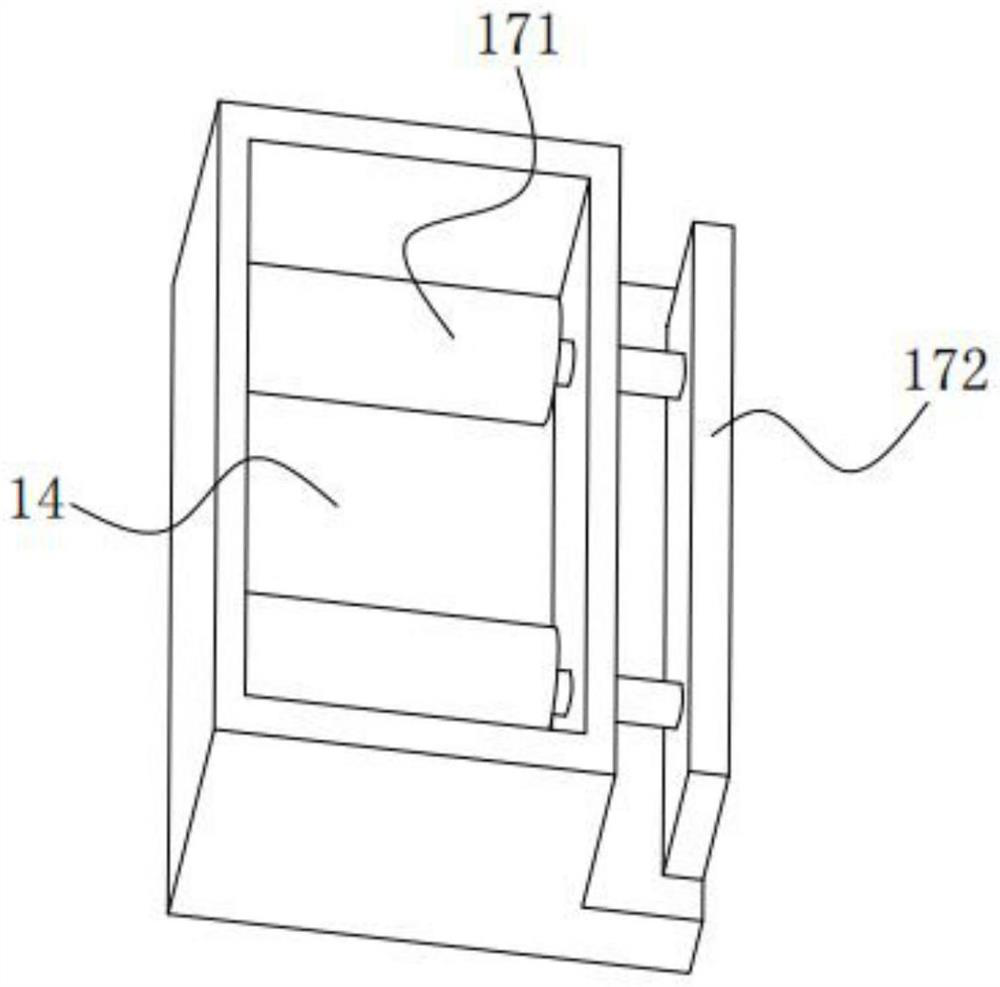

Secondary curing device for bio-organic fertilizer

InactiveCN114031437AHave a crushing effectAutomate processingBio-organic fraction processingOrganic fertiliser apparatusAgricultural engineeringStructural engineering

The invention belongs to the technical field of fertilizer processing and discloses a secondary curing device for a biological organic fertilizer. The device comprises a curing box and a driving box, a feeding hopper is arranged at the upper end of the curing box, a pushing shaft is arranged at the lower end of the curing box, a supporting block is arranged at the lower end of the pushing shaft, a first driving shaft is arranged at the lower end of the supporting block, a driving motor is arranged on the outer side of the driving box, a first driving chain shaft is arranged on one side of the first driving shaft, a second driving chain shaft is arranged on one side of the pushing shaft, a second driving shaft is arranged at the lower end of the first driving shaft, a plurality of smashing shafts are arranged on the second driving shaft, a first transmission chain shaft is arranged on one side of the second driving shaft, a second transmission chain shaft is arranged on one side of the first driving shaft, a sieve plate moving mechanism is arranged on one side of the second driving shaft, a second sieve plate is arranged at the lower end of the second driving shaft, and a stirring ventilation mechanism is arranged at the lower end of the second sieve plate. The secondary curing device solves the problems that in the prior art, organic fertilizer cannot be uniformly stirred, and the curing quality of the organic fertilizer cannot be guaranteed, and is suitable for curing treatment of the organic fertilizer.

Owner:新疆福纳斯生物工程有限公司

Carbon fiber river protection pile body, preparing method thereof and carbon fiber river protection pile

The invention belongs to the field of riverway peripheral facilities, and particularly provides a carbon fiber river protection pile body. The carbon fiber river protection pile body is mainly prepared from, by weight, 70-80 parts of polypropylene, 8-12 parts of ABS resin, 4-6 parts of carbon fibers, 4-6 parts of polyvinyl butyral, 0.5-1 part of antioxidant, 0.5-1 part of anti-aging agent and 1.2-1.7 parts of fire retardant. The invention further provides a preparing method of the carbon fiber river protection pile body and a carbon fiber river protection pile composed of the carbon fiber river protection pile body. The carbon fiber river protection pile body and the carbon fiber river protection pile obtained through the preparing method are low in manufacturing cost, high in strength, long in service life, convenient to disassemble and assemble and suitable for industrial application and popularization.

Owner:陈鹤忠

Building solid waste crushing, recycling and regenerating device

PendingCN114850188AHave a crushing effectImprove crushing effectConstruction waste recoverySolid waste disposalMaster cylinderArchitectural engineering

The invention provides a building solid waste crushing, recycling and regenerating device. The invention discloses a building solid waste crushing, recycling and regenerating device. The side beams are arranged on the two sides of the workbench respectively, a cylinder cap is fixedly installed on the top of one side of each side beam, a main cylinder is arranged in each cylinder cap, and the bottom of an output shaft of each main cylinder is fixedly connected with a sliding beam. According to the building solid waste crushing, recycling and regenerating device, an output shaft of a main cylinder moves up and down to drive a sliding beam to move up and down on the surface of a stand column, and then an output shaft of a side cylinder moves left and right to repeatedly extrude and impact solid waste on a workbench up, down, left and right, so that the crushing effect is achieved; the solid waste crushing device is simple in structure and high in practicability, the solid waste is subjected to impact crushing up and down and left and right through repeated extrusion of the main cylinder and the side cylinders, and the crushing effect of the solid waste is improved.

Owner:山东众友重工机械有限公司

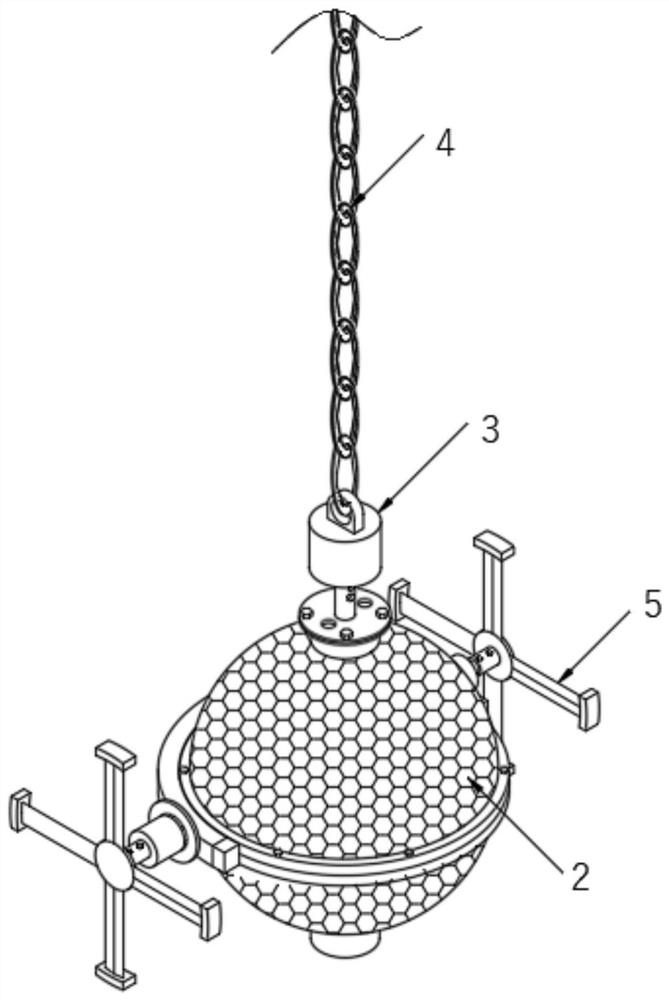

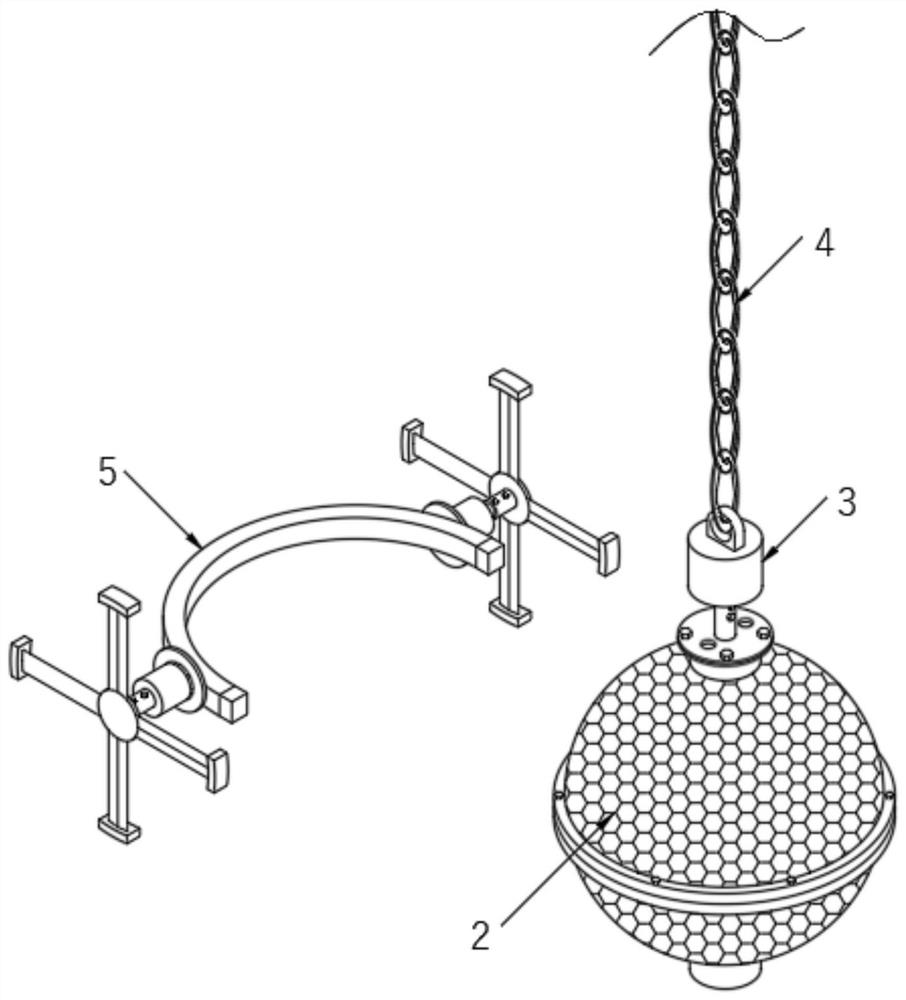

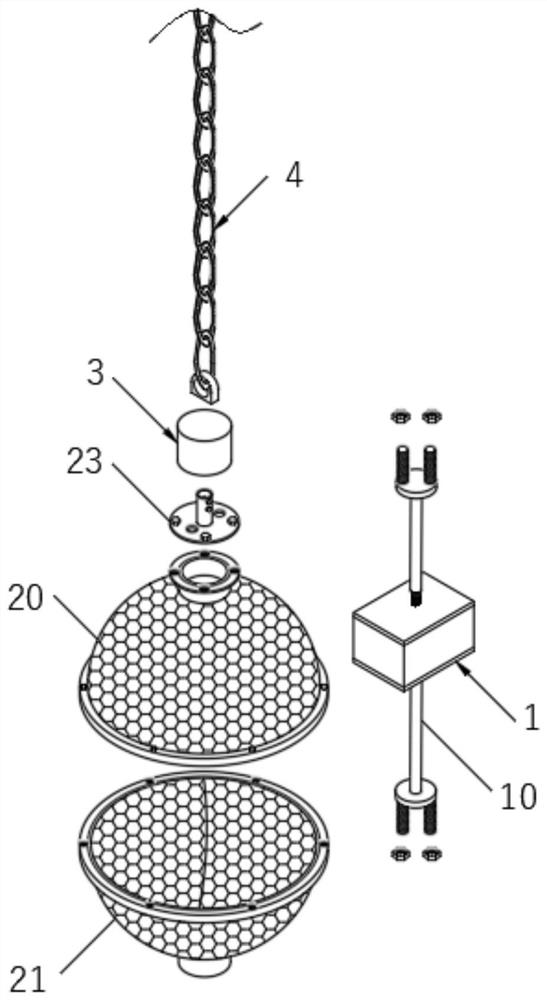

An all-round anti-collision device for a ship-borne marine underwater detection device

ActiveCN111688886BTo achieve the effect of all-round anti-collision protectionEasy to useGrain treatmentsGeological measurementsMarine engineeringOceanography

The present invention relates to the technical field of marine underwater detection equipment, in particular to an omni-directional anti-collision device of a ship-borne marine underwater detection device, including an all-round anti-collision protection arranged outside the main body of the ship-borne marine underwater detection device device, the all-round anti-collision protection device includes an upper protective cover and a lower protective cover arranged on the upper protective cover, and the ends of the upper protective cover and the lower protective cover that are close to each other are provided with fixed waist rings ; The upper protective cover is also provided with an iron chain, and the center position of the top surface of the blocking cover is also provided with a second sleeve, and the second sleeve is provided with a direction adjustment device, and the upper protective cover And a crushing device is also arranged on the lower protective cover. The invention realizes the protection of the main body of the ship-borne marine underwater detection device inside, has the effect of all-round anti-collision protection, is convenient to use, and brings convenience to users.

Owner:中船重工(青岛)海洋装备研究院有限责任公司

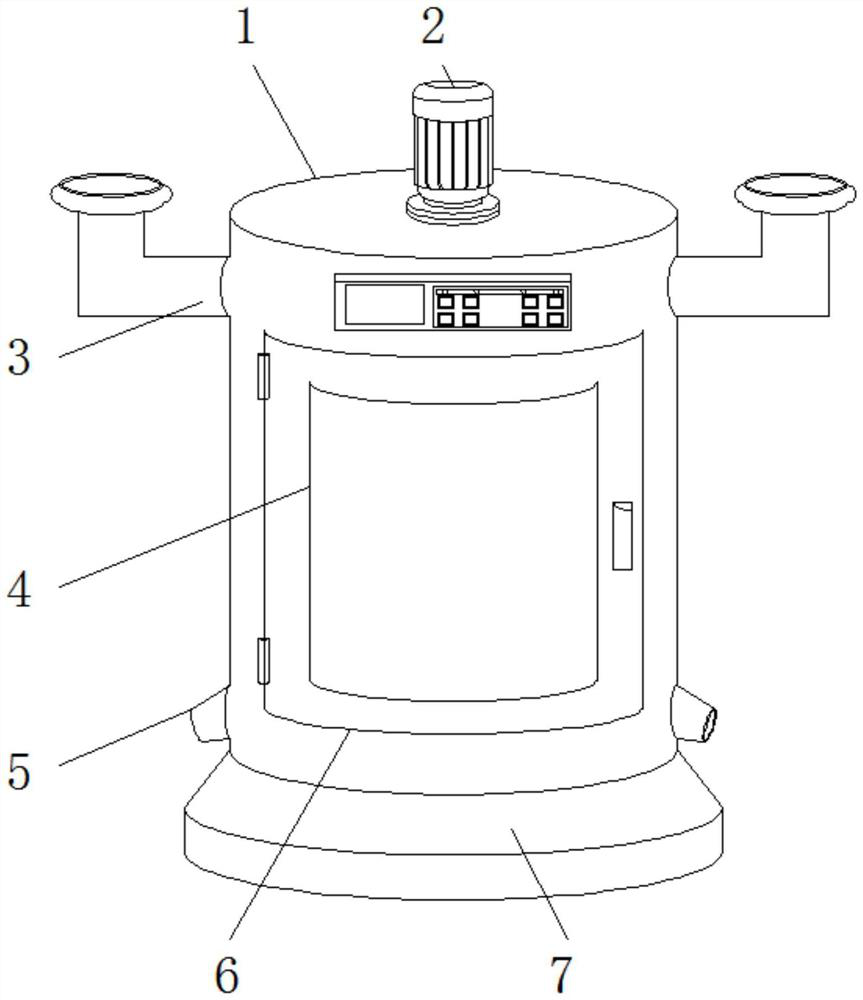

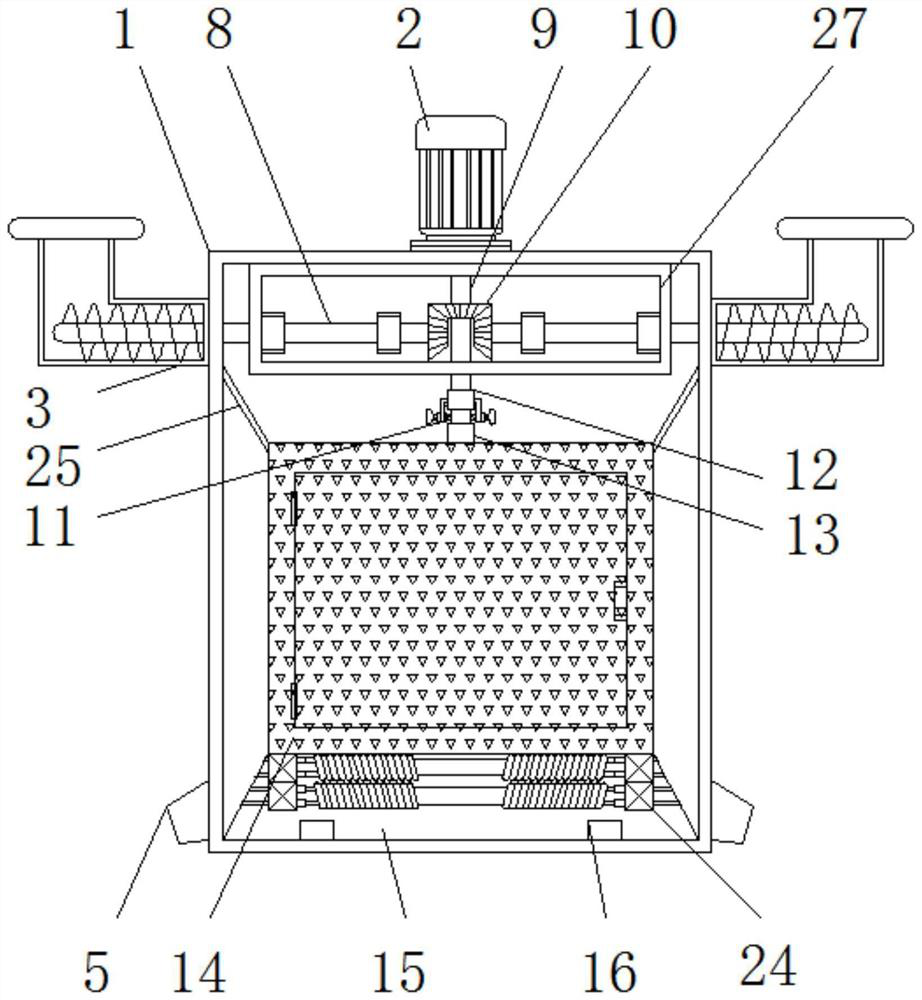

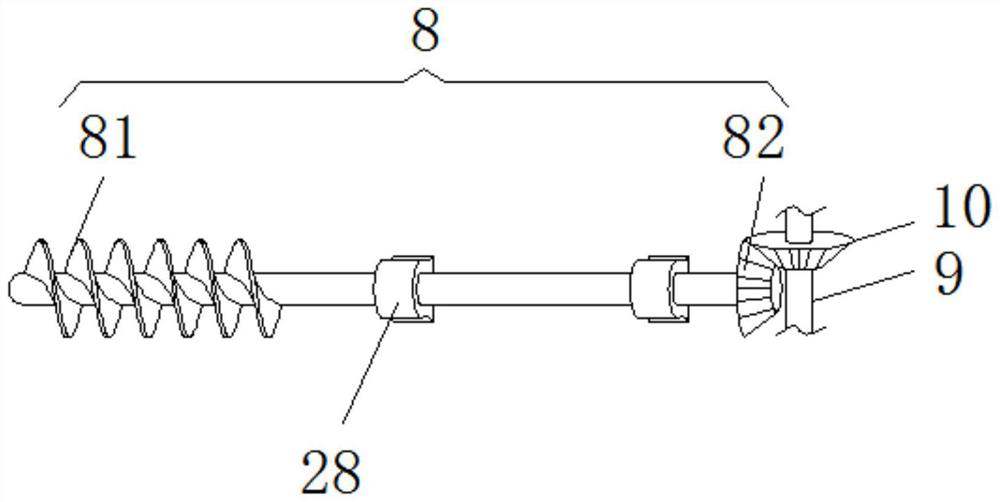

Biomass combustion furnace capable of easily discharging coke ash

PendingCN112524600AHave a crushing effectBurn fullySolid fuel combustionLump/pulverulent fuel feeder/distributionCokeProcess engineering

The invention discloses a biomass combustion furnace capable of easily discharging coke ash. The biomass combustion furnace capable of easily discharging coke ash comprises a furnace body, a feeding box is fixedly connected to the upper side of the furnace body, a feeding mechanism is arranged in the feeding box, a combustion bowl is installed between the left side wall and the right side wall inthe furnace body, a plurality of through holes are formed in the bottom of the combustion bowl, a cleaning mechanism for cleaning the interior of the combustion bowl is arranged in the combustion bowl, the feeding mechanism and the cleaning mechanism are in transmission connection through a transmission mechanism, and a storage box is placed at the bottom in the furnace body. The feeding mechanismis arranged, feeding is slowly pushed through a spiral packing auger, the uniform feeding effect is achieved, internal raw materials are fully combusted, ash can be assisted to enter the storage boxthrough the through holes in cooperation with the transmission mechanism and the cleaning mechanism, and the large-particle ash can achieve the crushing effect.

Owner:XIAN SENWAS AGRI SCI & TECH

A shaft structure and corn peeling and degerming slag breaking machine

ActiveCN107321417BGood slag breaking effectImproved slag breaking efficiencyGrain huskingGrain polishingElectric machineryStructural engineering

The invention belongs to the technical field of agricultural machinery and equipment. It proposes a shaft structure, which includes a main shaft. A beating plate is provided on the main shaft. Teeth are provided on the circumferential direction of the beating plate. A beating rod is provided on the beating plate. It also proposes a corn The peeling, degerming and slag breaking machine includes a shaft structure. A screen drum is arranged outside the shaft structure. A shell is arranged outside the screen drum. A collecting hopper is arranged below the shell. The two ends of the shell are respectively equipped with feed ports and At the discharge port, the spindle is connected to the motor through the spindle pulley. The invention solves the technical problem of low slag breaking efficiency in existing corn peeling, degerming and slag breaking machines.

Owner:SHIJIAZHUANG HONGDEFA MACHINERY CO LTD

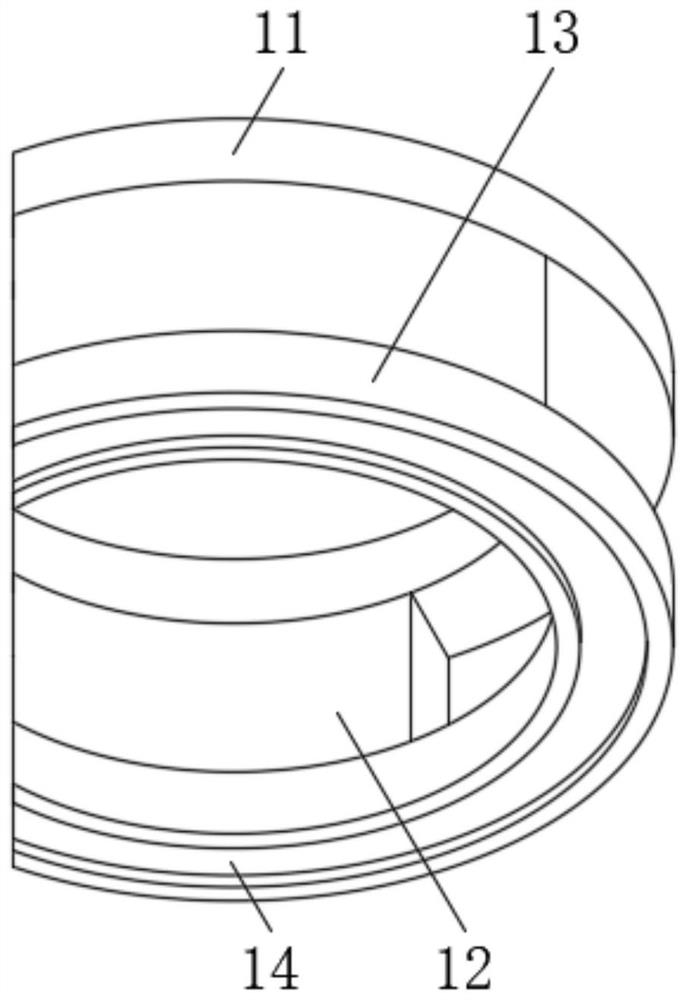

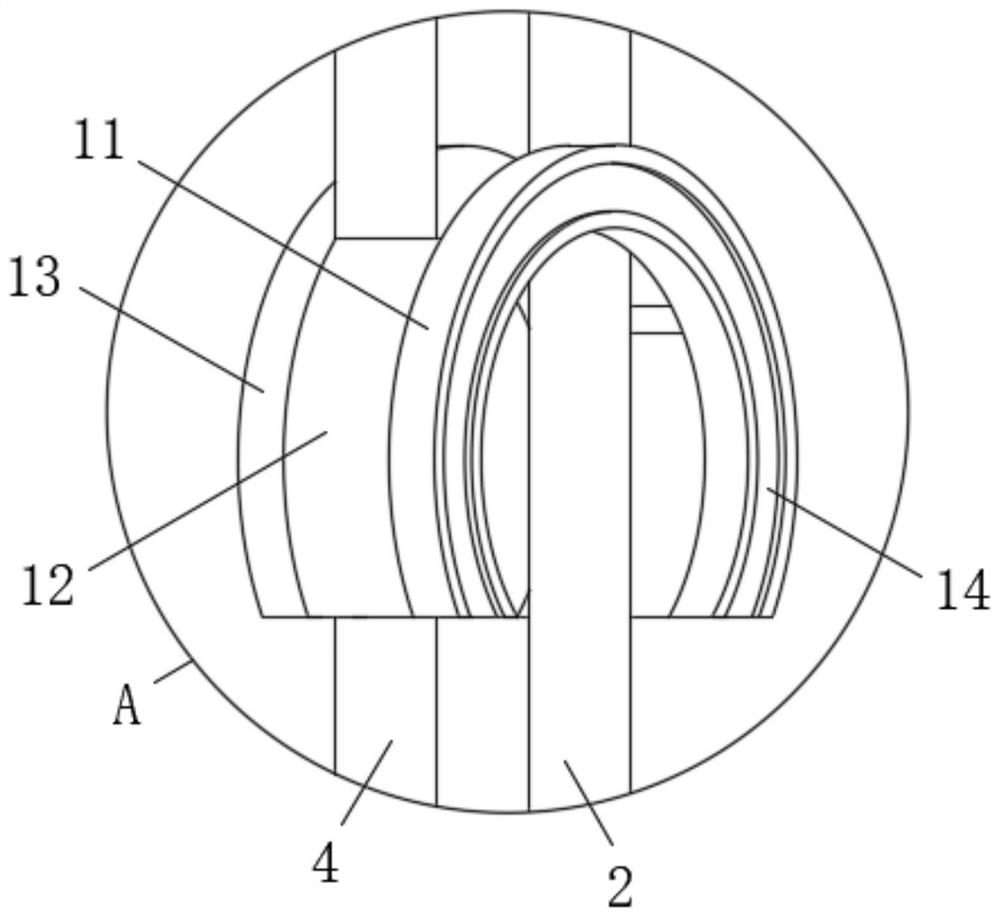

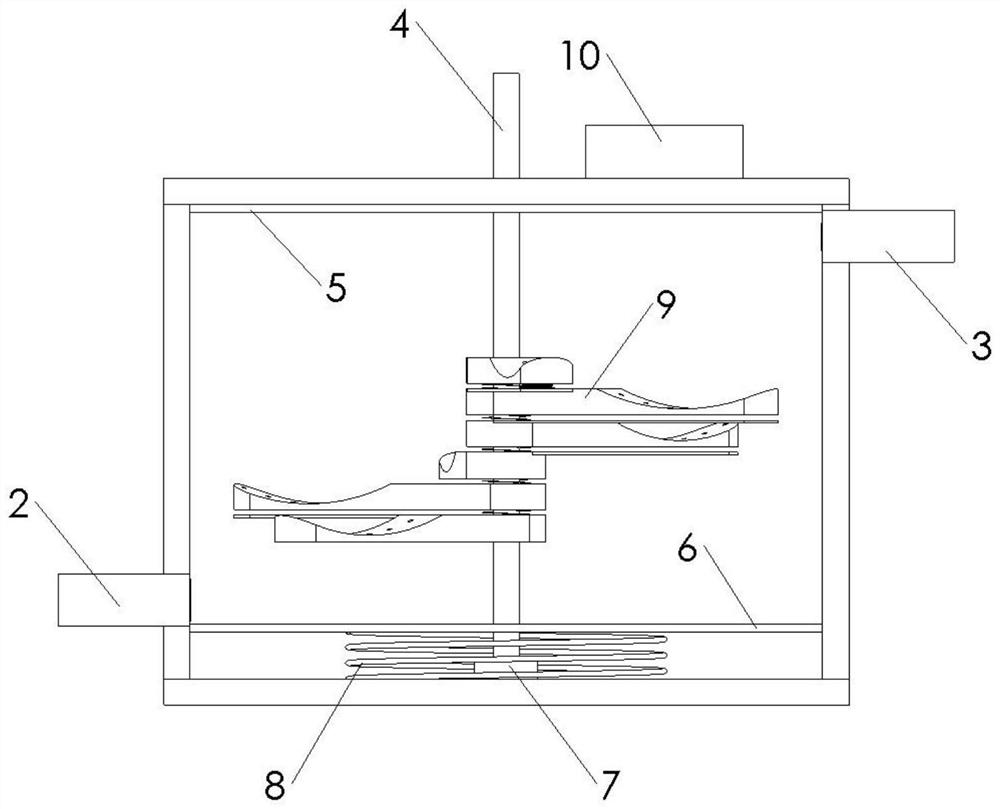

Lithium battery slurry vacuum stirring device

InactiveCN113750886AImprove sealingEnsure the effect of vacuumingMixer accessoriesEngineeringMechanical engineering

The invention relates to the technical field of lithium battery production, in particular to a lithium battery slurry vacuum stirring device which comprises a vacuum stirring tank, a liquid stirring tank, a solid stirring tank and a stirring mechanism. Sealing mechanisms are arranged on the two sides of the interior of the vacuum stirring tank, each sealing mechanism comprises a sealing plate and a scraping plate which are arranged at intervals, the plate edges of the sealing plates and the scraping plates are attached to the inner wall of the vacuum stirring tank in a matched mode, and driving mechanisms are arranged on the outer sides of the sealing plates. The driving mechanism can drive the sealing plates and the scraping plates on the left side and the right side to respectively cross pipeline joints of the liquid stirring tank, the solid stirring tank and the vacuum stirring tank. According to the invention, the scraping plates firstly scrape the inner wall of the vacuum stirring tank, and the sealing plates are in sealing fit with the inner wall of the vacuum stirring tank. The sealing plates and the scraping plates cross the pipeline joints of the liquid stirring tank, the solid stirring tank and the vacuum stirring tank, so that the excellent sealing effect of the sealing plates and the vacuum stirring tank is realized, and the vacuumizing effect is ensured.

Owner:毛龙壮

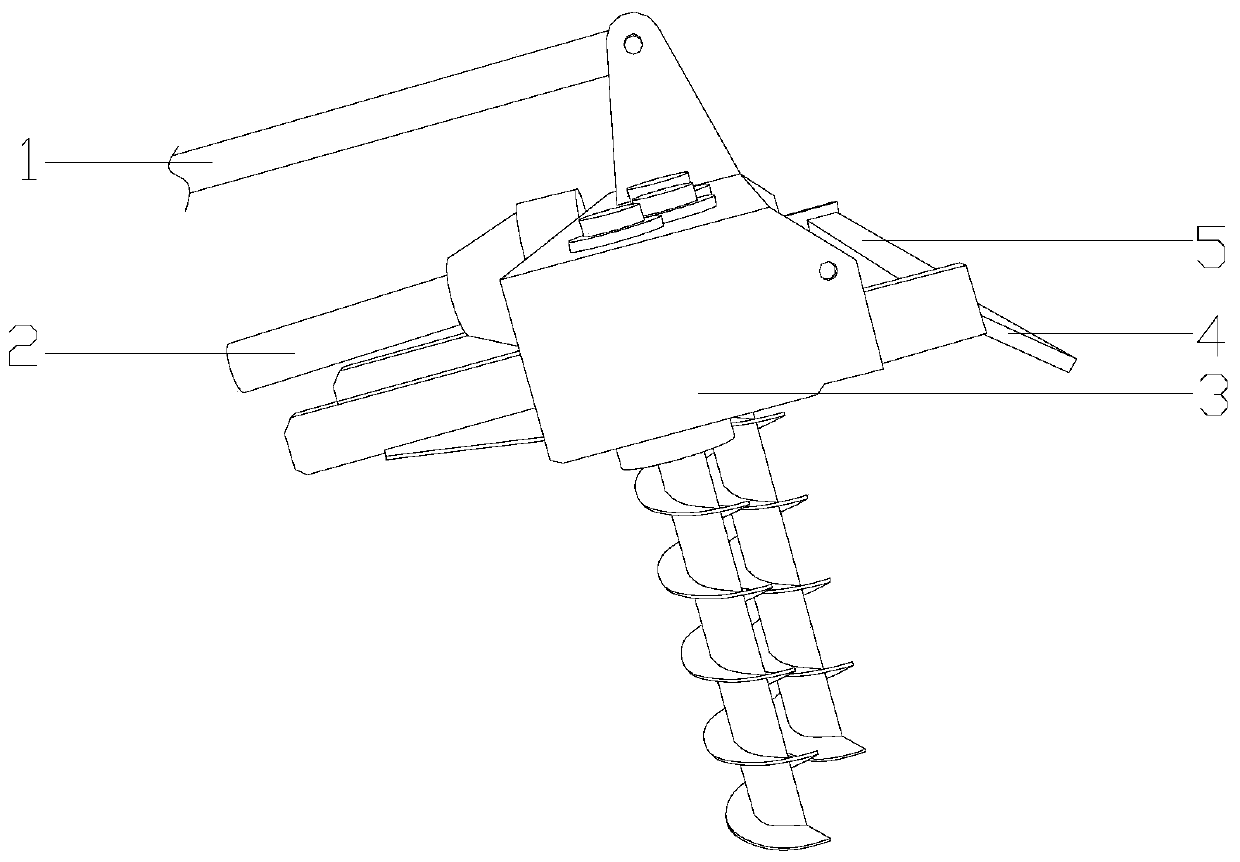

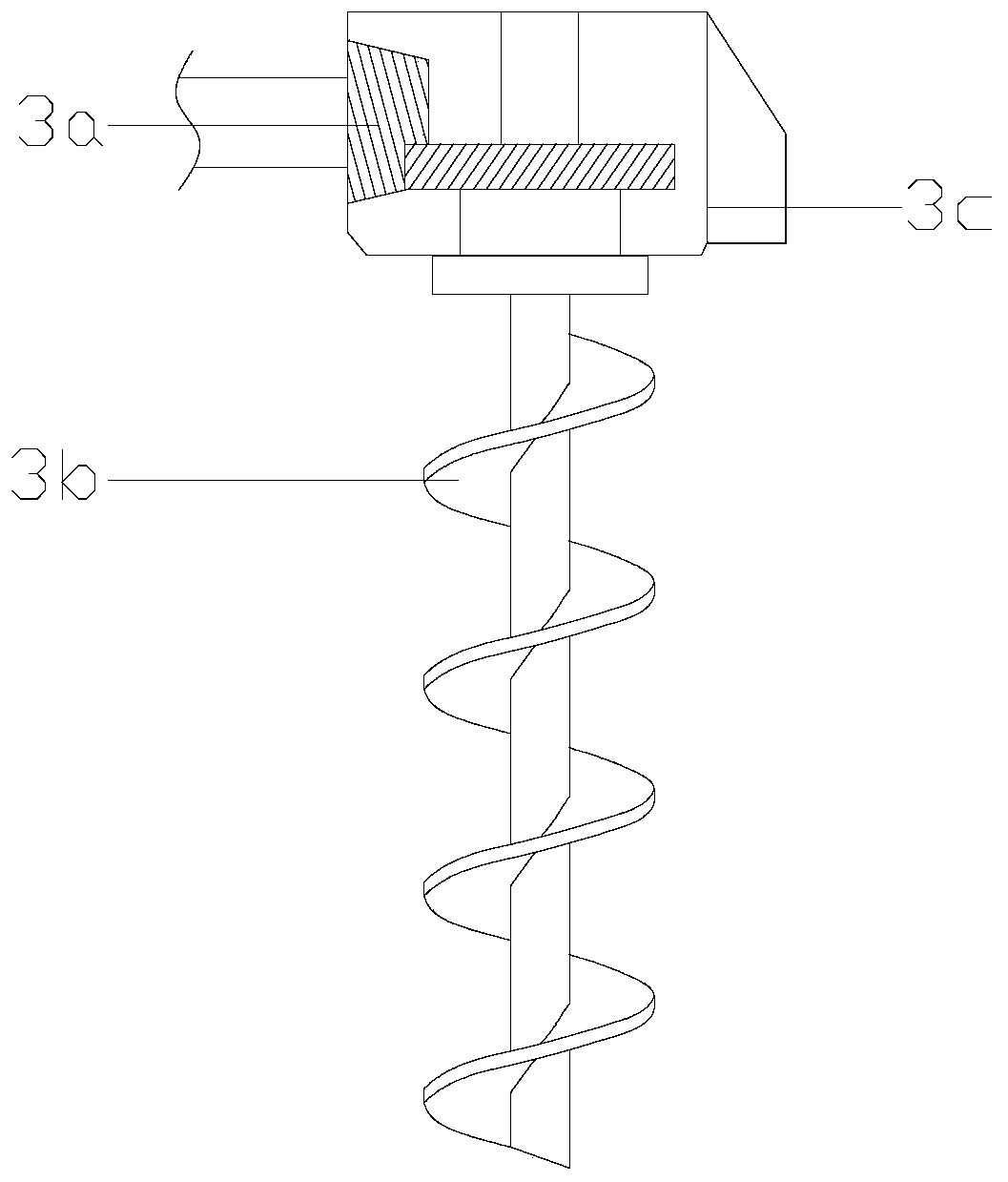

Lotus root field hydraulic smash-ridging device

The invention discloses a lotus root field hydraulic smash-ridging device. The device structurally comprises a hydraulic driving rod, a smash-ridging transmission shaft, a smash-ridging structure, a dustproof cover plate and a cover plate fixing frame. The smash-ridging device is combined with a propelling assisting mechanism through a stone crushing device, the stone crushing device can be used for crushing deep hard soil when a smash-ridging machine is used, the situation that a screw rod is bent and broken due to the action of radial force when the smash-ridging structure extends into the soil and moves forward and backward and the resistance is large in the soil loosening process is reduced, and the service life of the smash-ridging machine is effectively prolonged; the propelling assisting mechanism can perform pre-cutting and drilling operation on the soil, so that the soil loosening efficiency of a drill tillage blade is improved.

Owner:石狮市玛旭贸易有限公司

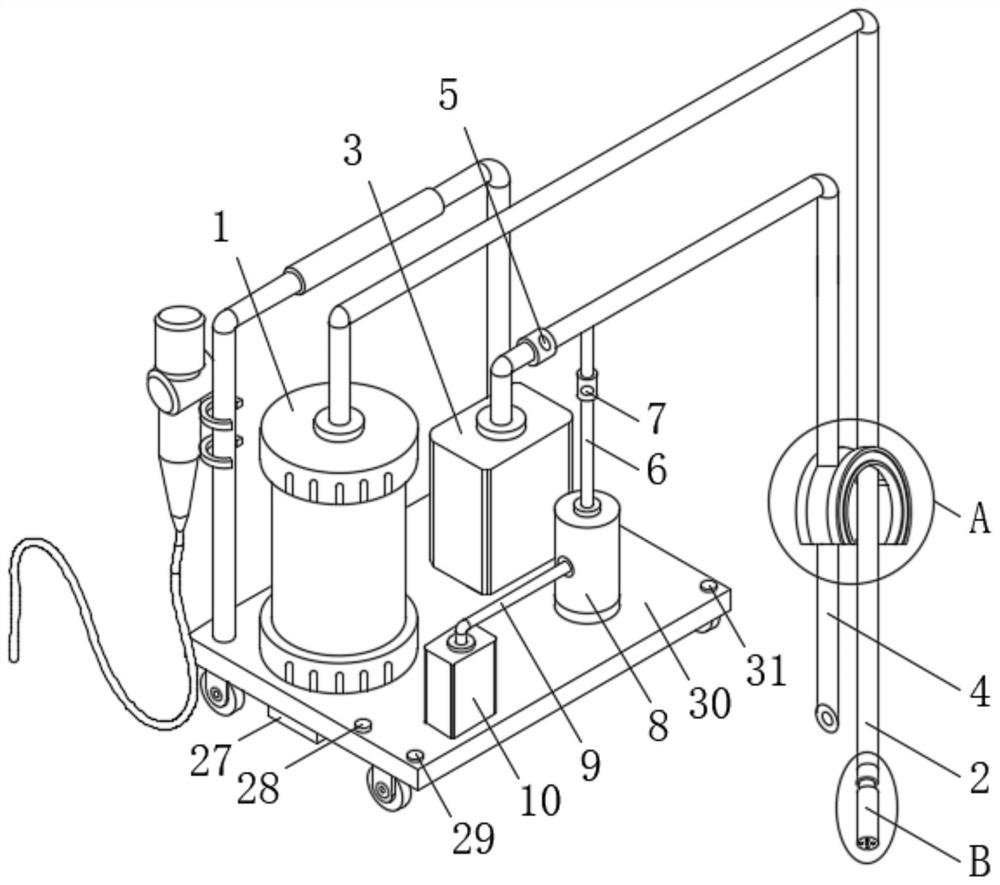

An anti-infection secretion collection device for bronchoscopic respiratory surgery

ActiveCN112138221BPlay a moisturizing effectHave a crushing effectRespiratorsIntravenous devicesSuction forceRespiratory surgery

The invention discloses an anti-infection secretion collection device for bronchoscopic respiratory surgery, which belongs to the technical field of medical devices and includes an electric negative pressure suction device and a negative pressure secretion drainage matched with the electric negative pressure suction device tube, and the periphery of the negative pressure secretion drainage tube is respectively provided with an upper brace and a lower brace, and an input pipeline is arranged between the upper brace and the lower brace, and the end of the input pipeline is connected with the connection port of the oxygen generator Pass. In the present invention, through the mutual cooperation between the designed electric negative pressure suction device, oxygen generator, ultrasonic atomizer, heat preservation water tank, motor, automatic pressure regulating device and cutting net, the drainage of negative pressure secretions is ensured. The patency of the tube and the input pipeline can crush the secretions, avoid the clogging caused by the large volume of the introduced secretions, and also have a blocking effect, effectively preventing excessive suction from damaging the patient's mucous membrane of the respiratory tract.

Owner:SUZHOU FRANKENMAN MEDICAL EQUIP

Municipal road solid waste crushing and transferring device

InactiveCN114308202AReduce usageReduce the burden onGrain treatmentsEnvironmental engineeringMaterial resources

The invention relates to the field of municipal cleaning equipment, in particular to a municipal road solid waste crushing and transferring device which comprises a conveying channel, a feeding port and a discharging port are formed in the two ends of the conveying channel respectively, and a crushing assembly used for crushing solid waste is arranged in the conveying channel. And the crushing assemblies comprise sliding rods slidably connected to the side wall of the conveying channel and extrusion blocks fixedly connected to the sliding rods, the two sliding rods are symmetrically arranged in the width direction of the conveying channel, the extrusion blocks on the two sliding rods are oppositely arranged, and the multiple crushing assemblies are evenly arranged in the length direction of the conveying channel. The device has the advantages that solid waste can be reasonably recycled, material resources are saved, and manpower resources are saved in the recycling process.

Owner:无锡市第五市政建设工程有限责任公司

Efficient anti-blocking device for municipal water supply and drainage

InactiveCN114382163AHave a crushing effectImprove drainage efficiencyFatty/oily/floating substances removal devicesSewerage structuresTransmission beltElectric machinery

The efficient anti-blocking device comprises a drainage tank, the right side of the drainage tank is fixedly connected with a water tank, the middle end of the right side of the water tank is fixedly provided with a water pump, the input end of the water pump is fixedly connected with a water pumping pipe, the output end of the water pump is fixedly connected with a liquid conveying pipe, and the surface of the liquid conveying pipe is fixedly connected with a flow meter. The inner cavity of the treatment box is fixedly connected with a filtering plate through bolts, the middle end of the filtering plate is fixedly connected with a filtering net, the effect of filtering sundries, leaves and the like is achieved, and therefore blocking can be conducted at the source, a second motor is fixedly installed at the top of the treatment box, and an output shaft of the second motor is in transmission connection with a transmission belt; and the inner surface of the transmission belt is in transmission connection with a transmission disc, and the surface of the transmission disc is fixedly connected with a second crushing cutter, so that the effect of crushing the sundries is achieved, the drainage efficiency can be improved, the sundries are crushed into small blocks, and blockage can be prevented.

Owner:郭玉如

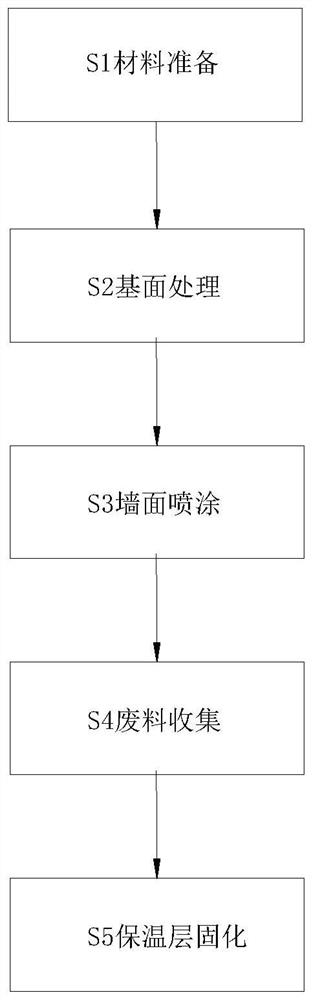

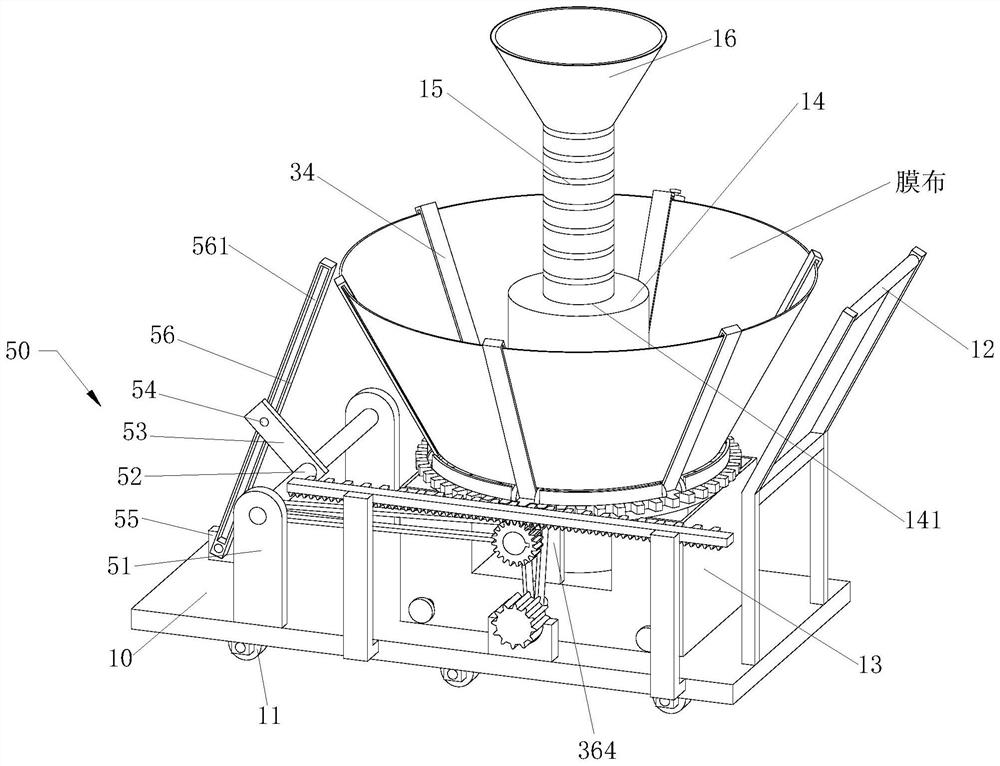

Interior decoration engineering thermal insulation layer manufacturing method

ActiveCN112609928AHave a crushing effectSpeed up dischargeBuilding constructionsPlane surface grinding machinesThermal insulationEngineering

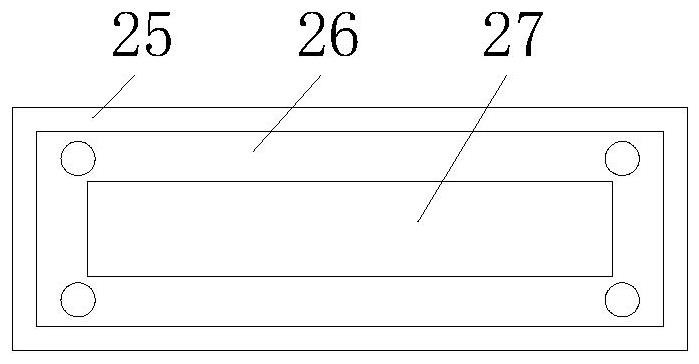

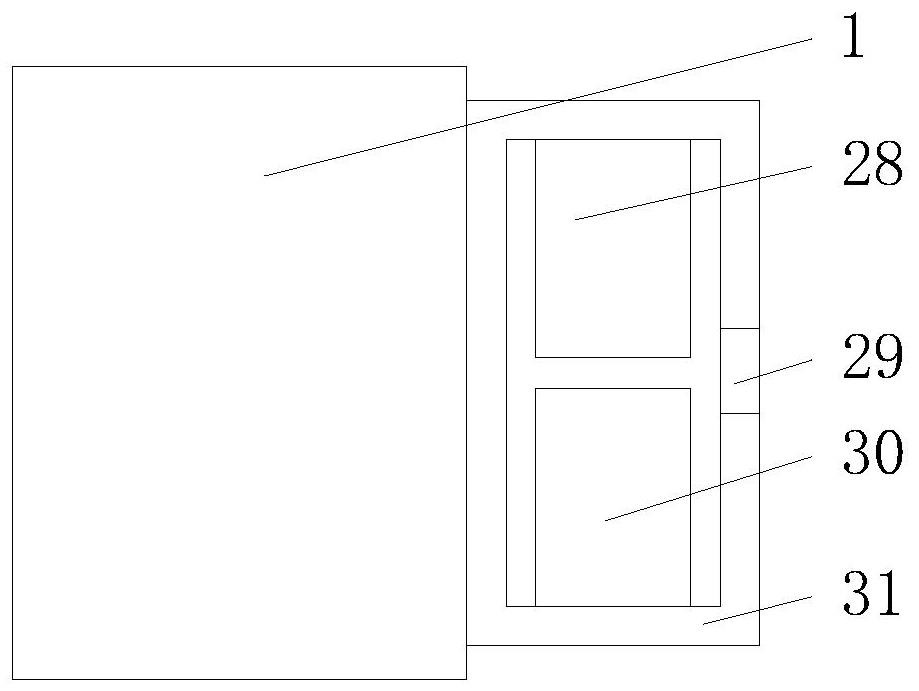

The invention relates to an interior decoration engineering thermal insulation layer manufacturing method. The interior decoration engineering thermal insulation layer manufacturing method uses thermal insulation layer processing and manufacturing equipment. The thermal insulation layer processing and manufacturing equipment comprises a concave box and a spraying device arranged in the concave box, and a collecting device is arranged at the top of the concave box. Through cooperation of a first annular plate, a first fan-shaped hole, a second annular plate, a second fan-shaped hole, a supporting rod, a first gear, a first rack, a second rack, a second gear and a first transmission belt, the first transmission belt can drive the second gear to rotate, the second gear drives a moving plate to reciprocate, and the moving plate drives the second annular plate to rotate; and when the second fan-shaped hole rotates to the top of the first fan-shaped hole, glass wool contained on film cloth is sequentially pushed to the top of the first fan-shaped hole from the top of the first annular plate through the second fan-shaped hole, at the moment, the glass wool contained on the film cloth slides into the concave box again to be collected, recycling can be achieved again, and resources are saved.

Owner:深圳市成豪建设集团有限公司

Efficient magnetite ore crushing device

PendingCN112371292AAvoid magnetic degradationMagnetic field stabilizationGrain treatmentsMining engineeringMagnetite

The invention discloses an efficient magnetic ore crushing device. The efficient magnetite ore crushing device comprises a rotating rod and a crushing box body which are fixedly connected with the output end of an external load motor, the rotating rod and the crushing box body are coaxially arranged, the rotating rod is rotationally connected with the crushing box body through a bearing, a feedingport is formed in the top of the crushing box body, a gas inlet pipe and a gas outlet pipe are arranged on the side walls of the bottom and the side wall of the top of the crushing box body respectively, a magnetic field stabilizing device comprising an N-pole magnetic pole plate, an S-pole magnetic pole plate and a buffer spring is arranged in the crushing box body, and a plurality of ore supporting frames with containing grooves and a plurality of telescopic holes are arranged on the rotating rod in a circumferential mode. Inert gas is introduced into the crushing box body through the gas inlet pipe, ferroferric oxide exposed outside in the crushing process of magnetite is prevented from being oxidized into hematite, meanwhile, heat generated by crushing can be taken away through flowing of gas flow, and the problem that magnetism is reduced when ore is heated in the crushing process can be effectively solved.

Owner:方荣

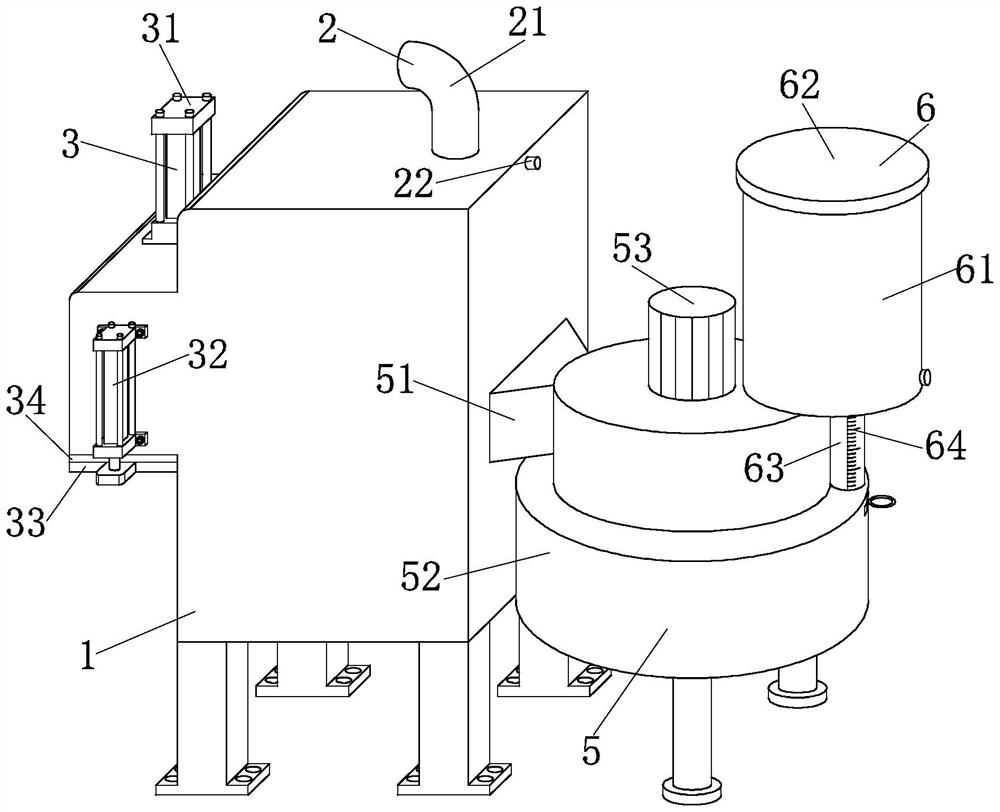

Low-impurity Baijiu brewing and cooking equipment and process

The invention discloses low-impurity white spirit brewing cooking equipment and process, and belongs to the technical field of white spirit brewing, the low-impurity white spirit brewing cooking equipment comprises a cooking machine shell, a dredging feeding assembly, a mounting assembly, a telescopic assembly, a filter cartridge and a conical inner barrel, the top and the bottom of the cooking machine shell are fixedly provided with a driving motor and a machine base respectively; a feeding pipe and a discharging pipe are fixedly installed on the outer walls of the two sides of the cooking machine shell, a protection inner shell is fixedly installed on the inner wall of the top face of the cooking machine shell, and a transmission main shaft is fixedly installed at one end of an output shaft of a driving motor; according to the present invention, the conical inner cylinder is designed to be conical, and the crushing convex sleeve is mounted at the bottom of the conical inner cylinder, such that the raw material can slowly fall and the gap between the raw material and the filtration cylinder becomes smaller and smaller due to the design of the narrow top and the wide bottom of the conical inner cylinder during the cooking of the raw material; and the raw materials can be crushed, the function is powerful, and meanwhile, the raw materials can be conveniently discharged.

Owner:袁艳华

Device for treating construction sewage containing construction waste

InactiveCN114470937AImplement classificationReduce space consumptionConstruction waste recoveryDischarging apparatusSewageSewage treatment

The invention relates to the field of building sewage treatment devices, in particular to a building waste-containing building sewage treatment device which comprises a box body, a steering structure, a compression structure, an opening and closing structure, a recycling structure, a mixing structure and a discharging structure, by installing the compression structure at one end of the box body, the functions of garbage classification and environmental protection can be achieved, the sorted garbage can be compressed, so that the space occupation of the garbage is reduced, the compression structure can act on the opening and closing structure while working, and the compression structure is arranged, so that the garbage can be conveniently and rapidly compressed through the opening and closing structure. According to the garbage compression device, the feeding port can be automatically blocked when garbage is compressed, so that manual closing is not needed, time and labor are saved, the recycling structure is installed at one end of the box body, gravel screened out from sewage can be smashed and stirred again so as to be recycled, emission of sewage pollutants can be reduced, waste can be turned into wealth, and the environment is protected. And recycling is realized.

Owner:徐州嘉德建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com