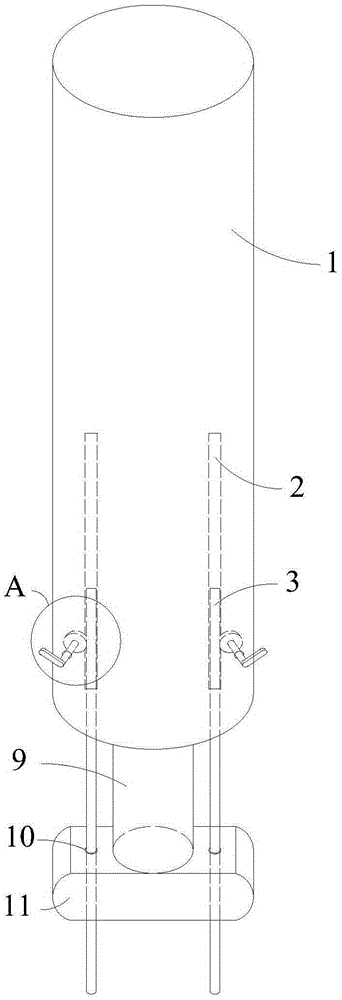

Carbon fiber river protection pile body, preparing method thereof and carbon fiber river protection pile

A body and carbon fiber technology, applied in the direction of coating, etc., can solve the problems of moisture absorption loss caused by humid environment, high cost, heavy workload, etc., and achieve the effect of improving product quality, prolonging service life and long service life

- Summary

- Abstract

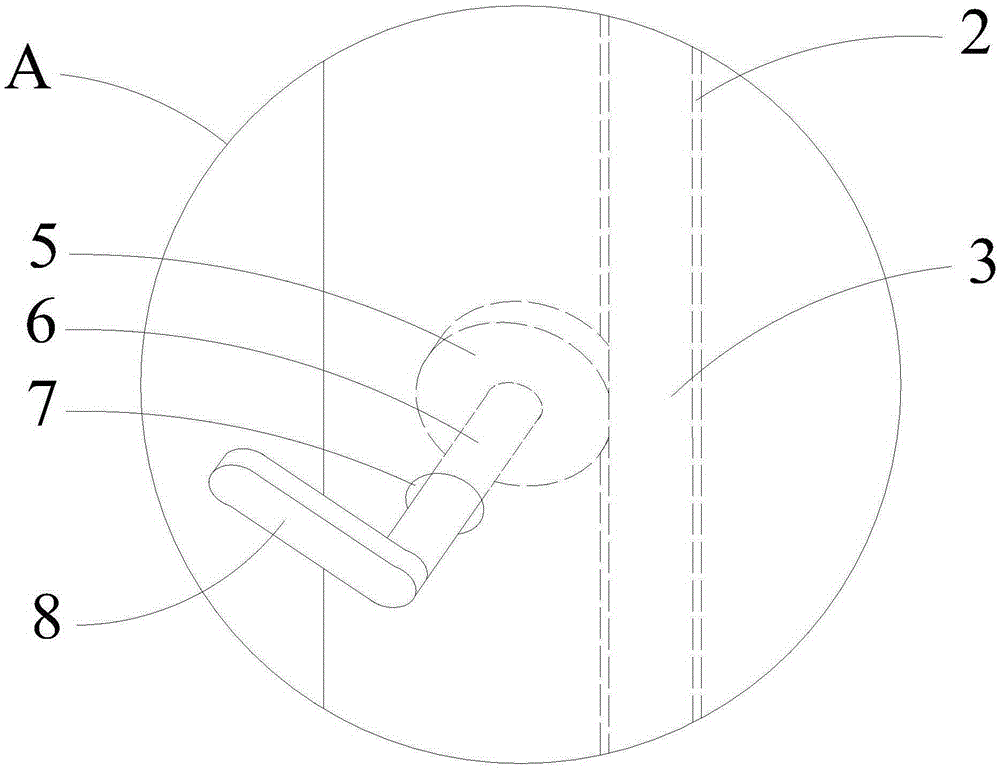

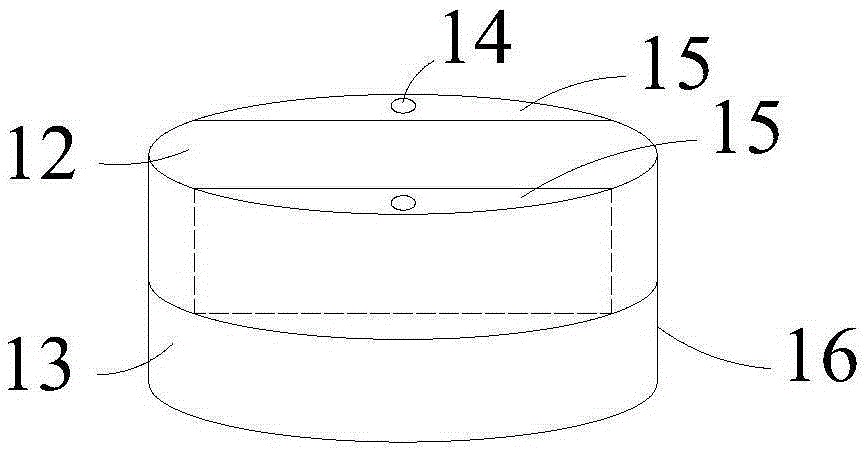

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The preparation method of the carbon fiber river protection pile body of the present embodiment is as follows:

[0049] Weigh the main raw materials: 70kg polypropylene, 8kg ABS resin and 4kg carbon fiber, cut the polypropylene and ABS resin into small pieces of 2mm × 2mm × 2mm respectively to obtain polypropylene small pieces and ABS resin small pieces; polypropylene small pieces The block and the ABS resin block are crushed and passed through a 100-mesh sieve to obtain polypropylene powder and ABS resin powder respectively; under vacuum conditions at 80°C, the polypropylene powder is dried until the moisture content is not greater than 0.13%, and the polypropylene dry material is obtained; Under vacuum conditions at 91°C, dry the ABS resin powder until the moisture content is not more than 0.1%, and obtain the dry material of the ABS resin; place the dry material of the polypropylene and the dry material of the ABS resin in a tumbler respectively, and under vacuum cond...

Embodiment 2

[0054] The antioxidant 1010, ultraviolet absorber uv-623 and light stabilizer 770 of this embodiment were all purchased from Nanjing Hualiming Chemical Co., Ltd., and the anti-aging agent MBP was purchased from Qingdao Huaen Chemical Co., Ltd. as a plastic anti-aging agent. Melamine pyrophosphate was purchased from Shenzhen Hongtaiji Industrial Co., Ltd.

[0055] The preparation method of the carbon fiber river protection pile body of the present embodiment is as follows:

[0056] Weigh the main raw materials: Weigh 75kg waste polypropylene, 10kg waste ABS resin and 5kg carbon fiber, cut the polypropylene and ABS resin into small pieces of 2mm×2mm×2mm respectively to obtain polypropylene small pieces and ABS resin small pieces ; The small pieces of polypropylene and ABS resin are crushed and passed through a 100-mesh sieve to obtain polypropylene powder and ABS resin powder respectively; under vacuum conditions at 80°C, the polypropylene powder is dried until the moisture cont...

Embodiment 3

[0061] The preparation method of the carbon fiber river protection pile body of the present embodiment is as follows:

[0062] Weigh the raw materials of main ingredients: weigh 80kg polypropylene, 12kg ABS resin and 6kg carbon fiber, cut the polypropylene and ABS resin into small pieces of 2mm×2mm×2mm respectively to obtain polypropylene small pieces and ABS resin small pieces; The small pieces of propylene and ABS resin are crushed and passed through a 100-mesh sieve to obtain polypropylene powder and ABS resin powder respectively; under vacuum conditions at 80°C, the polypropylene powder is dried until the moisture content is not greater than 0.13%, and dry polypropylene powder is obtained ; Under vacuum conditions at 91°C, dry the ABS resin powder until the moisture content is not more than 0.1%, and obtain the dry ABS resin material; place the dry material of polypropylene and the dry material of ABS resin in a tumbler respectively, and dry them under vacuum conditions. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com