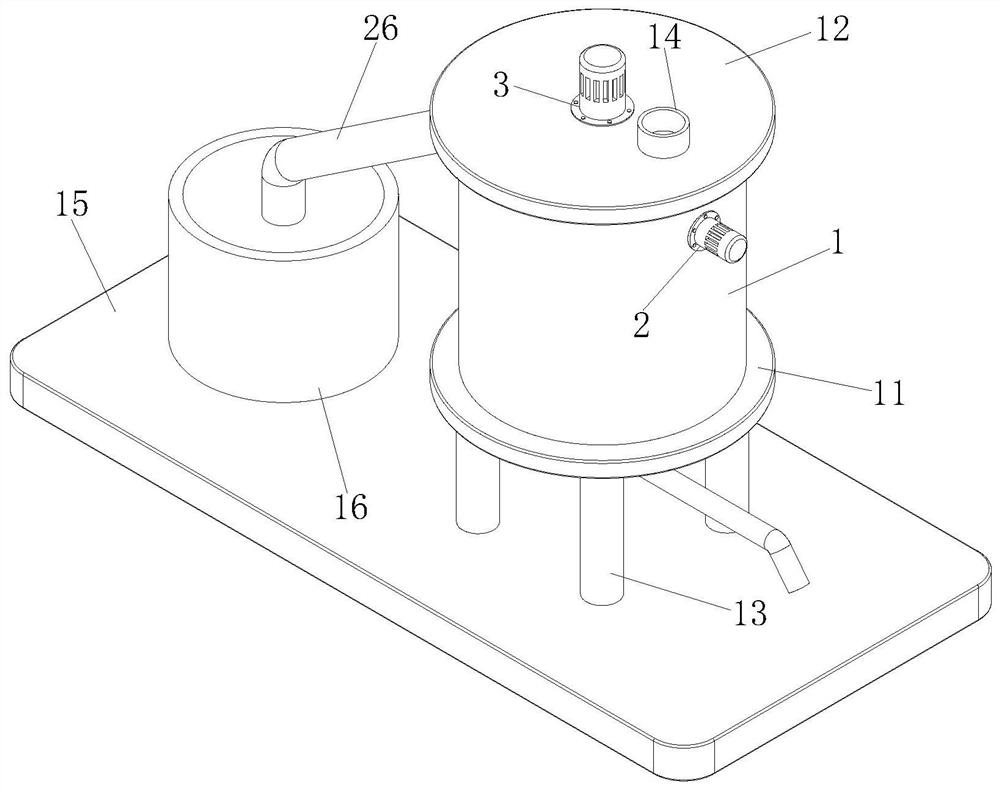

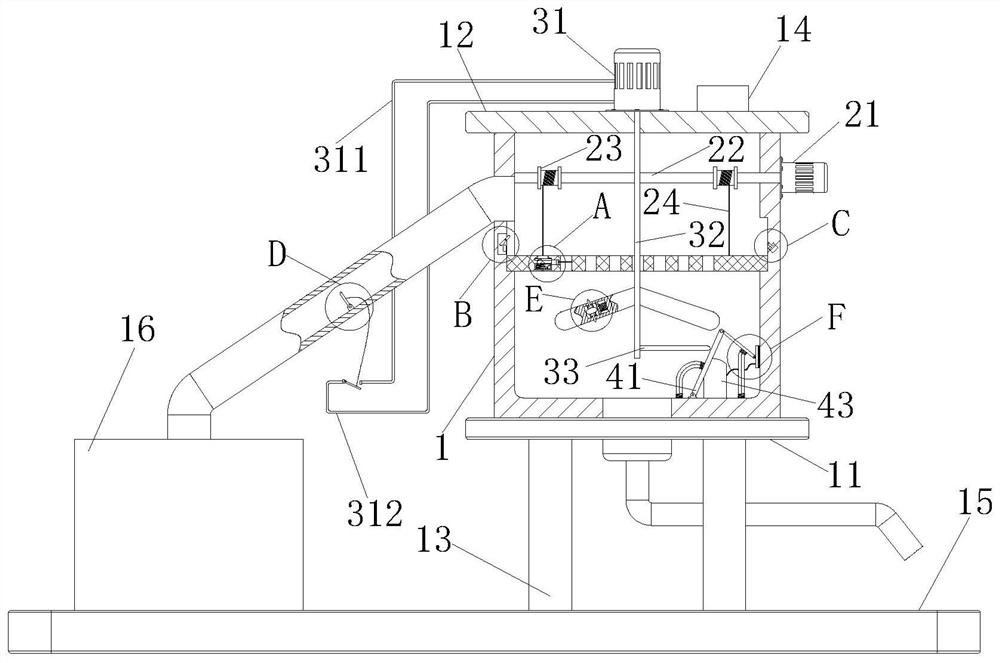

Blueberry sparkling wine brewing device

A brewing device and sparkling wine technology, which are applied in the preparation of alcoholic beverages, solid separation, wet separation, etc., can solve the problems of low efficiency, large manual screening workload, delay time, etc., so as to improve the output and shorten the screening time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

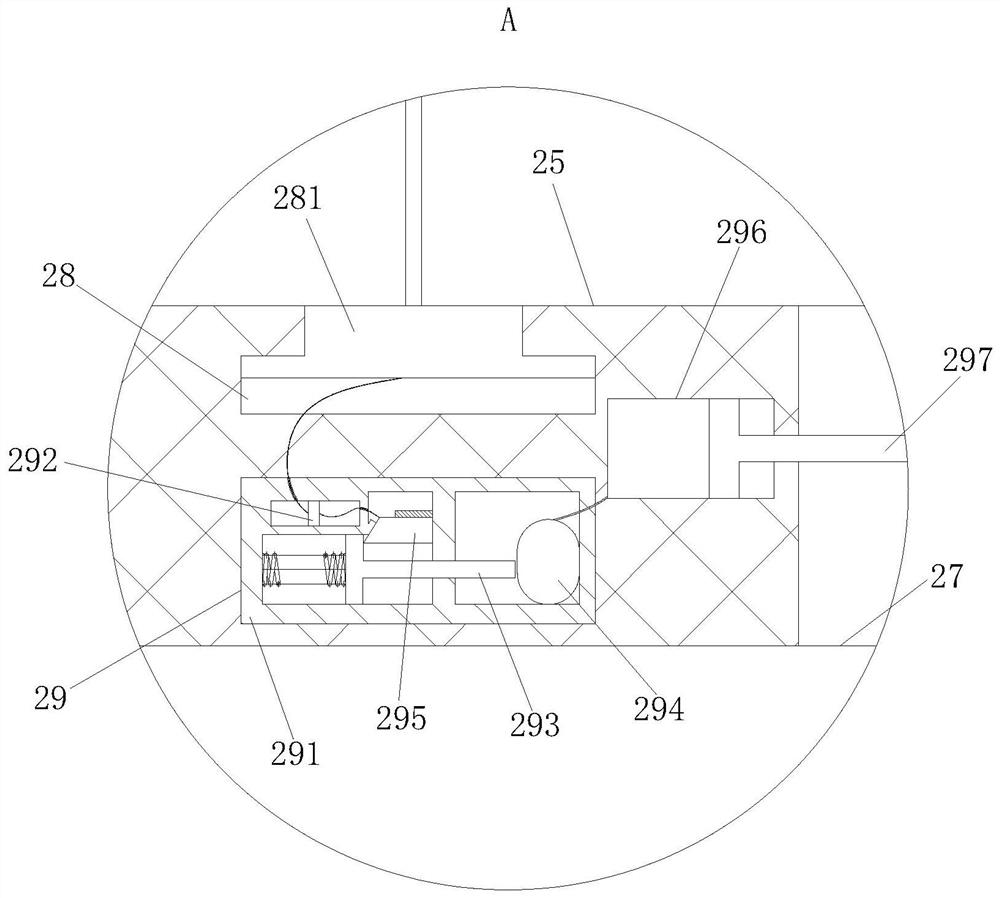

[0030] As an embodiment of the present invention, the stopper mechanism 29 includes a rectangular block 291, a slide block 292, a T-shaped bar 293, a first air bag 294, a block 295, a second chute 296 and a baffle 297; The rectangular block 291 is fixed on the inner wall of the screening plate 25; the slider 292 is slidably connected to the inner wall of the rectangular block 291, and one side thereof is connected to the bottom end of the trapezoidal block 281 by a round rope, and the other side is connected to the retaining block by a round rope. The block 295 is connected; the T-shaped bar 293 is slidably connected to the inner wall of the rectangular block 291; the first air bag 294 is fixed on the inner wall of the rectangular block 291; the second chute 296 is fixed to the inner wall of the rectangular block 291 on the inner side wall, and the inside communicates with the first air bag 294; the baffle plate 297 is slidably connected to the inside of the second chute 296; d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com