Patents

Literature

105results about How to "Achieve broken effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

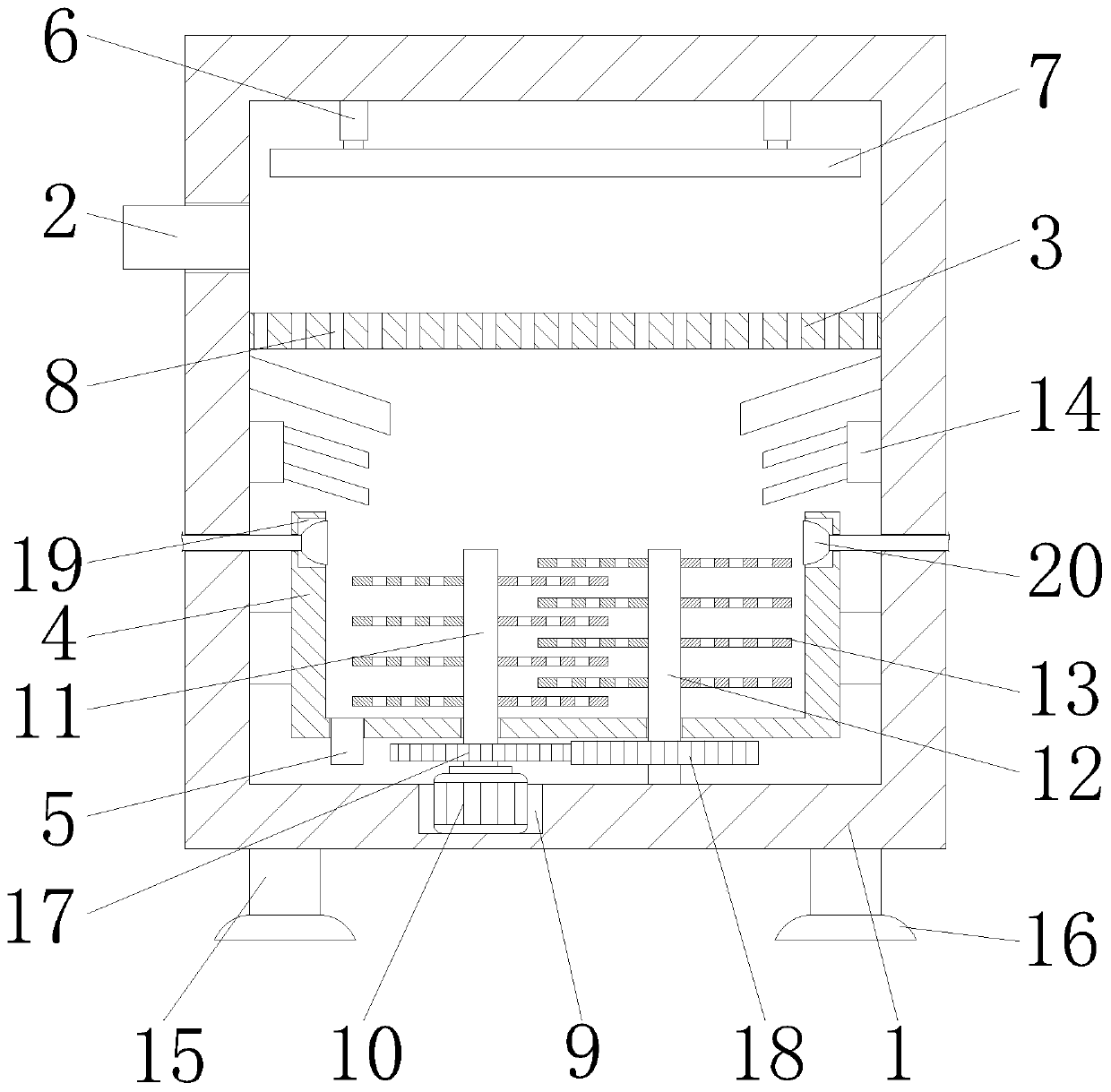

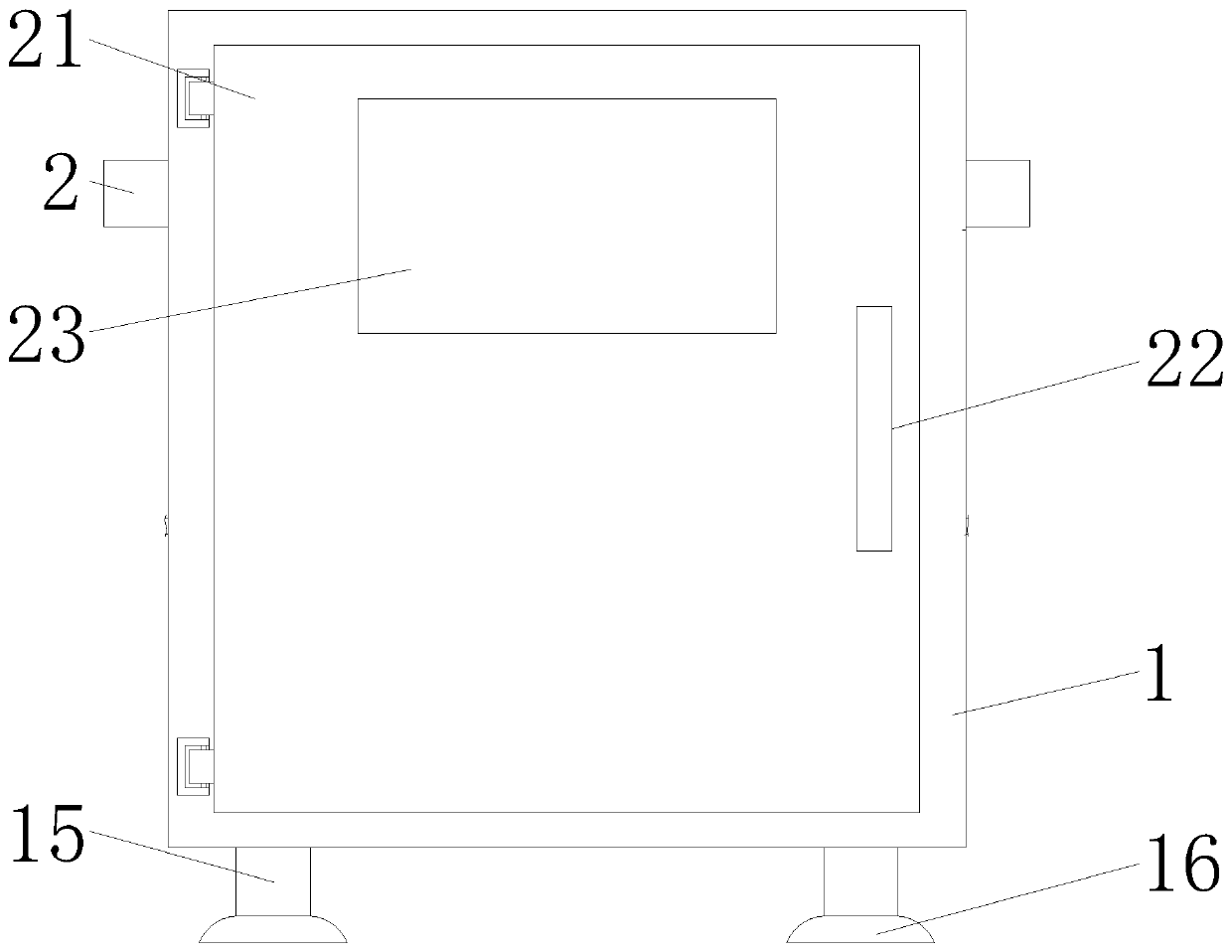

Crushing device for recycled concrete production

ActiveCN110523505AEasy to crushReduce the probability of cloggingCleaning using liquidsGrain treatmentsEngineeringMachining

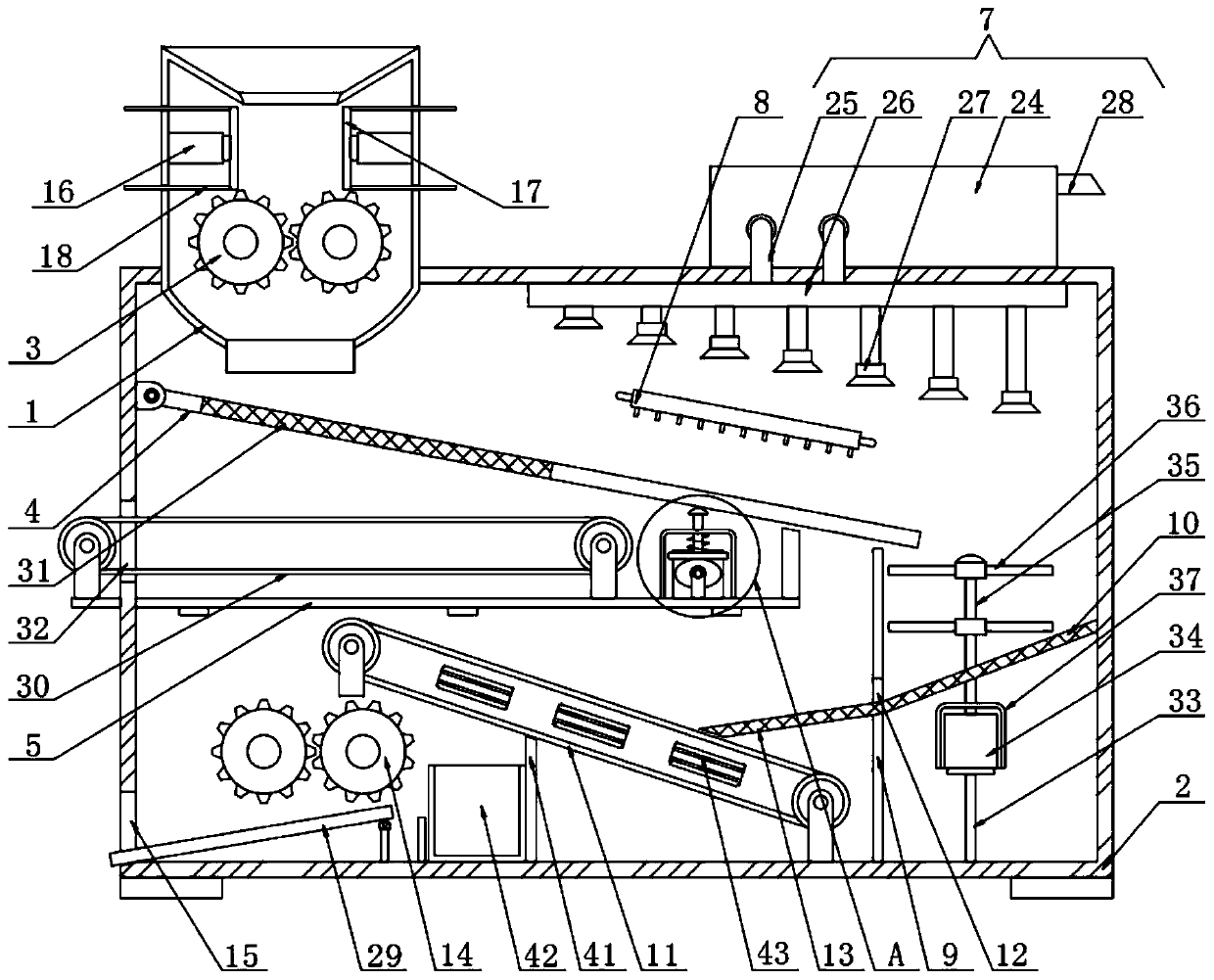

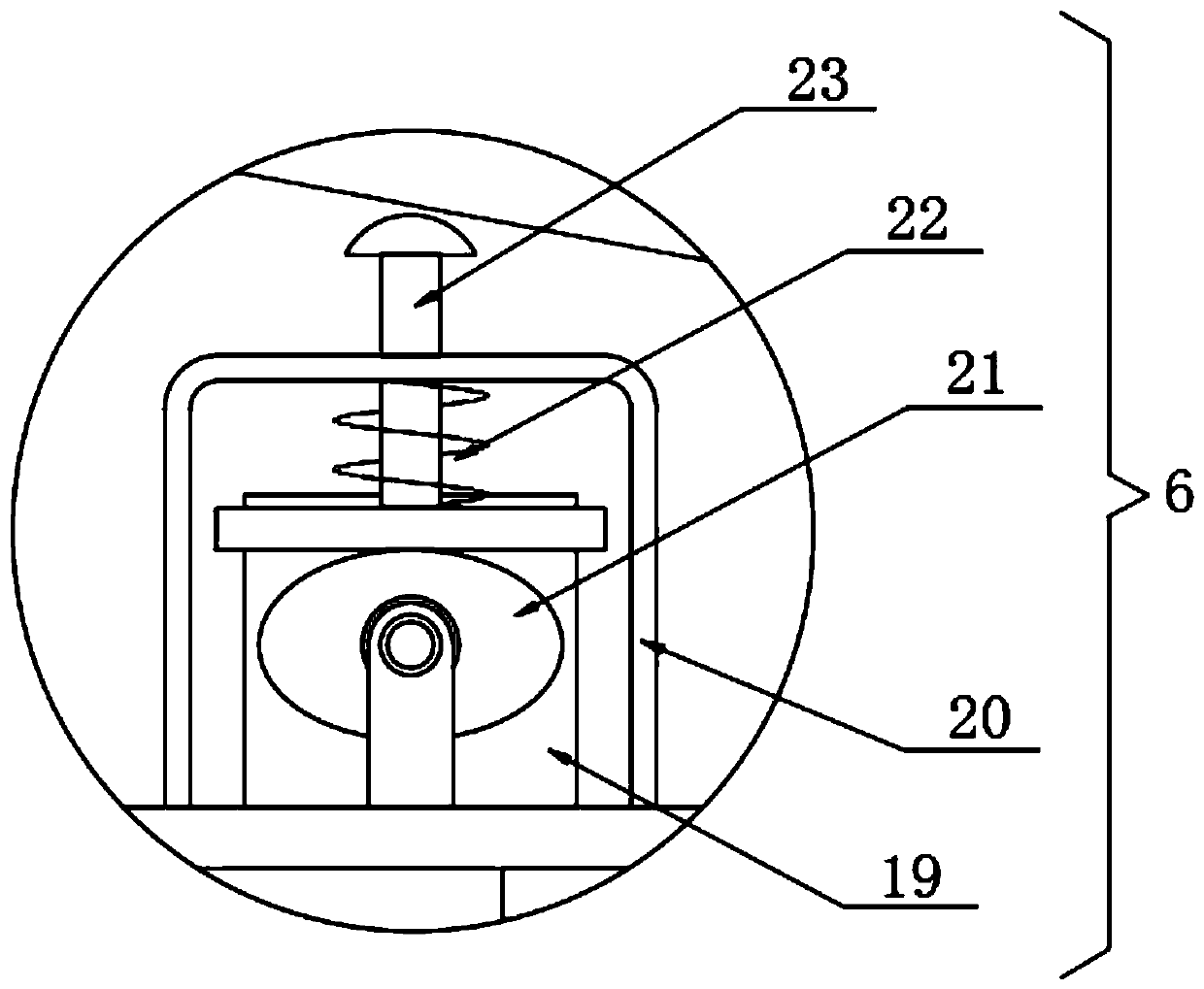

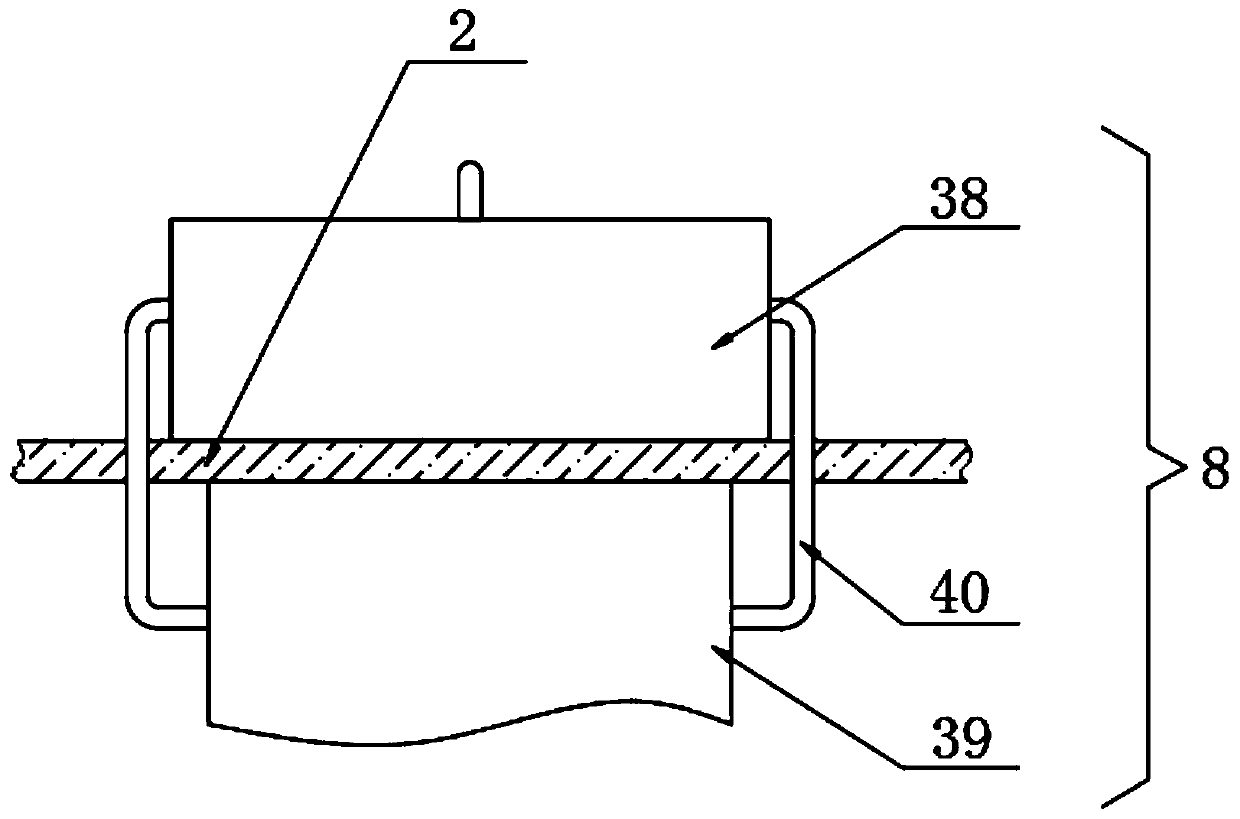

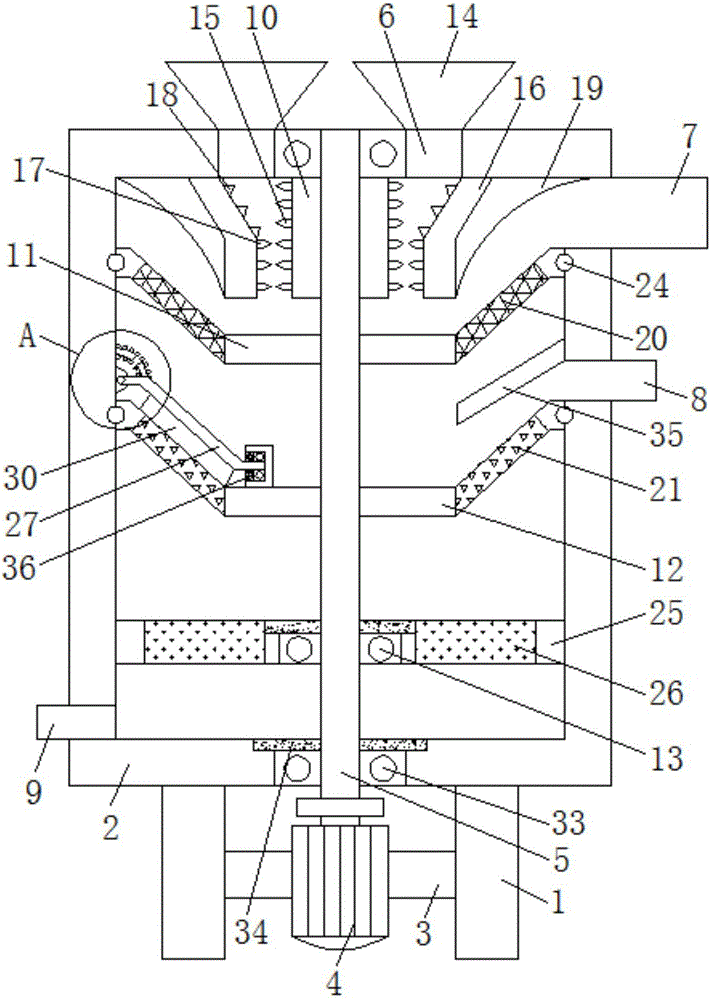

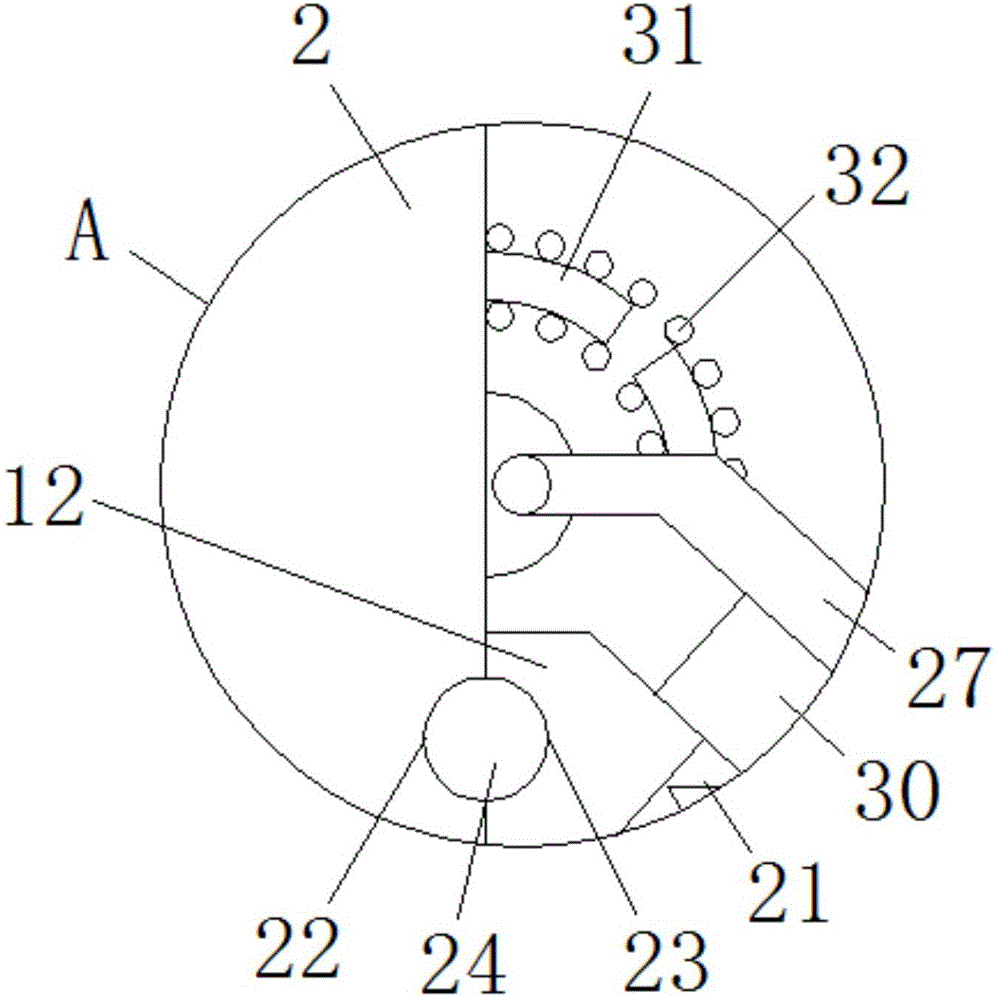

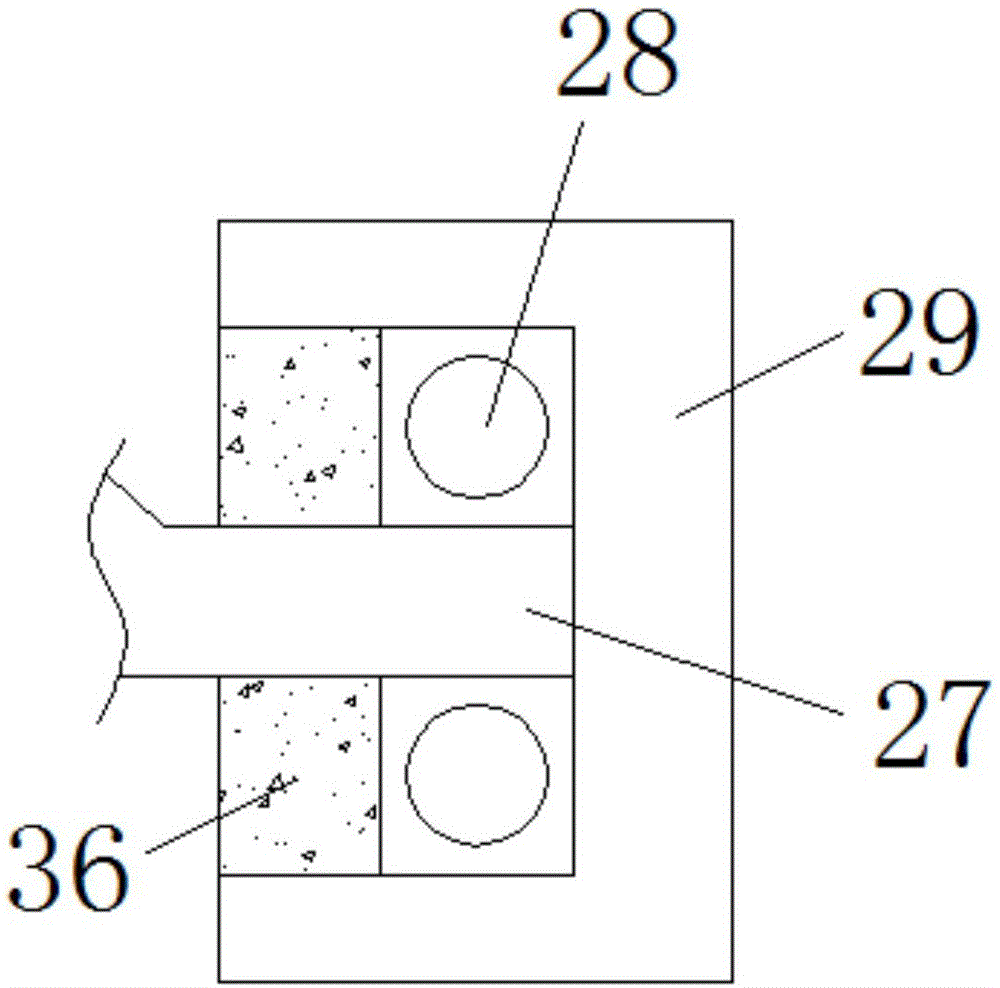

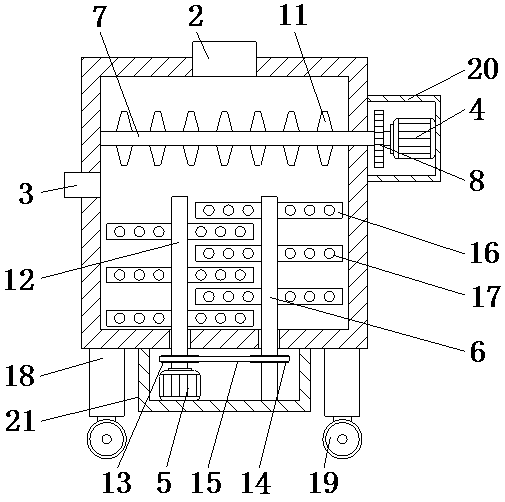

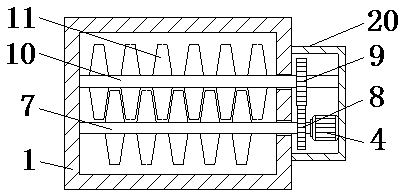

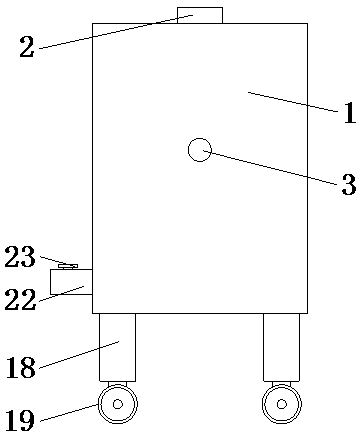

The invention discloses a crushing device for recycled concrete production. The device comprises a feeding box and a processing box, the bottom of the feeding box communicates with the left side at the top of the processing box, and a first crushing roller set is rotationally connected between the front side and the rear side of an inner cavity of the processing box through bearings. A conveying plate is rotationally connected to the top of the left side of the inner cavity of the processing box through a rotating block, and a transverse plate is fixedly connected to the position, located below the conveying plate, at the left side of the inner cavity of the processing box. The crushing device for recycled concrete production relates to the recycled concrete production technical field, after the preliminary crushing, the waste concrete is directly subjected to spray washing treatment, and the impurities are screened out, so that the treatment capacity of the device on the waste concrete can be reduced, the gaps on the surface of the waste concrete can be looser, the crushing is facilitated, and then the crushing treatment is conducted, and accordingly the crushing effect of the device on the waste concrete can be guaranteed, and the later-period reuse machining quality is guaranteed.

Owner:滁州高仁建设工程有限公司

Preparation method for high-purity melted quartz powder material

The invention discloses a preparation method for a high-purity melted quartz powder material. The method comprises the following steps of comprehensively removing impurities from crude vein quartz mine, namely performing rough crushing, manual selection, electrostatic impurity removal, fine crushing and screening, high-gradient magnetic separation, acid washing impurity removal, washing and air-drying to obtain clean quartz sand; placing the clean quartz sand in an active gas melting furnace for purification, namely introducing active gas in the high-temperature melting furnace to obtain a high-purity melted quartz block; crushing the melted quartz block into powder by using a centrifugal crusher, and performing high-gradient magnetic separation on the powder to obtain high-purity melted quartz powder. According to the method, quartz powder with purity of 99.99 percent can be obtained.

Owner:中材高新江苏硅材料有限公司

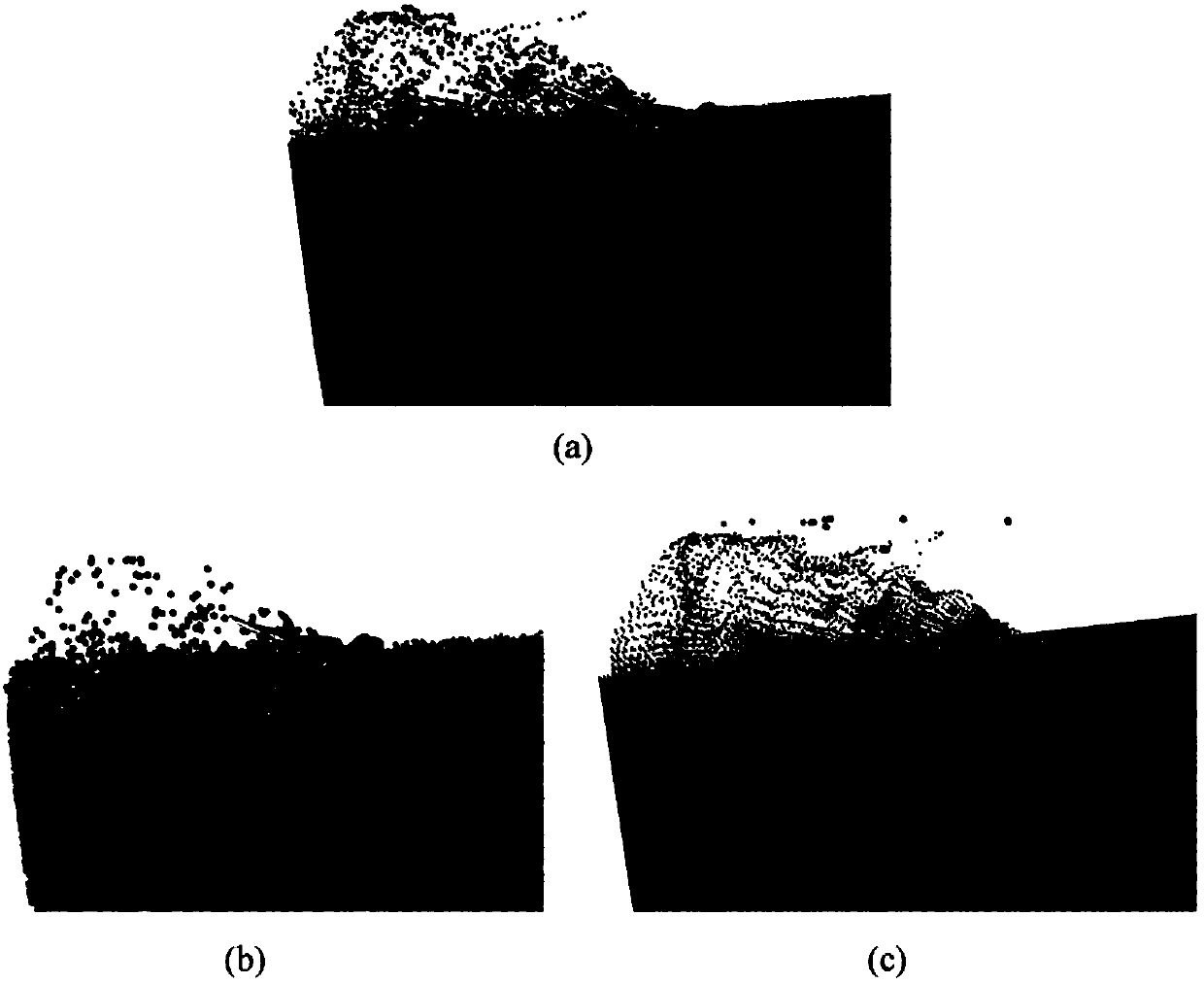

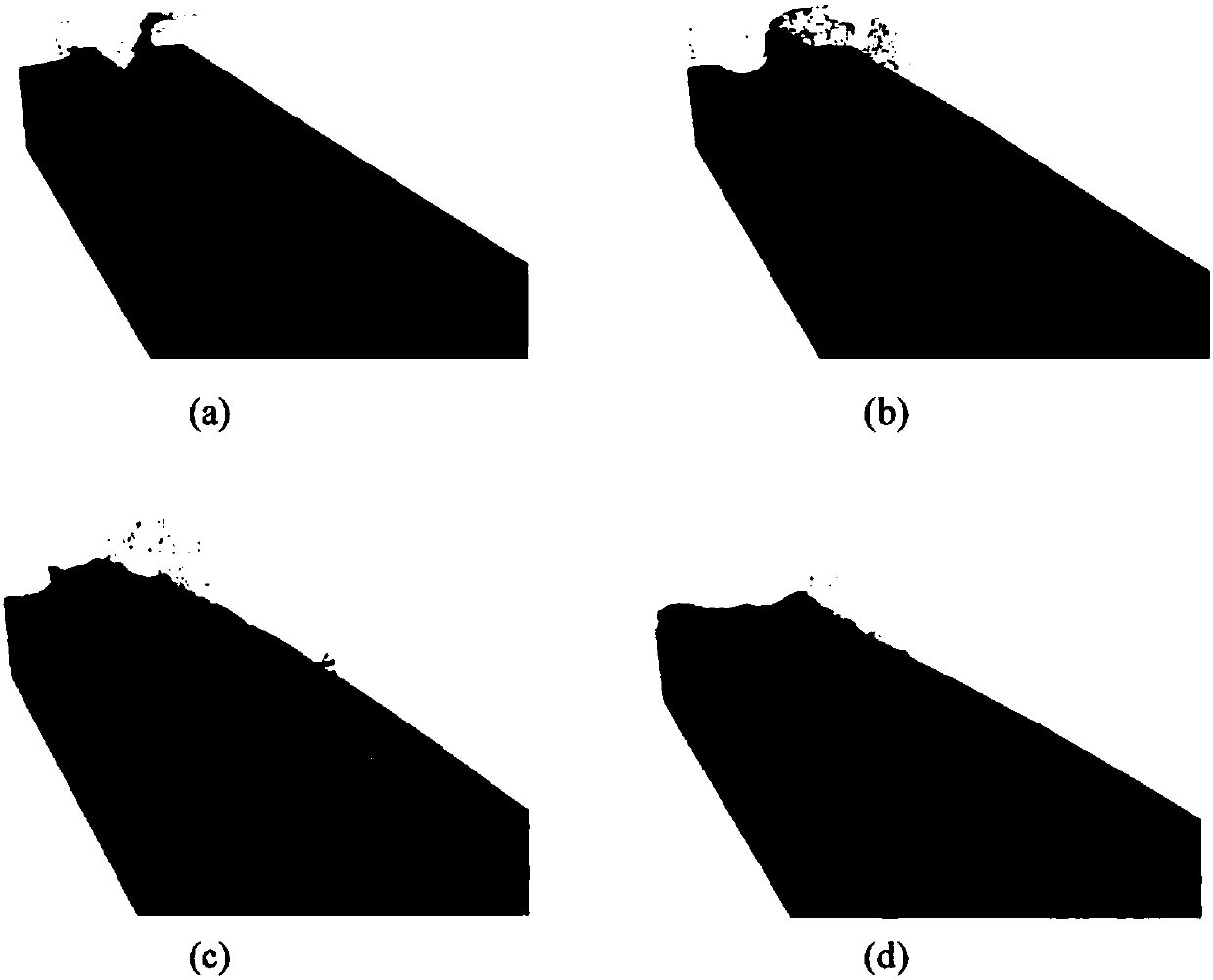

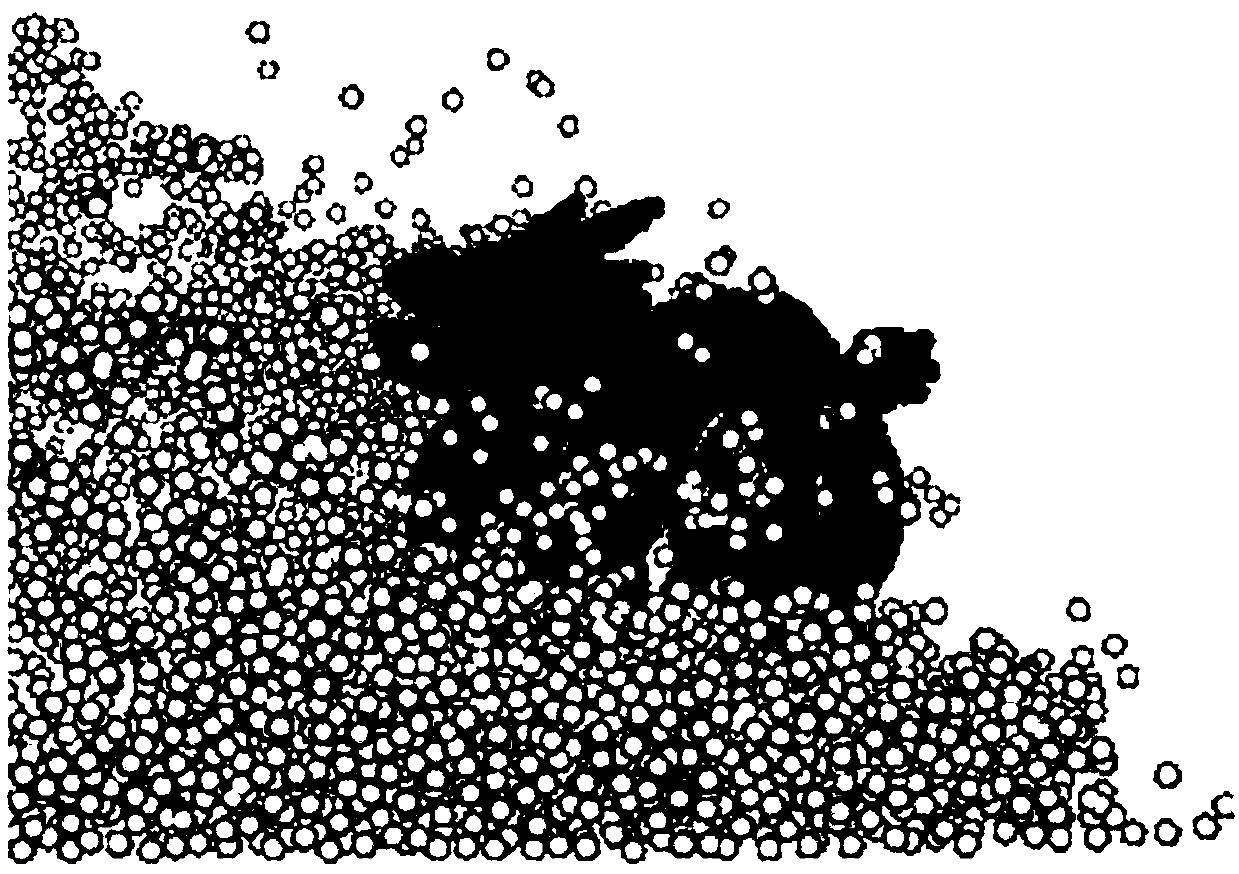

Physical and non-physical mixture-based complex scene fluid-solid coupling efficient simulation method

InactiveCN108491619AEnsure incompressibilityRich detail effectDesign optimisation/simulationSpecial data processing applicationsSmoothed-particle hydrodynamicsFracture mechanics

The invention discloses a physical and non-physical mixture-based complex scene fluid-solid coupling efficient simulation method. The method comprises the steps of 1) performing incompressible fluid simulation, combining an Euler method and a Lagrange method, and proposing an implicit particle method-based zero-divergence smooth particle fluid dynamics method; 2) performing dynamics problem solving in fluid-solid coupling, subdividing a motion problem of a simulation object into three sub-problems according to object attributes, and solving the three sub-problems by using different methods respectively to realize a multi-dimensional classification combination computing framework; and 3) combining a strain energy density concept in fracture mechanics with Voronoi spatial segmentation to realize a physical perception-based crushing method. The simulation efficiency problem difficult to solve in complex fluid-solid coupling scene simulation is solved. Compared with a conventional fluid-solid coupling method, the method can simulate a fluid scene with richer details under the same system resources, and can meet the demand of simulating solid crushing under fluid impact.

Owner:ZHEJIANG UNIV

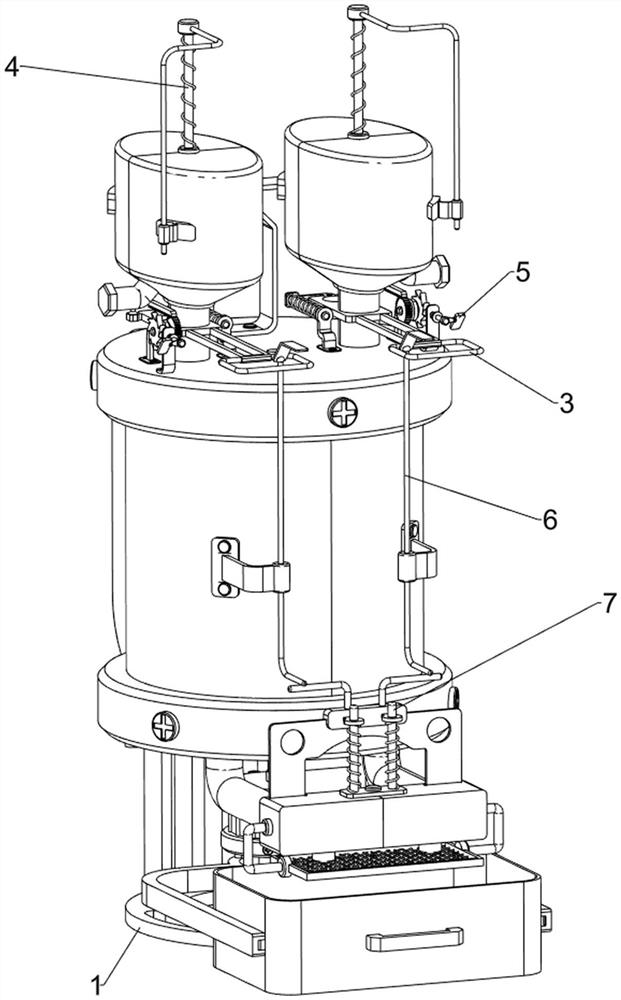

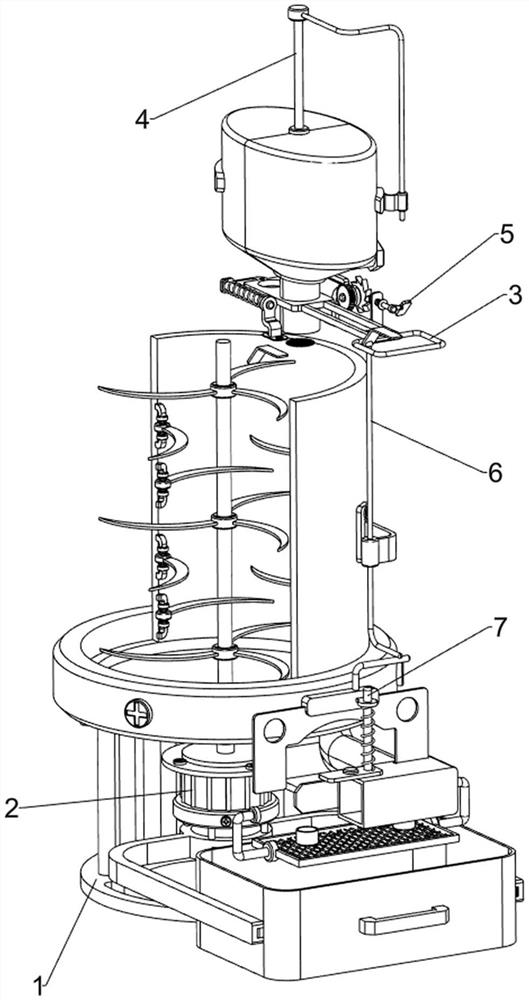

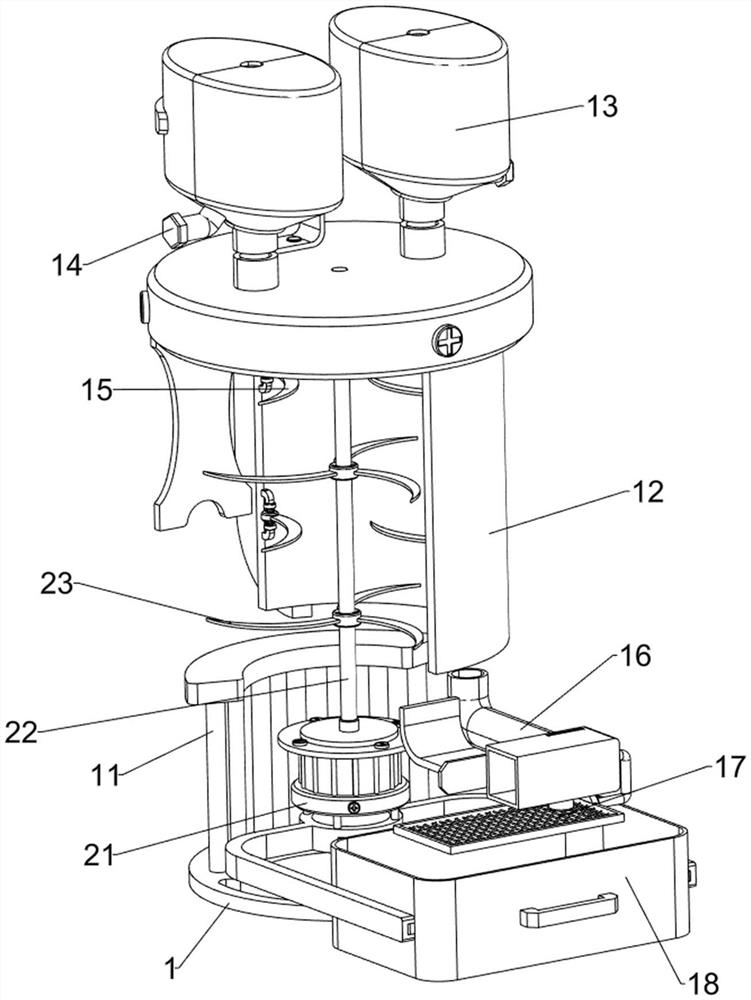

Automatic mixing device for colored glaze production

ActiveCN112844193AWell mixedAchieve broken effectTransportation and packagingRotary stirring mixersGlazeEngineering

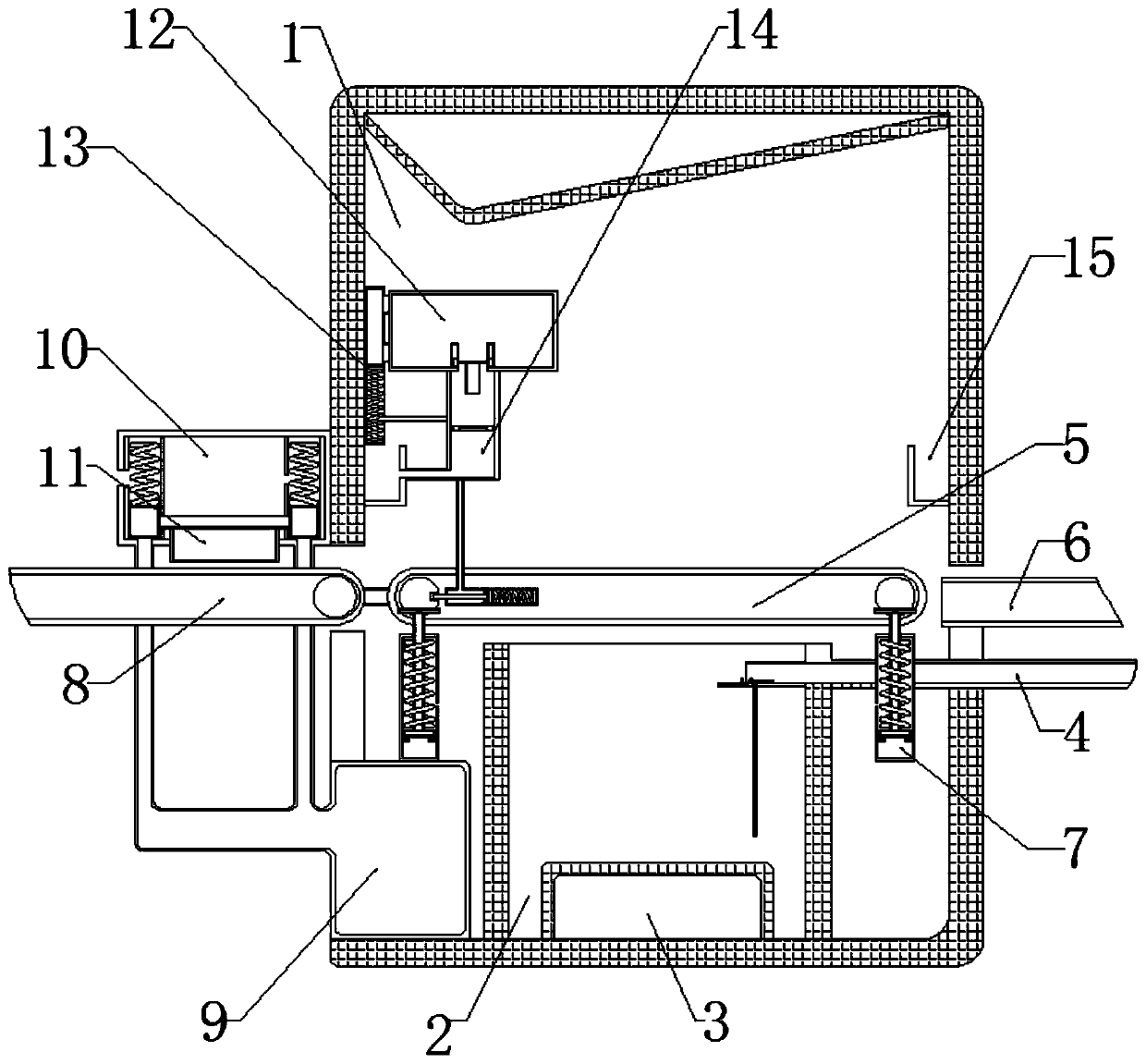

The invention relates to a mixing device, and particularly relates to an automatic mixing device for colored glaze production. The automatic mixing device for colored glaze production is good in mixing effect, capable of reducing the labor intensity of workers and easy and understandable to operate. The automatic mixing device for colored glaze production comprises a base, a fixed supporting column, a mixing box body, a discharging box, feeding openings, static crushing cutters, a discharging channel and a filter screen, wherein the fixed supporting column is arranged on the base; the mixing box body is arranged at the top of the fixed supporting column; the discharging box is arranged at the top of the mixing box body; the feeding openings are formed in the two sides of the lower part of the discharging box; three static crushing cutters are rotationally arranged on each of the upper side and the lower side in the mixing box body; the discharging channel is arranged at the bottom of the mixing box body; and the filter screen is arranged between the two sides of the discharging channel. By arranging the crushing mechanism, the colored glaze in the mixing box body is more uniformly mixed through the operation of the crushing mechanism, and the crushing effect is achieved.

Owner:高安常莹新型材料有限公司

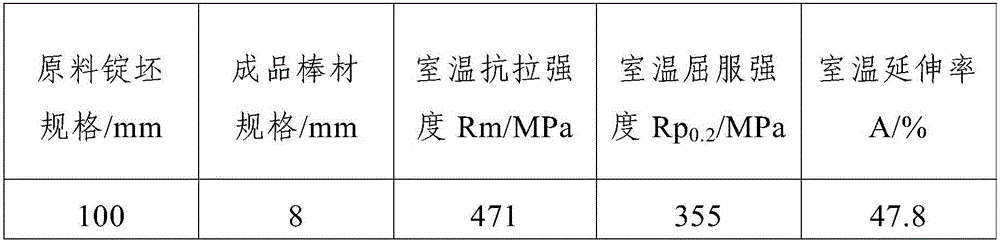

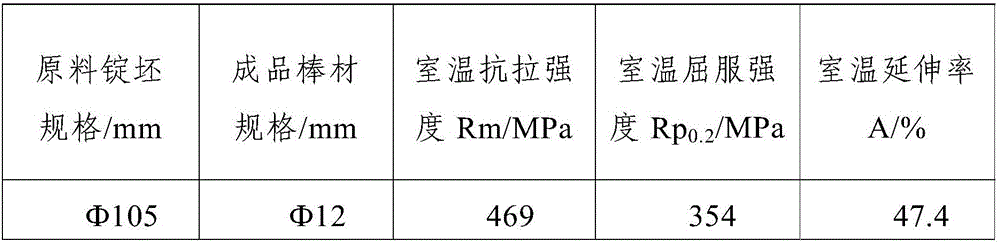

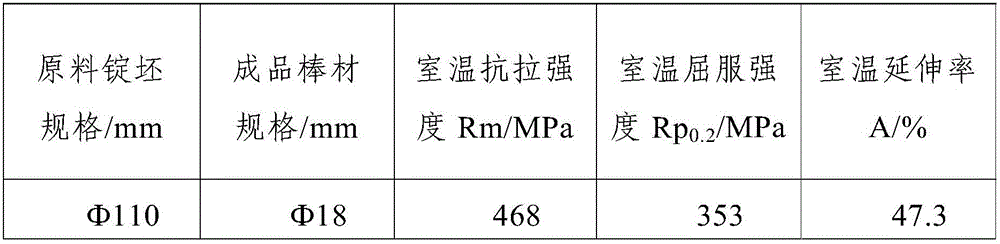

Processing method for small-size and high-strength niobium-hafnium alloy bar

The invention provides a processing method for a small-size and high-strength niobium-hafnium alloy bar. The processing method comprises the following steps that 1, a niobium-hafnium alloy ingot blank is sawn, and after being heated, the sawn niobium-hafnium alloy ingot blank is coated with an anti-oxidative protective lubricant; 2, the niobium-hafnium alloy ingot blank coated with the anti-oxidative protective lubricant is forged through upsetting and stretching to obtain a bar billet; 3, the bar billet is sequentially turned, ground and vacuum-annealed for the first time; 4, the vacuum-annealed bar billet is heated, the heated bar billet is coated with an anti-oxidative protective lubricant, and the bar billet coated with the anti-oxidative protective lubricant is formed through die forging to obtain a forging stock; 5, the forging stock is sequentially turned, ground and vacuum-annealed for the second time; 6, the vacuum-annealed forged stock is rolled with grooved rolls to obtain a small-size bar billet; and 7, the small-size bar billet is sequentially straightened, scalped, polished, pickled and annealed to obtain the small-size and high-strength niobium-hafnium alloy bar. The diameter of the section of the bar obtained according to the processing method is 8-20 mm, the room temperature tensile strength of the bar is up to above 465 MPa, the yield strength of the bar is up to above 350 MPa, the elongation of the bar is above 47%, and the grain structure of the bar is fine and uniform.

Owner:西安诺博尔稀贵金属材料股份有限公司

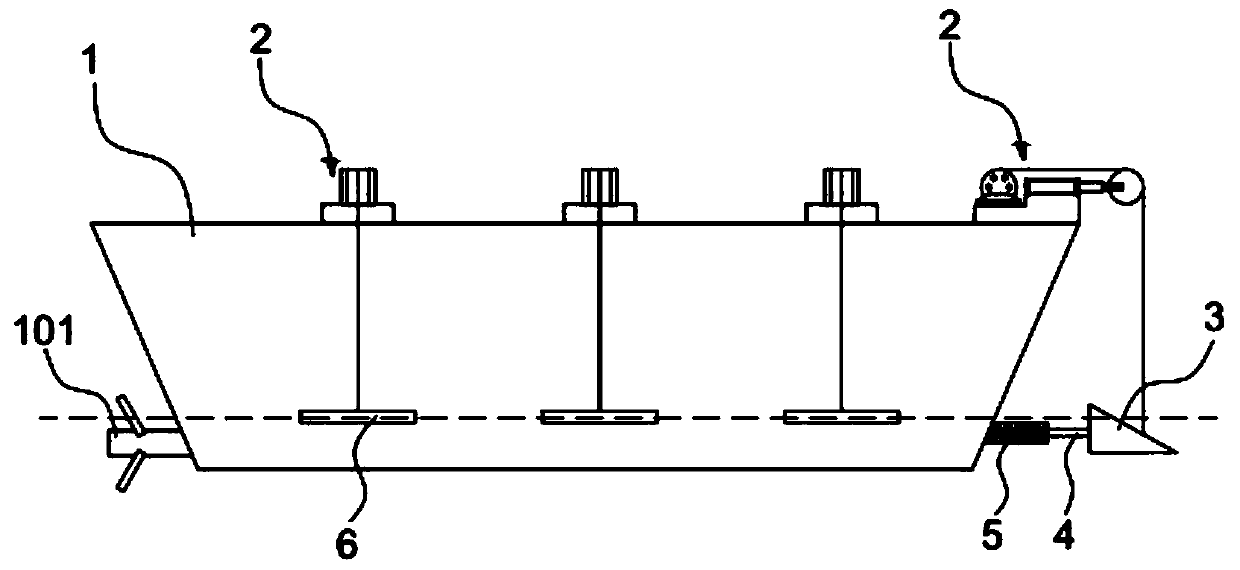

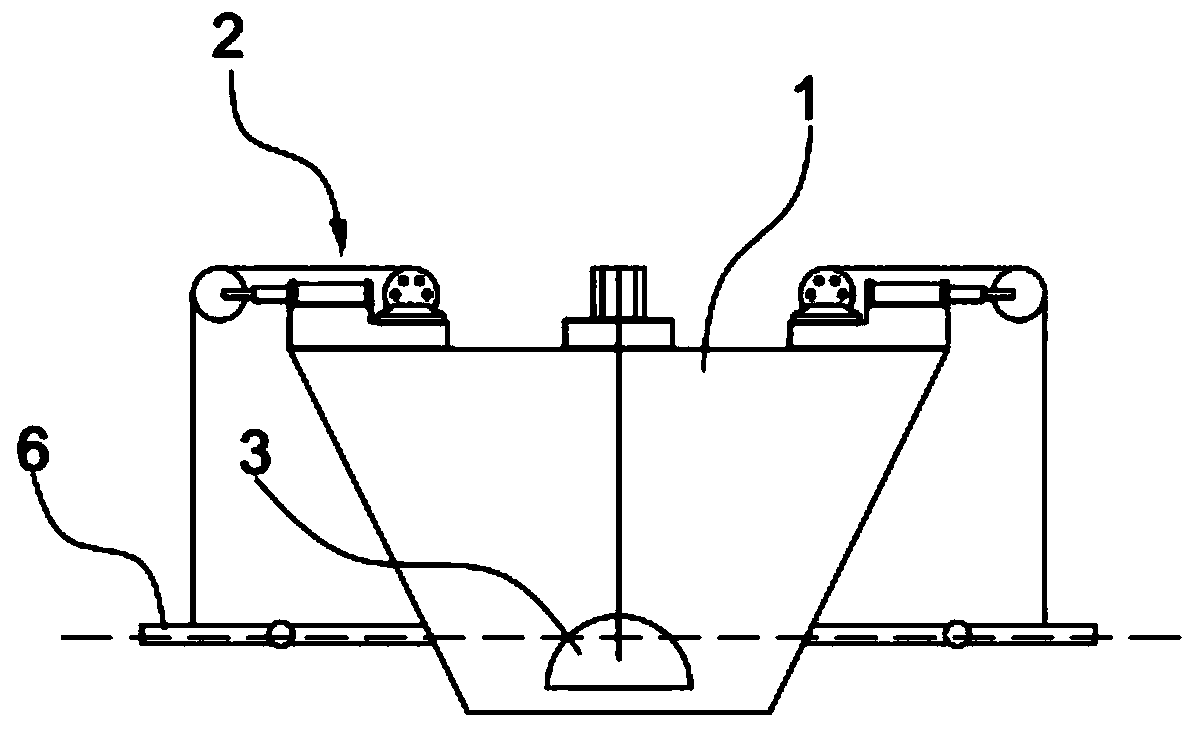

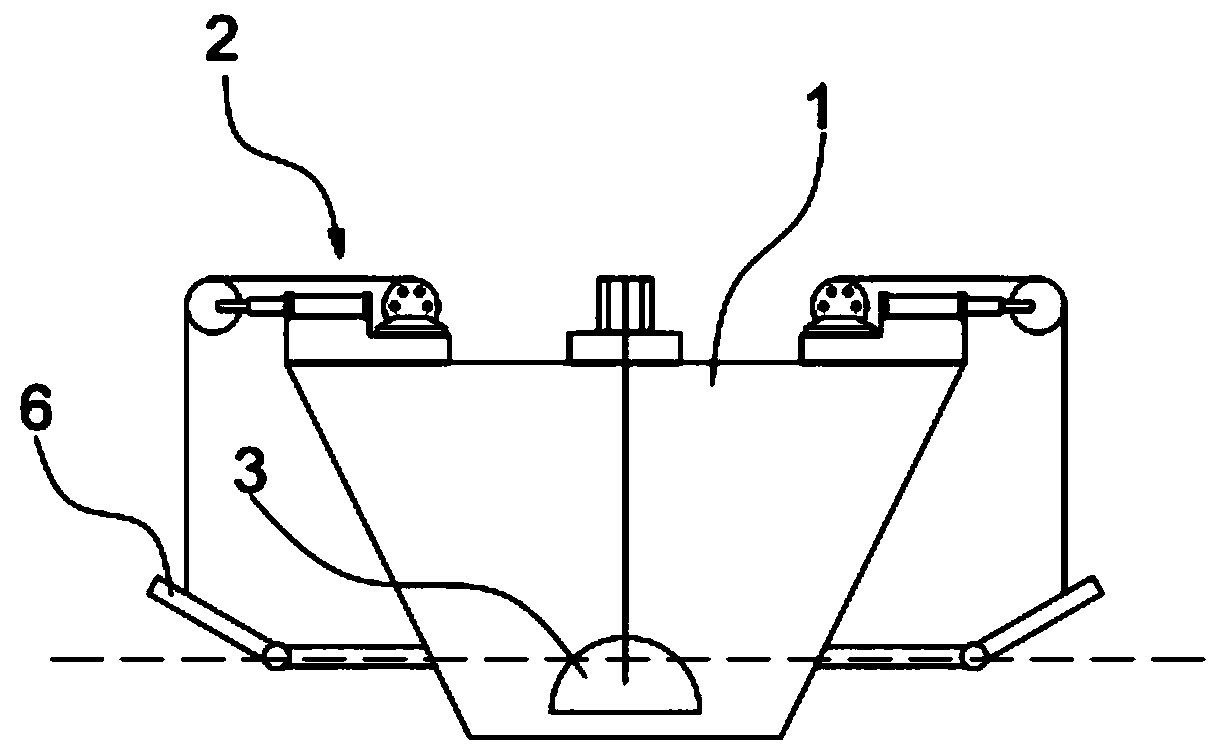

Self-sweeping type environment-friendly solid-liquid mixed water treatment robot with wide application range

InactiveCN107522315ATo achieve the effect of energy saving and environmental protectionAchieve broken effectWater/sewage treatment by centrifugal separationTreatment involving filtrationSlagCoupling

The invention discloses a self-cleaning environment-friendly solid-liquid mixed water treatment robot with a wide application range. The middle part of the crusher is fixedly connected with a crushing motor, and the output shaft of the crushing motor is fixedly connected with a crushing shaft through a coupling. The top of the crushing shaft runs through and extends to the inner top wall of the water treatment tank, and the top of the water treatment tank is provided with a feed inlet. , slag outlet and sewage outlet, and the inner bottom wall of the water treatment tank is provided with a purification outlet. The self-cleaning environmentally friendly solid-liquid mixed water treatment device with a wide range of applications can simultaneously drive the crushing rotor, the first filter layer, the second filter layer and the rotating bearing by the crushing shaft, and then drive the crushing rotor, the first filter layer, and the second filter layer. The effect of the second filter layer and the third filter layer effectively solves the problems of narrow application range and easy blockage of existing water treatment equipment.

Owner:阮森杰

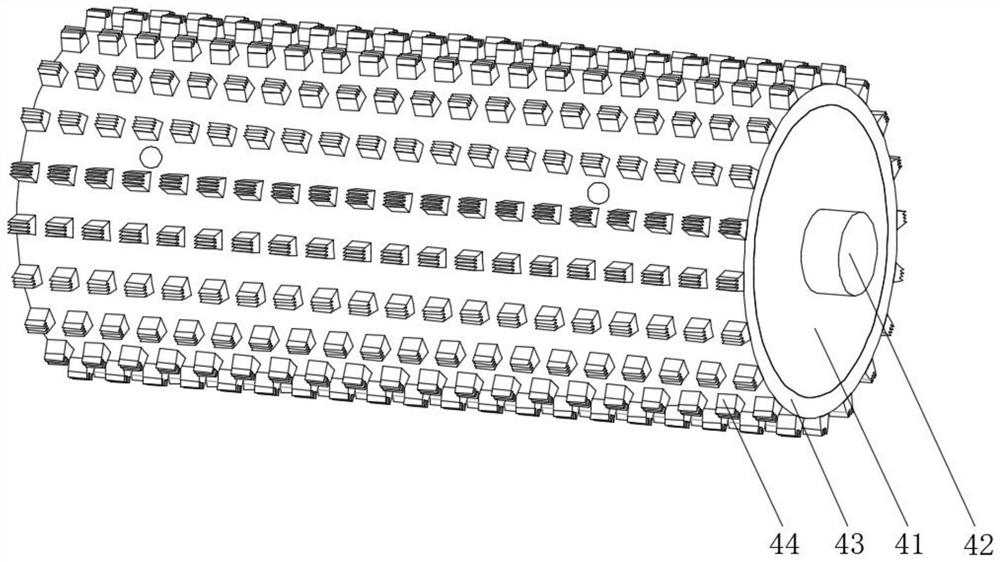

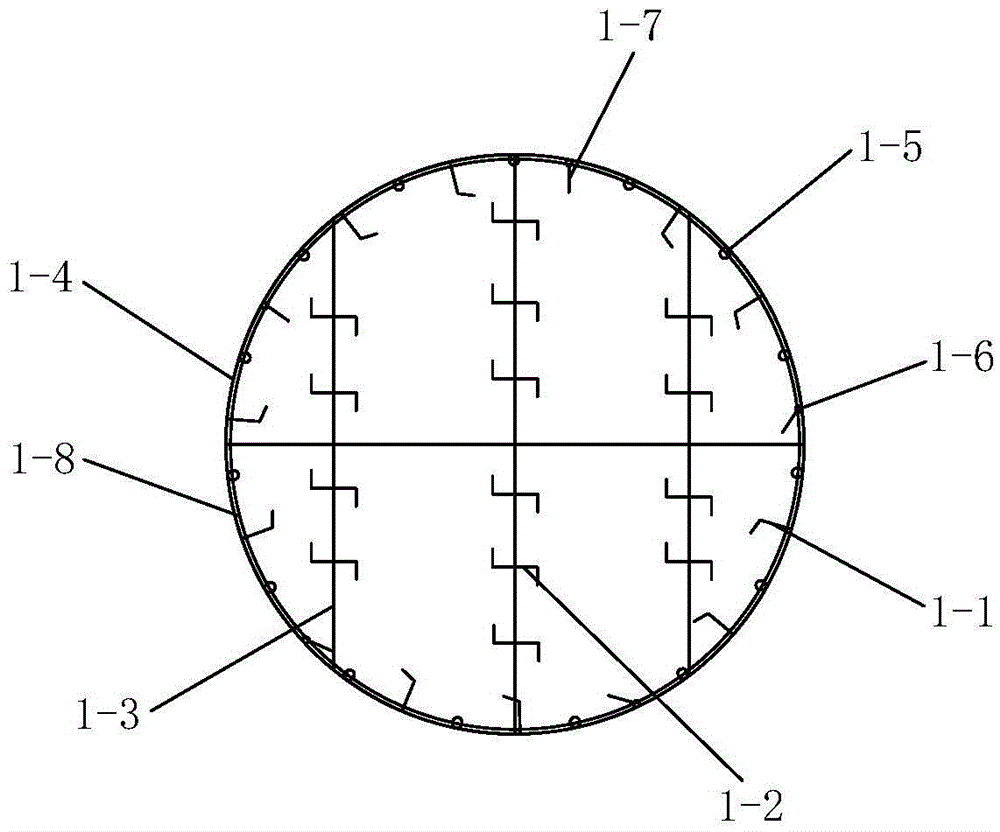

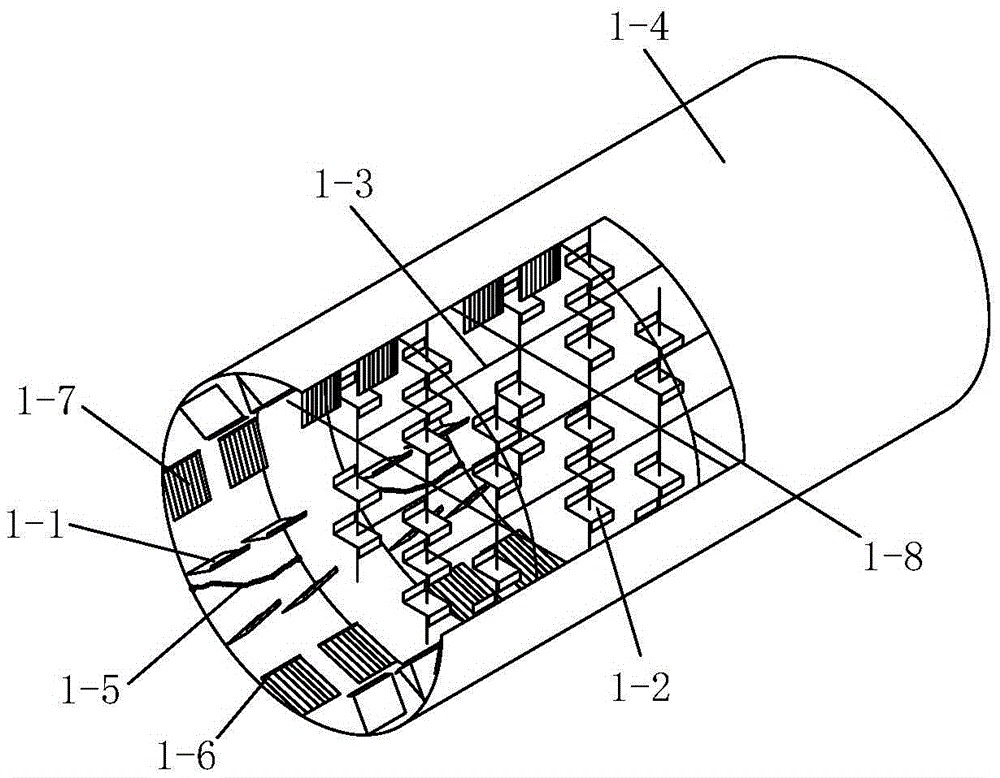

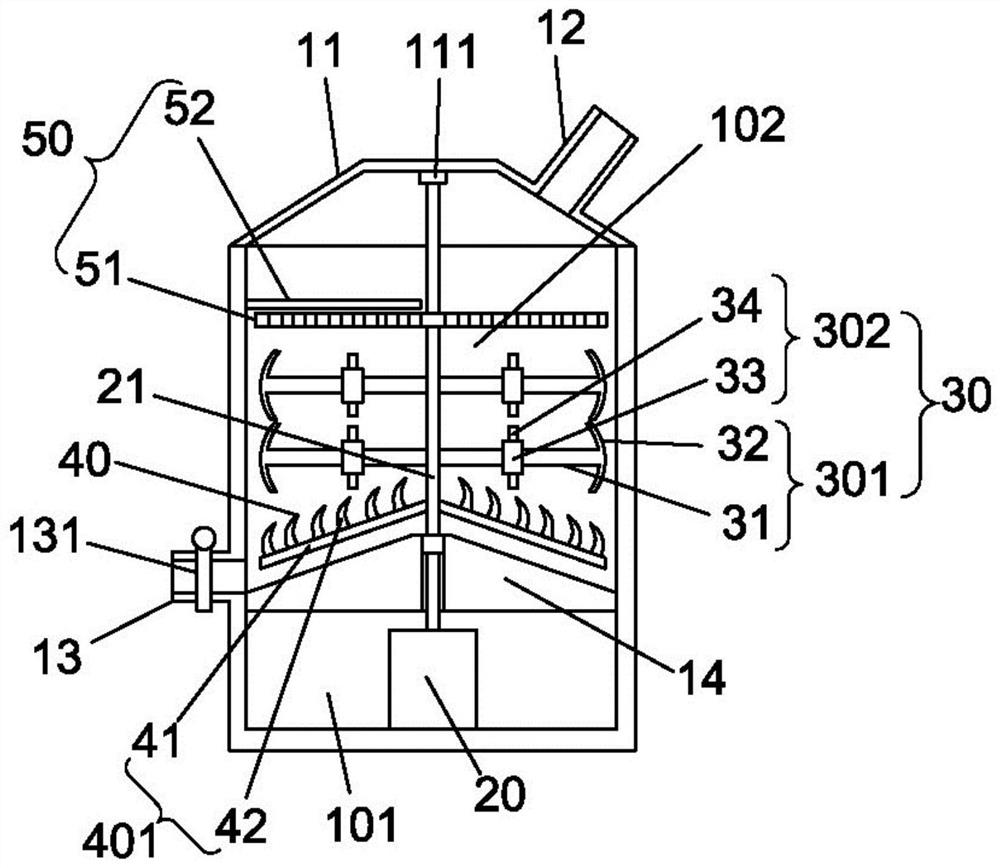

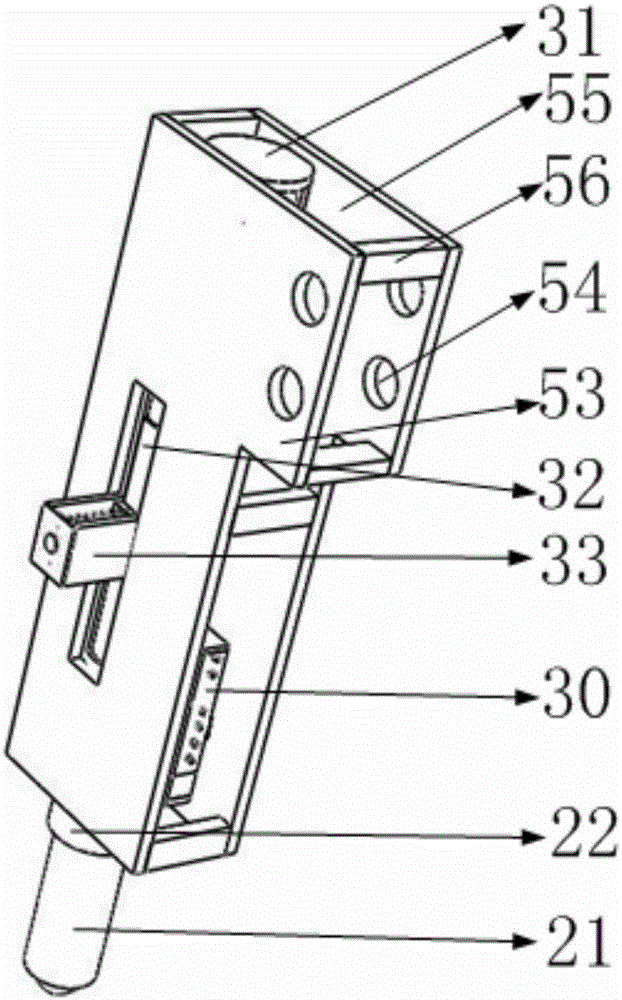

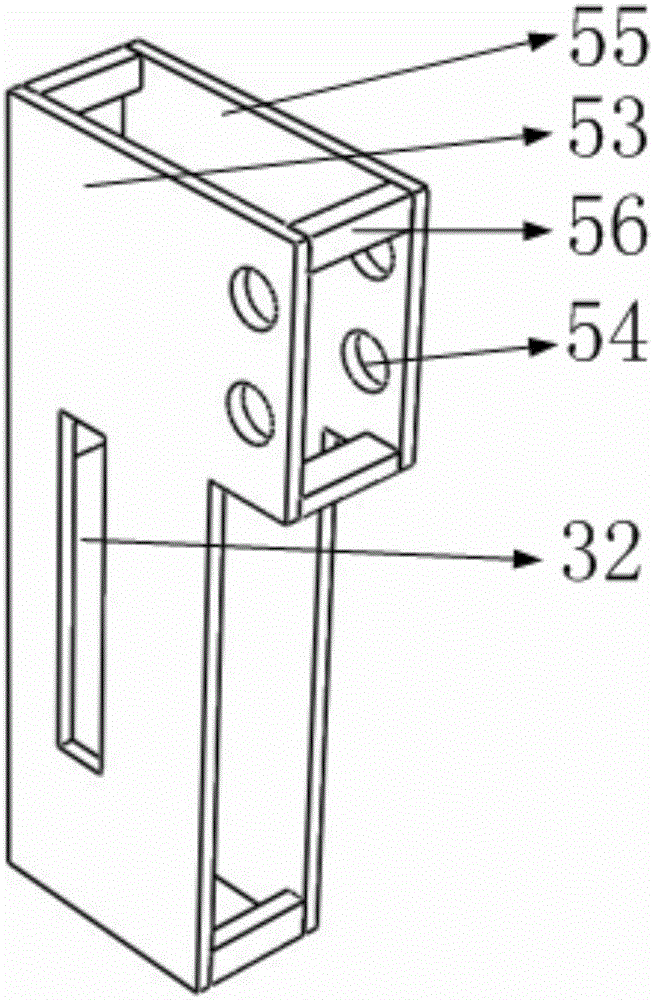

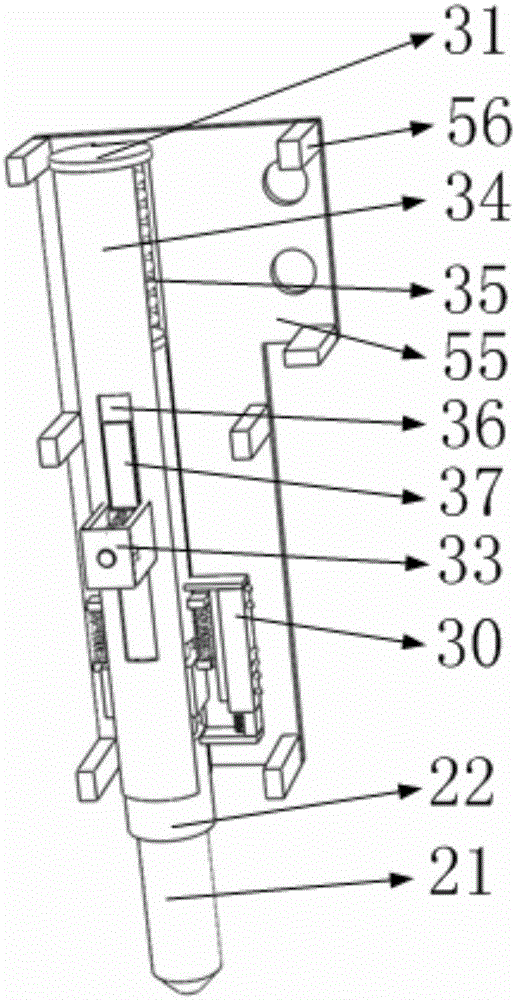

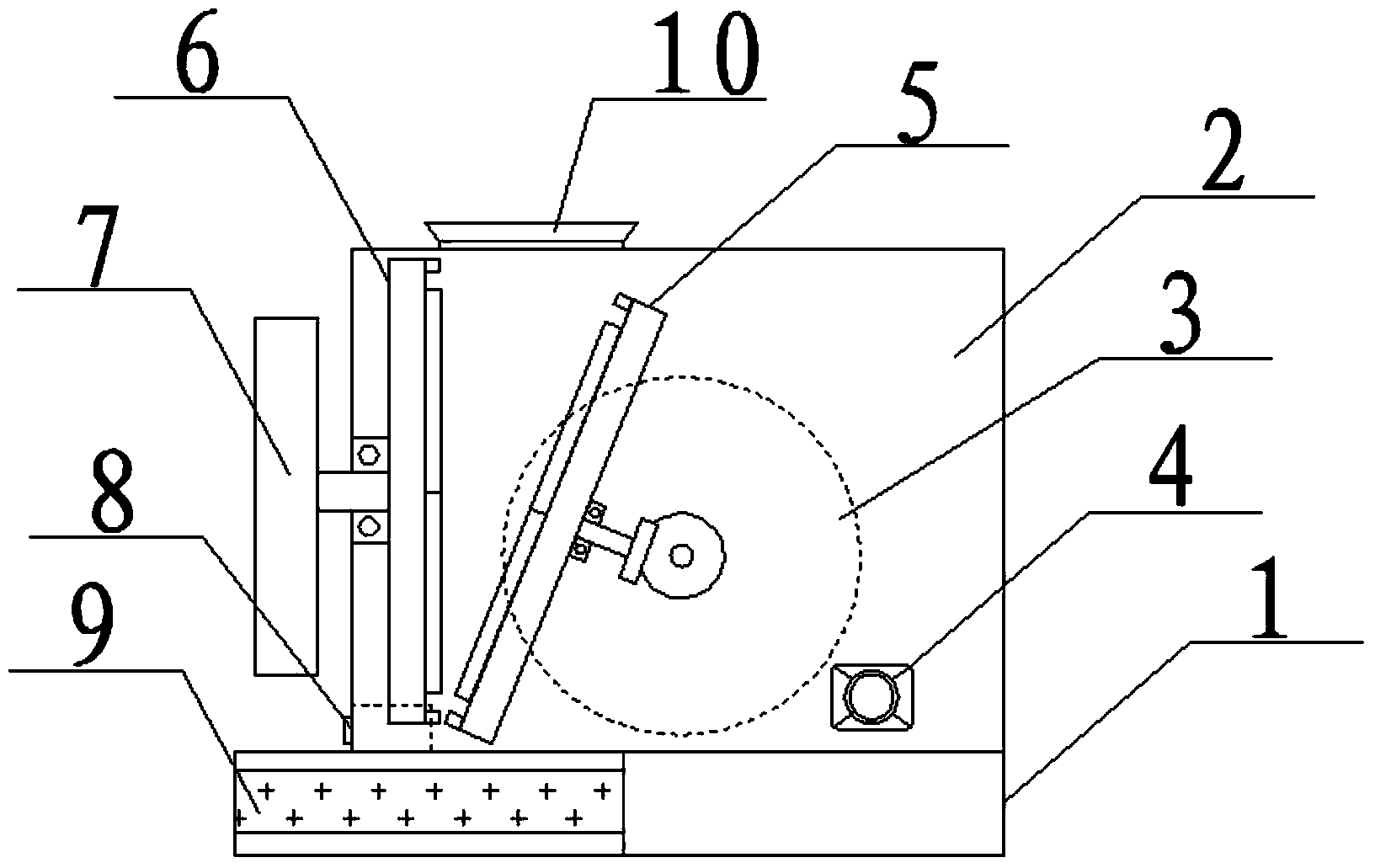

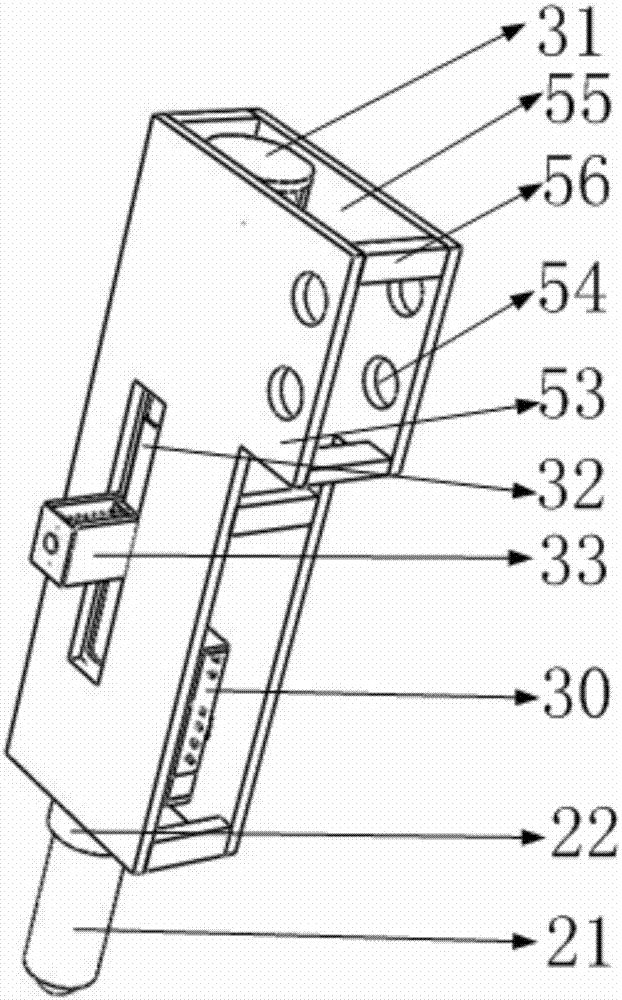

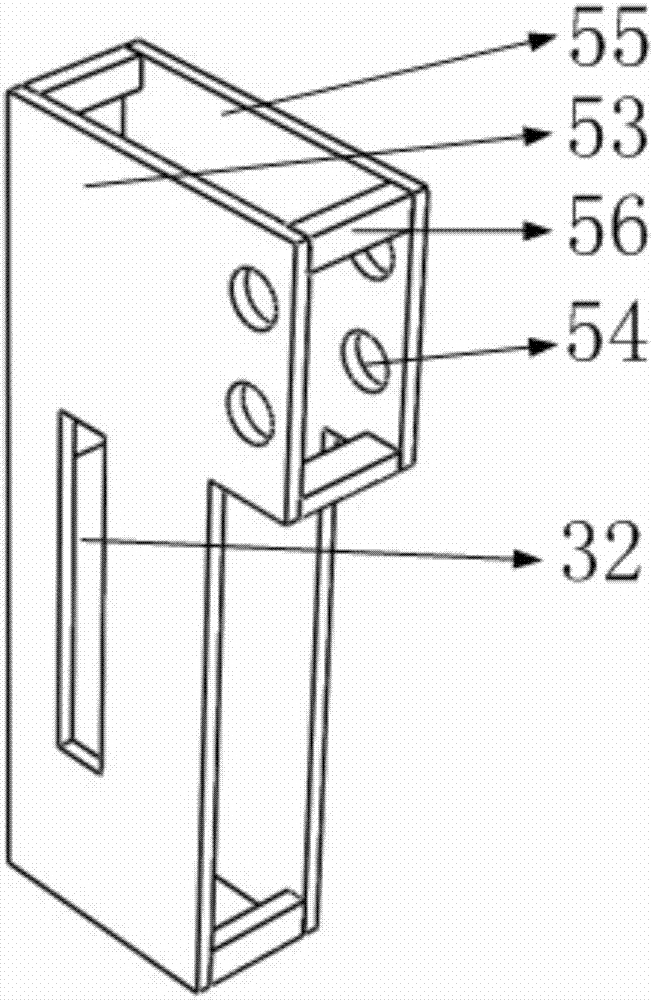

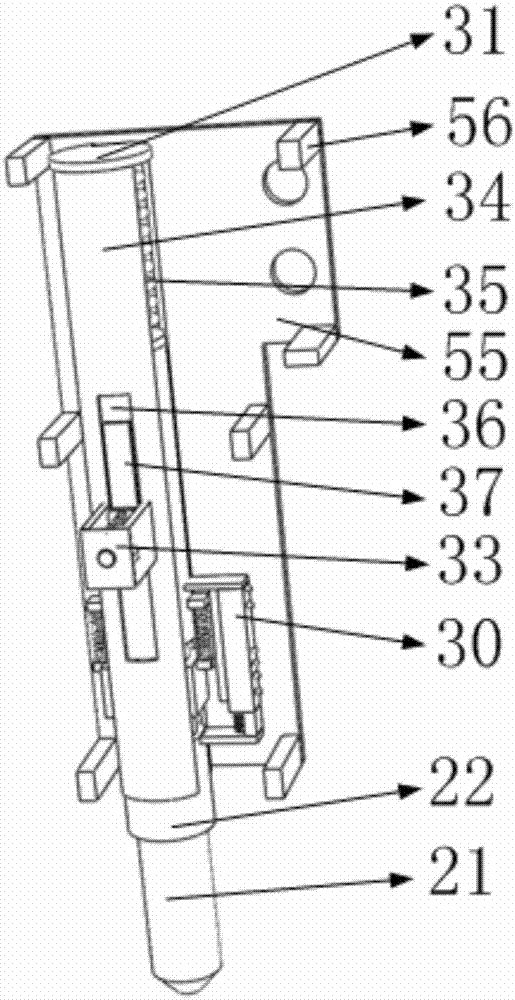

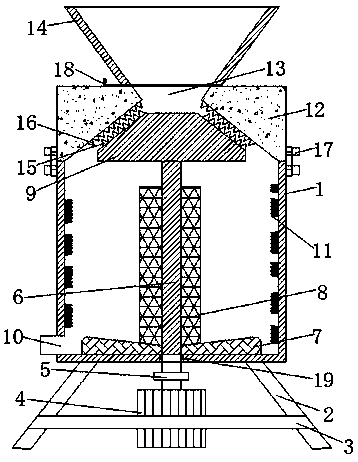

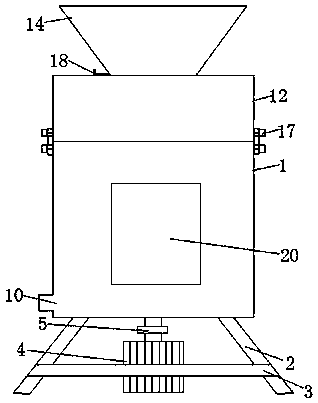

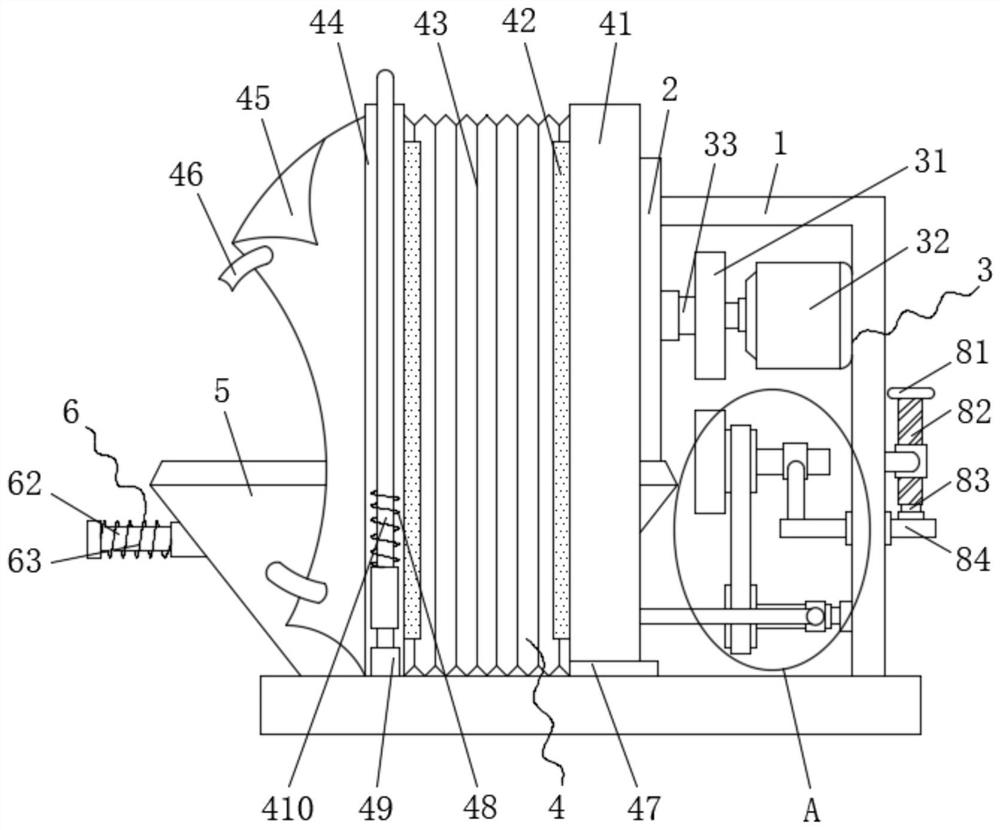

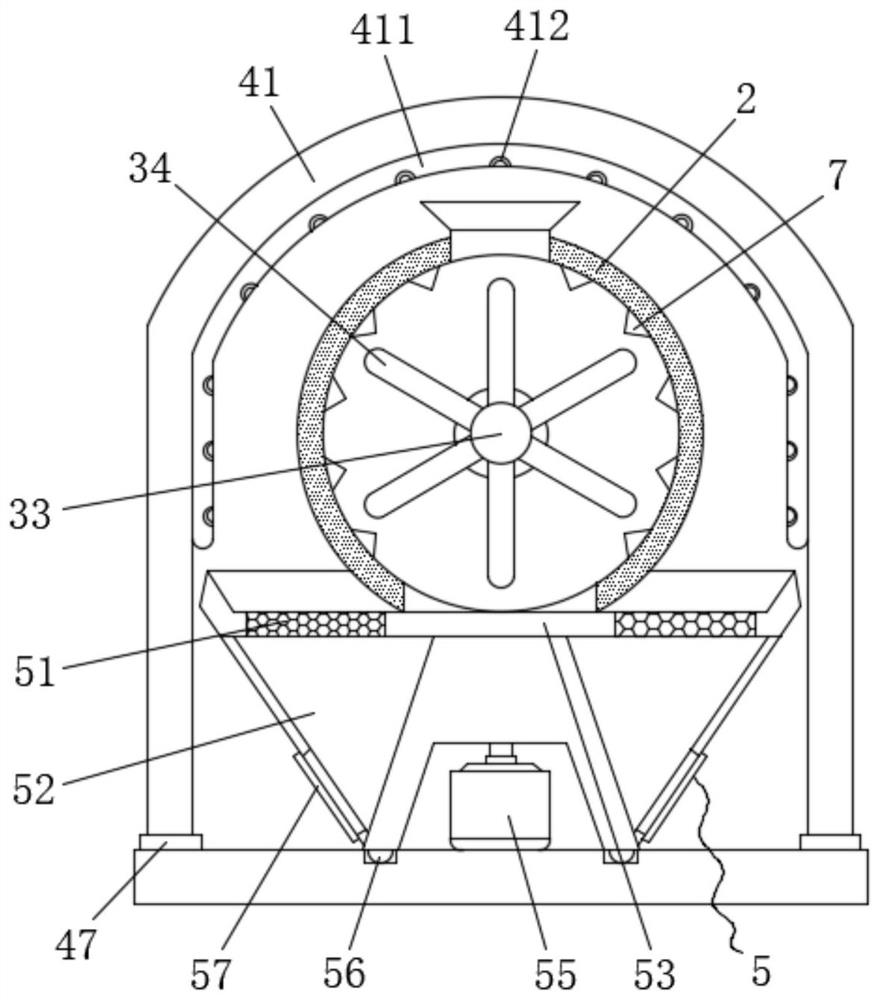

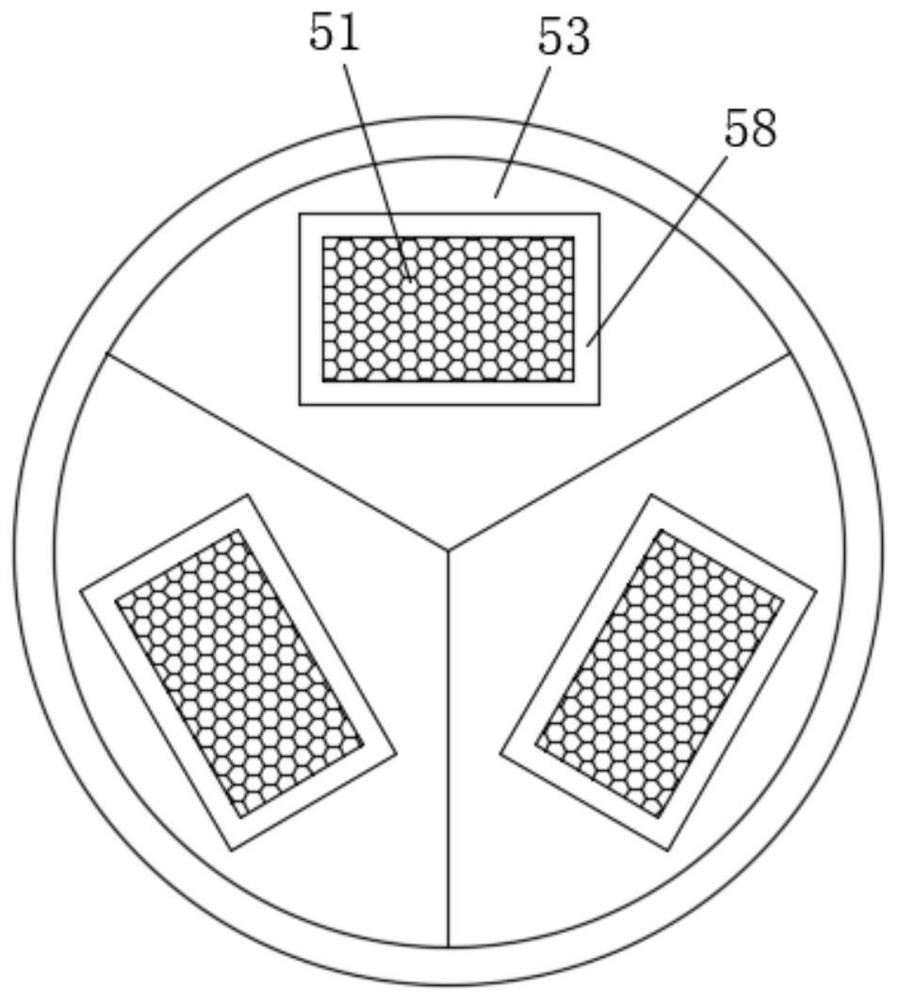

Silicon carbide integrated machining system

InactiveCN112138837AReduce manufacturing costImprove crushing effectGrain treatmentsCarbide siliconStructural engineering

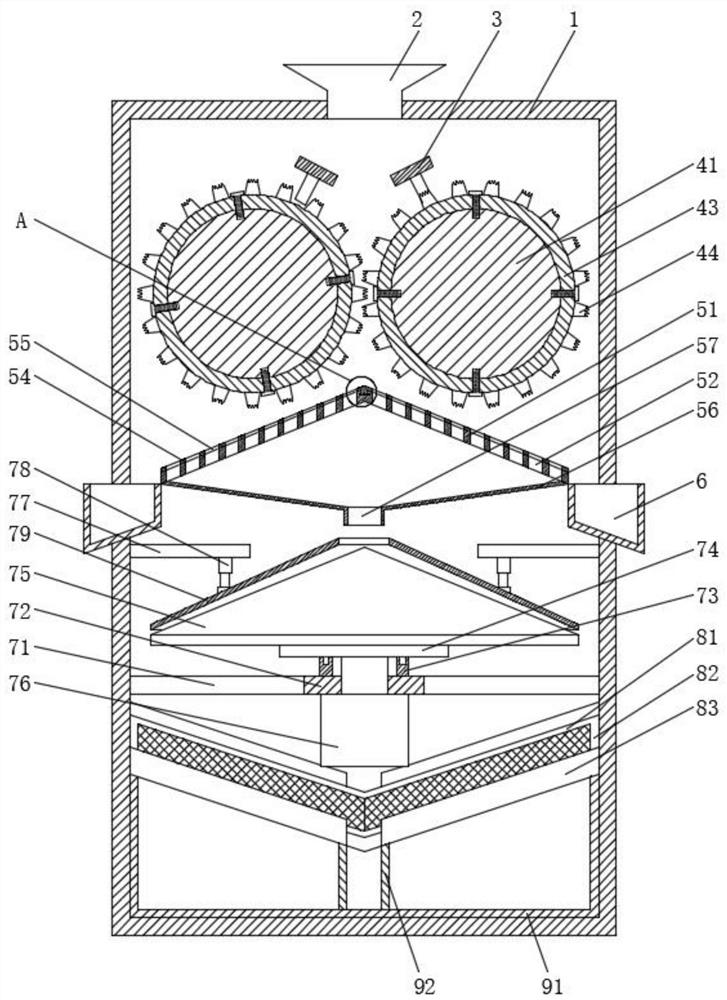

The invention relates to a silicon carbide integrated machining system which comprises a shell, a feeding hopper is fixedly installed in the middle of the top of the shell, two cleaning rakes are fixedly installed on the upper portion of the interior of the shell in a central symmetry mode, and crushing devices located on the lower portions of the cleaning rakes are movably installed on the upperportion of the interior of the shell in a central symmetry mode. A first-stage filtering device is fixedly mounted in the position, located in the shell, of the bottoms of the crushing devices, side collecting frames penetrating through the two side walls of the shell are fixedly mounted on the left side and the right side of the first-stage filtering device correspondingly, and a grinding deviceis fixedly mounted in the position, located in the shell, of the bottom of the first-stage filtering device. According to the silicon carbide integrated machining system, crushing ends are fixedly connected to the outer portions of outer rings at equal intervals in the circumferential direction, the ends of the crushing ends are in a sawtooth shape, the crushing ends on the outer rings can well extrude silicon carbide in a cutting mode through relative rotation of the outer rings, and therefore the crushing effect is better achieved.

Owner:洪娇娇

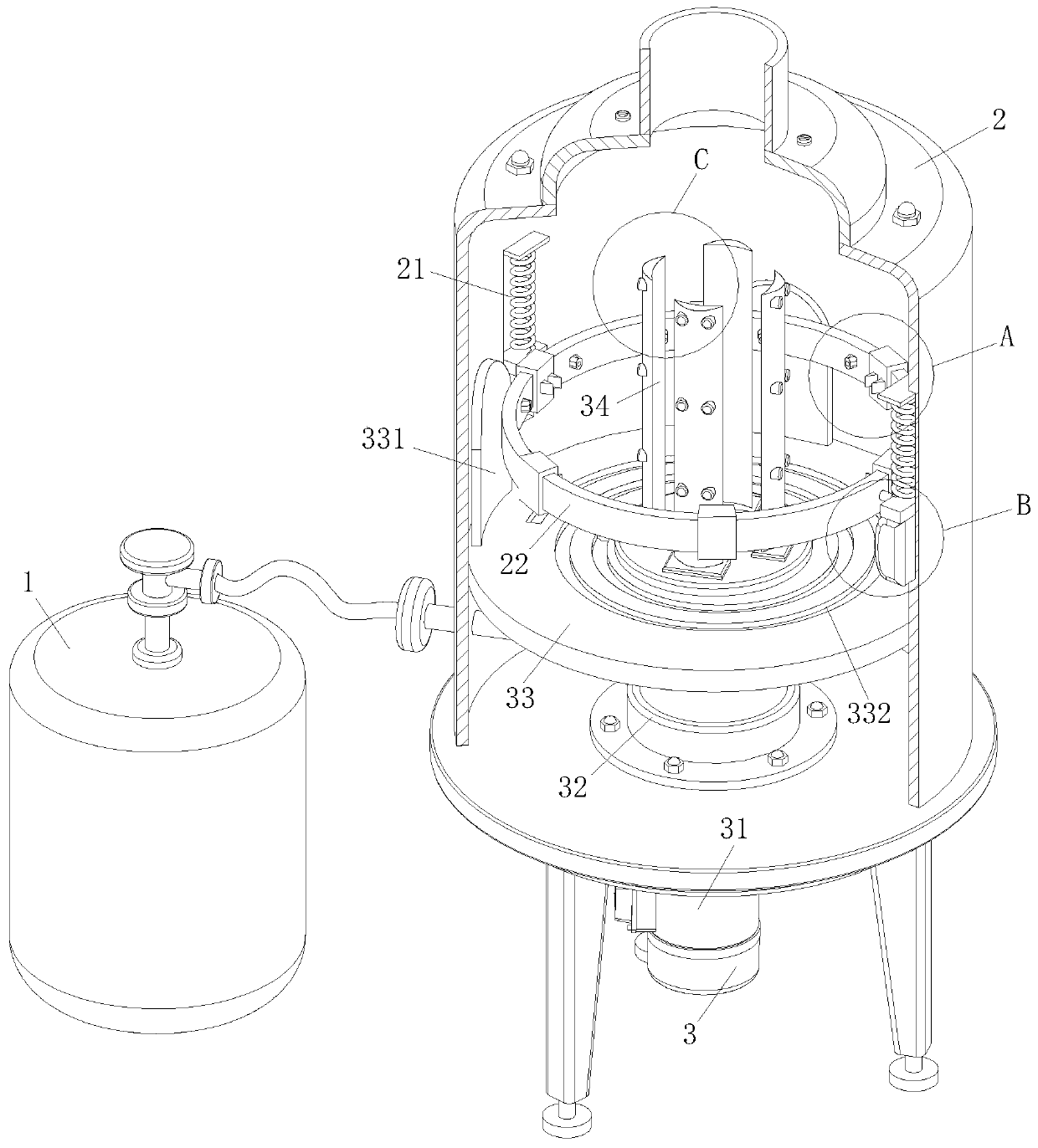

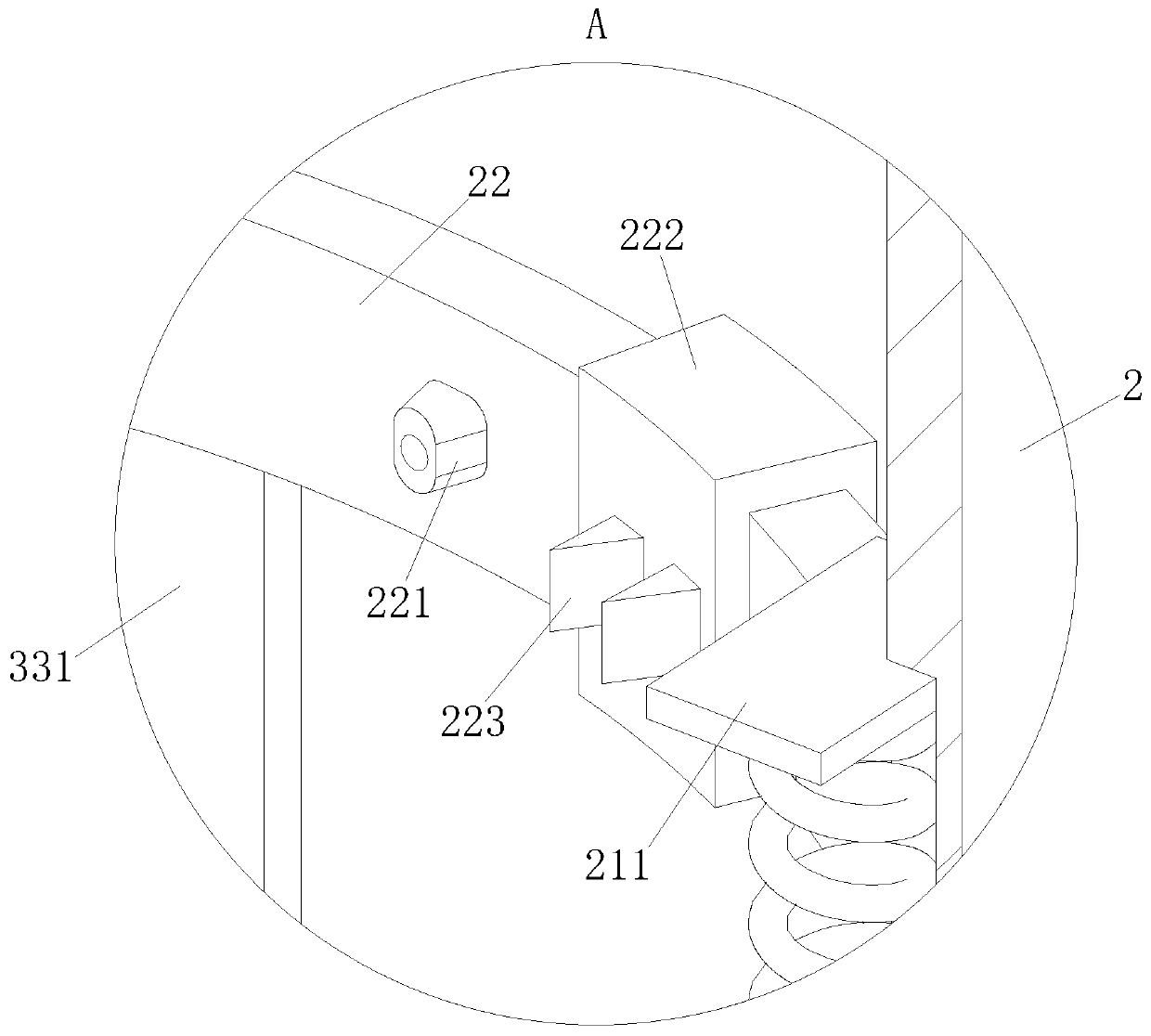

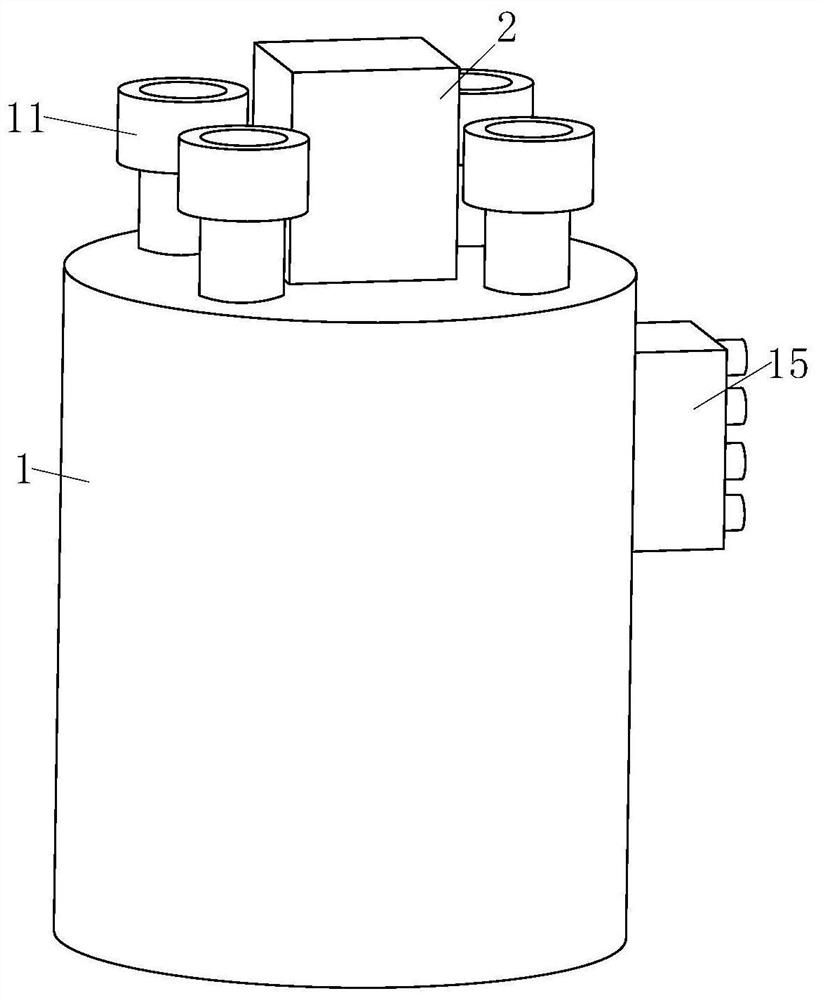

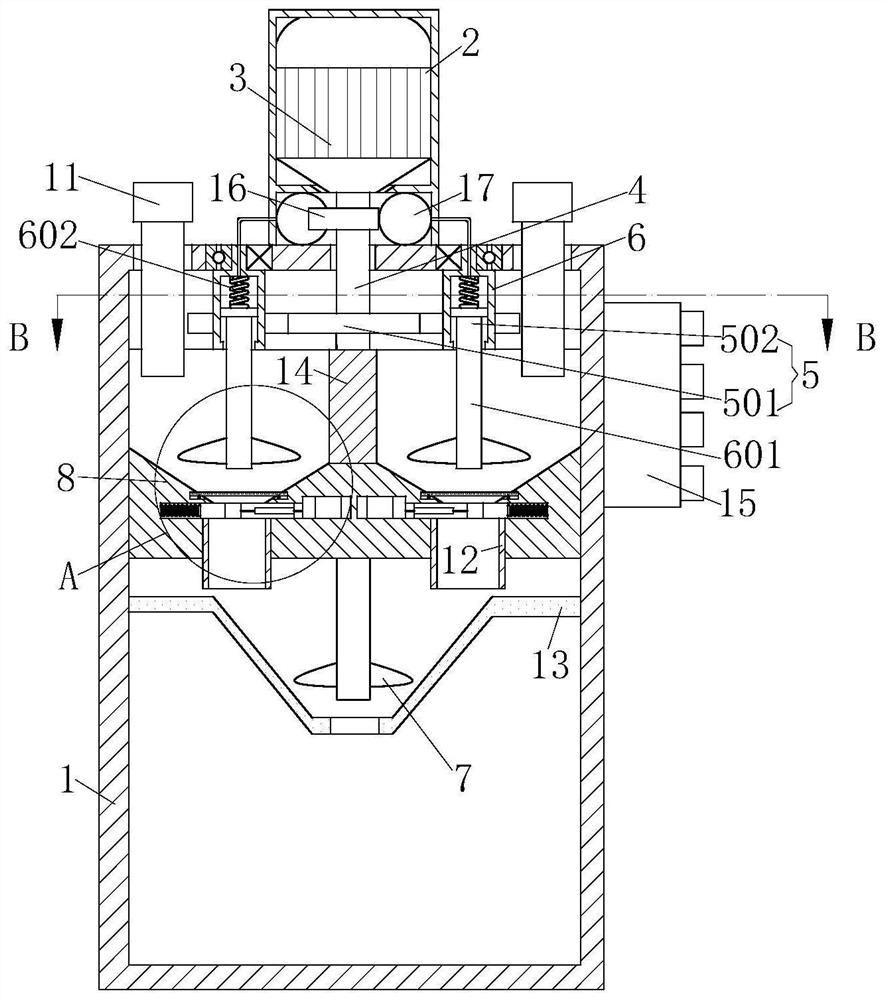

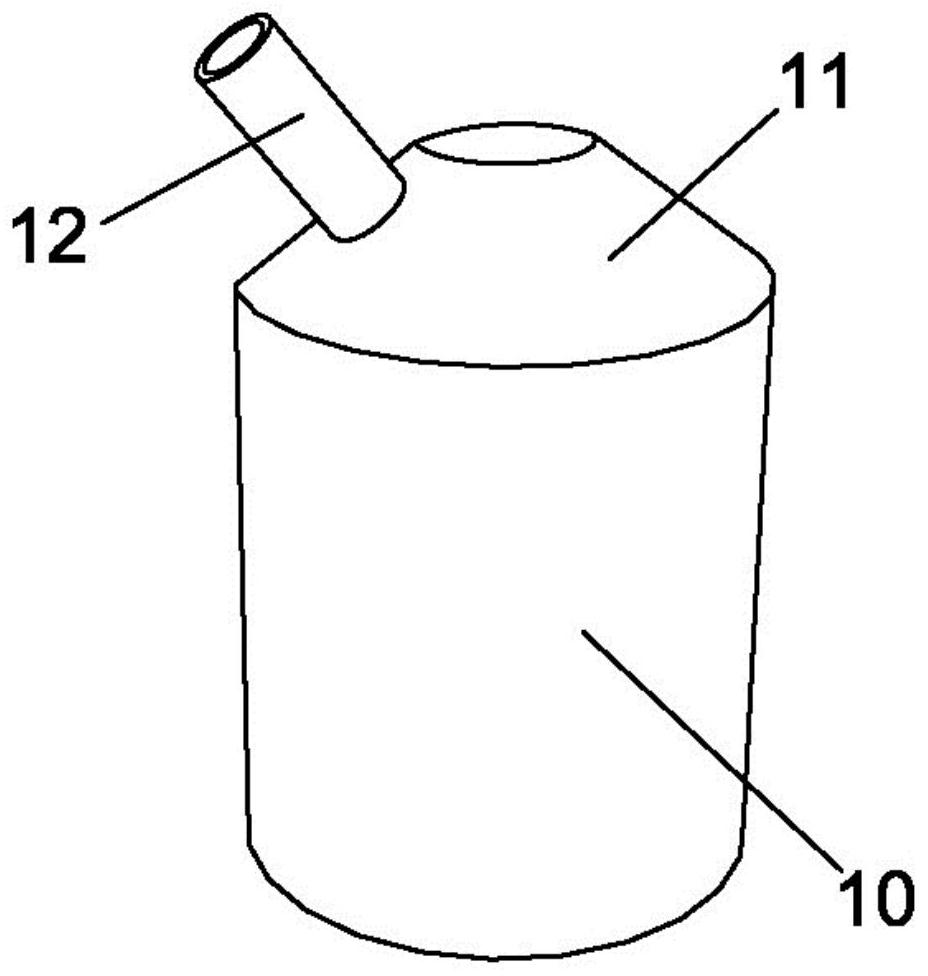

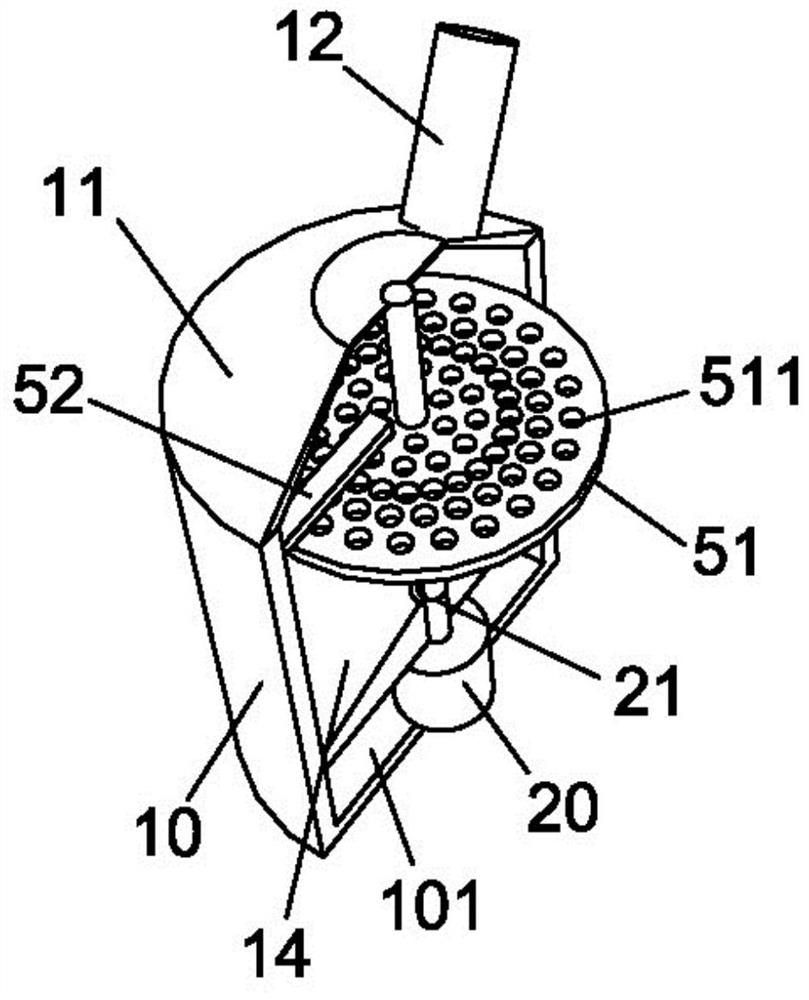

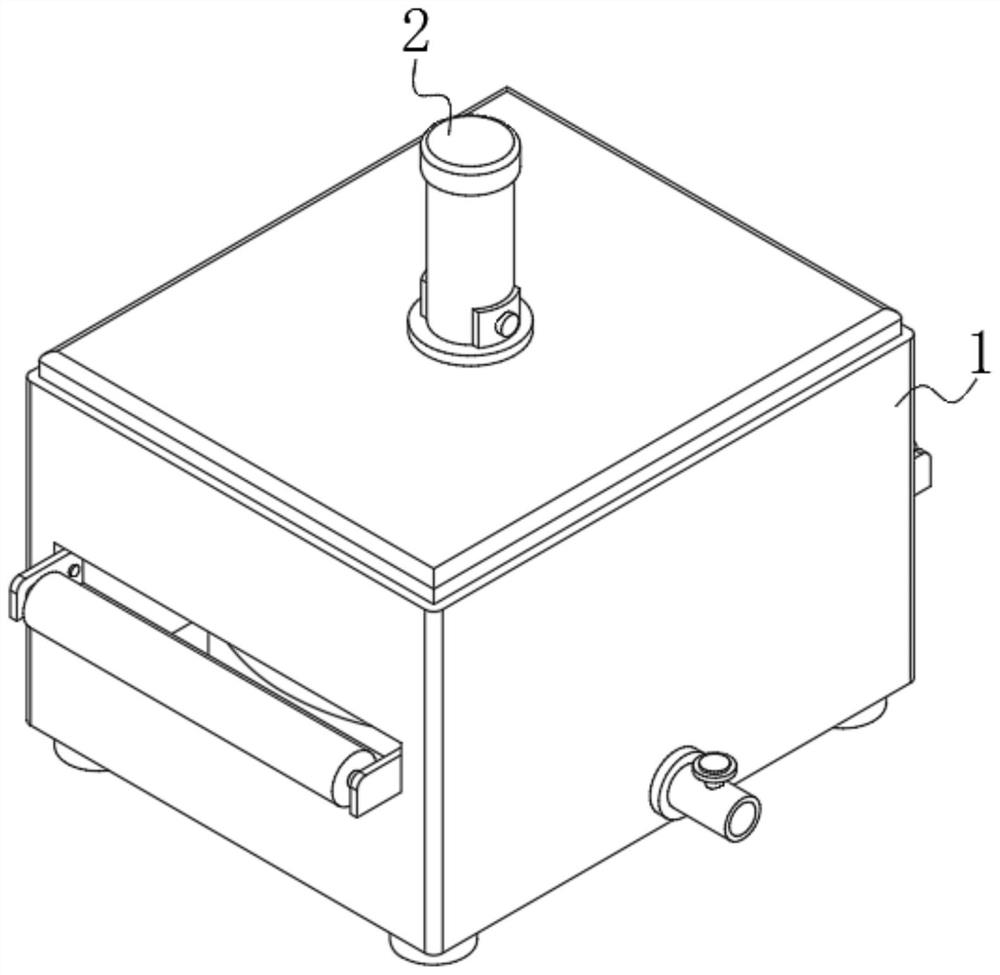

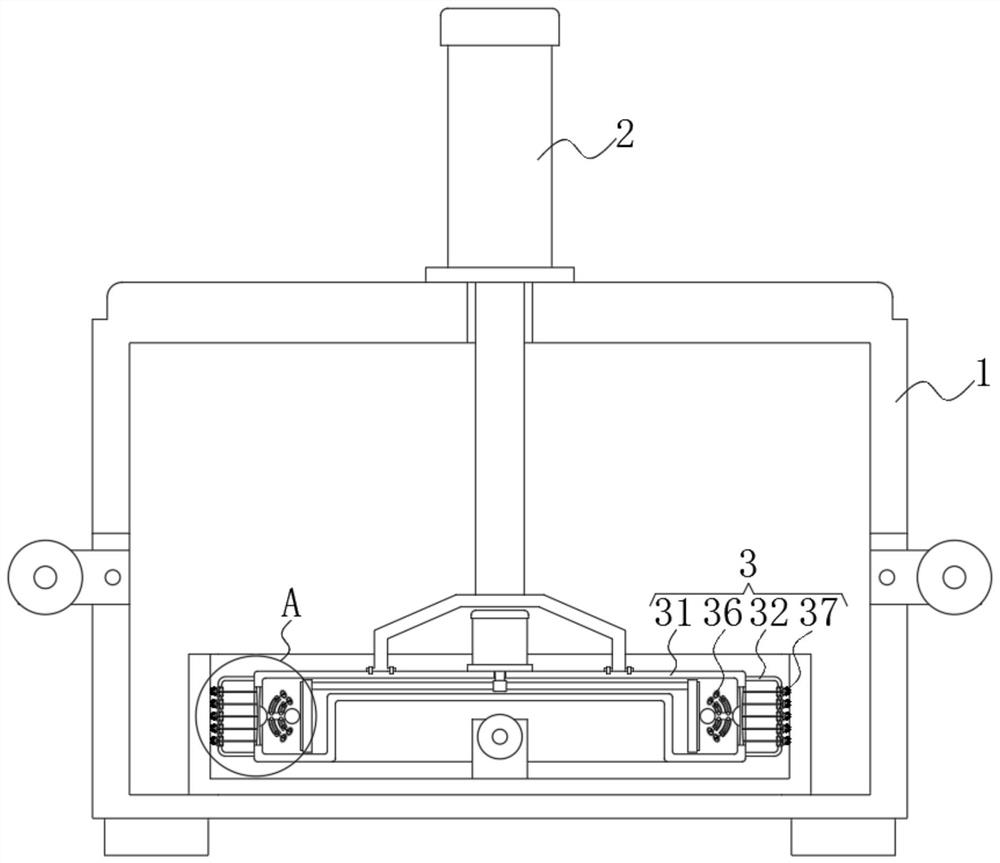

Microorganism fermentation jar

InactiveCN111518680AImprove fermentation effectIncrease reaction rateBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyMicroorganism

The invention belongs to the technical field of microorganism fermentation, in particular to a microorganism fermentation jar. The microorganism fermentation jar comprises an oxygen tank, a housing and a gas supply unit, wherein the gas supply unit is mounted in the housing, and comprises a motor, a rotating column, a baseplate and a ventilation plate. Through the adoption of the microorganism fermentation jar disclosed by the invention, through the cooperation of the oxygen tank, the housing and the gas supply unit, oxygen is provided for the inner part of a fermentation jar body; in the prior art, when oxygen is supplied for the fermentation jar, under the effect of buoyance, oxygen can quickly rise from the bottom end of the fermentation jar to the top end of the fermentation jar, so that liquid at the bottom end of the fermentation jar cannot sufficiently react with the oxygen; when the baseplate rotates, the ventilation plate is driven to stir in a solution at the same time, so that the reaction rate between the oxygen sprayed by the ventilation plate and the solution is accelerated; and in the rotating process of the ventilation plate, the effect of crushing oxygen bubbles isrealized, so that oxygen bubbles which are large in volume originally are separated into a plurality of oxygen bubbles which are small in volume, the contact area between the oxygen and the solutionis enlarged, and the fermentation effect of the fermentation jar is further accelerated.

Owner:赵云龙

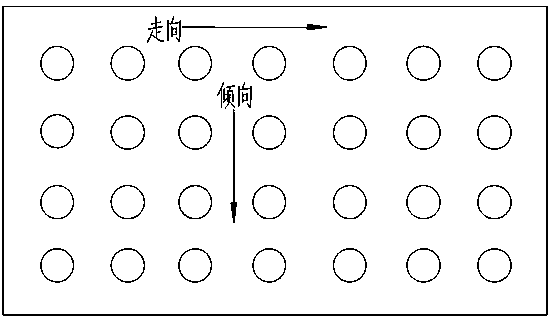

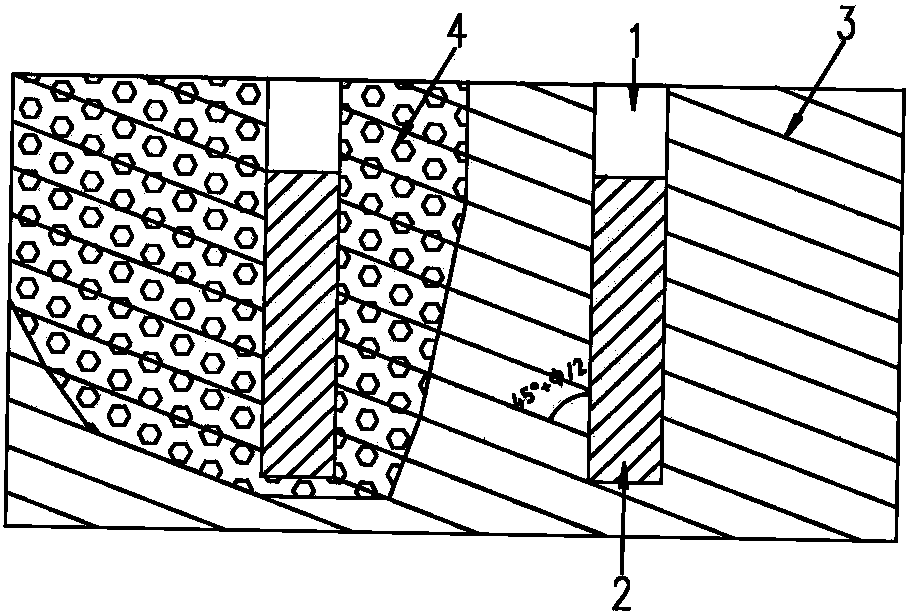

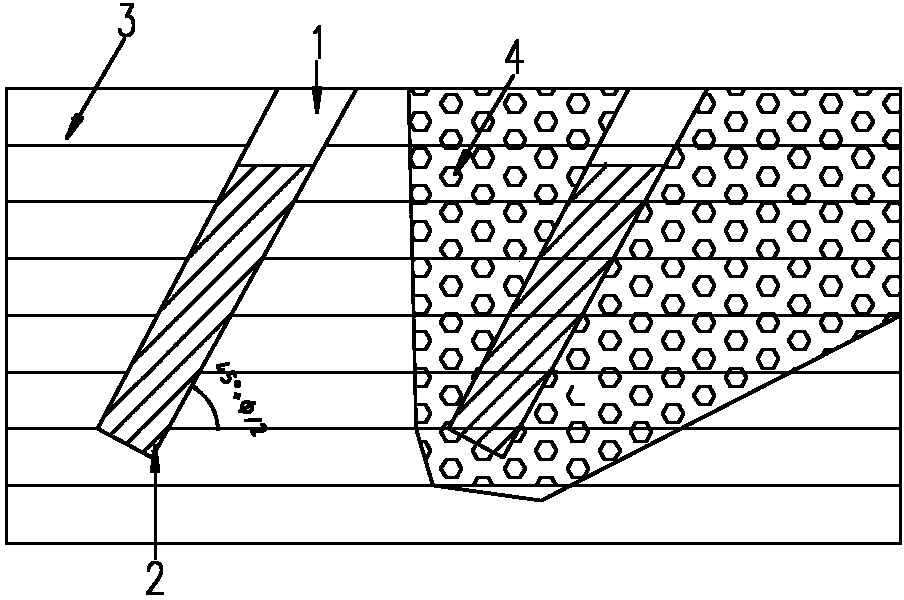

Blasting construction method based on certain angle formed between boreholes and joints

The invention discloses a blasting construction method based on certain angle formed between boreholes and joints. The blasting construction method mainly includes measuring occurrence of trend, inclination and dip angle X of to-be-blasted rock formation to acquire the internal friction angle phi, arranging drilling positions along the trend and the inclination crisscross, drilling holes by a drill with a drill pipe forming the angle of 45-degree +phi / 2+X with the horizontal plane, and performing charging, networking detonation and slag removal and the like. The blasting construction method can utilize the detonation energy of explosives to the utmost extent and prevents secondary breakage of rocks and large rock blocks from obstructing construction machines.

Owner:HOHAI UNIV

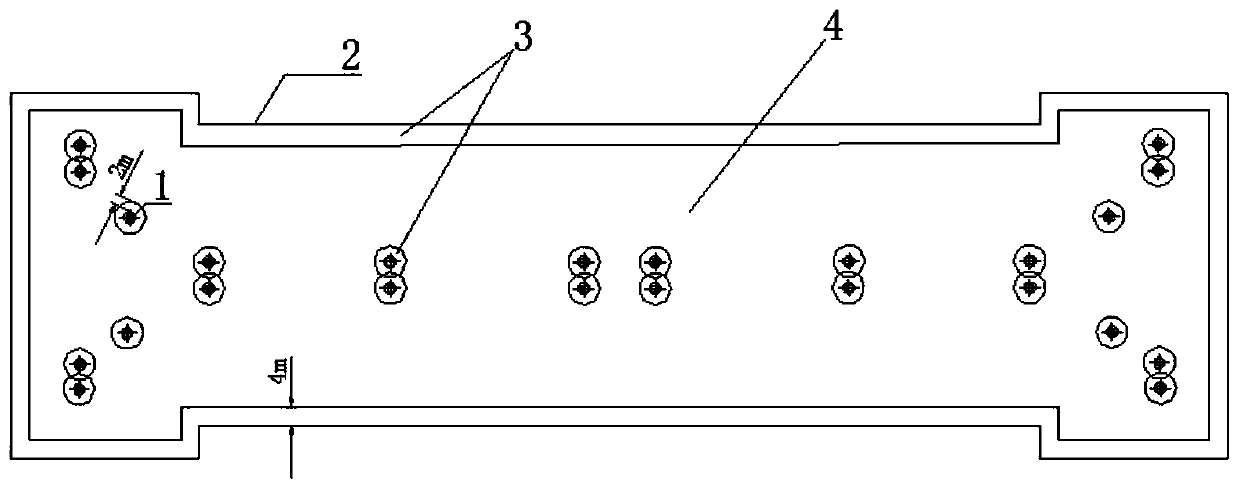

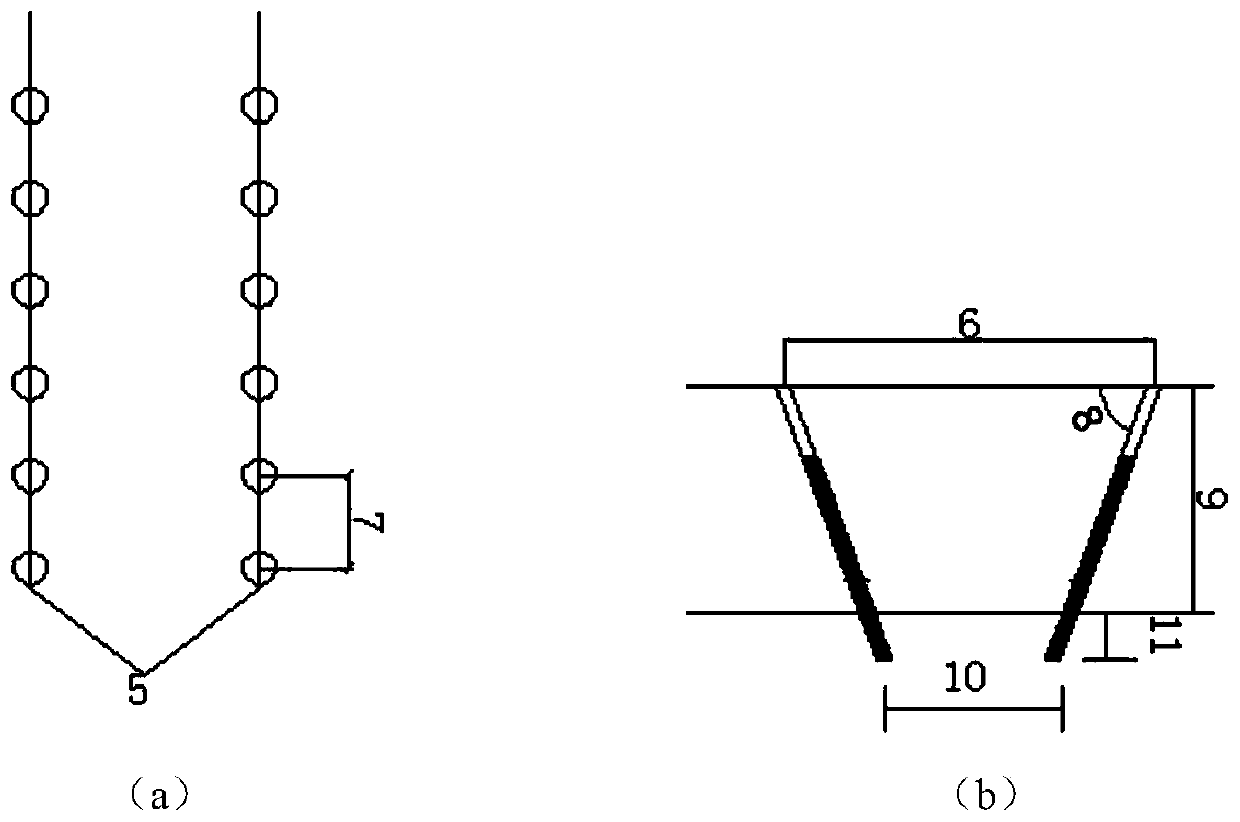

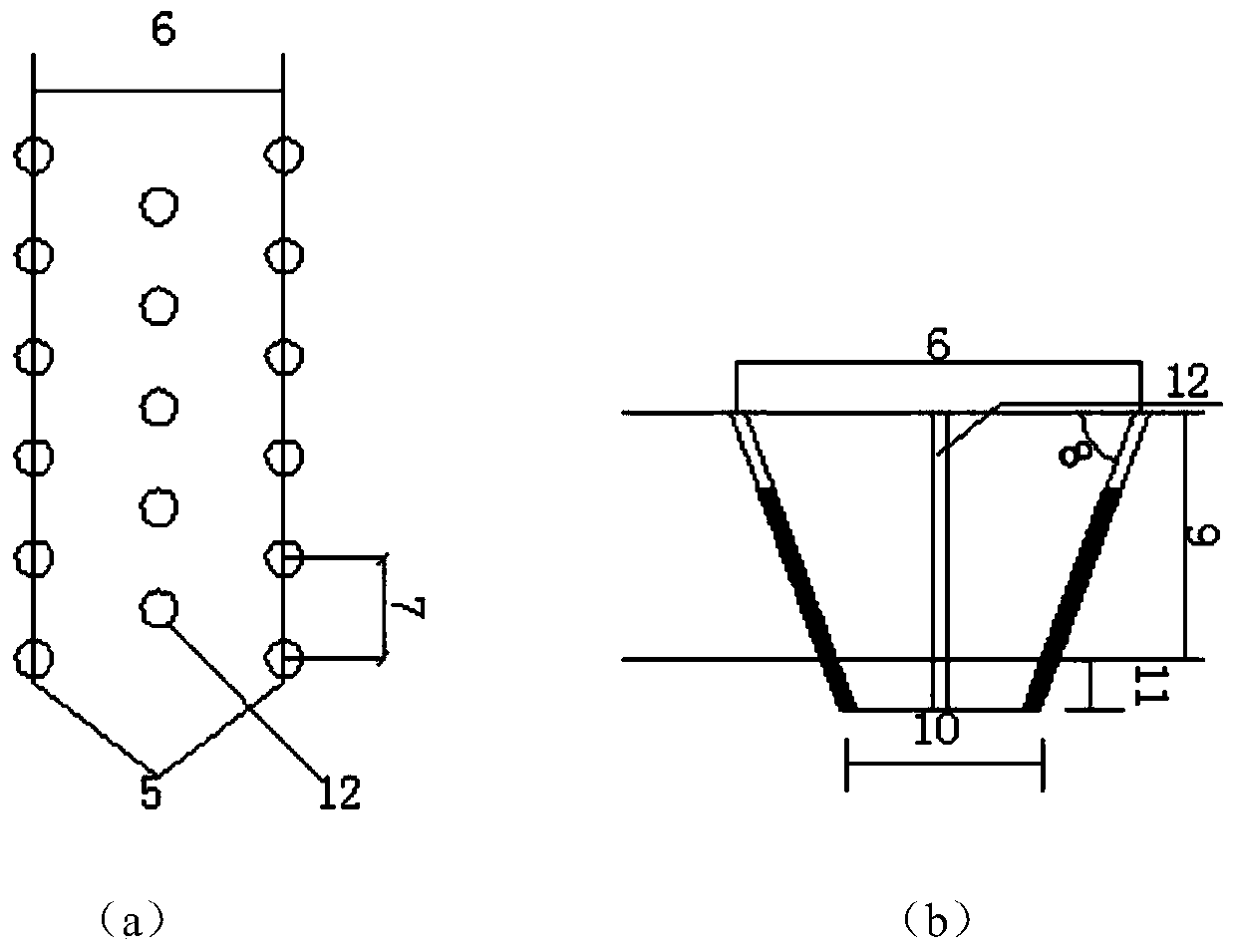

Refined blast construction method for narrow deep foundation pit under complicated geological condition

A refined blast construction method for a narrow deep foundation pit under a complicated geological condition comprises the following steps: step 1, flattening a field; step 2, excavating earth in a foundation pit area; step 3, carrying out trench blast construction and shallow hole step blast of a main blast area foundation pit; step 4, performing static breaking excavation on a diaphragm wall and rock in the area near latticed columns; and step 5, conducting waist beam and support construction, and then repeating construction in the steps 3-5 until the foundation pit is excavated. The methoddivides different blast areas, the refined combined blast excavation manner is adopted, and a convenient construction method is provided for excavation of the narrow rocky deep foundation pit. By arrangement of the protection scope of the latticed columns and diaphragm walls, the refined construction method combining trench blast, shallow hole step blast and static blast is adopted, and rapid breaking construction is performed on foundation pit rock. The arrangement of construction of edge expansion assisted holes fully utilizes the stress of rock, the excavation efficiency is improved, and the vibration damage of blast is reduced.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD +1

Chemical reaction tank

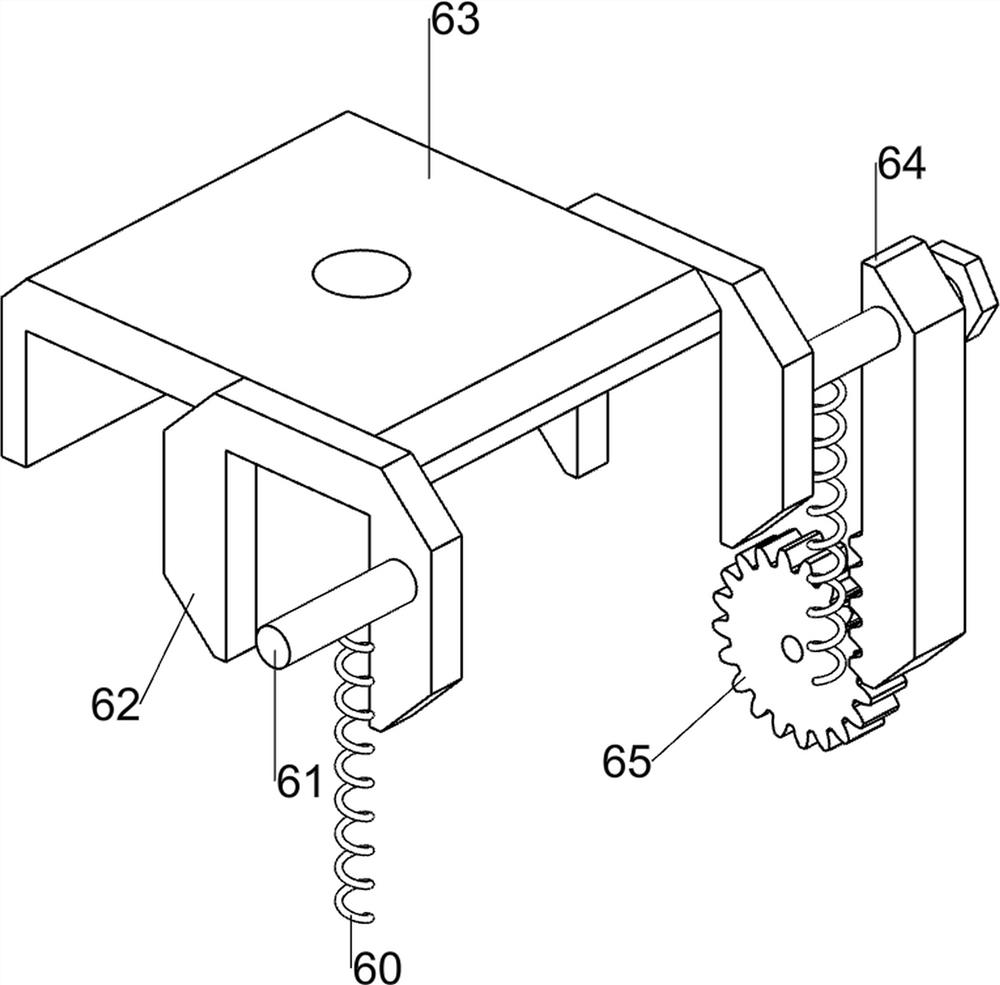

PendingCN113750940ARealize delivery controlAchieve broken effectMixersChemical/physical/physico-chemical stationary reactorsChemical reactionGear wheel

The invention relates to the technical field of chemical reaction tanks, in particular to a chemical reaction tank which comprises a tank body, a motor box is fixedly connected to the upper surface of the tank body, a motor is fixedly connected to the inner wall of the motor box, a rotating column is fixedly connected to the output end of the motor, and a gear mechanism is fixedly connected to the surface of the rotating column. The inner top wall of the tank body is rotatably connected with a stirring mechanism, a loading plate is fixed in the tank body, and a baffle mechanism is arranged on the loading plate. The chemical reaction tank can drive a rotating column to rotate by arranging the motor, can drive a driving gear to rotate by arranging the rotating column, and can drive a driven gear to rotate by arranging the driving gear. The stirring mechanism can be driven to rotate by arranging the driven gear, and conveying of different raw materials can be controlled by arranging a baffle mechanism, so that the problem that the working efficiency is affected due to the fact that different smashed raw materials cannot be controlled to be added for mixed reaction at the same time is solved.

Owner:高翌乔

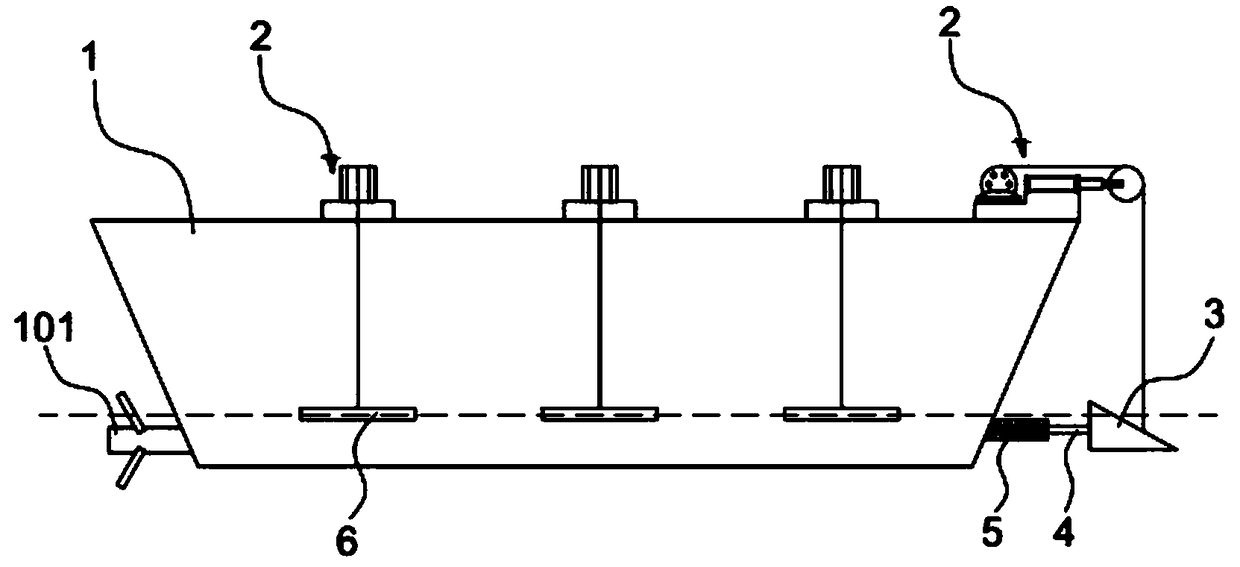

Unattended ship stabilizing device

ActiveCN109436233AImprove stabilityReduce hull contactVessel cleaningHullsMonitoring dataMarine engineering

The invention discloses an unattended ship stabilizing device, and belongs to the technical field of ship stabilizing. The unattended ship stabilizing device comprises a ship body. A flow breaking body is arranged at a stem position of the ship body and is in a conical shape. The rear end of the flow breaking body is connected with a connecting rod. The connecting rod is connected with the ship body through a damper. One end of the flow breaking body is connected with a rope body. The rope body is connected with a winding and unwinding mechanism on the ship body. The unattended ship stabilizing device has wave breaking, stabilizing and power generating functions and enhances the storing and balancing capacity and monitoring data precision of an unattended ship.

Owner:ZHEJIANG OCEAN UNIV

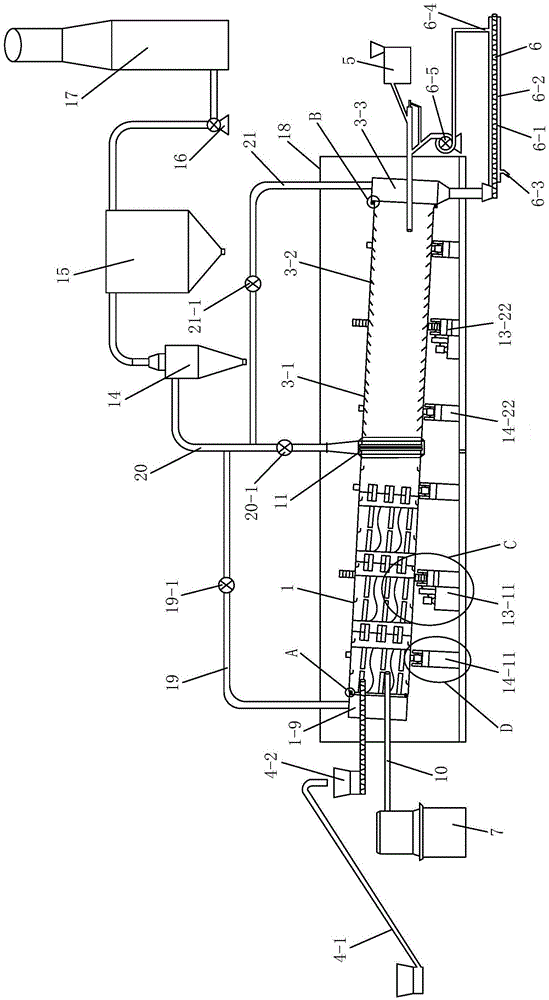

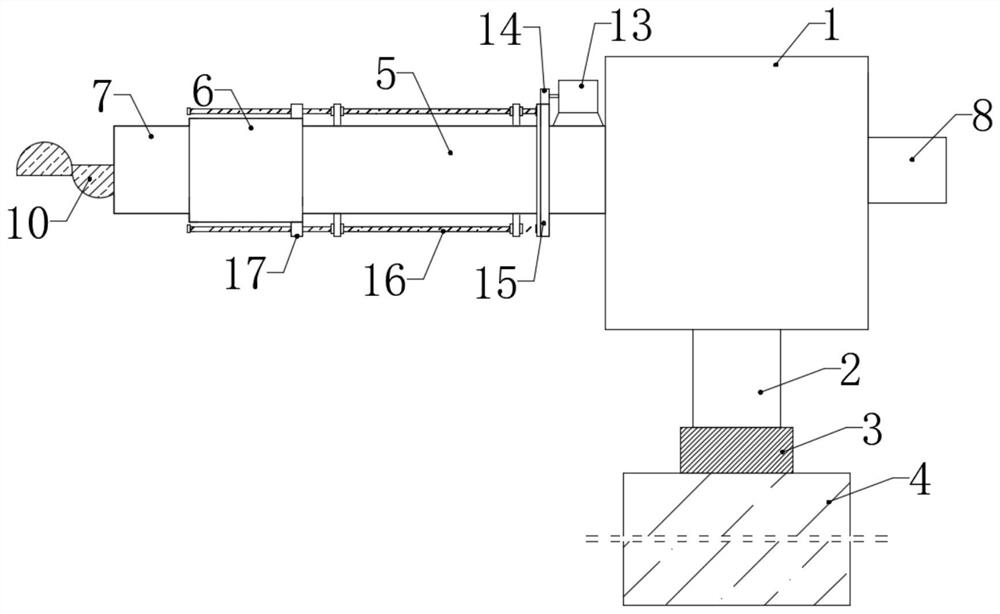

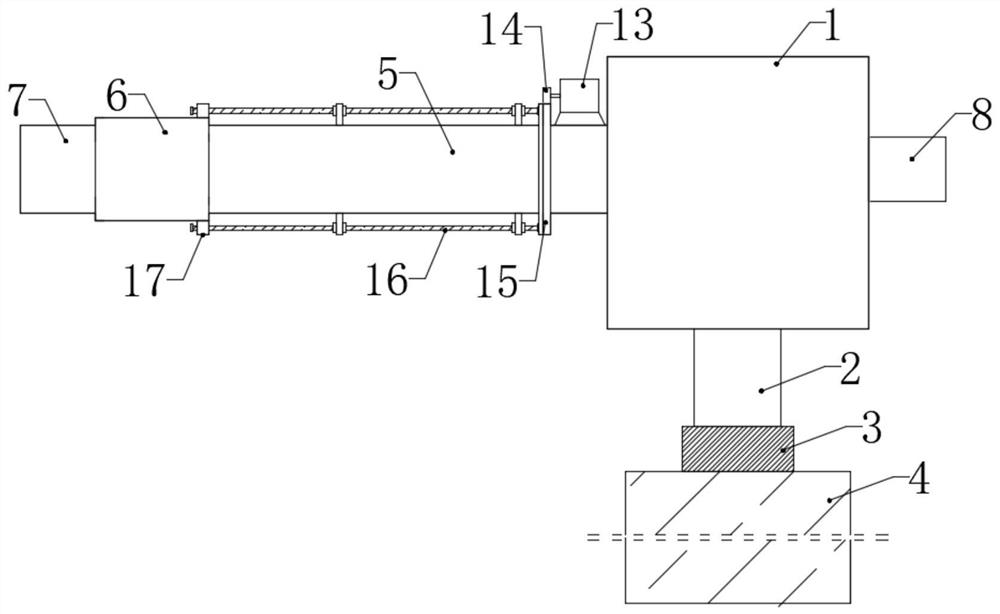

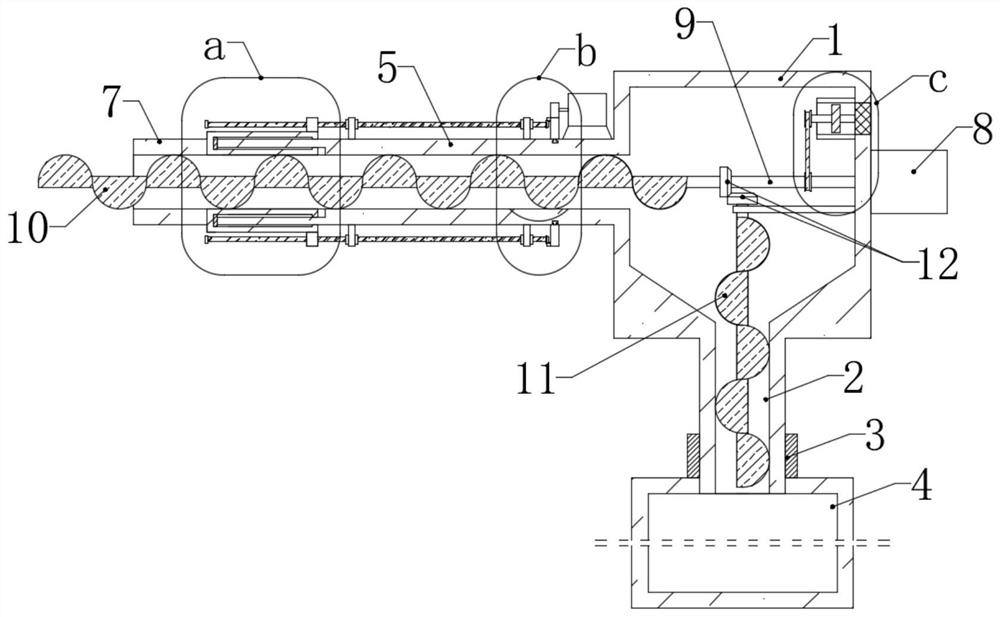

Drying calcining treatment system of drilling well waste mud

The invention discloses a drying calcining treatment system of drilling well waste mud. The system comprises a rotary type drying calcining device, a rotary driving mechanism and a rotary support mechanism, wherein the rotary type drying calcining device passes through the rotary driving mechanism and the rotary support mechanism, the drying end of the rotary type drying calcining device is provided with a raw material feeding system and a drying heat-supplying device, the calcining end of the rotary type drying calcining device is provided with a pulverized coal burner and a screw conveyor, the rotary type drying calcining device is inclined, the drying end is higher than the calcining end, the gas outlet of the drying heat-supplying device is connected with the hot wind inlet of the rotary type drying calcining device, the burning end of the pulverized coal burner extends into the calcining end, and the middle part of the rotary type drying calcining device is connected with a dust removal purification system. The system is quick, high efficient, convenient and low dissipative, the treatment of the drilling well waste mud does not need the secondary treatment, the treated ultimate products can be used as recycling materials and the pollution problem of the drilling well waste mud is thoroughly solved.

Owner:商洛市海蓝科技有限公司 +1

Waste water bottle crushing and briquetting device for resource regeneration

InactiveCN112718113AAchieve broken effectRealize the occlusion effectGrain treatmentsElectric machineryWastewater

The invention relates to a crushing and briquetting device, in particular to a waste water bottle crushing and briquetting device for resource regeneration. According to the waste water bottle crushing and briquetting device for resource regeneration, the working efficiency is improved, operation is convenient, and the cost is saved. The waste water bottle crushing and briquetting device for resource regeneration comprises bottom plates, a second supporting frame, an accommodating mechanism and a rotating mechanism; four first supporting frames are evenly arranged in the middles of the two bottom plates; the second supporting frame is connected between the upper parts of the two first supporting frames on the right side; the accommodating mechanism is connected among the four first supporting frames; and the rotating mechanism is arranged at the top of the second supporting frame. An output shaft of a first motor drives a first rotating shaft to rotate, so that stirring blades are driven to rotate to crush a waste water bottle, and the crushing effect is achieved.

Owner:广东捷标网信息科技有限公司

Electric revision instrument for hip joint revision surgery

The invention discloses an electric revision instrument for hip joint revision surgery, and belongs to the field of hip joint surgery. The electric revision instrument comprises a main box; a blow-offpipe is mounted on the lower side of the main box; a collecting bottle is detachably mounted at the bottom end of the blow-off pipe through a threaded pipe; a main pipe is mounted on one side of themain box; a telescopic pipe is slidably mounted at the end, away from the main box, of the main pipe; a sub-pipe is mounted at the end, away from the main pipe, of the telescopic pipe; a first spiralblade rod is rotatably mounted in the main pipe; a second spiral blade rod is rotatably mounted in the blow-off pipe; and a main shaft is rotatably mounted in the main box. According to the electric revision instrument, through the arrangement of all the structures, the functions of cutter crushing and dirt cleaning can be achieved at the same time, the two functions can be rapidly switched, operation is smoother, operation time consumption is reduced, and meanwhile, dirt such as bloody water, bone residues and tissue debris and the like can be rapidly and smoothly cleaned and collected, and pipeline blockage during collection is avoided.

Owner:THE AFFILIATED HOSPITAL OF XUZHOU MEDICAL UNIV

Building mortar mixing device

ActiveCN112976304AImprove efficiencyAvoid cloggingSievingScreeningStructural engineeringMechanical engineering

The invention provides a building mortar mixing device. The building mortar mixing device comprises a stirring barrel, a motor, a mixing stirring assembly, a crushing stirring assembly and a material distributing plate assembly, so that a crushing cone is arranged in the stirring barrel, and stirred materials inside the stirring barrel can be in contact with the crushing cone to achieve a crushing effect when moving downwards, the condition that the material forms a block at the inner bottom end of the stirring barrel to block a discharging pipe is prevented, and the effect of avoiding influencing the flowing-out of the materials is achieved. According to the building mortar mixing device, a material distributing plate and a discharging hole are arranged in the stirring barrel, so that the raw materials can be primarily screened after entering the stirring barrel, and the situation that large raw materials directly enter the stirring barrel and are non-uniformly stirred is prevented; and meanwhile, transverse and vertical synchronous stirring can be realized inside the whole stirring barrel, so that secondary stirring is realized, and the stirring efficiency is improved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

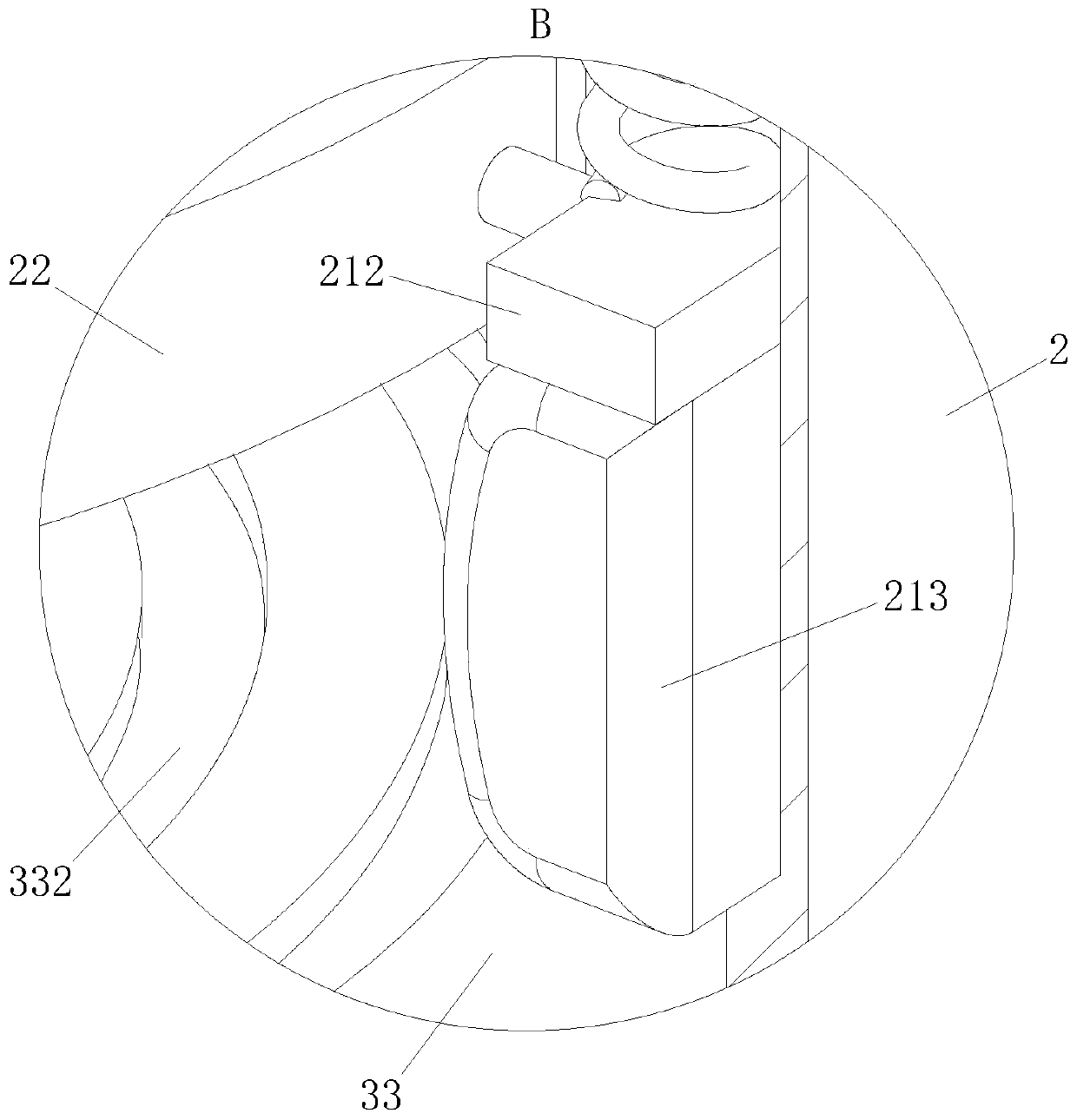

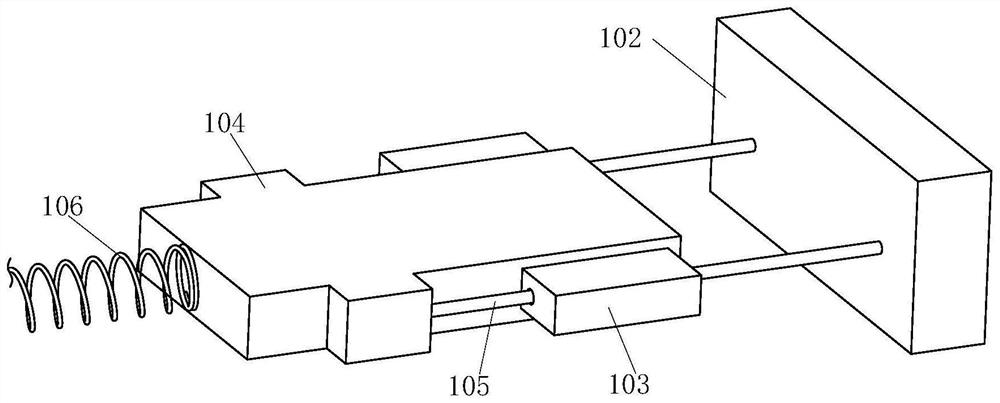

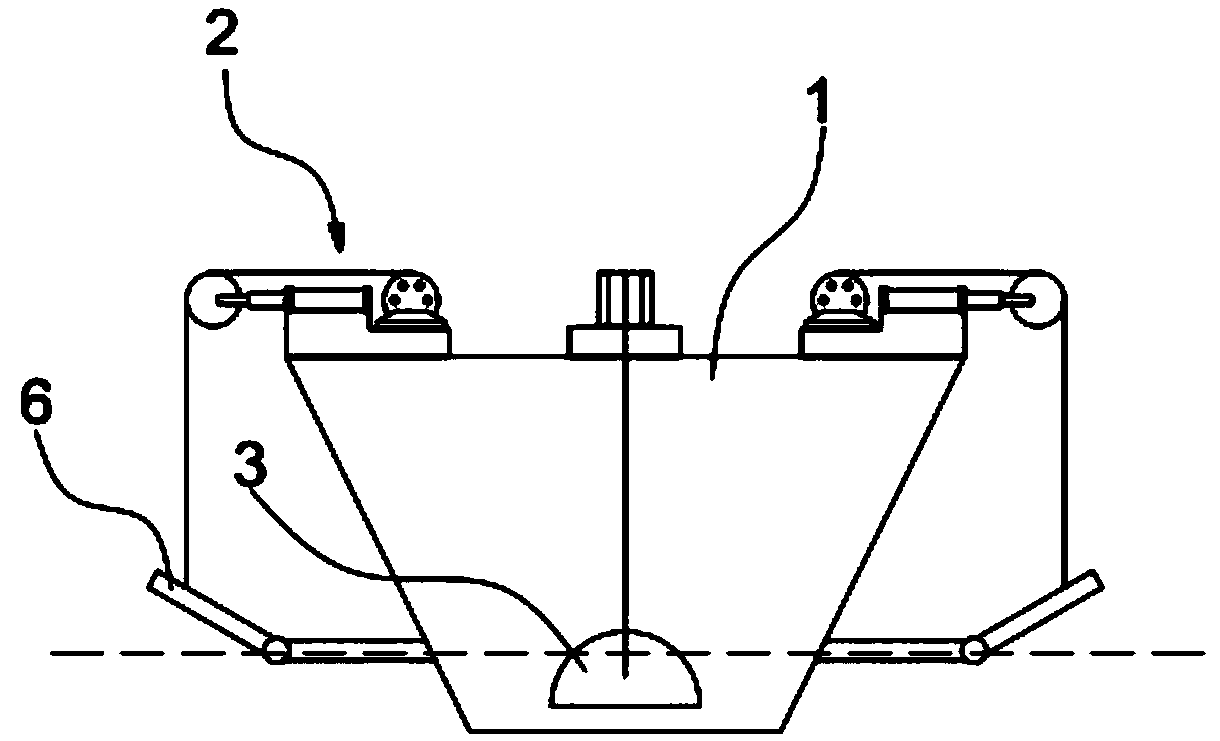

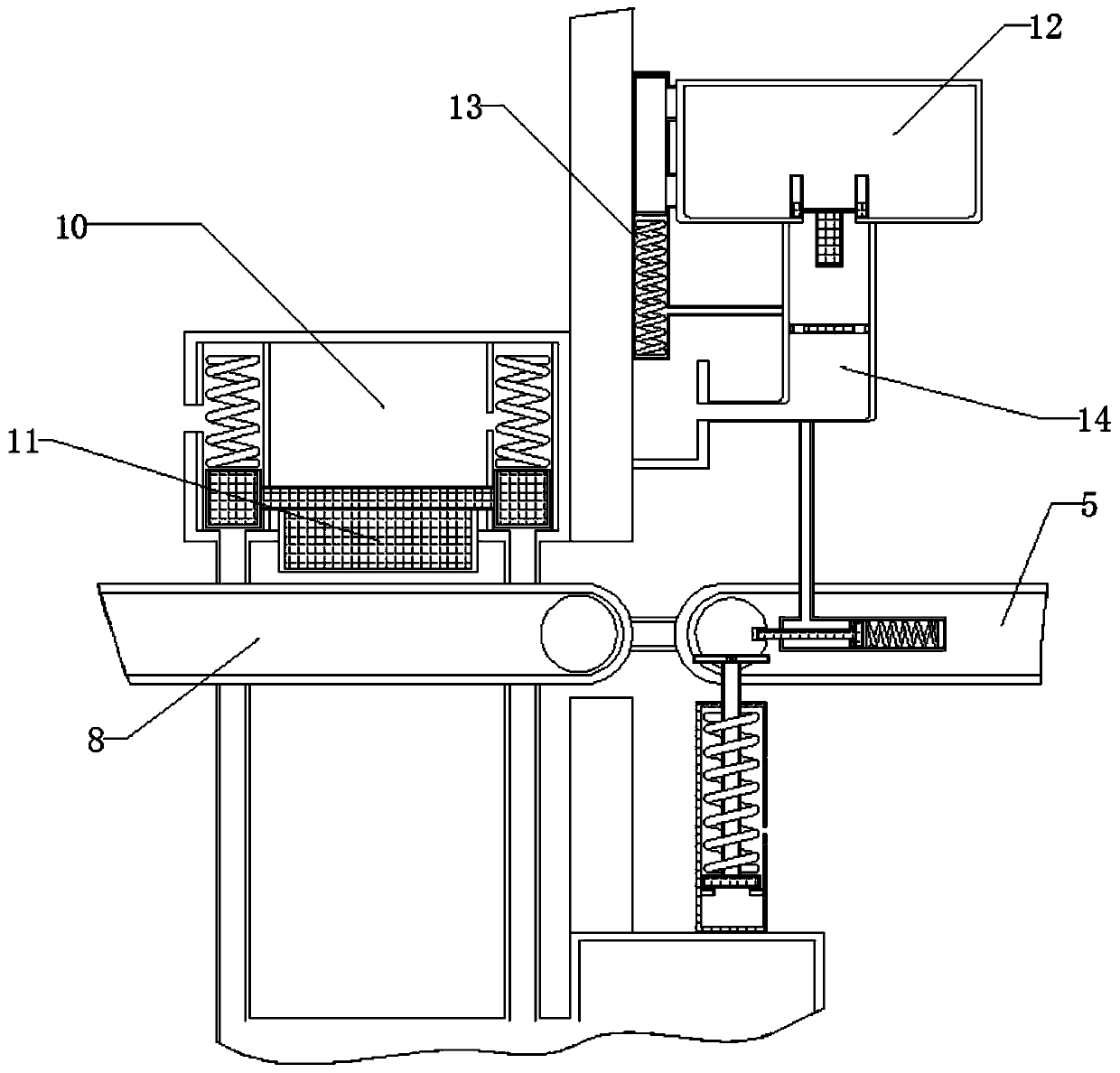

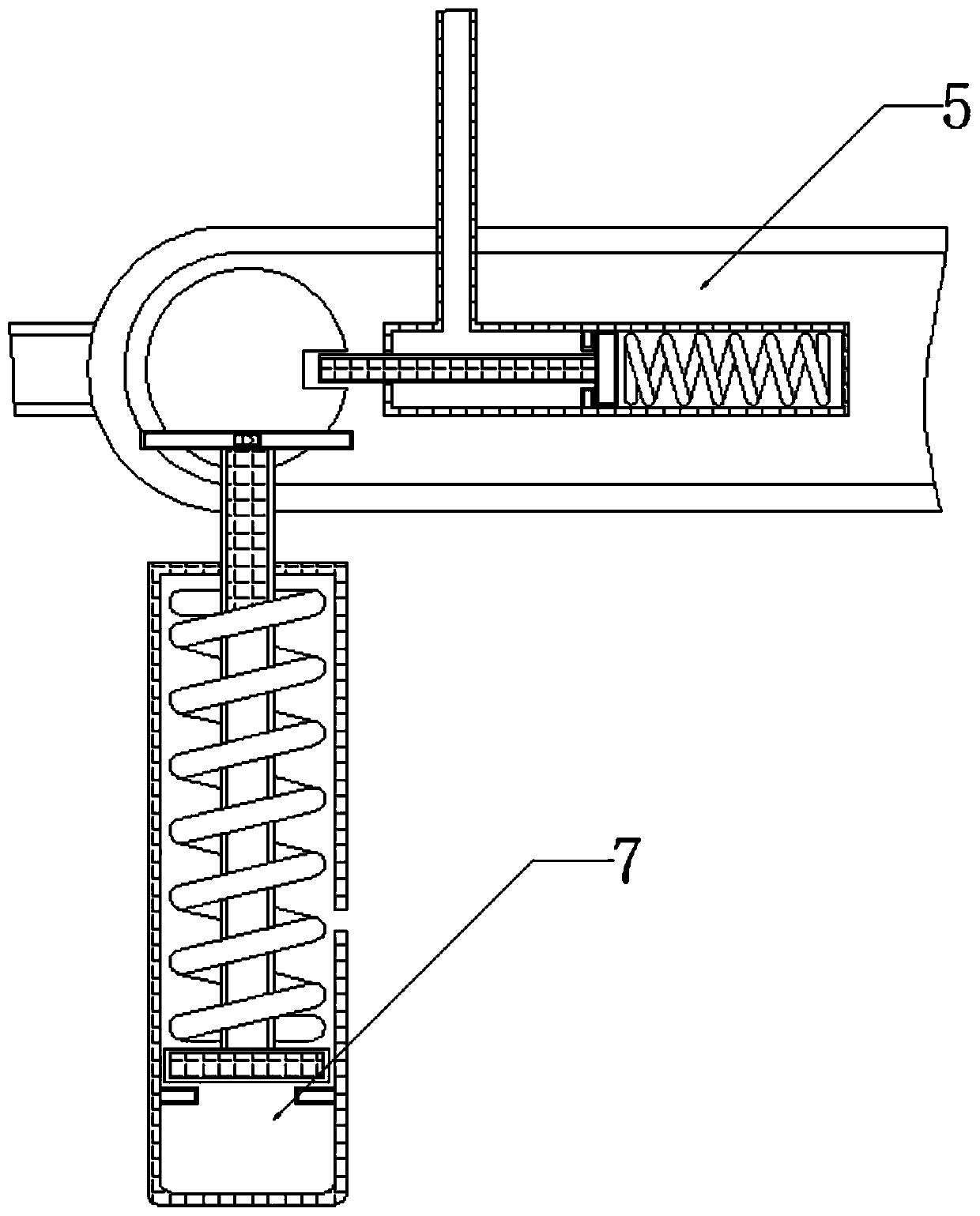

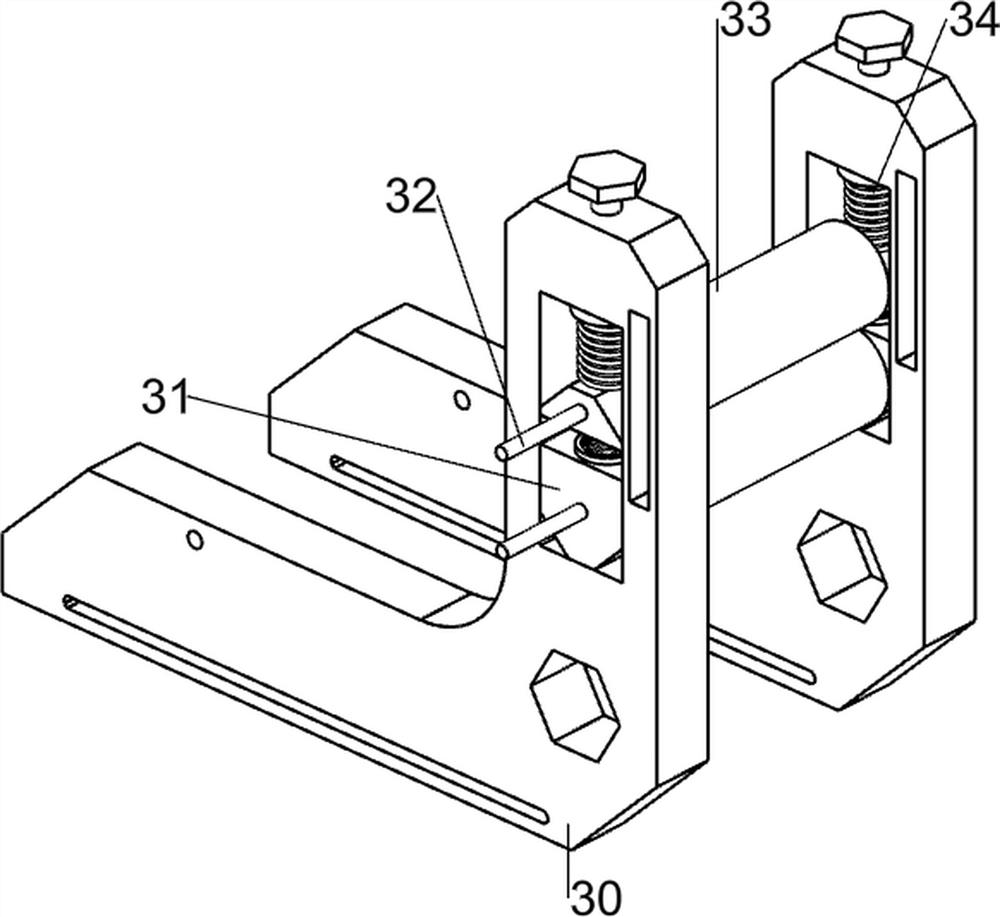

Small-amplitude tracking type breaking hammer

ActiveCN106013302APrevent air strikeExtended service lifeMechanical machines/dredgersSmall amplitudeLocking mechanism

The invention belongs to the technical field of breaking hammers, and particularly relates to a small-amplitude tracking type breaking hammer. The small-amplitude tracking type breaking hammer comprises a drill rod, a drill rod sleeve, a hydraulic knocking mechanism, a hydraulic control valve, clamp locking mechanisms and circular arc guide plates, wherein the drill rod is mounted inside the drill rod sleeve through the sliding cooperation of drill rod guide blocks and drill rod sleeve sliding holes; drill rod springs are mounted on the guide blocks; when the drill rod performs reciprocating knocking, the drill rod springs exert a drill rod resetting function; the hydraulic knocking mechanism is mounted inside the drill rod sleeve, and can knock the drill rod to achieve a breaking effect; the drill rod sleeve slides in the circular arc guide plates through drill rod sleeve sliding blocks; and the position of the drill rod sleeve is automatically adjusted through tracking springs, and the entire stretching length of the drill rod sleeve is changed along with the change of the breaking depth of a broken object. According to the small-amplitude tracking type breaking hammer, empty knocking phenomenon of the drill rod is prevented, the service life of the drill rod is prolonged, and the breaking hammer has a relatively good utilization effect.

Owner:TAICANG DENASEN MECHANICAL & ELECTRICAL ENG CO LTD

Grinding-type crusher

The invention discloses a grinding-type crusher which comprises a machine table and a base positioned at the bottom of the machine table, and the grinding-type crusher is characterized in that a jaw structure is formed by two grinding discs; a crushing effect is achieved by rotating the two grinding discs opposite to each other; a feeding hole is large in outlet space; the fed large materials are impacted and crushed at the inlet due to rotation of the grinding discs; medium-sized materials and small materials obtained after crushing of the large materials are crushed in the middle and at the bottom of the jaw structure. The defects in the prior art are overcome, the design structure is reasonable, and the working efficiency is effectively improved. Meanwhile, due to layered crushing, the size of the crushed mineral aggregate is uniform, the mineral aggregate is finally conveyed out through a conveyor belt, the labor force is saved, and the application range is wide.

Owner:ANQING LINGBAO MACHINERY

A small-amplitude tracking breaker

ActiveCN106013302BPrevent air strikeExtended service lifeMechanical machines/dredgersSmall amplitudeLocking mechanism

The invention belongs to the technical field of breaking hammers, and in particular relates to a small-amplitude tracking breaking hammer, which includes a drill rod, a drill rod sleeve, a hydraulic impact mechanism, a hydraulic control valve, a locking mechanism, and an arc guide plate, wherein the drill rod passes through the drill rod The sliding fit between the guide block and the sliding hole of the drill rod sleeve is installed inside the drill rod sleeve, and the drill rod spring is installed on the guide block, which plays the role of resetting the drill rod when the drill rod is reciprocatingly beating; the hydraulic impact mechanism is installed on the drill rod Inside the rod sleeve, the drill rod can be impacted to achieve the crushing effect; the drill rod sleeve slides in the arc guide plate through the drill rod sleeve slider, and the position of the drill rod sleeve is automatically adjusted by tracking the spring, so that the overall extension length of the drill rod sleeve can be adjusted accordingly. It varies with the crushing depth of the crushed object. The invention prevents the air strike phenomenon of the drill rod and improves the service life of the drill rod. It has good application effect.

Owner:TAICANG DENASEN MECHANICAL & ELECTRICAL ENG CO LTD

Soybean processing crushing and stirring device

InactiveCN109126601ATo achieve the effect of storageAchieve the effect of rotationTransportation and packagingMixer accessoriesMechanical engineeringEngineering

The invention discloses a soybean processing crushing and stirring device The soybean processing crushing and stirring device comprises a box, the top of the box is communicated with a first filling pipe, the left of the box is communicated with a second filling pipe, and the top of the right of the box is provided with a first motor. According to the soybean processing crushing and stirring device, the box can store soybeans, the first motor can drive a first rotating shaft and a first gear to rotate; the first gear and a second gear can drive a second rotating shaft to rotate; the first rotating shaft, the second rotating shaft and a crushing block can crush the soybeans; a second motor can drive a first stirring rod and a driving wheel to rotate; the driving wheel, a belt and a driven wheel can drive a second stirring rod to rotate; the first stirring rod, the second stirring rod and stirring blades can stir the soybeans. The soybean processing crushing and stirring device can crushand stir the soybeans and facilitate application by users.

Owner:许昌泰禾农业科技发展有限公司

Device for rapidly replacing raw material distillation at high temperature by distillation method

ActiveCN111500370AFast Distillation CollectionSave resourcesEssential-oils/perfumesThermodynamicsDistillation method

The invention relates to the technical field of cosmetic processing, and discloses a device for rapidly replacing raw material distillation at high temperature by using a distillation method. The device comprises a processing machine, a heating water tank is movably connected to the bottom of the interior of the processing machine, a heating plate is movably connected to the interior of the heating water tank, a water inlet pipe is movably connected to the upper right portion of the heating water tank, a distillation belt is movably connected to the upper portion of the heating water tank, a discharging belt is movably connected to the right side of the distillation belt, a power rail is movably connected to the lower portion of the distillation belt, and a feeding belt is movably connected to the left side of the distillation belt. A collecting sliding block movably connected in the collecting box makes contact with an oil outlet baffle fixedly connected in an oil outlet pipe, so thata solution with essential oil, collected in the collecting box, is discharged into an oil outlet groove through the oil outlet pipe, is finally discharged out of the processing machine and is subjected to next-step separation operation, so the effect of rapidly distilling and collecting the essential oil is achieved.

Owner:湖北瑞晟生物有限责任公司

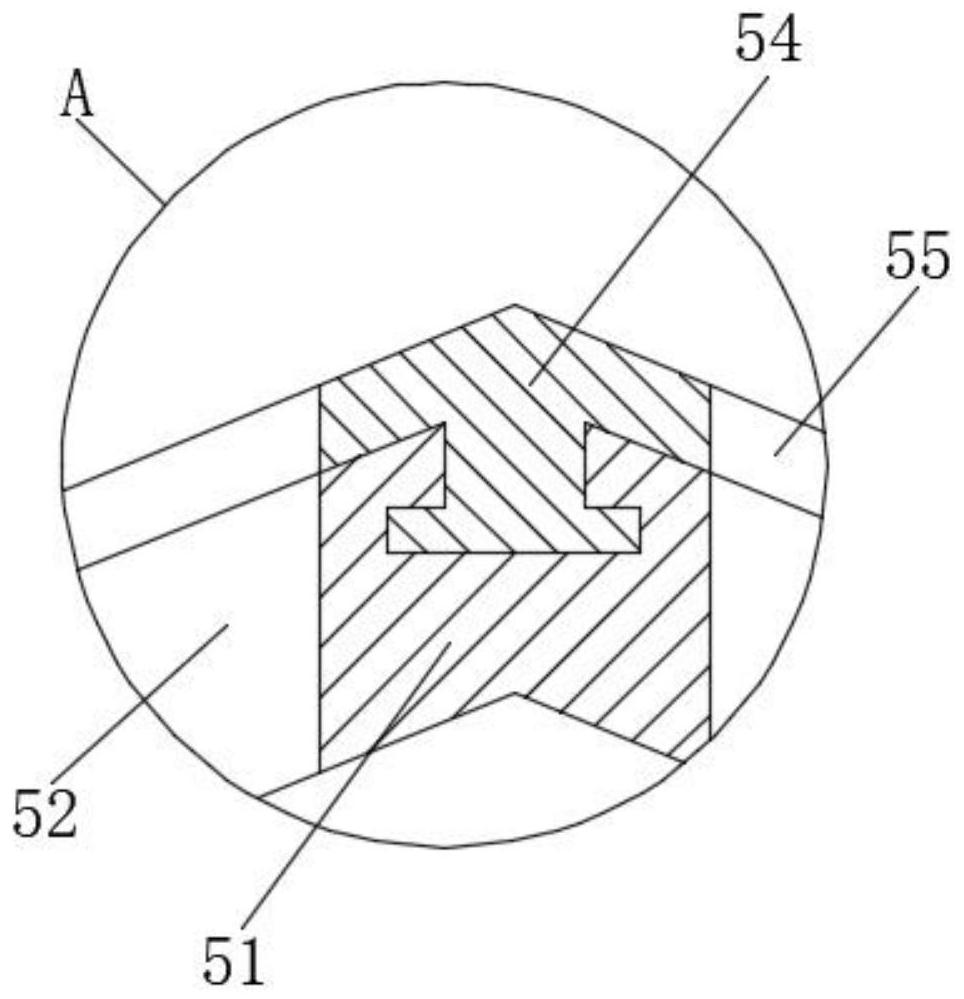

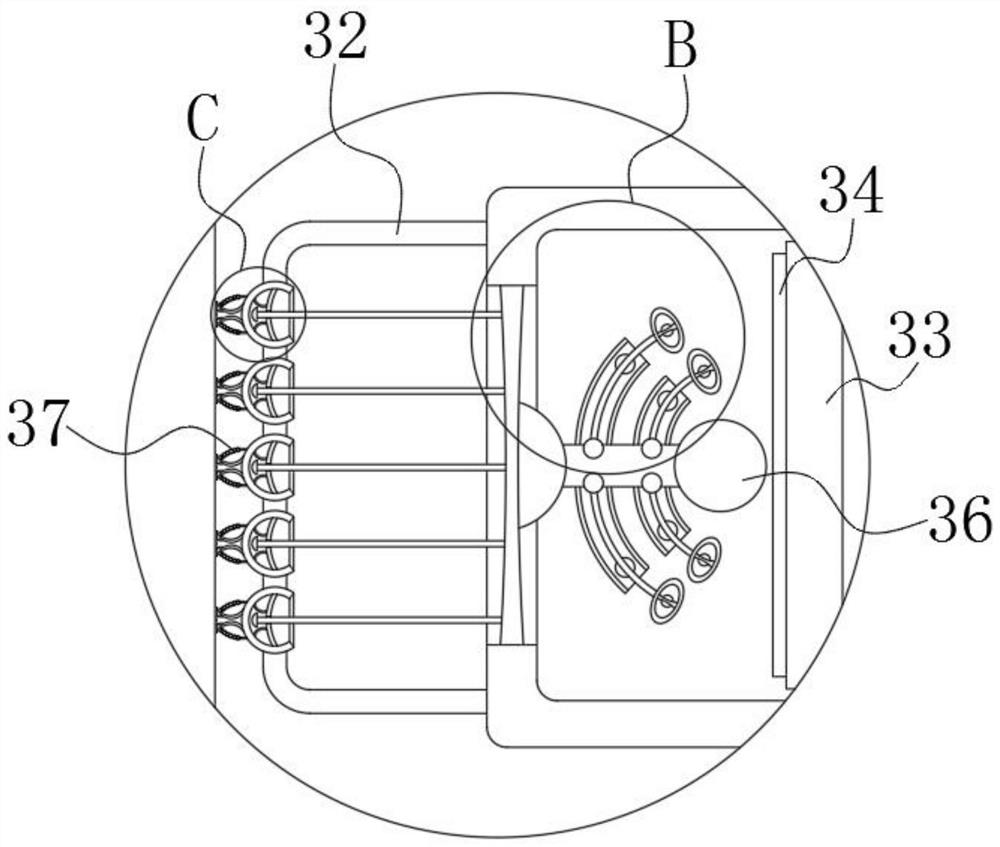

Crushing and cleaning machine

InactiveCN109590069AAchieve broken effectTo achieve the effect of water rotationCleaning using toolsCleaning using liquidsCouplingPulp and paper industry

The invention discloses a crushing and cleaning machine. The crushing and cleaning machine comprises a machine body, the bottom of the machine body is fixedly connected with supporting legs, the bottoms of the supporting legs are fixedly connected with fixing legs, the middle portions of the fixing legs are fixedly connected with a motor, an output shaft of the motor is fixedly connected with a rotating shaft through a coupler, the rotating shaft runs through the bottom of the machine body and extends into the machine body, one end of the rotating shaft is fixedly connected with blades and fanblades correspondingly, the other end of the rotating shaft is fixedly connected with a crushing roller shaft, the bottom of the machine body is provided with an outlet, and the inner wall of the machine body is fixedly connected with medicine brushes. According to the crushing and cleaning machine, by means of the arrangements of first crushing teeth and second crushing teeth, the effect of crushing Chinese medicinal materials is achieved; by means of the arrangements of the medicine brushes, the effect of brushing and cleaning the surfaces of the medicinal materials can be performed; and bymeans of circular arc tooth tips on the first crushing teeth and the second crushing teeth, medicinal material value loss in medicinal material crushing can be effectively reduced, so that the problems of large volume, high fabrication cost and the medicinal material value loss are effectively solved.

Owner:ZHENJIANG RUIDE ENERGY SAVING TECH

Construction waste solid waste treatment device with dustproof function

ActiveCN112718115AAchieve broken effectEasily sort and filter outUsing liquid separation agentDirt cleaningElectric machineryEnvironmental engineering

The invention discloses a construction waste solid waste treatment device with a dustproof function, and belongs to the technical field of construction waste treatment device. The construction waste solid waste treatment device comprises an L-shaped plate, the L-shaped plate is fixedly connected to the upper surface of a bottom plate, a stirring mechanism is arranged on the L-shaped plate, one end of the stirring mechanism penetrates into a crushing barrel, a plurality of crushing teeth are evenly and fixedly connected to the inner wall of the crushing barrel, and a feeding port is formed in the upper surface of the crushing barrel. According to the construction waste solid waste treatment device with the dustproof function, by arranging the stirring mechanism, when a first motor works, a stirring plate can be driven to rotate through a first rotating shaft, the stirring plate can stir construction waste, crushed materials can fall into a collecting box through screen nets, the collecting box is internally provided with an interlayer, and the pore sizes of the multiple screen nets are different, so that the crushed materials with different sizes can be screened, the crushed materials with different volumes and sizes are screened, the motor is controlled to work to drive the collecting box to rotate, the positions of the multiple screen nets can be adjusted, and waste can be screened out easily in a classified mode.

Owner:湖南省长沙磊鑫环保科技有限公司

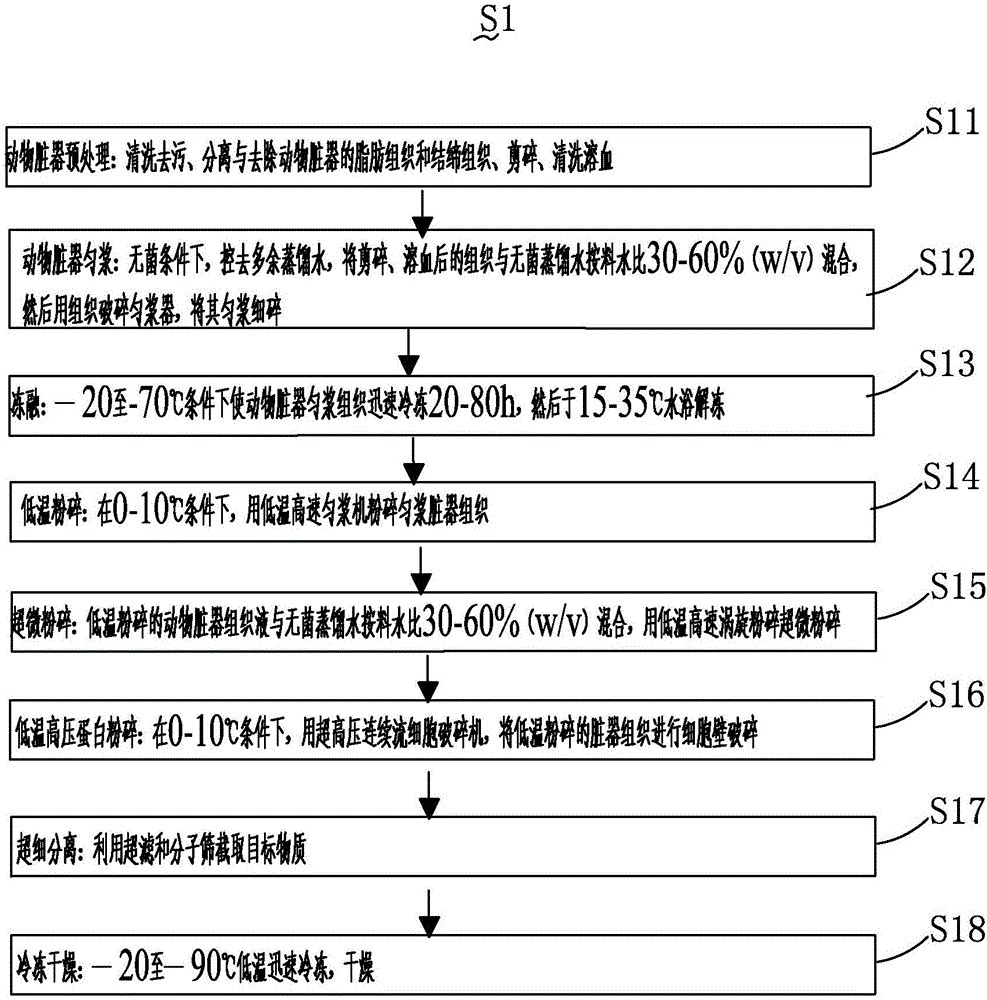

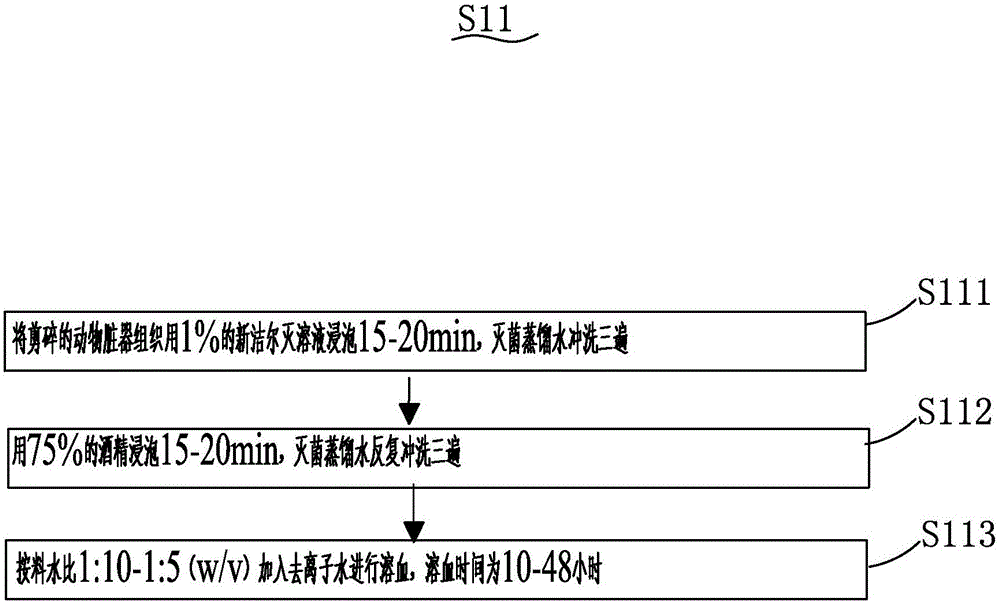

Method for preparing animal viscera micro-molecule polypeptide through complete physical method

InactiveCN106518960AIncrease profitKeep alivePeptide preparation methodsFreeze thawingAnimal science

The invention provides a method for preparing animal viscera micro-molecule polypeptide through a complete physical method. The method for preparing animal viscera micro-molecule polypeptide through the complete physical method comprises the following steps of 1 animal viscera organ preprocessing, 2 animal viscera homogenizing, 3 freeze thawing, 4 low-temperature grinding, 5 superfine grinding, 6 low-temperature high-pressure protein grinding, 7 superfine separation and 8 freeze drying. The method for preparing animal viscera micro-molecule polypeptide through the complete physical method applies the complete physical method for preparing the animal viscera micro-molecule polypeptide, the influence caused by a chemical reagent on micro-molecule polypeptide active ingredients and the like is avoided, and the natural and efficient small peptide active substances are obtained on the basis of ensuring product safety.

Owner:内蒙古蒙肽生物工程有限公司

An unmanned monitoring ship anti-rolling device

ActiveCN109436233BAchieve conversionIncrease driving speedVessel cleaningHullsDamperMechanical engineering

Owner:ZHEJIANG OCEAN UNIV

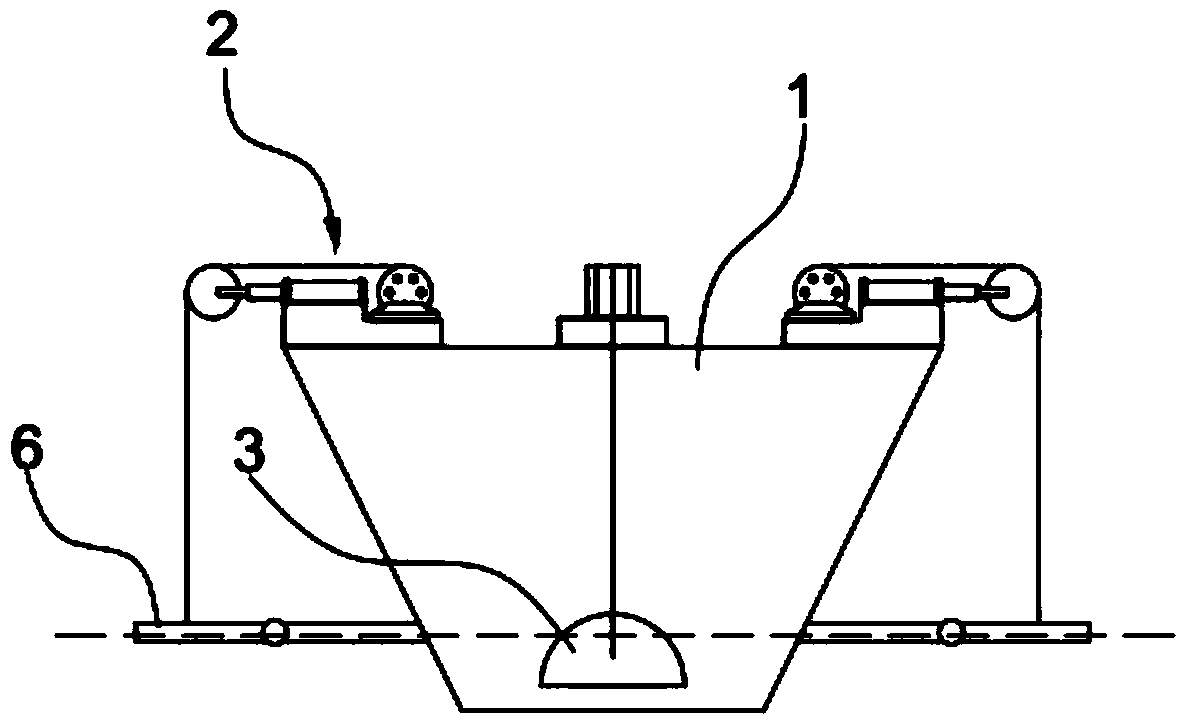

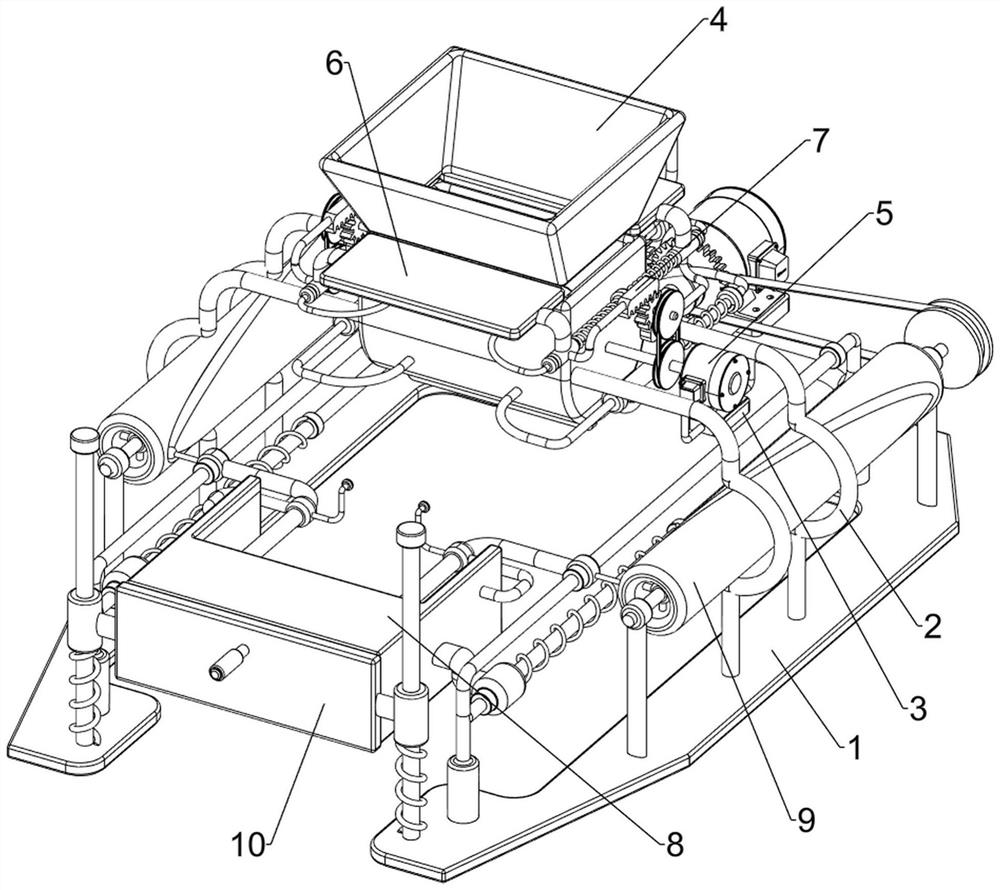

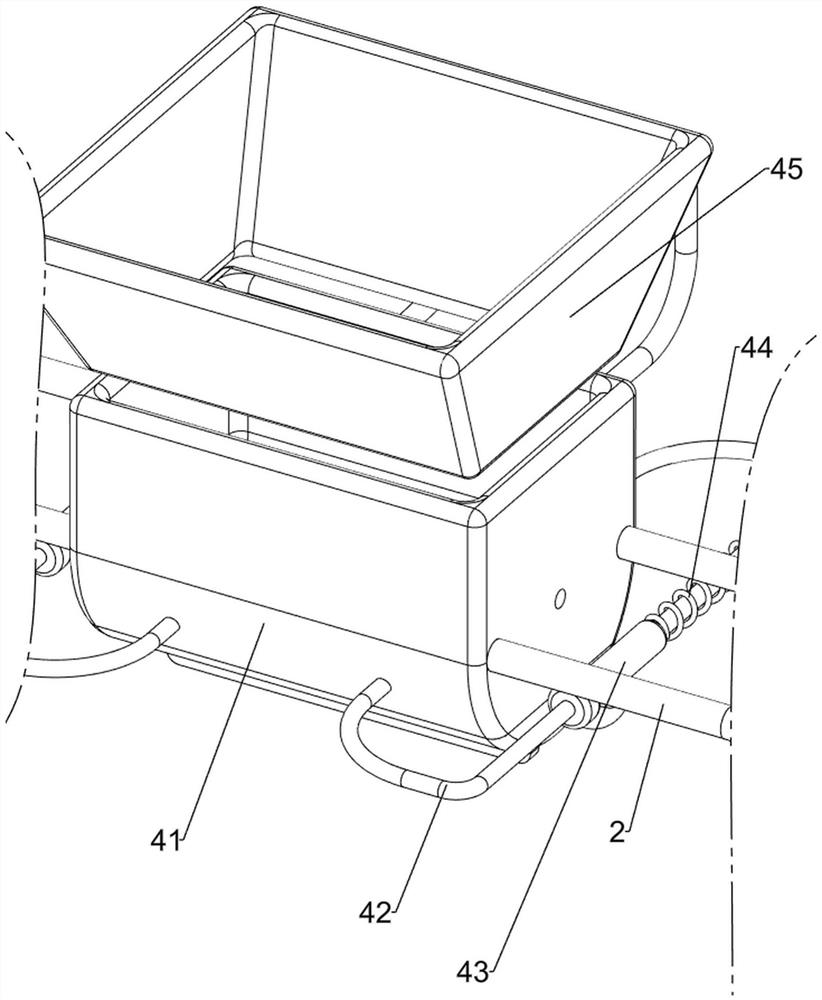

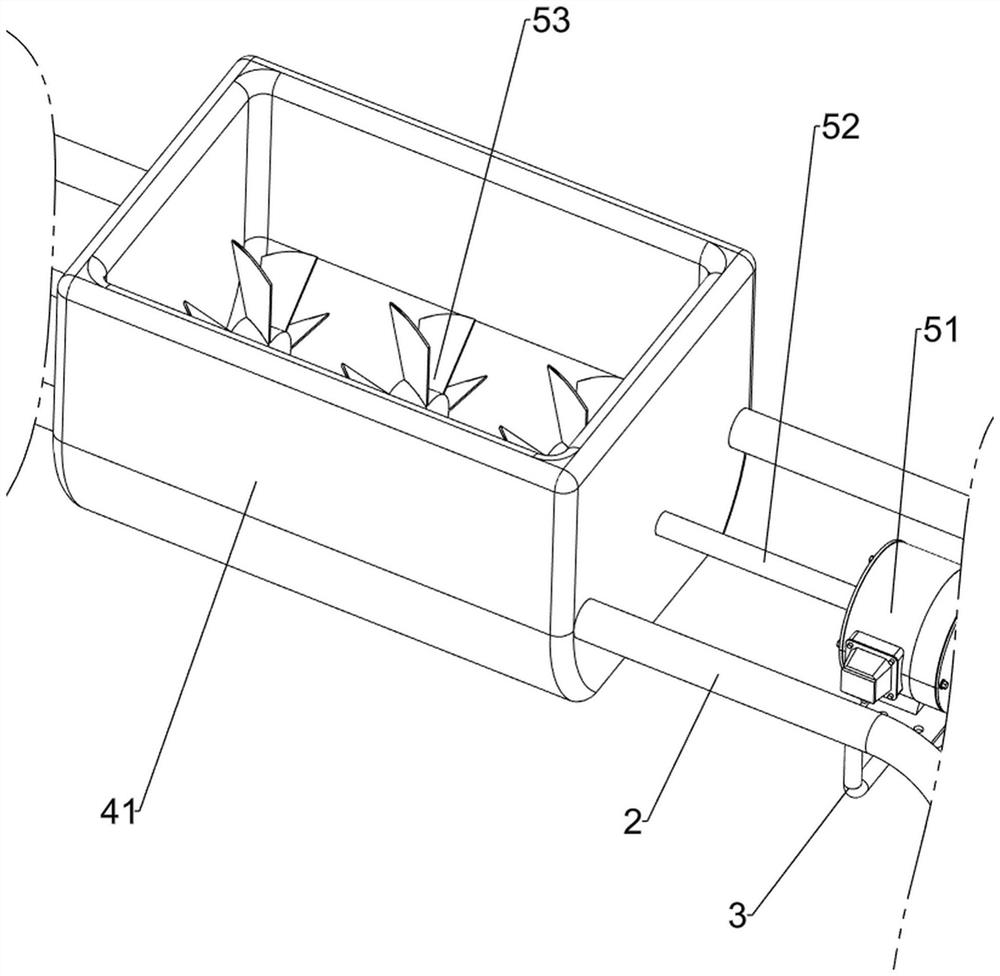

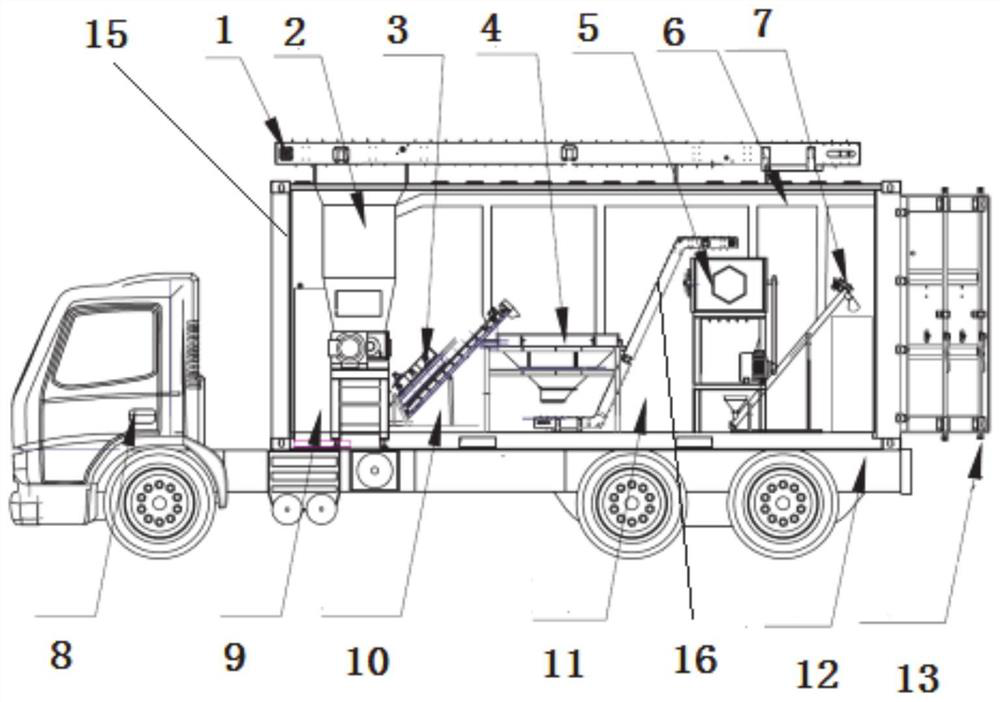

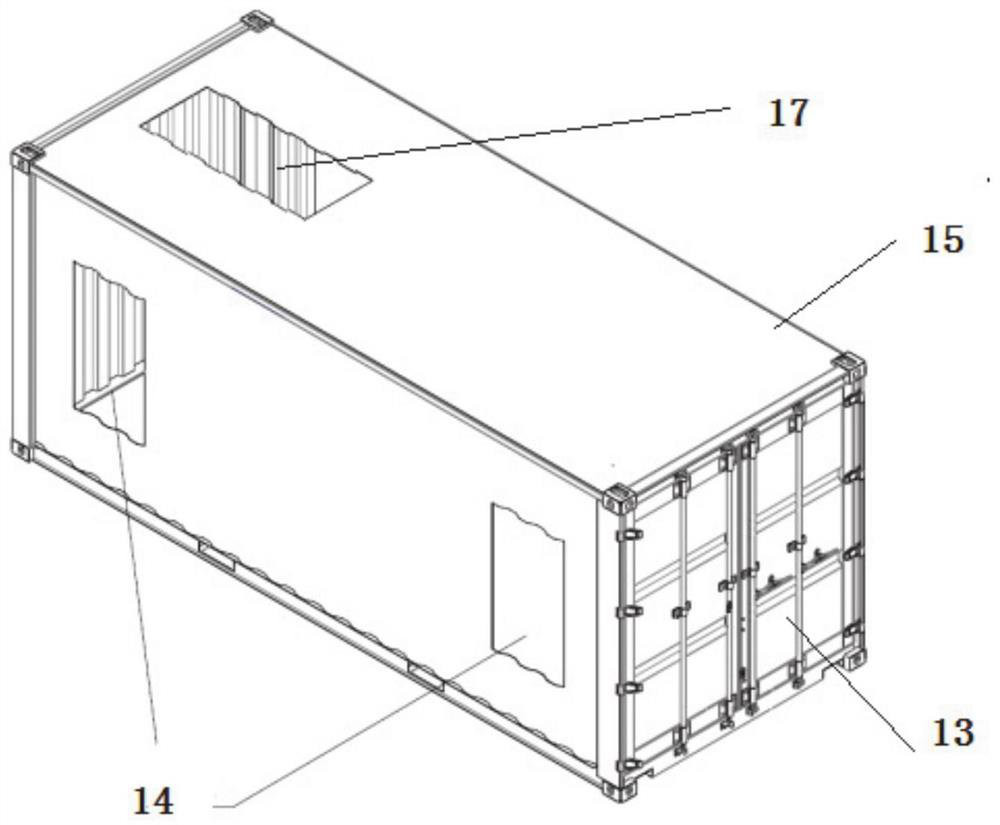

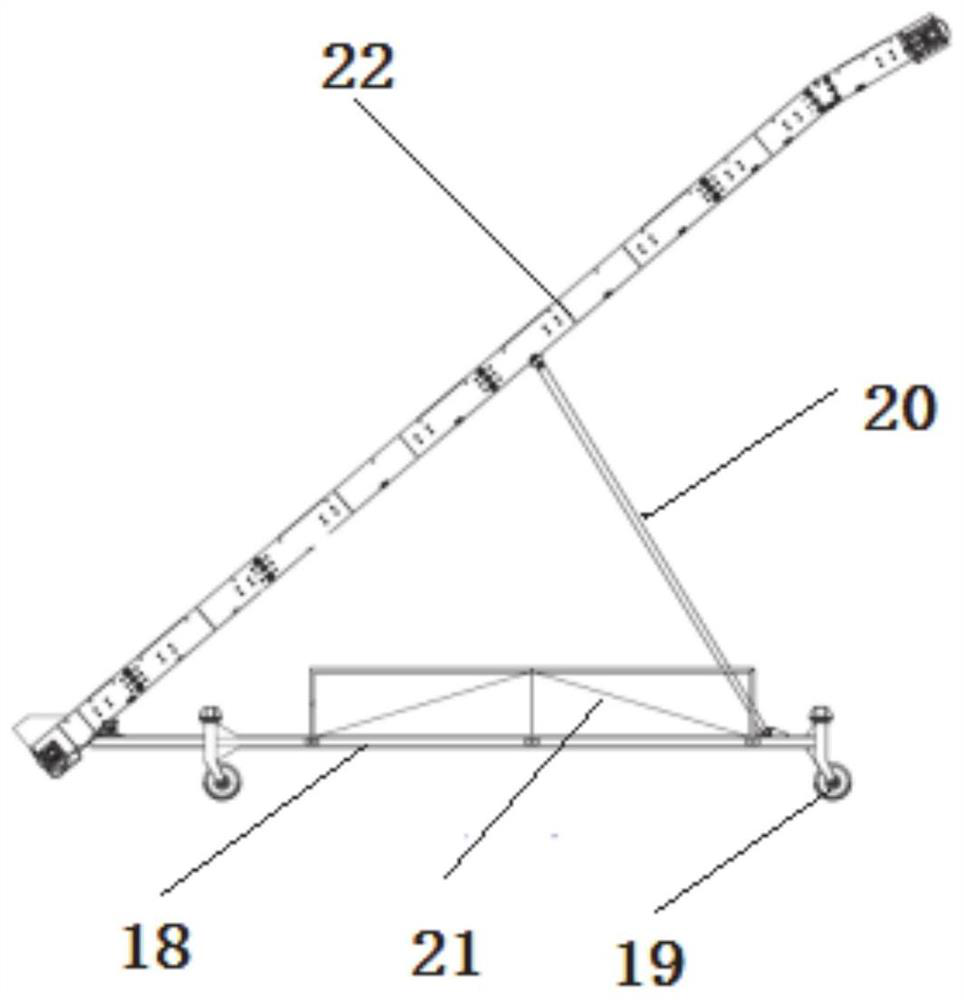

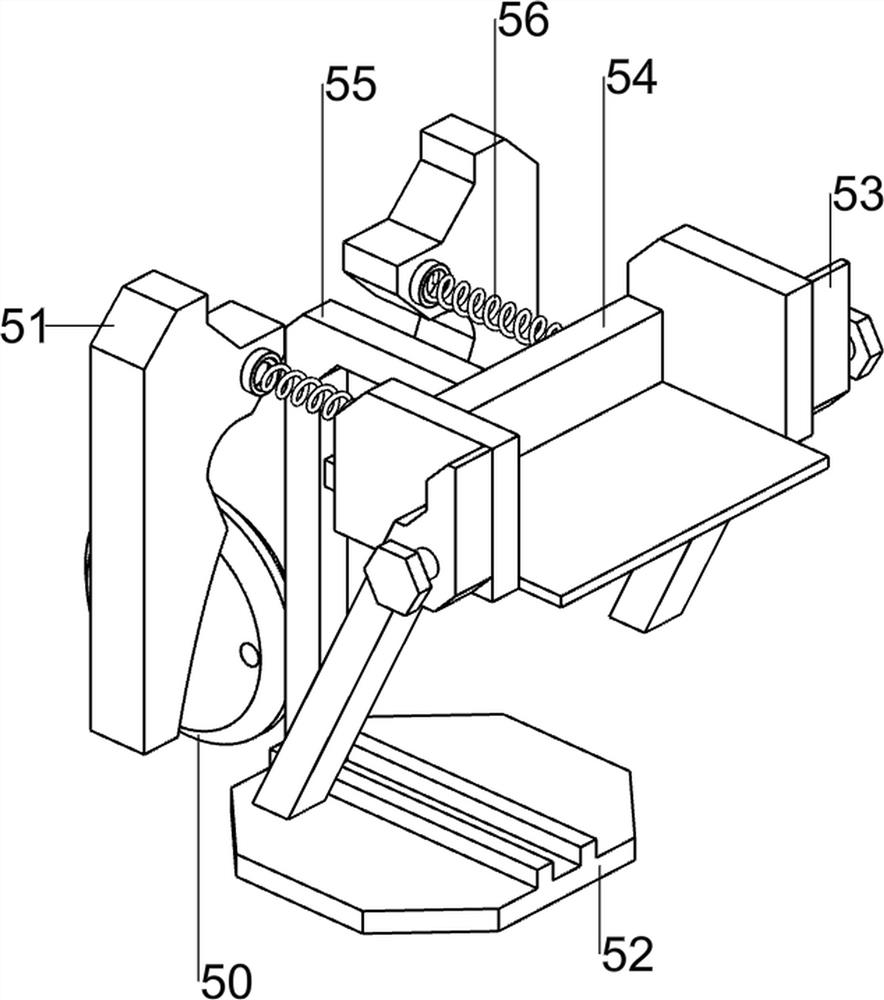

Movable industrial solid waste fiber composite material treatment system, working method and application

ActiveCN113856876AEffective control of floor spaceReduce construction costsSolid materialGrain treatmentsWaste collectionFibrous composites

The invention discloses a movable industrial solid waste fiber composite material treatment system, a working method and application. The problems that in the prior art, waste treatment cost is high, and on-site treatment cannot be achieved are solved. The movable industrial solid waste fiber composite material treatment system has the beneficial effects that cross-region transportation can be achieved, on-site treatment and waste collection can be achieved, and cost is reduced. According to the specific scheme, the movable industrial solid waste fiber composite material treatment system comprises a tray, the tray is installed on a walking mechanism so that the treatment system can move, the tray supports at least one set of crushing units so as to crush materials, the crushing particle sizes of the crushing units are different, a screening unit is arranged behind the at least one set of crushing units so as to screen the crushed materials, a magnetic separation unit is further arranged between the at least one set of crushing units and the adjacent screening unit so as to separate metal in the crushed materials, and the screening unit and the magnetic separation unit are both supported through the tray.

Owner:CRRC SHANDONG CO LTD

Harmful plastic article crushing and disinfecting equipment

PendingCN112873632AAchieve broken effectRealize the effect of continuous pushPlastic recyclingMedical waste disposalEngineeringWaste material

Owner:郭长强

Dye vat cleaning device for textile production

InactiveCN113070303AMake up for the disadvantages of sputtering to the outside of the dye vatAchieve cleaning effectHollow article cleaningGrain treatmentsFiberHydraulic cylinder

The invention discloses a dye vat cleaning device for textile production, and relates to the technical field of textile production. The dye vat cleaning device for textile production comprises a machine body, wherein a hydraulic cylinder is fixedly arranged at the top of the machine body, the output end of the hydraulic cylinder penetrates through the inner top of the machine body and is fixedly provided with a cleaning mechanism, a dye vat is fixedly arranged in the machine body, the cleaning mechanism is located in the dye vat, the cleaning mechanism comprises a hollow lifting plate, a fixing bag, a magnetic column, a fixing piece, a first elastic film, an amplitude enhancing mechanism and a scraping enhancing mechanism, and the hollow lifting plate is fixedly arranged at the bottom end of the output end of the hydraulic cylinder through a screw. According to the dye vat cleaning device for textile production, the cleaning mechanism can be moved into the dye vat in time when the dye vat needs to be cleaned, fine fibers attached to the inner wall of the dye vat and residual cured dye are cleaned in cooperation with cleaning water discharged into the dye vat, and compared with a traditional dye vat cleaning means, water resource consumption can be reduced.

Owner:陈颖

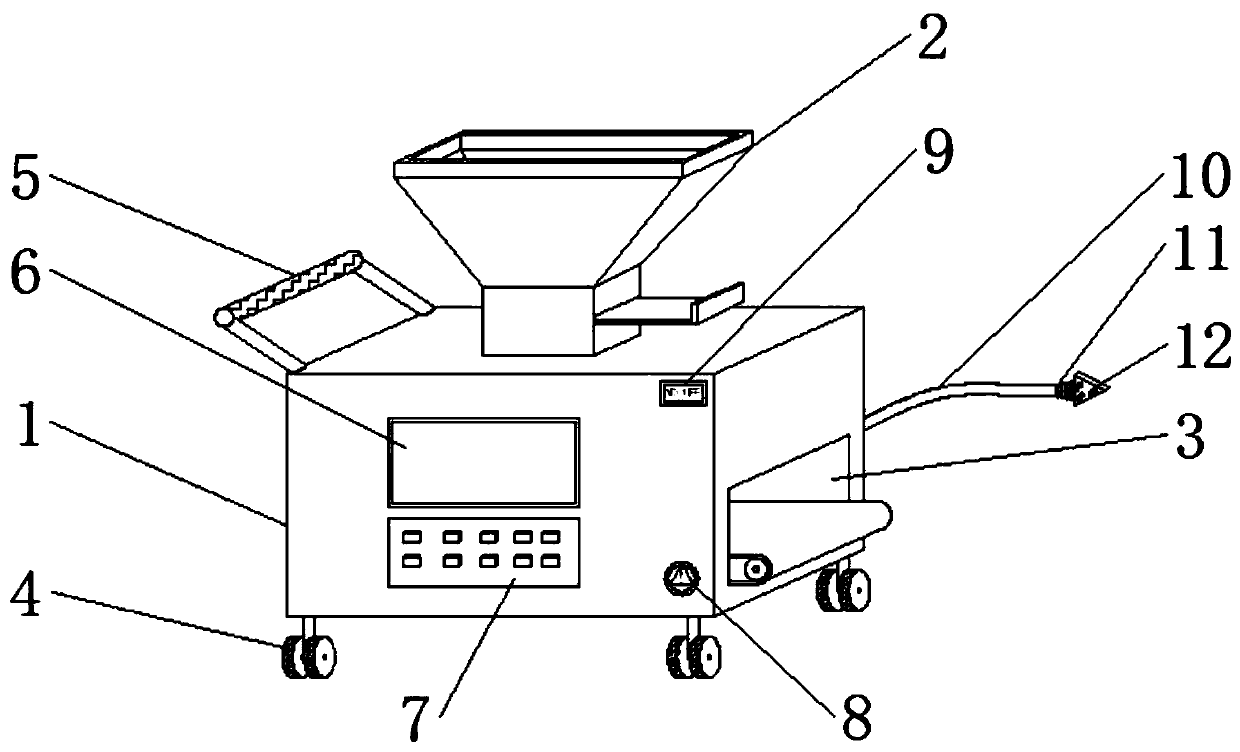

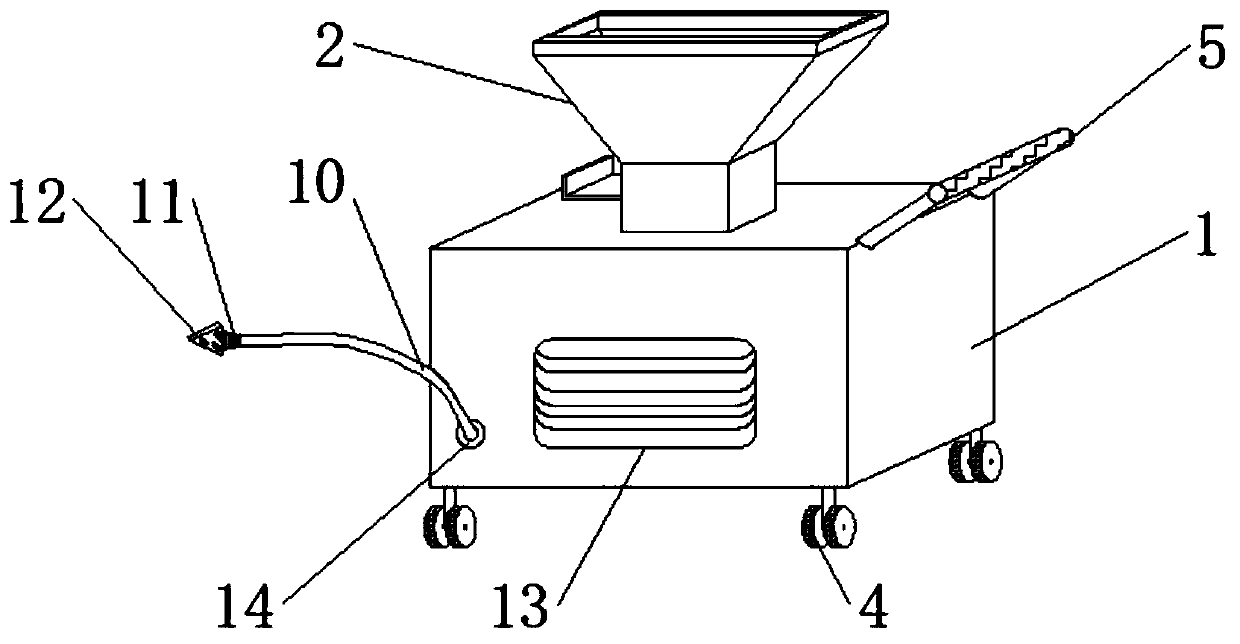

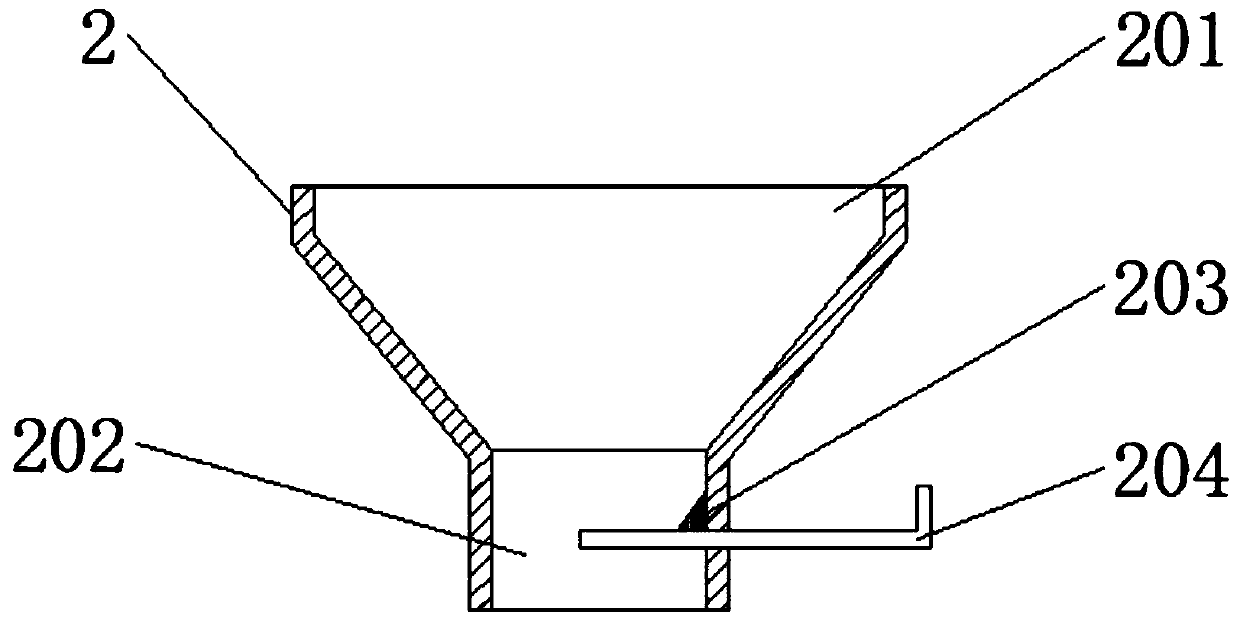

Engineering waste residue material crushing treatment device

InactiveCN109590065AImprove securityImprove efficiencyMedical waste disposalGrain treatmentsArchitectural engineeringImpurity

The invention discloses an engineering waste residue material crushing treatment device, comprising a connecting mechanism main body, wherein the left side of the top end of the device main body is fixedly connected with an anti-skid handle, a feeding hopper is fixedly connected to the middle position of the top end of the device main body, four corners of the bottom end of the device main body are movably connected with anti-skid universal wheels, a feeding port is fixedly connected to the inner top of the feeding hopper, the bottom of the feeding hopper is fixedly connected with a feeding neck, and a scraping block is fixedly connected to the inner right side of the feeding neck. When the engineering waste residue material crushing treatment device runs, the engineering waste residue material can be poured into the feed port, when the engineering waste residue material enters the engineering waste residue material crushing treatment device for crushing, a part of impurities can stickon a feeding adjusting plate, and the scraping block can clear other impurities sticking on the feeding adjusting plate, so as to avoid the condition that the feeding size of the engineering waste residue material in the feeding port cannot be normally controlled due to the blockage of the feeding adjusting plate, thus effectively improving the efficiency of the engineering waste residue materialcrushing treatment device.

Owner:辰溪县红新新型建筑材料有限公司

Microencapsulated phytosterol extraction device

InactiveCN110860107AAchieve broken effectReach supportSteroidsLiquid solutions solvent extractionSterolMechanical engineering

The invention discloses a microencapsulated phytosterol extraction device. The device comprises a box body, a filling pipe is communicated with the top on the left side of the box body, a support plate is fixedly connected to the top a surface on an inner cavity of the box body, the bottom of the surface on the inner cavity of the box body is fixedly connected to a placement box through connectingblocks, and a discharge pipe is communicated with the left side at the bottom of the containing box. According to the invention, electric telescopic rods are arranged to reach the effect of driving apress plate to move, by means of the press plate, the effect of crushing microcapsules can be achieved, a supporting plate and through holes are arranged to facilitate support of microcapsules and also help sterol to flow into the placement box, the placement box can reach the effect of placing sterol, and through a first rotating shaft, a second rotating shaft and stirring blades, the effect ofstirring sterol can be achieved, and through a spectrometer, the effect of detecting the sterol content is achieved. The device can effectively extract sterol, and is convenient for people to use.

Owner:林东楷

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com