Grinding-type crusher

A technology of crusher and grinding disc, which is applied in the direction of grain processing, etc., can solve the problem that the size of broken particles is not easy to control, and achieve the effect of wide application range, uniform size and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

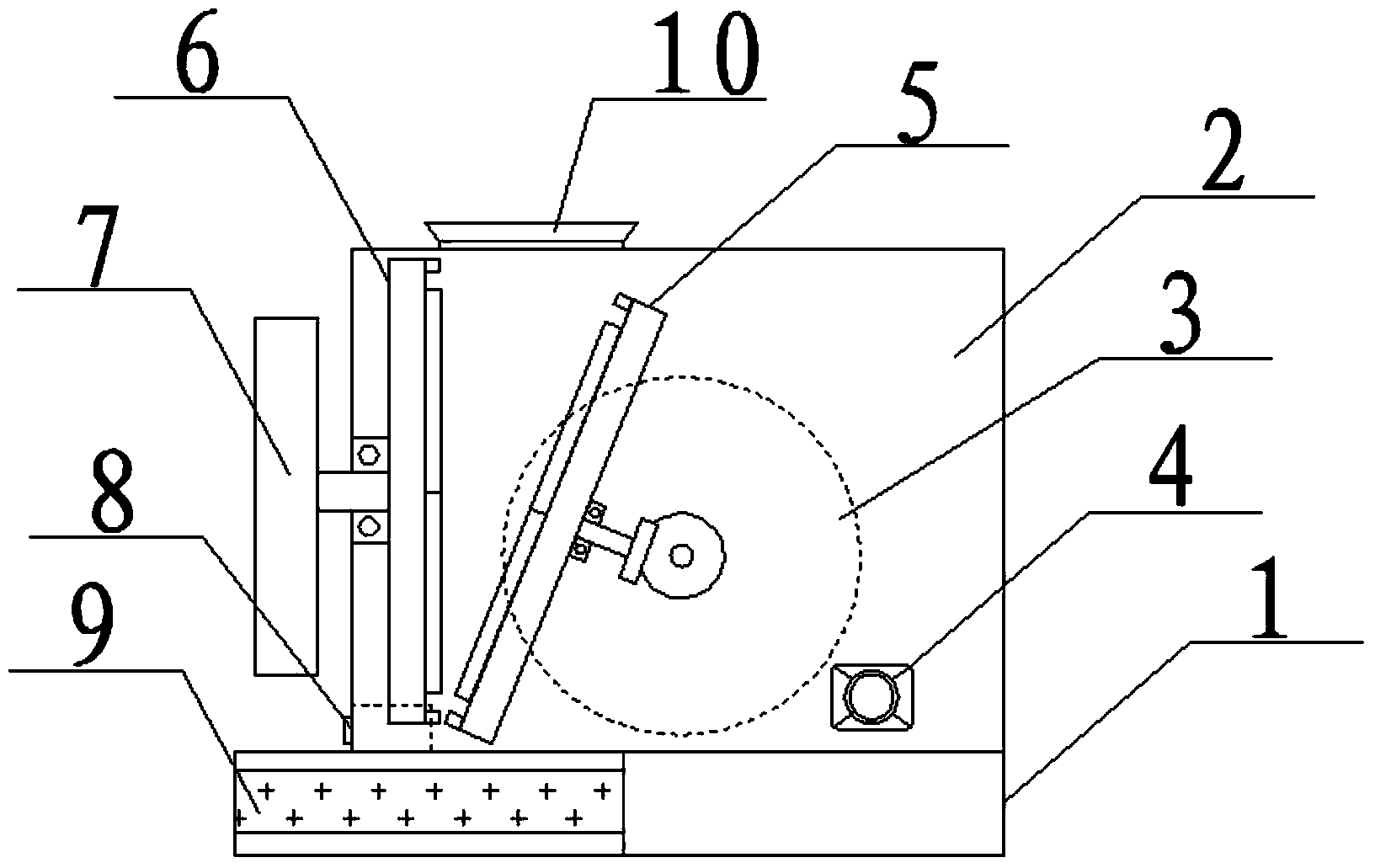

[0013] Referring to the accompanying drawings, a grinding type crusher includes a machine table 2 and a base 1 located at the bottom of the machine table. It is characterized in that: the side of the machine table 2 is equipped with a grinding disc 6 and the back of the grinding disc 6 passes through a shaft and a flywheel. 7 is connected, the flywheel 7 is connected to the motor 8 through a gear. The front of the grinding disc 6 is provided with a grinding disc 2 5 opposite to it. The front of the grinding disc 6 is opposite to the front of the grinding disc 2 5, forming a jaw The opening is upward. The second grinding disc 5 is connected to the second flywheel 3 through gears and shafts, and the second flywheel 3 is connected to the second motor 4 through gears. The rotation direction of the first grinding disc 6 is the same as that of the second grinding disc 5. The direction of rotation is opposite. The base is located at the lower end of the jaw structure and is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com