Patents

Literature

165 results about "Fluid simulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluid animation refers to computer graphics techniques for generating realistic animations of fluids such as water and smoke. Fluid animations are typically focused on emulating the qualitative visual behavior of a fluid, with less emphasis placed on rigorously correct physical results, although they often still rely on approximate solutions to the Euler equations or Navier–Stokes equations that govern real fluid physics. Fluid animation can be performed with different levels of complexity, ranging from time-consuming, high-quality animations for films or visual effects, to simple and fast animations for real-time animations like computer games.

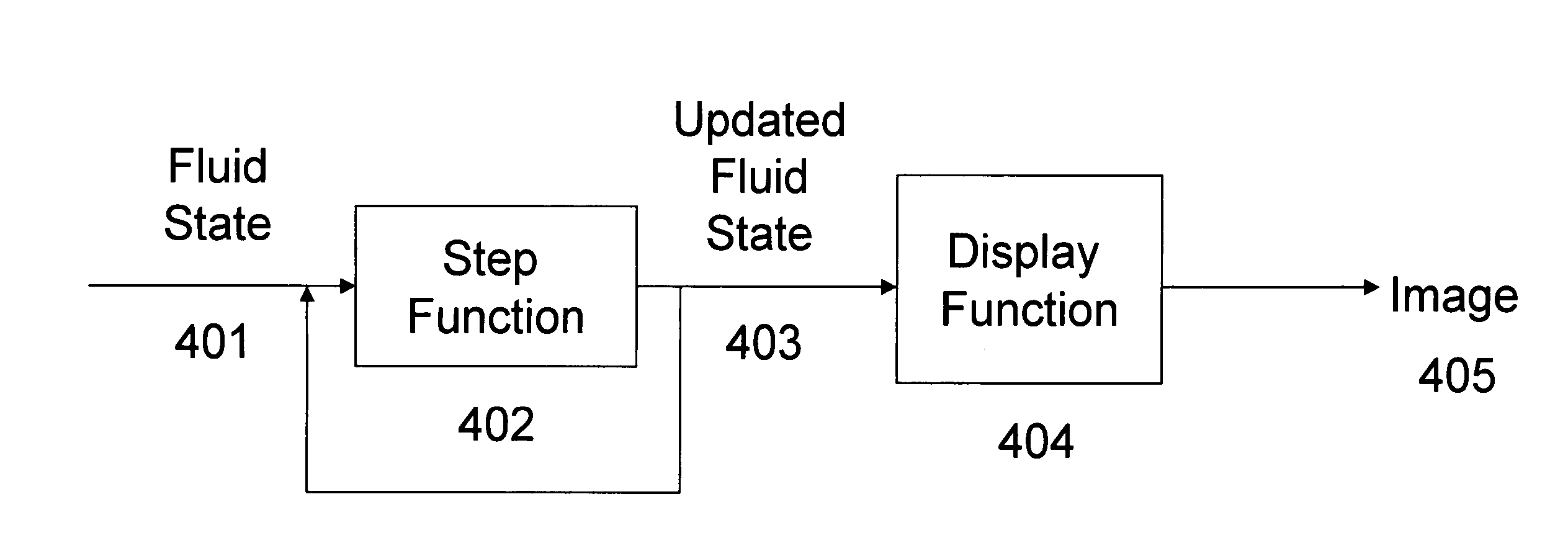

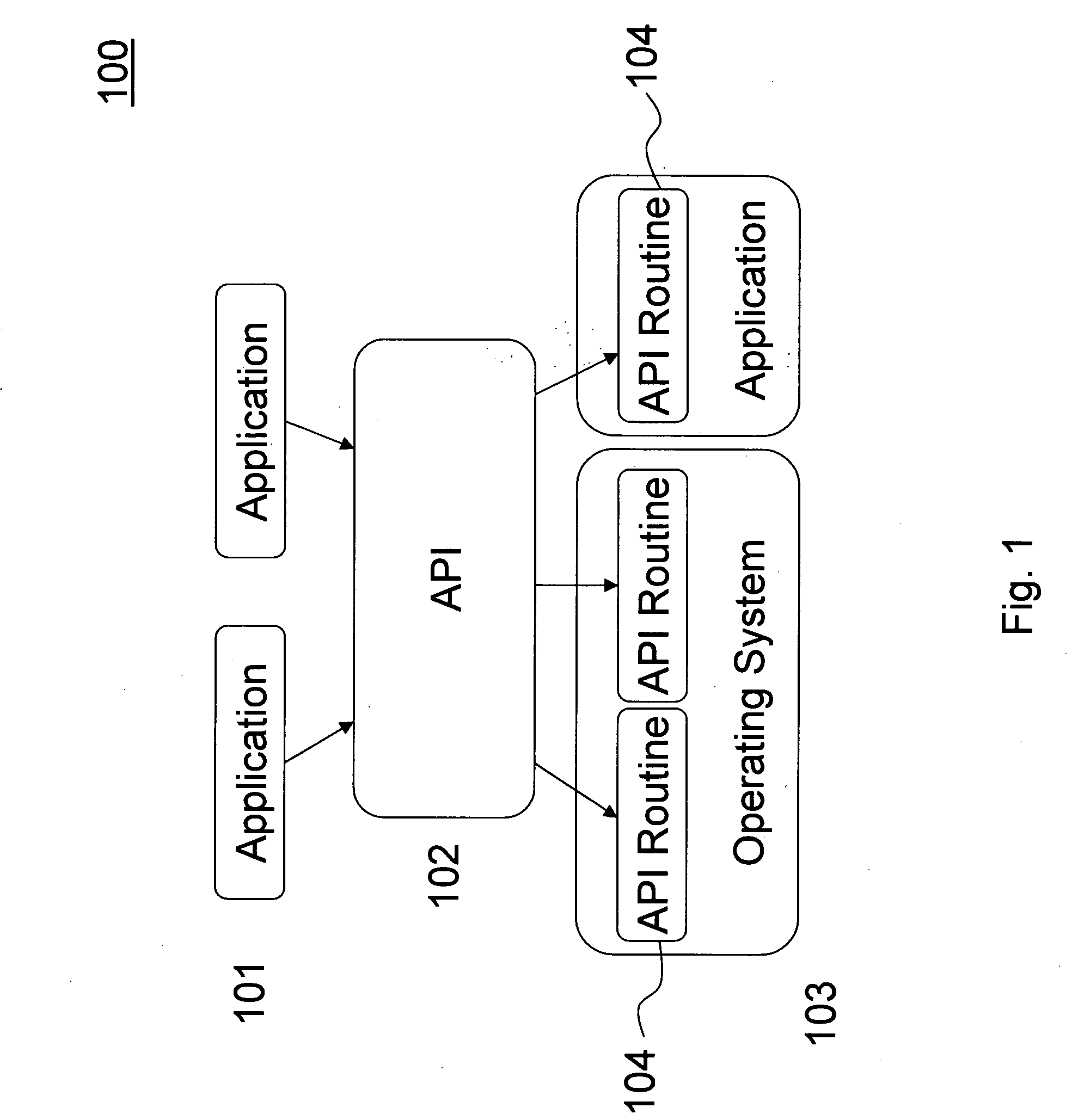

Application programming interface for fluid simulations

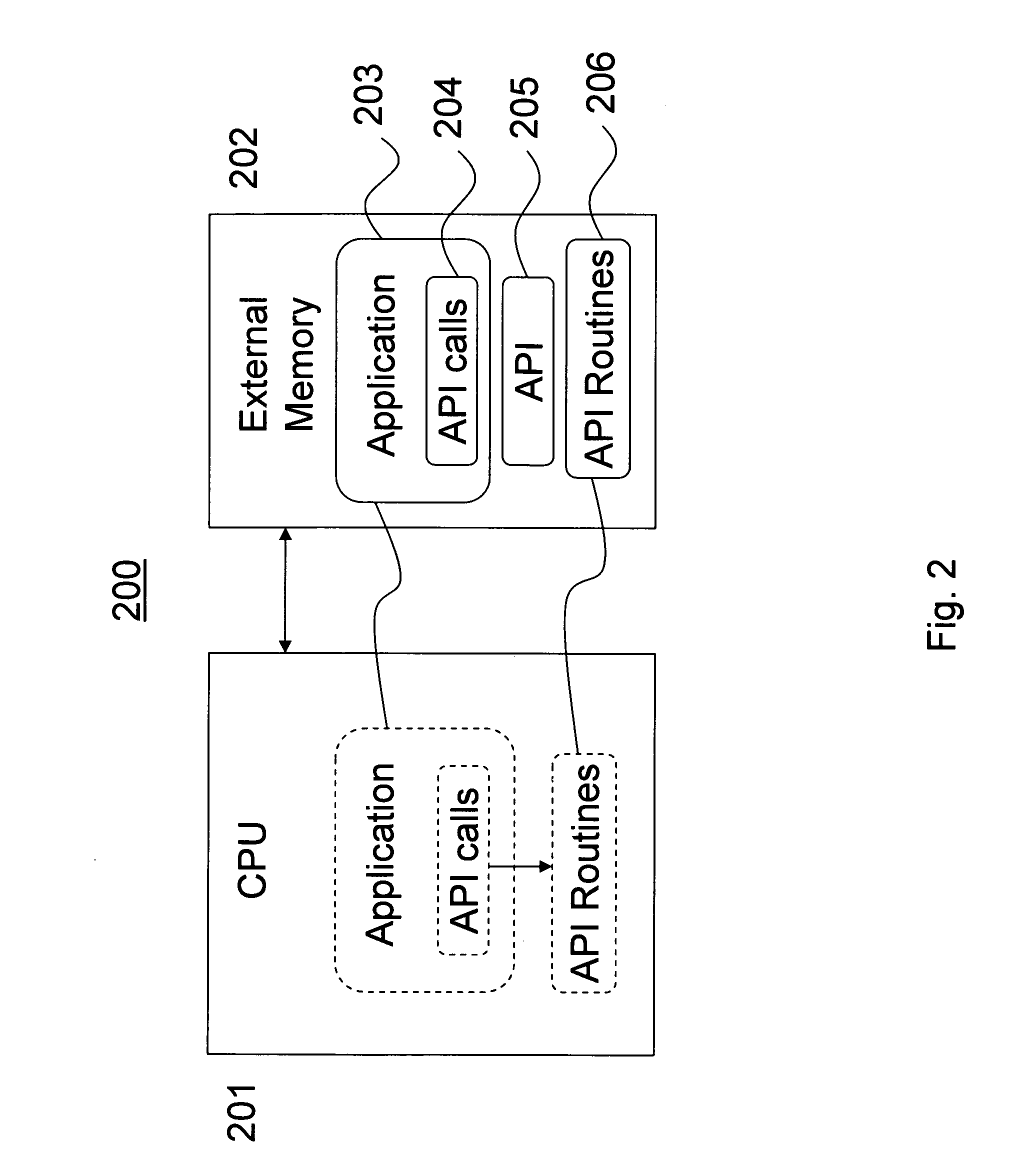

ActiveUS7580821B2Design optimisation/simulationAnimationSmoothed-particle hydrodynamicsApplication programming interface

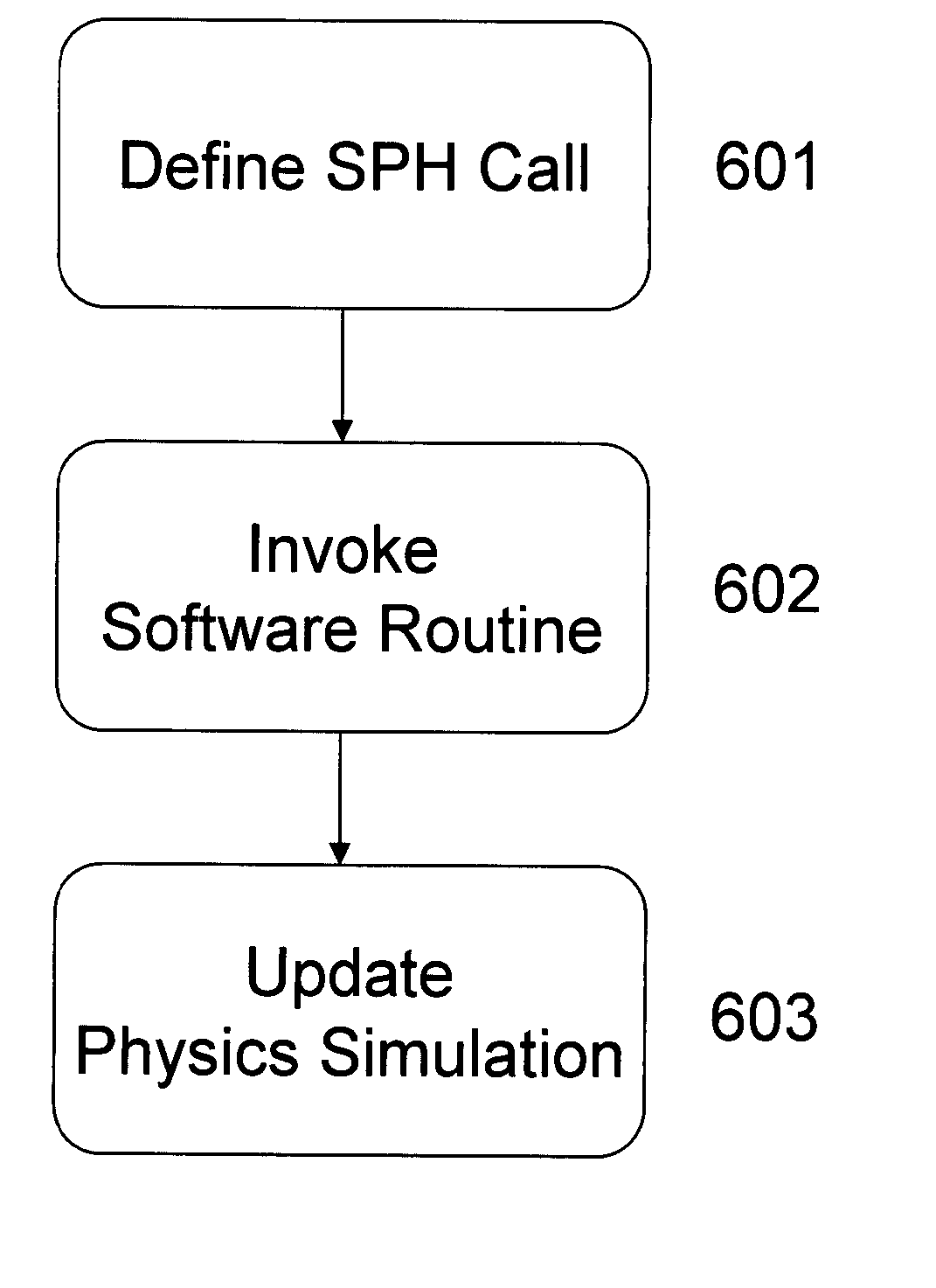

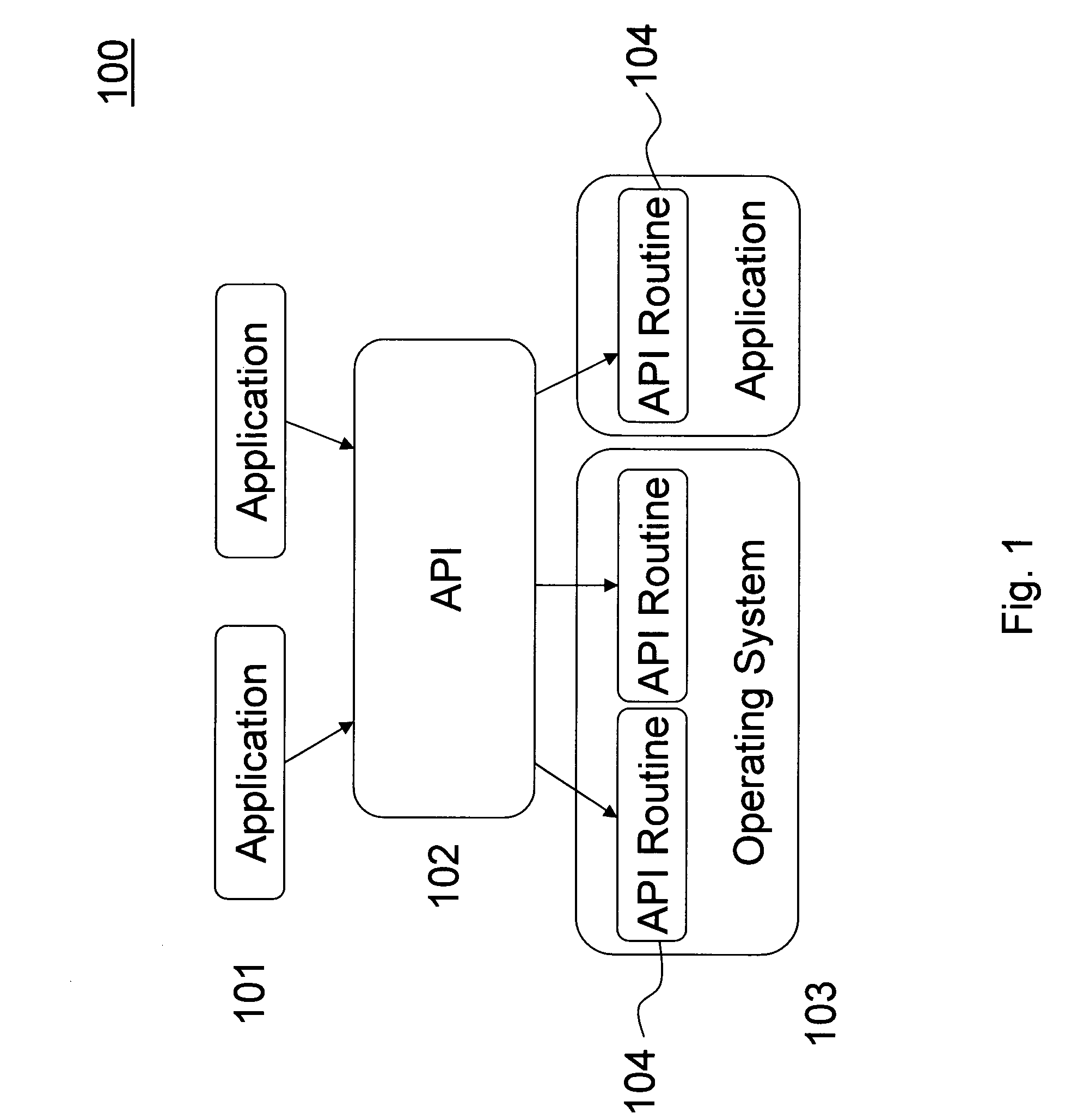

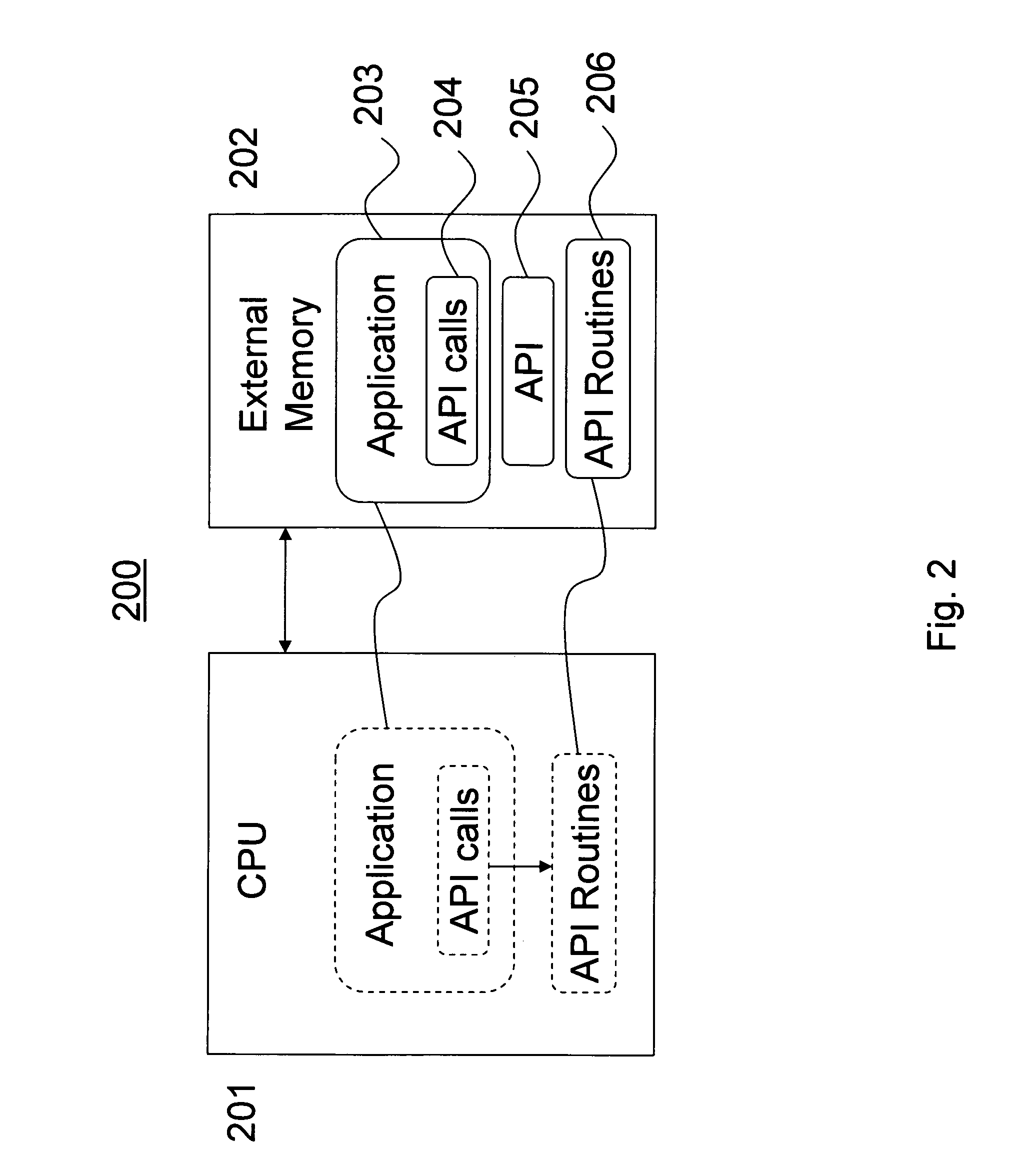

A method is disclosed for executing a physics simulation in a system comprising a computational platform, a main application stored in the computational platform, a secondary application stored in the computational platform, and a smoothed particle hydrodynamics (SPH) application programming interface (API) implemented in the computational platform. The method defines a SPH call in the SPH API, and by operation of the main application, invokes a software routine using the SPH call. Additionally, by operation of the secondary application, a state of the physics simulation is updated in response to the software routine.

Owner:NVIDIA CORP

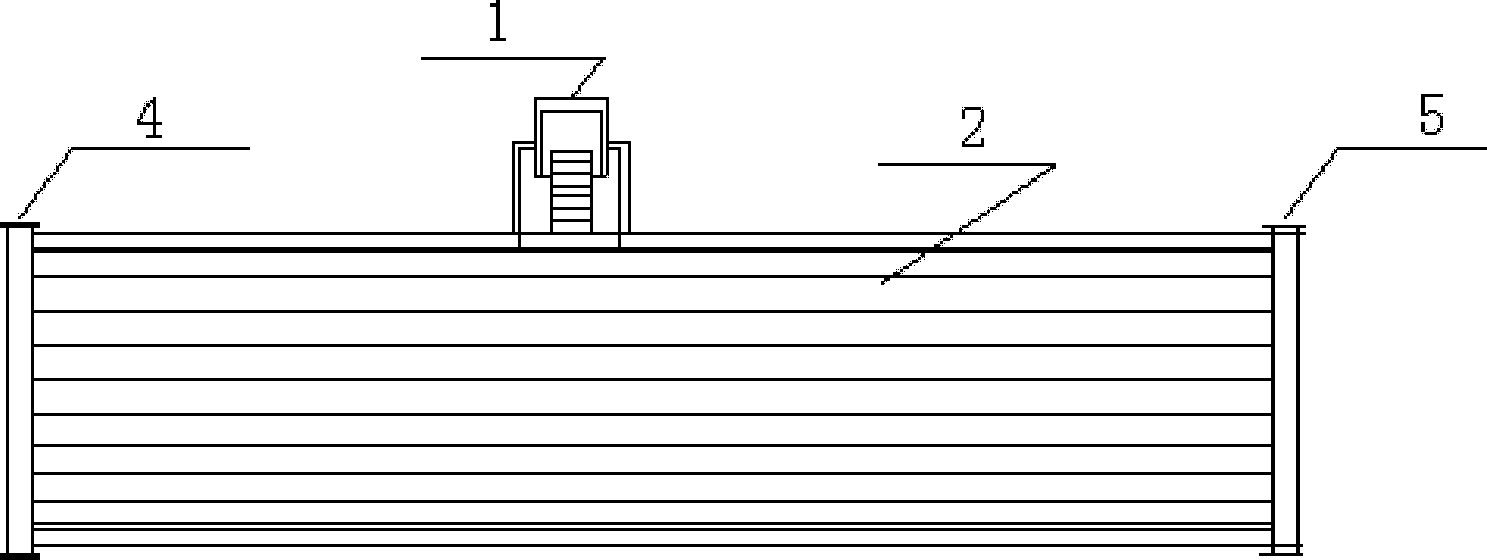

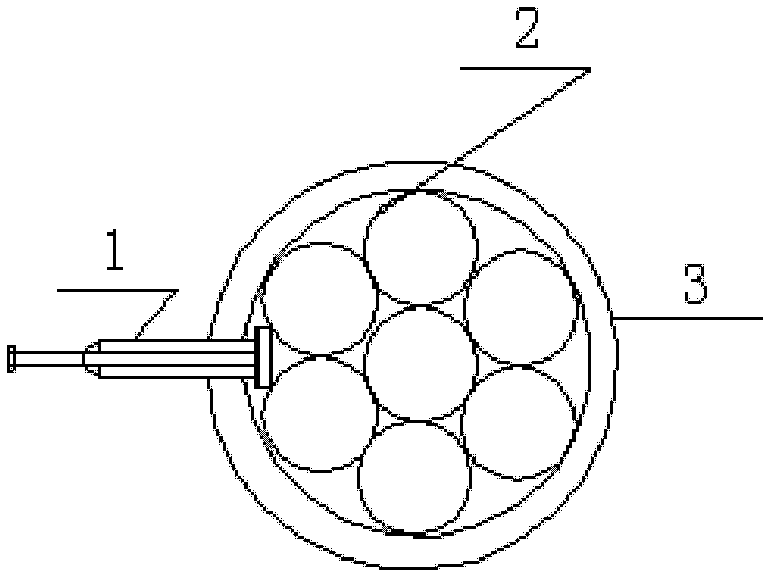

Flow equalizer

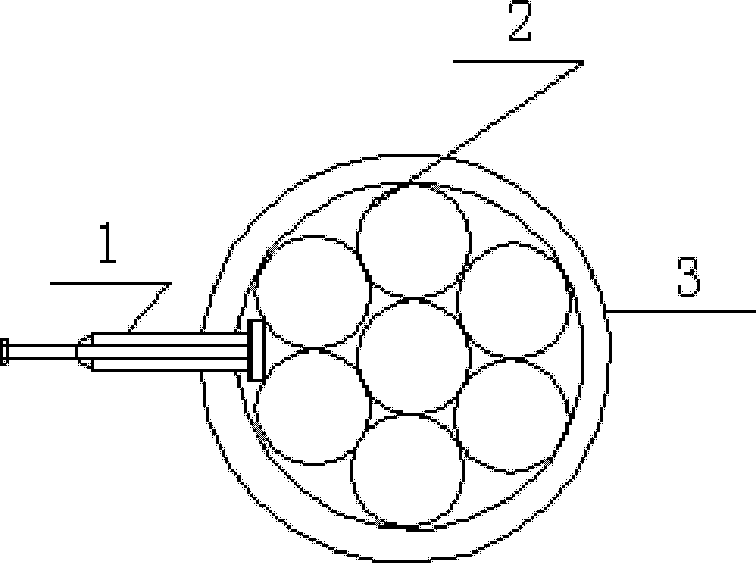

InactiveCN102588699AEvenly distributedHigh measurement accuracyBranching pipesEngineeringProcess conditions

The invention provides a flow equalizer, which comprises seven to nineteen distributing pipes (2) and a flange short pipe (3). The distributing pipes (2) are arranged in the flange short pipe (3), an inlet flange (4) is arranged at one end of the flange short pipe (3), and an outlet flange (5) is arranged at the other end of the flange short pipe (3). The distributing pipes (2) are fixed in the flange short pipe (3) through a screw fixator (1). According to the characteristics of fluid, diameter, number and length and the like of the distributing pipes are determined by means of simulation of fluid simulation software and computation of computing software, and accordingly fluid can be stable in flowing states and uniform in distribution by the aid of the distributing pipes. In addition, the flow equalizer is suitable for pump inlets on some process conditions.

Owner:北京中油联自动化技术开发有限公司

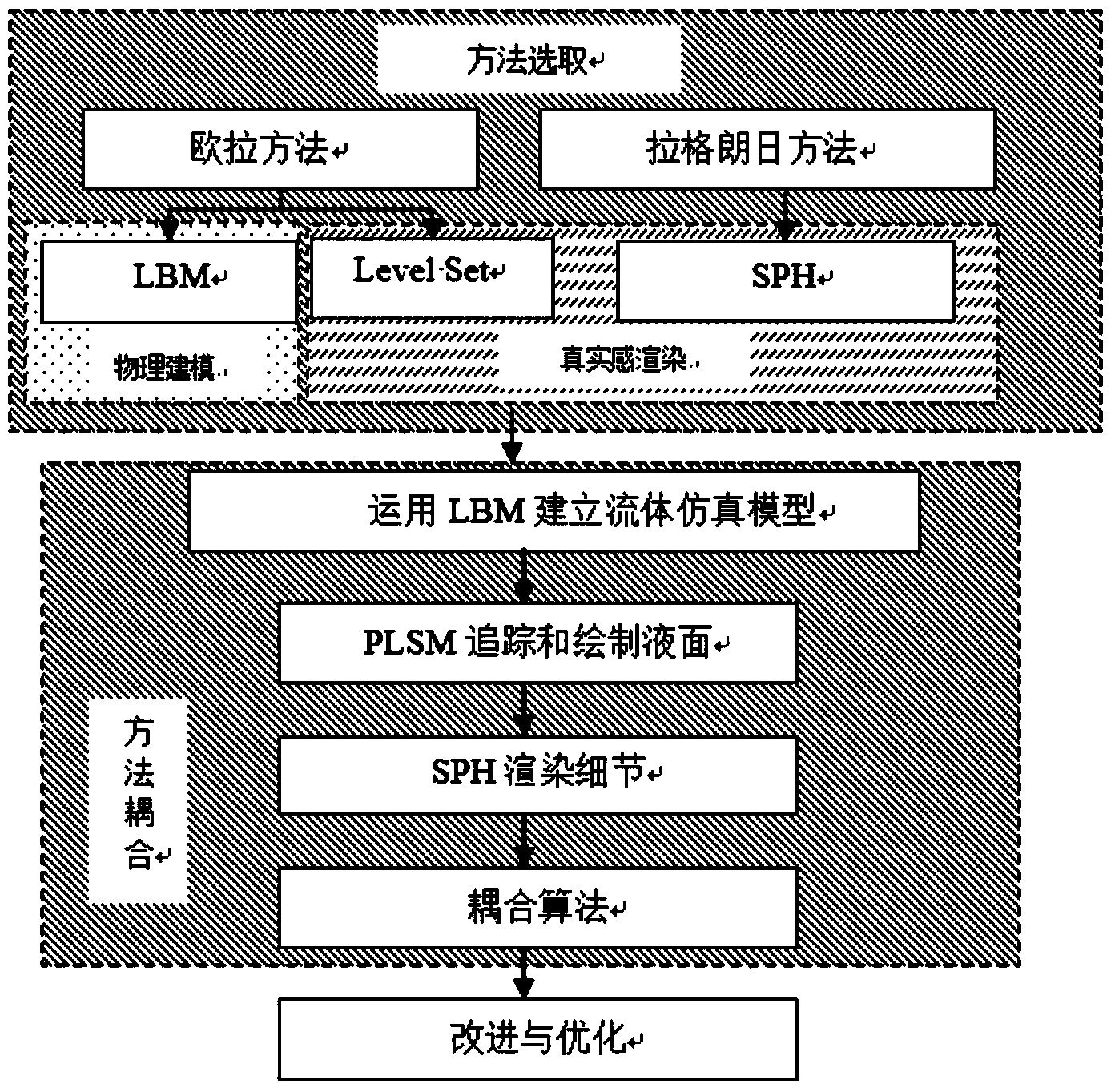

Fluid simulation method based on Eulerian-Lagrangian coupling method

ActiveCN104268943AGuaranteed Simulation ScaleGuaranteed speed advantage3D-image rendering3D modellingEulerian lagrangianCoupling

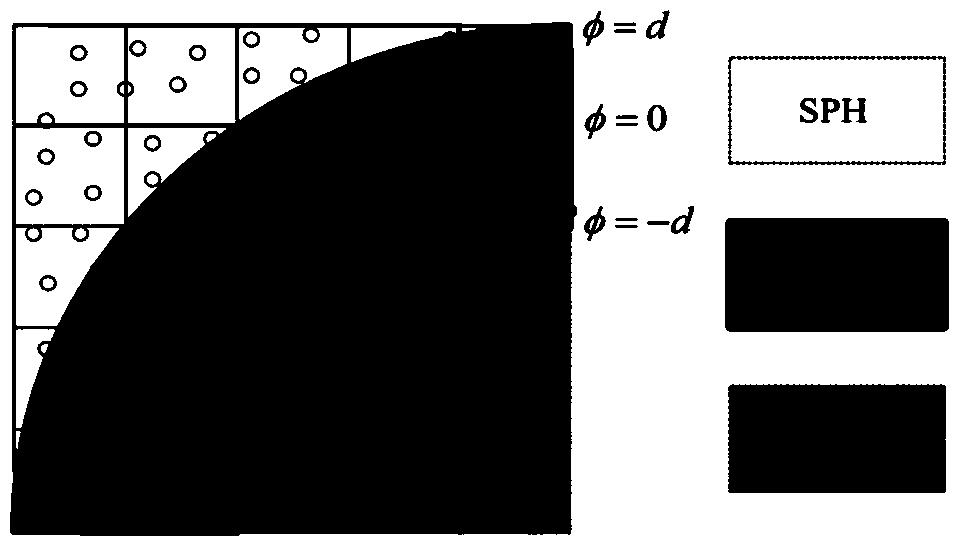

The invention discloses a fluid simulation method based on the Eulerian-Lagrangian coupling method. According to the aim of achieving efficient fluid simulation and the core idea of solving the N-S equation through the Eulerian method and the Lagrangian method to carry out fluid simulation, research is conducted through the multi-method coupling calculation method on the basis of SPH and LBM fluid simulation. Firstly, large-scale fluid field modeling is carried out through the LBM method based on Eulerian grids to build the main part of fluid simulation; then, simulation is carried out on fluid details such as spindrifts and water drops through the SPH method based on the Lagrangian particle idea, LBM fluid and SPH fluid are integrated by designing a coupling algorithm, and lifelike and rapid large-scale fluid simulation with details involved is achieved.

Owner:BEIHANG UNIV +1

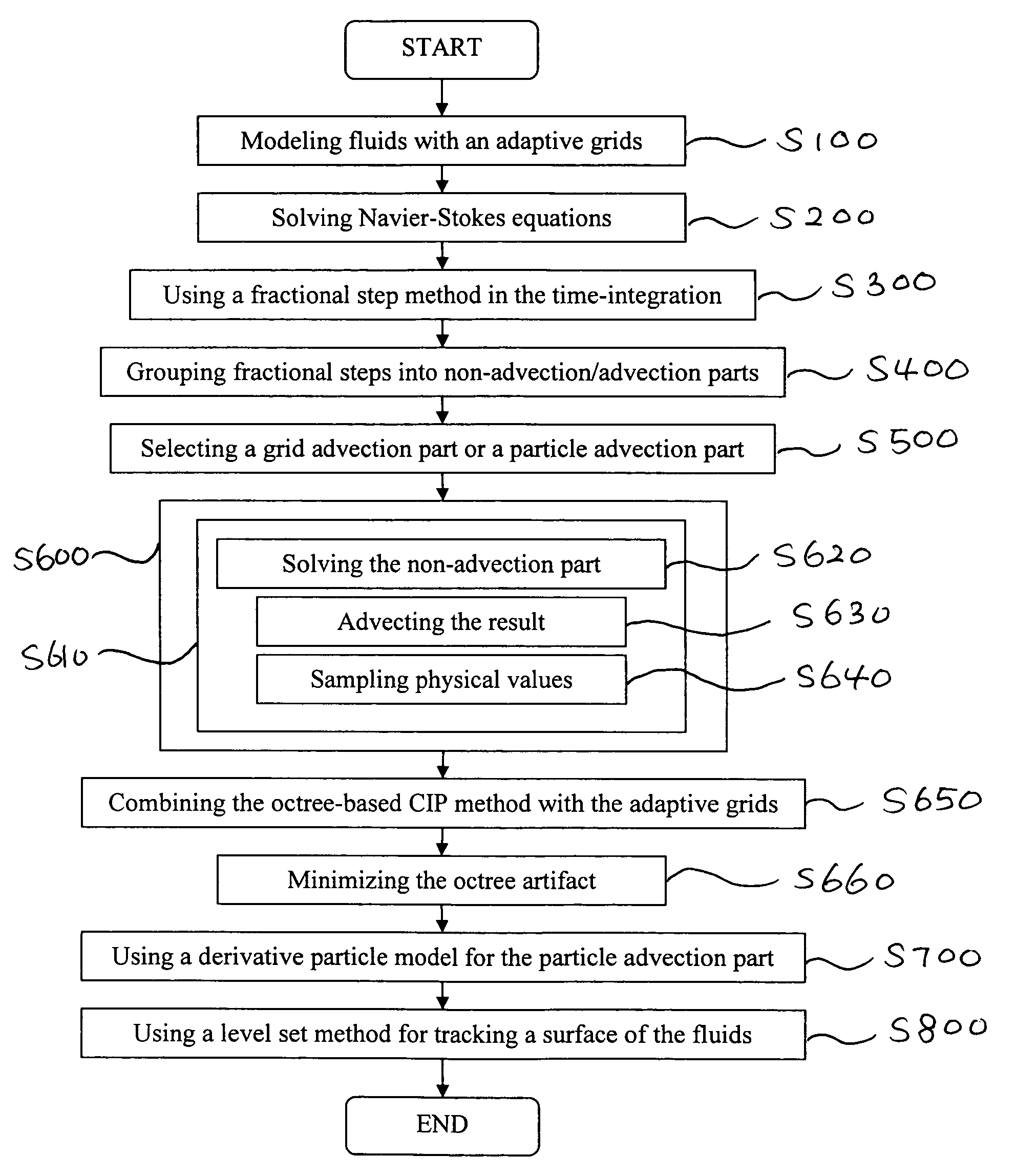

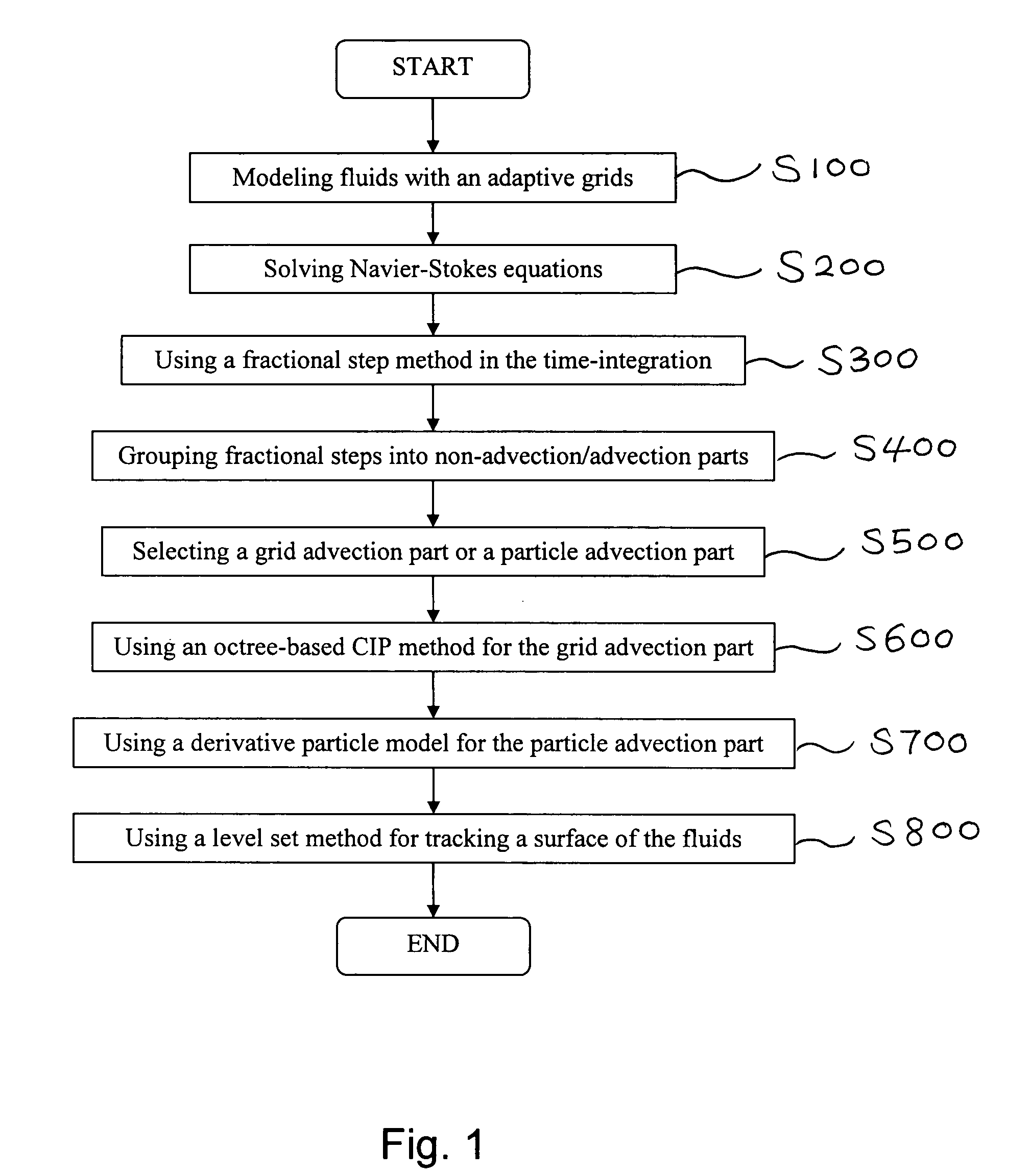

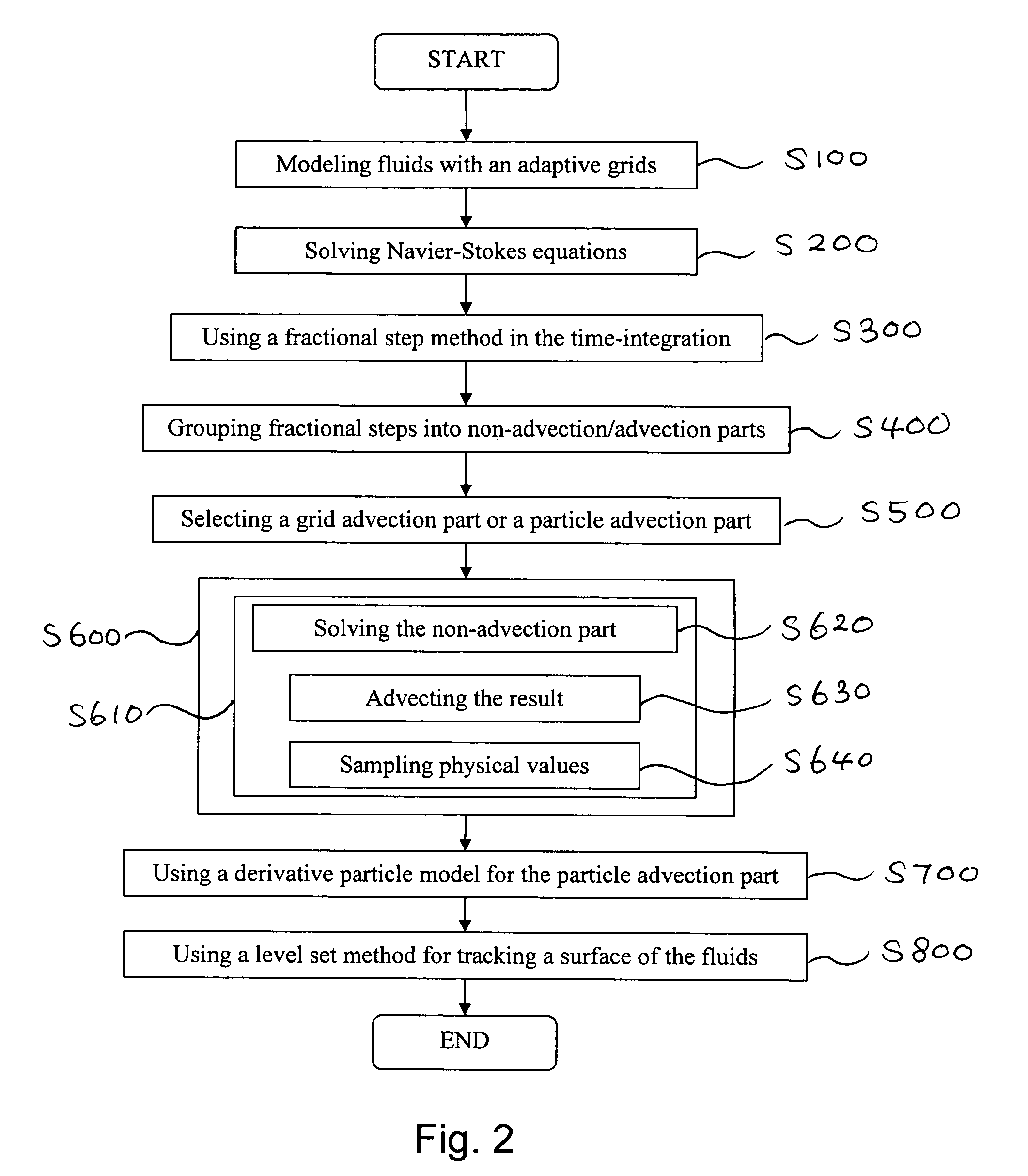

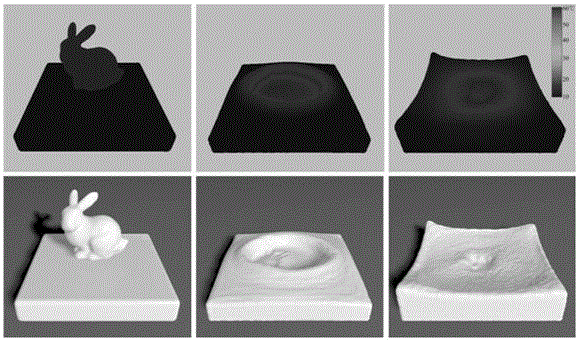

Method of simulating detailed movements of fluids using derivative particles

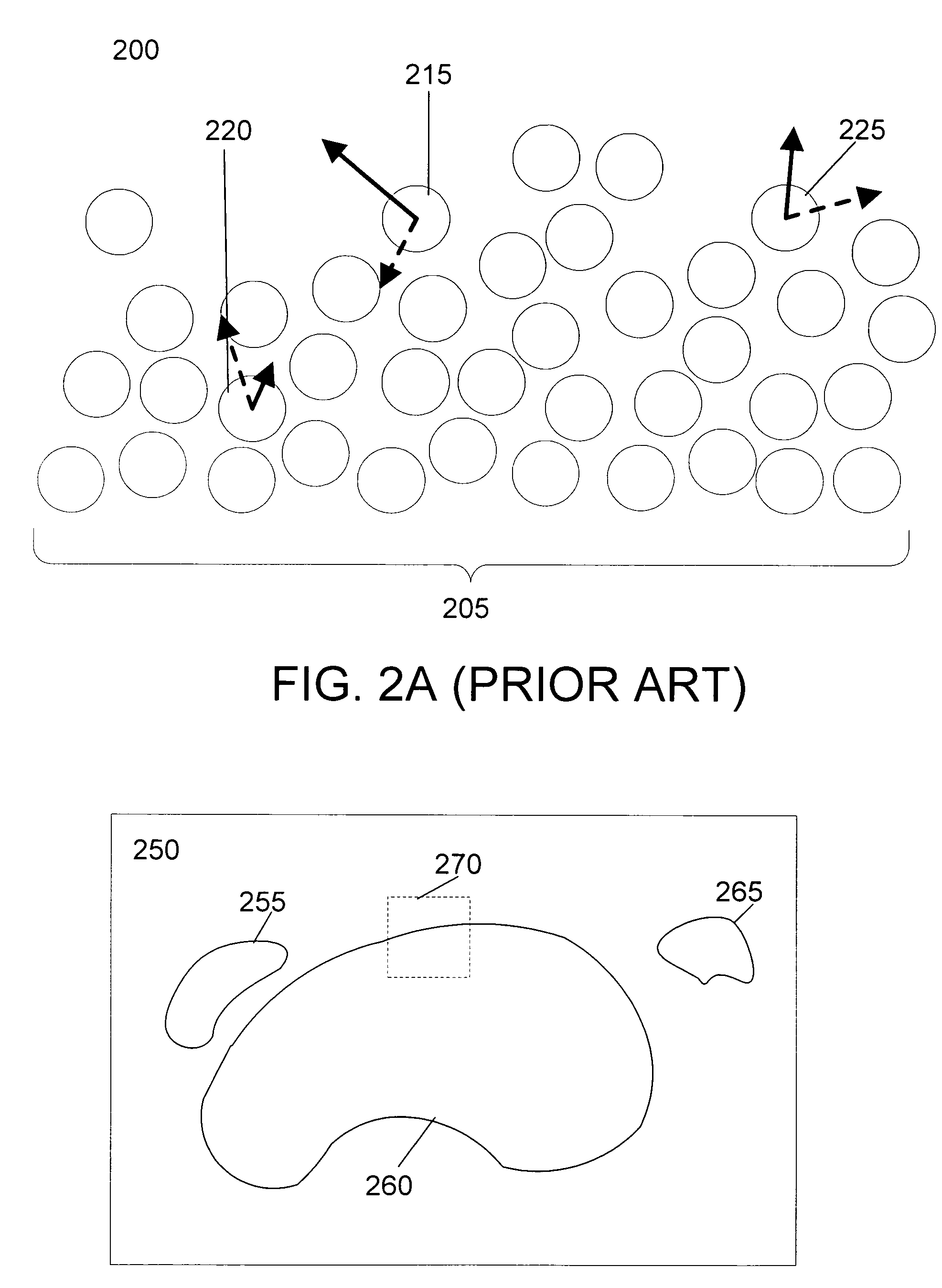

ActiveUS7565276B2Avoid interventionReduce the total massComputation using non-denominational number representationDesign optimisation/simulationGrid basedAdvection

The method provides a new fluid simulation technique that significantly reduces the non-physical dissipation of velocity using particles and derivative information. In solving the conventional Navier-Stokes equations, the method replace the advection part with a particle simulation. When swapping between the grid-based and particle-based simulators, the physical quantities such as the level set and velocity must be converted. A novel dissipation-suppressing conversion procedure that utilizes the derivative information stored in the particles as well as in the grid points is developed. Through several experiments, the proposed technique can reproduce the detailed movements of high-Reynolds-number fluids, such as droplets / bubbles, thin water sheets, and whirlpools. The increased accuracy in the advection, which forms the basis of the proposed technique, can also be used to produce better results in larger scale fluid simulations.

Owner:SEOUL NAT UNIV R&DB FOUND

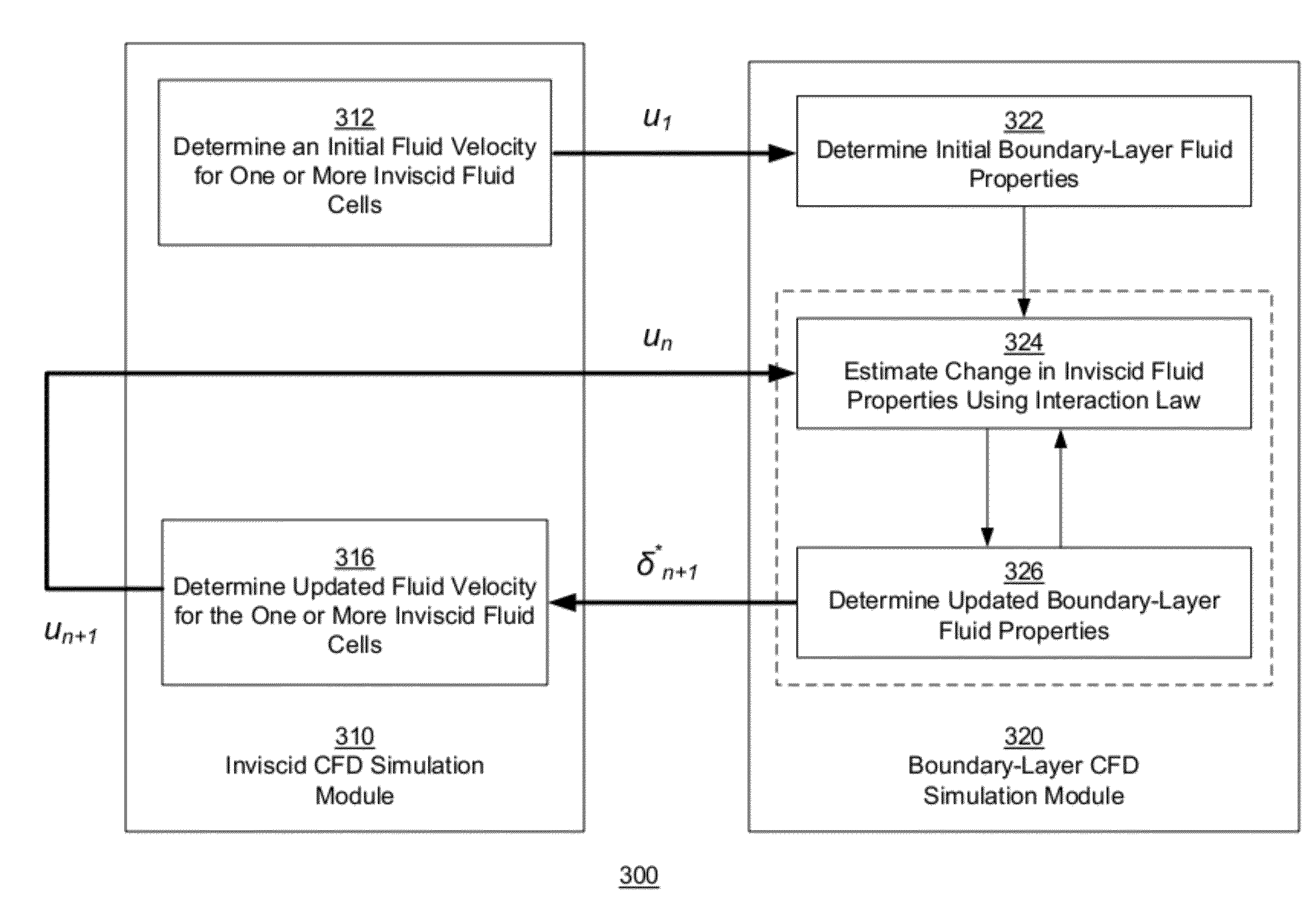

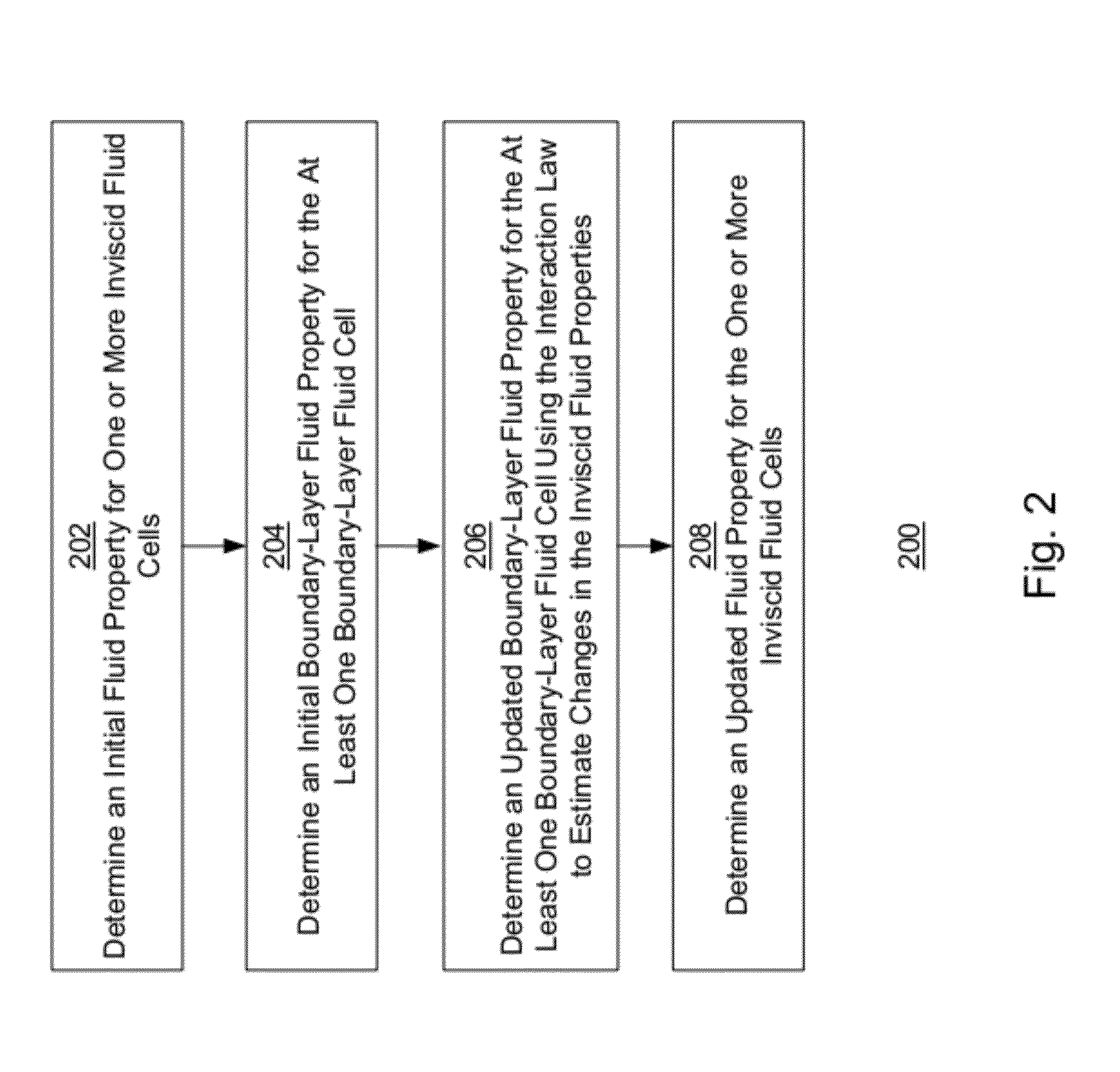

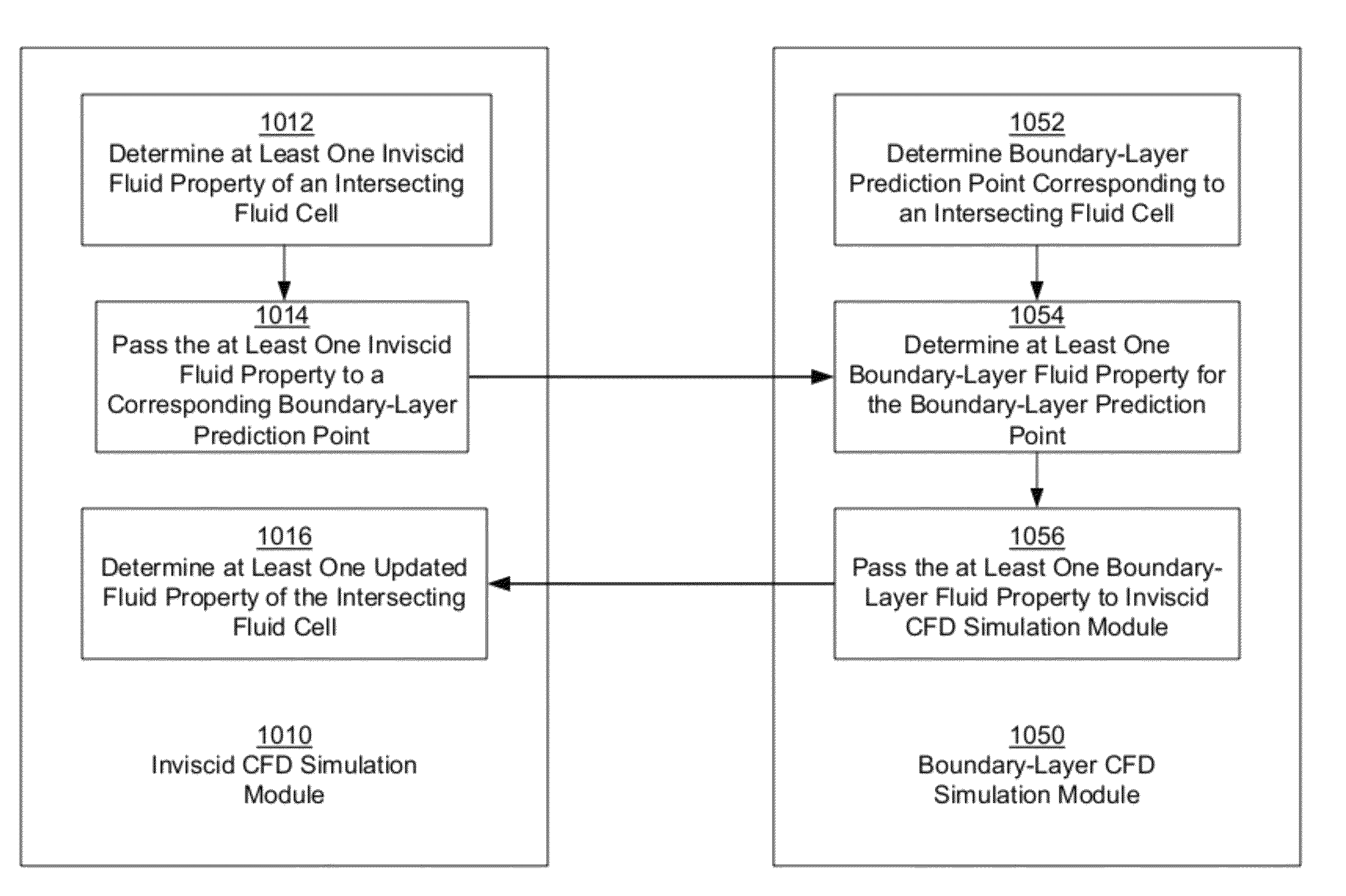

Generating inviscid and viscous fluid flow simulations over a surface using a quasi-simultaneous technique

ActiveUS20120245903A1Computation using non-denominational number representationDesign optimisation/simulationViscous effectLaws of thermodynamics

A fluid-flow simulation over a computer-generated surface is generated using a quasi-simultaneous technique. The simulation includes a fluid-flow mesh of inviscid and boundary-layer fluid cells. An initial fluid property for an inviscid fluid cell is determined using an inviscid fluid simulation that does not simulate fluid viscous effects. An initial boundary-layer fluid property a boundary-layer fluid cell is determined using the initial fluid property and a viscous fluid simulation that simulates fluid viscous effects. An updated boundary-layer fluid property is determined for the boundary-layer fluid cell using the initial fluid property, initial boundary-layer fluid property, and an interaction law. The interaction law approximates the inviscid fluid simulation using a matrix of aerodynamic influence coefficients computed using a two-dimensional surface panel technique and a fluid-property vector. An updated fluid property is determined for the inviscid fluid cell using the updated boundary-layer fluid property.

Owner:AERION INTPROP MANAGEMENT CORP

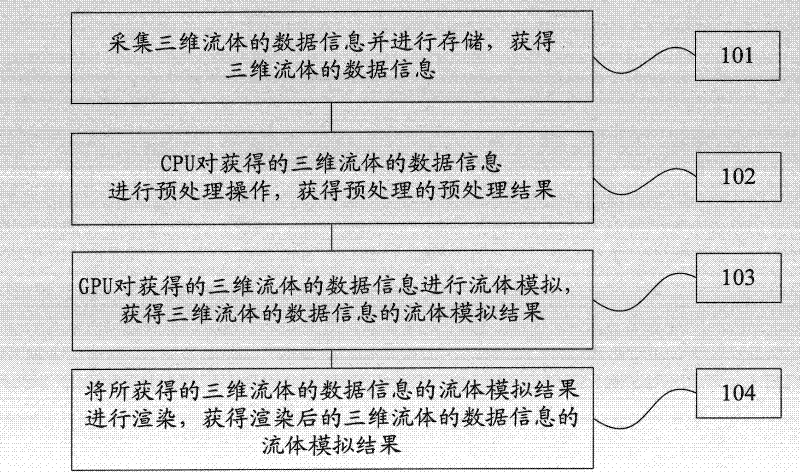

Three-dimensional fluid simulation method based on graphic processing unit (GPU)

ActiveCN102402791AMeet the needs of real-time environmentsSimple and real-time operationAnimationData informationGraphics processing unit

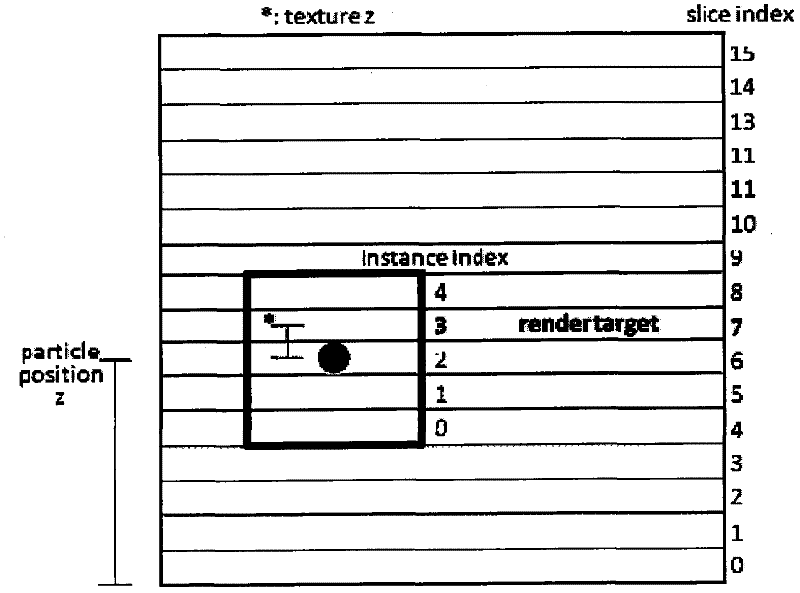

The invention provides a three-dimensional fluid simulation method based on a graphic processing unit (GPU). The method comprises the following steps of: acquiring and storing data information of a three-dimensional fluid to acquire the data information of the three-dimensional fluid; pre-processing the acquired data information of the three-dimensional fluid by the GPU to acquire a pre-processing result, and performing fluid simulation on the acquired data information of the three-dimensional fluid by the GPU to acquire a fluid simulation result of the data information of the three-dimensional fluid; and rendering the acquired fluid simulation result of the data information of the three-dimensional fluid to acquire a rendered fluid simulation result of the data information of the three-dimensional fluid. By the method, simple and real-time operation of the three-dimensional fluid simulation process can be realized.

Owner:KARAMAY HONGYOU SOFTWARE

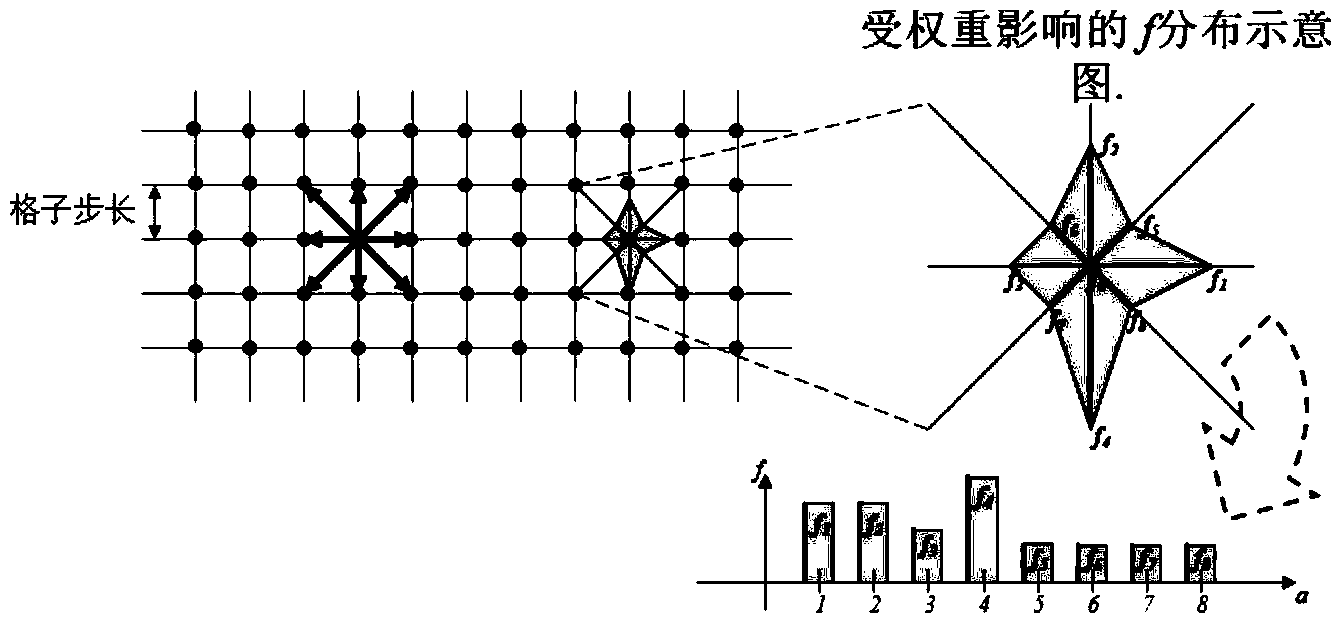

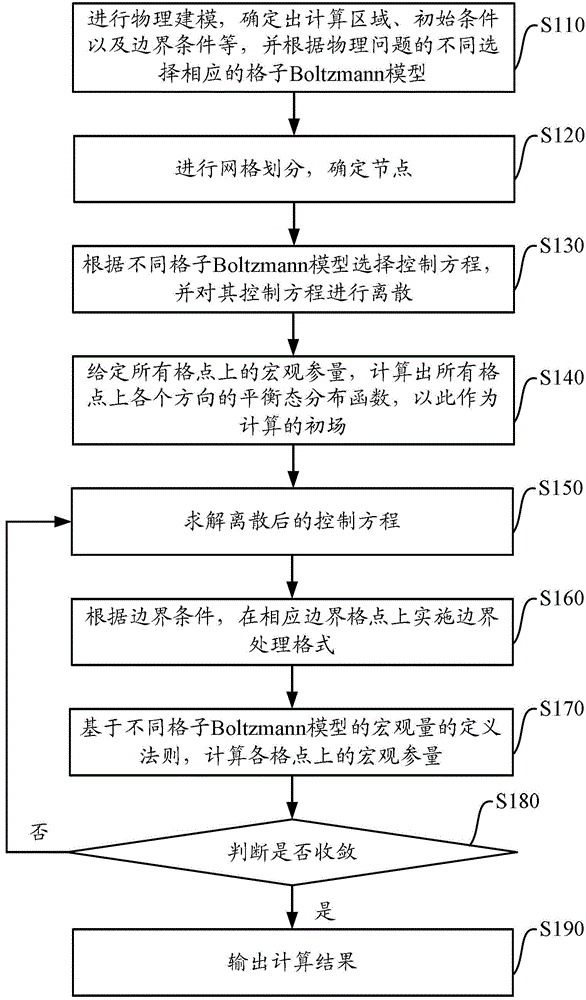

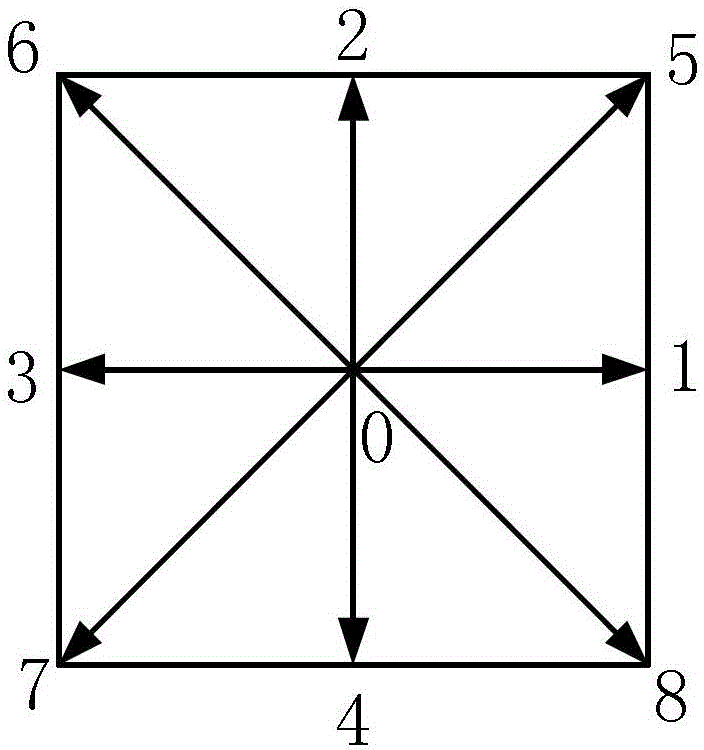

Parallel acceleration method and system of lattice Boltzmann method

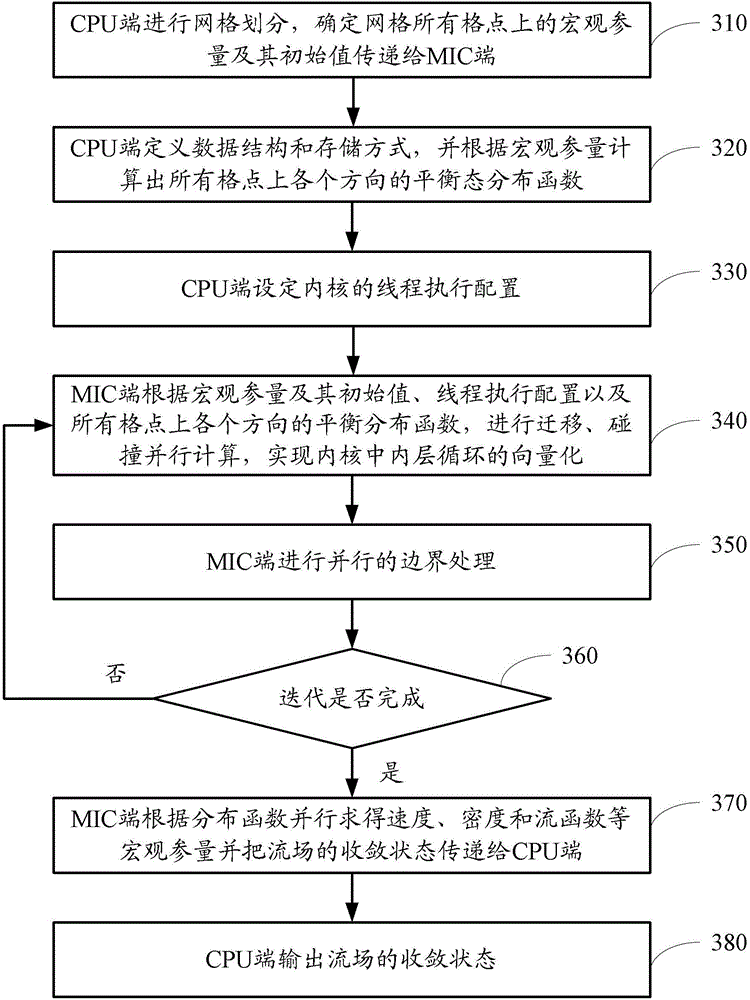

ActiveCN102945295AEasy to handleMeet the needs of simulationSpecial data processing applicationsComputer scienceMethod of undetermined coefficients

The invention discloses a parallel acceleration method and a system of a lattice Boltzmann method (LBM), which overcome the defect that an X86 server cluster is higher in consumption of time and the like for LBM treatment at present. The method comprises the steps that a CPU (Central Processing Unit) end determines macro parameters and initial values of the macro parameters of all lattice points of a grid, defines a data structure and a storage mode for storing equilibrium distribution functions of all the lattice points in all directions and the macro parameters of all the lattice points, computes the equilibrium distribution functions of all the lattice points in all the directions according to the macro parameters, and sets thread execution configuration of an inner core of an MIC (Many Integrated Core) card; an MIC end conducts parallel computation of migration and impact and parallel boundary processing according to the macro parameters, the initial values of the macro parameters, the thread execution configuration and the equilibrium distribution functions of all the lattice points of the grid in all the directions, and obtains a convergence status according to the equilibrium distribution functions of all the lattice points of the grid in all the directions. With the adoption of the method and the system, the processing property of the lattice Boltzmann method is improved, and the demand of fluid simulation is satisfied.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

Parallel fluid simulation acceleration method based on GPU (Graphics Processing Unit) cluster

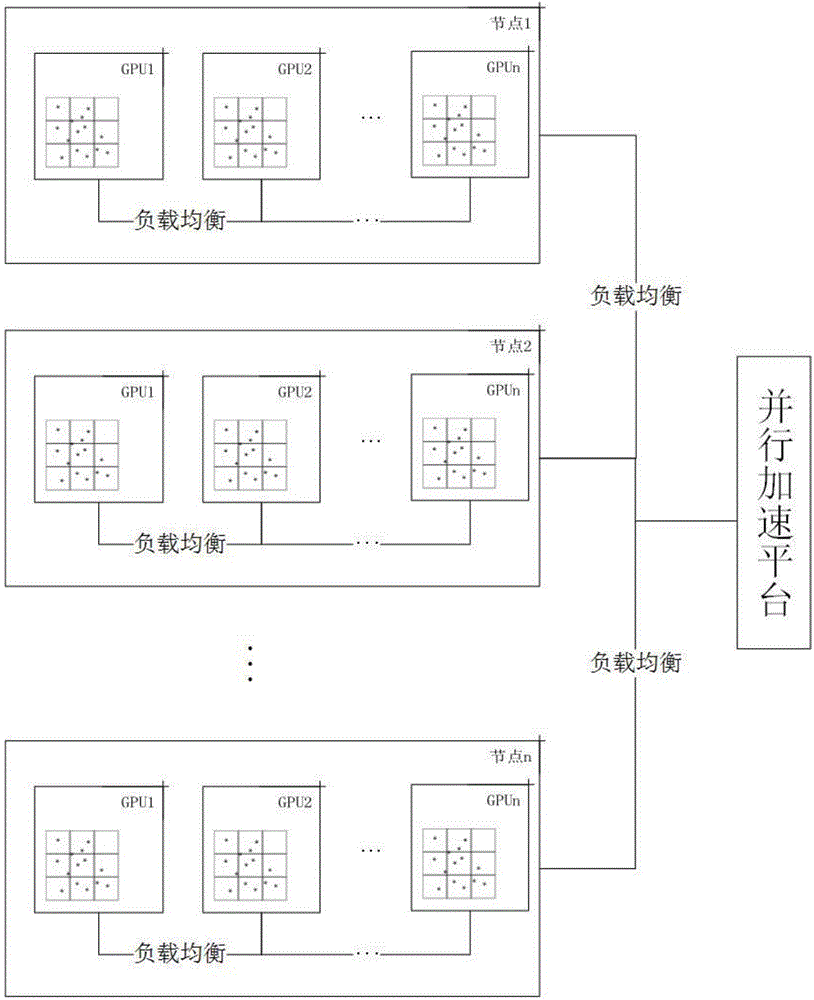

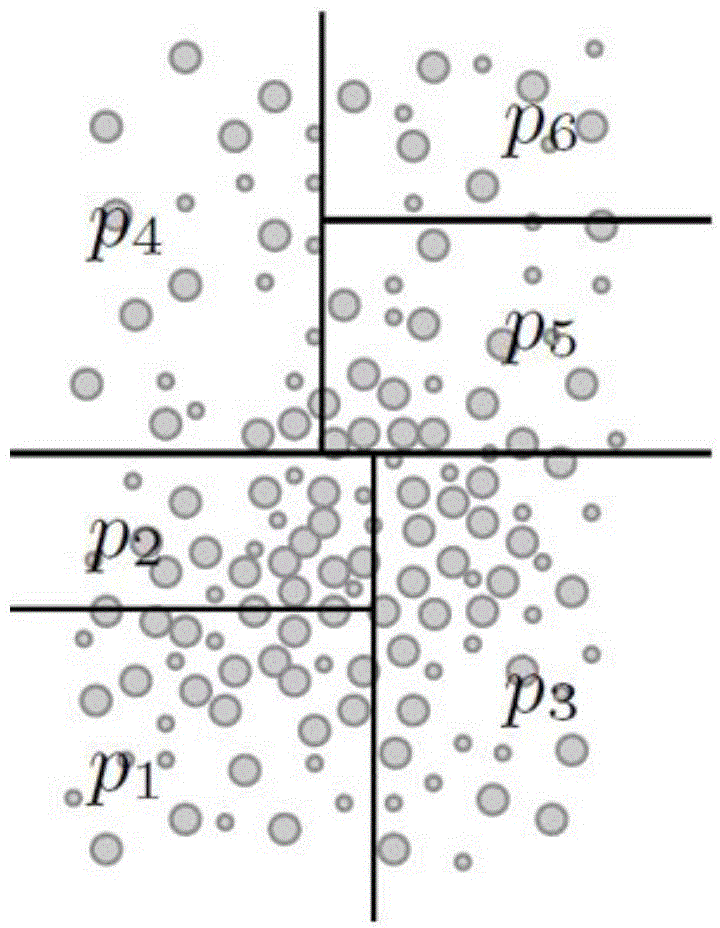

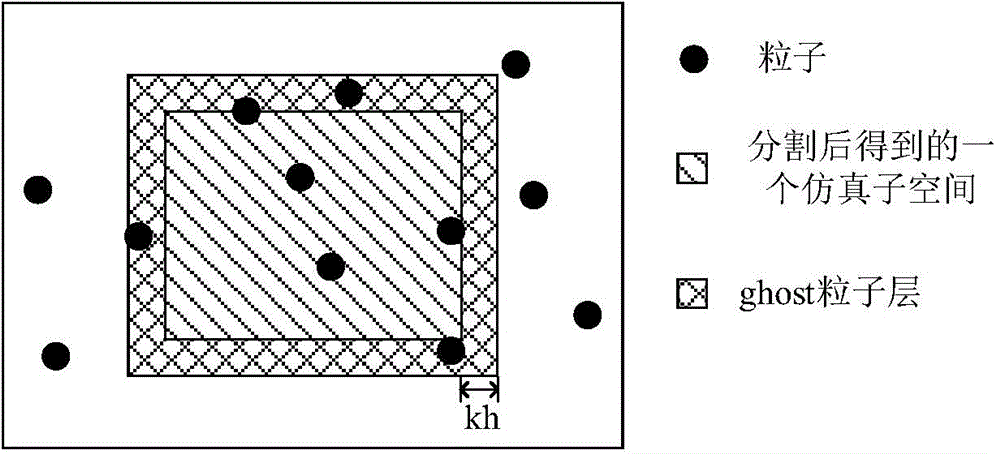

InactiveCN104360896ALoad balancingNarrow down the neighborhood search spaceResource allocationSoftware simulation/interpretation/emulationGPU clusterGraphics processing unit

The invention relates to a parallel fluid simulation acceleration method based on a GPU (Graphics Processing Unit) cluster. Aiming at the characteristics of large fluid simulation calculated quantity and high degree of parallelism, an automatic parallel acceleration method is designed to carry out simulation and algorithm research on fluid. The invention provides and realizes a load-balancing algorithm between multiple GPUs and between multiple nodes in the same node. In a given space, a fluid simulation algorithm based on location is used to simulate physical action of the fluid, and the algorithm is accelerated through reducing branches and shrinking a neighbor region searching range. The space where the fluid is located is divided, each node processes one sub-space, and the corresponding sub-space is further divided in each node according to the quantity of GPUs, so that the parallelization of fluid simulation on the GPU cluster is completed.

Owner:BEIHANG UNIV

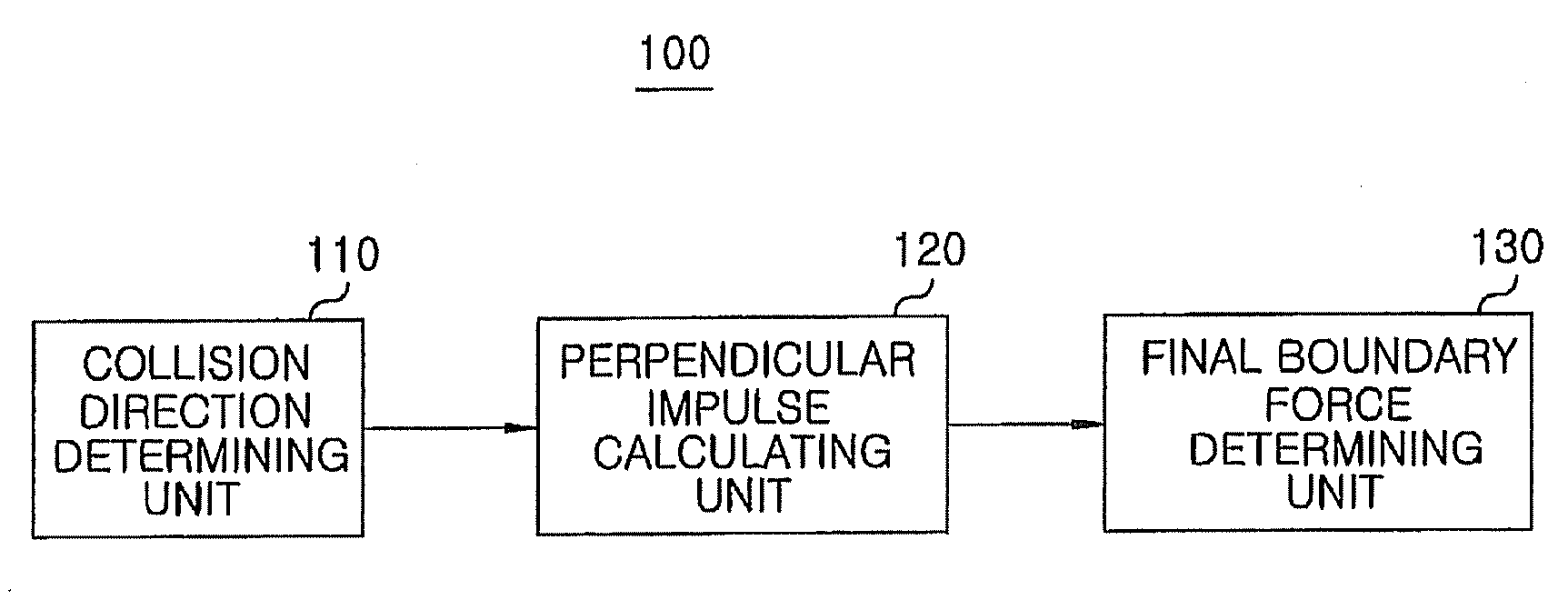

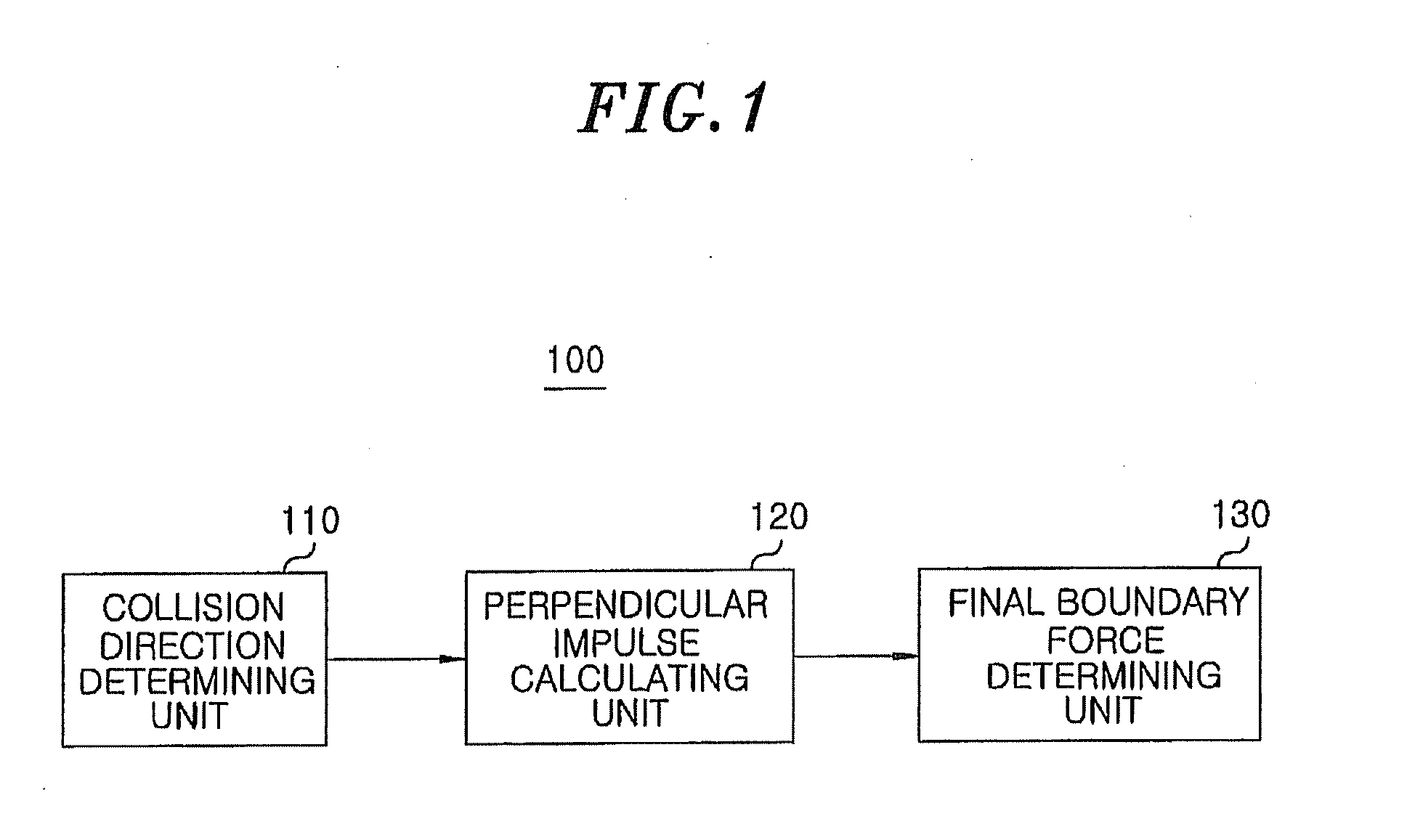

Method of processing rigid body interaction in particle-based fluid simulation

InactiveUS20100094608A1Stable simulationStable and precise particle-based rigid body simulationDesign optimisation/simulationSpecial data processing applicationsFriction forceComputer science

A method of processing a rigid body interaction in a particle-based fluid simulation includes determining a collision direction based on a normal vector of a pair of input particles and confirming whether parent objects of the particles actually collide against each other after the determination, and calculating a perpendicular impulse based on properties of the parent objects when the collision is confirmed. The method further includes calculating a final collision based boundary force by applying a tangential friction force to the calculated perpendicular impulse to apply the final collision based boundary force to the respective particles.

Owner:ELECTRONICS & TELECOMM RES INST

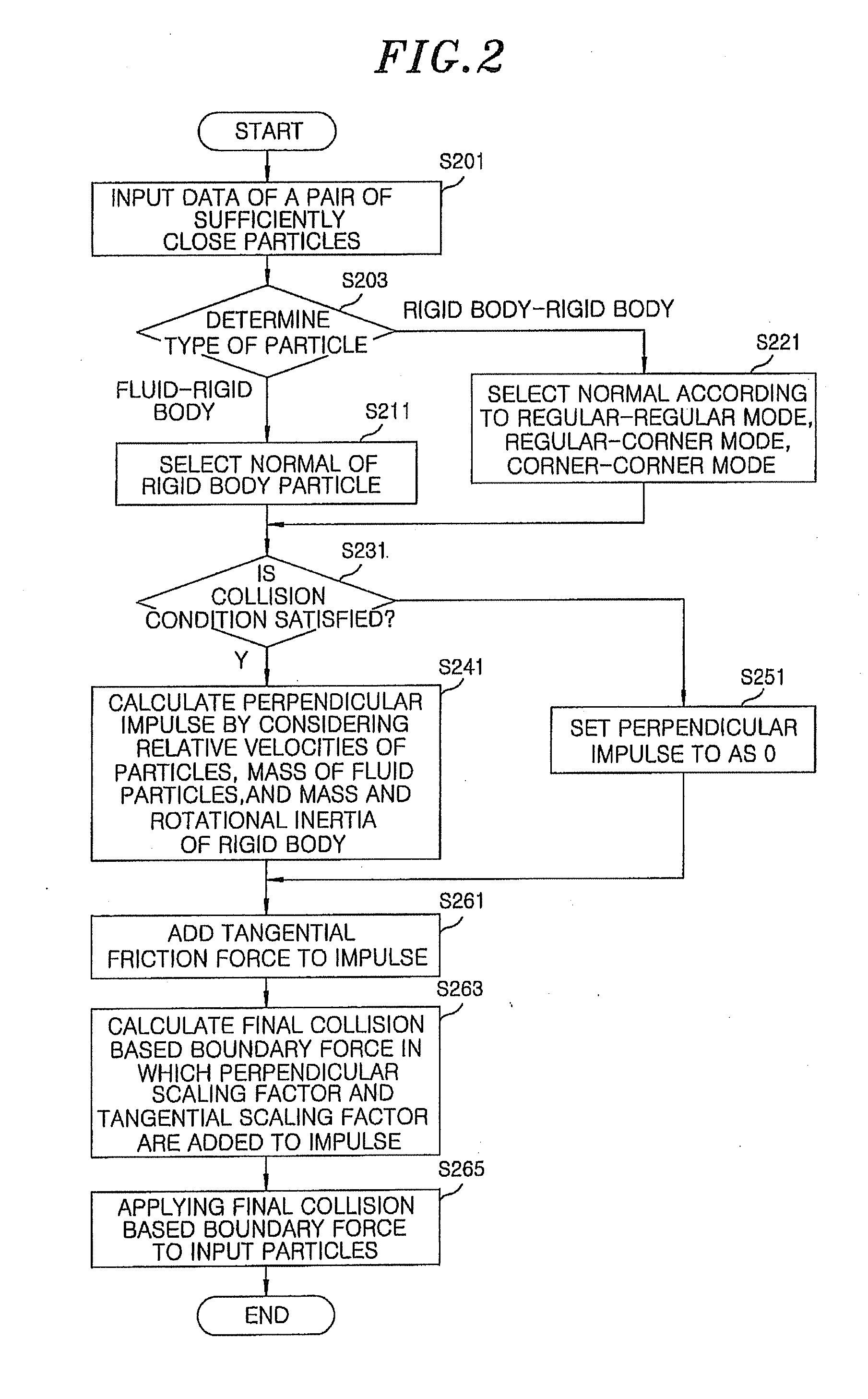

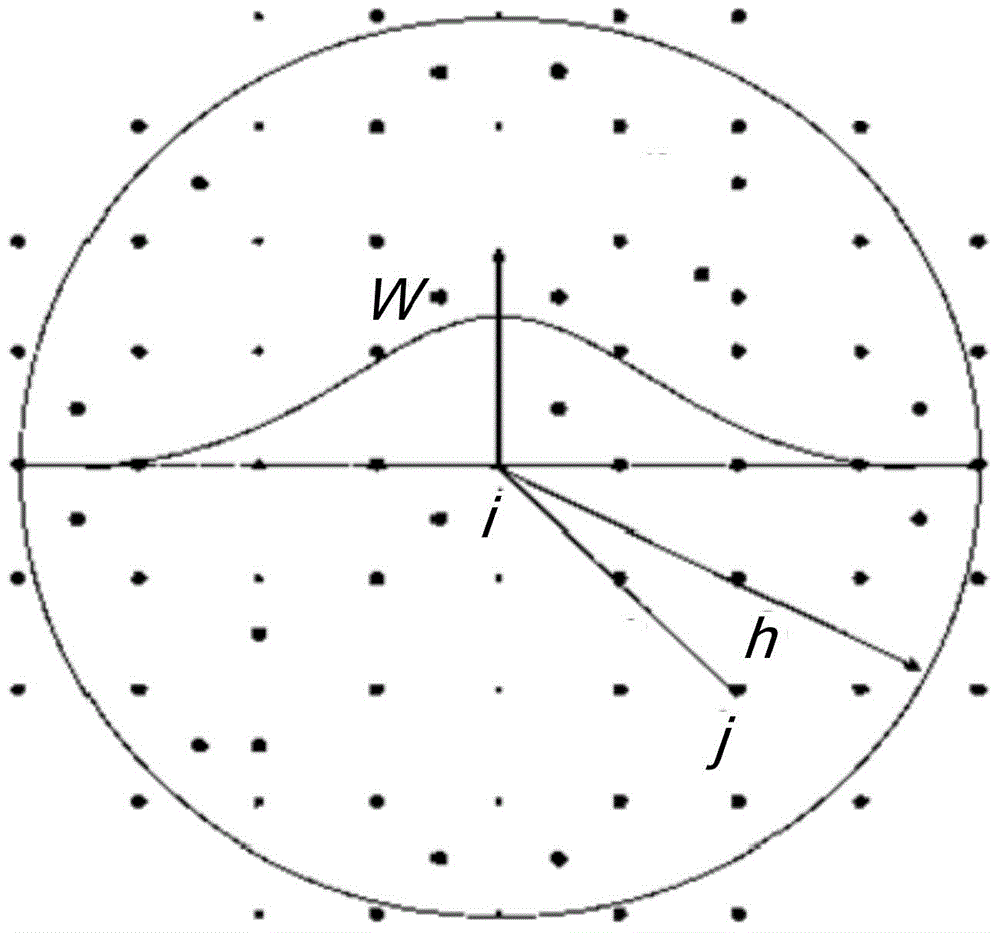

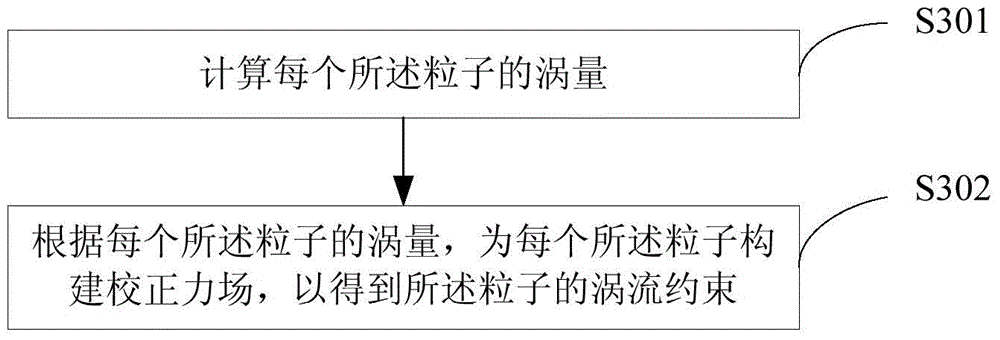

SPH-algorithm-based fluid simulation method and device

InactiveCN104537175AImprove detail performanceImprove fidelitySpecial data processing applicationsEddy currentComputer science

The invention belongs to the technical field of computer simulation, and provides an SPH-algorithm-based fluid simulation method and device. The method comprises the steps of initializing a flow field to generate discrete particles; calculating the density of each particle in the current flow field; according to the density of each particle, calculating the physical property of each particle, wherein the physical property comprises the eddy current confinement of each particle; according to the physical property of each particle, calculating the speed variation rate of each particle; according to the speed variation rate of each particle, updating the speed and position of each particle. Due to the fact that eddy current confinement is combined with the SPH algorithm in a seamless mode, the detail representation of fluid simulated based on the SPH algorithm is enhanced, and the fluid simulation fidelity is improved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Application programming interface for fluid simulations

ActiveUS20070038424A1Design optimisation/simulationAnimationSmoothed-particle hydrodynamicsApplication programming interface

A method is disclosed for executing a physics simulation in a system comprising a computational platform, a main application stored in the computational platform, a secondary application stored in the computational platform, and a smoothed particle hydrodynamics (SPH) application programming interface (API) implemented in the computational platform. The method defines a SPH call in the SPH API, and by operation of the main application, invokes a software routine using the SPH call. Additionally, by operation of the secondary application, a state of the physics simulation is updated in response to the software routine.

Owner:NVIDIA CORP

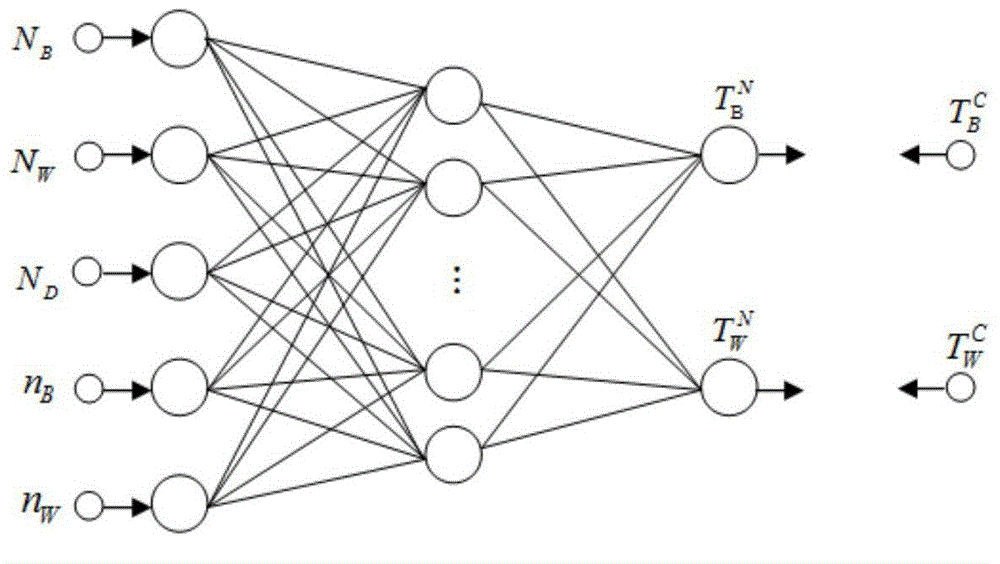

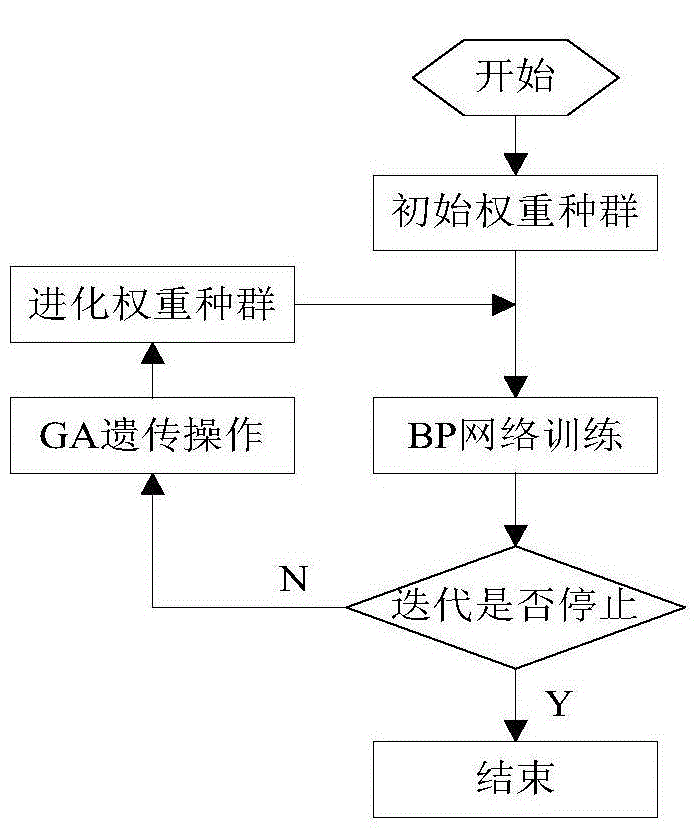

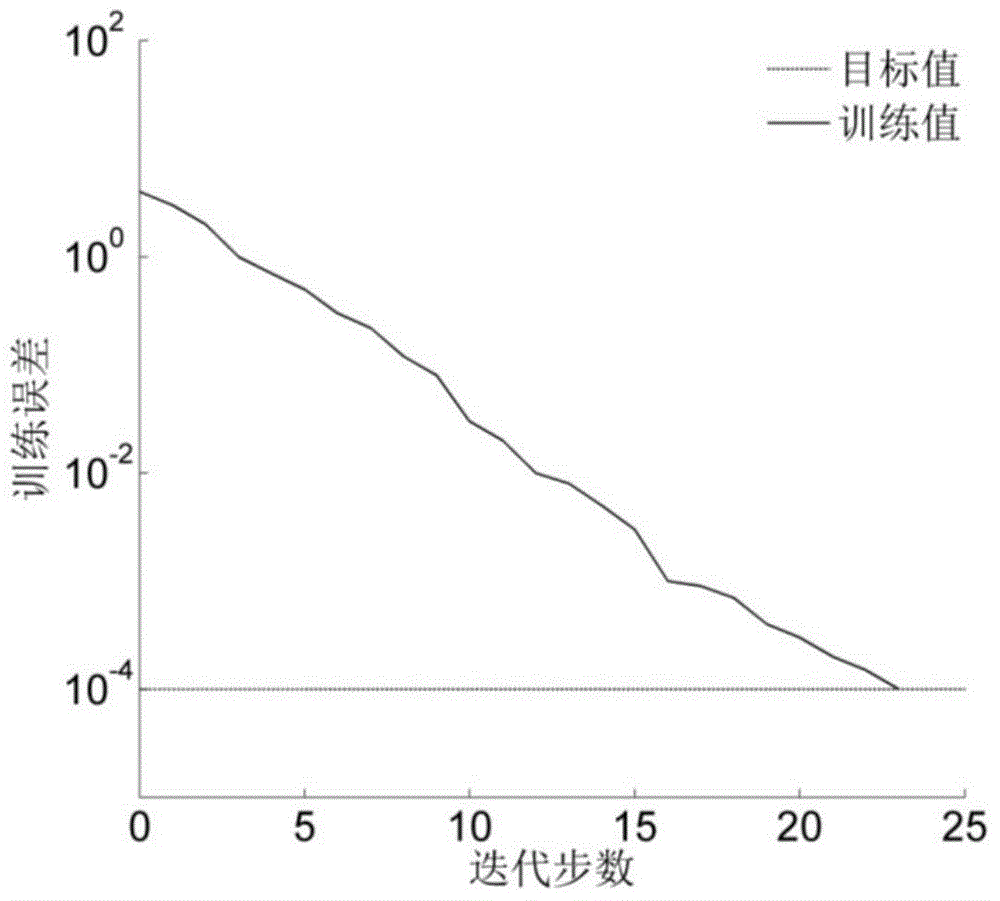

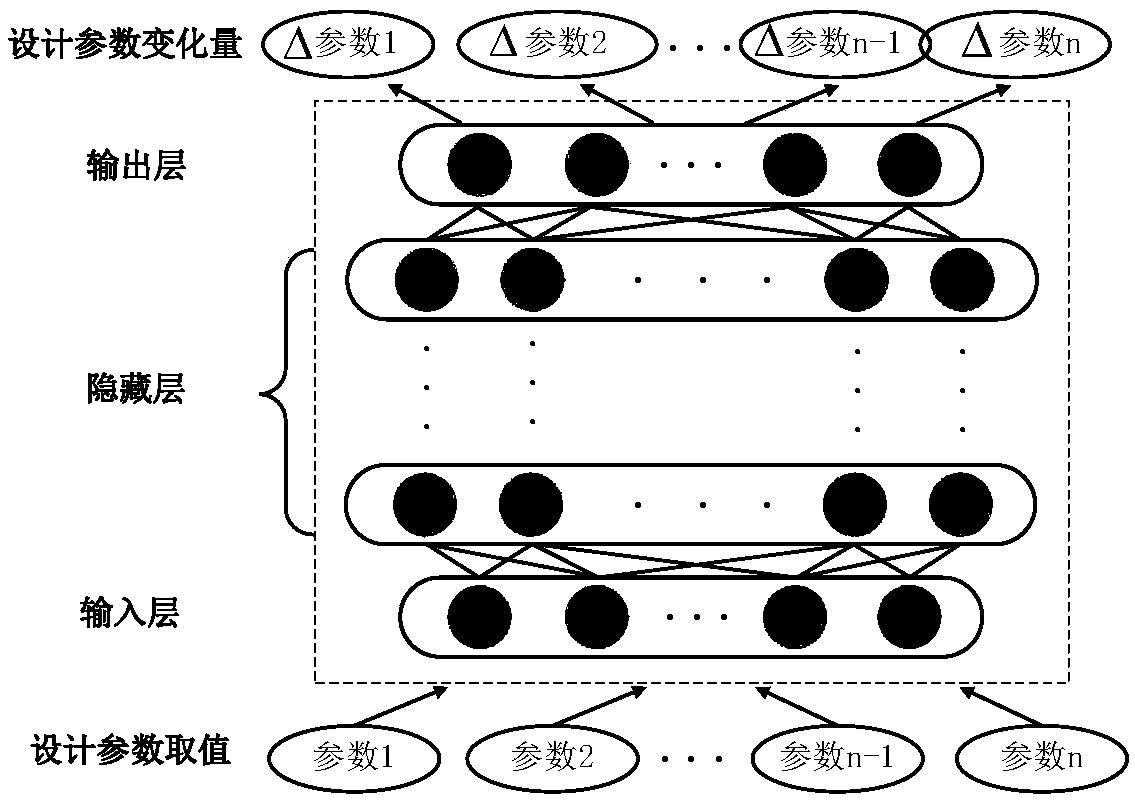

Blade number optimization method of hydraulic torque converter on the basis of neural network and complete machine

InactiveCN105022871AGo digitalRealize customized designBiological neural network modelsSpecial data processing applicationsImpellerGenetic algorithm

The invention discloses a blade number optimization method of a hydraulic torque converter on the basis of a neural network and a complete machine. A blade number neural network model is established and is combined with a digital model of a complete machine system to optimize a blade number. The blade number optimization method comprises the following steps: taking the blade numbers of the pump impeller, the turbine and the guide wheel of the hydraulic torque converter as input variables; utilizing an orthogonal experiment method to reasonably arrange an experiment; taking a pump impeller torque and a turbine torque of three-dimensional fluid simulation as target vectors of a training sample of the neural network so as to determine the structure and the training sample of the natural network; in order to improve the design efficiency and the convergence precision of the natural network, importing a genetic algorithm to optimize the initial weight and the threshold value of the natural network, accurately predicting the performance of the hydraulic torque converter of a non-training sample set by the trained natural network; and combining the blade number neural network model with a digital model of the complete machine system to optimize the blade number. The method has an important engineering application value on improving the operation efficiency of the complete machine.

Owner:TONGJI UNIV

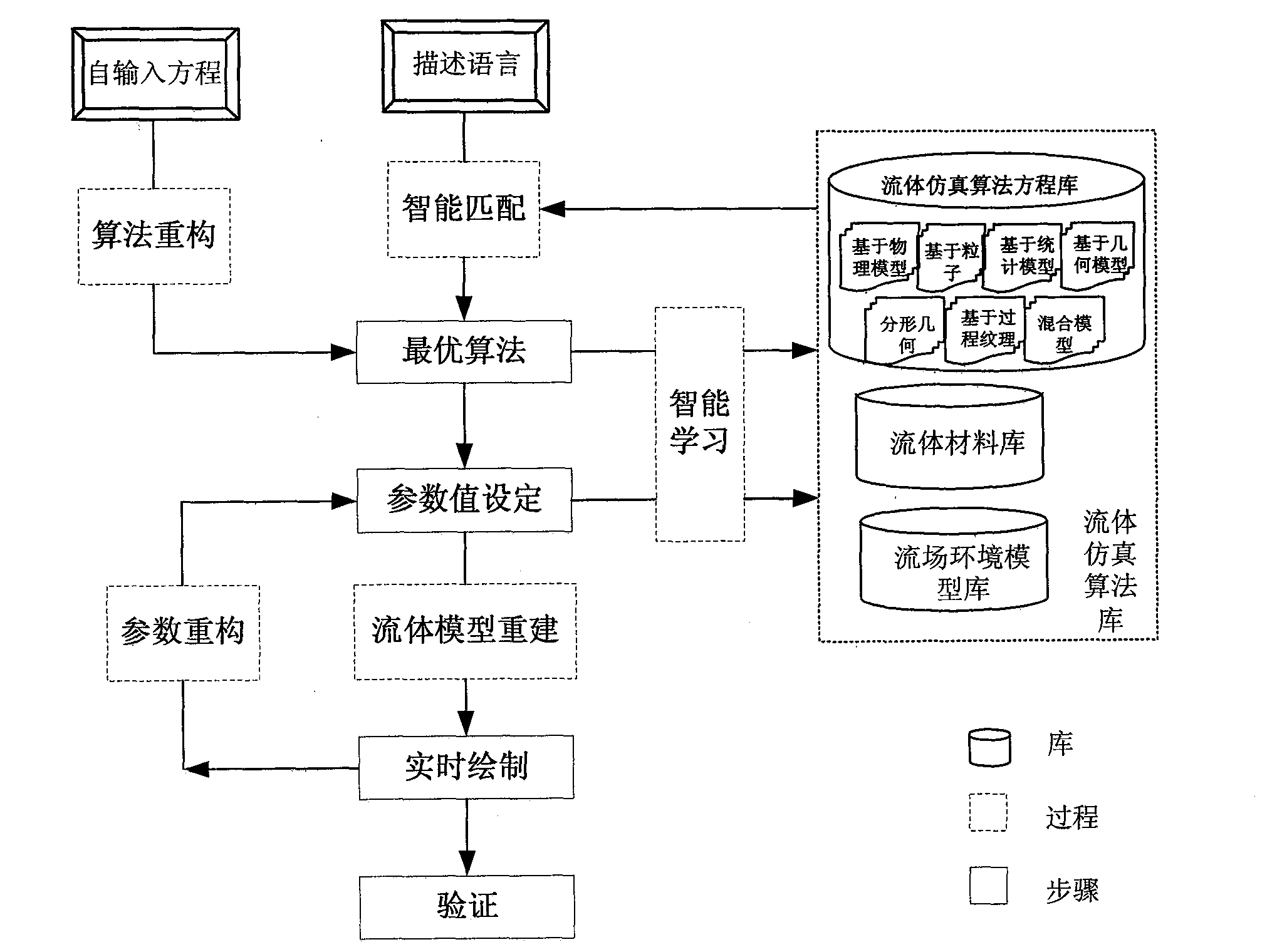

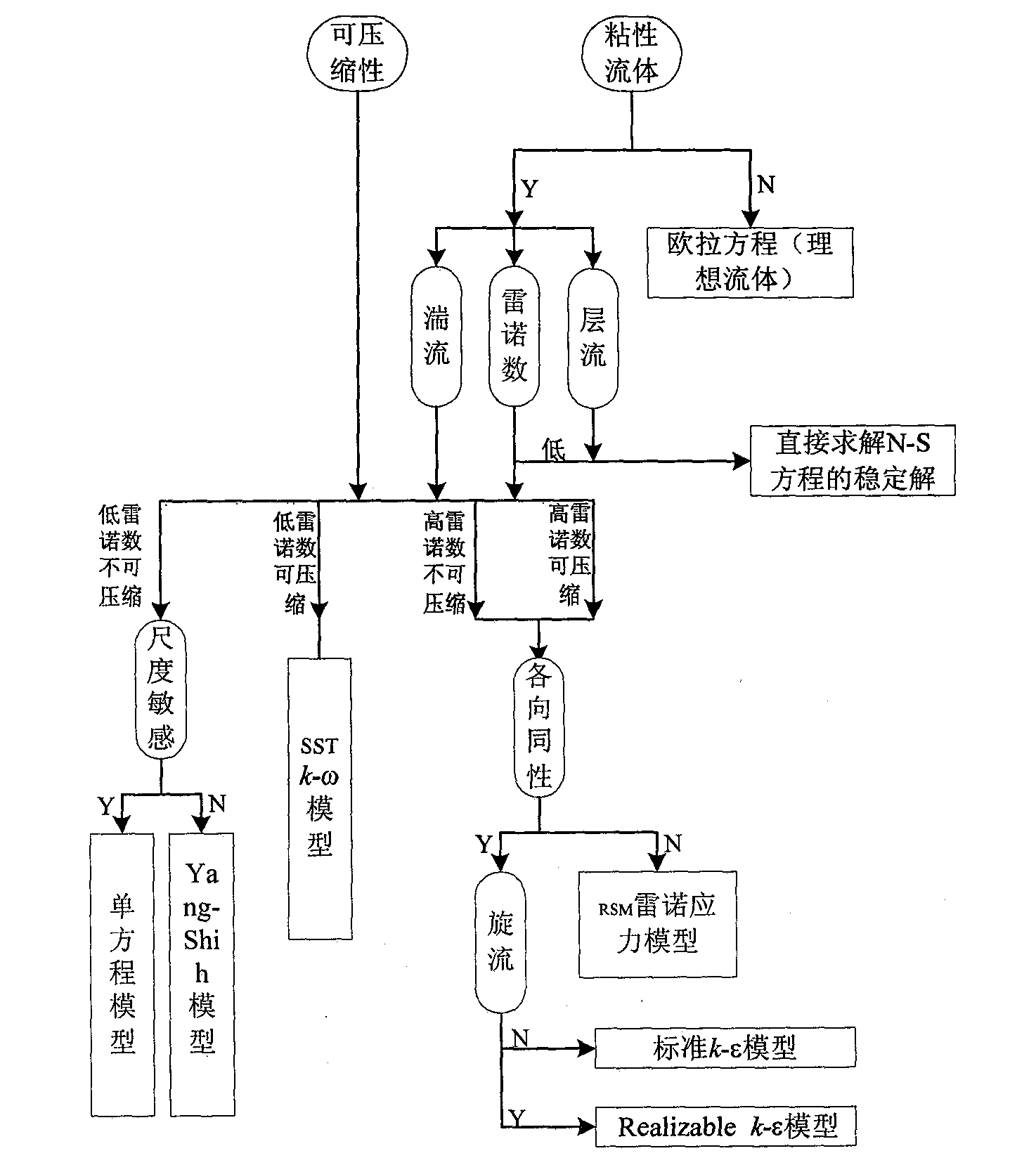

Intelligent simulation algorithm matching method for three-dimensional dynamic fluid

InactiveCN103294850AImprove unityAchieve sharingSpecial data processing applications3D modellingMatching methodsSimulation algorithm

The invention relates to an intelligent simulation algorithm matching method for three-dimensional dynamic fluid. The intelligent simulation algorithm matching method includes: building fluid simulation algorithm libraries comprising an algorithm equation library, a fluid material library, a three-dimensional flow field library and a target fluid describing language; intelligently matching fluid simulation algorithms: setting the target fluid describing language, finding the describing language corresponding to given conditions from the algorithm equation library by a system according to input condition information and utilizing an algorithm equation mapped by the describing language as a matched simulation algorithm equation of a target fluid; rebuilding a three-dimensional dynamic fluid model in real time, drawing three-dimensional fluid, proving simulation effect of the fluid and analyzing accuracy and effectiveness of the algorithms and parameters; controlling parameter and algorithm reconstitution; establishing an intelligent learning mechanism of the fluid simulation algorithms, storing the intelligent learning mechanism into the algorithm library together with the reconstitution algorithms and parameters passing effect proving, and setting up a matching relation between the intelligent learning mechanism and the keyed-in conditional information describing the fluid to be as a matching algorithm alternative item in future similar occasions, so that the system can complete the optimum screening configuration through intelligent learning.

Owner:苏州市数字城市工程研究中心有限公司

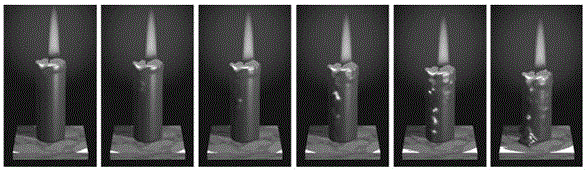

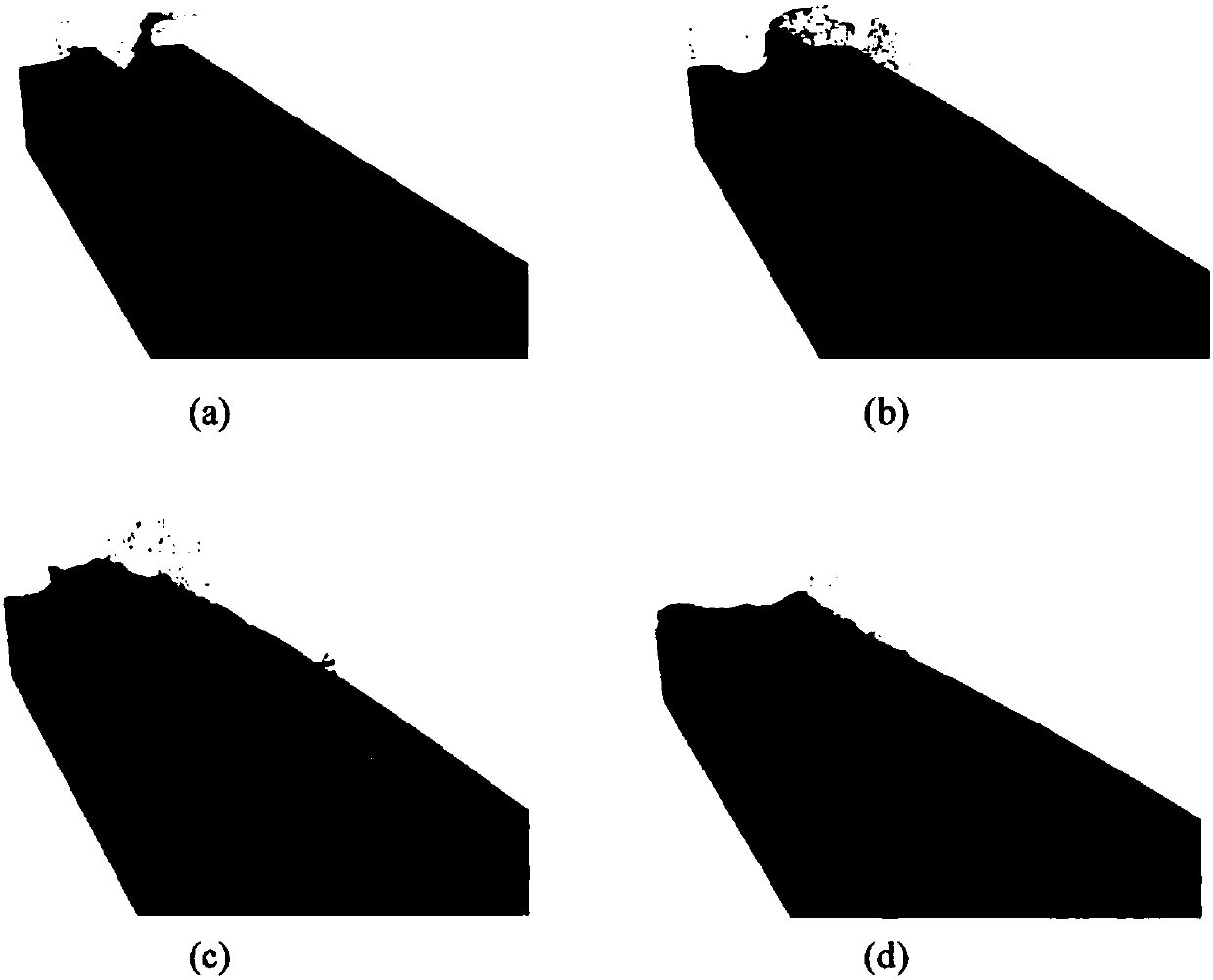

Third-dimensional fluid simulation method referring to heat conduction and dynamic viscosity

ActiveCN106096215ARealistic visual effectsGuaranteed realismComputer aided designSpecial data processing applicationsSmoothed-particle hydrodynamicsEngineering

The invention discloses a third-dimensional fluid simulation method referring to heat conduction and dynamic viscosity. The method comprises the steps that 1, discrete modeling is carried out on the heat conduction process in fluid and the heat conduction process between the fluid and the outside based on a smoothed particle hydrodynamics (SPH) model, and the phase change process is simulated according to the influence of enthalpy of phase change on the phase change temperature; 2, calculation of the dynamic viscosity is introduced to show details in the fluid motion process; 3, a PCISPH algorithm is called to complete the remaining fluid motion simulating process; 4, a GPU accelerating algorithm is utilized for processing the processes of heat conduction, phase change, fluid viscosity changes and the like in parallel on a compute unified device architecture (CUDA), and fast simulation of third-dimensional phase change fluid is achieved. By means of the method, the heat conduction process between different kinds of fluid and the outside and the viscosity change process of the fluid can be simulated really and efficiently, simulation details in an existing method are enhanced, and the sense of reality of fluid simulation is improved.

Owner:EAST CHINA NORMAL UNIV

Low-altitude wind shear three-dimensional backscattering wave simulation method for airborne meteorological radar

InactiveCN104597430AReflect meteorological characteristicsWave based measurement systemsJet aeroplaneWeather radar

The invention discloses a low-altitude wind shear three-dimensional backscattering wave simulation method for an airborne meteorological radar. The low-altitude wind shear three-dimensional backscattering wave simulation method comprises the following steps: establishing a three-dimensional meshed computational domain by utilizing scene parameters including a scene range and boundary conditions; performing fluid simulation on the computational domain to generate original wind field data; correcting the original wind field data; establishing an simulation scene and reading the corrected wind field data according to settings of the scene parameters; according to the simulation scene, simulating low-altitude wind shear of the airborne meteorological radar, and performing coherence stack on scattering points within a radar beam to form a radar backscattering wave signal of a scanning direction; respectively updating airplane position information, corrected wind field data and radar beam angle scanning information by utilizing the airborne parameters, the scene parameters and the scanning parameters; judging whether the scanning is completed or not according to a scanning range of the radar parameters. The method can be used for truly reflecting meteorological characteristics of the wind shear three-dimensional backscattering wave signal, so that the simulation data is effective and reliable.

Owner:CIVIL AVIATION UNIV OF CHINA

Blood flow dynamics parameter calculation method and system and electronic device

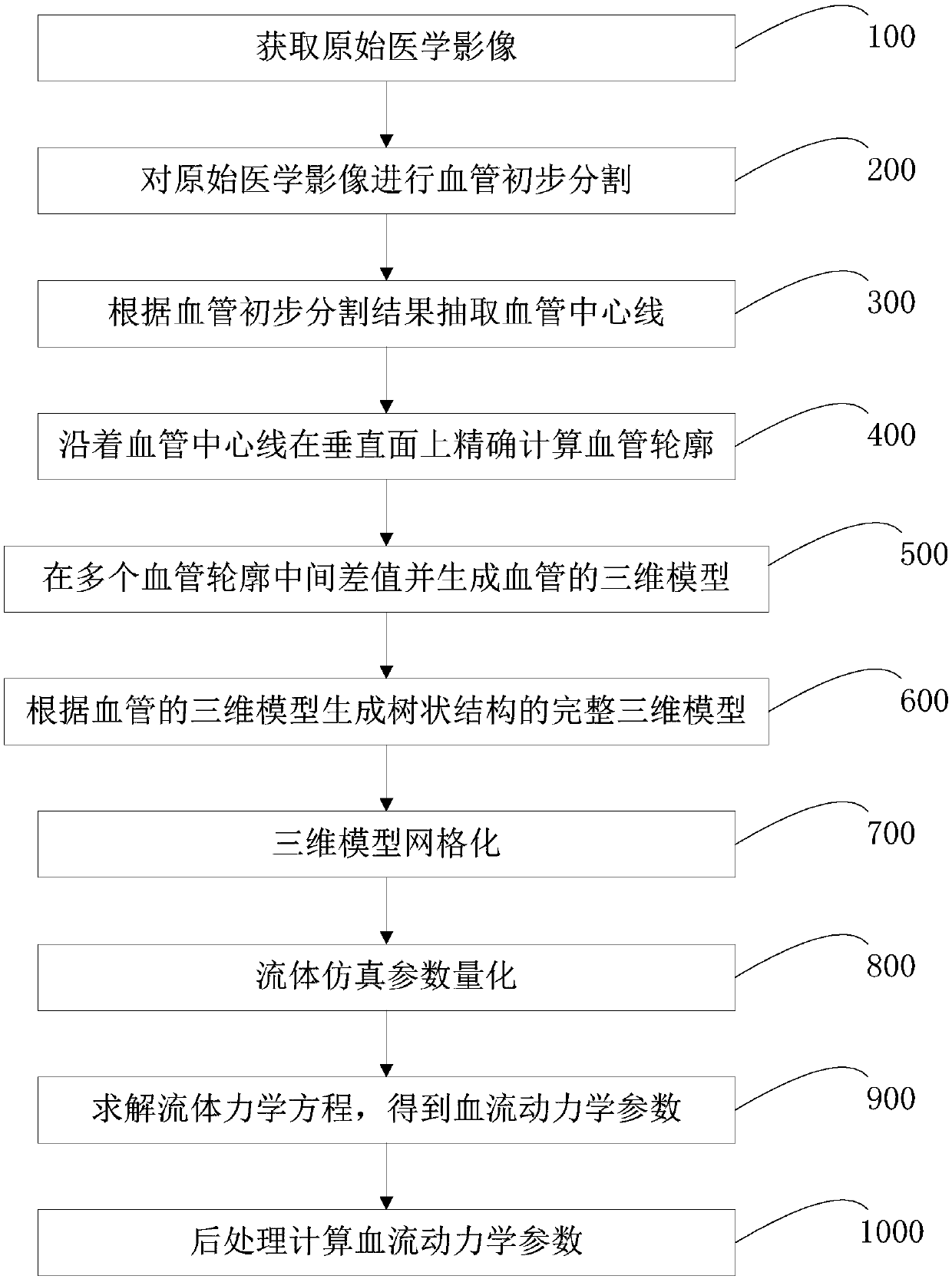

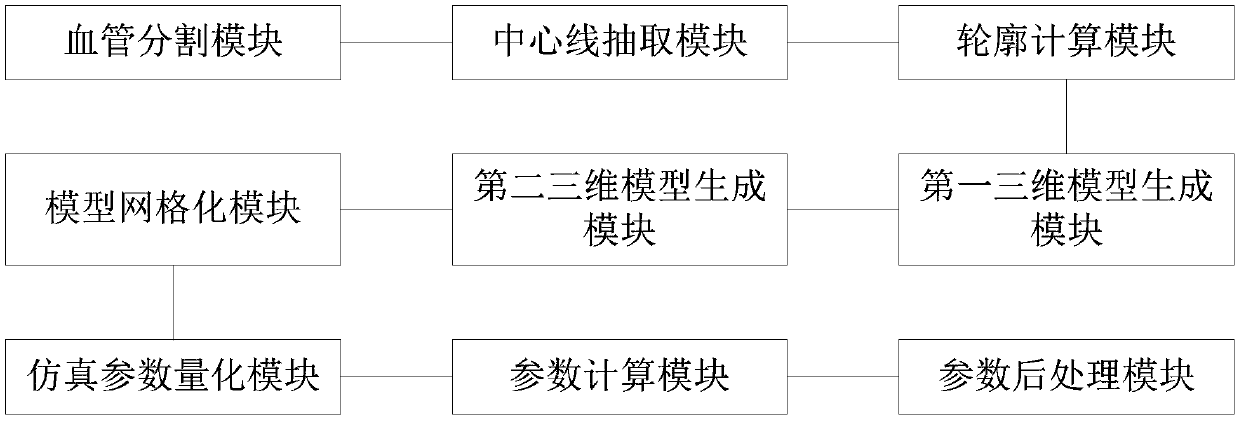

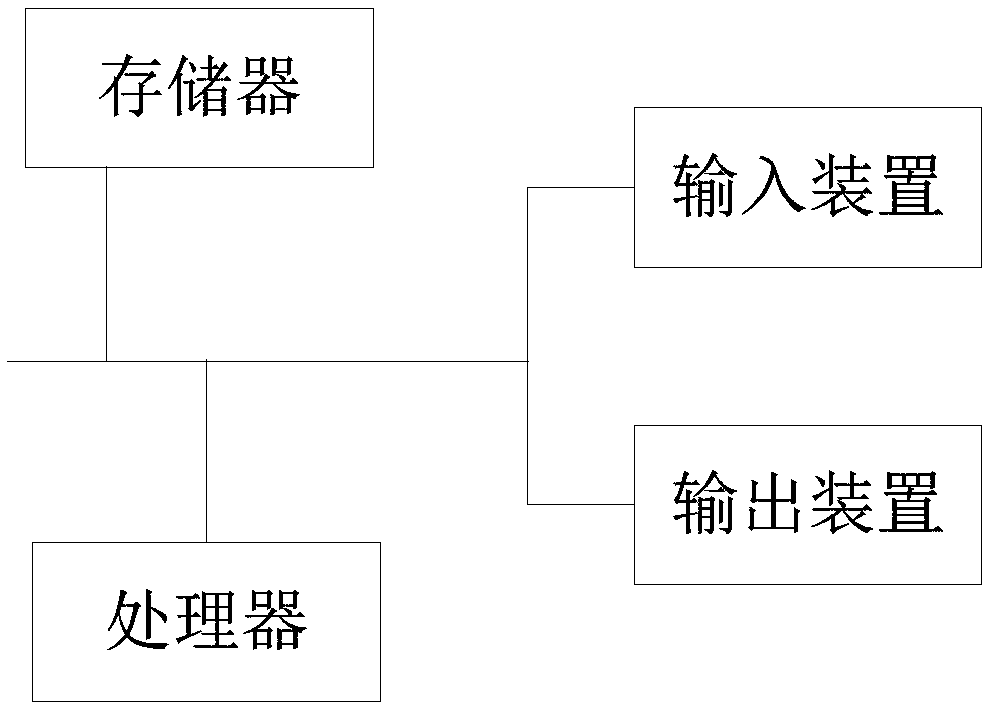

ActiveCN109559326AHigh precisionImprove versatilityImage enhancementImage analysisVertical planeModel system

The invention relates to a hemodynamic parameter calculation method and system and an electronic device. The method comprises the following steps of A carrying out preliminary blood vessel segmentation on an original medical image; B extracting a blood vessel center line according to the preliminary blood vessel segmentation result; C calculating a blood vessel contour on a vertical plane along the blood vessel center line; D generating a three-dimensional model of the blood vessel at the intermediate difference value of the blood vessel contour; E gridding the three-dimensional model of the blood vessel to obtain model grid information; F quantifying fluid simulation parameters; and G solving a fluid mechanics equation according to the model grid information and the fluid simulation parameters to obtain the hemodynamic parameters. Compared with the prior art, the application has a complete blood vessel modeling system and a parameter calculation system, by which errors can be greatlyreduced compared with the prior art, and the precision and universality of blood vessel dynamics parameter calculation are integrally improved.

Owner:SHENZHEN RAYSIGHT INTELLIGENT MEDICAL TECH CO LTD

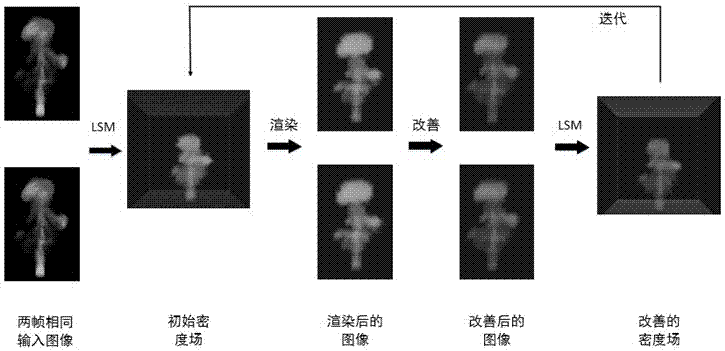

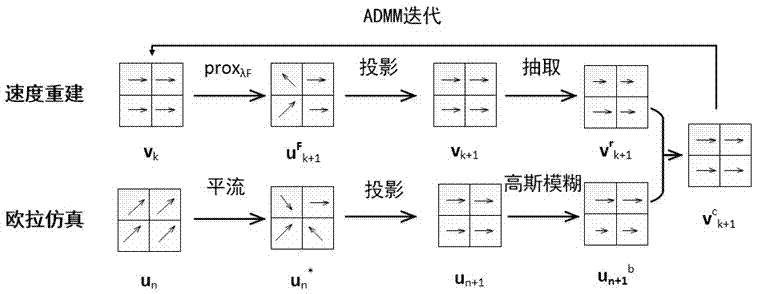

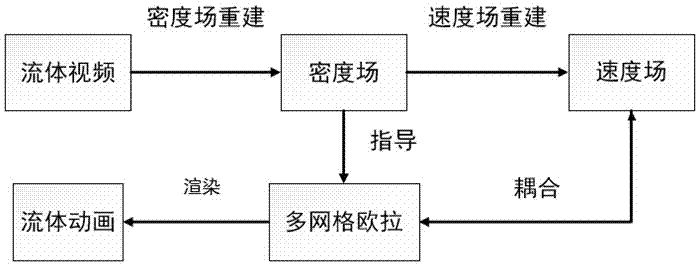

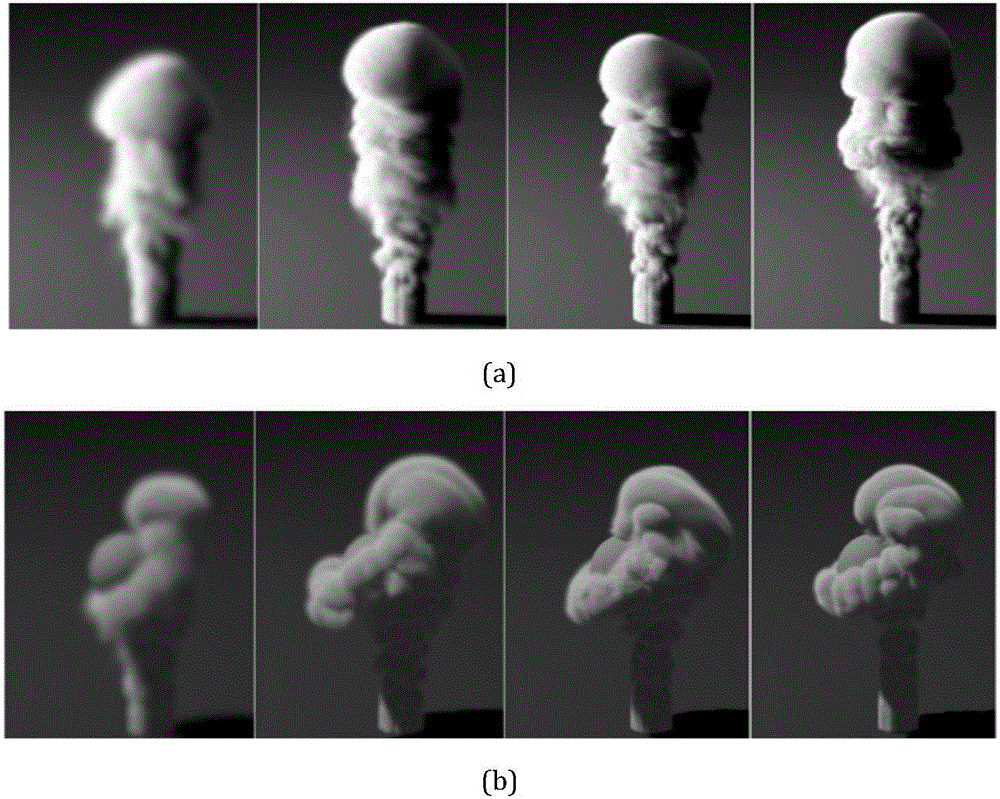

Fluid simulation method based on video reconstruction and eulerian model coupling

ActiveCN107085629AControllable detailsIn line with the real sceneDesign optimisation/simulationAnimationPrior informationCoupling

The invention discloses a fluid simulation method based on video reconstruction and eulerian model coupling. The fluid simulation method comprises the steps of 1) reconstructing a three-dimensional density field of each frame of a fluid according to an input video; 2) solving an N-S equation by adopting an eulerian method, and updating the speed field and density field of the fluid; 3) taking the reconstructed density field of adjacent two frames as prior information and taking the result of the eulerian method as correction to reconstruct a three-dimensional speed field of the fluid; and 4) guiding the eulerian fluid simulation by using the reconstructed density field and speed field to generate a new animation effect. By adoption of the fluid simulation method, the density field and the speed field of the fluid can be reconstructed with relatively high precision; and by tightly coupling the reconstructed data and a fluid geometrical model, a fluid animation effect which is more closer to an actual condition can be obtained, and controllable fluid details can be added.

Owner:EAST CHINA NORMAL UNIV

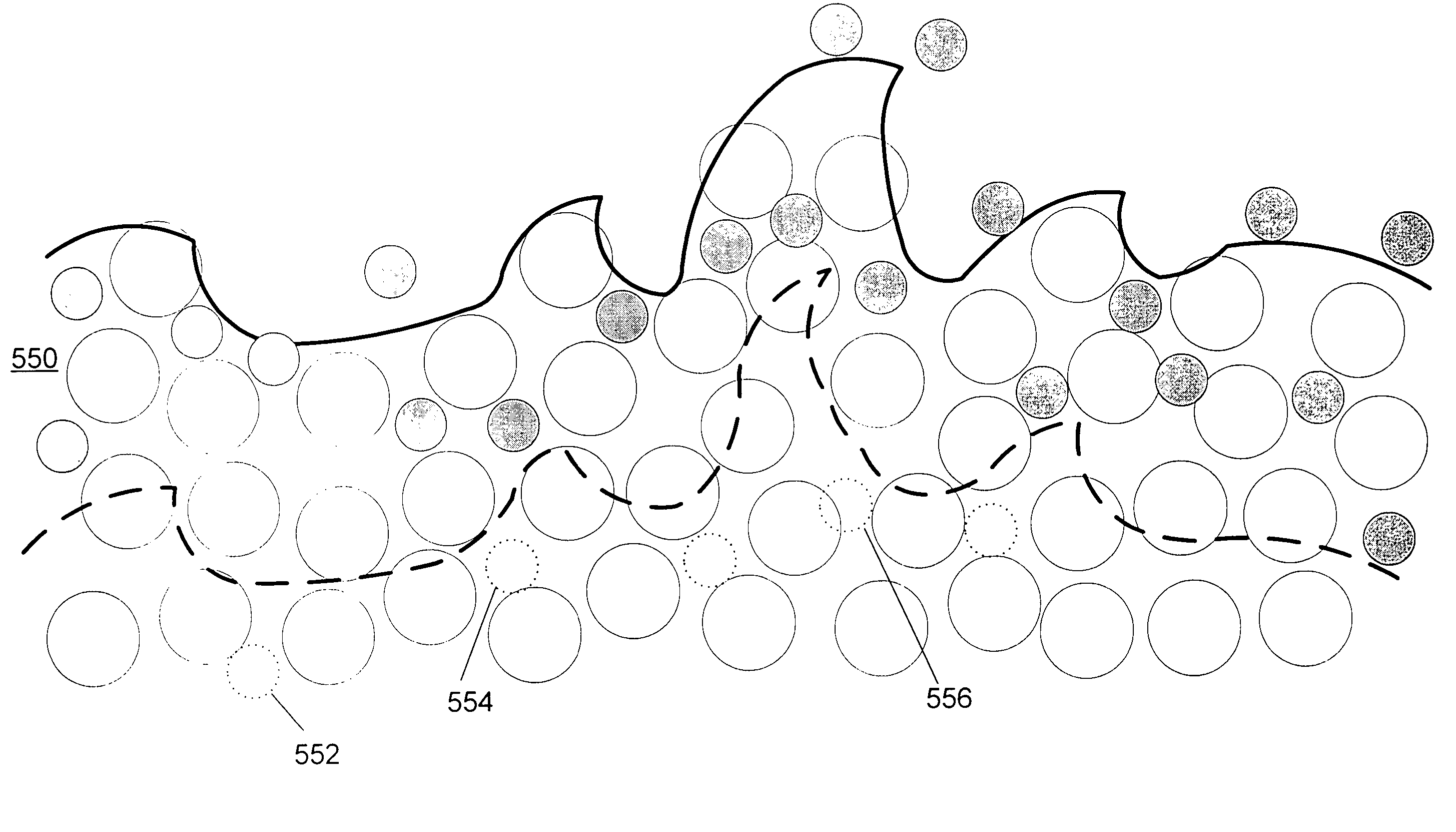

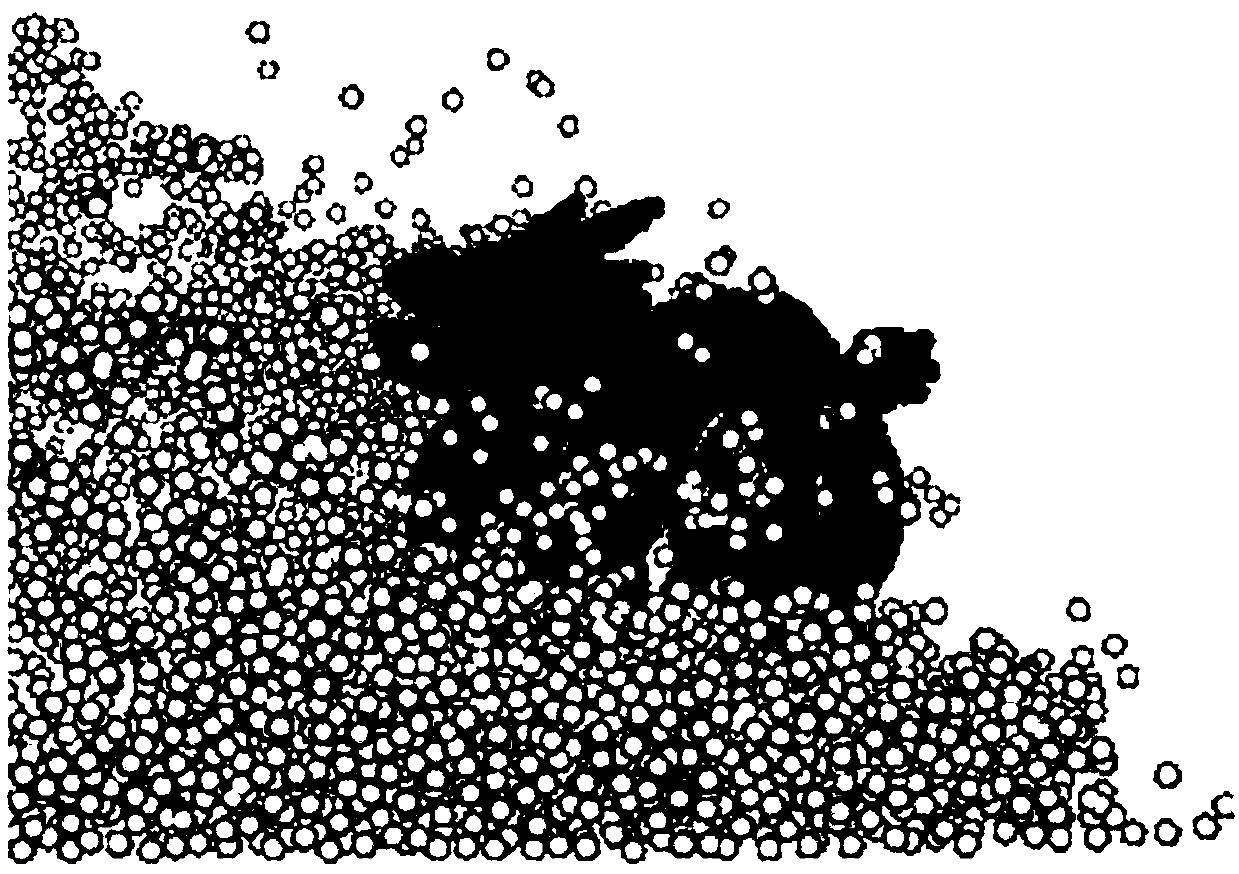

Water particle manipulation

ActiveUS7349832B2Lighten the computational burdenComputation using non-denominational number representationDesign optimisation/simulationBoundary regionWater particle

Realistic sprays for simulated fluids are created by adding a set of spray particles to a boundary region just below the fluid surface. The fluid surface is determined by solving a level set equation for a zero level corresponding to the fluid surface. Additionally, the boundary region is determined by solving the level set equation for a non-zero level corresponding to a surface at the specified depth from the fluid surface. The set of spray particles inherit an initial state, for example a velocity, from the fluid simulation. Subsequent motion of the spray particles is determined according to a ballistic simulation, rather than a fluid simulation, thereby substantially reducing the computational burden required to animate the fluid. Spray particles that sink below a specified depth from the fluid surface are removed.

Owner:PIXAR ANIMATION

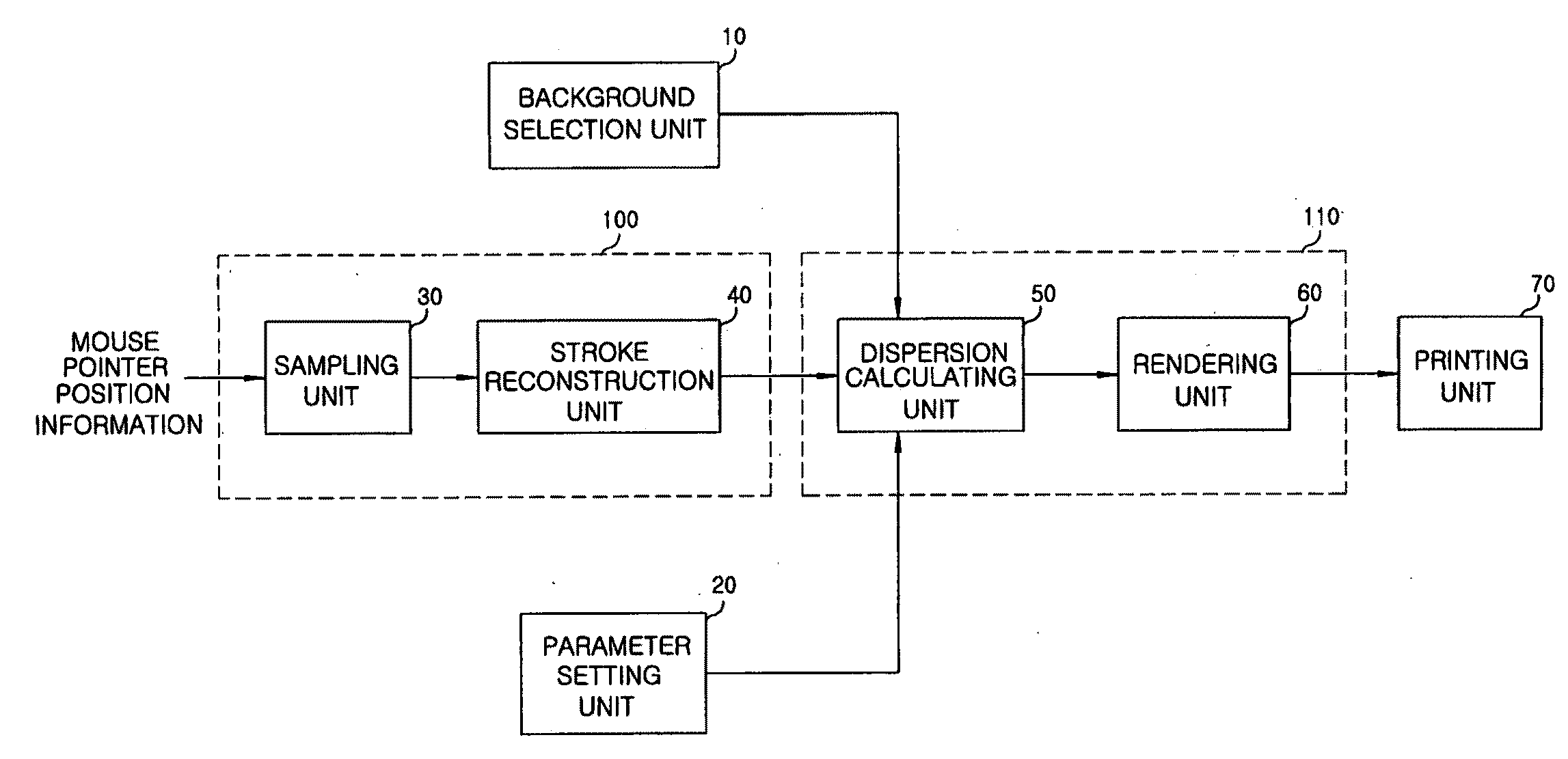

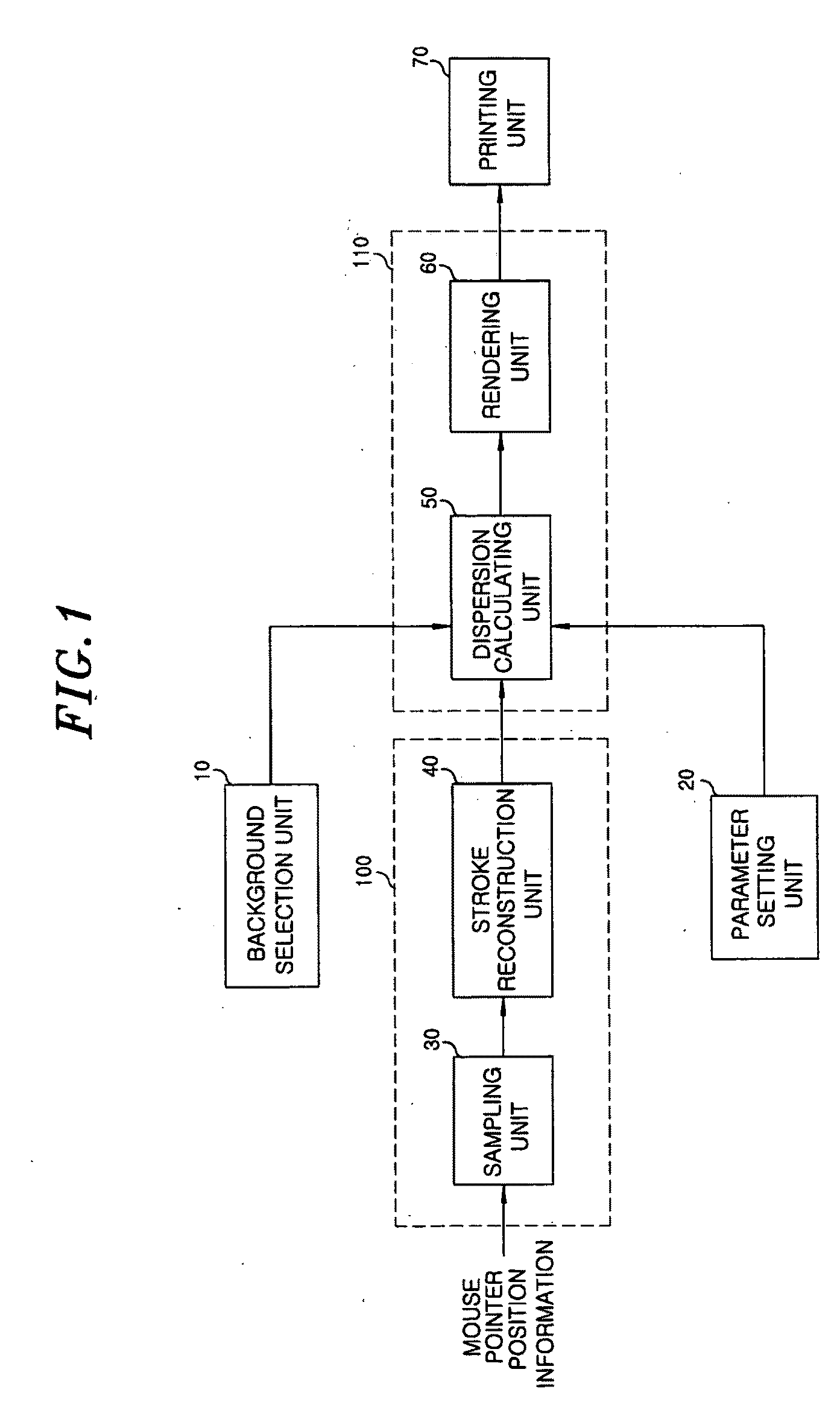

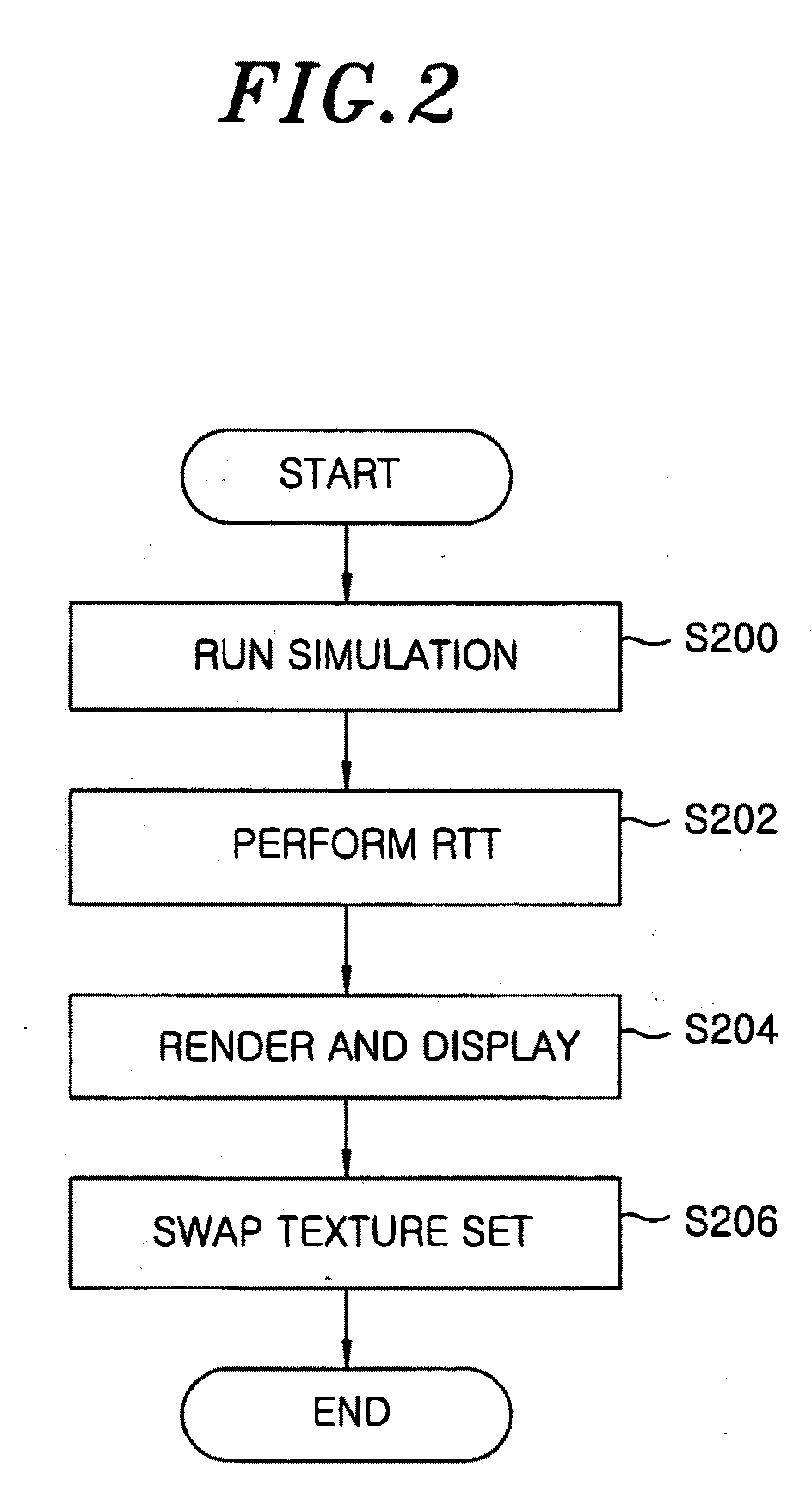

System for simulating digital watercolor image and method therefor

A method for simulating digital watercolor image includes: receiving a background texture on a virtual canvas where a watercolor image will be painted; receiving parameters for fluid simulation; and creating brushstrokes by a mouse pointer's movement on the virtual canvas. Further, the method includes converting coordinates of the brushstrokes on the virtual canvas to fit into simulation grids; calculating movement of colors and water through the fluid simulation by using the parameters and the brushstrokes; and simulating the watercolor image based on the brushstrokes by using the calculated movement of the colors and water.

Owner:ELECTRONICS & TELECOMM RES INST

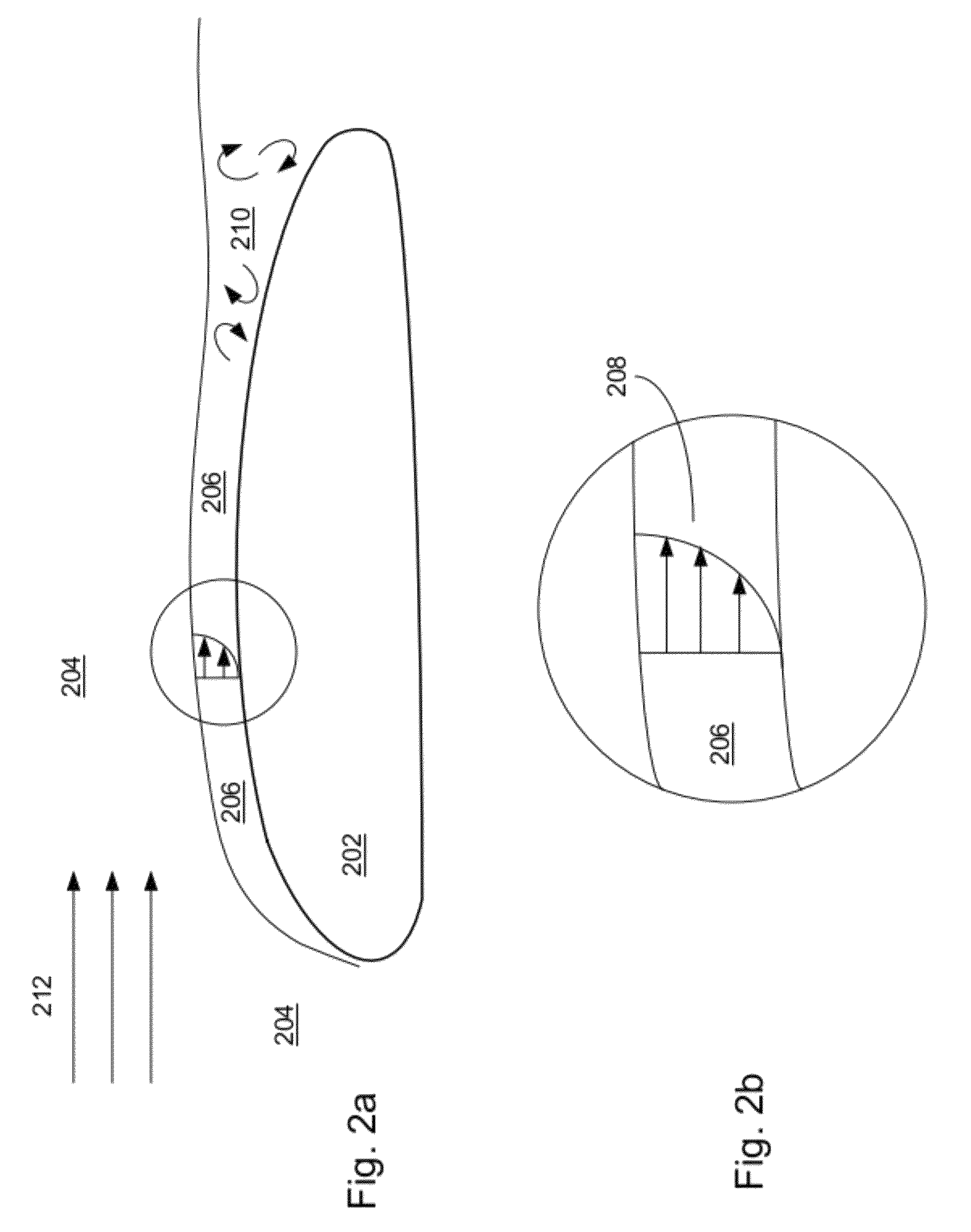

Generating inviscid and viscous fluid-flow simulations over an aircraft surface using a fluid-flow mesh

Fluid-flow simulation over a computer-generated aircraft surface is generated using inviscid and viscous simulations. A fluid-flow mesh of fluid cells is obtained. At least one inviscid fluid property for the fluid cells is determined using an inviscid fluid simulation that does not simulate fluid viscous effects. A set of intersecting fluid cells that intersects the aircraft surface are identified. One surface mesh polygon of the surface mesh is identified for each intersecting fluid cell. A boundary-layer prediction point for each identified surface mesh polygon is determined. At least one boundary-layer fluid property for each boundary-layer prediction point is determined using the at least one inviscid fluid property of the corresponding intersecting fluid cell and a boundary-layer simulation that simulates fluid viscous effects. At least one updated fluid property for at least one fluid cell is determined using the at least one boundary-layer fluid property and the inviscid fluid simulation.

Owner:AERION INTPROP MANAGEMENT CORP

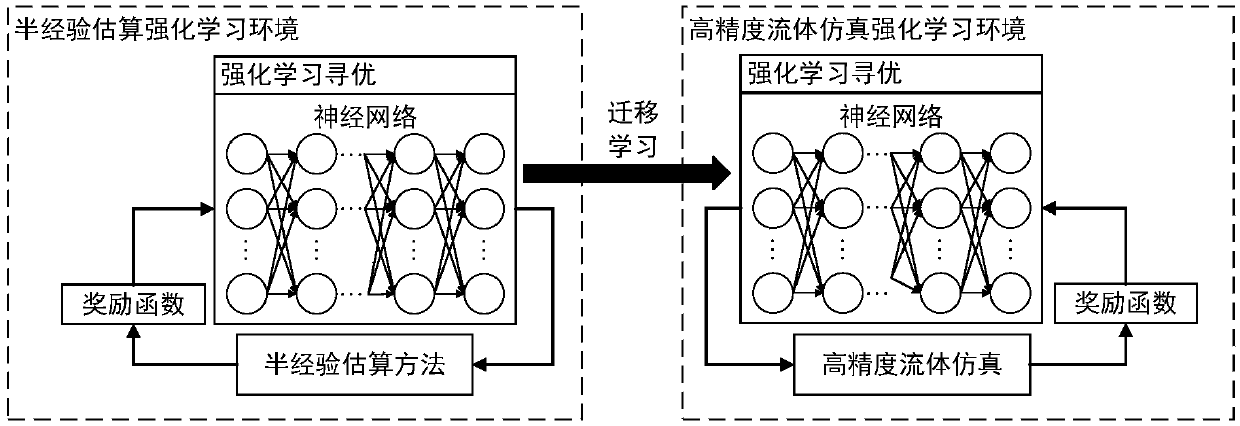

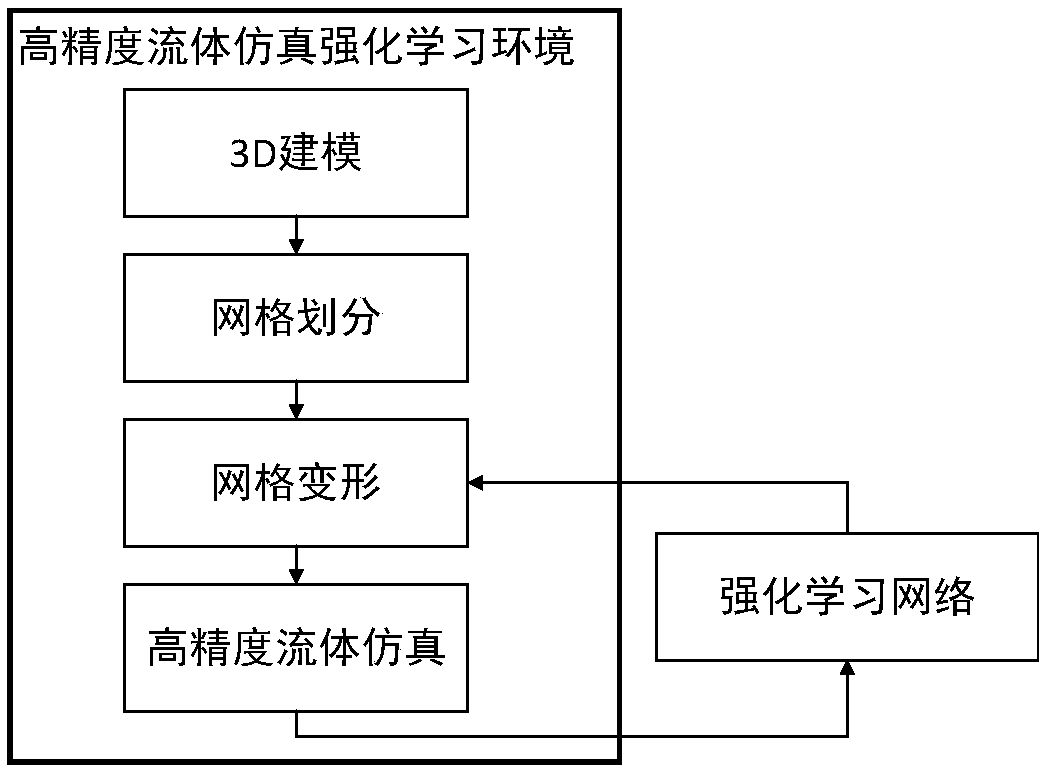

Aircraft full-automatic pneumatic optimization method based on reinforcement learning and transfer learning

ActiveCN109614631AAvoid duplicationAvoid meshingSustainable transportationDesign optimisation/simulationLocal optimumEstimation methods

The invention discloses an aircraft full-automatic aerodynamic optimization method based on reinforcement learning and transfer learning. The method is used for solving the problem that an existing pneumatic optimization method is prone to falling into local optimization or low in convergence speed, manual intervention is excluded in the final high-precision optimization stage through the optimization method, and the optimization efficiency is further improved. According to the technical scheme, firstly, a reinforcement learning environment based on semi-empirical estimation and high-precisionfluid simulation is established; a reinforcement learning neural network is constructed; a reward function is set, the global optimization capability of reinforcement learning is utilized; in the network training process, optimization experience is extracted from a semi-experience estimation method and stored in network parameters; then, another reinforcement learning neural network is constructed, migration learning is used for migrating the extracted optimization experience to the network, then the network is applied to aerodynamic optimization based on high-precision fluid simulation, andfinally, high-precision design parameters with excellent aerodynamic performance are obtained by training the network. Compared with a background technology method, the method has the advantages thatthe convergence speed is increased, the strong global optimization capability is realized, and the engineering value for high-precision pneumatic optimization is very high.

Owner:TSINGHUA UNIV

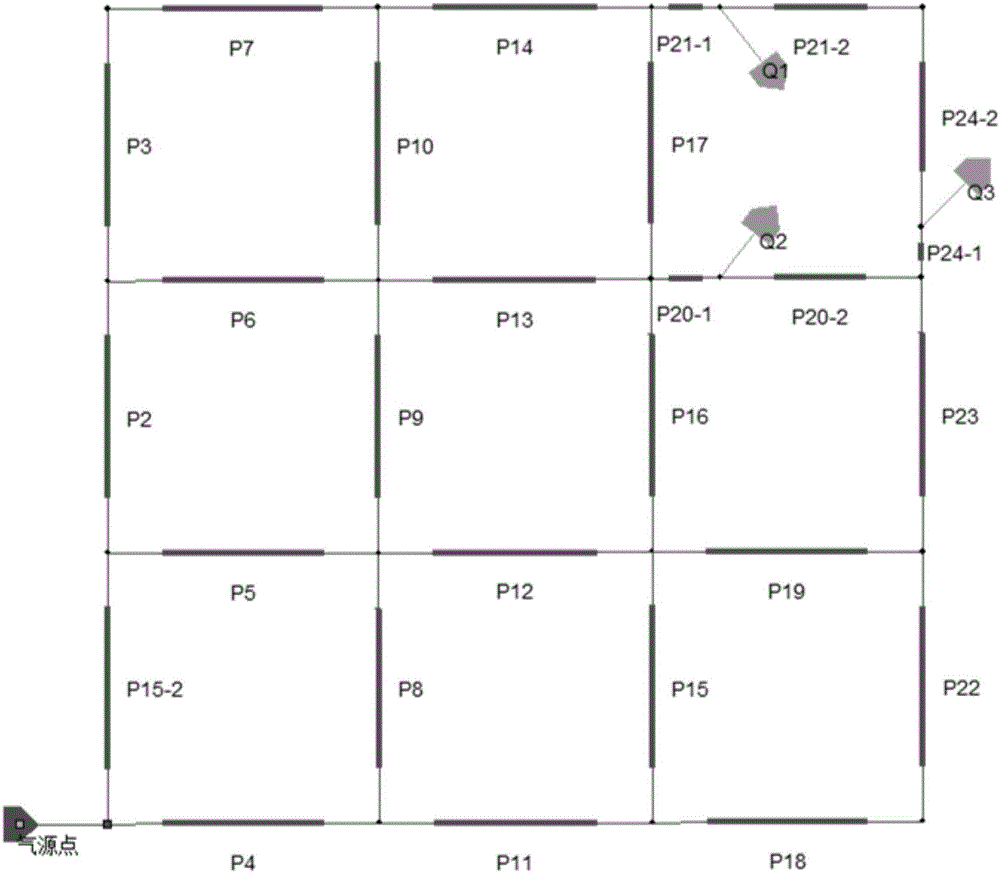

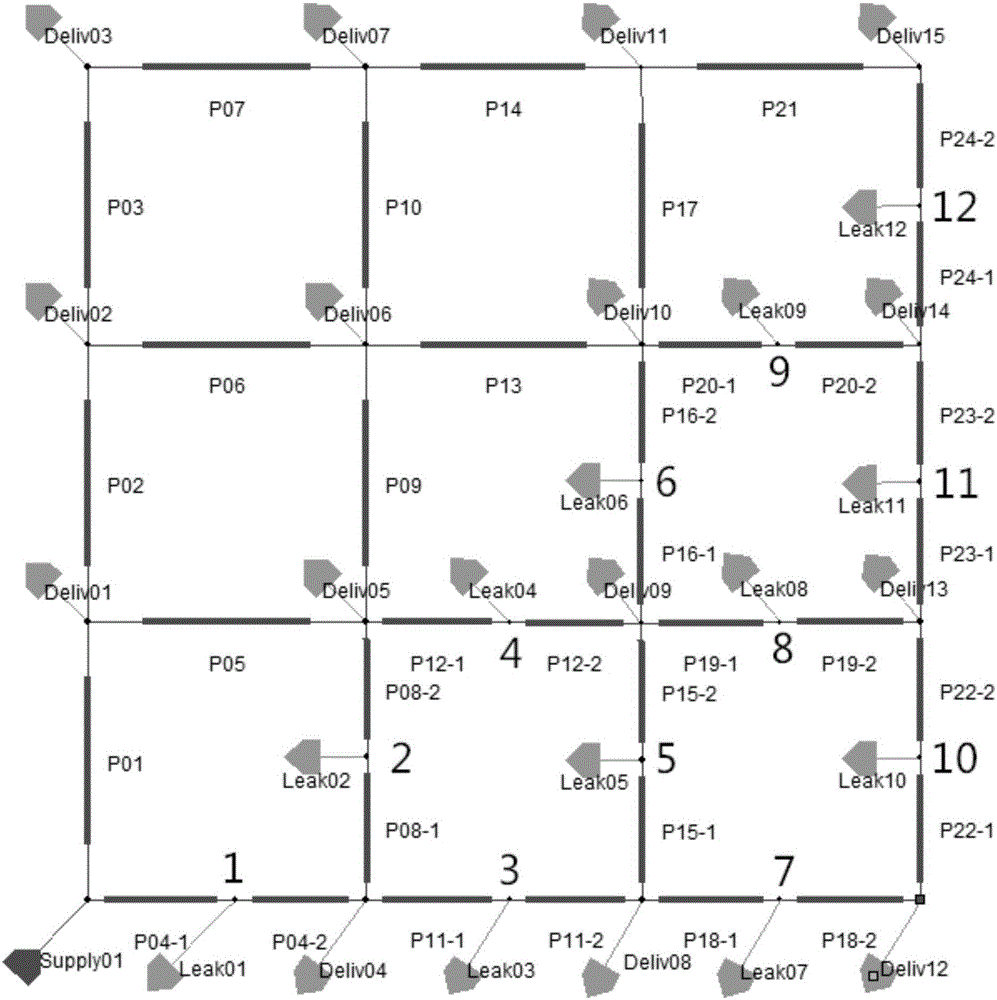

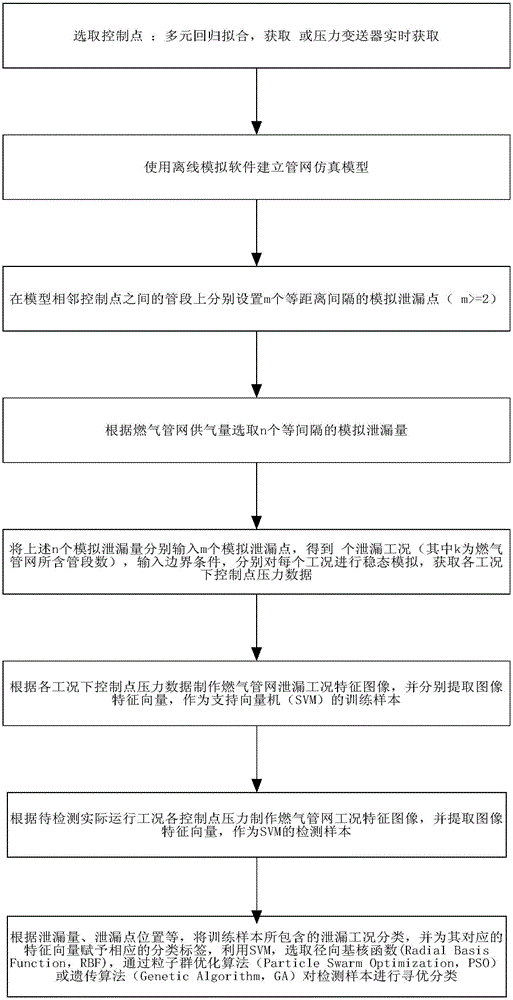

Feature image based gas pipeline network leakage detection and positioning method

ActiveCN105868444AQuick checkAccurate detectionCharacter and pattern recognitionDesign optimisation/simulationPressure dataNetwork simulation

The invention discloses a feature image based gas pipeline network leakage detection and positioning method. The method comprises the following steps of: 1, selecting all nodes of a gas pipeline network as control points; 2, establishing a gas pipeline network simulation model by employing offline fluid simulation software Pipeline Studio; 3, respectively disposing m equidistant simulation leakage points on pipe sections between adjacent control points of the gas pipeline network simulation model, wherein m is greater than or equal to 2; 4, selecting n equidistant simulation leakage amounts according to gas consumption of the gas pipeline network; 5, respectively inputting the n simulation leakage amounts to the m simulation leakage points, respectively carrying out steady-state simulation on each working condition to obtain control point pressure data of each working condition; 6, making a feature image of leakage working conditions of the gas pipeline network; 7, extracting image feature vectors as detection samples of an SVM (Support Vector Machine); and 8, classifying and identifying the detection samples many times by the SVM. According to the method, a leakage source position can be detected and positioned rapidly and accurately and provides the basis for emergency disposal.

Owner:HUASHEN GAS BURNING IND TIANJIN

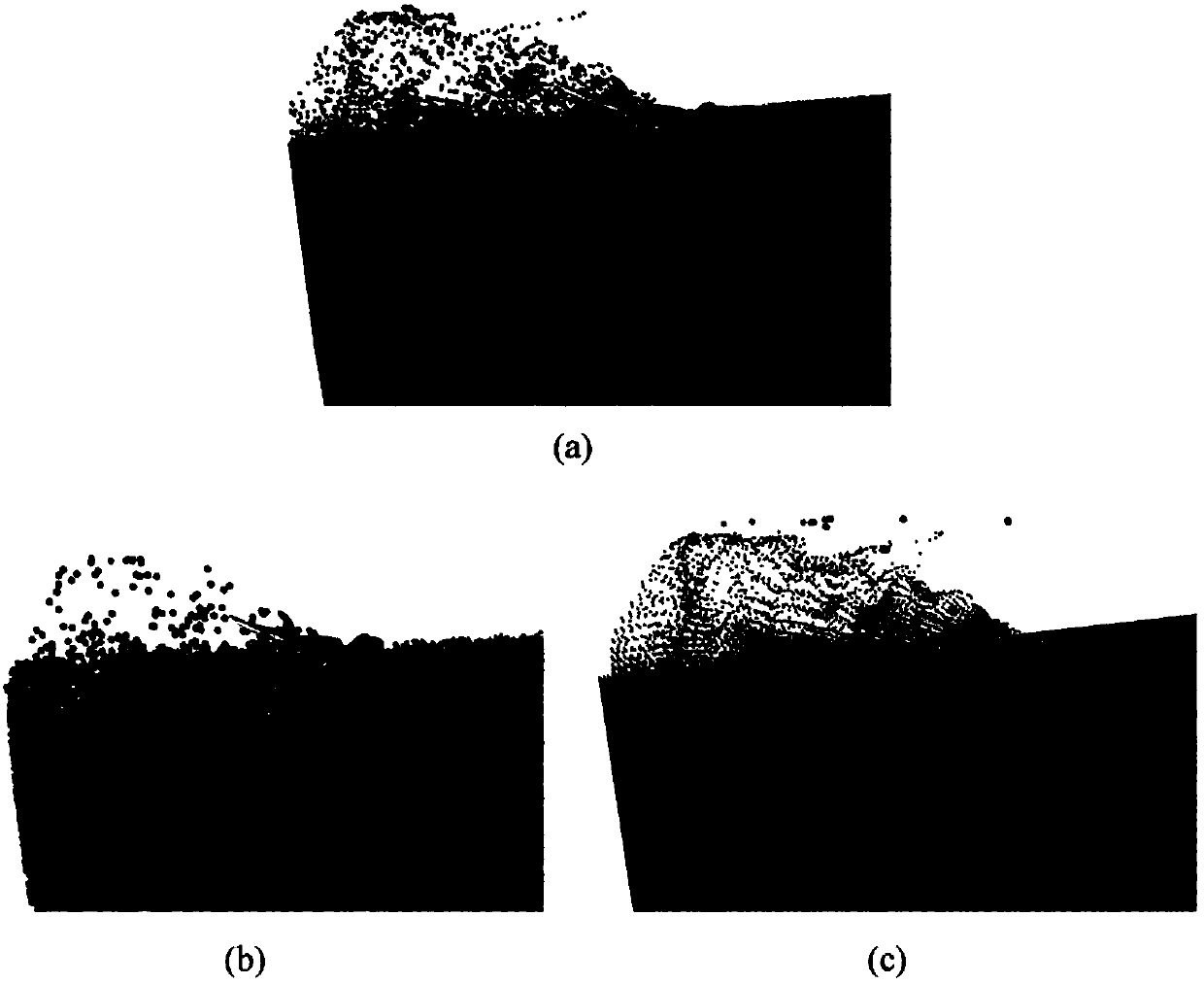

Physical and non-physical mixture-based complex scene fluid-solid coupling efficient simulation method

InactiveCN108491619AEnsure incompressibilityRich detail effectDesign optimisation/simulationSpecial data processing applicationsSmoothed-particle hydrodynamicsFracture mechanics

The invention discloses a physical and non-physical mixture-based complex scene fluid-solid coupling efficient simulation method. The method comprises the steps of 1) performing incompressible fluid simulation, combining an Euler method and a Lagrange method, and proposing an implicit particle method-based zero-divergence smooth particle fluid dynamics method; 2) performing dynamics problem solving in fluid-solid coupling, subdividing a motion problem of a simulation object into three sub-problems according to object attributes, and solving the three sub-problems by using different methods respectively to realize a multi-dimensional classification combination computing framework; and 3) combining a strain energy density concept in fracture mechanics with Voronoi spatial segmentation to realize a physical perception-based crushing method. The simulation efficiency problem difficult to solve in complex fluid-solid coupling scene simulation is solved. Compared with a conventional fluid-solid coupling method, the method can simulate a fluid scene with richer details under the same system resources, and can meet the demand of simulating solid crushing under fluid impact.

Owner:ZHEJIANG UNIV

Fluid simulation rendering method and device

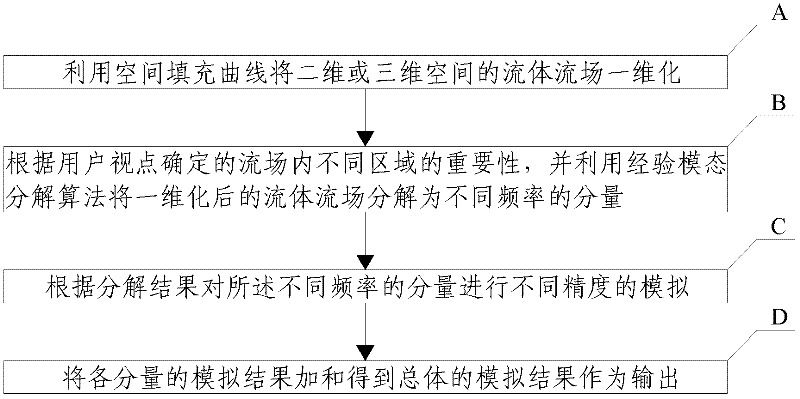

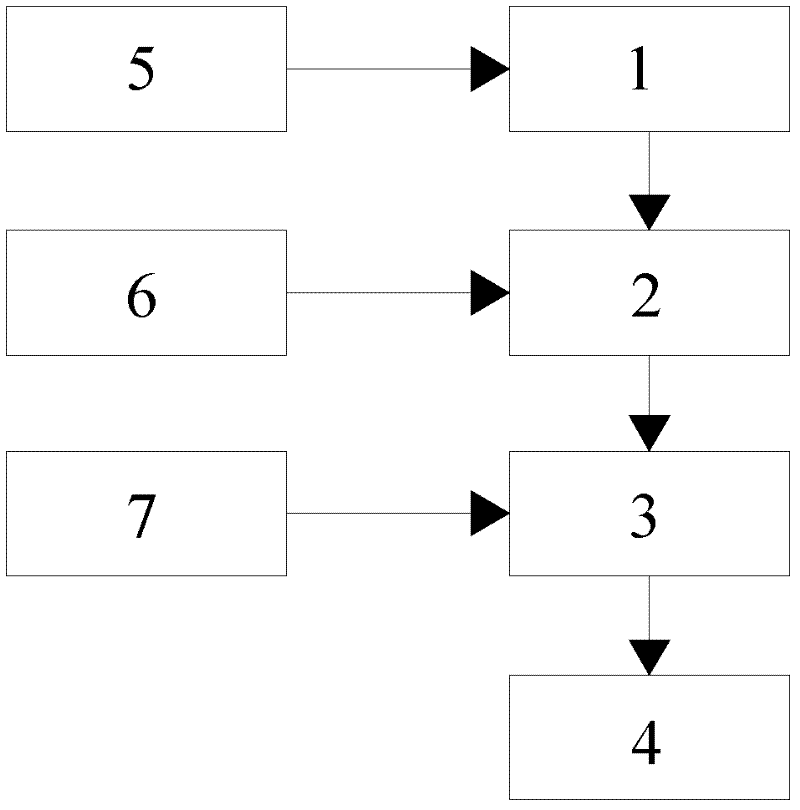

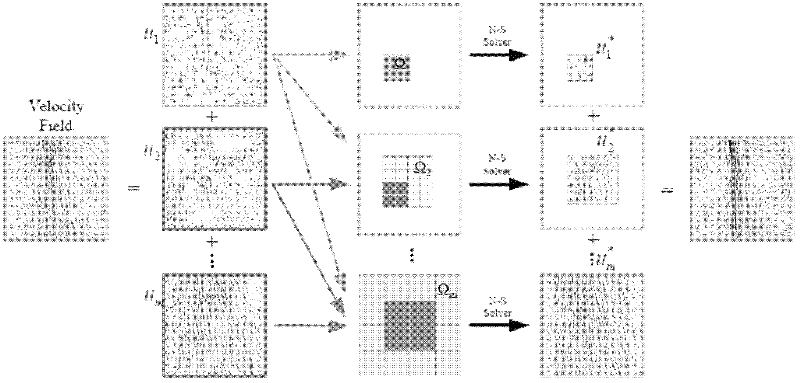

The invention discloses a fluid simulation rendering method, relating to the technical field of computer image rendering. The fluid simulation rendering method comprises the steps of: A, converting a fluid flow field in a two-dimension or three-dimension space into a one-dimension fluid flow field by using a space filling curve; B, decomposing the one-dimension fluid flow field into components with different frequencies by using an empirical mode decomposition algorithm according to the importance of different areas in the flow field determined on the basis of user view points; C, performing simulation with different precisions on the components with different frequencies according to analysis results; and D, summing the simulation results of the components to obtain a total simulation result serving as output. According to the fluid simulation rendering method and device, the speed and the fineness of the fluid simulation rendering can be improved; meanwhile, the system resources can be effectively saved.

Owner:TSINGHUA UNIV

Fluid simulation method based on inter-belt finite element and Lagrange coordinate

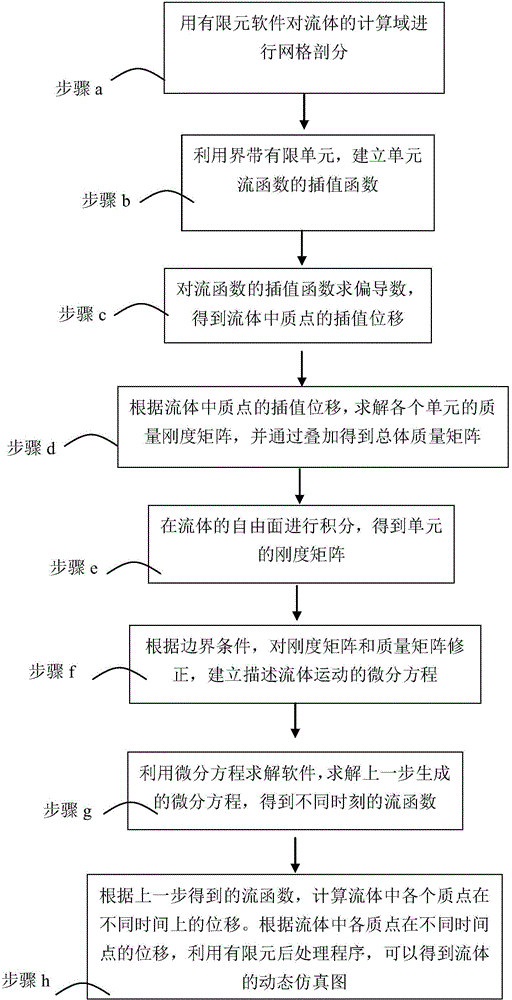

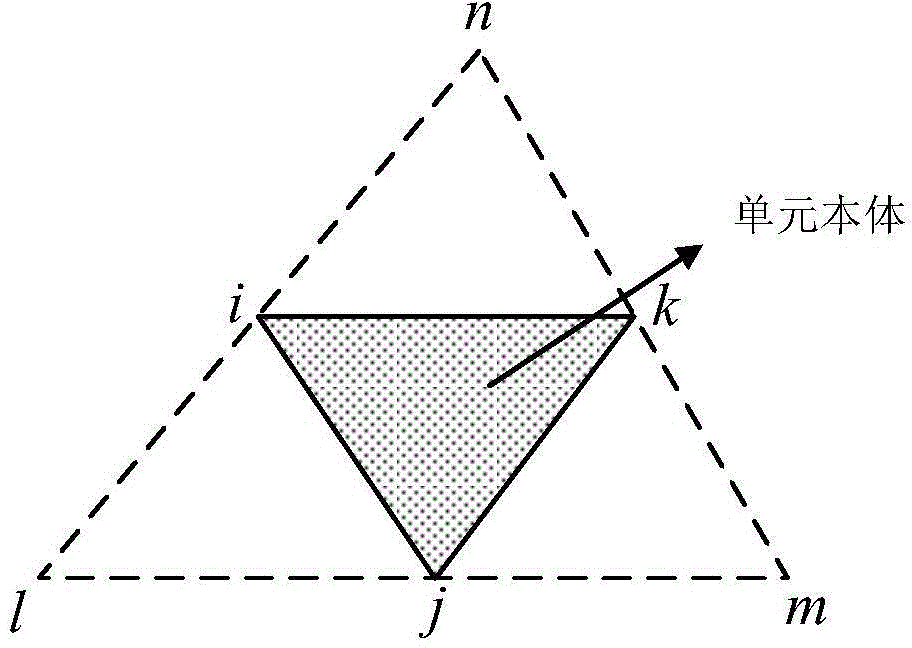

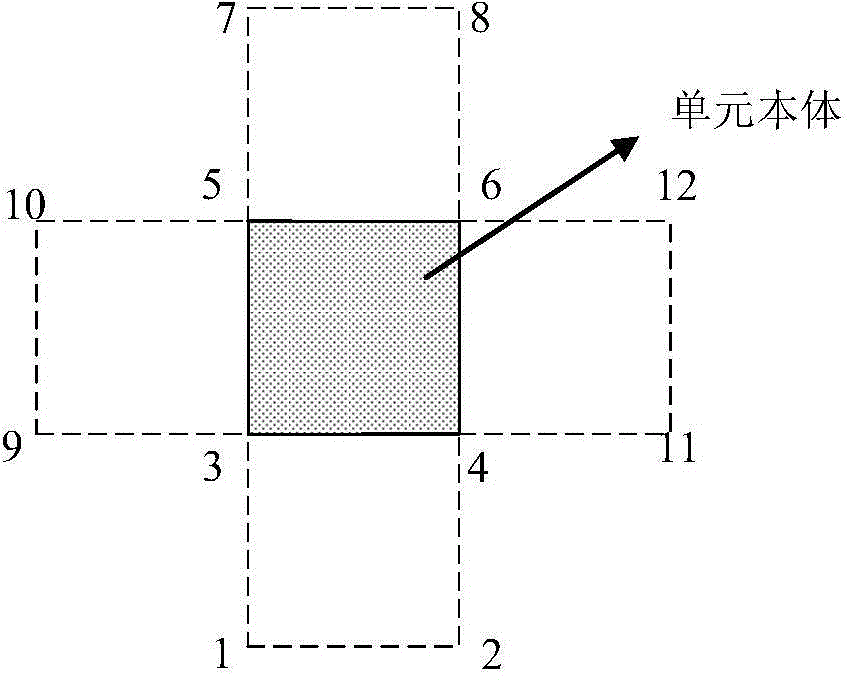

ActiveCN104317985APrecise handlingAvoid defects such as volume lock-upSpecial data processing applicationsMixed finite element methodSmoothed finite element method

The invention provides an incompressible fluid simulation analysis method based on an inter-belt finite element and a Lagrange coordinate. The incompressible fluid simulation analysis method comprises the following steps: dividing a computational domain [omega] of two-dimensional incompressible fluid into Ne units according to a traditional finite element mesh, wherein each unit is [omega i]; and constructing a displacement interpolation field of the unit [omega i], constructing a dynamic differential equation of the fluid according to the displacement interpolation field, and solving the dynamic differential equation to obtain each physical parameter of the fluid so as to carry out the kinematic analysis of the fluid. The invention is characterized in that the displacement interpolation field is constructed by utilizing an inter-belt finite element method, and the dynamic differential equation of the fluid is obtained on the basis of a descriptive method of the Lagrange coordinate. The descriptive method of the Lagrange coordinate is combined with the finite element method to solve a problem of the motion simulation of incompressible fluid, and the invention aims to improve the calculation efficiency and precision of analysis by utilizing the advantages of the high precision of the inter-belt finite element and convenience in lower boundary processing and good universality of the Lagrange coordinate.

Owner:DALIAN UNIV OF TECH

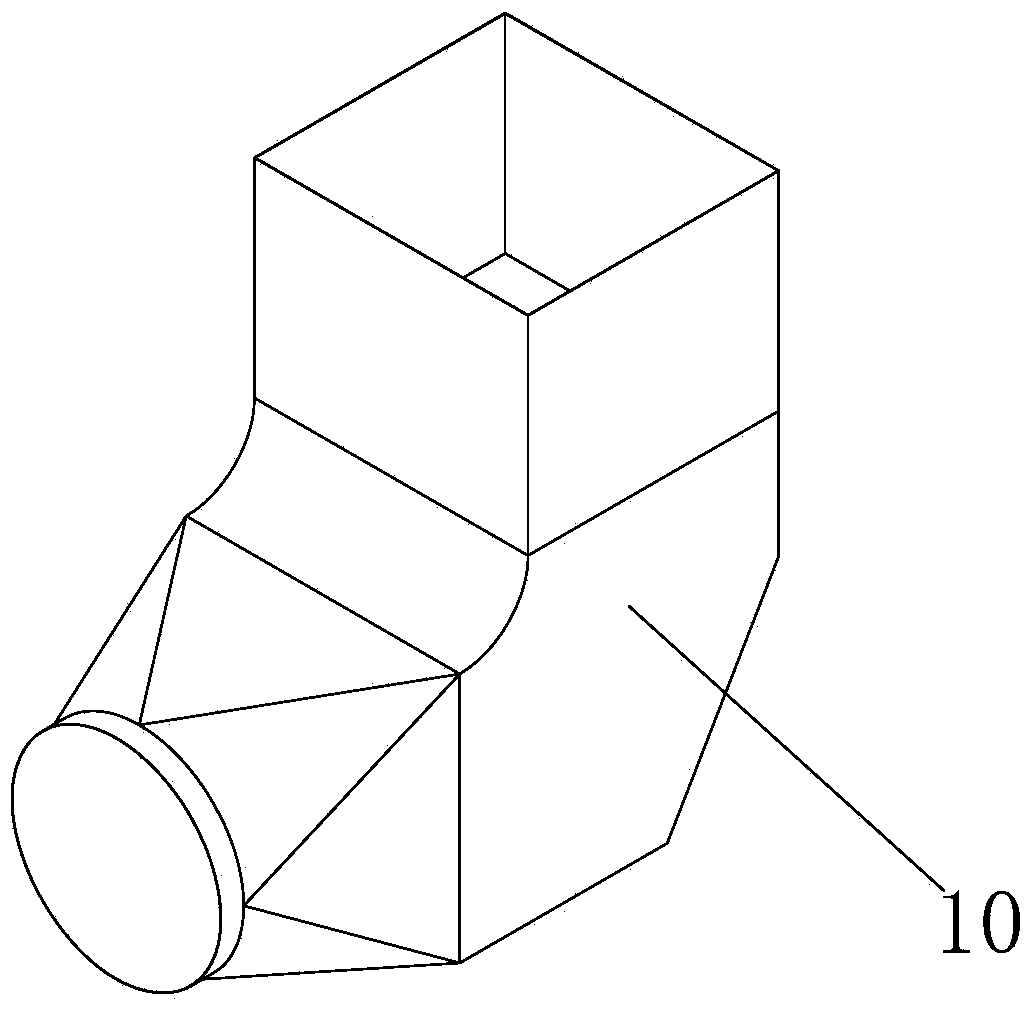

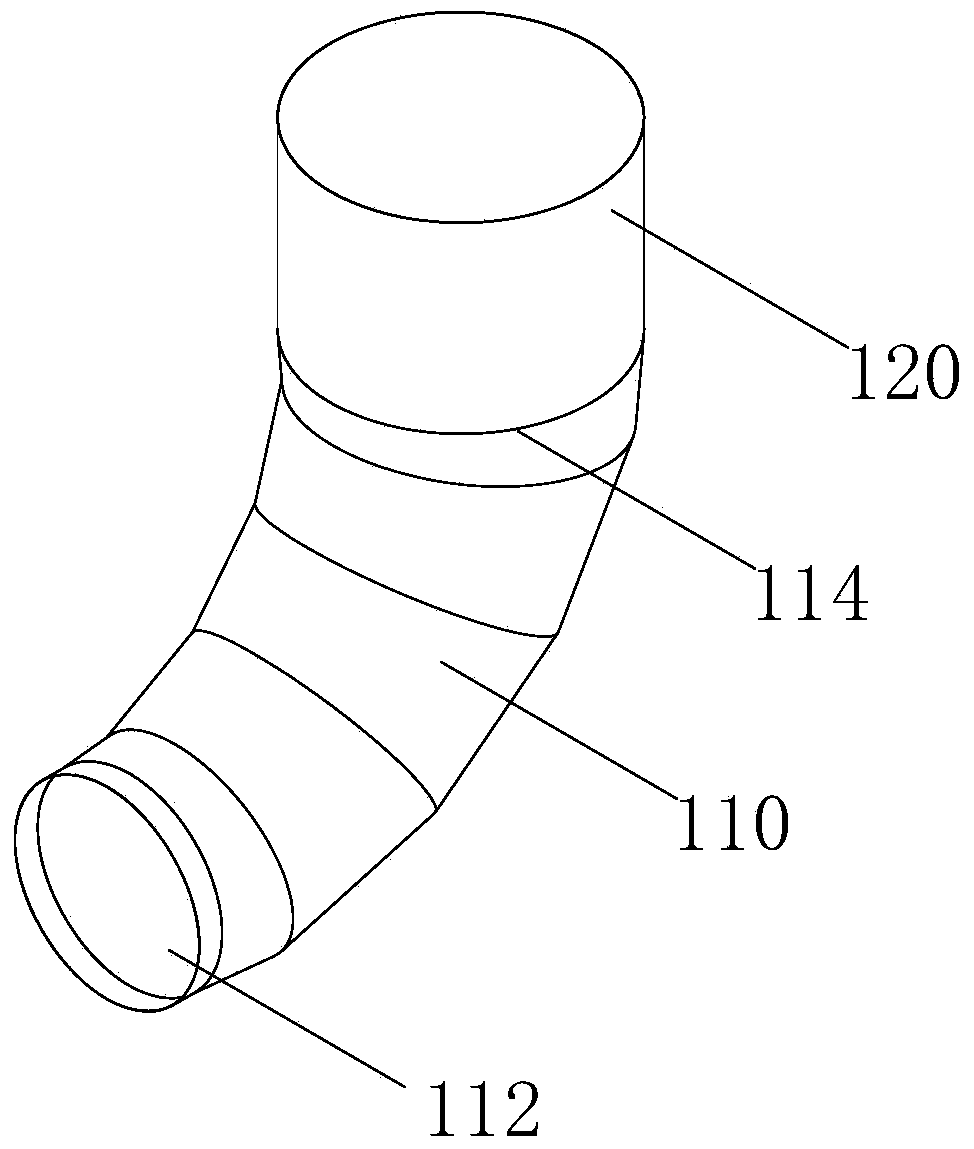

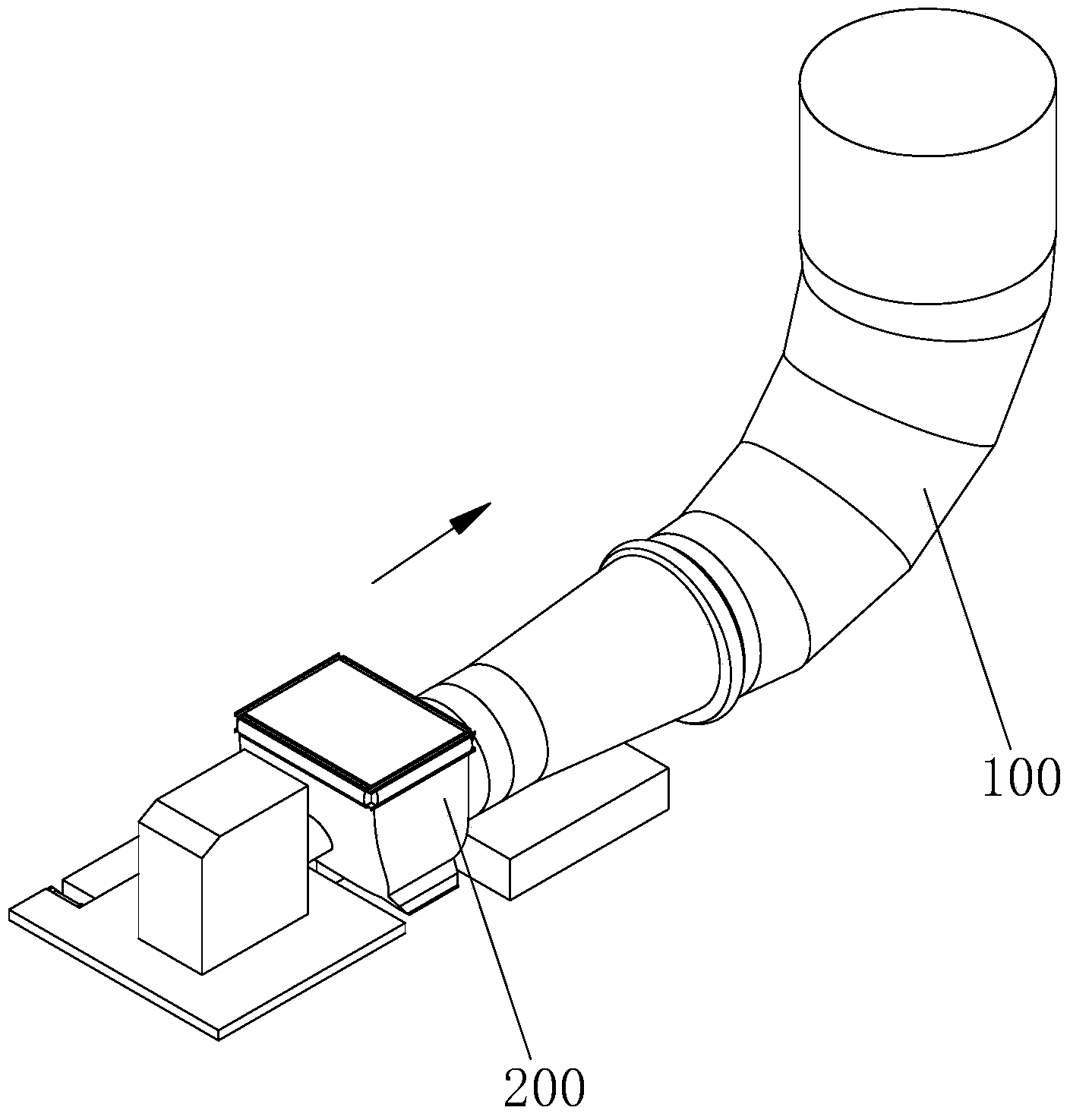

Smoke duct device and reducing elbow thereof

The invention discloses a reducing elbow which comprises a reducing section and a body section. The cross section of the reducing section and the cross section of the body section are circular, the reducing section comprises a large end and a small end, the diameter of the reducing section is gradually enlarged from the small end to the large end, the reducing section is curved, the large end of the reducing section is communicated with the body section, and the ratio of the curved radius of the reducing section to the diameter of the small end is 1.0-3.0. The cross section of the reducing section and the cross section of the body section are circular, the diameter of the reducing section is gradually enlarged from the small end to the large end, the reducing section is curved, the large end of the reducing section is communicated with the body section, and therefore reducing and turning are achieved synchronously, reducing has the enough diffusion section, turning has the enough turning radius, the reducing elbow is even in smoke flow field, and a smoke duct body is prevented from vibrating to generate noise. The conclusion that the resistance generated by the reducing elbow is far smaller than that generated by a traditional rectangular reducing elbow is obtained through FLUENT fluid simulation software analog computation. The invention further discloses a smoke duct device.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

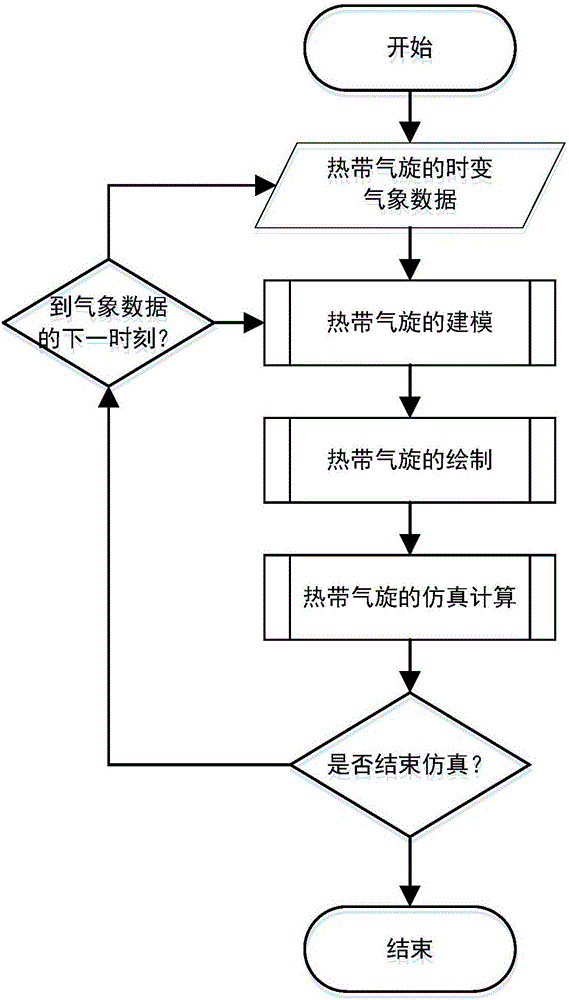

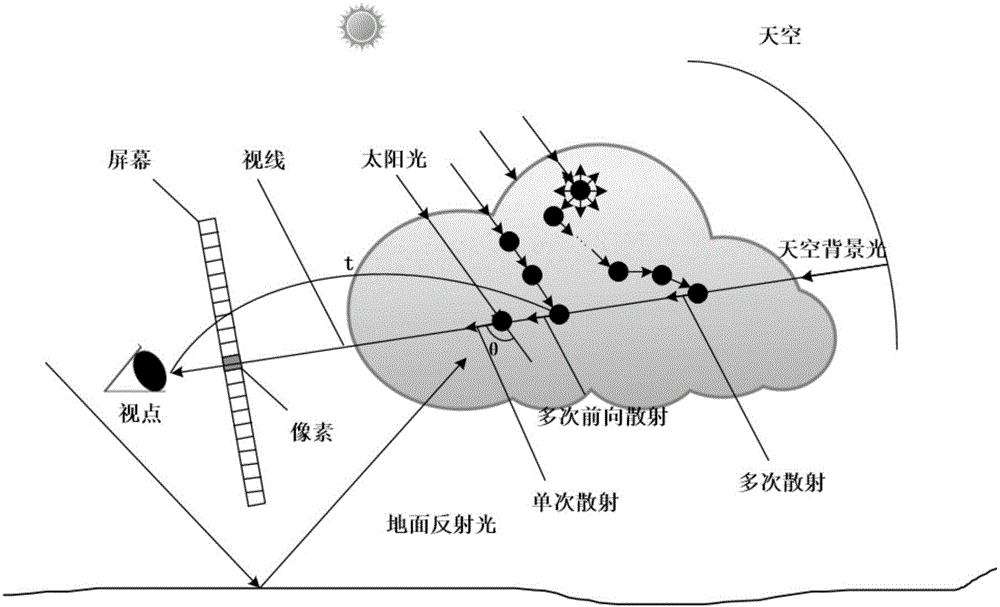

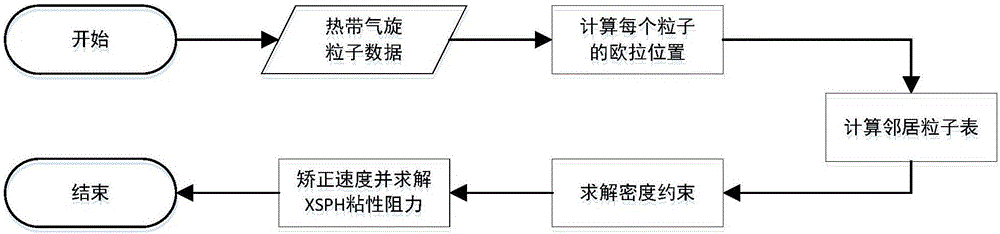

Tropical cyclone dynamic simulation method based on time-varying weather data

ActiveCN106570215AEasy to operateAccuracyDesign optimisation/simulationSpecial data processing applicationsHot bandComputer graphics

The invention discloses a tropical cyclone dynamic simulation method based on time-varying weather data, and belongs to the computer graphics related technology. The method mainly comprises a tropical cyclone modeling method based on the weather data, a cloud drawing algorithm method of multiple forward scatterings, and a tropical cyclone simulation algorithm method of a fluid based on a position, and the specific steps are as follows: first analyzing the time-varying weather data of the tropical cyclone to extract velocity field data for the fluid simulation use, extracting cloud intensity related data, establishing a particle model of a cloud at the same time, modeling graphic metadata suitable for the computer graphics drawing; and then vividly displaying the graphic metadata; and finally realizing the simulation display of the tropical cyclone in the weather data by use of the fluid simulation algorithm based on the position according to the established graphic model.

Owner:BEIHANG UNIV

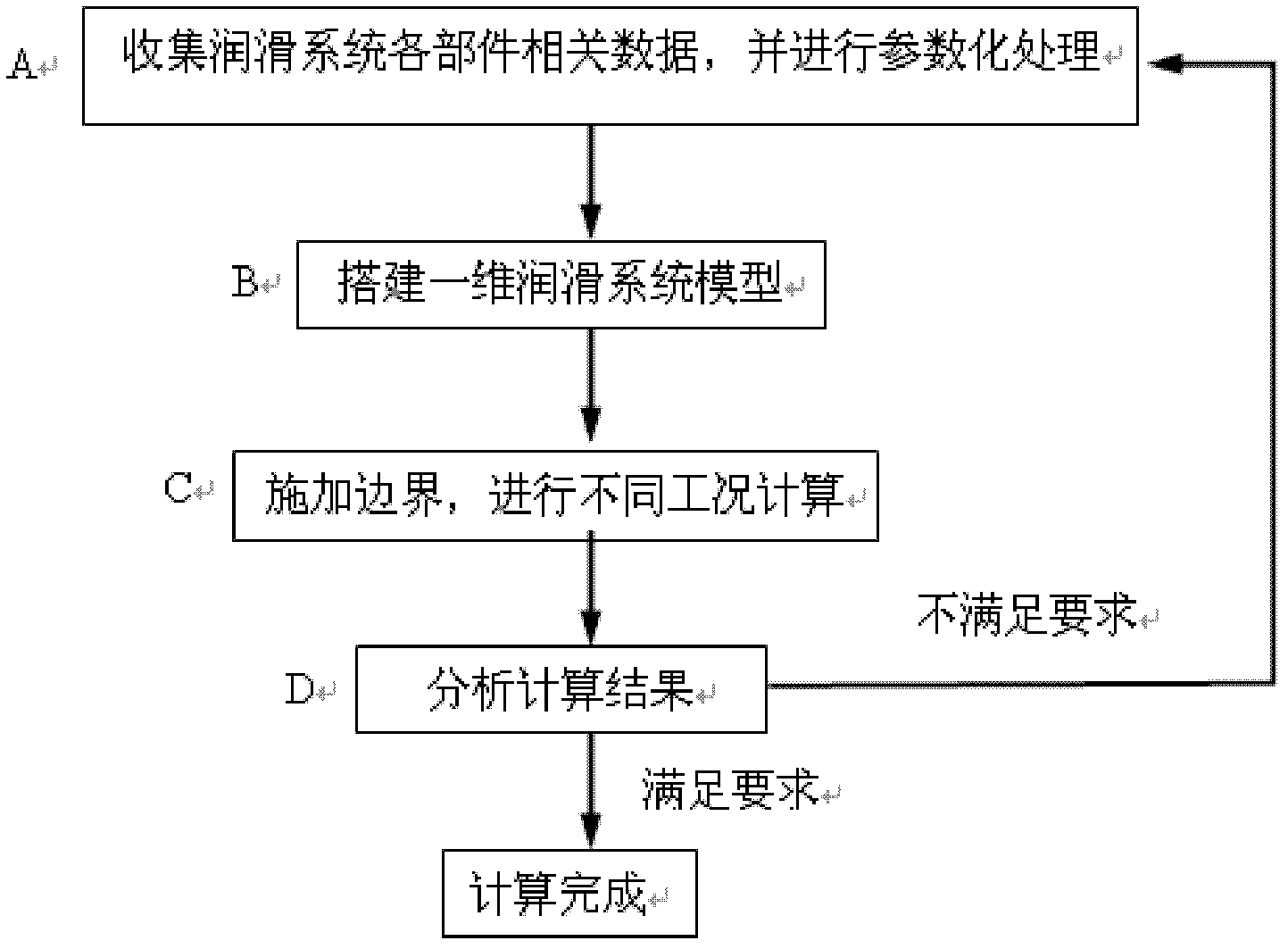

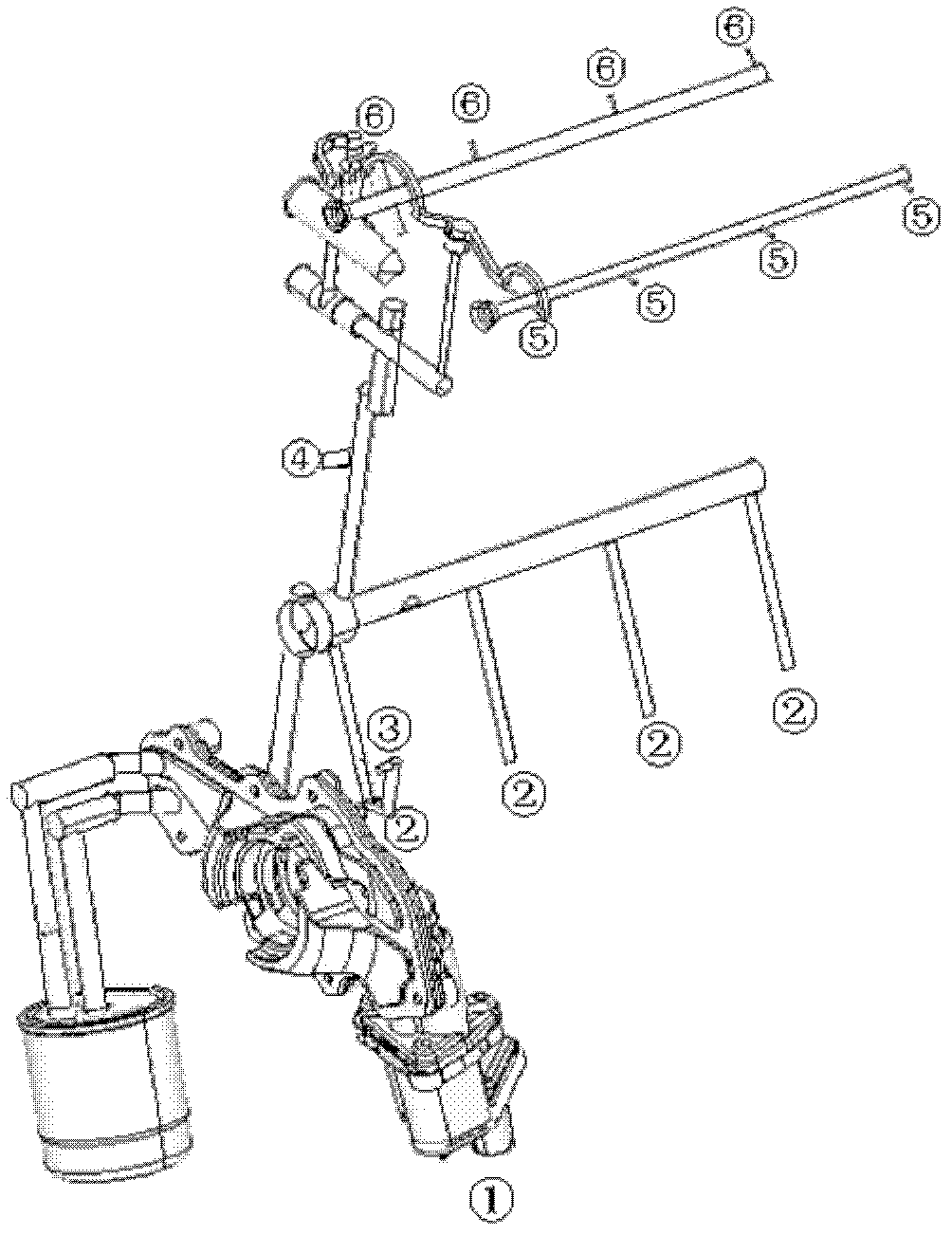

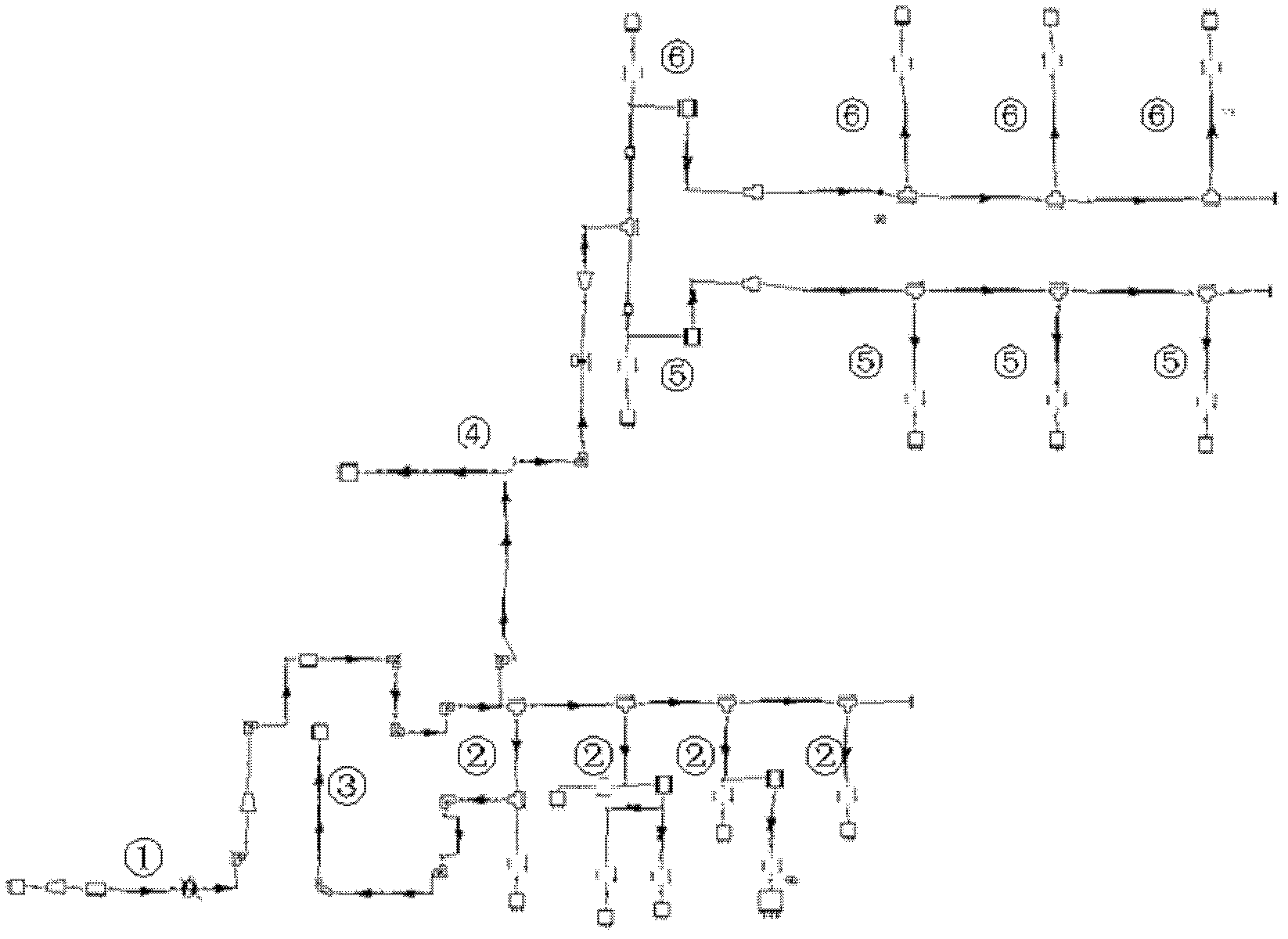

Simulative calculation method for engine lubrication system

ActiveCN102207996ASimple designIncrease pressureSpecial data processing applicationsComplete dataDimensional simulation

The invention relates to a simulative calculation method for an engine lubrication system. The method can better guide the design and the development of the lubrication system to improve the development efficiency and save the experimentation cost. Flow analysis is performed on the lubrication system by using a one-dimensional fluid simulation technology in the design method. The method comprisesthe following steps of: A, acquiring related data of each part of the lubrication system, and performing parametric processing; B, building a one-dimensional model; C, performing simulative calculation of different working conditions; and D, analyzing the calculation result, performing optimal design on the lubrication system when the design result does not reach the expectation, and repeating the steps till the calculation result reaches the design index. The simulative calculation method has unique advantages of low cost, high speed, complete data, capability of simulating various differentworking conditions and the like; by using strong functions of a computer and performing one-dimensional simulation on the lubrication system through commercial fluid software, pressure distribution, flow distribution, temperature distribution and the like of the lubrication system can be simulated at the initial stage of design; and by parameter optimization, optimal matching of parameters is obtained. The information acquired by simulation is more comprehensive compared with experimentation, and the simulation can be mutually verified and mutually supplemented with the experimentation. The development efficiency is improved, and massive experimentation cost is saved.

Owner:CHERY AUTOMOBILE CO LTD

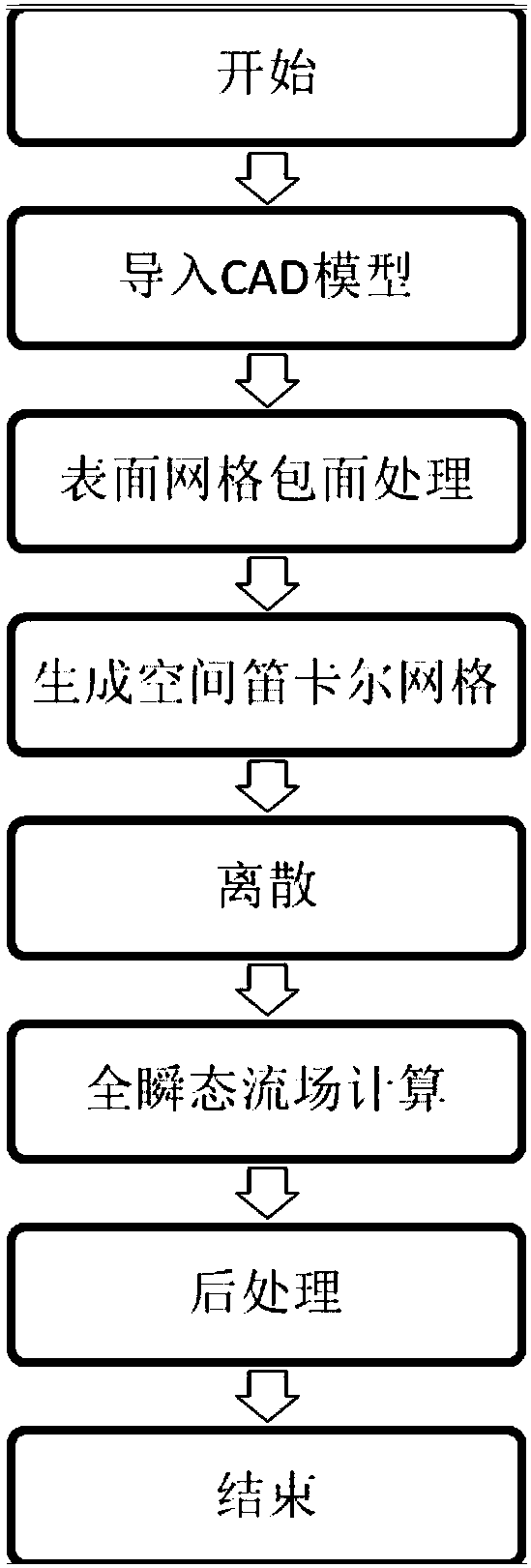

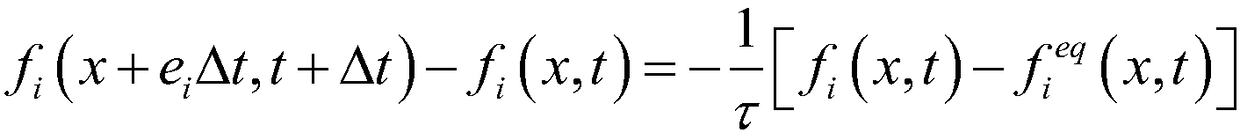

Method for fluid simulation by using Boltzmann equation

PendingCN109408836AGuarantee authenticityGuaranteed accuracyDesign optimisation/simulationSpecial data processing applicationsBoltzmann equationMolecular cluster

The invention discloses a method and a system for fluid simulation by using Boltzmann equation. The method for fluid simulation by using Boltzmann equation comprises the following steps: surface meshenvelope treatment; generating spatial Cartesian grids; full transient flow field calculation. This method calculates the molecular cluster density function of each point in the flow field at different time. The particle distribution function satisfies the lattice Boltzmann equation. The method for simulating a fluid by using the Boltzmann equation adopts a full-detail geometric model, does not need to be simplified, and ensures the authenticity and accuracy of the simulation result; full transient algorithm, accurate calculation of the real transient aerodynamic force; accurate solution of separated flow at hgh angle of attack (or stall state); time-marching explicit algorithm, so that there is no divergence problem in the solution process; high-precision automatic solution, so that no manual intervention is needed and high stability is achieved.

Owner:上海索辰信息科技股份有限公司

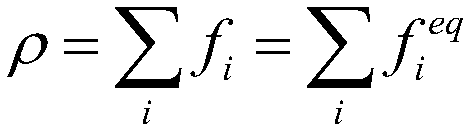

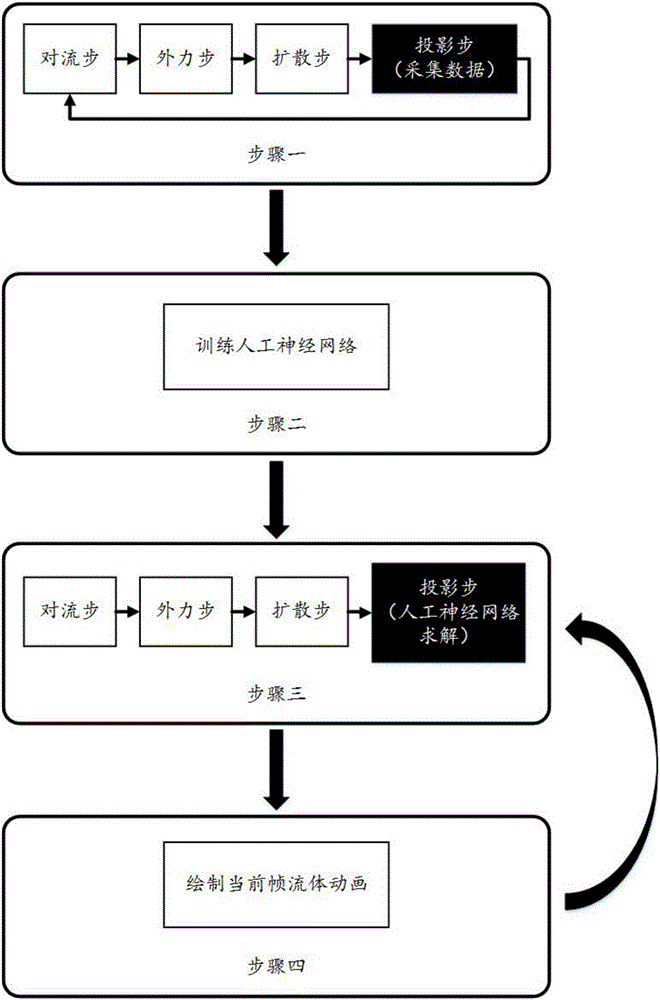

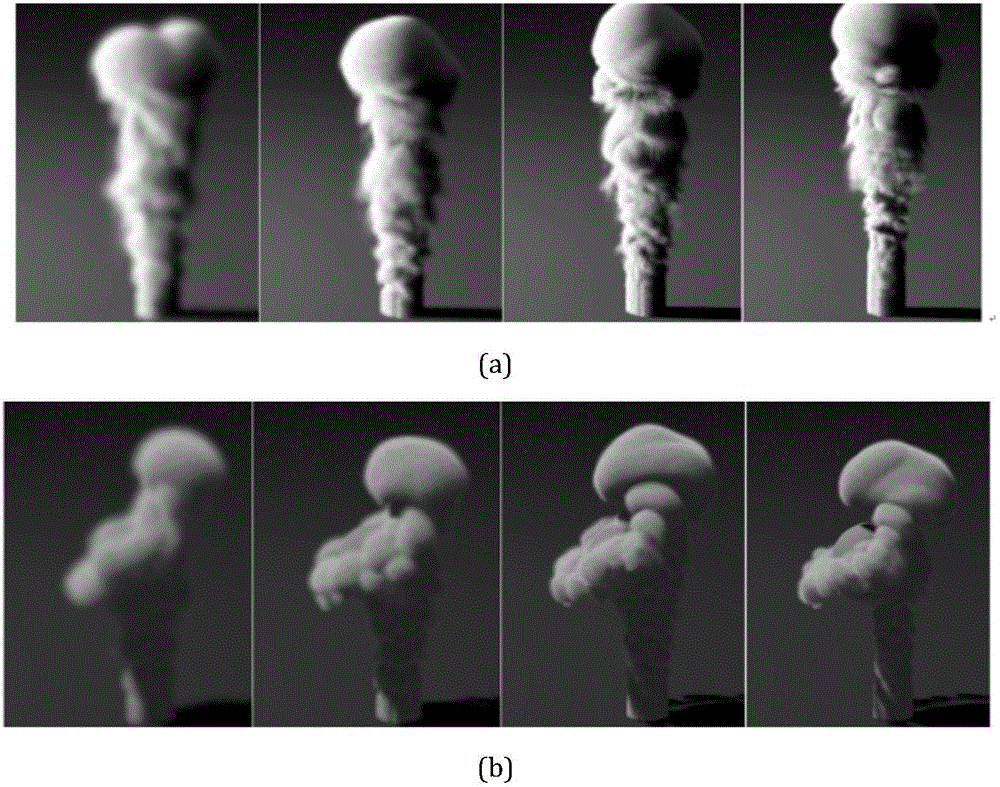

Fluid animation accelerated generation method based on data driving

InactiveCN106023286AAvoid projection step iterative computationGuaranteed accuracyAnimationAnimationEulerian method

A data-driven fluid animation acceleration generation method, using the artificial neural network after the training sample training as the solver, the solution of the projection step in the Euler method fluid simulation process is very fast, and can maintain a relatively fast solution while maintaining The small solution error ensures the accuracy of the solution results. The present invention uses the training data calculated before and after the projection step, and adjusts the weights of the transmission nodes of the artificial neural network through the training of the artificial neural network to directly obtain the final calculation model, completely avoiding the original time-consuming value calculation process of the projection step. The present invention is applicable to Euler's method for simulating fluid animation, and greatly accelerates the calculation of the solution projection step.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com